Abstract

Single-atom catalysts have been widely investigated for several electrocatalytic reactions except electrochemical alcohol oxidation. Herein, we synthesize atomically dispersed platinum on ruthenium oxide (Pt1/RuO2) using a simple impregnation-adsorption method. We find that Pt1/RuO2 has good electrocatalytic activity towards methanol oxidation in an alkaline media with a mass activity that is 15.3-times higher than that of commercial Pt/C (6766 vs. 441 mA mg‒1Pt). In contrast, single atom Pt on carbon black is inert. Further, the mass activity of Pt1/RuO2 is superior to that of most Pt-based catalysts previously developed. Moreover, Pt1/RuO2 has a high tolerance towards CO poisoning, resulting in excellent catalytic stability. Ab initio simulations and experiments reveal that the presence of Pt‒O3f (3-fold coordinatively bonded O)‒Rucus (coordinatively unsaturated Ru) bonds with the undercoordinated bridging O in Pt1/RuO2 favors the electrochemical dehydrogenation of methanol with lower energy barriers and onset potential than those encountered for Pt‒C and Pt‒Ru.

Subject terms: Electrocatalysis, Fuel cells, Materials for energy and catalysis, Nanoscience and technology

It is still challenging to engineer single-atom catalysts for electrocatalytic methanol oxidation. Here, the authors design Pt single atom supported on RuO2 for highly active methanol oxidation in contrast to the inert Pt single atom supported on carbon.

Introduction

Platinum is the most effective element for anodic methanol oxidation reaction (MOR) in direct methanol fuel cells1,2. The electrocatalytic activity of Pt is highly dependent on its geometrical structure and the surrounding environment1. To improve MOR activity and reduce Pt loading, conventional strategies have focused on2 (i) tailoring the structure and/or morphology of Pt (e.g., by making hollow/framed3 or core-shelled4 Pt); and (ii) hybridizing Pt with other elements (e.g., Co3, Ni5, Sn6, Bi7, etc.). However, the Pt in these catalysts is usually assembled as a nanoparticle of diameter greater than 1 nm, leading to unsatisfactory mass activity. Furthermore, in MOR, Pt nanoparticles are susceptible to poisoning by adsorbed intermediates (COads)5, resulting in activity loss. Hence, developing new types of Pt-based MOR electrocatalysts with high activity and anti-poisoning capability is of both practical and fundamental significance.

Single-atom catalysts (SACs) are now emerging as a new class of catalysts with extraordinary activity towards many electrocatalytic reactions, including oxygen and hydrogen evolution, oxygen, CO2, and N2 reduction, and hydrogen and formic acid oxidation8–12. Pt SACs have utmost utilization of Pt atoms and good capability for CO oxidation13. However, the electrochemical dehydrogenation of methanol to CO in MOR requires at least three contiguous Pt atoms14. Further, it has been reported that SACs consisting of Pt single atoms supported on carbon nanotubes are inactive towards MOR15. Yet, we should note that these studies focused only on the Pt active centers rather than the entire catalysts, thereby neglecting the environment surrounding Pt. In this regard, enhancing the activity of single atomic Pt towards MOR is a scientifically significant and challenging topic.

For SACs, the atomic coordination of single atoms also plays an important role in determining the catalytic activity16. It has been shown that the electronic structure and coordination of the central single atoms can be adjusted by tuning the bonds between the single atoms and the substrate17–20. Herein, we designed two types of Pt SACs. Thanks to a simple adsorption–impregnation preparation method21, single Pt atoms were immobilized on RuO2 and carbon black (VXC-72) to obtain Pt1/RuO2 and Pt1/VXC-72, respectively. The Pt1/RuO2 SACs showed superb mass activity (6766 mA mg‒1Pt) and stability towards the MOR, far superior to those of most Pt-based catalysts developed to date. The MOR mechanism including the dehydrogenation of methanol and CO electrooxidation is further studied by density functional theory (DFT), confirming the experimental observation that the prepared SACs are active for the alcohol oxidation reaction. This finding suggests an approach of SACs for direct alcohol fuel cells.

Results

Structure characterization of Pt1/RuO2

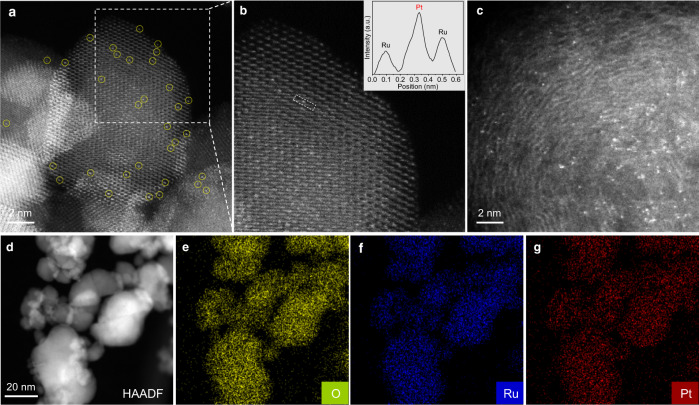

RuO2 and VXC-72 supports were characterized by transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), and X-ray diffraction (XRD) (Supplementary Fig. 1). Pt1/RuO2 and Pt1/VXC-72 catalysts with an identical Pt loading of 0.38 wt% were prepared by simple impregnation/adsorption followed by filtration and washing (for more details, see ‘Methods’ and Supplementary Fig. 2). Figure 1 shows the catalysts’ morphology and structure. As revealed by the bright spots marked as yellow circles in the high-angle annular dark-field (HAADF) scanning transmission electron microscopy (STEM) image, individual Pt atoms were randomly dispersed on RuO2 (Fig. 1a). The magnified HAADF-STEM image of Pt1/RuO2 suggests that the Pt atoms exactly substituted Ru (Fig. 1b). The presence of Pt single atoms was further verified by the intensity profile along with the dashed rectangle in the image (the inset in Fig. 1b), where the Pt atom brightness is more intense than that of Ru due to the higher Z number. The corresponding elemental mapping shows that Pt, Ru, and O were homogeneously distributed throughout the entire Pt1/RuO2 sample (Fig. 1d–g). For Pt1/VXC-72, Pt atoms were also atomically dispersed, as shown in the HAADF-STEM image (Fig. 1c). No Pt clusters/nanoparticles on VXC-72 were observed by low-magnification HAADF-STEM and TEM imaging (Supplementary Fig. 3). Due to the single-atom structure and low Pt loading, Pt peaks were, however, not detectable by XRD (Supplementary Fig. 4).

Fig. 1. Morphological and elemental characterization of Pt1/RuO2 and Pt1/VXC-72.

a, b Representative HAADF-STEM images of Pt1/RuO2. Inset in (b) is the intensity profile along with the dashed rectangle. c Representative HAADF-STEM image of Pt1/VXC-72. d–g EDS-mapping images of Pt1/RuO2.

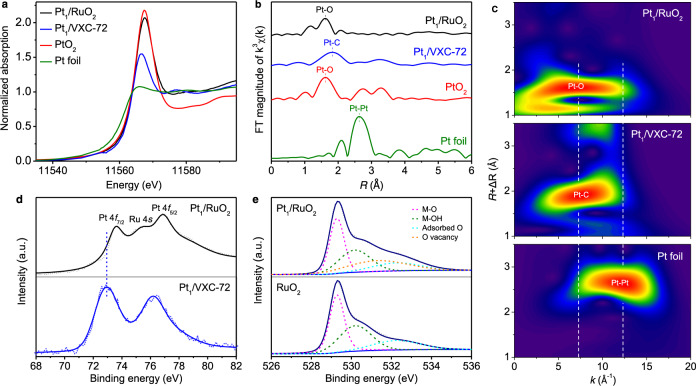

To study the coordination and electronic configuration of Pt single atoms in the Pt1/RuO2 and Pt1/VXC-72, X-ray absorption fine structure (XAFS) spectroscopy and XPS were carried out (Fig. 2). The normalized X-ray absorption near-edge structure (XANES) spectra of Pt1/RuO2 shows stronger white-line intensity at 11,568 eV compared to the Pt foil, suggesting that Pt is positively charged in Pt1/RuO2 due to the electron transfer from Pt to the surrounding O atoms in the RuO2 support (Fig. 2a)22,23. The Pt1/VXC-72 catalyst is characterized by a similar Pt-to-VXC-72 electron transfer. However, the white-line peaks suggest that the Pt in Pt1/VXC-72 has a lower charge state than the one observed for Pt1/RuO2. The average Pt oxidation numbers in Pt1/RuO2 and Pt1/VXC-72 are estimated to be +2.90 and +1.22, respectively, by integrating the XANES spectra (Supplementary Fig. 5)10,24. The different charge of Pt in RuO2 and VXC-72 is likely a result of the different coordination. As revealed by the k3-weighted extended XAFS (EXAFS) at the Pt L3-edge, no peak at 2.64 Å from Pt‒Pt is observed for either Pt1/RuO2 or Pt1/VXC-72, indicating full atomic dispersion for both catalysts (Fig. 2b), consistent with the HAADF-STEM images. Specifically, the R-space spectrum of Pt in Pt1/RuO2 has a dominant peak at 1.62 Å from Pt‒O coordination, in agreement with the PtO2 case (Fig. 2b)22,23. In contrast, the dominant peak of Pt1/VXC-72 shifted to 1.83 Å (Fig. 2b). To determine the coordination of Pt in both catalysts, the main R-space peaks were fitted against corresponding models (see ‘Computational details’) by Fourier transform. For Pt1/RuO2, the coordination number of Pt‒O is estimated to be 4 with an average bond length of 1.99 Å (Supplementary Fig. 6 and Supplementary Table 1). For Pt1/VXC-72, the Pt‒C bond coordination number is 3, and the average bond length is 1.93 Å (Supplementary Fig. 6 and Supplementary Table 1). Also, the wavelet-transform plots of Pt1/RuO2 and Pt1/VXC-72 show a maximum at ~7.5 Å−1 corresponding to the Pt‒O/C bonds (Fig. 2c). No intensity maximum at ~12.5 Å−1 corresponding to the presence of Pt‒Pt bonds was observed for either catalyst, consistent with the EXAFS (Fig. 2c).

Fig. 2. Structural characterization of Pt1/RuO2 and Pt1/VXC-72 by XAFS and XPS.

a Normalized XANES spectra at the Pt L3-edge. b k3-weighted R-space Fourier transformed spectra from EXAFS. c Wavelet transforms from experimental data. d XPS spectra for Pt 4f and Ru 4s. e XPS spectra for O 1s. In panels (a–c) and (e), the corresponding data for Pt foil, PtO2, and RuO2 are presented for comparison.

The RuO2 support contains Ru 4s with the binding energy at the range of ~70–85 eV (Supplementary Figs. 1b and 7), which is very close to the XPS signature of Pt 4f. Therefore, the Pt1/RuO2 XPS peaks in the ~68–82 eV range were deconvolved into Ru 4s and Pt 4f, i.e., Pt 4f7/2 and Pt 4f5/2 (Fig. 2d). The binding energies of the Pt 4f were measured to be 73.6 and 76.9 eV for Pt1/RuO2, and 72.9 and 76.2 eV for Pt1/VXC-72. The higher binding energy of Pt1/RuO2 compared to Pt1/VXC-72 implies that Pt in Pt1/RuO2 has a higher oxidation state, in agreement with the XANES results. Moreover, the O 1s spectrum of bare RuO2 was deconvolved into three characteristic peaks at 529.3, 530.2, and 532.3 eV (Fig. 2e), which can be attributed to M‒O, M‒OH, and adsorbed oxygen, respectively25. After the incorporation of Pt single atoms into RuO2, the O 1s of Pt1/RuO2 shows a new peak at 531.3 eV. This peak can be attributed to the appearance of oxygen vacancies on the surface resulting from Pt single atoms (Supplementary Fig. 8)22,26. These data support the existence of Pt‒O in Pt1/RuO2, in agreement with the XANES characterization. In addition, the O 1s of Pt1/VXC-72 is similar to that of VXC-72 (Supplementary Fig. 9), indicating that there is no Pt‒O interaction in Pt1/VXC-72. In other words, Pt‒C coordination is dominant in Pt1/VXC-72.

The preceding results indicate that Pt is atomically dispersed on both RuO2 and VXC-72 but surrounded by distinct coordination environments. Pt‒O coordination characterizes in Pt1/RuO2. In contrast, Pt‒C coordination is dominant in Pt1/VXC-72.

MOR electrocatalytic activity

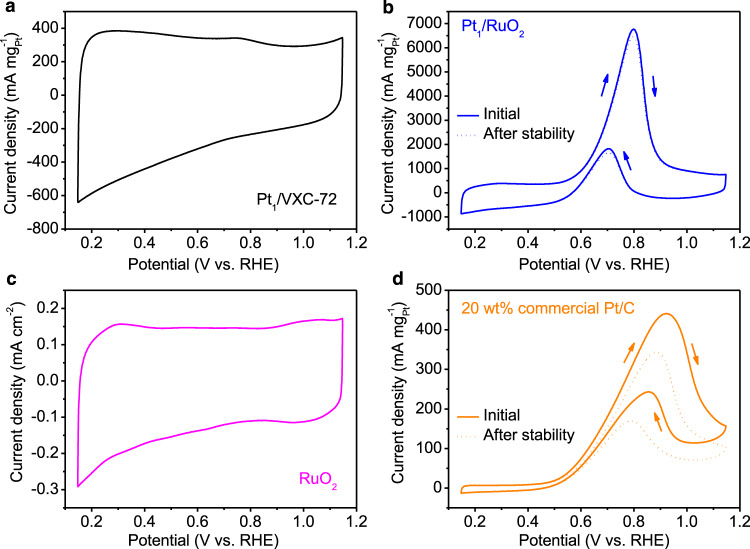

Although Pt-based nanoparticles have been the most efficient catalysts for MOR, individual Pt atoms on carbon support are inactive towards that reaction27. By replacing the carbon support with RuO2, the coordination of Pt single atoms changes. Herein, we evaluated in the N2-saturated 0.1 mol L‒1 KOH and 1 mol L‒1 methanol solution the MOR performance of the Pt1/RuO2 SACs. Concomitantly, these materials were compared to Pt1/VXC-72 and commercial Pt/C, see Fig. 3. As revealed by cyclic voltammogram (CV) of Pt1/VXC-72 SACs, no electrocatalytic peak was detected, indicating that Pt1/VXC-72 is inactive towards MOR (Fig. 3a). We also prepared a Pt1/VXC-72 catalyst with a higher Pt loading of 1.48 wt%, i.e., Pt/VXC-72-1.48, which had a negligible MOR activity (Supplementary Fig. 10). These results support the literature findings that single atoms or even clusters of Pt on carbon are MOR inactive. Unexpectedly, the CV curves of Pt1/RuO2 SACs displayed oxidation current peaks in both the forward and backward CV scans (Fig. 3b), corresponding to methanol and intermediate products oxidation, respectively7. In contrast, the CV scan of the RuO2 was featureless (Fig. 3c). Further, oxygen vacancies on the RuO2 surface could not contribute to MOR (Supplementary Fig. 11). These results suggest that its MOR activity was due to having Pt single atoms on RuO2. The Pt mass activity of Pt1/RuO2 was 6766 mA mg‒1Pt at 0.80 V vs. RHE (reversible hydrogen electrode), which is about 15.3 times higher than that of the commercial 20 wt% Pt/C (441 mA mg‒1Pt at 0.92 V vs. RHE) (Fig. 3b, d) and significantly larger than the data for the reported catalysts to date (Supplementary Table 2). The peak current ratio between the forward (If) and backward (Ib) scan can be used to demonstrate the COads tolerance28. The If/Ib of Pt1/RuO2 (3.67) is more than twice that of Pt/C (1.81), suggesting an enhanced anti-poisoning ability for Pt1/RuO2. Long-term durability is another important criterion to assess the quality of a catalyst5. The stability of the Pt1/RuO2 SACs and 20 wt% commercial Pt/C was evaluated by chronoamperometry at ‒0.1 V (vs. Ag/AgCl). After 10 h, the Pt1/RuO2 mass activity remained at 6463 mA mg‒1Pt with a slight degradation of 4.5% (Fig. 3b). In contrast, commercial Pt/C exhibited an ~22% decrease in mass activity (344 mA mg‒1Pt) (Fig. 3d). After the stability test, the Pt atoms in Pt1/RuO2 were isolated on the RuO2 support while the Pt nanoparticles in commercial 20 wt% Pt/C were aggregated (Supplementary Figs. 12 and 13).

Fig. 3. MOR performance of Pt1/RuO2 and control samples in 0.1 mol L‒1 KOH and 1 mol L‒1 methanol solution at a scan rate of 50 mV s‒1.

a Pt1/VXC-72. b Pt1/RuO2. c RuO2. d 20 wt% commercial Pt/C.

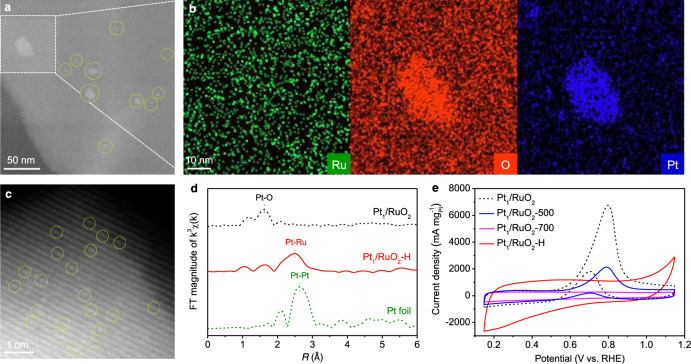

To reveal the origin of MOR activity, several control samples were used, see Fig. 4. In the first set of samples denoted as Pt1/RuO2−500 and Pt1/RuO2−700, Pt1/RuO2 was annealed in air at 500 and 700 °C, respectively. After heat treatment, Pt single atoms on RuO2 were aggregated into nanoparticles with a 1–2 nm diameter for Pt1/RuO2−500, or even 30 nm diameter for Pt1/RuO2−700 (Supplementary Fig. 14 and Fig. 4a, b), respectively. When characterized by CV, Pt/RuO2−500 showed a mass activity of 2140 mA mg‒1Pt, a value lower than the 6766 mA mg‒1Pt of Pt1/RuO2 SACs (Fig. 4e). For Pt/RuO2−700, the oxidation peak between 0.6 and 1.0 V disappeared, showing no MOR activity. The lower MOR performance of these catalysts can be attributed to the Pt aggregation. As is well known, catalytic activity is associated with the number of active sites29 and single atoms have many more of those compared to clusters or nanoparticles30. As expected, due to the presence of Pt clusters or nanoparticles, Pt/RuO2-0.75 and Pt/RuO2-1.48, two materials with higher Pt loading than Pt1/RuO2 SACs, showed decreased mass activity (Supplementary Fig. 15).

Fig. 4. Characterizations and MOR performance of Pt1/RuO2-500/Pt1/RuO2-700 and Pt1/RuO2-H in 0.1 mol L‒1 KOH and 1 mol L‒1 methanol solution at a scan rate of 50 mV s‒1.

a Typical HAADF-STEM images of Pt1/RuO2-700. b Corresponding EDS-mapping images of enlargement in (a). c Typical HAADF-STEM images of Pt1/RuO2-H. d k3-weighted R-space Fourier transformed spectra from EXAFS of Pt1/RuO2-H. e MOR performance. The curves in Figs. 2b and 3b are replotted here for convenient comparison.

In parallel, an additional sample, denoted as Pt1/RuO2-H, was prepared by reducing the Pt1/RuO2 SACs in H2 at 80 °C. In that sample, the RuO2 support was reduced to metallic Ru with a little RuO2 left as confirmed by XRD (Supplementary Fig. 16). The different structure led to a changed coordination environment for Pt single atoms. The HAADF-STEM of Pt1/RuO2-H shows that the Pt atoms are isolated on the support (Fig. 4c). Compared to that of Pt1/RuO2, the EXAFS spectra of Pt1/RuO2-H show a prominent peak at 2.49 Å due to Pt‒Ru bond (coordination number n = 9), and the 1.62 Å peak of Pt‒O is negligible (Fig. 4d, Supplementary Fig. 17, and Supplementary Table 1)31. These results suggest that the Pt atoms have distinct coordination in Pt1/RuO2 and Pt1/RuO2-H, i.e., Pt‒O coordination for Pt1/RuO2 and Pt‒Ru for Pt1/RuO2-H. Accordingly, the Pt1/RuO2-H shows no MOR activity (Fig. 4e). Instead, Pt1/RuO2-H shows enhanced capacitive current and polarization current starting from ~0.9 V in the forward scan, resulting from higher relative Ru content in Pt1/RuO2-H than Pt1/RuO2. In consideration of the coordination of Pt‒O in Pt1/RuO2 and Pt‒C in Pt1/VXC-72, it can be concluded that the coordination of Pt single atoms governs MOR activity. On the basis of the preceding results, the origin of MOR activity in Pt1/RuO2 SACs can be attributed to: (i) the existence of large numbers of atomic Pt sites; and (ii) the environment surrounding Pt single atoms (thanks to RuO2, Pt single atoms turned into MOR-active catalysts).

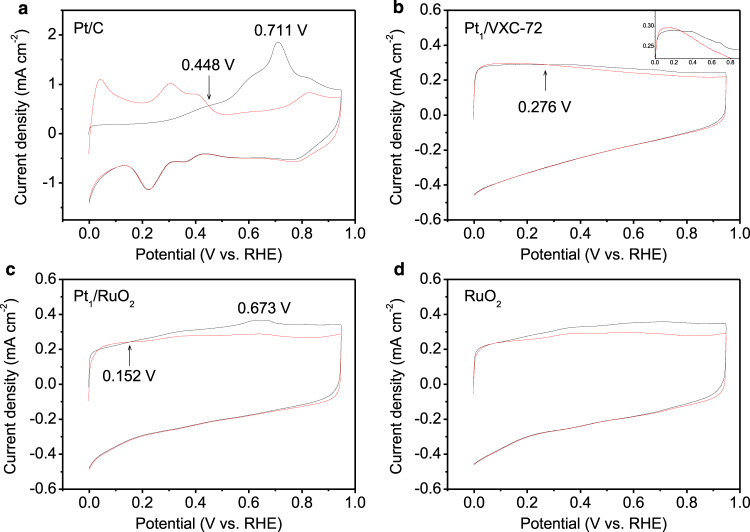

The CO resistibility of the catalysts was evaluated by CO stripping tests6,9, see Fig. 5. For commercial Pt/C, a main peak appeared in the first forward scan with onset and peak potentials at 0.448 and 0.711 V (Fig. 5a), respectively, where the latter value has been previously attributed to CO electrooxidation taking place on Pt nanoparticles5. Downsizing the Pt nanoparticles to the atomic scale in Pt1/VXC-72 reduces the onset potential of CO electrooxidation to ~0.276 V (Fig. 5b), a value much lower than that of commercial Pt/C (0.448 V). This reduction indicates that Pt single atoms trigger CO electrooxidation, consistent with the literature, where Pt single atoms have been shown to weaken CO adsorption, thereby facilitating the oxidation of CO at a lower potential9. Compared to Pt1/VXC-72 and commercial Pt/C, Pt1/RuO2 SACs triggered CO electrooxidation at a lower onset potential of 0.152 V with a minute peak around 0.673 V (Fig. 5c), suggesting an enhanced anti-poisoning capability for Pt1/RuO2. Such a change indicates that introducing RuO2 as a support favors CO electrooxidation. As is well known, oxophilic RuO2 boosts water dissociation, which, in turn, facilitates the formation of adsorbed OH and the oxidative removal of COads on Pt sites, which, in turn, facilitates their regeneration5,6. As shown in Fig. 5d, RuO2 alone electrooxidized CO at an low potential of 0.076 V. Hence, both single atomic Pt and RuO2 favor the electrooxidative removal of CO, leading to the superior stability of Pt1/RuO2.

Fig. 5. CO stripping tests in 0.1 mol L‒1 KOH at a scan rate of 50 mV s‒1.

a 20 wt% commercial Pt/C. b Pt1/VXC-72. Inset in (b) is the local enlargement. c Pt1/RuO2. d RuO2. The black and red curves correspond to the first and second scans, respectively. The first scan was recorded in the presence of CO adsorbed on the electrode, while the second scan was recorded in absence of CO.

Ethanol oxidation reaction (EOR) tests in alkaline medium show an ~5.7-fold higher mass activity of Pt1/RuO2 compared to benchmark Pt/C (2824 vs. 498 mA mg‒1Pt) (Supplementary Fig. 18). These results suggest that Pt1/RuO2 also has remarkable potential for alcohol oxidation reactions.

MOR mechanism

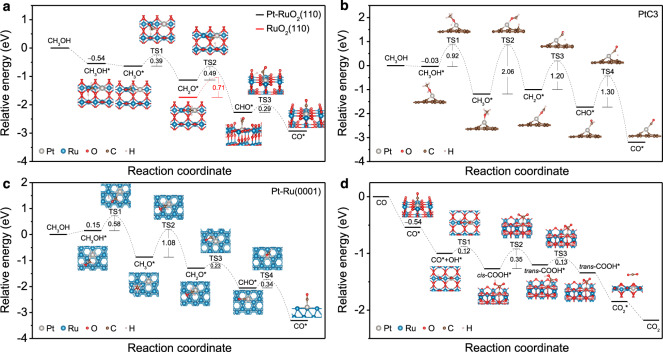

To understand the MOR mechanism, three different models were constructed to simulate the catalytic reaction. The first system had a Pt atom located at the Rucus (1-fold coordinatively unsaturated Ru) site of the RuO2(110) surface (Pt-RuO2(110)) corresponding to Pt1/RuO2. The second model had a Pt atom bonded to three C atoms on graphene (PtC3) corresponding to Pt1/VXC-72. The final model had a Pt substituting a surface Ru in Ru(0001) (Pt-Ru(0001)) corresponding to Pt1/RuO2-H, see ‘Methods’ and Supplementary Figs. 19–21. The calculated MOR free energy diagrams of these three samples are shown in Fig. 6.

Fig. 6. MOR mechanism.

a–c Calculated reaction free energy and energy barriers for methanol oxidation to CO at: a Pt-RuO2(110), b PtC3, and c Pt-Ru(0001). d Calculated reaction free energy and energy barriers for CO oxidation on Pt-RuO2(110). In (a), the relative energies of CH2O* and corresponding TS2 computed for RuO2(110) are shown for reference.

For the MOR on Pt-RuO2(110), the CH3OH molecule preferentially adsorbs on the site above Rucus with a free energy of ‒0.54 eV (Fig. 6a and Supplementary Fig. 22). Thanks to the highly active Obr, the scission of O‒H bond of the adsorbed CH3OH molecule (CH3OH* → CH3O* + H*) proceeds spontaneously (Fig. 6a). For this elementary step, the cleaved H atom bonds to its neighboring Obr with a reaction free energy of ‒0.26 eV (Supplementary Fig. 22b and Supplementary Table 3). More importantly, the removal of H* (H* + OH‒ → H2O + e‒) to leave the sole adsorbate of CH3O* is slightly endothermic with a free energy requirement of 0.17 eV at pH = 13 (Supplementary Table 3). Considering that the O‒H bond scission is energetically favorable, we may propose that the MOR starts with the break of the O‒H bond in the methanol molecule and follows the CH3OH* → CH3O* → CH2O* → CHO* → CO* pathway32,33. As illustrated in Fig. 6a, the subsequent activations of the C‒H bond require energy barriers of 0.39 (CH3O* → TS1 → CH2O*), 0.49 (CH2O* → TS2 → CHO), and 0.29 eV (CHO* → TS3 → CO*), respectively. The dehydrogenation of CH2O* has been predicted to be the rate-limiting step for the above-mentioned pathway to CO. This result is consistent with DFT calculations from the Nørskov group showing that MOR on RuO2(110) is limited by the dehydrogenation of CH2O*,34. Nevertheless, the activation barrier on Pt-RuO2(110) was predicted to be only 0.49 eV, which is lower than the 0.71 eV we computed for pure RuO2(110) (Fig. 6a and Supplementary Fig. 23). This barrier reduction can be mainly attributed to the upshift in CH2O* energy due to Pt, which lowers the energy difference between the initial and the transition state of TS2. The final dehydrogenation of CHO (CHO* → TS3 → CO*) was predicted to have a barrier of 0.29 eV, implying that the oxidation of CHO is energetically favored compared to the other two reaction steps (CH3O* →TS1 → CH2O* and CH2O* → TS2 → CHO). The smaller barriers of all the above-mentioned reactions, in particular, the lower barrier of the dehydrogenation of CH2O* (CH2O* → TS2 → CHO), suggest that the introduction of Pt single atom into RuO2 improves the MOR kinetics. Both experimental evidence and DFT simulations support that the Pt‒O3f‒Ru configuration together with the Obr atoms is the active center, which is responsible for catalyzing the CH3OH into CO*.

The calculated free energy diagrams for MOR on PtC3 and Pt-Ru(0001) are shown in Fig. 6b, c for comparison. The adsorption free energy of CH3OH on the PtC3 and Pt-Ru(0001) are ‒0.03 and 0.15 eV, respectively. Both values are less negative than that computed for Pt-RuO2(110) (‒0.54 eV), implying a weaker interaction between both PtC3 and Pt-Ru(0001) and the methanol molecule in comparison to Pt-RuO2(110). Moreover, the energy barriers needed to cleave the O‒H and C‒H bonds are significantly higher than those of Pt-RuO2(110) (Fig. 6a–c). The much higher barriers compared to those on Pt-RuO2(110) indicate that the MOR is energetically costly for both PtC3 and Pt-Ru(0001) substrates. These computational results agree with experiments as both suggest that Pt1/VXC-72 and Pt1/RuO2-H are inert towards MOR. As for Pt-RuO2(101), the highest reaction activation barrier (0.79 eV) is much lower than that of both PtC3 (2.06 eV) and Pt-Ru(0001) (1.08 eV) (Supplementary Fig. 24 and Fig. 6b, c), suggesting the enhanced activity of Pt1/RuO2 compared to Pt1/VXC-72 and Pt1/RuO2-H towards MOR.

We also theoretically studied the stability of Pt-RuO2(110) with respect to CO poisoning, or equivalently, the oxidation CO into CO2. When OH* is present, CO oxidation proceeds through the CO* + OH* → TS1 → cis-COOH* → TS2 → trans-COOH* → TS3 → trans-COOH* → CO2* pathway35, as shown in Fig. 6d. The rate-limiting step of the overall reaction was predicted to be the cis-COOH* → trans-COOH* step (i.e., the rotation of the H atom in cis-COOH*) with activation barrier of 0.35 eV. This value is even smaller than the barrier computed for the dehydrogenation of formaldehyde on Pt-RuO2(110), implying that the presence of Pt facilitates the full oxidation of methanol into CO2 on RuO2(110). We further note that the trans-COOH* → CO2* step (i.e., the desorption of CO2*) has a positive ΔG of 0.33 eV, indicating that the release of CO2 is spontaneous. It is worth mentioning that the adsorption free energies of CO on the PtC3 and Pt-Ru(0001) are ‒0.81 and ‒0.92 eV (Fig. 6b, c), respectively. Both values are much more negative compared to that computed for Pt-RuO2(110) (‒0.54 eV), suggesting an increased interaction between CO and the PtC3/Pt-Ru(0001). According to the Brønsted-Evans-Polanyi relationship36,37, higher binding energy correlates to higher activation energies and lower thermodynamic driving force for the reaction. Therefore, we predict that the CO electrooxidation on PtC3 and Pt-Ru(0001) is much more energetically unfavorable with sluggish kinetics in agreement with the experiments above.

In addition to the activation energy barriers, onset potentials were also calculated (Supplementary Fig. 25). The potential-determining step (i.e., the elementary step with the highest onset potential) was found to be, for all three catalysts, the stripping off methoxyl proton (CH3O* → CH2O*). Accordingly, the onset potentials were predicted to be 0.26, 0.92, and 0.33 V for Pt-RuO2(110), PtC3, and Pt-Ru(0001), respectively. Both the lower onset potential and smaller activation barriers suggest that Pt1/RuO2 SACs are more favorable towards the methanol oxidation than Pt1/VXC-72 and Pt1/RuO2-H, in agreement with experimental results.

To unravel the mechanisms underpinning the high MOR activity, we calculated the projected density of states (PDOS) and charge analysis for both Pt and Rucus atoms in the Pt-RuO2(110). It is apparent that only the spin-up state of the dz2 orbital of Pt is filled while the dz2 orbital of Rucus is empty (Supplementary Fig. 26). Consistent with the PDOS results, the charge density difference also suggests that more electrons are depleted for the Rucus than the Pt atom (Supplementary Fig. 27). Specifically, Bader charge analysis suggests that Rucus and Pt on Pt-RuO2(110) lose 1.61 e and 1.22 e, respectively (Supplementary Table 4). Thanks to the empty anti-bonding dz2 orbital, a stronger interaction between the adsorbate (e.g., CH3OH) and Rucus than that of Pt is predicted, in agreement with the calculated adsorption free energies (Supplementary Fig. 22a–c). The orbital interaction between adsorbate, e.g., CH3OH, and the dz2 orbital is shown in Supplementary Fig. 28. In the case of Rucus, for which the dz2 orbital is empty, the methanol molecule is well stabilized due to the favorable two-center two-electron interaction. Instead, the anti-bonding dz2 orbital of Pt is filled with one spin-up electron, resulting in the less-favorable two-center three-electron interaction, thereby destabilizing the adsorbate. Specifically, the filled anti-bonding Pt orbital leads to a weaker adsorption free energy of formaldehyde on Pt-RuO2(110) (‒0.26 eV) compared to that of RuO2(110) (‒0.88 eV) (Fig. 6a).The increased energy towards CH2O* thus lowers the activation barrier (TS2) for the subsequent dehydrogenation (Fig. 6a). We further evaluated the PDOS of the d orbitals with a Pt atom placed on different substrates. Compared to Pt-Ru(0001), the d orbitals of Pt on Pt-RuO2(110) are characterized by greater delocalization (Supplementary Fig. 29)32 as well as a larger density near the Fermi level. These features facilitate electron transfer and contribute to the enhanced MOR activity of Pt1/RuO235. In contrast, the Pt PDOS of PtC3 is small at the Fermi level (Supplementary Fig. 29), suggesting that Pt1/VXC-72 is an ineffective MOR catalyst9. Besides, the additional d electrons in the Pt of PtC3 and Pt-Ru(0001) cause stronger repulsion to the coming ligand, e.g., CH3OH, thus weakening the adsorption of methanol and hindering MOR.

Discussion

We successfully prepared Pt single atoms characterized by distinct coordination environment by leveraging a simple impregnation–adsorption method and tailoring the support. The Pt1/RuO2 SACs not only had a superb mass activity of 6766 mA mg‒1Pt but also CO resistibility towards the MOR. Pt1/RuO2 was shown to be a significantly better catalyst compared to the commercial Pt/C benchmark. Theoretical simulations revealed that the Pt‒O3f‒Rucus with Obr in Pt1/RuO2 favored dehydrogenation of methanol with a low energy barrier and onset potential compared to that of Pt‒C and Pt‒Ru bonds. Moreover, CO at Pt1/RuO2 can be removed via electrooxidation at low potentials, leading to enhanced anti-poisoning capability. The discovery of Pt1/RuO2 SACs provides an approach to explore Pt SACs for MOR and related alcohol oxidation reaction.

Methods

Materials

H2PtCl6·6H2O, RuO2, and commercial Pt/C (20 wt% Pt) were purchased from Sigma-Aldrich. Carbon black (Vulcan XC-72) was bought from The Cabot Corporation. Methanol and ethanol were purchased from Scharlab.

Synthesis of Pt1/RuO2 and control catalysts

The Pt1/RuO2 catalysts were prepared by an impregnation–adsorption method. Briefly, 50 mg of RuO2 were dispersed in 80 mL of distilled water. Next, 0.25 mL of a H2PtCl6·6H2O solution (2 mg mL‒1) was added dropwise; stirring at 70 °C for 5 h followed this. The product was obtained by filtration, repeated washing with water and ethanol, and drying at 70 °C overnight. Pt1/VXC-72 was prepared in a similar manner by using VXC-72. Pt1/RuO2-H catalyst was obtained by reducing Pt1/RuO2 in H2 at 80 °C. The Pt1/RuO2-500 and Pt1/RuO2-700 catalysts were obtained under the heat treatment of Pt1/RuO2 in the air at 500 and 700 °C, respectively.

Catalyst characterization

The structure and morphology of the catalysts were characterized by XRD (PANalytical X’pert Pro, Cu Kα radiation), XPS (Axis Ultra DLD), and TEM (JEOL-2010F). The electron paramagnetic resonance (EPR) spectra were recorded at room temperature by using JEOL JES-FA200. The HAADF-STEM and EDS mapping were carried out using a double Cs-corrected FEI-Themis microscope operated at 300 kV. The STEM images were obtained with a convergent semi-angle of 25.1 mrad. The HAADF collection angle was 48–200 mrad. The XAFS at the Pt L3-edge was obtained on beamline 10C at the Pohang Light Source (PLS) in the Pohang Accelerator Laboratory (PAL), Republic of Korea. The XAFS data were processed and analyzed using ATHENA and ARTEMIS38. The Pt content in the catalyst was measured by ultraviolet visible spectroscopy (UV-vis, Lambda 20, Perkin Elmer). An appropriate amount of a H2PtCl6·6H2O solution (2 mg mL‒1) was added to deionized water and diluted to 100 mL. After the adsorption of Pt species by RuO2 in solution, the residual solution was measured by UV-vis, and by the comparison of the absorbance with the working curve, the Pt content in RuO2 was estimated.

Electrochemical characterization

The electrochemical tests were conducted using a CHI 900D workstation (CH Instruments). A three-electrode setup was used and all tests were conducted at 25 °C. A graphite rod was used as a counter electrode; (KCl saturated) Ag/AgCl was selected as the reference electrode. To prepare the working electrode, 1 mg of catalyst and 1 mg of VXC-72 were ultrasonically dispersed in a mixture of 200 μL of water, 50 μL of ethanol, and 20 μL of Nafion (Dupont, 5 wt%). Next, 5 μL of the above ink was then placed onto a glassy-carbon electrode (4 mm in diameter) and dried at room temperature. In an N2-purged 0.1 mol L −1 KOH and 1 mol L −1 methanol/ethanol solution, the MOR/EOR electrocatalytic activity was evaluated by CV (scan rate was set at 50 mV s−1). CV scans were performed until a convergent response was recorded. For the CO stripping tests, CO was adsorbed on the catalyst by bubbling CO in 0.1 mol L −1 KOH for 10 min at a potential of −0.95 V vs. Ag/AgCl. CO in the solution was eliminated by bubbling the electrolyte with N2 for 20 min. Stripping tests were carried out from −0.95 to 0 V at 50 mV s−1 for two consecutive scans. All measured potentials were converted to the RHE using ERHE = EAg/AgCl + 0.198 + 0.059 × pH.

Computational details

Models

The RuO2 substrate was modeled by the p(3 × 1) unit cell of RuO2(110) in a six-layered slab with 18 Ru atoms and 36 O atoms. The RuO2(110) was chosen because this surface has previously been reported to have the most thermodynamically favorable free energy during most synthesis procedures34,39,40. The RuO2(110) surface was constructed from the relaxed RuO2 bulk in the P42/mnm space group, which has a lattice constant of a = b = 4.52 Å and c = 3.12 Å41. For a stoichiometric RuO2(110) surface, there are several different sites, i.e., the 1-fold coordinatively unsaturated Ru (Rucus), the coordinatively saturated Ru (Rusat), the undercoordinated bridging O (Obr), and the 3-fold coordinatively bonded O (O3f) (Supplementary Fig. 19a). Among these sites, Rucus and Obr are widely believed to be catalytically active for chemical reactions41,42. To simulate the Pt1/RuO2, two different structures with one Pt atom located at either the Rucus or the Rusat of RuO2(110) were considered (Supplementary Fig. 19b). It was noticed that the Pt at the Rucus shows lower energy by 0.21 eV compared to that at the Rusat, implying that the single Pt atom favors the Rucus (Supplementary Fig. 19b). A 5 × 5 graphene sheet and a five-layered slab of p(3 × 3) unit cell Ru(0001) were constructed to simulate the VXC-72 and the Ru substrate, respectively. One C atom in the graphene sheet and one top layer Ru atom in the Ru(0001) slab were replaced by the Pt to model the Pt1/VXC-72 and Pt1/RuO2-H, respectively (Supplementary Figs. 20 and 21). A vacuum space of 15 Å along the c direction was added for all substrates to avoid strong interactions between neighboring substrates.

DFT calculations

All the spin-polarized first-principle calculations were performed using the Vienna Ab initio Simulation Package (VASP)43,44 with a plane-wave basis set defined by a kinetic energy cutoff 400 eV. The projector augmented wave (PAW)45 pseudopotentials with valence-electron configurations of 2s22p2, 2s22p4, 1s1, 4p64d75s1, and 5d96s1 were employed for C, O, H, Ru, and Pt, respectively. The electron exchange-correlation was described using the Perdew-Burk-Ernzerhof (PBE)46 functional under the generalized gradient approximation (GGA) scheme. For all the calculations, a dipole correction along the c direction was also applied. The bottom three layers of the RuO2(110) and the Ru(0001) slabs were fixed during the relaxation, whereas the top three layers were fully relaxed until the energy and force converged within 10−5 eV and 0.02 eV Å−1, respectively. The Brillouin zones were sampled using Gamma centered k-points with spacing smaller than 2π × 0.04 Å−1.

The binding energy of one Pt atom with the substrate was evaluated as Ebind = E(Pt-sub) ‒ E(Pt) ‒ E(sub), where E(Pt-sub) and E(sub) are the energies of the system with one Pt atom and the pure substrate, respectively, and E(Pt) is the total energy per atom for Pt bulk metal. The transition states (TSs) were located by the combination of both the nudged elastic band (NEB) method and the dimer method47–49. All the TSs were confirmed by noticing only one imaginary vibrational frequency. The adsorption energy of the intermediate was calculated by ΔEads = E(adsorbate-sub) ‒ E(sub) ‒ E(adsorbate), where E(adsorbate-sub) is the energy of the system with the adsorbate on the substrate, E(sub) is the energy of the clean substrate, and E(adsorbate) is the energy of the isolated adsorbate molecule in the vacuum. The adsorption free energy was further calculated as ΔGads = ΔEads + ΔZPE ‒ TΔS, where ΔZPE is the change of zero-point energies, and ΔS is the entropy difference, and T is the temperature (298.15 K). The activation energy was calculated as Ea = E(TS) ‒ E(IS), where E(TS) and E(IS) are the energies for the TS and the initial state (IS).

The change in Gibbs free energy (ΔG) for all the reaction steps were calculated based on the method developed by Nørskov et al.50 At experimental condition (U = 0, pH, p = 1 bar, T = 298 K), the free energy ΔG is calculated as ΔG = ΔE + ΔZPE − TΔS + ΔGpH, where ΔE is the energy difference by DFT calculations, and ΔGpH corresponds to the correction due to the pH that is different from 0, i.e., ΔGpH = − kBT ln[H+] = 0.0592 pH. The free energy of OH− was calculated by G(OH−) = G(H2O(l)) – G(H+) = G(H2O(l)) – G(H2(g))/251, where G(H2O(l)) is the Gibbs free energy of one water molecule under the saturated vapor pressure (0.035 bar), and G(H+) is taken as half of G(H2(g)), i.e., the free energy of H2(g) at standard condition (p = 1 bar, T = 298 K).

The computational standard hydrogen electrode was used to calculate the onset potentials33,50. Under this framework, the influence of the applied potential U was computed by adding ∆GU = ‒eU to the free energy of a reaction involving the formation of a proton–electron pair. The electrochemical potential pertaining to each elementary step was calculated using Ui = ∆Gi/e, where ∆Gi is the reaction free energy calculated according to Supplementary Table 5. The overall onset potential was estimated as Uonset = max(∆Gi/e)33.

Supplementary information

Acknowledgements

This work was jointly supported by the Research Grants Council of Hong Kong (GRF Projects: 16201820 and 16206019), the Guangzhou Science and Technology Program (No. 201807010074), and the Science and Technology Planning Project of Guangdong Province, China (2017A050506014). M.G. and Q.W. acknowledge funding from the Guangdong Provincial Key Laboratory of Energy Materials for Electric Power with project no. 2018B030322001, Guangdong Innovative and Entrepreneurial Research Team Program (2016ZT06N500), Shenzhen Peacock Plan (KQTD2016022620054656), Shenzhen Clean Energy Research Institute (No. CERI-KY-2019-003). The authors also acknowledge the technical assistance from the Materials Characterization and Preparation Facilities (MCPF) of HKUST.

Author contributions

F.C. supervised the project. Z.Q.Z. conceived the idea, designed and performed the experiments. J.P.L. carried out the DFT calculations. J.W. and J.L. did the XAFS characterizations. Q.W. and M.G. performed the HAADF-STEM measurements. K.W. and Z.H.T. helped with the XPS measurements. Y.H.W. did the UV-vis measurements. Z.Q.Z., J.P.L., and F.C. wrote the manuscript. T.S.Z. commented on the manuscript. All the authors contributed to the manuscript.

Data availability

All the raw data used in this work are available on reasonable request from the corresponding author.

Competing interests

The authors declare no competing interests.

Footnotes

Peer review informationNature Communications thanks the reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

These authors contributed equally: Zhiqi Zhang, Jiapeng Liu, Jian Wang.

Supplementary information

The online version contains supplementary material available at 10.1038/s41467-021-25562-y.

References

- 1.Kakati N, et al. Anode catalysts for direct methanol fuel cells in acidic media: do we have any alternative for Pt or Pt–Ru? Chem. Rev. 2014;114:12397–12429. doi: 10.1021/cr400389f. [DOI] [PubMed] [Google Scholar]

- 2.Zhao X, et al. Recent advances in catalysts for direct methanol fuel cells. Energy Environ. Sci. 2011;4:2736–2753. doi: 10.1039/c1ee01307f. [DOI] [Google Scholar]

- 3.Chen S, et al. High-performance Pt–Co nanoframes for fuel-cell electrocatalysis. Nano Lett. 2020;20:1974–1979. doi: 10.1021/acs.nanolett.9b05251. [DOI] [PubMed] [Google Scholar]

- 4.Huang J, et al. PtCuNi tetrahedra catalysts with tailored surfaces for efficient alcohol oxidation. Nano Lett. 2019;19:5431–5436. doi: 10.1021/acs.nanolett.9b01937. [DOI] [PubMed] [Google Scholar]

- 5.Huang W, et al. Highly active and durable methanol oxidation electrocatalyst based on the synergy of platinum–nickel hydroxide–graphene. Nat. Commun. 2015;6:10035. doi: 10.1038/ncomms10035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Zhang Z, et al. Efficient ternary synergism of platinum/tin oxide/nitrogen-doped carbon leading to high-performance ethanol oxidation. ACS Catal. 2018;8:8477–8483. doi: 10.1021/acscatal.8b01573. [DOI] [Google Scholar]

- 7.Wang X, et al. Bismuth oxyhydroxide-Pt inverse interface for enhanced methanol electrooxidation performance. Nano Lett. 2020;20:7751–7759. doi: 10.1021/acs.nanolett.0c03340. [DOI] [PubMed] [Google Scholar]

- 8.Zhao D, et al. Atomic site electrocatalysts for water splitting, oxygen reduction and selective oxidation. Chem. Soc. Rev. 2020;49:2215–2264. doi: 10.1039/C9CS00869A. [DOI] [PubMed] [Google Scholar]

- 9.Xiong Y, et al. Single-atom Rh/N-doped carbon electrocatalyst for formic acid oxidation. Nat. Nanotechnol. 2020;15:390–397. doi: 10.1038/s41565-020-0665-x. [DOI] [PubMed] [Google Scholar]

- 10.Li Z, et al. Iridium single-atom catalyst on nitrogen-doped carbon for formic acid oxidation synthesized using a general host–guest strategy. Nat. Chem. 2020;12:764–772. doi: 10.1038/s41557-020-0473-9. [DOI] [PubMed] [Google Scholar]

- 11.Zhang Z, et al. Atomically dispersed materials for rechargeable batteries. Nano Energy. 2020;76:105085. doi: 10.1016/j.nanoen.2020.105085. [DOI] [Google Scholar]

- 12.Wang Q, et al. Ultrahigh-loading of Ir single atoms on NiO matrix to dramatically enhance oxygen evolution reaction. J. Am. Chem. Soc. 2020;142:7425–7433. doi: 10.1021/jacs.9b12642. [DOI] [PubMed] [Google Scholar]

- 13.Qiao B, et al. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 2011;3:634–641. doi: 10.1038/nchem.1095. [DOI] [PubMed] [Google Scholar]

- 14.Cuesta A. At least three contiguous atoms are necessary for CO formation during methanol electrooxidation on platinum. J. Am. Chem. Soc. 2006;128:13332–13333. doi: 10.1021/ja0644172. [DOI] [PubMed] [Google Scholar]

- 15.Kim Y-T, et al. Fine size control of platinum on carbon nanotubes: from single atoms to clusters. Angew. Chem. Int. Ed. 2006;45:407–411. doi: 10.1002/anie.200501792. [DOI] [PubMed] [Google Scholar]

- 16.Qin R, Liu K, Wu Q, Zheng N. Surface coordination chemistry of atomically dispersed metal catalysts. Chem. Rev. 2020;120:11810–11899. doi: 10.1021/acs.chemrev.0c00094. [DOI] [PubMed] [Google Scholar]

- 17.Zhang J, et al. Tuning the coordination environment in single-atom catalysts to achieve highly efficient oxygen reduction reactions. J. Am. Chem. Soc. 2019;141:20118–20126. doi: 10.1021/jacs.9b09352. [DOI] [PubMed] [Google Scholar]

- 18.Tang C, et al. Coordination tunes selectivity: two-electron oxygen reduction on high-loading molybdenum single-atom catalysts. Angew. Chem. Int. Ed. 2020;59:9171–9176. doi: 10.1002/anie.202003842. [DOI] [PubMed] [Google Scholar]

- 19.Li S, et al. Impact of the coordination environment on atomically dispersed Pt catalysts for oxygen reduction reaction. ACS Catal. 2020;10:907–913. doi: 10.1021/acscatal.9b04558. [DOI] [Google Scholar]

- 20.Gong Y-N, et al. Regulating the coordination environment of MOF-templated single-atom nickel electrocatalysts for boosting CO2 reduction. Angew. Chem. Int. Ed. 2020;59:2705–2709. doi: 10.1002/anie.201914977. [DOI] [PubMed] [Google Scholar]

- 21.Zhang Z, et al. The simplest construction of single-site catalysts by the synergism of micropore trapping and nitrogen anchoring. Nat. Commun. 2019;10:1657. doi: 10.1038/s41467-019-09596-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Chen Y, et al. Engineering the atomic interface with single platinum atoms for enhanced photocatalytic hydrogen production. Angew. Chem. Int. Ed. 2020;59:1295–1301. doi: 10.1002/anie.201912439. [DOI] [PubMed] [Google Scholar]

- 23.Zhou, K. L. et al. Seamlessly conductive Co(OH)2 tailored atomically dispersed Pt electrocatalyst with a hierarchical nanostructure for an efficient hydrogen evolution reaction. Energy Environ. Sci. 13, 3082–3092 (2020).

- 24.Yoshida, H., Nonoyama, S. & Hattori, Y. Y. T. Quantitative determination of platinum oxidation state by XANES analysis. Phys. Scr. T115, 813–815 (2005).

- 25.Cao L, et al. Dynamic oxygen adsorption on single-atomic ruthenium catalyst with high performance for acidic oxygen evolution reaction. Nat. Commun. 2019;10:4849. doi: 10.1038/s41467-019-12886-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Huang Z-F, et al. Chemical and structural origin of lattice oxygen oxidation in Co–Zn oxyhydroxide oxygen evolution electrocatalysts. Nat. Energy. 2019;4:329–338. doi: 10.1038/s41560-019-0355-9. [DOI] [Google Scholar]

- 27.Zhu C, Fu S, Shi Q, Du D, Lin Y. Single-atom electrocatalysts. Angew. Chem. Int. Ed. 2017;56:13944–13960. doi: 10.1002/anie.201703864. [DOI] [PubMed] [Google Scholar]

- 28.Zhang W, et al. Ultrathin PtNiM (M = Rh, Os, and Ir) nanowires as efficient fuel oxidation electrocatalytic materials. Adv. Mater. 2019;31:1805833. doi: 10.1002/adma.201805833. [DOI] [PubMed] [Google Scholar]

- 29.Seh ZW, et al. Combining theory and experiment in electrocatalysis: insights into materials design. Science. 2017;355:eaad4998. doi: 10.1126/science.aad4998. [DOI] [PubMed] [Google Scholar]

- 30.Liu M, et al. Atomically dispersed metal catalysts for the oxygen reduction reaction: synthesis, characterization, reaction mechanisms and electrochemical energy applications. Energy Environ. Sci. 2019;12:2890–2923. doi: 10.1039/C9EE01722D. [DOI] [Google Scholar]

- 31.Zhang L, et al. Atomic layer deposited Pt–Ru dual-metal dimers and identifying their active sites for hydrogen evolution reaction. Nat. Commun. 2019;10:4936. doi: 10.1038/s41467-019-12887-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Zhao L, et al. The oxidation of methanol on PtRu(111): a periodic density functional theory investigation. J. Phys. Chem. C. 2015;119:20389–20400. doi: 10.1021/acs.jpcc.5b03951. [DOI] [Google Scholar]

- 33.Ferrin P, Mavrikakis M. Structure sensitivity of methanol electrooxidation on transition metals. J. Am. Chem. Soc. 2009;131:14381–14389. doi: 10.1021/ja904010u. [DOI] [PubMed] [Google Scholar]

- 34.Latimer AA, Abild-Pedersen F, Nørskov JK. A theoretical study of methanol oxidation on RuO2(110): bridging the pressure gap. ACS Catal. 2017;7:4527–4534. doi: 10.1021/acscatal.7b01417. [DOI] [Google Scholar]

- 35.Wang X, et al. Materializing efficient methanol oxidation via electron delocalization in nickel hydroxide nanoribbon. Nat. Commun. 2020;11:4647. doi: 10.1038/s41467-020-18459-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Evans MG, Polanyi M. Further considerations on the thermodynamics of chemical equilibria and reaction rates. Trans. Faraday Soc. 1936;32:1333–1360. doi: 10.1039/tf9363201333. [DOI] [Google Scholar]

- 37.Bronsted JN. Acid and basic catalysis. Chem. Rev. 1928;5:231–338. doi: 10.1021/cr60019a001. [DOI] [Google Scholar]

- 38.Ravel B, Newville M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 2005;12:537–541. doi: 10.1107/S0909049505012719. [DOI] [PubMed] [Google Scholar]

- 39.Wang T, Jelic J, Rosenthal D, Reuter K. Exploring pretreatment–morphology relationships: ab initio wulff construction for RuO2 nanoparticles under oxidising conditions. ChemCatChem. 2013;5:3398–3403. doi: 10.1002/cctc.201300168. [DOI] [Google Scholar]

- 40.Wang H, Schneider WF. Effects of coverage on the structures, energetics, and electronics of oxygen adsorption on RuO2(110) J. Chem. Phys. 2007;127:064706. doi: 10.1063/1.2752501. [DOI] [PubMed] [Google Scholar]

- 41.Over H, et al. Atomic-scale structure and catalytic reactivity of the RuO2(110) surface. Science. 2000;287:1474–1476. doi: 10.1126/science.287.5457.1474. [DOI] [PubMed] [Google Scholar]

- 42.Knapp M, et al. Complex interaction of hydrogen with the RuO2(110) surface. J. Phys. Chem. C. 2007;111:5363–5373. doi: 10.1021/jp0667339. [DOI] [Google Scholar]

- 43.Kresse G, Furthmüller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 1996;54:11169–11186. doi: 10.1103/PhysRevB.54.11169. [DOI] [PubMed] [Google Scholar]

- 44.Kresse G, Furthmüller J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 1996;6:15–50. doi: 10.1016/0927-0256(96)00008-0. [DOI] [PubMed] [Google Scholar]

- 45.Blöchl PE. Projector augmented-wave method. Phys. Rev. B. 1994;50:17953–17979. doi: 10.1103/physrevb.50.17953. [DOI] [PubMed] [Google Scholar]

- 46.Perdew JP, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996;77:3865–3868. doi: 10.1103/PhysRevLett.77.3865. [DOI] [PubMed] [Google Scholar]

- 47.Henkelman G, Jónsson H. A dimer method for finding saddle points on high dimensional potential surfaces using only first derivatives. J. Chem. Phys. 1999;111:7010–7022. doi: 10.1063/1.480097. [DOI] [Google Scholar]

- 48.Henkelman G, Jónsson H. Improved tangent estimate in the nudged elastic band method for finding minimum energy paths and saddle points. J. Chem. Phys. 2000;113:9978–9985. doi: 10.1063/1.1323224. [DOI] [Google Scholar]

- 49.Henkelman G, Uberuaga BP, Jónsson H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 2000;113:9901–9904. doi: 10.1063/1.1329672. [DOI] [Google Scholar]

- 50.Nørskov JK, et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B. 2004;108:17886–17892. doi: 10.1021/jp047349j. [DOI] [Google Scholar]

- 51.Jiao Y, Zheng Y, Jaroniec M, Qiao SZ. Origin of the electrocatalytic oxygen reduction activity of graphene-based catalysts: a roadmap to achieve the best performance. J. Am. Chem. Soc. 2014;136:4394–4403. doi: 10.1021/ja500432h. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All the raw data used in this work are available on reasonable request from the corresponding author.