Abstract

Hospitals face catastrophic financial challenges in light of the coronavirus disease 2019 (COVID-19) pandemic. Acute shortages in materials such as masks, ventilators, intensive care unit capacity, and personal protective equipment (PPE) are a significant concern. The future success of supply chain management involves increasing the transparency of where our raw materials are sourced, diversifying of our product resources, and improving our technology that is able to predict potential shortages. It is also important to develop a proactive budgeting strategy to meet supply demands through early designation of dependable roles to support organizations and through the education of healthcare staff. In this paper, we discuss supply chain management, governance and financing, emergency protocols, including emergency procurement and supply chain, supply chain gaps and how to address them, and the importance of communication in the times of crisis.

Keywords: COVID, crisis, emergency preparedness, supply chain management, emergency management, hospital resiliency

Introduction

The “supply and demand” relationship of goods to our society is centered around a chain of events that must occur to enable the goods to reach their destination, the supply chain. Healthcare is an essential entity that can be affected by challenges that arise in the supply chain, which include any threat to breakdown the delivery of supplies at any stage of the distribution process. With the rapid advent of the coronavirus, coronavirus disease 2019 (COVID-19), in 2020, shifts in the supply chain of many goods, including personal protective equipment (PPE) occurred where the demand of these goods quickly outweighed the supply. Because nobody was prepared for or predicted the spread of COVID-19, a novel virus with no record of spread, side effects, or treatment, society was unsure of how to respond. This led to widespread panic and hoarding of medical supplies, face masks, gloves, hand sanitizer, soap, and everyday goods such as bottled water and toilet paper. Hospitals also became overwhelmed with a rapid increase in patient admissions to the ICU and patients who needed ventilators for respiratory support. This overwhelming demand for the supply of medical supplies was unprecedented, since the last major pandemic is considered to be the Spanish flu in the early 1900s. Therefore, COVID-19 exposed a large problem in supply chain management: preparedness for a worldwide pandemic.

The current system of supply chain methods employs a strategy which allows for little to no redundancy with extremely high efficiency [1]. For this reason, products including PPE and medications can be made for low prices. Unfortunately, this model is only successful when demand is predictable. When deviations from the streamlining process occur, gaps become apparent, and risks increase [1]. Therefore, this paper will discuss supply chain management in a crisis, governance and financing, emergency protocols, including emergency procurement and supply chain, supply chain gaps and how to address them, and the importance of communication in these tumultuous times.

Governance and financing

The ongoing fall-out from the current COVID-19 pandemic has served as a sobering illustration of the importance of sturdy healthcare supply chains to public health and economic well-being and even the most mundane elements of our daily lives. To mitigate these consequences, it is essential to have well-organized governing bodies to develop protocols well in advance of any potential crisis so that swift action can be taken if and when a threat arises. Two critical elements of supply chain management must be addressed if this is to be accomplished, namely, the designation of which parties will be responsible for developing, maintaining, and distributing the emergency supplies, and identifying a source of financing for the supplies. The 2018 USAID report on Best Practices in Supply Chain Preparedness for Public Health Emergencies outlines how this can be best achieved [2]. While these guidelines were developed to be implemented on the national and international levels, the same principles can be applied on a smaller scale for individual healthcare systems, hospitals, and departments.

The principal among the report's recommendations is the appointment of a single emergency supply chain (ESC) leader and the development of a transparent chain of command. The leader should combine a technical understanding of supply chain logistics with strong leadership and coordination skills. The ESC lead is responsible for recruiting a support team with expertise in forecasting needs and procurement, transport, and storage of supplies in emergencies. It is also valuable if the ESC lead has preexisting relationships with distributors, public health agencies, and other community organizations to help foster coordination between the different actors in the ESC. The successful response to the cholera outbreak in South Sudan in 2017 demonstrates the effectiveness of strong governance. Strong leadership, clear organizational structure, and preexisting coordination frameworks allowed for rapid action, leading to the outbreak [2]. Similarly, after witnessing the devastation imposed on healthcare by crises such as 2001's Hurricane Allison and the terror attacks of September 11, 2001, the Southeast Texas Regional Advisory Council (SETRAC), a coalition of providers, responders, and other healthcare-related partners, was formed. SETRAC has been lauded for its response to Hurricane Harvey in 2017. It helped facilitate the matching of patient needs with available resources within the area and guide transportation through a city ravaged by natural disasters [3].

Another important consideration in developing a plan for ESCs is determining how the ESC will be financed. The most vital element in funding the ESC is establishing a clear budget that identifies emergency funds sources and how they will be accessed. The 2018 USAID report on Best Practices in Supply Chain Preparedness for Public Health Emergencies recommends breaking down the ESC budget into two components: a preparedness fund and a response reserve fund. The preparedness fund is intended to cover such expenses as storage of emergency supplies, inventory management (i.e., rotating out old stock), administrative costs for emergency staff, and routine preparedness training. The reserve fund should be an allotted increase to the preparedness budget if an emergency occurs. Estimating the amount needed in a reserve fund is inherently challenging as insight to both supply and demand in a potential crisis is limited. As such, this budget should be revisited frequently and updated based on the latest forecasting and surveillance data. Sources of funding should be identified and will likely comprise contributions from government, non-profit organizations, and donors [2]. While it may seem unappealing to allocate money for events that are not certain to occur, research shows that investment in preparedness yields tremendous returns when a crisis inevitably occurs [4].

It is essential to conduct regular personnel training and readiness exercises in the same vein to prepare response staff for ESC operations. Simulation of crisis situations helps to keep staff aware of emergency protocols as well as identify areas for improvement in the ESC. A 2007 avian flu outbreak prompted the Nigerian government to begin conducting semiannual pandemic response simulations. As such, Nigeria has quelled the damage from subsequent influenza outbreaks [2]. Similarly, after the 2008 recession, regular “stress testing” testing of banks became standard practice. As a result, banks are now more resilient and better equipped for future economic crises. Indeed, in light of the devastation caused by COVID-19, many in the public health field call for mandatory rigorous stress testing of PPE manufacturers and others involved in ESC responses to ensure that they can adequately respond to future emergencies [5]. It is also necessary to have a work schedule plan of action to use in the event of a pandemic or disaster. Shift work of one week on one week off and an increased patient-to-worker ratio can decrease exposure of workers and allow for healthcare facilities to continue to function [6].

Emergency protocols

Routine supply chains (RSCs) are often complex. Gaps in supply chains develop from mismatched supply and demand. Disruptions can occur at any level for various reasons, for example, geopolitical unrest, climate-related events, and public health crises [7]. There is a heightened need for resilience of supply chain integrity and space for ESC protocols to be activated during these circumstances.

Governing bodies must establish a defined threshold to activate an ESC. Failure to identify crises can rapidly propagate the scale of damage. In 2017, the Democratic Republic of Congo (DRC) swiftly and decisively launched a coordinated response at the first Ebola case. As a result, the Ebola outbreak in DRC ended in 42 days, with only four deaths [8].

The efficacy of ESC relies on a multifaceted protocol to achieve the most significant benefit. Local and state offices play an essential role in identifying stakeholders and managing emergency support functions [9]. First, transportation, communication, and energy infrastructures are vital to effective emergency response. Maintaining patient access to care is essential, such as aviation or road access for emergency medical services (EMS). For example, compromised energy supplies hampered the 2005 response to Hurricane Katrina in New Orleans, Louisiana [10]. Next, logistical management is critical in providing real-time awareness and data to healthcare organizations. Public health leadership may need to forecast surge capacity. While good management can never substitute for dedicated practitioners, it is crucial that they have the resources to do their jobs [11]. The media can also have a significant effect on the supply chain. The media should focus on relevant messages to the affected population, such as directions or cautions along the peri-emergency timeline. Lastly, there should be plans in place for long-term community recovery with contingency conditions to return to conventional care models and RSCs [9].

The separation between the emergency and RSCs is imperative. ESCs should be stand-alone entities with routine maintenance [12]. Merging the ESC with RSC may lead to undersupply during a crisis, and could overwhelm or compromise the RSC, leading to a prolonged return to normalcy [13]. During the 2009H1N1 outbreak, emphasis was placed on vaccination delivery; however, oversight of vaccine administration's interdependency on syringe and bandage supply effectively slowed response as ancillary supplies depleted [13]. The full separation of ESC from RSC proves difficult in the modern supply chain structure that is pressured to reduce inventory costs [13]. For example, Kaiser Permanente boasts a “just-in-time” 24-h replenishment model, which offers little elasticity. Such inelastic models require difficult prediction of emergency events and rapid phase transitions, often creating lead time delay [13]. During the 2010 cholera outbreak in Haiti, early emergency responses supported by CDC funds were outpaced by disease spread; therefore, Haiti could compensate by utilizing existing supply chains to facilitate essential supply distribution until further measures were achieved [14] (see Table 1 ).

Table 1.

Emergency support functions necessary for an emergency protocol.

| 1) TRANSPORTATION | Aviation, prehospital/EMS support, water navigations kept open, etc. |

| 2) COMMUNICATION | Call centers, 911 available, etc. |

| 3) PUBLIC WORKS | Road access, electricity/generator supplies, drinking water, etc. |

| 4) LOGISTICS MANAGEMENT | Provide HCO with resources: personnel, supplies, etc. |

| 5) PUBLIC HEALTH | Mass care, human services, leadership direction, predicting needs, etc. |

| 6) EXTERNAL AFFAIRS | Media relations, community relations, etc. |

| 7) COMMUNITY RECOVERY | Long-term plan, return to functional normalcy |

EMS: emergency medical services; HCO: healthcare organization.

Emergency procurement and supply chain

Commodity planning plays an essential role in ensuring the prompt early phase of response during an outbreak. Before the occurrence of a public health disaster, the hospital and especially the operation rooms should have identified the required commodities' types and specifications. Although the outbreak's nature is unpredictable, efforts can still be made to ensure sufficient PPE and emergency response equipment supplies, which will be in high demand regardless of the types of the outbreak. Specification for emergency commodities could be challenging, again, due to the uncertainty of the nature of the upcoming disaster. It requires the government and the public health organization's assistance and guidance, which closely monitor the occurrence and progress of disease outbreaks. Furthermore, quantity forecasting (calculating the quantities of commodities required during a public health emergency) is another crucial element. The successful quantity forecasts rely on critical considerations of various factors, including the demographic data, the geographic factors, the timeframe of response, and the patterns and the epidemiological behavior of the pathogens. A useful model can then be established with inputs of data from the factors mentioned above, thus providing a valuable prediction of the quantity of the critical commodities on demands [15].

Once commodity planning and quantity forecasts are achieved, the commodities’ stockpiling should be carefully arranged to ensure the immediate response in an emergent situation [16]. Stockpiling is carried out at both national and local levels. It is crucial to identify the strategic stock locations at the national level according to the geographic probability of major public health threats. The best practice relies on a system that continually monitors the stock rotations to avoid product expiry. One aspect that is easily neglected is the restock of the commodity after an outbreak, which increases the risk of failing to respond promptly in the next emergency. In addition to an effective monitoring system, the infrastructures, mainly the warehousing and storage, directly impact the stockpiling of commodities. In public health emergencies, the already existing warehouses are often overflowed, and temporary expansion of warehousing will be necessary for a timely way. This can be achieved by either building up additional capacity or renting spaces. The conditions of newly expanded warehousing should be considered, depending on the nature of the new supplies, equipment, warehouse labor, the delivery site setup, and security. The last step for the commodity distribution is the transport of which the efficacy heavily depends on liaising with customs officials, transporters, transport protocols, and mapping routes. Environmental factors such as weather and road conditions and political factors (e.g., travel ban) may also primarily affect transport efficiency. After successfully delivering and using the supplies, waste management will emerge as an issue, especially in an outbreak of infectious disease [17]. Proper safety training of personnel operating the waste disposal is essential to minimize the contamination.

Supply chain gaps and how to address them

To maximize profit margins, manufacturing cycle management (MCM) may keep the strategic national stockpile (SNS) below the level required to meet the demand created by an emergency [18]. As a result, the onset of a crisis state can result in greater demand than the ability to supply, resulting in a shortage. This can be seen in a marked drop in fill rate for drugs needed for ventilator use during the COVID-19 pandemic [19]. However, a shortage may also arise if the area affected by a crisis state is a key supplier of the product. For example, sterile gloves’ production is highly dependent on latex, much of which came from Malaysia in 2016 [20]. Disruption in Malaysia could result in sterile glove shortage worldwide due to dependency on the region for raw material. To mitigate risk, sourcing materials from multiple sources globally would mean that crises encountered in one area would result in a smaller disruption [18]. In addition to the issue of a lack of diversity in sourcing raw materials for goods such as sterile gloves, a new problem arises further down the supply chain in the form of “phantom demand” [18]. This entails warehouses, retail sites, pharmacies, hospitals, and other non-individual consumers placing larger orders than required when expecting or amid crisis, and then canceling excess order once they can meet demand. As a result, there is an illusory spike in demand, disrupting the supply chain, and re-allocating resources unnecessarily. Pandemic supply chain networks (PSCNs) have begun to establish pre-determined guidelines to follow in the event of a crisis to mitigate this phenomenon [18,21]. A potential shortcoming of these PSCNs is their inability to account for variability in demand at the individual consumer level. For example, respiratory pandemics such as COVID-19 resulted in a shortage of N95 respirators caused, at least in part, due to individual consumers purchasing respirators for independent use outside of medical facilities.

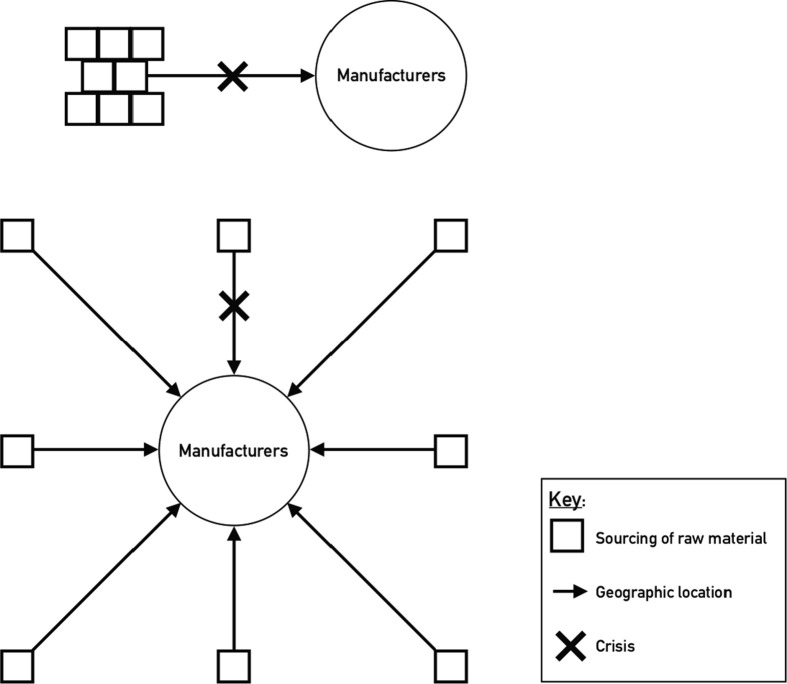

Problems may arise further down the supply chain, as is the case with “phantom demand” and individual consumer purchasing. However, issues faced early in the supply chain, such as at the level of sourcing materials and manufacturing, prove the most problematic as these disruptions can halt the supply chain in its entirety rather than a portion of it. By diversifying the geographic distribution of source materials, the likelihood of supply chain disruption in crisis is diminished (Fig. 1 ). This would involve increasing manufacturing in the USA, as is already being done with mechanical ventilators and sourcing materials globally [22]. Though this may prove more costly than the current supply chain model, as some material sources may charge higher rates than others, this cost is offset by the prevention of loss that would be incurred in the event of a shortage [1]. Diversity in sourcing may offer a way to mitigate damages on a nationwide or global scale (see Fig. 1).

Fig. 1.

A schematic of supply chain gaps and how to address them.

Importance of communication

Communication and proper information access between government agencies and hospitals are imperative, especially to face the challenges posed by the COVID-19 pandemic. Timely communication between supply chain members, including hospital staff, government agencies, and manufacturers, reduces the time needed to obtain essential medical equipment, prevents overstocking, and forestall shortages. Improved inter-communication between the parties involved in the supply of medical equipment leads to standardization of medical regulations. This further reduces the time taken to register essential medicines for the treatment of disease. Medical suppliers must distribute equipment broadly through independent wholesalers and retailers, so the maximum number of patients can be helped.

Moreover, the development of information network systems for improved communication among tiers ensures that high-quality information flows along with the supply chain system promptly. Increasing the number of articulate data analysis experts to the supply chain ecosystem can improve forecasting of need, reduce stock-outs, and avert overstocking medicines. It is essential that agencies align their incentives with patient care, but do not undervalue profitability. Products in high demand in remote areas offer manufacturers a financial incentive to employ individuals who can travel these long distances for the potential profit. In return, the patients in these areas get much-needed access to medications and supplies [23].

In developing countries that encounter continuous shortages of medical supplies, there are no processes by which essential data regarding the financing, supply, and distribution of medications can be easily accessed. Additionally, data on use and demand are not supplied or are unreliable. Improving access to such critical information requires a concerted effort to increase communication between the sectors. Hospitals in developing and developed countries often have little or no communication between those prescribing and those ordering the medications. This can also lead to an insufficient or excess supply of medicines. An inadequate supply of drugs means that patients do not get access to much-needed medications, and physicians cannot help their patients. Having medicines in excess is also problematic because medications expire. Poor information flow and weak incentives can lead to such outcomes [23]. Health agencies must be up to date about the supply of medications and medical supplies. Improved communication and information access are effective at delivering essential products to patients in Zimbabwe [23]. Hence, to ensure that the demand for medications and supplies needed for hospitals’ critical functioning is forecasted as accurately as possible, clear and effective communication is necessary.

Conclusion

Unpredictable supply shortages can occur from the imbalance of supply and demand or disruptions in the supply chain. Approximately, 80% of active pharmaceutical ingredients (APIs) are imported from China and India. Furthermore, India sources ~70% of APIs from China, therefore, a kink in either countries supply chain can cause problems for the USA [1]. However, diversifying the sources where products are supplied can also help mitigate these shortages. Increasing the transparency of where our raw materials are sourced, diversifying of our product resources, and improving our technology that is able to predict potential shortages are all necessary for the future success of supply chain management. It is also imperative to develop a proactive budgeting strategy to meet supply demands. This can be accomplished through early designation of dependable roles to support organizations and through the education of healthcare staff. Selection of a qualified ESC leader is crucial to the success and proper management during the pandemic. Surveillance of preparedness responses should be kept current, with regular training exercises of readiness programs. Strengthening of emergency protocols in universal, national, and local healthcare systems. Despite unpredictability and respective challenges, quantity forecasting of commodities for public health emergencies is paramount. Identify the recurring and outstanding issues with distribution shortcomings during different stages of the pandemic. There are consequences of not addressing logistical gaps and forecasting potential shortages, which could worsen the disaster. Finally, judicious communication at all levels throughout the supply chain reduces incidents or likelihood of shortages. Retain and continue to educate on the importance of communication during a crisis. It is evident that shortcomings appear to be simple and easy to fix during a pandemic but require a complex integrative solution.

Practice Points.

-

•

Hospitals face catastrophic financial challenges in light of the coronavirus disease 2019 (COVID-19) pandemic. Acute shortages in materials like masks, ventilators, intensive care unit capacity, and personal protective equipment (PPE) are a significant concern.

-

•

Correct supply chain strategies and management practices are needed to optimize resources, alleviate shortages, and expand production and storage capacity.

-

•

Improving the management of supply chains is necessary to ensure that healthcare professionals have the resources to do their jobs.

-

•

In the times of crisis, leaders need to address supply chain management, governance and financing, emergency protocols, including emergency procurement and supply chain, supply chain gaps and how to address them, and the importance of communication.

Research Agenda:

-

•

Strategies in diversifying the sources where products are supplied.

-

•

Ways to increase the transparency of where our raw materials are sourced, diversifying product resources, and improving technology that is able to predict potential shortages.

-

•

Develop and study a proactive budgeting strategy to meet supply demands.

-

•

Given the unpredictability and respective challenges, quantity forecasting of commodities for public health emergencies is paramount and needs to be optimized through research.

Declaration of competing interest

Chikezie N Okeagu; Devin S. Reed; Lu Sun; Matthew M. Colontonio; Arthur Rezayev; Yahya A. Ghaffar; Rachel J. Kaye; Henry Liu; Elyse M. Cornett; Charles J. Fox: None declared under financial, general, and institutional competing interests.

Richard D. Urman: Declared research funding from Merck, Medtronic, Acacia, and AcelRx, and fees from Takeda, Pfizer, and Heron.

Alan D. Kaye: Declares fees from Merck.

Acknowledgement

None.

References

- 1.Kaplan DA. How medical supply chains can diversify beyond COVID-19 | Supply Chain Dive, April 15, 2020. Available at: https://www.supplychaindive.com/news/coronavirus-health-pharma-medical-cost-diversify/576021/. [Accessed 25 November 2020].

- 2.USAID. Technical Report: Best practices in supply chain preparedness for public health emergencies. March 1, 2019. Available at: https://www.ghsupplychain.org/best-practices-supply-chain-preparedness-public-health-emergencies. [Accessed 25 November 2020].

- 3.Flynn S.E. Institute SouthEast Texas Regional Advisory Council; 2018. Higher ground: the sophisticated healthcare response of the Southeast Texas regional advisory Council to Hurricane Harvey the global resilience. [Google Scholar]

- 4.Meerkatt H., Kolo P. 2015. UNICEF/WFP return on investment for emergency preparedness study: final report. [Google Scholar]

- 5.Dai T., Bai G., Anderson G.F. PPE supply chain needs data transparency and stress testing. J Gen Intern Med. 2020:1–2. doi: 10.1007/s11606-020-05987-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Mascha E.J., Schober P., Schefold J.C., et al. Staffing with disease-based epidemiologic indices may reduce shortage of intensive care unit staff during the COVID-19 pandemic. Anesth Analg. 2020;131:24–30. doi: 10.1213/ANE.0000000000004849. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Bain & Company. Supply chain lessons from COVID-19: time to refocus on resilience. April 27, 2020. Available at: https://www.bain.com/insights/supply-chain-lessons-from-covid-19/. [Accessed 25 November 2020].

- 8.WHO | Ebola outbreak democratic republic of the Congo 2017. WHO; 2017. [Google Scholar]

- 9.Hanfling D., Hick J.L., Stroud C. National Academies Press; 2013. Crisis standards of care: a toolkit for indicators and triggers. [DOI] [PubMed] [Google Scholar]

- 10.Hurricane Katrina: lessons learned - chapter five: lessons learned. https://georgewbush-whitehouse.archives.gov/reports/katrina-lessons-learned/chapter5.html n.d.

- 11.Edmondson A., Bohmer R., Pisano G. Speeding up team learning. Harv Bus Rev. 2001:125–132. [Google Scholar]

- 12.WHO | emergency response framework (ERF) WHO; 2020. [Google Scholar]

- 13.National Academies of Sciences, Engineering, and Medicine. Impact of the global medical supply chain on SNS operations and communications. Proceedings of a workshop, 2018. Available at: https://www.nap.edu/read/25149/chapter/1. [Accessed 25 November 2020]. [PubMed]

- 14.Tappero J.W., Tauxe R.V. Lessons learned during public health response to cholera epidemic in Haiti and the Dominican Republic. Emerg Infect Dis. 2011;17:2087–2093. doi: 10.3201/eid1711.110827. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.De Frutos E.H., Trapero J.R., Ramos F. A literature review on operational decisions applied to collaborative supply chains. PloS One. 2020 doi: 10.1371/journal.pone.0230152. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Balicer R.D., Huerta M., Davidovitch N., et al. Cost-benefit of stockpiling drugs for influenza pandemic. Emerg Infect Dis. 2005 doi: 10.3201/eid1108.041156. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Yoada R.M., Chirawurah D., Adongo P.B. Domestic waste disposal practice and perceptions of private sector waste management in urban Accra. BMC Publ Health. 2014 doi: 10.1186/1471-2458-14-697. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Impact of the global medical supply chain on SNS operations and communications. National Academies Press; 2018. [DOI] [PubMed] [Google Scholar]

- 19.Fierce Healthcare. Vizient warns medicines needed for ventilator patients are running low. March 31, 2020. Available at: https://www.fiercehealthcare.com/hospitals-health-systems/vizient-warns-medicines-needed-for-ventilator-patients-are-running-low. [Accessed 25 November 2020].

- 20.Televisory Blogs. An analysis of Malaysian rubber glove industry. April 9, 2018. Available at: https://www.televisory.com/blogs/-/blogs/an-analysis-of-malaysian-rubber-glove-industry. [Accessed 25 November 2020].

- 21.United Nations World Food Programme. Innovative supply chain information platform will help prepare for the next pandemic. March 9, 2017. Available at: https://www.wfp.org/news/innovative-supply-chain-information-platform-will-help-prepare-next-pandemic. [Accessed 25 November 2020].

- 22.The Top Medical ventilator manufacturers, distributors, and suppliers in the US and Globally. [n.d].

- 23.Improving access to essential medicines for mental, neurological, and substance use disorders in Sub-Saharan Africa. 2014. [DOI] [PubMed] [Google Scholar]