Abstract

Consumption of nutritionally deficient complementary foods in developing countries is among the main contributing factors to infants and young children's malnutrition. Therefore, this study was aimed to optimize the nutritional and sensory properties of complementary food made from malted sorghum, blanched soybean, boiled karkade seeds and premix. A D-optimal mixture experimental design with 18 runs was generated by design expert software within in the constrained: 40–60% malted sorghum, 20–30% blanched soybean, 10–20% boiled karkade seeds and 10% premix (5.0% figl leaf powder, 4.5% sugar and 0.5% iodized table salt). Statistical model evaluation and optimization were done using D-optimal mixture design expert software. Sensory evaluation was conducted using 53 untrained panelists on two selected formulations and the control (local formulation). The study shows that with an increasing ratio of blanched soybean and boiled karkade seeds flour in the blend, a significant (p < 0.05) increase in protein, fat, energy and mineral contents, and a decrease in tannin and phytic acid contents of high mineral bioavailability except for oxalate: calcium ratio in the formulations were observed. The optimal blending ratio was 45.0% malted sorghum, 26.0% blanched soybean, and 19.0% boiled karkade seeds flour plus 10.0% premix. The gruel made from the new formula was significantly (p < 0.05) liked in terms of aroma, flavor, mouthfeel and overall acceptability than the control sample. The findings suggested that the optimal mix of these traditionally processed ingredients can potentially alleviate protein-energy malnutrition and micronutrient deficiency to mitigate expensive commercial infant complementary foods sold in the market.

Keywords: Blending ratio, Composite flour, Figl leaves, Food ingredients, Antinutrients to minerals molar ratios

Blending ratio, Composite flour, Figl leaves, Food ingredients, Antinutrients to minerals molar ratios

1. Introduction

A recent WHO report revealed 144 million children under five years stunted globally, 47 million wasted and 38.3 million overweight (World Health Organization, 2020). This report also highlighted 57.5 million children under five years of age are stunted in Africa, 12.7 million are wasted, and 9.3 million are overweight. In Ethiopia, 37% of children under five years old are stunted, 21% underweight, 7% wasted, and 2.9% overweight in 2019 (National Nutrition Program, Ethiopia, 2020). The limitation of quality and affordable complementary foods is one prime factor for child growth faltering. Inadequate nutrition in the first 1,000 days of a child's life and the consequences are irreversible stunted growth, impaired cognitive ability, reduced school and work performance, increased morbidity, and mortality (UNICEF, 2019).

Workie et al. (2020) reported that the high rates of child stunted growth problems in Ethiopia were mainly associated with inadequate dietary diversity. Low dietary diversity and dependence on regularly starchy staples, which do not provide adequate calories and essential micronutrients, contributes to the burden of malnutrition and micronutrient deficiencies (Lemma et al., 2020).

For most of the population in Ethiopia, the commercially produced complementary foods with improved nutrient profiles are beyond the purchasing power. According to CSA and ICF (International Classification of Functioning, Disability and Health) (2016) report, only 1.6% of children aged 6–23 months consumed factory processed infant formula. This consumption is also mainly true for urban families who have purchasing power. However, the story is different for rural areas, particularly in the border areas where poor infrastructure, low income, lack of awareness on utilization of improved factory processed complementary foods and poor marketing linkages prevails. Thus, children are prone to micronutrient deficiencies such as vitamin A, iron and zinc as they eat a less diversified diet from the family dish, which is predominantly cereal-based (Baye et al., 2019).

To tackle protein-energy malnutrition and micronutrient deficiency for infants and young children in Ethiopia, formulation and use of low-cost nutritious complementary foods from locally available food resources is proposed as a strategy in the National nutrition program II (2016–2020) and the Seqota declaration (2016). In line with this report, in Ethiopia, particularly in the Benishangul-Gumuz region, there is an enormous potential for the production of early maturing figl (Raphanus sativus L.) leaves (Keyata et al., 2021c) and drought-resistant crops such as sorghum (Legesse et al., 2019). In our recent study, two underutilized plants (karkade seeds and figl leaves) grown in the Benishangul-Gumuz region were identified, that their nutritional profiles are commendable (Keyata et al., 2020). The report indicated that karkade seeds are rich in protein, fat, energy, low in antinutrient contents that may favor mineral bioavailability can be potential. Leaves of figl were also a good source of protein and minerals that can be exploited in complementary food formulations to alleviate macro and micronutrient deficiency.

Besides this, sorghum is a staple food grain widely distributed and produced in the region (CSA, 2019) and contain a considerable carbohydrate, energy and minerals, but high in antinutrient contents, like condensed tannins (Tasie and Gebreyes, 2020). The processing of sorghum into flour using the malting technique was found to significantly reduce antinutrient contents such as tannin, phytate and oxalate with the improvement of mineral bioavailability (Keyata et al., 2021b). The malting also improves protein digestion which is vital to prepare malted sorghum grains based complementary foods by supplementation with other underutilized plants grown in the area. Furthermore, the region has a potential for soybean production, and the soybean is known to enrich protein and fat contents during the formulation of infant formula (Hagos and Bekele, 2018).

However, despite the presence of potential crops, the region is one of the least developed and food insecure hot spots (Guyu and Muluneh, 2016). According to Ethiopian Public Health Institute (EPHI), 2019 reports, 40.8% of children under the age of five years in the Benishangul-Gumuz region were stunted, 19.2% severely stunted, 6.1% wasted, 0.5% severely wasted, 31.4% underweight and 9.9% were severely underweight. Such severe malnutrition problems cannot be solved by providing nutrient-rich commercially available formulations due to high costs and unavailability in the local markets. Given this, in this study, the production of nutrient-rich complementary foods with better sensory acceptability from staple cereal crop (malted sorghum), blanched soybean and underutilized plants (boiled karkade seeds flour) with premix (figl leaves, sugar and iodized salt) are reported.

2. Materials and methods

2.1. Experimental materials

Sorghum Assosa I variety was collected from Assosa Agricultural Research Center. Soybean Clark 63k variety was collected from Jimma Agricultural Research Center, Ethiopia. The brown seeds of karkade were collected from the Assosa zone, Benishangul-Gumuz region, Ethiopia. The seeds of figl were purchased from the Benishangul-Gumuz region and then cultivated at Jimma University College of Agriculture and Veterinary Medicine research farm as described in Keyata et al. (2020) to use the leaves as a premix.

Assosa I sorghum grain variety was used because it is one of the region's staple crops and has the potential to improve the utilizable carbohydrate contents in the formula (Keyata et al., 2021b). Clark 63K soybean variety (Forsido et al., 2019) and karkade seeds (Keyata et al., 2020) were used to enrich protein and fat contents. Figl leaves were chosen as premix due to high minerals content (Keyata et al., 2020) and β-carotene and L-ascorbic acid (Keyata et al., 2021a). The iodized salts and sugar were added as premixes in all formulated products to improve iodine supply and improve the taste of the complementary food.

2.2. Raw material preparation

2.2.1. Malted sorghum flour

Sorghum grains were cleaned, washed, soaked for 18 h in tap water, with a 1 h air rest between each refill. The grains were allowed to germinate for 41 h at 28 °C, keeping relative humidity above 95% with water spraying on a tray twice daily using a hand sprayer. Germinated grains were kilned at 50 °C for 24 h (Bekele et al., 2012). The dried malted sorghum grain samples were milled separately into the flour using a laboratory mill (RRH-200, Zhejiang, China) to pass through a 0.5 mm sieve size (AACC, 2000). The flours were packed in heavy-duty polyethylene bags wrapped using aluminum foil and stored at 4 °C until used.

2.2.2. Blanched soybean flour

Soybean flour was prepared as described by Abolaji et al. (2019) with minor modification. The seeds were cleaned manually by removing any foreign material, damaged, broken, shriveled, and insect attacked seeds. The cleaned soybean was blanched at 96 °C for 10 min to inactivate the lipoxygenase and lipase enzymes that could alter the flavor of the flour during the formulation of the complementary food. Blanched soybean was placed in a basin of fresh water and agitated between fingers to remove the seed coat and then oven-dried (DHG-9203A, Shanghai, China) at 50 °C for 24 h. The dried blanched soybean was milled into flour, sieved (0.5 mm), then packed in moisture and airproof polyethylene bags, and stored at 4 °C until used.

2.2.3. Boiled karkade seed flour

Karkade seeds were processed according to Tounkara et al. (2011) with some modifications. The seeds were cleaned, boiled (96 °C) for 30 min, dried at 50 °C for 24 h and then were milled (RRH-200, Zhejiang, China) to pass through 0.5 mm sieve size (AACC, 2000). The dried sample powders were wrapped using aluminum foil and packed in moisture and airproof polyethylene bags, and then stored at 4 °C till used.

2.2.4. Figl leaves flour production

Uniform size and color of fresh mature leaves of figl were carefully harvested, washed with distilled water, chopped using a stainless-steel knife, and dried in an oven (DHG-9203A, Shanghai, China) at 45 °C. The dried leaves were milled separately into flour using a laboratory mill (RRH-200, Zhejiang, China) to pass through 0.5 mm sieve size, packed in moisture and airproof polyethylene bags, and stored at 4 °C until used.

2.2.5. Premix

Based on the mixture design generated for the proportion of mixing the sorghum, soybean and karkade seed flours were mixed with premix (figl leaves, sugar and iodized salt). The mixed fours were homogenized for 5 min in a planetary cake mixer (H.LB20/B, Hungary), and the representative flour samples were packed in polyethylene bags and stored at 4 °C until further analysis.

2.3. Experimental design

D-Optimal mixture design within the constrained 40–60% for malted sorghum, 20–30% for blanched soybean, and 10–20% for boiled karkade seeds flour generated 18 runs for mixing proportions. The proportion of the major ingredients were formulated to make 90%, and the remaining 10% were premix. Un-malted sorghum flour (100%) was used as a control. The experiment was arranged in a randomized complete block design (RCBD) for the sensory evaluations, considering variation among panelists in the selected three districts. The blocking principle took care of the variability among the panelists, which could inflate the error term and mask the treatment effect.

2.4. Proximate composition and energy content

The proximate composition moisture, crude protein, crude fat, crude fiber and total ash contents were determined according to the Association of Official Analytical Chemists AOAC (2000) Methods No: 925.10, 920.87, 920.39, 962.09 and 923.03, respectively. Utilizable carbohydrate content (UCC) was calculated by the difference method (FAO, 1998) and gross energy content by Atwater's conversion factors: 4 kcal/g for protein, 9 kcal/g for fat and 4 kcal/g for carbohydrate (FAO, 2002).

2.5. Mineral content

The minerals content of the samples were determined by atomic absorption spectrophotometer (AAS) (Agilent FS240 AA, USA) following AOAC (2000) method 985.35. Three grams of composite flour samples were carbonized on a heating plate and ashed in a muffle furnace (Sx2-4-10, Zhejiang, China) at 550 °C until ashing was completed. The white ash was dissolved using 5 mL of 6N HCl, dried on a hot plate, followed by the addition of seven mL of 3N HCl heating on a hot plate and then finally, the solution was diluted to the mark (50 mL) with de-ionized water.

The Fe, Zn and Ca contents were determined by AAS using air-acetylene as a source of flame energy for atomization. The absorbance for Fe was measured at 248.3 nm, and the Fe content was estimated from a standard calibration curve (0, 0.5, 1.0, 2.0, 3.0 and 4.0 μg/mL) prepared from analytical grade iron wire. The absorbance for Zn was measured at 213.9 nm, and the Zn content was estimated from a standard calibration curve (0.000, 0.125, 0.250, 0.500, 0.750 and 1.000 μg/mL) prepared from ZnO. The absorbance of Ca was measured at 422.7 nm after adding 2.5 mL of LaCl3 to sample solutions. The Ca content was then estimated from the standard solution (0.0, 0.5, 1, 1.5, 2.0 and 2.5 μg/mL) prepared from CaCO3.

The Na and K contents were determined using a flame photometer (ELICO CL 378, India) by measuring their emission at 589 and 767 nm, respectively. The Na content was estimated from standard solution (0.0, 0.5, 1.0, 1.5, 2.0 and 2.5 μg/mL) prepared from NaCl. The K content was estimated from a standard solution (0, 2, 4, 6, 8, 10 and 12 μg/mL) prepared from KCl.

The mineral element content was calculated using Eq. (1):

| (1) |

where: DF = dilution factor (50 mL for Ca, Fe, Zn, K and Na), and db is sample mass on a dry matter basis.

2.6. Antinutrient contents

2.6.1. Determination of condensed tannin content

The condensed tannin content was determined according to the method described by Maxson and Rooney (1972). About 1.000 g of the sample mixed with 10 mL of 1% HCl solution in methanol in a screw cap test tube was shaken for 24 h at room temperature on a mechanical shaker (Hy-2(C), Shanghai, China). The solution was centrifuged (sigma 2-16KC, UK) at 1000 rpm for 5 min. One mL of the supernatant was transferred to another test tube and mixed with 5 mL of vanillin-HCl reagent (prepared by combining equal volume of 8% concentrated HCl in methanol and 4% vanillin in methanol). A 40 mg of D-catechin standard was dissolved in 1000 mL of 1% HCl solution in methanol from which series of standard solutions (0, 12, 24, 36, 48 and 60 μg/mL) were prepared from stock solution by mixing with 5 mL 1% HCl in methanol. The absorbance of samples and the standard solutions were measured at 500 nm using UV-VIS Spectrophotometer [V-630, Jasco (USA)] after 20 min, and the condensed tannins content was estimated from the D-catechin calibration line (Y = 0.006X+0.0772, R2 = 0.9938). The result was expressed as mg/100g.

2.6.2. Determination of phytate content

The phytate content was determined as described in Vantraub and Lapteva (1988). About 0.100 g samples were extracted with 10 mL of 2.4% HCl in a mechanical shaker (Hy-2(C), Shanghai, China) for 1 h at room temperature and centrifuged (Sigma 2-16KC, UK) at 3000 rpm for 30 min. Clear sample solution (supernatant) or series of standard solution (3 mL) was mixed with one mL of wade reagent (solution of 0.03% FeCl3.6H2O and 0.3% of sulfosalicylic acid in water), vortex mixed for 5 s. Then absorbance was measured at 500 nm UV- VIS spectrophotometer [V-630, Jasco (USA)] using 3 mL de-ionized water as blank. The absorbance of blank was subtracted from the sample, the phytate content was determined from standard solutions (0, 4.5, 9, 18, 27 and 36 μg/mL) calibration line (Y = -0.0145X+0.7128, R2 = 0.992) prepared from sodium phytate (analytical grade) in 0.2 N HCl. The result was expressed as mg/100g.

2.6.3. Determination of oxalate content

The oxalate contents were determined by titration with KMnO4 after the formation of calcium oxalate and dissolving of the precipitate (AOAC, 2000 method 974.24). About 2 g samples were suspended in 190 mL of distilled water in a 250 mL volumetric flask; 10 mL of 6 M HCl was added, the suspension was digested at 100 °C for 1 h, cooled and made to 250 mL before filtration.

A 125 mL of the filtrate was measured into a beaker. Four drops of methyl red indicator were added, followed by concentrated NH4OH solution (drop wise) until the test solution changed from its salmon pink color to a faint yellow color (pH 4–4.5). Each portion was then heated to 90 °C, cooled, filtered to remove precipitate containing ferrous ion. The filtrate was again heated to 90 °C, and 10 mL of 5% CaCl2 solution was mixed while being stirred constantly, cooled and left overnight at 5 °C. The solution was centrifuged (2500 rpm for 5 min) (Sigma 2-16KC, UK), the supernatant decanted, the precipitate was entirely dissolved by 10 mL of 20% (v/v) H2SO4 solution, and the total filtrate was made up to 300 mL. Aliquots of 125 mL of the filtrate were heated to near boiling and then titrated against 0.05 M standardized KMnO4 solution to a faint pink color, which persisted for 30s, and the oxalate content was expressed as mg/100g.

2.7. Estimation of molar ratios of antinutrients to minerals

The molar ratio of phytate to minerals (Ca, Zn and Fe) was calculated by dividing the mole of phytate (660 g/mol) by the mineral mole (Ca = 40 g/mol; Zn = 65 g/mol; Fe = 56 g/mol) (FAO, 2018). The oxalate to Ca molar ratio was calculated by dividing oxalate mole (88 g/mol) by Ca mole. The molar ratios found were compared with the favorable ratios (WHO/FAO, 2004) in which phytate: Ca (<0.17), phytate: Fe (<1), phytate: Zn (<15), oxalate: Ca <1 and phytate∗Ca: Zn molar ratio <200.

2.8. Numerical optimization

Numerical optimization was carried out to determine the optimum blend of sorghum, soybean, karkade seeds flour and premix composite flour with desirable nutritional compositions as per the recommendation of Codex Alimentary Commission (1991) and World Health Organization (2004) on complementary foods for infants and young children feeding. Protein, fat, energy, sodium, calcium, potassium, iron and zinc contents were maximized based on this context. In contrast, moisture, fiber, ash, tannin, phytate, oxalate contents and for mineral bioavailability, the phytate: Ca, phytate: Fe, phytate: Zn, oxalate: Ca and phytate∗Ca: Zn molar ratios were minimized.

Accordingly, among 18 complementary flour samples formulated, 45.0% malted sorghum, 26.0% blanched soybean, and 19.0% of boiled karkade seeds flour with 10.0% premix were selected. The second formulation, 50.0% sorghum, 25.5% soybean, 14.6% karkade seeds flour with 10.0% of premix, was chosen from a list of 18 formulations considering the Codex Alimentary Commission minimum requirement for complementary food in which moisture content (<5%), protein (>15%), fat (10–25%), ash (<3%), utilizable carbohydrate (60–65%) and gross energy (400–425 kcal/100g). The two selected formulas and 100% un-malted sorghum grain flour (practiced in the local community) were subjected to sensory evaluation.

2.9. Gruel preparation

Based on the preliminary test conducted in the post-harvest management laboratory and the experience of mothers on gruels preparation for infants in the three study districts, hundred grams for the control and formulated complementary flours were mixed with 950 mL and 750 mL potable boiled tap water, respectively was cooked at 90 °C for 27 and 16 min. While mixing and cooking, the mixture was stirred with a wooden spoon to avoid lump formation and until it attains desirable gruels consistency. After preparation, the gruels were allowed to cool to 44 °C before sensory evaluation.

2.10. Sensory evaluation

Sensory evaluation of the gruel samples was conducted at Homesha, Kurmuk and Sherkole districts, Assosa zone, Benishangul-Gumuz region, Ethiopia. A total of 53 untrained panelists of mothers who have children aged between 6-24 months with experience of preparing infant foods were randomly selected from a list of mothers in the selected districts. After orientation, coded products were given randomly to the panelists to evaluate sensory attributes, namely color, aroma, taste, flavor, mouthfeel and overall acceptability. A five-point hedonic scale using smile emojis (5 = Like extremely, 4 = Like slightly, 3 = Neither like nor dislike, 2 = Dislike slightly, and 1 = Dislike extremely) was used.

2.11. Statistical analysis

The data obtained from the experiment were analyzed using D-optimal mixture design expert software. The statistical significance of the terms in the regression equations was examined by analysis of variance for each response, and the significance test level was set at p < 0.05. The fitted models for all the parameters were generated. The contour plots for the selected variables were constructed to determine the best formulation for the chosen response.

Numerical optimization was carried out to determine the optimum blend of sorghum, soybean and karkade seeds flour composite flour using the lower and upper contents for the responses (Montgomery, 2013). The data generated from sensory panelists were analyzed by one-way analysis of variance (ANOVA). All the statistical analyses were performed using JMP 13 Pro (a SAS company product), and a significant difference was considered at p ≤ 0.05. Mean differences were evaluated by Tukey's honestly significant difference (HSD) (p ≤ 0.05). The results were expressed as means ± standard deviations.

2.12. Ethical consideration

This study was approved by the Institutional Review Board of Jimma University. All procedures involving human participants were in accordance with the ethical standards of the 1964 Helsinki declaration and its later amendments. Written informed consent was obtained from all study panelists.

3. Results and discussion

3.1. Nutritional composition, antinutrient and in-vitro mineral bioavailability of formulated complementary flour

3.1.1. Model selection

The ANOVA p-values for proximate, energy and mineral contents are presented in Table 1. The p-values of antinutrient contents and antinutrients to minerals molar ratios are presented in Table 2. The result shows that the linear model can describe well changes in protein, calcium, sodium, zinc, tannin, phytate, oxalate, phytate: Ca, phytate: Zn and phytate∗Ca: Zn of the flours as a function of blending ratio (p < 0.01). The quadratic model can well describe the variations in the moisture, fat, ash and energy content of the complementary flour as a function of blending (Table 1). The special quadratic models for potassium and phytate: Fe had a high predictive power to express their changes in the formulations (p < 0.01).

Table 1.

Analysis of variance (ANOVA) for the proportion mixes of 18 runs of proximate composition, energy and mineral contents.

| Source |

Proximate compositions |

Energy |

Mineral contents |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MC |

PC |

FC |

FiC |

AC |

UCC |

Ca |

Na |

K |

Fe |

Zn |

||

| Model | Quadra∗∗∗ | Linear∗∗∗ | Quadra∗∗∗ | Cubic∗∗∗ | Quadra∗∗∗ | Cubic∗∗∗ | Quadra∗∗∗ | Linear∗∗∗ | Linear∗∗∗ | SQua∗∗∗ | SCubNS | Linear∗∗∗ |

| Linear mixture | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | 0.3106 | <0.0001 |

| A∗B | 0.0040 | 0.3219 | 0.0170 | <0.0001 | 0.3995 | 0.5414 | ||||||

| A∗C | 0.087 | - | 0.9183 | 0.2176 | 0.0623 | 0.1301 | 0.4947 | 0.0156 | 0.7387 | |||

| B∗C | 0.512 | - | 0.0253 | 0.1395 | 0.8495 | 0.5983 | 0.0011 | 0.2124 | 0.5140 | |||

| ABC | 0.2263 | 0.5409 | 0.2313 | |||||||||

| A2BC | 0.0168 | |||||||||||

| AB2C | 0.7652 | |||||||||||

| ABC2 | 0.0556 | |||||||||||

| AB (A-B) | 0.0071 | 0.0357 | ||||||||||

| AC (A-C) | 0.4298 | 0.1842 | ||||||||||

| BC (B–C) | 0.0062 | 0.0101 | ||||||||||

| R2 (adjusted) | 0.9695 | - | 0.9895 | 0.9772 | 0.9781 | 0.9839 | 0.9889 | 0.8608 | 0.9499 | 0.9372 | 0.1143 | 0.7614 |

| Lack of fit | 0.870 | 0.4089 | 0.4172 | 0.3523 | 0.6112 | 0.4216 | 0.7873 | 0.5331 | 0.4696 | 0.9729 | 0.7388 | 0.9888 |

A = malted sorghum; B = blanched soybean; C = boiled karkade; MC = moisture content; PC = protein content; FC = crude fat content; FiC = crude fiber content; AC = ash content & UCC = utilizable carbohydrate content; R2 = coefficient of determination; ∗∗∗ = P < 0.0001; NS = non-significant (P = 0.3387).

Table 2.

Analysis of variance (ANOVA) for the proportion mixes of 18 runs of antinutrient contents and in-vitro mineral bioavailability of formulated complementary flours.

| Source |

Antinutrient contents |

In-vitro mineral bioavailability |

||||||

|---|---|---|---|---|---|---|---|---|

| Tannin |

Phytate |

Oxalate |

Ph: Ca |

Ph: Fe |

Ph: Zn |

Ox:Ca |

Ph∗Ca: Zn |

|

| Model | Linear∗∗∗ | Linear∗∗∗ | Linear∗∗∗ | Linear∗∗∗ | Special Qua∗∗ | Linear∗∗∗ | Cubic∗∗ | Linear∗∗∗ |

| Linear mixture | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | 0.0001 | <0.0001 |

| A∗B | 0.0763 | 0.0163 | ||||||

| A∗C | 0.0219 | 0.6399 | ||||||

| B∗C | 0.0326 | 0.1629 | ||||||

| ABC | 0.2390 | |||||||

| A2BC | 0.0220 | |||||||

| AB2C | 0.2167 | |||||||

| ABC2 | 0.3121 | |||||||

| AB (A-B) | 0.0150 | |||||||

| AC (A-C) | 0.8383 | |||||||

| BC (B–C). | 0.0172 | |||||||

| R2 (adjusted) | 0.9256 | 0.9340 | 0.9121 | 0.9159 | 0.9246 | 0.9157 | 0.8990 | 0.8108 |

| Lack of fit | 0.4154 | 0.4365 | 0.2752 | 0.5391 | 0.3945 | 0.9561 | 0.9604 | 0.8460 |

A = Sorghum; B = soybean; C = Karkade; R2 = Coefficient of determination; ∗∗∗ = p < 0.0001; ∗∗ = P = 0.0002).

Where A: Malted sorghum flour, B: Blanched soybean flour. C: Boiled karkade seeds flour.

The cubic models can describe changes for fiber, utilizable carbohydrate and Oxalate: Ca in the formulations (p < 0.01). Conversely, the special cubic model was not significant (p = 0.34) in describing the relationship between mixing ratio and iron contents and had no predictive power to express their changes in the formulations. The non-significant (p > 0.05) lack of fit in models confirmed that the selected models fit well with the nutritional composition, antinutrient contents and antinutrients to minerals molar ratios of formulated complementary flours.

The selected models that relate blending ratios and responses determined in the formulation are presented in Tables 1 and 2. The blending ratio of sorghum and soybean in the formulation had a significant (p < 0.05) effect on moisture, fat, fiber, carbohydrate, energy contents and the molar ratio of oxalate: Ca. In addition to this, the blending ratio of soybean and karkade seed in the formulation had a significant (p < 0.05) effect in fiber, protein, fat and potassium contents and on the molar ratios of phytate: Fe.

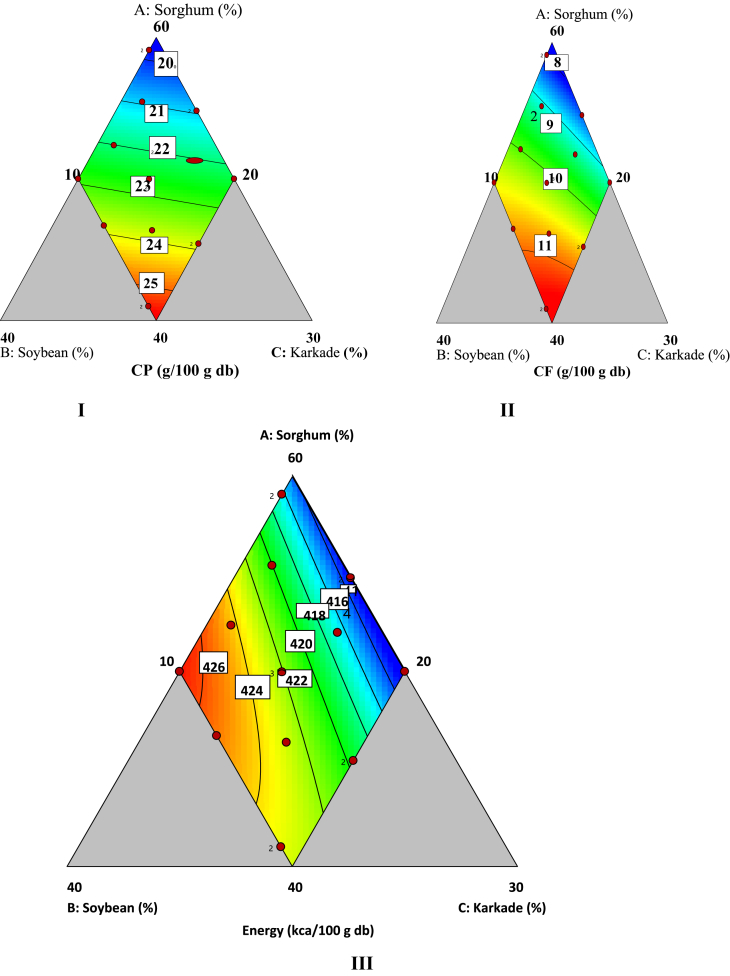

3.1.2. Proximate composition and energy contents

The proximate composition and gross energy contents of the complementary flours and control foods sample (un-malted sorghum flour) are presented in Table 3. The protein content of composite flour in this study increased from 19.73 to 25.52%, with a reduction in the proportion of sorghum and increase in soybean and karkade seeds flour (Figure 1I). Forsido et al. (2019) reported increased protein contents of extruded composites flour with an increase in soybean flour ratio. In this study, the protein content of composite flour was higher than the protein content (13.0–18.5%) of complementary flour formulated from barley, maize, and roasted pea flour (Fikiru et al., 2016). The protein contents in the blended complementary formations were higher than the protein contents of the control sample (un-malted sorghum) (9.55%) of this study, and a Nigerian traditional, complementary food (ogi) made from maize (6.5%) reported by Ijarotimi and Keshinro (2012). The higher protein content in this study could be related to the high protein content in soybean and karkade seeds flour. According to WHO/FAO (2004), a formulation with a protein content of greater than 15% is recommended for infants and young children feeding, which is fulfilled by all formulations produced in this study. Therefore, the protein content in the formulated complementary flour can be recommended as one of the best solutions to protein-energy malnutrition.

Table 3.

Proximate composition (% db) and gross energy (kcal/100 g) contents of the formulated complementary flours.

| FM | Sorghum (%) | Soybean (%) | Karkade (%) | PM (%) | MC (%) | PC (%) | FC (%) | FiC (%) | Ash (%) | UCC (%) | Energy (kcal/100g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 46.7 | 30.0 | 13.3 | 10 | 3.71 | 24.46 | 10.95 | 4.36 | 2.95 | 57.28 | 425.51 |

| 2 | 54.8 | 20.0 | 15.2 | 10 | 4.69 | 21.78 | 8.52 | 4.68 | 2.69 | 62.33 | 413.12 |

| 3 | 45.4 | 24.6 | 20.0 | 10 | 3.98 | 24.31 | 10.78 | 5.17 | 3.30 | 56.44 | 420.02 |

| 4 | 54.8 | 20.0 | 15.2 | 10 | 4.71 | 20.84 | 8.65 | 4.72 | 2.65 | 63.14 | 413.77 |

| 5 | 45.4 | 24.6 | 20.0 | 10 | 4.12 | 23.57 | 10.78 | 5.09 | 3.44 | 57.12 | 419.78 |

| 6 | 50.0 | 30.0 | 10.0 | 10 | 4.14 | 23.52 | 10.75 | 4.08 | 2.58 | 59.07 | 427.11 |

| 7 | 50.0 | 25.5 | 14.6 | 10 | 4.00 | 22.73 | 10.41 | 4.47 | 2.83 | 59.56 | 422.85 |

| 8 | 59.1 | 20.9 | 10.0 | 10 | 4.95 | 19.89 | 8.26 | 3.75 | 2.27 | 65.83 | 417.22 |

| 9 | 46.4 | 27.1 | 16.6 | 10 | 4.02 | 23.89 | 10.87 | 4.54 | 3.07 | 57.63 | 423.91 |

| 10 | 59.1 | 20.9 | 10.0 | 10 | 5.24 | 19.73 | 8.17 | 3.52 | 2.38 | 66.2 | 417.25 |

| 11 | 50.0 | 20.0 | 20.0 | 10 | 4.36 | 22.15 | 9.26 | 5.24 | 3.05 | 60.3 | 413.14 |

| 12 | 50.0 | 25.5 | 14.6 | 10 | 4.21 | 22.77 | 10.15 | 4.41 | 2.71 | 59.96 | 422.27 |

| 13 | 50.0 | 25.5 | 14.6 | 10 | 4.25 | 22.24 | 10.33 | 4.36 | 2.73 | 60.34 | 423.29 |

| 14 | 41.0 | 30.0 | 19.0 | 10 | 3.25 | 25.52 | 11.31 | 4.96 | 3.51 | 54.7 | 422.67 |

| 15 | 51.5 | 22.1 | 16.4 | 10 | 4.43 | 22.35 | 9.21 | 4.79 | 2.88 | 60.77 | 415.37 |

| 16 | 41.0 | 30.0 | 19.0 | 10 | 3.36 | 24.96 | 11.07 | 4.91 | 3.58 | 55.48 | 421.39 |

| 17 | 55.4 | 23.2 | 11.4 | 10 | 4.75 | 20.69 | 8.82 | 3.98 | 2.46 | 64.05 | 418.34 |

| 18 | 52.4 | 26.5 | 11.1 | 10 | 4.48 | 20.71 | 9.58 | 3.56 | 2.53 | 63.62 | 423.54 |

| Unmalted sorghum flour (control) | 8.70 | 9.55 | 3.68 | 2.96 | 1.60 | 82.2 | 400.2 | ||||

| Minimum RDA | <5 | ≥15 | ≥10 | <5 | <3 | ≥60 | ≥400 | ||||

| Adj R-Squared | 0.97 | - | 0.99 | 0.98 | 0.98 | 0.98 | 0.99 | ||||

| Lack of fit | 0.87 | 0.41 | 0.42 | 0.35 | 0.61 | 0.42 | 0.79 | ||||

FM: Formulations; PM: Premix; MC = Moisture content; PC = Protein content; FC = Fat content; FiC = Fiber content; UCC = Utilizable carbohydrate content; RDA = Recommended Dietary Allowance.

Figure 1.

Contour plots displaying selected proximate composition of complementary flour: I) Protein (%), II) Fat (%), III) Energy (%).

Fats are vital for infants and young children to provide energy and achieve several metabolic and physiological functions for their growth, development, and health (Delplanque et al., 2015). The fat content in the formulation was increased from 8.17 to 11.31% with an increase in soybean and karkade seeds flour ratios and decreased with a rise in the proportion of malted sorghum in the blend (Figure 1II). The increment of fat content results from the high fat contents in the soybean (Yao et al., 2020) and karkade seeds flour (Keyata et al., 2020). The fat contents of the formulated complementary flour samples were more than 2 to 3 times higher than the control sample (3.68%) but are within the recommended daily allowance reported by WHO/FAO (2004) (10–25%) except for some (formulations 2, 4, 8, 10,11, 15, 17 and 18). The lower fat contents in some formulations could be associated with a small proportion of soybean and karkade seeds flours in the blend.

The fiber content decreased from 5.24 to 3.52%, with a decrease in proportion of karkade seeds flours in the blend. Blending with a high proportion of karkade seeds flour in this study was directly associated with the increment of fiber contents in the formulation because of the high fiber content in the karkade seeds flour (Keyata et al., 2020). The daily recommended allowance of crude fiber content by the Codex Alimentary Commission (CAC) in the complementary food is <5% (CAC/GL 08, 1991). Thus, all the complementary flour formulated in this study meet this requirement except formulations 3 and 5 (45% sorghum, 24.6% soybean, 20% karkade seeds and 10% premix) and 11 (50% sorghum, 20% soybean, 20% karkade seeds and 10% premix). The crude fiber content was above the CAC standard when the maximum proportion of karkade seeds flour (20%) is in the blend. Reducing fiber content in complementary foods is essential for children to eat more nutrient-dense food that may contribute to their daily energy requirements (Ijarotimi and Keshinro, 2013).

The ash content shows an indication of the mineral contents in the food samples. In this work, the total ash contents (2.33–3.21%) in the complementary flour were acceptable when compared with the total ash contents recommended by WHO/FAO (2004) (<3%). However, the total ash content in the formulated complementary flour was higher than the control sample of un-malted sorghum flour (1.6%). The increments of total ash content were related to the soybean and karkade seed four in the mix. Similarly, an increase in the total ash content was reported with an increasing proportion of soybean in the complementary flour processed from red teff, soybean and papaya fruit powder blend (Mezgebo et al., 2018).

Utilizable carbohydrates (UCC) are important sources of dietary energy for infants and childhood (Stephen et al., 2012). The utilizable carbohydrate content of complementary flour increased from 54.7 to 66.2%, with an increase in sorghum and reduction in the proportion of soybean and karkade seeds flours increase in the blend. Similar was reported by Souci et al. (2008), where malted sorghum contains nearly twice the carbohydrate content than soybean.

The energy content of the formulations increased with an increase in the proportion of soybean and karkade seeds flour and decreased with an increase in malted sorghum flour (Figure 1III). The energy values (413.12–427.11 kcal/100g) of complementary flour formulation were higher than the control sample (400.2 kcal/100g) but was similar to “Cerelac” a commercial infant formula consumed in Nigeria (432 kcal/100g) (Ijarotimi and Keshinro, 2012). The values in this study were within the daily allowance recommended by the CAC (CAC/GL 08, 1991) (400–425 kcal/100 g). Therefore, energy-density found in the formulated complementary flour is essential for children with wasting, as they have an adequate intake of energy that supports optimal growth and development (Abeshu et al., 2016).

3.1.3. Mineral contents

The blending ratios resulted in a significant change (p > 0.05) in the calcium (Ca) content even though the value ranged from 232.24 to 285.56 mg/100g (Table 4). The values found are closer to the minimum daily allowance recommended for infants aged 6–12 months (260 mg/day) for normal development and maintenance of strong bones and teeth (Institute of Medicine, Food and Nutrition Board (IMFNB), 1997). However, the Ca content in this study was higher than (101.3–124.4 mg/100g) for extruded complementary flour made from oats, boiled soybean and linseeds (Forsido et al., 2019). The high Ca contents most probably are contributed by the adding 5% of figl leaves powder in the premix compared to 3% for moringa leaves powder in the premix by Forsido et al. (2019). However, similar Ca contents (206.90–275.95 mg/100g) were reported for a ready-to-eat food product from blending pearl millet, Irish potato and sesame seed flour (Aande et al., 2020).

Table 4.

Mineral contents (mg/100 g db) of formulated complementary flours.

| FM | Sorghum (%) | Soybean (%) | Karkade (%) | PM (%) | Ca | Na | K | Fe | Zn |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 46.7 | 30.0 | 13.3 | 10 | 260.45 | 270.4 | 787.57 | 7.46 | 3.8 |

| 2 | 54.8 | 20.0 | 15.2 | 10 | 246.73 | 131.37 | 767.75 | 7.18 | 3.5 |

| 3 | 45.4 | 24.6 | 20.0 | 10 | 268.05 | 215.83 | 832.94 | 7.09 | 4.39 |

| 4 | 54.8 | 20.0 | 15.2 | 10 | 232.24 | 144.49 | 756.76 | 6.67 | 3.46 |

| 5 | 45.4 | 24.6 | 20.0 | 10 | 270.83 | 223.56 | 812.33 | 7.28 | 3.86 |

| 6 | 50.0 | 30.0 | 10.0 | 10 | 262.14 | 255.57 | 749.99 | 7.01 | 3.51 |

| 7 | 50.0 | 25.5 | 14.6 | 10 | 256.8 | 228.77 | 798.95 | 7.46 | 3.67 |

| 8 | 59.1 | 20.9 | 10.0 | 10 | 237.49 | 171.86 | 729.84 | 6.64 | 3.26 |

| 9 | 46.4 | 27.1 | 16.6 | 10 | 259.48 | 245.84 | 771.9 | 6.8 | 3.68 |

| 10 | 59.1 | 20.9 | 10.0 | 10 | 230.83 | 154.01 | 722.79 | 6.63 | 3.21 |

| 11 | 50.0 | 20.0 | 20.0 | 10 | 264.11 | 189.87 | 803.09 | 6.7 | 3.75 |

| 12 | 50.0 | 25.5 | 14.6 | 10 | 261.1 | 228.8 | 783.56 | 6.67 | 3.63 |

| 13 | 50.0 | 25.5 | 14.6 | 10 | 261.31 | 233.92 | 766.72 | 7.1 | 3.66 |

| 14 | 41.0 | 30.0 | 19.0 | 10 | 285.56 | 298.49 | 825.69 | 6.89 | 4.5 |

| 15 | 51.5 | 22.1 | 16.4 | 10 | 256.03 | 198.41 | 777.07 | 7 | 3.67 |

| 16 | 41.0 | 30.0 | 19.0 | 10 | 278.53 | 320.74 | 818.68 | 6.96 | 3.97 |

| 17 | 55.4 | 23.2 | 11.4 | 10 | 242.74 | 220.21 | 749.28 | 6.9 | 3.39 |

| 18 | 52.4 | 26.5 | 11.1 | 10 | 258.41 | 241.53 | 746.38 | 7.05 | 3.48 |

| Unmalted sorghum flour (control) | 34.02 | 29.5 | 333.4 | 3.0 | 0.93 | ||||

| Minimum RDA-6 to 12 months (mg/100g) | 260 | 370 | 700 | 11 | 3 | ||||

| Minimum RDA-1 to 3 years (mg/100g) | 700 | 1000 | 3000 | 7 | 3 | ||||

| Adj R-Squared | 0.86 | 0.95 | 0.94 | 0.11 | 0.76 | ||||

| Lack of fit | 0.53 | 0.47 | 0.97 | 0.74 | 0.99 | ||||

FM: Formulations; PM: Premix.

The sodium (Na) content in this study was in the range 131.37–298.49 mg/100g (Table 4) which was below the recommended dietary allowance (RDA) for infants (370 mg/d) and young children (1000 mg/d) (IMFNB, 2005). A similar result was reported for complementary flour formulated from maize, pea and anchote by Gemede (2020) (252.00–278.01 mg/100g). These findings imply Na content in the formulated complementary flour is a good input for the food industry, which is stressed to produce low Na content foods for better health.

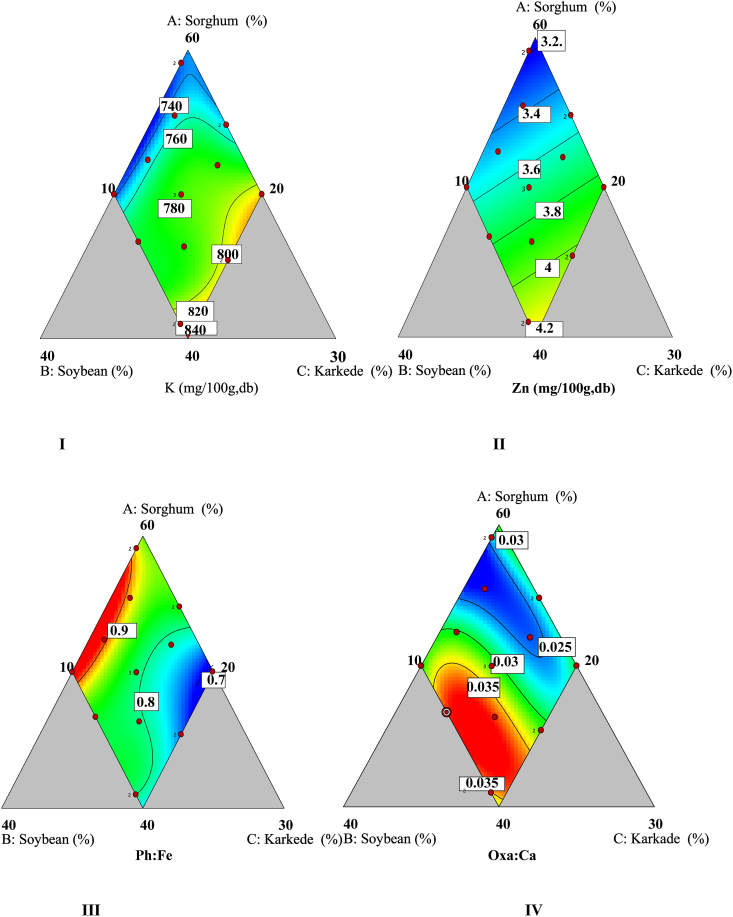

The potassium (K) content of the complementary flour increased from 722.79 to 832.94 mg/100g (Table 4) with an increasing proportion of soybean and karkade seeds flour and decreased by increasing sorghum flour (Figure 2I). The result was comparable with K contents (106–956.67 mg/100g) of complementary flour made from sorghum, Irish potato and groundnut (Adegbanke et al., 2018). The K content in the formulated complementary flours was more than two times higher than the control sample (333.4 mg/100g). The K content recorded can satisfy the recommended daily intake required for infants aged 6–12 months (700 mg/day) (IMFNB, 2005). The high amount of K contents in this study could be associated with the supplementation of 5% figl leaves used as a premix in the formulation of complementary flour, which contains high quantities of K (5250 mg/100g) (Keyata et al., 2020).

Figure 2.

Contour plots displaying selected mineral contents and antinutritional: mineral molar ratios of complementary flour: I) potassium (mg/100g), II) zinc (mg/100g), III) Ph:Fe IV) Ox:Ca. Where X1 = malted ssorghum flour; X2 = blanched soybean flour and X3 = boiled karkade seeds flour.

Supplementation of iron (Fe) in infants' diets is vital for mental health and the reducing anemia prevalence (Kumar et al., 2020). The Fe contents (6.63–7.46 mg/100g) (Table 4) of the formulated complementary flours found in this work are higher than in the range of the Estimated Average Requirement (EAR) for children aged between 1 to 8 years (3.0–4.1 mg/d) and but are similar for infants aged between 6 to 12 months (6.9 mg/d) (IMFNB, 2001). Somewhat similar Fe content (6.8–10.5 mg/100g) in the complementary flour formulated from bulla (dried exudate from the corm of Ensete ventricosum), pumpkin and germinated amaranthus flour were reported by Tadesse et al. (2018).

The zinc (Zn) content of the complementary flour increased from 3.21 to 4.50 mg/100g (Table 4) with an increase in the contents of soybean, karkade seed flour and figl leaves (p < 0.05) (Figure 2II). The Zn contents of the formulated complementary flour samples were more than three to four times higher when compared with the control sample (un-malted sorghum flour) (0.93 mg/100g). Similar Zn content (2.74–4.55 mg/100g) was reported from complementary flour formulated from maize, soybean and banana flour (Ezeokeke and Onuoha, 2016). The result found in this study meets the daily requirements for infants aged between 6 to 12 months (2.5 mg/d) and children aged between 1 to 8 years (2.5–4.0 mg/d) (IMFNB, 2001). The formulated complementary flour can help to alleviate Zn deficiency; hence there is potential to enhance the body's immune system and reduce stunting among children (Umeta et al., 2000).

3.1.4. Antinutrient contents

The tannin contents (13.83–25.46 mg/100g) (Table 5) found in this study are below the maximum tolerable level (560 mg/100g) (Anonymous, 1973). The result also indicated that the tannin contents of formulated complementary flour were significantly reduced by 49.08–75.22% compared to the control sample commonly practiced in the local communities (55.81 mg/100g). The significant reduction of tannin contents in the formulated complementary flour is mainly related to sample processing methods during the preparation of flour, such as malting for sorghum, blanching for soybean and removal of seed coats, and boiling for karkade seeds. The formulated complementary flour is low in tannin contents and most probably will not impair the digestibility of proteins significantly through complex formulation (Uzoechina, 2007).

Table 5.

Antinutrient contents (mg/100 g db) of formulated complementary flours.

| FM | Sorghum (%) | Soybean (%) | Karkade (%) | PM (%) | Tannin | Phytate | Oxalate |

|---|---|---|---|---|---|---|---|

| 1 | 46.7 | 30.0 | 13.3 | 10 | 17.49 | 71.05 | 20.97 |

| 2 | 54.8 | 20.0 | 15.2 | 10 | 22.24 | 66.68 | 13.9 |

| 3 | 45.4 | 24.6 | 20.0 | 10 | 16.93 | 60.75 | 18.41 |

| 4 | 54.8 | 20.0 | 15.2 | 10 | 21.58 | 65.84 | 14.97 |

| 5 | 45.4 | 24.6 | 20.0 | 10 | 16.25 | 63.08 | 18.62 |

| 6 | 50.0 | 30.0 | 10.0 | 10 | 19.75 | 77.3 | 17.67 |

| 7 | 50.0 | 25.5 | 14.6 | 10 | 18.89 | 68.7 | 17.47 |

| 8 | 59.1 | 20.9 | 10.0 | 10 | 24.27 | 71.66 | 11.86 |

| 9 | 46.4 | 27.1 | 16.6 | 10 | 19.27 | 66.84 | 19.99 |

| 10 | 59.1 | 20.9 | 10.0 | 10 | 25.46 | 71.06 | 12.95 |

| 11 | 50.0 | 20.0 | 20.0 | 10 | 21.73 | 57.91 | 16.01 |

| 12 | 50.0 | 25.5 | 14.6 | 10 | 19.33 | 67.69 | 17.46 |

| 13 | 50.0 | 25.5 | 14.6 | 10 | 20.41 | 70.69 | 16.23 |

| 14 | 41.0 | 30.0 | 19.0 | 10 | 13.83 | 63.12 | 24.02 |

| 15 | 51.5 | 22.1 | 16.4 | 10 | 19.98 | 63.4 | 15.08 |

| 16 | 41.0 | 30.0 | 19.0 | 10 | 15.05 | 64.04 | 22.5 |

| 17 | 55.4 | 23.2 | 11.4 | 10 | 21.16 | 69.5 | 13.98 |

| 18 | 52.4 | 26.5 | 11.1 | 10 | 21.33 | 75.06 | 18.77 |

| Unmalted sorghum flour (control) | 55.81 | 156.15 | 29.9 | ||||

| Minimum RDA (mg/100g) | <560 | <200 | <40 | ||||

| Adjusted R2 | 0.93 | 0.93 | 0.91 | ||||

| Lack of fit | 0.42 | 0.44 | 0.28 | ||||

FM: Formulations; PM: Premix.

Phytate, which is present in plant origin raw materials, is a major factor responsible for lowering the availability of minerals and digestibility of proteins (Kumar et al., 2010). The phytate concentration in the formulated flour samples was decreased from 77.30 to 57.91 mg/100g with reducing the proportion of soybean flours in the blend (Table 5). The findings showed that phytate contents in the formulated samples are below the maximum tolerable level (200 mg/100g) (Hurrell, 2004), which probably may not impair the bioavailability of zinc, calcium, iron and proteins digestibility (Oghbaei and Prakash, 2016). The low amount of phytate concentration in this study might be due to the processing methods applied for each major ingredient during sample preparations. The phytate content values found in this study are similar for the complementary flour formulated from maize, haricot bean and cooking banana (37.01–107.21 mg/100g) (Feyera et al., 2020).

The total oxalate contents (11.86–24.02 mg/100g) in this study were low compared to the un-malted control sorghum flour (29.9 mg/100g) (Table 5). The value found for the blended flour is below the American Dietetic Association (2005) recommended daily intake (40–50 mg/100g). This variation might be the effect of pretreatments on major ingredients flour preparation before blending with the components. The total oxalate content was decreased with an increase of malted sorghum flour in the blend. The low oxalate content in the formulated complementary flour is essential to inhibit oxalate binding to calcium to form calcium oxalate crystals which may cause diseases such as osteomalacia and rickets, particularly for infants and young children (Ladeji et al., 2004).

3.1.5. Antinutrients to minerals molar ratios

The estimated molar ratios of antinutrients: minerals of formulated complementary flour and the control sample with the reported critical toxicity values are given in Table 6. The molar ratios of phytate: Ca (0.013–0.019) was below the critical molar ratio (less than 0.17) (Castro-Alba et al., 2019Castro-Alba et al., 2019). This implies that the absorption of Ca in all formulations most probably will not be adversely affected by the existing phytate concentration. Similar phytate: Ca ratio for complementary composite flour made from maize, pea, and anchote (Coccinia abyssinica) tuber flours in the Eastern Wollega zone in Ethiopia was reported (0.016–0.018) (Gemede, 2020).

Table 6.

The estimated molar ratio between the antinutrients and minerals content of formulated complementary flours.

| FM | Sorghum (%) | Soybean (%) | Karkade (%) | PM (%) | Ph. Ca | Ph. Fe | Ph. Zn | Ox. Ca | Ph∗Ca: Zn |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 46.7 | 30.0 | 13.3 | 10 | 0.017 | 0.81 | 1.84 | 0.037 | 11.99 |

| 2 | 54.8 | 20.0 | 15.2 | 10 | 0.016 | 0.79 | 1.88 | 0.026 | 11.57 |

| 3 | 45.4 | 24.6 | 20.0 | 10 | 0.014 | 0.73 | 1.36 | 0.031 | 9.13 |

| 4 | 54.8 | 20.0 | 15.2 | 10 | 0.017 | 0.84 | 1.87 | 0.029 | 10.88 |

| 5 | 45.4 | 24.6 | 20.0 | 10 | 0.014 | 0.74 | 1.61 | 0.0312 | 10.9 |

| 6 | 50.0 | 30.0 | 10.0 | 10 | 0.018 | 0.93 | 2.17 | 0.0306 | 14.21 |

| 7 | 50.0 | 25.5 | 14.6 | 10 | 0.016 | 0.78 | 1.84 | 0.0309 | 11.84 |

| 8 | 59.1 | 20.9 | 10.0 | 10 | 0.018 | 0.92 | 2.17 | 0.023 | 12.85 |

| 9 | 46.4 | 27.1 | 16.6 | 10 | 0.016 | 0.83 | 1.79 | 0.035 | 11.6 |

| 10 | 59.1 | 20.9 | 10.0 | 10 | 0.019 | 0.91 | 2.18 | 0.0255 | 12.58 |

| 11 | 50.0 | 20.0 | 20.0 | 10 | 0.013 | 0.73 | 1.52 | 0.028 | 10.04 |

| 12 | 50.0 | 25.5 | 14.6 | 10 | 0.016 | 0.86 | 1.84 | 0.0304 | 11.99 |

| 13 | 50.0 | 25.5 | 14.6 | 10 | 0.016 | 0.84 | 1.9 | 0.028 | 12.43 |

| 14 | 41.0 | 30.0 | 19.0 | 10 | 0.013 | 0.78 | 1.38 | 0.038 | 9.86 |

| 15 | 51.5 | 22.1 | 16.4 | 10 | 0.015 | 0.77 | 1.7 | 0.027 | 10.89 |

| 16 | 41.0 | 30.0 | 19.0 | 10 | 0.014 | 0.78 | 1.59 | 0.037 | 11.06 |

| 17 | 55.4 | 23.2 | 11.4 | 10 | 0.017 | 0.85 | 2.02 | 0.026 | 12.25 |

| 18 | 52.4 | 26.5 | 11.1 | 10 | 0.018 | 0.9 | 2.12 | 0.033 | 13.72 |

| Unmalted sorghum flour (control) | 0.28 | 4.5 | 16.5 | 0.4 | 14 | ||||

| Minimum RDA (favorable ratio) | <0.17 | <1 | <15 | <1 | <200 | ||||

| Adjusted R2 | 0.92 | 0.93 | 0.92 | 0.90 | 0.81 | ||||

| Lack of fit | 0.54 | 0.40 | 0.96 | 0.96 | 0.85 | ||||

FM: Formulations; PM: Premix.

Bold values indicates lack of fit for all responses were non significant different (p > 0.05)

The phytate: Fe molar ratio decreased from 0.93 to 0.73, with a decreasing proportion of soybean flours in the blend (Figure 2III) because soybean is rich in phytate content. The phytate: Fe molar ratio of formulated complementary flour was less than the critical value, which was lower than 1.0 for favorable iron absorption (Hurrell, 2004). However, the phytate: Fe molar ratio for the control sample (4.5) can significantly hinder iron bioavailability which may lead to anemia in children under five years (Popova and Mihaylova, 2019). The phytate: Fe molar ratio of formulated complementary flour improved from 79.56 to 83.78% compared with the control sample.

Brown et al. (2001) reported when phytate: Zn molar ratio <5, high zinc bioavailability and when >15 as low bioavailability. The phytate: Zn ratio (1.36–2.18) in all formulations were below <5, which shows the unlikely inhibition of Zn bioavailability. On the contrary, the phytate: Zn molar ratio in the control sample was 16.5 of low bioavailability of zinc, which can adversely affect the zinc bioavailability. The zinc content in the formulated complementary flour improved by 34.79% from the control sorghum flour commonly consumed by the local communities.

Oxalic acid interferes with calcium by forming insoluble salts when consumed, decreasing calcium absorption, and aiding kidney stones formation (Hassan et al., 2011). The oxalate: Ca molar ratios decreased from 0.038 to 0.023 with decreasing proportion of soybean and karkade seeds flours in the bend (Figure 2IV). The oxalate: Ca molar ratios of formulated complementary flour and control sample (0.4) was below the critical level of less than one (Frontela et al., 2009). The result suggests that oxalate content found in the formulated complementary foods may not have adverse effects on the bioavailability of dietary calcium.

The effect of phytate on zinc absorption could be better explained by phytate ∗ Ca: Zn molar ratio than phytate: Zn molar ratio alone (Frontela et al., 2009). Oboh and Amusan (2009) showed that high calcium amounts in the food samples could promote the phytate-induced decrease in zinc bioavailability when the phytate∗Ca: Zn molar ratio is higher than 200. With this regard, the phytate∗Ca: Zn molar ratio (9.13–14.21) in the blend and control sample (14.00) was lower than the critical value. The findings showed that there would be insignificant interference in the availability of zinc in the formulated complementary flour. The results show Zn availability increased with increasing the proportion of karkade seeds flour and decreased with soybean flour increase in the blend.

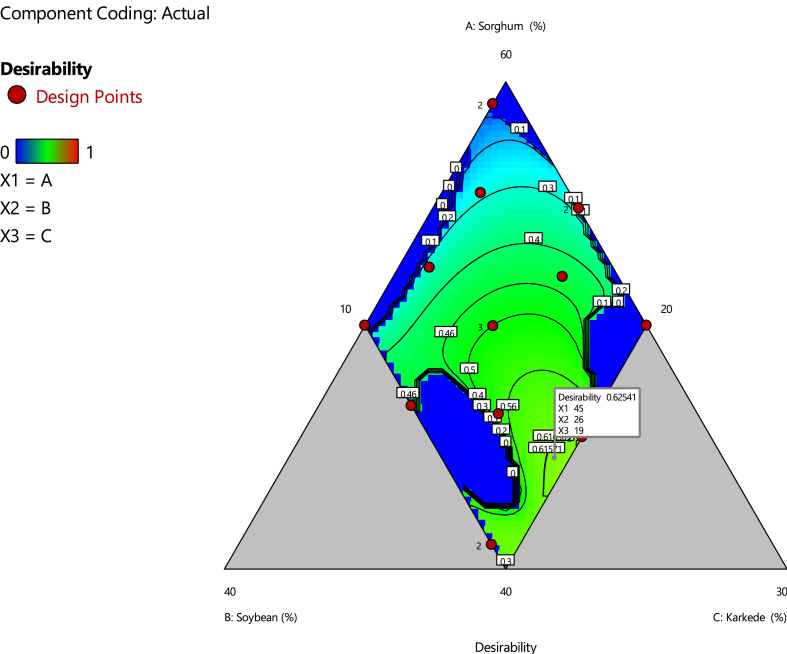

3.2. Numerical optimization

Numerical optimization result showed a blend ratio of 45% malted sorghum, 26% blanched soybean, and 19% boiled karkade seeds flour with 10% of premix (Figure 3) resulted in the best formulation with a desirability value of 0.625 with an improvement of protein, fat, energy, minerals, mineral bioavailability and reduction of antinutrients (tannin, phytate and oxalate). A similar desirability value (0.695) was reported by Temesgen (2018) for overall optimization of complementary food made with 50% taro, 30% maize and 20% soybeans.

Figure 3.

Numerical optimization of nutritional composition, antinutrient contents and in-vitro mineral bioavailability of formulated complementary flour.

3.3. Sensory properties

The mean sensory scores of complementary gruel and control samples are indicated in Table 7. The color of the gruel samples made from formulated products and control samples were ranged from 3.74 to 4.19. The values showed no significant (p > 0.05) differences in color among the control sample, formulation one and two. However, the mean score for the color of the gruel made from the control sample was higher than the formulated products. The more preference recorded for the control sample is probably contributed by the panelist innate behavior with common local products of gruels from un-malted sorghum flour, which was white. In contrast, others were dark brown (Figure 4). A similar result was reported by Tizazu et al. (2010), which stated that the most preferred porridge was the whitest than processed by the use of malted sorghum grains. The dark brown gruels prepared from malted sorghum flour was probably due to the formation of brown pigments through a Maillard reaction of reducing sugars from the hydrolyzed starches on malting with proteins probably during oven drying following malting.

Table 7.

Sensory scores of complementary gruel made from composite flour of sorghum, soybean, karkade seeds flour and premix (N = 53).

| Formulation | Color | Aroma | Taste | Flavor | Mouthfeel | Overall |

|---|---|---|---|---|---|---|

| Control | 4.19 ± 1.00a | 2.57 ± 1.00b | 3.47 ± 0.99bc | 3.38 ± 1.12b | 2.49 ± 1.12c | 3.32 ± 1.08b |

| Formulation one | 3.74 ± 0.77ab | 4.09 ± 0.71a | 4.13 ± 0.78a | 4.06 ± 0.72a | 4.09 ± 0.72a | 4.06 ± 0.71a |

| Formulation two | 3.92 ± 0.86a | 4.11 ± 1.00a | 3.96 ± 0.98ab | 4.17 ± 1.02a | 4.26 ± 0.92a | 4.25 ± 0.92a |

Where: Control: 100% un-malted sorghum, Formulation one = 50.0% malted sorghum, 25.5% blanched soybean and 14.6% boiled karkade seeds flour with 10% premix (5% figl leaves, 4.5% sugar and 0.5% salt).

Formulation two = 45.0% malted sorghum, 26.0% blanched soybean and 19.0% boiled karkade seeds flour with 10.0% premix (5.0% figl leaves, 4.5% sugar and 0.5% salt).

Means with different letters across a column are significantly different (p < 0.05).

Figure 4.

Control and formulated gruel samples for sensory evaluation. FM1: formulation 1; FM2: Formulation 2. Control: 100% un malted sorghum, Formulation 1 = 50.0% malted sorghum, 25.5% blanched soybean and 14.6% boiled karkade seeds flour with 10% premix (5% figl leaves, 4.5% sugar and 0.5% salt), Formulation 2: 45.0% malted sorghum, 26.0% blanched soybean and 19.0% boiled karkade seeds flour with 10.0% premix (5.0% figl leaves, 4.5% sugar and 0.5% salt).

A product having a pleasing aroma is more likely to be accepted by the children. Given this, the lowest aroma value was scored (2.57) by a gruel made from control. Still, the two formulations were preferred moderately (4.09–4.11), and there was also a significant (p < 0.05) difference between the control and formulated products. The difference in aroma between the products might be associated with Strecker degradation of each specific amino acid found in protein-rich supplemented complementary flour, like soybean and karkade seeds flour which produces a unique aldehyde with a distinctive aroma on the gruel during cooking (Fennema, 1996).

Taste is the one crucial factor that influences the acceptability of any product for consumption and determines the quality of ingested food (Feyera, 2020). The formulation one (50.0% malted sorghum, 25.5% blanched soybean and 14.6% boiled karkade seeds flour with 10% premix) gruel (4.13) had a significantly (p < 0.05) higher mean score in taste than the sorghum gruel control sample (3.47). The mean score in the taste of two developed gruel samples increased from 3.96 to 4.13, with an increase in malted sorghum flour in the blend. The high taste score in a high proportion of malted sorghum could be due to malting pre-milling techniques that could increase the soluble sugar from hydrolyzing starch to simple sugar, enhancing the sweetness of the gruel (Ratnavathi and Chavan, 2016).

In terms of flavor, gruel processed from formula one and two (45.0% malted sorghum, 26.0% blanched soybean and 19.0% boiled karkade seeds flour with 10.0% premix) were the most preferred (4.06–4.17) with significant (p < 0.05) difference form the sorghum control gruel (3.38). The result showed that the malting process positively affected the sensory attributes of the complementary food with a desirable dried malted flavor property (Syeunda et al., 2019). A similar result on flavor enhancement on dried grain malt use was also reported by Fikiru et al. (2016).

Mouthfeel arising from the consumption of food and beverages are critical to consumer choice and acceptability of the product (Stokes et al., 2013). There was a significant difference (p < 0.05) between the control and formulated gruel samples. The result indicated that gruel made from formulations 1 (4.09) and 2 (4.26) were liked moderately by panelists while gruel prepared from the control sorghum flour was the least preferred and recorded as neither like nor dislike (2.49). The improvement in mouthfeel in the formulated products might be due to dual pre-milling techniques applied during flour preparation of sorghum for enhanced gruel smoothness. For example, steeping and malting will soften the starch and hydrolyze the starch of sorghum to simple sugars. A similar result was also reported by Innocent et al. (2019) for complementary food formulated from malted sorghum and soybean. Additionally, the type of food consumed and for swallowing by infants should be smooth gruel rather than coarse.

The overall acceptability of the complementary gruel evaluated by panelists ranged from 3.32 to 4.25. Formulation two was the most preferred, followed by formulation one. However, the control sample was the least preferred in the overall acceptability. This shows that the overall acceptability of the developed gruel increased with a minimum proportion of malted sorghum and the maximum proportion of blanched soybean flour in the first formulation than the second. The better overall acceptability in the first formulation could be due to the texture of the gruel made from high proportion dried malted sorghum in which starches were hydrolyzed on malting to reducing sugars and a high proportion of blanched seed coats removed soybean that improves the smoothness of the gruel.

4. Conclusions

The nutrients and antinutrients for the constrained mixing of 40–60% malted sorghum, 20–30% blanched soybean, 10–20% boiled karkade seeds, and 10% premix (5.0% figl leaf powder, 4.5% sugar and 0.5% iodized table salt) flours were evaluated using un-malted sorghum flour as a control to optimize complementary weaning food processing. With an increase in the proportion of soybean and karkade seeds flour, the protein, fat, energy, calcium, potassium, sodium, iron and zinc contents increased. In contrast, tannin and phytic acid contents were reduced with improvement in the mineral bioavailability in the complementary food. The study showed formulation from 45.0% malted sorghum, 26.0% blanched soybean, and 19.0% boiled karkade seeds flour plus 10.0% premix was found with improved nutrient profiles, reduced antinutrients and acceptable than the control with the potential to minimize burdens of protein-energy malnutrition and micronutrient deficiency manifested in the region or beyond. However, for better quality products, further nutritional enrichments can be done through fortification for additional minerals and vitamins.

Declarations

Author contribution statement

Ebisa Olika Keyata: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Yetenayet B. Tola, Geremew Bultosa, Sirawdink Fikreyesus Forsido: Conceived and designed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This work was supported by Jimma University, College of Agriculture and Veterinary Medicine (JUCAVM) [AgVmPHM/18/02].

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

We thank Assosa and Jimma Agricultural Research Center for providing Assosa I sorghum variety and Soybean Clark 63k variety, respectively. The authors also acknowledge the panelists who participated in the sensory analysis. The authors would also like to thank Dr Tadesse Fikre for the assistance in the sensory data analysis.

References

- AACC . Approved Methods of the American Association of Cereal Chemists, 10th Ed. Methods 44-15 A. The Association; St. Paul, MN, US: 2000. pp. 40–44. [Google Scholar]

- Aande T.M., Agbidye I.G., Adah C.A. Formulation, proximate analysis and sensory evaluation of mumu from pearl millet, Irish potato and sesame seed blend. Agric. Sci. 2020;11:235–246. [Google Scholar]

- Abeshu M.A., Lelisa A., Geleta B. Complementary feeding: review of recommendations, feeding practices, and adequacy of homemade complementary food preparations in developing countries lessons from Ethiopia. Front. Nutr. 2016;3:41. doi: 10.3389/fnut.2016.00041. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Abolaji B.F., Edeke E.J., Ajoke S.M. Evaluation of chemical, functional and sensory properties of flour blends from sorghum, African yam bean and soybean for use as complementary feeding. Biotechnology. 2019;4(3):74–81. [Google Scholar]

- Adegbanke O.R., Dada T.A., Akinola S.A., Akintuyi T. Physicochemical and sensory qualities of complementary meal made from sprouted and unsprouted sorghum, Irish potato and groundnut. Food Sci. Nutr. 2018;6(2):307–317. doi: 10.1002/fsn3.556. [DOI] [PMC free article] [PubMed] [Google Scholar]

- American dietetic association . ADA Nutrition Care. American dietetics association; Chicago, USA: 2005. Urolithiasis/urinary stones. (275 manual) [Google Scholar]

- Anonymous . Toxicants Naturally Occurring in Foods. third ed. National Academy of Sciences; 1973. Tannic acid gain. Food cosmetol toxicol; p. 112. [Google Scholar]

- AOAC . seventeenth ed. II. AOAC International; Washington, DC, USA: 2000. Association of official analytical Chemists. (Official Methods of Analysis). Method Nos: 920.39, 920.87, 923.03, 925.10, 962.09, 974.24, 985.35 and 965.17. [Google Scholar]

- Baye K., Hirvonen K., Dereje M., Remans R. Energy and nutrient production in Ethiopia, 2011-2015: implications to supporting healthy diets and food systems. PloS One. 2019;14(3) doi: 10.1371/journal.pone.0213182. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bekele A., Bultosa G., Belete K. The effect of germination time on malt quality of six sorghum (Sorghum bicolor) varieties grown at Melkassa, Ethiopia. J. Inst. Brew. 2012;118(1):76–81. [Google Scholar]

- Brown K.H., Wuehler S.E., Peerson J.M. The importance of zinc in human nutrition and estimation of the global prevalence of zinc deficiency. Food Nutr. Bull. 2001;22(2):113–125. [Google Scholar]

- CAC . CAC/GL; Rome, Italy: 1991. Codex Alimentarius Commissions (CAC), Guidelines on Formulated Complementary Foods for Older Infants and Young Children. [Google Scholar]

- Castro-Alba V., Lazarte C.E., Bergenståhl B., Granfeldt Y. Phytate, iron, zinc, and calcium content of common Bolivian foods and their estimated mineral bioavailability. Food Sci. Nutr. 2019;7(9):2854–2865. doi: 10.1002/fsn3.1127. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Central Statistical Agency (CSA) Agricultural Sample Survey. Report on Area and Production of Major Crops. 2018/19. 589 Statistical Bulletin, Addis. 2019. Federal democratic republic of Ethiopia. [Google Scholar]

- Delplanque B., Gibson R., Koletzko B., Lapillonne A., Strandvik B. Lipid quality in infant nutrition: current knowledge and future opportunities. J. Pediatr. Gastroenterol. Nutr. 2015;61(1):8–17. doi: 10.1097/MPG.0000000000000818. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ethiopian Public Health Institute (EPHI) [Ethiopia] and ICF . EPHI and ICF; Rockville, Maryland, USA: 2019. Ethiopia Mini Demographic and Health Survey 2019: Key Indicators. [Google Scholar]

- Ezeokeke C.T., Onuoha A.B. Nutrient composition of cereal (maize), legume (soybean) and fruit (banana) as a complementary food for older infants and their sensory assessment. J. Food Sci. Eng. 2016;6:139–148. [Google Scholar]

- FAO . 1998. Carbohydrates in Human Nutrition. Report of a Joint FAO/WHO Expert Consultation. FAO Food and Nutrition Paper No.66. Rome, Italy. Date of access July 2020. [PubMed] [Google Scholar]

- FAO . 2002. Food Energy-Methods of Analysis and Conversion Factors. Report of a Technical Workshop. FAO Food and Nutrition Paper No. 77. Rome, Italy. Date of access, July 2020. [Google Scholar]

- FAO . 2018. Global Food Composition Database for Phytate Version 1.0, Rome, Italy. Date of access, July 2020. [Google Scholar]

- Fennema O.R. Marcel Dekker, Inc; New York: 1996. Food Chemistry. [Google Scholar]

- Feyera M. Review on some cereal and legume based composite biscuits. Int. J. Agric. Sci. Food Technol. 2020;6(2):101–109. [Google Scholar]

- Feyera M., Abera S., Temesgen M. Effect of fermentation time and blending ratio on nutrients and some antinutrient composition of complementary flour. Eur. J. Food Sci. Technol. 2020;8(3):1–12. [Google Scholar]

- Fikiru O., Bultosa G., Forsido S.F., Temesgen M. Nutritional quality and sensory acceptability of complementary food blended from maize (Zea mays), roasted pea (Pisum sativum), and malted barley (Hordeum vulgare) Food Sci. Nutr. 2016;5(2):173–181. doi: 10.1002/fsn3.376. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Forsido S.F., Duguma H.T., Lema T.B., Sturm B., Hensel O. Nutritional and sensory quality of composite extruded complementary food. Food Sci. Nutr. 2019;7(2):882–889. doi: 10.1002/fsn3.940. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Frontela C., Scarino M.L., Ferruzza S., Ros G., Martínez C. Effect of dephytinization on bioavailability of iron, calcium and zinc from infant cereals assessed in the Caco-2 cell model. World J. Gastroenterol. 2009;15(16):1977–1984. doi: 10.3748/wjg.15.1977. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gemede H.F. Nutritional and antinutritional evaluation of complementary foods formulated from maize, pea, and anchote flours. Food Sci. Nutr. 2020;8(4):2156–2164. doi: 10.1002/fsn3.1516. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guyu F.D., Muluneh W. Determinants of seasonal food insecurity in the green famine belt of Ethiopia: the case of households in Belo-jiganfoy District, Benishangul-Gumuz region. Afr. J. Food Sci. 2016;10(11):278–291. [Google Scholar]

- Hagos A., Bekele A. Cost and returns of soybean production in Assosa zone of Benishangul Gumuz Region of Ethiopia. J. Dev. Agric. Econ. 2018;10(11):377–383. [Google Scholar]

- Hassan L.G., Bagudo B.U., Aliero A.A., Umar K.J., Sani N.A. Evaluation of nutrient and antinutrient contents of Parkia biglobosa (L.) flower. Niger. J. Basic Appl. Sci. 2011;19(1):76–80. [Google Scholar]

- Hurrell R. Phytic acid degradation as a means of improving iron absorption. Int. J. Vitam. Nutr. Res. 2004;74(6):445–452. doi: 10.1024/0300-9831.74.6.445. [DOI] [PubMed] [Google Scholar]

- Ijarotimi O.S., Keshinro O.O. Formulation and nutritional quality of infant formula produced from germinated popcorn, Bambara groundnut and African locust bean flour. J. Microbiol. Biotechnol. Food Sci. 2012;9(4):1358–1388. [Google Scholar]

- Ijarotimi O.S., Keshinro O.O. Determination of nutrient composition and protein quality of potential complementary foods formulated from the combination of fermented popcorn, African locust and Bambara groundnut seed flour. Pol. J. Food Nutr. Sci. 2013;63(3):155–166. [Google Scholar]

- Innocent O.N., Lucy E.N., Joel N., Anthony U.N. Quality characteristics of soy-akamu powder formulated from sorghum and sprouted soybean flour blends for complementary feeding. World. 2019;3(4):48–57. [Google Scholar]

- Institute of Medicine, Food and Nutrition Board . 1997. Dietary Reference Intakes for Calcium, Phosphorus, Magnesium, Vitamin D, and Fluoride. Washington, DC. [PubMed] [Google Scholar]

- Institute of Medicine, Food and Nutrition Board . 2001. Dietary Reference Intakes for Vitamin A, Vitamin K, Arsenic, boron, Chromium, Copper, Iodine, Iron, Manganese, Molybdenum, Nickel, Silicon, Vanadium, and Zinc. Washington, DC, USA. [Google Scholar]

- Institute of Medicine, Food and Nutrition Board . 2005. Dietary Reference Intakes for Water, Potassium, Sodium, Chloride, and Sulfate. Washington, DC. [Google Scholar]

- Keyata E.O., Tola Y.B., Bultosa G., Forsido S.F. Proximate, mineral, and antinutrient compositions of underutilized plants of Ethiopia: figl (Raphanus sativus L.), girgir (Eruca sativa L.) and karkade (Hibiscus sabdariffa): implications for in-vitro mineral bioavailability. Food Res. Int. 2020;137:109724. doi: 10.1016/j.foodres.2020.109724. [DOI] [PubMed] [Google Scholar]

- Keyata E.O., Tola Y.B., Bultosa G., Forsido S.F. Phytochemical contents, antioxidant activity and functional properties of Raphanus sativus L, Eruca sativa L. and Hibiscus sabdariffa L. growing in Ethiopia. Heliyon Food Sci. Nutr. 2021;7(1) doi: 10.1016/j.heliyon.2021.e05939. 1-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Keyata E.O., Tola Y.B., Bultosa G., Forsido S.F. Premilling treatments effects on nutritional composition, antinutritional factors, and in-vitro mineral bioavailability of the improved Assosa I sorghum variety (Sorghum bicolor L.) Food Sci. Nutr. 2021;9:1–10. doi: 10.1002/fsn3.2155. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Keyata E.O., Tola Y.B., Bultosa G., Forsido S.F., Gidessa A. Production practices, post-harvest handling, and application of some neglected plants of nutritional importance in traditional farming systems of Benishangul-Gumuz region of Ethiopia. East Afr. J. Sci. 2021;15(1):79–94. [Google Scholar]

- Kumar V., Sinha A.K., Makkar H.P., Becker K. Dietary roles of phytate and phytase in human nutrition: a review. Food Chem. 2010;120(4):945–959. [Google Scholar]

- Kumar S., Anukiruthika T., Dutta S., Kashyap A.V., Moses J.A., Anandharamakrishnan C. Iron deficiency anemia: a comprehensive review on iron absorption, bioavailability and emerging food fortification approaches. Trends Food Sci. Technol. 2020;99:58–75. [Google Scholar]

- Ladeji O., Akin C.U., Umaru H.A. Level of antinutritional factors in vegetables commonly eaten in Nigeria. Afr. J. Nat. Sci. 2004;7:71–73. [Google Scholar]

- Legesse T., Demelash H., Seyoum A. Participatory variety selection for enhanced promotion and adoption of improved sorghum [Sorghum bicolor (L) Moench] varieties for the humid lowland of Assosa Zone, Western Ethiopia. Sci. Res. Rev. 2019;12:104. [Google Scholar]

- Lemma G., Gudina E., Tadesse A., Agegnehu B., Abebaw M. Minimum dietary diversity and associated factors among lactating mothers in Ataye district, North Shoa Zone, Central Ethiopia: a community-based cross-sectional study. J. Nutr. Metabol. 2020;2020:1–10. doi: 10.1155/2020/1823697. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maxson E.D., Rooney L.W. Evaluation of methods for tannin analysis in sorghum grain. Cereal Chem. 1972;49(6):719–728. [Google Scholar]

- Mezgebo K., Belachew T., Satheesh N. Optimization of red teff flour, malted soybean flour, and papaya fruit powder blending ratios for better nutritional quality and sensory acceptability of porridge. Food Sci. Nutr. 2018;6(4):891–903. doi: 10.1002/fsn3.624. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Montgomery D.C. eighth ed. Wiley; New York, NY: 2013. Design and Analysis of Experiments. [Google Scholar]

- National nutrition program . 2020. National Nutrition Program (2016-2020) Progress Analysis: Evidence for the Upcoming Food and Nutrition Strategy Development, Addis Ababa, Ethiopia. [Google Scholar]

- National Nutrition Program II . 2016-2020. Federal Democratic Republic of Ethiopia (FDRE). National Nutrition Program, 2016-2020. Addis Ababa, Ethiopia. [Google Scholar]

- Oboh G., Amusan T.V. Nutritive value and antioxidant properties of cereal gruels produced from fermented maize and sorghum. Food Biotechnol. 2009;23(1):17–31. [Google Scholar]

- Oghbaei M., Prakash J. Effect of primary processing of cereals and legumes on its nutritional quality: a comprehensive review. Cogent Food Agric. 2016;2(1):1136015. [Google Scholar]

- Popova A, Mihaylova D. Antinutrients in plant-based foods: A review. The Open Biotechnology Journal. 2019;13(1):68–76. [Google Scholar]

- Ratnavathi C.V., Chavan U.D. Sorghum Biochemistry. Academic Press; Oxford: 2016. Malting and brewing of sorghum; pp. 63–105. [Google Scholar]

- Seqota Declaration . 2016. Federal Democratic Republic of Ethiopia (FDRE). Seqota Declaration Implementation Plan (2016–2030): Summary Program Approach Document; FDRE: Addis Ababa, Ethiopia. [Google Scholar]

- Souci S.W., Fachmann W., Kraut H. 7rd ed. Medpharm Scientific Publishers; Stuttgart: 2008. Food Composition and Nutrition Tables. [Google Scholar]

- Stephen A., Alles M., De Graaf C., Fleith M., Hadjilucas E., Isaacs E., Gil A. The role and requirements of digestible dietary carbohydrates in infants and toddlers. Eur. J. Clin. Nutr. 2012;66(7):765–779. doi: 10.1038/ejcn.2012.27. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stokes J.R., Boehm M.W., Baier S.K. Oral processing, texture and mouthfeel: from rheology to tribology and beyond. Curr. Opin. Colloid Interface Sci. 2013;18(4):349–359. [Google Scholar]

- Syeunda C.O., Anyango J.O., Faraj A.K. Effect of compositing precooked cowpea with improved malted finger millet on antinutrients content and sensory attributes of complementary porridge. Food Nutr. Sci. 2019;10(9):1157–1178. doi: 10.1007/s13197-020-04569-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tadesse A, Y, Ibrahim A, M, Forsido S, F, Duguma H., T Nutritional and sensory quality of complementary foods developed from bulla, pumpkin and germinated amaranth flours. Nutrition and Food Science. 2018;49(3):418–431. [Google Scholar]

- Tasie M.M., Gebreyes B.G. Characterization of nutritional, antinutritional and mineral contents of thirty-five sorghum varieties grown in Ethiopia. Int. J. Food Sci. 2020;2020:1–11. doi: 10.1155/2020/8243617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Temesgen M. State of the art for development of optimized complementary food in Ethiopia. Res. J. Food Nutr. 2018;2(4):20–29. [Google Scholar]

- Tizazu S., Urga K., Abuye C., Retta N. Improvement of energy and nutrient density of sorghum based complementary foods using germination. Afr. J. Food Nutr. Sci. 2010;10(8):2927–2942. [Google Scholar]

- Tounkara F., Amadou I., Le G.W., Shi Y.H. Effect of boiling on the physicochemical properties of Roselle seeds (Hibiscus sabdariffa L.) cultivated in Mali. Afr. J. Biotechnol. 2011;10(79):18160–18166. [Google Scholar]

- Umeta M., West C.E., Haidar J., Deurenberg P., Hautvast J.G. Zinc supplementation and stunted infants in Ethiopia: a randomized controlled trial. Lancet. 2000;355(9220):2021–2026. doi: 10.1016/S0140-6736(00)02348-5. [DOI] [PubMed] [Google Scholar]

- UNICEF . UNICEF; New York: 2019. The State of the World’s Children 2019. Children, Food and Nutrition: Growing Well in a Changing World. [Google Scholar]

- Uzoechina O.B. Evaluation of the effect of processing techniques on the nutrient and antinutrient contents of Pigeon Pea (Cajanus cajan) seed flours. J. Food Sci. 2007;28:76–77. [Google Scholar]

- Vantraub I.A., Lapteva N.A. Colorimetric determination of phytate in unpurified extracts of seeds and the products of their processing. Anal. Biochem. 1988;175(1):227–230. doi: 10.1016/0003-2697(88)90382-x. [DOI] [PubMed] [Google Scholar]

- WHO/FAO . 2004. Vitamin and mineral Requirements in Human Nutrition. second ed.. Rome, Italy. [Google Scholar]

- Workie S.B., Mekonen T., Mekonen T.C., Fekadu W. Child development and nutritional status in 12–59 months of age in resource limited setting of Ethiopia. J. Health Popul. Nutr. 2020;39:1–9. doi: 10.1186/s41043-020-00214-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- World Health Organization . 2020. UNICEF/WHO/the World Bank Group Joint Child Malnutrition Estimates: Levels and Trends in Child Malnutrition: Key Findings of the 2020. [Google Scholar]

- Yao Y., You Q., Duan G., Ren J., Chu S., Zhao J., Jiao Y. Quantitative trait loci analysis of seed oil content and composition of wild and cultivated soybean. BMC Plant Biol. 2020;20(1):51. doi: 10.1186/s12870-019-2199-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.