Abstract

The COVID-19 pandemic has revealed the fragility of global supply chains arising from raw material scarcity, production and transportation disruption, and social distancing. Firms need to carefully anticipate the difficulties during recovery and formulate appropriate strategies to ensure the survival of their businesses and supply chains. To enhance awareness of the issues, this research aims to identify and model recovery challenges in the context of the Bangladeshi ready-made garment industry. A Delphi-based grey decision-making trial and evaluation laboratory (DEMATEL) methodology was used to analyze the data. While the Delphi method helped identify the major supply chain recovery challenges from the impacts of the COVID-19 pandemic, the grey DEMATEL approach helped categorize the causal relationships among these challenges. Of the 23 recovery challenges finalized, 12 are causal challenges. The study’s findings can assist decision-makers in developing strategic policies to overcome the recovery challenges in the post-COVID-19 era.

Keywords: COVID-19 pandemic, Supply chain management, Recovery challenges, Delphi method, Grey DEMATEL

1. Introduction

Supply chain recovery is fundamental to supply chain disaster management and resilience. Supply chains usually experience many challenges when formulating strategies for recovering from the impacts of disruptions (Son and Orchard, 2013, DuHadway et al., 2019). The extent of the challenges varies depending on the severity of the event(s). For example, firms may experience greater challenges in recovering from major outbreaks, such as epidemics or pandemics (Gurbuz and Ozkan, 2020, Queiroz et al., 2020). This is because such outbreaks have severe and long-term impacts on businesses and their operations and generally require more robust recovery strategies (Chou et al., 2004, Huber et al., 2018, Koonin, 2020). Therefore, during a major outbreak, it is vital to identify potential supply chain recovery challenges and their influence on post-disaster recovery to ensure supply chains formulate the appropriate strategies to overcome such issues (Koonin, 2020, Choi, 2020). Recognizing these challenges also enables supply chains to reimagine the value chains in the aftermath of the outbreak (Clarke & Boersma, 2017).

The COVID-19 pandemic has impacted global supply chains substantially (Clarke and Boersma, 2017, Sharma et al., 2020, Nikolopoulos et al., 2020, Xu et al., 2020, Ibn-Mohammed et al., 2021, Jabbour et al., 2020, Chowdhury et al., 2021). Significant adverse effects on finance, lead time, customer, and production performance have already occurred. To mitigate the COVID-19 impacts on supply chains, effective recovery management strategies are needed. The initial step in designing a recovery plan is to identify the recovery challenges the supply chain is facing. The COVID-19 pandemic is an exceptional incident—a high-impact low-probability event—that exceeds in scale some of the largest disruptions in the past two decades, such as SARS in 2003 and H1N1 in 2009 (Haren and Simchi-Levi, 2020, Koonin, 2020). Information on recovery challenges in this exceptional disruptive environment is not readily available or fully documented in the academic literature. This study is the first attempt to address this inadequacy and have broader implications. It will answer the following research questions (RQ):

RQ1: What recovery challenges are supply chains facing due to the COVID-19 pandemic?

RQ2: Why are these challenges important in supply chain recovery?

RQ3: What are the interrelationships among the different recovery challenges?

Data for this research were collected from Bangladesh’s ready-made garment (RMG) industry. Choosing an emerging economy as the study context is important because the findings can provide valuable insights to supply chain practitioners in these regions (Majumdar, Shaw, & Sinha, 2020). The RMG industry is one of the sectors most impacted by the COVID-19 pandemic. It contributed USD34.13 billion to Bangladesh’s export earnings in 2018–19, representing 84.21% of the total exports and demonstrating the sector’s importance for the country’s economic survivability (BGMEA 2020a). However, due to the current COVID-19 pandemic, export growth declined by 18.12% in 2019–20 compared to the previous year, and further decreased by 1.2% in the first four months (July–October) in 2020–21 compared to the same period in 2019–20 (BGMEA 2020a). The specific and detailed impacts of the COVID-19 pandemic on procurement, production, and distribution of the Bangladeshi garment industry are documented by Anner (2020), who sequences the impacts in three phases: material crisis in Phase 1, delayed payment in Phase 2, and order cancellation in Phase 3. Canceled orders have increased since the pandemic started. By September 2020, USD 3.18 billion in exports were canceled, which affected the livelihood of 2.28 million workers (BGMEA 2020b). Considering the severity of this impact, any effort to ensure supply chain recovery for the RMG industry is worth attempting. This study investigates various supply chain recovery challenges and their importance and interrelationships to facilitate practitioners to formulate the best recovery strategies and restructure their supply chains in the post-COVID-19 era.

This study uses an integrated approach to achieve the research objective. First, the Delphi method is implemented an expert survey to identify supply chain recovery challenges due to the COVID-19 pandemic. Then, a grey DEMATEL method is employed to analyze the importance and interrelationships of the identified supply chain recovery challenges. This research contributes to knowledge by identifying the key supply chain recovery challenges due to the COVID-19 global pandemic and analyzing those challenges to understand their interrelationships and importance in the recovery. Several decision support tools are reported in the existing literature that can be used to help make decisions in complex decision-making environments (Sivarajah et al., 2017, Yasmin et al., 2020). As there is limited information on supply chain recovery challenges available in the literature, a structured Delphi method is used in this study to identify and finalize the recovery challenges. The method is selected because of its four unique characteristics—ability to maintain anonymity, possibility of iteration in the decision-making process, scope of statistical validation, and ability to take experts’ feedback—when compared with other group decision-making processes, such as interviews, focus group discussion, brainstorming, and nominal group techniques. As such, the Delphi method can find an accurate and reliable consensus on the identification and finalization of recovery challenges quantitatively. The use of grey DEMATEL to analyse cause-and-effect relationships and determine the priorities of the recovery challenges is also an innovative approach. Regular DEMATEL cannot handle ambiguity and uncertainty. However, grey DEMATEL can identify interrelationships among the recovery challenges, and thereby help determine the causal relationships between them.

Insights from this study will also be beneficial to other industries or emerging economies. When major crises and disruptions in supply chains are investigated, the deep upstream portions are often ignored. This study delves into these areas to help understand how some of the most vulnerable regions of global supply chains can respond and recover quickly from disruptions.

This paper is organized as follows. Section 2 provides a literature review on the topic, and Section 3 describes the research methodology. Section 4 discusses the real-world application of the proposed method, Section 5 outlines the analysis and discussion of results, and Section 6 details the implications of the findings. Section 7 concludes the paper, identifies the study’s limitations, and proposes directions for future research.

2. Literature review

This section examines the foundational literature for supply chain disruption recovery. It reviews the literature on both general disruptions and extraordinary ones, such as an epidemic or pandemic outbreak.

2.1. Supply chain disruptions and recovery

Supply chain risk management has become an increasingly important topic in academic research. Literature on this topic introduces proactive and reactive policies for effective supply chain risk management. Proactive policies are formulated to mitigate the probability of occurrence of risk events (Chen et al., 2015, Chowdhury et al., 2019, Scholten et al., 2014, Sreedevi and Saranga, 2017). Reactive policies are established to minimize the impacts of risks and ensure smooth recovery (Hishamuddin et al., 2015, Ivanov et al., 2016, Ivanov, 2019, Ivanov, 2020b, Paul et al., 2014, Paul et al., 2015). Operational risks that occur due to managerial problems such as quality and long lead time concerns are controllable. Proactive strategies can control and mitigate the probability of these risks before they occur (Chen et al., 2013, Chowdhury et al., 2019). However, reactive policies are needed for disruptions arising from disease outbreaks, earthquakes, and terrorist attacks, as their occurrence is unpredictable and outside the control of business firms (Chen et al., 2015, Darom et al., 2018, Mithun Ali et al., 2021). In both cases, proper formulation of recovery strategies for managing disruptions is necessary to minimize the overall impact of disruptions on operations (Blos & Wee, 2020).

Formulating recovery strategies to return to normal or better operational states after catastrophic events is vital to rapid recovery and survival (Ponomarov & Holcomb, 2009). Results of previous research show that 80% of companies that failed to design recovery strategies for supply chain disruption during major outbreaks have closed down their operations within two years after the event (Cerullo & Cerullo, 2004). Statistics indicate that the frequency of such major supply chain outbreaks has increased in recent years. For example, the World Health Organization (WHO) has tracked more than 1,400 epidemic outbreaks between 2011 and 2018 (Hudecheck, Siren, Grichnik, & Wincent, 2020). As such, developing strategies for recovering from a major outbreak has become critical for the long-term survival of supply chains. Yet, surprisingly, the extant literature on major epidemic and pandemic outbreaks mostly considers humanitarian supply chain issues. There is a lack of studies on how traditional commercial supply chains can quickly recover from epidemic or pandemic outbreaks (Clarke & Boersma, 2020a).

Companies face many challenges in formulating supply chain recovery strategies. Resource constraint is one challenge many firms face, especially small and medium-sized enterprises (Melnyk et al., 2014, Pal et al., 2014). Efficient allocation of scarce resources is necessary as firms struggle to decide on investment priorities for rapid recovery. Major supply chain disruptions also affect broader socio-economic conditions and consumer buying power afterwards (Chou et al., 2004, Huber et al., 2018). Companies generally resort to backlogs and delayed orders during a disruption, thereby creating disruption tails in the post-disruption period (Ivanov, 2019, Ivanov, 2020b). Ripple and cascading supply chain disruption effects result in companies facing operational problems, such as future bullwhip effects (Dolgui et al., 2020, Pavlov et al., 2019), which further weaken a firm’s supply chain resilience and ability to formulate and implement recovery strategies (Li & Zobel, 2020).

Production planning problems during a disruption period also lead to product stock-out and short supply in the post-disruption period (Dolgui et al., 2020). Disruption recovery requires the formulation of flexible recovery strategies that take different scenarios and challenges into consideration (Wang & Yu, 2020). This flexibility is necessary because the impacts of supply chain disruptions will vary (Ivanov et al., 2015, Pavlov et al., 2019). Therefore, different combinations of recovery strategies need to be considered, which is a common challenge for many firms (Rahman, Taghikhah, Paul, Shukla, & Agarwal, 2021).

These issues appear arbitrarily mentioned in previous research. To date, no study has specifically and comprehensively focused on exploring supply chain recovery challenges empirically. Most studies focus on developing recovery models in the wake of supply chain disruptions (Ivanov et al., 2015, Darom et al., 2018, Hishamuddin et al., 2015, Ivanov, 2019, Ivanov, 2020b, Ivanov et al., 2017, Lücker et al., 2019, Paul et al., 2017, Paul et al., 2019, Sawik, 2019). These recovery models focus on supply, production, demand, and transportation disruptions (Ivanov et al., 2016, Ivanov et al., 2017, Paul et al., 2016, Paul and Rahman, 2018). While developing recovery models is necessary, identifying the potential challenges in disruption recovery is vital to properly plan to overcome these challenges.

2.2. Challenges in recovering from COVID-19 pandemic

Although not particularly focused on identifying recovery challenges, several recent studies (see Table 1 ) have directly or indirectly reported some challenges, along with other findings, for supply chains in recovering from the COVID-19 pandemic. According to these studies, the potential impacts of the COVID-19 pandemic on business and the global economy can be profound in both the short and long term (Clarke and Boersma, 2017, Ivanov and Dolgui, 2020, Paul and Chowdhury, 2020a). Supply chains are expected to experience the heat of the global financial crisis in the longer term (Cui et al., 2019, Singh et al., 2020, Sen, 2020, Lalon, 2020). This long-term global financial crisis will impact the end-customer demand for certain products, especially non-essential garments, luxury and electronic products (Guan et al., 2020, Majumdar et al., 2020, Yuen et al., 2020, Amankwah-Amoah, 2020, Chowdhury et al., 2021). Specifically, such products will suffer from sharp and long-term demand drop (Lalon, 2020, Majumdar et al., 2020). As a result, producers of such products will experience frequent order cancellation and payment withholding from business buyers during the recovery phase of the outbreak (Sen, 2020). Hence, these supply chains will need longer to recover from the pandemic (Laing, 2020).

Table 1.

Challenges in recovering from COVID-19 pandemic.

| Reference | Likely recovery challenges reported |

|---|---|

| Choi (2020) | Bankruptcy of supply chain partners |

| Chowdhury et al., (2020) | Layoff in the industry, rebuilding supply chain networks, and difficulties in maintaining relationships |

| Gurbuz and Ozkan (2020) | Adopting the latest technologies and applications and adapting to new approaches of working and management |

| Ishida (2020) | Although recovery challenges vary across industries, some likely challenges are restructuring supply chains and maintaining vertical integration |

| Clarke and Boersma (2020a) | Long time to recover due to long-lasting impacts on demand and supply, closure of operations of supply chain partners and lack of preparedness |

| Cui et al. (2020b) | Global economic recession in longer term and difficulties in recovery decision making |

| Lalon (2020) | Global economic recession, demand falls in longer term, order cancellation and balancing economic and social sustainability |

| Leite et al. (2020) | Lack of resources to implement rapid recovery plan and difficulties in increasing production capacities |

| Majumdar et al. (2020) | Sharp fall of demand in longer term, focusing on supply chain sustainability, payment withholding by buyers, closure of operations of supply chain partners permanently |

| Paul and Chowdhury (2020a) | Difficulties in increasing production capacity and maintaining a smooth flow of raw material supply |

| Sen (2020) | Global economic recession in longer term, payment withholding by buyers, order cancellation by the buyers due to demand drop, reduction of sourcing options, material price increase |

| Sharma et al. (2020) | Demand disruption, implementation of dynamic response and latest technologies, reconfiguring supply chain and synchronizing process |

| Sharma et al. (2021) | Low-level of preparedness and inadequate infrastructure and resources |

| Singh et al. (2020) | Global economic recession |

| van Hoek (2020) | Low level of preparedness, adaption to the new mode of distributions, implementation of digital technologies |

Moreover, due to the length of this crisis, companies are likely to suffer for more extended periods. As a result, many firms might go bankrupt from the impacts of COVID-19 (Choi, 2020), which will create difficulties in allocating funds and resources to implement recovery strategies. A recent review article (Queiroz eta l., 2020) also mentions that pre-allocation of resources for disruption recovery is necessary for a quick resurgence. However, supply chains are generally suffering from resource crises and are likely to face this challenge in the post-COVID-19 period (Xu et al., 2020).

Some studies on the current COVID-19 pandemic identify the impacts or challenges of major outbreaks on supply chain operations. For example, Ivanov, 2020a, Ivanov, 2020b notes the simultaneous impact on demand, production, supply, and other logistics operations of this extraordinary outbreak. Considering the multiple implications of the COVID-19 pandemic, production recovery models must simultaneously address these multiple impacts (Paul and Chowdhury, 2020a). Such holistic consideration in formulating recovery strategies is likely to increase complexity and ambiguity in supply chains. The impacts are immediate and greater for high-demand essential items (Singh et al., 2020, Deaton and Deaton, 2020, Abhishek et al., 2020, Hobbs, 2020, Quayson et al., 2020). For these supply chains, increasing production capacity and maintaining a smooth flow of material supply are vital challenges to recover from due to this outbreak (Paul and Chowdhury, 2020a). Comprehensive and effective strategies need to be introduced, as coordination and horizontal collaboration among producers at the national level may be required for such products (Paul and Chowdhury, 2020b).

Businesses have also been facing threats of shutting down due to temporary lockdowns in countries where their key supply chain partners operate. In the medium to long term, these firms will face economic shock, reduction of production capacity, fewer institutional supports, and other social challenges (Laing, 2020, Cappelli and Cini, 2020). Moreover, some supply chain partners may close their operations permanently if they cannot absorb the loss from temporary shutdowns (Majumdar et al., 2020). This will pose many challenges in the recovery phase. For example, firms may need to procure materials at higher prices due to decreased sourcing options (Sen, 2020). As a result, new partnerships in supply chains would need to be built, affecting existing collaborations and relationships (Chowdhury, Sarkar, Paul, & Moktadir, 2020). Moreover, a complete restructuring of supply chains and rebuilding supply chain networks might be needed in the post-COVID-19 era (Ishida, 2020, Sharma et al., 2020).

Difficulties in making prompt recovery decisions are also major challenges reported in the literature (Cui et al., 2020b). While firms have faced several major outbreaks in the past, the intensity of the current COVID-19 pandemic is significantly higher than in previous events. As a result, a lack of preparedness to deal with such an outbreak has been reported (Sharma et al., 2021, Clarke and Boersma, 2017, van Hoek, 2020), and this lack will delay decision-making (van Hoek, 2020). Further, due to deficits in infrastructure, digital technologies, and the latest applications and resources, supply chains are likely to struggle with implementing rapid recovery plans and strategies (Leite et al., 2020, Sharma et al., 2021).

A multiplicity of issues suggests that recovery from this extraordinary COVID-19 pandemic will be extremely challenging, requiring thoughtful and robust investigation of all the envisaged difficulties. This study aims to achieve this objective and uses the findings to help practitioners better understand the potential challenges in formulating and implementing strategies for recovering from the COVID-19 pandemic.

3. Research methodology

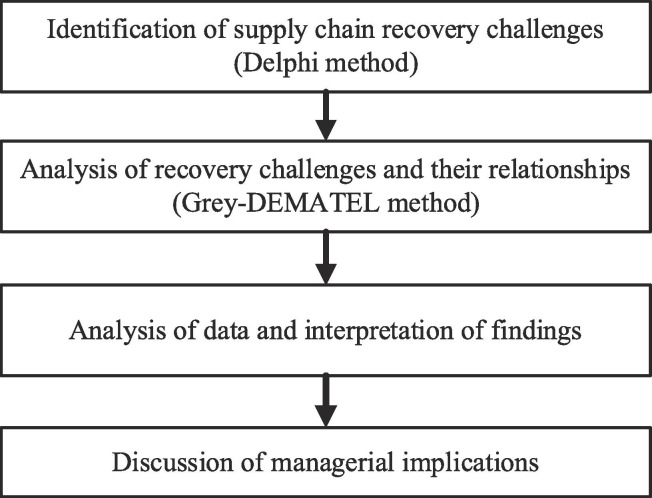

This study adopts a systematic methodology to identify and analyze recovery challenges (see Fig. 1 ).

Fig. 1.

Proposed research methodology.

3.1. Delphi method

Given the complexity of the issues involved, a structured Delphi method was employed to identify the post-COVID-19 supply chain recovery challenges. The structured Delphi method is a qualitative research technique aggregating data from a group of respondents using a set of questionnaires with statistical validation where appropriate (Melnyk, Lummus, Vokurka, Burns, & Sandor, 2009).

In the method, respondents share their pragmatic knowledge and experience to reach the desired goal (Moktadir et al., 2019, Kembro et al., 2017). There is no specific rule or guideline on how many respondents should be involved in data collection. For example, Murry and Hammons (1995) recommend using 10–30 experts for data collection, whereas Okoli and Pawlowski (2004) advocate 10–18. In typical Delphi studies, the general practice is to use at least 10 experts for consistent and reliable results; this study utilized 10 respondents and three rounds of data collection. An initial list of recovery challenges was collected in the first round, rating scores to finalize the list of recovery challenges in the second, and agreement from all respondents on the finalized list in the third.

3.2. Description of grey DEMATEL

The DEMATEL method is a mapping process that helps determine the causal relationship among factors using digraphs (Chowdhury & Paul, 2020, Jeng and Tzeng, 2012). In this study, a grey DEMATEL method was used to analyze the recovery challenges, mapping, and relationships. While DEMATEL helps determine interaction among factors, it cannot deal with uncertainty and ambiguity in an expert’s opinion. As grey DEMATEL helps address this ambiguity, it was employed in the study to obtain the desired output. Grey numbers are based on grey theory (Deng, 1982), which helps transform the uncertainties indicated in the experts’ qualitative answers into number ranges (Fu, Zheng, Zhao, & Xu, 2001). Grey system theory supports decisions with ambiguity, uncertainty, or indeterminacy (Julong, 1989). It also supports inconsistency in knowledge and information experienced by decision-makers in the group decision-making process (Zhu, Sarkis, & Lai, 2014). It can deal with the fuzziness and facilitate flexibility in the decision-making process (Wei, Liu, & Shi, 2019). Grey numbers can be easily converted to crisp numbers using a three-step process: transform grey numbers to crisp numbers, calculate the total normalized crisp value, and then calculate the final crisp value (Fu, Zhu, & Sarkis, 2012).

Grey DEMATEL has been applied in a variety of evaluation situations. Ren, Liang, Dong, Gao, He, Pan, and Sun (2017) investigated the barriers and technologies of a sewage sludge-to-energy system using grey DEMATEL. Moktadir, Ali, Rajesh, and Paul (2018) used grey DEMATEL to assess the causal relationship between sustainable supply chain implementation barriers in the leather industry. Bhatia and Srivastava (2018) employed grey DEMATEL to demonstrate the barriers to remanufacturing process in the Indian context, and Ali et al. (2019) used it to evaluate the risks in the food supply chain. Raj and Sah (2019) assessed the critical success factors of implementing drones in the logistics sector using grey DEMATEL. These studies clearly show that the method has gained popularity as a valuable sense-making tool when multiple factors with complex and ambiguous relationships exist in the problem. The methodological steps of grey DEMATEL are as follows:

Step 1: Construction of the initial matrices

In this step, grey relation matrices are constructed with the assistance of assigned experts using a five-level grey linguistic scale (see Table 2 ). The total number of recovery challenges is “n,” and the total number of assigned experts is “K.” Each expert “k” will evaluate the influence of recovery challenge “i” over the recovery challenge “j” from among “n” recovery challenges using the linguistic grey level. The linguistic grey level “No influence (NI)” indicates the grey number value of [0.00, 0.00], and the linguistic level “Very high influence (VHI)” denotes the grey number value of [0.75, 1.00].

Step 2: Construction of the initial grey relation matrices

Table 2.

Grey linguistic scale (Cui et al., 2019).

| Linguistic levels | Grey numbers |

|---|---|

| No influence (NI) | [0.00, 0.00] |

| Very low influence (VLI) | [0.00, 0.25] |

| Low influence (LI) | [0.25, 0.50] |

| High influence (HI) | [0.50, 0.75] |

| Very high influence (VHI) | [0.75, 1.00] |

The initial linguistic matrices are transformed using grey number values. For example, if expert “l” mentioned that the “VHI” of recovery challenge “i” over the recovery challenge “j,” then the grey number, including the upper and the lower values of that grey linguistic level, will be [0.75, 1.00]. The notation will include upper and lower-valued grey numbers as follows:

| (1) |

where and represent the lower limit and the upper limit value of the grey number for expert “k” accordingly. Therefore, for the “K” experts, the grey number values will be as follows: .

Step 3: Computation of the average grey relation matrix

The final average grey relation matrix can be formulated from “K” grey relation matrices given below:

| (2) |

Step 4: Determination of the crisp relation matrix from the average grey relation matrix

In this step, the crisp value from the grey number is obtained using the three steps modified-converting fuzzy values into crisp scores (CFCS) method, which is given below:

-

a.

Transforming grey numbers into crisp numbers

| (3) |

| (4) |

| (5) |

-

b.

Calculation of the total normalized crisp value

| (6) |

-

c.

Calculation of the final crisp value

| (7) |

and

| (8) |

where q is the crisp initial relation matrix.

4 Step 5: Construction of the normalized direct crisp relation matrix

The normalized direct crisp relation matrix S is calculated by computing q and multiplying the average relation matrix q with R. i.e.,

| (9) |

and

| (10) |

where S is the normalized direct relation matrix.

Step 6: Formulation of the total relationship matrix

| (11) |

where I denotes the identity matrix and M is the total relation matrix.

Step 7: Assessment of cause-effect parameter and development of a digraph

A three-step procedure is used to develop a digraph and cause-effect diagram as follows:

Step 7a: Calculation of the row (ri) and column (cj) sum for each row i and column j of the total relationship matrix (M) using

| (12) |

| (13) |

| (14) |

| (15) |

represents the overall importance of recovery challenge “i.” denotes the net effect of the recovery challenge “i.” If the value of is positive, the recovery challenge “i” is a net cause for other recovery challenges. If the value of is negative, the recovery challenge “i” is the net effect by other recovery challenges.

Step 7c: Calculation of the threshold and establishment of the digraph

A threshold value () helps avoid complexity to a digraph. The threshold value will only consider the most significant relationships among factors. One approach is to determine the mean and standard deviation values of all relationships in the total relationship matrix (M), and include only those relationships that are one standard deviation above the mean. In a digraph, a causal relationship can be plotted using the dataset of

5. Application of the proposed methodology

The proposed Delphi-based grey DEMATEL model was applied to understand the supply chain recovery challenges of Bangladesh’s RMG industry after COVID-19 and their interrelationships. The RMG sector of Bangladesh plays a crucial role in the country’s economic development (BGMEA 2020a). Given its significant contribution to the country’s economic development, the industry needs a proper strategic business policy to tackle the outbreak situation and maintain its position in the global market upon recovery from the COVID-19 pandemic. Therefore, this study identifies and assesses the recovery challenges the RMG sector might face due to COVID-19 through research conducted in two phases.

Phase 1: Identification of recovery challenges using a Delphi study

In this phase, initial recovery challenges based on the inputs from experts in the RMG industry were collected using a questionnaire created using Google Form (see Appendix A in supplementary material). A meeting was set up for a screening process with 10 experts to finalize the list of recovery challenges. In the finalization process, 23 identified recovery challenges were sent to the 10 experts who were asked to rate the relevancy of the identified challenges using a five-point Likert-type scale. Table A1 outlines the profiles of the 10 experts (see Appendix A in supplementary material).

For each recovery challenge, the mean score was calculated from the experts’ scores. A threshold value of the mean score was set to fix the initial cut-off of recovery challenges for the grey DEMATEL analysis. If the mean score was four out of five or above, the recovery challenge was selected. The feedback scores from the experts are provided Table A2 (see Appendix A in supplementary material). Using the threshold value, 23 recovery challenges remained in the final list, which all respondents approved. The list output and explanation are shown in Table 3 , in which the grey shaded elements were removed from the DEMATEL analysis. The final list of recovery challenges is presented in Table 4 .

Phase 2: Application of grey DEMATEL approach to assess interrelationships

Table 3.

Mean score for the identified recovery challenges.

| Name of the recovery challenges | Explanation of the recovery challenge | Mean score |

|---|---|---|

| Global economic recession in longer term | Due to the COVID-19 pandemic, a global economic recession is likely to occur, and the global economy will take a long time to recover. | 4.1 |

| Pressure from buyers on reducing delivery lead time | While manufacturers are facing difficulties in continuing with their production smoothly, buyers can exert great pressure on on-time delivery. This ongoing pressure may hamper the relationships during the recovery process. | 4.3 |

| Increase of bankruptcy of supply chain partners | Supply chain partners have a high risk of bankruptcy due to the COVID-19 pandemic. This may reduce the availability of partners during the recovery. | 4.2 |

| Complexities in real-time forecasting | Due to the sudden impacts of the COVID-19 pandemic, demand information becomes inaccurate and may not be available. This creates complexity in real-time forecasting. | 3.0 |

| Shortage of physical and financial resources | Lockdowns and other restrictions can hamper the provision of physical (material) and financial resources, which may slow down the recovery. | 4.1 |

| Sharp fall of demand for a longer period | There will be a challenge in maintaining the same level of product demands due to reduced purchasing along the supply chain for longer period. This could lead to a longer recovery process. | 4.0 |

| High level of layoff of highly paid workers | There is a high chance of layoff due to the COVID-19 pandemic. Employees will expect more sustainable job assurance from the industry owners. This may lead to a shortage of skilled manpower during the recovery process. | 4.0 |

| Long time to make a recovery decision | The COVID-19 pandemic is altering regular activities and impacting the supply chain drastically. It will be difficult to identify and make recovery decisions rapidly. | 4.3 |

| Closure of operations of supply chain partners | Due to the lack of demand of some items, there is a high risk of closure of operations of supply chain partners. It could hamper the normal supply chain operations during the recovery process. | 4.0 |

| More sustainable demand from the employees | Due to the impacts of the COVID-19 pandemic, social sustainability practices can be affected. The employees may become more demanding in ensuring social sustainability. | 3.5 |

| Changes in distribution networks | Global shutdown and spreading of the virus can disrupt the distribution networks during the recovery process. | 4.2 |

| Shortage of skilled manpower | A shortage of skilled manpower can be one of the recovery challenges as industry owners may lay off skilled manpower to cut costs. | 4.3 |

| A slow rise in productivity to normal levels | To slow down the spread of COVID-19, the social distancing requirement is commonly enforced with profound impacts. It can reduce productivity as employees will not be able to work normally during the recovery process. | 4.4 |

| Payment withholding from buyers | Buyers are facing demand shortages and may not have enough revenue to pay for inventory. Therefore, they may withhold payment. Suppliers could face challenges in maintaining normal activities during the recovery process. | 4.2 |

| Complexities in production planning | The COVID-19 has created multi-dimensional impacts and deep uncertainties in the production process which may increase complexity in its recovery planning. | 2.9 |

| Low level of preparedness | Many supply chain managers have no idea about the magnitude of impacts of the pandemic which indicates a low level of preparedness and this may slow down the recovery process. | 4.1 |

| Reduction in supply chain flexibility | Supply chain activities in a pandemic condition are subject to many restrictions. As such, flexibility of the supply chain during the recovery may decrease. | 4.0 |

| Difficulties in supply chain collaboration | Border closure has resulted in greater difficulties in collaborating with supply chain partners during the recovery. | 4.1 |

| Long-lasting impact on the activities of end customers | Panic buying and shifting of consumer goods demands are commonly observed during the pandemic. The impacts can be long-lasting. | 4.0 |

| Reduction in sourcing options | Due to the slowdown of manufacturing operations, border closure, and restriction of air transport facilities, sourcing options for supply chain partners could be reduced during the recovery. | 4.0 |

| Lack of air transportation facility | Due to the closure of international borders, availability of air transport has lessened. This may lead to disruption during the recovery. | 3.0 |

| Long time to recover | The COVID-19 is a unique type of pandemic and supply chain experts are not familiar with it. Therefore, it will take long time to recover. | 4.0 |

| Low level of financial flow in the market | A low level of financial flow will be one of the critical recovery challenges for supply chain partners. It can impact regular business activities during the recovery. | 4.0 |

| Problems in rapid communication | Most employees have been working from home during the COVID-19 pandemic, which may create issues with rapid communication during the recovery. | 3.0 |

| Frequent order cancellation from buyers | Buyers are canceling orders due to a reduction in consumer demand. This could impact normal supply chain activities during the recovery process. | 4.1 |

| Increase in price of raw materials | Raw material suppliers are not able to operate the supply activities due to restrictions throughout the world. This may increase the price of raw materials while supply chains recover from the pandemic. | 4.0 |

| Pressure from buyers on using faster transportation mode | As some items such as textile-related personal protective equipment have a high demand on the market, buyers are forced to ship the products using faster transportation mode. This could create financial pressure on sellers during the recovery process. | 4.0 |

| Dilemma of ‘survival vs. sustainability’ in making a decision | Supply chain practitioners and experts are facing difficulties in focusing on sustainability while they are struggling for survival. During the recovery, many supply chain partners may not be able to maintain sustainability practices while recovering from financial impacts. | 4.1 |

Table 4.

Final list of RMG industry recovery challenges (with IDs) due to the COVID-19 pandemic.

| Challenge ID | Name of the recovery challenges |

|---|---|

| RC1 | Global economic recession in a longer term |

| RC2 | Pressure from buyers on reducing delivery lead time |

| RC3 | Increase of bankruptcy of supply chain partners |

| RC4 | Shortage of physical and financial resources |

| RC5 | Sharp fall of demand for a longer period |

| RC6 | High level of layoff of highly paid workers |

| RC7 | Long time to make a recovery decision |

| RC8 | Closure of operations of supply chain partners |

| RC9 | Changes in distribution networks |

| RC10 | Shortage of skilled manpower |

| RC11 | A slow rise in productivity to normal levels |

| RC12 | Payment withholding from buyers |

| RC13 | Low level of preparedness |

| RC14 | Reduction in supply chain flexibility |

| RC15 | Difficulties in supply chain collaboration |

| RC16 | Long-lasting impact on the activities of end customers |

| RC17 | Reduction in sourcing options |

| RC18 | Long time to recover |

| RC19 | Low level of financial flow in the market |

| RC20 | Frequent order cancellation from buyers |

| RC21 | Increase in price of raw materials |

| RC22 | Pressure from buyers on using faster transportation mode |

| RC23 | Dilemma of ‘survival vs. sustainability’ in making a decision |

In this phase, a grey-based DEMATEL approach was applied to assess the interrelationships of the recovery challenges. The seven steps of the approach and the results are summarized below.

Step 1: Grey relation matrices among the 23 identified recovery challenges were constructed with the assistance of eight experts from the previously assigned experts (see Table A1) for the Delphi study using the five-level grey linguistic scales provided in Table 2. The eight experts were selected for their many years of experience in the industry and keen interest in participating in the evaluation process. Experts rated the influence of one recovery challenge on the other recovery challenges based on the grey linguistic scale.

Step 2: In this step, with the help of Eq. (1), eight grey relation matrices were formulated based on the feedback from the experts. The eight grey relation matrices are shown in Tables B1–B8 (see Appendix B in supplementary material).

Step 3: The average grey relation matrix was constructed using Eq. (2) and shown in Table B9 (see Appendix B in supplementary material).

Step 4: The crisp relation matrix (q) from the average grey relation matrix was obtained using Eqs. (3), (4), (5), (6), (7), (8), (9), (10), (11), (12), (13). The result is shown in Table B10 (see Appendix B in supplementary material).

Step 5: The normalized crisp relation matrix (S) was constructed using Eqs. (9), (10). The result is shown in Table B11 (see Appendix B in supplementary material).

Step 6: The total relation matrix (M) was formulated using equation (11), as shown in Table B12 (see Appendix B in supplementary material).

Step 7: Steps 7a, 7b, and 7c were used to determine the cause-effect relationships among the recovery challenges and build a digraph. Using Eqs. (10), (11), ri and cj values were determined for each recovery challenge. The overall importance of each recovery challenge and the net effect of each recovery challenge i were determined using Eqs. (12), (13). The results are shown in Table 5 . A higher value of indicates a more important challenge and vice versa. If is positive, the recovery challenge i is identified as a net cause. Negative value means that recovery challenge “i” is a net effect from the other recovery challenges.

Table 5.

The prominence and the net cause-effect for recovery challenges.

| Recovery Challenges | Ranking Order | Cause/Effect | ||||

|---|---|---|---|---|---|---|

| RC1 | 4.200 | 3.792 | 7.992 | 2 | 0.409 | Cause |

| RC2 | 3.450 | 3.385 | 6.835 | 10 | 0.065 | Cause |

| RC3 | 3.130 | 3.357 | 6.487 | 21 | −0.227 | Effect |

| RC4 | 4.421 | 3.725 | 8.146 | 1 | 0.696 | Cause |

| RC5 | 3.873 | 3.569 | 7.442 | 4 | 0.303 | Cause |

| RC6 | 3.784 | 3.678 | 7.461 | 3 | 0.106 | Cause |

| RC7 | 3.184 | 3.647 | 6.831 | 13 | −0.463 | Effect |

| RC8 | 3.366 | 3.422 | 6.788 | 15 | −0.056 | Effect |

| RC9 | 3.332 | 3.473 | 6.806 | 14 | −0.141 | Effect |

| RC10 | 3.417 | 3.425 | 6.841 | 9 | −0.008 | Effect |

| RC11 | 3.354 | 3.401 | 6.755 | 16 | −0.047 | Effect |

| RC12 | 3.472 | 3.450 | 6.922 | 8 | 0.022 | Cause |

| RC13 | 3.175 | 3.516 | 6.691 | 17 | −0.340 | Effect |

| RC14 | 3.257 | 3.669 | 6.925 | 7 | −0.412 | Effect |

| RC15 | 3.256 | 3.575 | 6.832 | 12 | −0.319 | Effect |

| RC16 | 3.545 | 3.437 | 6.982 | 6 | 0.108 | Cause |

| RC17 | 3.417 | 3.161 | 6.578 | 18 | 0.256 | Cause |

| RC18 | 3.456 | 3.552 | 7.008 | 5 | −0.096 | Effect |

| RC19 | 3.441 | 3.393 | 6.834 | 11 | 0.049 | Cause |

| RC20 | 3.209 | 3.364 | 6.573 | 19 | −0.155 | Effect |

| RC21 | 3.231 | 3.060 | 6.291 | 23 | 0.172 | Cause |

| RC22 | 3.285 | 3.273 | 6.558 | 20 | 0.012 | Cause |

| RC23 | 3.260 | 3.193 | 6.453 | 22 | 0.067 | Cause |

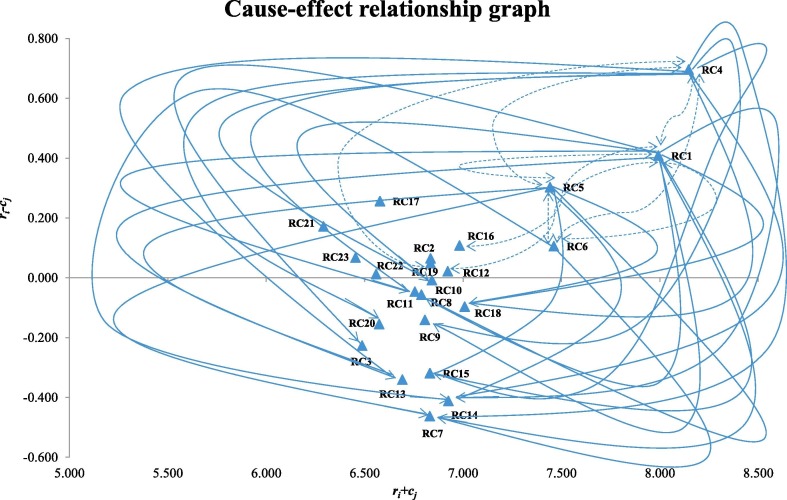

The threshold value () for including a relationship in the digraph is equal to 0.172. The mean value of all elements in the total relation matrix (M) is 0.1533, and the standard deviation of these elements is 0.0184. Finally, the digraph is made using the dataset and presented in Fig. 2 .

Fig. 2.

Causal relationships among recovery challenges in the supply chain due to the COVID-19 pandemic.

6. Results and discussions

This section provides the results obtained from the grey DEMATEL approach together with some observations.

The importance value of the recovery challenges can help identify their relative order. According to the findings, the ranking order of the recovery challenges are as follows:

RC4 > RC1 > RC6 > RC5 > RC18 > RC16 > RC14 > RC12 > RC10 > RC2 > RC19 > RC15 > RC7 > RC9 > RC8 > RC11 > RC13 > RC17 > RC20 > RC22 > RC3 > RC23 > RC21.

The ranking indicates that “shortage of physical and financial resources (RC4)” is the most prominent concern of the experts in this industry. It implies that the most crucial recovery challenge due to the impacts of the COVID-19 pandemic in the RMG sector would be a “shortage of physical and financial resources.” The shortage of materials and capital supply can significantly disrupt the global value chain’s continuity (Lalon, 2020). These organizations are unlikely to have sufficient supplies and capital to maintain operations, causing them to close their facilities and lay off workers permanently. As shown in Fig. 2, it is a net cause of many of the other concerns and a foundational issue and lifeblood of organizations that can address all the remaining recovery challenges. Notably, it is not the overall largest valued challenge based on the results shown in Table 3. This indicates that the experts do not fully perceive interrelationships of these factors as potentially the most central and critical element identified through the DEMATEL process.

Apart from RC4, the next five most essential recovery challenges are “global economic recession for a longer-term (RC1),” “high level of layoff of highly paid workers (RC6),” “sharp fall of demand for a longer period (RC5),” “long time to recover (RC18),” and “long-lasting impact on the activities of end customers (RC16).” This finding shows that the experts’ major concern seems to focus on the longer-term impacts of the COVID crisis on the global value chain of the RMG industry and not the short term. Although driven by a short-term scarcity of financial and material resources, a long-lasting COVID crisis can do more significant harm (Majumdar et al., 2020). The results indicate that for the RMG supply chain in the context of an emerging economy, COVID-19 is dramatically affecting the global value chain. In emerging countries, a large number of high-paid workers are being laid off. For the global value chain, demand for RMG items is decreasing and will take longer to recover (Chowdhury et al., 2020). This finding implies that firms without the necessary buffers will likely meet more significant challenges in the long run if they survive.

The next five key recovery challenges are “reduction in supply chain flexibility (RC14),” “payment withholding from buyers (RC12),” “shortage of skilled manpower (RC10),” “pressure from buyers on reducing delivery lead time (RC2),” and “low level of financial flow in the market (RC19).” Due to the COVID-19 pandemic, the global RMG value chain is facing major challenges in regaining supply chain flexibility as the nature of the outbreak is totally different from previous pandemics (Choi, 2020). Hence, in the context of emerging countries, the RMG supply chain is contending with difficulties in getting timely payments from buyers as they are worried their customers will not buy the RMG products. Also, labor shortages, pressure from buyers for quick delivery, and low levels of financial flow may create huge challenges for the RMG supply chain to maintain the business during COVID-19 and beyond.

The remaining important recovery challenges are “difficulties in supply chain collaboration (RC15),” “long time to make a recovery decision (RC7),” “changes in distribution networks (RC9),” “closure of operations of supply chain partners (RC8),” “a slow rise in productivity to normal levels (RC11),” “low level of preparedness (RC13),” “reduction in sourcing options (RC17),” “frequent order cancellation from buyers (RC20),” “pressure from buyers on using faster transportation mode (RC22),” “increase of bankruptcy of supply chain partners (RC3),” “dilemma of ‘survival vs. sustainability’ in making a decision (RC23),” and “increase in price of raw materials (RC21).” These recovery challenges are less important for the RMG supply chain but not totally negligible; they greatly impact global RMG value chains as supply chain collaboration may be hampered. Decision-making may take longer, distribution networks may change, and orders may be frequently canceled due to COVID-19 (Ishida, 2020, Clarke and Boersma, 2017). Therefore, decision-makers may also need to consider these recovery challenges for the RMG supply chain in the worst-case scenario.

Although every challenge has the potential to generate a high impact on the RMG business, understanding cause-effect relationships can help practitioners develop effective recovery policies and processes to mitigate the most impactful risks. The digraphs in Fig. 2 show a causal relationship among the challenges. A solid line represents a one-way directed relationship, whereas a dotted line represents a two-way relationship between the recovery challenges. A one-way relationship indicates that a particular challenge will likely influence another recovery challenge. Subsequently, an exogenous relationship is expected to exist between these challenges. A significant two-way relationship indicates that both recovery challenges could influence each other. In that case, a probable endogeneity may exist with causation not clearly delineated in terms of the direction of the relationship. A more nuanced, albeit still general evaluation of some of the cause-effect relationships are provided in the next two sections.

6.1. Cause group recovery challenges

Cause group recovery challenges are those that influence other challenges. The level of “causality” is based on the magnitude of the positive value of . The results show the following order for the 12 causal-oriented challenges: RC4 > RC1 > RC5 > RC17 > RC21 > RC16 > RC6 > RC23 > RC2 > RC19 > RC12 > RC22.

The study findings show that the recovery challenge “shortage of physical and financial resources (RC4)” has the highest causal group value. As shown in the previous section, “shortage of physical and financial resources” is also the most fundamental recovery challenge for the RMG sector, based on the views of the sample of experts. The experts opine that the shortage of material resources arises from increased complexities in the RMG supply chains due to the unexpected disruption risks of the COVID-19 pandemic (Sarkis et al., 2020, Boin et al., 2010). These disruptions may occur anywhere at any time, depending on whether there is an increase in infected cases and whether authorities resort to lockdown to curb the infection, thereby shutting down particular sources of physical materials. Setting up systems to help reduce this uncertainty may also help mitigate “effect group” recovery challenges (Gurbuz & Ozkan, 2020).

The next highest causal recovery challenges include “global economic recession for a longer term (RC1)” and “sharp fall of demand for a longer period (RC5).” The RMG sector exports most of its outputs to developed countries, which explains why the experts agree that global economic recession due to the COVID-19 pandemic—which impacts customers’ purchasing power—will be a great challenge for this industry. Also, a “sharp fall of demand for a longer period” would be a severe challenge to overcome amid global competition. Both of these challenges will cause many other concerns.

The findings also show that “reduction in sourcing options (RC17),” “increase in the price of raw materials (RC21),” and “long-lasting impact on the activities of end customers (RC16)” are ranked fourth, fifth, and sixth, respectively. This suggests that these challenges can be causal while also having an enormous impact on effect group challenges (see Fig. 2). As a result of the COVID-19 pandemic, there are fewer sourcing options for the RMG sector. Then, when demand for raw materials surges, prices may increase due to decreased supply (Cui et al., 2020b). Therefore, industrial practitioners should be more prudent and flexible in taking proper action to overcome the sourcing challenge.

Overall, the RMG sector should focus on initiatives to reduce these major causal recovery challenges due to their high impact on effect group challenges. However, while all challenges could eventually arise, prioritizing them may allow organizations to address the greatest ones first with the limited resources available.

The effects of the COVID-19 pandemic are very profound. Recent projections indicate that world trade is expected to decline by 13–32% in 2020 (WTO, 2020). As customer demand may be high due to the sudden slowdown of production activities, industrial practitioners must juggle survival and sustainability (Paul and Chowdhury, 2020a). Due to the expected growth of demand for RMG items after COVID-19, buyers will likely require industry owners to expedite delivery. With reduced cash and material flows, it would be a great challenge for the RMG sector to survive in the global market. With these considerations, the industry needs to develop proper strategies to manage COVID-19 influenced RMG supply chains.

6.2. Effect group recovery challenges

The effect group for recovery challenges is sorted on the negative value of and plotted in Fig. 2. Unlike the causal group, the prominence of the effect group along the prominence axis (x-axis of Fig. 2) is concentrated in the 6.5–7.0 range. A clear pattern exists that some recovery challenges have significant influences or causes. Overall, 11 factors fall into the effect group.

“Long time to make a recovery decision (RC7)” is the most influenced recovery challenge for most of the cause group recovery challenges, meaning it can be influenced by more causal group challenges. If decision-makers and managers succeed in addressing the major causal group recovery challenges, this challenge can be tackled more effectively. However, given the many significant causation factors, it can be the most difficult issue to deal with and may still exist even when most of the more prominent and influential challenges have been addressed (Sharma et al., 2020). As such, management will likely face a delay in making multiple decisions due to the uncertainties involved in addressing the many other challenges.

Conversely, “shortage of skill manpower (RC10)” and “frequent order cancellation from buyers (RC20)” are the two recovery challenges that are less influenced by the causal group challenges. For example, industry experts in the Delphi group indicate that limited skilled labor and buyers cancelling orders are the least of their concerns. If major causation challenges such as RC1 and RC4 are overcome, RC10 and RC20 will be mitigated. Industry experts are generally confident that order cancellations would not be an issue for the RMG sector. They believe that even in times of crisis, demand for these products is still regarded as essential. Also, the lessened concern over skilled worker shortages may be due to a declining need for workers. Nevertheless, given the prolonged length of the crisis, both of these and other challenges may eventually become critical.

6.3. Sensitivity analysis

To determine the robustness of the obtained results, a sensitivity analysis was conducted by giving the highest weighting to each expert separately and equal weightings to the other experts. Deviations in the final ranking were then observed. It is crucial to check the deviation in the final results to determine whether the cause-effect relationship among recovery challenges will be affected. In this study, the highest weighting of 0.3 was assigned to each expert separately and an equal weighting of 0.1 to the others (see Table 6 ). The cause/effect parameters obtained during sensitivity analysis are shown in Table B13 (see Appendix B in supplementary material).

Table 6.

Weights assigned to experts during sensitivity analysis.

| Expert 2 | Expert 4 | Expert 5 | Expert 6 | Expert 7 | Expert 8 | Expert 9 | Expert 10 | |

|---|---|---|---|---|---|---|---|---|

| Scenario 1 | 0.3 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Scenario 2 | 0.1 | 0.3 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Scenario 3 | 0.1 | 0.1 | 0.3 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Scenario 4 | 0.1 | 0.1 | 0.1 | 0.3 | 0.1 | 0.1 | 0.1 | 0.1 |

| Scenario 5 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.1 | 0.1 | 0.1 |

| Scenario 6 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.1 | 0.1 |

| Scenario 7 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.1 |

| Scenario 8 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 |

Results of the sensitivity analysis are detailed in Table 7 and show a minor deviation. Otherwise, the cause-effect group of the recovery challenges and the rankings are identical to the original results. This observation indicates a relative consistency in the evaluations across experts, implying that the study findings and the analysis are relatively robust.

Table 7.

Cause-effect relationships among recovery challenges obtained from sensitivity analysis.

| RC | Cause/Effect | Scenario 1 |

Scenario 2 |

Scenario 3 |

Scenario 4 |

Scenario 5 |

Scenario 6 |

Scenario 7 |

Scenario 8 |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C/E | ri − cj | C/E | ri − cj | C/E | ri − cj | C/E | ri − cj | C/E | ri − cj | C/E | ri − cj | C/E | ri − cj | C/E | ri − cj | ||

| RC1 | Cause | C | 0.362 | C | 0.380 | C | 0.294 | C | 0.433 | C | 0.552 | C | 0.465 | C | 0.538 | C | 0.370 |

| RC2 | Cause | E | −0.032 | E | −0.088 | C | 0.041 | C | 0.126 | E | −0.081 | C | 0.264 | C | 0.166 | C | 0.065 |

| RC3 | Effect | E | −0.271 | E | −0.157 | E | −0.195 | E | −0.416 | E | −0.329 | E | −0.389 | E | −0.106 | E | −0.030 |

| RC4 | Cause | C | 0.930 | C | 0.604 | C | 0.750 | C | 0.583 | C | 0.715 | C | 0.557 | C | 0.646 | C | 0.619 |

| RC5 | Cause | C | 0.368 | C | 0.242 | C | 0.307 | C | 0.395 | C | 0.271 | C | 0.477 | C | 0.142 | C | 0.247 |

| RC6 | Cause | C | 0.054 | C | 0.234 | C | 0.077 | C | 0.212 | C | 0.223 | C | 0.107 | C | 0.102 | C | 0.064 |

| RC7 | Effect | E | −0.377 | E | −0.356 | E | −0.462 | E | −0.427 | E | −0.583 | E | −0.546 | E | −0.478 | E | −0.472 |

| RC8 | Effect | E | −0.099 | E | −0.151 | E | −0.171 | C | 0.093 | E | −0.141 | C | 0.217 | E | −0.061 | E | −0.070 |

| RC9 | Effect | E | −0.116 | E | −0.067 | E | −0.239 | E | −0.009 | E | −0.036 | E | −0.300 | E | −0.366 | E | −0.046 |

| RC10 | Effect | E | −0.086 | E | −0.060 | E | −0.051 | C | 0.062 | C | 0.037 | C | 0.056 | E | −0.015 | E | −0.038 |

| RC11 | Effect | E | −0.140 | C | 0.013 | E | −0.181 | C | 0.033 | E | −0.069 | E | −0.019 | E | −0.016 | E | −0.031 |

| RC12 | Cause | E | −0.068 | C | 0.100 | E | −0.020 | E | −0.031 | C | 0.121 | C | 0.016 | C | 0.010 | C | 0.049 |

| RC13 | Effect | E | −0.375 | E | −0.228 | E | −0.209 | E | −0.254 | E | −0.427 | E | −0.398 | E | −0.250 | E | −0.304 |

| RC14 | Effect | E | −0.453 | E | −0.389 | E | −0.434 | E | −0.144 | E | −0.408 | E | −0.526 | E | −0.469 | E | −0.420 |

| RC15 | Effect | E | −0.176 | E | −0.383 | E | −0.225 | E | −0.544 | E | −0.285 | E | −0.183 | E | −0.456 | E | −0.256 |

| RC16 | Cause | C | 0.045 | C | 0.095 | C | 0.103 | E | −0.103 | C | 0.123 | C | 0.096 | C | 0.169 | C | 0.244 |

| RC17 | Cause | C | 0.301 | C | 0.208 | C | 0.430 | C | 0.209 | C | 0.141 | C | 0.330 | C | 0.351 | C | 0.099 |

| RC18 | Effect | E | −0.018 | E | −0.058 | E | −0.194 | E | −0.002 | E | −0.003 | E | −0.175 | E | −0.188 | E | −0.173 |

| RC19 | Cause | C | 0.031 | E | −0.085 | C | 0.260 | E | −0.143 | E | −0.126 | C | 0.163 | C | 0.015 | C | 0.140 |

| RC20 | Effect | E | −0.161 | E | −0.112 | E | −0.003 | C | 0.094 | E | −0.263 | E | −0.522 | E | −0.218 | E | −0.163 |

| RC21 | Cause | C | 0.154 | C | 0.137 | C | 0.144 | C | 0.205 | C | 0.340 | C | 0.136 | C | 0.244 | E | −0.024 |

| RC22 | Cause | E | −0.034 | C | 0.068 | E | −0.088 | E | −0.135 | C | 0.208 | C | 0.144 | C | 0.006 | C | 0.074 |

| RC23 | Cause | C | 0.161 | C | 0.053 | C | 0.065 | E | −0.238 | C | 0.022 | C | 0.030 | C | 0.237 | C | 0.056 |

Note:E means Effect and C means Cause.

7. Theoretical and managerial implications

This section outlines the theoretical and managerial implications of the study and its findings.

7.1. Theoretical implications

The findings of this study have several theoretical implications. First, it provides a holistic view of supply chain recovery challenges from the COVID-19 pandemic. While the current literature predominantly focuses on identifying and investigating the impacts of the pandemic (Chowdhury et al., 2021), this study is an early attempt to explore the recovery issue and evaluate the potential difficulties. The recovery challenges identified may be common across a variety of global crises that may occur. There are clear risks associated with many of these challenges arising from broad-based pandemics such as COVID-19. Also, this crisis may be a very long-term issue and requires effective strategies for post-crisis recovery. Results of this study have shown that considering strategic concerns and adopting broader strategies that focus on resilience—such as building competitive resources and dynamic capabilities as advocated by resource-based theory—can be a necessity in the future (Brandon-Jones et al., 2014, Cheng and Lu, 2017).

Second, this study identifies a set of recovery challenges in Bangladesh’s RMG sector. Theoretically, these issues may also be important to other emergent economies where financial and material resources are extremely critical, where resource dependence plays a predominant role (Tukamuhabwa, Stevenson, & Busby, 2017). Resource dependence is no longer a dyadic organizational concern for developing nations but a much broader global value chain issue (Islam, 2003, Dong et al., 2018). During crises such as the COVID-19 pandemic, resource dependence on locations in distant proximities may shift to localized sources. Whether this shift will remain and build localized capabilities and dependence after recovery will need to be evaluated.

Third, this study considers and evaluates the use of stakeholder theory (Freeman et al., 2010, Freeman, 1984) to help stakeholders (industry owners, government) understand the nature of recovery challenges to reduce the impacts of the COVID-19 pandemic in the RMG sector. In terms of theoretical contribution, it identifies a new set of recovery challenges and various cause-effect relationships to help reduce the pandemic impacts. While various supply chain stakeholders (buyers, suppliers, and employees) have been considered in this study, the analysis shows that primary stakeholders are more prominent. Recovery challenges that influence a broader set of stakeholders are not the main concern. Specifically, the issue of sustainability versus survival seems to be less prominent. The basic survival of firms is more critical in these difficult times than environmental concerns. This shift in stakeholder perspective may or may not continue after the crisis. Survival may cause a major shift to operational and primary stakeholder focus along the supply chain, which may preclude some sustainability practices across and within the supply chain.

7.2. Managerial implications

The study findings also have several managerial implications for RMG practitioners in a post-COVID-19 business environment. They enable RMG practitioners to understand the potential recovery challenges they may face. These findings will help managers reimagine their value chains and understand how global value chains will gradually alter in the post-COVID-19 era. For example, several challenges—such as changes in the distribution network, closure of operations of current supply chain partners, reduction of sourcing options, and lack of preparedness—indicate a clear need to restructure supply chains to better prepare for a future severe disruption like the current pandemic. While the Bangladesh garment industry is predominantly dependent on imported materials in production (Sen, 2020) and maintains long backward value chains (Nuruzzaman, Haque, & Azad, 2010), this pandemic has revealed how difficult it is to obtain materials from the global market during a crisis. Based on the findings of this research, practitioners involved in managing the value chains are advised to redesign their supply chains by considering potential future outbreaks. Thus, the strategies recommended to managers working in the Bangladesh garment industry include shortening value chains, building local sourcing capacities and encouraging key suppliers to operate closer to the production plants, and diversifying sourcing markets even if materials are originally sourced from the global market for cost efficiency. Such supply chain restructuring is expected to reduce the recovery time from the current pandemic and assist in minimizing the impact of a future disruption.

In addition to restructuring value chains, the findings of this study imply that apparel managers should implement the latest technologies and data-driven supply chains to accelerate the recovery process. Managers have reported that the lack of physical resources, such as IT capability and infrastructure, and financial resources shortages are the most critical challenges in the recovery process. Apparel practitioners should focus on data-driven supply chains to help avoid the most crucial recovery challenge, “shortage of physical and financial resources” (Tseng, Wu, Lim, & Wong, 2019). A data-driven predictive supply chain can help predict disruption and avoid physical and financial resources shortages by formulating appropriate strategic policies (Takeda Berger, Zanella, & Frazzon, 2019). Shortage of resources is also observed to substantially affect apparel manufacturers’ ability to quickly increase productivity. To overcome these problems, managers should implement the latest technologies to improve productivity and operational excellence. The Internet of Things (IoT), cloud computing, 3-D printing, artificial intelligence, big data analytics, and additive manufacturing are some of the emerging technologies for managers to consider (Chowdhury et al., 2021, Yasmin et al., 2020).

The issue related to financial and supply chain resources also suggests that external aid may be needed to address the multitude of challenges. Thus, seeking financial support from the government may be necessary to keep a supply chain running until the crisis subsides. Many governments have stepped up stimulus packages to facilitate recovery from this disruption risk (Mishkin, 2010). National and regional stimulus programs are needed to ride out the potential “global economic recession for a longer term” and ease communities’ concerns.

Based on the study findings, apparel manufacturers should also formulate appropriate strategies to improve supply chain collaboration. The recovery challenges “sharp fall of demand for a longer period,” “reduction in sourcing options,” “increase in price of raw materials,” and “long-lasting impact on the activities of end customers” are causal group challenges with the highest priorities. These causal group challenges also negatively affect supply chain collaboration. Conversely, building and maintaining good relationships with suppliers, buyers, and business partners to ensure the supply of raw materials and timely shipment would accelerate the recovery process in the RMG sector (Ma, Wang, & Chan, 2020). In this regard, maintaining continuous interactions and building capability to maintain decision synchronization are critical. However, current movement restrictions and social distancing limit the physical interactions of supply chain partners (Baveja, Kapoor, & Melamed, 2020). As a result, they face problems of information incompleteness that, in turn, cause information ambiguity and weaken relationships (Gunessee & Subramanian, 2020). Therefore, apparel manufacturers should utilize information technologies to maintain interactions and synchronization with their supply chain partners.

While recovery challenges identified in this study can help reimagine supply chains and formulate recovery strategies, investigating the cause-effect relationships among the challenges can further assist managers. Impacts of the COVID-19 pandemic on the RMG business can be mitigated by properly planning for and managing the cause group recovery challenges (Shao et al., 2016, Bai and Sarkis, 2013), as they are the most critical challenges. Addressing these foundational challenges can mitigate the 11 effect group recovery challenges. Therefore, it is recommended that managers prioritize the causal group challenges and formulate appropriate strategies to overcome such recovery challenges.

8. Conclusions

The main objectives of this study were to identify and analyze supply chain recovery challenges related to the COVID-19 pandemic in the RMG industry to assist practitioners in formulating strategies and reimagining value chains in its aftermath. The study provided a comprehensive set of recovery challenges for use in a variety of research and planning contexts. Further, it analyzed the interrelationships between recovery challenges to identify cause-effect groups of the challenges. The findings can help decision-makers set their priorities in allocating resources in the recovery process to optimize the outcome.

As the global COVID-19 pandemic is relatively unprecedented, recovery challenges have yet to be fully evaluated in research. Despite some learning from previous financial, environmental, and political crises, the uniqueness of this crisis makes it difficult to predict outcomes and potential challenges for recovery. For this reason, a survey using a Delphi method was conducted to identify new recovery challenges related to the COVID-19 pandemic. A grey DEMATEL method was then applied to analyze the recovery challenges and explore the interrelationships between them. This exploratory study contributes to the literature by focusing on a new and recent topic and by integrating the Delphi method with grey DEMATEL to arrive at some potential research and practical implications.

Through the Delphi survey with 10 industry experts, the study identified and confirmed 23 recovery challenges specifically related to the COVID-19 pandemic for the supply chain of the RMG industry in Bangladesh. Further analysis using grey DEMATEL revealed that 12 out of the 23 recovery challenges directly influence the remaining 11 recovery challenges. It was observed that the shortage of physical and financial resources, global economic recession in a longer term, sharp fall of demand for a longer period, reduction in sourcing options, and increase in price of raw materials are the top five challenges in the priority ranking. The sensitivity analysis conducted analyzed the changes in the priority ranking of recovery challenges. Further, it showed that the shortage of physical and financial resources was the top recovery challenge across all scenarios, indicating a relative consensus among the respondents.

This study and its findings are significant in practice. It assists decision-makers by providing a list of potential recovery challenges they may face during and beyond the COVID-19 pandemic. Awareness of these challenges can help them formulate appropriate strategies and reimagine their supply chains in the post-COVID-19 era. All the findings of this study, such as the list of recovery challenges, their priority rankings, and cause-and-effect relationships among challenges, will be useful in formulating the recovery strategies.

This study is exploratory in nature and, like other exploratory studies, limited by some inadequacies. These limitations provide the opportunity for further research. One limitation is that the results are a snapshot in time, as they are based on expert opinion at a particular time. Relationships between the various recovery challenges may change as the pandemic progresses. Therefore, longitudinal studies of these shifts are recommended. Also, the study’s findings and suggestions are only valid for industries that have experienced shrinkage in market demand because of the pandemic, such as apparel manufacturing. However, some other industries, such as food and health, may have different impacts and challenges that could be investigated in future research. Moreover, this study could be extended to a full empirical study to help formulate recovery strategies and evaluate their impacts on the recovery challenges. This broader study could help generalize the findings to other emergent crises. Another limitation is that the sample was drawn from one industry and one country. In future research, the same methodology can identify and analyze recovery challenges for other types of supply chains—such as electronics, food, healthcare, and pharmaceuticals—and other regions for comparison.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Biographies

Sanjoy Kumar Paul is currently working as a Senior Lecturer in operations and supply chain management at the University of Technology Sydney (UTS), Sydney, Australia. He has published more than 90 articles in top-tier journals including the European Journal of Operational Research, Transportation Research Part E, International Journal of Production Economics, Business Strategy and the Environment, Computers & Operations Research, International Journal of Production Research, Annals of Operations Research, Journal of Cleaner Production, International Journal of Physical Distribution and Logistics Management and so on. He is also an editor, editorial board member, and active reviewer of many reputed journals. His research interest includes supply chain risk management, applied operations research, and decision-making. Dr. Paul has received several awards, including ASOR Rising Star Award from the Australian Society for Operations Research, Excellence in Early Career Research Award from UTS Business School, the Stephen Fester prize for most outstanding thesis from UNSW, and high impact publications award for publishing articles in top-tier journals.

Priyabrata Chowdhury is a Lecturer of Supply Chain Management in the School of Accounting, Information Systems and Supply Chain at RMIT University. He received his PhD in Supply Chain and Logistics from RMIT University having been funded through the RMIT PhD International Scholarship (RPIS). He is an active researcher in the field of supply chain management and his research articles appear in the top-tier journals including Transportation Research Part E, International Journal of Operations and Production Management, International Journal of Physical Distribution and Logistics Management, and Journal of Cleaner Production. He is also a regular reviewer of many reputed top-tier journals. His current research interests include supply chain risk and disruption management, supply chain resilience, supply chain sustainability, and strategic alliances in supply chains.

Md. Abdul Moktadir is a Lecturer of Leather Products Engineering at the Institute of Leather Engineering and Technology, University of Dhaka, Bangladesh. He received his Bachelor of Science in Leather Products Engineering from the University of Dhaka and a Master of Engineering in Advanced Engineering Management from BUET. He has published more than 32 articles in various international reputed high impact journals including Journal of Cleaner Production, International Journal of Production Research, Resources, Conservation & Recycling, Computers & Industrial Engineering, Business Strategy and the Environment, Energy, Production Planning & Control, and Annals of Operations Research. He is also an active reviewer of many reputed international journals including the Journal of Cleaner Production, and Resources, Conservation & Recycling. He has received a good number of scholarly citations. His current research interests include sustainable supply chain management, risk management, energy-efficient supply chain, logistics, Industry 4.0, and circular economy.

Kwok Hung Lau is a Senior Lecturer in the School of Accounting, Information Systems and Supply Chain at RMIT University, Melbourne, Australia. He has published 80 articles in top-tier journals and international conferences including International Journal of Production Research, International Journal of Operations and Production Management, International Journal of Logistics Management, International Journal of Physical Distribution and Logistics Management, Supply Chain Management: An International Journal, International Journal of Logistics Research and Application, International Journal of Retail and Distribution Management, Asia Pacific Journal of Marketing and Logistics, Environment and Planning B: Planning and Design, Journal of Disaster Risk Reduction, Computers & Education, Education + Training and so on. His research interests include modeling and simulation in supply chain, supply chain optimization, supply chain analytics, outsourcing, reverse logistics, green supply chain management, supply chain complexity, and education in logistics and supply chain management.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jbusres.2021.07.056.

Appendix A. Supplementary material

The following are the Supplementary data to this article:

References

- Abhishek, Bhamoriya V., Gupta P., Kaushik M., Kishore A., Kumar R., Sharma A., Verma S. India’ s food system in the time of COVID-19. Economic and Political Weekly. 2020;55(15):12–14. [Google Scholar]

- Ali S.M., Moktadir M.A., Kabir G., Chakma J., Uddin J., Islam T. Framework for evaluating risks in food supply chain : Implications in food wastage reduction. Journal of Cleaner Production. 2019;228:786–800. [Google Scholar]

- Mithun Ali S., Kumar Paul S., Chowdhury P., Agarwal R., Fathollahi-Fard A.M., Jose Chiappetta Jabbour C., Luthra S. Modelling of supply chain disruption analytics using an integrated approach: An emerging economy example. Expert Systems with Applications. 2021;173:114690. doi: 10.1016/j.eswa.2021.114690. [DOI] [Google Scholar]

- Amankwah-Amoah J. Stepping up and stepping out of COVID-19: New challenges for environmental sustainability policies in the global airline industry. Journal of Cleaner Production. 2020;271:123000. doi: 10.1016/j.jclepro.2020.123000. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhu Q., Sarkis J., Lai K. Supply chain-based barriers for truck-engine remanufacturing in China. Transportation Research Part E: Logistics and Transportation Review. 2014;68:103–117. doi: 10.1016/j.tre.2014.05.001. [DOI] [Google Scholar]

- Anner, M. S. (2020). Abandoned? The impact of Covid-19 on workers and businesses at the bottom of global garment supply chains. Pennstate Center for Global Workers’Rights (CGWR).

- Bai C., Sarkis J. A grey-based DEMATEL model for evaluating business process management critical success factors. International Journal of Production Economics. 2013;146(1):281–292. [Google Scholar]

- Baveja A., Kapoor A., Melamed B. Stopping Covid-19: A pandemic-management service value chain approach. Annals of Operations Research. 2020;289(2):173–184. doi: 10.1007/s10479-020-03635-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- BGMEA (2020a). ‘Trade information’, accessed November 15, 2020, from https://www.bgmea.com.bd/home/pages/TradeInformation.

- BGMEA (2020b). Impact of COVID-19 on Bangladesh RMG indusry’, accessed September 3, 2020, from https://www.bgmea.com.bd/.