Abstract

Hematite was recently introduced as a weighting agent in drilling fluids; however, its use has some problems because of the settlement of solid particles (solid sagging). Particularly when it comes to high-pressure high-temperature (HP/HT) wells, sagging causes inconsistency in the drilling fluid and gives rise to serious drilling operational and technical challenges. This work provides a solution to this challenge via a thorough investigation of hematite sagging in water-based mud for HP/HT applications where ilmenite is combined with hematite. The particles of both hematite and ilmenite were first characterized to address their mineralogical and textural features. Field mud formulation was employed using several ilmenite/hematite contents (i.e., 0/100, 25/75, and 50/50% ilmenite/hematite). Then, laboratory experiments were conducted to study the density, pH, and sag performance of the produced drilling fluids. From the sagging tests, the optimal ilmenite/hematite ratio was determined, and rheology, viscoelastic behavior, and filtration properties of the formulated mud were addressed. The tests were conditioned to 300 psi and 250 °F. The results showed a reduction in mud density and pH with increasing ilmenite content, as the density reduced from15 ppg with base hematite until 14.2 ppg for the 50% ilmenite mixture and the pH reduced from 10.5 to 9.3. The static and dynamic sag tests indicated that the addition of 25% of ilmenite solved the hematite-incorporated sagging issue by well placing the sag tendency within the recommended safe range. The 25/75% combination enhanced the yield point (YP) by 37% with only 1 cP increment in plastic viscosity (PV) and an insignificant effect on the gel strength. The YP/PV ratio was improved by 31% indicating better hole cleaning and solid suspension. The filtration behavior of the 25% ilmenite mixture was superior compared to that of the blank hematite because it resulted in 35, 39, and 35% reduction in the filtrate volume, filter-cake weight, and thickness, respectively. This work contributes to improving and economizing the drilling cost and time by the formulation of a stabilized and distinguished-performance drilling mud using combined weighting agents at HP/HT.

1. Introduction

The drilling fluid plays a key role in successful drilling operations, which necessitates proper drilling fluid design to ensure the required properties and to fulfill its necessary functions. Over the years, two types of drilling fluids have been used (i.e., water-based and oil-based mud).1−3 The water-based mud (WBM) is widely used but with serious challenges in harsh environments such as in the case of high-pressure high-temperature (HP/HT) reservoirs in which the oil-based mud (OBM) has technical preference but with economic and environmental concerns.3,4 Accordingly, an optimization of the WBM will be required to make it suitable to overcome the harsh conditions of oil and gas reservoirs.5

Weighting agents in drilling fluids are used to obtain the required density for efficiently maintaining and controlling the hydrostatic and formation pressures throughout the drilling operation.6−9 The operational and technical challenges in HP/HT wells necessitate the selection of efficient weighting materials in a manner that ensures the mud consistency.

Although barite (BaSO4) is the commonly used weighting material, there are critical associated issues when using barite under HP/HT conditions.10−12 For instance, the relatively low specific gravity of barite dictates the use of a large amount of solid content to achieve the desired mud weight, which results in higher equivalent circulation density, more viscous fluid, exaggerated torque, and settlement of solid particles (sagging); these eventually lead to loss of circulation, wellbore instability, and pipe sticking because of the inconsistent drilling fluid properties.13−16 Different solutions were introduced to mitigate these serious issues, which include a range of alternative weighting materials.17−24

Hematite (Fe2O3) is a reddish-brown powder and electrically conductive with a molecular weight of 159.69 and a specific gravity of 4.9–5.3 g/cm3. It is commonly used as a blasting agent, absorbent, and adhesive agent and was recently introduced and applied as a weighting material showing technical benefits with a low solid content, as the field and laboratory implementation validated the low toxicity, ROP improvement, and acid-solubility of hematite.25−29 Moreover, the micronized particles of hematite showed a positive impact on rheology and filtration performance besides the advantages of iron oxide existence.30 However in HP/HT wells, solid sagging was still encountered, particularly, at mud density higher or equal to 14 ppg and temperature greater than or equal to 250 °F for different applied pressure ranges.30−32

The micronized ilmenite is a weakly magnetic titanium-iron oxide mineral (FeTiO3), with a specific gravity of 4.5–5.1 g/cm3 and a molecular weight of 157.76. It is acid-soluble with lower abrasiveness than hematite, which makes it suitable to be applied in drilling fluids.31 Many studies addressed the use of micronized ilmenite or its combination with barite in the WBM and OBM to enhance the mud stability with proven successful outcomes.14,33−37

Practically, the associated hematite sagging issue results in several well control challenges; therefore, avoiding these issues will reduce the nonproductive time and economize the drilling cost. Moreover, compared to hematite, ilmenite has a lower sagging tendency, but its cost is relatively higher. Accordingly, this study aimed to employ a combination of weighting agents (i.e., hematite and ilmenite) to enhance the fluid stability and prevent the hematite sagging challenge in the WBM under HP/HT conditions. The optimum combination percentage of hematite and ilmenite was determined based on the sagging tendency. The key mud characteristics were evaluated by identifying the density, alkalinity, sagging performance, rheology, filtration, and viscoelastic behavior.

2. Materials

A multimixer was utilized to prepare three field formulations of the WBM by combining hematite and ilmenite in different concentrations (i.e., 0/100, 25/75, and 50/50% of ilmenite/hematite). The functional additives were mixed sequentially to control the viscosity, alkalinity, fluid losses, shale swelling, and filter-cake formulation. Table 1 shows the mud formulation with an indication of the amounts, mixing duration, and functional role of each component.

Table 1. Drilling Mud Recipe.

| component | unit | amount | mixing duration (min) | function |

|---|---|---|---|---|

| water | cm3 | 245 | base fluid | |

| defoamer | cm3 | 0.08 | 1 | antifoam agent |

| soda ash | g | 0.5 | 1 | maintain calcium concentration |

| xanthan gum | g | 1.5 | 20 | viscosity controller |

| bentonite | g | 4 | 10 | viscosity controller |

| KOH | g | 0.5 | 1 | alkalinity controller |

| starch | g | 6 | 10 | fluid loss controller |

| PAC-R | g | 1 | 10 | fluid loss controller |

| KCl | g | 20 | 10 | shale stabilizer |

| CaCO3 | g | 5 | 10 | bridging material |

| hematite/ilmenite | g | 350 | 10 | weighting agents |

The mineralogical and textural features of hematite and ilmenite were studied using the particle size distribution (PSD), X-ray fluorescence (XRF), and scanning electron microscopy (SEM).

The median particle size (D50) of ilmenite is very small (5.2 μm) compared to the 16.9 μm size of hematite particles (Figure 1). This fine grain size of particles is helpful for minimizing the erosion of the equipment, as the larger particles of weighting materials increase its abrasiveness.38

Figure 1.

PSD of hematite and ilmenite.

XRF analyzed the chemical composition based on the main element multitudes for the studied sections, which showed that 56.2% iron, 37.3% titanium, and less than 5% of magnesium, silicon, and aluminum are the main components of ilmenite, while the hematite constitutes mainly of 95.9% iron and few amounts of aluminum and silicon (Table 2).

Table 2. Chemical Composition That Is Determined Using XRF for Hematite and Ilmenite.

| hematite |

ilmenite |

||

|---|---|---|---|

| element | mass (%) | element | mass (%) |

| iron (Fe) | 95.9 | iron (Fe) | 56.2 |

| aluminum (Al) | 1.1 | aluminum (Al) | 1.4 |

| silicon (Si) | 0.5 | silicon (Si) | 1.3 |

| titanium (Ti) | 37.3 | ||

| magnesium (Mg) | 2.3 | ||

From the SEM images (Figure 2), hematite has crystal-structure particles with a heterogeneous size which make it more abrasive while the ilmenite has a uniform and small particle size, which can overcome the hematite abrasiveness concern.

Figure 2.

SEM images of (a) hematite; (b) ilmenite.

3. Experimental Work

First, the weight and alkalinity of the mud under ambient conditions were determined for the three prepared mud samples with different concentrations of ilmenite.

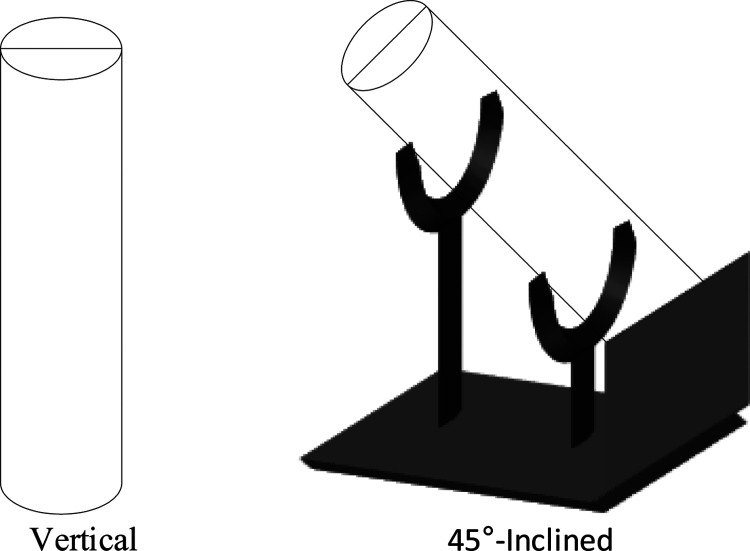

Then, the solid settlement was investigated by conducting the static and dynamic sagging tests to identify the optimal combination percentage of hematite/ilmenite that resulted in settling prevention. The static test was carried out at vertical and 45° slanted positions by applying a pressure of 300 psi and a temperature of 250 °F on the muds at aging cells for 24 h. The setup is sketched in Figure 3. The static sag factor was determined by measuring the fluid weights from the topmost and lowest parts of the cell and using eq 1.39

| 1 |

Figure 3.

Sketch of the vertical and inclined setup for the static sagging test.

A viscometer was used to rotate the formulations at 100 rpm for 30 min at atmospheric pressure and 120 °F to perform the viscometer sag shoe test (VSST), which reflects the dynamic sagging magnitude. The setup is shown in Figure 4. The VSST value was calculated from the fluid weights determined at the cup’s bottom prior and after rotation and using Equation 2.40

| 2 |

Figure 4.

Setup for the dynamic sagging test.

An Anton-paar rheometer was utilized to conduct the rheology tests at high temperature (250 °F) to evaluate the rheological features for the hematite ilmenite combinations in play (i.e., plastic viscosity (PV), yield point (YP), and gel strengths at 10 s, 10 min, and 30 min).

Also, the storage modulus (G’) and loss modulus (G″) were addressed in the oscillatory amplitude and frequency tests to evaluate the viscoelasticity of the prepared muds. In the former oscillatory test, the frequency was fixed at 10 rad/s throughout various shear strain values ranging from 0.01 to 100% to determine the linear viscoelastic range, while the latter test was performed at different frequencies (0.1–100 rad/s) and constant shear strain selected from the linear range to study the elasticity behavior of the inner structure.

The HP/HT filtration test was performed to address the filtration behavior of the ultimately recommended ilmenite/hematite combination. The test was conducted using a 50 μm ceramic disc at 250 °F and a differential pressure of 300 psi. The filtrate volume was monitored for 30 min, and the filter-cake thickness and its weight were measured.

The sequence of experimental steps that were followed in this study is summarized in Figure 5.

Figure 5.

Methodology flowchart.

4. Results and Discussion

4.1. Density and pH

The effect of combining ilmenite with hematite in different ratios (0, 25, and 50%) on mud density indicated that increasing the amount of ilmenite results in a reduction of the mud weight from 15.0 ppg for the base mud to 14.2 ppg with 50% ilmenite. The reason for this is the lower specific gravity of ilmenite. Similarly, the pH was reduced from 10.5 up to 9.3 with increasing ilmenite content; it stayed within the practical recommended range (i.e., 9–11), and it can be enhanced by the alkalinity controller additives should needs be. Figure 6 shows the resulting mud densities and pH values for the different amounts of ilmenite.

Figure 6.

Mud density and pH at different ilmenite ratios (ambient condition).

4.2. Sag Tests

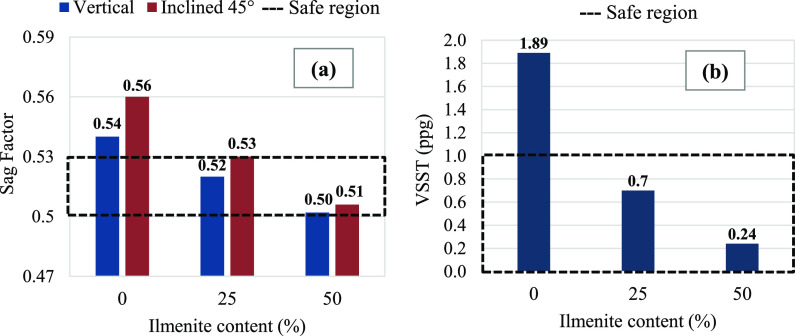

The results of the sagging tests confirmed the sagging issue of pure hematite-based mud at HP/HT, as the sag factors under static conditions were 0.54 and 0.56 in vertical and inclined situations (Figure 7a), respectively, while the practical acceptable range is 0.50–0.53.41 Under dynamic conditions, the VSST was 1.89 ppg (Figure 7b) which is well above the recommended value of maximum 1.0 ppg.40

Figure 7.

Results of sagging tests under (a) static conditions at 250 °F and (b) dynamic conditions at 120 °F.

Adding 25 and 50% of ilmenite resulted in muds with lower sagging tendency with values within the safe ranges under both static and dynamic conditions, showing minimal solid settlement and density inconsistency. For the 25% ilmenite formulation, the resulting factors in static sag tests were 0.52 and 0.53, whereas the dynamic test gave rise to a VSST value of 0.7 ppg, as shown in Figure 7. This improvement in sagging behavior was attributed to the surface charge, colloidal stability, and particle dispersions of ilmenite.14,15,36 Because the 25/75% ilmenite/hematite formulation satisfies the requirement with regard to sagging and cost performance, this combination was selected for further investigation.

4.3. Rheology Tests

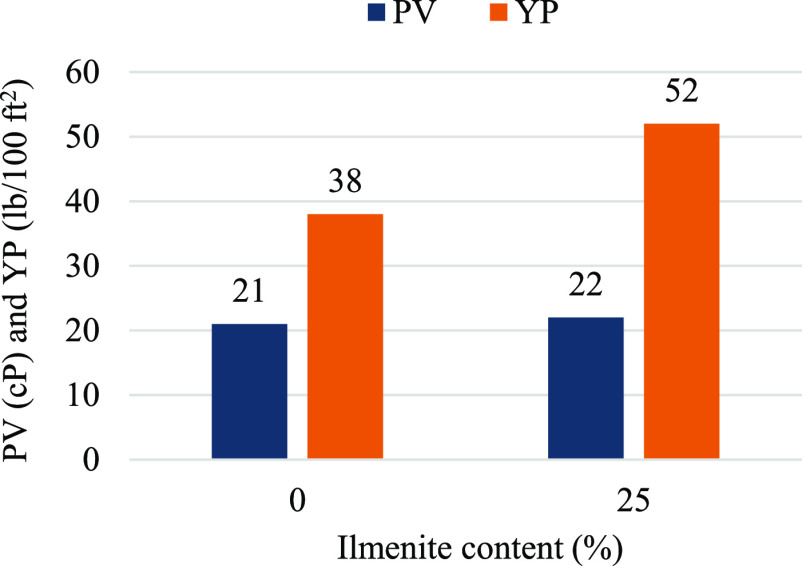

The results of rheology tests at 250 °F showed that adding 25% of ilmenite improved the YP significantly from 38 to 52 lb/100 ft2 with a trivial effect on PV as it increased from 21 to 22 cP. Sequentially, the YP/PV ratio was enhanced by 31% from 1.81 to 2.36 (Figure 8), which indicated an improvement in fluid stability and hole cleaning.42,43 This enhancement was expected as ilmenite has comparable fine particles in addition to the iron oxide content in the proposed formulation.

Figure 8.

PV and YP for base hematite and 25/75% ilmenite/hematite muds at 250 °F.

Figure 9a shows that the blank hematite and the 25% ilmenite/75% hematite muds have similar behavior at a low shear rate. Accordingly, the effect of 25/75% of ilmenite/hematite combination on gel strength values at 10 s, 10 min, and 30 min is insignificant (Figure 9b).

Figure 9.

Effects of ilmenite on (a) stress–strain relationship and (b) gel strength at 250 °F.

4.4. Oscillatory Amplitude and Frequency Tests

From the obtained storage and loss modulus perspective, adding 25% ilmenite results in higher G’ and G″ values, as recorded from the amplitude sweep test shown in Figure 10a, assigning better elasticity, sag resistance, and solid-like behavior. The better viscoelasticity behavior of the inner structure and fluid stability of the mud with 25% ilmenite (relative to the blank hematite mud) was proven by the frequency test with higher G’, as displayed in Figure 10b.

Figure 10.

Results of (a) oscillatory amplitude test and (b) frequency sweep test.

4.5. Filtration Tests

The HP/HT filtration experiment showed much better filtration properties when adding 25% ilmenite compared to the hematite mud. The obtained filtrate volume was 9.5 cm3 compared to 14.7 cm3 for the base mud with 35% improvement, as illustrated in Figure 11. Also, the weight and thickness of the created filter-cake resulting from the recommended combination were 20.4 g and 3.1 mm, which were less than 33.5 g and 4.7 mm for the blank hematite filter-cake (Figure 12). This better filtration behavior was attributed to the characteristics of ilmenite particles.

Figure 11.

Effect of adding ilmenite on the filtrate volume.

Figure 12.

Filter-cake with (a) 100% hematite and (b) 25% ilmenite.

The comparison between the obtained results of this study with the other work for solving the hematite sagging issue in the WBM that reported in the literature, where synthetic layered silicate (laponite) was used,31 indicated the technical feasibility of the proposed mud formulation, as it helped in sagging avoidance with preferable performance in terms of rheology, filtration, and viscoelasticity at the conditioned environment. Using laponite enhanced the YP by 33% but with very high gel strength values which can lead to difficulty in pumping start and the increase of the equivalent circulation density. Also, the laponite did not provide a significant enhancement of filtration properties. On the other hand, the proposed ilmenite hematite combination improved the YP by 37% without affecting the gel strength in addition to the outstanding resulting filtration performance. However, at higher temperature and pressure and different ranges of mud densities, the proposed formulation will need to be reevaluated.

5. Conclusions

A thorough laboratory study was undertaken to evaluate the effect of ilmenite inclusion with the focus on solving the hematite associated issues in drilling operations in the HP/HT state and to identify the optimal ilmenite/hematite ratio. The key mud characteristics were measured and analyzed. The conclusions can be inferred as follows:

The mud’s density and alkalinity were reduced with increasing the ilmenite content in the drilling fluid.

The surface charge, colloidal stability, and fine particle dispersions of ilmenite were contributed to eliminate the hematite sagging tendency.

The combination of 25/75% ilmenite/hematite satisfied the solid sagging avoidance under static and dynamic conditions.

The 25% ilmenite content enhanced the YP by 37% with measly 1 cP increment in PV; hence, the YP/PV ratio was improved by 31% showing better solid suspension and hole cleaning performance.

This combination of weighting materials did not change the behavior at a low shear rate so the effect on gel strength was insignificant.

The filtration behavior with 25% ilmenite was preferable than blank hematite because it resulted in 35, 39, and 35% reduction on the filtrate volume, filter-cake weight, and thickness, respectively.

Acknowledgments

The authors would like to thank King Fahd University of Petroleum and Minerals (KFUPM) for employing its resources in conducting this work. An acknowledgment is also due to BYK company for providing the garamite material.

Author Contributions

Conceptualization, S.E. and T.S.; methodology, A.A.; formal analysis, A.A. and S.B.; investigation, S.B. and T.S.; resources, S.E.; data curation, A.A.; writing—original draft preparation, A.A.; writing—review and editing, S.E. and T.S.; visualization, S.E. and T.S.; and supervision, S.E.; All authors have read and agreed to the published version of the manuscript.

The authors declare no competing financial interest.

References

- Gray G. R.; Young F. S. 25 Years of Drilling Technology - A Review of Significant Accomplishments. J. Petrol. Tech. 1973, 25, 1347–1354. 10.2118/4700-PA. [DOI] [Google Scholar]

- Caenn R.; Darley H.; Gray G. R.. Composition and Properties of Drilling and Completion Fluids, 7th ed.; Elsevier, 2016. [Google Scholar]

- Ahmed A.; Alsaihati A.; Elkatatny S. An Overview of the Common Water-Based Formulations Used for Drilling Onshore Gas Wells in the Middle East. Arab. J. Sci. Engineer. 2021, 46, 6867. 10.1007/s13369-020-05107-z. [DOI] [Google Scholar]

- Davison J. M.; Jones M.; Shuchart C. E.; Gerard C. Oil-Based Muds for Reservoir Drilling: Their Performance and Cleanup Characteristics. SPE Drill. Complet. 2001, 16, 127–134. 10.2118/72063-PA. [DOI] [Google Scholar]

- Basfar S.; Ahmed A.; Elkatatny S. Stability Enhancing of Water-Based Drilling Fluid at High Pressure High Temperature. Arab. J. Sci. Engineer. 2021, 6895. 10.1007/s13369-020-05126-w. [DOI] [Google Scholar]

- Bourgoyne A.T.; Millheim K.K.; Chenevert M.E.; Young F. S.. Applied Drilling Engineering; Society of Petroleum Engineers: Texas, 1986. [Google Scholar]

- Omland T. H.; Saasen A.; Van Der Zwaag C.; Amundsen P. A.. The Effect of Weighting Material Sag on Drilling Operation Efficiency. In SPE Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 30 October–1 November; SPE, 2007. [Google Scholar]

- Hossain M.E.; Al-Majed A. A.. Fundamentals of Sustainable Drilling Engineering; Wiley-Scrivener: USA, 2015. [Google Scholar]

- Bageri B. S.; Mahmoud M.; Abdulraheem A.; Al-Mutairi S. H.; Elkatatny S. M.; Shawabkeh R. A. Single Stage Filter Cake Removal of Barite Weighted Water Based Drilling Fluid. J. Petrol. Sci. Eng. 2017, 149, 476–484. 10.1016/j.petrol.2016.10.059. [DOI] [Google Scholar]

- Al-Awad M. N. J.; Al-Qasabi A. O. Characterization and Testing of Saudi Barite for Potential Use in Drilling Operations. J. King Saud Univ. - Eng. Sci. 2001, 13, 287–298. 10.1016/S1018-3639(18)30738-4. [DOI] [Google Scholar]

- Pozebon D.; Lima E. C.; Maia S. M.; Fachel J. M. G. Heavy Metals Contribution of Non-Aqueous Fluids Used in Offshore Oil Drilling. Fuel 2005, 84, 53–61. 10.1016/j.fuel.2004.08.002. [DOI] [Google Scholar]

- Bern P. A.; Zamora M.; Slater K. S.; Hearn P. J.. The Influence of Drilling Variables on Barite Sag. In SPE Annual Technical Conference and Exhibition, Denver, Colorado, 6–9 October; Society of Petroleum Engineers, 1996. [Google Scholar]

- Al-Yami A. S.; Nasr-El-Din H. A.. An Innovative Manganese Tetroxide/KCl Water-Based Drill-in Fluid for HT/HP Wells. In SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November; SPE, 2007. [Google Scholar]

- Mohamed A.; Basfar S.; Elkatatny S.; Al-Majed A. Prevention of Barite Sag in Oil-Based Drilling Fluids Using a Mixture of Barite and Ilmenite as Weighting Material. Sustainability 2019, 11, 5617. 10.3390/su11205617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Boyou N. V.; Ismail I.; Wan Sulaiman W. R.; Sharifi Haddad A.; Husein N.; Hui H. T.; Nadaraja K. Experimental Investigation of Hole Cleaning in Directional Drilling by Using Nano-Enhanced Water-Based Drilling Fluids. J. Petrol. Sci. Eng. 2019, 176, 220–231. 10.1016/j.petrol.2019.01.063. [DOI] [Google Scholar]

- Dye W.; Hemphill T.; Gusler W.; Mullen G.. Correlation of Ultra-Low Shear Rate Viscosity and Dynamic Barite Sag in Invert-Emulsion Drilling Fluids. In at SPE Annual Technical Conference and Exhibition, Houston Texas, 3–6 October; SPE, 1999. [Google Scholar]

- Ma J.; Yu P.; Xia B.; An Y. Micro-Manganese as a Weight Agent for Improving the Suspension Capability of Drilling Fluid and the Study of Its Mechanism. RSC Adv. 2019, 9, 35509–35523. 10.1039/C9RA07283G. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sloan J. P.; Brooks J. P.; Dear S. F. A New, Nondamaging, Acid-Soluble Weighting Material. J. Petrol. Tech. 1975, 27, 15–20. 10.2118/4782-PA. [DOI] [Google Scholar]

- Wagle V.; Maghrabi S.; Kulkarni D.. Formulating Sag-Resistant, Low-Gravity Solids-Free Invert Emulsion Fluids. In SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain 10–13 March; SPE, 2013. [Google Scholar]

- Dehkordi M. G.; Zitha P. L. J.; Dehaghani Y. H.; Belbasi M. Development of Oil-Based Drilling Fluid Using Iron Oxide Magnetic (Fe3O4) with Superior Properties Leading to Real Time Rheological Control. IJOGCT 2020, 25, 400. 10.1504/IJOGCT.2020.111154. [DOI] [Google Scholar]

- Davis C.L.; Livanec P.W.; Shumway W. W.. Additive to Enhance Sag Stability of Drilling Fluid. WO2017188946A1, 2018.

- Al-Bagoury M.; Steele C.. A New, Alternative Weighting Material for Drilling Fluids. In IADC/SPE Drilling Conference and Exhibition, San Diego, California, USA, 6–8 March; SPE, 2012. [Google Scholar]

- Li W.; Liu J.; Zhao X.; Jiang J.; Peng H.; Zhang M.; He T.; Liu G.; Shen P. Development and Screening of Additives for Biodiesel Based Drilling Fluids: Principles, Strategies and Experience. Proc. - SPE Int. Symp. Oilf. Chem. 2019, 2019, 193597. 10.2118/193597-ms. [DOI] [Google Scholar]

- Li W.; Liu J.; Zhao X.; Zhang J.; Jiang J.; He T.; Liu L.; Shen P.; Zhang M.. Novel Modified Rectorite Provides Reliable Rheology and Suspendability for Biodiesel Based Drilling Fluid. In SPE/IADC Middle East Drilling Technology Conference and Exhibition, 29–31 January; Society of Petroleum Engineers: Abu Dhabi, UAE, 2018. [Google Scholar]

- Yao R.; Jiang G.; Li W.; Deng T.; Zhang H. Effect of Water-Based Drilling Fluid Components on Filter Cake Structure. Powder Technol. 2014, 262, 51–61. 10.1016/j.powtec.2014.04.060. [DOI] [Google Scholar]

- Tovar J.; Rodriguez Z.; Quiroga F.; Greaves R.; Melendez H.; Arocha J.; Bland R.; Hebert M.. ORIMATITA®. An Improved Hematite for Drilling Fluids. In SPE Latin America and Caribbean Petroleum Engineering Conference, Caracas, 21–23 April; SPE, 1999. [Google Scholar]

- Scharf A. D.; Watts R. D.. Itabirite: An Alternative Weighting Material for Heavy Oil-Base Muds. In SPE Annual Technical Conference and Exhibition, Houston, 16–19 September; Society of Petroleum Engineers, 1984. [Google Scholar]

- Menzel D.A New Weighting Material for Drilling Fluids Based on Synthetic Iron Oxide. In Fall Meeting of the Society of Petroleum Engineers of AIME, Las Vegas, Nevada, September; SPE, 1973. [Google Scholar]

- Rajendran K.; Sen S. G. S.; Senthil S. L.; Kumar T. V. Evaluation of Cytotoxicity of Hematite Nanoparticles in Bacteria and Human Cell Lines. Colloids Surf. B Biointerfaces 2017, 157, 101–109. 10.1016/j.colsurfb.2017.05.052. [DOI] [PubMed] [Google Scholar]

- Tehrani A.; Cliffe A.; Hodder M. H.; Young S.; Lee J.; Stark J.; Seale S.. Alternative Drilling Fluid Weighting Agents: A Comprehensive Study on Ilmenite and Hematite. In IADC/SPE Drilling Conference and Exhibition, Dallas, TX, USA, 4–6 March; SPE, 2014. [Google Scholar]

- Basfar S.; Elkatatny S. Prevention of Hematite Settling Using Synthetic Layered Silicate While Drilling High-Pressure Wells. Arab. J. Geosci. 2020, 13, 459. 10.1007/s12517-020-05516-2. [DOI] [Google Scholar]

- Ahmed A.; Basfar S.; Elkatatny S.; Gajbhiye R. Enhancing Hematite-Based Invert Emulsion Mud Stability at High-Pressure High-Temperature Wells. ACS Omega 2020, 5, 32689–32696. 10.1021/acsomega.0c05068. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xiao J.; Nasr-Ei-din H. A.; Al-Bagoury M. Micro-manganese as a weight agent for improving the suspension capability of drilling fluid and the study of its mechanism. RSC Adv. 2019, 9, 35509–35523. 10.1039/C9RA07283G. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xiao J.; Nasr-El-Din H. A.; Al-Bagoury M.. Evaluation of Micronized Ilmenite as a Weighting Material in Oil-Based Drilling Fluids for HPHT Applications. In SPE European Formation Damage Conference and Exhibition, Noordwijk, The Netherlands, 5–7 June; SPE, 2013. [Google Scholar]

- Al-Bagoury M.Micronized Ilmenite - A Non-Damaging & Non-Sagging New Weight Material for Drilling Fluids. In SPE Bergen One Day Seminar, Bergen, Norway, 2 April; SPE, 2014. [Google Scholar]

- Elkatatny S. M.; Nasr-El-Din H. A.; Al-Bagoury M.. Evaluation of Micronized Ilmenite as Weighting Material in Water-Based Drilling Fluids for HPHT Applications. In SPE Kuwait International Petroleum Conference and Exhibition, Kuwait City, Kuwait, 10–12 December; SPE, 2012. [Google Scholar]

- Basfar S.; Mohamed A.; Elkatatny S.; Al-Majed A. A Combined Barite–Ilmenite Weighting Material to Prevent Barite Sag in Water-Based Drilling Fluid. Materials (Basel). 2019, 12, 1945. 10.3390/ma12121945. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yan L. L.; Wang J. H.; Xu X. G.; Feng J.; Liang H. J.; Xing X. N.. Study on Erosive and Magnetic Effects of Weighting Agent in a High Density Water-Based Drilling Fluid. In Offshore technology conference; OTC, Kuala Lumpur, Malaysia, 25–28 March 2014. [Google Scholar]

- Maxey J. Rheological Analysis of Static and Dynamic Sag in Drilling Fluids. Annu. Trans. Rheol. Soc. 2007, 15, 181–188. [Google Scholar]

- Aldea C.; Growcock F. B.; Lee L. J.; Friedheim J. E.; Van Oort E.. Prevention of Dynamic Sag in Deepwater Invert Emulsion Fluids. In AADE National Drilling Conference; Houston, Texas, 27–29 March 2001. [Google Scholar]

- AlAbdullatif Z.; Al-Yami A.; Wagle V.; Bubshait A.; Al-Safran A.. Development of New Kill Fluids with Minimum Sagging Problems for High Pressure Jilh Formation in Saudi Arabia. In Abu Dhabi International Petroleum Exhibition and Conference; SPE: Abu Dhabi, UAE, 10–13 November 2014. [Google Scholar]

- Hussaini S. M.; Azar J. J. Experimental Study of Drilled Cuttings Transport Using Common Drilling Muds. Soc.Petrol. Engineer. J. 1983, 23, 11–20. 10.2118/10674-PA. [DOI] [Google Scholar]

- Chilingarian G. V.; Alp E.; Caenn R.; Al-Salem M.; Uslu S.; Gonzales S.; Dorovi R. J.; Mathur R. M.; Yen T. F. Drilling Fluid Evaluation Using Yield Point-Plastic Viscosity Correlation. Energy Source. 1986, 8, 233–244. 10.1080/00908318608946052. [DOI] [Google Scholar]