Abstract

Single-atom-thick graphene is a particularly interesting material in basic research and applications owing to its remarkable electronic, mechanical, chemical, thermal, and optical properties. This leads to its potential use in a multitude of applications for improved energy storage (capacitors, batteries, and fuel cells), energy generation, biomedical, sensors or even as an advanced membrane material for separations. This paper provided an overview of research in graphene, in the area of synthesis from various sources specially from biomass, advanced characterization techniques, properties, and application. Finally, some challenges and future perspectives of graphene are also discussed.

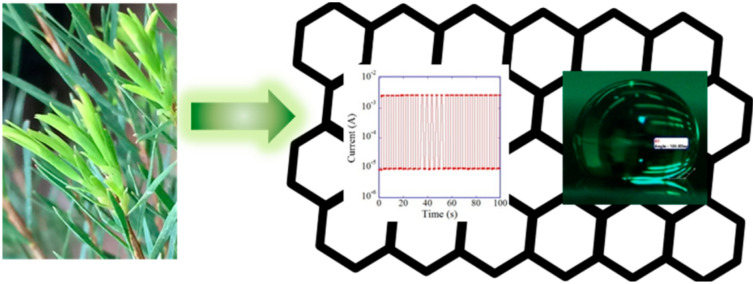

Graphic Abstract

Keywords: Graphene, Energy generation, Solar cells, Energy storage, Capacitors, Batteries, Fuel cells, Biomedical, Sensors, Membrane, COVID-19

Statement of Novelty

Reduction from graphene oxide is one of the most promising ways and is probably the most widely accepted method in graphene synthesis. Unfortunately, very few commercial technologies involving graphene-based materials have emerged, in large part due to the difficulty in processing these 2D sheets into useful, 3D materials with predicable structure and thus function. Our proposed novel graphene synthesis from biomass sources will provide an alternative, inexpensive, and more versatile approach to make large area graphene. The application of our graphene from biomass sources and with many polymer composites will lead to the revolution in many sectors including biomedical, energy sectors. Continued development and successful implementation of graphene from biomass sources that could lead to new jobs and a potentially huge source of revenue to fuel the future economy.

Introduction

Single-atom-thick graphene is a particularly interesting material in basic research and applications owing to its remarkable electronic, mechanical, chemical, thermal, and optical properties [1]. For a given surface area, it is the lightest weight electronic conductor of any material and can be produced relatively inexpensively, and in large volume, from natural graphite resource. This leads to its potential use in a multitude of applications for improved energy storage (capacitors, batteries, and fuel cells), energy generation (solar cells), biomedical, sensors or even as an advanced membrane material for separations.

A lot of effort had been devoted for creating high-quality large-area graphene. The earliest method, mechanical exfoliation of graphene from highly oriented pyrolytic graphite using scotch tape, yields good quality but μm-sized graphene [2]. In addition, it is uncontrollable and not scalable. Other formation techniques, such as epitaxial graphene from a single crystalline SiC substrate [3–8] or transition metals [9–14], can yield larger graphene domains. However, they encounter difficulty for large-scale production due to the high cost of the substrates, the requirement of ultrahigh vacuum, and limited scalability. Recently, high-quality monolayer or bilayer graphene was obtained via the chemical vapor deposition (CVD) of CH4 or C2H2 gases on copper or nickel substrates [15–20]. Commercial wafer-scale and 30-in. (76.2 cm) graphene films have been reported [20, 21]. Currently, CVD technique is widely employed and has great potential for the large-scale production of high quality films [22–29]. However, since the CVD growth of high quality graphene requires a nearly oxygen-free environment or high-vacuum (10−6 Torr) base pressure, a long pumping and/or purge time is needed to evacuate the air in the chamber [30–35]. In addition, some of the gaseous raw materials are hazardous. These disadvantages limit its use in some applications and are a concern for large-scale production. Recently, much simpler, less expensive, and less hazardous techniques for growing graphene have been demonstrated [36–42]. These techniques use solid carbon sources (e.g., polymers, SiC, and amorphous carbon). For a Ni catalyst, carbon atoms diffuse into the Ni film during a high-temperature annealing process. Some of the C atoms segregate from the bulk to the Ni surface due to lower solid solubility at lower temperature [43]. A graphene layer forms with a specific and well-controlled cooling rate in a high-vacuum environment [44, 45]. A nearly oxygen-free environment is required in the graphene growth process not only to prevent the precipitated carbon from reacting with oxygen but also to avoid catalyst surface oxidation at high temperature. If graphene can be grown in a non-vacuum environment could open new applications. Many recent works [29, 37, 46] have shown that graphene can be grown at the interface of silicon dioxide and metal catalysts and Pt-based catalyst approach is also useful and was discussed in reference [47]. Moreover, a very important catalyst-free approach was also presented in reference [48]. Presently, there are several synthesis routes of graphene such as mechanical, chemical exfoliation, chemical vapor deposition, pyrolysis, epitaxial methods for obtaining graphene films [49]. A scheme depicting various conventional synthesis methods of graphene along with their important features, and their current and prospective applications are discussed in reference [50].

Unfortunately, very few commercial technologies involving graphene-based materials have emerged, in large part due to the difficulty in processing these 2D sheets into useful, 3D materials with predicable structure and thus function. To address this challenge, this research aims to develop new sources, tools, and processes to create a platform of graphene-based materials whose structure can be manipulated and fine-tuned at the nanoscale. Among these methods, reduction from graphene oxide is one of the most promising ways and is probably the most widely accepted method in large scale preparation. Considering both the scalability of this method and the purity of the final product, reduction of graphene oxide is better than other techniques. Nevertheless, industrialization with low cost is one of the major challenges in graphene field. With such consideration, the mechanical exfoliation and reduction of graphene oxide are the two possible methods for bulk production of graphene. On the other hand, pyrolysis and other chemical etching and gasification have been common techniques to synthesize graphene on metal surfaces from different carbon sources or other activated carbons [36, 51–57]. These also can be achieved by developing processes capable of depositing large-area monolayer graphene films onto a variety of substrates from biomass sources. However, the preparation of graphene by surface growth is limited in yield.

To develop devices based on graphene based materials from various sources, several synthetic schemes for the preparation of graphene including 3D graphene-based materials, and their properties, advanced characterization techniques, properties and their application for energy generation and storage, sensing, biomedical areas. Finally, analysis and challenges along with their future perspectives have been reviewed in discussion section:

Materials and Methods

This section firstly presents an overview various synthesis technique that is used for the development of graphene from various sources including graphite, non-graphite sources followed by graphene synthesis from bio-mass sources.

Synthesis from Graphite Sources

Micromechanical Cleavage-the Scotch Tape Method

Graphene can be extracted from the high-quality of graphite using mechanical exfoliation, which is a simple peeling process. Mechanical exfoliation of graphite using scotch tape is obtained from a commercially available highly oriented pyrolytic graphite (HOPG) sheet by dry etching in oxygen plasma. These thin flakes are composed of monolayer or a few layers of graphene [58]. Optical microscope image of multilayer graphene using Micromechanical cleavage-the scotch tape method as shown in Fig. 1.

Fig. 1.

a Optical microscope image of multilayer graphene cleaved from bulk graphite using the “scotch tape method”. b AFM image of an edge of the flake. c AFM image of few-layer graphene. d SEM of a device used by Geim and Novoselov for their studies of the electric field effect in graphene. e Schematic of device in d. (Reprinted with permission from Ref. [1, 2])

Chemical Cleavage and Exfoliation

The two-step process to obtain graphene from graphite oxide requires first exfoliating the bulk material and then reducing the individual sheets back to graphene as shown in Fig. 2. Exfoliation is usually achieved by sonicating graphite oxide in water, followed by centrifugation. The supernatant from this procedure is colloidal and contains few- and single-layer sheets of graphene oxide. This liquid can be left as is or drop-cast onto a substrate for further processing.

Fig. 2.

Spin-coating technique employed in the deposition of graphene oxide on a surface. b AFM image of thin film spin-coated graphene oxide. c Optical microscope image of the delamination of rGO film from its substrate. d Floating rGO film ready for transfer onto an arbitrary substrate. (Reprinted with permission from Refs. [59, 60])

Synthesis from Non-graphitic Sources

Epitaxial Growth from Silicon Carbide

Among the many graphene synthesis methods, the epitaxial growth approach from silicon carbide could help large-size and single-domain graphene production in a controlled manner. Supporting substrate is very important to access the intrinsic electronic properties of graphene. This lack of suitable substrate has so far been a major hurdle for the epitaxial growth of graphene using PECVD [61].

Physical Vapor Deposition

Multiplayer graphene carbon films can be produced using simplified filtered cathodic vacuum arc (FCVA) deposition system. Carbon films were deposited using a FCVA system equipped with a double bend magnetic filter to minimize the deposition of macroparticles [61]. These macroparticle can be ejected from the carbon cathode as shown in Fig. 3.

Fig. 3.

Schematic diagram (not to scale) of the Filtered Cathode Vacuum Arc (FCVA) coating technology system. (Reprinted with permission from Ref. [62])

The schematic in Fig. 4 shows the steps involved in synthesis of the carbon films.

Fig. 4.

Schematic showing the growth sequence and transfer process employed to fabricate carbon films on silicon/silica substrates (Reprinted with permission from Ref. [63])

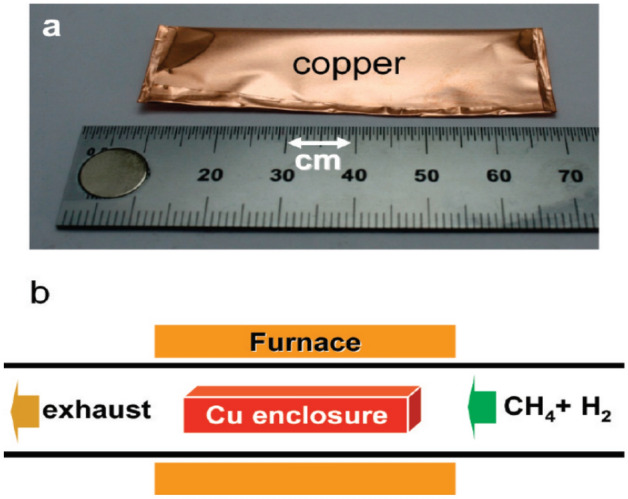

Chemical Vapor Deposition from CH4

Graphene single crystals can be grown using low-pressure chemical vapor deposition in copper-foil enclosures using methane as a precursor. The dimensions of graphene crystal could be up to 0.5 mm on a side (Fig. 5).

Fig. 5.

a Copper foil enclosure prior to insertion in the furnace. b Schematic of the CVD system for graphene on copper (Reprinted with permission from Ref. [19])

The CVD growth of graphene occurs on Cu grows by a surface adsorption process whereas the CVD growth of graphene on Ni occurs by a C segregation or precipitation process [64].

Conversion of Carbon Dioxide to Graphene

The methodology produces few-layer graphene captured directly from CO2 by burning Mg in it. The combustion of magnesium metal in carbon dioxide to form few-layer graphene is unprecedented and provides further incentives for exploration of several environmentally friendly ways for capturing carbon dioxide [36, 65]. The burning magnesium metal in a CO2 environment produces carbon materials as shown in Eq. (1).

| 1 |

Growth of Graphene from Solid Carbon Sources

Chemical Vapor Deposition (CVD) technique is limited to the use of gaseous raw materials, making it difficult to apply the technology to a wider variety of potential feedstocks. The large area, high quality graphene with controllable thickness can be grown from different solid carbon sources[ poly(methyl methacrylate) (PMMA), high impact polystyrene (HIPS), or acrylonitrile butadiene-styrene (ABS)] —such as polymer films or small molecules—deposited on a metal catalyst substrate at temperatures as low as 800 °C. Both pristine graphene and doped graphene were grown with this one-step process using the same experimental set-up [36].

Figure 6 illustrates the procedure for the growth of bilayer graphene directly on the SiO2 substrate. The SiO2 substrate was cleaned with oxygen-plasma and Piranha solution (4:1 sulfuric acid/hydrogen peroxide), and then a 400 nm thick nickel film was thermally evaporated onto the top of the SiO2 substrate used as the metal catalyst. Either solid polymers (PMMA, HIPS, or ABS) or gas-phase methane was used as a carbon source for the transfer-free growth of bilayer graphene.

Fig. 6.

Schematics of the growth of bilayer graphene from a solid carbon source. A 400 nm nickel film was thermally evaporated onto SiO2 substrate, followed by the spin-coating of polymers on the nickel. After annealing samples at 100 °C under a reductive Ar/H2 pressure for ∼ 10 min and then etching away the nickel, bilayer graphene is obtained directly on SiO2. The polymer film formation can be replaced by exposure to methane during the annealing step (Reprinted with permission from Ref. [66])

The two mechanisms of graphene growth on Ni and Cu can be understood from the C-metal binary phase diagram. The binary phase diagrams of C-Ni and C-Cu are similar in that C has a limited solubility in the metal without the presence of a metal-carbide line compound. The only significant difference is that the solubility of C in Cu is much lower than that in Ni. Since only a small amount of carbon can be dissolved in Cu, the source for graphene formation is mainly from the CH4 that is catalytically decomposed on the Cu surface with minimal carbon diffusion into the Cu. Once the surface is fully covered with graphene growth terminates because of the absence of a catalyst to decompose CH4 [19, 36, 63–66]

In contrast, Ni can dissolve more carbon atoms and hence it is difficult to get uniform graphene films due to precipitation of extra C during the cool-down. The C precipitation process is a nonequilibrium process, which should be suppressed if one aims to achieve monolayer graphene growth, for example, by using a controlled thin Ni film and/or high cooling rate. However, because of microstructural defects, predominantly grain boundaries, it is very difficult to fully eliminate the effect of precipitation for metals with high carbon solubility. Hence, metals with low C solubility such as Cu offer a possible path to large-area growth of graphene. Discrete regions of isotopically labelled graphene for growth on Cu may also yield novel devices and transport physics in future studies [19, 36, 63–66, 77–80]).

Moreover, a carbon diffusion mechanism through Ni layer is proposed for the growth mechanism of bilayer graphene on SiO2 substrates [66].

Graphene Ssynthesis from Polymers

Graphene films can be formed directly on a SiO2/Si substrate from solution-processed common polymers. Patterned graphene layers can also be directly formed on active electronic devices without any physical transfer process as shown Fig. 7. The metal capping layer is used to prevent of vaporization of dissociated molecules and catalysis of graphene formation.

Fig. 7.

a Graphene growth process and b chemical structure of polymers used as graphene precursors (

reproduced with permission from Ref [67].)

Facile Synthesis of Graphene from Plastic by Pyrolysis of Poly(methyl ethacrylate), PMMA

Figure 8 illustrates the preparation procedures of graphene by pyrolyzing PMMA composite. When the composite is heated at1000°C, PMMA is immediately decomposed into various carbon derivatives (Cn).

Fig. 8.

Illustration of the procedure for growth of the graphene on nickel particles by pyrolysis of PMMA composite: PMMA/OMT/Ni composite; (2) pyrolytic state in a specific microzone; (3) microstructure of hexagonal rings on Ni surface (4) continuous growth of graphene on Ni surface; (5) the graphene hybrid containing clay and catalyst; and (6) final purified graphene (Reprinted with permission from Ref. [68])

Based on the reported works, a summary and comparison of these preparation methods were listed in Table 1. Some of the groundbreaking efforts in synthesizing graphene are summarized for graphene production in Ref. [69]. Among these methods, mechanical exfoliation and CVD can produce good-quality graphene. However, the practical application of graphene is blocked by the high price and insufficient supply.

Table 1.

Summary of current approaches to produce graphene using various synthesis techniques

| Method | Source materials | Merits | Challenges | References |

|---|---|---|---|---|

| Mechanical cleave | Graphite | Pristine graphene | Low production | [2, 58] |

| Direct sanitation | Graphite | Pristine graphene | Low production | [59, 60] |

| Thermal treatment | Graphite oxide | High production |

Slow process Low bulk density Hard to transport Safety issue |

[43, 59, 60] |

| Colloidal dispersion & chemical treatment | Graphite oxide |

High production Bulk density |

Hazard chemicals Slow process Uncontrollable & Not scalable |

[59, 60] |

| Physical vapor deposition/sputtering (PVD) |

Single crystalline SiC substrate Transition metals |

Epitaxial graphene can yield larger graphene domains | Encounter difficulty for large-scale production due to the high cost of the substrates, the requirement of ultrahigh vacuum, and limited scalability | [62] |

| Chemical vapor deposition (CVD) | CH4 and C2H2 Gases | High-quality monolayer or bilayer graphene |

Requires a nearly oxygen-free environment or high-vacuum (10−6 Torr) base pressure, a long pumping and/or purge time is needed to evacuate the air in the chamber Some of the gaseous raw materials are hazardous. These disadvantages limit its use in some applications and are a concern for large-scale production |

[15–20, 64] |

| Pyrolysis |

Different carbon sources Other activated carbons |

Large-area monolayer graphene films onto a variety of substrates | The preparation of graphene by surface growth is limited in yield | [36, 51–57] |

Synthesis of graphene refers to any method for fabricating or isolating graphene from carbonaceous precursor. Numerous methods have been established to synthesis graphene with their merits and challenges of the specific product as listed in Table 1.

Recently, many researchers have suggested to develop green production methods for synthesizing graphene using environmentally friendly biomass resources such as sugar, chitosan, and alfalfa plants as discussed below.

Synthesis of Graphene from Biomass Sources

High-quality graphene can be formed using catalyst metal foil. The cost-effective, mass production of graphene can be formed using the biomass resource and waster materials.

The usage of biomass resource and waste materials as carbon sources is a promising method that results in a cost-effective, mass production of graphene. However, it is difficult to synthesize large amounts of graphene using a catalyst. Additionally, when plants and waste materials are used as a carbon source without using a catalyst, problems such as low quality and high defects might exist.

Thermochemical conversion of biomass has been a topic of intensive research and several techniques, such as pyrolysis, gasification, liquefaction, and hydrothermal carbonization (HTC). These techniques have been implemented to convert biomass into different products. Figure 9 shows the schematic representation of pyrolysis process and its product (biochar) applications from biomass sources.

Fig. 9.

The pyrolysis process of the biochar obtained (Reprinted with the permission from Ref. [70])

The HTC method leaves the biomass precursor “partially” carbonized, which can be upgraded into desired graphene-like carbon materials by subsequent activation/carbonization process (Fig. 10). Various chemicals can be added in the HTC or the pyrolysis step to realize graphene-like carbon formation. The fundamental investigation of the effects of different chemicals on the hydrothermal treatment and carbonization have been highlighted below [72].

Fig. 10.

Graphene-like carbon synthesis by coupling HTC with pyrolysis (Reprinted with the permission from Ref. [71])

Synthesis of Monolayer-Patched Graphene from Glucose via Pyrolysis

The synthesis process of Monolayer-Patched Graphene from Glucose and dicyandiamide (DCDA) via pyrolysis is discussed in Ref. [72]. A typical layered graphic carbon nitride, g-C3N4 can be formed by calcination of dicyandiamide (DCDA), urea, and melamine in the temperature range of 500–600 °C. Then it undergoes decomposition at above 750 °C by forming NH3, C2N2 + , C3N2 + , and C3N3 + species. Thus, g-C3N4 can be served as a sacrificial template for layered graphene-like carbon material synthesis. This method allows the nitrogen doping in the resultant carbon nanosheet with content about 3–5 at.% even at a high temperature pyrolysis of 1000 °C. By using this method, monolayer and two-layer graphene can be formed when using glucose or HMF (Hydroxymethylfurfural) as precursors.

Synthesis of Graphene from Fungus via Pyrolysis Coupling with Hydrothermal Carbonization Pretreatment

The hydrothermal pretreatment from fungus with the addition of KOH can yield graphene-like materials with subsequent carbonization [73]. A hydrothermal reaction of fungus (Auricularia) was conducted at temperature of 120 °C as shown in Fig. 11. The obtained samples were freeze-dried and activated using KOH under N2 at 800 °C. Finally, graphene-like carbon materials with the densely porous structure were synthesized, with 10 nm in thickness. Ban et al. [74] also found that the hydrothermal pretreatment of reed membranes using KOH before pyrolysis generates carbon materials with higher surface area, compared with traditional post-KOH activation method.

Fig. 11.

Schematic illustration of the formation of carbon with (porous graphene-like carbon, PGC) and without (HTC) treatment of KOH. a The optical figure of the originally dried fungus; b Swelled fungus after hydrothermal treatment in 0.1 M KOH solution; c Freeze-dried fungus; d The as-prepared carbon materials by pyrolysis of freeze-dried fungus (Reprinted with the permission from Ref. [73])

Synthesis of Graphene via Green Chemistry Approach

A simple, eco-friendly, and scalable method using one-step pyrolysis from dead camphor leaves (Cinnamomum Camphora) graphene can be produced as shown in Fig. 12.

Fig. 12.

Synthetic scheme for the preparation of graphene (Reprinted with the permission from Ref. [75])

In this pyrolysis process, dead camphor leaves were heated to 1200 °C at 10 °C/min in nitrogen atmosphere. After heating in nitrogen atmosphere, leaves were cooled down to room temperature without any external disturbances. Few layers graphene (FLG) can be separated from the final pyrolytic components, with the help of π–π interaction with D-Tyrosine and centrifugation [75].

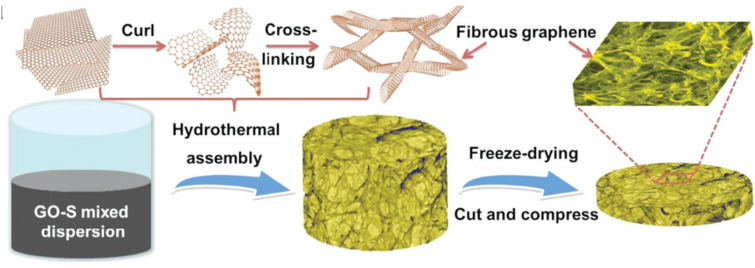

Porous 3D Graphene-Based Bulk Materials

The desired property including specific surface area (SSA) and conductivity of graphene can be achieved using a simple and green but very efficient and industrially scalable approach as shown in Fig. 13. Two standard industrial steps are used. Those steps are: (1) in-situ hydrothermal polymerization/carbonization of the mixture of cheap biomass or industry carbon sources with graphene oxide (GO) to firstly get the 3D hybrid precursor materials and then (2) a chemical activation is a step to achieve the desired SSA and conductivity. Both steps are very industrially scalable and efficient to make truly large quantity of products. Various structural and morphology analysis demonstrate that these materials consist of almost entirely defected/wrinkled single layer graphene sheets in the dimensional size of a few nanometers, with ultrahigh SSA (up to 3523 m2/g) and excellent bulk conductivity (up to 303 S/m). The pore size of these materials mainly distributes in the mesopore size range, significantly different from the conventional materials. These combined outstanding properties make them superior candidate materials for various applications, the best supercapacitor performance as demonstrated.

Fig. 13.

a A schematic show of the simple and green process of synthesizing porous 3D graphene-based materials. b Low magnification and c high-resolution scanning electron microscopy (SEM) images of products from the mixtures of PF [the simple mixture of phenol (P) and formaldehyde (F) as the carbon source (denoted as ‘‘PF’’)] and GO with optimized ratios, which exhibited sponge-like morphology and porous structure. d Low magnification and e high-resolution transmission electron microscopy (TEM) images of products from the mixtures of PF and GO with optimized ratios, which also showed a dense 3D pore structure with highly curved or wrinkled surface (Reprinted with the permission from Ref. [76])

Growth of Graphene from Food, Insects, and Waste

High-quality monolayer graphene can be produced directly on the surface of Cu foils under a H2/Ar flowing atmosphere from inexpensive carbon sources including food, insects, and waste (cookies, chocolate, grass, plastics, roaches, and dog feces) without purification as shown in Fig. 14 [77].

Fig. 14.

Diagram of the experimental apparatus for the growth of graphene from food, insects, or waste in a tube furnace (

Reproduced with permission from Ref. [77])

On the left, the Cu foil with the carbon source contained in a quartz boat is placed at the hot zone of a tube furnace. The growth is performed at 1050˚C under low pressure with a H2/Ar gas flow. On the right is a cross view that represents the formation of pristine graphene on the backside of the Cu substrate. (B) Growth of graphene from a cockroach leg. (a) One roach leg on top of the Cu foil. (b) Roach leg under vacuum. (c) Residue from the roach leg after annealing at 1050 °C for 15 min. The pristine graphene grew on the bottom side of the Cu film (not shown) (Reprinted with the permission from Ref. [77]).

Graphene from Rice Husk (RH) by Microwave Plasma Irradiation (MPI)

Figure 15a shows a schematic diagram of microwave plasma irradiation (MPI) technique for the RH-derived nanocarbons [78–80]. Firstly, 1 g rich husk (RH) powders, located in a home-made nickel case, were placed on the stage. The experimental setup and procedure are like the methods employed to fabricate graphene nanosheets from solid carbon [78] and Kapton polyimide [79] except for the pressure. Using this method, not only graphene but also CNTs and g-CNTs can produce. The pressure plays a critical role to synthesize diverse nanocarbons from RHS. After the plasma processing, the nickel cases were covered by soot-like appearance as shown in Fig. 15b.

Fig. 15.

a A schematic diagram of MPI technique for nanocarbon growth from RHs. b The conversion process of RHs into soot-like materials on the nickel surface, which include ball- and fiber-like structures (Reprinted with the permission from Ref. [79])

A possible growth model has been proposed for converting the rice husks into nanocarbons including graphene, CNTs, and g-CNTS as shown in Fig. 16.

Fig. 16.

A possible growth model for graphene, CNTs, and g-CNTs from RHs by MPI technique (Reprinted with the permission from Ref. [79])

As shown in Fig. 16, the nickel foil was irradiated to produce the nickel atoms, which tend to aggregate with each other by reducing surface energy, resulting in formation of nickel clusters. The resulting nickel clusters with irregular shapes in usual 30–150 nm size can initiate and accelerate the graphitization process by assembling carbon radicals into graphene surrounding the nickel clusters. At high pressure conditions, the graphene structures can wrap into tube-like structures to further reduce the surface energy. In this stage, the herringbone CNTs were formed at relatively lower growth temperatures, the bamboo-like CNTs at higher growth temperatures due to the different surface diffusion rates of carbon radicals on the surface of nickel particles [80].

Facile Synthesis of Few-Layer Graphene from Bbiomass Waste

A less expensive method has been developed to synthesize high-quality graphene sheets from wheat straw via a combined hydrothermal and graphitization approach for the first time [81]. The resulting graphene sheets show favorable features such as ultrathin nanosheet frameworks (2–10 atomic layers), high graphitization (up to 90.7%), graphite-like interlayer spacing (0.3362 nm), and the mesoporous structure. Figure 17 illustrates the overall evolution of synthetic processes.

Fig. 17.

Schematic diagram displaying the overall evolution of wheat straw into few-layer graphene (Reprinted with the permission from Ref. [81])

Catalyst-Free Plasma Enhanced Growth of Graphene from Sustainable Sources

High quality graphene films were grown using Melaleuca alternifolia, a volatile natural extract from tea tree plant as the precursor without aid of catalyst as shown in Fig. 18.

Fig. 18.

As-fabricated graphene films yielded a stable contact angle of 135°, indicating their potential application in very high hydrophobic coatings (Reprinted with the permission from Ref. [82])

Green Synthesis of Chemical Converted Graphene Sheets Derived from Pulping Black Liquor

Graphene sheets can be derived from black liquor and it is abbreviated as BL-G. These graphene sheets can be manufactured into flexible transparent conductive films (TCFs) through spin coating method on flexible PET substrate which exhibit good conductivity, high transparency and low sheet resistance as shown in Fig. 19.

Fig. 19.

a Digital photography and b scheme of BL-G after spin-coating on transparent and flexible PET substrate. c Left: blank PET, right: TCF fabricated with BL-G sheets in reaction time of 12 h. d Sheet resistance (left vertical axis in blue color) and transparency for 550 nm light (right vertical axis in red color) of BL-G-based TCFs changing with reaction time of 3 h, 6 h, 9 h and 12 h. (Reprinted with the permission from Ref. [83])

Large Area Few-Layer Graphene with Scalable Preparation from Waste Biomass

Peanut shell-derived few layer graphene (PS-FLG) was prepared by a simple activation (by KOH) followed by mechanical exfoliation method (Fig. 20). Figure 18 shows the schematic pathway used for the synthesis of PS-FLG from precursor PS-P and its subsequent integration into a solid-state device [84].

Fig. 20.

Schematic representation for the synthesis of PS-FLG active material and its subsequent integration into a solid-state device (Reprinted with the permission from Ref. [84])

The methods used to produce few layers graphene material compared to other methods for producing graphene-like carbon from biomass is shown in Table 2.

Table 2.

Comparison of different graphene-based materials synthesized from waste biomass as a carbon source and their applications

(Reprinted with the permission from Ref. [85])

| Waste source | Synthetic name | BET surface area (m2 g-1) | Application | References | |

|---|---|---|---|---|---|

| Activating agent | Graphitization process (graphitic catalyst precursor) | ||||

| Peanut shell | KOH | - | 2070 | Supercapacitor | [85] |

| Coconut shell | ZnCl2 | FeCl3 | 1874 | Supercapacitor | [86] |

| Soybean shell | KOH | Thermal treatment with NH3 injection for N-doped grapheme | 1152 | Oxygen reduction reaction | [87] |

| Wheat Straw | KOH | Thermal treatment in graphite furnace | 35.5 | Li-ion battery | [88] |

| Tea tree plant | Plasma enhanced chemical vapor deposition | Hydrophobic coating | [82] | ||

| Auricularia + GO | KOH | Hydrothermal carbonization with GO | 1723 | Supercapacitor | [89] |

| Waster paper (Co decorated porous graphene) | - | Graphitization & Co(acac)2 + 1,10 phenanthroline | 542 | Oxygen reduction reaction | [90] |

The summary of various synthesis techniques which can be used to develop graphene quantum dots from many biomass sources are shown in Fig. 21.

Fig. 21.

Synthesis techniques of graphene from biomass sources

Biomass-Waste Derived Graphene Quantum Dots

Quantum dots (QDs) are man-made nanoscale crystals that that can transport electrons. When UV light hits these semiconducting nanoparticles, they can emit light of various colours. These artificial semiconductor nanoparticles that have found applications including composites, solar cells, and fluorescent biological label.

Graphene, which basically is an unrolled, planar form of a carbon nanotube therefore has become an extremely interesting candidate material for nanoscale electronics. Researchers have shown that it is possible to carve out nanoscale transistors from a single graphene crystal (i.e., graphene quantum dots). Unlike all other known materials, graphene remains highly stable and conductive even when it is cut into devices one nanometer wide.

Vertically Aligned Graphene Nanosheet Arrays (VAGNA) from Biomass Wastes

Vertically aligned graphene nanosheet arrays (VAGNA) can be synthesized from biomass wastes. Figure 22 illustrates the overall synthesis process and mechanism of 3D VAGNAs derived from spruce bark [91, 92]. This process is a catalyst-free synthetic strategy towards high-quality graphene for electrochemical energy storage.

Fig. 22.

Schematic illustrations of a overall formation process and b the synthetic mechanism of 3D VAGNAs (Reprinted with the permission from Ref. [92])

Figure 23f gives the FESEM image of the as prepared VAGNA-900, revealing that the KOH activation resulted in curved nanosheets growing vertically on the surface of bulk carbon particles, and connected to each other to form the 3D interconnect framework. Obviously, in this case, the formation of 3D VAGNAs is due to the dual function of KOH: the penetrating behavior of molten KOH into layers of the as-obtained carbonized precursor and activation agent to induce porosity in carbon materials [91].

Fig. 23.

a Digital photo of spruce trees and b its bark. c SEM image of the cross-section and d longitudinal section of the spruce bark. e SEM image of the hydrothermal carbonized precursor, a distinct multilayered stacking up structure was clearly observed. f The as-prepared 3D VAGNA-900 (Reprinted with the permission from Ref. [92])

Table 3 shows the lists of biomass resources for Graphene Quantum Dots, GQDs synthesis via different techniques.

Table 3.

Lists the various biomass resources for Graphene Quantum Dots (GQDs) synthesis via different techniques from Biomass-waste derived graphene quantum dots and their applications (Reprinted with the permission from Ref. [70])

| Precursor | Preparation approach | Product | Yield (wt%) | Size (nm) | Height (nm) | References |

|---|---|---|---|---|---|---|

| Neem leaves | Pyrolysis and hydrothermal treatments |

GODs Am-GQDs |

– | 5–6 | 0.4–1.7 | [93] |

| Rice husks | Pyrolysis and hydrothermal treatment | GODs | 15 | 3–6 | 0.8–1.6 | [88, 94] |

| Wood charcoal | Electrochemical oxidation | GODs | – | 3–6 | ~ 6 | [88] |

| Coffee grounds | Hydrothermal treatment |

GQDs PEI-GQDs |

33 |

(GODs) 2.67(PEI-GQDS) |

2.23 (GQDs) 3.18(PEI-GQDs) |

[95] |

| Neem leaf extract | Pyrolysis and hydrothermal treatment | GQDs | 25.2 | 2–8 | – | [96] |

| Fenugreek leaf extract | Pyrolysis and hydrothermal treatment | GQDs | – | 3–10 | – | [96] |

| Honey | Emulsion templated carbonization | GODs | – | 1.8–2.8 | – | [97] |

| Rice grains | Pyrolysis | GODs | 56 | 2–6.5 | 1–2 | [97] |

Graphene quantum dots can be developed from wide range of synthesis techniques using various biomass sources is shown in Fig. 24. Each synthesis process has its own distinctive attributes that can be used for different types biomass sources to graphene development. In the next section, different advanced characterization techniques used to find out the properties for the specific purposes/application as discussed.

Fig. 24.

Synthesis of graphene quantum dots from various biomass sources

Results

In previous section II, the wide range of synthesis techniques of Graphene from various sources including biomass sources have been explored. The higher speed, larger capacity, and smaller size are required for advanced electronic devices during last few decades. Moreover, flexible, foldable, or even wearable properties are required for more comfortable electronics devices to attract the peoples. Thus, the paradigm of electronics is shifting from technology-oriented to user-oriented devices with various types of human interfaces. Figure 25 shows possible applications of flexible transparent electrodes for corresponding sheet resistance ranges [99]. In general sense, material characterization denotes a systematic analysis, measurement, testing, modeling, and simulation procedure that yield both qualitative and quantitative data of the specific attributed of specific purposes/applications. Therefore, it is imperative to find their various properties using advanced material characterization techniques.

Fig. 25.

Potential applications graphene has to offer, depending upon the resistivity of the type of graphene (Requested sought for printed with the permission from Ref. [99])

The advanced material analysis and characterization techniques of graphene include UV–VIS Absorption Spectroscopy, Thermogravimetric Analysis (TGA), X-ray Photoelectron Spectroscopy (XPS), Optical Microscope, Atomic Force Microscopy (AFM), Scanning Electron Microscopy (SEM), High-Resolution Transmission Electron Microscopy (TEM), X-ray Diffraction (XRD), Scan Electron Microscopy (SEM), Spectroscopic ellipsometry (SE) are discussed to understand the structural, surface, optical, electrical, microwave.behaviors of Graphene. Moreover, electrical, thermal, parameters (conductivity, stability, etc.), microwave properties (scattering parameters i.e. complex permittivity, attenuation, dielectric loss, and reflection loss in the gigahertz range) are also discussed. Figure 25 demonstrates that the advanced characterization techniques are required for graphene used to wide range of applications. In the following sections, the techniques are described in detail.

Ultraviolet–Visible (UV–VIS) Absorption Spectroscopy UV–visible (UV–VIS) absorption spectroscopy is necessary to understand the graphene oxide dispersions of known concentrations. Moreover, stability critically depends on the amount of reducing agent employed in relation to the mass of graphene oxide present in the dispersion. Figure 26 (inset) shows a digital picture of 0.1 mg mL−1 graphene oxide dispersion in water (left), together with its chemically reduced counterpart (right). The yellow brown color characteristic of the unreduced dispersion changes to black following reduction. This behavior suggests deoxygenation of the graphene nanosheets has effectively come about.

Fig. 26.

UV–Vis spectra for unreduced (orange) and chemically reduced (black) graphene oxide dispersions in water. Inset: digital picture of the unreduced (left) and reduced (right) aqueous dispersions (Reproduced with permission from [100])

TGA and XPS measurements are done to understand the chemical transformations induced by reduction.

Thermogravimetric Analysis (TGA) The thermogravimetric (TG) and differential thermogravimetric (DTG) plots for the unreduced graphene oxide material (full and dotted orange curves, respectively) and the reduced material (solid and dotted black curves, respectively) are shown in Fig. 27. The reduced material also displays a significant mass loss (∼10%) below 100 °C due to water desorption.

Fig. 27.

TG (solid curves) and DTG (dotted curves) plots for unreduced (orange) and chemically reduced(black) graphene oxide material (Reprinted with permission from Ref. [100])

X-ray Photoelectron Spectroscopy (XPS) Figure 28 shows the presence of oxygen on both samples of unreduced graphene oxide material and the reduced material was directly evidenced by XPS.

Fig. 28.

High-resolution XPS spectra for unreduced (a) and chemically reduced (b) graphene oxide material (Reprinted with permission from Ref. [100])

Optical Imaging Optical microscope, atomic force microscopy (AFM), scanning electron microscopy (SEM), high-resolution transmission electron microscopy (TEM) techniques are used to image single layers, bi-layers and few layers of graphene.

Optical Microscopy Optical microscopy image of single-, double- and triple- layer graphene on Si with a 300 nm SiO2 over-layer, labeled in the paper as 1L, 2L and 3L, respectively. The graphene regions were identified by both color contrast in the optical microscope image and atomic force microscopy (AFM) height measurements (as described next), as shown in Fig. 29.

Fig. 29.

Optical microscopy image of single-, double- and triple- layer graphene on Si with a 300 nm SiO2 over-layer, labeled in the paper as 1L, 2L and 3L, respectively (Reprinted with permission from Ref. [101])

Atomic Force Microscopy (AFM) AFM provides topographic information down to the Angstrom level. AFM technique of imaging of graphene can successfully determine the layer thickness at the nanometer scale as shown in Fig. 30. The images were recorded in the attractive regime of tip sample interaction. Superimposed onto each image is a line profile taken along the marked red line.

Fig. 30.

Height a and c and corresponding phase b and d tapping-mode AFM images of unreduced (a and b) and chemically reduced c and d graphene oxide nanosheets deposited from aqueous dispersions onto freshly cleaved HOPG (Printed with the permission [100])

Raman Spectroscopy Raman scattering has been widely used in the fundamental spectroscopy study of excitations in solids, liquids, and gases and has also been extensively used in material characterization. Raman Spectroscopy is an effective tool for characterization of mono- or few-layer graphene’s, and several theoretical and experimental studies have been reported recently [102].

Carbon allotropes show their fingerprints under Raman spectroscopy mostly by D, G, and 2D peaks around 1350 cm−1, 1580 cm−1, and 2700 cm−1 respectively due to the change in electron bands as shown in Fig. 31. Identification of these features allows characterization of graphene layers in terms of number of layers present, and their effect of strain, doping concentration, and effect of temperature and presence of defects. The single sharp 2D peak can be reported for mono layer that is four times more intense than the G peak. The properties of graphene crucially depend on the number of layers and purity. Various researchers have used Raman spectra as a non-destructive tool to characterize and quality control of mono and few layers of graphene. Various effects on graphene have also been studied using Raman spectra including thickness determination, strain in graphene layers, defects, and doping.

Fig. 31.

a Comparison of Raman spectra at 514 nm for the graphite and single layer graphene. b and c Evolution in 2D band as a function of layers at 514 and 633 nm excitations. d and e Comparison of the D band at 514 nm at the edge of bulk graphite and single layer graphene. The fit of the D1 and D2 components of the D band of bulk graphite is shown. e The four components of the 2D band in 2-layer graphene at 514 and 633 nm (Reprinted with the permission from Ref. [102, 103])

Transmission Electron Microscopy (TEM) Transmission Electron Microscopy, TEM is a technique used to observe modulations in chemical identity, crystal orientation, and electronic structure. The TEM images of amine terminated graphene quantum dots (Am-GQDs), amine terminated graphene quantum dots (Am-GQD@Ag, and Am-GQD-Ag-Cys samples are shown in Fig. 32a, b and c respectively.

Fig. 32.

HRTEM images of a Am-GQDs, b Am-GQD@Ag (with the addition of Ag + ions to the 5–6 nm size amine terminated GQDs results in the formation of a complex which arranges on the Am-GQD surface to get Am-GQD@Ag particles. Interestingly a distinct shell appears around the GQDs), c AmGQD-Ag-Cys (addition of L-cysteine solution this shell in b disappears), and d SAED pattern of Am-GQD@Ag (shell surrounding the quantum dots possibly arises due to nucleation of Na2SO4 and Ag2SO4 around the AmGQD-Ag particle system during the process of drying the sample on the TEM grid) (Reprinted with the permission fromRef. [104])

Scan Electron Microscopy (SEM) A scan electron microscope (SEM) is an imaging technique of a sample. Field emission SEM (FE-SEM) produces clearer, less electrostatically distorted images with spatial resolution down to 1.5 nm and it is 3–6 times better than conventional SEM. The morphologies of samples can be revealed by SEM based on the different brightness for different angels of the sample surface as shown in Fig. 33. At a vertical surface, the higher proportion of secondary electrons can be collected than at a horizontal surface. Therefore, the thin carbon sheets or wrinkles can be detected by the SEM [71].

Fig. 33.

SEM images of vertically aligned graphene nanosheet arrays (VAGNA) obtained by pyrolysis at 900 °C from spruce bark via coupling with hydrothermal carbonization method. a SEM image; b, c High-magnification of SEM; d) (

Reproduced with permission from Ref. [105])

X-ray Diffraction (XRD) XRD is a nondestructive technique and qualitative and quantitative analysis of crystalline materials, form of powder or solid. Figure 34 shows the XRD spectra of pristine graphite, graphite oxide, and graphene. The strong and sharp diffraction peak of pristine graphite at 26.6 completely disappeared after oxidization and instead a new peak at 13.9 appeared, indicating a complete oxidization of graphite, which is a prerequisite to obtain exfoliated graphene nanosheets by ultrasonication or thermal expansion. After thermal exfoliation of the completely oxidized graphite (GO), there was no apparent diffraction peak detected, which means the periodic structure of GO was eliminated and graphene nanosheets were formed.

Fig. 34.

X-ray diffraction patterns of pristine graphite, graphite oxide and graphene (

Reproduced with permission from Ref. [106])

Fourier Transform Infrared Spectroscopy (FTIR) In the FT-IR spectrum of the graphene oxide sample, the peaks at 3432 and 1711 cm−1 are attributed to –OH and C=O bands, respectively as shown in Fig. 35. Upon reduction of graphene oxide to graphene, the C=O band disappears and new bands at 2928 and 2865 cm−1 arise representing the C–H stretch vibrations of the methylene group. Functionalised graphene displays a peak at 1731 cm−1 characteristic band for C=O stretch of the COOH group. The presence of carboxylic functional group is further confirmed by the strong and broad band at 3412 cm−1.

Fig. 35.

FTIR spectra of graphene, thermally reduced graphite oxide and functionalized graphene (

Reproduced with permission from Ref. [107])

Spectroscopic Ellipsometry Spectroscopy ellipsometry (SE) technique is a nondestructive diagnostic test of thin films. SE is essential for determination of layer thickness, surface roughness, and the optical as well as electrical properties of thin films. For thin films, the optical properties vary considerably depending on the microstructure and growth conditions. The SE data analysis process for most samples begins by building a layered optical model, which corresponds to the nominal sample structure.

As shown in Fig. 36 below, where spectroscopic ellipsometry is used to characterize the complex refractive index of chemical vapor deposition CVD graphene grown on copper foils and transferred to glass substrates. The spectroscopic ellipsometry, with respective wavelength ranges extending into the ultraviolet and infrared IR, have been used to characterize the CVD graphene optical functions.

Fig. 36.

Color Comparison of n and k values between CVD graphene [108] and exfoliated graphene by Kravets et al. Ref. [109] and Weber et al. Ref. [110]; (

Electrical and Electronic Characterization

Microwave Characterization Microwave measurements of the dielectric properties of materials are finding increasing applications in new electrotechnology. Measurement of the bulk dielectric properties (dielectric constant, dielectric loss factor) is not only testing, but these properties are in intermediary vehicle for understanding, explaining, and empirically relating certain physicochemical properties of the test material. The EM (Electromagnetic) absorption characteristics of materials depend on its dielectric properties (complex permittivity), magnetic properties (complex permeability), thickness, and the frequency of operation.

Near-field measurements were performed at X-band frequencies (8–12 GHz) for graphene on copper microstrip transmission lines. An improvement in radiation of 0.88 dB at 10.2 GHz is exhibited from the monolayer graphene antenna which has dc sheet resistivity of 985 X/sq. Emission characteristics were validated via ab initio simulations and compared to empirical findings of geometrically comparable copper patches. The S-parameters of were measured, as depicted in Fig. 37. The graphene enhances the dielectric losses. The impedance mismatch caused by the copper patch, as illustrated in Fig. 37b, is similarly severe and increases reflections by at least 10 dB whilst reducing transmission by 1 dB.

Fig. 37.

a Reflection (S11) and b transmission (S21) coefficients of the bare transmission line (black), the graphene patch (green), and the copper patch (red). Inset: Optimized surface conductivity of graphene (

Reproduced with permission from Ref. from [111])

This section has presented various novel analysis and characterization techniques for graphene required for various application. These include structural, thermal, surface, optical, electrical, and microwave characterization for graphene as shown in Fig. 38. Moreover, electrical, thermal, parameters (conductivity, stability, etc.), microwave properties (scattering parameters i.e. complex permittivity, attenuation, dielectric loss, and reflection loss in the gigahertz range) are also discussed. The next section various applications of graphene are discussed.

Fig. 38.

Advanced materials characterization techniques for graphene

Application

Graphene can be used in a multitude of applications for improved energy storage (capacitors, batteries, and fuel cells), energy generation (solar cells), sensors or even as an advanced membrane material for separations. For example, graphene-based wireless sensor is used for bacteria detection on tooth enamel [112, 113].

Graphene in Energy Storage and Eenergy Generation Devices The Graphene Quantum Dots (GQDs) are strongly luminescent, biocompatible, dispersible in a number of solvents, and usually nontoxic, demonstrating a great potential for integration onto devices of bio-imaging, batteries, supercapacitors, photovoltaics and light emitting diodes (Fig. 39).

Fig. 39.

Schematic illustration of the conversion of biowaste into GQDs through various approaches and their energy applications (Reprinted with permission from [70])

Graphene-Based Ultracapacitors Figure 40A shows a schematic of the two-electrode ultracapacitor test cell and fixture assembly along with SEM and TEM images of the surface of the chemically modified graphene (CMG) agglomerate particles and individual graphene sheets. Figure 40B shows lithium batteries with cross-sectional TEM images of graphene nanoplatelets and CNT (carbon nanotubes).

Fig. 40.

Graphene for energy storage. A Ultracapacitors: (a) SEM image of CMG particle surface, (b) TEM image showing individual graphene sheets extending from chemically modified graphene surface, (c) low and high (inset) magnification SEM images of chemically modified graphene electrode surface, and (d) schematic of test cell assembly. B Lithium batteries: Cross-sectional TEM images of graphene nanoplatelets with almost the same numbers (5–6) of graphene stacking layers for (a) graphene nanosheets, (b) graphene nanosheets separated by CNT, and (c) grapheme nano-sheets separated by C60 (Reprinted with permission from Ref. [114–116])

Graphene in Biomedical applications The properties of graphene and its derivatives are strong UV absorption, fluorescence, fluorescence quenching ability, SERS, functionalizable surfaces. This unique property of graphene and its derivatives make them the desirable material for biosensors, tissue engineering, electronics, and therapeutics. Graphene also possesses excellent surface functionalizability, aqueous processability, hydrophobicity (important for cell growth and differentiation) and amphiphilicity which is desirable for biological applications [116]. Figure 41 shows the potential biomedical applications of graphene and graphene oxide in mass spectrometry, sensors, gene & drug delivery, cancer treatment, cell growth.

Fig. 41.

Biomedical applications of graphene and graphene oxide (

Yin Zhang et al. states that graphene has a vast scope in biomedical application because of its exceptional properties and structure. The main concern that lies in the full implementation is the toxicity of graphene and its effect on the body. If graphene and its derivatives can be functioned and modified in such a way that it does not display any toxic behavior or it can be eliminated from the body over a period, then it can be best used. Graphene and graphene oxide have many development of graphene and graphene derivatives for energy, sensing, and biomedical applications in biomedical field such as in cell replacement, bone tissue repair, restoring neuronal circuits and in cardiovascular diseases. The schematic overview of various biomedical applications of graphene is shown in Fig. 42. The main aim is to develop a material than can efficiently deliver the therapeutic agents without toxicity [120].

Fig. 42.

Schematic overview of various biomedical applications of graphene (

Reproduced with permission from Ref. [119])

Martin Pumera et al. reviews about the electrochemistry property of graphene for sensing and energy applications. Graphene sheets and nanoplatelets have exceptional conductivity, large surface area, lower cost and are free from impurity. There electrochemical properties are noteworthy as compared to other electrodes [121].

The fast heterogeneous electron transfer kinetics and sensitive sensing properties towards the detection of dopamine in the presence of typical interferences, such as ascorbic and uric acid, arises from the high density of edge plane sites at the ends of the graphene nanoplatelets and their ability to act as nano connectors for electrical connection with electrode substrates as shown in Fig. 43.

Fig. 43.

Graphene nanoplatelets for electrochemical biosensing. a and b Different magnification TEM images of nanoplatelets; c High-resolution TEM image of graphene nanoplatelets showing the nanoflake with a knife edge or conical structure with open graphitic planes; d EDX spectrum, showing the chemical composition of graphene nanoplatelet films [

Reproduced with permission from Ref. [121])

Fluorescence microscopy of MCF-7 cells incubated for 24 h, QDUS-rGO could be observed in the cytoplasm (Fig. 44a) and Henrietta Lacks (HeLa) cells, shown in Fig. 44b (QD-US-rGO). In vivo fluorescence imaging of mice bearing different tumors (indicated by arrows) after intravenous injection of Cy7-labeled GO are shown in Fig. 44b.

Fig. 44.

Optical imaging of graphene-based nanomaterials. a Cellular uptake of folic acid-conjugated QD–rGO in human breast cancer MCF-7 and HeLa cells, where QD fluorescence is shown in red orange. b A schematic representation of Cy7-labeled GO through six-arm branched PEG chains. c In vivo fluorescence imaging of mice bearing different tumors (indicated by arrows) after intravenous injection of Cy7-labeled GO.

Adapted from Ref. [122] and [123] with permission Fabrication and properties of a high-performance chlorine doped graphene quantum dot based photovoltaic detector

Yuqi Yang et al. talks about the use of graphene in drug delivery, phototherapy and in vivo imaging [124]. Due to its excellent properties, graphene-based materials have an excellent future in biomedical fields but there are some hurdles which need to be overcome to get a desired efficacy. There needs to be more study on its toxicity, intracellular pathway and cellular-uptake mechanism. Another concern is increasing the productivity of graphene quantum dots and developing effective methods to produce inerratic graphene sheets [125].

Owing to the excellent biocompatibility, ready cellular uptake, flexible chemical modifications and unique optical properties, GO has been explored for biological imaging. The protection of DNA from enzymatic digestion by the self-assembly of ssDNA on GO sheets was reported by Tang et al. [126] as shown in Fig. 45.

Fig. 45.

Schematic illustration of the constraint of DNA molecules on functionalized graphene and its effects. Single stranded DNA can be effectively constrained on the surface of graphene through adsorption. The enzyme DNase I can digest free DNA but not graphene-bound DNA (Printed with the permission Ref. [124, 125])

Shumao Cui et al. describes the use of graphene coupled with nanocrystals for sensing and energy applications. The biosensor developed using thermally reduced graphene oxide (TRGO) coupled with Au nanocrystals was highly sensitive and reliable with stable structure. The addition of nanocrystal proves to be appropriate in increasing the sensitivity of graphene. The main challenge lies in the understanding of interaction between graphene and nanocrystals on which the properties of the hybrid structure depends. The application and development of graphene-nanocrystals structure highly depends on the orientation and morphology of the structure [126]. A sensitive and selective field-effect transistor (FET) biosensor is demonstrated using vertically oriented graphene (VG) sheets labeled with gold nanoparticle (NP)-antibody conjugate in Fig. 46.

Fig. 46.

a Schematic of a TRGO FET device by direct growth of VG between the drain and the

source electrodes. Probe antibody is labeled to the VG surface through Au NPs. b Sensor sensitivity versus IgG concentration (g/mL). The dashed line represents the noise level (9.8%) from the buffer solution. c SEM image of the VG network deposited with Au NP-antibody conjugates (top view). d Dynamic response of the VG sensor exposed to different concentrations of IgG with probe proteins (Reprinted with permission from Ref. [127])

Ernie W. Hill et al. reviews the use of graphene as a material for different types of sensors. Graphene has properties which can be utilized to produce different types of sensors such as electrochemical sensors, magnetic sensors, bio sensors, photoelectric sensors, strain sensors, optical sensors, chemical sensors, and mass sensors. Graphene has superior mechanical stability comparatively which can be utilized for flexible touch screens. The future of graphene-based sensors looks bright but there must be an abundant source of high-quality of graphene available on wafer scale [128].

Application in COVID-19 Graphene joins the fight against COVID-19. The world is currently experiencing one of the most significant cases of lockdown since the second world war and has had a profound medical, economic and social impact on the lives of people in all corners of the world. The current situation is one that is likely to proceed for a significant period. Still, a concerted effort is being made by governments, scientists and healthcare professionals to test people with symptoms, to confirm if they have the novel SARS-CoV-2 coronavirus, so that they can either self-isolate or seek appropriate medical treatment if needed.

However, one of the issues around the globe is a lack of testing in some areas, whereas the quality of testing in other areas is coming under fire for producing false results. There are already several tests on the market which are being sold and used by many companies. Still, ways of creating more effective tests to diagnose if people have or had the coronavirus are coming to the fore. These tests will hopefully help to alleviate any issues about the quality of tests on the market soon—this will be especially important in the coming months before (and if) researchers find a vaccine that can contain the spread of the virus [129]. Graphene sensors arrays can be implemented on standard utility textiles and drug efficacy screening. Thanks to its high versatility, we foresee that graphene may have a leading role in the fight against COVID-19 [130].

Biomass Derived GQDs Graphene Quantum Dots, GQDs stand out as a new material combining the exceptional properties of both graphene and quantum dots [131]. As a result of the intriguing properties, such as good electrical conductivity, enlarged surface area, high solubility in many solvents, strong luminescence, high mobility, decreased chemical impedance, and tunable bandgap, GQDs exhibit an edge over other graphene based materials and have indicated a bright promise in fluorescence sensors, photovoltaic devices, light-emitting diodes, solar cells, fuel cells, batteries, and supercapacitors.

PL Sensors The numerous applications of biomass derived GQDs include PL Sensors for detection of chlorine in water, detection of range of metal ions in water based on their strong fluorescence properties,

Light Emitting Diodes The biomass derived GQDs are also used for the development of range of white, green, red, blue, orange light emitting diodes and other devices.

Biomedical Biomass derived GQDs from natural food precursor such as rice grains [98], rice husks [88, 94], coffee beans [95] and have been widely investigated for biomedical applications, especially bioimaging. Very recently, Ding et al. reported on the bioimaging of fibroblast cells with sulphur doped GQDs synthesized by the hydrothermal treatment of durian [132]. Different GQDs with varying amount of S doping indicate different color in bioimaging of the fibroblast cells, showing their high bioimaging capability (Fig. 47).

Fig. 47.

a PL spectra of S-GQDs with varying concentration of heteroatom doping, and b respective imaging of fibroblast cells incubated with S-GQD series 1, 3, 5, 7, and 9 (scalebar: 20 mm). Reprinted with permission from Ref. [132]

Energy Owning to the extraordinary properties of graphene, such as large surface area, good electrical conductivity, tunable luminescence, decreased chemical impedance, and tunable bandgap, GQDs have shown great promise in energy applications, such as photovoltaics devices, batteries, and supercapacitors.

Liu et al. [133] synthesized a GQD-based symmetric micro-supercapacitor by electrophoretic deposition of GQDs on the interdigital Au finger microelectrode and acquired fast power response, high rate performance, and long cycling life (97.8% stability after 5000 cycles) as shown in Fig. 48.

Fig. 48.

a The preparation of a symmetric micro-supercapacitor by depositing GQDs on an interdigital Au finger microelectrode, b specific capacitance retention after 5000 cycles (Reprinted with permission from Ref. [133]

Owning to the extraordinary electronic/optical properties, GQDs may be implemented in various components of photovoltaics, such as sensitizers, activators, active layers, catalysts for the counter electrode. GQDs are used as active layer to fabricate Si/GQD heterojunction solar cell [134] as shown in Fig. 49a. PbS QD/GQD core/shell hybrids were synthesized [135]. An improved current density (13.4 mA cm2), PCE (3.6%) and open voltage (0.58 V) was obtained for solar cell with PbS QD/GQDs active layers than that of organic molecules capped PbS QDsbased devices [135].

Fig. 49.

a CH3-Si/GQD heterojunction solar cell showing J-V curve at Am1.5G (the inset shows its energy band diagram), [

Reproduced with permission from Ref. [134]), b A schematic diagram of PbS QDs surface passivated by GQDs and PbS based solar cells' J-V curves under Am1.5G. Reprinted with permission from Ref. [135], c Schematic of a photovoltaic device based on GQD-Cl hybrid and its working mechanism (Reprinted with permission from Ref. [136]). d Illustration of a photovoltaic device based on GQDs in hole-transport layer (HTL) and hydrothermally reduced GQDs in the BHJ layer (Reprinted with permission from Ref. [137]). e SEM image (cross sectional view) of perovskite solar cell on left side, illustration of its working mechanism in middle, and J-V curves of the cell without or with GQD on right (Adopted with permission from Ref. [138])

Figure 50 shows the summary of application areas of Graphene including energy generation, energy storage, sensors, composites, coating membranes, biomedical fields.

Fig. 50.

Application areas of graphene

Discussion

Since 2004, the number of graphene-related academic publications has substantially increased. Figure 45 illustrates the surge in graphene as well as reporting some historical points of interest; there were over 14,000 papers published with the keyword ‘graphene’ (Web of Knowledge 2020). As of 2020, the time of writing this review, there are a range of graphene production methods (as briefly discussed above), each of which carry their respective benefits, whilst at the same time producing different types of graphene (monolayer, multi-layer, etc.) which have different applications depending on the properties exhibited by each type of graphene.

So far various synthesis techniques of graphene have been discussed and their properties are identified, analyzed, and classified. The synthesis of graphene can be divided into two main categories as listed in Table 4: the top-down approach and the bottom up approach. A general survey and comparison on the state of art synthesis of graphene are summarized with their merits and challenges.

Table 4.

State of art synthesis of graphene [141]

| Type | Method | Figure/Illustration | Merits | Challenges |

|---|---|---|---|---|

|

Top-down (from Graphite) |

Mechanical exfoliation |

|

Less defects |

Neither scalable nor capable for mass production |

| Chemical method |

|

Cost-effective and suitable for mass production |

Utilize many toxic chemical throughout the synthesis process |

|

|

Bottom-up Approach (From Carbon) |

Chemical Vapor Deposition (CVD) |

|

Compatible with the current complementary metal–oxide–semiconductor (CMOS) technology due to large area and high-quality graphene produced |

Expensive and involves complex transfer process |

| Epitaxial growth |

|

No defects for every single graphene island | Discontinuous |

Very few commercial technologies involving graphene-based materials have emerged, in large part due to the difficulty in processing these 2D sheets into useful, 3D materials with predicable structure and thus function. To address this challenge, for developing processes capable of depositing large-area monolayer graphene films onto a variety of substrates from biomass sources are summarized in Table 5.

Table 5.

Synthesis of graphene and its derivatives from biomass sources

| Method | Sources | Figure/Illustration | Features | References |

|---|---|---|---|---|

|

HTC, Pyrolysis |

Fungus, Glucose |

SEM image of the obtained densely porous layer-stacking carbon (PGC) material [Reproduced with permission from Ref. [73]) |

Low-cost and environmentally friendly design of electrode materials for high volumetric-performance supercapacitors | [73] |

| CVD | Cookies, Chocolate, Grass, Plastics, Roaches, Dog Feces |

Diffraction pattern and TEM images of the cookie-derived graphene. (A) SAED pattern, (B) suspended graphene film on a 1 μm diameter hole, and (C) the edge of monolayer graphene [Reproduced with permission from Ref. [77]) |

Monolayer graphene derived from carbon sources is of high quality |

[77] |

| Microwave Plasma Irradiation | Rice Husk |

SEM images of the Rice Husk -derived (a) graphene [Reproduced with permission from Ref. [80]) |

Fabricate high-added-value nanocarbons including graphene, CNTs, and g-CNTs, which were dependent of experimental pressure | [80] |

| Method | Sources | Figure/Illustration | Features | References |

|---|---|---|---|---|

|

Hydrothermal Calcination, Graphitization |

Wheat Straw |

TEM image (e) of graphene [Reproduced with permission from Ref. [81]) |

less expensive method to synthesize high-quality graphene sheets from wheat straw via a combined hydrothermal and graphitization approach |

[81] |

| Plasma Enhanced Growth | Tea Tree Plant |

TEM image of a graphene sample [Reproduced with permission from Ref. [82]) |

The as-fabricated graphene films yielded a stable contact angle of 135°, indicating their potential application in very high hydrophobic coatings | [82] |

| Chemical | Pulping black Liquor |

|

The pulping black liquor mainly consisting of lignin component was successively converted from amorphous heterogeneous chemical states to micron-sized graphene crystalline structure |

[83] |

| The HR-TEM image of gradual ordered graphene lattice, from amorphous to crystalline, indicating the forming mechanism of graphene formation process [Reproduced with permission from Ref. [83]) |

Table 6 shows the summary of critical material properties for each characterization techniques that have been discussed so far. This will lead to an interdisciplinary research field of graphene development from biomass sources.

Table 6.

Advanced material characterization techniques for graphene and its derivatives

| Name of techniques | Type of techniques | Materials properties | References |

|---|---|---|---|

| X-ray Diffraction, XRD | Structural | Crystalline Quality | [106] |

| Raman Spectroscopy | Structural | Order or disorder structural information, Crystalline Quality | [65, 102, 103] |

| Spectroscopic Ellipsometry, SE | Structural, Surface, Optical, Electronic | Layer thickness, surface roughness, and dielectric constant, refractive index | [108–110] |

| Ultraviolet–Visible (UV–VIS) Absorption Spectroscopy | Optical, Electronic | Transmittance, reflection, and absorption coefficient | [100] |

| Atomic Force Microscopy, AFM | Surface | Surface roughness, morphology, topographical images | [100] |

| Scan Electron Microscopy, SEM | Surface | Morphology | [105] |

| Transmission Electron Microscopy, TEM | Structural, thickness, surface, morphology | Examine fine detail—even as small as a single column of atom | [104] |

| Fourier Transformation Infrared Spectroscopy, FTIR | Surface | Surface bonding | [107] |

| X-ray Photoelectron Spectroscopy, XPS | Surface | Chemical nature, surface composition | [100] |

| Thermogravimetric Analysis (TGA) | Nature of the materials | Deviation of the weight with temperature | [100] |

| Electrical and Electronic Characterization | Electrical, Electronic | Electrical, Dielectric properties | [111] |

The various microscopic materials characterization techniques such as TEM, SEM, AFM are very different each other. SEM/TEM is conducted in vacuum environment, and AFM is conducted in an ambient or fluid environment. The above techniques are used for topography (the surface features of an object or how it looks, its texture), morphology (the shape and size of the particles making up the object), composition (the elements and compounds that the object is composed of and the relative amount of them), crystallographic information (how the atoms are arranged in the object) of materials.

If the expected value is in the > 100 nm range, standard SEM on sample cross section may be used. In the 30–100 nm range a FESEM (Field Emission SEM) is better. For thinner samples, a TEM cross sectional analysis is needed, that however require a proper sample preparation. Of course, some special care must be taken in all the above measurements. First, the sample must be properly prepared even in the case of SEM analysis. For example. if the interested film is the top most one, need to deposit a dummy thin coating (e.g. a thin Au layer) before cutting the cross-sectional sample. High-resolution transmission electron microscopy (HR-TEM) has been used as the ultimate method of thickness measurement for thin films. SEM/AFM images are three dimensional and are accurate representations while TEM pictures are two-dimensional and might require little bit of interpretation. In terms of resolution and magnification, TEM gains more advantages compared to SEM. SEM/TEM gives information regarding surface morphology, while AFM gives true surface topography and various types of surface measurements. Compared with SEM, AFM provides extraordinary topographic contrast direct height measurements and un-obscured views of surface features (no coating is necessary).

Table 7 shows the various applications of graphene and its derivatives eg. graphene oxide, graphene quantum dots (GQDs).

Table 7.

Applications for graphene and its derivatives

| Application | Capabilities | Examples | References |

|---|---|---|---|

| Energy storage and generation devices, membranes, coatings, composites |

Graphene could dramatically increase the lifespan of a traditional lithium ion battery, meaning devices can be charged more quickly—and hold more power for longer Graphene supercapacitors could provide massive amounts of power while using much less energy than conventional devices. Because they are light, they could also reduce the weight of cars or planes Graphene has the potential to create the next generation of electronics currently limited to sci-fi. Faster transistors; semiconductors; bendable phones and other electronics Storing wind and solar power |

Integration onto devices of bio-imaging, batteries, supercapacitors, photovoltaics, and light emitting diodes | [133–138] |

| Biomedical |

Graphene's unique properties allow for ground-breaking biomedical applications. Targeted drug delivery; improved brain penetration; health-testing kits and 'smart' implants Graphene applications in biomedicine are numerous and can be classified into several main areas: transport (delivery) systems, sensors, tissue engineering and biological agents (for example antimicrobials) Graphene detects. Ultra-sensitive sensors made from graphene could detect minute dangerous particles helping to protect potentially dangerous environments |

Mass spectrometry, gene & drug delivery, photothermal & cancer treatment, cell growth control, stem cell differentiation, COVID-19, sensors for food waste, crop protection, defence etc | [98, 117–132] |

Conclusion

Biomass is a sustainable and rich source of carbon production. For the proficient utilization of carbon resources, it is necessary to understand the carbon chemistry and factors influencing its properties. This review highlighted the novel research on different sources specially from biomass derived several synthetic schemes for the preparation of graphene including 3D graphene-based materials, advanced characterization techniques and their application for energy generation, storage, sensing, biomedical fields.

This article presents a comprehensive review of graphene synthesis, advanced characterization techniques, and their applications. The contributions of the article can be summarized as follows:

-

(i)

identification of synthesis techniques for the development of graphene from various sources including graphite, non-graphite sources specially from graphene synthesis from bio-mass sources.

-

(ii)

Synthesis techniques of graphene quantum dots (GQDs) from various biomass sources and biomass-wastes.

-

(iii)

Advanced material analysis and characterization techniques to understand the structural, surface and optical. behaviors of graphene as well as electrical, thermal parameters, microwave properties.

-

(iv)

Finally, multidimensional real-world applications for graphene.

-

(i)

Identification of synthesis techniques for the development of graphene from various sources including graphite, non-graphite sources specially from graphene synthesis from bio-mass sources.

The synthesis techniques section has presented a comprehensive review of various synthesis techniques for the development of graphene from various sources including graphite, non-graphite sources specially from graphene synthesis from bio-mass sources. The graphene synthesis from graphite sources such as micromechanical cleavage-the scotch tape method, chemical cleavage and exfoliation were discussed. Next graphene synthesis from non-graphitic sources such as epitaxial growth from silicon carbide, physical vapor deposition (PVD), chemical vapor deposition (CVD) from CH4, conversion of carbon dioxide to graphene, growth of graphene from solid carbon sources, graphene synthesis from polymers, facile synthesis of graphene from plastic by pyrolysis of poly(methyl ethacrylate) were discussed. Among these methods, mechanical exfoliation and CVD can produce good-quality graphene. However, the practical application of graphene is blocked by the high price and insufficient supply.