Abstract

From the onset of Covid-19 pandemic, the use of face masks has been adapted as one of the main measures to slow down the transmission of the SARS-CoV-2 virus worldwide. The inadequate handling and management of face masks lead to a massive dispersal in the environment, resulting in a new source of microfibers because of their breakdown and/or degradation. In addition, the laundering of reusable face masks of different polymeric composition can represent an additional sources of microfibers to natural ecosystems, but it was largely neglected. The present study explored the release of synthetic or natural microfibers from reusable and disposable face masks of five different fabrics when subjected to a cycle of laundering in a domestic washing machine. After a single wash, face masks released an average (± SE) of 284.94 ± 73.66 microfibers, independently of the fabrics. Focusing on the fabrics composing the face masks, polyurethane (541.33 ± 51.84 microfibers) and cotton-based (823.00 ± 112.53 microfibers) face masks released the highest amount of synthetic and natural microfibers, respectively. Considering the crucial role of face masks to counteract the pandemic and the increasing trend of their use, further studies represent a priority to estimate the contribution of face mask-derived microfibers to freshwater contamination.

Keywords: Covid-19, Microfibers, Face masks, Washing cycle

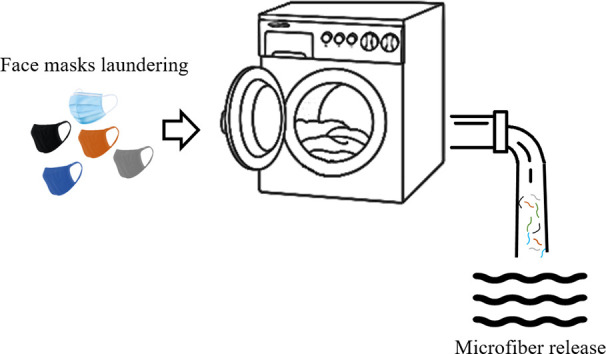

Graphical abstract

1. Introduction

From the declaration of the Covid-19 pandemic by the World Health Organization (WHO) on March the 11th 2020, a number of precautionary measures have been effected worldwide to protect individual health, to contain the SARS-CoV-2 virus and to hamper its spread. These measures included behavioral recommendations, such as social distancing and isolation, travel restriction, good hygiene (e.g., washing hands), dissuasion of public or crowded spaces and wearing of disposable face masks, as well as mandatory lockdown(s) (Chintalapudi et al., 2020; Freedman and Wilder-Smith, 2020; Lin et al., 2020). The use of face masks has been suggested as one of the most effective precautionary measures to slow down the “person by person” transmission of the SARS-CoV-2 virus (Wu et al., 2020). The WHO has estimated the monthly need of approximately 89 million of medical masks to tackle Covid-19 pandemic (WHO, 2020). Interestingly, a conservative extrapolation for the entire European population yields an estimated need 7.4 billion units of face masks on a monthly basis, while another approximations showed that nearly 130 billion face masks are used globally every month (Vasil, 2021). This sudden and huge demand has resulted in an unusual increase of the global production of face masks that is expected to increase further considering the persistence of the pandemic. For instance, the Japanese Ministry of economy, trade, and industry (METI), has declared that over 600 million order of face masks was secured per month as of April 2020 (METI, 2020). Specifically, reusable face masks have evolved as an essential item to counteract the pandemic, resulting in a rapid expansion of sales in online sources such as Amazon and Etsy (Kavilanz, 2020). According to this sale trend, the Chicago-based global market research has estimated that the face mask market would have reached $800 million in the US, and $3 billion globally, by the end of 2020 (Kavilanz, 2020).

The increased production and use of face masks worldwide has exacerbated the environmental issue related to plastic contamination. A growing number of monitoring studies has highlighted the presence of a heterogeneous array of plastic items with different sizes, shapes, colors, and polymer composition in the environment (e.g., Veerasingam et al., 2016; Piehl et al., 2018; Vidyasakar et al., 2018; Maharana et al., 2020), whereby plastic bags, bottles, food packaging and cigarette butts represent the predominant wastes (e.g., Blettler et al., 2018; Fadare and Okoffo, 2020; Winton et al., 2020). However, in recent years the deliberate or accidental release of personal protective equipment (PPE) related to Covid-19 pandemic, such as face masks, bouffant caps and gloves, have become an integral part of the waste found in aquatic and terrestrial ecosystems (Fadare and Okoffo, 2020; Aragaw and Mekonnen, 2021; De-la-Torre and Aragaw, 2021; Rakib et al., 2021; Aragaw, 2021). For instance, two recent monitoring studies performed at Cox's Bazar, the longest natural beach in the world (Bangladesh; Rakib et al., 2021), and along the coast of Lima (Peru; De-la-Torre et al., 2021) showed a massive presence of PPEs, whereby that vast majority were face masks. Similarly, face masks were also found in remote areas such as glaciers from Italian Central-Western Alps (Parolini et al., 2021a). Considering the huge amount of plastic waste entering natural ecosystems, laws and regulations have been established and implemented in many Countries on the prevention, and management of plastic wastes (Aragaw, 2021). Such initiatives suggested diverse sustainable options for plastic wastes management, including PPE, such as recycling, recovery, and reusing. For instance, Aragaw and Mekonnen (2021) suggested that fuels can be produced from polypropylene and polyvinyl chlorides plastic polymers, such as those used for single-use face masks and surgical gloves.

Disposable or reusable face masks can be manufactured from different synthetic polymers, including polypropylene (PP), polyurethane (PU), polyacrylonitrile (PAN), polystyrene (PS), polycarbonate (PC), polyethylene (PE) or polyester (PL), as well as natural ones (i.e., cellulose for cotton-based face masks). As many face masks are produced by nanofiber electrospinning (Zafar and Shah, 2016), micro- and nanofibers are most likely to be released under degradation conditions (De-la-Torre and Aragaw, 2021). Two recent studies have suggested that surgical face masks and N95 masks can act as a potential source of microfibers after entering in the environment (Aragaw, 2020; Fadare and Okoffo, 2020). In addition, some recent laboratory studies demonstrated the release of microfibers from disposable face masks through different experimental approaches (Shruti et al., 2020a; Shen et al., 2021; Sullivan et al., 2021; Ma et al., 2021; Wang et al., 2021; Han and He, 2021; Saliu et al., 2021). However, no study has explored the release of microfibers from reusable face masks. In contrast to disposable face masks, reusable ones can be washed multiple times and then reused after being well-dried (WHO, 2020; Shruti et al., 2020b). Thus, machine- (and hand-) laundering of reusable face masks might represent an additional source of both synthetic and natural microfibers, as previously demonstrated for clothing (e.g., Belzagui et al., 2019; De Falco et al., 2019; Zambrano et al., 2019; O'Brien et al., 2020). Such studies have suggested that the release of microfibers is mainly due to mechanical and chemical stresses during the washing process in the washing machine (Napper and Thompson, 2016). Microfiber release depends on the mode of laundering, the type and dosing of detergent and softener, the washing temperature and the type of laundered clothing (Napper and Thompson, 2016; Zambrano et al., 2019; Galvão et al., 2020).

Assuming that reusable face masks can experience similar conditions as other clothing during laundering, the release of microfibers and their entry into the aquatic system is expected and it could differ depending on the fabric composing the face masks. Despite these findings, the information on the release of microfibers from reusable and disposable face masks as a consequence of laundering in domestic washing machines is completely lacking. However, considering the ubiquitous presence of synthetic and natural microfibers in aquatic environments worldwide, with a large variation in terms of abundance and polymeric composition (Suaria et al., 2020), and their potential threat for aquatic organisms (e.g., Jemec et al., 2016; Li et al., 2019; Avio et al., 2020; Kutralam-Muniasamy et al., 2020; Kim et al., 2021; Setyorini et al., 2021), there is an urgent need to understand the contribution of face masks to microfibers contamination. Thus, the present study aimed at investigating the release of synthetic and natural microfibers from reusable and disposable face masks of different fabrics after the laundering in a domestic washing machine.

2. Materials and methods

2.1. Experimental setup

Face masks of different fabrics (i.e., with different polymer composition of the fabric) were purchased on the Amazon website on October 2020. As the goal of the present experiment was to explore whether laundering of face masks can release microfibers, we focused our attention mainly of washable face masks of common fabrics, including both synthetic and natural ones. In addition, we also tested the release of microfibers from surgical face masks made by polypropylene (PP) fabric because they can be accidentally washed in washing machine (e.g., forgotten in the pockets of clothes), contributing to the release of microfibers. Considering the wide array of face masks available on the market, we used as choice criteria for purchasing 1) the polymeric composition of the fabric; 2) the global rating and the customer reviews and 3) the color of the face masks. Only monochrome face masks whose fabric was made by a single polymer, excluding poly-laminates or multi-colored ones, with the highest number of global rating and best customer review were purchased. This choice was performed to facilitate the isolation and the identification of microfibers released from the face masks during laundering and to unequivocally discriminate them from external contamination (i.e., microfiber from washing water and laundering process). Face masks of different fabrics were not available with a consistent color, we purchased those made by eye-catching and distinguishable colors. All the face masks did not contain neither respirators nor nose bridge. In detail, we purchased reusable and re-washable face masks made by Polyamide (PA), Polyester (PL), Polypropylene (PP), Polyurethane (PU) and cotton (CO) fabrics, as well as disposable, surgical face masks (Sf), with the following features (i.e., color, polymeric composition of the fabric, mean weight ± SD of face mask):

-

1)

Orange polyamide face masks (PA - 95% Polyamide; 3% Elastan; 2% Polypropylene), 19.93 ± 1.95 g;

-

2)

Dark blue polyester face masks (PL - 100% Polyester), 20.58 ± 6.68 g;

-

3)

Grey polypropylene face masks (PP - 100% Polypropylene), 7.79 ± 0.83 g;

-

4)

Black polyurethane face masks (PU - 100% Polyurethane), 7.75 ± 0.17 g;

-

5)

Black cotton face masks (CO - 100% Cotton), 18.44 ± 4.62 g;

-

6)

Light blue disposable, surgical face masks (Sf - 100% Polypropylene), 4.41 ± 0.27 g.

To check for the release of microfibers, face masks were laundered in a Candy Smart CTDF 1006 6 Kg A+ Energy washing machine, using the washing program specific for synthetic clothing (1:19 h at 30 °C and a final centrifugation at 800 rpm). Previous study suggested that the use of different detergents and softeners can affect the release of fibers from clothing during a washing machine cycle (Napper and Thompson, 2016; Galvão et al., 2020). Thus, as detergent and softener dosing greatly differ depending on the household owner according to regular habits (Galvão et al., 2020), we decided to wash face masks without adding any detergent or softener. To estimate microfiber emission after laundering, we used an indirect method (Fig. S1). Usually, direct methods are used to estimate microfiber emission due to laundering of clothes, whereby a sample of the washing water is filtered, microfibers are counted using microscopy, and the results are expressed as the number of microfibers released per unit volume of washing water or per weight load of the washing machine (Galvão et al., 2020). Alternatively, also indirect methods can be used; according to these approaches, microfibers are retained in a filter and their mass is calculated to determine a release rate per garment or per unit area of fabric (Galvão et al., 2020). Our preliminary experiment relied on direct method, including face masks in the washing machine, with 5 kg of clothes of the same fabrics and color (red cotton clothes) wrapped in a washing bag (i.e., GUPPYFRIEND® washing bag), which protects the garments precluding the release of microfibers to water. However, after the collection and filtration of the washing water, a notable contribution of microfibers with a wide array of colors from the washing water was noted, precluding the estimation of the release of microfibers from the face masks. Thus, we decided to use a sort of indirect method, placing face masks into transparent nylon Press bags (8 × 12 cm) for filtration with a mesh size of 25 μm, sealed at the top with a brown cotton rope a washing bag, while the clothes were ‘free’ within the washing machine drum. To mimic a realistic laundering process, the washing machine basket was filled with about 5 Kg of red cotton clothes. This precaution was due to identify potential external contamination by <25 μm microfibers released from clothing that could be potentially enter the nylon bags during laundering. Three independent laundering processes were performed and, in each batch, the six types of face masks were simultaneously washed. The same clothes were used for every washing cycle. A blank sample (i.e., an empty nylon bag) was included in each batch to take in account potential external contamination. At the end of the laundering, face masks, still in the nylon bags, were wrapped in a tinfoil previously washed with acetone and air dried at room temperature. Then, nylon bags were cut, the face mask was carefully removed, displayed as an open book and microfibers were counted under a Leica EZ4 W stereomicroscope. No microfibers were found in blank samples. Each single microfiber of the same color of the face mask was transferred from the nylon bag to a white cellulose filter (StonyLab, pore size 1 μm; Ø = 47 mm) and a picture of each filter was captured. The length of each microfiber was measured using the Fiji freeware software (Schindelin et al., 2012). In addition, to confirm that microfibers were released by the face masks and were not due to external contamination, Scanning Electron Microscope (SEM) and Fourier transform infrared spectroscopy (FT-IR) analyses were performed. Before laundering, some microfibers were plucked from each face masks with a stainless steel forceps. Their shape was compared with that of five microfibers collected from the nylon bags using a SEM (IDSJSMIT - 500, Jeol - Tokyo, Japan; High Vac., 15.0 kV) after metallization with gold nanoparticles (Fig. 1). The polymeric composition of the fabric composing the face masks (i.e., placing the whole face mask under the FT-IR), of microfibers plucked from the face masks before the laundering, as well as pool of microfibers collected after laundering, was checked through FT-IR analysis. The FT-IR spectra were obtained through a Spectrum 100 spectrophotometer (Perkin Elmer) in attenuated total reflection (ATR) mode using a resolution of 4.0 and 256 scans, in a range of wavenumber between 4000 and 400 cm−1. Air at standard temperature and environmental moisture (23 °C and 50% RH) were used as a background (Fig. 2). The pressure applied was checked and maintained at about 50 N for all samples. A single-bounce diamond crystal was used with an incidence angle of 45°.

Fig. S1.

Schematic representation of the experimental set up used to investigate the release of microfibers from face masks of different fabrics after a washing cycle in a domestic washing machine.

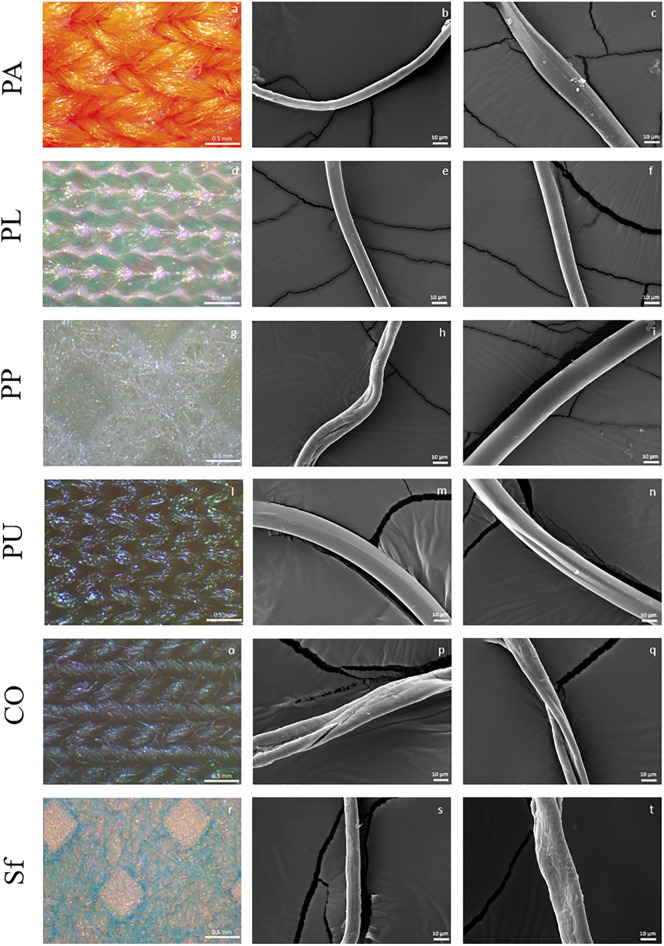

Fig. 1.

Images to show the original texture of the fabrics composing each face mask (a, d, g, l, o and r panels) and a scanning electron microscopy image (SEM) of a typical fiber from each fabric plucked from face mask before the laundering (b, e, h, m, p and s panels) and collected in nylon bags after laundering (c, f, i, n, q and t panels). PA = polyamide; PL = polyester; PP = polypropylene; PU = polyurethane; CO = cotton; Sf = surgical face mask (PP fabric).

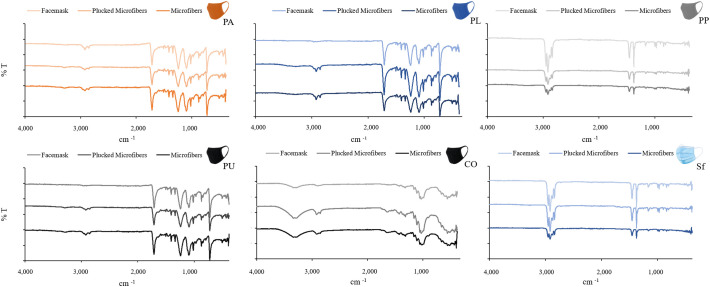

Fig. 2.

Comparison of Fourier transform infrared spectroscopy (FT-IR) spectra from face masks of different fabrics, microfibers plucked by each face masks and microfibers collected after laundering. PA = polyamide; PL = polyester; PP = polypropylene; PU = polyurethane; CO = cotton; Sf = surgical face mask (PP fabric).

2.2. Statistical analysis

The difference in the amount (i.e., total number of microfibers and number of microfibers/g of face mask) and length of microfibers released from face masks made by different fabrics after the laundering in a domestic washing machine was tested by Kruskal-Wallis test followed by Pairwise comparisons using Tukey and Kramer (Nemenyi) test with Tukey-Dist approximation for independent samples. Statistical analyses were run using the R statistical software (version 4.0.2; R Core Team, Vienna, Austria).

3. Results and discussion

The present study demonstrated that the laundering of reusable and disposable face masks in a domestic washing machine might represent an additional input of synthetic and natural microfibers to freshwater ecosystems.

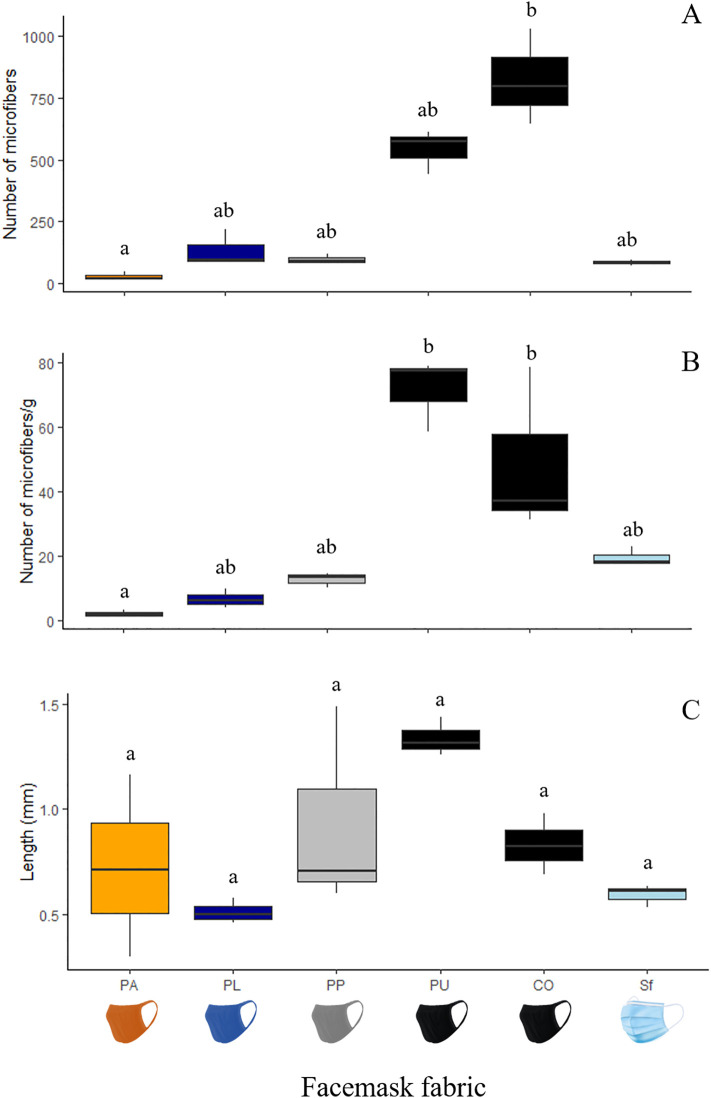

A number of studies has shown that a single household wash of 5 − 6 kg of laundry through different washing procedures lead to the release of thousands of synthetic and natural microfibers (Sillanpää and Sainio, 2017; De Falco et al., 2018; Zambrano et al., 2019, Zambrano et al., 2021). These studies suggested that textile parameters, including the composition of the fabric, the type of yarn and the textile construction can affect the microfiber release during laundering. Consequently, the same parameters can influence the release of microfibers from face masks, even though this capacity has been solely supposed (Aragaw, 2020; Fadare and Okoffo, 2020; De-la-Torre and Aragaw, 2021). This investigation demonstrated that a single cycle of laundering in a domestic washing machine lead to the release of microfibers from both reusable and disposable face masks. Overall, a mean (± SE) of 284.94 ± 73.66 microfibers were released after laundering, independently of the fabric composing the face mask. The analysis of SEM images confirmed that microfibers collected in the nylon bags after laundering were similar to those plucked from the corresponding face masks before the laundering (Fig. 1). Similarly, as shown in Fig. 2, the FT-IR spectrum obtained from a pool of microfibers collected in the nylon bag at the end of the laundering (lower spectrum in the panels) matched that of microfibers plucked by the face masks before the laundering (spectrum in the middle of the panels) and that of the fabric of origin (upper spectrum in the panels). The same laundering conditions resulted in a significant, differential release of microfibers depending on the polymeric composition of the fabric composing the face masks (Kruskal-Wallis test; χ2 = 15.174, df = 5, p = 0.009; Fig. 3 ). Focusing on synthetic fabrics only, face masks made by PU released the highest amount of microfibers (mean ± SE; 541.33 ± 51.84), followed by PL (133.66 ± 41.77 microfibers), PP (98 ± 11.93 microfibers) and PA (28.33 ± 9.83 microfibers) ones. Despite this huge variability, the number of PU microfibers found at the end of laundering was significantly higher compared to PA ones only (p = 0.045), while no statistically significant differences occurred with other fabrics. A similar release of microfibers was observed between reusable PP and disposable surgical face masks (85.33 ± 6.93 microfibers), as they were both made by the same polymer (p = 0.994). Interestingly, the highest release of microfibers was from cotton face masks (823.00 ± 112.53 microfibers), which was significantly higher compared to PA fabrics (p = 0.008), suggesting a notable input of natural polymers in the sewage from any cycle of washing in domestic washing machine. Despite the differences in the amount of microfibers released from face masks, their length was quite homogeneous and did not significantly differ among fabrics (Kruskal-Wallis test; χ2 = 10.287, df = 5, p = 0.067). The longer microfibers were released by PU face masks (mean ± SE; 1.33 ± 0.05 mm), followed by PP (0.93 ± 0.28 mm), cotton (0.83 ± 0.08 mm), PA (0.72 ± 0.25 mm) and PL (0.51 ± 0.03 mm). Overall, the length of microfibers from face masks was in the same dimensional range of those release by laundering of clothing (e.g., De Falco et al., 2020, De Falco et al., 2018).

Fig. 3.

Box-whiskers of number (A), number/g of face mask (B) and length (C) of microfibers released from face masks of different fabrics after a cycle in a domestic washing machine. PA = polyamide; PL = polyester; PP = polypropylene; PU = polyurethane; CO = cotton; SF = surgical face mask made by PP. Letters above the histograms in panel A show statistically significant differences in the microfiber release depending on the polymeric composition of face masks. Similar letters indicate no significant differences among groups.

Similar trend of microfiber release was also observed normalizing the number of microfibers on the weight of the face masks; PU (71.64 ± 6.50 microfibers/g) and cotton (48.83 ± 14.87 microfibers/g) face masks released the higher amount of fibers compared to the other fabrics (mean ± SE; 10.12 ± 3.78 microfibers/g). Significant differences in microfiber release among fabrics occurred (Kruskal-Wallis test; χ2 = 16.251, df = 5, p = 0.006), with a lower amount of microfibers released from PA face masks compared to PU (p = 0.013) and cotton (p = 0.043) ones. The higher shedding of microfibers per gram of laundered textile observed for cotton face masks compared to other fabrics was in agreement with previous studies performed on clothing, showing a higher release of microfibers from natural (i.e., cotton-based) fabrics compared to polyester ones (Sillanpää and Sainio, 2017; Zambrano et al., 2019). These differences in microfiber release may depend on fabric constructions and/or washing conditions (Zambrano et al., 2019). In particular, the higher release of cotton microfibers might be due to the lower tenacity or different chemical compositions of the fibers composing the cotton fabric compared to synthetic ones. In fact, the higher hydrophilicity of cellulosic fibers might affect the wettability of cotton fibers (Gordon Cook, 2001) during the washing process, enhancing their detachment from the fabric. Moreover, wet abrasion of cotton is high during laundering because the fibers could swell and generated fibrils that could be broken by mechanical action and/or physical forces of the washing process (McQueen et al., 2017). Although natural fibers are not considered plastics, they might represent a potential threat for aquatic ecosystems because of their widespread diffusion, as well as their capability to adsorb chemicals and to favor their dispersion (Ladewig et al., 2015). Cotton-based fibers enter freshwater as a consequence of fabrics wear and/or laundering, as demonstrated by their ubiquitous presence in wastewater effluents (Lares et al., 2018; Talvitie et al., 2017, Talvitie et al., 2015; Ziajahromi et al., 2017) and in different environmental matrices collected in aquatic and terrestrial ecosystems (e.g., Sanchez-Vidal et al., 2018; Stanton et al., 2019; Parolini et al., 2021b). Thus, monitoring the amount of cotton-based fibers represent a priority in environmental studies as much as synthetic ones. In fact, although cotton-based microfibers are considered as biodegradable (e.g., Zambrano et al., 2021), cotton fabrics are commonly treated with functional finishes including softening agents for hand feel, durable press for wrinkle resistance and dimensional stability, water/soil repellents and antimicrobials (Bajaj, 2001; Cotton Incorporated, 2004). A previous study has demonstrated that finishes can influence the rate of biodegradability of cotton-based fibers (Zambrano et al., 2021), resulting in a potential increase of their environmental persistence and hazard towards organisms. While a growing number of studies have demonstrated that the exposure to synthetic microfibers of different size and polymeric composition can be ingested by aquatic organisms belonging to different taxa, from crustaceans to fish, leading to the onset of potential adverse effects (Ziajahromi et al., 2017; Jemec et al., 2016; Rebelein et al., 2021), to date no information is available on natural microfibers but a similar ecotoxicological behavior cannot be excluded.

4. Conclusions

Our results showed that the laundering of reusable face masks, as well as accidental washing of disposable ones, can contribute to the load of synthetic and natural microfibers to freshwaters. The contribution from the laundering of face masks can be considered as lower compared to the washing of clothing. However, considering the recommendation to wear a face mask to avoid the transmission of SARS-CoV-2, and the expected market expansion of reusable face masks at an annual growth rate of 23.5% from 2020 to 2027 (www.grandviewresearch.com), the release of microfibers from these health devices cannot be neglected. In addition, the release of microfiber due to face mask laundering could be also higher compared to that observed in the present study. In fact, the indirect approach we used could have limited the pilling and/or the mechanical action experienced by face masks within the washing machine basket, reducing the release of microfibers. Similarly, the amount of microfiber released by face mask could be underestimated because they were washed at low temperature without detergents and softeners, which are considered as three factors that affect the release of microfibers from clothing. In addition, only microfibers >25 μm were collected in the nylon bags, while smaller ones that could putatively be released during laundering were missed. Lastly, we measured the release of microfibers after only one cycle of washing but, depending on their fabrics, face masks could be re-washed many times, as reported by manufacturer instructions. Although some studies demonstrated that the release, but also the size, of microfibers from synthetic clothing decreases after repeated washing processes (De Falco et al., 2018), it should be interesting to investigate whether this trend occurs also in face masks. The laundering of face masks can be therefore considered as an additional input of microfibers to freshwaters but further in-depth studies testing different laundering conditions (i.e., testing the effect of different temperatures, detergents and softeners, and repeated washing) are necessary to estimate the real contribution of these medical devices to the release of synthetic and natural microfibers to freshwaters, as well as to explore their potential hazard towards aquatic organisms.

The following is the supplementary data related to this article.

CRediT authorship contribution statement

Beatrice De Felice: Conceptualization, Investigation. Stefano Antenucci: Investigation. Marco Aldo Ortenzi: Investigation, Writing – review & editing. Marco Parolini: Conceptualization, Investigation, Formal analysis, Writing – original draft.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Editor: Damià Barceló

References

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020;159 doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A. The macro-debris pollution in the shorelines of Lake tana: first report on abundance, assessment, constituents, and potential sources. Sci. Total Environ. 2021;797 doi: 10.1016/j.scitotenv.2021.149235. [DOI] [PubMed] [Google Scholar]

- Aragaw T.A., Mekonnen B.A. Current plastics pollution threats due to COVID-19 and its possible mitigation techniques: a waste-to-energy conversion via pyrolysis. Environ. Sys. Res. 2021;10(1):1–11. doi: 10.1186/s40068-020-00217-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Avio C.G., Pittura L., d’Errico G., Abel S., Amorello S., Marino G., Regoli F. Distribution and characterization of microplastic particles and textile microfibers in adriatic food webs: general insights for biomonitoring strategies. Environ. Pollut. 2020;258 doi: 10.1016/j.envpol.2019.113766. [DOI] [PubMed] [Google Scholar]

- Bajaj P. Finishing of textile materials. J. Appl. Polym. Sci. 2001:631–659. [Google Scholar]

- Belzagui F., Crespi M., Álvarez A., Gutiérrez-Bouzán C., Vilaseca M. Microplastics' emissions: microfibers’ detachment from textile garments. Environ. Pollut. 2019;248:1028–1035. doi: 10.1016/j.envpol.2019.02.059. [DOI] [PubMed] [Google Scholar]

- Blettler M.C., Abrial E., Khan F.R., Sivri N., Espinola L.A. Freshwater plastic pollution: recognizing research biases and identifying knowledge gaps. Water Res. 2018;143:416–424. doi: 10.1016/j.watres.2018.06.015. [DOI] [PubMed] [Google Scholar]

- Chintalapudi N., Battineni G., Amenta F. COVID-19 virus outbreak forecasting of registered and recovered cases after sixty day lockdown in Italy: a data driven model approach. J. Microbiol. Immunol. 2020;53:396–403. doi: 10.1016/j.jmii.2020.04.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cotton Incorporated . 2004. Functional Finishes for Cotton. [Google Scholar]

- De Falco F., Cocca M., Avella M., Thompson R.C. Microfiber release to water, via laundering, and to air, via everyday use: a comparison between polyester clothing with differing textile parameters. Environ. Sci. Technol. 2020;54:3288–3296. doi: 10.1021/acs.est.9b06892. [DOI] [PubMed] [Google Scholar]

- De Falco F., Di Pace E., Cocca M., Avella M. The contribution of washing processes of synthetic clothes to microplastic pollution. Sci. Rep. 2019;9:1–11. doi: 10.1038/s41598-019-43023-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De Falco F., Gullo M.P., Gentile G., Di Pace E., Cocca M., Gelabert L., Avella M. Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ. Pollut. 2018;236:916–925. doi: 10.1016/j.envpol.2017.10.057. [DOI] [PubMed] [Google Scholar]

- De-la-Torre G.E., Rakib M.R.J., Pizarro-Ortega C.I., Dioses-Salinas D.C. Occurrence of personal protective equipment (PPE) associated with the COVID-19 pandemic along the coast of Lima, Peru. Sci. Total Environ. 2021;774 doi: 10.1016/j.scitotenv.2021.145774. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Aragaw T.A. What we need to know about PPE associated with the COVID-19 pandemic in the marine environment. Mar. Pollut. Bull. 2021;163 doi: 10.1016/j.marpolbul.2020.111879. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Freedman D.O., Wilder-Smith A. In-flight transmission of SARS-CoV-2: a review of the attack rates and available data on the efficacy of face masks. J. Travel Med. 2020;27:178. doi: 10.1093/jtm/taaa178. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Galvão A., Aleixo M., De Pablo H., Lopes C., Raimundo J. Microplastics in wastewater: microfiber emissions from common household laundry. Environ. Sci. Pollut. Res. 2020;27(21):26643–26649. doi: 10.1007/s11356-020-08765-6. [DOI] [PubMed] [Google Scholar]

- Gordon Cook . Woodhead Publishing Limited; Cambridge, England: 2001. Handbook of Textile Fibres, vol I: Natural Fibres. [Google Scholar]

- Han J., He S. Need for assessing the inhalation of micro (nano) plastic debris shed from masks, respirators, and home-made face coverings during the COVID-19 pandemic. Environ. Pollut. 2021;268 doi: 10.1016/j.envpol.2020.115728. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jemec A., Horvat P., Kunej U., Bele M., Kržan A. Uptake and effects of microplastic textile fibers on freshwater crustacean Daphnia magna. Environ. Pollut. 2016;219:201–209. doi: 10.1016/j.envpol.2016.10.037. [DOI] [PubMed] [Google Scholar]

- Kavilanz P. CNN; 2020. Etsy's on Fire as Reusable Face Mask Sales Surge. [Google Scholar]

- Kim L., Garg S., O’Halloran A., Whitaker M., Pham H., Anderson E.J., Langley G.E. Risk factors for intensive care unit admission and in-hospital mortality among hospitalized adults identified through the US coronavirus disease 2019 (COVID-19)-associated hospitalization surveillance network (COVID-NET) Clin. Infect. Dis. 2021;72:e206–e214. doi: 10.1093/cid/ciaa1012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kutralam-Muniasamy G., Pérez-Guevara F., Elizalde-Martínez I., Shruti V.C. An overview of recent advances in micro/nano beads and microfibers research: critical assessment and promoting the less known. Sci. Total Environ. 2020 doi: 10.1016/j.scitotenv.2020.139991. [DOI] [PubMed] [Google Scholar]

- Ladewig S.M., Bao S., Chow A.T. Natural fibers: a missing link to chemical pollution dispersion in aquatic environments. Environ. Sci. Technol. 2015;49(21):12609–12610. doi: 10.1021/acs.est.5b04754. [DOI] [PubMed] [Google Scholar]

- Lares M., Ncibi M.C., Sillanpää M., Sillanpää M. Occurrence, identification and removal of microplastic particles and fibers in conventional activated sludge process and advanced MBR technology. Water Res. 2018;133:236–246. doi: 10.1016/j.watres.2018.01.049. [DOI] [PubMed] [Google Scholar]

- Li L., Su L., Cai H., Rochman C.M., Li Q., Kolandhasamy P., Shi H. The uptake of microfibers by freshwater asian clams (Corbicula fluminea) varies based upon physicochemical properties. Chemosphere. 2019;221:107–114. doi: 10.1016/j.chemosphere.2019.01.024. [DOI] [PubMed] [Google Scholar]

- Lin Y., Alias H., Luo X., Hu Z., Wong L.P. Uncovering physical and attitudinal barriers to adherence to precautions for preventing the transmission of COVID-19 and anxiety level of people in Wuhan: 2 months after the lockdown. J. Acad. Consult Psych. 2020;62:201–210. doi: 10.1016/j.psym.2020.09.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ma J., Chen F., Xu H., Jiang H., Liu J., Li P., et al. Face masks as a source of nanoplastics and microplastics in the environment: quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021;288 doi: 10.1016/j.envpol.2021.117748. [DOI] [PubMed] [Google Scholar]

- Maharana D., Saha M., Dar J.Y., Rathore C., Sreepada R.A., Xu X.R., Li H.X. Assessment of micro and macroplastics along the west coast of India: abundance, distribution, polymer type and toxicity. Chemosphere. 2020;246 doi: 10.1016/j.chemosphere.2019.125708. [DOI] [PubMed] [Google Scholar]

- McQueen R., Batcheller J.C., Moran L.J., Zhang H., Hooper P.M. Reducing laundering frequency to prolong the life of denim jeans. Int. J. Consum. Stud. 2017;41:36–45. [Google Scholar]

- METI . 2020. Ministry of Economy, Trade and Industry. [Google Scholar]

- Napper I.E., Thompson R.C. Release of synthetic microplastic plastic fibres from domestic washing machines: effects of fabric type and washing conditions. Mar. Pollut. Bull. 2016;112:39–45. doi: 10.1016/j.marpolbul.2016.09.025. [DOI] [PubMed] [Google Scholar]

- O'Brien S., Okoffo E.D., O'Brien J.W., Ribeiro F., Wang X., Wright S.L., Thomas K.V. Airborne emissions of microplastic fibres from domestic laundry dryers. Sci. Total Environ. 2020;747 doi: 10.1016/j.scitotenv.2020.141175. [DOI] [PubMed] [Google Scholar]

- Parolini M., Antonioli D., Borgogno F., Gibellino M.C., Fresta J., Albonico C., De Felice B., Canuto S., Concedi D., Romani A., Rosio E., Gianotti V., Laus M., Ambrosini R., Cavallo R. Microplastic contamination in snow from Western italian Alps. Int. J. Environ. Res. Public Health. 2021;18:768. doi: 10.3390/ijerph18020768. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Parolini M., De Felice B., Lamonica C., Cioccarelli S., Crosta A., Diolaiuti G., et al. Macroplastics contamination on glaciers from Italian Central-Western Alps. Environ. Adv. 2021;5 [Google Scholar]

- Piehl S., Leibner A., Löder M.G., Dris R., Bogner C., Laforsch C. Identification and quantification of macro-and microplastics on an agricultural farmland. Sci. Rep. 2018;8:1–9. doi: 10.1038/s41598-018-36172-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rakib M.R.J., De-la-Torre G.E., Pizarro-Ortega C.I., Dioses-Salinas D.C., Al-Nahian S. Personal protective equipment (PPE) pollution driven by the COVID-19 pandemic in Cox's Bazar, the longest natural beach in the world. Mar. Pollut. Bull. 2021;169 doi: 10.1016/j.marpolbul.2021.112497. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rebelein A., Int-Veen I., Kammann U., Scharsack J.P. Microplastic fibers—underestimated threat to aquatic organisms? Sci. Total Environ. 2021 doi: 10.1016/j.scitotenv.2021.146045. [DOI] [PubMed] [Google Scholar]

- Saliu F., Veronelli M., Raguso C., Barana D., Galli P., Lasagni M. The release process of microfibers: from surgical face masks into the marine environment. Environ. Adv. 2021;4 [Google Scholar]

- Sanchez-Vidal A., Thompson R.C., Canals M., de Haan W.P. The imprint of microfibres in southern European deep seas. PLoS One. 2018;13(11) doi: 10.1371/journal.pone.0207033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schindelin J., Arganda-Carreras I., Frise E., Kaynig V., Longair M., Pietzsch T., Cardona A. Fiji: an open-source platform for biological-image analysis. Nat. Methods. 2012;9:676–682. doi: 10.1038/nmeth.2019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Setyorini L., Michler-Kozma D., Sures B., Gabel F. Transfer and effects of PET microfibers in Chironomus riparius. Sci. Total Environ. 2021;757 doi: 10.1016/j.scitotenv.2020.143735. [DOI] [PubMed] [Google Scholar]

- Shen M., Zeng Z., Song B., Yi H., Hu T., Zhang Y., et al. Neglected microplastics pollution in global COVID-19: disposable surgical masks. Sci. Total Environ. 2021;148130 doi: 10.1016/j.scitotenv.2021.148130. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shruti V.C., Pérez-Guevara F., Elizalde-Martínez I., Kutralam-Muniasamy G. Reusable masks for COVID-19: a missing piece of the microplastic problem during the global health crisis. Mar. Pollut. Bull. 2020;161 doi: 10.1016/j.marpolbul.2020.111777. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shruti V.C., Pérez-Guevara F., Elizalde-Martínez I., Kutralam-Muniasamy G. Reusable masks for COVID-19: a missing piece of the microplastic problem during the global health crisis. Mar. Pollut. Bull. 2020;161 doi: 10.1016/j.marpolbul.2020.111777. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sillanpää M., Sainio P. Release of polyester and cotton fibers from textiles in machine washings. Environ. Sci. Pollut. Res. 2017;24:19313–19321. doi: 10.1007/s11356-017-9621-1. [DOI] [PubMed] [Google Scholar]

- Stanton T., Johnson M., Nathanail P., Gomes R.L., Needham T., Burson A. Exploring the efficacy of Nile red in microplastic quantification: a costaining approach. Environ. Sci. Technol. Lett. 2019;6:606–611. [Google Scholar]

- Suaria G., Achtypi A., Perold V., Lee J.R., Pierucci A., Bornman T.G., Ryan P.G. Microfibers in oceanic surface waters: a global characterization. Sci. Adv. 2020;6:eaay8493. doi: 10.1126/sciadv.aay8493. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sullivan G.L., Delgado-Gallardo J., Watson T.M., Sarp S. An investigation into the leaching of micro and nano particles and chemical pollutants from disposable face masks-linked to the COVID-19 pandemic. Water Res. 2021;196 doi: 10.1016/j.watres.2021.117033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Talvitie J., Heinonen M., Pääkkönen J.P., Vahtera E., Mikola A., Setälä O., Vahala R. Do wastewater treatment plants act as a potential point source of microplastics? Preliminary study in the coastal Gulf of Finland, Baltic Sea. Water Sci. Technol. 2015;72:1495–1504. doi: 10.2166/wst.2015.360. [DOI] [PubMed] [Google Scholar]

- Talvitie J., Mikola A., Setälä O., Heinonen M., Koistinen A. How well is microlitter purified from wastewater? A detailed study on the stepwise removal of microlitter in a tertiary level wastewater treatment plant. Water Res. 2017;109:164–172. doi: 10.1016/j.watres.2016.11.046. [DOI] [PubMed] [Google Scholar]

- Vasil A. Corporate Knights; Toronto: 2021. Curing the Plastic Pollution Pandemic. [Google Scholar]

- Veerasingam S., Saha M., Suneel V., Vethamony P., Rodrigues A.C., Bhattacharyya S., Naik B.G. Characteristics, seasonal distribution and surface degradation features of microplastic pellets along the Goa coast, India. Chemosphere. 2016;159:496–505. doi: 10.1016/j.chemosphere.2016.06.056. [DOI] [PubMed] [Google Scholar]

- Vidyasakar A., Neelavannan K., Krishnakumar S., Prabaharan G., Priyanka T.S.A., Magesh N.S., Srinivasalu S. Macrodebris and microplastic distribution in the beaches of rameswaram Coral Island, gulf of Mannar, southeast coast of India: a first report. Mar. Pollut. Bull. 2018;137:610–616. doi: 10.1016/j.marpolbul.2018.11.007. [DOI] [PubMed] [Google Scholar]

- Wang Z., An C., Chen X., Lee K., Zhang B., Feng Q. Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. J. Hazard. Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.126036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- WHO . 2020. WHO Shortage of Personal Protective Equipment Endangering Health Workers Worldwide. [Google Scholar]

- Winton D.J., Anderson L.G., Rocliffe S., Loiselle S. Macroplastic pollution in freshwater environments: focusing public and policy action. Sci. Total Environ. 2020;704 doi: 10.1016/j.scitotenv.2019.135242. [DOI] [PubMed] [Google Scholar]

- Wu Y.C., Chen C.S., Chan Y.J. The outbreak of COVID-19: an overview. Chin. Med. J. 2020;83:217. doi: 10.1097/JCMA.0000000000000270. [DOI] [PMC free article] [PubMed] [Google Scholar]

- https://www.grandviewresearch.com/

- Zafar M.R., Shah M.A. Fingerprint authentication and security risks in smart devices. Advancing Technology for Humanity. 2016 [Google Scholar]

- Zambrano M.C., Pawlak J.J., Daystar J., Ankeny M., Venditti R.A. Impact of dyes and finishes on the aquatic biodegradability of cotton textile fibers and microfibers released on laundering clothes: correlations between enzyme adsorption and activity and biodegradation rates. Mar. Pollut. Bull. 2021;165 doi: 10.1016/j.marpolbul.2021.112030. [DOI] [PubMed] [Google Scholar]

- Zambrano M.C., Pawlak J.J., Daystar J., Ankeny M., Cheng J.J., Venditti R.A. Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar. Pollut. Bull. 2019;142:394–407. doi: 10.1016/j.marpolbul.2019.02.062. [DOI] [PubMed] [Google Scholar]

- Zambrano M.C., Pawlak J.J., Daystar J., Ankeny M., Venditti R.A. Impact of dyes and finishes on the microfibers released on the laundering of cotton knitted fabrics. Environ. Pollut. 2020;272 doi: 10.1016/j.envpol.2020.115998. [DOI] [PubMed] [Google Scholar]

- Ziajahromi S., Neale P.A., Rintoul L., Leusch F.D.L. Wastewater treatment plants as a pathway for microplastics: development of a new approach to sample wastewater-based microplastics. Water Res. 2017;112:93–99. doi: 10.1016/j.watres.2017.01.042. [DOI] [PubMed] [Google Scholar]