Abstract

The field of tissue engineering has advanced over the last decade, but the largest impact on human health should be achieved with the transition of engineered solid organs to the clinic. The number of patients suffering from solid organ disease continues to increase, with over 100,000 patients on the US national waitlist and approximately 730,000 deaths in the United States resulting from end-stage organ disease annually. While flat, tubular, and hollow non-tubular engineered organs have already been implanted in patients, in vitro formation of a fully functional solid organ at a translatable scale has not yet been achieved. Thus, one major goal is to bioengineer complex, solid organs for transplantation, composed of patient-specific cells. Among the myriad of approaches attempted to engineer solid organs, 3D bioprinting offers unmatched potential. This review highlights the structural complexity which must be engineered at nano-, micro-, and mesostructural scales to enable organ function. We showcase key advances in bioprinting solid organs with complex vascular networks and functioning microstructures, advances in biomaterials science that have enabled this progress, the regulatory hurdles the field has yet to overcome, and cutting edge technologies that bring us closer to the promise of engineered solid organs.

Graphical Abstract

1. Introduction

The field of tissue engineering is maturing toward creating opportunities that provide complex tissues and organs to impact human health more significantly. The total patients suffering from end-stage solid organ disease continues to increase, with a patient being added to the national transplant waiting list every ten minutes. Whole-organ transplantation remains the gold standard for treatment of end-stage organ disease. However, only select patients receive functional organ transplants, and it is exceptionally difficult to obtain a histocompatibility, requiring permanent use of immunosuppressive agents. Despite the herculean efforts of UNOS and transplant centers across the country to provide over 30,000 organ transplants per year, over 100,000 patients on average with end-stage organ disease remain on the national waitlist year-over-year1–3. Furthermore, end-stage organ disease is responsible for approximately 730,000 US deaths annually4.

To address these, and other unmet clinical needs, regenerative medicine has made major strides over the last decade with 1,028 clinical trials underway by the end of 2018, and 41 specific to tissue engineering5.These efforts have led to a significant need to improve reproducibility, increase the specificity of cell placement, improve manufacturing techniques, and engineer more extensive, human-like tissue6. Engineered flat, tubular, and hollow organs have already been successfully implanted in patients, but in vitro formation of solid organs has not yet been achieved. Thus, a major goal of regenerative medicine is to bioengineer complex, solid organs for transplantation composed patient-specific cells7.

Among the myriad of techniques attempted to engineer solid organs, 3D bioprinting today offers the best potential. Bioprinting is a powerful resource in tissue engineering and has a role to play in advancing the fabrication of solid, viable organs. 3D printing utilizes computer-controlled systems to deposit biomaterials (with or without cells) into precise geometries to create anatomically correct structures8. These devices can print cell aggregates, cells encapsulated in hydrogels, supported by cell-free polymer structures9. Bioprinting builds upon the reproducibility seen in mold casting techniques by improving the ability to layer and interweave constructs with improved control of the placement and specificity of bioink and cell distribution10. Cells used in constructs may be isolated and expanded from patient-specific biopsies, allowing for autologous implants11. 3D reconstruction images from MRI may also allow for patient-specific implants.

Even with significant advances in bioprinting machinery, engineers aspiring to fabricate solid organs face challenges. The cell and structural diversity within solid organs, coupled with a constant demand for nutrients and oxygen from perfusable vasculature, adds layers of complexity to organ engineering12. In this review, we address the challenges presented by whole organ bioprinting and opportunities for growth within the field. First, we will present an overview of organ anatomy by structural resolution: Macrostructure, Mesostructure, Microstructure, and Nanostructure. Next, we will review how tissue engineers seek to overcome the challenge of organ microstructure engineering by addressing: 1) Mesostructure: vascularity is crucial to organ integration, 2) Microstructure: advances in engineering organ-specific structures to enable organ function, and 3) Nanostructure: biomaterials promote cellular self-assembly and provide structural support. The review will conclude with a description of the most recent advances for rapid microstructural printing, detailed printing, post-printing organ maturation and assessment, manufacturing scale-up, and regulatory considerations.

2. Organ structure and classification

2.1. Organ anatomy by structural resolution

The great challenge in solid organ printing is the complexity of structural elements, ranging from macrostructural shape to nanostructural detail (See Figure 1). As an example, the kidney, macrostructurally (resolution >1cm), is a bean-shaped organ with three major tubular structures connecting to the body’s vascular supply and renal network; the renal artery, the renal vein, and the ureter. Once dissected further, mesostructured elements (1mm-1cm) help transport key products to and from the functional kidney units: the renal pelvis as the collecting place for urea deposited by minor and major calyxes produced within renal pyramids of the renal medulla, with a clear separation from the renal cortex; interlobular and arcuate blood vessels stemming from and depositing into the renal artery and vein supply nutrients. On the microstructural level (1μm-1mm) are a network of complex structures which make up the nephron, composed of the proximal and distal convoluted tubules, the loop of Henle, and the collecting duct, the known functional unit of the kidney; and a complex capillary network composed of the glomerulus, afferent, and efferent arterioles13, 14. Their unique cellular composition can further categorize each of these microstructural units. Finally, the kidney nanostructure (1nm -1μm), can be characterized, with its unique extracellular matrix (ECM) components, diffusion channels, and enzymes.

Figure 1. Organ Anatomy by Structural Resolution.

Organ complexity can be arranged into 4 primary structural resolutions, macrostructure, mesostructure, microstructure, and nanostructure. As an example, the kidney macrostructurally (resolution >1cm), is an organ with three major tubular structures connecting to the body’s vascular supply and renal network. Mesostructural elements (1mm-1cm) help transport key products to and from the functional kidney units. On the microstructural level (1μm-1mm) are a network of complex structures that make up the kidney’s functional unit: the nephron made up of the proximal and distal convoluted tubules, the loop of Henle, and the collecting duct. Finally, the kidney nanostructure (1nm -1μm), can be characterized, with its unique extracellular matrix (ECM) components, diffusion channels, and enzymes (the SEM image is reprinted under creative commons license from reference15. Copyright 2018, Springer Nature).

In embryonic development, the body takes a nano to a macro approach to organ formation16. From a single fertilized egg, the entire human body develops. Cells differentiate and use their inherent machinery to form the nanostructural organ scaffold. Capillary networks develop with angiogenesis providing essential nutrients and growth factors. Eventually, meso- and macrostructural anatomy can be recognized as the organ prepares to perform its intended function. Thus, human development takes a Nano to Macro approach to organ development.

Biomaterials that closely mimic organ nanostructure can be employed to replicate the Nano- to Macro- approach for human organ development17. Providing essential ques can help guide cellular assembly into the functional microstructural elements of human organs. However, proper biomaterial placement is necessary to direct cellular self-assembly18. Current bioprinting capabilities rely on the mechanical placement of cells that can produce low-resolution structures (>1cm) down to very high-resolution 20μm (LIFT)19. However, even the highest resolution printing methods are limited in replication of the microstructural anatomy with high fidelity. Bioprinters can replicate Macro- and Meso-structural resolution by utilizing the CAD/CAM coding from CT/MRI images to recreate normal anatomy. In essence, bioprinting takes a Macro to Micro approach to organ development. To fully realize the potential for whole organ bioprinting, a Macro to Micro (bioprinting) and a Nano to Meso (biomaterials/cell self-assembly) approach must work in harmony.

2.2. Macrostructural organ classification

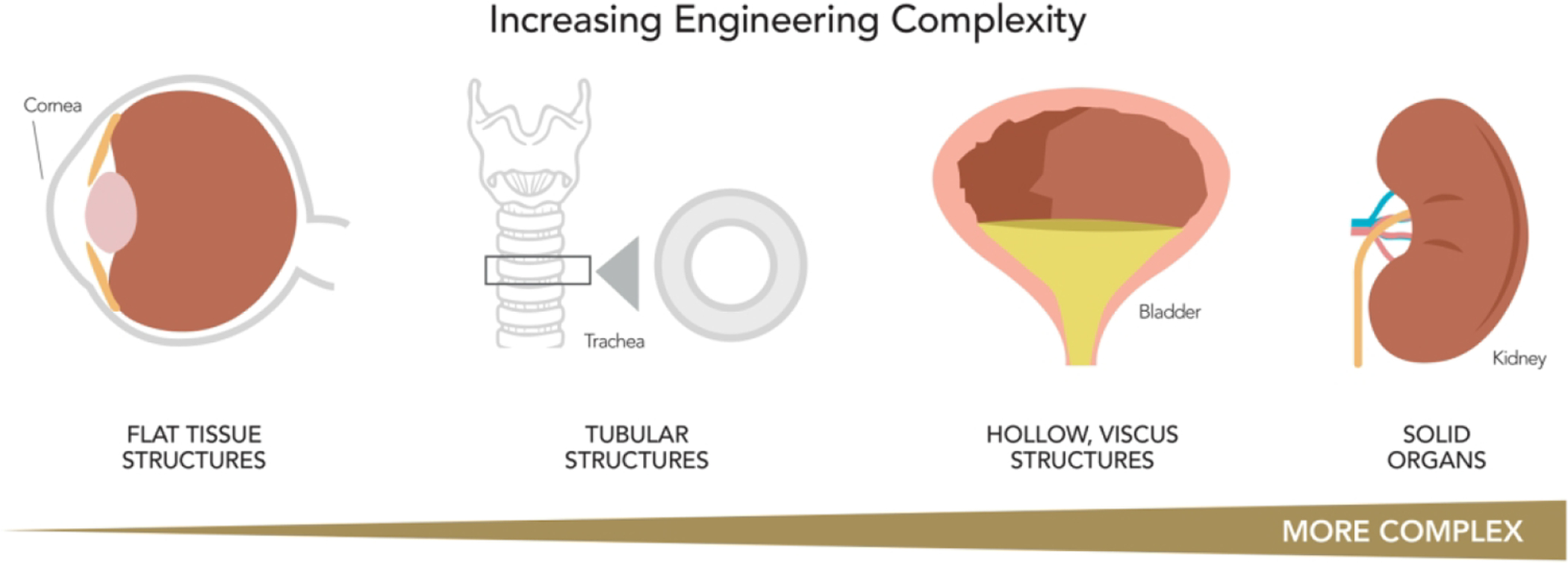

There are four general levels of tissues and organ macrostructural complexity; flat tissue, such as the skin; tubular structures, such as blood vessels; hollow structures, such as the bladder; and solid organs, such as the kidney (See Figure 2). Tissue engineering complexity generally increases along this continuum as increased metabolic functions and structural requirements are needed for targeted for repair of the tissue or organ20.

Figure 2. Organ Anatomy by Structural Complexity.

There are four general levels of tissues and organ macrostructural complexity: flat tissue structures, such as the skin or cornea; tubular structures, such as blood vessels; hollow structures, such as the bladder; and solid organs, such as the kidney. Tissue engineering complexity generally increases along this continuum as increased metabolic functions and structural requirements are needed for targeted for repair of the tissue or organ (adapted with permission from ref7. Copyright 2012 Science Translational Medicine).

First, flat tissues are composed of cell sheets stacked in multiple layers. Skin is one example of flat tissue. Skin is the largest organ in the body, and provides an essential barrier to provide protection, both physically and immunologically from the outside world. Due to the relative structural simplicity of skin, it was one of the first tissue engineering targets using autologous cells from patients21, demonstrating the feasibility for human cell isolation, culture, and re-implantation. Furthermore, flat structures are relatively thin, allowing for nutrient diffusion without complete vascularization. Nearly all the structural elements of the skin are reproducible through bioprinting, however further work must be done to replicate the delicate microstructures such as hair follicles and glands22.

Second, tubular organs are composed of cell sheets formed into circular, bilayer tissues. Blood vessels are a natural example of tubular structures, with endothelial cells forming an inner layer and functional barrier; and smooth muscle and connective tissue form an outer layer to provide support23. Similar to flat tissues, the relatively thin wall thickness of tubular tissue enables nutrient diffusion and oxygen exchange. Thus, large diameter blood vessels are relatively easy to manufacture, while microstructural arterioles, capillaries, and venules remain a challenge.

Third, hollow organs consist of epithelial cells forming the inner layer of surrounded by smooth muscle forming an outer layer of with or without connective tissue. The bladder is a clear example of a hollow organ. Compared with the flat and tubular structures, the bladder has higher metabolic requirements, functional parameters, and complex interactions with other organs. Even with an organ of this complexity, tissue engineers have regenerated bladder tissue using autologously derived urothelial and smooth muscle cells24. These and other studies have demonstrated that the macro- and meso-structural elements of hollow organs can be replicated. However, recreating organ microstructure, including glands and vascularity, remains a challenge.

Finally, solid organs such as the kidney, liver, heart, and pancreas are the most complex. The goal of fabricating solid organs presents major hurdles due to the developmental process and tissue complexity of these organs. Whole organs require mature vascular networks with extensive branching for cells to remain viable. Whole organs also require precise organization of multiple cell types. To this end, present endeavors focus on developing biomaterial-based approaches and the use of 3D printing methods25, 26.

2.3. Critical opportunities for development: mesostructure, microstructure, nanostructure

As bioprinting technology has enabled macrostructural (>1cm) and mesostructural (1mm-1cm) mimicry with high fidelity, there are vital areas for further development. Tunable biomaterials that closely replicate the nanostructure ECM of native organs are required to replicate organ nanostructure and provide mechanical stability for maturing organs. Improvements in vascular network bioprinting will be crucial for the integration and delivery of oxygen and nutrients27. Finally, organ-specific microstructures essential for organ function must form by directing the inherent ability of cells to self-assemble with guidance from growth factors and biophysical cues.

3. Biomaterials promote cellular self-assembly and provide structural support

Biomaterials are crucial to achieving the ultimate goal of whole organ bioprinting (see table 1). Tunable biomaterials aim to replicate extracellular matrix properties and are designed to promote cell attachment, proliferation, and self-assembly into microstructures.

Table 1.

Summary of hydrogel formulation by bioink, year, and target organ

| Bioink | Formulation | Crosslinking Mechanism | Bioprinting Method | Target Organ | Structural Elements Targeted | Year | Reference |

|---|---|---|---|---|---|---|---|

| Agarose | agarose 1% collagen .8%, agarose 1% chitosan .33% | Covalent and Physical | Extrusion | General | Microstructure and Nanostructure | 2015 | 28 |

| 3% agarose with 3% alginate printed into a gluorcarbon support liquid | Physical | Extrusion | Vascular | Mesostructure (Blood vessel) | 2013 | 29 | |

| 3% agarose | Physical | Extrusion | Vascular | Mesostructure (blood vessel) | 2013 | 30 | |

| Alginate | 3% Alginate | CaCl2 | Extrusion | Liver | Microstructure (Liver) | 2017 | 31 |

| 1.5% RGD-Coupled Alginate | CaCl2 and Sodium Borohydride and barium chloride | Microvalve | Liver | Microstructure (Liver) | 2015 | 32 | |

| 4% Alginate, 5% Gelatin | CaC12 | Extrusion | Pancreatic | Microstructure (Islet of Langerhans) | 2015 | 33 | |

| .06 g/mL Gelatin, .05 g/mL Alginate | CaC12 | Extrusion | Cardiac | Mesostructure (Heart Valve) | 2013 | 34 | |

| 7.5% Aglinate | CaC12 | Extrusion | Cardiac | Microstructure (Cardiac Muscle) | 2012 | 35 | |

| Cell aggregate | Media | None | Microvalve | Kidney | Microstructure | 2013 | 36 |

| Agarose | Physical | Extrusion | Neuro | Mesostructure | 2013 | 37 | |

| Agarose | Physical | Extrusion | Vascular | Mesostructure | 2009 | 38 | |

| Media | None | Extrusion | Cardiac | Microstructure | 2008 | 39 | |

| Collagen | 890uL type I collagen gel, 60uL sodium hydroxide, 250 uL sodium bicarbonate | Physical | Extrusion | Lymphatic | Macrostructure, Microstructure, and Nanostructure (Thyroid Gland) | 2017 | 40 |

| .2% Collagen | NaHCO3 | Microvalve | Bladder | Mesostructure | 2010 | 41 | |

| Decellularized matrix | Liver ECM, Cardiac ECM, Skeletal Muscle ECM | Physical | Extrusion | Liver | Nanostructure | 2015 | 42 |

| Cardiac ECM, | Physical | Extrusion | Heart | Microstructure and Nanostructure | 2014 | 43 | |

| Fibrin | 15% Gelatin and Fibrin 50mg/mL | Thrombin and CaCl2 | Extrusion | Kidney | Microstructure | 2016 | 44 |

| elatin (35~45 mg/ml), fibrinogen (20–30 mg/ml), HA (3 mg/ml) and glycerol (10% v/v) | Thrombin | Extrusion | Muscle | Macrostructure (Ear) Microstructure (Mu scle Fibers) | 2016 | 45 | |

| 10mg/mL Fibrinogen | Thrombin | Extrusion | Pancreatic | Mesostructure and Microstructure | 2016 | 46 | |

| Gelatin | HyStem Gelatin and HA | Thiol | Extrusion | Cardiac | Microstructure and Nanostructure | 2015 | 47 |

| Gellangum | .5% RGD-Gellan Gum | CaCL2 | Extrusion | Neural | Mesostructure and Microstructure | 2015 | 48 |

| Hyaluronic Acid | HAMa | Photo-Crosslink | Extrusion | Cardiac | Mesostructure and Microstructure | 2014 | 49 |

| GelMA HAMa | Photo-Crosslink | Extrusion | Vascular | Mesostructure | 2010 | 50 | |

| Matrigel | Matrigel | Physical | Inkjet | Lung | Microstructure | 2015 | 51 |

| 3/1 Matrigel to Alginate | Physical | Extrusion | Vascular | Microstructure | 2014 | 52 | |

| Media | Spheroid | Physical | Needle Array | Cardiac | Microstructure | 2017 | 53 |

| Spheroid | Physical | Needle Array | Liver | Microstructure | 2017 | 54 | |

| PBS and C2C12 Myoblasts | Physical | Inkjet | Muscle | Microstructure (myotube) | 2013 | 55 | |

| Polyethylene glycol | 2% Thyolate HA, 4% TetraPA | PEGDA | Extrusion | Vascular | Mesostructure | 2010 | 50 |

| Polyurethane and Matrigel | Physical | Laser | Cardiac | Mesostructure | 2011 | 56 |

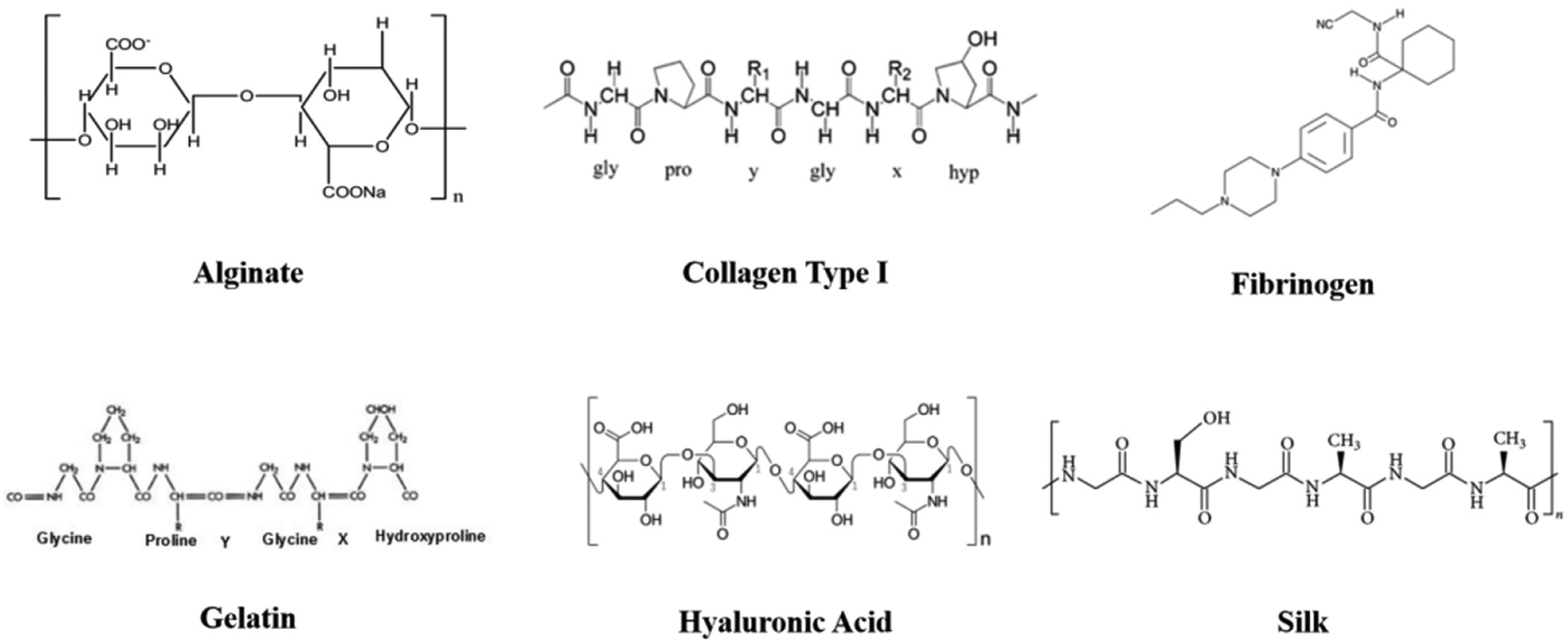

3.1. Naturally derived materials

There is an abundance of natural polymers available for use in biofabrication (see figure 3). These polymers may be utilized independently with their natural structure or may be chemically modified to achieve further tunable hydrogel characteristics. Furthermore, these materials can be combined to utilize the favorable elements inherent in each.

Figure 3.

Natural Polymers Chemical Structure.

Alginate is a natural polymer from brown algae that has been used extensively for biomedical applications57. Alginate structures can gel through multiple crosslinking mechanisms, including ionic crosslinking, covalent crosslinking, and thermal gelation, with the most common activator being divalent cations such as Ca2+. A 7.5% alginate bioink was used to engineer cardiac tissue from human cardiac progenitor cells35. By using an extrusion-based bioprinting approach, they were able to distribute the cells throughout the construct homogeneously and saw increased expression of cardiac transcription factors (NKx2.5, Gata-4, and Mef-2c) and Troponin T after 3D culture. It is also common for alginate to be coupled with RGD to improve its mechanical properties. This form of alginate has been used to fabricate hypertrophic cartilage58. The RGD-Alginate printed with polycaprolactone fibers produced a 350-fold increase in the compressive modulus of the construct. When placed in vivo, the reinforced cartilaginous template allowed for vascularized bone containing trabecular-like endochondral bone to form. Another way to improve alginate hydrogel properties is to add other natural and synthetic polymers to form specialized composite hydrogels. Investigators used a composite gel of glycosylated alginate, collagen, and PVLA to develop liver microstructures. PVLA contains galactose chains that are known to increase ASGPR expression by hepatocytes, which in turn improves adhesion cell adhesion. However, since PVLA is a hydrophobic polymer, it could not be directly used with hydrophilic alginate hydrogel. Thus, galactosylate alginate was synthesized to control cell polarity and promote hepatocyte adhesion59.

Collagen is the most common protein in the human body, and collagen-based biomaterials have been extensively studied and applied over the past decade60. It is biodegradable, biocompatible, and readily available. It makes up approximately 25% of the total dry weight of humans. Fibroblasts produce the majority of collagen in connective tissue with 29 different currently known forms. Type I collagen is the common form uses in tissue engineering and represents 90% of the total collagen content in the human body61. Collagen is commonly isolated in two primary forms. First, decellularized organs retain the collagen matrix with the original tissue shape, which may be used for direct cell seeding62. Alternatively, collagen can be extracted, purified, and polymerized to form functional scaffolds. The crosslinking mechanism for collagen relies on amine and carboxyl group modification of collagen molecules to allow for covalent bonds. This can be done through physical crosslinking (UV or thermal), or Chemical (aldehydes, carbodiimide, isocyanate) and enzymatic (transglutaminases) reactions. A collagen hydrogel was used to encapsulate bladder smooth muscle cells (SMC) for bioprinting41. The investigators found that encapsulated SMCs proliferated within the fabricated collagen building blocks, which were then assembled to create a SMC patch. The patch formed a 3D tissue-like construct over 50 day of culture, and was found to be histologically similar to native rat bladder. Another group formed a composite hydrogel of type I collagen, sodium hydroxide, and sodium bicarbonate, which they used to fabricate a functional vascularized thyroid gland40. First, thyroid, allantoic spheroids were generated, which were then encapsulated in collagen hydrogel and deposited in close association by a 3D bioprinter. During culture, spheroids placed near each other fused into a single structure, and endothelial cells from the allantoic spheroid vascularized the thyroid spheroid, while thyroid spheroid epithelial cells formed follicles. A capillary network formed around the follicular cells, similar to what is seen during in utero thyroid development. The cultured bioprinter construct was functional in vivo after being grafted under the kidney capsule of hypothyroid mice, and were able to normalize body temperature and blood thyroxine levels.

Fibrinogen is a natural monomer that reacts with thrombin to form the biopolymer fibrin63. Fibrin is a crucial protein element of the blood coagulation cascade. In this form, fibrinogen is converted to fibrin by a thrombin mediated cleavage of fibrinopeptide-a, which causes a conformational change and exposure of polymerization sites. Fibrin monomers then self-associate to form insoluble fibrin. Further covalent bonding produces a stable fibrin network that is resistant to protease degradation. However, a commonly cited weakness of fibrin hydrogels is its relatively weak rheological properties64. Even so, fibrinogen has been used extensively for engineering adipose, cartilage, bone, cardiac, liver, nervous, ocular, and skin tissue engineering. Song and Millman created a microporous device of for β cell transplantation with polylactic acid to house stem cell-derived β cell clusters with a degradable fibrin gel46, 65. In order to load and secure SC-β cell clusters within the 3D-printed devices, SC-β cell clusters were suspended in a fibrinogen solution and inserted into the device. Thrombin solution was immediately added into the cellular suspension, which crosslinked rapidly. The devices with cell suspension were then implanted into immunocompromised mice. Following glucose injection, they found a significant increase in human insulin, indicating that the transplanted grafts were functional and glucose-responsive. Our group has utilized a composite fibrin hydrogel of fibrin, gelatin, HA, and glycerol. Kang et al. used this composite gel to demonstrate the capabilities of our integrated tissue organ printing (ITOP) platform by fabricating cartilage, complex models of the mandible and calvarial bone, and skeletal muscle45. The shape of the tissue constructs was made using clinical imaging data that was converted into a computer CAD/CAM model, which was then translated a code to control the printer nozzles pneumatic dispenses and motions to distribute the bioink in precise locations. They further utilized polycaprolactone (PCL) to confer mechanical strength to tissue constructs. The ITOP printer allowed for fabrication of micro channels composed of a porous lattice network design to facilitate diffusion of nutrients and oxygen. The bioprinted ear, bone, and muscle constructs showed evidence of vascularization without necrosis when implanted in vivo, and the muscle constructs formed neuromuscular junctions.

Gelatin is a natural polymer that is highly advantageous as a biomaterial for organ printing due to its off-the-shelf availability, low immunogenicity, cell-adhesive structure, biodegradability, and low cost66. It is manufactured by acid or alkaline hydrolysis of animal collagen, and is generally-regarded as Safe GRAS by the FDS. Gelatin molecules contain repeating sequences of Gly-X–Y, where X and Y are most often proline (Pro) and hydroxyproline (Hypro) amino acids67. Gelatin is often used in combination with other biomaterials to improve cell adhesion, spreading, and proliferation. Investigators have employed a gelatin/hyaluronic acid composite bioink to produce a cardiac patch47. In their design, human cardiac myoprogenitor cells were encapsulated in hyaluronic acid/gelatin composite gel at a density of 30 × 106 cells/ml. There construct was made of six perpendicularly printed layers, with an overall thickness of 400 μm. The printed construct was transplanted in a mouse model of myocardial infarction. The applied patch resulted in improved cardiac performance, and reduced scarred remodeling on both MRI and histology. The matrix-supported long-term survival and in vivo engraftment of the human cardiomyocytes, which continued to differentiate into cardiac and vascular structures over a 4-weeks.

Hyaluronic Acid is a glycosaminoglycan consisting of repeating units of D-glucuronic Aid and N-acetyl D-Glucosamine68. It is found in the ECM of all tissues but is highly concentrated in mechanically active tissues including the vocal folds, cartilage, and dermis. Hyaluronic acid is non-allergic and non-inflammatory; however, it is quickly degraded by reactive oxygen or nitrogen species and hyaluronidases69. Hyaluronan has been shown to promote cell invasiveness and epithelial-mesenchymal transition70. Its breakdown products have further been shown to stimulate angiogenesis, a crucial component of successful tissue-engineered organs71. It is highly viscous and has a strong ability to retain water. Due to readily available reactive functional groups, HA can be chemically modified to be biocompatible for use in tissue engineering. One common form of chemically modified hyaluronic acid is methacrylated hyaluronic acid (HAMA), which improves tissue formation and enhances printability. HAMA has be added to thermosensitive hydrogels composed of methacrylated poly [N-(2-hydroxypropyl)] methacrylamide mono/dilactate]72. This was used on for cartilage engineering and demonstrated a dose-dependent effect of HAMA concentration on cartilage matrix synthesis by chondrocytes. The investigators also found that Glycosaminoglycan and type II collagen content increased with intermediate HAMA concentrations. They also found that relatively high HAMA concentration greater than 1% formed more fibrocartilage.

Silk is a macromolecular protein polymer found in nature that is synthesized by lepidopteran larvae using epithelial cells of specialized glands and ultimately spun into fibers73. The spun fiber is made of a central protein known as fibroin that is encased by a glue-like coating sericin. It has been shown that the bio-incompatibility of silk is due to the sericin glue and that sericin free fibroin fiber has excellent biocompatibility74. The copolymer organization of silk fibroin with hydrophobic and hydrophilic blocks combine to give a highly elastic and mechanically robust polymer. Furthermore, its degradation kinetics are tunable75. Silk has more recently been used in composite hydrogels, particularly in cartilage bioprinting. Investigators developed clinically relevant cartilage tissue by bioprinting human cartilage tissue-derived mesenchymal progenitor cells encapsulated in a silk fibroin-gelatin composite bioink76. The bioink gelation was induced by enzymatic crosslinking with mushroom tyrosinase and physical crosslinking by sonication. Optimization of the rheology of their bioink, resulted in maximum cell viability and ultimately lineage differentiation of the mesenchymal progenitor cells.

3.2. Synthetic polymers

Synthetic polymers are widely used in biofabrication applications (see figure 4). The significant advantage of synthetic polymers is their flexibility for chemical modification to allow for tunable hydrogel characteristics. Furthermore, these materials can be combined to utilize favorable elements inherent to each material.

Figure 4.

Synthetic Polymers Chemical Structure.

Agarose is a biocompatible polysaccharide extracted from marine red algae, which contains repeating of agarobiose77. It is thermoreversible, gelling at 30–40c and can be easily dissolved in hot water or DMSA, and the presence of oxygen and hydrogen supports its self-gelling behavior. Investigators have encapsulated human mesenchymal stem cells and MG-63 cells into agarose hydrogels supported in high-density fluorocarbon, and printed to form structures30. The fidelity of the printed constructs improved by performing the procedure in the fluorocarbon shape, while also adding stability during the procedure and maintaining cell viability. In subsequent work, agarose coupled with collagen and chitosan was used to determine if hydrogels stiffness impacted cell differentiation28. The human MSCs, encapsulated chitosan–agarose and type I collagen bioinks were differentiated toward osteoblasts and adipocytes. Osteogenic differentiation occurred more often in soft substrates that were collagen-rich, while adipogenic differentiation mostly occurred in stiff matrices that were agarose-rich.

Gelatin methacryloyl has been used extensively as result of its tunable physical properties and promising biological characteristics78. When printed in 3D, hydrogels strictly retain the naïve extracellular matrix with cells attaching and MMP peptide motifs. GelMA is crosslinked by photoinitiated radical polymerization under UV light exposure with photoinitiation. It improves upon its gelatin only counterpart, in that it has better solubility and less antigenicity. Hybrid forms of GelMA include GelMA with carbon nanotubes, graphene oxide, inorganic nanoparticles, and other biopolymers and synthetic polymers have been documented. A biphasic artificial vascularized bone construct with regional bioactive factors using a GelMA hydrogel was recently reported79. The construct was fabricated on a dual bioprinting platform comprised of both SLA 3D and FDM 3D bioprinter, with alternating deposition of biodegradable polylactide filament and cell-laden GelMa. To promote osteogenesis and angiogenesis, a p regional immobilization of bone morphogenetic protein 2 (BMP2) and vascular endothelial growth factor (VEGF) peptides was introduced. This resulted in a highly osteogenic bone construct with organized vascular networks. GelMA/HAMA composite hydrogel was used to generate a clinically translatable bioscaffold for cartilage repair. For improved clinical application, a handheld 3D printer called a “Biopen” was developed to allow for freeform biofabrication and scaffold delivery for chondral repair, with both high cell viability and structural stiffness80. The system was composed a co-axial hydrogel containing infrapatellar adipose-derived MSCs encapsulated in a GelMA-HAMA composite hydrogel. The outer shell component contained the same hydrogel along with a photoinitiator. Hardening the shell provided the structural support, allowing for cell preservation in relatively cell-friendly environment inside the core separated from the damaging effects of the ithium-acylphosphinate (LAP) photo-activated cross-linking. The LAP photo-initiator is generated by Dimethyl phenylphosphonite reaction with 2,4,6-trimethylbenzoyl chloride via a Michaelis-Arbuzov reaction81. The water-soluble LAP photo-initiator can generate crosslinked hydrogels with a high modulus value with short exposure time (10 seconds), increased polymerization rates, and absorbance above 400 nm82.

Polyethylene glycol (PEG) is a hydrophilic synthetic polymer commonly used in bioprinting applications83. It is known for its biocompatibility, non-immunogenicity, and limited protein absorption. PEG is made up of linear and branched structures and is a diol with two tunable hydroxyl end groups. The key crosslinking mechanism includes radiation of branch PEG polymers, free radical polymerization, chemical reaction, and enzymatic. Most commonly photopolymerization is used to convert liquid PEG macromers into stable hydrogels at physiological temperature and pH. One weakness of the highly bio-inert nature of PEG hydrogels is the low adhesion results and low viability when cells are added. Attempts have been made for tethering ECM derived bioactive molecules in order to enhance cell adhesion, proliferation, and viability. Investigators demonstrated the use of a PEG - alginate composite hydrogel for cartilage biofabrication84. The hydrogel relied two mechanisms: the reversible Ca2+ crosslinking of alginate dissipates mechanical energy, while the covalent crosslinking of PEG maintains elasticity under large deformations. Due to these crosslinking mechanisms the composite hydrogel could undergo both tension and compression stress, making it tougher than natural cartilage with a fracture toughness above 1500 J m−2. The investigators printed the robust hydrogel into complicated 3D structures with encapsulated human MSCs with high viability maintained over seven days.

Polyurethane is a synthetic polymer with a unique segmented structure that allows for diverse, tunable properties. The range of physical and mechanical properties associated with polyurethane includes thermoplastic to thermosetting, stability, and biodegradability, and can be either hydrophobic or hydrophilic depending on the composition and synthesis procedure applied85. While polyurethane has been widely used for medical applications, more recent uses include the formulation of polyurethane-based hydrogels. Investigators described the formation of an elliptic hybrid hierarchical polyurethane encapsulated cell/hydrogel construct86. They used synthetic polyurethane to form an external scaffold material to provide mechanical support with hydrogel as the internal scaffold material for adipose-derived stem cell encapsulation. The 3D composite construct was able to be cultured in vitro and was stable enough to embed in vivo. More recently, a study demonstrated that a composite gel of graphene and polyurethane could be used for 3D printing and the differentiation of neural stem cells87. The polyurethane was synthesized to contained poly (ε-caprolactone) and (1.5 kDa) poly (D, L-lactide) chains. Graphene was then added for neural stem cell printing. The graphene significantly improved oxygen metabolism and ultimately increase neural differentiation of the neural stem cells.

3.3. Tissue-specificity from ECM-derived hydrogels

Scaffolds derived from a natural extracellular matrix (ECM) are under investigation for use in therapeutic applications43. Decellularized organs are known to provide an ideal transplantable scaffold since they contain all the necessary microstructure and extracellular cues for cell attachment and differentiation, vascularization, and function88, 89. Furthermore, biological ECM scaffolds are rapidly degraded and replaced in vivo, resulting in the generation of downstream bioactive molecules with bioreductive properties90, 91.

Extensive studies have been published in the field of ECM biomaterials. Investigators demonstrated a method for producing ECM of porcine small intestinal submucosa (SIS) to form a resorbable tissue repair and remodeling scaffold. Their study demonstrated that the ECM scaffolds rapidly and extensively degraded when used as a bioscaffold for augmentation cystoplasty in the dog model; however, the scaffold positively impacted tissue repair92. In later studies, they found that the material induced angiogenesis when implanted in wounds. To further investigate this finding in vitro, the group administered ECM in a fibrin gel-based angiogenesis assay. Human microvascular endothelial cells embedded in the fibrin gel formed vascular tubes comparable to those formed by constructs treated with VEGF. Furthermore, tube formation was blocked when an anti-VEGF neutralizing antibody was added, further demonstrating that VEGF is present in the decellularized extracellular matrix93. In later studies, investigators compared the utility of organ-specific ECM to improve tissue remodeling following injury. The ECM of each tissue type can have a direct effect on the host response due to its unique structure and composition. To test this hypothesis, muscle ECM was compared vs. to non-muscle ECM of the small intestine. It was clear that the muscle ECM contained basement membrane structural proteins, glycosaminoglycans, and growth factors that were unique from those present in small intestine. However, implantation of the scaffold into an abdominal wall injury model in a rat demonstrated comparable constructive remodeling in both the muscle and small intestine scaffold. The improved remodeling appears to have been related to degradation of the scaffold, followed by myogenesis in the implant area, suggesting that superior tissue remodeling is not universally dependent on ECM scaffolds derived from homologous tissues94. Another group addressed volumetric muscle loss by engineering muscle constructs composed of cell-laden dECM bioinks with a granule-based printing reservoir. The muscle constructs were prevascularized with a hierarchical architecture through coaxial nozzle printing with muscle and vascular dECM bioinks. The tissue-specific dECM bioinks appeared to offer organized microenvironmental cues for the differentiation cells and improved vascularization, innervation, and functional recovery95.

At the cutting edge of biomaterials for 3D bioprinting has been the discovery that decellularized organ ECM materials can be solubilized to form hydrogels. Organ-specific hydrogels have been found to direct remodeling and influence cell behavior by mechanisms through structural and biological signals retained from the natural source tissue96. It is thought that these tissue-specific cues are relayed by bound growth factors or the exposure of bioactive motifs97, 98. The method for decellularization and formation of hydrogels has been described in detail in the literature96, 97, 99. Several factors must be considered in determining the most efficient agents for decellularization, including the tissue’s thickness, density, cellularity, and lipid content. A full description of the various agents used is outside the scope of this review but can be referenced elsewhere100. Following decellularization and lyophilization of organ tissue, ECM derived hydrogel formation is performed through solubilization of the ECM material and temperature or pH-controlled neutralization to induce re-formation of the intramolecular bonds to form a gel.

Engineers have successfully produced decellularized ECM (dECM) hydrogels specific to nearly every organ in the body, including the brain, heart, liver, lung, and pancreas96. Investigators developed a composite consisting of biodegradable elastomeric fibers and dECM gel from porcine dermal tissue demonstrated that the ECM gel is biocompatible and bioactive. To overcome this, the ECM gel was supplemented with electrospun biodegradable poly (ester urethane) urea. Next, electrospinning method was employed to create fiber composites with high flexibility and strength. The composite constructs were then tested in vivo with implantation into a full-thickness abdominal wall defect in rats, with herniation or infection over 4 weeks101. Later, a hydrogel was fabricated using spinal cord and brain ECM. The investigators found clear rheological differences between ECM from the brain, spinal cord, and urinary bladder, with the greatest rheologic modulus seen with the spinal cord-derived. Interestingly, all ECM types, including the bladder matrix, increased the number of cells expressing neurites and promoted neurite outgrowth, but only brain-derived ECM increased neurite length102. Recently, proteomic analysis of dECMs from four tissues was performed to determine the tissue-specific functionalities of unique dECM103. In the study, dECM bioinks were printed with encapsulated human bone marrow mesenchymal stem cells, which differentiated in association with variable matrisome proteins within each dECM. Furthermore, tissue-specific differentiation was evident depending on the multipotency of MSCs. These findings provide strong evidence of tissue-specific advantages of homologous dECM bioinks.

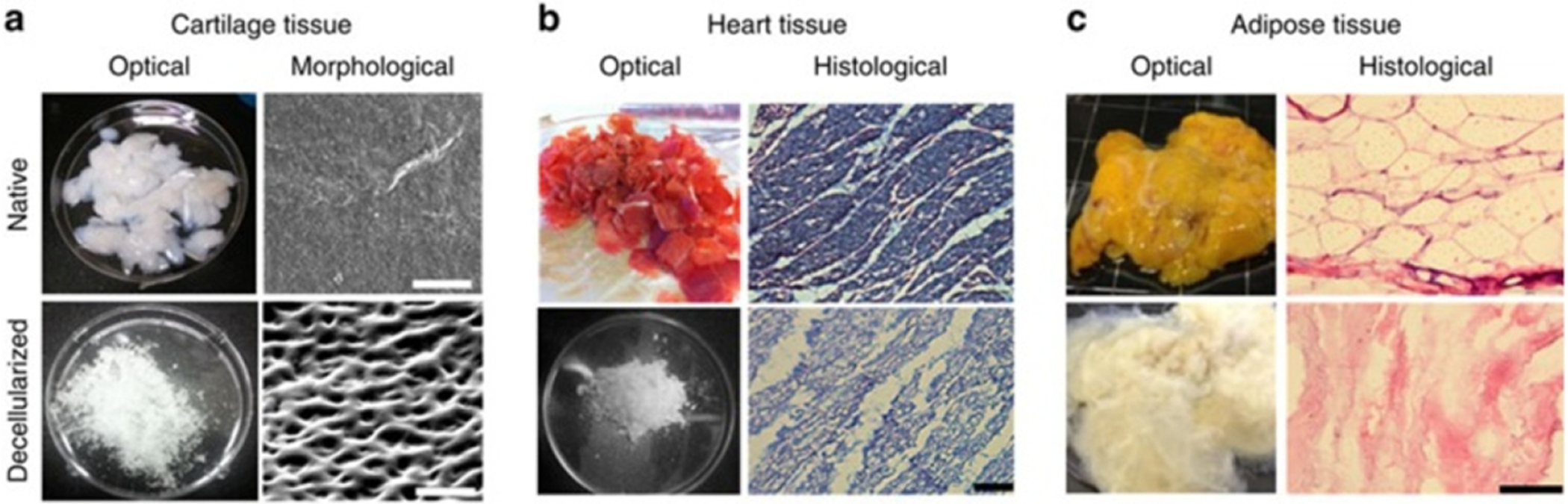

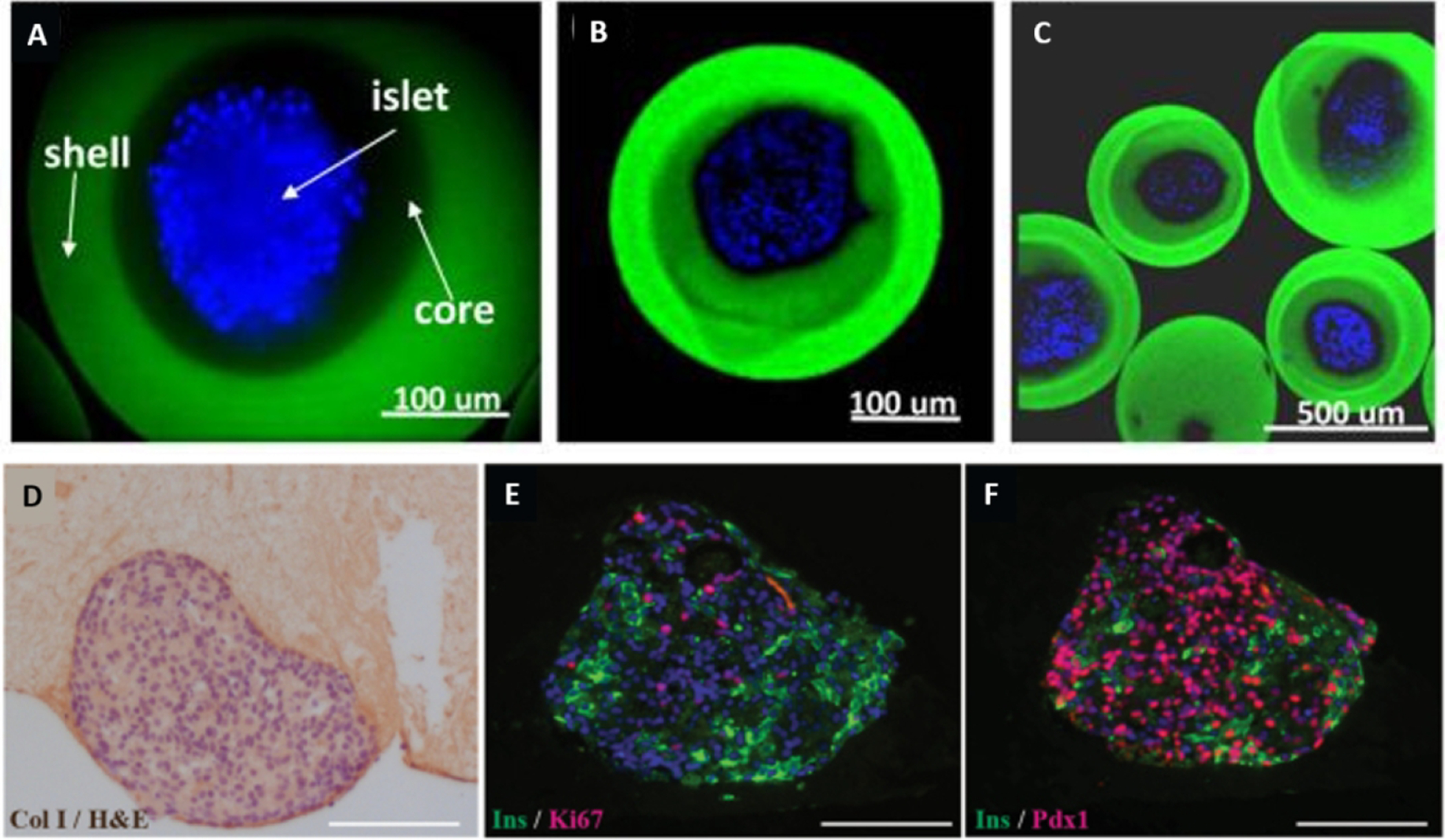

Another research team developed a method for printing cell-laden dECM bioink with microenvironment conducive to the growth of 3D structured tissue43 (see figure 5). Derived stem cells or mesenchymal stem cells were encapsulated in dECM gel, there was an increased number of cells that differentiated towards chondrogenic lineage within cartilage dECM or adipogenic lineage within adipose-derived dECM. Myoblasts formed in constructs prepared with dECM from heart tissue, which ultimately organized into the myofibers and expressed slow myosin heavy chain. The myofibers then synchronized with native tissue, suggesting that myoblasts printed in heart dECM can be used for myocardial reconstruction. Other groups have also used dECM to print cardiac tissues43, 104.

Figure 5. Decellularization of tissues with biochemical analysis.

Images of decellularized (a) cartilage tissue (scale bar, 50 μm), (b) heart tissue (scale bar, 100 μm), and (c) adipose tissue (scale bar, 100 μm). (Reprinted with permission from ref43. Copyright 2014 Nature Communications).

Our group has similarly formulated composite hydrogels composed of decellularized ECM-based solution incorporated into highly tunable combinations of PEG crosslinkers with varying molecular weights, geometries, and functional groups to manufacture bioinks for extrusion bioprinting42. We have found that the ECM-derived solutions contain complex combinations of collagens, glycosaminoglycans, elastin, and growth factors, which enhance cell viability and eventual tissue construct function. We found high cell viability in a liver-specific hydrogel when compared with the extremely poor viability of cells printed in the gelatin-based hydrogel. Furthermore, liver function assays demonstrated that the spheroids secreted albumin and urea, suggesting that tissue-specific hydrogel bioink allow the bioprinted liver constructs to remain viable and function properly. More recently, our team has developed a photo-cross-linkable kidney ECM-derived bioink with a kidney-specific microenvironment for renal tissue bioprinting. The bioink is formed by decellularizing whole porcine kidneys by perfusion, dissolving in an acid solution, and chemically modifying by methacrylation. Human kidney cells encapsulated in the in the bioink maintained high viability and matured to exhibit the functional and structural characteristics of renal tissue. This tissue-specific ECM-derived bioink enhances cellular maturation and could eventually improve tissue formation105.

3.4. Media-based printing

While most bioprinting methods require the use of biomaterials for printing, other methods, including inkjet bioprinting, require the use of media-based liquid cell suspensions. In this technique, cells are suspended in media or PBS, and then carefully extruded into specific locations or small co-cultured spheroids106. Spheroids then form through microwell centrifugation, hanging drop, and other known methods. Once these spheroid cell aggregates have formed, they can be placed by a bioprinter. This method has been used with a microvalve printer to form kidney microstructures36. The investigators utilized gradients of bio-ink, one with hESCs in medium and the other media only, and then flipped the culture dish to form hanging drop spheroids with high cell viability. It has also been shown that isolated cardiac cells can be extruded in media to form cardiac microstructures39. The microstructures then self-assembled into beating solid tissue blocks, with synchronous contraction and early signs of vascularization by endothelial cells. This method has also been implemented to form functional myotubes that responded synchronously to electrical stimulation55.

Another media-based bioprinting technique uses cell spheroids that are formed, resuspended, and skewered onto a needle array. Closely aligned spheroids then self-aggregate to form larger structures that can be removed from the needle array as a fabricated tissue. The feasibility of this scaffold-free approach has been demonstrated for liver microstructure development54. The self-assembled tissue maintained the expression of several hepatic drug transporters and metabolic enzymes. Glucose production by the fabricated tissue was suppressed by insulin, and bile acid secretion was evident. Also, structural sinusoid-hepatocyte-bile duct routes formed. The use of needle array tissue fabrication has also been used to form cardiac patches53. After fabrication, the patches exhibited ventricular-liked action potential waveforms with uniform electrical conduction in a spontaneous beat through the patch. The patch also vascularized when implanted into native rat myocardium in vivo.

4. Vascularity is crucial for integration of bioprinted organs

Central to bioprinting whole organs is the need for vascularity to provide nutrients, oxygen, and waste removal107. These challenges are not as drastic in flat and tubular organs, as their wall thickness can remain below 300 μm108. However, in hallow and solid organs, the wall thickness may exceed 300 μm109. Attempts to promote the infiltration of blood vessels to form capillary networks within bioprinted constructs are relevant, but ultimately replication of the hierarchical vascular network is necessary for biofabrication of complex tissues at clinically appropriate sizes110. In this section, we will present the current state of the art of vascular bioprinting as it applies to whole organ engineering.

4.1. Vascular anatomy

Vascular tissue composition includes extracellular matrix and cells organized into concentric layers in a tubular structure composed of three layers; the endothelial tunica intima, the muscular tunica media, and epithelial tunica externa111. Arteries that extend to whole organs branch into an anatomically unique microvasculature composed of arterioles, capillaries, and venules. Arterioles have a diameter of 10–200μm with an average lumen of 30 μm, and retain the three tunica layers (intima, media, and externa)14. Arterioles then branch into capillaries, characterized by a narrow lumen diameter of around 5–10 μm. Capillaries retain the endothelial layer and a basement membrane. Pericytes act to stabilize the vessel and allow for diffusion of solutes into nearby cells and tissues. Capillary permeability results from their structure, which can be continuous, fenestrated, or sinusoid112. Continuous capillaries are primarily found in skin, muscle, lung, and the central nervous system, and are typically distinguished by their “continuous” basement membrane. Fenestrated capillaries are in renal glomeruli, intestinal mucosa, and exocrine glands. Finally, sinusoidal capillaries have even larger intercellular gaps, and are present in the liver, spleen, and bone marrow. The capillaries reunite and empty into venules (8–100μm lumen), composed of the externa, a thin media layer, and endothelium. Multiple venules empty into much larger veins for blood to be transported back to the heart for pulmonary circulation113.

The most vital organs that researchers currently engineer (i.e., heart, liver, lung, kidney, pancreas, and brain) are highly vascularized in vivo and require a vascular network with high fidelity and functionality. The vascular network must be present throughout the solid organ, with arterioles separated by a maximum distance of 300μm to ensure that the tissue diffusion limit is not exceeded114. In addition to the vital necessity for nutrient and oxygen exchange within structures greater than 300μm, there is evidence that vascular formation may govern tissue formation itself115. Furthermore, innervation regulated by mechanisms shared with blood vessel formation could promote the integration of engineered organs116–118.

The first attempt to replicate vascular tissue includes synthetic vascular grafts119. However, these have only been effective in large (>8mm) and medium-large vessels. Success in synthetic grafting of crucial small vessels (<6mm), such as the coronary arteries, remains poor compared with autologous grafting of the internal thoracic and radial arteries120. Challenges typically arise in these applications due to a lack of endothelial cells, diameter, and compliance mismatch resulting in graft failure due to intimal hyperplasia, thrombosis, and graft site infections121. Consequently, the FDA has not approved synthetic small-caliber vascular grafts (<5mm). However, bioprinting with endothelial cells in lumens in the small caliber category has become an attractive alternative. Indeed, fabrication of small-diameter arteries and veins seem feasible, however, the central challenge of replicating the delicate anatomy of arterioles, capillaries, and venules remains a key limitation122, 123. To address the need for these smaller diameter vessels, tissue engineers have employed angiogenic remodeling and biofabrication strategies.

4.2. Angiogenic remodeling

Two main strategies for angiogenic remodeling of tissue-engineered organs are to provide growth factors that will cause rapid capillary formation inside implanted constructs, or by stimulating blood vessel infiltration by host vasculature. Agents including vascular endothelial growth factor (VEGF), fibroblast growth factor (FGF), platelet-derived growth factor (PDGF), and transforming growth factor (TGF), have been delivered alone or in combination. Researchers demonstrated the use of gelatin microparticles to prolong VEGF activity in 3D bioprinted scaffolds52. Matrigel encapsulated endothelial progenitor cells along with VEGF encased in gelatin nanoparticles have been used. Implantation of the scaffolds in nude mice showed significantly higher vessel formation in the sustained-release group. In another study, a vertical organization of hallow channels was designed to replicate the liver vascular network using a gelatin/alginate/fibrinogen gel124. Hepatocytes combined with gelatin/alginate and chitosan provided structural support around the vascular network. The group was able to induce stromal cells to differentiate into endothelial cells and form a vascular network by administering EGF. Others printed hematopoietic stem cells encapsulated in hydrogels cross-linked on-demand in patterns with liquid media. Differentiation into multiple lineages then occurred125. Other methods include promoting the recruitment of circulating stem cells through specific antibodies.

4.3. Direct printing of vascular constructs

In direct printing of vascular constructs, a pre-designed three-dimensional structure forms through one of several bioprinting methods (i.e., Extrusion, inkjet, LIFT) by depositing cell-laden hydrogels or media126. Within this context, one method of vessel printing is through vertically stacking circles or pores within the Z-Plane in concentric layers. In one study, a multi-nozzle extrusion-based technique allowed for the vertical fabrication of alginate-based tubular constructs. The design incorporated a large outer circular structure (12mm diameter) of alginate followed by an inner circle (8mm diameter) of deposited crosslinker (CaCl2) stacked to 15mm vertically127. However, one limitation of the vertical printing design was shrinkage occurring during the crosslinking process. Vertical channels can be implemented into larger tissue constructs to overcome this challenge. Other researchers demonstrated this idea using a drop-on-demand modified HP Deskjet 500 and showed that a bioink composed of human microvascular endothelial cells in fibrin could fabricate micron-sized channels. Cell viability improved by implementing an aqueous printing process. Following depositing, structures were cross-linked with thrombin to provide structural stability. Cells within printed channels proliferated and aligned to form confluent 3D tubular structures. Thus, combining cell and scaffold printing promotes cell proliferation and formation of microvasculature128.

The challenge of vertical shrinkage has also been addressed by printing vessels horizontally. In one study, a horizontal printing strategy with a four-armed polyethylene glycol derivative to improve hydrogel rheological stiffness and allow higher density cell suspensions. NIH 3T3 cells were encapsulated in PEG gel and then printed in sausage-like hydrogel microfilaments using a layer-by-layer deposition50. This method was later used to produce tubular constructs with a core and structural halo. Encapsulated cells gradually remodeled the synthetic environment into a tissue-like extracellular matrix129. While horizontally printing vascular constructs can reduce some of the physical demands on fabricated vessels, the stability of the lateral walls must remain in consideration in terms of compensation shrinkage. Consequently, groups recognized this need and optimized a tubular printing technique by accounting for concavity deformation by compensating and adopting a non-circular printing trajectory, resulting in a nearly circular product130.

In whole organs, vascular networks have complex vascular trees. To replicate branched tubular structures, Norette et al. used a combination of cell spheroids and extrusion bioprinting. In their design, HUVMCS, fibroblasts, and SMCs were printed as small multicellular cylindrical rods, and rounded into spheroids. Printed agarose rods formed horizontal bifurcations, followed by dispensing spheroids into the mold. The spheroids fused in the mold and matured, and a vascular network developed after removing the agarose mold38. However, in vivo vascular branching is not limited to a horizontal plane. Thus, fabricated fibroblast-based vertical conduits with zig-zag overhangs can be formed using a specialized platform-assisted 3D inkjet bioprinting system131. This technology was later improved with an inkjet printing approach with a liquid support-based of calcium chloride solution. The solution was multi-modal, acting as both the support material and as a cross-linking agent. This enabled freeform printing of overhanging features by providing a buoyant force. Vascular-like channels with both vertical and horizon bifurcations, as well as overhangs, were successfully printed132.

Further attempts to improve the structural integrity of bioprinted vasculature have also utilized support baths to provide physical support during tissue development. Feinberg et al. modified a MakerBot Replicator for syringe-based extrusion deposition of bioink solutions, termed freeform reversible embedding of suspended hydrogels (FRESH). Bioink solutions printed within the gelatin support that served as a temporary, thermoreversible, and biocompatible support133. Using a similar approach, Blaeser et al. used liquid fluorocarbon as liquid support. The high buoyant density of the fluorocarbon allowed their soft hydrogels to float, allowing for freeform printing thin-walled hydrogel cylinders29.

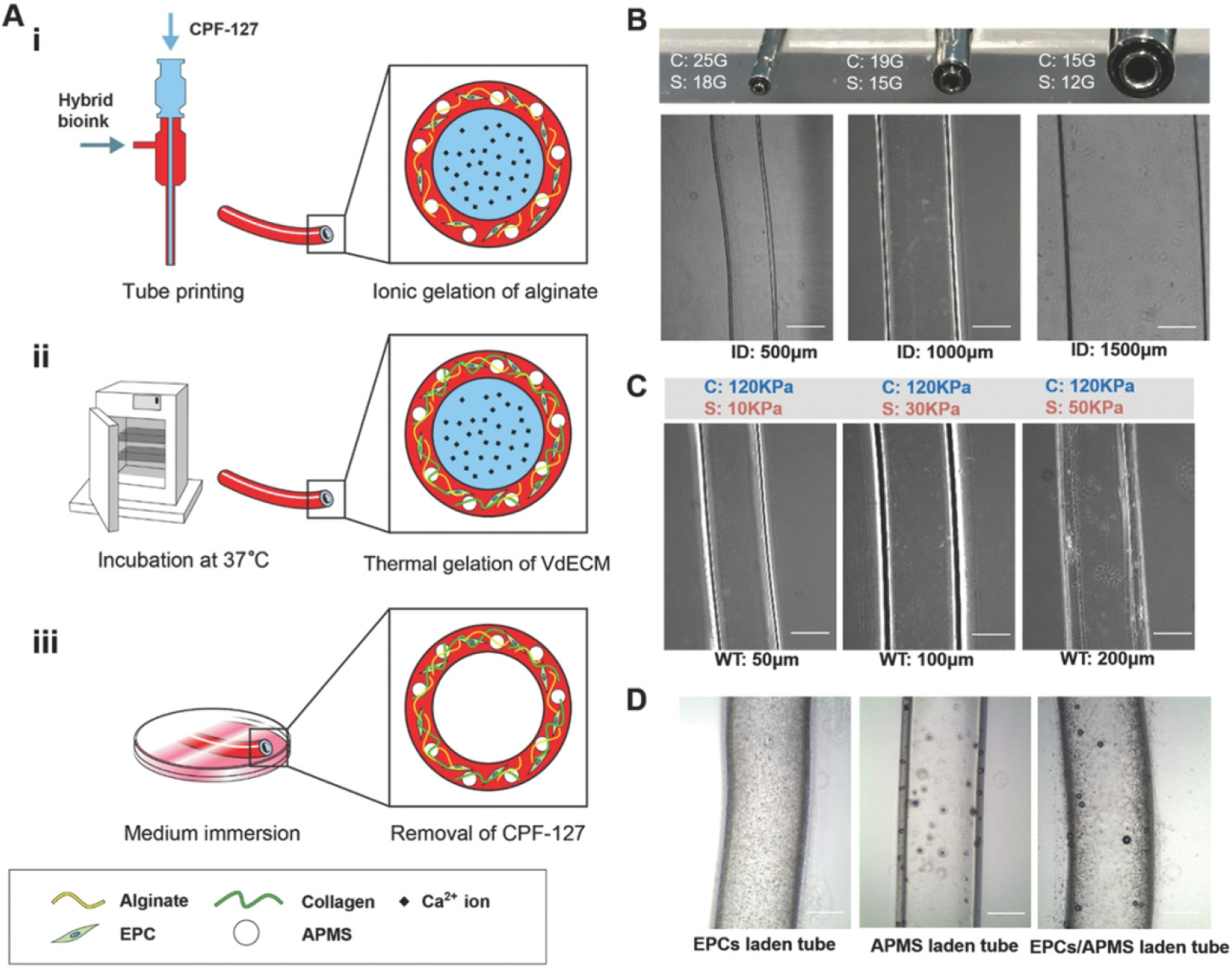

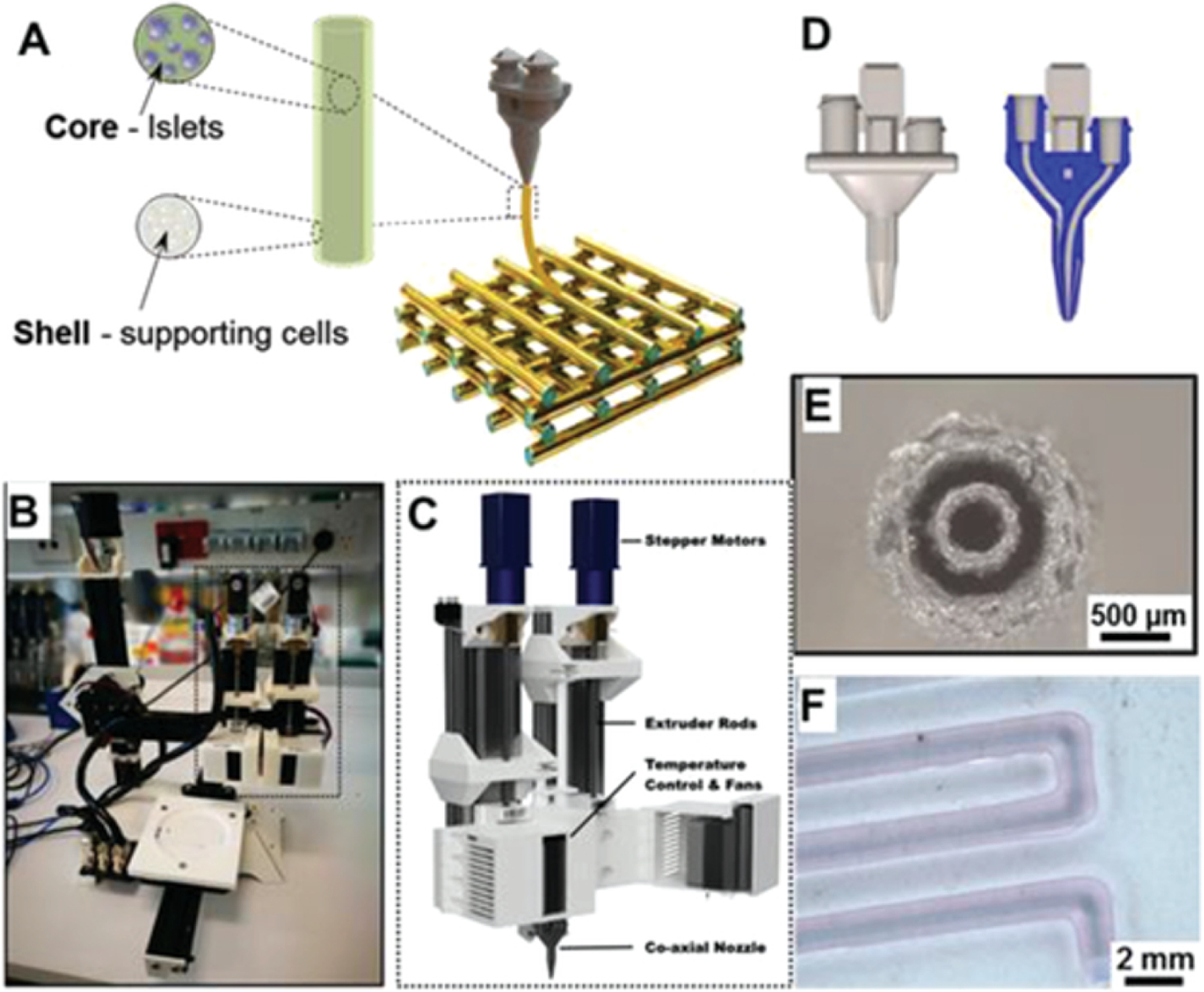

While direct printing of porous structures method has proved successful, the ultimate goal would be to print vessels with patent lumens in a single step134. Coaxial nozzle printing is a significant step in this effort. In coaxial printing, a nozzle is prepared with an inner and outer tube, and a connected feed nozzle (See Figure 6). The feed nozzle is filled with a bioink crosslinker that is distributed through the inner tube, while the outer tube contains the desired matrix bioink with encapsulated cells. During printing, the outer and inner tubes dispense simultaneously, resulting in an outer tube with a matrix bioink and an inner cylinder with the crosslinker. The crosslinking mechanism occurs instantaneously from the luminal center outward, maintaining patency during printing.

Figure 6. Coaxial Printing.

A) A schematic depiction of the coaxial printing process fabrication process. Alginate gelation is realized in coaxial printing (i), thermal crosslinking of collagen fibers is then induced by incubation at 37 °C (ii), followed by immersion in medium to the and obtain a hollow tubular shape (iii). B) Combining a variety of core and shell allows for printing tubes with different inner diameters. C) By adjusting the flow rate in the shell nozzle permits tubular structures with unique wall thicknesses with a 15/19 gauge coaxial nozzle. D) The 15/19 gauge coaxial nozzle produced successful tubular, vessel like structures with EPCs, AMPS, and EPC/AMPS laden BBVs (scale bar: 500 μm). (Reprinted with permission from ref138. Copyright 2019 Advanced Functional Materials)

Zhang et al. demonstrated the use of coaxial nozzle blood vessel bioprinting, wherein alginate hydrogel flowed through the feed tube while a crosslinking solution of CaCl2 flowed through the central tube, creating a patent lumen. The investigators printed microfluidic channels embedded within a bulk hydrogel to test functionality. Cells within the construct maintained high viability, suggesting that vascular networks could be produced using a coaxial nozzle135. Subsequent work has improved the structural stability of printed coaxial vascular conduits through reinforcement with carbon nanotubes (CNTs). Conduits were printed with encapsulated human coronary artery smooth muscle cells. The multi-walled carbon nano-tube reinforcement increased the tensile strength and allowed the conduits to be printed at a lumen diameter of less than 1mm136.

Recently, Gao et al. combined bioprinting with coaxial vascular conduits to create microchannels for nutrient delivery (See Figure 7). The scaffolds were printed using L929 mouse fibroblasts encapsulated in sodium alginate and CaCl2 to partially crosslink filaments as they were laid within a CaCl2 bath137. It was easier to form high-strength structures when a higher concentration sodium alginate solution is used, and the distance between adjacent hollow filaments was smaller. In subsequent work, the investigators encapsulated endothelial progenitor cells with the proangiogenic drug atorvastatin in vascular tissue derived decellularized ECM and alginate composite hydrogel. Vascular conduits were then fabricated from this bioink using their coaxial method. Bioprinted vessels were then ligated onto the venous area of an ischemic model in mice. A functional blood vessel graft developed, resulting in recovery from ischemic injury138. Most recently, this coaxial printing technique was implemented for the direct printing of an in vitro vascular model. Upon endothelialization, the vessels exhibited representative vascular function, including selective permeability, antiplatelets/leukocyte adhesion, and self-remodeling in response to physiological shear stress and directional proangiogenic signals134.

Figure 7. Coaxial blood vessel bioprinting.

Maturation of coaxial cell printed vasculatures. The formed endothelium layer in the luminal wall of tube expressed VE-cadherin on day 7 (scale bar: 100 μm) (Reprinted with permission from ref134, 138. Copyright 2019 Advanced Healthcare Materials). Assessment of functional recovery in a murine hind limb ischemia model with representative images of six treatment groups with transplanted coaxially printed vessel-like constructs showing different outcomes, including limb loss, foot necrosis, toe loss, and limb salvage. Blood perfusion was evaluated by laser Doppler perfusion imaging analysis in the ischemic limbs of the mice transplanted with PBS, BBV, ABBV, EPCs (EPC), EBBV, and EABBV. (Reprinted with permission from ref134. Copyright 2019 Advanced Functional Materials).

One cutting edge technology, SLATE (stereolithography apparatus for tissue engineering) has been developed by Miller et al. to generate biologically compatible complex multi vascular networks with functional intravascular topologies139. The photopolymerizable hydrogels can be used to establish intravascular and multi vascular design with great freedom with projection stereolithography. In a recent study, researchers demonstrated that monolithic transparent hydrogels comprising functional bicuspid valves and intravascular fluid mixers and could be formed. Interwoven vascular networks were generated with space-filling topologies to test oxygenation and flow of human red blood cells during tidal ventilation and distension of a proximate airway140 (see figure 8).

Figure 8. SLATE printed lung structure with oxygenation and tidal ventilation with vascularized alveolar topologies.

(A) A design of the alveolar model offset to derive an unsheathing vasculature, and a cutaway view to illustrate the shared airway atrium of the model alveoli. (B) A Photographs of a bioprinted construct during RBC perfusion with the air sac ventilated with O2 (scale bar, 1 mm). (Reprinted with permission from ref140. Copyright 2019 Science).

4.4. Indirect printing with sacrificial material

In addition to direct printing of vascular networks, luminal support made of sacrificial materials (i.e., gelatin or agarose) can maintain a patent internal lumen during vessel formation using a method termed indirect printing. Wust et al. described this process in-depth to determine the effects of material, orientation, geometry, and cell embedding on the indirect printing of vascular channels. For their experiment, an alginate-based bioink was used to embed human MSCs while a central tube of gelatin served to stabilize the luminal center. The gelatin was then leached from the center with tissue maturation, leaving a hollow channel141. Other indirect printing methods used to form microchannel networks include the use of agarose gel fibers were bioprinted with a highly controlled 3d architecture followed by casting cell-laden GelMA hydrogel over agarose gel fibers and photopolymerization. The agarose cylinders were then removed from the photo crosslinked cast, forming perfusable microchannels142. The vascular networks improved cellular viability, differentiation, and mass transport in the tissue constructs, and endothelial monolayers formed in the channels.

Dai et al. designed their own novel indirect bioprinting method. First, a layer of collagen hydrogel was printed in a flow chamber, followed by a single strand of human umbilical vein endothelial cells (HUVECs) embedded in gelatin. Collagen was then cast around the gelatin strand, and the construct was incubated at 37c. A flow of media was then sent through the open channel, which removed the thermoresponsive gelatin, leaving HUVECs attached to the remaining collagen matrix. A confluent endothelial channel formed, which was able to maintain cell viability up to 5mm from the channel under physiological flow conditions143. To build on this method, two cylindrical tubes were printed, separated by a fibrin support center imbedded with endothelial cells and fibroblasts. Under physiological flow conditions, a microvascular bed formed within the fibrin support center, connecting the two parallel fluidic vessels123.

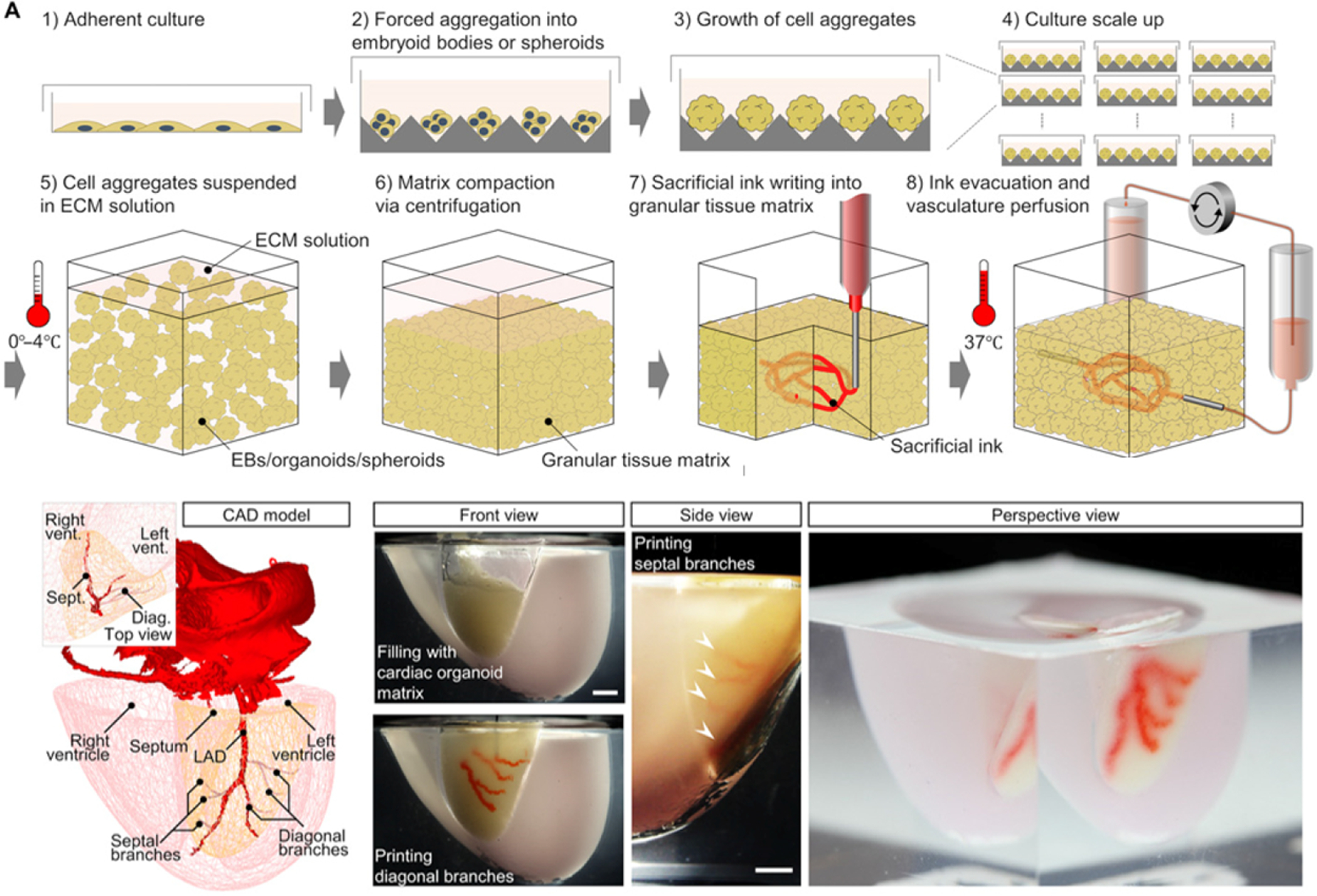

Lewis et al. have reported embedded three-dimensional bioprinting to functionalize tissue segments with patient-specific induced pluripotent stem cell-derived organoids, in an attempt to achieve tissues high cellular density and function (See Figure 9). The organoid matrices exhibited self-healing behaviors and had clear viscoplastic properties required for sacrificial writing into functional tissues. To further demonstrate the functionality of the printed constructs, the group created perfusable microarchitectural cardiac tissue fragments that fused and beat synchronously over a 7-day period144.

Figure 9. SWIFT indirect printing method.

An illustration of the SWIFT process, step-by-step. A 3D CAD model of a normal human heart was downloaded from the NIH 3D Print Exchange. A scale mold was formed using human CT imaging data, and the left anterior descending artery, diagonal and septal branches were printed by embedding into the septal-anterior wall wedge of the cardiac tissue matrix. Scale bar, 5 mm. (Reprinted with permission from ref144. Copyright 2019 Science Advances).

5. Advances in engineering organ-specific structures to enable organ function

Organ-specific microstructures are crucial for bioprinted whole organs to function properly. Microstructures are often highly complex, with intricate and delicate structural elements arranged in complex patterns and composed of multiple cell types. Attempts to engineer microstructures have proven successful in less complex organs, such as skin. Christiano et al. described a method for engineering hair follicle spheroids, which formed primitive hair follicles when embedded in a biomimetic skin structure then implanted on mice. The 3D structure of the spheroids increased hair follicle specific genetic markers145. To further improve this method, the group implemented a casting method in which hair follicle columns were engineered with high-density FDPC cells at the base, followed by a column of keratinocytes. These structures matured into hair follicles-like structures that were evident on H/E. When implanted on full-thickness skin wounds in mice, the engineered hair follicles formed hair146. In like manner, the complex microstructures of whole organs will need to be formed using both mechanical and cellular ques, while also maintaining the macro and mesostructural elements necessary for organ function. For some organs, technology has advanced to the point where organ bioprinting, or bioprinting of critical organ structure, is currently being developed. For more complex organs, such as the lungs and kidney, alternative methods such as organoid formation are providing preliminary efficacy and organ-like function which may serve as the building blocks toward the goal of complete organ engineering. For this reason, we have included studies that describe the spectrum of organ bioprinting development.

5.1. The heart

Cardiovascular tissue is composed of fully differentiated cells, which are organized to constitute the various anatomical elements of the heart. Cardiovascular diseases, including acute coronary syndrome, arrhythmias, hypertension, and congenital heart disease account for over 17 million deaths per year, with a predicted increase to over 23 million by 2030147–149. Adult cardiovascular tissue exhibits a very limited ability to self-renew after injury, thus later stage cardiovascular disease, extensive intervention may be required, such as artificial mechanical replacements150. Mechanical valves have been used with great success for several decades; however, these treatments have limited efficacy in pediatric patients, as the growing size of their heart necessitates multiple procedures to implant larger valves151. Ventricular Assist devices have become a standard of care for patients on the transplant waitlist152. Further development and implementation of the total artificial heart has proved successful. However, this is very costly. Ultimately, functional replacement with transplantation is the main therapy that can provide a permanent resolution for heart failure patients153. As with other organs, donor’s hearts are difficult to acquire. Thus, the demand for tissue-engineered human hearts would be great. Engineered hearts have traditionally had limited success due to their onerous load requirements, a constant flow of blood through the organ, and the complex network of vessels necessary for the delivery of oxygen and nutrients.

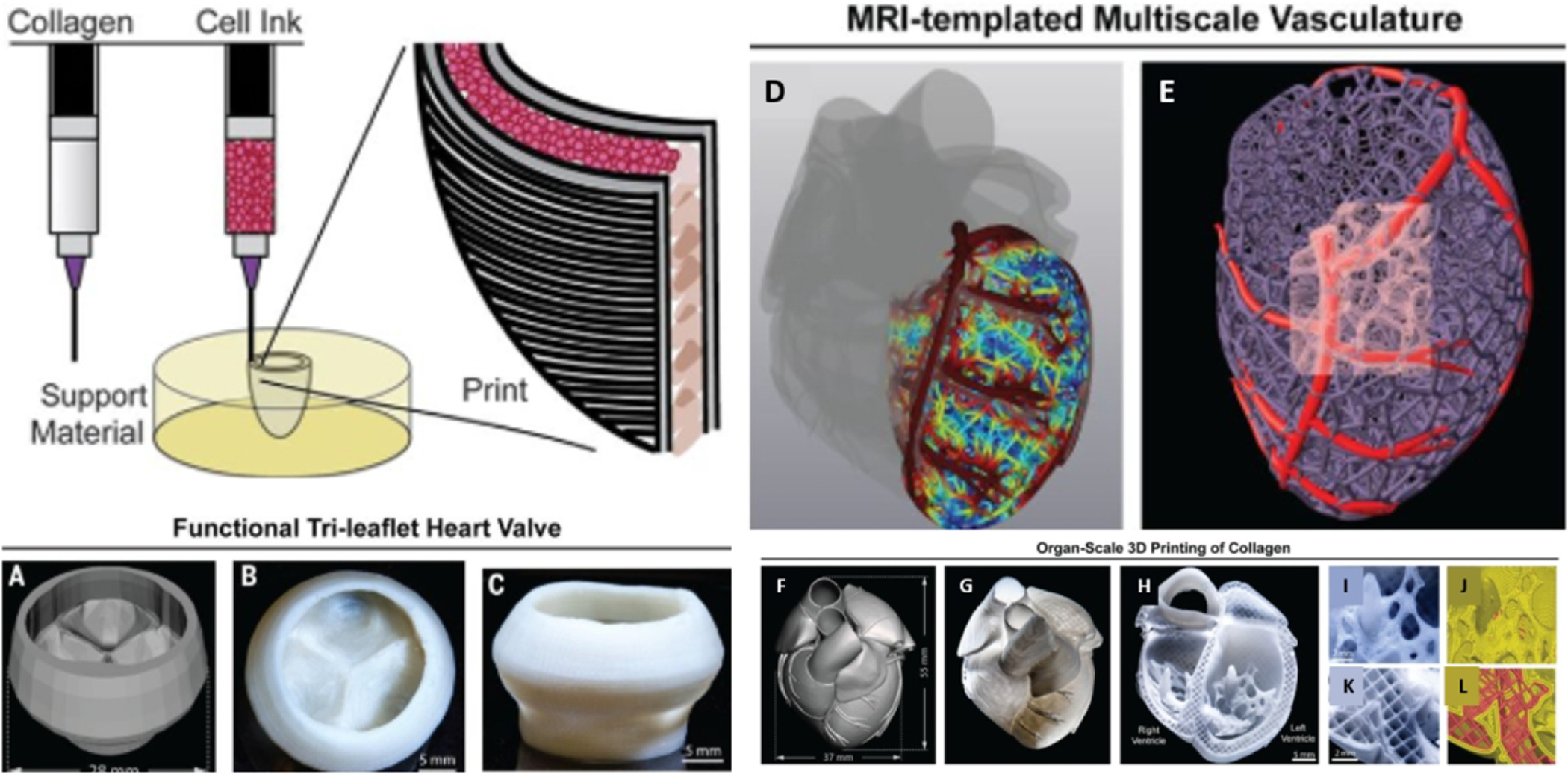

Heart valves are one of the most delicate structures in the heart and are necessary to control against the backflow of blood in the heart and for creating a pressurized chamber for blood to be pumped throughout the body154. Thus, valves, while incredibly thin, must withstand incredible amounts of mechanical pressure155. Deficiencies of traditional bio-prosthetic and mechanical valves, such as durability of the device, the need for anticoagulation, implant anti-immunogenicity, and the capacity for growth, may be improved through tissue engineering. Our lab has specifically addressed this challenge through an in situ healing approach156. Specifically, donor heart valves were decellularized and seeded with CD144 antibody to allow for the capture of circulating endothelial progenitor cells. Once implanted in the tricuspid position, the valves remodeled to form physiologically normal heart valves that grew with the growing lamb157. However, 3D bioprinting can further help to fabricate specific valve constructs that can be fitted specifically into patients with their personalized anatomy. Other printing strategies involve both scaffolds and cells. In one study, 3D printing of an aortic valve scaffold was performed by incorporating alginate and poly (ethylene glycol)-diacrylate (PEG-DA) hydrogels aortic valve interstitial cells158. Micro-CT was used to compare native aortic valve geometries with the printed construct, demonstrating high fidelity printing. Additionally, the aortic heart valves were capable of encapsulating aortic root sinus smooth muscle cells and aortic valve interstitial cells for the leaflets. Methacrylated hyaluronic acid gelatin methacrylate bioink encapsulating human aortic valvular interstitial cells were also developed by extrusion bioprinting34, 49. By using 3D printing technology, the group was able to optimize cell distribution and viability. Additionally, the use of variable bioink components resulted in high cellular ECM deposition of collagen, glycosaminoglycan, and muscle actin. Still, these technologies and studies do not adequately answer the questions of longevity and mechanical performance that will be required of these bioprinted valves. The complex biomechanical requirements of these valves are outside of the scope of this review, but have been addressed in detail in other reviews159.

Bioprinting the complex cardiac vascular network is the crucial next challenge faced by cardiac tissue engineers. 3D bioprinted vessels can replicate the anatomical structure and physiological characteristics of vessels, especially for small diameter vessels less than 6mm in diameter160. Perfusable vasculature relies on an endothelial lining for biomechanical support161. Multiple methods have been described in printing vascularized tissue, including 1) the use of sacrificial templates and indirect bioprinting to form open channels in solid constructs, 2) printing channels directly into a construct in an interconnected network, and 3), direct printing tubular blood vessels in a vasculature network162. However, thus far, these preliminary methods are inadequate for the generation of clinically relevant tissues163, particularly for complex, and hierarchically scaled structures complete with cells and relevant physiology164 (see section 4 for more details).

Ultimately the goal of the coronary vasculature is to allow for perfusion of blood and delivery of nutrients to the myocardium to allow for synchronous contraction. In place of fully engineered vasculature, some groups have chosen to forgo “over-engineering” in favor of cellular self-assembly. In a study by Forcas et al., cardiac tissues were bioengineered using a self-assembly approach, allowing for multicellular spheroids to fuse and form a beating patch. The solid tissue blocks demonstrated synchronous beating, and endothelial cells organized into primitive vessels39. More recently, a novel biomaterial-free method was developed to deliver stem cells using printed cardiac patches53. Similar to the Forcas method, cells were aggregated to create mixed cardiac spheroids with pluripotent stem cell cardiomyocytes, fibroblasts, and endothelial cells, and then assembled into a cardiac patch. The beating printed constructs exhibited action potential waveforms and uniform electrical conduction similar to those seen in the native ventricle. The patch successfully vascularized when engrafted into rat myocardium53. However, long term follow up and functional analysis was not reported. The short culture of the cardiac patches and cellular immaturity resulted in weak mechanical properties. Future studies of cardiac patches should include additional characteristics, including modulation with electrical and mechanical stimulation with a bioreactor, and implantation into more translatable myocardial injury are more likely to yield viable therapeutics.

Laser-Induced-Forward-Transfer (LIFT) and extrusion bioprinting can also be used in combination to form cardiac patches with angiogenesis at the edge of myocardial infarction, which have been shown to preserve cardiac function after acute MI56. A cardiac patch was printed using a decellularized heart ECM derived bioink. The constructs contained cardiac progenitor cells and stem cells, and the native ECM derive bioink created a suitable biochemical and biophysical microenvironment for cell differentiation and functionality. When implanted in vivo, the printed cardiac patch demonstrated enhanced cardiac function with minimal infarct complications and promoted robust vascularization within the engineered tissue matrix104. Implantation of constructs with primary human derived cardiomyocyte progenitor cells into a mouse MI model demonstrated that transplanted cells were able to survive for up to one month and improved cardiac function, demonstrating the capacity for autologous myocardial printing47.

Our group has fabricated contractile myocardial tissue through 3D bioprinting165. The cardiac tissue constructs contained primary cardiomyocytes isolated from infant rat hearts and suspended fibrin-based bioink, a sacrificial hydrogel, and a supporting polycaprolactone frame. Like other bioprinted cardiac tissue, ours demonstrated spontaneous synchronous contraction in vitro. Immunostaining for α-actinin and connexin 43 confirmed that the cardiac tissues electromechanically coupled, dense, and aligned cardiomyocytes. The constructs demonstrated a physiologic responses cardio inductive drugs with contraction forces and beating frequency similar to the expected response in native tissue165.

Dvir and colleagues 3D-bioprinted a heart-like model using decellularized ECM hydrogel, demonstrating that human cardiomyocytes and endothelial cells could be integrated into their printing design166. In their method, an omental tissue biopsy was excised from the patient. Cells isolated from the tissue were reprogrammed towards stem cells, and ultimately differentiated into endothelial cells and cardiomyocytes. Simultaneously, a personalized hydrogel was processed from a patient-specific extracellular matrix. The two reprogrammed cell types were then encapsulated to form hydrogel bioinks that were printed to generate the parenchymal cardiac tissue and blood vessels. To prove this concept, cellularized miniature hearts were printed, and although not functional, demonstrated the potential for the approach to engineer functional and personalized hearts166.

Feinberg et al. utilized freeform reversible embedding of suspended hydrogels (FRESH) technique to generate a large-scale and complex, 3D construct of the heart133. The technique utilizes a support bed of a thermally reversible, viscous gelatin slurry that offers somewhat flexible support for the printing nozzle133. The gelatin slurry allows the nozzle to easily penetrate the support bed without resistance while still holding the printed hydrogel structure in place without collapse. After printing, the hydrogel is released by heating to 37°C, which melts the support gelatin. Using their model, they bioprinted a heart construct for 5-day-old chick embryo, using a gelatin microparticle slurry supported by a fibrinogen collagen Matrigel bioink with myoblasts (See Figure 10). Their method was the first to bioprint the complex trabecular structures unique to cardiac anatomy by utilizing CAD modeling, and their low-viscosity collagen bioinks were printed in the gelatin slurry133. Most recently, The FRESH technique was used to rebuild elements native to the human heart, ranging from small capillaries to the full organ. PH-driven gelation allowed for unprecedented filament resolution (20-micrometer). This allowed them to print porous microstructure to enable rapid microvascularization and cell infiltration. The gelatin microparticle slurry supported the relatively weak, low viscosity collagen hydrogel, which was printed with physiological cell numbers of 300 million cells/mL. Micro-computed tomography confirmed that the FRESH bioprinted heart reproduce patient-specific anatomical structure. Furthermore, the ventricles printed with human cardiomyocytes contracted synchronously with directional action potential propagation, and wall thickening at peak systole. Finally, the group combined all elements of their printing process to print a neonatal sized heart model, and although not functional, microCT confirmed the shape fidelity of the construct167. Even so, significant challenges remain before bioprinting hearts of adult human scale is realized, including generating the billions of cells required for bioprinting large tissues, scaling up the manufacturing, and creating a standardized regulatory process for translation to the clinic. Furthermore, engineered cardiac tissue studies published to date lack long term follow-up, biomechanical and functional analysis, and in most cases do not include in vivo implantation. In order to address the critical need for transplantable organs, addressing the biomechanical requirements and longevity of the engineered organ is paramount. Future studies should aim for this standard of translation.

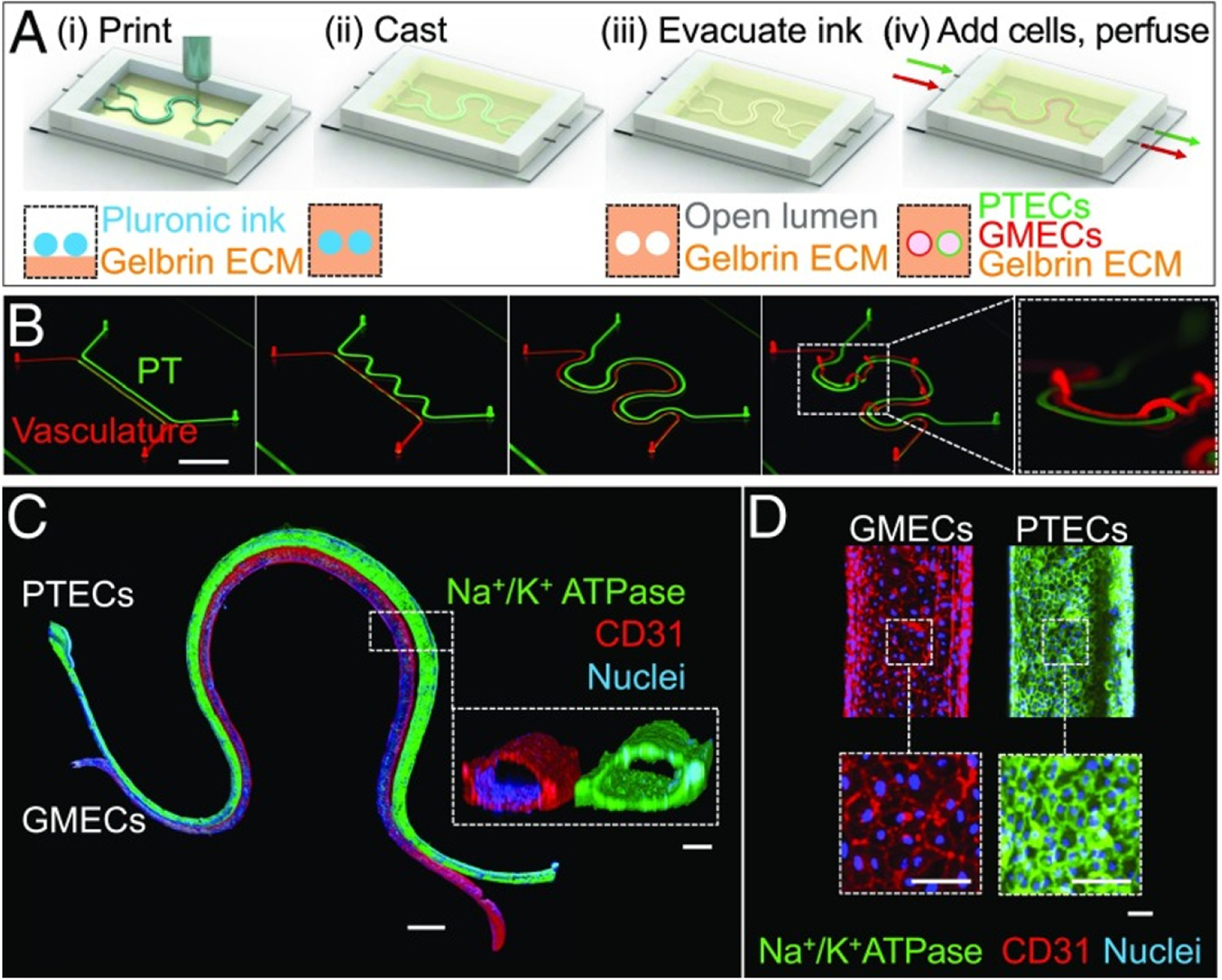

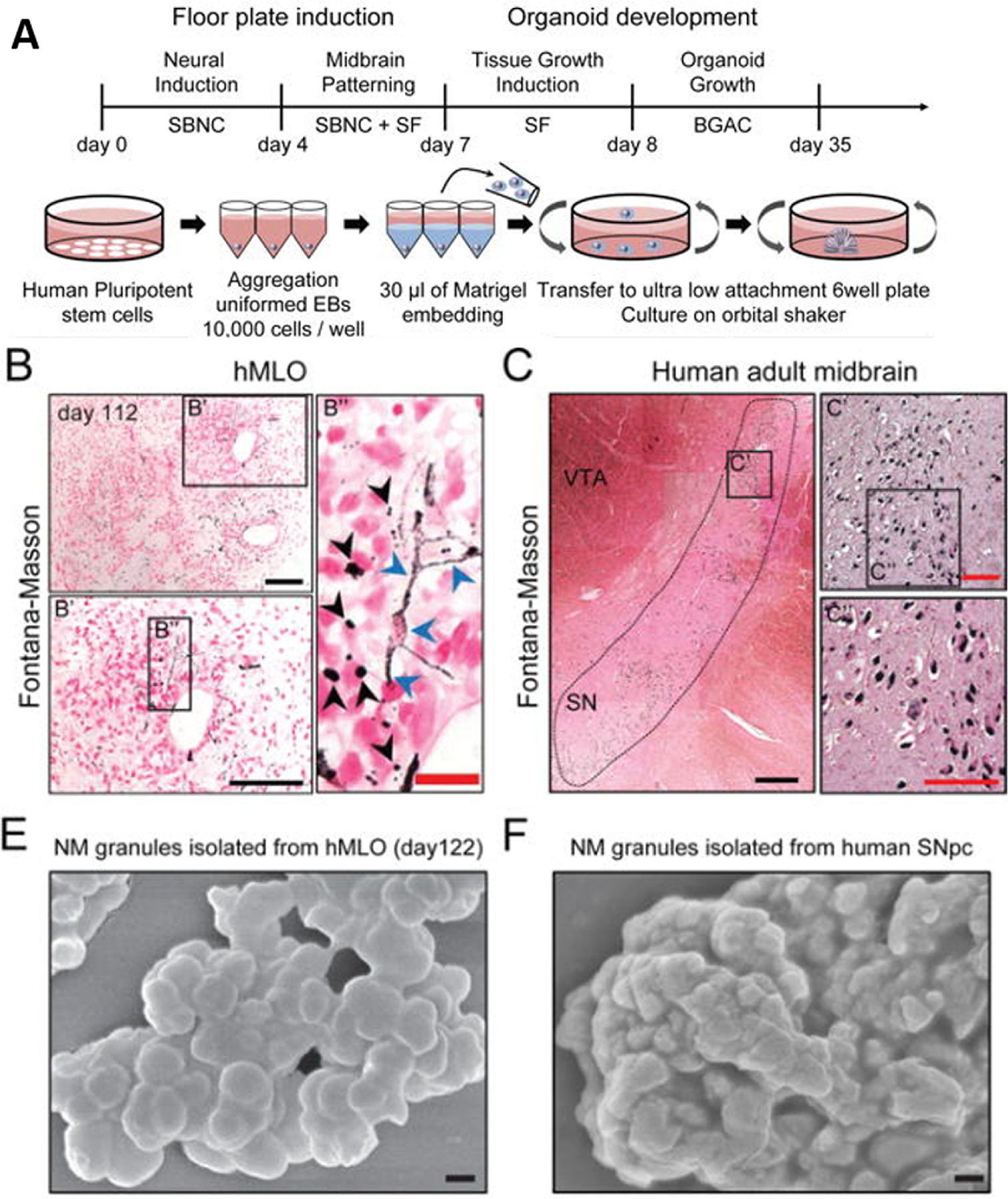

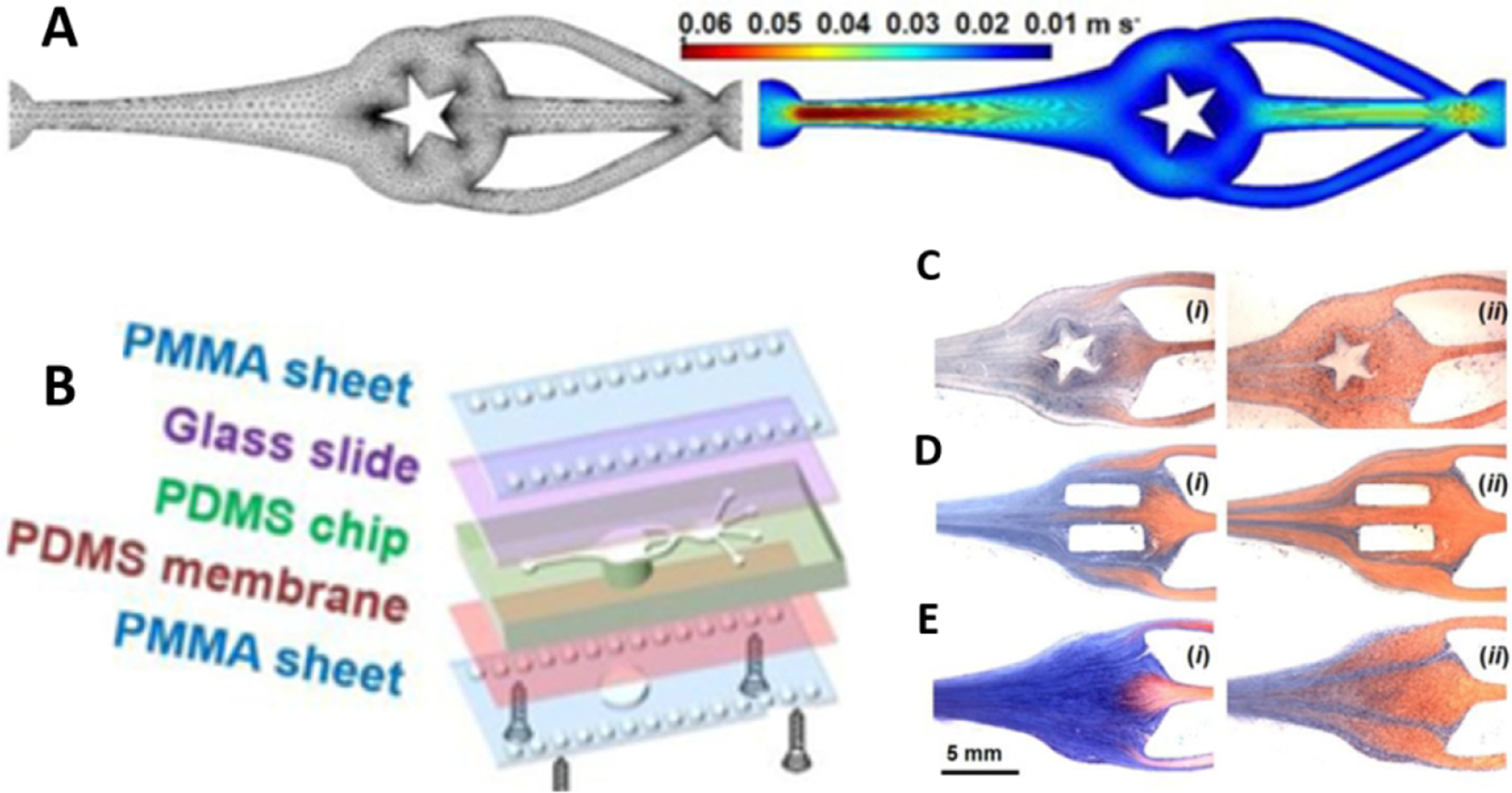

Figure 10. 3D Bioprinted neonatal-scale human heart fabricated using the FRESH 3D bioprinting technique.