Abstract

In recent years, there has been an increase in demand for bioactive techniques in the food packaging industry. Although edible packaging is popular, it has yet to be effectively implemented into the market. Packaging made of plastics and chemicals is widely employed in the market today, posing a threat to the environment and living creatures. This research attempts to show current breakthroughs and progress in the field of biodegradable packaging. When compared to ancient packaging materials, bio-based packaging materials are safer. Sustainable biodegradable packaging materials can be made from edible films, coatings, and other bio food packaging techniques made from various biological resources. This paper discusses the important qualities and advantages of several bio-based packing materials. It is highlighted the advantages of bio-based packaging materials over synthetic packaging materials. It has been debated the importance of employing bio-based packaging to mitigate the environmental risks associated with traditional packaging technologies. Many researchers may be prompted by this study to focus on packaging reformulation options. Thus, we can attain food packing materials by considering customer's economic and sustainability aspects.

Keywords: Sustainable development, Bioactive strategies, Biopolymers, Edible films, Environmental pollution

Sustainable development; bioactive strategies; biopolymers; edible films; environmental pollution

1. Introduction

The fundamental purpose of the food sector in today's generation is to protect food from contamination and environmental damage. This entails transporting food from one location to another as well as providing consumers with correct nutritional information about the packaged contents [1]. Food packaging incorporates a number of factors, including power and resource economic viability, recyclability, sustainability, and disposability. The packaging materials are carefully chosen to provide the desired mechanical, physical, and thermal resistance, as well as optical, barrier, and antibacterial properties. To enhance the shelf life, the food production and packaging standards are governed over the above-specified features [2].

Packaging is a necessity in today's society, as practically all consumer items on the market appear to be packaged with a restricted amount of packaging materials. A packaging material should be appealing to the consumer and convey all relevant information about the food item, in addition to protecting the food material from external damage. Traditionally, a variety of materials such as glass, metal, wood, plastic, paper, or a combination of materials have been used for various types of packaging such as primary, secondary, and tertiary packaging. Primary packaging materials that come into contact with consumer items are frequently applied domestically with the help of the customer and disseminated at the family level can become infected or fractured as a result of coming into contact with various chemicals. Secondary packaging materials, on the other hand, are used to percent the various devices of primary packaged commodities, whereas tertiary packaging materials help convey synthetic items in wood pellets, cardboard boxes, or plastic wrap. As a result, merchants, distributors, and manufacturers rely heavily on secondary and tertiary packing materials. Hence, they are less difficult to gather and identify for reuse or recycling. The major packaging substances, on the other hand, typically cause reuse or recycling issues because separation is a time-consuming procedure [3]. As a result, garbage disposal becomes more difficult, raising environmental concerns.

Biopolymer-derived films have been shown to be the ideal matrix for developing useful packaging substances including a variety of additives such as antibacterial agents, antioxidants, nutrients, and colours, among other things. Active ingredients keep food wholesome and safe while also extending the shelf life of the product by preventing microbial development. One of the significant advancements in food packaging technology is the incorporation of antimicrobial agents into biopolymer-based entirely edible films. Furthermore, the addition of antimicrobial agents to packaging materials may result in a complete lack of antimicrobial activity. As a result, selecting the appropriate antimicrobial agent as the packaging material for a certain product and the proper packaging for a specific quantity of food is critical [4]. Antimicrobial packaging is a fantastic way to decrease, limit, or prevent the growth of spoilage and pathogenic bacteria in food products, and it has piqued the interest of the packaging industry because of its positive influence on food safety as well as shelf life extension.

In the food sector, synthetics, metals, and glass are commonly utilised as packaging materials. Traditional processing techniques are used to prepare these materials, which are then used in a variety of food packaging applications. Polyethylene, a petroleum-based polymer, is the most often used polymer in the food packaging industry. PE and other forms of synthetic polymers are difficult to degrade biologically after disposal in land or water bodies, resulting in hazardous amounts of contamination [4]. People all across the world are worried about the loss of naturally available resources like fossils for the manufacturing of synthetic polymers, which takes millions of years to replenish [5]. These non-biodegradable plastics are causing considerable harm and destruction to the environment, water bodies, and the entire ecosystem, despite their convenience and use. Consumers of today are aware of issues such as the environment, ethics, food safety, food quality, and product pricing. As a result, they are paying more attention to sustainable development elements and demanding that efforts be made to develop biodegradable packaging.

Biodegradable packaging materials have a number of benefits over synthetic plastics, including biodegradability and compostability, as well as the use of renewable raw resources. Biopolymers and paper-based products are examples of biodegradable and recyclable packaging materials [6]. Many of these bio-based chemicals have been demonstrated to minimise moisture loss, leak, reduce oxidation concerns, and increase scent qualities, as well as improving properties including colour retention and resistance to microbial attack.

Food packaging has undergone a major transformation as a result of edible films and coatings' capacity to reduce the use of traditional and harmful polymers. With rising concerns about food safety and a shift in people's attitudes toward healthy eating and living, the food industry is being compelled to fine-tune a number of factors to match customer demands. Food packaging is one of the many factors to consider. This section has been continually groomed to fit the changing customer perspective. As a result, the purpose of this review is to explain the many types of food packaging, as well as their benefits and drawbacks, in order to provide a better understanding of the subject.

2. Bio-based polymers

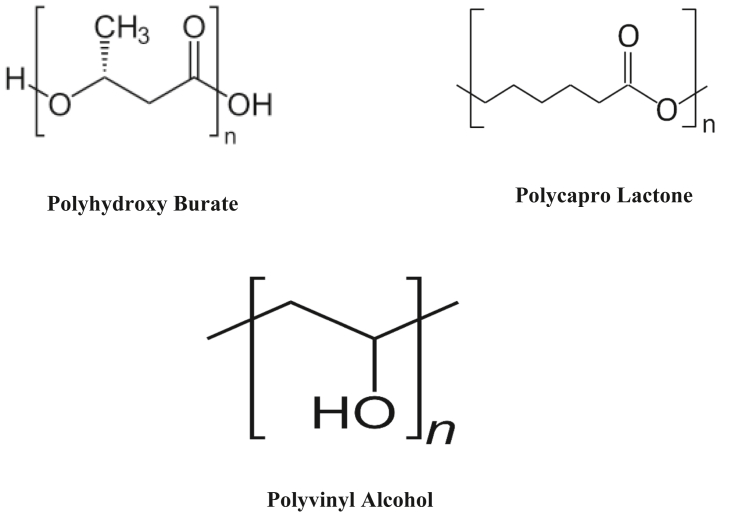

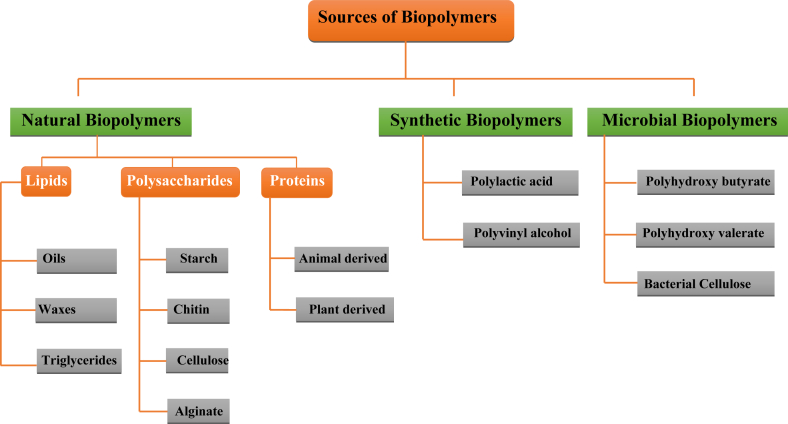

Biopolymers derived from entirely renewable organic substances are used to make bio-based packaging, which must be biodegradable at the end of its life cycle. While biodegradable packaging can be made primarily from fossils, fossil-based chemicals, or a combination of renewable and fossil materials, the material must be totally decomposed and returned to the natural world. Based on certain criteria, biodegradable packaging material can be classified into a variety of types. They can be categorised into numerous categories based on the presence of essential elements. Inherently biodegradable polymers have a specific level of biodegradability. These are essentially artificial oil-derived polymers like polyhydroxy butyrate (PHB), polycaprolactone (PCL), and polyvinyl alcohol (PVA) [Figure 1]. Biopolymers are biologically formed polymers or long-chain biomolecules such as starch, cellulose, proteins, and other biopolymers that breakdown into green metabolic products. However, the most prevalent criterion used to classify biodegradables is the source of raw materials and the process by which they are synthesised. Biodegradable compounds are divided into three groups based on this classification. Polymers made from natural materials, mainly plants, are known as natural polymers. Natural polymers include polysaccharides such as starch and glucose. Synthetic polymers are polymers made chemically from renewable polymers, such as poly acetate from lactic acid monomers [7]. Polymers generated from microorganisms or genetically modified bacteria are known as microbial polymers. Polyhydroxy alkanoates are a famous example of microbial polymers in the energy substrate function. The numerous sources of biopolymers are depicted in Figure 2.

Figure 1.

Structures of oil derived biopolymers.

Figure 2.

Sources of biopolymers.

Biopolymers (biobased polymers) are materials made from renewable resources [8]. Their key distinguishing trait is biodegradability, which means they decompose quickly. Polymers derived from biological sources and derived from renewable resources must be biodegradable and decomposable, allowing for packaging disposal in the soil, where they can work as fertilisers and minimise soil contamination, which is more energy-efficient than recycling [9]. Natural polymers have challenging structures and consequently pose processing challenges in the context of sustainable development. For improved conversion and widespread usage of bio-based polymers from renewable resources, the technique of reactive extrusion (REX) and enzymatic action has been used [10].

Third-generation food packaging is made entirely of biobased materials and can be divided into three groups based on their origin and manufacturing method. Polymers directly produced from biomass, polymers processed by traditional chemical fusion from biomass monomers, and polymers shaped directly by natural or genetically modified organisms are all characterised as such [11].

2.1. Polymers directly obtained from biomass

This category includes polymers that are extracted or removed straight from biomass. This includes polysaccharides like chitin, starch, and cellulose, as well as proteins like casein and gluten. These compounds have a degree of hydrophilicity and crystallinity, which might present issues during processing. Furthermore, these polymers function poorly, particularly when it comes to the packaging of moist food goods. Biopolymers, on the other hand, perform as good gas barriers and are consequently used in the food packaging business [12].

Polysaccharides, such as starch, cellulose, chitosan, gums, and other polysaccharides, proteins, such as animal extracted protein (casein, collagen, gelatin, etc.) and plant-derived protein (zein, gluten, soy, etc.), and lipids, including related triglycerides, are among the commonly available natural polymers derived from animal, marine, and agricultural sources. The majority of those polymers are hydrophilic and crystalline, which could explain why there are so many issues with wet food packaging. Aside from these limitations, these polymers act as a strong barrier to gas transport.

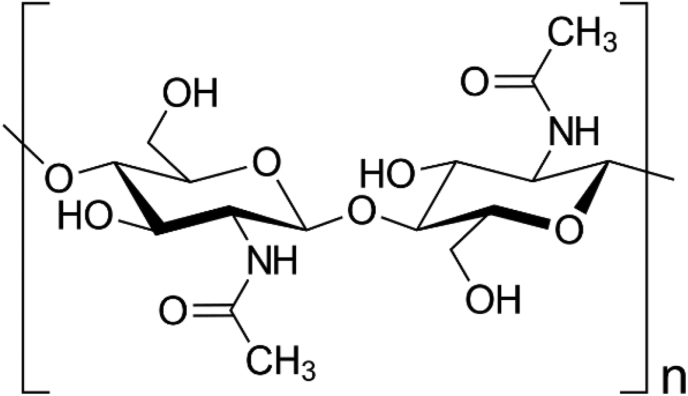

2.1.1. Polysaccharide: chitin and its derivatives

Chitin is the second most abundant natural biopolymer on the planet. Chitin is a major structural component of invertebrates' exoskeletons, insects' exoskeletons, yeast's cell walls, and fungi's cell walls [13]. White, rigid, and inelastic nitrogenous polysaccharides make up chitin's physical qualities [14]. Chitin is made up of N-acetyl-2-amino-2-deoxy-d-glucose units that are bonded together in a linear polysaccharide (1 4) structure [Figure 3]. The distinction between chitin and cellulose is that in chitin, the hydroxyl group of the C2 carbon is replaced with an acetamide group [15]. However, due to its insolubility in many solvents, chitin's industrial applicability is limited [16]. Chitosan is a polymer made from chitin that has been partially N-deacetylated. Chitosan is a biodegradable polymer made from partial N-deacetylation of chitin in the presence of alkaline deacetylation (in the presence of 40–50 percent NaOH). Deproteination, demineralization, and decolorization are all steps in the process of isolating chitin from other substances, and they remove protein, salts, and colour, respectively [17].

Figure 3.

Structure of chitin.

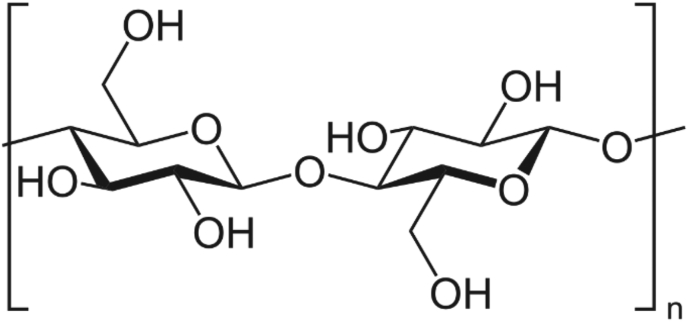

2.1.2. Starch

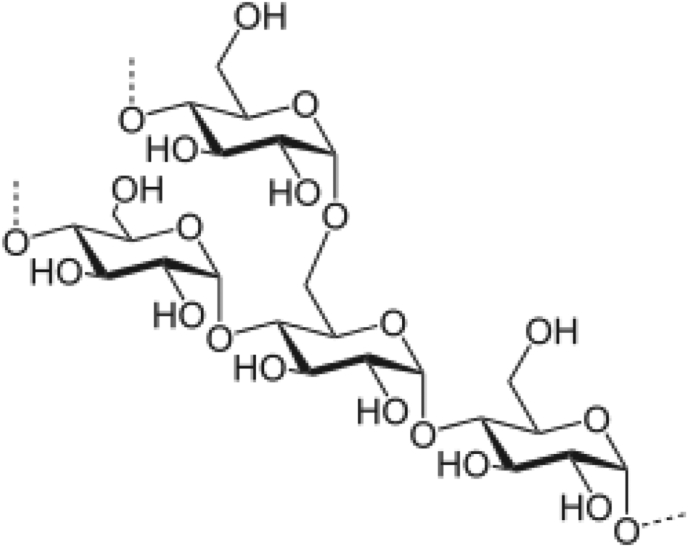

Starch is known as one of the economically feasible and widely available groups of biodegradable polymers [Figure 4]. They are considered a cheap source of polysaccharides and are classified as hydrocolloid biopolymers. Starch is generally utilized as a thermoplastic. Different varieties of starch including rice, corn, cassava, potato, and tapioca are used for the synthesis of biodegradable polymers [18].

Figure 4.

Structure of starch.

Casting and extrusion are common methods for creating starch-based films. Polylactic acid (PLA), polycaprolactone (PCL), or polyethylene are commonly used to combine starch with less moisture-sensitive polymeric compounds (PE). Because starch has a high moisture sensitivity, blending is required to create a bio-based product that is totally biodegradable in the environment [19]. The UV-irradiated starch films have increased moisture sensitivity. The physical and mechanical properties of UV-based starch films have also been changed [20]. Plasticizers are used to minimise brittleness. The commonly used plasticizers include glycerol, sorbitol, and xylitol. The physical and mechanical properties of starch films blended with glycerol were estimated to be greater. Increased concentrations of xylitol and sorbitol showed variations in the characteristic features of films [21].

Starch is commonly used as a biodegradation additive. Starch is important for enhancing oxygen permeability since it is broken down by bacteria. Starch additives are broken down faster by microorganisms than synthetic polymers used in interior blends. Biodegradable packaging materials include starch-filled and starch-based polymers. After being restructured in the presence of a particular amount of water and heating, plasticized starch can be extruded for use as a thermoplastic. The most common plasticizers are polyols and glycerol. Retrogradation, which is a recrystallization reaction, can also be caused by polyols. The parameters of extruded starch are influenced by the water content and relative humidity. TPS (thermoplastic starch) is a material that is particularly sensitive to moisture. The thermal properties of TPS have been demonstrated to be proportional to the amount of water present in the material. If the total volume of moisture content exceeds the molecular weight of starch, the TPS produced is amorphous.

2.1.3. Cellulose

Cellulose [22] [Figure 5] is a natural polymer made up of beta D-glucose. In the petrochemical industry, cellulose has been used as a necessary alternative. This organic material is abundantly available, degradable, and reusable. Fiber strength is generated through hydrogen interchain bonds, which prevent melting. The cellulose structure can absorb a large amount of water, but it cannot dissolve in water [23]. Because of the existence of hydroxyl structures and a regular structure that leads to the creation of crystalline microfibrils and fibres with strong hydrogen bonds, cellulose is commonly utilised in packaging as paper or cardboard. Cellulose in its natural state could be difficult to employ as a packaging material since it is hydrophilic and crystalline, with mechanical qualities that are undesirable. As a result, it must be treated with chemical chemicals such as NaOH, H2SO4, and others to produce cellophane with suitable mechanical properties for use as a packaging material. Cellophane has long been used in commercial food packaging for products that require a long shelf life. Similarly, carboxymethyl cellulose, methylcellulose, ethylcellulose, cellulose acetate, hydroxyethylcellulose, and other cellulose derivatives are widely utilised.

Figure 5.

Structure of cellulose.

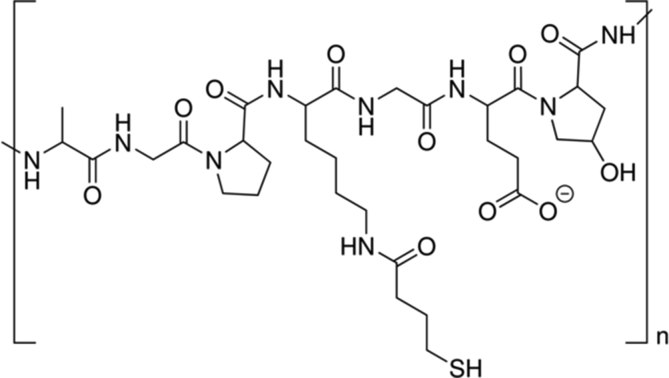

2.1.4. Gelatin

Gelatin consists of 50.5% carbon, 6.8% hydrogen, 17% nitrogen and 25.2% oxygen [Figure 6]. Chemical denaturation is used to create gelatin from the fibrous insoluble protein collagen. Gelatin is extracted from bones, skin, and connective tissues that are discarded during processing of animals. Based on the gelatin pretreatment, gelatin can be classified into two categories. Acid-treated collagen yields Type A gelatin with an isoionic factor of six to nine, while alkali-treated collagen yields Type B gelatin with an isoionic factor of five. Pig skin gelatin is referred to as Type A gelatin, whereas pork skin gelatin is referred to as Type B gelatin. The fundamental characteristics of the source, the age of the animal, and the kind of collagen have a major impact on the properties of gelatin, according to Johnston-Banks. In addition to the existence of lower molecular weight protein fragments, the physical properties of gelatin are influenced by the amino acid composition, the relative material content of -chains, - or -additives, and better molecular weight aggregates. Due to their low cost and easy availability, they are employed for the synthesis of film packaging. Covalent bonds are interconnected in collagen-like rigid molecules [24]. Gelatin is a good bio-based polymer because of its low melting point [25].

Figure 6.

Structure of gelatin.

The most essential physical features of gelatin are gel energy and viscosity. Gel energy, also known as Bloom value, is a measure of the gelatin's energy and stiffness, indicating the constituents' shared molecular weight, and is normally between thirty and three hundred bloom (Below 150 is taken into consideration to be a low Bloom, 150–220 is considered to be a medium Bloom and 220–300 is termed as excessive Bloom). With about 175 gel energy, higher bloom values indicate more gelatin. Gelatin, whether powdered or granulated, is an odourless and tasteless material. It can be employed as a thickening, gelling, foaming, emulsifying, and film-forming agent, among other things. Because gelatin is hygroscopic, it absorbs water depending on the relative humidity of the environment in which it is dried and stored. Gelatin films are used to extend the shelf life of some foods. Gelatin has a high oxygen retention capacity when compared to other biodegradable polymers.

Gelatin is widely used in the food, pharmaceutical, cosmetic, and photography sectors due of its unique qualities. Gelatin is used in the food sector for bread, dairy, beverages, and confectionary gelling, stabilisation, texturization, and emulsification. Meanwhile, gelatin is used in the pharmaceutical industry to make hard and smooth capsules, plasma expanders, ointments, wound dressings, and emulsions. Gelatin has been utilised as coating layers, emulsion layers, and non-curl layers on photographic materials in the photographic industry.

2.2. Polymers processed by classical chemical fusion from biomass monomers

2.2.1. Polylactic acid (PLA)

The building block for PLA is lactic acid, which may be obtained via the fermentation of maize or other agricultural resources. PLA is advantageous owing to its biocompatibility, processability, renewability, and minimal strength consumption. In contrast with biopolymers, inclusive of poly (hydroxy alkanoates) (PHAs) and poly (ethylene glycol) (PEG), PLA has good thermal processability. It could be made synthetic via diverse processing strategies inclusive of extrusion, movie casting, and fiber spinning. PLA has been approved by the Food and Drug Administration (FDA) for use in packaging with direct contact with the food inside, and has become a good candidate for the packaging of clean meals or quick service lifestyle goods, including overwrapping, lamination filming, and blister packaging, due to its biodegradable and biocompatible properties. PLA's characteristics are likewise similar to those of polyolefin and polyethylene terephthalate (PET), therefore those compounds can be used in a wide range of applications. Due to its functional features, such as excessive transparency, good barrier residences, good sealability, good oil and grease resistance, and outstanding organoleptic characteristics, there are possible options for food packaging.

Using sustainable bio-based monomers, some polymers are created using traditional chemical processing procedures. Polylactic acid is a nice example of a chemically synthesised polymer. Polylactic acid [26] is a biodegradable polyester made from of lactic acid monomers. PLA is biodegradable, eco-friendly, recyclable, and decomposable, among other qualities. PLA is biocompatible since it has no harmful or carcinogenic properties. PLA can resist a wide range of temperatures. PLA can be manufactured with less energy (between 25 and 55 percent) [27]. PLA is made from maize starch, which is collected from plants like corn. During the growing period of maize, carbon dioxide from the environment is used for photosynthesis. As a result of the photosynthesis process, glucose is converted to starch, resulting in PLA chain formation. The fermentation of maize and agricultural biomass yields lactic acid, a building block for PLA [28].

2.2.2. Polyvinyl alcohol

Because of its enhanced capabilities to shape the film, artificial water-soluble polymer, chemical resistance, top biodegradability, and ease of manufacturing, polyvinyl alcohol (PVA) offers a wide range of benefits. Because of its hydroxyl groups, PVA has unique physical properties that encourage the formation of hydrogen bonding [29]. Polyvinyl alcohol can quickly destroy biological polymers. In the last century, a wide range of goods using PVA were manufactured in a variety of industries. Medication, food, surgical threads, resins, and lacquers were among the items. Therefore, it may be concluded that the PVA can be used as a coating for specific dietary supplements of food and it does not have any issues of safety.

2.3. Polymers shaped directly by natural or genetically modified organisms

Bacteria can produce a wide range of biopolymers with different biological activities and properties that can be used in a variety of industrial and medical applications. Polysaccharides, polyesters, polyamides, and inorganic polyanhydrides (such as polyphosphates) are the four principal types of polymers produced by bacteria [30]. Polyhydroxyalkanoates (PHAs) are plant-based intercellular sugars or lipids that contribute to linear polyesters by microbial fermentation [31]. Polystyrene (PS), polyethylene terephthalate (PET), low-density polyethylene (LDPE), and high-density polyethylene (HDPE) are all effective alternatives to PHAs (HDPE). The techniques used to process PHA films are injection moulding, melt-extrusion techniques, and thermoforming. PHA-based composite films are employed in food packaging industries due to their enhanced film barrier properties, thermal stability, and mechanical features [32].

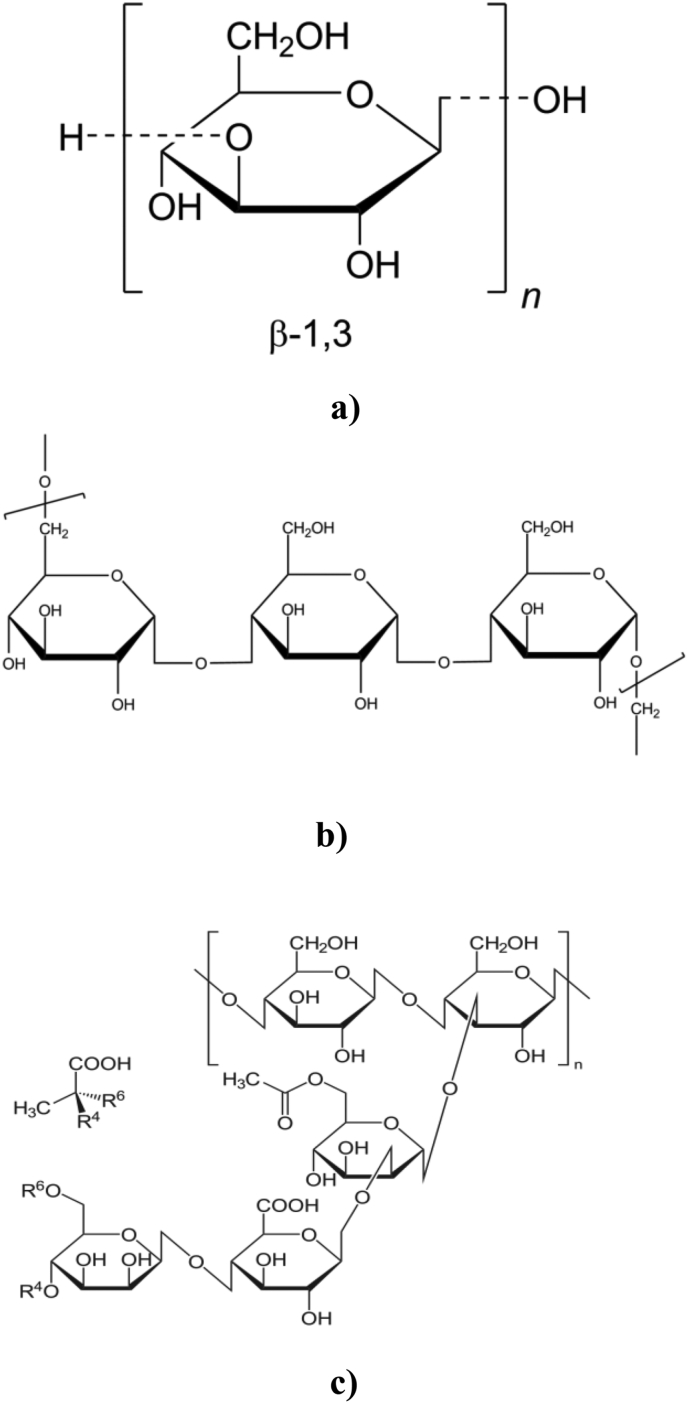

The use of microbial polysaccharides as packing materials, such as xanthan, pullulan, and curdlan, necessitated the use of biotechnological processes [Figure 7]. Pullulan is a water-soluble, linear, and exopolysaccharide that is produced by Aureobasidium pullulans from sugar-containing substrates. It's used in a variety of industries, including food, medicine, and cosmetics, for packing. It has no taste or odour and is non-toxic and biodegradable. Pullulan-based films are normally transparent, homogenous, heat sealable, printable, flexible, and edible, with excellent oxygen barrier qualities. However, they have poor mechanical properties.

Figure 7.

Structures of a) Curdlan b) Pullulan and c) Xantham.

Xanthan, on the other hand, is made by the aerobic fermentation of Xanthomonas campestris with sucrose or glucose as the main carbon source. It's a heteropolymer made up of repeating glucose, mannose, and glucuronic acid units in a 2:1:1 ratio, as well as pyruvate and acetyl substituent groups. It's viscous, soluble in water, and non-toxic. There aren't many records about xanthan's ability in the packaging industry. This is due to the high cost of production.

3. Edible films, coatings, and gels

Polysaccharides and proteins are a major class of biopolymers that are currently being studied for the preparation of films and coatings whose features can be altered to achieve the packaging needs of various categories of food products [33]. Emulsions have proven to be an efficient means to increase the storage life of a variety of fresh and processed fruits, vegetables, cheeses, and other food products [34]. Edible films and coatings consist of materials that can be consumed directly having an advantage of being decomposable and eco-friendly [35]. These films and coatings may be utilized as specific food packaging substances, coatings, and active carriers of matter and to distinguish between the sections of various ingredients within foods [36]. Based on the substances used for the synthesis of edible films and coatings, they are categorized into four main divisions: hydrocolloids, proteins, lipids, and composite films.

Dissolving the edible component in solvents such as water, alcohol, or a mixture of solvents is how films are made. A plasticizer is added to the solution to improve flexibility and elasticity. Antimicrobial agents, colours, and flavours can be added to the mix to obtain various film characteristics and functional properties depending on the application. Techniques like continuous film casting, mould casting, and drawdown bar are utilised in the commercial manufacture of edible films. Mold casting and a drawdown bar are employed in the lab-scale manufacturing of a film. These are thought to be less expensive and simpler [35]. Edible films and coatings are promising methods when it comes to improving food quality, shelf life, safety, and usefulness [36].

Proteins have a good adhesive nature and operate as barriers against O2 and CO2 on hydrophilic surfaces. Caseins can form films from aqueous solutions without any extra processing due to their random coil nature and propensity to establish hydrogen bonds. Electrostatic interactions cause the production of casein-based edible films. Gelatin is used in edible coatings to prevent moisture, oxygen, and oil from escaping. Collagen is one of the most well-known commercial edible protein films. Hydrolyzed collagen films with high concentrations have homogenous surfaces. Plasma proteins are made up of albumin, globulins, and fibrinogen, and they have characteristics including gelation, foaming, and film formation. Caffeic acid, tannic acid, and ferulic acid are phenolic chemicals that can improve the mechanical stability of films by causing protein aggregation [37].

Integrating functional elements such as antibacterial agents and antioxidants into edible films and coatings can improve the effectiveness of active food packaging materials. Antimicrobial enzymes, phenolic compounds, essential oils, and bacteriocins are among the most commonly employed active ingredients [38]. Starch, alginate, cellulose, ethers, chitosan, carrageenan, and pectin are all polysaccharides. They give the films thickening, viscosity, adhesion, and gel-forming properties. The films have exceptional gas permeability due to the presence of polymer chains, resulting in changed atmospheres within the packaging environment to extend the shelf life of the product without anaerobic contact [39].

Because of their environmental appeal, cheap cost, flexibility, and transparency, starch-based films in the food packaging business are a potential option. Because starch-based edible films are tasteless and odourless, they prevent food items from changing their taste, flavour, or appearance. In the amorphous phase, macromolecular chain mobility determines the tensile strength and flexibility of starch films. Starch films have strong barrier characteristics to O2 and CO2, but they have weak barrier capabilities to water due to their high hydrophilicity [40].

Antimicrobial-infused chitosan coatings and films increase the storage quality and shelf life of harvested fruits and vegetables. Chitosan coatings and films have properties such as the ability to form a thin film on the surface of the fruit, the ability to prevent moisture loss, the ability to block oxygen penetration into plant tissue or microbe growth, and the safety of using the film on food. Antimicrobial substances such as essential oils, acid compounds, and nanoparticles have been put into the chitosan coated films. The antimicrobial-enhanced chitosan covering inhibited the growth of bacteria, yeast, and moulds extremely well [41]. Modifying the rate of respiration, maintaining firmness, reducing weight loss, controlling decay, delaying senescence and ripening, maintaining quality, acting as a carrier for active substances, controlling lost nutrients, and maintaining the aroma of the components are all advantages of chitosan-based coatings and films on fruits and vegetables [42].

4. Antimicrobial films

The incorporation of antimicrobial chemicals into edible films used in food packaging gives the concept of biodegradable food packaging a whole new meaning. They've been used to minimise and inhibit microbial development on the surfaces of food products. The antimicrobial agent is introduced directly into the food particles or into the packaging material to maintain the food's quality and safety. It is released over time, resulting in a longer shelf life. On food, antimicrobial medicines can have a microbicidal or microbiostatic effect [43].

Essential oils are mixed into basic chemicals that are coated on packaged foods and then inserted into antibacterial sachets. Aside from these methods, a mix of essential oils and polymers is commonly utilised in industrial production since it is easier and more convenient. Scientific research currently focuses on environmental sustainability. Blending essential oils with biodegradable polymers like PLA, skate skin gelatin, and chitosan is common all around the world under this criteria.

Bacteriocins are bacteria-produced bactericidal agents. Bacteriocins come from a variety of sources and have a variety of structures, which aids in the utilization of bacteriocins as a unique type of antibacterial agent. Nisin and Pediocin are two regularly used bacteriocins. A key type of enzyme, lysozyme, is made up of hydrophilic monopeptide chains. This enzyme can control bacterial infections, particularly those caused by Gram-positive bacteria. The beta-1–4 glycosidic linkages between N-acetylmuramic acid and N-acetylglucosamine in peptidoglycans can be hydrolyzed by lysozyme, resulting in antibacterial action. Lysozyme causes bacterial death by destroying the cell wall through the hydrolysis of peptidoglycan, an important cell wall component. Organic acids like propionic acid, lactic acid, malic acid, and tartaric acid are utilized as common food additives [44].

Due of its biodegradability, biocompatibility, cytotoxicity, and antimicrobial nature, chitosan films have gained substantial consideration as antimicrobial films for food preservation among other polymeric films. Evaporation of dilute acid solutions is used to create chitosan films. Chitosan has antibacterial capabilities because of its positively charged amino group, which interacts with negatively charged microbial cell membranes, causing protein and other intracellular microbe compounds to leak out. Peptidoglycan is a major component of Gram-positive bacteria's cell wall, as well as tiny proteins [45].

The carbon and hydroxyl groups found at positions 6 and 3 in chitin and chitosan exhibit active functional characteristics. The most significant distinction between these two sites is the amount of amino acid responsible for the film. The qualities of antimicrobial films are influenced by a number of parameters, including deacetylation weight, concentration, and pH. Antimicrobial substances, such as enzymes, polymers, and organic acids, have been utilised in the packaging of food goods. Every microbiological material has unique properties in terms of its mechanism. Most of the films inhibit the growth of the microorganism and its reproductivity and some undergo conformational changes in their outer membrane [46]. Films are divided into two categories, films that enable antimicrobials into food and films that prevent germs from growing in food [47]. Several studies have been conducted on antimicrobial film and bacterial growth. Several film qualities, such as density, heat, and physical properties, have an impact on the films. The antimicrobial agents used are solely determined by their level of impact on the food. They are crucial in determining the application of the film as well as the product's lifespan. These agents are combined in a polymer matrix to create packaging films that help to limit the growth of microorganisms [48]. In order to use antimicrobial films in food packaging, several polymers are combined with them increase their efficiency. It's an efficient alternative strategy for reducing and inhibiting the growth of microorganisms that are harmful to food. It has proven beneficial impacts in terms of food quality and safety, as well as a longer shelf life. It works by extending the log phase, lowering the cell count, and effectively inhibiting microbial growth. Fruits, meat, and dairy items are susceptible to microbial deterioration and can be prevented utilising packaging techniques. The packaging system primarily attempts to achieve three goals: maintenance, safety, and a longer shelf life [49]. Antimicrobial drugs' actions and features can also be explored [50]. The mechanism and physiology of these agents influence their activity.

The microbial cell's negative group reacts with the positive side of chitosan, causing a change in the cell membrane. The microbial cell becomes permeabilized as a result of this process, and the cell dies. When chitosan diffuses into the cell membrane, it inhibits RNA and promotes protein formation. Metal ions react with chitosan's negative groups. Chitosan covers the permeability of gas and nutrients into the microbial cell. Table 1 shows the benefits and drawbacks of bio-based polymers.

Table 1.

Advantage and disadvantage of bio-based polymers.

| Advantages | Disadvantages |

|---|---|

| Carbon dioxide levels can be decreased by bio-based polymers | Procedure of disposal must be precise |

| Emission of greenhouse gas levels can be reduced | Biopolymers comprises of some metal particles |

| Polymers are broken down by bacteria which occurs naturally | Recycling amount may be educed |

| Amount of waste can be reduced | Protection is required because they contain toxins |

| It can be mixed along with the olden forms | Limited lifetime for the bio-based polymers |

| It is chemical free and cost effective | Compared to oil-based polymer it is cost extensive |

| Only less energy is required | Elimination of hard substance takes place slowly |

| In the decomposition dangerous items are not exposed | Pollution in ocean and sea cannot be resolved by these biopolymers |

| They have good chemical, physical and mechanical properties | Low physical and mechanical resistance |

5. Nanocomposites in bio-food packaging

A bionanocomposite is a substance made up of two or more components, which include a continuous and a non-continuous phase [51]. With the merging of nano products, the use of nanotechnology in food packaging has expanded in recent years. This method uses nanostructure materials to improve the level of food packaging while also improving the product's safety [52]. When Nanofillers are used in a packaging system, they interact with the food material and function as an antibacterial agent, extending the shelf life of the product [53, 54]. In place of synthetic substances, inorganic nanostructures are employed in packaging. Nanocomposite multiphase materials have both continuous and discontinuous phases and are typically made from renewable resources. Bio-based nanocomposites have been widely used in food packaging in recent years. They have the dual function of safeguarding food while also extending the shelf life of food. This ensures that the food being packed is as safe as possible. The bulk of food items are kept at the right temperature. Even if it is kept in perfect condition, its factors vary, affecting the quality and shelf life of the food products. Encapsulation in nano-systems is a two-step procedure for nanoparticle synthesis that is currently being developed in the food industry. The nanocarriers are first sealed with antimicrobial film materials, and then their size is drastically reduced in the next stage. This speeds up the adsorption process. Also, when the surface area is large, bioactive chemicals are released [55, 56]. It shields the agents from a variety of external influences [57]. Nanoliposomes coated with nisin, for example, had a greater rate of material retention [58]. Contaminants can be detected using nanosensors [59].

6. Future perspectives

With the constantly elevating demand and consequential broadening of the marketplace for minimally processed food products, efficient and innovative packaging technology have grown to become an indispensable part of the emerging guidelines employed for making food protection. Recently, biopolymers are extensively studied for analyzing their usage in the packaging area. This can create an opportunity to standardize their usage as a result of their ecological and trustworthy nature. However, their commercialization continues to be hindered by the existing restrictions on their barrier, thermal and mechanical attributes in addition to the related high production and processing expenses. The materials which are based on the fiber for the preservation of food are coated with a matrix of biopolymers which are then controlled by volatile antimicrobials. Thus, the industrialization of biopolymer-primary-based packaging substances calls for similar investigations and studies aimed towards enhancing the morphological and characterization studies to extend the shelf existence along with the growing dietary value. Various forms of strategies were effectively employed to improve the physical traits and overall performance of the packaging substances, several of which encompass chemical and physical alterations, polymeric blending, and nanocomposites.

7. Conclusion

The growing environmental awareness has resulted in increased concern over plastics and plastic-related packaging. Though this paved way for the use of biopolymers, their commercial usage and value are still limited due to various factors such as variations in temperature, high cost, and variation of quality. To overcome these setbacks there is utmost need to perform profound research in the field of biopolymer and bioactive packaging. Research is to be conducted to bring out a suitable pathway for production that can contribute to an increased standard of product quality at a reasonable price resulting in its increased market value. A substantial consortium of a biopolymer enhanced with bioactive materials from plant sources can be a prospective alternative in the field of food packaging.

Declarations

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

The data that has been used is confidential.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Trinetta V. Definition and function of food packaging. Ref. Mod. Food Sci. 2016 [Google Scholar]

- 2.Ramos Ó.L., Pereira R.N., Cerqueira M.A., Martins J.R., Teixeira J.A., Malcata F.X., Vicente A.A. Bio-based nanocomposites for food packaging and their effect in food quality and safety. Food Pack. Pres. 2018:271–306. [Google Scholar]

- 3.Song J.H., Murphy R.J., Davies G.B.H. 2016. Biodegradable and Compostable Alternatives to Conventional Plastics. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Zhong Y., Godwin P., Jin Y., Xiao H. Biodegradable polymers and green-based antimicrobial packaging materials: a mini-review. Adv. Ind. Eng. Polym. Res. 2019 [Google Scholar]

- 5.Al-Tayyar N.A., Youssef A.M., Al-hindi Rashad. Antimicrobial food packaging based on sustainable bio-based materials for reducing foodborne pathogens: a review. Food Chem. 2019;125915:1–54. doi: 10.1016/j.foodchem.2019.125915. [DOI] [PubMed] [Google Scholar]

- 6.Majhi S., Tyagi A., Mishra A. Bio-polymeric packaging material for packaging of raw food. Ref. Mod. Mater. Sci. Mat. Eng. 2019 [Google Scholar]

- 7.Hujanen M., Linko Y.Y. Appl. Microbiol. Biotechnol. 1996;45:307–313. doi: 10.1007/s002530000501. [DOI] [PubMed] [Google Scholar]

- 8.Cutter C.N. Opportunities for bio-based packaging technologies to improve the quality and safety of fresh and further processed muscle foods. Meat Sci. 2006;74(1):131–142. doi: 10.1016/j.meatsci.2006.04.023. [DOI] [PubMed] [Google Scholar]

- 9.Ferreira A., Alves V., Coelhoso I. Polysaccharide-based membranes in food packaging applications. Membranes. 2016;6(2):22. doi: 10.3390/membranes6020022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Xu E., Campanella O.H., Ye X., Jin Z., Liu D., BeMiller J.N. Advances in conversion of natural biopolymers: a reactive extrusion (REX)–enzyme-combined strategy for starch/protein-based food processing. Trends Food Sci. Technol. 2020 [Google Scholar]

- 11.Rahman Rukhsana, Sood Monika, Gupta Neeraj, Bandral Julie D., Hameed Fozia, Ashraf Shafia. Bioplastics for food packaging: a review. Int. J. Curr. Microbiol. App. Sci. 2019;8(3):2311–2321. [Google Scholar]

- 12.Yadav Ajay, Mangaraj S., Singh Ranjeet, Das Sanjay Kumar, Naveen Kumar M., Arora Simran. Biopolymers as packaging material in food and allied industry. Int. J. Chem. Stud. 2018;6(2):2411–2418. [Google Scholar]

- 13.Srinivasa P.C., Tharanathan R.N. Chitin/chitosan — safe, ecofriendly packaging materials with multiple potential uses. Food Rev. Int. 2007;23(1):53–72. [Google Scholar]

- 14.Kumar Gadgey Kishore, Dr, Amit Bahekar. Investigation on uses of crab based chitin and its derivatives. Int. J. Mech. Eng. Technol. (IJMET) 2017;8(3):456–466. [Google Scholar]

- 15.Peniche C., Argüelles-Monal W., Goycoolea F.M. Chitin and chitosan: major sources, properties and applications. Monom, Polym. Compos. Renew. Res. 2008:517–542. [Google Scholar]

- 16.Kumari S., Rath P.K. Extraction and characterization of chitin and chitosan from (Labeo rohit) fish scales. Proc. Mater. Sci. 2014;6:482–489. [Google Scholar]

- 17.Sjaifullah A., Santoso A.B. Autolytic isolation of chitin from white shrimp (penaues vannamei) waste. Proc. Chem. 2016;18:49–52. [Google Scholar]

- 18.Yadav Ajay, Mangaraj S., Singh Ranjeet, Das Sanjay Kumar, Naveen Kumar M., Arora Simran. Biopolymers as packaging material in food and allied industry. Int. J. Chem. Stud. 2018;6(2):2411–2418. [Google Scholar]

- 19.Ozeren H.D., Olsson R.T., Nilsson F., Hedenqvist M.S. Prediction of plasticization in real biopolymer system (starch) using molecular dynamics simulations. Mater. Des. 2019:108387. [Google Scholar]

- 20.Shahgholian-Ghahfarokhi Davoud, Amin Shahsavar. 2020. Static Deflection and Free Vibration Analysis of Functionally Graded and Porous Cylindrical Micro, Nano Shells Based on the Three Dimensional Elasticity and Modified Coupled Stress Theories. [Google Scholar]

- 21.Shahabi-Ghahfarrokhi I., Goudarzi V., Babaei-Ghazvini A. Production of starch based biopolymer by green photochemical reaction at different UV region as a food packaging material: physicochemical characterization. Int. J. Biol. Macromol. 2018 doi: 10.1016/j.ijbiomac.2018.10.154. [DOI] [PubMed] [Google Scholar]

- 22.Sahu Mamata, Sahoo P.K. Bio polymers: sustainable alternative for food packaging. Int. J. Eng. Manag. Res. 2017:28–32. [Google Scholar]

- 23.Farmahini-Farahani M., Bedane A.H., Pan Y., Xiao H., Eic M., Chibante F. Cellulose/nanoclay composite films with high water vapor resistance and mechanical strength. Cellulose. 2015;22:3941–3953. [Google Scholar]

- 24.Wolf, Meredith Agiordano. 2003. Sharing Waters International Water Management. [Google Scholar]

- 25.Chentir Imene, nasri Moncef. 2019. Biofunctional Gelatin Based Incorporated with Food Grade Phycocyanin Extracted from the Saharaian Cyanobacterium. [Google Scholar]

- 26.Sahu Deepak, Swain Sarat .K. 2017. Nanosilver Imprinted Polyvinyl Alcohol Nanocomposite Thin Film for Hg Sensor. [Google Scholar]

- 27.Oz A.T., Sufer O., Çelebi Sezer Y. Poly (lactic acid) films in food packaging systems. Food Sci. Nutr. Technol. 2017;2(4) ISSN: 2574- 2701. [Google Scholar]

- 28.Gan I., Chow W.S. Antimicrobial poly (lactic acid)/cellulose bio nanocomposite for food packaging application: a review. Food Pack. Shelf Life. 2018;17:150–161. [Google Scholar]

- 29.Suput Danijela Z., Lazic Vera L., Popovic Senka Z., Hromis Nevena M. Edible films and coatings – sources, properties and application. Food Feed Res. 2015;42(1):11–22. [Google Scholar]

- 30.Rehm B.H.A. Bacterial polymers: biosynthesis, modifications and applications. Nat. Rev. Microbiol. 2010;8(8):578–592. doi: 10.1038/nrmicro2354. [DOI] [PubMed] [Google Scholar]

- 31.Soares R.M.D., Siqueira N.M., Prabhakaram M.P., Ramakrishna S. Electrospinning and electrospray of bio-based and natural polymers for biomaterials development. Mater. Sci. Eng. C. 2018 doi: 10.1016/j.msec.2018.08.004. [DOI] [PubMed] [Google Scholar]

- 32.Cano Amalia, Chafer Maite. 2016. Development and Characterization of Active Films Based on Starch PVA Containing Silver Nanoparticles. [Google Scholar]

- 33.Jimenez A., Requena R., Vargas M., Atares L., Chiralt A. Food hydrocolloids as matrices for edible packaging applications. Role Mater. Sci. Food Bioeng. 2018:263–299. [Google Scholar]

- 34.Mohamed S.A.A., El-Sakhawy M., El-Sakhawy M.A.-M. Polysaccharides, protein and lipid -based natural edible films in food packaging: a review. Carbohydr. Polym. 2020:116178. doi: 10.1016/j.carbpol.2020.116178. [DOI] [PubMed] [Google Scholar]

- 35.Trinetta V. Definition and function of food packaging. Ref. Mod. Food Sci. 2016 [Google Scholar]

- 36.Han J.H. Edible films and coatings. Innov. Food Pack. 2014:213–255. [Google Scholar]

- 37.Lacroix M., Vu K. Edible coating and film materials. Innov. Food Pack. 2014:277–304. [Google Scholar]

- 38.Chiralt A., Gonzalez-Martinez C., Vargas M., Atares L. Edible films and coatings from proteins. Proteins Food Proc. 2018:477–500. [Google Scholar]

- 39.Dhanapal Aruna, Sasikala P., Rajamani Lavanya, Kavitha V., Yazhini G., Shakila Banu M. Edible films from polysaccharides. Food Sci. Qual. Manag. 2012;3 ISSN 2224-6088 (Paper) ISSN 2225-0557 (Online) [Google Scholar]

- 40.Suput Danijela Z., Lazic Vera L., Popovic Senka Z., Hromis Nevena M. 2015. Edible. [DOI] [PubMed] [Google Scholar]

- 41.Films and coatings – sources, properties and application. Food Feed Res. 2015;42(1):11–22. [Google Scholar]

- 42.Xing Y., Xu Q., Li X., Chen C., Ma L., Li S., Lin H. Chitosan-based coating with antimicrobial agents: preparation, property, mechanism, and application effectiveness on fruits and vegetables. Int. J. Polym. Sci. 2016;2016:1–24. [Google Scholar]

- 43.Malhotra B., Keshwani A., Kharkwal H. Antimicrobial food packaging: potential and pitfalls. Front. Microbiol. 2015;6 doi: 10.3389/fmicb.2015.00611. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Huang T., Qian Y., Wei J., Zhou C. Polymeric antimicrobial food packaging and its applications. Polymers. 2019;11(3):560. doi: 10.3390/polym11030560. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Tripathi S., Mehrotra G.K., Dutta P.K. Chitosan based antimicrobial films for food packaging applications. e-Polymers. 2008;8(1) [Google Scholar]

- 46.Han J.H. Edible films and coatings. Innov. Food Pack. 2014:213–255. [Google Scholar]

- 47.Soares R.M.D., Siqueira N.M., Prabhakaram M.P., Ramakrishna S. Electrospinning and electrospray of bio-based and natural polymers for biomaterials development. Mater. Sci. Eng. C. 2018 doi: 10.1016/j.msec.2018.08.004. [DOI] [PubMed] [Google Scholar]

- 48.Sung S.Y., Sin L.T., Tee T.T., Bee S.T., Rahmat A.R., Rahman W.A.W.A. Antimicrobial agents for food packaging applications. Trends Food Sci. Technol. 2013;33(2):110–123. [Google Scholar]

- 49.Bastarrachea L., Dhawan S., Sablani S.S. Engineering properties of polymeric- based antimicrobial films for food packaging: a review. Food Eng. Rev. 2011;3(2):79–93. [Google Scholar]

- 50.Pan Y., Xiao H., Song Z. Hydrophobic modification of cellulose fibers by cationic modified polyacrylate latex with core–shell structure. Cellulose. 2013;20:485–494. [Google Scholar]

- 51.Zubair M., Ullah A. Recent advances in protein derived bionanocomposites for food packaging applications. Crit. Rev. Food Sci. Nutr. 2020;60(3):406–434. doi: 10.1080/10408398.2018.1534800. [DOI] [PubMed] [Google Scholar]

- 52.Anderson A., Dawes E.A. Microbiol. Rev. 1990;54:450–472. doi: 10.1128/mr.54.4.450-472.1990. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Ates B., Koytepe S., Ulu A., Gurses C., Thakur V.K. Chemistry, structures, and advanced applications of nanocomposites from biorenewable resources. Chem. Rev. 2020;120(17):9304–9362. doi: 10.1021/acs.chemrev.9b00553. [DOI] [PubMed] [Google Scholar]

- 54.Wróblewska-Krepsztul J., Rydzkowski T., Borowski G., Szczypiński M., Klepka T., Thakur V.K. Recent progress in biodegradable polymers and nanocomposites based packaging materials for sustainable environment. Int. J. Polym. Anal. Char. 2008;23(4):383–395. [Google Scholar]

- 55.Assadpour E., Jafari S.M. A systematic review on nanoencapsulation of food bioactive ingredients and nutraceuticals by various nanocarriers. Crit. Rev. Food Sci. Nutr. 2019;59(19):3129–3151. doi: 10.1080/10408398.2018.1484687. [DOI] [PubMed] [Google Scholar]

- 56.Assadpour E., Jafari S.M. A systematic review on nanoencapsulation of food bioactive ingredients and nutraceuticals by various nanocarriers. Crit. Rev. Food Sci. Nutr. 2019;59(19):3129–3151. doi: 10.1080/10408398.2018.1484687. [DOI] [PubMed] [Google Scholar]

- 57.Esfanjani A.F., Jafari S.M. Biopolymer nano-particles and natural nano- carriers for nano-encapsulation of phenolic compounds. Colloids Surf. B. 2016;146:532–543. doi: 10.1016/j.colsurfb.2016.06.053. [DOI] [PubMed] [Google Scholar]

- 58.Ibarra V.G., Sendón R., de Quirós A.R.B. In: Antimicrobial Food Packaging. Barros-Velázquez J., editor. Academic Press; San diego, CA: 2016. Antimicrobial food packaging based on biodegradable materials; pp. 363–384. [Google Scholar]

- 59.Suput Danijela Z., Lazic Vera L., Popovic Senka Z., Hromis Nevena M. Edible films and coatings – sources, properties and application. Food Feed Res. 2015;42(1):11–22. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data that has been used is confidential.