Graphical abstract

Keywords: Superabsorbent, Soil conditioner, Cross-linking, Grafting, Swelling index, Slow nutrient release, Water retention

Abstract

Background

The cumulative influence of global warming, climate abrupt changes, growing population, topsoil erosion is becoming a threatening alarm for facing food challenges and upcoming global water issues. It ultimately affects the production of food in a water-stressed environment and slows down the production with more consumption of fertilizers by plants. The superabsorbent hydrogels (SAHs) have extensive applications in the agricultural field and proved very beneficial for plant growth and soil health. These polymeric materials are remarkably distinct from hygroscopic materials owing to their multidimensional network structure. It retains a lot of water in its 3D network and releases it slowly along with nutrients to plant in stressed environment.

Aim of review

A soil conditioner boosts up the topology, compactness, and mechanical properties (swelling, water retention, and slow nutrient release) of soil. The superabsorbent hydrogel plays an astonishing role in preventing the loss of nutrients during the heavy flow of rainwater from the upper surface of soil because these SAHs absorb water and get swollen to keep water for longer time. The SAHs facilitate the growth of plants with limited use of water and fertilizers. Beyond, it improves the soil health and makes it fertile in horticulture and drought areas.

Key scientific concept of review

The SAHs can be synthesized through grafting and cross-linking polymerization to introduce value-added features and extended network structure. The structure of superabsorbent hydrogel entirely based on cross-linking that prompts its use in the agricultural field as a soil conditioner. The properties of a SAHs vary due to its nature of constituents, polymerization process (grafting or cross-linking), and other parameters. The use of SAHs in agricultural field comparatively enhances the swelling rate up to 60–80%, maximum water retaining, and slowly nutrient release to plants for a longer time.

Introduction

The superabsorbent hydrogels are three-dimensional matrix (3D) constituted by linear or branched hydrophilic polymers. Hydrophilic gels usually possess polymeric chains that may resemble colloidal gels in which water acts as dispersion medium [1]. The hydrogel polymer network can swell and retain the defined amount of water within its matrix but never dissolve itself in water [2]. The water absorption tendency of hydrogels arises from the hydrophilic functional groups of the polymer, while their reluctance to dissolution in water due to cross-linking of network chains [3].

The most common of these hydrogels are grafted and cross-linked polymeric networks that may be produced by the simple reaction of one or more monomers [4]. Hydrogels mostly consisted of two- or more components system extended over a three-dimensional network of polymer chains and water fills the space created between macromolecules to exhibit swelling and water retaining properties [5]. The swelling property of hydrogels depends upon nature and density of the monomer in an extended network of the polymer chain [6].

The soil hydrogels are frequently used as soil conditioners that boost up the growth of plants by providing them nutrients and water content periodically [7]. These hydrogels facilitate the growth of plants by giving a nutrient rich environment, maximum water absorbency, and slow release of nutrients. The slow release is a tremendous quality of soil hydrogels because the valuable nutrients get released slowly from hydrogel matrix and a plant can avail these nutrients for a longer time [8].

As it is concerned with hydrogel’s historical background, the term “hydrogel” was introduced first time in the scientific literature in 1894 for the description of colloidal gels made from inorganic salts [9]. Later on, in 1960, “Wichterle and Lim” reported on hydrogel as water swollen macromolecules. Hydrogels can be classified into three generations depending upon their structural pattern (simple to complex), their properties, and different eras of research work. The first generation (1960–1980) hydrogels based on simple water swollen capability of macromolecular networks [10]. They include three categories of hydrogels, cellulose based, polymerization of water-soluble monomers like Poly-hydroxyethyl methacrylate (PHEMA), and cross-linking of water-soluble synthetic polymers like polyvinyl alcohol (PVA) and Polyethylene glycol (PEG) [1].

The second generation (1990–2000) hydrogels tend to respond to abiotic factors (pH, temperature, and concentration of monomer) of the environment [11]. The 2nd generation hydrogels include temperature-sensitive hydrogels (like poly lactide, PEG-polyester block copolymers [1], poly glycolic-co-lactic acid, poly ε-caprolactone, poly-N-isopropyl-acrylamide), degradable hydrolytic hydrogels (like N-2-hydroxypropyl methacrylamide) and pH sensitive based hydrogels (acidic or basic moieties). In this era, the hydrogels were synthesized by using different techniques like redox based radical polymerization, photo-polymerization, gamma radiation polymerization, inclusion complex formation, cross-linking through Michal addition and atom transfer radical polymerization (ATRP) [12]. In third generation, the hydrogels consisted of stereo-complexes (in 2000) and smart hydrogels (2010 onward): in situ chemically cross-linked hydrogels by enzymes, radical polymerization, double-network hydrogels, the combination of natural & synthetic polymers and composite hydrogels [13]. Shortly, for the last 50 years, the hydrogels have received attention due to their exceptional properties and 3D structural pattern of monomers either cross-linked or grafted. They exhibit a little degree of flexibility similar to the natural tissues owing to their absorption of large water content [14]. Fig. 1 is illustrating the road map for different agricultural hydrogel in last two decades.

Fig. 1.

Illustrating the road map for different agricultural hydrogels in last two decades. First arrow is Showing the hydrogels in era of 2001–2005, second arrow for 2005–2010, third arrow for 2010–2015 and fourth arrow is for 2015–2020.

The soil hydrogels are either made up of natural sources or synthetic material. The natural materials included the most common and degradable components that are polysaccharides (PS) and polypeptides (PP) whereas synthetic material (petrochemical based) consisted of acrylic acid (AA), its salts, and acrylamide (AM) [15]. The first generation hydrogels were mainly consisted of natural based hydrogels owing to their biocompatibility, feasibility, and biodegradability [16]. Later on in second generation, synthetic hydrogels were substituted with synthetic hydrogels due to their longer life and more intensifying features than natural based hydrogels [17]. During the last twenty years, synthetic hydrogels and combo of natural with synthetic hydrogels got more importance and replaced the traditional natural hydrogel [18]. The synthetic hydrogels have a comparatively high capacity of water absorption, long service life, and high gel strength. Fortunately, synthetic polymers usually have well-defined structures that can be modified to produce tailored functionality and degradability [19].

Synthesis of hydrogels through cross-linking

The hydrogels are mostly synthesized through cross-linking polymerization process and it can be done either by physical or chemical process.

Physical cross-linking

The physical cross-linking, also known as self assembled hydrogels owing to absence of any chemical bonding, generally proceeds through a very easy and convenient method to avoid the use of any cross-linking agent [20]. They are usually reversible hydrogels because of temporary junctions and reversible interactions that can be distorted by making a minor change in any condition or applying stress to the reacting conditions [21]. Physical cross-linking avoid any chemical interactions thus there is no dissolution occur. A bunch of methods can be used for physical cross-linking in the synthesis of hydrogels. Fig. 2 is showing different types of physical cross-linking processes.

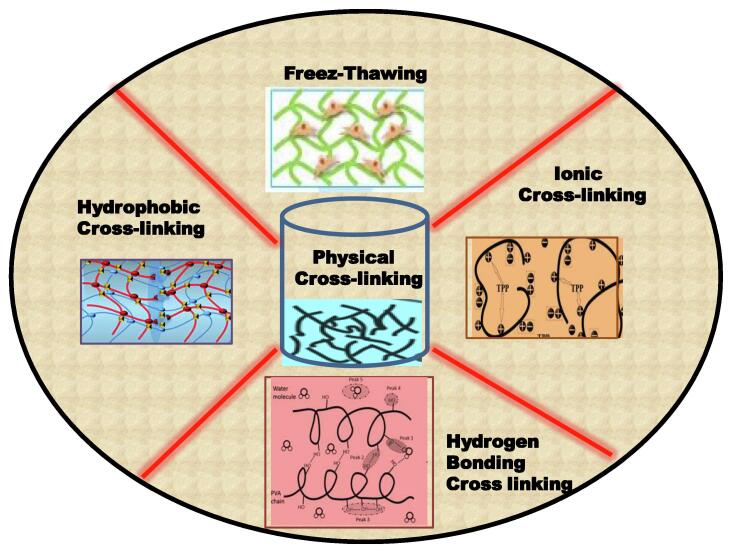

Fig. 2.

Different types of physical cross-linking processed.

Freeze –thawing process: It is the best and simplest process used for the preparation of natural material based hydrogels. Thawing is exactly the contrary process of freezing and carried out in mild temperature conditions without any aid of organic solvents. The freeze-thawing process is repeated two or more times for the preparation of physical hydrogels. Mostly cellulose and cellulose derived based materials used in this process. These hydrogels also exhibit well-defined properties of swelling in soil and water [22].

Cross-Linking by Hydrophobic Interaction: The hydrogels exhibiting hydrophobic interactions must have a hydrophobic co-monomer in addition to hydrophilic monomers and are synthesized by free radical copolymerization [23]. It was experimentally observed that these hydrophobic interactions are comparatively stronger than other intermolecular forces like Vander Waal and hydrogen bonding [24]. These interactions vary according to variations in temperature, carbon atomicity, and shape of hydrophobes. There should be higher carbon atomicity to develop strong hydrophobic interactions between polymer chains. These hydrogels are very sensitive to temperature that strongly affects the hydrophobic interaction (existing between hydrophobic segments of polymer) and hydrophilic interactions (existing between hydrophilic segments of polymer). Generally alkylated cellulose based polymers exhibit hydrophobic interactions between the OH-group of an alkylated chain. Cellulose gets hydrated at low temperature while the OH-group makes interaction with each other and turns to hydrogel at high temperature [25].

Cross-Linking by Ionic Interaction: It is very easy to make ionic cross-linked materials by the addition of multivalent counter ion and follows the gelling principle of poly-electrolytic solution [26]. The polyelectrolyte can easily be cross-linked through ionic bond with multivalent counter-ions by a simple ion-exchange method. For example, sodium alginate (polymer of glucuronic and mannuric acids) solution can easily be cross-linked with opposite charges (Ca+2) of calcium chloride solution. The ionic cross-linking usually takes place at lower temperatures and broadly applicable in the medical field like drug delivery; wound healing, and tissue engineering [27].

Cross-Linking by Hydrogen Bonds: The hydrogen interactions exist between the hydroxyl groups of cellulose chain and are responsible to develop hydrogen bonding with water to make hydrogel [23]. These hydrogels are sensitive to change in concentration of polymers, temperature, solvent nature, and the degree of association of functional groups. The higher concentration of polymers will cause more hydrogen bonding thus there is more organized and stable gel prepared [28]. When polyethylene is added to the cellulose polymer then hydrogen bonding interactions developed between the oxygen of glycol and hydrophilic OH-group of cellulose polymer [29].

Chemical cross-linking

The chemical cross-linking must contains a covalent bonding in polymer chain. There are three major categories of methodologies that fall under chemical cross-linking.

Chain growth polymerization

This process follows initiation, propagation and termination steps similar to the free radical polymerization. It is necessary to follow the chain growth polymerization that a monomer must contain unsaturation (double bond) in it to makes polymer chain. When the reaction mixture turns to gel formation, at this instant, the polymerization can be classified into three categories; solution polymerization, suspension polymerization, and photo-polymerization [30].

Solution polymerization: In this polymerization the reactants, initiator, and final polymer can easily dissolve in solvent. Solution polymerization needs a very low conc. of catalyst, high conc. of monomers, and solvent. This polymerization has low cost, controllable heat of polymerization and more convenient in synthesis, so prefer to use than other homogenous polymerization [31]. For example, the solution polymerization was used for the synthesis of carboxymethyl cellulose (CMC) and hexaethyl cellulose (HEC hydrogels) in the presence of cross-linking agents and initiators. Besides, in many studies, the acrylic acid and acrylamide were grafted on CMC by using solution polymerization [32]. It yields high rate of polymerization and provides a safe environment of reactant’s dealing in aqueous media without the aid of additional heating because it takes place at room temperature [33].

Suspension Polymerization: Contrary to the solution polymerization, the suspension polymerization occurs in non-polar solvent (organic phase) media. So the hydrophilic reacting species (monomers, cross-linking agent, and initiators) are insoluble in media and get suspended in non-polar phase. The properties of hydrogels prepared from suspension polymerization entirely depend upon viscosity difference of monomers & liquid phase, agitation speed and dispersant type [34].

Photo-polymerization: Entirely opposite to aforementioned categories, photo-polymerization proceeds with the initiation of radicals in the presence of radiations like UV, visible, or infrared in situ form of cross-link networking. This polymerization also follows the radical polymerization but the photo-sensitive monomers interact with light radiation and induce radicals [35]. The initiation of radicals may occur through photo-cleavage, cationic photo-polymerization, and hydrogen abstraction. These radicals follow the same propagation and termination steps of free radical polymerization. This polymerization method got superiority in context of controlled gelation process. Photo-polymerization involves in the preparation of alginate, guar gum, and polyethylene glycol based hydrogels that depends upon the exposure and intensity of UV radiation [36].

Irradiation polymerization

The irradiation polymerization differs from photo-polymerization in aspect of high energy radiations used in former category. In some studies, the microwave radiations were also used to develop cross-linking in hydrogels [6]. In irradiation polymerization, ionizing or high energy radiation like gamma rays and electron beams are used to initiate radicals of unsaturated monomer substances. These radicals follow the chain growth mechanism for cross-linked polymer synthesis. This new forefront technology has superiority over traditional technologies is that it never requires a catalyst or modifying agent and swelling properties can be controlled by managing degree of cross-linking and hydrogel’s particle size [37].

Step-growth polymerization

The step growth polymerization proceeds slowly in steps and poly-functional monomers react together through covalent bonding. This polymerization is usually self catalyzed and covalent bond was developed with the release of water or HCl molecule. Step growth polymerization yields slowly increase in average molecular weight but high reaction rates are needed to get longer chains of polymer [38]. The distinct characteristic of step growth polymerization is that its terminal ends remains still active whereas the chain growth polymerization process terminates when all reactive sites fixed through a chemical bond [39].

Although the soil hydrogels can be classified on the basis of source material used as precursor in their synthesis methodology. Fig. 3 shows all processes of chemical cross-linking polymerization methods.

Fig. 3.

Processes of chemical cross-linking polymerization methods.

Natural precursor materials based hydrogels

Pure natural

There are three types of natural materials used as precursor in the synthesis of soil hydrogels; one is polysaccharides like cellulose, chitosan and starch (majorly used), second is by-products of agriculture like rice husk ash (RHA) and wheat straw (WS) (moderately used) and third in least priority is pectin, guar gum, sawdust and arabic guar gum [40], [41]. All the above categories of natural materials used in grafting or cross-linking mechanism for synthesis.

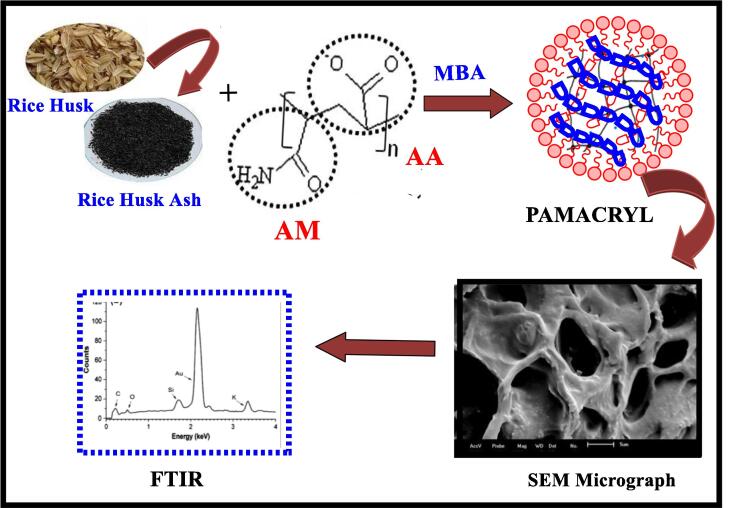

Poly (acrylamide-co-acrylate)/RHA hydrogel: The PAMACRYL; (poly acrylamide-co acrylate) hydrogel can be synthesized by cross-linking of acrylic acid (AA) and acrylamide (AM) with utilization of a cross-linker N, N-methylene bisacrylamide and a reactive catalyst tetramethylethylenediamine (TMED). The main role of K2S2O8 in hydrogel synthesis is to initiate the radicals for polymerization process. The radicals of monomers combine effectively with each other and make a valuable hydrogel. The size of particle ranged from 2 to 0.71 mm by using 9–24 mesh sieves. The rice husk ash based composite PAMACRYL/RHA was prepared as free radical polymerization in the same aforementioned method but monomers (acrylamide and potassium acrylate have been taken in 50:50% mole concentration) mixed in rice husk ash and cross-linker [42]. The rice husk ash based PAMACRYL composite obtained at different calcination temperature range (400–900 °C) to get data for their chemical properties. It has been found that the PAMACRYL hydrogel and PAMACRYL/RHA composite possess different swelling ratios; the former has least swelling ratio (645 gwater/gabsorbent) whereas the composite calcinated at 900 °C shows comparatively maximum swelling ratio than others that is 1077 gwater/gabsrobent. The swelling ratio of composite has variations according to pH change and salt concentrations of swelling media [43]. Fig. 4 illustrates the process of synthesis of PAMACRYL/RHA hydrogel.

Fig. 4.

The process of synthesis of PAMACRYL/RHA hydrogel.

CSt-g-PAA/NR/PVA semi-IPN hydrogel: The cost effective and eco-friendly soil hydrogels are gathering more attention for researchers and need biodegradable material for the synthesis of superabsorbent hydrogels. This novel synthesis based on grafting polymerization of 70% neutralized acrylic acid (AA) on cassava starch followed by cross-linking of one polymeric chain with another through N,N-methylene bisacrylamide (MBA) with the aid of ammonium persulfate (APS as an initiator) in the presence of nitrogen atmosphere [44]. For interpenetration, the polyvinyl alcohol (PVA) is blended with natural rubber (NR) latex and an emulvin introduced to prohibit premature coagulation. The cassava starch cross-linked hydrogel is subsequently mixed with PVA/NR blend to develop semi-interpenetrating network with hydrogel for compact structuring organization [45].

This compact structuring enhances the flexibility and mechanical properties of hydrogel owing to the presence of hydrogen bonding between PVA and OH group of polymeric chain. The swelling rate of hydrogel is comparatively greater in de-ionized water (7 9 4) than in 0.9% wt of NaCl solution (2 4 4). The superabsorbent hydrogel exhibits maximum swelling at 1% wt cross-linking agent concentration, 7.5 g of cassava starch, 6 ml of acrylic acid, 3% wt of ammonium persulfate concentration at pH-7. The lower pH causes higher protonation and cross-linking whereas the higher pH than 7 causes in “charge shielding effect” of sodium ions so reduces the anion to anion repulsions and finally results in decreasing the swelling [46]. The water retaining capability directly depends upon temperature and the experimental results show that it has maximum water retention (63.5%) at 30 °C [45].

Wheat straw based hydrogel: A synthetic approach is used to fabricate the Wheat straw (WS) for the synthesis of hydrogel. It started to prior preparation of carboxymethyl intermediates (CM-intermediates) by using agricultural by-products like wheat straw mixed with isopropanol, sodium hydroxide, and monochloroacetate (MCA) along with anhydrous glucose unit (AGU) [47]. After getting CM- intermediates, it is cross-linked with different concentrations of citric acid monohydrate. The citric acid got priority over other cross-linking agents owing to its non-toxic effect and easily available at low cost. Cross-linking plays a crucial role in the swelling properties of the hydrogel. The reaction mixture ultimately cured at different temperature ranges and time duration to boost up gel stiffness, gel yield, and swelling properties. The particle size of hydrogel ranges from 150 to 800 μm. The fabrication of wheat straw into a soil hydrogel proved as a sustainable source and enhanced the water absorption up to 70% for sandy soil. The concentration of citric acid (4% wt), 140 °C temperature along with maximum time duration of reaction cross-linking significantly enhances the gel stiffness, strain resistance and swelling properties [48].

Sawdust cellulose based hydrogel slow release fertilizer (SC-HSRF): A novel sawdust hydrogel slow released fertilizer (HSRF) is an eco-friendly, biocompatible and bio-decomposable that has been synthesized by first converting the sawdust into its functional form of sawdust cellulose (SC) by mixing its powder in an aqueous ammonia solution in the ratio of 1:12 respectively [49]. A graft copolymerization methodology has been used for grafting of acrylic acid (AA), acrylamide (AM) in the presence of N, N-methylene bisacrylamide (MBA) as a cross-linker. The potassium persulfate (KPS) is a reaction initiator for the radical generation. The complete synthesis process of SC-HSRF hydrogel is shown in Fig. 5. The introduction of urea accomplished to make it nutrient rich fertilizer based hydrogel and plays a dual role in soil that it is a good soil conditioner as well as provides an essential nutrient rich environment for plant growth [50]. The HSRF cut into small pieces of 2 × 2 mm for storage and further utilization in soil. When its sample loaded to soil that has original water retention (WR) value is 38.7%, it found that soil exhibits 166.2% value and enhances the water retention capacity of soil 122.5% times more than its original value. Besides, the incorporation of SC exaggerated the swelling ratio (210 g/g) in de-ionized water and can absorb more water in saline solution (NaCl) in the range of 7–10 pH [49]. The presence of hydrophilic groups and SC in hydrogel provides more skeletal nodes that are responsible for water absorption.

Fig. 5.

Synthesis process of SC-HSRF hydrogel.

Tapioca starch based Urea-Encapsulated Hydrogel: The urea encapsulated hydrogel also falls in fertilizer based superabsorbent hydrogel that starts with prior synthesis of tapioca starch based hydrogel that later on encapsulated with urea fertilizer [50]. The tapioca starch usually gets from cassava root that is broadly used as precursor in the synthesis of superabsorbent soil hydrogels. The hydrogel constituted on cross-linking of tapioca starch with acrylic acid (AA) with the aid of N, N-methylene bisacrylamide (MBA as cross-linker) [51]. At the end the obtained hydrogel is mixed with urea in an aqueous NaOH solution to make urea encapsulated fertilizer hydrogel. The use of NaOH is very mandatory for neutralization of acrylic acid protons, to balance the electrical charges and helps in hydration of hydrogen upon contact with water. The superabsorbent hydrogel (SAH) shows maximum swelling rate at 1:1.05 starch to AA ratio, 0.48% cross-linking and 1.94% concentration of ammonium persulphate as an initiator [52]. Besides urea encapsulated fertilizer based hydrogel has controlled release of urea and the experiments showed that it has increased the soil porosity and water retaining capacity on implication in soil for plant growth examination [53].

Poly-g (AA-cl-EGDMA) superabsorbent hydrogel: The guar gum (GG) is a naturally occurring galactomannan polysaccharide that usually derives from guar beans. Although it has stabilizing and thickening properties so it is potentially used as a precursor for soil hydrogels as polymer backbone chain [54]. The guar gum (GG) grafted with acrylic acid (AA) and cross-linked with ethylene glycol dimethacrylic acid (EGDMA) in the presence of benzoyl peroxide (BPO; as initiator), for the synthesis of novel poly-g(AA-cl-EGDMA) hydrogel [55]. The bulky groups created steric hindrance so primary hydroxyl group (–OH) of polymer chain more vulnerable to initiator attack than secondary hydroxyl group. As a result more polar bonds have more tendency to rotate and leading to the generation of the active sites for grafting polymerization. In this procedure, cross-linking and grafting took place simultaneously [56].

The swelling ratio may alter with change in concentration of cross-linking agent and has maximum swelling at 0.5 mM and decrease signifcantly with both below and above 0.5mM concentration. Lesser quantity leads to insufficient cross-linking while greater quantity makes hydrogel structure very compact and hard due to excessive cross-linking. Similarly the initiator content also depends on swelling index, the hydrogel show maximum swelling index (625 ml/g) at 0.25 mM initiator concentration in alkaline media (pH-9). The initiator less than 0.25 mM may cause slow polymerization owing to insufficient free radicals for initiating the process. In an acidic medium (pH-4), the swelling rate decreases because of incomplete ionization of cross-linking. In soil implementation, the hydrogel has increased water retaining capacity (51.7%) and 9% porosity of soil than original at 0.3% concentration of hydrogel [55]. Owing to magnifying features, this potent hydrogel is broadly used in agriculture industry as best soil conditioner and water reservoir.

GG-cl-(poly-(AA-ipn-PANI) Hydrogel: The guar gum (GG) hydrogel is potentially synthesized by using response surface methodology to get modified surface morphology with ascending swelling ratios. This novel guar gum hydrogel comprises of cross linking polymerization of acrylic acid (AA) on guar gum by using hexamine as cross-linker and ammonium persulfate (APS) as an initiator [56]. It is subsequently cross-linked with poly-aniline, along with addition of hydrochloric acid (HCl) and sodium hydroxide (NaOH) for neutralization, to get inter-penetrating network of hydrogel [57]. The mixture’s color turns soon from brown to light green with the addition of hexamine and ammonium persulfate. The inter-penetration of polyaniline takes 16 h for completion and formed a swollen product. The SEM images explain the coarse surface of (GG-cl-poly-(AA-ipn-PANI) that proves cross-linked networking of hydrogel whereas the original guar gum has smooth surface with tiny dots. Like others, this hydrogel also depends upon initiator, monomer, cross-linking agent concentration, pH sensitive and exhibit maximum water absorbency (5307%) at 22.3 × 10−3 mol/L, 166.8 × 10−6 mol/L and 53.4 × 10−3mol/L in neutral medium respectively [58].

Porous cl-GG-g-poly (acrylate) hydrogel: The free radical grafting polymerization can be used for the synthesis of porous cl-GG-g-poly (acrylate) hydrogel by the use of redox pair initiator the persulphate- N, N, N, N tetramethylenediamine (TEMED). This method proceeds with polymerization in situ, by the addition of acrylic acid, N, N methylene bisacrylamide (MBA as crosslinker), initiator redox pair, and foaming acid (acetic acid) in distilled water step by step at 70–80 °C under nitrogen bubbling. The porosity of hydrogel depends upon bubbling of CO2 gas that evolves when foaming acid combines with NaHCO3. When the viscosity of gel increased by increasing cross-linking concentration then CO2 gas finds difficulty in releasing, hence this trapped gas results in porous structure of hydrogel that ultimately increases the swelling behaviour [59]. The backbone polymer chain to monomer ratio has considerable influences on swelling along with foaming stabilizer. The former ratio tries to keep below 0.2 while later has concentration limit up to 7.35% in acidic medium to get maximum water absorbency [40]. The illustration of synthesis schemes for guar gum based hydrogels is given in Fig. 6.

Fig. 6.

Illustration of synthesis schemes for guar gum based hydrogels. a) Synthesis of (GG-cl-poly-(AA-ipn-PANI) hydrogel. b) Synthesis of GG-poly-g (AA-cl-EGDMA) hydrogel. c) Synthesis of porous cl-GG-g-poly (acrylate) hydrogel. d) Synthesis of GG-g-P(NaA-co-St)/APT hydrogel.

Modified natural materials

Modified natural material includes chemically modification of pure natural materials and used as precursor in the synthesis of soil hydrogels [60]. This review section includes modified natural materials like carboxymethyl cellulose (CMC), sodium sulfonated corn starch (SSS), salep phosphate (SP) and cellulose acetate (CA). All these modified natural materials act as precursor base of the dispersion medium. Both categories of natural materials play important role in biodegradable hydrogel, biocompatible with soil and eco-friendly with environment [61].

GEDTA hydrogel: The GEDTA based hydrogel prepared by grafting and subsequently esterification cross-linking polymerization process in the homogenous medium using cellulose acetate (CA) with ethylenediamine tetraacetic dianhydride (EDTAD) as a crosslinker. A viscous reaction mixture obtained immediately after the addition of EDTAD and triethylamine (catalyst) [62]. The one molecule of EDTAD (possess two anhydric bonds) grafted onto a cellulose acetate through one anhydric (-CO-O-OC-) bond cleavage then simultaneously cross-linked with another CA molecule through opposite anhydric bond cleavage. The un-reacted carboxyl group of precursor (cellulose acetate) reacts with aqueous sodium bicarbonate (NaHCO3) to convert it into sodium carboxylate. The role of sodium bicarbonate is to boost up the water affinity of reactants. The product (GEDTA hydrogel) sifted through 60 mesh sieve and tested on Typical Red Oxisol soil to analyze its functional properties for growth of plant. The GEDTA hydrogel was mixed with NPK and 20% ammonium hydroxide solution to neutralize it [63]. It is necessary to neutralize to prevent protonation of carboxylate group that may decrease the water absorption capacity. The GEDTA hydrogel is efficiently proved as a large amount of water absorber, slow release behavior, and soil moisture retainer. These efficient properties of GEDTA hydrogel enforce to widely use in limited water soils (drought-prone), horticulture and agriculture [62].

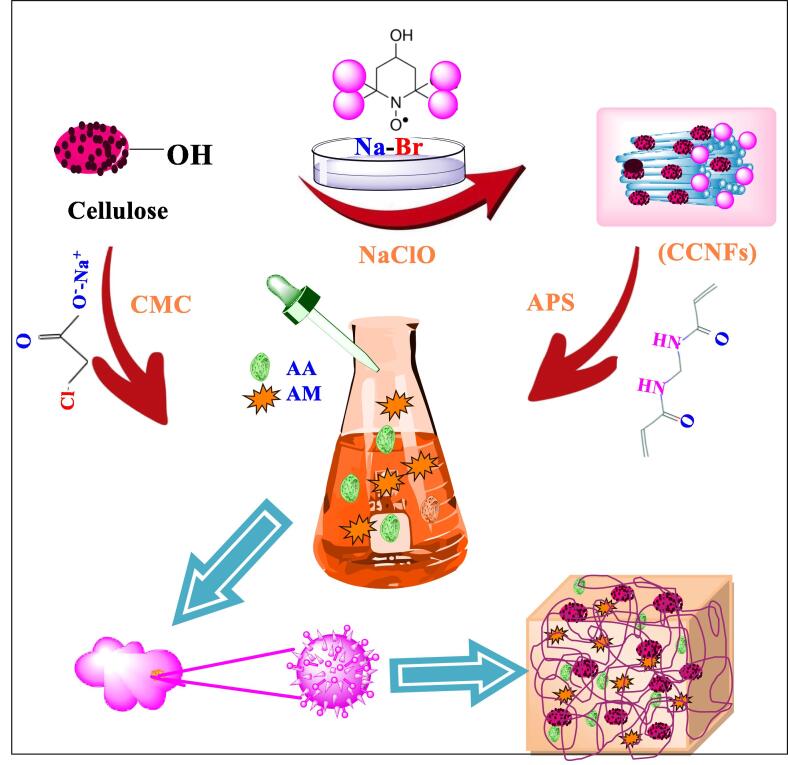

CMC-g-p(AA-co-AM)/CCNFs nanocomposite hydrogels: Nanocomposites are considered as comparatively better than micro or macro-composites in enhancing the water retaining and absorbency properties of hydrogels [64]. Carboxylated cellulose nanofibrils (CCNFs) can be synthesized by suspending microcrystalline cellulose (MCC) in distilled water, sodium bromide and tetramethylpiperidine-1-oxyl radical (TEMPO) [65], [66]. The solution subsequently oxidized by the addition of sodium hypochlorite (NaClO) solution with gentle agitation. The aqueous solution of NaOH used to maintain pH at 10.5 and then oxidized cellulose passed through ultrasonication process, by using an ultrasonic homogenizer. For the synthesis of CMC-g-p(AA-co-AM)/CCNFs, defined amount of sodium carboxymethyl cellulose (CMC), acrylamide (AM), acrylic acid (AA), methylenebisacrylamide (MBA) and carboxylated cellulose nanofibrils, (CCNFs) along with APS added with heating at 60 °C for production of free radicals. Fig. 7 is showing the schematic illustration for synthesis of CMC-g-p(AA-co-AM)/CCNFs nanocomposite hydrogels.

Fig. 7.

Schematic illustration fro synthesis of CMC-g-p (AA-co-AM)/CCNFs nanocomposite hydrogels.

The most vital and distinguishing role of CCNFs in swelling property is that it is responsible for the production of more carboxylate groups (0.94 mmol/g) at the consumption of 2.5%wt CCNFs. The presence of CCNFs (as filler) in CMC-g-p(AA-co-AM)/CCNFs hydrogel exaggerates the swelling property up to 428.4 g/g in distilled water at 10 mmol/L of NaCl solution with a smaller particle size of hydrogel. The small particle size provides interstitial volume that is more supportive for up taking extra water. Besides, the water retention increases up to 81.1% at 30 °C due to intervention of CCNFs [65].

Salep phosphate hydrogel: The introduction of salep phosphate in hydrogel, as an innovative polymer backbone substituent to cellulose, proved as a good carrier for slow release of agrochemicals with enhanced hydrogel properties [67]. The salep is usually obtained from dried tubers of natural terrestrial Orchids and it is a biopolymer constituted of multi-component polysaccharides, glucomannan (16–60%), etc. It is modified by introducing phosphate group on its backbone chain by reacting with disodium hydrogen phosphate dodecahydrate and sodium dihydrogen phosphate dihydrate in basic environment of pH-11. The salep phosphate can easily be cross-linked with acrylic acid (AA) in the presence of N,N-methylene bis-acrylamide under grafting copolymerization for cross-linking mechanisms [68]. The (salep phosphate)-g-polyacrylic acid hydrogel is biodegradable and eco-friendly for both plants and environments. The incorporation of bio-polymeric substances (salep phosphate) empowered the water absorbency with maximum water retention property achieved at moderate phosphate content [69].

Cellulose/CMC-cl-ECH hydrogel: Among the physically cross-linked hydrogels, the cellulose and its derivatives like carboxymethyl cellulose (CMC) are more prominent. A CF-11 whaatman paper (as a source of cellulose) is being transformed into the functional cellulosic group by dissolving it in a urea/NaOH solution. The functional cellulose and CMC passed through freeze-thawing process in the presence of epichlorohydrin (ECH) as a cross-linker for the synthesis of natural based hydrogels [70]. The CMC and cellulose solutions have been prepared in different ratios for studying the variations of hydrogel properties. The swelling equilibrium data shows that all solutions are proved as superabsorbent hydrogels but the composition with higher concentration of CMC (9:1) exhibits comparatively more swelling than rest of hydrogels. The hydrogel properties are greatly influenced by the nature and concentration of salt solution (CaCl2 decreases swelling ratio more than NaCl solution). Thus the hydrogel properties are controllable by managing the CMC concentration and nature of salt aqueous solution. The cellulose/CMC-cl-ECH hydrogels exhibit 1000 times more swelling ratio than that of cellulose based hydrogels. Although these hydrogels also express the slow nutrient release of bovine serum albumin (BSA) and vary with the content of CMC accordingly [71].

Synthesis of soil hydrogels based on synthetic materials

Pure synthetic material

Owing to the confined benefits of natural material based hydrogels, the researcher paid their attentions to make chemical based hydrogels that have a bunch of enhanced benefits with their prolonged life time. Synthetic materials are usually based on acrylic acid (AA), acrylamide (AM), sodium acrylate (NaA), polyvinyl alcohol (PVA), urea, aluminium zinc ferrate (AlZnFe2O4), poly-2-Acrylamide-2-Methyl-1-Propane Sulphonic Acid (PAMPS), attapulgite, sodium humate [72].

LCSH by urea and acrylic acid: The low cost superabsorbent hydrogel (LCSH) has been prepared by solution polymerization of acrylic acid (AA) with urea in the presence of reactive cross-linker N,N'-methylenebisacrylamide (MBA). This polymer was synthesized by neutralization of acrylic acid with NaOH to form sodium acrylate. The sodium acrylate reacts with urea and polymerization process started with using a chemical initiator K2S2O8 in the presence of nitrogen atmosphere [73]. The final product’s granular size is maintained up to 0.18 to 0.212 mm for use. The hydrogel’s properties are strongly affected by the weight ratio of MBA to AA (wt %), mole ratio of urea to AA and neutralization degree of AA [74].

The absorbency of LCSH depends upon the ascending mole ratio of urea to acrylic acid (AA) and its maximum value was achieved at 1.6:1 mol ratio. The absorbency of water increases with increasing urea concentration that resultantly enhances the affinity for grafting of hydrophilic groups on acrylic acid. While crossing 1.6 mol ratio of urea results in descending the absorbency of LCSH. The LCSH shows maximum absorbency 835 g/g in distilled water at 0.005% weight ratio of MBA to AA with 85% degree of neutralization of AA [33].

Poly(acrylic acid-co-acrylamide)/sodium humate/attapulgite (PAA-AM/SH/APT) superabsorbent hydrogel: For the synthesis of novel multifunctional (PAA-AM/SH/APT) hydrogel, the sodium humat (SH), attapulgite (APT), acrylic acid (AA) having 50% degree of neutralization, and acrylamide (AM) mixed in a defined ratio in the presence of N, N- methylene bisacrylamide [75]. The concentration ratio of AA to AM is very accountable because the water absorbency increases up to 1.2 M ratio and decreases sharply beyond this limit. The purging of nitrogen gas for 30 min removes dissolved oxygen in the solution. The presence of sodium humate and attapulgite plays a vital role in enhancing the polymeric network by cross-linking between the chain’s ends thus elevates the water absorbency (996 g/g in water) of hydrogel at 10%wt and 20%wt concentrations respectively. The particle size of multifunctional hydrogel ranges from 40–80 mesh [31].

Slow Release Fertilizer based Hydrogel (SRFH): The combined utilization of hydrogel and nutrient rich fertilizer is very demanding in agriculture field. The fabulous characteristics of slow release fertilizer hydrogel (SRFH) focusing on the formulations of different monomers for fertilizer based hydrogels. The neutralization of monomer is a very essential step to enhance the electrostatic repulsions among carboxylate anions of slow release fertilizer hydrogel (SRFH) [76]. The high degree of neutralization enhances the water absorbency of hydrogel owing to the attached carboxylate anions to the polymer chain that develops electrostatic repulsions to expand the network. The SRFH constituted neutralized acrylic acid (AA: 60% degree of neutralization), urea and acrylamide (AM) in the presence of N-N, methylene bisacrylamide (MBA). The use of SRFH potentially reduces the fertilizer loss rate, provides nutrients slowly. The SRFH has maximum swelling rate and water retention along with positive effect on plant growth [64].

PAMPS Hydrogel: The PAMPS hydrogel synthesis is based on the polymerization of reactive monomer, 2-Acrylamide-2-Methyl-1-Propane Sulphonic Acid (AMPS), in the presence of N, N-methylene-bis-acrylamide and ammonium persulphate (APS). The hydrogel has been examined for different parameters like cross-linking densities, water pH (acidic, basic, or neutral media), and temperature (40 °C or 60 °C) [77]. The experimental results show that PAMPS exhibit maximum water absorbency at lowest (0.03) concentration than higher at 60 °C in alkaline media [20].

Combo materials

Another surprising material for the synthesis of hydrogel as dispersion medium is combination of natural (either pure or modified) and chemical salts. This combination of materials provides astonishing qualities that elevates the demand for soil hydrogel in agriculture. The combo materials include a combination of cellulose with acrylic acid, CMC with acrylic acid and acrylamide, guar gum (GG) with acrylic acid and acrylamide, CMC with an attapulgite, agricultural by-products like rice husk ash and wheat straw with AA and AM, clinoptilolite with AA and AM, chitosan with PVA and AA [78].

CRF-hydrogels: The three different controlled release fertilizer (CRF) based hydrogels have been synthesized by mixing fertilizer solution (dihydrogen ammonium phosphate, potassium nitrate, and ammonium nitrate) with hydrogels. The first hydrogel based on the combination of chitosan solution with fertilizer solution in the presence of glutaraldehyde and labeled as CRF-CS. The second hydrogel is the combination of PVA with fertilizer solution in presence of acetic acid, H2SO4, and methanol (acting as pH controller, catalyst and cross-linking agent respectively) along with glutaraldehyde and labeled as CRF-PVA hydrogel. The third hydrogel has composition of PVA, chitosan and fertilizer solution with a suitable cross-linking agent labeled as CRF-CS/PVA [79].

All these CRF hydrogels were examined in the context of water absorbency, water retention, and potassium release factors. CRF hydrogels showed high swelling ratio ranging from 70 to 300%. The CRF-PVA hydrogel has maximum swelling that is 300% and CRF-PVA/CS hydrogel exhibit 225% while CRF-CS showed up to 70%. The water retention property of all these hydrogels vary in similar fashion, the CRF-PVA has highest water retention capacity of 25% and CRF-PVA/CS has 10% while CRF-CS has only 4% absorbencies [80]. The diffusion or release property of fertilizers depends upon swelling ratio of hydrogel. All three hydrogels showed less swelling ratio in soil than in de-ionized water. So diffusion of soluble fertilizer components is less in soil than water. Hence CRF hydrogels have a slower release of potassium in soil than water. All CRF hydrogels have less (n < 0.5) exponent of potassium release in de-ionized water showing quasi-Fickian movement; the movement in which potassium releases partially from water filled pores and swollen matrix [81].

In contrast, these hydrogels exhibit different release exponent values in soil, CRF- PVA has 0.52 and CRF-PVA/CS hydrogel exhibit greater exponent value i.e., 0.92 and both hydrogels show non-Fickian movement (anomalous movement) while the CRF-CS hydrogel has a maximum release exponent value of 1.05 and show case II transport [82]. The release of potassium from fertilizer depends upon chemical structure that affects on swelling ratio of hydrogel. The CRF-PVA hydrogel has greater initial swelling ratio and hence potassium release coefficient is also greater. The swelling ratio and potassium release follow the descending order among three CRF hydrogels [80].

CRF-PVA > CRF-PVA/CS > CRF-CS

Chitosan- PAADU (double coated) based hydrogel: A novel synthesis of double coated fertilizer based superabsorbent and water retainer hydrogel includes coatings of chitosan and polyacrylic acid diatomite on a common fertilizer (NPK). The fertilizer was taken as core material whereas chitosan is directly coated on it [83]. The diameter of NPK fertilizer granules was taken within the range of 2.36–2.85 mm. The granules with damaged or defective surfaces were separated during sieving. After adding granules into the rotary drum, the chitosan powder stuck on NPK granules in the presence of epoxy dissolved in acetone and a strong adhesive agent HYUOP at regular intervals to get the first homogeneous and compact coating. For second coating (Polyacrylic acid diatomite – containing urea; PAADU) preparation, the acrylic acid (AA) neutralized with ammonia followed the addition of urea and diatomite to the solution. Subsequently, the aqueous solution of N, N- bismethylene acrylamide and potassium persulfate added to original solution with constant, vigorous stirring and nitrogen line [84].

The chitosan coated NPK fertilizer then used to have a coating of PAADU on it. For this purpose, the chitosan coated NPK fertilizer dipped in water to get moisture on it for sticking of PAADU powder and shaken continuously. The surface product has been cross-linked with the spray of 1% v/v methanol solution of epoxy chloropropane, dried in an oven at 70 °C to get double-coated slow-release NPK compound fertilizer with superabsorbent and water-retention. This double coated superabsorbent hydrogel has swollen up to 75times of original weight after 2 h of dissolution in tap water at room temperature [85]. The slow release, biodegradable, eco-friendly, and water retention properties of superabsorbent have increased its rating to use it in agriculture and horticulture.

Sulfonated corn starch polyacrylic acid phosphate rock (SCS/PAA/PHR) hydrogel: The phosphate rock (PHR) or phosphorite is a conventional fertilizer used as the source of essential elements for growth but the plants could not avail themselves easily. The researchers utilize this rock mineral with the combination of soil hydrogels to make it available for plants with controlled release properties [86]. The solution polymerization process has been followed for the preparation of sulphonated corn starch and phosphate rock based (SCS/PAA/PHR) hydrogel [87]. For the synthesis of sulfonated corn starch (SCS), the corn starch potentially combined with sulfur trioxide pyridine solution in the presence of Chloro-sulphonic acid. The sulfonated corn starch was grafted with acrylic acid (neutralized with KOH) in the presence of N, N- methylene bisacrylamide (MBA) and potassium persulfate (KPS). The phosphate rock is penetrating the SCS/PAA network to enhance the feasibility of fertilizer along with superabsorbent hydrogel. The hydrogel dried at 100 °C and particle size maintained up to 20 mesh [87].

The hydrogel tested for its properties and results showed that it has maximum swelling capacity in distilled water (498 g/g) while decreased in 0.9 wt% saline solution (65 g/g). The high water absorbency can be achieved by sustaining 0.3% wt of cross-linking agent, 1.7 wt% of ammonium persulfate, and 60% charge density of neutralized acrylic acid in distilled water. Besides, the availability of phosphorus and potassium depends on the feeding content of PHR directly. This study has opened the gates of utilization of PHR as fertilizer with hydrogel combo to facilitate its consumption by plants and prohibits the production of hazardous ions while using the manufacturing of phosphate fertilizers. The release of soluble phosphate from SCS/PAA/PHR is enhanced by the presence of SCS. It is found that hydrogel releases 0.058% phosphorus after 15 days and 0.060% after 30 days that is comparatively 4.5 times greater than direct usage of PHR [87], [88]. Table 1 contains the details of Precursor, monomer, initiator and cross-linking agent involved in the synthesis of Superabsorbent hydrogels. The list of natural and synthetic materials is classified in Fig. 8.

Table 1.

Details of Precursor, monomer, initiator and cross-linking agent involved in the synthesis of Superabsorbent hydrogels.

| Types of hydrogel | Precursor | Monomer | Initiator | Cross-linker | Conditions temp/time/pH | Mesh size/particle size | |

|---|---|---|---|---|---|---|---|

|

Cross-linked polymerization |

Pure natural |

Rice husk ash | AA,AM, | Potassium persulfate | MBA | 25°/15hrs | 9–24/2–0.71 mm |

| Wheat straw-CM | Citric acid monohydrate | – | MBA | 25°/24hrs | 150–800 μm | ||

| Sawdust cellulose | AA,AM, Urea | Potassium persulfate | MBA | 70°/4hrs | 2 × 2 mm(small pieces) | ||

| Cassava starch | AA | Potassium persulfate | MBA | 60°/2hrs | 40 mesh | ||

| Tapoica starch | AA, Urea | Potassium persulfate | MBA | 70°/0.5hrs/7 | 40 mesh | ||

| Guar gum (GG) | AA | Benzoyl peroxide | EGDMA | 55°/4hr | 40mesh | ||

| Guar gum (GG) | AA, Aniline | Ammonium persulfate | Hexamine | 35°/16hr | 60mesh | ||

| Guar gum (GG) | AA | TEMED | MBA | 80°/2hr | 60mesh | ||

| Modified Natural | Cellulose acetate | NaHCO3Esterification process | – | EDTAD | 25°/48hrs | 60 mesh | |

| CMC, CCNFs | AA, AM | Ammonium persulfate | MBA | 60°/48hrs/10 | 20-80mesh | ||

| Salep phosphate | AA | – | MBA | 55°/1hrs | 40mesh | ||

| CMC | Urea | NaOH | ECH | 40°/6hrs | 60mesh | ||

| Pure synthetic | Urea | AA | Potassium persulfate | MBA | 0.18 to 0.212 mm | ||

| Attapulgite | AA,AM | MBA | 40–80 mesh | ||||

| Urea | AA,AM | Ammonium persulfate | MBA | ||||

| AMPS | AMPS | Ammonium persulfate | MBA | 60°/1hrs | |||

| Combo | Chitosan + DAP | PVA | Base | Ethanol | |||

| Chitosan + NPK | AA, Urea, Diatomite | Potassium persulfate | MBA, epoxy Chloropropane | 35°/6hrs, 70°/2hrs |

2.36–2.85 mm | ||

| Sulphonate-d corn starch | AA, PHR | Potassium persulfate | MBA | 60°/1hrs | 20mesh | ||

| Graft polymerization | Pure Natural | Rice husk ash, NaAlg | AA,AM | Ammonium persulfate | MBA | 40°/3hrs | 40-80mesh |

| Chitosan | HEA | Ammonium persulfate | – | 65°/1hrs | 40mesh | ||

| Guar gum | NaA | Ammonium persulfate | MBA | 45°/2hrs | 40-80mesh | ||

| Father keratin | AA | Potassium persulfate, SBS | MBA | 60°/8hrs | 60mesh | ||

| Modified Natural | Sodium starch sulfate | AA, DMDAAC | Ammonium persulfate | – | 35°/2hrs | 60mesh | |

| CMC | AA | Gamma rays | MBA | 60°/48hrs | – | ||

| Pure Synthetic | Sodium humate | AA, AM | Potassium persulfate | DEG, SMB | 45°/2hrs/4.5 | 40mesh | |

| Combo | CMC, MMT | AA, AM, AMPS | Potassium persulfate | MBA | 40°/3hrs | 10-80mesh | |

| NaAlg, clinoptilolite | Ammonium persulfate | MBA | 60°/2hrs/10 | 40mesh | |||

| CMC, Attapulgite | AA, AMPS | Ammonium persulfate | MBA | 45°/5hrs/2–6 | 200mesh | ||

| Guar gum, Attapulgite | NaA, Styrene | Ammonium persulfate | MBA | 75°/3hrs/2–7.5 | 40-80mesh | ||

Fig. 8.

Flow diagram of hydrogels explaining the material and process used for synthesis.

Synthesis of hydrogels through grafting

Contrary to the cross-linking, the graft polymer usually consisted of a consecutive sequence of one type of the monomer horizontally that makes the backbone of polymer. Whereas the second monomer consecutively joined to form short chain connected vertically at any joint of the first monomer chain, thus a graft polymer is known as copolymer [89]. The use of two different monomers imparts versatile and attractive properties to the desired polymer because of possessing different functional groups.

The graft copolymerization of a monomer onto polymer backbone chain is usually accompanied by three methods; free radical polymerization, living radical polymerization and ring opening polymerization [90]. All these methods are primarily based on three approaches; i) grafting to, ii) grafting from and iii) grafting through. A “grafting to” methodology involves the coupling mechanism of functional groups “A,” distributed randomly on backbone chain, with active ends of polymer branches, to be attached on backbone chain [91]. On the other hand, the “grafting from” methodology starts with the generation of initiating sites that will react with monomer and extend vertically in the form of graft polymer. This “grafting from” methodology can easily be used to control the percentage grafting and number of grafting branches by introducing number of initiating sites [92]. The “grafting through” or “macro-monomer” method involves the copolymerization of one macro-monomer containing acrylate functional group with low molecular weight monomer. It is comparatively convenient method to synthesize cellulose based macro-monomers. The most commonly used approach is “grafting from” because it yields high density grafted polymer by reacting chain ends of branch polymer [93].

The grafting polymerization usually proceeds with initiation of active sites for the grafting of monomer on backbone chain of polymer. In this regard, chemical initiation can be done by four different techniques like a) free radical by using ammonium persulfate (APS) or potassium persulfate (KPS) b) ionic initiation c) irradiation and d) photochemical initiation [94].

Free radical graft co-polymerization

Researchers have concentrated their attention on this most frequently used methodology for the synthesis of graft polymerization. Almost 60% of market polymers were synthesized by using free radical polymerization [95]. It is a chain reaction process mainly comprised of three major steps, initiation, propagation, and termination. The chain polymerization starts with the generation of radicals that make a covalent bond with monomer and followed by the subsequent addition of a several monomers for propagation [96]. The termination of polymerization process may ends with the combination of propagating radicals with growing polymer chain through disproportionation (abstraction of a hydrogen atom by other growing polymer) or chain transfer method [97].

All acrylic and vinyl based graft polymerization on cellulose follow the free radical mechanism by using the “grafting from” approach. This methodology includes marvelous feature like mass production of countless co-polymers, inexpensive and ease of implementation. It is mostly used for the polymerization of different vinyl based monomers (meth-acrylamide, methyl acrylates, vinyl acetate), water soluble monomers (hydroxyacrylates, acrylic acid and N-vinyl pyrrolidone) and organic monomers like styrene and butadiene [98]. In graft polymerization, potassium persulfate is the most commonly used initiator. It was reported in research that graft copolymerization of itconic acid was done on cellulose by the use of potassium persulfate, xanthate mixtures and cellulose thiocarbonate reaction systems [99].

The initiation of cellulose radical in the “grafting from” technique can also be done by chemical initiation method: the direct oxidation of cellulose through cerium+4 ions [89]. It got more significance among all redox initiation system (like Fenton’s reagent: ferrous ion with hydrogen peroxide) because of its high grafting efficiency and easy implementation [25]. In this method, the cerium ions generate cellulose radicals in the presence of nitric acid. It follows the oxidation of cellulose by cerium based salt by a single electron transfer mechanism. These cellulose radicals combine with vinyl monomers to yield graft copolymerization. This initiation mechanism involves the formation of a cellulose-Ce complex that later on follows the disproportionation process to yield cellulose radicals [100]. The purpose of this mechanism is to get high rates of polymerization at a very low temperature.

The initiation of cellulose radical can also proceed with radiation induced mechanism by using energy rich gamma radiations from electron beam or radioactive isotopes and UV light [68]. The irradiation of cellulose generates free cellulose radicals that can follow the route of graft copolymerization of acrylic and vinyl monomers. The use of gamma radiations, for generation of radical, follow two approaches, one is pre-irradiation and second is mutual irradiation [101]. The pre-irradiation got priority in application because it yields a comparatively less number of homo-polymers as in mutual irradiation. On the other hand, the use of UV-light for irradiation is more conveniently used because it has very low energy radiation that will cause less degradation of cellulose backbone chain and can have controlled grafting copolymerization [102].

Ionic & ring opening graft polymerization

The ionic graft polymerization may have proceeded in two different conditions the nature of ionic species either cation or anion [103]. The graft polymerization of isobutylene and methyl styrene initiated cationically onto a cellulose substrate. For initiation of cellulose cation, a Lewis acid or electron deficient molecule can be used. The most frequently Lewis acids used are BF3 or AlCl3, in the presence of a co-catalyst (ethanol or water) to captures the proton from cellulose, its substituent or derivative after getting adsorbed on cellulose surface [104]. The production of initiator would be the same as in free radical polymerization but the entire mechanism is different for both categories. This cellulose cation makes a complex that later on follow the graft polymerization by reacting with α-methyl styrene or isobutylene (monomers) [105].

The polymerization of methacrylonitrile, acrylonitrile, and methyl methacrylate on cellulose was done anionic graft polymerization in the presence of inert solvent like ammonia at low temperature conditions. The most commonly used initiator for anionic graft polymerization is IA metal alkoxides of cellulose. In this case, the alkoxide of cellulose attacks the vinylic carbon of acrylonitrile and shifts its negative charge to the other vinylic carbon of acrylonitrile [106]. Thus several acrylonitriles go on reacting with propagating anion and extend chain growth. The anionic polymerization will terminate by the chain transfer of proton to the hydroxyl group of other cellulose and leaves an anionic initiator. The chain transfer may occur with monomer or solvent molecules [56]. The anionically graft polymerization of cellulose possesses 15000 g/mol of its molecular weight with high degree of substitution. Although it is still a challenge for scientists and researchers because it is quite difficult to control the reactivity of cellulosic-OH group with carbanion to get avoid from side product formation [107].

Ring opening polymerization is a less common method for polymerization of cellulose through ring opening. The ring opening polymerization of paper cellulose and solid cotton was first time done with a cyclic monomer that is ε-caprolactone in the presence of tartaric acid acting as a catalyst [108]. The yield of grafting of caprolactone on cellulose paper was 490% and it has increased 11% weight of paper than original. In another study, it was reported that cellulose fibers were grafted with L-lactic acid and ε-caprolactone by using ring opening polymerization [109]. The percentage of grafting can be controlled by adjusting the ratio of concentrations of monomers to the initiators. The polymers obtained from ring opening polymerization exhibit high resistance against degradation by the enzymes [109].

Living radical polymerization

The living polymerization is also known as chain growth process that proceeds without breakage of the reaction chain. It is the opposite of irreversible termination and chain transfer processes. This polymerization facilitates the equal distribution of molecular weight, architecture, and controlled composition of polymer [110]. Although the coupling of living radical polymerization with free radical polymerization provide more options to choose a bunch of monomers under different conditions to yield outstanding featured polymers. Now a day, living radical polymerization is being applied for cellulose grafting by using the “grafting from” approach. This approach usually provides an opportunity to control the graft length, composition, architecture, and surface properties of polymer [111].

Synthesis of soil hydrogels based on natural precursors

Pure natural precursors

Sodium alginate grafted poly acrylic acid co-acrylamide rice husk ash (NaAlg-g-poly(AA-co-AAm)/RHA) hydrogel: The synthesis of superabsorbent hydrogel involved two steps: the first step includes the preparation of rice husk ash while the 2nd step follows the synthesis of NaAlg-g-poly (AA-co-AAm)/RHA superabsorbent hydrogel. First of all, the rice husk washed with distilled water and rinsed off completely to get rid of dust particles. The acid leaching process was applied for the removal of metal based impurities. The boiling process takes place in the presence of an aqueous solution of hydrochloric acid and sulphuric acid solution in two turns and followed by burning in a furnace to get white ash [112]. This rice husk ash added in a four neck flask along with monomers AA, AM, sodium alginate. The use of ammonium persulfate initiates the alginate radicals and N, N- methylenebisacrylamide (MBA) catalyzes the reaction mixture under constant stirring in the presence of a nitrogen atmosphere. The temperature of the solution elevated to terminate the graft polymerization [113]. In another study, the authors used this formulation of hydrogel to prepare a nutrient rich fertilizer containing NPK the essential elements required for the growth of plant [114].

HEA grafted chitosan based hydrogels: The hydroxy ethyl acrylate (HEA) can be easily grafted on chitosan by the addition of HEA and ammonium persulfate as an initiator into the solution of chitosan. The solution purged with argon gas in a glass ampoule. After polymerization, it gets precipitated by acetone, filtered, and separated by using exhaustive extraction of the product with ethanol. The hydrogel examined for the influence of reaction variables on grafting efficiency (%E) and grafting percentage (%G) [115]. Both parameters consistently increase as the feed of HEA monomer increased and 60 min duration for polymerization. The maximum %G and %E have been found at 2% wt of chitosan and 10 mmol of APS concentration. If the amount of initiator crosses the limit of 10 mmol then it surely breaks the ether bond (C-O-C) of chitosan backbone chain results in fragmentation of chitosan. The HEA grafted hydrogel is temperature sensitive and yields maximum %G and %E at 50–60 °C [115].

Guar gum-g-poly sodium acrylate (GG-g-PNaA)hydrogel: The novel GG-g-PNaA based hydrogel can be prepared by dispersing guar gum (GG) sodium hydroxide (NaOH), acrylic acid (AA; neutralized with an aqueous solution of sodium hydroxide) and N, N-methylene bisacrylamide (MBA) under magnetic stirring. The reaction proceeds with grafting polymerization with the initiation of radicals by the use of ammonium persulfate solution (APS).. The biodegradable hydrogel shows high water absorbency (1107 g/g) at optimum conditions and reaction proceeds at 70° [116].

Hydrolyzed feather keratin-poly acrylic acid (HFK-PAA) Hydrogel: The chicken feather is abundant by-products of Poultry farms and these feathers are chemically protein in nature that consists of keratin protein majorly. The keratin is contained a higher content of amino acid cysteine (7%) than present in canola (0.63%) and soy (1.26%). The researchers have focused to utilize these waste products of poultry farms in fruitful form for agricultural benefits. The feather keratin hydrogel is based on a protein solution of hydrolyzed feather keratin (hydrolyzed by 1 M hydrochloric acid) with subsequent addition of two initiators (potassium persulfate (KPS) and sodium bisulfate;SBS), N, N methylene bisacrylamide and neutralized acrylic acid. The stirring continues till the end of the polymerization process then hydrogel washed by ethanol (two times). The maximum water absorbency (501 g/g) in water has achieved at the optimum composition. The utilization of HFK in hydrogel makes it biodegradable and eco-friendly with significant properties required for a soil conditioner. It will be more eco-friendly with the environment if keratin hydrolysis takes place under microwave radiations or superheated steam. This hydrogel is very sensitive to a minute change in pH and saline concentration [117].

Modified natural materials

Sodium starch sulfate based amphoteric hydrogel: The amphoteric hydrogel synthesis includes the first preparation of sodium starch sulfate (SSS) from corn starch by following Schweiger’s method. The water content can be eliminated from freshly synthesized SSS by acetone. The second step includes the polymerization process for the synthesis of an amphoteric hydrogel. In this regard, the SSS solution mixed with acrylamide, diallyldimethyl ammonium chloride (DMDAAC), ammonium persulfate and N, N methylene bisacrylamide under nitrogen atmosphere. At last, un-reactive monomer and homopolymers are separated by washing the hydrogel with methanol and distilled water. The swelling properties of amphoteric hydrogel vary concerning the content of acrylamide (10 g), initiator (0.3%) and cross-linking agent (0.07%) at low temperature [118]. The low temperature facilitats the decomposition of the initiator and increases the diffusion of monomer. Besides these parameters, the amphoteric hydrogel has an important salt linkage that may also influence the swelling properties. The amphoteric hydrogel contains additional sulfate, amino, and carboxylate groups that makes intermolecular linkage thus the cross-linking agent is used in less quantity as compared to other hydrogels [119].

Synthesis of CMC-PAA radiation grafted hydrogel: Radiation based grafting for the synthesis of superabsorbent hydrogel provides marvellous benefits and reduces the consumption of energy (proceeds at room temperature), initiator, and produce contamination free hydrogel [120]. For the synthesis of radiation based grafted hydrogel, the mixture of carboxymethyl cellulose (CMC), acrylamide (AA) and MBA homogenized, bubbled with nitrogen and exposed to gamma radiations at a dose of 0.14 kGy/min with a total dose of 2 kGy. The radiation grafting increases the functionality of carboxylate groups of polymeric backbone to impart highly demanding properties. The radiated material has gone through the disposal of water soluble un-reactive monomers and subsequent purification by a soxhlet extractor for the removal of homopolymer. The gamma radiation dose is very crucial for this hydrogel because doses less than 2 kGy do not start it and beyond this dose will reduce swelling properties ultimately. For the concern of the ionic strength, the role of multivalent anion (Cl−1 > CO3−2 > PO4−3) also decrease the swelling ratio due to effective concentration of anions in surrounding medium [52].

Synthesis of soil hydrogels based on synthetic materials

Pure synthetic material

Poly (AA-co-AM)/AlZnFe2O4/Na hydrogel: The humic substances releases organic content to the soil, increases the photosynthesis & biomass absorption, and develops the soil structure. Thus, they are potentially used in the agriculture field in the form of a humic salts with low cost and high affinity for water [121]. The synthesis of graft polymer superabsorbent hydrogel nano-composite (abbreviated as PSHNC) like poly (AA-co-AM)/AlZnFe2O4/SH hydrogel synthesis based on the dissolution of acrylic acid (AA) and acrylamide (AM) in de-ionized water. The AlZnFe2O4 nanoparticles (prepared by the co-precipitation method; Shahid et al. 2012) added along with triton X-100, sodium humate (SH), diethylene glycol (DEG), metabisulfite (SMB) and potassium persulfate (KPS) into reaction mixture. The 1 M aqueous solution of sodium hydroxide (NaOH) used to maintain pH at 4.5 with elevated temperature at 75 °C. The temperature of the mixture is lowered to 45 °C with the addition of 37% formaldehyde. This superabsorbent hydrogel is specially designed and applied to the sandy soil and grass seedling growth. The PSHNC exhibit maximum water absorption (892 g/g) in distilled water at 2.5 g of AlZnFe2O4, 1.5 g of sodium humate (SH), 5 g of diethylene glycol and 0.2 g of initiator [75]. The 0.4% application of PSHNC to sandy soil has increased the 130% of water retention with prominent decrease in hydraulic conductivity of soil. Thus, it can be used broadly in agriculture for drought prone conditions, horticulture, and sandy soil to get a high yield of grass [122].

Combo materials

Sodium carboxymethyl cellulose-g-poly (AA-co-AM-co-AMPS)/MMT hydrogel: The Synthesis of sodium carboxymethyl cellulose-g-poly(AA-co-AM-co-AMPS)/MMT superabsorbent hydrogel based on the mixing of sodium carboxymethyl cellulose (CMC) with sodium salt of montmorillonite (MMT), potassium persulfate, acting as an initiator to generate radicals, in distilled water. The temperature of reactants dropped to 40 °C, the mixture of acrylamide, acrylic acid, N, N-methylenebisacrylamide (MBA) and acrylamido-2-methyl-1-propane sulfonic acid (AMPS) mixed along with Sodium hydroxide (NaOH) to maintain the pH and heated for 2 h at 70° for completion of grafting polymerization reaction [123]. The precipitates of the product can be collected by adding methanol to water (5:1) mixture. The chemistry of cellulose-g-poly(AA-co-AM-co-AMPS)/MMT hydrogel is shown in Fig. 9.

Fig. 9.

Chemistry of cellulose-g-poly(AA-co-AM-co-AMPS)/MMT hydrogel.

The hydrogel comprises of porous structure based on cross-linking of AA, AM on CMC backbone along with MMT content. Similar to the ionic hydrogel, this is also pH-sensitive within the range of 5–9. The strongly affected factor on swelling is the ionic strength of salt solution. The monovalent ion (K+1 > Na+1) has comparatively less ionic strength but imparts maximum swelling than divalent ions (Ca+2 > Mg+2). These ions penetrate to the porous structure of hydrogel so that it compensates for the electrostatic effect of carboxylate and sulfite ions. The hydrogel exhibits high swelling and water retention properties at 10–80 mesh size to maintain the maximum interstitial volume of small particle size [97].

NaAlg-g-Poly (AA-co-AM)/Clin hydrogel nanocomposite: The clinoptilolite (natural zeolite), has microporous structure of silica and tetrahedral alumina that has highly ion exchange properties and affinity for ammonium ions, so broadly used in agriculture with a combination of alginate. This zeolite combines with alginate and dispersed in water for the synthesis of NaAlg-g-Poly (AA-co-AM)/Clin hydrogel [124]. This solution passes through ultra-sonication and then added into sodium alginate, acrylamide, acrylic acid having 70% degree of neutralization (neutralized by adding 6 mol/L freshly prepared aqueous solution of NaOH), and N, N -methylene bisacrylamide (MBA). The ammonium persulfate (APS) can generate free radicals to proceed free radical polymerization process. The process terminated after heating the mixture with continuous stirring at 1000 rpm speed under a nitrogen atmosphere. The procedure of sodium alginate graft polymerization of (AA-co-AAm)/clinoptilolite is similar to the sodium alginate graft polymerization of (AA-co-AAm) hydrogel. The introduction of 10% clinoptilolite at pH-10 to the hydrogel enhances the swelling rate and the release of nutrients to the soil required for plant growth because it also behaves as physical cross-linking agent. In the comparison of a local hydrogel, this nanocomposite hydrogel has a record of 54.23% of nutrient release in 30 days whereas the former case has 50% release within 2 days [90].

CMC-g-poly (AA-co- AMPS)/ATP Hydrogel: The attapulgite has the composition of magnesium aluminium phyllosilicate, found in clay, mostly used in medical field for treatment of diarrhea and in agriculture field for the synthesis of hydrogels [99]. For the synthesis of CMC-g-poly (AA-co- AMPS)/ATP Hydrogel, the carboxymethyl cellulose (CMC), the inorganic clay Attapulgite (ATP), PEG and Na2CO3 were dissolved in distilled water. Another mixture of ammonium persulfate (APS), N,N-methylene bisacrylamide (MBA), neutralized acrylic acid (AA) and 2-acrylamido-2- methylpropane sulfonic acid (AMPS) mixed with solution and agitated ultrasonically for 30 min. The polymerization terminates with the addition of H2O2 and NaHCO3 at 75 °C. This eco-friendly hydrogel exhibit a maximum swelling ratio of 864 g/g in distilled water at 0.25 g/g ratio of AMPS to AA, 0.2% of cross-linking concentration with 1:0.22 of CMC to ATP weight ratio in acidic medium (pH ranges from 2 to 6) [125]. The swelling may also be affected by the metallic ion activity on the coordination of carboxylate groups for the production of inter-molecular complexes. The swelling ratio varies with the nature of metallic ions in descending order (Na+1 > Mg+2 > Ca+2 > Fe+3) [99]. The water retention capacity also enhanced by the introduction of ATP at its lowest concentration (0.05) and has improved the water retention by up to 74%.

Porous GG-g-P(NaA-co-St)/APT hydrogels: The synthesis of novel fast porous GG-g-P(NaA-co-St)/APT superabsorbent hydrogel comprised of guar gum solution, acrylic acid (AA), styrene (St), attapulgite (APT) and a cross-linker MBA mixture. The ammonium persulfates (APS) generates the radical in free radical graft polymerization that terminates after 3 h while turning to a gel. The hydrogel follows the surfactant self-assembling template pore-forming technique with the use of sodium n-dodecyl sulfate (SDS) as a surfactant in gel formation [126]. The pore formation is facilitated by the use of surfactant as a template but it never becomes part of hydrogel and can be removed by washing with methanol–water (8:1) solution. The launching of SDS plays a vital role in enhancing the swelling rate, salt solution, and pH. The maximum swelling (948 g/g) achieved at the dose of 1.8 mmol/L of SDS, 5 mmol/L of Nacl solution at pH ranging 2.1 to 7.4 in distilled water. The swelling of hydrogel is strongly affected by the cation nature (Na+1 > Mg+2 > Al+3) in salt solution [56]. The synthesis process, properties and its application are summarized in Table 2.

Table 2.

Superabsorbent hydrogel process, properties and its application.

| Hydrogel | Author | Year | Polymerization process |

Property |

Application | ||

|---|---|---|---|---|---|---|---|

| % Water retention | Swelling g/g | Slow release | |||||

| PAMACRYL/RHA | Rodrigues et al. | 2013 | Cross-linking | 67 | 1077 | – | Agriculture |

| CSt-g-PAA/NR/PVA semi-IPN | Sayant et al. | 2018 | Grafting+ Cross-linking | – | 794 | – | Agriculture |

| SC-HSRF | Panfang Lu* et al. | 2019 | Grafting+Cross-linking | 122 | 210 | – | Sandy, horticulture |

| TS-PAA-Urea encapsulated | Karak et al. | 2019 | Cross-linking | 81 | 700 | – | Agriculture |

| GG based poly-g (AA-cl-EGDMA | Thombare et al. | 2018 | Grafting+Cross-linking | 52 | 625 | – | Agriculture |

| GG-cl-poly-(AA-ipn-PANI | Kalia et al. | 2014 | Grafting+Cross-linking | – | 5307 | – | Sandy soil |

| porous cl-GG-g-poly (acrylate) | Singh et al. | 2016 | Grafting+Cross-linking | – | 523 | – | Agriculture |

| MC-g-p (AA-co-AM)/CCNFs | Shiyu Fu et al. | 2013 | Cross-linking | – | 458 | – | Agriculture |

| LCSH | Cheng et al. | 2017 | Cross-linking | – | 835 | – | |

| PAA-AM/SH/APT | Wang et al. | 2005 | Cross-linking | – | 996 | – | Horticulture |

| PAA-SRFH | Rabat et al. | 2016 | Cross-linking | – | 167 | – | Agriculture |

| PAMPS | Elazab et al. | 2017 | Cross-linking | – | 223 | – | Clay, loam, silt |

| CRF-CS/PVA | Tongsai et al. | 2010 | Cross-linking | 70 | 300 | 0.92% | Agriculture |

| SCS/PAA/PHR | Jiang et al. | 2012 | Cross-linking | – | 498 | 0.06% | Agriculture |

| NaAlg-g-poly(AA-co-AAm | Ali olad et al. | 2017 | grafting | – | 1070 | – | Agriculture |

| guar gum-g-poly sodium acrylate | Wang et al. | 2010 | grafting | 8% water retain up to 30 days | 1107 | – | Sandy soil |

| HFK-PAA | Wattie et al. | 2016 | grafting | – | 501 | – | Agriculture |

| CMC-PAA | Suwanmala et al. | 2013 | Radiation grafting | – | 190 | – | Agriculture |

| poly (AA-co-AM)/AlZnFe2O4/SH | Nada et al. | 2015 | Grafting | 130% retention | 892 | – | Sandy soil + grass seedling growth |

| NaAlg-g-Poly (AA-co-AM)/Clin | Ali Olad et al. | 2014 | grafting | – | 60% | 54.23% released in 30 days | Agriculture |

| CMC-g-poly (AA-co- AMPS)/ATP | Suliman et al. | 2016 | grafting | 74% retention | 864 | – | Agriculture |

| porous GG-g-P(NaA-co-St)/APT | Wang et al. | 2011 | grafting | – | 948 | – | Agriculture |

Properties of soil hydrogels

Soil hydrogels are substantially used in agriculture field in the perspective of soil conditioner and plant growth promoter. The plant growth promotion directly depends upon two main parameters; one is moisture content in soil which to be used by plants and the second is nutrient holding capacity of soil [127]. The soil hydrogels boost up both these parameters by making them more feasible and suitable for plant growth. A soil hydrogel has a high swelling rate, maximum water absorbency with slow nutrient release to the soil so that plants can avail nutrients for a longer time. Different soil hydrogels have a varying degree of these properties depending on the nature of monomers and polymerization process used. All soil hydrogels exhibit mainly three given properties [128].

-

•

Swelling

-

•

Water absorbency

-

•

Nutrient release

Soil hydrogel as a conditioner

Soil hydrogel as a conditioner enhances the physical, mechanical as well as fertility properties of soil. Soil conditioner is usually considered in the meanings of soil amendments and majorly a nutrient rich fertilizer or inorganic based chemicals [129]. A soil conditioner rebuilds the damaged soil, boosts up the soil features to make it feasible for proper plant growth. Soil hydrogels as a soil conditioner is an inclusive terminology that covers four major areas like water retention, soil nutrient, soil structure, and cation exchange [130]. Soil hydrogels play an important role in the first two categories.

Swelling behavior

Swelling is the consequence process of the relation between a matrix of hydrogel and a solvent [131]. Swelling is the initial process of salvation of salt or hydrogel into a solvent and extended three dimensionally [61]. It is a tool to measure the available free space between joints or cross-links of polymer hydrogel to know increased cross-link density after swelling. The swelling property of superabsorbent hydrogels overcome the worldwide issues of water consumption in agriculture, helps in improving soil water retaining property and reduction in plant’s wither rate [74].

Factors affecting swelling

The swelling behavior of a soil hydrogel directly depends upon the structure of hydrogel, polymerization process (either grafting of cross-linking), the concentration of cross-linking agent and particle size of hydrogel. All factors affect the swelling but the last factor affects the more. If the concentration of cross-linking agent rises, as a result, high densification of hydrogel and the structure of hydrogels become more congested due to the increased number of cross-links on polymer chain [131]. This densification of hydrogel prohibits the expanding of structure on water absorption. There must be flexibility in the structure of hydrogel so that it can expand and exhibit swelling behavior on absorbing a defined amount of water [154]. The swelling behavior facilitates the water absorption for sandy soils with less water holding capacity and provides water content to plant slowly for a long time. Fig. 10 is showing the factors affecting the swelling of the hydrogel.

Fig. 10.

Factors affecting the swelling of hydrogel.

Effect of hydrogel composition on swelling