Abstract

The halwa is a traditional thick sweet generally consumed by millions in the Middle East with more concentrated population in the South and Central Asia. Sweet corn halwa is one such traditional type prepared in the tribal region of middle Gujarat, India. It is one of the dairy delicacies of traditional Indian desserts, which needs to be optimized and dehydrated to assure the availability of the product during off-season and to provide good value in terms of money and enhancement of shelf life. The milk and sugar were added in 50 to 250 g/100 g and 12 to 14 g/100 g respectively for cooking of ingredients for 10 to 20 min to provide value to this traditional product for getting higher return to the entrepreneurs. The optimized sweet corn halwa was dehydrated in thin layers at 60 °C and drying data was fitted thin layer drying models. The physico-chemical properties and sensory evaluation of sweet corn halwa were evaluated during this experiment. The rehydrated product maintained similar overall acceptability, indicating comparable sensory characteristics with fresh sweet corn halwa.

Keywords: Traditional halwa, Sweet corn, Dehydration, Mathematical modelling

Introduction

Traditional food products are popular due to their unique tastes across the world according to biodiversity based on conventional knowledge, which are generally practiced in the unorganized sectors. The flavour, aroma and taste of such ethnic products varies from place to place due to the variations of ingredients and processing parameters. The origin of the word ‘Halwa’ in English language dates back to the nineteenth century and was introduced by the Ottoman Turks of Constantinople (Marks 2010). Halwa, traditional thick sweet generally consumed by millions in the Middle East. The popularity of the dish is quite more in the South and Central Asia. Halwa is a quite popular dish and is consumed in other parts of the world but is not referred as “Halwa”. Halwa is a historical dish and can be classified into numerous types but generally there are two types of Halwa i.e. flour-based halwa and nut-butter based halwa. In the former case, physical appearance of halwa is jelly-like and is prepared from flour like of cereals, pulses etc. In various parts of the world “Semolina” locally referred as Suji is popular for preparation of Halwa with a blend of proper proportions of clarified butter (Ghee), sugar and many more. The method of preparation is a traditional knowledge that is passed on from generation to generation, especially in the Middle-East. However, nut-butter based halwa can be referred as recycle of the defatted waste. When the oil is extracted from the oil seeds like sesame, almond, sunflower, then the defatted waste is unutilized, but it contains a tremendous amount of fibers and proteins so the same are utilized.

The origin of halwa is from the Arabs and has become famous worldwide nowadays. As this knowledge was being shared among the generations that led to varieties in halwa often referred as “The Sweet of Festivals” in the Middle-East. Halwa is a must for every festival or occasion in India, and the occasion is felt incomplete without this sweet and more often people name the dishes, but out of the box, this dish itself has named by people who prepare and sell halwa as “Halwai”. Halwa is a cultural dish and related to the varied heritage and culture of India. In the “Land of Gods”, this sweet is used as an offering to Gods and Goddesses. It is a holy offering during the world-famous festival of “Navratri” and also the “Kada Prasad” of Gurudwaras too.

The processed products made traditional knowledge are based on localized biological resources and can be associated with culture (Atadesse et al. 2020), which need to be standardized for developments of value-added products with longer shelf life to assure the availability during the off season and in extreme conditions. Corn (Zea mays L.) is recognized as queen of cereals crops and sugar content differentiates sweet corn from cereal corn. Sweet corn has 76% moisture content, 3.27% protein, 18.7% carbohydrate, and 6.26% total sugars (USDA 2020). It is being used in preparation of various culinary dishes like sweet corn soup, sweet corn bhel, vegetable salad, pasta and with other seasonal vegetable recipes. The storage life of sweet corn is very limited because sweetness and tenderness are dropped rapidly. Sweet corn has satisfactory culinary for a maximum of 6–8, 3–4 and 2 days at the storage temperature of 0, 5 and 10 °C respectively (Ryall et al. 1972). The optimization of processing parameters for the development of standard technology for the preparation of traditional products has immense importance.

Halwa is generally defined in the term of sweet dairy confection prepared in India. It is made from various forms of cereals/pulse flours, vegetables, and fruits with the uniformity of a very thick sweet deserts (Dhiman et al. 2017). The presentations of halwa varies from spongy to plane and glowing to lustrous appearances. Different variations in milk based halwa desserts with popular ingredients such as carrot, bottle gourd, split moong, beetroot are popular across the world. The freshly prepared halwa remains one of the popular desserts in sweet shops. However, packaged halwa in processed convenient form is still missing, which makes it not available throughout the season even at extreme locations (Itagi et al. 2013).

Dehydration is defined as removal of free available water, which reduces water activity of perishable foods to enhance the shelf life (Roberts et al. 2008). During the dehydration process, free moisture of the product reduces up to a very low level to prevent spoilage due to microbes and other deteriorative mechanisms (Sangamithra et al. 2015). High moisture foods are dehydrated in thin layers over a metallic plate with faster moisture removal rate and retention of nutrients, which considers dehydration in a single layer and drying characteristics are illustrated by thin layer drying models (Kumar et al. 2012).

The optimization of processing parameters of ready to reconstitute products has a great importance for the development of value-added dairy products. The dehydrated carrot halwa using response surface methodology was optimized by Basantpure et al. (2003), however, no work has been reported for the development of dehydrated sweet corn halwa. Therefore, a study was carried out to investigate processing parameters including the proportion of raw material for the preparation of dehydrated sweet corn halwa by using response surface methodology followed by drying kinetics study of milk based sweet corn halwa.

Materials and methods

Materials

Sweet corn, milk, other necessary ingredients like sugar and ghee/clarified butter were procured from commercial market, Godhra, India.

Experimental design

The experiments were designed using response surface methodology (Kumar et al. 2010). The concentration of milk, sugar and cooking time were considered as the factors having five different levels maintaining equal distances from the center (Montgomery 2012). The independent factors were milk (50–250 ml), sugar (12–20 g) and cooking time (10–20 min). The design of coded with actual values and regression coefficients are provided in Tables 1 and 2, respectively.

Table 1.

Central composite rotatable experimental design for development of dehydrated sweet corn halwa and responses of developed product

| S. no. | Independent variables | Dependent variables | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Milk (ml) | Sugar (g) | Cooking time (min) | Colour-L* | Colour a* | Colour-b* | Titratable acidity | Reducing sugar (g/100 g) | Total sugar (g/100 g) | TSS ° Brix |

Moisture content (%) | ||||

| Coded | Uncoded | Coded | Uncoded | Coded | Uncoded | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | Y8 | |

| 1 | − 1 | 100.0 | − 1 | 14.0 | − 1 | 12.5 | 35.33 | 27.08 | 39.69 | 0.29 | 10.30 | 27.42 | 3.10 | 55.7 |

| 2 | + 1 | 200.0 | − 1 | 14.0 | − 1 | 12.5 | 48.94 | 105.40 | 64.79 | 0.19 | 11.20 | 38.29 | 2.10 | 49.8 |

| 3 | − 1 | 100.0 | + 1 | 18.0 | − 1 | 12.5 | 38.62 | 22.12 | 41.48 | 0.48 | 11.60 | 45.78 | 4.00 | 67.5 |

| 4 | + 1 | 200.0 | + 1 | 18.0 | − 1 | 12.5 | 51.60 | 11.95 | 49.78 | 0.29 | 11.80 | 33.46 | 2.50 | 51.3 |

| 5 | − 1 | 100.0 | − 1 | 14.0 | + 1 | 17.5 | 33.81 | 28.37 | 37.36 | 0.77 | 8.67 | 31.02 | 3.90 | 59.7 |

| 6 | + 1 | 200.0 | − 1 | 14.0 | + 1 | 17.5 | 42.18 | 11.42 | 38.04 | 0.48 | 10.54 | 25.83 | 3.00 | 61.5 |

| 7 | − 1 | 100.0 | + 1 | 18.0 | + 1 | 17.5 | 40.67 | 10.69 | 34.33 | 0.38 | 9.47 | 42.39 | 3.70 | 51.5 |

| 8 | + 1 | 200.0 | + 1 | 18.0 | + 1 | 17.5 | 43.25 | 6.49 | 29.88 | 0.29 | 10.05 | 33.62 | 3.50 | 50.0 |

| 9 | − 1.68 | 65.9 | 0 | 16.0 | 0 | 15.0 | 41.91 | 10.97 | 32.30 | 0.38 | 7.50 | 39.39 | 3.50 | 54.0 |

| 10 | + 1.68 | 234.1 | 0 | 16.0 | 0 | 15.0 | 55.96 | 6.36 | 27.08 | 0.19 | 8.18 | 35.78 | 2.80 | 75.0 |

| 11 | 0 | 150.0 | − 1.68 | 12.6 | 0 | 15.0 | 36.87 | 18.14 | 32.30 | 0.29 | 8.67 | 27.66 | 3.70 | 55.5 |

| 12 | 0 | 150.0 | + 1.68 | 19.4 | 0 | 15.0 | 39.15 | 15.46 | 27.58 | 0.29 | 7.99 | 32.50 | 3.90 | 54.5 |

| 13 | 0 | 150.0 | 0 | 16.0 | − 1.68 | 10.8 | 46.38 | 9.09 | 34.70 | 0.38 | 11.53 | 43.98 | 3.50 | 69.5 |

| 14 | 0 | 150.0 | 0 | 16.0 | + 1.68 | 19.2 | 35.91 | 19.20 | 37.06 | 0.38 | 11.85 | 41.67 | 3.00 | 43.0 |

| 15 | 0 | 150.0 | 0 | 16.0 | 0 | 15.0 | 45.75 | 26.90 | 41.65 | 0.29 | 11.67 | 42.79 | 3.00 | 59.0 |

| 16 | 0 | 150.0 | 0 | 16.0 | 0 | 15.0 | 43.68 | 27.10 | 41.82 | 0.29 | 11.34 | 43.98 | 3.30 | 59.0 |

| 17 | 0 | 150.0 | 0 | 16.0 | 0 | 15.0 | 46.04 | 27.63 | 40.03 | 0.38 | 11.36 | 42.41 | 3.10 | 64.0 |

| 18 | 0 | 150.0 | 0 | 16.0 | 0 | 15.0 | 47.71 | 26.95 | 39.96 | 0.29 | 11.39 | 42.22 | 3.20 | 58.0 |

| 19 | 0 | 150.0 | 0 | 16.0 | 0 | 15.0 | 46.25 | 26.55 | 41.07 | 0.29 | 11.64 | 43.58 | 3.00 | 64.5 |

| 20 | 0 | 150.0 | 0 | 16.0 | 0 | 15.0 | 45.65 | 27.64 | 40.35 | 0.19 | 11.72 | 43.77 | 3.00 | 61.5 |

Table 2.

Regression coefficients of second order polynomial and their significance on process parameters

| Coefficient | Color L* | Acidity | Reducing sugar | Total sugar | TSS | Moisture content | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coeff. value | F | P | Coeff. value | F | P | Coeff. value | F | P | Coeff. value | F | P | Coeff. value | F | P | Coeff. value | F | P | |

| x1-Milk | + 4.48 * | 116.99 | < 0.0001 | − 0.073* | 9.49 | 0.0116 | + 0.34ns | 1.78 | 0.2117 | − 1.57* | 3.83 | 0.0787 | − 0.35 * | 12.8 | 0.005 | + 0.33 | 0.25 | 0.6257 |

| x2-Sugar | + 1.3 * | 9.8 | 0.0107 | − 0.021ns | 0.79 | 0.3957 | + 0.078ns | 0.093 | 0.7668 | + 2.99* | 13.85 | 0.004 | + 0.14ns | 2.1 | 0.1776 | − 0.59 | 0.091 | 0.7697 |

| x3-Cooking time | − 2.36 * | 32.44 | 0.0002 | + 0.049* | 4.33 | 0.0641 | − 0.41ns | 2.57 | 0.1399 | − 1.17ns | 2.12 | 0.176 | + 0.11ns | 1.36 | 0.27 | − 3.38 | 2.95 | 0.1164 |

| x1x2 | − 0.80ns | 2.2 | 0.1691 | + 0.012ns | 0.15 | 0.7059 | − 0.25ns | 0.54 | 0.4779 | − 3.35* | 10.15 | 0.0097 | + 0.025ns | 0.038 | 0.8488 | − 1.70 | 0.44 | 0.5232 |

| x1x3 | − 1.96 * | 13.07 | 0.0047 | − 0.012ns | 0.15 | 0.7059 | + 0.17ns | 0.25 | 0.6254 | − 1.56ns | 2.22 | 0.167 | + 0.18ns | 1.88 | 0.2007 | + 2.80 | 1.19 | 0.3015 |

| x2x3 | + 0.25ns | 0.21 | 0.6587 | − 0.11* | 12.22 | 0.0058 | − 0.20ns | 0.35 | 0.5672 | + 0.70ns | 0.45 | 0.5182 | − 0.12ns | 0.96 | 0.3509 | − 4.12 | 2.58 | 0.1395 |

| x21 | + 0.94 * | 5.46 | 0.0415 | + 0.016ns | 0.46 | 0.5147 | − 1.03* | 16.77 | 0.0022 | − 2.32* | 8.81 | 0.0141 | − 0.023ns | 0.059 | 0.8132 | + 0.70 | 0.13 | 0.7235 |

| x22 | − 2.92 * | 52.49 | < 0.0001 | + 0.016ns | 0.46 | 0.5109 | − 0.85* | 11.58 | 0.0067 | − 4.98* | 40.45 | < 0.0001 | + 0.21 * | 4.72 | 0.055 | − 2.66 | 1.93 | 0.1946 |

| x23 | − 1.81 * | 20.17 | 0.0012 | + 0.049* | 4.62 | 0.0571 | + 0.33ns | 1.78 | 0.2122 | − 0.47ns | 0.36 | 0.5614 | + 0.012ns | 0.017 | 0.9 | − 2.22 | 1.36 | 0.2732 |

| F value | 28.15 | < 0.0001 | 3.57 | 0.03 | 3.95 | 0.0216 | 8.74 | 0.0011 | 2.67 | 0.0707 | 1.21 | 0.3854 | ||||||

| R-squared | 0.962 | 0.7627 | 0.7804 | 0.8872 | 0.7065 | 0.5203 | ||||||||||||

| Adj R-squared | 0.928 | 0.5492 | 0.5828 | 0.7856 | 0.4423 | 0.0885 | ||||||||||||

| Adeq precision | 19.603 | 7.833 | 7.61 | 9.686 | 6.197 | 4.010 | ||||||||||||

*Significant at 5% level

ns not significant

Preparation of pulp

Sound and healthy sweet corn cobs were selected. The husk was separated manually. Sweet corn was washed subsequently detaching kernels using corn peeler. These was crushed and sieved twice for getting uniform sweet corn pulp.

Cooking of ingredients

The cooking started with the pouring of 10 g ghee in the pan followed by the addition of 100 g sweet corn pulp and stirred for 3 min for getting a dark yellow colour of pulp. Thereafter, sugar and milk were added in predetermined levels and followed by stirring all the ingredients for predetermined time as per Table 1. The cooking temperature ranged between 85–90 °C for all the experiments. All the prepared samples were kept in closed containers for further analysis.

Analysis of responses

Colour

The colour values L*, a* and b* for indicating lightness, redness, and yellowness in comparison to darkness, greenness, and blueness were obtained using colorimeter (Make-3nh, China) after calibration with the standard.

Biochemical properties

The biochemical parameters of sweet corn halwa viz. titratable acidity, reducing sugar, total sugar total soluble solids were estimated using the standard procedures as described by Ranganna (2000).

Sensory characteristics

Sensory characteristics were evaluated on a hedonic rating test conducted with 15 semi trained panelists for colour, flavour, taste, odour and overall acceptability as described by Ranganna (2000).

Dehydration of sweet corn halwa

The optimized product obtained from response surface methodology, was dehydrated at 60 °C temperature in tray dryer in a 10 mm thick layer of the sample. The mass of dish with representative sample was recorded with digital balance at every 10 min interval, till the reduction in mass reached to minimum by carried the sample on digital balance and brought back in drying chamber within 10 s. The moisture content of the sample was also determined using laboratory hot air oven at a temperature of 105 ± 1 °C for the duration of 24 h (Kachhadiya et al. 2018).

Modelling of the thin-layer drying curves

The experimental moisture data of optimized sweet corn halwa was converted in to dimensionless moisture ratio (MR), which is defined as the ratio of instantaneous free moisture content (M–Me) to the initial free moisture content of the product (Mo–Me) where M, Mo and Me are the instantaneous, initial and equilibrium moisture contents of the samples. The moisture ratio can be simplified to M/Mo considering the relatively lower value of the equilibrium moisture content, and unregulated relative humidity of drying air (Kumar et al. 2012). The models were evaluated based on the maximum coefficient of determination, and minimum values of reduced Chi square and root mean square error as a measure of goodness of fit (Kumar et al. 2011). The regression analysis was implemented using OriginPro 2020 (Originlab, Northampton). The constant rate drying was not observed, and drying was performed in a falling rate period considering diffusion using Fick’s model to characterize the drying behaviour of milk based sweet corn halwa (Wang et al. 2006).

Results and discussion

Colour

Colour is a very essential parameter for every food product as it directly affects the final product as well as consumer preference. The colour L* of sweet corn halwa extended from 33.81 to 55.96 with a normal estimation of 43.28 (Table 1). The F, R2, adjusted R2, adequate precision values were 28.15, 0.962, 0.928 and 19.603 respectively (Table 2), indicates the model as significant (P < 0.05) to predict colour L* values within studied range.

| 1 |

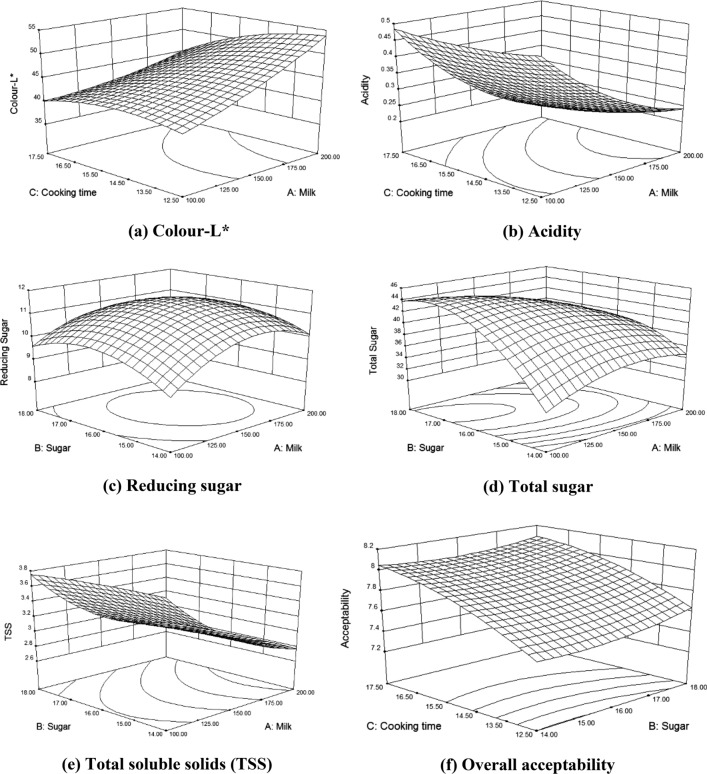

F-values for square terms of corn halwa proportion of milk (x21), Sugar (x22) and cooking time (x23) are 5.46, 52.49 and 20.17 respectively (P < 0.05), indicating x21, x22 and x23 terms are significant. The F-value for interaction term proportions of milk with cooking time (x1x3) is 13.07 indicating significance (P < 0.05). It can be observed from Fig. 1a that colour L* value increased indicating an increase in whiteness by an increase in proportion of milk, which is evident due to the presence of more whiteness of milk. The colour-a* and colour-b* values remained from 6.36 to 105.4 with an average value of 23.28 and 27.08 to 64.79 with an average value of 38.56 respectively. However, the variation due to colour-a* and colour-b* values indicating the change in red/green and yellow/blue colours was not significant (P > 0.05).

Fig. 1.

Variation of colour-L*, acidity, reducing sugar, total sugar, total soluble solids and overall acceptability of sweet corn halwa with respect to processing conditions

Titratable acidity

The titratable acidity is used to ascertain keeping quality and heat stability of dairy products. The acidity of sweet corn halwa ranged from 0.19 to 0.77 with a normal estimation of 0.34 (Table 1).

The model F, R2, adjusted R2 and adequate precision values were 3.57, 0.7627, 0.5492 and 7.833 respectively (Table 2), implies that the model is significant (P < 0.05). Following models may be used for predicting the titratable acidity within studied range.

| 2 |

It can also be noted from Fig. 1b that titratable acidity reduced with the increase in milk, which is obvious due to the lower acidity value of milk.

Reducing sugar

Reducing sugar of milk based sweet corn halwa ranged from 7.50 to 11.85 with an average value of 10.42 (Table 1). The model F, R2, adjusted R2 and adequate precision values were 3.59, 0.7804, 0.5828 and 7.61 respectively (Table 2), implies model as significant (P < 0.05). The following model indicates the variation of reducing sugar within studied range.

| 3 |

The maximum value of reducing sugar can be pointed at the central zone of the study Fig. 1c. The initial increase in reducing sugar by the increase of milk is due to the addition of reducing sugar present in milk, whereas it might be reduced further due to chemical reaction among reducing sugars and various amino acids, i.e. non-enzymatic browning due to providing heat during cooking of sweet corn halwa (Fennema et al. 2017).

Total sugar

The Total sugar of sweet corn halwa ranged from 25.83 to 45.78 with an average value of 37.88 (Table 1). The model F, R2, adjusted R2 and adequate precision values were 8.74, 0.8872, 0.7856 and 9.686 respectively (Table 2), indicates the total sugar model as significant (P < 0.05). The following model may be used for representing the variation of total sugar.

| 4 |

The maximum value of total sugar can be noted at the centre point of milk proportion (Fig. 1d), and it increased with an increase in addition of sugar. The decrease of total sugar by an increase in milk is evident due to an addition of more water available in dispersion phase in milk, which confers dilution of the sugar, whereas an increase by addition of sugar is due to the increase in the concentration of sucrose in the sweet corn halwa.

Total soluble solids

The total soluble solids (TSS) of sweet corn halwa ranged from 2.10 to 4.0 with an average value of 3.24. The model F, R2, adjusted R2 and adequate precision values were 2.67, 0.7065, 0.4423 and 6.197 respectively (Table 2), indicates TSS model as significant (P < 0.05) and the model can be used to estimate TSS within the studied range.

| 5 |

Further, it may be observed from Fig. 1e that total soluble solid reduced with the addition of milk in the proportion, which is evident due to the dilution of exiting soluble solids by an addition of water available in milk.

Moisture content

The Moisture content of sweet corn halwa ranged from 43.0 to 75.0% with an average value of 58.23%. The model F value was 1.21 indicates the model is not significant (P > 0.10).

Overall acceptability

The sensory characteristics in terms of overall acceptability of milk based sweet corn halwa varied from 6.5 to 8.3 with an average value of 7.63. The maximum overall acceptability was obtained with 65.9 ml milk, 16 g sugar and 15 min cooking time. The increase in overall acceptability with more cooking time can be observed from Fig. 1f, which may be due to the desired consistency and cooking flavour at a higher level of cooking time.

Optimization of process parameters

The product was optimized according to the sensory characteristics for maximum overall acceptability. The numerical optimization was performed and a sample with higher sensory was obtained with 132.71 ml milk, 18.00 g sugar and 17.50 min cooking time for maximum overall acceptability with a value of 8.12.

Drying kinetics

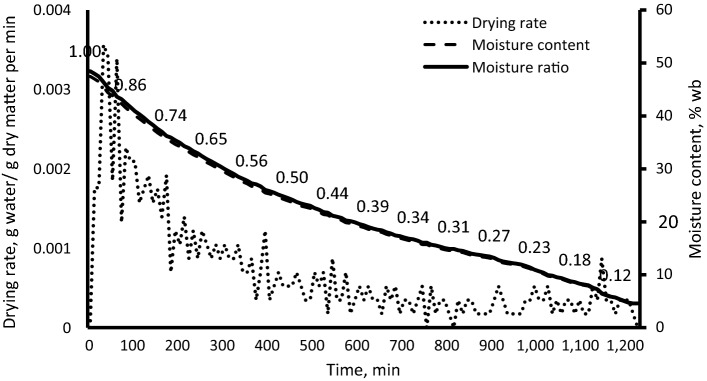

The dehydrated sweet corn halwa was dried at temperatures of 60 °C in a tray dryer in 10 mm layer. The original moisture content of sweet corn halwa was 47.46% which was reduced to 3.19% during drying operation of 22 h.

The change in moisture content (wb) on primary the y axis is plotted with respect to time on x axis in Fig. 2. The drying rate is plotted on secondary y axis with respect to time too. The variation of moisture ratio is also plotted with numerical values in legends in the same plot.

Fig. 2.

Variation of Drying rate, moisture content and moisture ratio with respect to drying time

It was observed that the moisture content of sweet corn halwa decreased with drying time, which may be due to removal of water through conversion in to vapour using heat supplied from drying air. The moisture content reduced rapidly during the initial phase of drying, whereas slower removal in later phase was observed due to less availability of free moisture in the later stage. Moisture ratio also reduced with drying time and only 440 min are required to eliminate initial 50% moisture (MR = 0.5), which remains about 1/3 of complete drying duration of 1320 min to remove the remaining moisture from sweet corn halwa. The slower drying rate in later phase of drying is evident due to a slow diffusion level. The absence of the constant rate period may be attributed to reduction of water surface rapidly. A small increase in drying rate was observed, which decreased further till the end of drying. The movement of water from the inner part of milk based sweet corn halwa was higher in the starting due to more availability of moisture initially, which reduced further till the end of drying.

Fitting of the drying curves

The change in moisture ratio (MR) with drying duration was fitted to 9 popular models (Table 3). The models were evaluated by estimating R2, χ2 and RMSE. It can be observed that R2 values were within 0.9841 to 0.9949 indicated all models fitted well. The χ2 value of models were lower and within 3.34 × 10−04 to 1.03 × 10−03 indicating goodness of fit, whereas lower RMSE values of 0.0181 to 0.0319 indicating level of absolute fitting. The Logarithmic model has maximum R2 and minimum χ2 and RSME values, therefore recommended for prediction.

Table 3.

List of mathematical models, references, coefficients and statistical parameters

| Sr. no. | Models name, mathematical expression and refence | Coefficients | R2 | χ2 | RMSE |

|---|---|---|---|---|---|

| 1 |

Lewis model (Bruce 1985) MR = exp(− kt) |

k = 0.0016 | 0.9900 | 6.50×10−4 | 0.0254 |

| 2 |

Page model (Page 1949) MR = exp(− ktn) |

k = 0.0013, n = 1.0296 | 0.9903 | 6.31×10−4 | 0.0249 |

| 3 |

Henderson and Pabis model (Henderson and Pabis 1961) MR = a exp(− kt) |

k = 0.0016, a = 0.9997 | 0.9899 | 6.54×10−4 | 0.0254 |

| 4 |

Logarithmic Model (Togrul and Pehlivan 2002) MR = a exp(− kt) + c |

k = 0.0012, a = 1.1214, c = −0.1584 | 0.9949 | 3.34×10−4 | 0.0181 |

| 5 |

Two term model (Henderson 1974) MR = a exp(− k0t) + b exp(− k1t) |

k0 = 0.0464, k1 = 0.0016, a = 0.0058, b = 0.9987 | 0.9898 | 6.64×10−4 | 0.0254 |

| 6 |

Wang and Singh Model (Wang and Singh 1978) MR = 1 + at + bt2 |

a = −0.0013, b = 4.3485×10−7 | 0.9841 | 1.03×10−3 | 0.0319 |

| 7 |

Approximation of diffusion Model (Yaldiz et al. 2001) MR = a exp(− kt) + (1 − a) exp (−kat) |

k = 0.0018, a = 1.4276 | 0.9908 | 5.98×10−4 | 0.0243 |

| 8 |

Verma Model (Verma et al. 1985) MR = a exp(− kt) + (1 − a) exp(− gt) |

a = 1, g = 1.1217, k = 0.0016 | 0.9899 | 6.54×10−4 | 0.0254 |

| 9 |

Hii, Law & Cloke Model (Hii et al. 2009) MR = a exp(− ktn) + c exp(− gtn) |

n = 1.0773, k = 9.1985×10−4, a = 0.4298, g = 9.2010×10−4, c = 0.5409 | 0.9908 | 5.97×10−4 | 0.0240 |

Reconstitution of dehydrated product

The product was reconstituted with the equal amount of boiled distilled water and kept for 2 min and served to sensory panelist. The received sensory score was 8.1, that was similar to the fresh sweet corn halwa, indicates the acceptability of the dehydrated ready to reconstitute milk based sweet corn halwa.

Conclusion

The milk based ready to reconstitute dehydrated sweet corn halwa was optimized at concentration of milk, sugar and cooking time of 132.71 ml, 18.00 g, and 17.50 min respectively for maximum sensory characteristics with an overall acceptability 8.12. The colour- L*, a* and b*, TSS, acidity, reducing sugar, total sugar and moisture content were 39.84, 24.22 and 35.26, 3.50° Brix, 0.29, 10.21 g/100 g, 42.22 g/100 g and 47.46% wb respectively. The moisture content of optimized halwa was reduced from 47.46% to 3% in tray dryer in 22 h. The Logarithmic model fitted well in moisture kinetics having higher R2 and lower values of χ2 and RSME, and therefore, recommended for prediction. The rehydrated product obtained an overall acceptability value of 8.1, indicating the retention of sensory characteristics even after reconstituted the dehydrated product.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Atadesse NS, Beyene GF, Hordofa TB, Hailu AA. Traditional foods and beverages in Eastern Tigray of Ethiopia. J Ethnic food. 2020;7:16. doi: 10.1186/s42779-020-00050-8. [DOI] [Google Scholar]

- Basantpure D, Kumbhar BK, Awasthi P. Optimization of levels of ingredients and drying air temperature in development of dehydrated carrot halwa using response surface methodology. J Food Sci Technol. 2003;40(1):40–44. [Google Scholar]

- Bruce DM. Exposed-layer barley drying: three models fitted to new data up to 150 & #xB0;C. J Agric Eng Res. 1985;32:337–348. doi: 10.1016/0021-8634(85)90098-8. [DOI] [Google Scholar]

- Dhiman AK, Negi V, Attri S, Ramachandran P. Optimization of instant halwa mix from dehydrated pumpkin and its stability during storage. Int J Agric Sci. 2017;9:4026–4030. [Google Scholar]

- Fennema OE, Damodaran S, Parkin KL. Fennema’s food chemistry. London: Routledge; 2017. [Google Scholar]

- Henderson SM. Progress in developing the thin layer drying equation. Trans ASABE. 1974;17:1167–1168. doi: 10.13031/2013.37052. [DOI] [Google Scholar]

- Henderson SM, Pabis S. Grain drying theory II. Temperature effects on drying coefficients. J Agric Eng Res. 1961;6:169–174. [Google Scholar]

- Hii CL, Law CL, Cloke M, Suzannah S. Thin layer drying kinetics of cocoa and dried product quality. Biosyst Eng. 2009;102:153–161. doi: 10.1016/j.biosystemseng.2008.10.007. [DOI] [Google Scholar]

- Itagi HN, Singh V, Indiramma AR, Prakash M. Shelf stable multigrain halwa mixes: preparation of halwa, their textural and sensory studies. J Food Sci Technol. 2013;50:879–889. doi: 10.1007/s13197-011-0423-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kachhadiya S, Kumar N, Seth N. Process kinetics on physico-chemical and peroxidase activity for different blanching methods of sweet corn. J Food Sci Technol. 2018;55:4823–4832. doi: 10.1007/s13197-018-3416-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar N, Sarkar BC, Sharma HK. Development and characterization of extruded product of carrot pomace, rice flour and pulse powder. Afr J Food Sci. 2010;4:703–717. [Google Scholar]

- Kumar N, Sarkar BC, Sharma HK. Effect of air velocity on kinetics of thin layer carrot pomace drying. Food Sci Technol Int. 2011;17:459–469. doi: 10.1177/1082013211398832. [DOI] [PubMed] [Google Scholar]

- Kumar N, Sarkar BC, Sharma HK. Mathematical modelling of thin layer hot air drying of carrot pomace. J Food Sci Technol. 2012;49:33–41. doi: 10.1007/s13197-011-0266-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marks G. Encyclopedia of Jewish food. New York: Wiley; 2010. [Google Scholar]

- Montgomery DC. Design and analysis of experiments. New York: Wiley; 2012. [Google Scholar]

- Page GE (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. M.S. thesis. Purdue University. 1949. Dissertation No. AAI1300089

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. New York: Tata McGraw-Hill Education; 2000. [Google Scholar]

- Roberts JS, Kidd DR, Zakour OP. Drying kinetics of grape seeds. J Food Eng. 2008;89:460–465. doi: 10.1016/j.jfoodeng.2008.05.030. [DOI] [Google Scholar]

- Ryall AL, Lipton WJ Handling. Transportation and storage of fruits and vegetables. Westport: Avi; 1972. [Google Scholar]

- Sangamithra A, Venkatachalam S, John SG, Kuppuswamy K. Foam mat drying of food materials: a review. J Food Process Pres. 2015;39:3165–3174. doi: 10.1111/jfpp.12421. [DOI] [Google Scholar]

- Togrul IT, Pehlivan D. Mathematical modelling of solar drying of apricots in thin layers. J Food Eng. 2002;55:209–216. doi: 10.1016/S0260-8774(02)00065-1. [DOI] [Google Scholar]

- USDA (2020) Food data centre, U.S. Department of Agriculture. Nutrient Database for Standard Reference, Nutrient Data Laboratory Research Service, Riverdale, MD. https://fdc.nal.usda.gov/

- Verma LR, Bucklin RA, Endan JB, Wratten FT. Effects of drying air parameters on rice drying models. Trans Am Soc Agric Eng. 1985;28:296–301. doi: 10.13031/2013.32245. [DOI] [Google Scholar]

- Wang CY, Singh RP. Use of variable equilibrium moisture content in modeling rice drying. Trans Am Soc Agric Eng. 1978;11:668–672. [Google Scholar]

- Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X. Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int. 2006;40:39–46. doi: 10.1016/j.foodres.2006.07.017. [DOI] [Google Scholar]

- Yaldiz O, Ertekin C, Uzun HI. Mathematical modeling of thin layer solar drying of sultana grapes. Energy. 2001;26:457–465. doi: 10.1016/S0360-5442(01)00018-4. [DOI] [Google Scholar]