Abstract

The aim of this study was to evaluate the physicochemical properties of beef burger after substitution of animal fat with the ethylcellulose (EC) oleogel. Therefore, sesame oil oleogels were prepared using EC in concentrations of 10%, and cooled at 25 °C. The fatty acid profile of EC oleogel compared with animal fat. Then, the EC oleogel was incorporated to hamburger at the 0, 25 and 50% instead of animal fat and color and textural properties as well as cooking loss, cooking shrinkage, fat absorption, and lipid oxidation of the beef burgers were evaluated. As an outcome, the EC oleogel contained high levels of linoleic and linolenic acids, while the palmitic and stearic acids were lower than the animal fats, and myristic acid was not detectable. Replacement of animal fat with EC oleogel upgraded the quality of final product by reducing cooking loss and fat absorption. Production of beef burger with EC oleogel decreased the oxidation process during frozen storage as well as cooking loss and fat absorption, and enhanced textural properties including chewiness and hardness. Improvement of nutritional and technological properties of hamburgers contained EC oleogel makes it a desirable candidate for animal fat substitution.

Supplementary Information

The online version contains supplementary material available at(10.1007/s13197-021-04970-4)

Keywords: Fat replacement, Beef burger, Ethylcellulose, Unsaturated oil

Introduction

The busy lives of today have led people to consume ready-to-use and fast foods (Gamit et al. 2020). Among them, burger considered as the most preferred fast food types between different genders and cultures (Ozcelik et al. 2007). It contains 70–75% semi-frozen meat and 20–25% animal fat (Feiner 2006). However, due to their high fat content and saturation of their fatty acids, they are not well accepted by consumers and absent in people’s food habits. Today, the industry is facing increasing demand for foods with low saturated fatty acids due to the increased consumer’s nutritional awareness (Stortz et al. 2012). Many efforts have been made to develop healthier burgers in recent years that one of them is the replacement of animal fat with more healthier fats such as unsaturated vegetable oils (Papadima and Bloukas 1999). However, direct replacement of animal fat with these oils does not have the desired effects since the required structure of oil is not formed. In fact, the high content of unsaturated fatty acids increases hardness and shear force (Selani et al. 2016) which in turn reduces texture score of beef burgers in sensory evaluation (Shiota et al. 1995). Rodríguez-Carpena et al. (2012) investigated the effects of olive, sunflower, and avocado oils incorporation to burger patties instead of pork back-fat. They found that this substitution reduced saturated fatty acid percentage; and due to the presence of tocopherols in vegetable oils, prepared burgers encountered less lipid and protein oxidation. Moreover, using vegetable oils enhanced color and texture of burgers. However, one of the disadvantages of using vegetable oil in the burgers was a significant reduction in hardness, gumminess and chewing ability (Rodríguez-Carpena et al. 2012). Keenan et al. (2015) studied the effect of encapsulated and non-encapsulated fish oil as a fat replacer on the sensory and technological characteristics of beef burger. Increasing fish oil resulted in enhancement of unsaturated fatty acids content. On the other hand, this substitute increased cooking loss and reduced hardness (Keenan et al. 2015). In another study, the effects of canola oil and by-product of pineapple on the sensory and physicochemical characteristics of low fat hamburger were investigated. It was found that low-fat burgers were harder and had more chewiness and cohesiveness than that of full fat burgers (Selani et al. 2016).

One of the new methods for the preparation of healthier food products is to use oleogelation (Marangoni 2012). Oleogelation is known as the production of gel network with three-dimensional structure from oil with self-standing, thermo-reversible, and viscoelastic characteristics. The most advantage of this oil structuring procedure is preservation of fatty acid profile; so that unsaturated fatty acids which are beneficial from nutritional view point are unchanged (Yılmaz and Öğütcü, 2015). In this approach, a low concentration of oleogelator forms a network with the ability to entrap a mass of liquid oil (Pernetti et al. 2007). Compounds can act as oleogelator which have certain physicochemical properties such as hydrophobicity, self-assembling and surface activity properties, tolerating a higher structural arrangement based on super-molecular reactions, and preferably have reversible thermal properties such as crystallization (Marangoni 2012). In recent years, the application of oleogels in different meat products has been investigated. Recently, the replacement of saturated fats with oleogels in breakfast sausage (Barbut et al. 2016b), frankfurter sausage (Barbut et al. 2016a, b, c; Barbut et al. 2016a; Panagiotopoulou et al. 2016), pork liver patties (Gómez-Estaca et al. 2019a, b), pork burger (Gómez-Estaca et al. 2019a, b), and comminuted meat product (Barbut and Marangoni 2019) has been the subject of investigation.

Although oleogelation is used for the structuring of vegetable oil, the incorporation of olegel to beef burger may influence on physicochemical properties of the meat products. To the best of our knowledge, EC oleogels have not been applied as a fat replacer in the production of burgers. Hence, the aims of this research were to assess some physicochemical properties of hamburgers such as chemical composition, textural properties, color, cooking loss, cooking shrinkage, fat absorption, lipid oxidation, and sensorial properties after replacement of various percentage of animal fat with EC oleogel.

Materials and methods

Materials

EC with a viscosity of 10 mPa.s and all other reagents and chemicals were purchased from Sigma © (St. Louise, Missouri, United States) with analytical grades. Sesame oil produced in KMP © (Kolkata, West Bengal, India) was obtained from local supermarket and was kept at 4 °C until use. Sesame oil was selected for production of the EC oleogel for both dietary and therapeutic properties. Furthermore, its resistance to oxidation and rancidity can decrease the oil oxidation during production of the EC oleogel at high temperature.

Preparation of oleogel

15 g sesame oil and 1.5 g EC (10% W/W EC ratio to sesame oil) were poured in 100 mL Pyrex beaker. They were completely mixed; and under vacuum and continuous mixing, they were heated to 170 °C in oil-bath. The molten oleogels, after complete dissolution of EC, were cooled at 25 °C in polypropylene tubes (4 cm internal diameter) overnight (Davidovich-Pinhas et al. 2015).

Extraction of fat from animal tissue

Animal fat (animals slaughter in accordance with the Iran's guidelines) was extracted from beef FF and SF (2 important parts of carcass used in the production of beef burger). Fresh beef FF and SF containing a high amount of fat were obtained from a local supermarket. Following drying of meat using a lyophylizer (Dena vacuum, FD-5003-BT, Iran), Soxhelet method was applied for the extraction of animal fat (AOAC 2005). In this method, 3–5 g dried meat were extracted with petroleum ether as solvent during 5 h heating. Then, the solvent was separated from animal fat using vacuum rotary evaporator at temperature of 60 °C.

Burger manufacture

Beef burger was produced from fresh shank and flank (with 8% fat and 70% moisture) obtained from a local supermarket (human slaughter practices were followed in accordance with the Iran’s guidelines.). A meat grinder with 8 mm plate was used to grind the extracted FF and SF as well as the beef. Thereupon, 52% ground beef composed of equal amounts of flank and shank meat was completely mixed with 14% extracted fat (equal amounts of SF and FF), 4% wheat flour, 8% grated onion, 1% seasoning, 1% salt, and 20% water. After preparing the uniform mixture, it was ground again using a 5 mm plate, and was molded with 1 cm thickness and 10 cm diameter. After freezing of burgers at − 30 °C, they were stored 3 months at − 18 °C. The amount of fat in the control sample was 16% which 25% and 50% of them was replaced with the oleogel.

Chemical composition

The AOAC (2005) methods was used for determination of beef burger composition. Fat, protein, moisture and ash content of raw and cooked burger were measured (AOAC 2005).

To determine the fatty acid profile of the animal fats and oleogel, the methyl ester of fatty acid was produced. In this regard, 1 mL n-hexane was added to 50 µL sample. The mixture was vigorously stirred for 15 min after adding 100 µL sodium methoxide (0.5 M). Then, the moisture was removed by passing the hexane phase through anhydrous sodium sulfate. After injection of 1 µL of dehydrated mixture to Agilent 6890 nitrogen gas chromatography, temperature was raised at a rate of 4 °C/min from 140 °C to 240 °C, and was kept constant for 25 min at 240 °C. The gas chromatography was equipped with flame ionization detector whose temperature was adjusted at 300 °C. A HP-88 capillary column with 100 m length, 0.2 µm film thickness, and 0.25 mm internal diameter was applied to separate fatty acids. The injector temperature was 280 °C and the experiment was performed under nitrogen as carrier gas (Goli et al. 2013).

Texture profile analysis

Textural properties of raw and fried hamburgers were evaluated using texture profile analysis. After separation of a sample with thickness of 1 cm and dia of 2 cm from each beef burger, it was compressed twice to 60% of initial thickness at 100 mm/min speed. For compression of samples 5 cm cylindrical probe in diameter and a load cell of 0.5–5 kg was used in analyzer (model 1140, Instron company, United Kingdom) (Li et al. 2011). From the obtained force–displacement profile; hardness, Maximum force required to squeeze the sample (N); cohesiveness, the intensity of sample deformation before tissue decomposition (A2/A1, where A1 was the total energy required for the first compression and A2 the total energy required for the second compression); springiness, sample ability to regain its original shape after the force is removed (cm); gumminess, the force required to disassemble the sample to swallow (hardness × cohesiveness) and chewiness, work required for sample chewing (springiness × gumminess) were calculated (Bourne 1978).

Color evaluation

Nippon Denshoku colorimeter (ZE6000, Japan) was used for determination of redness (a* ± red-green), lightness (L*), and yellowness (b* + yellow-blue) in raw and fried hamburgers. The measurement was done at 10° standard observer angle using the light source D 65 on a sample stage with 10 mm dia. For determination of numerical total color difference (ΔE*), the following equation was used:

| 1 |

Cooking loss

For evaluation of cooking loss, three beef burger were randomly selected from each treatment. They were fried using Delonghi fryer (F38436, USA) in sunflower oil. Before and after frying at 110 °C for 5 min, the samples were weighed and cooking loss was obtained by Eq. 2.

| 2 |

where W1 and W2 are the weight of beef burgers before and after frying, respectively.

Cooking shrinkage

Three hamburgers were randomly selected and their surface with a resolution of 600 dpi was scanned using a scanner (HP G4050, USA) before and after frying. Then, Image J software 1.3.4.6.7 was used for separation of burger images from background, and measurement of surface area. The Eq. 3 considered for calculation of cooking shrinkage:

| 3 |

where S1 and S2 are the surface area of raw and cooked beef burger, respectively.

Fat absorption

The fat absorption was obtained by measurement of fat content (AOAC 2005) in the raw and cooked burgers and using Eq. 4 (Soltanizadeh and Ghiasi-Esfahani, 2015).

| 4 |

where F1 and F2 are the fat content of raw and cooked beef burger, respectively.

Lipid oxidation

Briefly, 20 g hamburger was 2 min homogenized (IKA, Germany) with 50 ml TCA 20%. Then, 50 ml distilled water was added to the mixture and filtered using filter paper of Whatman #1. A 5 ml 2-thiobarbituric acid with the concentration of 0.01 M in acetic acid was mixed with 5 ml TCA extract, thoroughly. The absorbance of solution was recorded at 532 nm after 1 h heating at 100 °C in water bath. Lipid oxidation was obtained immediately after beef burger production and after 1, 2 and 3 months storage at − 18 °C by calculation of milligram malonaldehyde per kilogram burger using Eq. 5.

| 5 |

where A532 is the solution absorbance (Soltanizadeh and Ghiasi-Esfahani, 2015).

Sensory analysis

From each treatment, the samples were randomly selected and prepared by frying at 110 °C for 5 min. Each sample was randomly numbered by a three digit code and was placed in a container to evaluate in a random order by panelists. 36 trained panelists (aged 20–30 years) from among the staff and students of College of Agriculture, Isfahan University of Technology, were selected; and each panelist tested all treatments and compared them with each other. The burgers were scored for flavor, color, texture, and overall acceptability using a seven-point hedonic scale ranging from extreme dislike (score = − 3) to extreme like (score = 3). They cleaned the palate with water and cracker in interval between evaluations of each sample.

Statistical analysis

All of hamburgers were produced in three different batches. Hamburger properties were compared by application of mixed procedure in Statistical Analysis System (SAS) 9.0 with the fixed effect of fat replacement amount. TBARs value in hamburgers was analyzed with repeated measure of mixed procedure so that the fixed effect of fat replacement amount, time and their interaction as well as random effect of replication were considered in statistical model. For evaluation of fat replacement effect over months of frozen storage, compound symmetric covariate was applied. Also, for determination of treatment differences in each month of frozen storage, the slice option of SAS was used. The significance level of p < 0.05 was considered for evaluation of confidence interval.

Results and discussion

Fatty acid profile

As expected, there was a significant difference in fatty acid profile of the animal fats, sesame oil and oleogel (Table 1). The amounts of poly unsaturated fatty acids of linoleic and linolenic acids in sesame oil were higher, and it did not contain myristic acid. On the other hand, the animal fats were lacking linolenic acid and had high amounts of myristic acid, a saturated fatty acid. Even the fatty acid profile between FF and SF was different so that the level of stearic acids was higher in SF. This is while the FF contained more palmitic, oleic and linoleic acids (Table 1).

Table 1.

Fatty acid profile of the EC oleogel, animal fats and sesame oil

| Lipid type | Myristic acid | Palmitic acid | Stearic acid | Oleic acid | Linoleic acid | Linolenic acid |

|---|---|---|---|---|---|---|

| EC oleogel | ND | 9.61C ± 0.37 | 5.79C ± 0.41 | 42.53BC ± 0.47 | 40.06A ± 0.57 | 0.31A ± 0.08 |

| Sesame oil | ND | 9.70C ± 0.36 | 5.80C ± 0.41 | 42.24BC ± 0.20 | 40.54A ± 0.78 | 0.29A ± 0.01 |

| Flank fat | 8.64A ± 3.45 | 28.37A ± 0.36 | 8.00B ± 0.69 | 51.09A ± 1.65 | 17.90B ± 1.69 | ND |

| Shank fat | 7.99A ± 2.36 | 14.34B ± 3.16 | 12.37A ± 2.40 | 40.04C ± 3.60 | 11.20C ± 4.41 | ND |

ND Not detected

Values indicate the average of 3 replicates + standard deviation. Different letters in each column indicates significant difference between treatments (p < 0.05)

Like sesame oil, the EC oleogel contained high levels of linoleic and linolenic acids, while the palmitic and stearic acids were lower than the animal fats, and myristic acid was not detectable. Regarding the role of linoleic acid in the prevention of cardiovascular diseases, and the role of myristic and palmitic acids in increasing cholesterol (Sowmya et al. 2009), the importance of animal fat replacement with the oleogels becomes obvious. On the other hand, due to high saturation animal fat plays an important role in texture and oral sensation of many products including meat products (Sowmya et al. 2009). With a solid structure as well as high amount of unsaturated fatty acids, oleogel can improve both nutritional and textural properties of food products.

Chemical composition

As can be seen in Table 2, moisture, fat, protein and mineral content in raw burgers produced by different levels of animal fat replacement were not significantly different. Hence, we can be sure that all the differences found in the beef burgers properties are due to the replacement of fat, and that the chemical composition did not have any effect. In contrast to raw burgers, there was a significant difference in moisture and fat content of cooked samples produced with different levels of EC oleogel so that by increasing the percentage of replacement, the fat content decreased and the moisture content increased. However, animal fat replacement has not caused a significant difference in the mineral and protein content. It seems that EC oleogel acts as a barrier against moisture loss during the cooking of beef burgers, and increases water holding capacity of beef burgers. Since less oil was absorbed to food products containing higher amounts of moisture, the lower fat content in beef burgers containing 50% EC oleogel is logical (Mellema 2003). It should be noted that replacing animal fat with oleogel can not only improve the fatty acid profile of beef burger, but also affect the amount of fat in cooked burger; and it will have a positive effect on the health of consumers by having about 2% less fat content in the product.

Table 2.

Proximate composition of raw and cooked burger containing the EC oleogel

| Burger | Replacement (%) | Moisture (%) | Fat (%) | Protein (%) | Ash (%) |

|---|---|---|---|---|---|

| Raw | 0 | 45.50 A ± 0.50 | 15.75 A ± 0.25 | 12.28 A ± 0.01 | 2.00 A ± 0.07 |

| 25 | 45.75 A ± 0.75 | 16.16 A ± 0.38 | 12.29 A ± 0.02 | 1.98 A ± 0.12 | |

| 50 | 45.75 A ± 0.75 | 15.86 A ± 0.50 | 12.29 A ± 0.01 | 1.98 A ± 0.09 | |

| Cooked | 0 | 32.74 B ± 1.86 | 24.00 A ± 0.00 | 14.55 A ± 0.02 | 1.94 A ± 0.03 |

| 25 | 36.87 A ± 0.93 | 23.83 A ± 0.76 | 14.44 A ± 0.14 | 1.97 A ± 0.07 | |

| 50 | 36.63 A ± 0.77 | 22.00 B ± 0.00 | 14.48 A ± 0.25 | 1.92 A ± 0.03 |

Values indicate the average of 3 replicates + standard deviation. Different letters between treatment in each raw and cooked burgers indicate significant difference (p < 0.05)

Texture profile analysis

The results showed that the fat replacement had a significant effect on hardness, cohesiveness, springiness and gumminess of raw beef burgers (p < 0.05). In fact, change of fat structure is the main factor influencing the texture of food products while replacing fat (Wood 2013). Based on Table 3, hardness of raw beef burgers prepared with EC oleogel decreased compared to the burger containing animal fat. These results are consistent with the research carried out by Zetzl et al. (2012). They believed that the use of EC oleogel prevents increasing hardness observed in samples containing animal fat (Zetzl et al. 2012). Youssef and Barbut (2009) proposed that the smaller size of fat globules lead to the hardness of meat products. The fat globules are covered with salt soluble proteins during production of meat products. These proteins constitute an interfacial protein film on the surface of fat globules. The reduction in fat globules size increases the interfacial protein film area exponentially, and results in the enhancement of products hardness (Youssef and Barbut 2009). The back extrusion results (Data not shown) exhibited the lower force for reduction of fat globule size in the animal fats compared to the oleogels. As a consequence, the larger fat globules may be produced during burger production with EC oleogel, which, in turn, decreases the hardness after animal fat replacement.

Table 3.

Texture parameters of raw and cooked burger containing the EC oleogel

| Burger | Oleogel replacement | Hardness | Springiness | Cohesiveness | Gumminess | Chewiness |

|---|---|---|---|---|---|---|

| Raw | 0 | 23.11A ± 0.11 | 0.96C ± 0.04 | 0.13C ± 0.01 | 3.08A ± 0.15 | 2.95C ± 0.05 |

| 25 | 13.51B ± 0.09 | 1.78B ± 0.05 | 0.20B ± 0.03 | 2.81A ± 0.42 | 5.03B ± 0.13 | |

| 50 | 13.63B ± 0.25 | 2.22A ± 0.07 | 0.24A ± 0.01 | 3.27A ± 0.17 | 7.26A ± 0.53 | |

| Cooked | 0 | 68.67C ± 2.95 | 2.92B ± 0.03 | 0.26A ± 0.03 | 18.02A ± 1.34 | 52.54A ± 3.97 |

| 25 | 104.42B ± 1.86 | 3.52A ± 0.06 | 0.11B ± 0.02 | 11.47B ± 1.97 | 40.30B ± 4.03 | |

| 50 | 126.17A ± 3.92 | 3.32A ± 0.04 | 0.09C ± 0.01 | 12.11B ± 3.44 | 40.11B ± 5.18 |

Values indicate the average of 3 replicates ± standard deviation. Different letters between treatments in each raw and cooked burgers indicate significant difference (p < 0.05)

Contrary to raw burgers, the hardness of cooked samples increased by replacing animal fats. Based on the Davidovich-Pinhas et al. (2015) study, rising temperature causes breaking of hydrogen bond in the oleogel structure (Davidovich-Pinhas et al. 2015). It seems that the opening of EC oleogel structure provides more sites for interaction with proteins during thermal process which in turn can increase burger hardness. Barbut et al. (2016a, b, c) evaluated mechanical properties of frankfurter containing different level of canola oil oleogel produced with EC and sorbitan monostearate as organogelator. They reported that at 80% oleogel incorporation, sensory hardness was higher than beef fat control which indicated the importance of oleogel formulation in meat products hardness (Barbut et al. 2016a, b, c). However, in pork breakfast sausages produced with 8, 12, or 14% EC organogels (Barbut et al. 2016b), or frankfurters prepared with monoglycerides and phytosterols structured oleogel (Kouzounis et al. 2017), and pork liver patty formulated with bees wax and ethylcellulose oleogel (Gómez-Estaca et al. 2019a, b), significant difference was not observed as compared to beef fat control.

The springiness means the ability of samples to retrieve the original shape after the force is removed (Fernández-López et al. 2006). According to the results, by increasing the percentage of EC oleogel, the springiness of raw and cooked beef burgers is significantly increased (Table 3). Springiness is a mechanical characteristic strongly relying on the intensity of the inter-molecular bonds participating in the formation of the product body (Marquez et al. 1989). The addition of EC oleogel instead of animal fats may enhance molecular interactions via hydrogen bonds due to the presence of EC in beef burger formulation. The same result was reported by Ferrer-González et al. (2019) in cooked meat batter produced with oleogel structured with the combination of EC, Avicel RC-591 and α-cellulose (Ferrer-González et al. 2019). Also, Barbut et al. (2016a, b, c) observed the enhancement of springiness in frankfurter prepared with canola oil oleogel containing 12 and 14% EC (Barbut et al. 2016a). However, Barbut and Marangoni (2019) reported an opposite trend after replacement of animal fat with EC oleogel in comminuted meat product (Barbut and Marangoni 2019).

Cohesiveness is another characteristic that increases significantly with an increase in the replacement percentage in raw beef burger containing EC oleogel (Table 3). It was also influenced by intermolecular bonds (Marquez et al. 1989). Therefore, the formation of hydrogen bonds between EC and meat proteins can enhance cohesiveness in the beef burgers after adding the oleogel to the formulation. This feature makes it possible to maintain the integrity of the burgers produced with EC oleogel during production and to facilitate its molding and transfer processes. In cooked burgers containing oleogel of EC by increasing replacement percentages, cohesiveness decreased (Table 3). The results are in agreement with those obtained by Wolfer et al. (2018) who reported lower cohesiveness in frankfurter containing rice bran wax oleogel (Wolfer et al. 2018). It may be related to the oil leakage from the EC oleogel structure. The leaked sesame oil can locate between myofibrillar protein strands, and prevent protein–protein interaction during heating which can lead to the reduction of cohesiveness. Reduction of the cohesiveness after cooking is an undesirable characteristic that causes the burgers to break down while cooking and thereafter.

Gumminess was not significantly different in raw burgers containing different percentages of the EC oleogel, and in cooked ones, addition of the oleogel could significantly decrease it (Table 3). Barbut et al. (2016a, b, c) did not find any significant difference in gumminess of frankfurter containing EC oleogel (Barbut et al. 2016a). However, a direct relationship between animal fat replacement with structured sunflower oil and gumminess was obtained in frankfurter (Panagiotopoulou et al. 2016).

Increasing the amount of EC oleogel in raw beef burgers significantly enhanced chewiness; this is while chewiness is decreased in cooked burgers by adding the EC oleogel. Zetzl et al. (2012) related the difference in chewiness of frankfurter to strength of protein network (Zetzl et al. 2012). It seems that in raw beef burger, the strength of protein network increases by addition of EC oleogel through formation of hydrogen bound. However, the release of oil from gel network after heat treatment may prevents protein–protein interaction and decrease the protein network strength. The reduction of chewiness in frankfurter after replacement of pork fat with 10% rice bran wax oleogel (Wolfer et al. 2018), and after addition of sunflower oil structured with monoglycerides and phytosterols (Kouzounis et al. 2017) also reported. This is while the chewiness of frankfurter prepared by the incorporation of EC oleogel did not have any significant difference with those containing animal fat (Zetzl et al. 2012).

Color evaluation

The results of color parameters as a function of animal fat replacement were shown in Table 4. The lightness was not different between raw burgers produced with 100% animal fat and 50% animal fat replacement. The least value of lightness belonged to the raw burger produced with 25% EC oleogel (Table 4). A possible reason for such observation can be the increase in heterogeneity in the food structure. Light was strongly scattered inside the heterogeneous medium. This can decrease the lightness of beef burger. The cooked hamburgers produced with EC oleogel had lower L* than those prepared with animal fat, and the lowest value belonged to the products containing 25% oleogel (Table 4). Again, these changes in lightness can be attributed to the light scattering in heterogeneous structure of beef burgers. Barbut and Marangoni (2019) also observed the reduction of lightness after replacement of EC oleogel with animal fat in comminuted meat product. They related the change in L* to fat globule size and its effect on light scattering (Barbut and Marangoni 2019).

Table 4.

Color parameters of raw and cooked burger containing the EC oleogel immediately after production

| Burger | Oleogel replacement | L value | a value | b value | ∆E |

|---|---|---|---|---|---|

| Raw | 0 | 51.11A ± 0.57 | 10.19C ± 1.29 | 16.68B ± 1.57 | – |

| 25 | 48.19B ± 1.46 | 17.94A ± 0.85 | 32.45A ± 0.81 | 17.81 A ± 1.27 | |

| 50 | 52.69A ± 0.10 | 15.01B ± 0.10 | 31.41A ± 0.18 | 15.61 A ± 3.82 | |

| Cooked | 0 | 42.82A ± 1.25 | 9.11B ± 1.13 | 14.91B ± 0.19 | – |

| 25 | 25.09C ± 0.56 | 11.87A ± 0.53 | 14.44B ± 0.47 | 17.94 A ± 0.64 | |

| 50 | 33.58B ± 0.46 | 9.62B ± 0.52 | 15.86A ± 0.12 | 9.30 B ± 0.46 |

Values indicate the average of 3 replicates + standard deviation. Different letters between treatments in each raw and cooked burgers indicate significant difference (p < 0.05)

The highest redness was obtained in raw beef burgers after 25% substitution of animal fat with the EC oleogel. The samples containing 50% EC oleogel also had higher values than the control sample (Table 4). The difference between burgers produced with the EC oleogel and control can be partly due to the more redness of the oleogel. In addition, the non-enzymatic browning reaction of EC through caramelization maybe a reason for the higher value in burgers produced with the EC oleogel. Gravelle et al. (2012) indicated that by increasing the temperature of EC-oil to more than 160 °C, EC depolymerized and non-enzymatic browning of glucose occurred (Gravelle et al. 2012). Like raw samples, the more redness in cooked burgers was related to those containing 25% oleogel. Unfortunately, no logical reason for such observations could be found. Gómez-Estaca et al. (2019a, b) also reported the enhancement of redness in pork burger after replacement of animal fat with EC oleogel (Gómez-Estaca et al. 2019a, b).

Yellowness also significantly increased with an increase in the amount of EC oleogel in raw and cooked beef burgers (Table 4). The best explanation for such difference can be the higher b value of EC oleogel, and caramelization reaction, as stated before. The same result was reported by Gómez-Estaca et al. (2019a, b) after replacement of animal fat with EC oleogel in pork burger (Gómez-Estaca et al. 2019a, b).

According to the total color difference (Table 4), the most color change in the raw and cooked burgers was seen after 25% replacement of animal fat with EC oleogel. As previously mentioned, replacement of 25% animal fat leads to the most changes in color parameters which in turn can influence on total color difference. This change in the color of cooked beef was detectable by panelists (Table 1-supplementary); however, panelist preferred the color of burgers produced with EC oleogel.

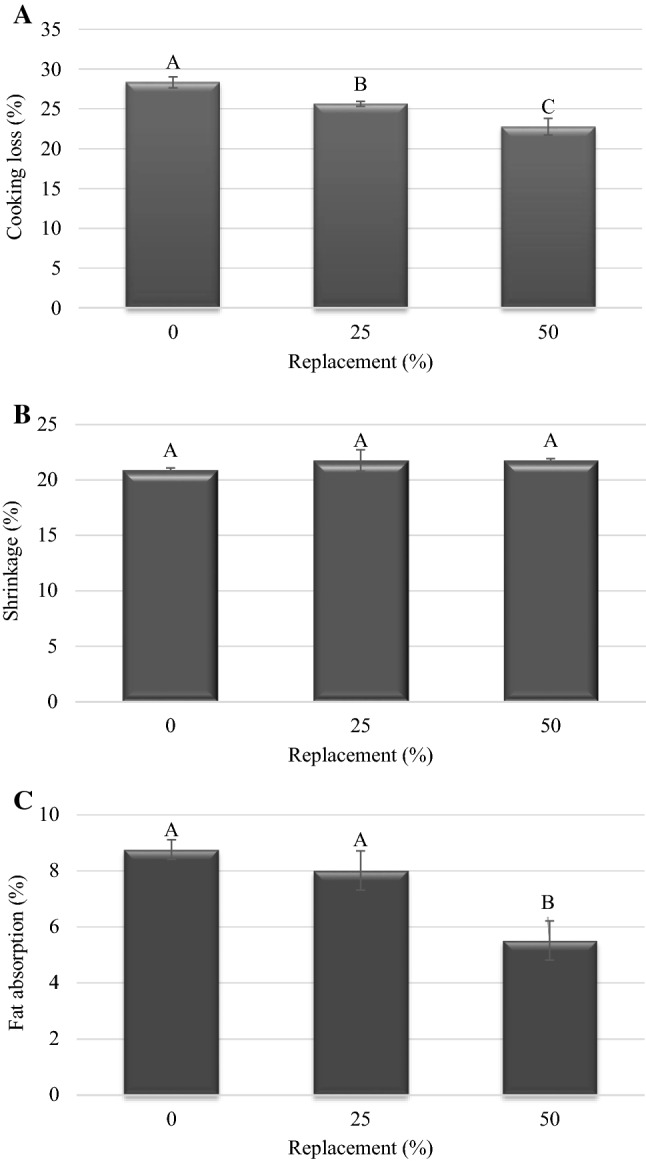

Cooking loss

Figure 1a indicates the cooking loss of burgers containing 25 and 50% oleogel instead of animal fat. Beef burgers produced with animal fat had the most cooking loss, and this parameter decreased significantly as a function of animal fat replacement. In fact, EC oleogel acts as a barrier to moisture loss during the cooking of the burgers. Barbut et al. (2016b) suggested a possible explanation for this event which was related to fat globules size. They believed that by increasing the number of fat globules in the meat batter, they pack together tightly and prevent the removal of water from meat products (Barbut et al. 2016b). Evaluation of rheological properties (data not shown) indicated that animal fats had several times higher elastic modulus in comparison to the EC oleogel. Therefore, it seems that more fat globules are produced from the EC oleogel, which needs the higher amount of protein to surround them during the production of burger. The unfolding of protein for covering the fat globules can put more hydrophilic groups on the surface, and higher amount of water is absorbed by the hydrophilic groups. Moreover, some water can be absorbed by EC, and diminish cooking loss. The same results were reported after replacing animal fat with oleogel from canola oil and EC in Frankfurter (Wood 2013), and structured canola oil with EC and sorbitan monostearate in frankfurter (Barbut et al. 2016a).

Fig. 1.

Cooking loss a cooking shrinkage b and fat absorption c of beef burgers produced with the EC oleogel as the replacement of animal fat. Bars indicate the average of 3 replicates ± standard deviation. Different letters indicates significant difference between treatments (p < 0.05)

Cooking shrinkage

Shrinkage is an important qualitative indicator in burgers occurring during cooking due to the denaturation of myofibrillar proteins and the release of water and fat. Based on the results of cooking shrinkage (Fig. 1b), there was no significant difference between samples. It is surprising that despite the higher amount of cooking loss in the beef burgers produced with animal fat, there was no significant difference in shrinkage of the burgers. It should be noted that the incompatibility of results is related to the fat absorption (Fig. 1c).

Fat absorption

Based on the results, there was a significant difference in fat absorption of beef burgers produced with various percentages of animal fat substitution. According to Fig. 1-C, with the increase in the percentage of EC oleogel in hamburgers, oil absorption of burgers decreased significantly. During frying, water evaporates from the fried hamburger, and the formed cavities are occupied by the oil. Therefore, the food absorbs more oil during frying by losing more moisture content (Mellema 2003). The incorporation of EC oleogel to beef burgers could decrease fat absorption due to the lower cooking loss (Fig. 1a) and higher amount of moisture (Table 2) in samples containing EC oleogel. Reducing the absorption of oil alongside with more amounts of unsaturated fatty acids has a significant effect on the nutritional quality of these hamburgers.

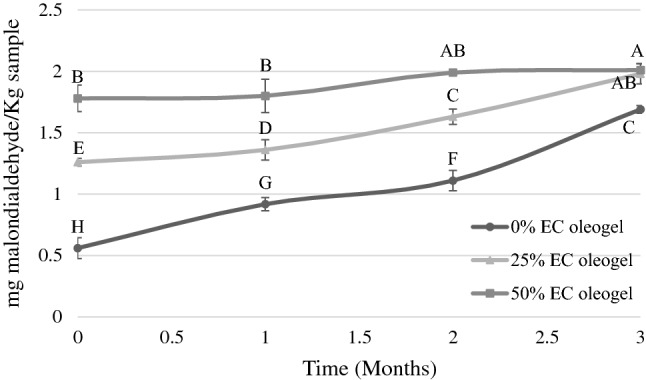

Oxidative stability

To evaluate the oxidative stability in beef burgers produced with different levels of the EC oleogel, mg malondialdehyde/Kg sample was measured. The produced malondialdehyde was significantly different during storage and at various levels of animal fat replacement. Regarding Fig. 2, in all samples, TBARs value was significantly enhanced through three months frozen storage. The highest TBARs value belonged to the burgers prepared with 50% EC oleogel, while the presence of 100% animal fat could increase the oxidative stability of the beef burgers. It is obvious that the difference could be attributed to 2 important parameters of production method of the EC oleogel, and the presence of high amount of unsaturated fatty acids in the composition of the EC oleogel. In fact, high temperature applied in production of the EC oleogel triggers the oxidative reactions by forming free radicals, and unsaturated fatty acids accelerate the propagation reactions in oxidation. Gómez-Estaca et al. (2019a, b) evaluated the lipid oxidation of ethylcellulose oleogel prepared with olive, linseed, and fish oils and related the higher rate of oxidation to the high temperature (170 °C) used for preparation of EC oleogel (Gómez-Estaca et al. 2019a, b).

Fig. 2.

TBARs of beef burgers produced with the EC oleogel as the replacement of animal fat during 3 months of frozen storage. Each point is the average of 3 replicates ± standard deviation. Different letters indicates significant difference between treatments during time (p < 0.05)

Sensory analysis

The sensory panelist attitude towards the sensory properties of the beef burgers produced with different levels of animal fat replacement was presented in Table 1-supplementary. In this regard, panelists could detect a significant difference between burgers prepared with animal fat and the EC oleogel. The presence of oleogel led to the record of higher scores for all sensory parameters including color, flavor, and texture by the consumers. The results of texture profile analysis (Table 3) indicated the significant difference between burgers produced with the EC oleogel and those produced with animal fat. Based on the results, panelists preferred the hardness of burgers containing the EC oleogel. The difference in color, which was recorded previously by instrumental color evaluation (Table 4), was also detectable by the panelists. Even in overall acceptability, sensory panelists were able to distinguish the difference between burgers produced with various amounts of EC oleogel. It is interesting that panelists preferred the beef burgers containing higher levels of the oleogel. It seems that the specific smell and taste of sesame oil might affect the panelists’ sense. Also the animal fats create waxy sense during mastication which can decrease the panelists acceptance.

Conclusion

Based on the aims of this study, EC oleogel was replaced in beef burgers. The lower fat content, cooking loss, and fat absorption, as well as more hardness, cohesiveness, and unsaturated fatty acid content are technological and nutritional strengths of beef burgers containing the EC oleogel compared to those produced with 100% animal fat. Although the incorporation of EC oleogel to the formulation of beef burger did not have any significant effect on other parameters, the reduction of oxidative stability is an indispensable point which should be considered during storage. The addition of antioxidant compounds to oleogel formulation for improvement of oxidative stability as well as in-vitro and in-vivo analysis, toxicology tests, and nutritional analysis should be considered in future studies.

Supplementary Information

Acknowledgement

The authors are grateful to Isfahan University of Technology (Iran) and Iran National Science Foundation (INSF) for their financial support.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AOAC (2005). Official methods of analysis of AOAC International Virginia: AOAC.

- Barbut S, Marangoni A. Organogels use in meat processing–effects of fat/oil type and heating rate. Meat Sci. 2019;149:9–13. doi: 10.1016/j.meatsci.2018.11.003. [DOI] [PubMed] [Google Scholar]

- Barbut S, Wood J, Marangoni A. Effects of organogel hardness and formulation on acceptance of frankfurters. J Food Sci. 2016;81(9):C2183–C2188. doi: 10.1111/1750-3841.13409. [DOI] [PubMed] [Google Scholar]

- Barbut S, Wood J, Marangoni A. Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci. 2016;122:155–162. doi: 10.1111/1750-3841.13409. [DOI] [PubMed] [Google Scholar]

- Barbut S, Wood J, Marangoni A. Quality effects of using organogels in breakfast sausage. Meat Sci. 2016;122:84–89. doi: 10.1016/j.meatsci.2016.08.003. [DOI] [PubMed] [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- Davidovich-Pinhas M, Gravelle AJ, Barbut S, Marangoni AG. Temperature effects on the gelation of ethylcellulose oleogels. Food Hydrocoll. 2015;46:76–83. doi: 10.1016/j.foodhyd.2014.12.030. [DOI] [Google Scholar]

- Feiner G (2006) Meat products handbook: practical science and technology: Elsevier, Boca Raton, Florida, USA

- Fernández-López J, Jiménez S, Sayas-Barberá E, Sendra E, Pérez-Alvarez J. Quality characteristics of ostrich (Struthio camelus) burgers. Meat Sci. 2006;73(2):295–303. doi: 10.1016/j.meatsci.2005.12.011. [DOI] [PubMed] [Google Scholar]

- Ferrer-González B, García-Martínez I, Totosaus A. Textural properties, sensory acceptance and fatty acid profile of cooked meat batters employing pumpkin seed paste or soybean oil oleogel as fat replacers. Grasas Aceites. 2019;70(3):320. doi: 10.3989/gya.1055182. [DOI] [Google Scholar]

- Gamit M, Gupta S, Savalia CV. Quality characteristics of chicken meat cutlets incorporated with finger millet (Eleusine coracana) flour. J Anim Res. 2020;10(1):111–116. doi: 10.30954/2277-940X.01.2020.15. [DOI] [Google Scholar]

- Goli SAH, Sahafi SM, Rashidi B, Rahimmalek M. Novel oilseed of Dracocephalum kotschyi with high n-3 to n-6 polyunsaturated fatty acid ratio industrial crops and products. Ind Crops Prod. 2013;43:188–193. doi: 10.1016/j.indcrop.2012.07.036. [DOI] [Google Scholar]

- Gómez-Estaca J, Herrero AM, Herranz B, Álvarez MD, Jiménez-Colmenero F, Cofrades S. Characterization of ethyl cellulose and beeswax oleogels and their suitability as fat replacers in healthier lipid pâtés development. Food Hydrocoll. 2019;87:960–969. doi: 10.1016/j.foodhyd.2018.09.029. [DOI] [Google Scholar]

- Gómez-Estaca J, Pintado T, Jiménez-Colmenero F, Cofrades S. Assessment of a healthy oil combination structured in ethyl cellulose and beeswax oleogels as animal fat replacers in low-fat. PUFA-enriched pork burgers Food Bioproc Tech. 2019;12(6):1068–1081. doi: 10.1007/s11947-019-02281-3. [DOI] [Google Scholar]

- Gravelle AJ, Barbut S, Marangoni AG. Ethylcellulose oleogels: manufacturing considerations and effects of oil oxidation. Food Res Int. 2012;48(2):578–583. doi: 10.1016/j.foodres.2012.05.020. [DOI] [Google Scholar]

- Keenan DF, Resconi VC, Smyth TJ, Botinestean C, Lefranc C, Kerry JP, Hamill RM. The effect of partial-fat substitutions with encapsulated and unencapsulated fish oils on the technological and eating quality of beef burgers over storage. Meat Sci. 2015;107:75–85. doi: 10.1016/j.meatsci.2015.04.013. [DOI] [PubMed] [Google Scholar]

- Kouzounis D, Lazaridou A, Katsanidis E. Partial replacement of animal fat by oleogels structured with monoglycerides and phytosterols in frankfurter sausages. Meat Sci. 2017;130:38–46. doi: 10.1016/j.meatsci.2017.04.004. [DOI] [PubMed] [Google Scholar]

- Li X, Li J, Zhu J, Wang Y, Fu L, Xuan W. Postmortem changes in yellow grouper (Epinephelus awoara) fillets stored under vacuum packaging at 0 C. Food Chem. 2011;126(3):896–901. doi: 10.1016/j.foodchem.2010.11.071. [DOI] [Google Scholar]

- Marangoni AG. Organogels: an alternative edible oil-structuring method. J Am Oil Chem Soc. 2012;89(5):749–780. doi: 10.1007/s11746-012-2049-3. [DOI] [Google Scholar]

- Marquez E, Ahmed E, West R, Johnson D. Emulsion stability and sensory quality of beef frankfurters produced at different fat or peanut oil levels. J Food Sci. 1989;54(4):867–870. doi: 10.1111/j.1365-2621.1989.tb07901.x. [DOI] [Google Scholar]

- Mellema M. Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci Technol. 2003;14(9):364–373. doi: 10.1016/S0924-2244(03)00050-5. [DOI] [Google Scholar]

- Ozcelik AO, Akan LS, Surucuoglu MS. An evaluation of fast-food preferences according to gender. Humanity Soc Sci J. 2007;2(1):43–50. [Google Scholar]

- Panagiotopoulou E, Moschakis T, Katsanidis E. Sunflower oil organogels and organogel-in-water emulsions (part II): Implementation in frankfurter sausages. LWT. 2016;73:351–356. doi: 10.1016/j.lwt.2016.06.006. [DOI] [Google Scholar]

- Papadima S, Bloukas J. Effect of fat level and storage conditions on quality characteristics of traditional Greek sausages. Meat Sci. 1999;51(2):103–113. doi: 10.1016/S0309-1740(98)00103-X. [DOI] [PubMed] [Google Scholar]

- Pernetti M, van Malssen KF, Flöter E, Bot A. Structuring of edible oils by alternatives to crystalline fat. Curr Opin Colloid Interface Sci. 2007;12(4–5):221–231. doi: 10.1016/j.cocis.2007.07.002. [DOI] [Google Scholar]

- Rodríguez-Carpena J, Morcuende D, Estévez M. Avocado, sunflower and olive oils as replacers of pork back-fat in burger patties: effect on lipid composition, oxidative stability and quality traits. Meat Sci. 2012;90(1):106–115. doi: 10.1016/j.meatsci.2011.06.007. [DOI] [PubMed] [Google Scholar]

- Selani MM, Shirado GA, Margiotta GB, Rasera ML, Marabesi AC, Piedade SM, Contreras-Castillo CJ, Canniatti-Brazaca SG. Pineapple by-product and canola oil as partial fat replacers in low-fat beef burger: effects on oxidative stability, cholesterol content and fatty acid profile. Meat Sci. 2016;115:9–15. doi: 10.1016/j.meatsci.2016.01.002. [DOI] [PubMed] [Google Scholar]

- Shiota K, Kawahara S, Tajima A, Ogata T, Kawano T, Ito T. Sensory evaluation of beef patties and sausages containing lipids with various component fatty acids. Meat Sci. 1995;40(3):363–371. doi: 10.1016/0309-1740(95)00039-N. [DOI] [PubMed] [Google Scholar]

- Soltanizadeh N, Ghiasi-Esfahani H. Qualitative improvement of low meat beef burger using aloe vera. Meat Sci. 2015;99:75–80. doi: 10.1016/j.meatsci.2014.09.002. [DOI] [PubMed] [Google Scholar]

- Sowmya M, Jeyarani T, Jyotsna R, Indrani D. Effect of replacement of fat with sesame oil and additives on rheological, microstructural, quality characteristics and fatty acid profile of cakes. Food Hydrocoll. 2009;23(7):1827–1836. doi: 10.1016/j.foodhyd.2009.02.008. [DOI] [Google Scholar]

- Stortz TA, Zetzl AK, Barbut S, Cattaruzza A, Marangoni AG. Edible oleogels in food products to help maximize health benefits and improve nutritional profiles. Lipid Technol. 2012;24(7):151–154. doi: 10.1002/lite.201200205. [DOI] [Google Scholar]

- Wolfer TL, Acevedo NC, Prusa KJ, Sebranek JG, Tarté R. Replacement of pork fat in frankfurter-type sausages by soybean oil oleogels structured with rice bran wax. Meat Sci. 2018;145:352–362. doi: 10.1016/j.meatsci.2018.07.012. [DOI] [PubMed] [Google Scholar]

- Wood J (2013) Reduction of saturated fat in finely comminuted and ground meat products by use of canola oil organogels and the effect on Organoleptic qualities, texture and microstructure

- Yılmaz E, Öğütcü M. Oleogels as spreadable fat and butter alternatives: sensory description and consumer perception. RSC Adv. 2015;5(62):50259–50267. doi: 10.1039/C5RA06689A. [DOI] [Google Scholar]

- Youssef M, Barbut S. Effects of protein level and fat/oil on emulsion stability, texture, microstructure and color of meat batters. Meat Sci. 2009;82(2):228–233. doi: 10.1016/j.meatsci.2009.01.015. [DOI] [PubMed] [Google Scholar]

- Zetzl AK, Marangoni AG, Barbut S. Mechanical properties of ethylcellulose oleogels and their potential for saturated fat reduction in frankfurters. Food Funct. 2012;3(3):327–337. doi: 10.1039/C2FO10202A. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.