Abstract

The fermented foods are same as traditional food, in appearance and consumed as normal foods but have modified by the addition of certain pro & pre-biotics or fortification with the plant extract, which have specific physiological roles beyond just satisfying nutrition requirement. Fresh leaves of Moringa oleifera were collected from the field of Institutes of Agriculture Sciences, then dried and grounded. The proximate analysis of dried moringa leaf powder and milk was performed. In four different concentrations (0.5%, 1%, 1.5% and 2%) Moringa Oleifera leaf powder, was used for the production of fortified flavoured yogurt, while mango flavor and color was added to enhance its sensory characteristics. Physicochemical analysis (pH, acidity, ash, fat, protein, fiber, synersis, total solid content and moisture content) was done to check the yogurt nutritional profile and effect of moringa dried leaf powder on it. Sensory evaluation (body texture, appearance, color, taste, aroma, flavor and overall acceptability) is also done by expert panel of food scientist (n = 20) by using hedonic scale to check the acceptability and quality of product.To check the product shelf life stability, product is stored at 5 ± 1 ºC for 15 days and observed for its physicochemical changes and sensory attributes. The sample were analyzed for their stablity as fresh and during storage interval of 10th day and 15th day. Results shows that mango flavored yogurt supplemented with 1% Moringa Oleifera leaf powder has got the highest score in majority of the sensory attributes such as body and texture, flavor, taste and overall acceptability over the storage period of 15 days at 5 ± 1 °C. All treatment showed significantly different (p ≤ 0.05) result from each other. However, higher acidity%, total solids%, protein% and synersis value were observed, than control samples on 0 days (fresh), 10 days and 15 days storage, respectively. While all treatments have less pH and moisture content than control during fresh condition and over storage time of 15 days while fat content was nearly same in all treatments and control sample.

Keywords: Moringa oleifera, Inoculum, Fortification, Syneresis, Organoleptic analysis, Yogurt

Introduction

Pakistan is second biggest country in terms of milk production renowned around the globe, for majorly utilizing the milk to make yogurt, cheese, butter and other dairy products including confectionaries. Yogurt is gaining much importance for having numerous health benefits and functional properties that promotes better intestinal health and immune system. The protein present in milk creates the buffering action for active cultures (Lactobacillus bulgaricus and Streptococcus thermophilus) and proves to be the excellent medium for their activity during yogurt manufacturing. But now in the era of developing and improving new scientific technologies, nutrition is also being adapted with novel concept such as food fortifications (Milner 2002). This process involves addition of different vitamin, minerals, or ingredients to existing staple food to improve the micronutrient status of population. Mostly such foods are targeted for fortification with compatible constituents that have increased demand and consumption level and are readily available, easily accessible and affordable among the population. That could improve the health status of population rapidly at reasonable budget (Dary et al. 2006).

Moringa oleifera (drumstick tree, horse reddish tree, purifying tree, sohanjna, mulangay) belongs to family mMoringaceae is known to be the twenty-first century's "Super food" and famous medicinal herb. It is mostly found in diverse regions of tropical and sub-tropical areas around the globe specifically Sub-himalyan tract, India, Pakistan, Asia, Arabia and Africa. It is resistant to bacteria, fungi, tolerant to sandy condition and drought condition of soil. It is termed as life plant, miracle plant and multi-purpose plant owing to its miraculous nutritional, pharmacological and industrial applications as mentioned by Foidl et al. (2001). It is highly nutritious and naturally enriched with double amount of protein than yogurt, it contains Vitamin C which is seven times more than as present in oranges, fifteen times more Potassium than banana, Calcium is seventeen times more than milk, 10 folds’ additional vitamin A than carrots and 25 folds’ additional iron than Spanish with respect to gram–in –gram comparison. It also contains considerable amount of natural antioxidant including ascorbic acid, flavonoid, phenolic and carotenoid (Daba et al. 2016; Gao et al. 2009). Moringa oleifera have natural biomolecules having particular vital response such as anti-inflammatory, inhibit oxidation, inhibit carcinogenic compounds, inhibit hypertension, anti-spasmodic, controls diabetic, cure ulcer, controls pyretic responses, anti-epileptic, anti-arthritis, diuretic, cholesterol lowering and hepatoprotective properties (Fahey 2005). It is also proposed for different disease and conditions including anemia, anxiety, blood impurities, bronchitis, chest congestion and cholera. It has revolutionized the cosmetic industry by contributing various health care products e.g. body and hair moisturizers and conditioner. Since Previous history, oil from moringa was utilized in the making of different kinds of ointments (Razis et al. 2014).

Although all parts of Moringa oleifera have its own distinctive property, but leaves are miraculously rich in nutrition containing 30% protein, essential amino acids which even lack in certain legumes i.e. cysteine and methionine, and have high amount of micronutrients (Fuglie 2001; Madukwe et al. 2013). Moringa leaves contain 14 times higher iron than beef and have as sufficient, vitamin A as to meet the RDA of 17 children aged between 1 and 3 years, 7 lactating mothers and 10 pregnant women. It can also combat the numerous chronic diseases by reducing the oxidative stress, such reducing agents are flavonoids, carotenoids and ascorbic acid (Reweyemamu 2006; Anwar et al.2005).

Still, the utilization of this miraculous plant in everyday life is very rare, and fewer studies are conducted on the nutrient enhancement characteristic of moringa leaf powder, especially in Pakistan. In recent past much research was conducted on yogurt enrichment by incorporation of exotic combinations with banana, raspberry, vanilla, mango and strawberry etc. However now scientist are more focused on developing the prdouct by incorporation of underutilized fruits, vegetables and herbs for example Moringa oleifera Moringa oli oleirfera leaves powder in distinct variety of food product i.e. sauce, drinks, spice, bread and milk-based product. But still there is dire need to enhance the consumption and utilization of such underexploited plant i.e. Moringa Oliefera. But the major challenge while making the innovative food product is consumer acceptance and their preference because they are more cautious about taste, appearance and nutritional profile. As moringa leaves gave bland and slight bitter taste to the product upon incorporation thus another aspect of this research was explored to overcome this challenge i.e. mango flavor was utilized during production to mask the bitter taste and flavor. Parallel to this, also analyzed either Moringa oleifera leaf powder will impart any positive impact on nutritional benefit, chemical properties, shelf life and storage stability of the yogurt.

Material and methods

This research was conducted in Food Science & Technology Lab at Institute of Agricultural Sciences, University of the Punjab, Lahore Pakistan.

Procurement of raw materials

The raw material required for the research project including liquid whole milk and sugar were purchased from local market.

Fresh leaves of Moringa oleifera were collected from the field of Institutes of Agriculture Sciences, University of the Punjab.Lahore. Levaes were dried for 30 min at 60 °C, grounded and seived on 0.5–10 mm mesh.

Required starter culture strains Streptococcus thermophillus FCBP-LB-0389 were got from fungal culture bank of Institute of Agricultural Sciences, University of the Punjab, Pakistan. Lactobacillus bulgaricus Lb14 were purchased from ATCC used in yogurt manufacturing with the ratio of 2:1 respectively. Mango flavor (Sun shine mango flavor) and Yellow Food Color (E101) were obtained from approved vendor.

Milk analysis

The basic composition of milk used for the manufacturing of yogurt was analyzed and its moisture percentage, ash percentage, fat percentage, protein percentage, total soluble solids percentage and solid not fat (SNF) in percentage was determined by following standard procedures detailed by AOAC (2005).

Moringa Oleifera leaf powder analysis

The Moringa oleifera leaf powder was analyzed for its chemical properties such as moisture, crude fiber, protein and ash in percentage was determined by following standard procedures detailed by AOAC (2005).

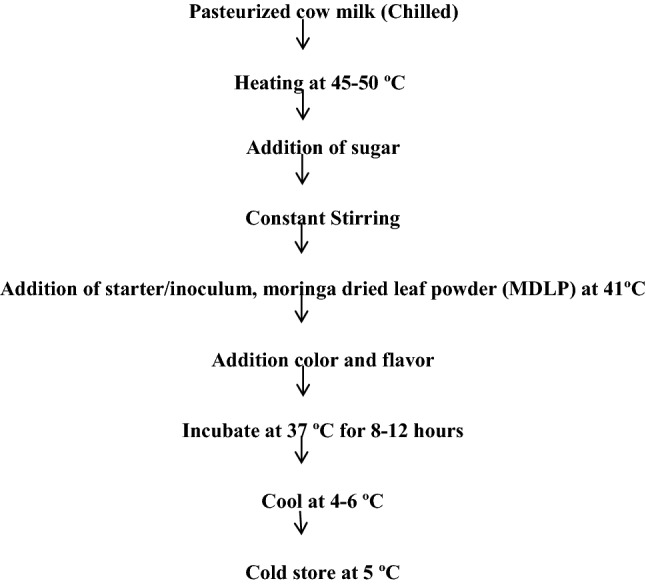

Preparation of yogurt

The yogurt was prepared by following the method with some modifications, adopted by Akajiaku et al. (2018) and Hassan et al. (2016), by using inoculum 3%, sugar 10%, mango flavor 1% and color 100 µg in all treatments except for the control sample. Only the concentration of Moringa dried leaves powder was differed and depicted in the following Table 1. The steps involved in the production of yogurt are illustrated in Fig. 1.

Table 1.

Concentration of Moringa oleifera leaves powder used during the manufacturing of mango flavored yogurt

| Ingredients | T0 | T1 | T2 | T3 | T4 |

|---|---|---|---|---|---|

| Moringa dried leaf powder (MDLP) | 0.0% | 0.5% | 1% | 1.5% | 2% |

Fig. 1.

Flow Diagram for manufacturing of flavored yogurt fortified with Moringa oleifera leaves powder

Physico-Chemical Analysis of Fortified Yogurt

Determination of pH

The yogurt samples fortified with different concentration of dried moringa leaf powder (T0, T1, T2, T3 and T4) were subjected to the physical analysis such as, pH was done by digital pH meter (Ins Mask Model number: IS12BL) following the method described by AOAC (2005). The pH meter was standardized with Buffer solution having pH 4.00 and pH 7.00 before use. To check the pH of sample it was taken into beaker mixed thoroughly and electrode of the pH meter is dipped into the sample, and pH was noted.

Determination of Acidity

Acidity was determined by the method mentioned in AOAC (2005). A well-mixed homogeneous 10 mL yogurt sample was taken in a beaker and diluted with 20 mL distilled water. Then 2–3 drops of phenolphthalein were added as indicator into beaker and was titrated against N/10 sodium hydroxide (0.1 N NaOH) solution until a pink color appears as end point and it was retain for 30 s. The percentage of acidity was calculated as following:

Determination of total solids

Total solids were determined by the methods described by AOAC (2005). Five gram yogurt sample were taken in weighed china dish. Then it was heated by placing on water bath for 15 min. It was kept in hot air drying oven for 3 h at 100 ºC. Then it was cool by placing it in desiccator for half an hour. The dish was again weighed by weighing balance. The percentage residues were total solids calculated as following:

Determination of Synersis

(This heading should be in same font like other headings) (This paragraph should start as 2nd line i.e. under the heading)Synersis is basically the watery whey like liquid on the surface of the yogurt which separates out when it is held on room temperature. For the determination of synersis in yogurt, set type yogurt specimen (450 mL) was placed at room temperature for two hours. The watery whey separated and syphoned of the sample and taken into graduated cylinder and its volume was measured. This method is in relevant with method described by Soukoulis et al. (2010).

Protein Determination

Chemical analysis including total protein was determind by the method mentioned in AOAC (2005).The total protein was determined by Kjeldhal method. The 1 g of the yogurt sample is taken into digestion flask and 2-3 g of digestion mixture (copper sulphate: potassium sulpate: ferrous sulphate:: 5:94:1) was added to it and then add 25 mL of concentrated sulphuric acid allowed for digestion until the clear solution appear. The content of the flask was taken into 250 mL volumetric flask. Rinse with small portion of water and then make up to the volume. 50 mL from the sample present in volumetric flask was taken and 10 mL of NaOH (40%) is added to it till alkaline. Distill into 25 mL boric acid (4%) solution. Then methyl red indicator was added to it and titrate it against N/10 H2SO4 in order to determine the amount of nitrogen. Nitrogen was calculated by following formula.

Percent Protein = Percent Nitrogen × Factor*

Factor used for the determination of yogurt was 6.38*

Moisture determination

Moisture was determined by moisture analyzer (Radwag MA 50.R), as mentioned in AOAC (2005). The 5 g of homogeneous sample of yogurt was taken into round flat bottom metal plate and place in the moisture analyzer at 100 °C and dried till constant weight, cooled and weighed. Loss in weight was expressed as its moisture content.

Crude fat determination

For estimating the percentage of fat in yogurt sample, Gerber method was adopted. The 10 mL of concentrated H2SO4 was taken into butyrometer and yogurt sample was gently poured on the H2SO4, into butyrometer, and 1 mL of amyl alcohol is also added to butyrometer. Stoppered and shake thoroughly. The samples were centrifuged at 12,000 rpm for 5 min. After completion of the centrifugation procedure, fat percentage was checked and noted. This method was adopted as mentioned in AOAC (2005).

Fiber determination

The crude fiber is the organic residue which remained after the food sample is digested in a chemical solution. The weight of the residue after digestion is corrected for the ash content. Approximately, 3–5 g from the defatted sample was weighed in conical flask followed by the addition of 200 ml of 0.255 N H2SO4. then the flask was connected to digestion unit and sample was boiled for 30 min. The precipitate left after digestion, was washed repeatedly with distilled boiling water. Followed by second digestion in 200 mL of sodium hydroxide 0.313 N under the reflux condenser for 30 min. Precipitate was filtered with gooch crucible and washed with hot distilled water followed by 15 ml of ethyl alcohol. Then the crucilble is dried to 105ºC until the constant weight. Cooled in desiccator, weighed and ashed in muffle furnace at 550-600 °C until the constant weight is attained and difference in weight was consider as crude fiber calculated as following:

Organoleptic analysis

For sensory evaluation expert panel of 20 judges from Lab of Food Science andTechnology, University of the Punjab were selected/ They rated the product using numeric scoring system of 9-point hedonic scale for the quality evaluation of appearance, taste, aroma, texture, flavor and overall acceptability, where 9 represents “extremely liked” and 1 represents “extremely disliked” as described by Ahmed (2011). The procedure was carried out in separate room with maintained privacy and suitable environment for accurate sensory evaluation. Judges were advised to flush their mouth with clean water every time testing the samples to overcome the carryout effect.

Statistical analysis

Statistical Two-way Factorial analysis and Tukey’s HSD pairwise comparison test was done by using SPSS Software (Statistic 8.1). Probability of (P < 0.05) was used to develop the statistical significance and to analyze the effect of varying concentration of moringa on treatments over the storage period of time.

Results and discussion

Since Moringa oleifera has immerged being unique miraculous plant having high nutrition profile, as results show that it has particularly high mineral content ranging between 1.21 and 5.66%, high protein content 4.11 to 4.75% and high fiber content 3.5 to 3.47% in fortified yogurt, urging researchers to make its enriched products. But the lingering after bitter taste made it overall less acceptable, so this study shows that certain changes in formulation such as addition of mango flavor and sugar enhance its overall acceptability and physicochemical properties. The formulation with 1% Moringa oleifera showed the best blend of ingredients.

Cow milk and Moringa Oleifera dried leaf powder

The chemical analysis of cow milk, included the detremination of percentage moisture content, total solids content, ash content, protein content, solid not fat (SNF) and fat content, as shown in Table 2. The obtained value of the milk fat was nearly similar to the findings of Khalid et al. (2013) i.e. 3.5% fat, total solids was higher 12.70% comparative to the 11.29%, solid not fat was 8.68% nearly same comparative to 8.62% and protein percentage was slightly higher 3.2% comparative to 2.97%. This might be as the result of different breed of cow or difference in the climatic conditions which directly affect the physiological condition of animal and their productivity.

Table 2.

Chemical analysis of Cow Milk and Moringa Oleifera Leaf Powder

| Sample | Moisture % | Total Solids % | Fat % | Solid not Fat % | Ash % | Protein % | Crude Fiber % |

|---|---|---|---|---|---|---|---|

| Cow milk | 88.22 | 12.70 | 3.5 | 8.68 | 0.78 | 3.2 | |

| Moringa oleifera leaves | 8.36 ± 0.01 | 10.72 ± 0.10 | 25.43 ± 0.01 | 19.47 ± 0.10 |

In Table 2 the chemical composition of dried moringa leaves powder are also mentioned in which moisture content, ash, protein and crude fiber content are shown. The results indicates that dried leaf powder contains high amount of fiber, protein, moisture and total mineral content i.e. 19.47%, 25.43%, 8.36% and 10.72% respectively. This specifies that dried Moringa oleifera leaf powder is one of the best sources of protein and minerals. Which is in accordance with the study of Hassan et al. (2016) that mentioned moringa leaves powder contain great amount of protein 22.87% and also rich source of mineral. Yaméogo et al. (2011) suggested that moringa dried leaves contain moisture 11.9%, protein 10.6% and fiber 23.4% correspondingly. Rasha et al. (2018) also found the protein content of dried leaves of mMoringa oleiefera to be 8.1 g and fiber was 2.1 g. This variation among the values are dependent on the different soil condition and variety of Moringa tree.

Physicochemical analysis of mango flavored yogurt fortified with Moringa oleifera dried leaf powder

Total solids

Table 3 revealed that as the quantity of Moringa oleifera in the yogurt treatments enhances, the mean values of total solids for all the treatments also increases over the storage period of 15 days. The statistical analysis shows that,the mean values of total solid content for the treatments showed significantly different (p ≤ 0.05) results over the storage period up to 15 days. The highest total solid content was calculated for treatment T4 which was 22.057, 23.35, 24.02 in fresh, after 10 days and 15 days respectively, and lowest was observed for control sample with the 0% moringa dried leaf fortification 13.5, 13.56, 9.97.

Table 3.

Phyisco-chemical composition of mango flavored yogurt fortified with 0%, 0.5%, 1%, 1.5% and 2% Moringa Ooleifera dried leaf powder, fresh and during cold storage of 5 ± 1 °C

| Yogurt Treatments | Storage Period (Days) | TSC (g/100 g) ± S. D | Moisture% (g/100 g) ± S.D | F.C ± S.D (g/100 g) |

T.P ± S.D (g/100 g) |

pH ± S.D | Acidity ± S.D (g/100 g) |

Ash% (g/100 g) |

|---|---|---|---|---|---|---|---|---|

| Control | Zero | 13.5 ± 0.1 | 86.5 ± 0.1 |

3.5133 ± 0.01 |

4.11 ± 0.005 | 4.44 ± 0.01 | 0.871 ± 0.001 | 1.21 ± 0.01 |

| 10 | 13.56 ± 0.005 | 86.7 ± 0.1 |

3.4867 ± 0.005 |

4.12 ± 0.01 | 4.19 ± 0.01 | 0.92733 ± 0.005 | 2.0733 ± 0.06 | |

| 15 | 9.97 ± 6.936 | 87.647 ± 1.146 | 3.5067 ± 0.005 | 4.15 ± 0.01 | 4.036 ± 0.015 | 1.013 ± 0.001 | 2.95 ± 0.01 | |

| T1 | Zero | 17.803 ± 0.005 | 82.167 ± 0.05 | 3.4867 ± 0.005 | 4.13 ± 0.01 | 4.2667 ± 0.015 | 1.081 ± 0.001 | 1.61 ± 0.01 |

| 10 | 19.077 ± 0.02 | 82.3 ± 0.1 | 3.5003 ± 0.005 | 4.17 ± 0.01 | 4.0533 ± 0.015 | 1.131 ± 0.001 | 2.4633 ± 0.01 | |

| 15 | 19.22 ± 0.02 | 82.57 ± 0.01 | 3.4733 ± 0.005 | 4.21 ± 0.01 | 3.87 ± 0.01 | 1.21633 ± 0.005 | 3.4633 ± 0.015 | |

| T2 | Zero | 18.767 ± 0.05 | 81.027 ± 0.005 | 3.51 ± 0.01 | 4.32 ± 0.01 | 4.26 ± 0.02 | 1.106 ± 0.001 | 2.51 ± 0.01 |

| 10 | 20.14 ± 0.01 | 81.223 ± 0.005 | 3.4867 ± 0.005 | 4.36 ± 0.01 |

4.03 ± 0 .01 |

1.15633 ± 0.005 | 3.4567 ± 0.005 | |

| 15 | 20.24 ± 0.01 | 81.39 ± 0.01 | 3.4867 ± 0.005 | 4.21 ± 0.01 | 3.85 ± 0.01 | 1.233 ± 0.001 | 3.85 ± 0.01 | |

| T3 | Zero | 21.013 ± 0.01 | 79.167 ± 0.05 | 3.4733 ± 0.005 | 4.52 ± 0.01 | 4.22333 ± 0.015 | 1.1263 ± 0.005 | 3.41 ± 0.01 |

| 10 | 22.32 ± 0.01 | 79.2 ± 0.1 | 3.4767 ± 0.005 | 4.55 ± 0.01 | 3.99 ± 0.01 | 1.175 ± 0.001 | 4.48 ± 0.01 | |

| 15 | 22.42 ± 0.01 | 79.27 ± 0.01 | 3.5003 ± 0.005 | 4.58 ± 0.01 | 3.8133 ± 0.005 | 1.24 ± 0.001 | 4.75 ± 0.01 | |

| T4 | Zero | 22.057 ± 0.015 | 77.3 ± 0.1 | 3.4767 ± 0.005 | 4.68 ± 0.01 | 4.17 ± 0.01 | 1.137 ± 0.001 | 4.31 ± 0.01 |

| 10 | 23.35 ± 0.47 | 77.5 ± 0.1 | 3.51 ± 0.0 | 4.72 ± 0.01 | 3.94 ± 0.01 | 1.186 ± 0.001 | 5.4133 ± 0.015 | |

| 15 | 24.02 ± 0.02 | 77.57 ± 0.01 | 3.4733 ± 0.005 | 4.75 ± 0.01 | 3.74 ± 0.01 | 1.26267 ± 0.005 | 5.66 ± 0.01 |

*The same column (for storage periods) is significantly different (p < 0.05), each value is a mean of 3 replicates, TSC: Total solids and TP: Total protein F.C: Fat Content

El-Gammal et al. (2017) also illustrate the same observation in the yogurt by the addition of aqeous extract of moringa oleifera. The mean values for total solid contents of all the treatments increases progressively with the time of storage. Above results are in line with study conducted by Hassan et al. (2011), which shows the enrichment of yogurt with moringa powder showed the total solid value ranges from 18.46 to 18.96%. The differnce in the total solid content is might beacuse of differnet origin of Moringa in our study.

Moisture content

Moisture content and total solid content have inverse relation for any commodity i.e. total solid content increases with decrease in moisture content and vice versa. According to Table 3 the overall mean value of moisture content enhances for yogurt samples over storage time of 15 days, and have inverse relation with the concentration of Moringa oleifera leaves powder. The highest moisture content value was observed for control sample T0 with 0 percent of moringa leaf powder supplementation, 86.5% for fresh sample and lowest was observed for treatment T4 (2% moringa leaves powder fortification). Statistical analysis showed the significantly different (p ≤ 0.05) results for all the treatments and control sample over the storage period for 15 days at 5 °C and only slight decrease was observed in the mean values for moisture content for the control sample and all the treatments over the storage period. These results are partialy in line with the findings of Bakr et al. (2015) who showed that differnce in the yougurt samples during storage were insignificant but it was significant among the treatment.

Fat content

All the treatments nearly had similar mean values of fat content and no, as such difference was observed during the cold storage at 5 ± 1 C for over the period of 15 days. The fat content overall range from 3.4 to 3.50% for all the samples.The highest value was observed for T1 3.50%. It was clearly shown that moringa leaf powder does not affect noticeable change to the fat content of the yogurt treatments. Shokery et al. (2017), also found that, green tea leaves extract and moringa leave extract will not change the fat content in addition to set type yogurt trial and also over the storage time of 15 days at 7C the fat content remain unchanged.

All the treatments and control sample did not show the significantly (p ≤ 0.05) different results for fat content over the storage period of 15 days, which is in accordance with the study of El-Gammal et al. (2017) and Shalini and Shivaprasad (2017).

Protein content

Whereas it is evident from Table 3 that as moringa leaf powder fortification increased in yogurt the percentage of total protein content also increases. The highest protein content was observed in T4 (2% moringa leaf powder) which was 4.68%. And lowest protein content was observed in treatment T0 (0% moringa leaf powder and without flavor) 4.11%,. It is also evident from the table the all the treatments mean value of protein content gradually increases over the storage period of 15 days.The results illustrate that the mean values of protein content for the all treatments were significantly differnt (p ≤ 0.05) over the storage period of 15 days at 5 °C. That is in accordance with the observation of Shokery et al. (2017) in buttermilk supplemented with moringa leaves and moringa pods powder. Sodamode et al. (2013) also reported that in Solanum microcapon, leaves protein concentration was greater than 8.44%, thus the leaf protein could prove to be the healthier replacment of other proteinous diet.

pH value

The highest mean value for pH of the sample were observed for control sample during fresh condition i.e. 4.44, that gradually decrease over the storage period of 10 days i.e. 4.19, and further decreased at 15th day i.e. 4.036.The lowest mean value for pH showed by T4 (2% moringa leaves powder fortification) which was 4.17, 3.94 and 3.74, for fresh, 10th day and 15th day of storage at 5 °C. The overall trend depicted the decrease in pH values for all the treatments over the storage period. Reason being, the conversion of lactose (milk sugar) into lactic acid with increasing acidity will lower the pH. The inferences from the result showed that by supplementation of moringa dry leaves powder in yogurt, pH of yogurt in all treatments decreased, because moringa leaves powder will stimulate the growth rate of starter culture. The results for pH showed significantly different (p ≤ 0.05) values for all the treatments over the storage period up to 15 days at 5 ± 1 °C that is similar to the study of El-Gammal et al. (2017), who reported that significant reduction in pH was observed in the yogurt supplemented with aqueous extract of moringa leaves than to the control samples.

Acidity

The result illustrate in same table are contrary to the mean vales of pH for all the treatments that is, by increasing the percentage of mMoringa oleifera leaf powder in the yogurt samples the percentage of acidity also increases over the period of 15 days. The results revealed that T4 showed highest titrable acidity values than other treatments i.e. 1.137, 1.186 and 1.26267 at zero day, 10th day and 15th day of storage, that decreases with decrease in concentration of Moringa oleifera leaf powder. Thus lowest was observed for control sample i.e. 0.871, 0.92733 and 1.013 at zero day, 10th day and 15th day of storage. Due to bacterial activity lactose (milk sugar) is converted into lactic acid, causing the decline of pH and rise of acidity.The mean for acidity values showed significantly different results (p ≤ 0.05) for all the treatments over the storage period of 15 days at 5 °C. Results of titrable acidity were also same as the observation of Amal et al. (2016) such as with the passage of storage time the bacterial activity increases, hence the acidity also increased.

Ash content

Ash content determines the total mineral content in the sample. Table 3 depicted that, with enhanced quantity of moringa leaves powder, ash content of the treatments will also increase. Therefore, the highest mean values were observed for T4 i.e. 4.31% -5.66 over the storage period of 15 days. Lowest mean value for ash content was observed for control sample i.e. 1.21 to 2.95% over the storage period.. The mean values for ash content showed significantly differnt (p ≤ 0.05) results for all treatments over the storage period of 15 days at 5 °C. The results are in agreement with the observation of Dixit et al. (2018) during development of Lassi using whey and moringa powder.

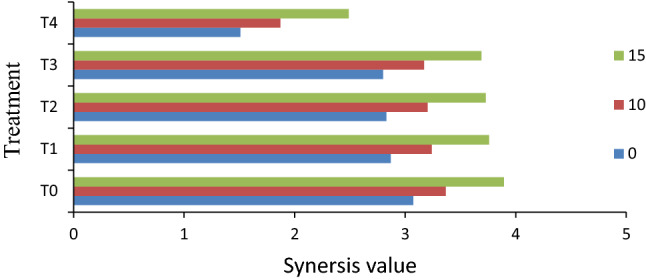

Synersis

It is obvious from the Fig. 2 that wheying off, slightly decreased as quantity of moringa leaves powder increases. Highest syneresis was observed in treatment T0 i.e. 3.0733 to 3.893.While the decreasing trend was seen in other treatments evident in Fig. 2 i.e. on x-axis the value of synersis in ml is shown while on y-axis treaments are shown. Treatment T4 showed the lowest synersis value ranging from 1.51 to 2.49.

Fig. 2.

Graphical representation of effect on syneresis content of flavored yogurt samples fortified with moringa oleifera leaf powder, on x-axis the increasing value of synersis and y-axis treatments are presented

Statistical analysis illustrates that syneresis value for the treatments showed significantly different (p ≤ 0.05) results from each other over the storage period up to 15 days at 5 °C. It was also observed by Abou El Samh et al. (2013) that increase of pumpkin addition to the yogurt reduce the synersis up to 22%.

Sensory evaluation

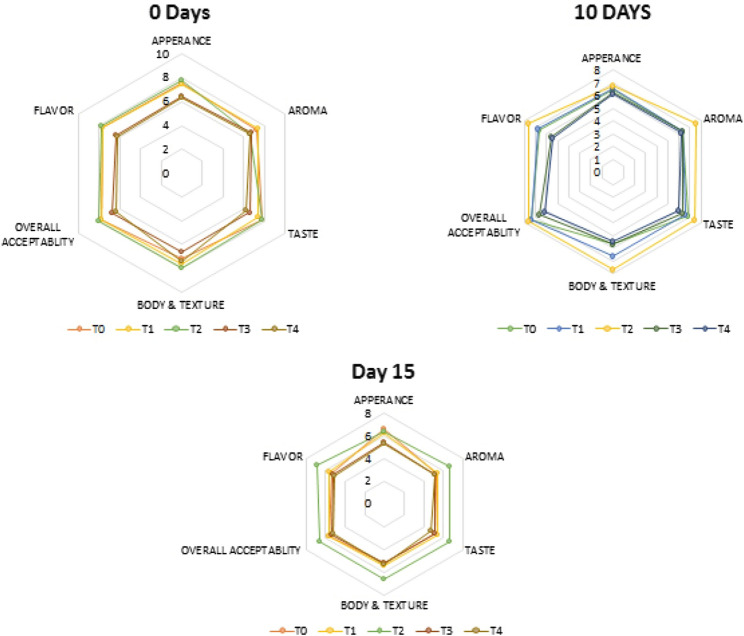

Zero Day of storage period (fresh samples)

The scores for the sensory properties (appearance, aroma, body and texture, taste, flavor, and overall acceptability) are illustrated in Fig. 3 by radar chart. The highest scores were observed for appearance, taste, body and texture, overall acceptability and flavor of treatment T2 with 1% of fortification of Moringa oleifera dried leaf powder having mean values 7.8, 7.8, 8.016, 8.11, 7.8 respectively and highest score for aroma was observed for T1 fortified with 0.5% moringa dried leaf powder which was 7.4 in fresh mango flavored fortified sample. The lowest score for all the sensory characteristics except body and texture was observed for T4 treatment having fortification of 2% moringa dried leaf powder, which was appearance, aroma taste, overall acceptability and flavor 6.3, 6.6, 6.2, 6.4 and 6.2 and treatment T3 (1.5% moringa dried leaf powder fortification) showed the lowest score for body and texture properties with the score of 6.61.

Fig. 3.

The effect of addition of moringa leaves powder in different concentration on the sensory characteristics of fresh (day 0) yogurt, 10 days & 15 days of storage at 5 ± 1ºC

10th day of storage period

The sensory properties (appearance, aroma, body and texture, taste, flavor, and overall acceptability) were analyzed for its sensory characteristics and illustrated in Fig. 3 in the form of radar chart. The highest scores were observed for appearance, aroma, taste, body and texture, overall acceptability and flavor for treatment T2 with 1% of fortification of Moringa oleifera dried leaf powder having mean values 6.8, 7.6, 7.4, 7.6, 7.633 and 7.60 respectively. The lowest score for all the sensory characteristics except body and texture was observed for T4 treatment having fortification of 2% moringa dried leaf powder, which was appearance, aroma taste, body and texture overall acceptability and flavor 6.1, 6.2, 6.03, 5.4, 6.203 and 5.4.

15th day of storage period

The sensory properties (appearance, aroma, body and texture, taste, flavor, and overall acceptability) were observed at 15th days of storage for its sensory characteristics and illustrated in Fig. 3 in the form of radar chart. The highest scores were observed for treatment T2 with 1% of fortification of Moringa oleifera dried leaf powder appearance, aroma, taste, body and texture, overall acceptability and flavor having mean values 6.4, 6.6, 6.6, 6.63, 6.603 and 6.80 respectively. The lowest score for all the sensory characteristics except body and texture was observed for T4 treatment having fortification of 2% moringa dried leaf powder, which was appearance, aroma taste, body and texture overall acceptability and flavor 6.2, 5.1, 4.8, 5.2, 5.2 and 5.03. T2 treatment proves to be the best combination of flavor and moringa fortification (1% moringa dried leaf powder) at 0 day, 10th day and even 15th day of storage, which was not in accordance with the observation of Hassan et al. (2015), that control sample got the highest score than other treatments although the concentration used for the sample was nearly same as used for this research which was 1% moringa powder, 1.5% moringa powder and 2% moringa powder supplemented in yogurt treatments. The possible reason could be the difference in the people tastes and eating habits or the additional mango flavor mask the bitter taste, aroma and overall appearance in the yogurt sample. In fact, it enhances the overall acceptability. The result for body and texture were similar to the observation of El-Gammal et al. (2017). He explained that, by using the extract (aqueous) of moringa in the yogurt fortification it improves the hardness, gumminess, cohesiveness, springiness, indeed overall body and texture of the product. Thus, scores were significantly higher for the treatments than control.

Conclusion

1% Moringa oleifera dried leaves powder with the addition of mango flavor and color was the best combination for the production of flavored yogurt. This ratio will enhance and positively affect the nutritional profile, physicochemical properties and sensory characteristics, of resultant yogurt. The addition of mango flavor and sugar further mask the lingering bitter taste and unpleasant odour of moringa leaves and enhance the overall acceptability of the product. This study can help the food technologist, nutritionist, end consumer and nutrition intervention policy makers or stake holders in regard of processing the miraculous plant in different stable super food recipes designs. This study is believed to provide the opportunity to enhance the cultivation of Moringa Oleifera particularly in middle income countries where most of the population is nutrient deficient and facing food insecurity.

Acknowledgements

We acknowlagde Dr.Amna saeed and Dr.Hafiz Roy Umair’s effort to provide help regarding proof reading and giving writting assitance for the article. The work described has not been published before (except in the form of an abstract, a published lecture or academic thesis) in any journal before and data transparency is maintained. It is not under consideration for publication elsewhere. Its submission to JFST publication has been approved by all authors.If accepted, it will not be published elsewhere in the same form, in English or in any other language, including electronically without the written consent of the copyright holder, and JFST will not be held legally responsible should there be any claims for compensation or dispute on authorship.

Authors' contributions

MS concieved and carried out the experiments and wrote the MS, while SWA concieved the idea, superviosed the research and helps in editting the manuscript.SR helps in statistical analysis of the resaerch data.

Funding

This study was not funded by any organization.

Data availability

The data generated or analysed during this study are included in this published article in supplimentory information files.

Declarations

Conflict of interest

All the authors do not have any objection or conflict of interest towards this submission.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Maryam Saeed, Email: maryamsaeed06@gmail.com.

Shinawar Waseem Ali, Email: shinawar.iags@pu.edu.pk.

Saniya Ramzan, Email: saniyaramzan8@gmail.com.

References

- Abbas RK, Elsharbasy FS, Fadlelmula AA. Nutritional values of Moringa oleifera, total protein. amino acid, vitamins, minerals, carbohydrates, total fat and crude fiber, under the semi-arid conditions of sudan. J Microb Biochem Technol. 2018;10:56–58. [Google Scholar]

- Abou El Samh MM, Sherein AA, Essam HH. Properties and antioxidant activity of probiotic yoghurt flavored with black carrot, pumpkin and strawberry. Intern j Dairy Sci. 2013;8:48–57. doi: 10.3923/ijds.2013.48.57. [DOI] [Google Scholar]

- Ahmed EL-Soda NHM, Hassan AN, Frank J. Improving the textural properties of an acid-coagulated (Karish) cheese using exopolysaccharide producing cultures. LWT. 2005;38:843–847. doi: 10.1016/j.lwt.2004.10.001. [DOI] [Google Scholar]

- Amal A, Eman A, Nahla SZ. Fruit flavored yogurt: Chemical, functional and rheological properties. Int j Environ Agric Res. 2016;2:57–66. [Google Scholar]

- Anwar F, Ashraf M, Bhanger MI. Interprovenance variation in the composition of Moringa oleifera oilseeds from Pakistan. J Am Oil Chem Soc. 2005;82(1):45–51. doi: 10.1007/s11746-005-1041-1. [DOI] [Google Scholar]

- AOAC (2005) Official methods of analysis, 18th edn. Association of Officiating Analytical Chemists, Washington, DC

- Asfour HAE, Anwer AM. Some bacteriological and immunological studies on camel’s milk. Alex J Vet Sci. 2015;47:38–46. [Google Scholar]

- BakrI A, MohamedTH TAA, El-Gazzar F. Characteristics of bioyoghurt fortified with fennel honey. Int J Curr Microbiol Appl Sci. 2015;4:959–970. [Google Scholar]

- Daba M. Miracle tree: A review on multi-purposes of moringa oleifera and its implication for climate change mitigation. Journal of Earth Science & Climatic Change. 2016;7:1. doi: 10.4172/2157-7617.1000366. [DOI] [Google Scholar]

- Dary O, and Hurrell R (2006) Guidelines on food fortification with micronutrients. World Health Organization, Food and Agricultural Organization of the United Nations: Geneva, Switzerland, 1–376.

- Dixit N K, HossainS K A, Bharti B K, Singh S S, Mishra S (2018) Development of lassi using whey and moringa powder.Int J Curr Microbiol Appl Sci 7: 602–612

- El-GammalRE AEA, Darwish MS. Utilization of aqueous extract of moringa oleifera for production of functional yogurt. JFDS. 2017;8:45–53. [Google Scholar]

- Fahey JW. Moringa oleifera: a review of the medical evidence for its nutritional, therapeutic, and prophylactic properties. Part 1. TFLJ. 2005;1(5):1–15. [Google Scholar]

- Foidl N, MakkarH PS, Becker K (2001) The potential of Moringa oleifera for agricultural and industrial uses. The Miracle Tree: The Multiple Attributes of Moringa, 45–76

- Fuglie L J (2001) The miracle tree; the multiple attributes of moringa ,Technical Centre for Agricultural and Rural Co-operation, Wageningen Países Bajos.

- GaoX,Wang W,Wei S L, LiW(2009) Review of pharmacological effects of Glycyrrhiza radix and its bioactive compounds. China Journal of Chienese Materia Medica. 21 2695–2700. [PubMed]

- Hassan FAM, Bayoumi HM, El-Gawad MA, EnabAK YYB. Utilization of moringa oleifera leaves powder in production of yoghurt. Int j Dairy Sci. 2016;11:1811–9743. doi: 10.3923/ijds.2016.69.74. [DOI] [Google Scholar]

- Hassan LK, Hagag HF, Elkalyoubi MH, El-Aziz MA, El-Sayed MM, SayedA F. Physico-chemical properties of yoghurt containing cress seed mucilage or guar gum. AOAS. 2015;60:21–28. [Google Scholar]

- HorwtizW, Latimer GW(2006). Association of Officiating Analytical Chemists. 18 Edittion. Washinton DC.

- Khalid AR, MustafaMI BMQ, Lateef M. Quality assessment of milk available to the consumers in Faisalabad. Punjab University Journal of Zoology. 2013;28:7–13. [Google Scholar]

- Madukwe EU, Ezeugwu JO, EmeP E. Nutrient composition and sensory evaluation of dry moringa oleifera aqueous extract. Int J Sci Basic Appl. 2013;13:100–102. [Google Scholar]

- Milner JA. Functional foods and health: a US perspective. Br J Nutr. 2002;88:152–158. doi: 10.1079/BJN2002680. [DOI] [PubMed] [Google Scholar]

- Razis AFA, Ibrahim MD, Kntayya SB. Health benefits of Moringa oleifera. Asian Pac j Cancer Prev. 2014;15:8571–8576. doi: 10.7314/APJCP.2014.15.20.8571. [DOI] [PubMed] [Google Scholar]

- Rweyemamu LM (2006) Challenges in the development of micronutrient-rich food ingredients from soya beans and Moringa oleifera leaves. Proceedings on Moringa and Other Highly Nutritious Plant Resources: Strategies, Standards and Markets for a Better Impact on Nutrition in Africa. Accra, Ghana, 37–40.

- SalemA S, SalmaW M, HassaneinA M, El-GhandourH MA. Enhancement of nutritional and biological values of Labneh by adding dry leaves of moringa oleifera as innovative dairy products. World Appl Sci j. 2013;22:1194–1602. [Google Scholar]

- Schmidt B.D. (2005), Association of Official Analytical Chemists. 18 Edition.Virginia.

- Shalini S, Shivaprasad HN. Moringa oleifera - Nutritional rich functional food. Int j Herb. 2017;5:83–86. [Google Scholar]

- ShokeryE S, El-Ziney M G,Yossef A H, Mashaly R I (2017) Effect of green tea and Moringa leave extracts fortification on the physicochemical, rheological, sensory and antioxidant properties of set-type yoghurt. ADR

- Sodamode A. Proximate analysis, mineral contents and functional properties of Moringa oleifera leaf concentrate. AQCJ. 2013;4(6):47–51. [Google Scholar]

- Soukoulis C, Lyroni E, Tzia C. Sensory profiling and hedonic judgement of probiotic ice cream as a function of hydrocolloids, yogurt and milk fat content. LWT. 2010;9:1351–1358. doi: 10.1016/j.lwt.2010.05.006. [DOI] [Google Scholar]

- Yaméogo CW, Bengaly MD, Aly S, Nikiema PA, Traore SA. Determination of chemical composition and nutritional values of Moringa oleifera leaves. Pakistan Journal Nutr. 2011;10:264–268. doi: 10.3923/pjn.2011.264.268. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data generated or analysed during this study are included in this published article in supplimentory information files.