Abstract

Squalene, a triterpenoid compound is proven to possess immense bioactivities by virtue of its high antioxidant activity. The present study was designed to investigate the quality attributes of muffins as influenced by addition of encapsulated squalene. Nutritional analysis showed that calorific value of prepared muffins has ranged from 480.78 ± 0.10 to 501.61 ± 0.38 kcal. Baking loss was lowest in case of muffins prepared with encapsulated squalene with its crumb region recorded higher moisture content. Color kinetics study indicated that browning index (BI) was higher in crust portion of encapsulated squalene enriched muffins. Scanning electron micrographs showing that muffins with encapsulated squalene had stronger structural organization. This was further supported by the textural studies showed that the muffins with encapsulated squalene was cohesive, springier and chewy with less gumminess and stiffness indicating their efficacy in improving the textural quality. Oxidative stability and microbiological quality were also high in squalene enriched foods suggesting that squalene might have some antimicrobial effects. Outcome of the study indicated that encapsulated squalene can be very well utilised as a functional food ingredient in ready -to-eat functional foods.

Supplementary information

The online version contains supplementary material available at (10.1007/s13197-020-04955-9).

Keywords: Muffins, Encapsulated squalene, Encapsulation efficiency, Textural quality, Color kinetics, Scanning electron microscopy

Introduction

Enrichment of foods with bioactive compounds having health promoting properties has become a prime research area in food science. Accordingly, researchers have started screening several natural resources for isolation of health beneficial compounds to employ them as functional food ingredients. However, the inclusion effect of any such bioactive compound has to be studied in detail as it depends to a greater extent on the food matrix type, nature of compound added, its physio-chemical properties, its impact on the overall nutritional attributes of the final product etc. Inclusion of polyunsaturated fatty acids in foods has shown an increasing trend of late. Squalene, a bio functional lipid compound, is reported to have diverse bioactivities ranging from cardioprotective, antioxidant, chemopreventive, anticancerous, antilipidemic, membrane stabilizing properties etc. (Kim and Karadeniz 2012). The notable health benefits and wide applications has prompted extraction of squalene from various sources using different techniques. Though the health benefits of squalene have been well established, it is not being widely employed as a dietary supplement owing to its oxidative instability. Encapsulation of squalene can be an effective method to address the oxidative instability issue (Saifullah et al. 2019). If effectively encapsulated, it can be used as a food fortificant to develop ready-to-eat or ready-to-drink functional foods.

Baked products such as cakes, muffins etc. are frequently consumed foods and have high acceptability and consumer preference all over the world. Such foods can be easily converted into functional foods through fortification. Muffins are sweet, baked products of high calorific value, with great consumer acceptance owing to their superior texture and textural attributes. Muffins batter is an oil-in water emulsion with egg-oil-sugar-water mixture as continuous phase. Batter preparation is followed by the process of baking and converted into baked muffins by virtue of the mass and heat transfer phenomenon happened during the process. During the process of baking, several physico-chemical and structural interactions will happen which can have serious implications on the quality of the final product. Baked products can easily be converted into functional foods by adding suitable fortificants. Similar studies of fortification in bakery products such as biscuits, muffins, cakes etc. using encapsulated fish oil, grape skin extract, encapsulated shrimp oil were already reported by several researchers (Santhanam et al. 2015; Dordoni et al. 2019; Takeungwongtrakul and Benjakul 2017. The present study was designed to investigate the feasibility of encapsulated squalene as a functional food ingredient by its incorporation in muffins. The outcome of the study will help in exploring the possibilities of encapsulated squalene as a functional food ingredient.

Materials and methods

Biopolymers, chemicals used

Maltodextrin (degree of Dextrose equivalents (DE) 16.5–19.5) was obtained from Sigma–Aldrich (USA). Whey protein isolate (protein content- > 80%) was obtained from Sattvic foods, Goa. All the other chemicals used in the analytical study were of analytical grade and were obtained from Sigma-Aldrich (USA).

Ingredients used for functional food preparation

All-purpose flour, powdered sugar, vanilla essence, butter, egg, baking powder. All the ingredients were procured from local market.

Methods

Encapsulation of squalene

Whey protein and maltodextrin of adequate quantity (1:7 on w/w basis) was weighed, mixed and dissolved thoroughly in distilled water. After complete dissolution of the biopolymers, squalene was added to it at the ratio of 1: 0.3 (wall material to squalene on w/w basis) which was optimized previously (Lekshmi et al. 2017). This was followed by emulsification and spray drying to produce encapsulated squalene at conditions described in our previous studies (Lekshmi et al. 2019). The spray dried powder was then stored at 4 °C for further studies.

Preparation of muffins

For comparative analysis, 3 treatments were prepared: Muffins without squalene–A (Control); Muffins with pure squalene–B; Muffins with encapsulated squalene–C. Equal quantity of butter and sugar were taken and mixed for 3 min using a food processor (Philips intelligent food processor, HL 1659, India). Refined flour and baking powder of required quantity was taken and blended thoroughly. The butter-sugar mixture was added to the pre-mixed blend, mixed for 2 min. Finally, vanilla essence and egg were added to the homogenized mixture and blended well. In case of treatments B and C, squalene (pure and encapsulated) was added after this step at the rate of 350 mg per 100 g of muffins and mixed well. The batter thus prepared was poured into a metallic muffin mould which was previously greased with butter to prevent any batter adhesion. This was baked in a microwave oven (IFB microwave oven, Model: 30SC4) at 150 °C for 18 min. After the baking time, the pans were taken out and allowed to cool to room temperature. The muffins were then packed in high density polyethylene (HD-PE) tray covered with polyester–polyethylene laminate film and subjected to further characterization studies by storing at room temperature.

Proximate composition of muffins

Proximate analysis of different treatments (moisture, protein, fat, and ash content) was measured as per the standard procedures (AOAC, 2003). The Muller and Tobin 1980 method was used to calculate the crude carbohydrate content (Eq. 1). The total caloric intake per 100 g of muffins was also determined based on the percentage of proteins, carbohydrates and fat (Eq. 2).

| 1 |

| 2 |

Fatty acid composition of muffins

Lipid extraction of muffins were carried out as per Folch et al. (1957). Fatty acid methyl esters (FAME) were prepared from the extracted lipids by following the method of Metcalfe et al. 1966. Methyl esters of the fatty acids thus obtained were separated by gas chromatography (Thermo Trace GC Ultra) equipped with a Perkin Elmer capillary column, SPTM-2560 (100 m × 0.25 mm × 0.20 μm) and a flame ionization detector. The carrier gas was nitrogen with flow rate of 0.7 mL/min. The initial temperature of column oven was set as 140 °C which increased at the rate of 4 °C/min until 240 °C, followed by a hold for 5 min. Injector and detector temperature was kept at 300 °C. Hydrogen and air flow rates were adjusted to 45 mL/min and 450 mL/min, respectively. The individual components were identified by comparing retention times with those obtained from the FAME mixture standard (supelcoTM 37 component FAME mix, 100 mg neat (Sigma Aldrich, catalog No: 18919-1AMP).

Baking loss

Weight loss happened during the process of microwave baking was estimated by taking into account the percentage difference between initial (Wi) and final product (Wf) weight (Eq. 3).

| 3 |

Analysis of other physico-chemical qualities

Moisture content of both crust and crumb of all the muffins were analysed (AOAC, 2003). The crumb portion of muffin was exposed by removing the upper part (crust) using a serrated knife. The color coordinates (L* a* b*) of both the crust and crumb portions of muffins was measured using Hunter lab colorimeter (Hunter lab, Reston, VA, USA). Based on the colour parameters (L*, a*, b*), browning intensity (BI), hue angle and chroma were computed using the following Eq. (4, 5, 6) respectively. AOAC Official Method 965.33 was employed to measure the peroxide value of different treatments (Eq. 7). The external morphology of the baked muffins was analysed using scanning electron microscopy (SEM, JEOL Model JSM-6390LV, Tokyo, Japan).

| 4 |

where,

| 5 |

| 6 |

| 7 |

where, S is titre value for sample, B titre value of the blank; N is the normality of Na2S2O3, and W is the weight of sample (g).

Texture profile analysis (TPA) of different treatments was analysed using texture analyser (TA Plus, Lloyd instruments-Ametek, Hampshire, UK) equipped with a load cell of 50 kg. For performing the texture analysis, 2 bite method was followed by keeping the pre-test speed: 5 mm/s, test speed–5 mm/s, post-test speed–10 mm/s, trigger force–10 g and compression distance–60%. A cylindrical probe of radius 75 mm was used for the analysis. The textural parameters were taken using Nexygen software. The sensory acceptance of the product was evaluated by following the method of Murray et al. (2001) by a 9-point hedonic scale.

Microbiological analysis

Total plate (total mesophilic count) and fungus counts (Yeast and mold) were carried out for batter A, B, C and muffins on alternate days of storage period to check the microbial load as per American Public Health Association (APHA). 10 g of samples were serially diluted in PBS (pH: 7.4) and aseptically spread plated over the media plates. For mesophilic count, samples spreaded over trypticase soy agar (TSA) (Bd & Difco, USA) and incubated at 37 °C for 48 h. Sabouraud Dextrose agar (SDA) (Bd & Difco, USA) was used to check the yeast and mold count by incubating at room temperature for 4 to 5 days.

Statistical analysis

All the measurements were carried out in triplicates. The data obtained were subjected to one-way analysis of variance (ANOVA) using the statistical software, SPSS version 16.0, Chicago IL. USA. Differences among means were evaluated by Duncan's multiple range test at a significant level of p ≤ 0.05.

Results and discussions

Encapsulation efficiency

Encapsulation efficiency of the spray dried squalene powder was found to be 96.50 ± 0.06% with a surface oil content of 4.17 ± 0.06 mg/g powder and total oil content 118.75 ± 1.29 mg/g powder. Whey proteins are considered as effective emulsifiers due to its ability to form a stable layer over oil droplets by its unfolding and adsorption on the oil–water interface. In addition to this, maltodextrins (MD) can also confer excellent protection to encapsulated lipophilic materials and their efficacy can be related to its dextrose equivalents. It has been already proven that MD with higher DE can act as an impermeable barrier to atmospheric gases and thereby resulting in higher encapsulation efficiency (Campelo et al. 2017; Jafari et al. 2008). Botrel et al. (2014) and Turasan et al. (2015) have reported lowest surface oil content when MD and WPI was employed in the microencapsulation of fish oil and rosemary essential oil respectively. In line with our results, Akhtar and Dickinson (2007) have also reported that MD-WPI based conjugates can work as effective emulsifying agent than gum Arabic.

Nutritional analysis of muffins

The highest moisture content was observed in encapsulated squalene enriched muffins and this can be due to the presence of MD-WPI as wall materials. MD-WPI might have acted as an emulsifier and retained more moisture in the emulsified form. Nelson (2000) reported that the addition of bulking agents such as maltodextrin can have a significant effect on moisture retention in the products. Fat and ash content were also found to be high in muffins with encapsulated squalene. Similar to our results, Umesha et al. (2015) have reported an increase in protein and ash content in biscuits enriched with microencapsulated garden cress oil than control. Calorific values of the treatments have ranged from 480.78 ± 0.10 to 501.61 ± 0.38 kcal with the highest value noted for muffins. As per the nutritional analysis results, it can be concluded that muffins prepared can be categorised under high energy foods (Table 1).

Table 1.

Nutritional composition, Baking loss of various treatments

| Properties | A-Control | B-Pure | C-Encapsulated |

|---|---|---|---|

| Moisture (%) | 8.16 ± 0.09a | 10.31 ± 0.06b | 11.25 ± 0.05c |

| Protein (%) | 7.03 ± 0.02a | 8.33 ± 0.04c | 7.57 ± 0.05b |

| Fat (%) | 25.78 ± 0.03a | 26.35 ± 0.03b | 27.43 ± 0.02c |

| Ash (%) | 0.73 ± 0.02a | 0.75 ± 0.01b | 0.78 ± 0.01c |

| CHO (%) | 56.64 ± 0.06c | 54.25 ± 0.06a | 54.62 ± 0.11b |

| Total energy (Kcal) | 501.61 ± 0.38c | 487.47 ± 0.38b | 480.78 ± 0.10a |

| Baking Loss (%) | 11.49 ± 3.40a | 15.25 ± 5.59a | 8.22 ± 4.43a |

| Crust Moisture (%) | 9.54 ± 0.02b | 8.09 ± 0.02a | 12.53 ± 0.05c |

| Crumb Moisture (%) | 10.57 ± 0.02b | 9.67 ± 0.04a | 13.90 ± 0.01c |

| Water activity | 0.55 ± 0.002a | 0.64 ± 0.01b | 0.75 ± 0.002c |

All data are given as mean ± SD, n = 3; a–c Different letters with mean value indicate differences (p ≤ 0.05) between treatments

The lowest baking loss was observed in encapsulated squalene enriched muffins. This can be attributed to the presence of maltodextrin which might have a positive impact upon water retention. Irrespective of treatments, the crust region of muffins has recorded the lowest moisture content and this can be due to the dehydration that occurred at the surface layer during the baking process. The dried crust layer of muffins acts as an insulator after baking and this might have helped in controlling further moisture loss from the inner zones. Behaviour of crust layer as a weight loss barrier has already been studied and reported (Wahlby and Skjoldebrand 2002). Water activity was found to vary significantly among the treatments with control muffins having the lowest value.

Fatty acid composition of different treatments was analyzed (supplementary data 1). The highest fatty acid content was observed in muffins enriched with encapsulated squalene. The predominant saturated fatty acids were palmitic (C16), stearic (C18) and mystric acid (C14). The predominant monounsaturated and polyunsaturated fatty acids were oleic (C18:1) and linoleic acid (C18:2) respectively.

Kinetics of color development in muffins

Crust color kinetics

The color co-ordinates, L*, a* and b* of crust regions has decreased significantly throughout the storage period with encapsulated squalene enriched muffins having the lowest values (Table 2a.). In general, the crust of all the treatments had a brown color. Maillard reactions and caramelization are the 2 important phenomenon that can cause browning of baked products. For maillard reactions to occur, pH should be around 4–7, temperature > 50 °C and an intermediate moisture content whereas caramelization requires pH < 3 or > 9 and temperature > 120 °C. In general, brownish color of muffins can be attributed to maillard reaction since the pH of all the treatments was around 7 and temperature above 120 °C (150 °C). Browning Index (BI) was found to increase during the storage period with encapsulated squalene having the highest brown intensity. Similar results of increasing browning reactions in the crust of muffins have been reported by Marco and Rosell (2008) and Shaabani et al. (2018). In case of muffins with encapsulated squalene, the presence of whey protein and maltodextrin in the treatments as wall materials might have also accelerated the browning. Similar results of Maillard reaction contributed by the reaction between free amino groups of the proteins and the reducing sugars has already been reported by Martins et al. (2000). Takeungwongtrakul et al. (2015) reported similar results in cakes fortified with microencapsulated shrimp oil and suggested the presence of sugar and proteins in the wall material as the possible reason for browning in the crust regions. Chroma values of all the treatments was found to decrease throughout the storage period.

Table 2.

Crust color analysis of muffins

| Treatment | Storage days | Lightness | Redness | Blueness | BI | Chroma |

|---|---|---|---|---|---|---|

| A | 1 | 39.463 ± 1.25c | 15.16 ± 0.27c | 23.20 ± 1.29b | 112.51 ± 1.82b | 27.71 ± 1.22b |

| 2 | 36.3 ± 0.48ab | 14.75 ± 0.12ab | 22.22 ± 0.91a | 119.16 ± 5.12a | 26.67 ± 0.69a | |

| 3 | 37.52 ± 2.03b | 14.46 ± 0.13a | 22.08 ± 1.48a | 113.63 ± 15.53a | 26.39 ± 1.28a | |

| 4 | 37.58 ± 0.22b | 15.41 ± 0.29b | 22.00 ± 0.12a | 113.74 ± 1.511a | 26.86 ± 0.23a | |

| 5 | 37.30 ± 0.70b | 15.11 ± 0.30ab | 20.03 ± 1.77a | 103.84 ± 8.56a | 25.11 ± 1.39a | |

| 6 | 34.96 ± 0.16a | 14.98 ± 0.72ab | 19.54 ± 2.27a | 109.9 ± 13.62a | 24.64 ± 2.05a | |

| 7 | 34.89 ± 0.18a | 14.84 ± 0.27ab | 21.41 ± 0.67a | 120.76 ± 4.44a | 26.05 ± 0.41a | |

| B | 1 | 37.04 ± 0.83bc | 14.52 ± 0.09a | 22.26 ± 0.20b | 115.82 ± 4.54a | 26.57 ± 0.13b |

| 2 | 36.44 ± 0.69bc | 14.33 ± 0.25a | 22.26 ± 0.20b | 117.94 ± 1.47a | 26.47 ± 0.27b | |

| 3 | 37.27 ± 0.08bc | 14.26 ± 0.22a | 21.44 ± 1.26b | 109.83 ± 7.05a | 25.75 ± 1.17b | |

| 4 | 37.65 ± 1.11c | 14.47 ± 0.46a | 21.48 ± 1.95b | 108.97 ± 8.31a | 25.91 ± 1.75b | |

| 5 | 37.63 ± 0.90c | 14.40 ± 0.32a | 21.99 ± 0.79b | 111.7 ± 5.42a | 26.29 ± 0.57b | |

| 6 | 35.73 ± 0.12ab | 15.10 ± 0.10b | 21.08 ± 1.58b | 115.7 ± 9.12a | 25.94 ± 1.34b | |

| 7 | 34.31 ± 1.35a | 14.30 ± 0.13a | 18.94 ± 1.33a | 107.37 ± 2.47a | 23.74 ± 1.01a | |

| C | 1 | 32.74 ± 1.19c | 15.84 ± 0.19c | 19.92 ± 0.44ab | 123.82 ± 8.52b | 25.45 ± 0.35ab |

| 2 | 32.11 ± 0.50bc | 15.79 ± 0.30bc | 21.39 ± 1.60bcd | 137.41 ± 14.45ab | 26.59 ± 1.45bcd | |

| 3 | 31.9 ± 0.81bc | 15.73 ± 0.21bc | 22.10 ± 0.19d | 143.53 ± 6.67b | 27.13 ± 0.18d | |

| 4 | 30.97 ± 0.06ab | 15.82 ± 0.30c | 21.74 ± 0.34 cd | 146.68 ± 2.65b | 26.89 ± 0.257 cd | |

| 5 | 31.71 ± 0.47bc | 15.39 ± 0.22ab | 19.45 ± 0.34a | 124.79 ± 4.39b | 24.81 ± 0.17a | |

| 6 | 31.47 ± 0.06b | 15.26 ± 0.12b | 20.65 ± 0.43abcd | 134.16 ± 3.28ab | 25.68 ± 0.39abc | |

| 7 | 30.16 ± 0.48a | 14.39 ± 0.18a | 20.18 ± 1.54abc | 136.97 ± 11.7ab | 24.80 ± 1.15a |

Values are indicated as Mean ± standard error with n = 3

a–d Different letters with mean value indicate differences (p ≤ 0.05) between treatments)

Crumb color kinetics

It was observed that L*, a* and b* values were higher in crumb region than that of the crust portions (Table 3b). However, the lightness value was found to decrease with the increase in storage days. Similarly, the redness and blueness also followed a decreasing trend with the storage period. The highest lightness value was observed in muffins with pure squalene and lowest in muffins with encapsulated squalene. Marco and Rosell (2008) has reported similar results stating the increase in lightness value of crumb regions when compared to the outer crust region. The browning intensity of muffin crust (irrespective of the treatments) on 0th day ranged from 112.51 to 143.53 whereas the crumb region had exhibited a BI value in the range of 53.03 to 62.69. This shows that browning reaction has happened mainly at the surface and has not affected the inside color. In accordance with our results, Wählby and Skjöldebrand (2002) reported browning was mainly a surface phenomenon and hence the crumb region remained unaffected compared to that of crust.

Table 3.

Crumb color parameters of muffins

| Treatment | Storage days | Lightness | Redness | Blueness | BI | Chroma |

|---|---|---|---|---|---|---|

| A | 1 | 72.86 ± 0.950bc | 2.41 ± 0.46a | 29.7 ± 0.38ab | 53.34 ± 0.88ab | 29.80 ± 0.40ab |

| 2 | 71.54 ± 0.40abc | 2.61 ± 0.21a | 30.66 ± 1.29b | 57.02 ± 3.08b | 30.77 ± 1.3b | |

| 3 | 73.41 ± 1.08d | 2.32 ± 0.06a | 30.01 ± 0.01ab | 53.42 ± 0.97ab | 30.10 ± 0.00ab | |

| 4 | 71.24 ± 1.98abc | 2.08 ± 0.45a | 28.5 ± 0.81a | 51.86 ± 2.10a | 28.58 ± 0.79a | |

| 5 | 70.14 ± 0.22a | 2.16 ± 0.35a | 28.50 ± 1.24a | 52.99 ± 2.83ab | 28.59 ± 1.23a | |

| 6 | 69.22 ± 2.24a | 2.27 ± 0.17a | 28.74 ± 0.69a | 54.61 ± 3.11ab | 28.83 ± 0.69a | |

| 7 | 70.81 ± 0.90ab | 2.15 ± 0.17a | 28.79 ± 0.26a | 52.96 ± 0.48ab | 28.87 ± 0.25a | |

| B | 1 | 73.55 ± 0.48c | 1.33 ± 0.1a | 29.56 ± 0.39b | 51.23 ± 1.33a | 29.59 ± 0.40b |

| 2 | 73.55 ± 0.48c | 1.62 ± 0.35ab | 29.56 ± 0.39b | 51.55 ± 1.62a | 29.60 ± 0.40b | |

| 3 | 72.52 ± 0.88bc | 1.59 ± 0.18ab | 28.47 ± 0.60ab | 50.01 ± 1.79a | 28.51 ± 0.59ab | |

| 4 | 72.20 ± 1.84bc | 1.71 ± 0.18b | 28.07 ± 0.79a | 49.72 ± 3.46a | 28.13 ± 0.80a | |

| 5 | 72.22 ± 0.49bc | 2.41 ± 0.15c | 27.64 ± 0.64a | 49.45 ± 0.98a | 27.75 ± 0.64a | |

| 6 | 71.09 ± 0.45ab | 2.17 ± 0.08c | 27.46 ± 1.16a | 49.78 ± 2.32a | 27.54 ± 1.16a | |

| 7 | 69.93 ± 0.10a | 1.81 ± 0.07b | 27.45 ± 0.80a | 50.40 ± 1.90a | 27.51 ± 0.80a | |

| C | 1 | 70.52 ± 1.47a | 3.27 ± 0.11e | 32.28 ± 0.58c | 62.69 ± 1.75c | 32.44 ± 0.59c |

| 2 | 72.19 ± 1.11a | 3.56 ± 0.15f | 32.29 ± 0.58c | 61.13 ± 1.79c | 32.48 ± 0.57c | |

| 3 | 72.26 ± 0.83a | 2.88 ± 0.02d | 30.83 ± 1.09b | 56.99 ± 3.07b | 30.97 ± 1.09b | |

| 4 | 71.24 ± 1.68a | 2.41 ± 01c | 28.83 ± 0.52a | 52.99 ± 2.90a | 28.93 ± 0.54a | |

| 5 | 72 ± 0.09a | 2.44 ± 0.08c | 29.18 ± 0.75a | 53.03 ± 1.74a | 29.28 ± 0.75a | |

| 6 | 70.10 ± 1.38a | 2.13 ± 0.07b | 28.53 ± 0.45a | 53.03 ± 0.85a | 28.61 ± 0.46a | |

| 7 | 70.11 ± 1.26a | 1.66 ± 0.06a | 28.65 ± 0.57a | 52.74 ± 0.60a | 28.69 ± 0.58a |

Values are indicated as Mean ± standard error with n = 3

a–c Different letters with mean value indicate differences (p ≤ 0.05) between treatment

Textural quality of muffins

Hardness of control, pure and encapsulated squalene enriched muffins has ranged from11.57 ± 1.77 to 17.98 ± 4.77 N, 11.16 ± 1.36 to12.79 ± 1.58 N and 7.39 ± 0.02 to 5.69 ± 0.83 respectively upon storage. From the TPA analysis, it was clear that the inclusion of encapsulated squalene gave a comparatively softer texture as it had the lowest hardness value and it has shown a decreasing trend with the increase in storage time (Table 4). The lower hardness in muffins with encapsulated squalene can also be related to its increased moisture content. Water helps to make foods softer by reducing the intermolecular attraction. Cohesiveness, springiness, springiness index and chewiness were highest in muffins with encapsulated squalene followed by muffins with pure squalene. This shows that inclusion of squalene in its pure or encapsulated form had significant effect on the textural parameters. Sanz et al. (2009) have reported that the springiness value is greatly associated with fresh, elastic and aerated products of high specific volume. On the other hand, the decrease in springiness in other treatments may be attributed to the lower number of air bubbles and a denser matrix. The lower springiness and cohesiveness of other treatments indicated their non-homogenous distribution. The lower chewiness value was recorded in muffins with encapsulated squalene suggesting the ease of chewing and thereby proving its superior textural quality. When the gumminess parameter was analysed, muffins with pure squalene had the highest value, whereas muffins with encapsulated squalene had the lowest value. Stiffness was found lowest in muffins with encapsulated squalene. The lowest stiffness can also be related to the higher moisture content and similar results has been reported by Furlán et al. (2015). In general, muffins prepared with encapsulated squalene were cohesive, springier and chewy with less gumminess and stiffness than the other treatments indicating their efficacy in improving the textural quality.

Table 4.

Textural quality of muffins

| Days | Hardness (N) | Cohesiveness | Springiness(mm) | Springiness Index | Gumminess(kgf) | Chewiness(kgf) | Fracture Force (kgf) | Stiffness(kg/mm) | Adhesiveness (kg.mm) | |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 1 | 11.57 ± 1.77a | 0.08 ± 0.02bc | 2.91 ± 0.35b | 0.23 ± 0.02c | 0.93 ± 0.10a | 2.71 ± 0.60a | 0.51 ± 0.01a | 3.75 ± 0.39abc | 0.4 ± 0.23a |

| 2 | 9.62 ± 1.61a | 0.10 ± 0.01c | 3.15 ± 0.09c | 0.23 ± 0.01c | 0.80 ± 0.17a | 2.53 ± 0.6a | 0.51 ± 0.01a | 3.21 ± 0.38ab | 0.66 ± 0.36a | |

| 3 | 9.12 ± 0.77a | 0.09 ± 0.02c | 3.11 ± 0.46c | 0.2 ± 0.04bc | 0.87 ± 0.27a | 2.16 ± 1.25a | 0.51 ± 0.00a | 2.77 ± 0.77a | 0.62 ± 0.15a | |

| 4 | 12.24 ± 0.93a | 0.06 ± 0.01ab | 2.44 ± 0.33ab | 0.17 ± 0.01ab | 0.78 ± 0.09a | 1.88 ± 0.25a | 0.52 ± 0.01a | 5.01 ± 0.46c | 0.34 ± 0.50a | |

| 5 | 12.80 ± 0.29a | 0.05 ± 0.01a | 2.32 ± 0.29a | 0.14 ± 0.03a | 0.61 ± 0.07a | 2.42 ± 0.38a | 0.53 ± 0.02a | 4.16 ± 0.97abc | 0.25 ± 0.25a | |

| 6 | 12.78 ± 1.70a | 0.057 ± 0.01ab | 2.39 ± 0.05ab | 0.19 ± 0.05abc | 0.72 ± 0.08a | 1.85 ± 0.28a | 0.52 ± 0.01a | 4.79 ± 1.38bc | 0.22 ± 0.26a | |

| 7 | 17.98 ± 4.77b | 0.05 ± 0.02a | 2.51 ± 0.21ab | 0.17 ± 0.03ab | 0.88 ± 0.31a | 2.25 ± 0.96a | 0.58 ± 0.05b | 7.24 ± 1.30d | 0.17 ± 0.21a | |

| B | 1 | 11.16 ± 1.36ab | 0.1 ± 0.04a | 3.04 ± 0.31a | 0.26 ± 0.03ab | 1.14 ± 0.18a | 3.5 ± 0.91a | 0.51 ± 0.00a | 5.64 ± 2.09a | 0.82 ± 0.04a |

| 2 | 10.1 ± 0.88ab | 0.07 ± 0.01a | 3.21 ± 0.35a | 0.24 ± 0.03ab | 1.0 ± 0.11a | 3.45 ± 0.82a | 0.51 ± 0.01a | 4.33 ± 0.21a | 0.70 ± 0.05a | |

| 3 | 11.74 ± 1.13ab | 0.11 ± 0.03a | 3.4 ± 0.23a | 0.273 ± 0.05b | 1.26 ± 0.35a | 3.28 ± 0.07a | 0.51 ± 0.02a | 4.41 ± 0.45a | 0.37 ± 0.75a | |

| 4 | 12.40 ± 3.44ab | 0.08 ± 0.02a | 3.48 ± 0.41a | 0.22 ± 0.03ab | 1.02 ± 0.33a | 3.65 ± 1.52a | 0.54 ± 0.01b | 5.10 ± 1.32a | 0.19 ± 0.19a | |

| 5 | 9.55 ± 1.67ab | 0.09 ± 0.03a | 3.24 ± 0.98a | 0.21 ± 0.04ab | 1.02 ± 0.12a | 2.25 ± 2.21a | 0.53 ± 0.01b | 3.99 ± 0.37a | 0.67 ± 0.06a | |

| 6 | 8.97 ± 1.98a | 0.077 ± 0.02a | 3.18 ± 0.70a | 0.19 ± 0.03a | 0.83 ± 0.05a | 2.64 ± 1.02a | 0.54 ± 0.01b | 3.66 ± 1.51a | 0.72 ± 0.12a | |

| 7 | 12.79 ± 1.58b | 0.09 ± 0.01a | 3.43 ± 0.28a | 0.22 ± 0.02ab | 1.15 ± 0.22a | 3.96 ± 1.09a | 0.54 ± 0.01b | 5.34 ± 0.64a | 0.43 ± 0.35a | |

| C | 1 | 7.39 ± 0.02b | 0.13 ± 0.01c | 4.51 ± 0.44a | 0.28 ± 0.01a | 0.91 ± 0.14c | 4.06 ± 0.25b | 0.51 ± 0.00a | 2.31 ± 0.45a | 0.97 ± 0.21a |

| 2 | 7.14 ± 0.64b | 0.12 ± 0.01bc | 4.45 ± 0.27a | 0.27 ± 0.01a | 0.81 ± 0.12bc | 3.61 ± 0.38ab | 0.51 ± 0.01ab | 2.24 ± 0.41a | 0.94 ± 0.09ab | |

| 3 | 7.89 ± 0.54b | 0.09 ± 0.03ab | 4.25 ± 0.71a | 0.23 ± 0.04a | 0.6 ± 0.15a | 2.63 ± 1.04a | 0.51 ± 0.01ab | 1.92 ± 0.18a | 0.90 ± 0.13ab | |

| 4 | 7.53 ± 0.48b | 0.07 ± 0.01a | 3.48 ± 1.96a | 0.22 ± 0.04a | 0.68 ± 0.03ab | 2.71 ± 0.26a | 0.52 ± 0.00b | 1.95 ± 0.16a | 0.94 ± 0.18ab | |

| 5 | 6.94 ± 0.13b | 0.10 ± 0.02abc | 4.06 ± 0.03a | 0.25 ± 0.03a | 0.85 ± 0.08bc | 3.26 ± 0.62ab | 0.52 ± 0.01ab | 2.62 ± 0.29a | 0.66 ± 0.11b | |

| 6 | 6.97 ± 0.10b | 0.07 ± 0.03a | 4.14 ± 0.10a | 0.25 ± 0.04a | 0.72 ± 0.04abc | 2.65 ± 0.05a | 0.51 ± 0.01ab | 3.51 ± 0.85b | 0.75 ± 0.09ab | |

| 7 | 5.69 ± 0.83a | 0.11 ± 0.01bc | 4.16 ± 0.55a | 0.24 ± 0.03a | 0.69 ± 0.14ab | 2.90 ± 0.97ab | 0.52 ± 0.01ab | 0.26a | 0.85 ± 0.19ab |

Values are indicated as Mean ± standard error with n = 3

a–f Different letters with mean value indicate differences (p ≤ 0.05) between treatments

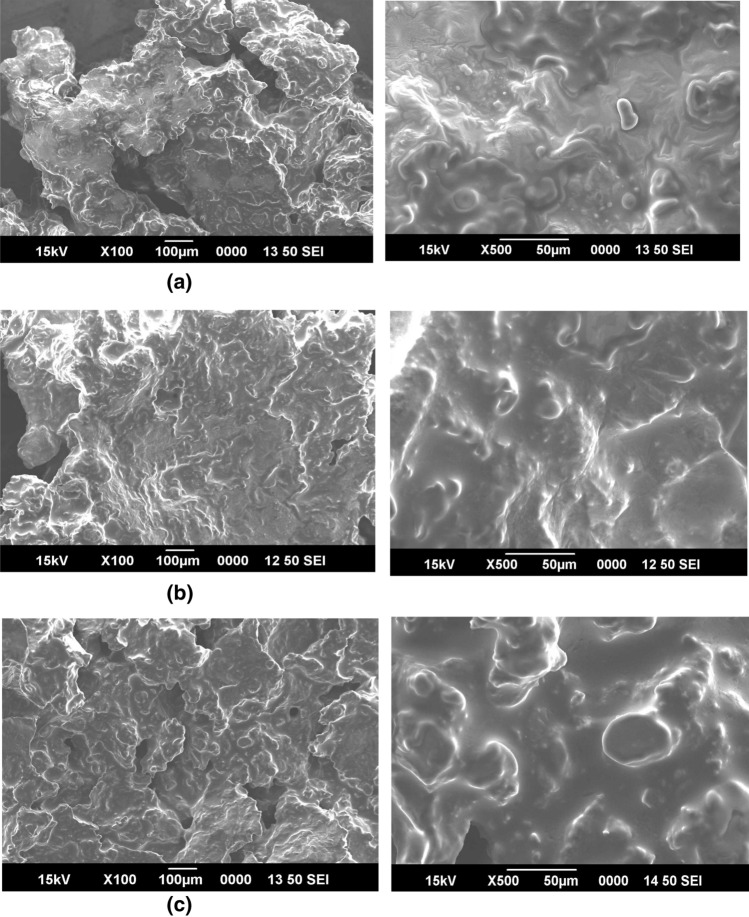

External morphology of muffins

External morphology of the different treatments was analysed using scanning electron microscopy (SEM). The SEM images of various treatments had significant observable variations (Fig. 1). Control muffins exhibited many cracks and discontinuous networks with loose distribution nature. It shows that control muffins had a non-homogenous distribution whereas muffins with pure and encapsulated squalene had a denser network. The presence of whey proteins as wall materials in the encapsulated formulation might have helped in forming crosslinks in dough to form a denser network. The results show that squalene inclusion in its pure or encapsulated form had a significant effect in forming a strong and denser network. Several small or medium sized pores were visible in muffins with squalene (pure of encapsulated), suggesting that squalene addition had a significant effect. The formation of a denser network is important from the view point of muffins textural quality. From the textural study, it was clear that the control muffins had a harder texture. This can be due to the poor gas holding capacity of the dough owing to its loose and discontinuous network structure. Similar results have been reported by Cao et al. (2019) who showed that baked products (dough) may not be able to retain gas in case of discontinuous structures and thereby leading to a harder texture. Apart from this, the micrographs showed the presence of lager number of pores in muffins with encapsulated squalene, confirming that they had a much porous and aerated structure. The results showed that muffins with encapsulated squalene were more organized structurally with larger number of gas cells contributing to superior textural attributes.

Fig. 1.

External morphology of muffins. a, b, c represents control, pure and encapsulated squalene enriched muffins respectively. Left and right side represents micrographs taken at 100 and 500X magnification respectively)

Oxidative stability of muffins

Peroxide value of the muffins stored at room temperature were analyzed to study their oxidative stability. Peroxide values showed an increasing trend throughout the storage period, however, values of all the samples were within the acceptable range (20 meq peroxide/kg oil) as proposed by CODEX/FAO standards (Table 5). The highest peroxide value was observed in control and lowest in encapsulated squalene enriched muffins. The absence of any preservatives or antioxidant compounds along with the storage at room temperature might be one reason for oxidation in control muffins. The only compositional difference between the control and the other samples was squalene, either in its pure or encapsulated form. Squalene might have exerted an antioxidant effect and helped in lowering the oxidation rates. In case of muffins with encapsulated squalene, the wall materials used might have also played an important role in reducing the oxidation rates. It has been reported that the inclusion of maltodextrin of higher dextrose equivalence has an important in extending the shelf life by slowing the starch retrogradation. Similar observations have been made by Witczak et al. (2010). Furthermore, the higher baking temperature employed in the baking process might have caused the maillard reaction. The maillard reaction products has proven to have antioxidant capability (Einhorn-Stoll et al. 2005). Though maillard reaction might have happened in all the treatments, results of browning intensity show that the higher maillard reaction has happened in encapsulated squalene enriched muffins because of its higher BI values. This might be the reason for better oxidative stability in such treatments.

Table 5.

Peroxide value of muffins

| Days | A | B | C |

|---|---|---|---|

| 1 | 1.68 ± 0.03a | 0.97 ± 0.01a | 0.83 ± 0.11a |

| 2 | 2.38 ± 0.16b | 1.21 ± 0.09b | 0.97 ± 0.01b |

| 3 | 2.76 ± 0.09c | 1.38 ± 0.06c | 1.09 ± 0.01c |

| 4 | 3.11 ± 0.02d | 1.81 ± 0.03d | 1.36 ± 0.02d |

| 5 | 3.59 ± 0.03e | 2.10 ± 0.02e | 1.69 ± 0.03e |

| 6 | 4.05 ± 0.07f | 2.28 ± 0.03f | 1.92 ± 0.01f |

| 7 | 4.32 ± 0.90 g | 2.61 ± 0.05 g | 2.11 ± 0.02 g |

(Values are indicated as Mean ± standard error with n = 3

a–g Different letters with mean value indicate differences (p ≤ 0.05) between treatments)

Microbiological quality of muffins

Microbiological quality of the batter and the baked muffins stored at room temperature were studied to establish their shelf life. Initial total plate counts ranged from 8.2 × 102 cfu/g, 4.8 × 102 cfu/g and 1.3 × 103 cfu/g respectively for A, B and C batters. Fungal growth was noticed in batter A and C whereas muffins with pure squalene had no fungal growth (Table 6a.). However, fungal growth was not observed in the baked muffins signifying the potential of baking process in inhibiting their growth. TPC also had decreased after the baking process. However, upon storage it has exhibited an increasing trend (Table 7b.). As per the TPC, the control samples were rejected on 6th day whereas muffins with pure and encapsulated squalene were rejected on the 8th day. In general, gram positive bacteria were the predominant group. Among the normal mesophilic biota, Bacillus and Staphylococcus spp. were found to be predominant, whereas in pigmented mesophilic biota, Micrococcus spp. was the dominant. Ijah et al. (2014) has reported similar results indicating the presence of Bacillus, Micrococcus, and Staphylococcus spp. as dominant groups in breads prepared from wheat and potato flour blends. Bacterial contamination might have occurred from the raw materials used in the preparation of muffins such as all-purpose flour, sugar, butter etc. The presence of Bacillus spp. as a dominant bacterial group has already reported by Ijah et al. (2014). Bacillus spp. or their spores might have been present in the raw material, especially in the flour, and their ability to withstand the higher temperature processes have already been studied (Saranraj and Geetha 2012). The presence of Staphylococcus spp. might have been attributed to the secondary contamination occurred during handling or packaging of the final product as it cannot withstand high temperature processes.

Table 6.

Microbiological quality of batter prior to baking

| Treatments | TPC (cfu/g) | Fungal count (cfu/g) |

|---|---|---|

| A | 8.2 × 102 | 2 × 101 |

| B | 4.8 × 102 | Nil |

| C | 1.3 × 103 | 1 × 101 |

Table 7.

Microbiological quality of muffins after baking

| Days of storage | Muffins A | Muffins B | Muffins C |

|---|---|---|---|

| 0th Day | 4.2 × 101 | 2.6 × 101 | 3.1 × 101 |

| 2nd Day | 3.4 × 102 | 6.2 × 101 | 9.3 × 101 |

| 4th Day | 3.9 × 103 | 2.8 × 102 | 7.6 × 102 |

| 6th Day | 2.7 × 104 (Rejected) | 3.6 × 103 | 8.1 × 103 |

| 8th Day | Nil | 3.2 × 104 (Rejected) | 6.8 X 104 (Rejected) |

Sensory analysis

The sensory attributes such as appearance, colour, odour, texture, overall acceptability were recorded for the initial day (supplementary material 2). Except in case of flavour, there was significant differences in the sensory attributes (p < 0.05) among the treatments. It was clear from the sensory attributes that muffins enriched with encapsulated squalene were well received by the sensory panellist as they scored high in all the sensory parameters. In agreement with the texture studies, the sensory quality of encapsulated enriched muffins was found to have better acceptance. In general, the initial sensory analysis has proven that inclusion of encapsulated squalene as a functional food ingredient is found to have improved the sensory acceptance of muffins when compared to that of control.

Conclusion

The present study was designed to investigate the incorporation of encapsulated squalene as a functional food ingredient in a baked product. The significant findings of the study show that the incorporation of encapsulated squalene improved the textural quality of muffins making it more cohesive, springier and chewy with less gumminess and stiffness than other treatments. There was a pronounced change in the color kinetics as indicated by the color attributes, especially the browning intensity of the crust and crumb color. Importantly, the sensory acceptance study also highlighted the acceptability of the squalene enriched muffins as it scored high in terms of the appearance, color, odor, texture, flavor and taste. It is hence concluded that encapsulated squalene is an effective functional food ingredient.

Supplementary information

Acknowledgements

The authors are grateful to Director, CIFT, Cochin for providing necessary facilities and support needed for the research. Authors also express sincere gratitude to Smt.Lekha.N., Technical Officer for their technical assistance.

Abbreviations

- Maltodextrin

Whey protein (MD-WPI)

- BI

Browning intensity

Author Contributions

Lekshmi R.G Kumar: Conceptualization, Tejpal C.S, Anas K.K: Writing, Review and Editing; Investigation & Draft preparation; Sanath Kumar H: Investigation & Draft – Review and Editing; Nayak B.B: Draft- Review and Editing; Sarika K, Greeshma S.S, Chatterjee N.S: Resources, Editing; Suseela Mathew: Investigation, Draft preparation, Review and Editing; Ravishankar C.N: Investigation

Funding

No funding received.

Data availability

Not applicable.

Code availability

Not applicable.

Compliance with ethical standards

Conflicts of interest

None.

Consent to participate

Not applicable.

Consent for publication

All authors agreed for publishing the manuscript in the present format.

Ethical approval

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Akhtar M, Dickinson E. Whey protein–maltodextrin conjugates as emulsifying agents: an alternative to gum arabic. Food Hydrocoll. 2007;21:607–616. doi: 10.1016/j.foodhyd.2005.07.014. [DOI] [Google Scholar]

- AOAC (2003) Official methods of analysis of AOAC International, 17th edn., revision 2, Vol II (Horwitz W Ed). Association of Official Analytical Chemists (AOAC) International, Gaithersburg, MD

- Botrel DA, de Barros Fernandes RV, Borges SV, Yoshida MI. Influence of wall matrix systems on the properties of spray-dried microparticles containing fish oil. Food Res Int. 2014;62:344–352. doi: 10.1016/j.foodres.2014.02.003. [DOI] [Google Scholar]

- Campelo PH, do Carmo EL, Zacarias RD, Yoshida MI, de Barros Fernandes RV, Borges SV. Effect of dextrose equivalent on physical and chemical properties of lime essential oil microparticles. Ind Crops Prod. 2019;102:105–114. doi: 10.1016/j.indcrop.2017.03.021. [DOI] [Google Scholar]

- Cao Y, Zhang F, Guo P, Dong S, Li H. Effect of wheat flour substitution with potato pulp on dough rheology, the quality of steamed bread and in vitro starch digestibility. LWT. 2019;111:527–533. doi: 10.1016/j.lwt.2019.01.034. [DOI] [Google Scholar]

- Dordoni R, Duserm Garrido G, Marinoni L, Torri L, Piochi M, Spigno G. Enrichment of whole wheat cocoa biscuits with encapsulated grape skin extract. Int J Food Sci. 2019;2019:1–11. doi: 10.1155/2019/9161840. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Einhorn-Stoll U, Ulbrich M, Sever S, Kunzek H. Formation of milk protein–pectin conjugates with improved emulsifying properties by controlled dry heating. Food Hydrocoll. 2005;19:329–340. doi: 10.1016/j.foodhyd.2004.07.005. [DOI] [Google Scholar]

- Folch J, Lees M, Stanley GS. A simple method for the isolation and purification of total lipides from animal tissues. J Biol Chem. 1957;226:497–509. doi: 10.1016/S0021-9258(18)64849-5. [DOI] [PubMed] [Google Scholar]

- Furlán LTR, Padilla AP, Campderrós ME. Improvement of gluten-free bread properties by the incorporation of bovine plasma proteins and different saccharides into the matrix. Food Chem. 2015;170:257–264. doi: 10.1016/j.foodchem.2014.08.033. [DOI] [PubMed] [Google Scholar]

- Ijah UJJ, Auta HS, Aduloju MO, Aransiola SA. Microbiological, nutritional, and sensory quality of bread produced from wheat and potato flour blends. Int J Food Sci. 2014;2014:1–6. doi: 10.1155/2014/671701. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jafari SM, Assadpoor E, He Y, Bhandari B. Encapsulation efficiency of food flavours and oils during spray drying. Dry Technol. 2008;26:816–835. doi: 10.1080/07373930802135972. [DOI] [Google Scholar]

- Kim SK, Karadeniz F (2012) Biological importance and applications of squalene and squalane. In Advances in food and nutrition research (pp. 223–233). Academic Press. [DOI] [PubMed]

- Lekshmi RGK, Chatterjee NS, Tejpal CS, Vishnu KV, Anas KK, Asha KK, Anandan R, Mathew S. Evaluation of chitosan as a wall material for microencapsulation of squalene by spray drying: Characterization and oxidative stability studies. Int J Biol Macromol. 2017;104:1986–1995. doi: 10.1016/j.ijbiomac.2017.03.114. [DOI] [PubMed] [Google Scholar]

- Lekshmi RGK, Rahima M, Chatterjee NS, Tejpal CS, Anas KK, Vishnu KV, Sarika K, Asha KK, Anandan R, Mathew S. Chitosan-whey protein as efficient delivery system for squalene: characterization and functional food application. Int J Biol Macromol. 2019;135:855–863. doi: 10.1016/j.ijbiomac.2019.05.153. [DOI] [PubMed] [Google Scholar]

- Marco C, Rosell CM. Bread making performance of protein enriched, gluten-free breads. Eur Food Res Technolo. 2008;227:1205–1213. doi: 10.1007/s00217-008-0838-6. [DOI] [Google Scholar]

- Martins SI, Jongen WM, Van Boekel MA. A review of maillard reaction in food and implications to kinetic modelling. Trends Food Sci Technol. 2000;11:364–373. doi: 10.1016/S0924-2244(01)00022-X. [DOI] [Google Scholar]

- Metcalfe LD, Schmitz AA, Pelka JR. Rapid preparation of fatty acid esters from lipids for gas chromatographic analysis. Anal Chem. 1966;38:514–515. doi: 10.1021/ac60235a044. [DOI] [Google Scholar]

- Muller HG, Tobin G (1980) Nutrition and food processing. Croom Helm

- Nelson AL. Sweeteners: alternative, 59–75. American Association of Cereal Chemists: Eagan Press, St. Paul, MN; 2000. [Google Scholar]

- Saifullah M, Shishir MRI, Ferdowsi R, Rahman MRT, Van Vuong Q. Micro and nano encapsulation, retention and controlled release of flavor and aroma compounds: a critical review. Trends Food Sci Technol. 2019;86:230–251. doi: 10.1016/j.tifs.2019.02.030. [DOI] [Google Scholar]

- Santhanam AK, Lekshmi M, Chouksey MK, Tripathi G, Gudipati V. Delivery of omega-3 fatty acids into cake through emulsification of fish oil-in-milk and encapsulation by spray drying with added polymers. Dry Technol. 2015;33:83–91. doi: 10.1080/07373937.2014.934832. [DOI] [Google Scholar]

- Sanz T, Salvador A, Baixauli R, Fiszman SM. Evaluation of four types of resistant starch in muffins. II Effects in texture, colour and consumer response. Eur Food Res Technol. 2009;229:197–204. doi: 10.1007/s00217-009-1040-1. [DOI] [Google Scholar]

- Saranraj P, Geetha M. Microbial spoilage of bakery products and its control by preservatives. Int J Pharm. 2012;3:38–48. [Google Scholar]

- Shaabani S, Yarmand MS, Kian H, Emam-Djomeh Z. The effect of chickpea protein isolate in combination with transglutaminase and xanthan on the physical and rheological characteristics of gluten free muffins and batter based on millet flour. LWT. 2018;90:362–372. doi: 10.1016/j.lwt.2017.12.023. [DOI] [Google Scholar]

- Takeungwongtrakul S, Benjakul S. Biscuits fortified with micro-encapsulated shrimp oil: characteristics and storage stability. J Food Sci Technol. 2017;54:1126–1136. doi: 10.1007/s13197-017-2545-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Takeungwongtrakul S, Benjakul S, Aran H. Characteristics and oxidative stability of bread fortified with encapsulated shrimp oil. Ital J Food Sci. 2015;27:476–486. doi: 10.1007/s13197-017-2545-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Turasan H, Sahin S, Sumnu G. Encapsulation of rosemary essential oil. LWT. 2015;64:112–119. doi: 10.1016/j.lwt.2015.05.036. [DOI] [Google Scholar]

- Umesha SS, Manohar RS, Indiramma AR, Akshitha S, Naidu KA. Enrichment of biscuits with microencapsulated omega-3 fatty acid (Alpha-linolenic acid) rich garden cress (Lepidium sativum) seed oil: physical, sensory and storage quality characteristics of biscuits. LWT. 2015;62:654–661. doi: 10.1016/j.lwt.2014.02.018. [DOI] [Google Scholar]

- Wählby U, Skjöldebrand C. Reheating characteristics of crust formed on buns, and crust formation. J Food Eng. 2002;53:177–184. doi: 10.1016/S0260-8774(01)00154-6. [DOI] [Google Scholar]

- Witczak M, Korus J, Ziobro R, Juszczak L. The effects of maltodextrins on gluten-free dough and quality of bread. J Food Eng. 2010;96:258–265. doi: 10.1016/j.jfoodeng.2009.07.022. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Not applicable.

Not applicable.