Abstract

In the current research, the possibility of using carob powder as a substitute for cocoa powder in milk and dark compound chocolates was investigated. Five chocolate samples containing carob powder (20, 40, 60, 80 and 100%) along with control were produced and the physico-chemical analyzes were measured. Chocolate samples were assessed for sensory acceptance by a hedonic scale. The outcomes indicated that chocolate formulations with lower content of carob powder presented higher quality in terms of color parameters, mean particle size and hardness (values close to control). The addition of carob powder resulted in decreased yield stress in dark chocolates. Also dark chocolate formulations containing high levels of carob powder recorded Casson viscosity values similar to control. Moreover, the milk chocolates containing 40% carob powder illustrated no significant differences in sensory properties with control. However acceptance of the dark chocolate samples was similar to control in all attributes. The results proved that it is possible to utilize carob powder to replace cocoa powder in chocolate production in order to improve nutritional values (higher fiber and fewer calories) with agreeable sensory attributes.

Electronic supplementary material

The online version of this article (10.1007/s13197-020-04943-z) contains supplementary material, which is available to authorized users.

Keywords: Carob powder, Chocolate, Substitute, Sensory attributes, Casson viscosity

Introduction

Nowadays, research on novel food products is intended to amend the nutritional quality of products and to join consumer demand for foods. The properties of the new replacers should downgrade the impacts of replacement and end in product that has an appropriate color, good texture and a palatable flavor (Borges et al. 2006).

Carob powder is recently used as an alternative in many products such as chocolate, and it contains 0.4–1.3% fat (Gubbuk et al. 2010). It is considered a natural sweetener and has an appearance and aroma analogous to chocolate therefore it is widely applied in the food professions as a cocoa replacement in different products such as, drinks, ice cream, cakes and candies (Pereira et al. 2011). Carob powder owns a high concentration of dietetic fibers, and it can be categorized as product with high fiber (Santos et al. 2015). It contains a high level of sugars (40.69–57.74%), desirable content of protein (3.07–4.42%) and low amount of fat (0.45–0.86%) (Sigge et al. 2011). Carob possesses some benefits as a cocoa substitute in chocolate. It is also found that carob contains greater calcium and do not possess the addictive attributes of chocolate such as caffeine. Thus it makes an excellent substitute for cocoa in formulations.

The constant increase of prices and resource constraint of cocoa because of high worldwide demand motivated some companies to develop cocoa substitutes. The utilization of carob flour for cocoa replacement in milk chocolate productions has been assessed lately (Salem and Fahad 2012). The results indicated that there were no remarkable differences in the aroma of the milk chocolate with increasing carob flour levels. Rosa et al. (2015) studied the influence of using carob flour for the production of gluten-free cakes. The sensory properties illustrated no considerable differences for the samples with substitution of up to 75% of cocoa powder by carob flour. Srour et al. (2018) used the carob powder in milk beverage production as a replacement for chocolate. The samples containing carob powder illustrated higher polyphenolic content and antioxidant activity. Moreover, the samples possessing the carob powders obtained higher sensory scores from the panelists.

In the current study milk and dark compound chocolates were prepared with carob powders and the influence of substituting cocoa powder with carob powder on the physicochemical and sensory properties were evaluated.

Materials and methods

Materials

Raw materials for chocolate production were supplied from Elvan Gıda. Carob pod powder was purchased from the local market (Bağdat Baharat, Ankara, Turkey). The chemical composition of the cocoa and carob powder used is indicated in S1.

Preparation of compound chocolate

The chocolates were produced according to the general formulation presented in Table 1 (Beckett 2009). Compound chocolate samples containing carob powder were produced by substituting 100%, 80%, 60%, 40%, 20%, 0% cocoa powder in the formulation. Ball mill was used for chocolate production. The palm oil was melted at 40 °C and mixed with the powdered raw materials which were homogeneously mixed. Then the mixture was poured into the ball mill at 40–45 °C before and subjected to refining process at 8 rpm. The total refining process was two hours. After 2 h, the temperature of the mass (45 °C) was reduced to 37 °C. Then chocolate was poured into the moulds and placed to the air conditioning cabinet (0% humidity level, 10 °C) for half an hour and at the end of this period samples was removed from the moulds. The finished chocolates were wrapped in aluminum foil and stored at 25 °C for one week before analyzed. Production flow chart of the compounds chocolate is stated in S2. The chocolate samples were produced in triplicate.

Table 1.

Formulation of milk and dark compound chocolate (g/100 g)

| Raw materials | Milk compound chocolate | Dark compound chocolate |

|---|---|---|

| Cacao | 7 | 13 |

| Powdered sugar | 41.45 | 54.45 |

| Palm oil | 32 | 32 |

| Whey powder | 10 | – |

| Milk powder | 9 | – |

| Lecithin | 0.4 | 0.4 |

| PGPR | 0.1 | 0.1 |

| Ethyl vanillin | 0.02 | 0.02 |

| Salt | 0.03 | 0.03 |

Color measurements

Color of samples was determined using a colorimeter (Chroma Meter CR-400, Konica Minolta, Japan). The color expressed in terms of the CIELAB system L* (luminance ranging from 0 (black) to 100 (white)), a* (green to red) and b* (blue to yellow). Also chroma (C*) and hue (h0) values were determined. Prior to the measurements, the device was calibrated with a standard white tile. Mean values from 3 replicate measurements and standard deviations were calculated.

Hardness

Hardness values of samples were determined by applying Texture Analyzer (Stable Micro Systems, TA-XT-plus, UK). 5 kg load cell was used and the force required to break chocolate samples (size 80 × 40 × 4 mm) was determined using 3 point bending apparatus. The pre-test speed, test speed and post-test speed used during texture analysis were 1.00 mm/s, 1.00 mm/s and 10.00 mm/s, respectively. Before hardness measurements, chocolate samples were placed in a refrigerated incubator for 2 h and the temperature was set at 20 °C. Mean values from 5 replicate assessments were assessed.

Mean particle size

After refining, the mean particle size of the compound chocolate samples was determined applying a micrometer device (Mitutoyo, Manufacturing Co. Ltd., Japan). Approximately 2 g of chocolate at 45 °C was dispersed in white mineral oil before being placed in an optical micrometer and a mean particle size was measured. Mean values from 10 replicate assessments were assessed.

Rhelogical properties

Rheological properties of the molten chocolates were measured applying a rheometer (Anton Paar, MCR302, Austria). The samples were melted at 45 °C for 60 min and pre-sheared (10 min, shear rate = 5 s−1) at 40 °C before measurement cycles started. Then, shear stress was specified as a function of shear rate over a broad range 2 to 50 s−1 (Oba et al. 2017). Mean values from 3 replicate measurements and standard deviations were calculated.

Sensory anaylsis

Sensory attributes (hardness, aroma, odor, sweetness, appearance, color, melting in the mouth, mouth feel and general acceptance) of the chocolates were determined with one-way ANOVA which was used to determine considerable differences between different formulations (Shah et al. 2010). The sensory analysis was performed by 27 trained panelists. Responses were recorded using a hedonic scale where the trained panelists scored from 1 to 5 for different attributes mentioned above (1 = detective product, 2 = dislike, 3 = tolerable quality, 4 = desired quality, 5 = extremely desired quality). Samples were coded with randomly selected three-digit numbers. Approval for the study was obtained from the Ethics Committee of the Scientific and Technological Research Council of Turkey (TUBITAK) (Project No. 1139B411802256), and written satisfaction was given by all candidates.

Statistical analysis

Statistical analysis was performed using Minitab 16 and the level of significance was preset at p < 0.05. The results were analyzed using the Tukey’s test. MATLAB software (v. R2012a) was used for the fitting the rheological data to the mentioned four rheological models.

Results and discussion

Color properties

Color parameters of milk and dark compound chocolates prepared with different concentrations of carob powders were presented in Table 2. Replacing cocoa powder with carob powder did not change lightness in milk chocolates (p > 0.05). There were no remarkable differences in the lightness of the product when increasing carob amounts (p > 0.05). Regarding the parameters of a* and C* were decreased in line with the increased replacement of cocoa powder. Color parameters values for chocolate samples produced with 20% carob powder were close to control samples. It can be observed that the samples with lower concentrations of carob powder (20% carob powder), showed higher color parameters.

Table 2.

Color properties of milk and dark compound chocolates made with different proportions of carob powder

| Type of chocolate | Chocolate samples | L* | a* | b* | C* | h0 |

|---|---|---|---|---|---|---|

| Milk chocolate | Control | 47.29 ± 0.14a | 9.94 ± 0.09a | 8.05 ± 0.09a | 12.78 ± 0.12a | 39.01 ± 0.17c |

| 100% Carob powder | 47.44 ± 0.22a | 8.82 ± 0.12c | 7.68 ± 0.12a,b | 11.69 ± 0.17b | 41.06 ± 0.23a | |

| 80% Carob powder | 47.35 ± 0.32a | 8.86 ± 0.13c | 7.57 ± 0.26a,b | 11.65 ± 0.26b | 40.54 ± 0.62a,b | |

| 60% Carob powder | 46.91 ± 0.68a | 8.89 ± 0.39b,c | 7.28 ± 0.75b | 11.49 ± 0.76b | 39.22 ± 1.82b,c | |

| 40% Carob powder | 46.82 ± 0.15a | 9.20 ± 0.11b | 7.39 ± 0.22b | 11.80 ± 0.22b | 38.75 ± 0.52c | |

| 20% Carob powder | 46.86 ± 0.44a | 9.82 ± 0.14a | 8.04 ± 0.19a | 12.64 ± 0.28a | 39.31 ± 0.32b,c | |

| Dark chocolate | Control | 38.76 ± 0.47a | 8.29 ± 0.26a | 9.95 ± 0.59a | 12.95 ± 0.49a | 50.19 ± 0.43c |

| 100% Carob powder | 38.79 ± 0.78a | 5.44 ± 0.25d | 8.52 ± 0.68b.c | 10.11 ± 0.67c | 57.37 ± 1.48a | |

| 80% Carob powder | 37.17 ± 0.68b | 6.34 ± 0.24c | 8.08 ± 0.43c | 10.27 ± 0.48c | 51.86 ± 0.74b | |

| 60% Carob powder | 38.48 ± 0.63a | 7.26 ± 0.27b | 9.44 ± 0.56a,b | 11.90 ± 0.59a,b | 52.42 ± 0.86b | |

| 40% Carob powder | 37.99 ± 0.71a,b | 7.34 ± 0.38b | 9.07 ± 0.64a,b,c | 11.67 ± 0.73b | 51.01 ± 0.68b,c | |

| 20% Carob powder | 37.95 ± 0.56a,b | 7.62 ± 0.35b | 9.46 ± 0.49a,b | 12.15 ± 0.60a,b | 51.17 ± 0.40b,c |

L* lightness, a* green to red, b* blue to yellow, C* chroma, h0 hue

Different letters within columns indicate significant differences (P < 0.05)

High amounts for a* and chroma indicated chocolates with a dark color. As the substitution of cocoa by carob decreased, a* and chroma increased and accordingly the darkening of the chocolates occurred. Three color parameters, basically a*, C* and b* values, diminished with utilizing carob as cocoa substitute. b* values for samples produced with 20%, 80% and 100% carob powder were not notably different from control but were notably different from other chocolates (p < 0.05).

According to the results of sensory analysis, the most favorable sample contained 40% carob which the color values were not different from the control sample. In addition, when all chocolate samples were compared with the control sample, it was concluded that the chroma, hue, a* and b* values were not very different from each other. It was finalized that the compositional diversity plays an important function in color attributes of the final product.

Rosa et al. (2015) evaluated the influence of replacing cocoa powder by carob flour (with 0, 25, 50, 75 and 100%) in gluten-free cakes. Results indicated that the cake prepared with 100% carob was darker in color in comparison to other samples. The increase in carob flour increased the chroma and a* value and decreased the b* value. The samples containing lower carob content (the control and the sample containing 25% carob), indicated higher b* values. Hu et al. (2017) stated that the color attributes of a food can be influenced by absorptivity and scattering elements. Also the structure of the surface of chocolates has an important role in visual quality appearance (Briones et al. 2006).

Hardness

The results for the hardness values of milk chocolates are presented in Table 3. The hardness results indicated that the control chocolate varied statistically from the other samples. Among the chocolate samples, control formulations containing cocoa powder illustrated the least hardness values with a mean value of 4.41 N (Table 3). Chocolate samples with 60% carob powder were the hardest (average value of 8.23 N).

Table 3.

Hardness values and mean particle size of milk and dark compound chocolates made with different proportions of carob powder

| Type of chocolate | Chocolate samples | Hardness (N) | Mean particle size (µm) |

|---|---|---|---|

| Milk chocolate | Control | 4.41 ± 1.78b | 22.4 ± 3.62b |

| 100% Carob powder | 8.19 ± 0.63a | 33.4 ± 4.52a | |

| 80% Carob powder | 7.70 ± 0.39a | 27.7 ± 5.07b | |

| 60% Carob powder | 8.23 ± 1.01a | 25.8 ± 4.10b | |

| 40% Carob powder | 6.43 ± 0.69a,b | 26.7 ± 4.90b | |

| 20% Carob powder | 7.22 ± 1.66a | 22.9 ± 2.07b | |

| Dark Chocolate | Control | 4.40 ± 0.48c | 22.0 ± 2.0c |

| 100% Carob powder | 2.89 ± 0.43d | 34.8 ± 1.9b | |

| 80% Carob powder | 6.41 ± 0.50a | 46.4 ± 4.6a | |

| 60% Carob powder | 5.73 ± 0.73a,b | 36.0 ± 2.8b | |

| 40% Carob powder | 5.42 ± 0.31b | 34.4 ± 2.3b | |

| 20% Carob powder | 4.08 ± 0.20c | 33.0 ± 1.7b |

L* lightness, a* green to red, b* blue to yellow, C* chroma, h0 hue

Different letters within columns indicate significant differences (P < 0.05)

The differences in hardness can be associated with the internal structure and more intermolecular bonds in chocolate samples prepared with carob powder. Since carob powder addition enhanced the fiber and carbohydrates of the produced samples, these compounds may act with the other compounds in chocolate (sugar, cellulose compounds) and make more intermolecular bonds. Any alterations in raw compounds such as proteins and dietary fibers results in texture and quality modifications (Dhingra et al. 2012).

In dark chocolates the greatest hardness values were noticed for samples with 80% carob content (6.41 N) (Table 3). The current result indicated that fiber addition lead to hardening of chocolate. It can be seen that the dark chocolates containing 100% carob powder showed the lowest hardness. The samples containing 20% carob powder showed no significant differences with control.

In dark chocolate, due to the absence of some ingredients such as milk powder, the possibility of interaction of carob compounds with chocolate ingredients was reduced. This might decrease the hardness values of dark chocolates in comparison to milk chocolates. Therefore formulations containing 100% carob powder recorded the least hardness values (average value of 2.89 N). One of the main reasons of this phenomenon may be due to the larger particle size of the carob powder.

Padilha et al. (2010) reported that high fiber content absorbs more water, which can lead to a reduction in quality of some of the technological characteristics of products, such as elasticity, cohesiveness, firmness and conformation. In the study of Tsatsaragkou et al (2012) carob flour in different proportions (%5, 10% and 15%) were used in production of gluten free breads. Results indicated that an increase in the water and carob flour content lead to a softening of the crumb. The greatest crumb firmness values were noticed in breads with 5% carob content. Wang et al. (2002) reported that the addition of carob fiber gives a softer bread crumb, although fiber addition usually leads to crumb hardening.

Mean particle size

Mean particle size of milk compound chocolate were found to be < 35 μm with control sample containing the smallest and 100% carob powder containing the largest size (Table 3). Particle size of the samples were in the admitted range (< 35 μm) stated for chocolate (Homayouni Rad et al. 2019). However in dark chocolates, samples containing 60% and 80% carob powder recorded higher mean particle size. One reason may be due to higher moisture level of carob powder used in the chocolates formulations. Water molecules commonly participate in intermolecular hydrogen bonds. Within chocolate production the mentioned groups create intermolecular (non-polar) interactions in chocolate matrix. This ends in particle agglomeration. Therefore, the particle size of the chocolate will not decrease significantly (Rasouli Pirouzian et al. 2016). Biner et al. (2007) have stated that the particle size is mainly determined by the moisture level of the raw ingredients.

The possibility of processing roasted carob powder using different time–temperature combinations has been studied by Yousif and Alghzawi (2000). The results illustrated that the carob powders is characterized by a larger particle size than that of the cocoa powders which might adversely affect their incorporation in formulated food products. The failure to reach a smaller particle size for the carob powder might be ascribed to their high sugar, moisture and aw values compared with cocoa powder.

Rheological properties

Chocolate rheology is generally quantified in manufacturing processes using two parameters: yield stress and plastic viscosity. Yield stress is a material property which defines the transition from elastic to viscous deformation. Plastic viscosity determines pumping characteristics, filling of rough surfaces, coating and sensory character of chocolate mass. The determination of rheological properties of chocolate is important in manufacturing processes for obtaining high-quality products with well-defined texture. Factors such as fat content, moisture content, particle size distribution, emulsifiers, conching time, and temperature influence the rheological properties. Molten chocolate is a non-Newtonian fluid with an apparent yield stress, and it can be described by a number of mathematical models such as Bingham, Herschel–Bulkley, and Casson models (Sokmen and Gunes 2006). The Casson model is a well-known and the most used rheological model for describing the non-Newtonian flow behavior of fluids with a yield stress. The model was developed for viscous suspensions of cylindrical particles. Some fluids are particularly well described by this model because of their nonlinear yield-stress-pseudoplastic nature and chocolate is among those fluids.

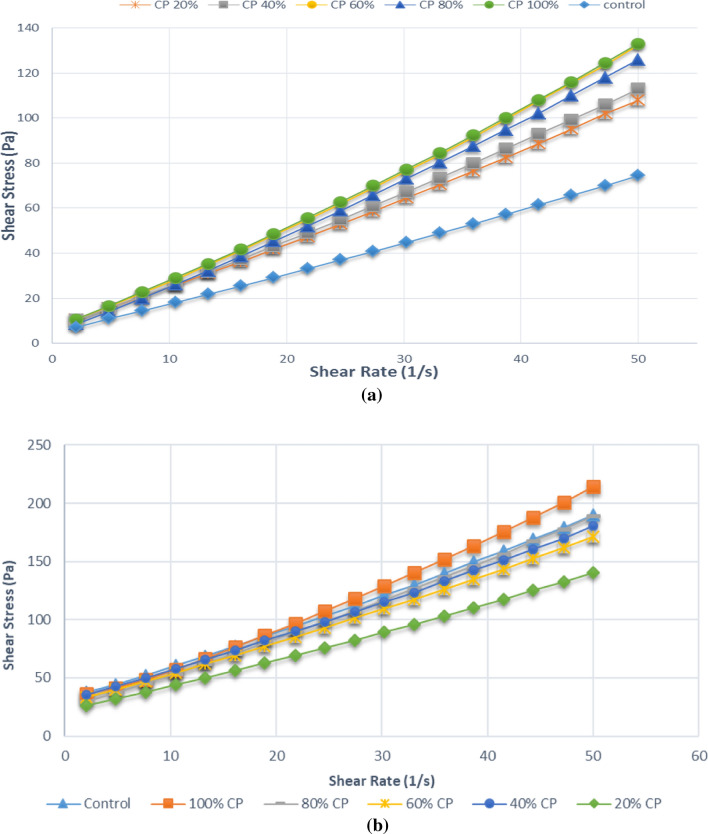

Milk and dark compound chocolates indicated shear thinning behavior (Fig. 1). Using carob powder increased the apparent viscosity of samples. The shear stress vs. shear rate data was fitted with different mathematical models. The Casson model illustrated the best fitting for all the chocolate samples. These findings show that any variation in cocoa content and its replacement with various amounts of carob pod powder cannot affect the thixotropic behaviour of chocolates.

Fig. 1.

Effects of carob powder on shear stress-shear rate rheograms of compound chocolates a milk b dark

Casson plastic viscosity

The Casson plastic viscosities of milk and dark chocolates samples were between 1.08–1.57 Pa s and 1.34–1.80 Pa s respectively (Table 4). Significant differences (p < 0.05) were observed between chocolates. Dark chocolates containing 40%, 60%, 80% and 100% carob powder displayed Casson viscosity values similar to control (p > 0.05). However, the samples with 20% carob powder showed lower viscosity in comparison to others (p < 0.05). In milk chocolates, samples containing 100% and 80% carob powder illustrated the highest Casson viscosity (p < 0.05).

Table 4.

Rheological parameters of milk and dark compound chocolate samples

| Type of chocolate | Chocolate samples | Casson model parameters | ||

|---|---|---|---|---|

| Yield stress τ0 (Pa) | Plastic viscosity ηpl (Pa.s) | R2 | ||

| Milk chocolate | Control | 1.41 ± 0.004c | 1.08 ± 0.006d | 0.9926a |

| 100% Carob powder | 1.40 ± 0.03c | 1.57 ± 0.01a | 0.9872bc | |

| 80% Carob powder | 0.95 ± 0.0006d | 1.57 ± 0.00007a | 0.9893b | |

| 60% Carob powder | 1.41 ± 0.005c | 1.56 ± 0.006a | 0.9850c | |

| 40% Carob powder | 1.67 ± 0.02b | 1.40 ± 0.02b | 0.9890b | |

| 20% Carob powder | 1.80 ± 0.01a | 1.35 ± 0.02c | 0.9893b | |

| Dark chocolate | Control | 6.46 ± 0.41a | 1.80 ± 0.09a | 0.9782a,b |

| 100% Carob powder | 4.72 ± 0.43b | 1.79 ± 0.04a | 0.9721b | |

| 80% Carob powder | 4.44 ± 0.30b | 1.69 ± 0.003a,b | 0.9850a | |

| 60% Carob powder | 5.31 ± 0.09a,b | 1.49 ± 0.05a,b | 0.9851a | |

| 40% Carob powder | 5.55 ± 0.62a,b | 1.53 ± 0.05a,b | 0.9847a | |

| 20% Carob powder | 4.55 ± 0.47b | 1.34 ± 0.18b | 0.9849a | |

L* lightness, a* green to red, b* blue to yellow, C* chroma, h0 hue

Different letters within columns indicate significant differences (P < 0.05)

The level and types of the ingredients applied in the formulation and particle size distribution are the main elements affecting chocolate viscosity (Afoakwa et al. 2007). Increased amounts of carob powder led to an increase in milk chocolate viscosity. An increase in the viscosity can be due to higher moisture level of chocolates including carob powder. In the presence of water, the interactions between particles will increase and this can increase the internal friction ending in higher viscosity. Also the low mean particle size of control samples could be a main reason for the lower values of Casson viscosity (Table 4). In smaller particles with more surface area, more fat will coat the solid particles and reduces the viscosity (Homayouni Rad et al. 2019). The chemical analysis of carob and cocoa powder illustrated that the cocoa powder contained higher fat content (22.57%) compared to carob powder (6.63%). This can be one more reason for high viscosity of chocolate samples containing carob powders.

As a result there was a slight variation in the shear thinning trend and plastic viscosity values. This means that carob presents an ideal cocoa substitute, since it contains various phytochemicals that are similar to those found in cocoa (Loullis and Pinakoulaki 2018).

Casson yield stress

The Casson yield stress of milk and dark chocolates samples were between 0.95–1.80 Pa and 4.44–6.46 Pa.s respectively (Table 4). Remarkable differences (p < 0.05) were observed between chocolates. Control dark chocolate indicated the highest Casson yield value (p < 0.05). The obtained data (Table 4) demonstrated that in dark chocolates the yield stress decreased with the addition of carob powder (p > 0.05).

The mean particle size and thus specific surface area of particles in chocolate suspension influence yield value. The smaller particles increase the surface area of the dispersed particles and therefore, the stronger the particle–particle interactions will be, ending in higher yield values (Beckett 2009). This explains the high yield values for control formulations.

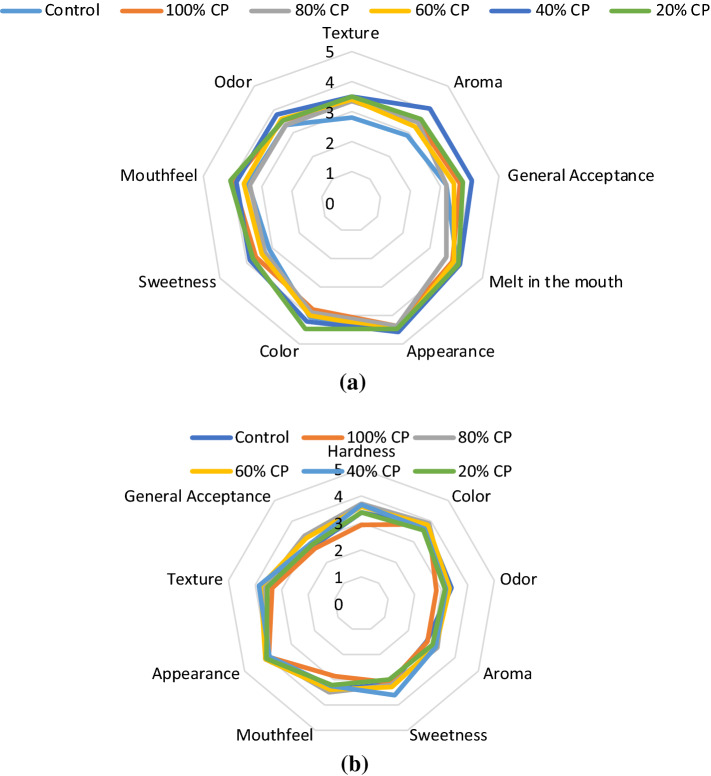

Sensory properties

The results of sensory analysis of milk and dark compound chocolates are shown in Fig. 2a and Fig. 2b respectively. Among milk chocolates, samples containing 40% carob powder obtained the highest scores in the most sensory attributes (odor, aroma, appearance, sweetness, melting and general acceptance) (Fig. 2a). Chocolate including 80% carob powder were determined with the lowest acceptability.

Fig. 2.

Spider chart representing sensory attributes of a milk compound chocolate samples and b dark compound chocolate samples

Cocoa replacement with carob significantly enhanced the texture acceptability while milk chocolate containing cocoa powder illustrated the least hardness acceptability (p < 0.05). The melting rate scores indicated that chocolates with 80% carob powder had considerably (p < 0.05) lower preference than the other samples (Fig. 2a). This may be due to the decrease in the percentage of cocoa powder in the samples and the increase in the percentage of carob powder, which may cause to chocolate melt slowly.

In terms of color, the control sample and formulations prepared with 20% carob powder illustrated the highest mean scores. The formulation with 100% carob powder recorded the lowest acceptability, an element that may have been related with the dark color caused by the carob powder (Silanikove et al. 2006).

In terms of aroma and odor, chocolate formulation containing 40% carob powder differed significantly from the others (p < 0.05). In the research of Fadel et al. (2006) carob pods was applied for production of cocoa substitute via Maillard technology. The sensory analysis illustrated high quality of the cocoa substitute sample. Carob were incorporated in five formulations in South Africa such as, porridge, bread, breakfast cereal, mousse and milk-based drinks and the results indicated acceptable sensory analysis (Iipumbu and Britz 2008). The bioactive ingredients that are present and enhanced by carob powder roasting, guarantees the potential utilization of carob as a cocoa substitute in various food products.

The carob powder was used in milk chocolate formulation (Salem and Fahad 2012). The carob powder enhanced the sensory properties and the nutritional value of the product thus being regarded as a suitable cocoa powder substitute in chocolate production. In another study, cocoa powder was replaced by carob flour (25, 50, 75 and 100%) for production of gluten-free cakes from soy and banana flours (Rosa et al. 2015). The sensory properties indicated no remarkable differences for the cakes with replacement of up to 75% of cocoa powder by carob flour.

In the study of Srour et al. (2016), the samples containing carob powder obtained higher sensory scores from the panelists. That was related to aldehydes, pyrazines, pyridines and ketones.

Results showed no considerable differences on the acceptance of the dark chocolates produced with cocoa powder and carob powder (p > 0.05). The high scores of all examined sensory attributes (Fig. 2b) indicated the high quality of the dark chocolate samples prepared with carob powder.

Conclusion

The outcomes of the current study proved that it is feasible to prepare chocolates with carob powder with high dietary fiber. The chocolate samples with lower concentrations of carob powder displayed satisfactory physicochemical outcomes. In milk compound chocolate using 40% carob powder showed no differences in sensory properties. Also there were no significant differences on the acceptance of the dark chocolates produced with cocoa powder and carob powder (p > 0.05). Carob powder possesses lower content of fat and remarkably higher contents of dietary fiber in comparison to cocoa. The lower fat level of carob induces fewer calories and the high dietary fiber level suggests several health benefits. As a whole, the nutritional and economic advantages of carob make it an appropriate nomination for the replacement of cocoa.

Supplementary information

Below is the link to the electronic supplementary material.

Acknowledgement

This work was funded by the Scientific and Technological Research Council of Turkey (TUBITAK), Project No. 1139B411802256.

Compliance with ethical standards

Conflict of interest

There are no conflicts to declare.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Afoakwa E, Paterson A, Fowler M. Factors influencing rheological and textural qualities in chocolate – a review. Trends Food Sci Technol. 2007;18:290–298. doi: 10.1016/j.tifs.2007.02.002. [DOI] [Google Scholar]

- Beckett ST. Industrial chocolate manufacture and use. United Kingdom: Blackwell Publishing; 2009. [Google Scholar]

- Biner B, Gubbuk H, Karhan M, Aksu M, Pekmezci M. Sugar profiles of the pods of cultivated and wild types of carob bean (Ceratonia Siliqua L) in Turkey. Food Chem. 2007;100:1453–1455. doi: 10.1016/j.foodchem.2005.11.037. [DOI] [Google Scholar]

- Borges JT, Pirosi M, Della Lucia S, Pereira P, Moraes A, Castro V. Utilização de farinha mista de aveia e trigo na elaboração de bolos. Bol do CEPPA Curitiba. 2006;24:145–162. [Google Scholar]

- Briones V, Aguilera JM, Brown C. Effect of surface topography on color and gloss of chocolate samples. J Food Eng. 2006;77:776–783. doi: 10.1016/j.jfoodeng.2005.08.004. [DOI] [Google Scholar]

- Dhingra D, Michael M, Rajput H, Patil RT. Dietary fibre in foods: a review. J Food Sci Technol. 2012;49:255–266. doi: 10.1007/s13197-011-0365-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadel HHM, Abdel Mageed MA, Abdel Samad AKME, Lotfy SN. Cocoa substitute: evaluation of sensory qualities and flavour stability. Eur Food Res Technol. 2006;223:125–131. doi: 10.1007/s00217-005-0162-3. [DOI] [Google Scholar]

- Gubbuk H, Kafkas E, Guven D, Gunes E. Physical and phytochemical profile of wild and domesticated carob (Ceratonia siliqua L.) genotypes. Span J Agric Res. 2010;8:1129–1136. doi: 10.5424/sjar/2010084-1209. [DOI] [Google Scholar]

- Homayouni Rad A, Rasouli Pirouzian H, Konar N, Toker OS, Genc Polat D. Effects of polyols on the quality characteristics of sucrose-free milk chocolate produced in a ball mill. RSC Adv. 2019;9:29676–29688. doi: 10.1039/C9RA04486H. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hu YT, Ting Y, Hu JY, Hsieh SC. Techniques and methods to study functional characteristics of emulsion systems. J Food Drug Anal. 2017;25:16–26. doi: 10.1016/j.jfda.2016.10.021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Iipumbu LSGO, Britz TJ. Compositional analysis of locally cultivated carob (Ceratonia Siliqua) cultivars and development of nutritional food products for a range of market sectors. Stellenbosch: Stellenbosch University; 2008. [Google Scholar]

- Loullis A, Pinakoulaki E. Carob as cocoa substitute: a review on composition, health benefits and food applications. Eur Food Res Technol. 2018;244:959–977. doi: 10.1007/s00217-017-3018-8. [DOI] [Google Scholar]

- Oba S, Toker OS, Palabiyik İ, Konar N, Goktas H, Cukur Y, Artik N, Sagdic O. Rheological and melting properties of sucrose-free dark chocolate. Int J Food Prop. 2017;20:2096–2106. doi: 10.1080/10942912.2016.1230872. [DOI] [Google Scholar]

- Padilha V, Rolim PM, Salgado SM, Livera A, Andrade SA, Guerra N. Perfil sensorial de bolos de chocolate formulados com farinha de yacon (smallanthus sonchiflus) Ciencia Techol Alime. 2010;30:735–740. doi: 10.1590/S0101-20612010000300026. [DOI] [Google Scholar]

- Pereira CAM, Sabatini DR, Silva KM, Picinin ME, Del Santo V, Souza GB. Composição centesimal e mineral da alfarroba em pó e sua utilização na elaboração e aceitabilidade em sorvete. Alim Nutr. 2011;22:129–136. [Google Scholar]

- Rasouli Pirouzian H, Peighambardoust SH, Azadmard Damirchi S. Sucrose–free milk chocolate sweetened with different bulking agents: effects on physicochemical and sensory properties. BFIJ. 2016;8:340–349. [Google Scholar]

- Rosa CS, Tessele K, Prestes RC, Silveira M, Franco F. Effect of substituting of cocoa powder for carob flour in cakes made with soy and banana flours. Int Food Res J. 2015;22:2111–2118. [Google Scholar]

- Salem EM, Fahad AO. Substituting of cacao by carob pod powder in milk chocolate manufacturing. Aust J Basic Appl Sci. 2012;6:572–578. [Google Scholar]

- Santos LM, Tulio LT, Campos LF, Dorneles MR, Krüger CCH. Glycemic response to carob (Ceratonia siliqua L) in healthy subjects and with the in vitro hydrolysis index. Nutr Hosp. 2015;31:482–487. doi: 10.3305/nh.2015.31.1.8011. [DOI] [PubMed] [Google Scholar]

- Shah AS, Jones GP, Vasiljevic T. Sucrose-free chocolate sweetened with Stevia rebaudiana extract and containing different bulking agents effects on physicochemical and sensory properties. Int J Food Sci Technol. 2010;45:1426–1435. doi: 10.1111/j.1365-2621.2010.02283.x. [DOI] [Google Scholar]

- Sigge GO, Lipumbu L, Britz TJ. Proximate composition of carob cultivars growing in South Africa. S Afr J Plant Soil. 2011;28(1):17–22. doi: 10.1080/02571862.2011.10640008. [DOI] [Google Scholar]

- Silanikove N, Landau SOD, Kababya D, Brukental I, Nitsan Z. Analytical approach and effects of cndensed tannins in carob pods (Ceratonia siliqua) on feed intake on the digestive and metabolic responses of kids. J Livest Sci. 2006;99:29–38. doi: 10.1016/j.livprodsci.2005.05.018. [DOI] [Google Scholar]

- Sokmen A, Gunes G. Influence of some bulk Sweeteners on rheological properties of chocolate. LWT Food Sci Technol. 2006;39:1053–1058. doi: 10.1016/j.lwt.2006.03.002. [DOI] [Google Scholar]

- Srour N, Daroub H, Toufeili I, Olabi A. Developing a carob-based milk beverage using different varieties of carob pods and two roasting treatments and assessing their effect on quality characteristics. J Sci Food Agric. 2016;96:3047–3057. doi: 10.1002/jsfa.7476. [DOI] [PubMed] [Google Scholar]

- Tsatsaragkou T, Yiannopoulos S, Kontogiorgi A, Poulli E, Krokida M, Mandala I. Mathematical approach of structural and textural properties of gluten free bread enriched with carob flour. J Cereal Sci. 2012;56:603–609. doi: 10.1016/j.jcs.2012.07.007. [DOI] [Google Scholar]

- Wang J, Rosell CM, de Barber CB. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002;79:221–226. doi: 10.1016/S0308-8146(02)00135-8. [DOI] [Google Scholar]

- Yousif AK, Alghzawi HM. Processing and characterization of carob powder. Food Chem. 2000;69:283–287. doi: 10.1016/S0308-8146(99)00265-4. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.