Abstract

The precombustion washing and washability of coal are increasingly gaining attention as a clean coal technology in China. In this study, the raw coal was collected from different coal seams in the south of Qinshui Coalfield, and flotation experiments were carried out in the laboratory after simple crushing. X-ray diffraction was used for qualitative analysis of the minerals in coal, and mineral morphology and disseminated particle size were measured with the help of an optical microscope. The samples were characterized to determine the original mineral content, combination type, occurrence characteristics, and dissemination type in coals of different lithotypes to establish a relationship with the coal-forming environment and to evaluate coal selectivity from a geological perspective. The results were obtained from the float–sink experiment by which the coal washability of different lithotypes is evaluated, combined with the information resulting from investigating the change law of the mineral occurrence and dissemination characteristics of the raw coal and the clean coal before and after the flotation experiment. The content of minerals with the particle size larger than 200 μm accounts for 35–50% of the easy-to-wash coal. The particles were mostly concentrated in the 50–100 μm size range in moderate difficulty washability coal, and the mineral occurrence forms are diverse. The disseminated particle size distribution of 10–20 μm in the refractory washability coal is between 35 and 45%, and the massive and fracture filling minerals are rarely found in the coal. The proportion of minerals smaller than 2 μm in the extremely difficult washability coal is more than 60%, and cell filling, dispersed, and banding forms are plentiful in this type of coal. The removal rates of ash and sulfur obtained through elution match well with the mineral form and distribution characteristics. The reason for the difference was the influence of the coal-forming environment on the occurrence of minerals in coal, which led to the removal of minerals in the coal washing procedure. The process is controlled by the occurrence and dissemination characteristics of minerals.

Introduction

China is the largest global consumer of coal and uses approximately 50% of total mining production in the world. The large-scale coal industry laid the foundation for rapid economic development in China.1−3 Nearly 80% of the energy required for power generation, 70% of raw chemical materials, and 60% of energy consumed in commerce are provided by coal.4,5 This energy structure determines the characteristics of coal-based energy consumption in China. The large-scale use of coal has been an important driver of economic development. However, coal is considered a “dirty” fuel that seriously impacts the environment.6,7 At present, the proportion of non-high-quality coals such as high-ash and high-sulfur coals is relatively high in the coal resource structure of China. Due to the characteristics of high ash and high sulfur in its own endowment, its use is limited to some extent.8,9 The 14th Five-Year Plan for National Energy Science and Technology in 202110 indicates that improving the clean utilization and efficient conversion of coal should be the core of the future development of coal energy. Coal washing is the most economical and effective clean coal technology, which can separate coal and minerals. Coal washing is an effective way to clean coal and significantly reduce environmental pollution by improving the utilization efficiency of coal. The focus of coal washing is to remove the minerals in the coal.11 The occurrence and distribution characteristics of the minerals in the coal are the fundamental factors that affect the coal washability. At present, the development of coal preparation is mainly focused on process selection,12−16 and the influence of geological factors such as mineral genesis, occurrence, and dissemination characteristics in coal has not been fully considered. The existing methods are satisfactory for coal preparation technology but make coalfield prediction, washability exploitation, and the evaluation and prediction of coal seams formed in different coal-accumulating environments complex and difficult.17 From a geological viewpoint, the minerals in coal that have been formed in different environments have different occurrence forms, assemblage characteristics, and dissemination of minerals with macerals, which can directly lead to different mineral removal rates.18−20 In view of the depletion of high-quality coal resources and the urgent need for green utilization of difficult washability coal resources in China, research on the geological control of minerals in the washing process identifies the fundamental factors that affect the selectivity of coal and guides coal industrial washing technology, and improving the removal rate of minerals in coal has very important practical significance. This study uses coal seams in the same region to assess the influencing factors of coal-forming environments on coal washing and analyzes the internal changes from a geological perspective.

Geological Setting

The study area is located in the southeast Qinshui coalfield, Shanxi Province, and the regional tectonic zone is located in the middle of the third uplift belt of the Neocathaysian tectonic system in the Taihang uplift belt in eastern China, which is a large anticlinorium uplift with a steep slope from west to east and the overall extension direction 20–30° east of north. The Taihang belt is parallel to other uplift belts and has an echelon arrangement that is reflected by the orientation of the main axes of the first tectonic belt and in the uplifts, depressions, folds, and fractures of the second, third, and fourth levels.21,22 The primary exposed strata in the region are the lower Ordovician, lower Majiagou, upper Majiagou, and Fengfeng formations of the Middle Ordovician, the Benxi Formation of the Middle Carboniferous, the Taiyuan Formation of the Upper Carboniferous, the Shanxi and lower Shihezi formations of the Lower Permian, and the upper Shihezi Formation of the Upper Permian.21 The Taiyuan Formation (Figure 1) is the principal coal-bearing stratum and includes minable coal seams.22 The Taiyuan Formation is a typical sea-land interbedding facies deposition, which reflects the sedimentary characteristics of the early transgression, high tide, and regressive stages.23−25 The regularly deposited strata can be divided into two basic sequences: coarse to fine grain and fine–coarse grain. The first sequence consists of one to three basic sequences. Coal seams are often found at the top. The bottom of the second type of the sequence is marine limestone underneath mudstone, siltstone, and coal seams at the top of this sequence, which reflects frequent transgression.26

Figure 1.

Tectonic outline and lithology of the study area. (A) Tectonic outline map. (B) Coalfield lithology.

Materials and Methods

Samples and Flotation Experiment

Raw coals were collected following the Chinese Standard Method GB/T482-2008.27 Six raw coal samples were collected from the underground and cut from a volume (10 × 10 × 10 cm) of the Taiyuan Formation of the Upper Carboniferous (Figure 2). The no. 9 and no. 15 coal seams are minable coal seams of Taiyuan Formation in the study area. Study on the mineral characteristics of no. 9 and no. 15 coal seams can compare the difference of dissemination types and the geological factors that cause this difference.

Figure 2.

Columnar coal section.

The particle size of the coal sample was maintained between 0.5 and 0.3 mm to prevent the blocking of the bubble generator. The conventional flotation machine equipment was a laboratory XFD single-slot flotation machine with a tank volume of 0.5 L, impeller speed of up to 2800 rpm, rated main shaft power of 75 W, and a unit air intake of 0.25 m3/h. The feeding coal sample weighed 50 g, and the coal slurry concentration was 100 g/L. The flotation experiment was conducted following the method outlined by GB/T4757-2001.28

Analytical Methods

Proximate analyses were performed on the raw coal samples following the ASTM standards D3173-11,29 D3174-11,30 and D3175-11.31 The sulfur content was determined according to the ASTM standard D3177-02.32 Ash grades were determined according to ISO 11760, 2005,33 and sulfur property grades were classified according to the Chinese Standard Method GB/T 15224.2-2010.34 The contents of the major element oxides in the coal were determined using an Axios mAX X-ray fluorescence spectrometer (XRF) with a voltage and current of 50 kV and 50 mA, respectively. The polished sections were prepared according to the Chinese Standard Method GB/T16773-200835 for coal sample preparation at the China University of Mining and Technology, Beijing. Minerals were analyzed by field emission scanning electron microscopy (SEM) and X-ray energy spectrometry (EDS). To obtain the spatial structure characteristics of the mineral in the original state, the samples were sprayed with carbon to increase the electrical conductivity. After documenting the characteristics of the pyrite and clay minerals, we determined the particle size of the minerals by point counting, and from this, we calculated the volume percentage.

Results and Discussion

Basic Sample Properties

Coal is classified based on its lithotypes according to the standard GB/T 18023-2000.36 To describe clearly and conveniently, bright coal is referred to as BC here, and similarly, semibright coal, semidull coal, and dull coal are represented by SB, SD, and DC abbreviations, respectively.

YQ9-BC, YQ15-BC, and GZ9-BC bright coal were mainly composed of vitrain and clarain (86, 89, and 94% content in the three coals, respectively), with the strongest glossiness among other lithotypes, and a barely visible banded structure. The endogenetic fractures were formed in the samples. Moreover, a conchoidal fracture was detected in the samples.

The content of vitrain and clarain in YQ9-SB semibright coal was 59%, followed by durain and fusain with weaker glossiness. The main feature of semibright coal was the obvious banded structure, and endogenetic fractures were relatively developed with step-like fractures.

GZ9-SD semidull coal was composed of durain and fusain. The vitrain and clarain account for 37% of the composition. The glossiness was weak, and the hardness was large in this type of coal. The semidull coal has a banded structure with uneven fracture patterns and without endogenetic fractures.

GZ9-DC dull coal was mainly composed of durain and fusain, and the content of vitrain and clarain was less than 14%. This type of coal has a massive structure, with barely visible bedding and angular or uneven fractures.

Because the coal in the study area is anthracite, liptinite was not detected in the coal composition. The contents of macerals are shown in Table 1. The composition characteristics of macerals in coal reflect the controlling factors of the mire environment and its evolution. The classification of macerals was based on the ICCP System 1994 (ICCP, 2001).37,38 The most commonly used indexes in the classification of macerals are TPI—Plant tissue preservation index,39 GI—gelatification index,40 GWI—groundwater index, and V/I—vitrinite/inertinite index.41 The TPI values of YQ9-BC and YQ15-BC are 1.04 and 1.12, respectively. The average TPI values of GZ9-BC, GZ9-SD, and GZ9-DC are 1.10. This TPI value indicates that the plant tissues are relatively well preserved. It also represents acidic marsh medium, weak microbial activity, and incomplete gelatinization. The TPI of YQ9-SB is only 0.35, indicating that the medium of mire was alkaline at that time, and the gelification was strong. The GI value is consistent with the trend of TPI, which can better explain the strength of gelification during peat deposition. The GWI values of YQ9-SB, GZ9-DC, and GZ9-SD are between 3.83 and 5.75, which are four times higher than that of YQ9-BC, YQ15-BC, and GZ9-BC (1.13–1.44), which implies that the hydrodynamic conditions and the oxidation of bright coal are weak. The V/I is negatively correlated with GWI, indicating that YQ9-BC, YQ15-BC, and GZ9-BC were formed in a reductive environment.

Table 1. Maceral Composition of the Coals (vol %)a.

| vitrinite |

inertinite |

mineral |

coal

facies parameters |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| samples | T | CT | CD | VD | CG | F | SF | Mac | Fun | ID | Py | Cl | Qz | TPI | GI | GWI | V/I |

| YQ9-BC | 2.2 | 22.4 | 23.8 | 15.6 | 0.6 | 6.0 | 5.0 | 1.8 | 1.0 | 7.4 | 7.6 | 5.0 | 1.6 | 1.04 | 4.23 | 1.44 | 3.80 |

| YQ9-SB | 1.8 | 16.8 | 18.4 | 25.2 | 0.0 | 1.6 | 2.6 | 0.0 | 0.0 | 7.0 | 16.0 | 9.0 | 1.6 | 0.35 | 1.20 | 5.75 | 1.20 |

| YQ15-BC | 3.0 | 23.6 | 33.2 | 8.4 | 0.0 | 5.6 | 7.6 | 4.2 | 0.0 | 4.6 | 7.0 | 1.8 | 1.0 | 1.12 | 3.47 | 1.42 | 3.16 |

| GZ9-DC | 2.4 | 6.4 | 17.8 | 46.2 | 0.0 | 2.4 | 1.0 | 1.0 | 0.0 | 2.0 | 3.0 | 15.0 | 2.8 | 0.94 | 1.02 | 4.20 | 0.98 |

| GZ9-SD | 3.6 | 16.2 | 39.0 | 6.2 | 0.6 | 8.0 | 3.6 | 0.0 | 0.8 | 6.0 | 1.8 | 13.8 | 0.4 | 1.27 | 1.16 | 3.83 | 1.33 |

| GZ9-BC | 1.6 | 31.0 | 30.6 | 16.4 | 0.0 | 4.2 | 1.6 | 0.0 | 0.0 | 4.0 | 4.2 | 6.2 | 0.2 | 1.16 | 4.25 | 1.13 | 4.25 |

YQ9-BC, YQ-9 bright coal; YQ9-SB, YQ-9 semibright coal; YQ15-BC, YQ-15 bright coal; GZ9-BC, GZ-9 bright coal; GZ9-SD, GZ-9 semidull coal; GZ9-DC, GZ-9 dull coal; T, telinite; CT, collotelinite; CD, collodetrinite; VD, vitrodetrinite; CG, corpogelinite; F, fusinite; SF, semifusinite; Mac, macrinite; Fun, funginite; ID, inertodetrinite; Py, pyrite; Cl, clay mineral; and Qz, quartz.

According to the proximate analysis of coal (Table 2), YQ9-BC and GZ9-BC are categorized as medium ash–high sulfur coal, YQ9-SB is moderately high ash–high sulfur coal, YQ15-BC is low ash–high sulfur coal with organic sulfur accounting for 54.15% of total sulfur, GZ9-DC is moderately high ash–medium sulfur coal, GZ9-SD is medium ash–medium sulfur coal, and GZ9 is medium ash–moderately high sulfur coal.

Table 2. Proximate Analysis and Sulfur form of Coal (%)a.

| samples | Mad | Ad | Vdaf | St,d | Sp,d | Ss,d | So,d |

|---|---|---|---|---|---|---|---|

| YQ9-BC | 0.81 | 15.24 | 9.52 | 3.15 | 2.29 | 0.00 | 0.86 |

| YQ9-SB | 0.72 | 26.56 | 16.77 | 4.76 | 3.39 | 0.01 | 1.37 |

| YQ15-BC | 0.67 | 9.92 | 9.66 | 4.34 | 1.92 | 0.08 | 2.35 |

| GZ9-DC | 1.13 | 21.00 | 9.94 | 1.20 | 0.91 | 0.10 | 0.19 |

| GZ9-SD | 0.96 | 17.85 | 12.18 | 1.11 | 0.85 | 0.04 | 0.22 |

| GZ9-BC | 0.88 | 12.83 | 11.16 | 4.59 | 4.02 | 0.03 | 0.54 |

M, moisture; A, ash yield; V, volatile matter; St, total sulfur; Sp, pyrite sulfur; Ss, sulfate sulfur; So, organic sulfur; ad, as-received basis; d, dry basis; and daf, dry and ash-free basis.

According to the chemical analyses of the samples shown in Table 3, the major elements of the raw coals are SiO2, Al2O3, Fe2O3, SO3, and CaO. The content of Na2O in GZ9 coal is higher than that of YQ coal, and the content of TiO2 in YQ9-BC and GZ9-DC coal exceeded 1%, reaching 1.83 and 1.86%, respectively. The content of TiO2 does not exceed 1% in other coals.

Table 3. Major Element Content in the Raw Coal (%)a.

| samples | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | SO3 | P2O5 | Na2O | K2O | MnO2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| YQ9-BC | 44.42 | 28.11 | 16.71 | 2.31 | 0.45 | 1.83 | 1.45 | 0.02 | 0.95 | 0.25 | 0.02 |

| YQ9-SB | 38.05 | 26.59 | 12.58 | 10.20 | 0.35 | 0.82 | 6.69 | 0.02 | 0.51 | 0.19 | 0.06 |

| YQ15-BC | 27.21 | 27.35 | 30.38 | 5.13 | 0.31 | 0.87 | 5.15 | 0.09 | 0.33 | 0.11 | 0.14 |

| GZ9-DC | 54.34 | 30.88 | 6.02 | 1.83 | 0.45 | 1.86 | 1.32 | 0.02 | 1.92 | 0.06 | 0.02 |

| GZ9-SD | 46.16 | 32.64 | 4.80 | 9.24 | 0.38 | 0.96 | 2.32 | 0.01 | 1.40 | 0.04 | 0.03 |

| GZ9-BC | 32.85 | 27.58 | 4.51 | 3.88 | 0.29 | 0.88 | 1.56 | 0.01 | 1.33 | 0.07 | 0.02 |

Occurrence of minerals in coal.

X-ray diffraction (XRD) experiments were performed on six samples to find types and content of minerals in raw coal with more accuracy. XRD analyses of the raw coal samples show that the minerals consist mainly of quartz, pyrite, kaolinite, montmorillonite, and illite (Table 4). The gypsum, dawsonite, anatase, and dolomite only appeared in a few samples. The content of pyrite is very high in YQ9-SB and GZ9-BC.

Table 4. Type and Content of Minerals Detected by XRD (%)a.

| samples | Qtz | Kln | Mnt | Ill | Py | Dol | Cal | Anl | Gp | Daw | Ant |

|---|---|---|---|---|---|---|---|---|---|---|---|

| YQ9-BC | 0.7 | 16.8 | 0.3 | 0.2 | 5.2 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| YQ9-SB | 0.5 | 22.5 | 0.4 | 0.2 | 12.8 | 9.1 | 0.6 | 12.5 | 2.1 | 0.0 | 7.3 |

| YQ15-BC | 0.7 | 9.7 | 0.2 | 0.3 | 7.3 | 0.5 | 0.8 | 1.0 | 2.2 | 0.4 | 0.5 |

| GZ9-DC | 9.0 | 45.8 | 1.2 | 0.9 | 2.5 | 0.0 | 2.4 | 0.2 | 0.0 | 0.0 | 2.3 |

| GZ9-SD | 7.6 | 40.1 | 1.4 | 1.0 | 3.2 | 0.0 | 17.2 | 5.0 | 0.0 | 0.0 | 0.0 |

| GZ9-BC | 1.2 | 15.1 | 0.3 | 0.2 | 16.8 | 0.0 | 5.1 | 0.0 | 0.0 | 0.0 | 0.0 |

Qtz, quartz; Kln, kaolinite; Mnt, montmorillonite; Ill, illite; Py, pyrite; Dol, dolomite; Cal, calcite; Anl, analcite; Gp, gypsum; Daw dawsonite; and Ant, anatase.

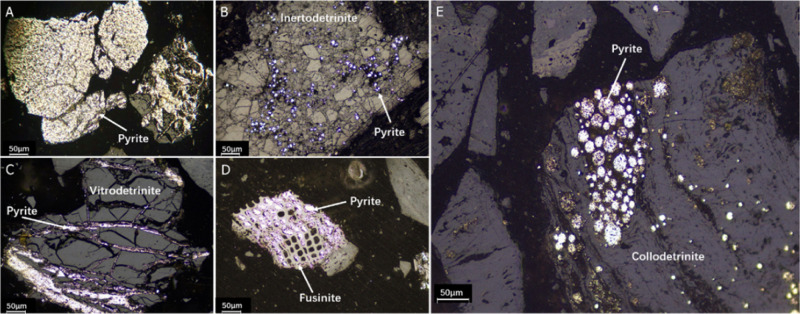

The petrological characteristics of the raw coals were observed under the optical microscope. The characteristics of pyrite and clay minerals were examined at 500× magnification with a reflected-light microscope using oil immersion. Massive pyrite (Figure 3A) was common in raw coal samples. The dissemination size of massive pyrite varied from 100 to 400 μm, and the particle size of some pyrite exceeded 500 μm. A few types of pyrite (Figure 3B) with particle sizes of ∼2–4 μm were uniformly distributed in the inertodetrinite. Fracture-filling pyrite (Figure 3C) generally adopted the shapes of fractures and joints, often cutting various macerals contained in the coal. Cell-filling pyrite (Figure 3D) had no specific form. Framboidal pyrite (Figure 3E), composed of more than 40 pyrite particles (ranging 1–2 μm), was unevenly distributed and associated with macerals.

Figure 3.

Pyrite occurrence in raw coal (500×, oil immersion, reflected light). (A) Massive pyrite, (B) disseminated pyrite, (C) fracture-filling pyrite, (D) cell-filling pyrite, and (E) framboidal pyrite.

Massive clay minerals were widely and nonuniformly distributed in the coal. The largest massive clay minerals measured 200 μm approximately, whereas the size of common clay particles was smaller than 100 μm. Massive clay minerals adhered to the surface (Figure 4A) or inlaid of maceral (Figure 4C,F). Cell-filling clay minerals (Figure 4B,E) were the most widely distributed clay minerals in the study area, with sizes ranging from 2 to 50 μm. Banded clay minerals, with a bandwidth smaller than 4 μm (Figure 4D), were not widely distributed in raw coals. Dispersed clay minerals (Figure 4F) were extensively found in raw coals, distributed as fine particles (mostly <2 μm), and usually mixed with macerals.

Figure 4.

Clay mineral occurrence in raw coal (320×, oil immersion, reflected light). (A) Massive clay mineral (layered textures), (B) cell-filling clay mineral, (C) massive clay minerals, (D) banded clay mineral, (E) cell-filling clay mineral (deformation presents boudins), and (F) disperse clay mineral.

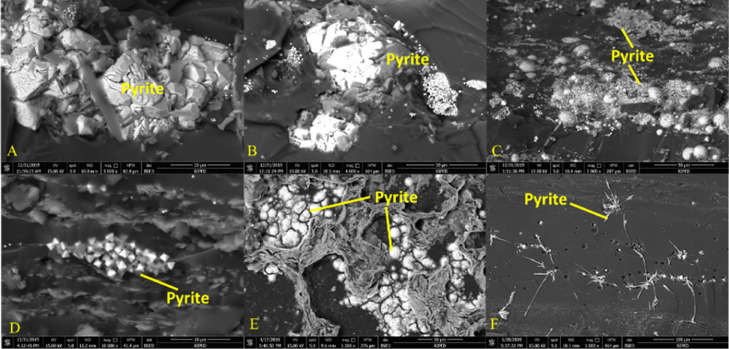

Morphological characteristics of minerals in coal can be determined by the SEM technique with high accuracy. SEM observation shows irregular, framboidal, disseminated, and massive morphology for pyrite occurring with euhedral crystals. The aggregate pyrite has a relatively large particle size and is composed of multiple massive pyrites (Figure 5A). The massive pyrite in YQ9-BC and GZ9-BC coal was not uniformly distributed and was also in symbiosis with the euhedral crystal pyrite (Figure 5B). The dissemination type was primarily massive–unequigranular–aggregation, denoting massive pyrite aggregates. The most common form of aggregate was the framboidal pyrite monocrystalline. It was observed that the framboidal pyrite (Figure 5C) in the raw coal was composed of regular tetrahedral pyrite particles with different particle sizes. The formation of massive pyrite was after framboidal and euhedral crystal pyrite and before epigenesist.42 The monocrystalline grain size was 1–3 μm, and a large portion of the monocrystalline grain size was less than 1 μm (Figure 5D). The intact crystal shape reflects the stability and continuity of the coal-forming environment.43 Pyrite was distributed in maceral or clay minerals as dispersed granules (Figure 5E) with fine-grained, equigranular, and uniform dissemination primarily. Pyrite in the abovementioned occurrence forms was the product of autogenesis in the syngenetic or quasi-syngenetic stage.44−47 Moreover, some pyrite minerals filled the cracks and produced in veins, indicating the epigenetic cause.45 The radioactive pyrite over 100 μm in length has been spotted in GZ9-SD coal (Figure 5F), which was mainly formed in the syngenesis–epigenetic period.44,48,49

Figure 5.

SEM images of the polished section of the raw coal (backscattered electron image). (A,B) Massive pyrite in YQ9-BC; (C,D) framboidal and euhedral crystals pyrite in YQ9-SB; (E) disseminated pyrite in GZ9-DC; and (F) radioactive pyrite in GZ9-SD.

The clay minerals in YQ and GZ coal mainly contain kaolinite, illite, and montmorillonite. Kaolinite is the most common clay mineral in coal. In addition to the usual lamellar forms, the clay minerals in raw coal were mostly lamellar and platelike, sandwiched in the coal seam. The vermicular kaolinite in the coal is uniform in thickness and curved (Figure 6A), which is thought to have been formed from crystal feldspar alteration.50 The plate-shaped clay minerals (Figure 6B) and maceral were superimposed on each other, which may be reflected in the coal-forming stage, and the whole was in a relatively stable and quiet environment. Massive kaolinite (Figure 6C) is distributed parallely to bedding, and the voids are often filled with other minerals such as pyrite. The terrigenous clastic kaolinite (Figure 6D) in coal is typically in thin flakes, distributed parallely to the bedding. This characteristic of kaolinite may differ from feldspar and mica. A small amount of kaolinite was filled in the organic cells (Figure 6E), indicating its authigenic origin.51,52 Some kaolinites were produced as well-crystallized without traces of erosion and handling, indicating that they were formed by crystallization in situ.53,54 Authigenic kaolinite in coal is possibly produced by the interaction of alumina and silica in solution at a high pH environment.54

Figure 6.

SEM images of kaolinite from the raw coal (backscattered electron image). (A,B) Vermicular and plate-shaped kaolinite in YQ9-BC; (C,D) massive and thin-flake kaolinite in YQ9-SB; and (E) cell-filling (laminated) kaolinite in GZ9-SD.

Quartz is a common mineral in YQ coal and occurs primarily in small particles (Figure 7A). Authigenic quartz particles are smaller and individually distributed in macerals. Dawsonite, an authigenic mineral distributed in YQ15-BC (Figure 7B), may be formed by carbonate pyrolysis.55 The formation of dawsonite requires a carbonic acid solution or excess of CO2, which may be provided by the limestone of the roof. Gypsum (Figure 7C) in coal is primarily an authigenic mineral formed by Ca2+ and SO42– precipitation in pore water. Anatase content in coal was low and filled the kaolinite cracks (Figure 7C), indicating an epigenetic cause. Dolomite in coal usually filled the veins in cracks (Figure 7A); organic fragments were occasionally present in dolomite veins, indicating an epigenetic dolomite origin.

Figure 7.

SEM images of other minerals in raw coal (backscattered electron image). (A) Quartz and dolomite in YQ9-SB; (B) dawsonite in YQ15-BC; (C) gypsum in YQ9-SB; and (D) anatase and kaolinite in GZ9-DC.

Figure 8 displays the proportion of distributed particle size of pyrite and clay minerals in coal. The pyrite particle size distribution has a large variation compared to the three types of bright coal. YQ9-BC has the highest proportion of the particle larger than 200 μm, and the least content of the particles is smaller than 2 μm. The proportion difference of pyrite with other grain sizes was not evident. The particle size distribution in YQ15-BC was close to the normal distribution, with the highest fraction of particles in the 10–20 μm size range and a very small proportion of particles larger than 120 μm. The particle size distribution of GZ9-BC was different from that of the other two types of bright coal, where the proportion of its pyrite particle size increases as the particle size increases. In YQ9-SB, the pyrite content of the 50–80 μm size range was the highest, while the content of particles smaller than 2 μm and between 80 and 120 μm was less. The diameter of pyrite was mainly between 10 and 80 μm. Pyrite particle size distribution in GZ9-DC and GZ9-SD was fairly similar, where pyrite with particle sizes smaller than 20 μm accounted for more than 50% of the total number of the particles. Particles larger than 200 μm were rarely found in the samples.

Figure 8.

Relative content of pyrite and clay mineral particle sizes.

The size distribution of clay minerals in coal was not as uniform as that of pyrite, and the proportion of each size grade in all samples was different. In YQ9-BC, the proportion of 10–20 μm clay minerals was the highest, and the proportion of clay minerals smaller than 50 μm was 67.4%. The clay minerals were mainly disseminated in medium grains. The particle size distribution of clay minerals in YQ9-SB was relatively concentrated, where the clay minerals smaller than 20 μm accounted for 72.8% of the particles. The proportion of clay minerals smaller than 2 μm was higher than that of YQ9-BC, and the clay minerals were mainly disseminated in fine–medium grains. In YQ9-BC, the proportion of clay minerals smaller than 2 μm was the highest among all coals, and the proportion of fine clay minerals (<20 μm) was nearly 80%, which was disseminated in fine grains. The size of the clay minerals in GZ9-DC was larger than that of YQ9-BC and GZ9-SD. The proportions of particles between 2 and 20 μm and 50 and 80 μm were the highest, which were disseminated in medium grains. The proportion of clay mineral particles larger than 120 μm in GZ9-BC coal was more than 65%, typically disseminated in coarse-massive grains.

Washability of Coal

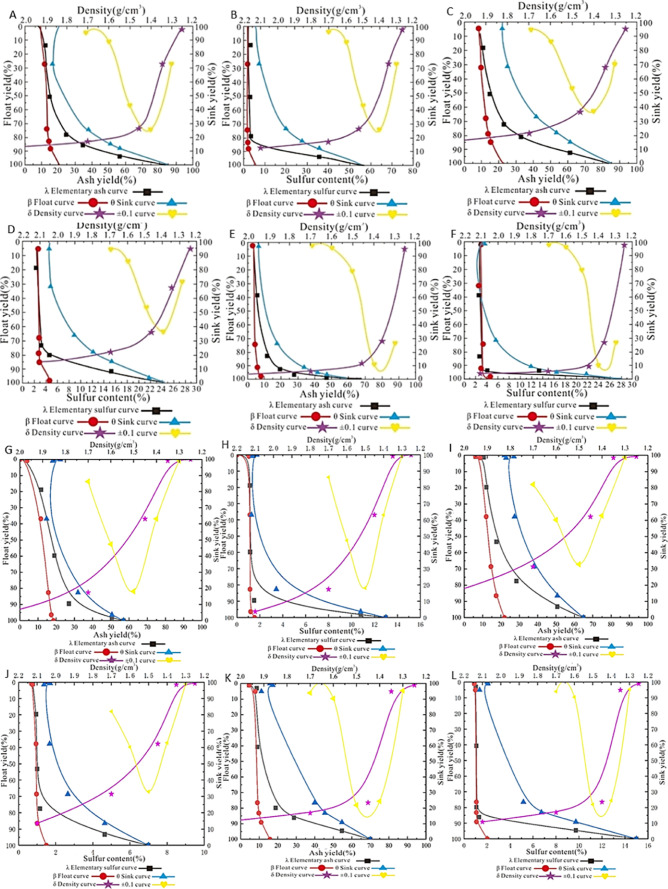

The washability curves (density curve, cumulative curve, float curve, elementary ash/sulfur curve, and near-density curve) were plotted based on the sink–float results for coal seams GZ9, YQ9, and YQ15 and different macroscopic types including bright coal and semibright coal. Washability evaluation was conducted following the provisions of the national standard GB/T16417-2011.56

A washability curve of +0.5 mm granular coal was drawn, according to float and sink test results. The relationship between ash yield and sulfur content of different density grades was studied (Figure 9). The primitive curve λ represents the ash/sulfur distribution in each raw coal density grade. The ash yield increased (slowly then rapidly) as the separation density decreased. The degree of concavity of the ash primitive curve reflects raw coal washability.

Figure 9.

Washability curves. (A) Ash of YQ9-BC coal. (B) Sulfur of YQ9-BC coal. (C) Ash of YQ9-SB coal. (D) Sulfur of YQ9-SB coal. (E) Ash of YQ15-BC coal. (F) Sulfur of YQ15-BC coal. (G) Ash of GZ9-DC coal. (H) Sulfur of GZ9-DC coal. (I) Ash of GZ9-SD coal. (J) Sulfur of GZ9-SD coal. (K) Ash of GZ9-BC coal. (L) Sulfur of GZ9-BC coal.

According to the results obtained from the washability (Table 5), when the ash yield of clean coal was assumed to be 10%, the GZ9-BC was easy to wash. The semibright, semidull, and dull coal were extremely difficult to wash. Comparing the washability and mineral content of the six coals, it can be seen that the YQ9-SB and GZ9-DC coals with the highest mineral content have extremely difficult washability, and the YQ15-BC coal with the least mineral content has also extremely difficult washability. The washability of the other coals (YQ9-BC, GZ9-SD, and GZ9-BC) does not show any correlation with its mineral content. It is not accurate to say that the content of minerals in coal is the main factor that affects the coal washability. The occurrence characteristics and dissemination types of minerals in coal are the key to the difference in washability. Observation by optical microscopy and scanning electron microscopy revealed that the occurrence characteristics of clay minerals in YQ9-SB coal were mainly finely dispersed, banded, and cell-filled, even though some clay minerals are ultraflaky and tightly adhere to maceral (Figure 4D). This type of clay mineral often exhibits fine or medium–equigranular–uniform dissemination. When the coal particles were not completely pulverized, such film-like clay minerals still adhere tightly to the maceral and cannot achieve a good dissociation effect. The main occurrence characteristics of clay minerals in YQ9-BC coal are massive, vermicular, plate-shaped, and so forth. This plate-shaped clay mineral was present in coal with a stable thickness and was not tightly embedded in maceral. It was like a sandwich structure—the superimposed relationship between bread and bacon. When the coal was crushed along the bedding by a small force, this clay mineral easily fell off, and its dissociation was better than other clay minerals. The ash yield of YQ15-BC was 9.92% (low ash coal), so we assume that it was extremely difficult to wash the coal when the coal ash content was 5%. The occurrence characteristics were dispersed, it was difficult to see massive and vermicular clay minerals, and the content of other minerals (except pyrite) was very small. It was difficult to achieve the ideal dissociation effect to reduce the ash yield, even if the coal particles are broken into very fine pieces. On the whole, bright coal has the best ash washability with the same standard, and the ash washability of other lithotypes was at the same level. The difference in the particle size and dissemination type resulted in better washability of the bright coal than the other lithotypes.

Table 5. Washability of Coal.

| samples | setting | δ ± 0.1 content/% | class |

|---|---|---|---|

| YQ9-BC | ash of 10% | 28.66 | general difficulty |

| sulfur of 2% | 8.79 | easy | |

| sulfur of 1% | 72.56 | extremely difficult | |

| YQ9-SB | ash of 10% | 64.81 | extremely difficult |

| sulfur of 2% | 14.26 | middle | |

| sulfur of 1% | 66.68 | extremely difficult | |

| YQ15-BC | ash of 5% | 69.95 | extremely difficult |

| sulfur of 2% | 88.08 | extremely difficult | |

| GZ9-DC | ash of 10% | 67.54 | extremely difficult |

| sulfur of 1% | 23.34 | general difficulty | |

| GZ9-SD | ash of 10% | 40.57 | extremely difficult |

| sulfur of 1% | 64.73 | extremely difficult | |

| GZ9-BC | ash of 10% | 2.8 | easy |

| ash of 5% | 18.55 | middle | |

| sulfur of 1% | 6.73 | easy |

We used the sulfur washability curve, the total sulfur content of the four coals, and pyrite sulfur and organic sulfur content analyses to compare the washability of different coals. It was found that the washabilities of the sulfur content of YQ9-BC coal and YQ9-SB coal were similar. When it was assumed that the sulfur content of the clean coal was 2%, YQ9-BC coal was easy to wash, and YQ9-SB coal was moderately difficult to wash. YQ9-BC and YQ9-SB were high-sulfur coals, and the pyrite content accounts for more than 50% of total sulfur. When the sulfur content of the clean coal was set to 2%, the easily dissociable pyrite in the two types of coal was removed. However, the YQ9-SB was identified as moderately difficult to wash due to the occurrence characteristics of pyrite. Pyrite was disseminated (existed in the form of a single crystal) or framboidal, with a dissemination grain size smaller than 20 μm in YQ9-SB. The disseminated pyrite has a dissemination particle size of 1–2 μm, while the overall particle size of framboidal pyrite was between 10 and 20 μm. Framboidal pyrite comprises 30–80 equigranular single crystals that were closely combined with macerals and often disseminated in them only half or even one-third of the volume exposed. The particle size of a single pyrite crystal does not exceed 1 μm. The dissemination characteristics represent a fine–equigranular–uniform dissemination.

The organic sulfur content of YQ15-BC exceeds half of the total sulfur. For this reason, it was unrealistic to control the sulfur content of clean coal under 2%. Besides, the occurrence of pyrite in YQ15-BC is mainly framboidal, and the dissemination characteristics represented a medium–equigranular–uniform dissemination. It was not easy to remove half of the pyrite by conventional washing. Similarly, the sulfur washability of bright coal is optimal, and the washability of semibright coal was better than that of dull coal in the same grade. The sulfur washability of GZ9-SD was the poorest, which was closely related to pyrite dissemination characteristics.

Geological Control Factors of Mineral Occurrence

Four lithotype samples were floated to produce clean and tailing coal. We compared the sulfur content and ash yield of clean coal and provided data for the prediction of selectivity and the effect of mineral removal in coal under different coal-forming environments to explain the problem in terms of the mineral removal rate. Equation 1 is widely used to calculate removal rates.57,58

| 1 |

Rr: removal rate; Cr: sulfur and trace element content and ash yield in raw coal; Cc: sulfur and trace element content and ash yield in clean coal; and λ: clean coal yield. (λ = Pc/Q; Pc: clean coal production; Q: quantity of raw coal).

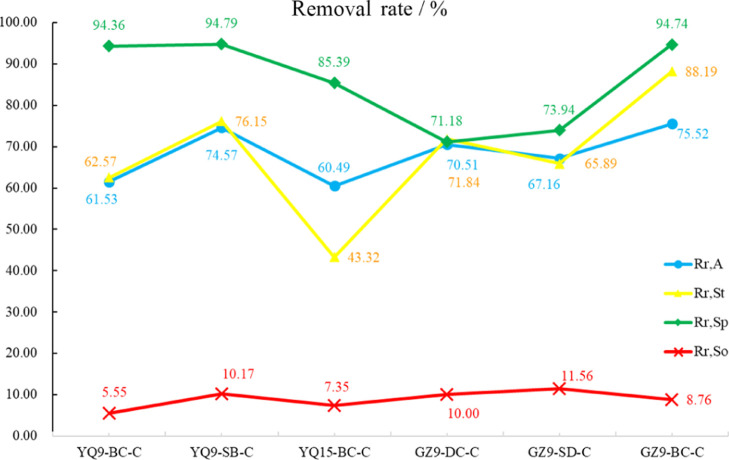

The ash yield and sulfur content of clean coal obtained from the flotation experiment revealed that ash and sulfur removal rates differed by the macroscopic type (Table 6). Ash and sulfur removal rates are visually represented by a broken line diagram. The change law of ash and sulfur in clean coal was closely related to the occurrence and dissemination type of the minerals. The removal rates of GZ9-BC were the highest, reaching 75.52 and 88.19% respectively. The removal rate of pyrite was remarkable, which also reaches the highest in YQ9-SB coal. There were large amounts of massive pyrite in YQ9-SB and GZ9-BC coal, which can be effectively removed by flotation.

Table 6. Ash and Sulfur Removal Rates (%)a.

| sample | λ | Ad | Rr,A | St,d | Rr,St | Sp,d | Rr,Sp | So,d | Rr,So |

|---|---|---|---|---|---|---|---|---|---|

| YQ9-BC-C | 58.57 | 10.01 | 61.53 | 2.01 | 62.57 | 0.22 | 94.36 | 1.79 | 5.55 |

| YQ9-SB-C | 55.10 | 12.26 | 74.57 | 2.06 | 76.15 | 0.32 | 94.79 | 1.73 | 10.17 |

| YQ15-BC-C | 80.17 | 4.89 | 60.49 | 3.07 | 43.32 | 0.35 | 85.39 | 2.71 | 7.35 |

| GZ9-DC-C | 32.69 | 15.98 | 70.51 | 1.46 | 71.84 | 0.44 | 71.18 | 1.00 | 10.00 |

| GZ9-SD-C | 54.82 | 12.58 | 67.16 | 0.84 | 65.89 | 0.29 | 73.94 | 0.55 | 11.56 |

| GZ9-BC-C | 66.14 | 5.04 | 75.52 | 0.82 | 88.19 | 0.32 | 94.74 | 0.50 | 8.76 |

YQ9-BC-C, YQ9-SB-C, YQ15-BC-C, GZ9-DC-C, GZ9-SD-C, and GZ9-BC-C: clean coal; λ: clean coal yield; Rr,A: removal rate of ash; Rr,St: removal rate of total sulfur; Rr,Sp: removal rate of pyrite sulfur; and Rr,So: removal rate of organic sulfur.

It was worth noting that YQ15-BC coal has the lowest removal rate of ash and sulfur. This is because YQ15-BC minerals in coal were mainly in framboidal and disseminated occurrence, and the particle size was between 10 and 50 μm. The removal effect of pyrite was not good, which is likely due to the coal-forming environment of YQ15-BC coal. As shown in Figure 10, the ash and sulfur removal rates of GZ9-DC and GZ9-SD coal were not low, but the ash yield and total sulfur content of clean coal were not much different from those of raw coal. This is the case because the two types of coal had low clean coal yield, resulting in a high removal rate index and unsatisfactory flotation effect. Therefore, it was necessary to focus on the embedment characteristics of minerals in coal to explore the relationship between lithotype and washability.

Figure 10.

Removal rate of ash and sulfur.

After documenting the characteristics of the pyrite and clay minerals, the occurrence forms of the minerals were determined by point counting. The occurrence forms of pyrite and clay minerals were classified into eight categories: massive, framboidal, disseminated, cell fillings, fracture fillings, banded, disperse, and others (Table 7). According to the statistics of mineral occurrence forms in coal, In GZ9-BC, YQ9-BC, and YQ9-SB, the massive and fracture-filling pyrite accounts for the largest proportion, and the content of framboidal pyrite was the least. After flotation, the massive and fracture-filling pyrites were removed thoroughly, and the disseminated pyrite was mainly left in the clean coal. In YQ15-BC, the content of pyrite was lower than that of YQ9 coal, the content of framboidal and disseminated pyrite accounts for more than 60% of the total content, and the content of massive pyrite was less. The content of massive and fracture-filling pyrite in clean coal was small, and the main mineral was framboidal pyrite. The content of clay minerals with different forms of occurrence varies significantly among the three kinds of coal. The content of dispersing and banded clay minerals in YQ9-BC, GZ9-DC, and GZ9-SD was the highest. The YQ9-SB and GZ9-BC were mainly massive clay minerals, while the YQ15-BC was mainly banded clay minerals. In clean coal, only the massive clay minerals demonstrate a good removal effect, and the other clay minerals showed the enrichment phenomenon.

Table 7. Relative Content of Pyrite and Clay Minerals, Classified by Size and Morphologya.

| raw coal | YQ9-BC | YQ9-SB | YQ15-BC | GZ9-DC | GZ9-SD | GZ9-BC | |

|---|---|---|---|---|---|---|---|

| pyrite | massive | 21.4 | 28.8 | 12.2 | 18.6 | 7.7 | 48.5 |

| framboidal | 6.8 | 4.4 | 36.8 | 21.5 | 22.3 | 3.8 | |

| disseminated | 10.2 | 5.6 | 27.6 | 24.8 | 36.8 | 5.7 | |

| cell fillings | 16.6 | 11.2 | 9.8 | 11.2 | 18.2 | 11.3 | |

| fracture fillings | 34.4 | 41.6 | 7.6 | 14.2 | 5.5 | 27.2 | |

| others | 10.6 | 8.4 | 6.0 | 9.7 | 9.5 | 3.5 | |

| total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | |

| raw coal | YQ9-BC | YQ9-SB | YQ15-BC | GZ9-DC | GZ9-SD | GZ9-BC | |

|---|---|---|---|---|---|---|---|

| clay mineral | massive | 18.4 | 46.0 | 14.2 | 5.8 | 8.7 | 65.5 |

| manded | 29.8 | 22.6 | 34.8 | 39.6 | 30.5 | 14.3 | |

| disperse | 36.4 | 16.2 | 25.4 | 46.1 | 33.7 | 7.7 | |

| cell fillings | 15.4 | 15.2 | 25.6 | 8.5 | 27.1 | 12.5 | |

| total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | |

| clean coal | YQ9-BC-C | YQ9-SB-C | YQ15-BC-C | GZ9-DC-C | GZ9-SD-C | GZ9-BC-C | |

|---|---|---|---|---|---|---|---|

| pyrite | massive | 2.4 | 1.0 | 1.8 | 5.8 | 3.2 | 0.7 |

| framboidal | 26.8 | 19.6 | 48.0 | 36.7 | 15.8 | 16.1 | |

| disseminated | 54.6 | 58.2 | 37.8 | 46.2 | 55.8 | 76.0 | |

| cell fillings | 14.2 | 18.6 | 10.6 | 10.4 | 23.0 | 5.5 | |

| fracture- fillings | 0.4 | 0.4 | 0.2 | 0.3 | 0.3 | 0.2 | |

| others | 1.6 | 2.2 | 1.6 | 0.6 | 1.9 | 1.5 | |

| total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | |

| clean coal | YQ9-BC-C | YQ9-SB-C | YQ15-BC-C | GZ9-DC-C | GZ9-SD-C | GZ9-BC-C | |

|---|---|---|---|---|---|---|---|

| clay mineral | massive | 0.8 | 1.2 | 1.8 | 0.5 | 1.2 | 0.6 |

| banded | 24.4 | 28.4 | 33.4 | 39.8 | 33.5 | 17.8 | |

| disperse | 49.8 | 48.2 | 51.4 | 43.9 | 42.7 | 63.5 | |

| cell fillings | 25.0 | 22.2 | 13.4 | 15.8 | 22.6 | 18.1 | |

| total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | |

Influence of mineral occurrence on washability.

In the Late-Middle Carboniferous, the research area formed a depression, and the complicated sedimentary environment since the beginning of the Late Carboniferous was caused by frequent transgression, regression, and sediment change, which primarily consists of a set of delta systems containing coal-clastic and marine carbonate rocks.25 During this period, coals 9 and 15 were deposited. Coal is characterized by differential mineral symbiosis combinations influenced by the depositional environment, and the oxidation–reduction and pH of the depositional medium are influential factors contributing to such differences. The use of indicator elements can provide a basis for the variation of coal-forming environments in the study area.59

The Ga and Sr elements can indicate the degree of dryness and wetness of the sedimentary environment, with high Ga and Sr content indicating that the environment is relatively dry and has a terrestrial origin; in contrast, low Ga and Sr indicate marine deposit. Judging from the Sr/Ba, it indicated that the formation environment of YQ9 coal seam is mainly transitional facies (Figure 11), and the indexes of Ni/Co, V/Cr, and U/Th show that the formation process of YQ9 coal seam is mainly in an oxidation environment with high oxygen content, and it is possible that the geological processes that occurred after the formation of the coal seam led to these parameters, indicating an oxidation environment. The YQ9-SB coal was weakened by the influence of seawater at the initial stage of deposition, and the depositional environment was perennial under a reducing condition, which contained a lot of pyrites. The V/(V + Ni) shows that the hydrodynamic conditions of YQ9-BC changed from weak to strong, and the bottom of YQ9-BC was in a calmer water environment.60,61

Figure 11.

Indicator element and geochemical parameters of YQ9.

The coal seam 9 is developed in the lower deltaic plain, which was affected by seawater and tidal double action. Terrigenous clastic brought by freshwater, especially clay minerals, was deposited. YQ9-SB was formed in the early stage, and the input of terrestrial debris was greater than the influence of seawater. The oxidation and reduction conditions are responsible for the formation of high sulfur content in YQ9-SB. This environment influences the occurrence of clay minerals and the type of dissemination, where the disseminated particle size is between 50 and 100 μm, and the corresponding washability was ranked as moderately difficult. YQ9-BC was formed in the late stage of coal accumulation. During this period, the terrestrial debris was weakened and the mineral content in the coal decreased. The seawater action changed slightly and the iron ion supply was relatively lacking, so the pyrite content decreased. The continuous invasion of seawater has caused the content of authigenic minerals to increase. The minerals occurred in dispersed morphology, and dissemination with maceral was relatively close. In particular, the removal rate of authigenic minerals with a small disseminated size by flotation is not as good as that of YQ-SB.

The Sr/Ba of YQ15-BC has a wide range of variation (Figure 12), but all of them were within the indicated range of littoral facies. The Ni/Co, V/Cr, and U/Th could objectively reflect the strength of the reducing environment during the formation of coal seams. The V/(V + Ni) of YQ15-BC shows that the hydrodynamics of the coal seam is under a weak-medium condition. The YQ15-BC coal experienced three regressive and two transgressive processes during the deposition period. The deposits were of the coastal type, and the depositional environment was generally in a reducing environment. The reducing environment and transgression led to the formation of extremely high pyrite content at the bottom of YQ15-BC, while the sulfur content in the top section ofYQ15-BC coal is predominantly organic sulfur.

Figure 12.

Indicator element and geochemical parameters of YQ15.

The occurrence of clay minerals in YQ15-BC was mainly dispersed. The content of other minerals (except pyrite) was very limited, and the disseminated particle size was mostly 20 μm. It was difficult to achieve the desired dissociation effect even if the coal particles were broken into very small pieces to reduce the ash yield. It is very challenging to remove sulfur by conventional washing because the organic sulfur content of YQ15-BC coal was more than half of the total sulfur. The occurrence of pyrite is primarily framboidal, with the disseminated particle size of 40 μm at most. In this environment, low-ash and high-sulfur coal was formed with high organic sulfur content, and the sulfur content was not significantly reduced after flotation, indicating that conventional washing could not achieve the desired effect on the coal formed in this environment, so microbial desulfurization might be tried.

The change in Sr/Ba in GZ9 coal was stable (Figure 13), indicating that the sedimentary environment is terrestrial facies. The V/(V + Ni) ratio implies that with the increasing function of rivers, the hydrodynamics of GZ9 coal increases strongly. The fluvial facies control the types and combinations of minerals and trace elements in coal. The GZ9 coal seam was continuously affected by marine regression during its formation. During the deposition period from GZ9-BC to GZ9-SD, the marine regression occurred. The oxidation–reduction environment gradually changed from the lean oxygen to the oxygen-containing environment, and the hydrodynamics of the bottom also changed from moderate strength to high level. The pyrite content in GZ9-BC was extremely high, and the massive pyrite with a particle size larger than 2 mm can be seen by the naked eye. The stable regression continued as long as the hydrodynamics of the bottom remained stable at a high level. The redox environment was always in an oxidizing environment as the oxygen content increased.

Figure 13.

Indicator element and geochemical parameters of GZ9.

The sedimentary environment of the GZ9 coal seam is the most complex one, and the bottom of the GZ9 coal seam is mainly affected by seawater, while the middle and upper coal seams mainly receive the terrigenous clastic deposit. This results in the formation of various lithotypes in GZ9 coal seam. The GZ9-BC is affected by seawater, biological, physical, and chemical effects, coupled with a sufficient supply of iron, manganese, and sulfur. In this way, a large amount of pyrite is formed which largely occurs in agglomerates. The authigenic pyrite particles are larger than 50 μm, and the particle size of epigenetic pyrite exceeds 200 μm. Its disseminated particle size is far greater than that of other coal pyrites.

Massive pyrite is mostly distributed in the fractures or pores of the maceral with an uneven distribution in coal. The dissemination type of pyrite resembles giant–equigranular–uneven dissemination according to the distribution characteristics of the mineral. This type of pyrite can be effectively removed. When GZ9-SD is formed, the action of seawater gradually weakens, and the hydrodynamics does not change considerably. Moreover, the supply of iron ions and sulfide ions is short, and the content of pyrite formed is small, which mainly occurs in finely dispersed and framboidal structures. The disseminated extent is smaller than 2 μm (Figure 8), and dissemination of pyrite is typically fine–equigranular–uniform in such an environment. GZ9-DC is controlled by rivers and terrigenous clastic, which has strong hydrodynamics and always in the oxidizing environment which increases the mineral content in coal. The oxidizing environment does not lead to the formation of pyrite, and clay minerals are subject to deposition. The mineral has a small particle size in coal, and the dissemination characteristics of clay minerals are fine medium–unequigranular–uneven (Figure 8), and the mineral removal rate is not good.

Conclusions

-

1

The minerals in the coal of the study area consist of quartz, clay minerals, pyrite, dolomite, calcite, analcite, gypsum, dawsonite, and anatase. The two main minerals in coals were found to be clay minerals and pyrite. It was observed that the occurrence of pyrite in the coal was massive, radioactive, fracture fillings, disseminated, euhedral crystals, framboidal, and cell fillings, while the occurrence of clay minerals was massive aggregate, vermicular, plate-shaped, thin flakes, cell fillings, banded, disperse, and tabular aggregate. The pyrite particle size in bright coal has the highest proportion of the particle larger than 200 μm. In semibright coal, the pyrite content of the 50–80 μm size range was the highest, while the content of particles smaller than 2 μm was less. Pyrite particle size distribution in semidull and dull coal was fairly similar, where pyrite with particle sizes smaller than 20 μm accounted for more than 50% of the total number of the particles.

-

2

The disseminated particle size characteristics of minerals in coal with different ease of washability levels were investigated. The content of minerals with the particle size larger than 200 μm accounted for 35–50% of the easy-to-wash coal, where the massive occurrence form is dominant. The particles were mostly concentrated in the 50–100 μm size range in moderate difficulty washability coal, where the proportion of particles within this size range exceeds 40%, and the mineral occurrence forms are diverse. The disseminated particle size distribution of 10–20 μm in the refractory washability coal is between 35 and 45%, and the massive and fracture filling minerals are rarely found in the coal. The proportion of minerals smaller than 2 μm in the extremely difficult washability coal is more than 60%, and cell filling, dispersed, and banding forms are plentiful in this type of coal. The removal rates of ash and sulfur obtained through elution match well with the mineral form and distribution characteristics.

-

3

The changes in sedimentary environment and the regular transgression and regression have resulted in obviously different lithotypes in the coal seam. The coal is divided into four lithotypes. The difference of mineral content in coal is affected by transgression and terrigenous detrital. The content of clay minerals in coal stratified by seawater is relatively small. The authigenic minerals in the coal affected by seawater are combined with maceral in a rich pyrite environment, which results in a poor removal rate of minerals. The characteristics of clay mineral dissemination in coal affected by the terrestrial debris are complex, which makes the washability of semidull coal and dull coal formed in this environment unsatisfactory. The periodic transgression and stable terrigenous debris supply make the pyrite particle size from 20 to 300 μm in the coal. Therefore, the coal-forming environment has a certain controlling effect on the removal of minerals.

Acknowledgments

This research was supported by the National Natural Science Foundation of China (NSFC) (no. 41572146), Key Projects of National Natural Science Foundation of China (no. 42030807), and Geological Exploration Project of Shanxi Province (HXCT01-2018F005-77). I would like to thank Professor Finkelman Robert for guidance and help in improving this paper during the writing process. We appreciate the help of the Research Institute of Petroleum Exploration and Development and the Shanxi Coal Geological Bureau with the tests conducted.

The authors declare no competing financial interest.

References

- Li L.; Lei Y.; Pan D. Economic and environmental evaluation of coal production in China and policy implications. Nat. Hazards 2015, 77, 1125–1141. 10.1007/s11069-015-1650-9. [DOI] [Google Scholar]

- Bai X.; Ding H.; Lian J.; Ma D.; Yang X.; Sun N.; Xue W.; Chang Y. Coal production in China: past, present, and future projections. Int. Geol. Rev. 2018, 60, 535–547. 10.1080/00206814.2017.1301226. [DOI] [Google Scholar]

- Yuan J. The future of coal in China. Resour. Conserv. Recycl. 2018, 129, 290–292. 10.1016/j.resconrec.2016.12.006. [DOI] [Google Scholar]

- National Bureau of Statistics of China . http://data.stats.gov.cn/easyquery.htm?cn=C01&zb=A070R&sj=2018.

- China Mineral Resources; Ministry of Natural Resources of the People’s Republic of China: Beijing, China, 2019.

- Zhao C.; Luo K. Sulfur, arsenic, fluorine and mercury emissions resulting from coal-washing byproducts: A critical component of China’s emission inventory. Atmos. Environ. 2017, 152, 270–278. 10.1016/j.atmosenv.2016.12.001. [DOI] [Google Scholar]

- Liu H.; Wang Y.; Zhao S.; Hu H.; Cao C.; Li A.; Yu Y.; Yao H. Review on the Current Status of the Co-combustion Technology of Organic Solid Waste (OSW) and Coal in China. Energy Fuels 2020, 34, 15448–15487. 10.1021/acs.energyfuels.0c02177. [DOI] [Google Scholar]

- Xie K.-C. Breakthrough and innovative clean and efficient coal conversion technology from a chemical engineering perspective. Chem. Eng. Sci.: X 2021, 10, 100092. 10.1016/j.cesx.2021.100092. [DOI] [Google Scholar]

- Chen W.; Xu R. Clean coal technology development in China. Energy Policy 2010, 38, 2123–2130. 10.1016/j.enpol.2009.06.003. [DOI] [Google Scholar]

- Liu F.; Cao W. J.; Zhang J. M.; Cao G. M.; Guo L. F. Current technological innovation and development direction of the 14th Five–Year Plan period in China coal industry. J. China Coal Soc. 2021, 46, 1–15. [Google Scholar]

- Wang W. F.; Qin Y.; Song D. Y. Cleaning potential of hazardous elements during coal washing. J. Fuel Chem. Technol. 2003, 31, 295–299. [Google Scholar]

- Gui X.; Liu J.; Cao Y.; Miao Z.; Li S.; Xing Y.; Wang D. Coal Preparation Technology: Status and Development in China. Energ. Environ. 2015, 26, 997–1013. 10.1260/0958-305x.26.6-7.997. [DOI] [Google Scholar]

- Wang W.; Hao W.; Xu S.; Qian F.; Sang S.; Qin Y. Ash limitation of physical coal beneficiation for medium-high ash coal-A geochemistry perspective. Fuel 2014, 135, 83–90. 10.1016/j.fuel.2014.06.041. [DOI] [Google Scholar]

- Nguyen T. D.; Nguyen A. V.; Lin C.-L.; Miller J. D. Application of high-resolution X-ray microcomputed tomography for coal washability analysis. Miner. Eng. 2018, 124, 137–148. 10.1016/j.mineng.2018.05.027. [DOI] [Google Scholar]

- Duan P.; Wang W.; Liu X.; Sang S.; Ma M.; Zhang W. Differentiation of rare earth elements and yttrium in different size and density fractions of the Reshuihe coal, Yunnan Province, China. Int. J. Coal Geol. 2019, 207, 1–11. 10.1016/j.coal.2019.03.014. [DOI] [Google Scholar]

- Duan P.; Wang W.; Sang S.; Ma M.; Wang J.; Zhang W. Modes of occurrence and removal of toxic elements from high-uranium coals of Rongyang Mine by stepped release flotation. Energy Sci. Eng. 2019, 7, 1678–1686. 10.1002/ese3.384. [DOI] [Google Scholar]

- Galvin K. P. Options for Washability Analysis of Coal-A Literature Review. Coal Prep. 2006, 26, 209–234. 10.1080/07349340601104289. [DOI] [Google Scholar]

- Yao Q.; Du M.; Wang S.; Liu J.; Yang J. Modes of Occurrence and Washability Evaluation of Sulfur in High-Sulfur Coal. Coal Convers. 2013, 36, 24–27. [Google Scholar]

- Bu X.; Evans G.; Xie G.; Peng Y.; Zhang Z.; Ni C.; Ge L. Removal of fine quartz from coal-series kaolin by flotation. Appl. Clay Sci. 2017, 143, 437–444. 10.1016/j.clay.2017.04.020. [DOI] [Google Scholar]

- Tang Y.; Yang C.; Finkelman R. B.; Feng K.; Ma W.; Li X. Behavior of Minerals and Trace Elements during Cleaning of Three Coals with Moderately High Ash Yields. Energy Fuels 2020, 34, 2501–2515. 10.1021/acs.energyfuels.9b02842. [DOI] [Google Scholar]

- Liu S.; Su S.; Zhang G. Early Mesozoic basin development in North China: indications of cratonic deformation. J. Asian Earth Sci. 2013, 62, 221–236. 10.1016/j.jseaes.2012.09.011. [DOI] [Google Scholar]

- Cao D. Y.; Qian G. M.; Guan Y. B.; Zhang J. L. Development of Jinhuo fault zone and its effect on the structures of coal mining districts. J. China Univ. Min. Technol. 1998, 1, 7–10. [Google Scholar]

- Shao L.-Y.; Yang Z.-Y.; Shang X.-X.; Xiao Z.-H.; Wang S.; Zhang W.-L.; Zheng M.-Q.; Lu J. Lithofacies palaeogeography of the Carboniferous and Permian in the Qinshui Basin, Shanxi Province, China. J. Palaeogeogr. 2015, 4, 384–412. 10.1016/j.jop.2015.06.001. [DOI] [Google Scholar]

- Hou H.; Shao L.; Wang S.; Xiao Z.; Wang X.; Li Z.; Mu G. Influence of depositional environment on coalbed methane accumulation in the Carboniferous-Permian coal of the Qinshui Basin, northern China. Front. Earth Sci. 2019, 13, 535–550. 10.1007/s11707-018-0742-8. [DOI] [Google Scholar]

- Huang J. J.; Sun F. J.; Wang B.; Zhao Y. Permo–Carboniferous Sequence Stratigraphy and Coal Accumulation in South Qinshui Basin. China Coalbed Methane 2015, 12, 17–22. [Google Scholar]

- Shao L.; Xiao Z.; Lu J.; He Z.; Wang H.; Zhang P. Permo-Carboniferous coal measures in the Qinshui basin: Lithofacies paleogeography and its control on coal accumulation. Front. Earth Sci. 2007, 1, 106–115. 10.1007/s11707-007-0014-5. [DOI] [Google Scholar]

- Chinese Standard GB/T482-2008 Sampling of Coal in Seam; ANSI, 2008.

- Chinese Standard GB/T4757-2001 Method for the Batch Flotation Testing of Fine Coal, 2001.

- ASTM Standard D3173-11 Standard Test Method for Moisture in the Analysis Sample of Coal and Coke; ASTM International, 2011.

- ASTM Standard D3174-11 Standard Test Method for Ash in the Analysis Sample of Coal and Coke From Coal; ASTM International, 2011.

- ASTM Standard D3175-11 Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke; ASTM International, 2011.

- ASTM Standard D3177-02 (Reapproved 2007) Standard Test Methods for Total Sulfur in the Analysis Sample of Coal and Coke; ASTM International, 2002.

- ISO 11760:2018 Classification of Coals; International Organization for Standardization: Geneva, 2005.

- Chinese Standard GB/T 15224.2-2010 Classification for Quality of Coal–Sulfur Content, 2010.

- Chinese Standard GB/T 16733-2008 Method of Preparing Coal Samples for the Coal Petrographic Analysis, 2008.

- Chinese Standard GB/T18023-2000 Classification of Macrolithotype for Bituminous Coal, 2000.

- New inertinite classification (ICCP system 1994). Fuel 2001, 80, 459–471. 10.1016/s0016-2361(00)00102-2. [DOI] [Google Scholar]

- The new vitrinite classification (ICCP System 1994). Fuel 1998, 77, 349–358. 10.1016/s0016-2361(98)80024-0. [DOI] [Google Scholar]

- Diessel C.Coal Facies and Depositional Environment; Springer: Berlin, Heidelberg, 1992. [Google Scholar]

- Calder J. H.; Gibling M. R.; Mukhopadhyay P. K. Peat formation in a Westphalian B piedmont setting, Cumberland Basin, Nova Scotia; implications for the maceral–based interpretation of rheotrophic and raised paleomires. Bull. Soc. Geol. Fr. 1991, 162, 283–298. [Google Scholar]

- Hower J. C.; Eble C. F. Coal facies studies in the eastern United States. Int. J. Coal Geol. 2004, 58, 3–22. 10.1016/j.coal.2003.03.001. [DOI] [Google Scholar]

- Chou C.-L. Sulfur in coals: A review of geochemistry and origins. Int. J. Coal Geol. 2012, 100, 1–13. 10.1016/j.coal.2012.05.009. [DOI] [Google Scholar]

- Kortenski J.; Kostova I. Occurrence and morphology of pyrite in Bulgarian coals. Int. J. Coal Geol. 1996, 29, 273–290. 10.1016/0166-5162(95)00033-x. [DOI] [Google Scholar]

- Ward C. R. Analysis and significance of mineral matter in coal seams. Int. J. Coal Geol. 2002, 50, 135–168. 10.1016/s0166-5162(02)00117-9. [DOI] [Google Scholar]

- Dai S.; Chou C.-L. Occurrence and origin of minerals in a chamosite-bearing coal of Late Permian age, Zhaotong, Yunnan, China. Am. Mineral. 2007, 92, 1253–1261. 10.2138/am.2007.2496. [DOI] [Google Scholar]

- Dai S.; Ren D.; Tang Y.; Shao L.; Li S. Distribution, isotopic variation and origin of sulfur in coals in the Wuda coalfield, Inner Mongolia, China. Int. J. Coal Geol. 2002, 51, 237–250. 10.1016/s0166-5162(02)00098-8. [DOI] [Google Scholar]

- Querol X.; Chinchon S.; Lopez-Soler A. Iron sulfide precipitation sequence in Albian coals from the Maestrazgo Basin, southeastern Iberian Range, northeastern Spain. Int. J. Coal Geol. 1989, 11, 171–189. 10.1016/0166-5162(89)90004-9. [DOI] [Google Scholar]

- Berner R. A. Sedimentary pyrite formation: An update. Geochim. Cosmochim. Acta 1984, 48, 605–615. 10.1016/0016-7037(84)90089-9. [DOI] [Google Scholar]

- Ward C. R. Minerals in bituminous coals of the Sydney basin (Australia) and the Illinois basin (U.S.A.). Int. J. Coal Geol. 1989, 13, 455–479. 10.1016/0166-5162(89)90104-3. [DOI] [Google Scholar]

- Ward C. R.; Taylor J. C. Quantitative mineralogical analysis of coals from the Callide Basin, Queensland, Australia using X-ray diffractometry and normative interpretation. Int. J. Coal Geol. 1996, 30, 211–229. 10.1016/0166-5162(95)00044-5. [DOI] [Google Scholar]

- Spears D. A. The origin of tonsteins, an overview, and links with seatearths, fireclays and fragmental clay rocks. Int. J. Coal Geol. 2012, 94, 22–31. 10.1016/j.coal.2011.09.008. [DOI] [Google Scholar]

- Susilawati R.; Ward C. R. Metamorphism of mineral matter in coal from the Bukit Asam deposit, South Sumatra, Indonesia. Int. J. Coal Geol. 2006, 68, 171–195. 10.1016/j.coal.2006.02.003. [DOI] [Google Scholar]

- López I. C.; Ward C. R. Composition and mode of occurrence of mineral matter in some Colombian coals. Int. J. Coal Geol. 2008, 73, 3–18. 10.1016/j.coal.2007.03.005. [DOI] [Google Scholar]

- Dai S.; Li T.; Seredin V. V.; Ward C. R.; Hower J. C.; Zhou Y.; Zhang M.; Song X.; Song W.; Zhao C. Origin of minerals and elements in the Late Permian coals, tonsteins, and host rocks of the Xinde Mine, Xuanwei, eastern Yunnan, China. Int. J. Coal Geol. 2014, 121, 53–78. 10.1016/j.coal.2013.11.001. [DOI] [Google Scholar]

- Qu X.; Gao Y.; Liu L. Gemesis of dawsonite and its indication significance of CO2 migration and accumulation. Adv. Earth Sci. 2005, 20, 1083–1088. 10.11867/j.issn.1001-8166.2005.10.1083. [DOI] [Google Scholar]

- Chinese standard GB/T16417–2011 Method for Evaluating the Washability of Coal, 2011.

- Vejahati F.; Xu Z.; Gupta R. Trace elements in coal: Associations with coal and minerals and their behavior during coal utilization - A review. Fuel 2010, 89, 904–911. 10.1016/j.fuel.2009.06.013. [DOI] [Google Scholar]

- Senior C. L.; Zeng T.; Che J.; Ames M. R.; Sarofim A. F.; Olmez I.; Huggins F. E.; Shah N.; Huffman G. P.; Kolker A.; Mroczkowski S.; Palmer C.; Finkelman R. Distribution of trace elements in selected pulverized coals as a function of particle size and density. Fuel Process. Technol. 2000, 63, 215–241. 10.1016/s0378-3820(99)00098-3. [DOI] [Google Scholar]

- Jones B.; Manning D. A. C. Comparison of geochemical indices used for the interpretation of palaeoredox conditions in ancient mudstones. Chem. Geol. 1994, 111, 111–129. 10.1016/0009-2541(94)90085-x. [DOI] [Google Scholar]

- Xiong G.; Jiang X.; Cai X.; Wu H. The Characteristics of Trace Element and REE Geochemistry of the Cretaceous Mudrocks and Shales from Southern Tibet and Its Analysis of Redox Condition. Adv. Earth Sci. 2010, 25, 730–745. 10.11867/j.issn.1001-8166.2010.07.0730. [DOI] [Google Scholar]

- Wang S. F.; Dong D. Z.; Wang Y. M.; Huang J. L.; Pu B. L. Geochemistry Evaluation Index of Redox-sensitive Elements for Depositional Environments of Silurian Longmaxi Organic-rich Shale in the South of Sichuan Basin. Mar. Petrol. Geol. 2014, 19, 27–34. [Google Scholar]