Abstract

The key to the efficient development of a tight reservoir is its accurate evaluation. In this study, the pore throat structure characteristics of sandstone samples in the study block were analyzed by high-pressure mercury injection technology. According to the characteristics of the capillary pressure curve, the sandstone samples in the study block were divided into three types: the first type has a reservoir permeability greater than 0.7 mD and a core mercury injection saturation of 96% with a good reservoir quality; the second type has a reservoir permeability ranging from 0.4 to 0.7 mD and a core mercury injection saturation of 80% with a moderate reservoir quality; and the third type has a reservoir permeability between 0.1 and 0.4 mD and a core mercury injection saturation of 50% with a poor reservoir quality. Also, high-resolution synchrotron radiation imaging and scanning electron microscopy were used to observe the pore throat structure, connectivity, and microscopic heterogeneity of sandstone samples, showing an increasing level of pore disconnection, serious microscopic heterogeneity, and poor reservoir performance as reservoir permeability declines. As mineral composition tests show, the lithology of the tight sandstone in the target block is mainly medium-grained and fine-grained feldspar lithic sandstone and the longitudinal heterogeneity of lithology and mineral components of tight sandstone is relatively weak at above the centimeter level. Besides, based on the high-pressure mercury injection test data, fractal theory is applied to calculate the fractal dimensions of the three types of reservoirs. The result shows a gradual increase in fractal dimensions with the decrease of reservoir quality, in which the closer the fractal dimension is to 3, the more serious the microscopic heterogeneity is, and the stronger the roughness of the pore surface is. As a result, the more heterogeneous the tight reservoir gets, the more likely the injected fluid is to flow along the developed and connected pore regions.

1. Introduction

The exploration and development of unconventional oil and gas is the only way to ensure national energy security,1−3 wherein the efficient development of tight oil is at a pivotal position. A fine characterization of the pore throat structure in tight oil reservoirs lays a solid foundation for subsequent development.4−6 As the main factor that affects reservoir capacity and seepage characteristics, the pore throat structure of the reservoir refers to the geometric shape, size, distribution, and interconnection of pores and throats in rock.7,8 Characterizing the microscopic pore structure by effective experimental means is one of the core problems in the study of reservoir characteristics. At present, some new technologies and methods have been applied to the characterization of tight oil reservoirs, such as mercury injection (constant rate mercury injection, conventional mercury injection, etc.), low-temperature nitrogen adsorption, low-field nuclear magnetic resonance, small-angle scattering, focused ion beam (FIB), computed tomography (CT) scanning, casting thin sections, scanning electron microscopy (SEM), and other techniques.9−17 However, as far as the current research is concerned, all of the research methods and methods listed above have their limitations or disadvantages. For instance, the minimum effective pore radius detected by constant rate mercury injection technology can only reach 0.12 μm,13 while, as known to all, a majority of pore throat radii in tight oil reservoirs are less than 1 μm. Therefore, constant rate mercury injection technology is not advantageous in the detection of nanoscale pores. For another instance, conventional CT technology can hardly reach an ideal state in detecting pore throat structures in a tight reservoir due to its resolution limitation.

Also, the microscopic heterogeneity of a tight reservoir is an important factor that affects its seepage process. In other words, the study of microscopic heterogeneity can help us to further understand the seepage characteristics of the tight reservoir. The research methods of reservoir heterogeneity can be summarized into three aspects: comprehensive geological analysis, reservoir geological modeling, and experimental methods. In recent years, many scholars have comprehensively studied the macroscopic heterogeneity of tight reservoirs by geological means and analyzed the microscopic heterogeneity characteristics of tight reservoirs by experiments. They believed that a tight sandstone reservoir has a strong heterogeneity in both the macroscopic level and the microscopic level, which affects oil migration and distribution.18−21 Among them, the experimental method is one of the important means to study reservoir heterogeneity. Using different technical means from different perspectives, researchers have studied reservoir microscopic heterogeneity and realized that it is controlled by diagenesis and pore structure.22 Different original pore conditions lead to reservoir diagenetic heterogeneity.23 The development of microfractures enhances the microscopic heterogeneity of tight sandstones.24,25 The classification and matrix mineral composition of sandstones influence and control the diagenetic evolution process and eventually lead to the heterogeneity of diagenesis, pore throat, and physical properties in spatial distribution.26

The research studies worldwide on microscopic pore throat structure and heterogeneity of tight reservoirs mainly utilize single test technology, and the research on microscopic heterogeneity of tight reservoirs remains in the stage of qualitative research. The complex microscopic pore throat structure of a tight oil reservoir can hardly be characterized by conventional techniques. Due to its strong heterogeneity, the reservoir develops pore systems of different size levels, ranging from nano-sized pore throat to millimeter level fractures, which require a combination of various experimental testing techniques for quantitative analysis. A clear understanding of the microscopic pore throat structure and microscopic heterogeneity of tight oil reservoirs is vital to the subsequent study of the seepage mechanism and efficient development of tight oil. In this study, high-resolution synchrotron radiation scanning technology, SEM, and high-pressure mercury injection technology were used to effectively characterize the microscopic pore throat structure characteristics of the tight oil reservoir in H oilfield, and the microscopic heterogeneity was studied in detail, laying a theoretical foundation for the efficient development of tight oil.

2. Research Region and Experimental Method

2.1. Research Region Overview and Reservoir Petrological Characteristics

H oilfield is located on the main body of a delta front developed in an alluvial fan-delta depositional system in the southwest margin of the Ordos Basin with the reservoir sand body relatively developed. At the same time, it is close to the transition of a semideep lake-deep lake in the northeast direction with favorable oil generation conditions, sufficient oil source, and well-sealing conditions, forming the self-generation and self-storage type reservoir combination, wherein the Chang 8 and Chang 9 layers of the Yanchang Formation are the main research target reservoirs in this study. The reservoir is characterized by poor physical properties, local natural fractures, primarily large-angle structural fractures and microfractures with small pore throats and poor connectivity, and obvious start-up pressure gradient. In the oil field’s actual production, the production declines quickly and can hardly maintain its stability. The performance of development by elastic energy is overall unsatisfactory.27

The lithology of the Chang 8 reservoir in the Yanchang Formation is classified as mainly medium-grained and fine-grained feldspar lithic sandstone with a small amount of mica that has an equal amount of potassium feldspar and plagioclase, and the rock debris mainly consists of igneous rock, followed by metamorphic rock debris. The fillings are mainly calcite, followed by authigenic clay and kaolinite. The cementation type is mainly the pore type and the thin-film pore type. The lithology of the Chang 9 reservoir is classified as mainly medium-grained and fine-grained feldspar lithic sandstone with a small amount of mica that has an equal amount of potassium feldspar and plagioclase, and the rock debris mainly consists of igneous rock, followed by metamorphic rock debris. The main fillings are the clay, followed by increased authigenic quartz and authigenic clay (Figure 1). In addition, in general (Figure 2), a certain positive correlation exists between porosity and permeability in the research region: as the permeability increases, the porosity increases. Most of the tested cores have a permeability of less than 1 mD, which belongs to typical tight reservoir cores.28

Figure 1.

Type and composition diagram of sandstones in the reservoir group in the research region.

Figure 2.

Cross plot of porosity and permeability of tight sandstones in the reservoir group in the research region.

Specifically, rock mineral compositions of different wells in the research block were tested; the results are shown in Figure 3. The main mineral types of the tight sandstone in the research block are quartz, followed by potassium feldspar, plagioclase, and clay minerals. The mass fraction of quartz minerals in the HH 44 well (Chang 8 reservoir) ranges from 44.13 to 61.81%, with an average of 55.41%; the potassium feldspar mineral content ranges from 17.67 to 25.28%, with an average of 21.62%. The content of clay minerals ranges from 8.77 to 12.65%, with an average of 10.55% (Figure 3a). The mass fraction of quartz minerals in the HH56 well (Chang 9 reservoir) ranges from 18.50 to 35.20%, with an average of 28.51%; the mineral content of plagioclase ranges from 35.00 to 46.30%, with an average of 41.46%. The mineral content of clay ranges from 14.20 to 17.00%, with an average of 15.21% (Figure 3b). In general, there is no significant difference in the mineral composition and mass fraction of the samples. At the centimeter scale and above, the longitudinal heterogeneity of lithology and mineral components of the HH 44 well (Chang 8 reservoir) and the HH56 well (Chang 9 reservoir) tight sandstones is relatively weak. Moreover, the HH 44 well (Chang 8 reservoir) can be more easily fractured than Chang 9.

Figure 3.

Mineral compositions of different wells.

2.2. Experimental Method

2.2.1. Synchrotron Radiation Imaging Technology

The basic imaging principle of synchrotron radiation CT is the same as that of conventional X-CT. The main difference lies in the light source. The synchrotron radiation has a light source with a very high brightness, usually 1 million times higher than the X-ray tube, while it can also obtain a very high signal-to-noise ratio, thus greatly improving the measurement accuracy and detection sensitivity. Besides, the light of synchrotron radiation is very pure as it is produced in an ultrahigh vacuum, without any contamination brought by impurities. The emission of synchrotron radiation light is concentrated in a very narrow cone centered on the direction of electron motion, making the beam angle so small that the beam is almost parallel. Therefore, the beam structure can easily be transformed and is comparable to a laser. The coherence between the partial synchrotron radiation and free-electron laser emitted by synchrotron radiation wiggler gives incomparable application potentials to the coherent X-ray synchrotron radiation. The characteristics of a synchrotron radiation source make the SR-CT more accurate and clearer than the conventional CT in rock imaging. The synchrotron radiation imaging used in this study mainly tested cores from three research regions with a permeability of 1.257, 0.565, and 0.335 mD.

2.2.2. Scanning Electron Microscopy (SEM) Technology

Under the action of the accelerating voltage, the electron beam emitted by scanning microscopy via an electronic gun converges through the magnetic lens system to form an electron optical system with a diameter of 5 nm. After passing through two or three electromagnetic lenses, the electron beam converges into a fine electron beam focusing on the surface of the sample. A scanning coil is installed above the final lens, causing the electron beam to scan across the surface of the sample. As a result of the interaction between the high-energy electron beam and the sample material, various kinds of information are generated: secondary electrons, back-reflected electrons, absorption electrons, X-ray electrons, Auger electrons, cathodoluminescence and transmission electrons, etc. These signals are picked up by the corresponding receiver and amplified to the grid of the image tube to modulate the tube brightness since the current passing through the scanning coil has a one-to-one correspondence to the certain brightness of the image tube. In another word, when the electron beam hits a point on the sample, a bright spot appears on the fluorescent screen. In this way, scanning electron microscopy (SEM) uses point-by-point imaging to convert the different characteristics of the sample surface into video signals in sequence and in proportion to complete a frame of an image so that we can observe various features of the sample surface on the fluorescent screen.

2.2.3. High-Pressure Mercury Injection Technology

The principle of high-pressure mercury injection is mostly the same as that of the conventional mercury injection method. The main advantage is that the maximum mercury injection pressure is high enough (up to 350 MPa) to test small pores (the minimum test pore diameter is about 2 nm). The high-pressure mercury injection device used in the experiment was Autopore IV 9520, with a maximum analytical pressure of 206 MPa and a corresponding throat radius of 3.5 nm, which covered the size requirements of the pore throat in tight oil reservoirs. The injection method was continuous mercury injection. The capillary pressure curve obtained by the mercury injection method can provide microscopic pore structure information of the reservoir. On the one hand, the shape of the curve can provide support for the research studies of reservoir pore structure classification and sorting. On the other hand, the measured parameters obtained would include massive reservoir characteristics parameters such as the pore throat radius and distribution, sorting and homogeneity, reservoir property and permeability, fluid availability of the rock, and pore throat bending degree.

3. Results and Discussion

3.1. Qualitative Analysis of the Microscopic Pore Throat Structure

In recent years, some high-tech methods have been applied for the evaluation of tight oil reservoirs, such as synchrotron radiation CT, nano-CT, and scanning electron microscopy. The innate advantage of these methods is that they can directly observe the shape and connectivity of rocks. Therefore, this study uses these new high-tech methods to test tight sandstones, study their pore morphology and connectivity, and understand the reservoir characteristics to lay a foundation for the study of the seepage mechanism of the research block. In this study, three cores with different permeabilities in the reservoir were used for synchrotron radiation CT imaging to investigate the heterogeneity of tight sandstones. As shown in Figure 4, with the decrease of permeability and the improvement of imaging resolution, the pore morphology and connectivity of tight sandstones can be easily observed. Tight sandstones have a strong microscopic heterogeneity, and the lower the permeability, the worse the pore connectivity. Figure 5 shows the scanning electron microscopy photos of tight cores. It can be seen that for cores with a permeability greater than 0.4 mD, the pore types are mainly well-developed intergranular pores; most of the particles are wrapped in a thin film by granite, and the surface pore rate is about 3–5%. Most of the pores are connected with good reservoir performance. For cores with a permeability from 0.1 to 0.4 mD, the dissolved pores in grains are relatively well-developed while the intergranular pores are not. The intergranular pores are mostly filled with an argillaceous material, and the surface pore rate is about 2–3%. The intergranular pores are connected with each other with medium reservoir performance. For cores with permeability less than 0.1 mD, there are few intergranular pores, and dissolution micropores and intergranular pores are developed. The particles are filled with irregular clay, and the surface pore rate is about 1–2%. Most of the pores are not connected with severe microscopic heterogeneity and poor reservoir performance.

Figure 4.

Synchrotron radiation results of cores with different permeability levels. (a) Surface pore rate at about 3–5%; (b) particles wrapped in thin-film; (c) connected intergranular pores; (d) surface pore rate at about 2–3%; (e) well-developed dissolved pores in grains; (f) partially connected intergranular pores; (g) surface pore rate at about 1–2%; (h) particles filled with irregular clay; and (i) most of the pores compressed into silts.

Figure 5.

Scanning electron microscopy test results of cores with different permeabilities.

3.2. High-Pressure Mercury Injection Test Results

As a new research method, high-pressure mercury injection provides microscopic pore structure information through the pressure curve formed by the mercury injection volume, the mercury extraction volume, and the pressure, together with the curve of the pore radius and the volume distribution density, and the curve of the pore radius and the normalized volume distribution curve. On the one hand, the shape of the curve can provide support for the research studies of reservoir pore structure classification and characteristics. On the other hand, the measured parameters obtained would include massive reservoir characteristics such as pore throat radius and distribution.

In this study, the mercury injection curves of reservoir cores from Chang 8 and Chang 9 were drawn in the same diagram, which becomes the basis of the implemented reservoir classification and evaluation. Figure 6 shows the distribution curve between capillary pressure and mercury saturation obtained by high-pressure mercury injection in different tight oil reservoirs. As can be seen from the figure, based on mercury injection test results, the reservoirs are divided into three categories according to different permeabilities: type I: 0.7 mD < K < 1.2 mD; type II: 0.4 mD < K < 0.7 mD; and type III: 0.1 < K < 0.4 mD. Specifically, the type I reservoir has the highest mercury saturation, about 96%, in the core with a good reservoir quality, whereas the mercury saturation of type II reservoir is about 60%, with a medium reservoir quality; the type III reservoir has the worst reservoir quality with a mercury saturation of about 30%. Also, the high-pressure mercury injection curve fluctuates greatly with almost no horizontal section, indicating a relatively severe reservoir heterogeneity. Meanwhile, according to the pore throat radius distribution of tight sandstones, the distribution of pore throat radius in the research block presents bimodal distribution, which indicates the presence of at least two or more pore types in tight sandstones. Moreover, since these two types of pore throats have great significance in the seepage flow, they are shown in the mercury injection curve. In addition, according to SEM results, there are multiple kinds of pores in tight sandstones (Figure 5b,c,i). The pore throat radius of most tight sandstones in the research block is less than 1 μm, and the curve gradually moves to the right with the increase of permeability (Figure 7). Figure 8 shows the relationship curve between the permeability of the tight sandstone core and the average throat radius in the research block. It can be seen that the lower the permeability, the smaller the average throat radius, which also indicates that some large and connected pores in tight sandstones have positive effects on seepage flow. On the contrary, the displacement pressure is just the opposite. The higher the permeability is, the lower the threshold pressure will be (Figure 9), indicating the permeability as an important index for the evaluation of core seepage ability. There is no obvious correlation between porosity and core average throat radius (Figure 10). However, as the porosity of the core increases, the displacement pressure required to enter the core decreases (Figure 11).

Figure 6.

Capillary pressure curve of high-pressure mercury injection in tight sandstones.

Figure 7.

Distribution of pore throat radii of different types of tight cores.

Figure 8.

Relationship between permeability and average pore throat radius of tight sandstones.

Figure 9.

Relationship between permeability and displacement pressure of tight sandstones.

Figure 10.

Cross plot of the average radius and porosity of tight sandstones.

Figure 11.

Cross plot of displacement pressure and porosity of tight sandstones.

3.3. Geological Significance of Fractal Dimensions

The pore throat structure of the tight sandstone reservoir in the research block has self-similarity and conforms to the fractal characteristics. At the same time, the fractal dimension calculated by fractal theory can effectively characterize the heterogeneity and structural complexity of the microscopic pore throat structure of the tight reservoir. According to the results of research studies and calculations, the fractal dimension of tight reservoirs concentrates between 2 and 3. On the one hand, as the fractal dimension approaches 2, the pore throat space tends to be simpler, and the microscopic heterogeneity is weaker; on the other hand, as the fractal dimension approaches 3, the pore throat space is more complex, and the microscopic heterogeneity is stronger. Its magnitude is affected by multiple factors (Table 1).

Table 1. High-Pressure Mercury Injection Test Results of Tight Sandstonesa.

| classification | sample | K | φ | H | lithology | ra | pt | Ew |

|---|---|---|---|---|---|---|---|---|

| I | HH69-1 | 0.897 | 16.61 | 2067.10 | sandstone | 0.42 | 0.300 | 38.1 |

| HH69-26 | 0.762 | 15.23 | 2070.56 | sandstone | 0.45 | 0.300 | 33.4 | |

| HH183-1 | 0.631 | 11.26 | 2209.80 | sandstone | 0.187 | 0.810 | 36.3 | |

| HH183-33 | 0.718 | 15.75 | 2216.33 | sandstone | 0.281 | 0.500 | 37.6 | |

| HH69-31 | 1.041 | 10.61 | 2071.59 | sandstone | 0.62 | 0.300 | 28.3 | |

| HH183-23 | 0.769 | 9.82 | 2214.63 | sandstone | 0.358 | 0.300 | 37.0 | |

| II | HH101-5 | 0.445 | 12.03 | 1926.78 | sandstone | 0.254 | 1.029 | 26.5 |

| HH101-7 | 0.555 | 16.32 | 1926.76 | sandstone | 0.202 | 0.684 | 36.3 | |

| HH183-53 | 0.426 | 13.15 | 2220.32 | sandstone | 0.236 | 0.600 | 36.5 | |

| HH183-63 | 0.398 | 12.02 | 2222.96 | sandstone | 0.255 | 0.700 | 38.3 | |

| HH56-21 | 0.341 | 7.60 | 2102.45 | sandstone | 0.029 | 2.461 | 43.9 | |

| HH56-6 | 0.530 | 9.50 | 2096.39 | sandstone | 0.155 | 2.119 | 46.6 | |

| III | HH101-27 | 0.284 | 10.06 | 2124.56 | sandstone | 0.021 | 1.559 | 21.6 |

| HH101-37 | 0.155 | 10.94 | 2127.83 | sandstone | 0.039 | 1.363 | 39.1 | |

| HH101-40 | 0.218 | 12.02 | 2129.35 | sandstone | 0.023 | 1.362 | 39.2 | |

| ZJ5-12-2 | 0.240 | 10.19 | 2145.61 | sandstone | 0.185 | 1.345 | 39.9 | |

| HH56-14 | 0.202 | 9.10 | 2109.29 | sandstone | 0.171 | 3.425 | 43.1 | |

| HH56-29 | 0.223 | 8.30 | 2110.04 | sandstone | 0.203 | 3.214 | 40.3 |

Note: Ra, average pore throat radius; pt, displacement pressure; Ew, mercury withdrawal efficiency.

3.4. Fractal Characteristics of Tight Oil Reservoirs

In the high-pressure mercury injection experiment, the capillary pressure curves of mercury injection and withdrawal were obtained, and based on the curves, the characteristics of the pore throat of tight sandstones were analyzed. Also, through the relationship between capillary pressure (Pc) and pore throat radius (r), the pore throat radius curve for the pore throat structure evaluation of tight sandstone was obtained. Its calculation formula is as follows:

| 1 |

where Pc is the capillary pressure (MPa), σ is the surface tension (N/m), θ is the wetting angle (°), and r is the pore throat radius (μm). Besides, the surface tension is 485 mN/m, and the wetting angle is 140°.

As a type of porous media, the pore throat system has self-similarity. Previous studies have shown that in the high-pressure mercury injection experiment, the fractal relation between the wetting phase saturation Sw and the capillary pressure can be expressed as29

| 2 |

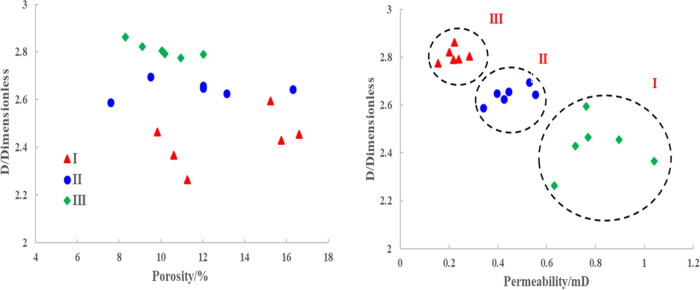

According to eq 2, based on the experimental data of high-pressure mercury injection, we can calculate the fractal dimension of the rock pore throat network system and describe the microstructure characteristics of porous media. Because of the self-similarity of the tight sandstone pore network system, the fractal method can be used to study the microscopic heterogeneity of the pore throat. According to the capillary pressure curve of the tight sandstone core obtained by the high-pressure mercury injection experiment, the fitting lines of log PC and log SW were drawn using fractal theory. As shown in Figure 12, a strong correlation with R2 above 0.9 exists between log PC and log SW. Besides, from the fractal dimension map of the three reservoir types, the fractal dimension of class I is 2.2646–2.5945, with an average of 2.4291; the fractal dimension of class II is 2.5881–2.6956, with an average of 2.6425; the fractal dimension of class III is 2.7737–2.8634, with an average of 2.8077. According to fractal theory, the closer the fractal dimension is to 3, the stronger the microscopic heterogeneity is and the rougher the pore surface is. On the contrary, a fractal dimension closer to 2 indicates weaker microscopic heterogeneity and a smoother pore surface. Therefore, it can be seen from Figure 13 that the porosity of the three types of reservoir cores does not correlate with the fractal dimension. However, with the decrease of permeability, a fractal dimension closer to 3 indicates a lower permeability and a stronger microscopic heterogeneity (Table 2).

Figure 12.

Cross plot of log PC and log SW.

Figure 13.

Porosity, permeability, and fractal dimension map.

Table 2. Fractal Dimension Results of Tight Sandstones.

| classification | sample | K (×10–3 μm2) | φ (%) | D | R2 |

|---|---|---|---|---|---|

| I | HH69-1 | 0.897 | 16.61 | 2.4549 | 0.9251 |

| HH69-26 | 0.762 | 15.23 | 2.5945 | 0.9085 | |

| HH183-1 | 0.631 | 11.26 | 2.2646 | 0.9275 | |

| HH183-33 | 0.718 | 15.75 | 2.4299 | 0.9046 | |

| HH69-31 | 1.041 | 10.61 | 2.3659 | 0.9269 | |

| HH183-23 | 0.769 | 9.82 | 2.4650 | 0.9258 | |

| II | HH101-5 | 0.445 | 12.03 | 2.6558 | 0.9933 |

| HH101-7 | 0.555 | 16.32 | 2.6432 | 0.9673 | |

| HH183-53 | 0.426 | 13.15 | 2.6247 | 0.9958 | |

| HH183-63 | 0.398 | 12.02 | 2.6474 | 0.9941 | |

| HH56-21 | 0.341 | 7.60 | 2.5881 | 0.9869 | |

| HH56-6 | 0.530 | 9.50 | 2.6956 | 0.9936 | |

| III | HH101-27 | 0.284 | 10.06 | 2.8042 | 0.9827 |

| HH101-37 | 0.155 | 10.94 | 2.7737 | 0.9719 | |

| HH101-40 | 0.218 | 12.02 | 2.7906 | 0.9787 | |

| ZJ5-12-2 | 0.240 | 10.19 | 2.7928 | 0.9781 | |

| HH56-14 | 0.202 | 9.10 | 2.8215 | 0.9866 | |

| HH56-29 | 0.223 | 8.30 | 2.8634 | 0.9696 |

3.5. Influence of Microscopic Heterogeneity on Seepage in Tight Sandstones

Research studies worldwide have shown that tight sandstones have poor physical properties and strong heterogeneity.30,31 Moreover, some scholars have studied the influence of pore throat heterogeneity on the tight sandstone seepage process.32Figure 14 shows a typical pore throat heterogeneity, where large intergranular or intragranular pores are mainly developed in tight sandstones (dashed red line in the figure). At the same time, micropores in clay minerals often act as connecting throats between pores (intergranular pores or intragranular pores), and in general, these areas have a strong seepage capacity. The injection flow will prefer to enter these channels and form the dominant injection channels, which is the seepage inhomogeneity caused by the microscopic heterogeneity. This is also consistent with the study of Dou et al. in Chang 6–Chang 7 in the southwestern Ordos Basin.33

Figure 14.

Typical photo of pore throat heterogeneity of tight sandstones.

4. Conclusions

-

(1)

The research area is classified as a typical tight oil reservoir, where the rock types are mainly medium-grained and fine-grained feldspar lithic sandstone; a logarithmic relationship exists between permeability and porosity. As synchrotron radiation studies show, with the decrease of permeability and the improvement of imaging resolution, the pore morphology and connectivity of tight sandstones can be easily observed. Tight sandstones have strong microscopic heterogeneity, and as the permeability gets lower, the pore connectivity worsens.

-

(2)

As shown by scanning electron microscope (SEM) images, for the cores with a permeability greater than 0.4 mD, the pore types are mainly well-developed intergranular pores with a surface pore rate of about 3–5%. Most of the intergranular pores are connected, and the reservoir performance is good. For cores with a permeability of 0.1–0.4 mD, the dissolved pores in grains are well-developed with a surface pore rate of about 2–3%. The intergranular pores are partially connected with moderate reservoir performance. For cores with permeability less than 0.1 mD, dissolved micropores and intergranular pores are developed with a surface pore rate of about 1–2%. Most of the pores are disconnected with severe microheterogeneity and poor reservoir performance.

-

(3)

The reservoirs are divided into three categories based on permeability: type I: 0.7 mD < K < 1.2 mD; type II: 0.4 mD < K < 0.7 mD; and type III: 0.1 < K < 0.4 mD. Among them, the mercury injection saturation of three reservoir types decreases successively. Meanwhile, most of the pore throat radii of the tight sandstone in the research area is less than 1 μm. With the increase of permeability, the curve moves gradually to the right. As the permeability declines, the average pore throat radius becomes smaller, which indicates the positive effect caused by some large and connected pores of tight sandstone on seepage flow.

-

(4)

The fractal dimension can characterize the microscopic heterogeneity of tight reservoir rock. The fractal dimensions of the three types of reservoirs in the research block are 2.2646–2.5945, 2.5881–2.6956, and 2.7737–2.8634, respectively. As the fractal dimension of type III approaches 3, the microscopic heterogeneity becomes stronger. On the contrary, as the fractal dimension of type III approaches 2, the microscopic heterogeneity gets weaker. The more heterogeneous the tight reservoir is, the more likely the injected fluid is to flow along the porous and connected region.

Acknowledgments

This work was supported in part by the National Science and Technology Major Project (2017ZX05013-001 and 2016ZX05048) and artificial intelligence 2019D-500809, Natural Science Foundation of Chongqing under Grant cstc2020 jcyj-msxmX0216, and in part by the Bayu Scholars Program.

The authors declare no competing financial interest.

References

- Du J. H.; Liu H.; Ma D. S.; Fu J. H.; Wang Y. H.; Zhou T. Y. Discussion on effective development techniques for continental tight oil in China. Pet. Explor. Dev. 2014, 41, 198–205. 10.1016/S1876-3804(14)60025-2. [DOI] [Google Scholar]

- Zheng T. Y.; Yang Z. M.; Liu X. G.; Luo Y. T.; Xiao Q. H.; Zhang Y. P.; Zhao X. L. Understanding Immiscible Natural Gas Huff-N-Puff Seepage Mechanism in Porous Media - A Case Study of CH4 HNP Laboratorial and Numerical Simulations in Chang-7 Tight Core. Nat. Resour. Res. 2021, 30, 2397–2411. 10.1007/s11053-021-09836-2. [DOI] [Google Scholar]

- Li Y. L.; Li Y. X.; Hu Z. M.; Duan X. G.; Liu X. G.; Chen X. K.; Mu Y.; Zhao X. L. Unsteady Intermittent Coordination Mechanism of Adsorbed Gas Desorption and Transport in the Late Stage of Shale Gas Development. J. Nat. Gas Sci. Eng. 2020, 86, 103748 10.1016/j.jngse.2020.103748. [DOI] [Google Scholar]

- Zhao X. L.; Yang Z. M.; Lin W.; Xiong S. C.; Luo Y. T.; Wang Z. Y.; Chen T.; Xia D. B.; Wu Z. K. Study on Pore Structures of Tight Sandstone Reservoirs Based on Nitrogen Adsorption, High-Pressure Mercury Intrusion, and Rate-Controlled Mercury Intrusion. J. Energy Resour. 2019, 141, 112903 10.1115/1.4043695. [DOI] [Google Scholar]

- Zhao X. L.; Yang Z. M.; Lin W.; Xiong S. C.; Luo Y. T.; Liu X.; Xia D. B. Fractal study on pore structure of tight sandstone based on full-scale map. Int. J. Oil Gas Coal Technol. 2019, 22, 123–139. 10.1504/IJOGCT.2019.102788. [DOI] [Google Scholar]

- Lin W.; Li X. Z.; Yang Z. M.; Manga M.; Fu X.; Xiong S. C.; Gong A.; Chen G.; Li H.; Pei L.; et al. Multiscale digital porous rock reconstruction using template matching. Water Resour. Res. 2019, 55, 6911–6922. 10.1029/2019WR025219. [DOI] [Google Scholar]

- Cao Z.; Liu G.; Zhan H.; Li C.; You Y.; Yang C.; Jiang H. Pore structure characterization of Chang-7 tight sandstone using MICP combined with N2GA techniques and its geological control factors. Sci. Rep. 2016, 6, 36919 10.1038/srep36919. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhao X. L.; Yang Z. M.; Lin W.; Xiong S. C.; Wei Y. Y. Characteristics of microscopic pore-throat structure of tight oil reservoirs in Sichuan Basin measured by rate-controlled mercury injection. Open Phys. 2018, 16, 675–684. 10.1515/phys-2018-0086. [DOI] [Google Scholar]

- Xi K. L.; Cao Y. C.; Haile B. G.; Zhu R. K.; Jahren J.; Bjørlykke K.; Zhang X. X.; Hellevang H. How does the pore-throat size control the reservoir quality and oiliness of tight sandstones? The case of the Lower Cretaceous Quantou Formation in the southern Songliao Basin, China. Mar. Pet. Geol. 2016, 76, 1–15. 10.1016/j.marpetgeo.2016.05.001. [DOI] [Google Scholar]

- Yao Y. B.; Liu D. M. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. 10.1016/j.fuel.2011.12.039. [DOI] [Google Scholar]

- Wu H.; Zhang C. L.; Ji Y. L.; Liu R.; Liu G. Pore-throat size characterization of tight sandstone and its control on reservoir physical properties: a case study of yanchang formation, eastern gansu, ordos basin. Acta Pet. Sin. 2017, 38, 876–887. [Google Scholar]

- Pittman E. D. Relationship of Porosity and Permeability to various Parameters Derived from Mercury Injection Capillary Pressure curves for Sandstones. AAPG Bull. 1992, 76, 191–198. [Google Scholar]

- Zhao H. W.; Ning Z. F.; Wang Q.; Zhang R.; Zhao T. Y.; Niu T. F.; Zeng Y. Petrophysical characterization of tight oil reservoirs using pressure-controlled porosimetry combined with rate-controlled porosimetry. Fuel 2015, 154, 233–242. 10.1016/j.fuel.2015.03.085. [DOI] [Google Scholar]

- Xiao Q. H.; Yang Z. M.; Wang Z. Y.; Qi Z. L.; Wang X. W.; Xiong S. C. A full-scale characterization method and application for pore-throat radius distribution in tight oil reservoirs. J. Pet. Sci Eng. 2020, 187, 106857 10.1016/j.petrol.2019.106857. [DOI] [Google Scholar]

- Clarkson C. R.; Solano N.; Bustin R. M.; Bustin A.; Chalmers G.; He L.; Melnichenko Y.; Radlinski A.; Blach T. Pore structure characterization of North American shale gas reservoirs; using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. 10.1016/j.fuel.2012.06.119. [DOI] [Google Scholar]

- Xiao Q.; Wang Z.; Yang Z.; Xiang Z.; Liu Z.; Yang W. Novel method for determining the lower producing limits of pore-throat radius and permeability in tight oil reservoirs. Energy Rep. 2021, 7, 1651–1656. 10.1016/j.egyr.2021.03.011. [DOI] [Google Scholar]

- Wang X.; Hou J.; Song S.; Wang D.; Gong L.; Ma K.; Liu Y.; Li Y.; Yan L. Combining pressure-controlled porosimetry and rate-controlled porosimetry to investigate the fractal characteristics of full-range pores in tight oil reservoirs. J. Pet. Sci. Eng. 2018, 171, 353–361. 10.1016/j.petrol.2018.07.050. [DOI] [Google Scholar]

- Aydin A. Fractures, faults, and hydrocarbon entrapment, migration and flow. Mar. Pet. Geol. 2000, 17, 797–814. 10.1016/S0264-8172(00)00020-9. [DOI] [Google Scholar]

- Gasparrini M.; Sassi W.; et al. Natural sealed fractures in mudrocks: A case study tied to burial history from the Barnett Shale, Fort Worth Basin, Texas, USA. Mar. Pet. Geol. 2014, 55, 122–141. 10.1016/j.marpetgeo.2013.12.006. [DOI] [Google Scholar]

- Morad S.; Al-Ramadan K.; Ketzer J.; et al. The impact of diagenesis on the heterogeneity of sandstone reservoirs: A review of the role of depositional facies and sequence stratigraphy. AAPG Bull. 2010, 94, 1267–1309. 10.1306/04211009178. [DOI] [Google Scholar]

- Barbiera M.; Hamon Y.; Callot J. Sedimentary and diagenetic controls on the multiscale fracturing pattern of a carbonate reservoir: The Madison Formation (Sheep Mountain, Wyoming, USA). AAPG Bull. 2012, 29, 50–67. [Google Scholar]

- Liu L.; Wang Zh.; Liu Y. Experimental analysis of micro-heterogeneity of Chang 8 sandstone in Xifeng area of Ordos Basin. Rock Miner. Test. 2008, 01, 29–32. [Google Scholar]

- Gong F.; Bao Z.; Ji H.; Fan Z.; Liu L. Study on the reservoir diagenesis heterogeneity of chang 6 member of upper triassic in jiyuan area of ordos basin. J. Jilin Univ. 2011, 41, 639–646. [Google Scholar]

- You Y.; Liu J.; Feng S.; Jing H.; Liang X.; Niu X. Heterogeneity of the massive tight sandstones and its inspirations for the exploration and development of the tight oil. Pet. Geol. Oilfield Dev. Daqing 2015, 34, 168–174. [Google Scholar]

- Li A.; Zhang J.; Li W.; Wang Y.; Wang Y. The reservoir macroscopic heterogeneity and its influence factors in yujiaping area, Ordos Basin. J. Northwest Univ. (Nat. Sci. Ed.) 2016, 46, 246–255. [Google Scholar]

- Luo J.; Liu X.; Fu X.; Miao L.; Rui K.; Jia Y. Impact of petrologic components and their diagenetic evolution on tight sandstone reservoir quality and gas yield: a case study from he 8 gas-bearing reservoirs of upper paleozoic in northern ordos basin. Earth Science (J. China Univ. Geosci.) 2014, 39, 537–545. 10.3799/dqkx.2014.051. [DOI] [Google Scholar]

- Guo M.; Chen Y.; Zheng Zh.; Li J.; Yu L.; Liu L. A rapid assessment method for the recoverable reserves probability of tight oil reservoirs: A case study of Chang 8 reservoir in Honghe Oilfield. Pet. Geol. Exp. 2021, 43, 154–160. [Google Scholar]

- Geological Evaluation Method for Tight Oil: GB/T 34906-2017; National standards of People’s Republic of China: Beijing, 2018.

- Zhao X.; Yang Z.; Liu X.; Wang Z.; Luo Y. Analysis of pore throat characteristics of tight sandstone reservoirs. Open Geosci. 2020, 12, 977–989. 10.1515/geo-2020-0121. [DOI] [Google Scholar]

- Hu J.; Sun R.; Zhang Y. Investigating the horizontal well performance under the combination of micro-fractures and dynamic capillary pressure in tight oil reservoirs. Fuel 2020, 269, 117375 10.1016/j.fuel.2020.117375. [DOI] [Google Scholar]

- Xiao D.; Jiang S.; Thul D.; Huang W.; Lu Z.; Lu S. Combining rate-controlled porosimetry and NMR to probe full-range pore throat structures and their evolution features in tight sands: A case study in the Songliao Basin, China. Mar. Pet. Geol. 2017, 83, 111–123. 10.1016/j.marpetgeo.2017.03.003. [DOI] [Google Scholar]

- Li S.; Dong M.; Luo P. A crossflow model for an interacting capillary bundle: development and application for waterflooding in tight oil reservoirs. Chem. Eng. Sci. 2017, 164, 133–147. 10.1016/j.ces.2017.01.059. [DOI] [Google Scholar]

- Dou W.Study on the Tightness and Heterogeneity of Sandstones from Chang 6 to Chang 7 in the Southwest of Ordos Basin; China University of Petroleum: Beijing, 2018.