Abstract

Over the years, sustainable supplier selection (SSS) has become increasingly popular among scholars and practitioners as a viable means to actualize supply chain sustainability. Little, however, is known about the impact of the COVID-19 pandemic on sustainable supplier selection particularly in the manufacturing sector. In this paper, we present pandemic response strategies as a significant aspect of the COVID-19 pandemic’s impact and investigate the relative importance of such strategies in SSS implementation. Drawing upon a rich data pool from the Nigerian manufacturing sector, we proposed an integrated multi-criteria decision making (MCDM) methodology to analyse the interrelationships between the COVID-19 pandemic response strategies and Triple-Bottom-Line (TBL) criteria for SSS. Our analysis shows that economic criteria and pandemic response strategies are the highest ranked in terms of relative importance and thereby pinpoints the need for manufacturing firms to emphasize such during SSS implementation in the COVID-19 pandemic. Specifically, quality, cost, use of personal protective equipment and use of information technologies for customer demand prediction are inferred as highly significant in SSS implementation in the COVID-19 pandemic era. Furthermore, the efficiency of the proposed methodology was validated by a comparative analysis with other MCDM methods. Therefore, this study presents implications on the significance of pandemic response strategies in SSS and thereby enriches literature on the COVID-19 pandemic’s impact on supply chains.

Keywords: Sustainable supplier selection, COVID-19 pandemic, Manufacturing sector, Triple-Bottom-Line (TBL), Supply chain sustainability

1. Introduction

The COVID-19 pandemic has affected millions of people around the globe and resulted in unprecedented supply chain disruptions such as vulnerabilities in lead times and order quantities, structural disruptions and severe demand fluctuations (Chowdhury et al., 2021, Ivanov and Dolgui, 2021). Clearly, there has been an increased demand for medical supplies such as gloves, face masks, ventilators and other personal protective equipment (PPE), face masks and ventilators in addition to food products and toiletries in the wake of the COVID-19 pandemic. Likewise, governments have implemented certain measures such as imposing nation-wide lockdowns and border closures and maintaining social distancing to contain the spread of the outbreak. Notably, these measures have further resulted in negative impact on consumer spending coupled with large-scale disruptions to international trade and supply chains (Behaldi et al, 2021). As the COVID-19 pandemic progresses and evolves from country to country, scholars and industry practitioners have increasingly garnered their attention to the topic. Consequently, various published studies exist in extant literature particularly on the impact of the COVID-19 pandemic on supply chains (Belhadi et al., 2021, Choi et al., 2020, Chowdhury et al., 2021, Goodarzian et al., 2021, Karmaker et al., 2021, Kumar et al., 2021, Majumdar et al., 2020, Nagurney, 2021a). Yet still, the dearth of studies on the COVID-19 pandemic’s impact on supply chain sustainability decisions like the sustainable supplier selection especially in the manufacturing sector has been observed. The COVID-19 pandemic provides opportunities for manufacturing firms to implement sustainability objectives in their underlying supply chain networks for increased global competitiveness (Orji and Liu, 2020, Ranjbari et al., 2021, Sarkis, 2020, Sarkis et al., 2020). Likewise, manufacturing firms face incessant pressure from stakeholders to balance economic benefits with sustainable development in their supply chain networks for improved organizational performance (Goodarzian et al., 2021, Jain and Singh, 2020, Severo et al., 2021). In such a context, sustainable supplier selection is regarded as a potent means for manufacturing firms to actualize supply chain sustainability for expected performance gains (Hendiani et al., 2020, Orji and Wei, 2015, Stevic et al., 2020, Tayyab and Sarkar, 2021). Moreover, manufacturing firms are bound to implement response strategies in the COVID-19 pandemic era, and as a result, such strategies can be considered as a significant aspect of the pandemic’s impact on their supply chains. Therefore, in our study, we investigated the COVID-19 pandemic’s impact on sustainable supplier selection (SSS) by exploring the relative importance of pandemic response strategies in SSS in the manufacturing sector. This is believed to be able to equip manufacturing firms with the understanding on how to achieve supply chain sustainability in the COVID-19 pandemic era and likewise avoid perceptual reaction to future pandemics (Choi et al., 2020).

In this paper, we focused on the Nigerian manufacturing sector which is characterized by inefficient technologies and unsustainable production patterns manifested in high pollution rates and other human and environmental hazards (Bolaji et al, 2018). Evidently, the Nigerian manufacturing sector is an attractive case given its role in contributing to Nigeria’s GDP of $244 billion in 2011, making it one of the largest economies in Africa and arguably the largest market in Africa (Egbetokun, 2015). Recently, there is growing awareness on sustainability trends in emerging economies like Nigeria and this has increasingly pressured manufacturing firms to implement sustainability strategies to satisfy stakeholders’ requirements and also, reduce negative environmental impacts (Sanni, 2018). In fact, manufacturing companies in emerging economies that aspire to implement sustainability strategies along their supply chains consider sustainable supplier selection as being highly essential for expected outcomes (Bai & Sarkis, 2010). Moreover, prior researchers have shown that supply chain operations in emerging economies like Nigeria is most significantly impacted by disasters, either catastrophic or non– catastrophic (Kumar et al, 2021). However, a research gap remains on how the catastrophic COVID-19 pandemic has impacted and become a significant moderator of sustainable supplier selection in emerging economies like Nigeria. This study exists to fill this gap. Hence, this study aims to answer the following research questions, “How has the COVID-19 pandemic impacted the SSS implementation in the Nigerian manufacturing sector?” and “Are the pandemic response strategies considered significant in SSS in the COVID-19 pandemic era?” By answering the above stated research questions, this study proposes a research agenda with huge prospects to provide an in- depth insight into the relative importance of pandemic response strategies while implementing SSS in the COVID-19 pandemic. Generally, SSS is implemented by a set of criteria that are classified under the economic, environmental and social dimensions using the triple-bottom-line (TBL) approach (Liu et al. 2021). Consequently, our study will investigate the interrelationships between the pandemic response strategies and TBL criteria for SSS implementation in the manufacturing sector, to ultimately serve as guidelines for managers and industry practitioners.

This study proposes to make important contributions to theory and practice. Firstly, the current study introduces pandemic response strategies (Belhadi et al., 2021, Dwivedi et al., 2020, Pantano et al., 2020, Sheth, 2020) as a critical aspect of the COVID-19 pandemic’s impact on sustainable supplier selection (SSS) within the manufacturing sector. As such, this study is consistent with the dynamic capability theory which posits that dynamic capabilities can be utilized by firms to resolve problems, scan opportunities and mitigate threats in rapidly changing environments (Alswafi et al., 2021, Cao et al., 2019, Chowdhury and Quaddus, 2017, Parast, 2020). A vital component of the dynamic capability theory is the firm’s capability to respond to risks/ threats, seize opportunities and maintain competitiveness through reconfiguring resources. Since, response strategies are utilized by firms to mitigate the threats from the COVID-19 pandemic (Parast, 2020, Teece, 2007), dynamic capability theory is an appropriate theoretical lens to study the COVID-19 pandemic’s impact on SSS. Secondly, this study presents a set of criteria for sustainable supplier selection (Jain and Singh, 2020), classified based on the TBL approach within the manufacturing industry in Nigeria- an African emerging economy. By so doing, this study differs from prior studies that focused on the topic of sustainable supplier selection in the Asian emerging economies and even the developed economies (Mohammed and Harris, 2019, Moheb- and Handfield, 2019, Orji and Wei, 2015, Stevic et al., 2020). Thirdly and lastly, the current study pioneers the application of an integrated multi- criteria decision making (MCDM) methodology to analyse the interrelationships between pandemic response strategies and TBL criteria for SSS with the aid of experts’ inputs in the Nigerian manufacturing sector. The MCDM methodology is based on Fuzzy set theory, Analytical Hierarchy Process (AHP) and Multi-Objective Optimization based on Ratio Analysis with full multiplicative form (MULTIMOORA).

Multi-criteria decision making (MCDM) methods (Al- and Khorramshahgol, 2020, Calabrese et al., 2018, Dong and Cooper, 2016, Gupta and Barua, 2017, Gupta et al., 2020, Kusi-Sarpong et al., 2019, Mastocinque et al., 2020, Orji et al., 2020, Subulan et al., 2015) are generally applied to solve various real life problems that comprise plural criteria and alternatives. Indeed, the Analytical hierarchy process (AHP) has gained wide popularity as one of the MCDM methods that can proffer accurate solutions to complex problems in supply chain management and other research domains (Awasthi et al., 2017, Mital et al., 2017, Sirisawat and Kiatcharoenpol, 2018). The AHP allows the problem to be structured into different levels and sub-criteria in a hierarchical manner, which simplifies it for decision makers to accurately rate different factors and alternatives (Mastocinque et al, 2020). Being able to make and aggregate relative measurements even among intangible parameters that can be determined subjectively, is one of the strengths of the AHP in comparison to other MCDM methods (Dong and Cooper, 2016, Lopez and Ishizaka, 2017). Given the complexity of the problem and the consequent risk of inconsistency, another reason to choose the AHP is the flexibility of its consistency thresholds, against other methods that need perfect consistency in order to calculate weights (Calabrese et al, 2018). However, it is challenging to utilize the AHP to analyse system criteria due to inherent vagueness and uncertainties in human predictions and judgments, thus, necessitating the integration with fuzzy logic resulting in Fuzzy-AHP (Khan et al, 2021). Since, the Fuzzy-AHP has widely and successfully been applied in supply chain problems (Mangla et al., 2015, Shete et al., 2020, Sirisawat and Kiatcharoenpol, 2018, Wang et al., 2012), we employed it in this study to firstly determine the hierarchical interrelationships between the pandemic response strategies and TBL criteria for SSS under uncertainty. Then, the Multi-Objective Optimization based on Ratio Analysis with full multiplicative form (MULTIMOORA) was employed with the inputs from the Fuzzy-AHP computations to determine the weights and robust ranking of the pandemic response strategies and TBL criteria for SSS. This is because, the MULTIMOORA is a comprehensive MCDM method that is significant and much preferred to other methods due to its low computation process, low set up time and non-requirement of the use of software packages (Akkaya et al., 2015, Omrani et al., 2020). In fact, the MULTIMOORA provides a robust ranking of system criteria through utilizing three ranking methods namely ratio system, reference point and full multiplicative form (Liu et al., 2021, Wang et al., 2021). Furthermore, the study findings from the proposed Fuzzy-AHP-MULTIMOORA methodology were compared with results from other MCDM methods such as the AHP and BWM to ensure result validity and reliability. Thus, the proposed methodology will be crucial for managers and practitioners in the Nigerian manufacturing sector to synergize their efforts for effective SSS implementation in the COVID-19 pandemic. Ultimately, this study outlines some research implications that can act as guidelines to decision makers to effectively channel their limited resources towards change management for sustainability in the pandemic era.

The remainder of the paper is structured into sections as follows: the detailed review of the literature on COVID-19 pandemic’s impact on supply chains, the evaluation framework of the COVID-19 pandemic’s impact on SSS and the proposed model are presented in Section 2. In Section 3, the detailed presentation of the proposed model is given. Section 4 presents the case study for testing the feasibility of the proposed model with some insights on the data collection and the results from the proposed model. The discussions on the study results, model validation and, in addition, to the theoretical and practical implications are highlighted in Section 5. The conclusion of the study, its limitations and future research directions are elaborated in Section 6.

2. Literature review

This section reviews some of the studies that are related to supply chain operations in the wake of the COVID-19 pandemic and also highlights the evaluation framework of the COVID-19 pandemic’s impact on SSS coupled with the state-of-art on the proposed model.

2.1. The COVID-19 pandemic’s impact on supply chains

Broadly, this study contributes to the growing stream of research that provides insights into the impact of the COVID-19 pandemic on supply chain operations. Although, the full implications of the COVID-19 pandemic remains to be seen, but deep and pervasive transformations are likely to be implemented in supply chain operations as a result (Ranjbari et al., 2021, Sarkis et al., 2020). Indeed, the COVID-19 pandemic is a sharp reminder that pandemics, like other rarely occurring catastrophes, have happened in the past and will continue to happen in the future (Donthu and Gustafsson, 2020). So, it is not a question of if a pandemic is likely to occur but rather its resulting impact particularly within the supply chain context. As such, the COVID-19 pandemic has energised the relevance of supply chains to the forefront in both practice and in the news and is currently stimulating the investigation of theoretical as well as empirical constructs by academics (Nagurney, 2021b). For instance, Govindan et al (2020) attested to the long-term demand disruptions and increasing propagation of the COVID-19 and then developed an effective model for demand management than can break down the propagation chain and generally mitigate disruptions in the healthcare supply chains. Nagurney (2021b) noted that the COVID-19 pandemic led to labour disruptions in supply chains and further developed a game theory of firms competing non-cooperatively in the production, storage and ultimate distribution of their differentiated products in the presence of labour constraints. Likewise, some researchers consider response strategies as a significant moderator of the COVID-19 pandemic’s impact in various supply chain environments. For example, Kumar et al (2021) in their study presented the contingencies faced by perishable food supply chains in the COVID-19 pandemic and highlighted the risk mitigation strategies to manage such contingencies. Among the risk mitigation strategies, they highlighted proactive business continuity planning, financial sustainability and collaborative management. Belhadi et al (2021) assessed the short and long-term response strategies adopted by automobile and airline supply chains in the COVID-19 pandemic using a combination of qualitative and quantitative techniques. They specifically inferred that the use of advanced industry 4.0 technologies, developing localized supply sources and defining business operations were the best response strategies. In a similar vein, some researchers have presented the sustainability perspective to the impact of COVID-19 pandemic in supply chain systems. For instance, Goodarzian et al (2021) lauded a growing concern with sustainability in the wake of the COVID-19 pandemic and developed a model to solve a production–distribution-inventory-allocation-location problem in the medical supply chain network. Their study provides insights on how to achieve sustainability in the pharmaceutical industry through effective production and distribution of COVID-19 related medicines. Majumdar et al (2020) provided insights into the impact of the COVID-19 pandemic on supply chain social sustainability in their study and suggested that a sustainable sourcing model that incorporates disruption risk be adopted by firms in the post COVID-19 era. Karmaker et al (2021) in their study illustrated the impact of the COVID-19 pandemic on supply chain sustainability by presenting the critical drivers of implementing sustainable supply chain in an emerging economy.

However, there is a dearth of studies that provide understanding on the impact of the COVID-19 pandemic on sustainable supplier selection. This is in spite of the vital role of sustainable supplier selection for firms to enhance the overall sustainable development capacity of supply chains (Chang et al, 2021). Notably, prior studies exist in extant literature on the topic of sustainable supplier selection particularly in the manufacturing sector (Gao et al., 2020, Hendiani et al., 2020, Jain and Singh, 2020, Kannan et al., 2020, Khan et al., 2018, Orji and Wei, 2015, Rashidi et al., 2020, Stevic et al., 2020). Moreover, the TBL criteria for sustainable supplier selection have long operated in fairly stable environments particularly in the Nigerian manufacturing sector without significant impact from a global disruption such as the COVID-19 pandemic. Thus, there is virtually no study that shows how the COVID-19 pandemic has impacted SSS and whether Nigerian manufacturing firms have revised the SSS criteria framework to effectively implement SSS in the pandemic era. It is this gap that this study set out to fill.

2.2. Identification of COVID-19 pandemic response strategies and TBL criteria for sustainable supplier selection

In this study, the COVID-19 pandemic response strategies and TBL criteria for sustainable supplier selection were identified from extensive literature and inputs of experts in the Nigerian manufacturing sector. The literature review involved searching the keywords, abstracts and titles of journal contributions available in the world largest database- Scopus using “sustainable supplier selection”, “manufacturing industry”, emerging economy”, “criteria”, “triple-bottom-line”, “COVID-19 pandemic”, “Supply chain” and “pandemic response strategies” and then manually adjusting the inconsistencies that arose from the search. The inputs of experts in the Nigerian manufacturing sector were sourced using questionnaires designed to ascertain whether identified TBL criteria and COVID-19 pandemic response strategies were ‘relevant’ or ‘not relevant’ to SSS in the Nigerian manufacturing sector. To ensure inclusivity of all-important information, the experts were also requested to include missing TBL criteria and COVID-19 pandemic response strategies. A mode of the expert responses on the relevance of the TBL criteria and COVID-19 pandemic response strategies was computed to determine the finalized list of identified system criteria and ensure content validity. Finally, twelve TBL criteria and four COVID-19 pandemic response strategies were confirmed to be relevant to SSS in the Nigerian manufacturing sector as shown in Table 1 . As shown in Table 1, the twelve TBL criteria for sustainable supplier selection were categorized under economic, environmental and social dimensions.

Table 1.

Proposed system criteria.

| Category | Criteria/Strategies | References |

|---|---|---|

| Economic criteria | Product price/cost (EC1) | Gao et al., 2020, Jain and Singh, 2020, Kannan et al., 2020, Khan et al., 2018, Laura and Julia, 2019, Orji and Wei, 2015, Rashidi et al., 2020, Stevic et al., 2020, Taherdoost and Brard, 2019, Zhou and Xu, 2018 |

| Financial capability (EC2) | ||

| Quality (EC3) | ||

| Efficient production methods (EC4) | ||

| Environmental criteria | Environmental competencies (EV1) | Chen et al., 2020, Ghadimi et al., 2019, Jain and Singh, 2020, Khan et al., 2018, Moheb- and Handfield, 2019, Yadavalli et al., 2019 |

| Green product design (EV2) | ||

| Regular environmental audits (EV3) | ||

| Presence of training facilities (EV4) | ||

| Social criteria | Work safety procedures (SC1) | Amos and Uniamikogbo, 2016, Grant et al., 2017, Jain and Singh, 2020, Kannan et al., 2020, Khan et al., 2018, Moheb- and Handfield, 2019, Suraraska and Shin, 2019, Villena and Gioia, 2018, Zhou and Xu, 2018 |

| Respect for policy/compliance with regulations (SC2) | ||

| Information disclosure (SC3) | ||

| Social responsibility (SC4) | ||

| Pandemic response strategies | Use of personal protective equipment (PD1) | Donthu and Gustafsson, 2020, Govindan et al., 2020, Kumar et al., 2021, Majumdar et al., 2020, Pan and Zhang, 2020, Pantano et al., 2020, Sarkis et al., 2020, Sheth, 2020 |

| Presence of information technologies (PD2) | ||

| Adhering to regulatory changes (PD3) | ||

| Development of economic recovery programs (PD4) |

2.2.1. Economic dimension

The criteria classified under the economic dimension are a top priority for selecting sustainable suppliers since such criteria consider the impact of the supplier’s activities on the local economy (Chamberlain, 2013). We have classified four criteria under the economic dimension namely product price, financial capability, quality and efficient production methods. Prior published studies suggest that product price (EC1) is a significant tool used by companies in their struggle to gain competitive advantage over rival companies and is usually determined by total cost involved in manufacturing a particular product (Gao et al., 2020, Khan et al., 2018). Financial capability (EC2) is critical to sustainable supplier selection as it entails the sound financial position of suppliers to effectively undertake necessary supplies (Thiruchelvam and Tookey, 2011). Knowledge about the financial capability of the supplier can reveal the degree to which a company may depend on a supplier and the volume of materials, products or services the supplier can supply (Taherdoost & Brard, 2019). Quality (EC3) refers to the conformance to relevant standards, specifications and requirements for actualising supply chain sustainability (Orji and Wei, 2015, Rashidi et al., 2020, Stevic et al., 2020). Efficient production methods (EC4) entail suppliers’ utilisation of sustainable production methods for reducing negative environmental impacts and increasing overall supply chain sustainability (Zhou and Xu, 2018, Laura and Julia, 2019).

2.2.2. Environmental dimension

In this study, four criteria are classified under the environmental dimension namely, environmental competence, green product design, regular environmental audits and presence of training facilities. Environmental competence (EV1) refers to the suppliers’ possession of the necessary skills, expertise and competencies to address sustainability related issues in order to reduce negative environmental consequences (Ghadimi et al., 2019, Yadavalli et al., 2019). Green product design (EV2) involves suppliers supporting sustainable development by effectively designing products that comply with environmental protection requirements (Chen et al., 2020, Jain and Singh, 2020). Regular environmental audits (EV3) entail conducting regular audits through environmental management system to ascertain the effects of suppliers’ existing practices on the environment (Khan et al., 2018, Moheb- and Handfield, 2019). Presence of training facilities (EV4) is associated with suppliers actively organizing sustainability training and development programmes for their workers, who may be without the knowledge and resources to practice sustainability (Yadavalli et al, 2019). As a result, of such deficiencies, there might be incidences of violations of sustainability standards, which expose firms to financial, social and environmental risk (Villena and Gioia, 2020).

2.2.3. Social dimension

The social dimension is highly significant in sustainable supplier selection for overall supply chain sustainability. In this study, we classified four criteria under the social dimension, namely social responsibility, compliance with regulations (respect for policy), information disclosure and work safety procedures. Work safety procedures (SC1) refer to the processes that suppliers implement to ensure the safety of the work environment and the healthy well-being of employees (Grant et al., 2017, Suraraska and Shin, 2019). Respect for policy/ compliance with regulations (SC2) is associated with suppliers’ compliance with regulations and policies enacted by the industrial sector and other regulatory agencies for actualizing sustainability objectives (Orji and Wei, 2015, Villena and Gioia, 2018). Information disclosure (SC3) entails suppliers’ disclosure of relevant information like the green impact activities and scrutiny of environmental impact throughout product lifecycle (Kannan et al., 2020, Zhou and Xu, 2018). Social responsibility (SC4) is associated with suppliers’ extent of community initiatives or welfare activities in relation to value creation for stakeholders and shareholders for actualizing sustainability benefits (Amos and Uniamikogbo, 2016, Charharsooghi and Ashrafi, 2014, Moheb- and Handfield, 2019).

2.2.4. Pandemic response strategies

The pandemic response strategies can be presented as a significant aspect of the COVID-19 pandemic’s impact on supply chain operations such as sustainable supplier selection. Hence, in the current study, four pandemic response strategies that can impact on SSS include the use of personal protective equipment, presence of information technologies for customer demand prediction, adherence to policy changes and development of economic recovery programs. The use of personal protective equipment (PD1) entails suppliers’ provision of health supplies such as face masks, hand sanitizers and others to maintain the well-being of employees and community during the pandemic era (Choi et al., 2020, Govindan et al., 2020, Pan and Zhang, 2020). Presence of information technologies for customer demand prediction (PD2) is associated with suppliers’ use of IT tools to determine customer demand patterns for actualizing supply chain sustainability (Pantano et al., 2020, Sheth, 2020). Adherence to policy changes (PD3) refers to suppliers’ adequate abiding by regulatory changes in response to the pandemic era for maximum sustainability gains (Donthu and Gustafsson, 2020, Sarkis et al., 2020). Development of economic recovery programs (PD4) entail suppliers’ designing programs to mitigate the negative impact of economic disruptions caused by the COVID-19 pandemic (Belhadi et al., 2021, Chowdhury et al., 2021, Pantano et al., 2020).

2.3. Application of Fuzzy-AHP-MULTIMOORA methodology

From a methodological point of view, our study contributes to the growing research domain that determines the relative importance of system criteria under uncertainty through illustrating their hierarchical relationships and utilizing robust ranking methods. Past studies which exist in extant literature pinpoints the wide and successful applications of the Fuzzy AHP method. For instance, Shete et al (2021) applied the Pythagorean fuzzy AHP to investigate the enablers of sustainable supply chain innovation in the Nigerian manufacturing sector. Mangla et al (2015), aided by insights of managers and officials in the Indian poly product- manufacturing companies applied the fuzzy AHP to analyse the risks to implementing green supply chain management aided by insights of managers and officials of Indian poly product-manufacturing companies. Wang et al (2012) proposed the fuzzy AHP to investigate the green initiatives and policies in the fashion supply chain and presented useful insights. Some other applications of fuzzy AHP are available in extant literature (Buyukozkan et al., 2020, Karatop et al., 2021, Khan et al., 2021, Ogundoyin and Kamil, 2020, Shete et al., 2020, Sirisawat and Kiatcharoenpol, 2018, Zhu et al., 2020). Likewise, the MULTIMOORA method has been successfully applied and integrated with other MCDM methods to proffer accurate and robust ranking of studied criteria (Liu et al., 2021, Omrani et al., 2020, Wang et al., 2021). Therefore, given the extensive and successful utilization of the fuzzy AHP and the MULTIMOORA in extant literature, it becomes convincing that a suitable methodology be proposed in this study based on the Fuzzy-AHP-MULTIMOORA. The proposed methodology will accurately determine the interrelationships between the COVID-19 pandemic response strategies and TBL criteria for SSS in the Nigerian manufacturing sector and also estimate their ranking. By so doing, this study will provide a clearer perspective on the impact of COVID-19 pandemic on sustainable supplier selection in the Nigerian manufacturing sector.

3. Proposed model

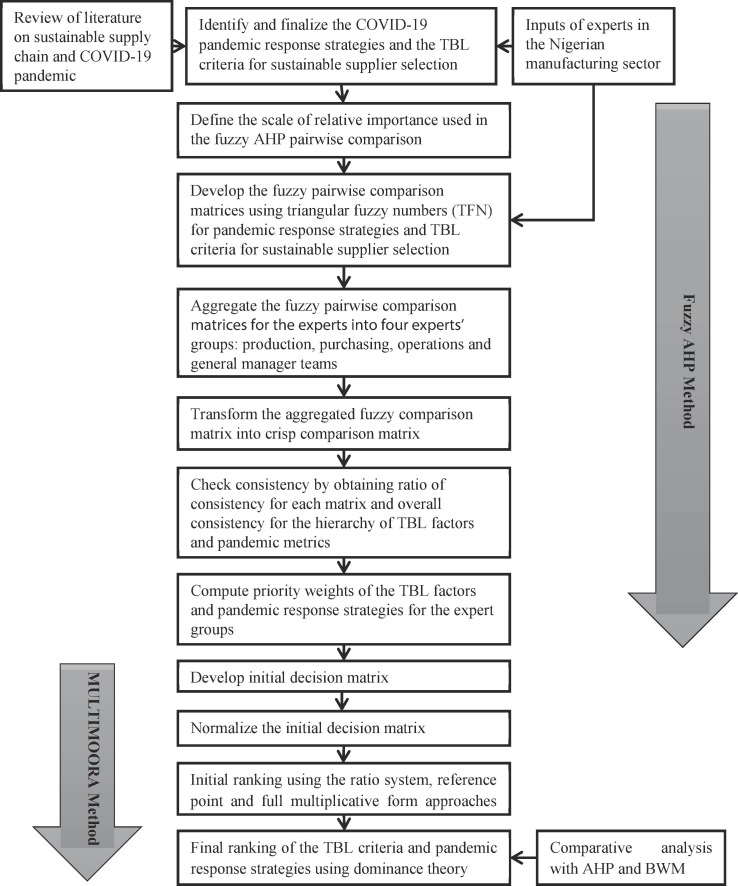

This section presents the proposed methodology and the analysis procedures. Firstly, the Fuzzy-AHP was utilized to generate the pairwise comparisons between the pandemic response strategies and the TBL criteria for SSS in the COVID-19 pandemic. Then, the MULTIMOORA was applied to compute the weights of the pandemic response strategies and TBL criteria and likewise obtain their ranking. The proposed model is detailed in Fig. 1 .

Fig. 1.

Proposed methodology.

3.1. Fuzzy sets

Generally, decision making can be difficult due to the vagueness and uncertainty of human judgments and these can only be effectively handled through the use of the fuzzy set theory, proposed by Zadeh in 1965. Fuzzy set can be defined as a membership function that maps elements to degrees of membership within a certain interval, which is usually [0, 1] (Karatop et al., 2021, Patil and Kant, 2014). As such, an assigned element is said to have no membership when a value of 0 is assigned, said to have full membership when the value of 1 is assigned and said to have a certain degree of membership when a value within the interval is assigned. In order, to handle uncertainty and ambiguity that exist in human judgments, the linguistic attributes are usually transformed into fuzzy numbers of which triangular fuzzy numbers (TFN) are the most commonly utilized. Notably, “~” is placed above a particular function/symbol if such represents a fuzzy set. The following definitions are considered essential in fuzzy set theory:

Definition 1

A fuzzy setis regarded as a subset of a set M with ordered pairs that are represented byillustrated by. It is usually assumed that, where a condition that m is a part ofis represented by = 1 while a condition that m is not a part of is represented by = 0.

| (1) |

Where, the membership function is represented by while the group of elements m is represented by M = {m}.

Definition 2

A fuzzy setis considered to be convex if it satisfies the following condition:

| (2) |

Definition 3

A fuzzy setis considered to be normal if the following condition is satisfied:

| (3) |

Definition 4

A fuzzy numberis said to be a fuzzy set in the set of M that is considered as both convex and normal.

Definition 5

The α–cut of the fuzzy set that belongs to a universal set M is defined as

| (4) |

Definition 6

A triangular fuzzy number (TFN) with a membership function that belongs to a fuzzy set where × , y, z are real numbers and × ≤ y ≤ z is defined as follows:

| (5) |

Definition 7

The confidence level interval of α can also be defined during which the TFN can be represented using Eq. (6):

| (6) |

Definition 8

If two TFNs are denoted by c = (c1, c2, c3) and d = (d1, d2, d3), then the distance between the TFNs is computed as follows:

| (7) |

3.2. Fuzzy AHP method

The AHP method comprises the structuring of the decision problem into various levels of hierarchy namely goal, main dimensions, sub- criteria and alternatives which is then followed by developing pairwise comparison at each of the levels (Mastrocinque et al, 2020). By developing the pairwise comparison matrices, the AHP treats the criteria differently by not regarding the latter as being equally important during the determination of the optimal combination of decisions (Al- and Khorramshahgol, 2020, Moktadir et al., 2019). Although, the pairwise comparison matrices in the AHP method are usually high in number, they are regarded as the most transparent and technically reliable approach for determining weights that eventually indicate the relative importance of alternatives and criteria. Furthermore, the AHP method has been successfully applied within the sustainable supply chain management domain owing to its ease of application by inexperienced users and result reliability (Awasthi et al, 2018; Chan et al., 2019, Kumar et al., 2021, Luthra et al., 2016; Mastrocinque et al, 2020; Mejia et al, 2019). Nevertheless, the AHP method has some limitations due to the unbalanced linguistic scale, uncertainty and human bias in judgments (Ali et al., 2021, Sirisawat and Kiatcharoenpol, 2018). Consequently, integrating AHP with fuzzy set theory is highly preferred to overcome these limitations (Karatop et al, 2021). The Fuzzy AHP method has seen wide and successful applications in various decision making problems (Karatop et al., 2021, Mangla et al., 2015, Moktadir et al., 2018, Ogundoyin and Kamil, 2020, Patil and Kant, 2014, Shete et al., 2020, Sirisawat and Kiatcharoenpol, 2018). Generally, the fuzzy AHP method consists of these steps:

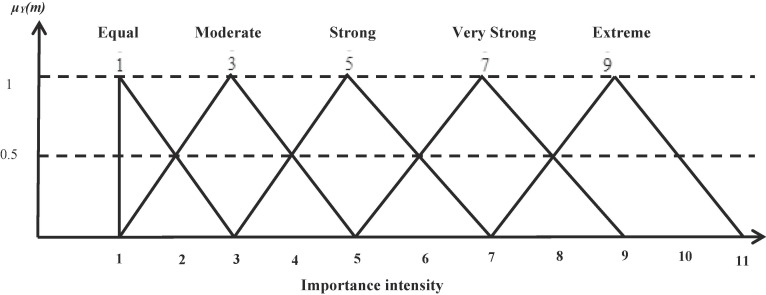

Step 1: Define linguistic scale for pairwise comparisons

In this step, the imprecision in human judgments is taken into consideration by modifying the AHP linguistic scale to include five TFNs as shown in Table 2 . The corresponding fuzzy membership functions for the linguistics scores are indicated in Fig. 2 .

Table 2.

Linguistic scale for Fuzzy AHP pairwise comparison.

| Linguistic attributes | Importance intensity | Fuzzy numbers | Triangular-fuzzy numbers |

|---|---|---|---|

| Equal importance | 1 | (1,1,3) | |

| Moderate importance | 3 | (1,3,5) | |

| Strong importance | 5 | (3,5,7) | |

| Very strong importance | 7 | (5,7,9) | |

| Extreme importance | 9 | (7,9,11) |

Fig. 2.

Fuzzy membership functions for linguistic scores.

Step 2: Develop the fuzzy pairwise comparison matrix

In this step, the fuzzy pairwise comparison matrix is developed using experts’ preferential judgments on the system criteria (See Table 1). An aggregation of the experts’ judgments is carried out by means of arithmetic mean in each of the four expert groups as presented mathematically in Eq. (8). (Expert groups include general managers, operations managers, production managers and R&D managers).

(8)

Where, =1, if i = j and = (,,,) or ,,,, if i is not equal to j. Therefore, , if is a matrix score assigned to the preferential judgment on i to j.

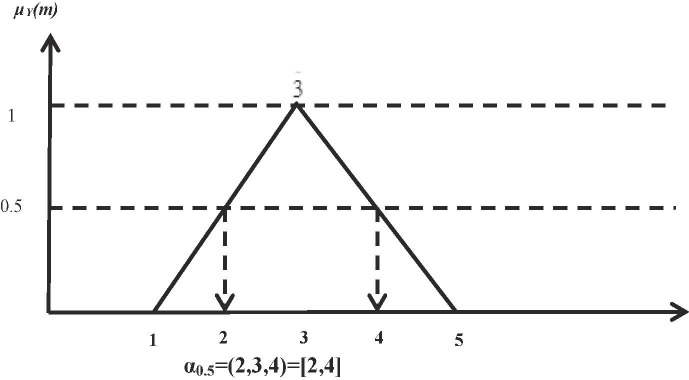

Step 3: Transform the fuzzy pairwise comparison matrix into a crisp pairwise comparison matrix

In this respect, the α-cut approach is utilized to rank the fuzzy numbers due to its potential to integrate the confidence of experts over their respective preferential judgments and thereby yield an interval set of scores from each fuzzy number (see Fig. 3 ). As shown in Fig. 3, α0.5 = 0.5 will yield α0.5 = (2, 3, 4).

Fig. 3.

TFN α-cut operation.

The fuzzy pairwise comparison is utilized to determine the α- cut comparison matrix, after which the degree of satisfaction is estimated from the index of optimism µ determined by the expert/ decision maker. The larger scores of µ signify higher degree of optimism.

= (9)

The index of optimism µ is usually defined by Eq. (10).

=µ+ (1- µ) Where, 0< µ≤1 (10)

Finally, the crisp pairwise comparison matrix K is obtained from the α- cut pairwise comparison matrix as shown in Eq. (11).

= (11)

Step 4: Check consistency

In this step, the consistency of the crisp pairwise comparison matrix K is checked and if consistent, then the parent fuzzy pairwise comparison is considered to be consistent as well. The consistency is checked by firstly, computing the largest Eigen value of the matrix as shown in Eq. (12).

| (12) |

Where, the principal Eigen matrix vector is represented by u.

Secondly, the ratio of consistency of the crisp pairwise comparison matrix can be determined using Eq. (13).

| (13) |

Where, FR signifies the ratio of consistency, FI signifies the index of consistency and CI signifies the random index of consistency. The values of the random index of consistency CI are presented in Table 3 . The value that is determined for FR is preferably less than 0.10 in order to attain a greater level of consistency. Likewise, the FI values are calculated using the Eq. (14). m signifies the size of matrix.

| (14) |

Table 3.

Random index of consistency.

| m | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| FI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

Step 5: Compute priority weights

In this step, the weight of each criterion is computed by normalizing the respective rows or columns of crisp pairwise comparison matrix K.

3.3. MULTIMOORA method

MULTIMOORA (Multi-Objective Optimization based on Ratio Analysis with the Full Multiplicative Form) is a new MCDM proposed in 2010 by Braues and Zavadskas, that is notable for its simple mathematics, low-computational time and robustness (Chen et al, 2021). The robustness of MULTIMOORA is derived from its ranking of system criteria by the use of three approaches namely ratio system, reference point and full multiplicative form (Sarabi and Darestani, 2021). Compared with DEMATEL, TOPSIS and TODIM, the MULTIMOORA method has some advantages such as high stability, being less time consuming and more concise, and greater ease of calculations (Liu et al, 2021). As such, the MULTIMOORA method has seen wide and successful applications in extant literature (Chen et al., 2021, Liu and Li, 2019, Maghsoodi et al., 2018, Omrani et al., 2020, Sir and Caliskan, 2019). Generally, the MULTIMOORA method consists of the following steps:

Step 1: Develop the initial decision matrix

In this step, the initial decision matrix is developed consisting of the alternatives (i.e. the TBL criteria and pandemic response strategies) and criteria (expert groups namely, production managers, general managers, R&D managers and operations managers).

Step 2: Normalization process

Herein, the developed initial decision matrix is normalized using different approaches representing the three MULTIMOORA ranking systems namely ratio system, reference point and full multiplicative form.

Ratio system

In the ratio system, the initial decision matrix is normalized by using Eq. (15).

| (15) |

Where, q indicates the weight of the criterion obtained from the expert groups and q* is the normalized weight of the criterion which is distributed within the interval [0, 1].

Then, the normalized weights of the benefit criteria are summed up while the normalized weights of the cost criteria are subtracted to obtain the final score of the criterion in the ratio system as shown in Eq. (16).

| (16) |

Where, r*i represents the ratio system computed score of the criterion, j = 1, 2, 3,…, t represents the benefit criteria and j = t + 1,t + 2,t + 3…., n represents the cost criteria. Ranking of criteria is based on descending order of final scores.

Reference point

In the reference point approach, the reference point is obtained by utilizing scores from Eq. (15) and applying a Tchebycheff Min-Max metric to estimate the reference point pj.

| (17) |

The deviation of the normalized weight q*ij from the reference point pj is estimated using Eq. (18). Likewise, the final score gi is obtained using Eq. (19). Ranking of the criteria is based on ascending order of final scores.

| (18) |

| (19) |

Full multiplicative form

In the full multiplicative form, the final scores are estimated using Eq. (20).

| (20) |

Where, w is the weight of the criterion and t is the benefit criteria; the benefit criteria are aggregated by the numerator while the cost criteria are aggregated by the denominator. Ranking of the criteria is based on the descending order of the final score U*i.

Step 3: Initial ranking

In this step, the criteria are ranked using the final scores obtained from each of the ratio system approach, reference point and full multiplicative form. The final scores obtained from the ratio system and full multiplicative form are ranked in descending order, while the final scores obtained from the reference point are ranked in ascending order.

Step 4: Final ranking

In this step, the rankings of the criteria obtained from the three ranking approaches in the MULTIMOORA method are aggregated using the dominance theory to determine the final ranking.

4. Case study to demonstrate the feasibility of the proposed model

We conducted a case study in the Nigerian manufacturing sector to provide an illustration of the process of using the proposed Fuzzy-AHP-MULTIMOORA to investigate the COVID-19 pandemic’s impact on SSS. The process of data sourcing from the Nigerian manufacturing sector is duly highlighted in this section. Furthermore, the results of the pairwise comparisons of the system criteria obtained from the fuzzy-AHP based computations coupled with the weights of the system criteria obtained from the MULTIMOORA based computations are presented.

4.1. Data collection

In this study, data was sourced through the means of designed questionnaires from experts in the middle and top level managerial positions with more than fifteen years of working experience within the Nigerian manufacturing sector. The experts in middle and top management positions are considered knowledgeable enough to provide information on company decisions and complete the study survey to ensure result accuracy (Orji et al, 2020). The questionnaires for the study survey were in two stages; the first stage entails finalization of study criteria by ascertaining the relevance of the identified TBL criteria and pandemic response strategies in sustainable supplier selection within the Nigerian manufacturing sector. In the second stage, the relative importance of each of the TBL factor and pandemic response strategy was determined in order to establish the impact of the COVID-19 pandemic on sustainable supplier selection. The responses of the experts from the second stage of the survey were utilized to develop the fuzzy AHP pairwise comparison matrices. Furthermore, the questionnaire was designed to include questions on the demographic characteristics of the experts (See Table 4 ). Open ended questions to ensure that no relevant criteria were omitted in the study survey and increase result validity were also included in the designed questionnaire.

Table 4.

Demographic characteristics of study survey respondents.

| Attribute | Number of experts |

|---|---|

| Age | |

| 25–35 | 15 |

| 36–60 | 33 |

| Education | |

| High school | 8 |

| Bachelor’s degree | 40 |

| Gender | |

| Male | 38 |

| Female | 10 |

| Years of experience | |

| 16–20 | 13 |

| 21–35 | 35 |

| Management position | |

| Production manager | 16 |

| Purchasing manager | 13 |

| General manager | 8 |

| Operations manager | 11 |

| Annual turnover (10 Million Nigerian Naira) | |

| 3–10 | 5 |

| 11–100 | 25 |

| 101–200 | 18 |

| Number of employees | |

| Less than 500 | 21 |

| 501–1000 | 18 |

| 1001–2500 | 9 |

Initial contacts were made with experts in the Nigerian manufacturing firms to urge participation in the study survey after which the questionnaires were sent via emails to the experts that consented to participate in the study. The experts were assured that the study results were for only academic purposes and that information from the survey would remain confidential so as to instil trust and increase the rate of participation in the survey. Additionally, the experts were given reminders through emails, phone calls and even personal visits to increase the response rate. A total of forty-eight completed questionnaires were received out of the one hundred questionnaires that were sent out to the experts, a response rate of 48%. A statistical saturation test was applied to observe the variation in the results obtained with each addition of an expert and it showed that no result variation was noted after the tenth expert was added in the survey. This confirms previous research works that indicate that fuzzy AHP can proffer accurate study findings with a small sample size of ten experts (Awasthi et al., 2017, Luthra et al., 2016, Mital et al., 2017, Sirisawat and Kiatcharoenpol, 2018). Furthermore, t-test (McGovern et al, 2018) was applied to minimize the bias in the survey responses and also to check if the results could be generalized. By checking the changes in the demographic attributes of the experts, namely firm size (number of employees and annual turnover in the first and second time periods of the study survey), the t-test indicated a score of p less than 0.056 which signifies no response bias and that the results can be generalized.

4.2. Pairwise comparison of the TBL criteria and pandemic response strategies using fuzzy AHP

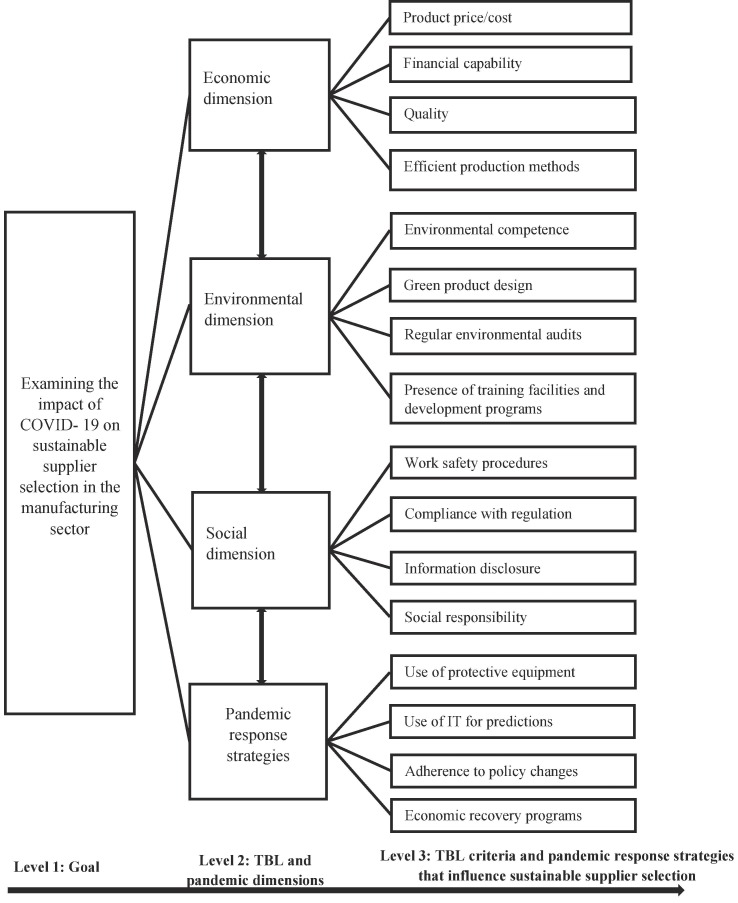

Firstly, the fuzzy AHP decision hierarchy for estimating the impact of COVID-19 pandemic on sustainable supplier selection was formed as shown in Fig. 4 , comprising of three levels. The first level signified the goal of the study which was to determine the impact of COVID-19 pandemic on sustainable supplier selection. The second level indicated the dimensions while the third level signified the COVID-19 pandemic response strategies and TBL criteria for sustainable supplier selection.

Fig. 4.

Decision hierarchy for determining the impact of COVID- 19 pandemic on sustainable supplier selection.

Then, the experts developed a fuzzy pairwise comparison matrix for the TBL criteria and pandemic response strategies and their respective dimensions with the aid of the fuzzy AHP linguistic scale (See Table 2). The fuzzy pairwise comparisons of the experts in each group in the study survey were aggregated into a single fuzzy pairwise comparison for the TBL and pandemic dimensions and respective factors/ strategies with the aid of arithmetic mean. Table 5 shows the pairwise comparison matrix of the TBL and pandemic dimensions as determined by an expert group in the Nigerian manufacturing sector. Likewise, Table 6 , Table 7 , Table 8 and Table 9 show an expert group’s fuzzy pairwise comparison matrices of the economic criteria, pandemic response strategies, social criteria and environmental criteria respectively.

Table 5.

Fuzzy pairwise comparison matrix of TBL and pandemic response dimensions for an expert group.

| Dimension | EC | PD | SC | EV |

|---|---|---|---|---|

| Economic (EC) | 1 | |||

| Pandemic (PD) | 1 | |||

| Social (SC) | 1 | |||

| Environmental (EV) | 1 |

Table 6.

Fuzzy pairwise comparison matrix of economic criteria for an expert group.

| Criteria | EC1 | EC2 | EC3 | EC4 |

|---|---|---|---|---|

| Price (EC1) | 1 | |||

| Financial capability (EC2) | 1 | |||

| Quality (EC3) | 1 | |||

| Efficient production methods (EC4) | 1 |

Table 7.

Fuzzy pairwise comparison matrix of pandemic response strategies for an expert group.

| Strategies | PD1 | PD2 | PD3 | PD4 |

|---|---|---|---|---|

| Use of personal protective equipment (PD1) | 1 | |||

| Presence of information technologies (PD2) | 1 | |||

| Adhering to regulatory changes (PD3) | 1 | |||

| Development of economic recovery programs (PD4) | 1 |

Table 8.

Fuzzy pairwise comparison matrix of social criteria for an expert group.

| Criteria | SC1 | SC2 | SC3 | SC4 |

|---|---|---|---|---|

| Work safety procedures (SC1) | 1 | |||

| Compliance with regulations (SC2) | 1 | |||

| Information disclosure (SC3) | 1 | |||

| Social responsibility (SC4) | 1 |

Table 9.

Fuzzy pairwise comparison matrix of environmental criteria for an expert group.

| Criteria | EV1 | EV2 | EV3 | EV4 |

|---|---|---|---|---|

| Environmental competence (EV1) | 1 | |||

| Green product design (EV2) | 1 | |||

| Regular environmental audits (EV3) | 1 | |||

| Presence of training facilities (EV4) | 1 |

The fuzzy pairwise comparison matrices for the dimensions and respective TBL criteria and pandemic response strategies were transformed into crisp pairwise comparison matrices through using the α-cut pairwise comparison matrix. The ratios of consistency determined for the crisp pairwise comparison matrices were all less than 0.10, signifying that all the developed fuzzy pairwise comparison matrices were consistent. The computed ratios of consistency for the criteria are presented in Table 10 . Then, the priority weights of the TBL criteria and pandemic response strategies were determined by finding the product of the relative importance (ratio) weight of the factor and that of the respective dimension as presented in Table 10. Also indicated in Table 10 are the ratio of consistency and the global ranking of the TBL criteria and pandemic response strategies which were derived from the priority weights.

Table 10.

Fuzzy AHP priority weights of TBL criteria and pandemic response strategies for an expert group.

| Dimension | Dimension weight | Consistency ratio | Criteria | Ratio weight | Priority weight |

|---|---|---|---|---|---|

| Economic(EC) | 0.471 | 0.073 | Product price/cost (EC1) | 0.332 | 0.156 |

| Financial capability (EC2) | 0.255 | 0.120 | |||

| Quality (EC3) | 0.563 | 0.265 | |||

| Efficient production methods (EC4) | 0.216 | 0.101 | |||

| Environmental (EV) | 0.113 | 0.081 | Environmental competencies (EV1) | 0.368 | 0.0415 |

| Green product design (EV2) | 0.465 | 0.0525 | |||

| Regular environmental audits (EV3) | 0.376 | 0.0424 | |||

| Presence of training facilities (EV4) | 0.219 | 0.0247 | |||

| Social (SC) | 0.152 | 0.078 | Work safety procedures (SC1) | 0.439 | 0.0667 |

| Compliance with regulations (SC2) | 0.384 | 0.0583 | |||

| Information disclosure (SC3) | 0.237 | 0.0360 | |||

| Social responsibility (SC4) | 0.375 | 0.057 | |||

| Pandemic (PD) | 0.324 | 0.067 | Use of personal protective equipment (PD1) | 0.456 | 0.147 |

| Presence of information technologies (PD2) | 0.424 | 0.137 | |||

| Adhering to regulatory changes (PD3) | 0.328 | 0.106 | |||

| Development of economic recovery programs (PD4) | 0.121 | 0.0392 |

4.3. Computation of weights and ranking of the pandemic response strategies and TBL criteria for sustainable supplier selection using MULTIMOORA

The fuzzy AHP outputs for the expert groups were utilized as the initial decision matrix of the MULTIMOORA method. Thus, the MULTIMOORA initial decision matrix for the four expert groups is presented in Table 11 .

Table 11.

MULTIMOORA initial decision matrix.

| Criteria | Fuzzy AHP outputs of Expert group 1 | Fuzzy AHP outputs of Expert group 2 | Fuzzy AHP outputs of Expert group 3 | Fuzzy AHP outputs of Expert group 4 |

|---|---|---|---|---|

| Product price/cost (EC1) | 0.156 | 0.166 | 0.232 | 0.162 |

| Financial capability (EC2) | 0.120 | 0.161 | 0.203 | 0.226 |

| Quality (EC3) | 0.265 | 0.240 | 0.237 | 0.312 |

| Efficient production methods (EC4) | 0.101 | 0.121 | 0.105 | 0.156 |

| Environmental competencies (EV1) | 0.0415 | 0.0440 | 0.0562 | 0.0376 |

| Green product design (EV2) | 0.0525 | 0.0865 | 0.0693 | 0.0339 |

| Regular environmental audits (EV3) | 0.0424 | 0.0564 | 0.0104 | 0.0647 |

| Presence of training facilities (EV4) | 0.0247 | 0.0978 | 0.0734 | 0.0572 |

| Work safety procedures (SC1) | 0.0667 | 0.0376 | 0.0195 | 0.0595 |

| Compliance with regulations (SC2) | 0.0583 | 0.0884 | 0.0951 | 0.0792 |

| Information disclosure (SC3) | 0.0360 | 0.0519 | 0.0936 | 0.0339 |

| Social responsibility (SC4) | 0.057 | 0.0339 | 0.0792 | 0.0519 |

| Use of personal protective equipment (PD1) | 0.147 | 0.176 | 0.394 | 0.113 |

| Presence of information technologies (PD2) | 0.137 | 0.161 | 0.393 | 0.213 |

| Adhering to regulatory changes (PD3) | 0.106 | 0.142 | 0.0839 | 0.199 |

| Development of economic recovery programs (PD4) | 0.0392 | 0.0719 | 0.0600 | 0.104 |

The developed MULTIMOORA initial decision matrix was normalized for the three ranking methods namely ratio system, reference point and full multiplicative form and the normalized weighted scores are presented in Table 12 . The average percentage scores for the TBL criteria and pandemic response strategies were also determined as indicated in Table 12. The dimension percentage scores were determined by aggregating the average percentage scores of the criteria within each dimension as indicated in Table 12. Then, the normalized weighted scores of the TBL criteria and pandemic response strategies for the three ranking methods were utilized to obtain the initial ranking as shown in Table 13 . The dominance theory was then applied to the initial ranking of the TBL criteria and pandemic response strategies to obtain the final ranking as indicated in Table 13.

Table 12.

Normalized weighting matrix for the MULTIMOORA ranking methods.

| Dimension | TBL criteria and pandemic response strategies | Normalized weighted scores from ratio system | Normalized weighted scores from reference point | Normalized weighted scores from full multiplicative form | Average scores (%) | Category score (%) |

|---|---|---|---|---|---|---|

| Economic(EC) | Product price/cost (EC1) | 0.455 | 0.171 | 0.439 | 8 | 30 |

| Financial capability (EC2) | 0.418 | 0.217 | 0.368 | 7 | ||

| Quality (EC3) | 0.527 | 0.154 | 0.456 | 9 | ||

| Efficient production methods (EC4) | 0.342 | 0.277 | 0.251 | 6 | ||

| Environmental (EV) | Environmental competencies (EV1) | 0.151 | 0.549 | 0.0884 | 5 | 20.6 |

| Green product design (EV2) | 0.260 | 0.413 | 0.127 | 5.6 | ||

| Regular environmental audits (EV3) | 0.196 | 0.421 | 0.116 | 5 | ||

| Presence of training facilities (EV4) | 0.0566 | 0.663 | 0.0331 | 4 | ||

| Social (SC) | Work safety procedures (SC1) | 0.302 | 0.323 | 0.235 | 6 | 22.4 |

| Compliance with regulations (SC2) | 0.297 | 0.313 | 0.196 | 5.9 | ||

| Information disclosure (SC3) | 0.112 | 0.611 | 0.0792 | 5 | ||

| Social responsibility (SC4) | 0.273 | 0.348 | 0.153 | 5.5 | ||

| Pandemic (PD) | Use of personal protective equipment (PD1) | 0.487 | 0.192 | 0.397 | 8 | 27 |

| Presence of information technologies (PD2) | 0.432 | 0.199 | 0.376 | 7.9 | ||

| Adhering to regulatory changes (PD3) | 0.368 | 0.234 | 0.298 | 6.1 | ||

| Development of economic recovery programs (PD4) | 0.0971 | 0.615 | 0.0566 | 5 |

Table 13.

Initial and final rankings of the TBL criteria and pandemic response strategies.

| Criteria | Initial ranking by ratio system | Initial ranking by reference point | Initial ranking by full multiplicative form | Dominance based final ranking |

|---|---|---|---|---|

| Product price/cost (EC1) | 2 | 2 | 2 | 2 |

| Financial capability (EC2) | 5 | 5 | 5 | 5 |

| Quality (EC3) | 1 | 1 | 1 | 1 |

| Efficient production methods (EC4) | 7 | 7 | 7 | 7 |

| Environmental competencies (EV1) | 13 | 13 | 13 | 13 |

| Green product design (EV2) | 11 | 11 | 11 | 11 |

| Regular environmental audits (EV3) | 12 | 12 | 12 | 12 |

| Presence of training facilities (EV4) | 16 | 16 | 16 | 16 |

| Work safety procedures (SC1) | 8 | 9 | 8 | 8 |

| Compliance with regulations (SC2) | 9 | 8 | 9 | 9 |

| Information disclosure (SC3) | 14 | 14 | 14 | 14 |

| Social responsibility (SC4) | 10 | 10 | 10 | 10 |

| Use of personal protective equipment (PD1) | 3 | 3 | 3 | 3 |

| Presence of information technologies (PD2) | 4 | 4 | 4 | 4 |

| Adhering to regulatory changes (PD3) | 6 | 6 | 6 | 6 |

| Development of economic recovery programs (PD4) | 15 | 15 | 15 | 15 |

5. Discussion and management implications

This section presents some relevant discussions on the relative importance of the pandemic response strategies in SSS in the COVID-19 pandemic era. The validation of the proposed model coupled with the theoretical and practical implications of this study are also duly presented.

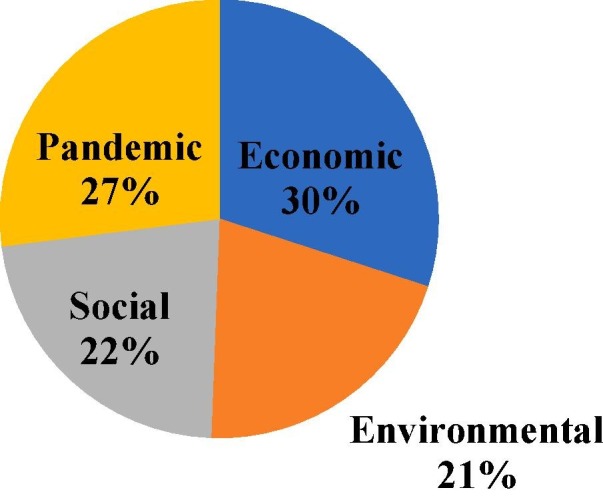

5.1. Ranking of pandemic response strategies and TBL criteria for sustainable supplier selection

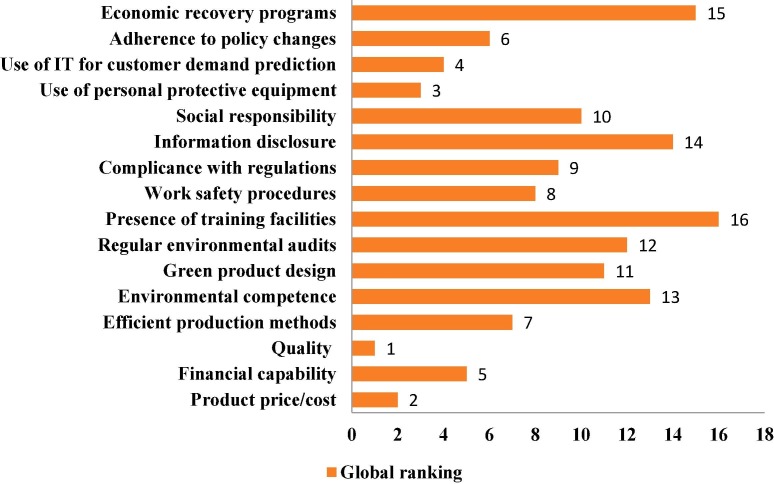

A diagrammatic representation of the rankings of the dimensions of the pandemic response strategies and the TBL criteria is shown in Fig. 5 while Fig. 6 shows the ranking of the specific pandemic response strategies and TBL criteria for sustainable supplier selection. According to the results on Fig. 5, the ‘Economic dimension’ is the most significant in SSS implementation within the Nigerian manufacturing sector in the COVID- 19 pandemic. This corroborates prior studies that laud economic factors to be highly significant during the selection of sustainable suppliers in the manufacturing industry of emerging economies (Kannan et al., 2020, Khan et al., 2018). The next ranked dimension is ‘Pandemic dimension’ and this is followed by ‘Social dimension’. This strengthens the significance of pandemic response strategies in sustainable supplier selection in addition to the rising concerns to meet social necessities in the COVID-19 pandemic era (Goodarzian et al, 2021). The least ranked dimension in decisions to implement sustainable supplier selection in the manufacturing sector during COVID- 19 pandemic is the ‘Environmental dimension’. The findings indicate that although environmental factors are critical to sustainable supplier selection, such factors are not considered highly significant when compared with the other TBL dimensions in the manufacturing sector during the COVID-19 pandemic. This might be attributable to the low awareness of the negative environmental impact of manufacturing activities in emerging economies thereby necessitating the promotion of sustainability issues to encourage the organizational change for sustainability (Orji, 2019).

Fig. 5.

Weights of dimensions of pandemic response strategies and TBL criteria (Percentage).

Fig. 6.

Global ranking of the TBL criteria and pandemic response strategies.

Among the investigated pandemic response strategies and TBL criteria for sustainable supplier selection, quality of product is the highest ranked criterion based on the Fuzzy-AHP-MULTIMOORA computations and this is followed by product price. The third ranked is use of personal protective equipment while the fourth ranked is presence of information technologies for customer demand prediction. Specifically, within the economic dimension, quality is the highest ranked investigated criterion in terms of relative importance weight. Quality is highly significant in sustainable supplier selection since it represents the way manufactured product characteristics satisfy customer requirements (Stevic et al, 2020). Thus, to actualize supply chain sustainability, there is a need to improve the quality of products even as the customer requirements become increasingly dynamic (Bastas and Liyanage, 2019, Sarkar et al., 2021). The second and third ranked most significant criteria are product price and financial capability. There is a need for effective considerations of product price during supply chain sustainability decisions like the sustainable supplier selection (Assa et al., 2021, Taleizadeh et al., 2019). This is in line with prior studies on the criticality of price in selecting sustainable suppliers in manufacturing firms since it portrays the capability for marketing outstanding product quality at a reasonable cost (Luthra et al., 2017, Yadavalli et al., 2019). Moreover, the availability of sufficient capital for sustainability investments is regarded as significant while implementing sustainable supplier especially in the COVID-19 pandemic that is characterized by economic disruptions (Orji, 2020). In fact, government agencies usually provide financial incentives to industrial firms and by so doing ensure sufficient budgetary allocations in order to meet sustainability objectives (Chen et al, 2019). The least ranked criterion within the economic dimension is efficient production methods. Nevertheless, efficient technologies support the achievement of the corporate sustainable goals through the execution blocks represented by sustainable supplier selection (Centobelli et al, 2020).

Within the environmental dimension, green product design is the highest ranked criterion during implementing sustainable supplier selection in the COVID-19 pandemic era. This suggests that green product design by aiding increased consumers’ acceptance due to strong environmental awareness and a more favourable tax policy can be critical to the process of sustainable supplier selection (Gao et al., 2018, Gao et al., 2020). The next ranked in terms of relative importance in sustainable supplier selection is regular environmental audits. Manufacturing companies require an effective environmental management system coupled with regular environmental audits to ensure environmental performance improvements and overall competitiveness (Jain and Singh, 2020, Orji and Wei, 2015). In fact, in recent years, auditing mechanisms have been used by manufacturing firms to induce the compliance of suppliers with environmental and social standards (Castka et al., 2020, Zarei et al., 2020). The third ranked criterion is environmental competence and this is followed by presence of training facilities. This confirms that a reasonable level of competence in environmental issues can minimize environmental pollution and is regarded as highly essential to evaluate the performance of sustainable suppliers (Ghadimi et al, 2019; Khan and Qianli, 2017). Within the social dimension, the highest ranked criterion is work safety procedures and this is followed by compliance with regulations. This signifies that effective sustainable supplier selection can be facilitated by firms through implementing measures to minimize accidents and safeguard their employees’ at the workplace (Kannan et al., 2020, Villena and Gioia, 2018, Fallahpour et al., 2017). Consequently, firms are encouraged to put in more efforts and resources to improve the safety of the work environment so as to contribute towards increasing sustainable performance and competitiveness (Khan et al, 2018). Moreover, effective policy planning and respect for enacted regulations can assist industry managers to increase productivity and actualize sustainability objectives in their companies (Orji, 2019). Thus, this buttresses the significance of respect for policy while implementing sustainable supplier selection in the manufacturing sector during a pandemic. The next ranked criterion in terms of relative importance during SSS implementation is information disclosure. This indicates that due presentation of company information on sustainability measures to the relevant stakeholders can facilitate improved social image for increased organizational performance (Ahmadi et al., 2020, Khan et al., 2018, Stevic et al., 2020, Zhou and Xu, 2018). The least ranked social factor is social responsibility. Notably, the organizations’ commitments to internal labour standards, policies and dignity in addition to the social outreach, support schemes and other voluntary activities are pre- requisites for actualizing sustainability objectives (Li et al, 2019).

Among the investigated COVID-19 pandemic response strategies, the highest ranked that is most critical to sustainable supplier selection in the manufacturing sector during the COVID-19 pandemic is the use of personal protective equipment. During the pandemic, health concerns are critical in most firms’ decisions and companies are mandated to make plans to identify and eliminate operations that pose a direct health risk to the company’s employees and consumers (Sheth, 2020). As such, firms strive to imbibe behavioural changes that are related to pandemic outbreaks which seem to be connected with personal protection such as the use of masks, eye protection, gloves and protective gowns (Klemes et al., 2020a, Klemes et al., 2020b, Rowan and Laffey, 2021). The second ranked pandemic response strategy is use of information technologies for customer demand prediction. Consumer demand can be highly dynamic during a pandemic situation as evidenced by the panic buying of food, medicines, sanitation products and other items, which induce a high level of uncertainty (He and Harris, 2020). As such, it becomes highly critical for suppliers to integrate digital technologies for effective customer demand prediction (Hopkins, 2021). The third ranked pandemic response strategy is adherence to policy changes while the least ranked pandemic response strategy is economic recovery program. The COVID- 19 pandemic has shut down economies, prompting governments to impose drastic lockdown measures on the economy and the society (Ocampo and Yamagishi, 2020). In fact, government and regulatory agencies worldwide have implemented several precautionary measures to control/ mitigate the high transmission of the SARs-CoV- 2 (Silva et al, 2020). Thus, many organizations were forced to undergo significant transformation and rethinking of business operations’ during SSS implementation while adhering to a changing landscape of guidelines and new procedures (Dwivedi et al, 2020). Furthermore, the COVID- 19 pandemic has created unprecedented adverse economic conditions in the manufacturing industries of emerging economies and this situation impacts on the decision for such companies to implement sustainability initiatives (Karmaker et al., 2021, Sarkis et al., 2020).

The results of this study provide an insight into the significance of COVID-19 pandemic response strategies in SSS in the manufacturing sector and by so doing confirms prior studies on the impact of the COVID-19 pandemic on supply chains (Goodarzian et al., 2021, Kumar et al., 2021, Majumdar et al., 2020, Sarkis, 2020). Ultimately, the results signify that there is a huge need for manufacturing firms to prioritize the integration of response strategies during SSS implementation in the COVID-19 pandemic era for sustainable development and increased competitiveness.

5.2. Model validation

A comparative analysis with two multi-criteria decision making methods, namely the Analytical Hierarchy Process (AHP) and the Best-Worst Method (BWM), was conducted to verify and validate the efficiency and strengths of the proposed research methodology. The AHP method is one of the most successfully applied MCDMs in extant literature (Al- and Khorramshahgol, 2020, Awasthi et al., 2017, Chan et al., 2019, Luthra et al., 2016, Mastocinque et al., 2020, Moktadir et al., 2019). However, the AHP suffers drawbacks due to the high number of pairwise comparisons, unbalanced linguistics scale and bias in judgments of decision makers (Karatop et al., 2021, Sirisawat and Kiatcharoenpol, 2018). In an attempt to overcome the drawback of a high number of pairwise comparisons, the BWM is usually applied which has the presumed benefit of reducing the number of pairwise comparisons and obtaining consistent results (Gupta et al., 2020, Orji et al., 2020). In fact, the BWM is one of the widely utilized MCDMs due to its computational advantages (Kusi-Sarpong et al., 2019, Orji et al., 2020). Yet still, the BWM just like the AHP suffers a common limitation of uncertainty and bias in preferential judgments of decision makers and as such necessitates the integration of fuzzy set theory to overcome the limitation. The input data for the AHP computations was derived from AHP designed questionnaires that were collected from 48 experts considered in this study to obtain the initial pairwise comparison matrices. The AHP criteria weights and global (priority) weights of the pandemic response strategies and the TBL criteria for sustainable supplier selection are presented in Table 14 . Likewise, the input data (pairwise comparison matrices) for the BWM was obtained from BWM designed questionnaires that were collected from the 48 experts considered in this study. The BWM criteria weights and global weights of the pandemic response strategies and TBL criteria for sustainable supplier selection with their respective dimensions are presented in Table 15 .

Table 14.

AHP determined global ranking of TBL criteria and pandemic response strategies.

| Dimension | Dimension weight | Criteria | Criteria weight | Global weight | Global rank |

|---|---|---|---|---|---|

| Economic (EC) | 0.44 | Product price/cost (EC1) | 0.470 | 0.207 | 1 |

| Financial capability (EC2) | 0.140 | 0.062 | 7 | ||

| Quality (EC3) | 0.250 | 0.11 | 3 | ||

| Efficient production methods (EC4) | 0.144 | 0.063 | 6 | ||

| Environmental (EV) | 0.11 | Environmental competence (EV1) | 0.150 | 0.017 | 15 |

| Green product design (EV2) | 0.470 | 0.052 | 8 | ||

| Regular environmental audits (EV3) | 0.290 | 0.032 | 12 | ||

| Presence of training facilities (EV4) | 0.089 | 0.009 | 16 | ||

| Social (SC) | 0.16 | Work safety procedures (SC1) | 0.480 | 0.077 | 4 |

| Compliance with regulations (SC2) | 0.153 | 0.025 | 13 | ||

| Information disclosure (SC3) | 0.220 | 0.035 | 11 | ||

| Social responsibility (SC4) | 0.150 | 0.024 | 14 | ||

| Pandemic (PD) | 0.29 | Use of personal protective equipment (PD1) | 0.423 | 0.122 | 2 |

| Presence of information technologies (PD2) | 0.241 | 0.0698 | 5 | ||

| Adherence to policy changes (PD3) | 0.132 | 0.0382 | 10 | ||

| Economic recovery programs (PD4) | 0.145 | 0.042 | 9 |

Table 15.

BWM determined global ranking of TBL criteria and pandemic response strategies.

| Dimension | Dimension weight | Criteria | Criteria weight | Global weight | Global rank |

|---|---|---|---|---|---|

| Economic (EC) | 0.37 | Product price/cost (EC1) | 0.325 | 0.120 | 1 |

| Financial capability (EC2) | 0.251 | 0.092 | 3 | ||

| Quality (EC3) | 0.134 | 0.0495 | 5 | ||

| Efficient production methods (EC4) | 0.288 | 0.106 | 2 | ||

| Environmental (EV) | 0.14 | Environmental competence (EV1) | 0.236 | 0.0330 | 10 |

| Green product design (EV2) | 0.230 | 0.0322 | 11 | ||

| Regular environmental audits (EV3) | 0.211 | 0.0295 | 12 | ||

| Presence of training facilities (EV4) | 0.183 | 0.0256 | 14 | ||

| Social (SC) | 0.17 | Work safety procedures (SC1) | 0.137 | 0.0232 | 15 |

| Compliance with regulations (SC2) | 0.229 | 0.0389 | 8 | ||

| Information disclosure (SC3) | 0.171 | 0.0290 | 13 | ||

| Social responsibility (SC4) | 0.226 | 0.0384 | 9 | ||

| Pandemic (PD) | 0.32 | Use of personal protective equipment (PD1) | 0.171 | 0.0547 | 4 |

| Presence of information technologies (PD2) | 0.148 | 0.0473 | 6 | ||

| Adherence to policy changes (PD3) | 0.0687 | 0.0219 | 16 | ||

| Economic recovery programs (PD4) | 0.131 | 0.0419 | 7 |

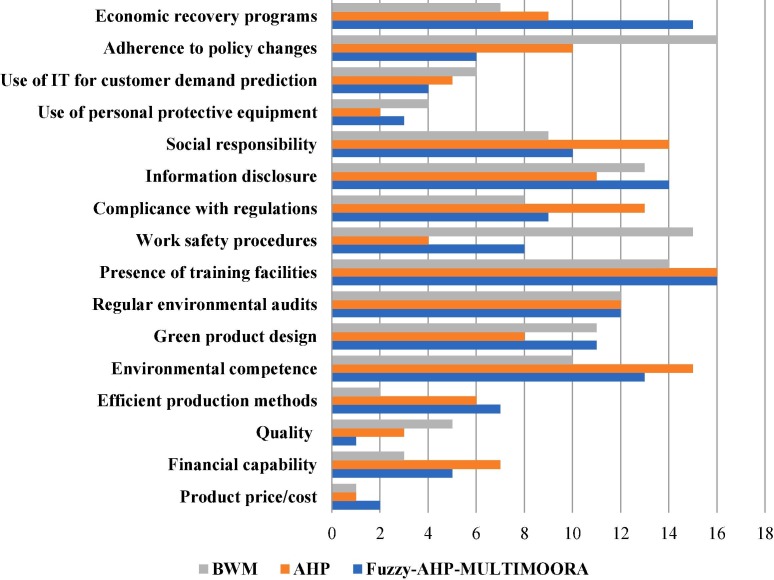

The comparison of the results of the Fuzzy-AHP-MULTIMOORA methodology applied in the current study and the results of the AHP and BWM are presented in Table 16 . A diagrammatic representation of the comparison of the results from these three MCDM methods is presented in Fig. 7 . As indicated in Table 16 and Fig. 7, the Fuzzy-AHP-MULTIMOORA indicates that the highest ranked criterion is quality while the AHP suggests that cost is the highest ranked. There are differences in the specific order of ranking obtained from the Fuzzy-AHP-MULTIMOORA and the AHP. The differences between the ranking obtained from the Fuzzy-AHP-MULTIMOORA and the AHP can be attributed firstly, to the consideration of the vagueness of judgments of decision makers through utilizing fuzzy set theory. Another possible reason might stem from the use of three ranking methods in MULTIMOORA, thereby resulting in a more robust ranking. Nevertheless, the rankings obtained from the Fuzzy-AHP-MULTIMOORA and the AHP are similar by inferring that presence of training facilities is the least ranked TBL criterion for sustainable supplier selection in the COVID-19 pandemic.

Table 16.

Comparative analysis of the ranking of pandemic response strategies and TBL criteria for sustainable supplier selection.

| Criteria | Fuzzy-AHP-MULTIMOORA | AHP | BWM |

|---|---|---|---|

| Product price/cost (EC1) | 2 | 1 | 1 |

| Financial capability (EC2) | 5 | 7 | 3 |

| Quality (EC3) | 1 | 3 | 5 |

| Efficient production methods (EC4) | 7 | 6 | 2 |

| Environmental competencies (EV1) | 13 | 15 | 10 |

| Green product design (EV2) | 11 | 8 | 11 |

| Regular environmental audits (EV3) | 12 | 12 | 12 |

| Presence of training facilities (EV4) | 16 | 16 | 14 |

| Work safety procedures (SC1) | 8 | 4 | 15 |

| Respect for policy (SC2) | 9 | 13 | 8 |

| Information disclosure (SC3) | 14 | 11 | 13 |

| Social responsibility (SC4) | 10 | 14 | 9 |

| Use of personal protective equipment (PD1) | 3 | 2 | 4 |

| Presence of information technologies (PD2) | 4 | 5 | 6 |

| Adhering to regulatory changes (PD3) | 6 | 10 | 16 |

| Development of economic recovery programs (PD4) | 15 | 9 | 7 |

Fig. 7.

Comparative ranking of the TBL criteria and pandemic response strategies.

According to the results presented in Table 16 and Fig. 7, the BWM method infers, contrary to Fuzzy-AHP-MULTIMOORA, that the highest ranked criterion is cost while implementing sustainable supplier selection in the COVID-19 pandemic. As such there are clear variations between the rankings obtained from the Fuzzy-AHP-MULTIMOORA and the BWM. We also attributed the reason for these variations to the application of fuzzy set theory in Fuzzy-AHP-MULITMOORA methodology which can effectively handle the uncertainty and vagueness in preferential judgments of decision makers. Furthermore, the differences between the rankings obtained from the Fuzzy-AHP-MULTIMOORA and the BWM can be attributed to the utilization of three MULTIMOORA ranking methods in the Fuzzy-AHP-MULTIMOORA resulting in ranking robustness. Consequently, we consider the the Fuzzy-AHP-MULTIMOORA as being more preferable to the other two compared methods by virtue of its overcoming vagueness in human judgments, presenting simple mathematical computations and ensuring robust ranking.

5.3. Research implications

The current study contributes theoretically to a better understanding of the COVID-19 pandemic’s impact on supply chain by providing a detailed illustration of the relative importance of pandemic response strategies in SSS in the COVID-19 pandemic era. As such, our study suggests that COVID-19 pandemic response strategies can influence supply chain operations like SSS and thus, such strategies can be critical to supply chain sustainability (Belhadi et al, 2021). Consequently, this study corroborates prior studies on sustainable supply chain management from the pandemic perspective (Bui et al., 2020, Hendiani et al., 2020, Karmaker et al., 2021, Klemes et al., 2020a, Klemes et al., 2020b). Moreover, by investigating the COVID-19 pandemic’s impact on SSS, our study contradicts previous research efforts on sustainable supplier selection that failed to provide the COVID- 19 pandemic perspective to the sustainable supplier selection problem (Khan et al., 2018, Luthra et al., 2017, Orji and Wei, 2015). The scientific research community has been making consistent efforts, since the onset of the COVID- 19 pandemic, to provide insights into various issues that relate to the adaptation plans and policies and of course, the pandemic’s impact on various supply chain operations. Indeed, it becomes highly important to study the impact of the COVID-19 pandemic on sustainable supplier selection.

Going further, this study falls within the category of studies that lay emphasis on sustainable supplier selection in the manufacturing sector of an emerging economy (Ahmadi et al., 2020, Fallahpour et al., 2017, Khan et al., 2018, Luthra et al., 2017, Orji and Wei, 2015). Notably, the manufacturing sector is a system that relates directly and indirectly to economic wealth creation and impact on the natural environment along the product’s life cycle (Kusi-Sarpong et al., 2019). Moreover, the emerging economies of the world have succeeded in generating financial gains through their manufacturing sector as the backbone of the economy; but, it is important to notice that these nations have been far away from achieving sustainability (Yadav et al., 2020). Consequently, manufacturing companies in the emerging economies need to evaluate their sustainable supplier selection process especially in the current COVID-19 pandemic crisis. A wealth of solutions is expected from such a venture by the manufacturing firms, which will enable them to be best equipped to contain future pandemics and still maintain a sustainable supply chain network.