Abstract

Vascularization of 3D models represents a major challenge of tissue engineering and a key prerequisite for their clinical and industrial application. The use of prevascularized models built from dedicated materials could solve some of the actual limitations, such as suboptimal integration of the bioconstructs within the host tissue, and would provide more in vivo‐like perfusable tissue and organ‐specific platforms. In the last decade, the fabrication of vascularized physiologically relevant 3D constructs has been attempted by numerous tissue engineering strategies, which are classified here in microfluidic technology, 3D coculture models, namely, spheroids and organoids, and biofabrication. In this review, the recent advancements in prevascularization techniques and the increasing use of natural and synthetic materials to build physiological organ‐specific models are discussed. Current drawbacks of each technology, future perspectives, and translation of vascularized tissue constructs toward clinics, pharmaceutical field, and industry are also presented. By combining complementary strategies, these models are envisioned to be successfully used for regenerative medicine and drug development in a near future.

Keywords: 3D cell culture, bioprinting, microfluidics, tissue engineering, vascularization

Vascularization strategies of 3D tissue engineered models are reviewed in this article. The integration of a vascular network in vitro is fundamental to achieve tissue constructs with physiological relevance. Nowadays, numerous approaches have been developed to vascularize tissue and organ models, mainly by using microfluidic technology, 3D cell culture, and bioprinting. Recent advances and the combination of these strategies are promoting a rapid translation toward the clinical and industrials fields.

1. Introduction

In physiological conditions, the tissues of the human body are vascularized thanks to an abundant network of blood vessels, known as the vascular network. Human vasculature has essential biological functions, such as nutrients and gas exchange, metabolic waste removal, and homeostasis maintenance.[ 1 , 2 ] Its role is fundamental at the macro as well as at the microscale, where a diffusion limit of oxygen and nutrients has been reported to be around 200 µm,[ 3 , 4 ] meaning that the cells located farther from a capillary undergo hypoxia and apoptosis. Thus, vascularization plays a pivotal role in achieving physiologically relevant tissue and organ substitutes for tissue engineering (TE) and regenerative medicine applications. Despite the unprecedent advancements of tissue engineering in the last decades, the integration of a functional vascular network in tissue constructs still represents a challenge that hampers an efficient and fast scale‐up toward the clinical application.

In bioengineered models, the presence of vasculature would ensure the proper exchanges, preventing cellular death in constructs thicker than 200 µm and contribute in mimicking the tissue physiology and cell microenvironmental cues. Overall, a functional capillary network would allow for a long‐term maintenance of the construct in terms of viability, morphology, and functionality. Furthermore, organ‐specific vasculature has shown to strongly affect the behavior of the parenchymal cells and to drive organ‐related biological events.[ 5 ] Vasculature plays a key role also in many diseases, such as cancer metastasis, atherosclerosis, or tumor angiogenesis.[ 6 ] For in vitro studies, the use of vascularized models could give more realistic insights of human response to drug testing, toxicology assays, or in pathological models.[ 7 ] Particularly in the pharmaceutical field, the urgent need to speed up the drug development process, lower R&D costs, and overcome the use of inadequate animal models strongly relies on the development of more predictive and clinically accurate systems.[ 8 , 9 , 10 ] In regenerative medicine, the implantation of prevascularized constructs compared to constructs that spontaneously vascularize in situ would enhance the grafting to the host tissue and fasten its regeneration. Moreover, although the successful implantation of thin constructs like skin has been reported, the formation of abundant and functional vascular network is a key prerequisite for the generation of thick and metabolically active organs, such as liver, heart, or kidney.[ 2 ] In fact, the host vasculature needs time to integrate and vascularize the implanted tissue and the use of avascular scaffolds could be inefficient due to the impossibility to be instantly perfused. The implantation of prevascularized scaffolds would thus represent one of the most favorable strategies for regenerative medicine purposes.

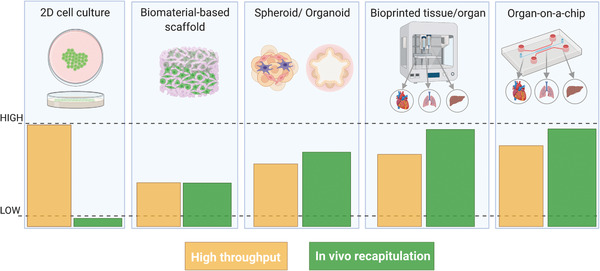

Many efforts have been conducted over the past years to build 3D physiologically relevant models that could fully recapitulate the tissues and organs functioning. The traditional 2D cell culture systems on polystyrene surfaces, which have been the gold standard of in vitro models for many decades, are unable to mimic the in vivo conditions. Tissue engineering has thus developed a plethora of 3D cell culture models, which have proven to be more physiologically relevant compared to 2D cell culture, providing accurate results in biological studies, such as in vivo‐like cell viability, morphology, differentiation, and proliferation, as well as cellular response to stimuli, protein synthesis, and drug metabolism (Figure 1 ).[ 11 ]

Figure 1.

Evolution of tissue engineering platforms from 2D to 3D models. The bottom panel shows the comparison of model throughput versus physiological relevance: the in vivo recapitulation increases when moving from 2D cell cultures to 3D models and the throughput of complex models can be enhanced by means of automated bioprinting processes or parallel microfluidics. Created with BioRender.com.

In recent decades, some research lines have thus moved from culturing of single cell types on flat and rigid substrates, to the coculture of cells, first in 2D (i.e., Transwell systems) and later in 3D, with the introduction of spheroids and organoids models. Complex physiological conditions, such as blood flow, oxygen gradients, or mechanical stimuli, can be mimicked nowadays by using microfluidic devices, that allow for perfusion of cells by means of microchannels networks. In parallel, new biomaterials have been developed to mimic the cell niche, with advancements from 2D culture on extracellular matrix (ECM) gels (i.e., Matrigel) to 3D scaffolds with tunable physical–chemical and mechanical properties.[ 12 , 13 , 14 ] These systems have been extensively used as in vitro models consisting of multiple cell types and the combination with bioreactors has allowed researchers to provide the cells with physiological‐like biochemical and mechanical cues. Recently, these in vitro models have often adopted the emerging strategy of 3D bioprinting to engineer more complex systems, eventually replacing the conventional fabrication methods. The synergistic use of these technologies would allow for a precise control of the cell culture conditions and the microenvironment and it would represent a key strategy to engineer biostructures that mirror human tissues and organs while ensuring high throughput, fundamental for the translation of these models toward their application in industrial and clinical settings. Nevertheless, lacking or inefficient perfusion and vascularization remains one of the main limitations of tissue engineered constructs as the need for vascularization exists from the moment the tissue‐engineered constructs are assembled in vitro, to the moment when they are implanted in a patient.[ 15 ]

In this review, we discuss the latest advancements on vascularization strategies in tissue engineering, focusing on different approaches, namely, organs‐on‐a‐chip (OOaC), spheroids, organoids, and 3D bioprinted tissues. After a brief overview of the physiological properties of the vascular network, we describe the fabrication techniques used to engineer prevascularized 3D physiologically relevant tissue and organ models. Finally, we critically discuss the current technical limitations and evaluate some perspectives for industrial and clinical applications.

2. Physiological Properties of the Vascular Network

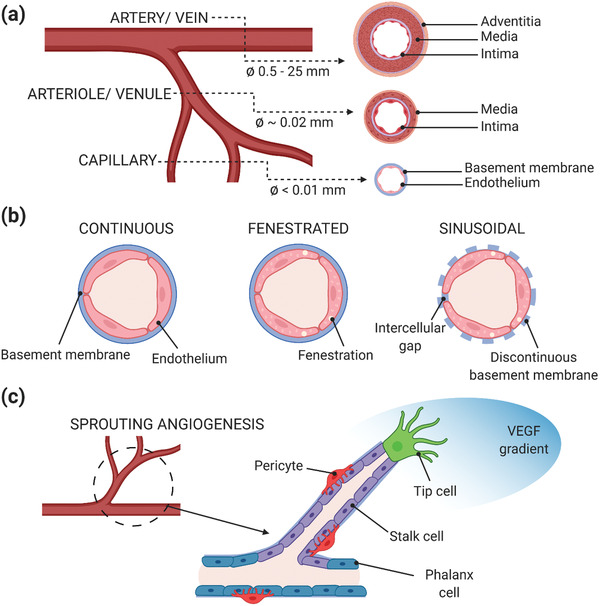

The vasculature is a network of blood vessels consisting of the arterial system, the venous system, and the microcirculation (Figure 2a). The arterial system, composed of arteries and arterioles, distributes oxygenated blood from the lungs while the venous system, composed of veins and venules, returns low oxygenated blood to the heart. Separating these two systems is the microcirculation, where nutrients and cellular wastes exchange is carried out by the capillaries. The distinct anatomy and size of the blood vessels are dictated by the different physiological functions they play. To withstand high blood pressures and shear stress, the larger vessels, namely, arteries and veins, are composed of three layers. The external layer, called tunica adventitia, is mainly composed of collagen and nerve fibers, with a protective and support function. The middle layer, tunica media, is composed of smooth muscle cells (SMCs) and elastic connective tissue, responsible for vasodilation and vasocontraction. The inner layer, tunica intima, is the lumen wall, lined with endothelial cells (ECs) and surrounded by a thin basement membrane.[ 16 , 17 ] The arteries and veins are large diameter vessels, ranging from 25 mm for the aorta and about 2 mm for the pulmonary veins to hundreds of micrometers for the smallest arteries and veins. While moving down into the vascular tree, the blood pressure decreases and less elasticity is needed: that is why arterioles, with a size of 10–100 µm, are composed of the tunica media and intima only and the capillaries (less than 5 µm) are composed of a single ECs monolayer. It is interesting to notice that with the decrease of the vessels size, the vascular wall also becomes thinner. At the tissue level, the anatomy is extremely complex: in healthy conditions, the capillary density is about 300–400 capillaries mm−3 in skeletal muscles and above 2000 capillaries mm−3 in myocardium, brain, liver, and kidney.[ 18 ] Furthermore, the parenchymal tissues are composed of cells at high concentration, of about 105 cells mm−3.[ 19 , 20 ] Due to its direct contact with blood, the endothelium participates in numerous physiological functions including selective barrier membrane, thrombosis prevention, blood pressure regulation, and angiogenesis.[ 21 ] Although ECs in different regions of the body fulfil similar physiological demands, heterogeneity in their morphology, function, gene expression, and antigen composition has been reported.[ 22 , 23 ] Specifically, the morphology of the endothelium varies to adapt to the specific functions of their underlying tissue (Figure 2b). Most of the vessels of the brain, lungs, and skeletal muscles, present a continuous endothelium, where ECs are held together by tight junctions and a continuous basement membrane, allowing mainly for water and ion exchange. For organs that are involved in filtration and secretion (i.e., exocrine and endocrine glands, intestinal villi, kidney glomeruli, choroid in the eyes, and a subpopulation of renal tubules), the endothelium is fenestrated. These fenestrations, or pores, exist along with tight junctions in the endothelial lining, and their permeability can vary depending on the underlying tissue needs. For the vessels in the liver, spleen, and bone marrow, the endothelium is sinusoidal or discontinuous, where the lining has larger fenestration (100–200 µm), extensive intercellular gaps, and an incomplete basement membrane.[ 21 ]

Figure 2.

Physiological properties of the vascular network. a) Anatomical properties and dimensions of the human vasculature. b) Phenotypic heterogeneity of organ‐specific endothelium. c) Differentiated role of endothelial cells during angiogenesis. Created with BioRender.com.

For the development of more biomimetic vascularization strategies, we summarize here the main aspects of the two key biological processes through which neovascularization occurs: vasculogenesis and angiogenesis. Vasculogenesis is the process in which de novo blood vessels are generated from endothelial precursors, the angioblasts, in the embryo. Once the primitive vascular network is formed, more blood vessels arise from pre‐existing ones and expand through the angiogenesis process. During angiogenesis, ECs are activated through a complex cascade of proangiogenic signals and undergo division, sprouting, branching, and lumen formation to form a network of arteries and veins. Currently, most vascularization approaches intended for clinical applications focus on the latter phenomenon. ECs demonstrate a structural and functional heterogeneity during angiogenesis, when they differentiate into two phenotypes, known as tip cells and stalk cells. Tip cells produce filopodia, which explore and perceive local signals from the environment, while guiding new vessel sprouts and forming connections with neighboring cells to build vessel loops.[ 24 , 25 , 26 ] In contrast, stalk cells follow tip cells and proliferate to support sprout elongation and lumen morphogenesis and secrete basement membrane components, which further stabilize newly formed vessels (Figure 2c).[ 27 ] The phenotypic differentiation of ECs is a transient and reversible process, modulated by complex signaling pathways, as the interplay between the vascular endothelial growth factor (VEGF) and Notch signaling.[ 28 , 29 ] Tip cell migration is regulated by VEGF gradients while the Notch signaling is essential for stalk cell barrier function, polarity, and lumen formation. New vascular network connections are then stabilized through the recruitment of pericytes and vascular smooth muscle cells, followed by the deposition of ECM. Once the vessels have been perfused, ECs switch to quiescent state (phalanx phenotype), where they are immobile and nonproliferating and promote vascular stability through increased cell adhesion and reduced response to VEGF signals. Nevertheless, quiescent ECs maintain their plasticity to sense and respond to angiogenic signals.[ 30 ] We refer the reader to existing reviews for a detailed overview of the angiogenetic process.[ 27 , 31 , 32 ]

3. Requirements for the Fabrication of Engineered Vascularized Tissues

Based on the morphological and physiological aspects illustrated so far, the engineering of functional vascularized constructs should fulfill several parameters:

-

i)

The artificial vessels should have circular cross‐section to guarantee optimal cell seeding and physiological‐like shear stress, fundamental to maintain healthy endothelial phenotype.[ 26 , 33 , 34 ]

-

ii)

The bioengineered vascular network should be branched and multiscale as it is in vivo, with larger vessels branching into capillaries to ensure a proper blood flow and gas and nutrients exchange at the microscale. The presence of large vessels (hundreds of micrometers) is also required when the artificial network needs to be surgically anastomosed to the host vasculature.[ 3 ]

-

iii)

For vessels other than capillaries, a multilayered structure should be recreated in vitro and include not only the endothelium composing the tunica intima but also the other cellular components as the SMCs. Coaxial technology holds great promise for the fabrication of the different vessel layers, as we will illustrate in Sections 4.1.1 and 4.3.2.

-

iv)

The tissue construct should take into account the organ‐specific morphology of the vascular endothelium (i.e., continuous, fenestrated or sinusoidal ECs), which regulates the barrier properties and the interaction between the parenchymal tissue and the blood.[ 35 ] This prerequisite would necessarily require an accurate selection of cell sources, preferring primary cells over cell lines, further complicating the challenge.

-

iv)

The in vitro vasculature microenvironment should integrate basement membrane proteins, as laminin and collage type IV, and other ECM components (fibronectin, glycosaminoglycans, …),[ 14 , 36 ] which actively influence the endothelial barrier function, differentiation, and proliferation during angiogenesis as well as tissue maintenance and remodeling.[ 37 , 38 , 39 , 40 , 41 ]

-

v)

The in vitro vasculature should be perfused to ensure adequate cell survival and tissue functioning. The perfusion parameters of the vascular network should mirror the hemodynamics and blood flow properties:[ 42 ] pulsatile flow should be applied for vessels mimicking the arteries and laminar flow in the microcirculatory system, with shear stresses below 10 dyne cm−2, values have shown to influence ECs cytoskeleton remodeling and nitric oxide levels.[ 43 ] The mechanical properties of the surrounding tissue and ECM components should be designed to match the physiological values.[ 44 , 45 , 46 , 47 ]

-

vi)

The prevascularized model should mimic the in vivo capillary density and cellular concentration to respect the 200 µm diffusion limit and build functional dense and highly vascularized tissue substitutes or in vitro platforms.

4. Vascularization Approaches for Physiologically Relevant 3D Models

In this section, the fabrication strategies to prevascularize 3D physiologically relevant tissues are illustrated, classifying the vascularized models in microfluidic‐based, 3D cell culture (spheroids and organoids), and 3D bioprinted constructs. The fabrication methods described here, the features of each 3D approach, and their applications are summarized in Table 1 . It is worth highlighting that some of these approaches are used also as fabrication strategies for other models; in particular, bioprinting is currently used for engineering microfluidic platforms and 3D cell cultures and microfluidic devices have been used for culturing and vascularizing spheroids and organoids. Here, the vascularization strategies of each model are discussed separately while the recent trend toward the combination of these techniques is discussed in Section 4.4 about hybrid strategies.

Table 1.

Fabrication strategies for each vascularized 3D model, comparison of their properties, and main applications. SL: soft lithography; T: templating; B: bioprinting; EB: extrusion‐based; DB: droplet‐based; LAB: laser‐assisted; Vat‐P: vat photopolymerization. Created with Biorender.com

| Vascularized 3D model | ||||

|---|---|---|---|---|

| Microfluidic‐based | 3D cell culture | Bioprinted | ||

| Fabrication strategy |

|

|

|

|

| Vessel geometry |

|

Capillary‐like structures in vitro | Tubular interconnected channels | |

| Vessel dimensions | Hundreds to tens of micrometers (>30 µm) | Hundreds to tens of micrometers |

|

|

| Microenvironment | Possibility to integrate ECM proteins and growth factors |

|

Possibility to integrate ECM proteins and growth factors and to print multiple cell types | |

| Advantages |

|

|

|

|

| Disadvantages |

|

|

|

|

| Application |

|

|

|

|

4.1. Vascularization Techniques for Microfluidic‐Based Models

In the last decade, microfluidics has emerged as relevant technology to build 3D in vitro microphysiological systems for the study of human pathophysiology and drug development.[ 48 , 49 ] The capability of engineering perfusable channels in microfluidic devices makes this technology particularly interesting to generate vascular networks in vitro and important efforts have been conducted to recreate and integrate microvasculature in OOaC models.[ 50 ] The recent combination with tissue engineering approaches and biomaterials has accelerated the transition from traditional nonbiomimetic materials (glass, silicon, and polydimethylsiloxane (PDMS)) and 2D cell culture to 3D ECM‐like hydrogel‐based platforms.[ 17 , 51 ] Microfluidic‐based vascular models have been used to study the response of endothelium to a plethora of stimuli under both physiological and pathological conditions,[ 6 , 52 , 53 ] the interaction between endothelium and parenchyma in organ‐specific vascular platforms and to understand key factors in vasculogenesis and angiogenesis processes.[ 43 , 54 ] Microfluidics has been used as well for investigating the interaction between blood cells (platelets, leukocytes, and red blood cells) and vasculature and their response to mechanical or biochemical cues, which cannot be studied with static traditional in vitro platforms.[ 55 , 56 , 57 , 58 ]

4.1.1. Strategies to Create Vasculature On‐Chip

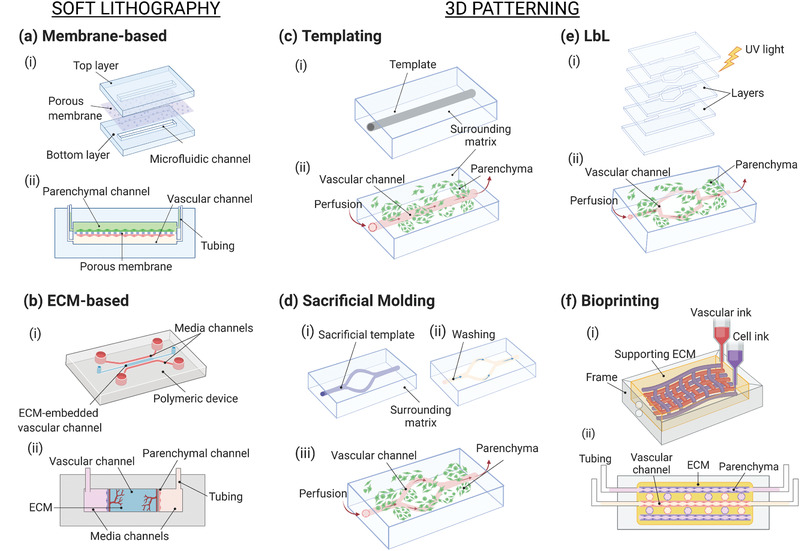

The vascularization approaches on‐chip are commonly classified based on the fabrication method into two main categories, namely, prevascularized patterning methods and self‐vascularization approaches.[ 1 , 59 ] Prevascularized patterning methods consist of engineering polymeric or biological materials to create a vascular‐like network on‐chip, which can provide physical support and guidance for cells. To form the vascular component, cells are seeded or patterned and cultured in these preformed channels (Figure 3 ). In the self‐vascularization approach, ECs are embedded in a matrix and supplied with biological, chemical or mechanical cues to induce spontaneous morphogenesis of the vascular network. Self‐vascularized microfluidic platforms are commonly used to study vasculogenesis and angiogenesis processes in vitro (see Section 2) and they become particularly significant in the context of vasculature‐related diseases, such as cancer metastasis or atherosclerosis.[ 6 , 48 ] Comprehensive reviews on the topic are available.[ 1 , 17 , 48 , 60 , 61 ] In this section, we provide an overview of the main prevascularization patterning strategies used for fabricating vascularized microfluidic platforms, focusing on relevant organ‐on‐a‐chip models integrating vasculature and discussing the current bottlenecks of this approach.

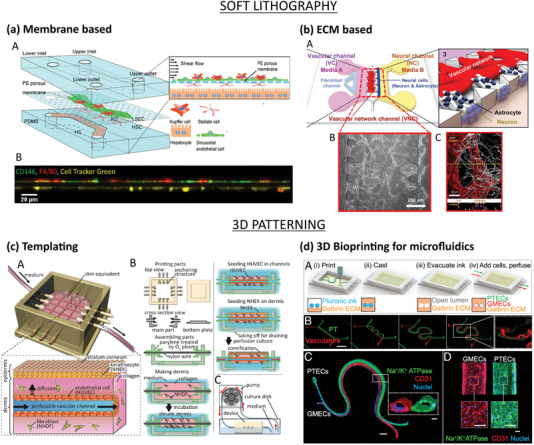

Figure 3.

Schematic of the strategies used to vascularize microfluidic‐based models. a,b) Soft lithography and c–f) patterning. a) Membrane‐based vascularized device: i) the fabrication process consists of assembling the microfluidic layers and a porous membrane and the assembled chip with the typical sandwiched structure. b) ECM‐based microfluidic platform: i) the chip usually contains one or more channels filled with ECM proteins that ii) embed the parenchymal and vascular components. c) Templating: i) a matrix is casted around the template equipment (needle, fiber), which is ii) subsequently removed to form the channel. d) Sacrificial molding: i) the patterned template is fabricated and encased in the surrounding matrix, ii) the template is removed, and iii) the device is seeded and perfused. e) Layer‐by‐layer: the modular layers are assembled, for instance, i) by photocrosslinking before ii) the device seeding. f) Bioprinting for microfluidics: usually performed on ECM matrix—eventually bioprinted—in which vascular and parenchymal inks can be used to i) build the tissue before ii) perfusion of the device. Created with BioRender.com.

Soft Lithography Techniques

The mimicry of the vascular interface in vitro has been mainly achieved by using microfluidic platforms produced by soft lithography. This approach involves the production of a silicon or glass mold containing the microchannel features by photolithography and using it as stamp to pattern PDMS devices by replica molding. The device is then sealed by bonding it to a substrate to create perfusable channels (Figure 3a).[ 5 ] Despite the lack of a proper 3D lumen and geometrical similarity to in vivo vasculature, these models have demonstrated to be efficient platforms to build a functional organ‐vasculature interface, showing significant advantages compared to static 2D models.

Vascular Interface on a Membrane

The visionary work of Ingber's group led to the development of the most used organ‐on‐a‐chip model nowadays. They reproduced the air–liquid interface (ALI) of the lung by culturing alveolar epithelial cells and human pulmonary microvascular ECs on two sides of a porous 10 µm thick PDMS membrane in a two‐channel PDMS device.[ 62 ] Cyclic mechanical strain was applied to mimic physiological breathing by lateral vacuum channels. This simple yet functional platform was used to recreate a long‐term model (>2 weeks) of the ALI, showing in vivo‐like barrier permeability, enhanced production of surfactants by the epithelium when exposed to air and endothelium alignment under mechanical stretching. Exposure to cytokines and nanoparticles showed the active role of vasculature and mechanical forces under inflammatory conditions, underlying the need to integrate these components to build complex in vitro platforms capable of recreating physiological organ functions.[ 53 ]

This pioneering platform paved the way for the study of tissue‐vasculature interactions in organ‐specific models such as kidney,[ 63 , 64 ] brain and blood–brain barrier (BBB),[ 65 , 66 , 67 ] heart,[ 68 , 69 ] gut,[ 70 , 71 ] and liver.[ 72 , 73 ] Recently, a liver sinusoid on‐chip was built by integrating four primary hepatic cell types from the same murine source.[ 73 ] Liver sinusoidal endothelial cells (LSECs) and Kupffer cells (KCs) were cultured on the apical side of a porous polyester membrane to mimic the sinusoidal interface. Hepatic stellate cells (HSCs) were cultured on the basolateral side and hepatocytes (HCs) were seeded on the PDMS bottom channel to recreate the Disse space and the parenchymal tissue respectively (Figure 4a). Shear stress was applied in the device and imaging analyses confirmed the formation of a discontinuous endothelium composed of fenestrated LSECs, typical of in vivo liver sinusoid.[ 5 ] Results showed that the presence of nonparenchymal cells (NPCs) and shear stress enhanced hepatocytes functionality and metabolism compared to HCs static monoculture and neutrophil recruitment resulted to be higher when LSECs were cultured with the other NPCs under flow. Despite the use of murine cell source and the short‐term evaluation, this model reveals the synergistic effect of mechanical cues and paracrine pathways in regulating liver metabolism and its response to inflammatory conditions.

Figure 4.

Microfluidic‐based vascularization strategies: soft lithography (top) and 3D patterning (bottom). a) Liver sinusoid on‐chip fabricated by soft lithography. LSECs and KCs were seeded on the apical side of a PE membrane while HSCs on its basolateral side and HCs on the PDMS substrate (top). Lateral view of the sinusoidal endothelium (bottom): LSECs (green) and KCs (red) on the top and HSCs (yellow) on the bottom of the membrane. Reproduced with permission.[ 73 ] Copyright 2017, The Royal Society of Chemistry. b) ECM‐based vascularized BBB platform: A) HUVECs and fibroblasts were seeded in the vascular channel (VC), and neural cells (astrocytes and neurons) were seeded in the neural channel (NC). The formation of vascular network in the central vascular network channel (VNC) ensured a direct interface between the capillaries and the astrocytes through astrocytic endfeet (B,C: ECs stained in red, astrocytes stained in white). Adapted with permission.[ 66 ] Copyright 2017, Springer Nature. c) Skin‐equivalent platform generated by templating: A,B) The culture device was 3D printed and filled with collagen and fibroblasts to form the dermis layer. After removal of the nylon wires, the hollow channel was seeded with HUVECs to form the capillary, and keratinocytes were cultured on the top of the dermis and exposed to liquid–air interface for cornification of the epidermal layer. C) Perfusion of the device via peristaltic pump. Reproduced with permission.[ 74 ] Copyright 2017, Elsevier Inc. d) Hybrid strategy: 3D printed vascularized proximal tubule model. A,B) The colocalized vascular and renal channels are both 3D printed by using a Pluronic F127‐based fugitive ink within an ECM solution and different designs can be easily printed. C,D) The construct is then seeded with epithelial (green) and endothelial (red) cells. Reproduced with permission.[ 75 ] Copyright 2019, PNAS.

Multiorgan‐on‐a‐Chip (MOC): A New Promising Tool for Drug Development

The growing need for accurate and reliable in vitro models for drug screening and development has led to the design of MOC platforms (also known as body‐on‐a‐chip), that allow for the study of pharmacokinetic–pharmacodynamic (PK–PD) pathways of drugs and interactions among organ equivalents.[ 76 ] The integration of vasculature is fundamental due to the active role of microvascular circulation in maintaining homeostasis.[ 48 , 59 ] Novak et al. have recently engineered a vascularized eight‐organ‐on‐a‐chip (BBB, brain, skin, lung, heart, liver, intestine, and kidney) coupled with liquid‐handling robotics and in situ microscopy that enabled automated culture, perfusion and control on‐chip.[ 77 ] Interestingly, the device used a universal blood‐like medium for the vascular compartment and a specific medium for each organ. Although the vascular component was part of each organ platform, it was not included in the connections between chips. Schimek et al. lined uniformly the connecting tubes of a MOC with primary human dermal microvascular endothelial cells (hDMECs) under pulsatile shear stress and created branching microvessels of 40 µm in diameter by two‐photon laser ablation technique.[ 78 ] Similarly, PDMS tubes with tunable diameter and thickness that can mimic different blood vessel types have been endothelialized and coupled to MOC platforms and the exposure to drugs showed the formation of a responsive endothelium.[ 79 ]

ECM‐Based Microfluidic Devices

Standard lithographic processes lead to rectangular or squared cross‐sectioned channels, a geometry that has been proven inadequate to build functional microvasculature in vitro and to model phenomena such as coagulation.[ 80 , 81 ] Thus, channels with circular cross‐sections have been fabricated by different strategies as micromilling of metal molds,[ 82 ] flow of nitrogen gas in a PDMS solution,[ 33 ] reflow of positive photoresists,[ 83 ] or by viscous fingering of ECM substrates, as collagen or Matrigel.[ 84 , 85 ] Moreover, in standard microfluidic devices, cells are cultured on flat substrates such as polymeric membranes or PDMS sheets. To address these limitations, microfabrication strategies have been adapted to create hydrogel‐based microfluidic platform, for instance, by molding ECM gels upon PDMS stamps,[ 86 , 87 ] or embedding hydrogels in PDMS devices (Figure 3b).[ 66 , 88 ] In a recent work, Bang et al. engineered a BBB device with contact of astrocytes and vascular network through astrocytic endfeet to overcome the lack of direct interface of the two components in common BBB‐on‐chip platforms, that hampers the achievement of in vivo‐like barrier permeability values (Figure 4b).[ 66 ] The PDMS device was composed of two parallel microchannels, representing the vascular and neural compartments respectively, embedded in a fibrin hydrogel and supplied with specific medium through lateral channels. In a first step, a mixture of endothelial cells (human umbilical vein endothelial cells, HUVECs) and fibroblasts was seeded in the vascular channel and vasculogenesis was induced to create the vascular network. After 3 days, the neural channel was seeded with astrocytes and neurons and the formation of functional BBB was observed within one week. Results confirmed the growth of a functional lumen, the migration of astrocytes to form a direct contact with HUVECs, permeability values comparable to in vivo coefficients and formation of synapses.

3D Patterning Methods

The recent adoption of tissue engineering fabrication methods has paved the way for engineering more sophisticated 3D in vitro vascular networks on‐chip, overcoming the main drawbacks of conventional OOaC platforms, namely, the use of nonbiomimetic materials and lack of a 3D geometrical complexity.[ 89 ] Hydrogel‐based devices reproducing the role of ECM in vivo offer several advantages such as tunable mechanical properties, biodegradability, control over the cellular microenvironment, and a wide choice of materials.[ 90 ] We classify below the patterning methods used for microfluidics as templating, layer‐by‐layer (LbL) manufacturing and 3D bioprinting.

Templating Strategies

Templating, also known as micromolding, is a subtractive technique in which a material with the desired vasculature shape is embedded in a bulk matrix and subsequently removed or dissolved to create a hollow perfusable microvasculature. Microneedles and fibers have been widely used to fabricate simple vascular geometries in gels (Figure 3c). Mori et al. used needle‐based micromolding to create a skin‐equivalent model composed of epidermal and dermal layer and perfusable vascular channels.[ 74 ] A culture device was 3D printed and nylon wires (500 µm thickness) were used as channel templates. Collagen solution loaded with normal human dermal fibroblasts (hNDFs) was gelled to fabricate the dermal layer and, after removal of the wires, the vascular channel was formed by seeding HUVECs. The subsequent addition of normal human epidermal keratinocytes (NHEKs) on the top of the dermal layer and exposure to the ALI enabled the formation of the stratum corneum of the epidermis (Figure 4c). Water repellency and capacitance tests confirmed the barrier function of the epidermal layer and permeability studies on the vascular channel showed the formation of a selective barrier for the diffusion of nutrients. Percutaneous absorption studies conducted by flowing caffeine and drugs in the vasculature confirmed the adequacy of the model as a platform for vascular absorption studies, fundamental in drug and cosmetics testing.

The needle‐based vascularized platforms are mainly limited to straight channel geometries and some manufacturing steps (needle removal, stability of the gel after crosslinking) have to be taken into account during the design process. Sacrificial molding uses templating materials that are dissolved after the hydrogel bulk gelation and represents a versatile technique to create stable and more complex 3D vascular networks.[ 89 ] Gelatin (Gel),[ 91 ] agarose,[ 92 ] alginate,[ 93 , 94 ] Pluronic,[ 95 ] and poly(vinyl alcohol) (PVA)[ 96 ] have been used as sacrificial materials for creating meshes either by micromolding or 3D printing (Figure 3d and Section 4.3). Vollert et al. fabricated large (15 × 25 × 3 mm3) perfusable engineered heart tissues for cardiac regeneration by using either straight or branched alginate fibers as lumen template.[ 93 ] The tissue was composed of a neonatal rat heart cells mix (cardiomyocytes (CMs), ECs, fibroblasts, and SMCs),[ 97 ] embedded in a fibrin matrix and ECs showed formation of an intima‐like layer by spontaneously covering the vessels after alginate dissolution. The engineered tissues showed contractile forces and the continuous perfusion enhanced oxygen concentration, with a significant increase in the CMs density.

To overcome the use of potential cytotoxic dissolving agents during sacrificial molding, researchers have engineered vascular templates that can be dissolved in cell media, such as Pluronic and 3D‐printed self‐standing carbohydrate glass lattices and caramel templates, which have been used to create complex hierarchical networks of tubular channels with interconnected lumens and permeable walls.[ 98 , 99 ]

Layer‐by‐Layer Manufacturing

LbL represents a versatile bottom‐up method for manufacturing complex 3D vasculature in vitro and consists of assembling 2D prepatterned gel slabs into multilayered (modular) 3D devices (Figure 3e).[ 17 ] Zhang et al. fabricated vascularized cardiac and hepatic constructs by stacking 25 µm thick poly(octamethylene maleate (anhydride) citrate) (POMaC) layers patterned by UV photolithography.[ 69 , 100 ] The presence of microholes and nanopores in the scaffold walls ensured physiological‐like mass transport and cell migration and the formation of vessels with a thickness of 2–3 cells. The use of a photocrosslinkable hydrogel provided for tunable stiffness, thus creating an anisotropic construct that closely mimics the myocardium mechanical properties. The pump‐free perfusion in vitro was performed by connecting the device to a custom‐made bioreactor and the open configuration enabled direct access to the cellular compartments by pipetting. Culturing of the vascular network with HUVECs led to formation of a functional lumen, capable to respond to angiogenic and inflammatory stimuli and compatible with human whole blood flow. By integrating liver or heart parenchymal cells embedded in ECM, functional tissue constructs were built, exhibiting metabolic response to drug administration and contractile behavior, respectively. In vivo implantation by anastomosis confirmed the nonthrombogenic properties of the device and successful angiogenesis in a rat model.

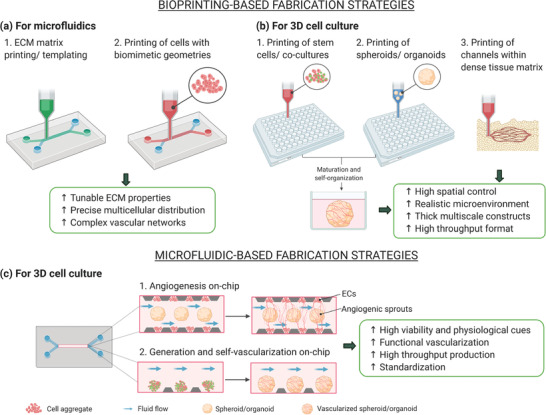

3D Bioprinting for Microfluidics

Cells and hydrogels can be used as bioinks for direct fabrication on‐chip of perfusable or vascularized models with complex geometries by means of 3D bioprinting approaches (Figure 3f). Here, we consider 3D bioprinting for fabrication of microfluidic devices as hybrid strategy, discussed in Section 4.4.

Although soft lithography, templating and additive manufacturing are commonly used for fabrication of perfusable vasculature, other methods have been explored. Heintz et al. used a laser‐based degradation technique to create complex and tortuous 3D microfluidic poly(ethylene glycol diacrylate) (PEGDA) hydrogel networks from a stack image of mouse cerebral cortex vasculature.[ 101 ] The high spatial resolution offered by the technique led to microvessels with a diameter of less than 10 µm and a dense network, fundamental for providing the parenchymal tissue with nutrients and oxygen within the diffusion limit.[ 3 ] Interestingly, vascular microfluidic chips have been engineered by reversibly assembling explanted mouse arteries on automated platforms, showing the capability to study intact vessels functionality by performing immunofluorescence studies and quantitative analyses on‐chip.[ 5 , 102 ]

Table 2 summarizes significant case studies for the microfluidic‐based vascularization strategies, cited or discussed in the text. Data such as channel shape, perfusion parameters and duration of in vitro studies have been reported to provide the reader with a detailed overview of different specifications and address some drawbacks, which will be discussed in the next paragraph.

Table 2.

Summary of case studies for microfluidic‐based vascularization strategies

| Vascularization method | Organ/tissue model | Vessel caliber (d)/channel size (h × w) | Channel shape | Chip composition | Cellular composition | Perfusion parameters | Duration of in vitro study | In vivo evaluation/drug testing | Refs. | |

|---|---|---|---|---|---|---|---|---|---|---|

| Soft lithography | Liver | 100 µm × 1 mm | Rectangular, straight | PDMS; PE (polyester) membrane | LSECs, HCs, KCs, HSCs (all primary from mouse) | 0.1 or 0.5 dynes cm−2, syringe pump | 1 day | No/No | [ 73 ] | |

| BBB |

|

Rectangular, straight |

|

|

– | 7 days | No/No | [ 66 , 88 ] | ||

| Kidney | 0.2 × 1 mm (vascular), 1 × 1 mm (urinary) | Rectangular, straight | PDMS (chip, membrane) | Glomerular ECs; hIPS‐derived podocytes | 0.017 dynes cm−2 (vascular), 0.0007 dynes cm−2 (urinary), peristaltic pump | 8 days | No/Yes | [ 64 ] | ||

| Intestine | 0.15 × 1 mm | Rectangular, straight | PDMS (chip, membrane) | Capillary ECs or lymphatic microvascular ECs, Caco‐2 intestinal epithelial cells, immune cells | 0.02 dynes cm−2 | >7 days | No/Yes | [ 70 ] | ||

| Multiorgan | (100 × 500 µm) to 40 µm | Rectangular, curved | PDMS | Dermal microvascular ECs | 10–40 dynes cm−2, on‐chip micropump | Up to 4 weeks | No/No | [ 78 ] | ||

| Templating | Liver |

|

|

|

|

|

|

|

[ 19 , 103 ] | |

| Skin |

|

|

|

|

|

|

|

[ 74 , 94 ] | ||

| Heart | 100–500 µm | Circular | Fibrin matrix | Neonatal rat heart cells mix | 20 µL h−1, syringe pump | 21 days | No/No | [ 93 ] | ||

| 3D bioprinting | Urothelial/vascular tissue a) | ≈700 µm (inner), ≈1 mm (outer) | Circular, multilayer, flexible | Bioink: PEGOA + GelMA | Urothelial: human urothelial cells + human bladder SMCs; vascular: HUVECs + human SMCs | – | 14–21 days | No/No | [ 104 ] | |

| Kidney | 200 µm | Circular, colocalized | Gelatin + fibrin ECM; bioink: pluronic F127 + PEO | Glomerular microvascular ECs; proximal tubule epithelial cells | 0.3 dynes cm−2 | 18 days | No/Yes | [ 75 ] | ||

| Heart | 500 µm (200–900 µm) | Circular, hierarchical, multibranched | Agarose hydrogel, PCL network | Rat cardomiocytes | Syringe pump | 5 days | Yes/No | [ 99 ] | ||

| Vasculature a) | 1.5 × 3 mm | Rectangular, straight | PMMA case, GelMA | Aortic ECs; aortic SMCs; fibroblasts | 100 µL h−1, peristaltic pump | 7 days | No/No | [ 105 ] | ||

| Alternative strategies | LbL | Liver/heart | 100 × 50 to 100 µm | Rectangular, straight | POMaC, fibrin gel/Matrigel for parenchyma | Liver: HUVECs + hESC‐derived hepatocytes + hMSCs; heart: HUVECs + hESC‐derived CMs + hMSCs | 0.6 dynes cm−2, bioreactor | 7 days | Yes/Yes | [ 69 , 100 ] |

| Laser‐based | – | <10 µm | Tortuous, dense | PEGDA | Mouse brain ECs | 10 µL min−1 | 11 days | No/No | [ 101 ] | |

| Explanted vessels | Brain | 120 µm | Circular, physiological | PDMS | ECs, SMCs | 0.5 µL min−1, no external pump | – | No/Yes | [ 102 ] |

Bioinks containing cells.

4.1.2. Limitations of Microfluidic‐Based Vascularized Models

Microfluidic technology has shown great potential for the development of in vitro vascularized models for the study of the microenvironment under healthy and pathological conditions and for drugs screening and development. Soft lithography and membrane‐based models represent a landmark for recreating the vascular interface and have been used to mimic complex organ‐specific pathophysiological mechanisms. However, they fail in recapitulating a 3D microenvironment and the membranes, made usually of artificial polymers, prevent the direct interaction of the vascular and parenchymal components. The use of ECM‐based membranes or channels has allowed researchers to move toward more physiologically relevant models,[ 66 , 106 ] but still soft lithography requires expensive equipment and makes the platforms often difficult to be used by a wide end‐users range. Templating represents a straightforward method to create hollow channels in a matrix. Although the use of 3D additive manufacturing to print the sacrificial patterns has increased the potential of the technique in fabricating more in vivo‐like networks,[ 94 ] the platforms are usually limited to relatively simple geometries and large vessels of hundreds of micrometers. These methods usually require several fabrication and seeding steps and the template removal step should be designed carefully to avoid device or cellular damage. Layer‐by‐layer manufacturing, offers the possibility to design more versatile and flexible platforms via a multilayer assembling process and represents a valuable technique for engineering large‐scale thick constructs.[ 107 , 108 ] However, the precise alignment of the layers often represents a critical step in the process design. Recently, 3D bioprinting has been widely used for vascularization of biomaterials and fabrication of perfusable vessels due to its scalability, versatility, wide materials selection, and precision in engineering complex 3D cell laden constructs,[ 109 , 110 ] and its combined use with microfluidics will be further discussed in Section 4.4.

4.2. 3D Cell Culture Models: Spheroids and Organoids

Spheroids and organoids are 3D, multicellularized structures usually devoid of any exogenous materials. In the last decade, these structures have gained significant popularity in 3D cell culture research due to their ability to mimic the physiological conditions of cells in vivo. Although the two terms have been used interchangeably, there are fundamental differences and application varieties between them. Spheroids are established from simple clusters of cells, ranging from immortalized cell lines, primary cells, or fragments of human tissue.[ 13 , 111 ] Spheroid technology was developed based on the ability of cells to self‐organize during embryonic development. This self‐assembly process takes place in vitro when cells cannot attach to their biomaterial surface, hence aggregate into spherical 3D structures, namely, spheroids. Organoids are complex clusters of cells derived from stem cells such as adult stem cells, embryonic stem cells (ESCs), and induced pluripotent stem cells (iPSCs). When given a scaffolding ECM environment (usually collagen or Matrigel matrix), they self‐assemble into microscopic analogs of their parent organs.[ 112 , 113 ] As a result, organoids are widely regarded as miniature versions of organs. Organoids retain the parental organs’ genetic features over several passages, which allows for long‐term in vitro expansion of cells and guaranties long‐term viability.

Spheroids have shown potential in mimicking tumor tissues, which could help researchers develop more physiologically relevant cancer models, hence develop better cancer treatments. Vascularized spheroids, which can be achieved via coculture with ECs, have been employed as a model to study angiogenesis in vitro and as a prevascularization approach for tissue engineering applications.[ 114 ] However, as spheroids are formed via cell–cell adhesion, they only transiently mimic physiological cell organization.[ 111 ] In contrast, organoids formation relies on internal developmental processes, which gives rise to a higher order of self‐assembly, hence, the unique ability to recapitulate in vivo physiological functions.[ 112 ] Since organoids can be derived from patient tissues, they are interesting for disease modeling, development of personalized medicine, as well as drug testing and toxicity studies (see Section 6).[ 115 ]

4.2.1. Spheroids and Organoids Generation

Spheroids are formed by culturing cells in hanging drops, round‐bottom nonadherent or low adhesive substrates, and in suspension to induce self‐aggregation. Alternatively, spinner flask cultures can be employed to induce spontaneous cell aggregation for the fabrication of both spheroids and organoids. In this method, cell suspension is housed inside a spinner flask bioreactor with continuous mixing via a stirring bar, which generates a convectional force that induces cell aggregates formation.

Organoid fabrication methods involve formation of 3D aggregates from stem cells, followed by embedding in a biogel such as Matrigel and culturing in a specialized mixture of media and factors to obtain specific organoid generation. To date, a wide range of organoid systems including heart, lung, brain, lung, liver, kidney, intestine, retina, etc., have been developed.[ 116 , 117 , 118 , 119 , 120 ]

Table 3 summarizes the different methods for the fabrication of spheroids and organoids, their advantages, and challenges. To further explore these topics, we refer the reader to published reviews.[ 121 , 122 , 123 , 124 ]

Table 3.

Overview of spheroid and organoid formation methods

| Method | 3D culture system | Description | Advantages | Challenges | Refs. |

|---|---|---|---|---|---|

| ECM scaffolding | Organoids | Stem cells are placed in Matrigel (or ECM mix) and maintained in culture |

|

|

[ 117 , 125 , 126 ] |

| Hanging drop | Spheroids | Cells are suspended in media droplet. Cell aggregation occurs at the air–liquid interface |

|

|

[ 127 , 128 ] |

| Low‐adherent surfaces | Spheroids | Cells are suspended and cultured on a low‐adherent plate, or hydrophilic substrates (i.e., hydrogel) to form aggregates |

|

|

[ 129 ] |

| Spinning bioreactor | Spheroids and organoids | Cell suspension is housed inside a spinner flask or a bioreactor with continuous mixing. Cell aggregation is induced by convectional force |

|

|

[ 130 , 131 ] |

| Magnetic levitation | Spheroids and organoids | Nanoparticles are ingested by cells, which are then placed in a low‐adherent substrate. A magnet lid is used to induce cell aggregation |

|

|

[ 132 ] |

| Bioprinting | Organoids | Additive manufacture of cytokines, cells, and ECM |

|

|

[ 133 , 134 , 135 ] |

| Micropatterning | Spheroids | Microcontact printing and soft‐lithography patterning of ECM |

|

|

[ 136 ] |

| Microfluidics | Spheroids and organoids | 3D structures housed inside microstructures, integrated with microsensors |

|

|

[ 137 ] |

4.2.2. Strategies to Vascularize Spheroids and Organoids

Researchers have shown that the incorporation of ECs increases cell viability and functions in multicellular spheroids and enables the formation of rudimentary vascular networks within the spheroid structures.[ 138 , 139 , 140 , 141 , 142 ] The concept of using spheroids containing ECs dated back in 1998 when Korff and co‐workers used EC‐covered spheroids to analyze angiogenesis in vitro: ECs on the spheroids surface exhibited quiescent phenotype, which increased their sensitivity to angiogenic stimulation and differentiation.[ 142 ] The incorporation of ECs in the coculture system mimics the physiological interactions between ECs and other cell types, which consequently preserves cell viability and promotes proliferation and vascularization. Along with ECs, mesenchymal stem cells (MSCs) play a key role in the angiogenic process by facilitating blood vessel stabilization and maturation.[ 143 , 144 ] Specifically, MSCs actively participate in angiogenesis via secretion of proangiogenic factors (i.e., VEGF, MCP‐1, IL‐6, etc.) and MSC‐released paracrine factors are responsible for activation of the ECs angiogenic functions.[ 143 , 145 ] Given their multipotency, MSCs also induce direct differentiation and cell–cell interactions with endothelial lineage, suggesting that MSCs could be used to facilitate vascularization in spheroids and organoids.[ 144 ] For example, spheroids fabricated using only MSCs was found to generate vascularized spheroids with improved osteogenic differentiation and bone formation.[ 146 ] Similarly, when human mesenchymal stem cells (hMSCs) were cocultured with HUVECs, the resulting spheroids formed capillary‐like vessels, hence improved adipogenic differentiation upon transplantation.[ 147 ]

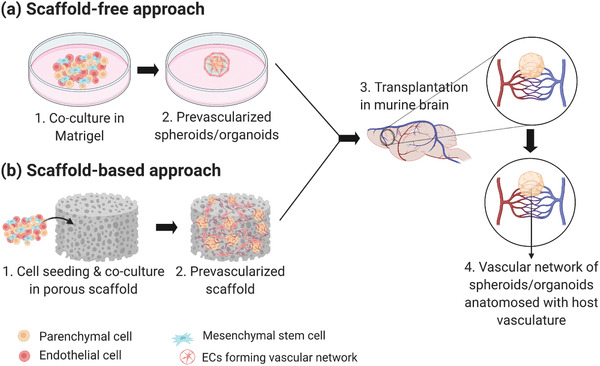

In general, the strategies used to vascularize spheroids and organoids are conducted in two steps: first, the spheroids/organoids are formed by coculturing parenchymal cells with ECs and/or MSCs to induce prevascularization in vitro. Then, spontaneous vascularization is induced via in vivo transplantation in highly vascularized regions such as skin, liver, heart, lung, or brain (Figure 5 ). The coculture step can be achieved either via i) scaffold‐free approach (Figure 5a), or ii) scaffold‐based approach, with incorporation of a biomaterial as instructive guide (Figure 5b), discussed in the next paragraphs. Here, we consider low‐adherent substrates, hanging‐drop technique (in the case of spheroids) and Matrigel (in the case of organoids) as scaffold‐free since they do not require additional procedures, as compared to biomaterial‐based scaffolds, which are synthesized in the lab. Alternative options to standard culture techniques are the incorporation of 3D printing, bioprinting, and microfluidic platforms to form vascularized spheroids and organoids. We refer the integration of several techniques as hybrid strategies for vascularization of in vitro models, including 3D cell cultures, which are discussed in Section 4.4.

Figure 5.

Schematic of the strategies used to vascularize 3D cell culture models. a) Scaffold‐free approach: Coculture with ECs/MSCs to form prevascularized network. b) Scaffold‐based approach: Coculture with ECs/MSCs in porous biomaterials. Both (a) and (b) can be followed by spontaneous vascularization via in vivo transplantation in highly vascularized organ such as the brain. Created with BioRender.com.

Vascularization of Spheroids: Scaffold‐Free Approach

Multicellular spheroids consisting of hDMECs, human osteoblasts (HOBs), and normal hNDFs were reported to have promising potential as vascularization units for bone tissue engineering.[ 139 ] Spheroids have been generated using the low‐adherent surface fabrication method. Coculture spheroids with round morphology formed after 72 h, with endothelial cells showing CD31 markers. Additionally, the presence of microvessels formation within the coculture spheroids suggests prevascularization/intrinsic vascularization. The prevascularized spheroids were then harvested and transplanted into the dorsal skin of immunodeficient mice for 2 weeks. Intravital analysis of the transplanted spheroids revealed the presence of vessel‐like structures: human microvascular networks grew outside of the spheroids border and eventually connected to the host vasculature.

Cocultures of ECs with other organ‐specific cell types such as dental pulp stem cells (DPSCs), rat neonatal cardiomyocytes (RNCMs), rat hepatocytes, and human brain astrocytes and pericytes have also shown vascularization potential.[ 128 , 129 , 140 , 148 ] In Dissanayaka's study, DPSCs were cocultured with HUVECs and results showed microvascular networks forming within the in vitro spheroids.[ 129 ] Upon in vivo transplantation, the lumens of the grafts were lined with ECs and graft vessels and mouse vessels were both present in the implanted site, suggesting integration of prevascularized spheroids into the host vasculature. This study finding highlights the potential of EC‐incorporated spheroids as functional vascularized units that can promote successful dental pulp regeneration.

Bhang and colleagues were among the first researchers to demonstrate the feasibility of generating spheroids using only MSCs.[ 149 ] Human cord blood MSC (hCBMSC)‐derived spheroids were grown and transplanted into mouse ischemic tissue. The hCBMSC spheroids were evaluated for apoptotic signaling, angiogenesis‐related signal pathways, and blood vessel formation both in vitro and in vivo. As expected, cell survival was higher in spheroids as compared to cells in monolayer culture. The spheroids improved viability of the transplanted cells and promoted angiogenesis, as evident by an increase in the number of microvessels within the spheroids.[ 149 ] Similarly, when β‐cell pseudoislets were cocultured with MSCs, they exhibited insulin‐producing phenotype and secreted angiogenic and antiapoptotic proteins.[ 141 , 150 ] Both reports demonstrated that MSC‐incorporated spheroids had enhanced viability, paracrine secretion, and vascularization after transplantation.

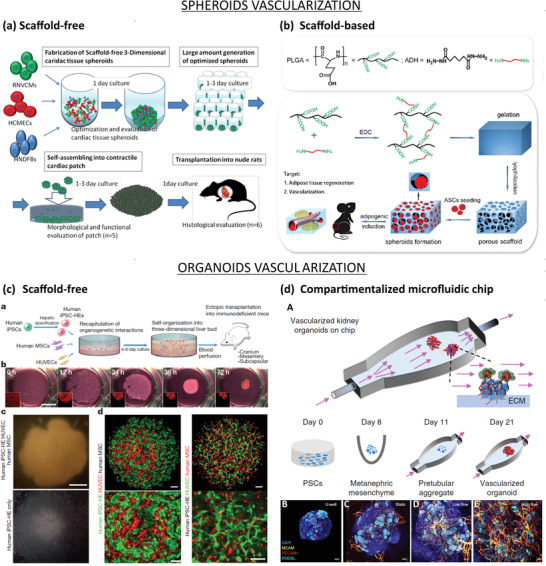

Coculture of EC‐incorporated spheroids with fibroblasts can also enhance vascularization. Fibroblasts are essential for production precursors for the ECM and therefore, it contributes to the stabilization of the newly formed vessel‐like structure.[ 151 ] Noguchi et al. developed cardiac tissue spheroids by coculturing rat neonatal ventricular cardiomyocytes (RNVCMs), human cardiac microvascular endothelial cells (HCMECs), and hNDFs (Figure 6a). The spheroids were then fused into a patch‐like construct and transplanted into rat hearts. Results showed that microvascular networks formed inside the spheroids, both in vitro and in vivo experiments.[ 148 ]

Figure 6.

Vascularization approaches for spheroids (top) and organoids (bottom). a) Scaffold‐free approach to vascularize spheroids. RNVCMs, HCMECs, and hNDFs were cocultured at optimal cell ratios (70%:15%:15%) and plated into ultralow attachment 96 U‐well plates to form cardiac tissue spheroids. Then, the spheroids were collected and plated in low‐attachment dishes, allowing them to self‐organize into cardiac patch grafts under static conditions. Finally, the cardiac patch grafts were transplanted on the anterior wall of the left ventricle of arhythmic rats to induce spontaneous vascularization. Reproduced with permission.[ 148 ] Copyright 2016, Elsevier Inc. b) Scaffold‐based approach to vascularize spheroids. PLGA activated by 1‐ethyl‐3‐(3‐dimethylaminopropyl) carbodiimide hydrochloride (EDC) and crosslinked with adipic dihydrazide, followed by lyophilization forms porous hydrogel. Seeding of ASCs onto hydrophilic surface induced cell aggregations, which resulted in ASC‐spheroids. Then, the spheroids were transplanted in the dorsum of nude mice to induce spontaneous vascularization. Reproduced with permission.[ 147 ] Copyright 2017, Elsevier Inc. c) Scaffold‐free approach to vascularize organoids: a) Schematic representation of the paper's strategy: hiPSCs, hMSCs, and HUVECs cocultured on Matrigel to form liver organoids, which were transplanted into mice to induce spontaneous vascularization. b) Observation of cells in coculture overtime. Organoids formed within 72 h. c) Observation of hiPSC‐organoids (top panel) and conventional 2D cultures (bottom panel). Scale bar = 1 mm. d) Confocal images showing the presence of hiPSC‐derived hepatic endoderm cells (green) and HUVECs (red) inside liver organoids (left panel), or HUVECs (green) and hMSCs (red) inside hiPSC‐derived organoids. Scale bar = 100 µm. Adapted with permission.[ 117 ] Copyright 2013, Springer Nature. d) Compartmentalized microfluidic‐based hybrid strategy: A) Kidney organoids were cultured in ECM substrate housed inside a perfusable millifluidic chip, subjected to controlled fluidic shear stress. B–E) Confocal 3D observations showing vascular markers in whole‐mount organoids, cultured under static U‐well, static, low‐FSS, and high‐FSS conditions. Scale bars = 100 µm. Adapted with permission.[ 137 ] Copyright 2019, Springer Nature.

Vascularization Strategies of Spheroids: Scaffold‐Based Approach

Biomaterial‐based scaffolds have also been adopted for vascularization of spheroids as instructive guides to improve spheroid function and promote angiogenesis. In one study, adipose‐derived stem cells (ASCs) spheroids were covered with hyaluronan (HA) gel and chitosan–hyaluronan (CSHA) membrane and seeded onto the wound area on the dorsal skin of Sprague‐Dawley male rats. In vitro analysis demonstrated that ASC spheroids had higher gene expression of chemokines and cytokines when cultured on HA gel and CSHA membrane, suggesting an improvement in paracrine effects. Following transplantation, spheroids were observed near microvessels in the healing region of the skin. The enhanced paracrine effects upregulate angiogenic factors secretion, thereby stimulating angiogenic and wound healing processes.[ 152 ]

In another approach, MSC spheroids were entrapped within Arginine‐Glycine‐Aspartate (RGD)‐modified alginate hydrogels and transplanted into the dorsum of immunodeficient mice for 8 weeks. In vitro analysis demonstrated that these spheroids underwent osteogenic differentiation and exhibited enhanced VEGF secretion and reduced apoptosis. Furthermore, explants of hydrogels containing spheroids demonstrated improved osteogenesis in vivo.[ 146 ]

Human ASCs were used to generate spheroids, which were then seeded into dried porous poly(lactic‐co‐glycolic acid) (PLGA) scaffolds. The resulting constructs exhibited improved vascularization and adipogenic differentiation upon transplantation.[ 147 ] Similarly, ASC spheroids in porous polyurethane scaffolds demonstrated enhanced angiogenic potential, as evidenced by greater microvessel density.[ 153 ] In another study, hMSC/HUVEC spheroids seeded onto poly(propylene fumarate)/fibrin scaffolds showed enhanced vascular network formation.[ 154 ]

Vascularization of Organoids: Scaffold‐Free Approach

Prevascularized organoids have been transplanted into kidney,[ 118 , 119 ] brain,[ 116 , 155 , 156 ] and liver.[ 117 ] Among the various labs which attempt to form vascularized organoids, the most notable is the work of Takebe's group. They have successfully fabricated complex vascularized organ buds for kidney, heart, lung, brain, intestine, and pancreas using murine PSC‐derived progenitors, HUVECs, and MSCs.[ 126 , 157 ]

Watson generated human intestinal organoids using hESCs or hiPSCs and transplanted them in the kidney capsule of immunocompromised mice.[ 119 ] The grafted organoids were vascularized by the host vasculature and resembled the native human intestine with crypt‐villus architecture and underlying laminated submucosal layers. Cross‐section of the transplanted organoids, which showed mucous‐filled lumens and sheets of villi with capillary network, further indicated vascularization and good engraftment of organoids into the host kidney. The in vivo tissue was more differentiated and matured over time compared to in vitro tissue prior to transplantation.[ 119 ] Similarly, spontaneous vascularization upon transplantation was also achieved for kidney organoids. Using the ALI method, van den Berg et al. generated kidney organoids from podocytes and grafted them into the renal capsule of immunocompromised mice for 28 days. The organoids developed in vitro anatomical‐like structures resembling a nephron including the glomerulus, the distal and proximal tubes, and the collecting duct. However, the in vitro tissue did not form a vascular network, probably due to the limited VEGF production of podocytes and the absence of ECs during in vitro development. Upon transplantation to a highly vascularized site, the organoids grew in size, differentiated progressively into mature kidney tissue, and developed their own vascular network that connected to the mouse vasculature, which supplied blood to their core.[ 118 ]

Stem cells can be codifferentiated into organ‐specific structures and ECs to obtain vascularized organoids and hESCs or hiPSCs have been successfully used to form cerebral organoids and ECs by codifferentiation.[ 116 , 155 , 156 ] In this case, different protocols and culture conditions have been developed by different research groups and all studies showed organoids which formed tubular structures and perfused vascular networks in vitro. In Ham and Pham protocols, hESCs or hiPSCs were induced into neuroectoderms which were then introduced in cerebral organoids media and VEGF‐supplemented cerebral organoids media for organoid and endothelial differentiation, respectively. Alternatively, Cakir et al. induced the expression of ETV2, a transcription factor contributing to vessel development, to differentiate hiPSCs into ECs.[ 116 ] Moreover, they reported their organoids could promote neuronal maturation and development of vascular networks with BBB characteristics. Thus, the preformed functional vessels eventually anastomosed with the host vasculature upon transplantation while the organoids generated without ECs did not survive after 2 weeks of transplantation.[ 116 , 155 ] All results strongly suggest the presence of endothelial cells is highly essential for proper vascularization and engraftment of organoids prior to transplantation.

Along with ECs, MSCs are also included in coculture experiments for vascularization due to their angiogenesis properties. When liver cells were cocultured with HUVECs and MSCs to form liver buds, the resulting 3D structures had liver‐specific functions, developed vascular networks and integrated with the host transplantation sites (Figure 6c).[ 125 , 158 ] Beside the liver, Takebe's group has also successfully developed complex vascularized organ buds for kidney, heart, lung, brain, intestine, and pancreas through self‐condensation procedures using murine PSC‐derived progenitors, HUVECs, and MSCs following implantation in host mice.[ 126 ]

Table 4 summarizes the significant case studies for the 3D cell culture vascularization strategies, cited or discussed in the text.

Table 4.

Summary of case studies for 3D cell culture vascularization strategies

| Vascularization method | Tissue/organ model | Biomaterial composition | Cellular composition | Duration of in vitro study | In vivo evaluation | Refs. | |

|---|---|---|---|---|---|---|---|

| Spheroids | Scaffold‐ free | Bone | – | Osteoblasts, dermal microvascular ECs, normal dermal fibroblasts (all from human) | 3 days | 2 weeks | [ 139 ] |

| Dental pulp | – | Dental pulp stem cells, HUVECs | 3 days | 4 weeks | [ 129 ] | ||

| Liver | – | Rat hepatocytes, HUVECs | 25 days | No | [ 140 ] | ||

| Heart | – | Rat neonatal ventricular cardiomyocytes, human dermal fibroblasts, human CMECs | 7 days | 7 days | [ 148 ] | ||

| BBB | – | Brain ECs, pericytes, astrocytes (all from primary human source) | 3 days | No | [ 128 ] | ||

| Scaffold‐based | Skin | Hyaluronan; chitosan | ASCs | 3 days | 8 days | [ 152 ] | |

| Adipose tissue | PLGA hydrogel | ASCs | 2–3 weeks | 3 months | [ 147 ] | ||

| Bone |

|

|

|

|

[ 146 , 153 , 154 ] | ||

| Organoids | Scaffold‐free | Brain/BBB | – | hiPSCs | Up to 4 months | No | [ 156 ] |

| Intestine | – | hESCs/hiPSCs | 35 days | 6 weeks | [ 119 ] | ||

| Kidney | – | hPSCs | 25 days | 28 days | [ 118 ] | ||

| Brain |

|

|

|

|

[ 116 , 155 ] | ||

| Liver | – | hiPSC‐endoderm cells, hiPSC‐ECs, MSCs | 3 days | 14 days | [ 125 , 157 ] | ||

| Pancreatic islet, brain, heart, lung, intestine, kidney, liver fragments | – | Tissue fragment, HUVECs, hMSCs | 1 day | 1 month | [ 126 ] | ||

4.2.3. Limitations of Vascularized 3D Cell Culture Models

Both spheroids and organoids have great potential as vascularized models for disease modelling and drug development purposes. While they bring about promising outlook for the biomedical field, several limitations remain. First of all, both spheroids and organoids generation need a large number of cells to obtain a substantial quantity of tissue. Second, cellular microenvironment is the key factor to achieve viable and functional 3D structures with in vivo characteristics, while at the same time promoting angiogenesis.[ 159 ] Therefore, ECM or a similar matrix, such as Matrigel, which is a complex protein mixture from mouse, is commonly used, mainly for organoids. However, due to the heterogeneous composition and immunogenic potential of currently used matrices, an alternative ECM‐mimicking source should be considered.[ 13 ] Alternatively, biomaterial‐based 3D scaffolds have been employed to mimic the components of the ECM while providing structural support and external cues to guide cell–cell and cell–matrix interactions, leading to functional and vascularized spheroids.[ 147 , 152 , 153 , 154 ] While these scaffolds can provide mechanical and biochemical cues for cell growth within the 3D structures, lack of access to adequate supply of oxygen and nutrients to the center of the structure often results to necrotic core and premature growth in the outer layer of organoids, when missing an adequate vascularization of the 3D constructs.[ 159 ]

The key requirement for vascularization concerns the surrounding microenvironment, which has to support both angiogenesis and organoid formation.[ 159 ] The incorporation of ECs in the cell culture can alleviate this problem by inducing in vitro prevascularization, leading to the formation of functional tubular vessels. This increase access to oxygen and nutrients, thanks to functional vessels, promotes cells survival, maturation, and differentiation to specific tissue. HUVEC‐covered hepatocyte spheroids had improved cell viability and liver‐specific functions such as increased albumin secretion and ammonia removal rates.[ 140 ] Cerebral organoids generated from hPSCs formed tubular vessels with pericyte‐like cells wrapping around them, while promoting neural differentiation.[ 156 ]

As these techniques work with cocultures, factors such as cell ratios, seeding density, appropriate cell culture medium, and coculture time must be optimized. For example, while it was possible to form spheroids composed of human adipose‐derived mesenchymal stromal cells (hASCs) and HUVECs, vascular structures were only observed when 20% ASCs were cultured with 80% HUVECs in a 1:1 mixture of endothelial and adipogenic medium.[ 160 ] Similarly, Noguchi's work showed that contracting vascularized cardiac spheroids were obtained by maintaining the following cell mixture: 70% CMs, 15% ECs, and 15% FBS.[ 148 ]

Despite their ability to nourish spheroids/organoids, preformed vessels need to be transplanted in a highly vascularized region to achieve optimal perfusion. The need to experiment on animal models poses a paradox since the one of the main goals of using 3D cell culture models is to reduce animal use in research. Nevertheless, vascularized brain organoids raise ethical concerns and call for consciousness assessment of animal models used in these experiments.[ 161 ]

Furthermore, the combination of spheroids/organoids platform with 3D bioprinting and microfluidic technology are necessary to achieve more comprehensive vascularized, physiologically relevant 3D models.[ 134 , 137 , 162 ] A more in‐depth discussion on this topic is presented in Section 4.4.

4.3. 3D Bioprinted Vascularized Models

In the last decades, the word biofabrication has been widely used in the scientific community to describe a plethora of processes aimed to manufacture complex products with a biologically relevant function built from biological building blocks, such as biomaterials, cells, or molecules.[ 163 , 164 , 165 , 166 ] Although biofabrication techniques for tissue engineering and regenerative medicine have been commonly classified into top‐down and bottom‐up,[ 167 , 168 , 169 ] we adopt here the classification proposed by Groll et al.[ 170 ] Considering the fabrication unit, two approaches can be distinguished, namely, bioprinting and bioassembly. While bioprinting uses molecules, that are assembled by means of additive manufacturing techniques based on computer‐aided design (CAD) models, bioassembly uses prefabricated cellular building blocks that can be automatically assembled. Both strategies are followed by a tissue remodeling and maturation phase, which is an integral part of the biofabrication process.[ 169 ] Though some bioassembly strategies have achieved successful applications in vascularized tissue models (Section 4.3.4), bioprinting represents nowadays the cutting‐edge biofabrication technology in the field and will be the main focus of this section.

4.3.1. Current Bioprinting Technologies

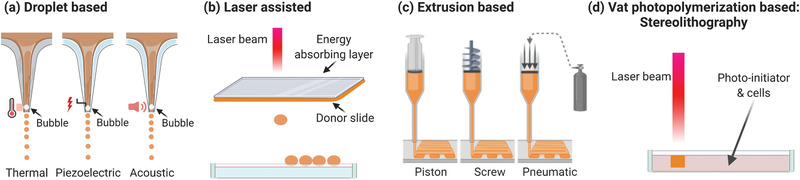

Although the concept of 3D printing encompasses different technologies, as summarized in Figure 7 , most of them show common advantages for the vascularization of biomaterials: 1) the possibility to print vessels of different diameters, ranging from microvessels to vessels in the mm range, that can be surgically anastomosed; 2) the use of bioinks, whose composition can improve vascularization; 3) the ability to control the spatial arrangement of cells to promote the formation of vessel networks, eventually with branched, complex geometries.[ 109 ] We provide here a general overview of the current 3D bioprinting technologies employed to vascularize tissue constructs. Later in this section, we summarize the definitions adopted and the critical bioprinting parameters. A more detailed description of the most used commercial bioprinters can be found, for instance, in the work by Ozbolat et al.[ 171 ]

Figure 7.

Schematic of bioprinting methods. a) Inkjet‐based bioprinting involves the formation of droplets of bioink by generating bubbles in the tip of the printer through thermal, piezoelectric, or acoustic energy. b) Laser‐assisted bioprinting is also based on the generation of droplets of bioink by the incidence of a laser beam on an energy absorbing layer coupled with a donor slide constituted of bioink. The droplets are then recovered on a dedicated platform. c) Extrusion is the most commonly used method; the ink is pressed through the nozzle either with a piston, a screw, or using pneumatic pressure. d) Vat photopolymerization requires the presence of a photoinitiator to cure the polymer loaded with cells. Created with Biorender.com.

Inkjet‐Based

This technology can be applied in a continuous mode or in a drop on demand mode. In the first case the printing ink needs to be electroconductive, which limits its application for biological purposes. Besides, the drop on demand mode is based on the deposition of droplets on the printing surface. To generate and eject the drops, thermal, piezoelectric, or acoustic approaches are used (Figure 7a). Thermal printing heads heat the bioink locally creating a bubble that pushes the drops through the nozzle. In the case of piezoelectric and acoustic actuators, vibration is at the origin of drop deposition. Compared to other printing techniques, inkjet bioprinting is low‐cost and allows for fast printing with high resolution (50 µm). This is a suitable technology for low viscosity bioinks (<10 mPa s) with a low cell density. Cell viability has been reported in the range of 80–95% using this method, due to the temperature and the mechanical stress.[ 172 , 173 ]

Laser‐Assisted Bioprinting (LAB)

This technology, also known as laser‐induced forward transfer, is a drop on demand method based on the incidence of a pulsed laser beam on top of a donor slide in contact with an energy‐absorbing layer. When a bioink is placed next to the energy‐absorbing layer, a shockwave appears forming a jet of the bioink that is deposited as a drop on a collector slide (Figure 7b). High resolution (5–10 µm) and the possibility to work with a wide range of densities (1–300 mPa s) and to print the cells on solid or liquid substrates are the main advantages of this strategy. Other benefits are automation, reproducibility, and high throughput. Nevertheless, it is a very expensive technology that might cause cell damage. Other drawbacks are cell sedimentation and, when printing 3D constructs, the risk that working wavelengths alter cell organization.

Extrusion‐Based

The most popular 3D bioprinting technologies nowadays are pressure‐assisted, which are well adapted for highly viscous and, ideally, structurally stable solutions to avoid loss of shape (Figure 7c). For this purpose, most approaches in the literature combine bioprinting of the ink with in situ crosslinking after injection.[ 109 ] It is also frequent to work at controlled temperature to assure good viscosity of the bioink and to induce in situ gelation. A drawback is that reproducibility depends on numerous parameters, namely, needle diameter, air pressure, speed of printing, temperature, and humidity. Assuring homogeneity of the bioink during the printing process is particularly relevant in cell‐loaded bioinks. Also, excessive pressure can result in cell damage caused by shear stress. Other disadvantages are low speed, low resolution, and clogging.

There are several commercially available 3D bioprinters, but the simplicity of the technology leads many research laboratories to manufacture customized printer based on their needs. To print different bioinks without crosscontamination, the use of multiple injectors is often adopted. In the case of vascularized materials, the use of coaxial needles is particularly advantageous to print tubular structures as will be seen in Section 4.3.2.

Vat Photopolymerization‐Based

The possibility to photocure polymers loaded with biomolecules and/or cells has open new perspectives to create tissue constructs. The process is based on a laser beam that irradiates a resin composed of a solvent, a photoinitiator and a polymer. The photoinitiator reacts to the light source releasing radicals or cations that start the polymerization of the resin. This technology was first applied to 3D print low cell compatible resins in the presence of photoinitiators, which were however highly cytotoxic. In the last years, the development of new photoinitiators has expanded the application of this technique to the biomedical field.[ 174 ] The high precision and resolution, together with the possibility to incorporate photoabsorbers to prevent photopolymerization in defined regions, makes this technology particularly interesting to engineer vasculature.[ 175 ] The extraordinary freedom of design to pattern highly complex hollow vascular‐like structures within biomaterials has been recently demonstrated.[ 176 ]

Another advantage of vat photopolymerization compared to extrusion is the possibility to use low viscosity resins that improve the resolution compared to high viscosity ones but that can lead to cell sedimentation. The major drawback of the technology is the cell damage caused by the laser and by oxidative stress due to the activation of the photoinitiators. Laser sources in the UVA–visible spectrum are preferred since they are less toxic than shorter wavelengths in the UVB and UVC regions. In the field of vascularization, the most used photoinitiators are Irgacure 2959 (maximum efficiency wavelength 275 nm) and lithium phenyl‐2,4,6‐trimethylbenzoylphosphinate (LAP, maximum efficiency wavelength 375 nm), the latter being the less cytotoxic one.[ 174 , 177 ]

Depending on the light source to cure the polymers, vat photopolymerization can be classified in stereolithography (SLA) (polymer cured with a laser), digital light processing (DLP) (polymer cured with a projector), and continuous digital light processing (CDLP)/continuous liquid light processing (CLIP) (polymer cured with oxygen and light emitting diodes (LEDs)).[ 174 , 178 ]

Definitions and Relevant Parameters in Bioprinting

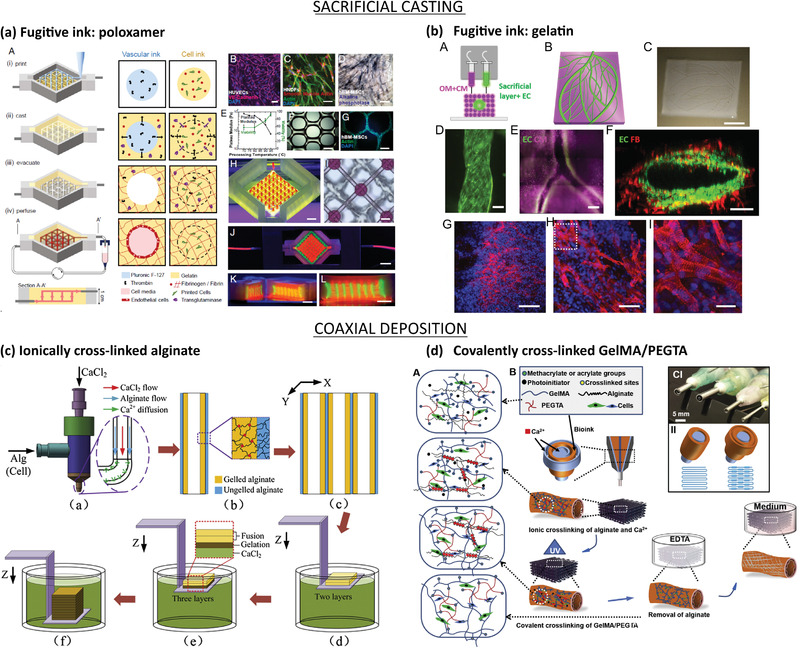

Definitions are given to differentiate between cell‐loaded bioinks, hereinafter “bioinks,” and acellular bioinks that will be named “biomaterial bioinks,” according to Groll et al.[ 179 ] Most of bioinks are composed of one or several materials, other than cells, being the number of studies using a material‐free approach very small, as described in Section 4.3.2. Biomaterial bioinks are generally printed to form a scaffold where cells are seeded in a following step, being the risk of heterogenous cell distribution greater, compared to cellular bioinks. In both cases, biomolecules can be incorporated in the ink to exert a biological effect on cells. Other nonbiological materials can also be added to affect cell function via mechanical or electrical cues. Materials can also act as mere supports during the printing process, or as sacrificial inks that are removed after the printing process.