Abstract

Orange peel by-products generated in the food industry are an important source of value-added compounds that can be potentially reused. In the current research, the effect of oven-drying (50–70 °C) and freeze-drying on the bioactive compounds and antioxidant potential from Navelina, Salustriana, and Sanguina peel waste was investigated using pressurized extraction (ASE). Sixty volatile components were identified by ASE-GC-MS. The levels of terpene derivatives (sesquitenenes, alcohols, aldehydes, hydrocarbons, and esters) remained practically unaffected among fresh and freeze-dried orange peels, whereas drying at 70 °C caused significative decreases in Navelina, Salustriana, and Sanguina peels. Hesperidin and narirutin were the main flavonoids quantified by HPLC-MS. Freeze-dried Sanguina peels showed the highest levels of total-polyphenols (113.3 mg GAE·g−1), total flavonoids (39.0 mg QE·g−1), outstanding values of hesperedin (187.6 µg·g−1), phenol acids (16.54 mg·g−1 DW), and the greatest antioxidant values (DPPH•, FRAP, and ABTS•+ assays) in comparison with oven-dried samples and the other varieties. Nanotechnology approaches allowed the formulation of antioxidant-loaded nanoemulsions, stabilized with lecithin, starting from orange peel extracts. Those provided 70–80% of protection against oxidative UV-radiation, also decreasing the ROS levels into the Caco-2 cells. Overall, pressurized extracts from freeze-drying orange peel can be considered a good source of natural antioxidants that could be exploited in food applications for the development of new products of commercial interest.

Keywords: pressure-extraction, phenolic compounds, flavonoids, volatile compounds, GC-MS, HPLC-MS, antioxidant activity, circular economy, Caco-2, oxidative stress

1. Introduction

About one-third of citrus production is industrially processed for orange juice, which generates a huge amount of citrus waste [1]. Citrus peel, the main byproduct of the citrus industry, is a valuable source of bioactive compounds including flavonoids, phenolic acids, tannins, stilbenes, limonoids, coumarins, terpenoids, carotenoids, vitamins, minerals, and dietary fiber [2]. This distinctive profile of bioactive compounds is closely related with diverse biological activities and health-promoting benefits including hypolipidemic, hypoglycemic, anticancerogenic, antibacterial, antifungal, anti-inflammatory, and neuroprotective effects [3,4,5,6,7,8,9] based on their antioxidant ability to reduce oxidative stress [10,11,12,13,14].

Moreover, recent evidence has shown that polyphenols and volatile compounds from citrus peel, with levels around 3–5-fold higher than in citrus juice [15], have a market value for their exploitation [16,17,18] mainly in dried form, although more research is necessary to better understand the effect of different drying techniques on these phytochemicals.

Currently, there is a growing research interest in isolating bioactive compounds from citrus wastes, especially using environmentally friendly technologies [19,20]. Some conventional methods, including liquid-liquid extraction (LLE), solid-liquid extraction (reflux, shaking, stirring, pressing, or heating systems), microwave-assisted extraction (MAE), ultrasound-assisted extraction (UAE), have been used for recovery bioactive compounds from citrus peels [21,22,23,24,25]; nevertheless, sample pre-treatment, processing, and extraction protocols may result in a loss of valuable compounds.

The methods based on the high pressure extraction, such as supercritical fluid extraction (SFE) and pressurized liquid extraction (PLE), have shown many advantages in a green extraction context, reaching the highest isolation efficiency of citrus bioactive compounds [26,27,28]. High pressure extraction constitutes a suitable strategy for the extraction of citrus waste compounds [29] allowing the full exploitation of their properties in potentially new value-added food products [30,31,32,33].

Supercritical fluid extraction (SFE) combines CO2 at high temperatures and pressures 20–140 Kpa [34]. In citrus peel residues, SFE has achieved outstanding recovery extraction for hesperidin and narirutin (20 mg·g−1 and 2.33 mg·g−1, respectively) from mandarin, orange, lemon, and grapefruit waste [35,36].

The use of SFE-CO2 can represent a solution for organic solvent elimination and selective extraction of bioactive compounds from vegetal extracts. Indeed, the relative solubilities of the chemical families should be considered, for example using a fractional extraction at increasing pressures, for compounds with low-medium molecular weight [37].

Pressurized water extraction (PLE), also known as accelerated solvent extraction (ASE), is an emerged technique to isolate bioactive compounds using both water and organic solvents in combination with elevated temperature and high pressure (4–20 MPa) [38]. Solvents at subcritical conditions increase the diffusion rate and decrease the viscosity, thus facilitating its matrix penetration, enhancing the contact with the analytes and improving the effective extraction [39]. The pressure extraction with ASE has provided extracts highly enriched in total phenols, terpenoids, polymethoxylated flavones, and phenolic acids and with a high radical scavenging activity in citrus pomaces, grapefruit peel, and mandarin [40,41,42,43,44,45].

At this moment, citrus cast-offs can constitute a new source of antioxidants at low-cost for the food industry in order to develop and valorize innovative reformulations, functional foods, dietary supplements, or nutraceuticals as a part of a strategy for sustainability and contributing to the circular economy. However, citrus polyphenols display a low water-solubility, restricting their integration into aqueous-based food matrices [46]. In addition, many polyphenols suffer degradation when they are exposed to oxygen, light, temperatures, and extreme pH [47]; and even after ingestion they can be degraded in the gastrointestinal tract [48].

Several of these obstacles can be solved using technological approaches focused on the encapsulation of bioactive compounds such as colloidal systems that behave like carriers improving the water-dispersibility, stability, and bioaccessibility and also protecting the encapsulated compounds against degradation [49,50,51,52]. In this sense, the use of platforms that protect bioactive molecules from their premature degradation could be a successful strategy to promote their efficient use. Currently, promising improvements have been made to incorporate nanotechnology into food processing techniques [53,54], to enhance the viability of food antioxidants [55,56,57]. Although little literature is available, naringenin nanoemulsions have proven a complete release, increasing the solubility and bioavailability [58]. Recently, emulsions for citrus polymethoxyflavone encapsulation (mandarin, orange, sweet orange, and bergamot oil) have been designed [59].

However, further studies are required to determine the usefulness of colloidal systems from citrus and its gastrointestinal behavior, as well as comparative studies involving different drying techniques and temperatures in citrus peel since this is how these wastes can be reused.

For all these reasons, the main objectives of the present research were as follows: (I) describe the volatile and phenolic profile of three less-studied orange peels: Navelina, Salustriana, and Sanguina, widely consumed in Spain, using pressurized extraction by ASE; (II) elucidate the effect of oven-drying and freeze-drying pre-treatments on the bioactive compounds and antioxidant potential of the orange peels extracts; (III) incorporate nanotechnology to formulate antioxidant-enriched nanoemulsions of orange peel extract estimating its antioxidant behavior; and (IV) study the protective effectiveness of nanoemulsion against induced oxidative stress on Caco-2 cell line.

2. Material and Method

2.1. Material: Orange Peel and Cell Line

The three oranges varieties Salustriana (Citrus sinensis L. Osbeck cv. “Salustriana”), Navelina (Citrus sinensis L. Osbeck cv. “Navelina”), and Sanguina (Citrus x sinensis var. “Sanguina”), grown in Valencia (Spain), were purchased at Corte Ingles supermarket. These three Spanish orange varieties have a great interest from the point of view of cultivation as well as food technology and sale.

Human colon carcinoma Caco-2 clone type C2BBe1 cell line was obtained from the American Type Culture Collection (ATCC, Manassas, VA, USA). Dulbecco’s Modified Eagle Minimal Essential Medium (DMEM), fetal bovine serum (FBS), heat-inactivated HyClone, penicillin-streptomicin (PEST), Hanks Balanced Salt Solution (HBSS), phosphate buffer saline (PBS), trypsin-EDTA (0.05%), and non-essential aminoacids (NEAA) were purchased from Labclinics (Barcelona, Spain). Dimethyl sulphoxide (DMSO), triton-X 100, and dichlorofluorescein diacetate (DCFDA) were purchased from Sigma-Aldrich (Madrid, Spain).

2.2. Heat Treatment: Oven-Drying and Freeze-Drying of Orange Peels

Oranges were cleaned with distilled water in the laboratory, and they were immediately peeled. Orange peels from Salustriana, Navelina, and Sanguina were cut into pieces (sized approximately 0.5 × 0.5 cm thick). Sliced peel was divided into four portions: (i) one fresh peel portion to be directly analyzed; (ii) two fractions which were oven-dried at 50 °C and 70 °C, respectively, until their water content was between 9 and 12%; and (iii) one orange peel fraction which was freeze-dried in a vacuum (2.4 × 10−2 mB) for 24 h, previously frozen at −78 °C for 12 h, with a condenser temperature of −49 °C.

All biomass resulting from (i), (ii), and (iii) for every variety of orange peel was extracted by ASE and the resulting extracts were analyzed by HPLC-MS and GC-MS to determine volatile compounds, individual flavonoids, phenolic acids, and antioxidant potential.

2.3. Isolation of Volatile Compounds by ASE and GC-MS Analysis

Isolation of volatile compounds was performed using of pressurized liquid extraction with an accelerated solvent extractor ASE 200 (Dionex Corp., Sunnyvale, CA, USA). Samples consisted of 10 g of fresh orange peels without albedo (Salustriana, Navelina, and Sanguina) and moisture 68–73%; and 10 g of freeze-dried and 10 g of oven-dried samples of the three varieties (moisture between 5–9%). Extractions were carried out using optimized conditions. Dichloromethane was used as the extraction solvent at 60 °C, and two cycles of 10 min each were carried out under 1500 psi (10.34 MPa) of pressure. The complete system was then rinsed to avoid any carry-over. Next, 50 µL of 4-nonanol solution (1 g/L) was added as an internal standard [60]. Extracts were concentrated under nitrogen gas flow to a final volume of 200 µL and then stored at −20 °C until GC-MS analysis was performed. Extractions were carried out in duplicate.

An Agilent 6890 N gas chromatograph coupled to a 5973 Inert mass selective detector in electron impact mode at 70 eV was used to carry out the identification and quantification of volatile compounds. One microliter (1 μL) of extracts were injected in spitless mode (0.6 min) on a polyethylene glycol capillary column BP-21 (50 m × 0.32 mm × 0.25 μm of film thickness). The oven temperature program was: 60 °C (3 min) − 2 °C/min − 200 °C (30 min). Helium was used as carried gas at a flow rate of 0.8 mL/min−1. Injector and transfer line temperatures were 250 °C and 280 °C, respectively. Mass detector conditions were electronic impact (EI) mode at 70 eV; mass acquisition range: 40–450 amu. Identification of the volatile components was performed comparing their GC Kovats index (KI) and mass spectra with the pure standards compounds from Sigma-Aldrich when they were available. Peak identifications were based on comparison with spectral data and retention indices from pure standard compounds when they were available; otherwise, the Wiley G 1035 spectrum library was used. Semiquantitative analyses were carried out assuming a response factor equal to 1 for all the compounds.

2.4. Isolation of Individual Flavonoids by ASE and HPLC-DAD-ESI-MS Analysis

The isolation of Salustriana, Navelina, and Sanguina peels was carried out by means of an accelerated solvent extractor ASE 200 (Dionex Corp, Sunnyuale, CA, USA). The ASE-extraction parameters were optimized in previous works [45]: “extractions were performed using 5 g of orange peel which was placed into inox extraction cells of 22 mL. Every cell was filled with methanol and raised to 60 °C. Then, two static extraction phases lasting 10 min was carried out under 1500 psi (10.34 MPa)”. Between extractions, a rinse of the complete system was performed to avoid any carry-over.

Extracts were evaporated using a rotavapor with a vacuum controller (Heidolph, Schwabach, Germany) at 40 °C. Samples were redissolved with 5 mL of methanol, and they were filtered through a Whatman No. 1 filter paper. Samples were kept at −20 °C prior to being used to determine antioxidant activity and phenolic compounds.

The separation, identification, and quantification of phenolic compounds were performed as previously described Castro-Vazquez et al. [45] “by HPLC-DAD-ESI-MS on an Agilent 1100 series system (Agilent, Waldbronn, Germany), equipped with a DAD photodiode detector (G1315B) and a LC/MSD Trap VL (G2445C VL) electrospray ionization mass spectrometry (ESI/MSn) system, both coupled to an Agilent Chem Station (version B.01.03) for data processing.

The samples after filtration (0.20 μm, polyester membrane, Chromafil PET 20/25, Machery-Nagel, Düren, Germany) were injected in duplicate on a reversed-phase narrow-bore column Zorbax Eclipse XDB-C18 (2.1 × 150 mm; 3.5 μm particle; Agilent) protected by a guard column Zorbax Eclipse XDB-C8 (2.1 × 12.5 mm; 5 μm particle; Agilent), both thermostated at 40 °C.

The solvents were as follows: solvent A (acetonitrile/water/formic acid, 3:88.5:8.5, v/v/v), solvent B (acetonitrile/water/formic acid, 50:41.5:8.5, v/v/v), and solvent C (methanol/water/formic acid, 90:1.5:8.5, v/v/v). The flow rate was 0.190 mL/min. The linear solvents gradient was as follows: zero min, 99% A and 1% B; 8 min, 97% A and 3% B; 37 min, 70% A, 17% B, and 13% C; 40 min, 50% A, 30% B, and 20% C; 51 min, 10% A, 40% B, and 50% C; 56 min, 50% B and 50% C; 59 min, 50% B and 50% C; and 65 min, 99% A and 1% B.

For identification, ESI-MSn was used in both positive and negative modes, setting the following parameters: dry gas, N2, 11 mL/min; drying temperature, 350 °C; nebulizer, 65 psi; capillary, −2500 V (positive ionization mode) up to 42 min and +2500 V (negative ionization mode) until the end of the chromatogram; target mass, 600 m/z; compound stability, 40% (negative ionization mode) and 100% (positive ionization mode); trap drive level, 100%; and scan range, 50–1200 m/z”.

The identification of individual flavonoid compounds was carried out by comparing their retention times and mass spectra provided by the pure standards (from Sigma St. Louis, MO, USA). This was the case for hesperidin, naringin, naringenin, nobiletin, and tangeretin. The identification of compounds for which the standards were not available was performed by comparing the UV spectra, and the [M + H]+, [M − H ]− m/z, with those reported in the literature. These were rutin, neohesperidin, sinensetin, and quercetogen.

Quantification was made by means of external standard calibration lines and were expressed as milligrams of compounds per gram of dry weight (DW). Quantitative results for compounds without chemical standards were expressed in mg naringin equivalents x g−1.

2.5. Determination of Phenolic Acids

The phenolic acid of orange peel extracts was determined according to previous procedure [61]. Standards of phenolic acids were acquired from Sigma (St. Louis, MO, USA) and Fluka (Buchs, Switzerland). HPLC separation, identification, and quantification of phenolic acids were performed on an Agilent 1100 series system (Agilent, Waldbronn, Germany), equipped with a DAD photodiode detector (G1315B) and a LC/MSD Trap VL (G2445C VL) electrospray ionization mass spectrometry (ESI/MSn) system, both coupled to an Agilent Chem Station (version B.01.03) for data processing. After filtration (0.20 µm, polyester membrane, Chromafil PET 20/25, Machery-Nagel, Düren, Germany), 50 µL samples were injected in duplicate, onto a reversed-phase column Zorbax Eclipse XDB-C18 (4.6 × 250 mm; 5 µm particle), thermostated at 40 °C.

The solvents were water/formic acid (999:1 v:v:v) as solvent A; and MeOH/formic acid (999:1 v:v:v) as solvent B. The flow rate was 0.70 mL min−1. The linear gradient for solvent B was as follows: 0 min, 5%; 15 min, 35%; 30 min, 43%; 32 min, 100%; 40 min, 5%.

Quantification was made using the DAD chromatograms obtained at 320 nm, respectively, by means of external standard calibration curves. The identity of each compound was established by comparing the retention time, UV-Vis spectra and mass spectra of the peaks in every sample with those previously obtained by injection of standards. For identification, ESI-MSn was used, setting the following parameters: positive ion mode; dry gas, N2, 11 mL min−1; drying temperature, 350 °C; nebulizer, 65 psi; capillary, −2500 V; capillary exit offset, 70 V; skimmer 1, 20 V; skimmer 2, 6 V; and scan range, 50–1200 m/z.

2.6. Determination of Total Phenolic Content

The total phenol content (TPC) of orange peel extracts was determined according to the Folin-Ciocalteu procedure [62]. Thus, 1.8 mL of deionized water was added to 0.2 mL of each orange peel extract. Then, 0.2 mL of Folin-Ciocalteu reagent was added, and tubes were shaken vigorously. After 3 min, 0.4 mL sodium carbonate solution (35% w/v) was added together with 1.4 mL of deionized water. Samples were mixed and left in the dark for 1 h. The absorbance was measured at 725 nm using a UV-vis spectrophotometer (Lambda 5, Perkin-Elmer, Seer Green, UK) and the results were expressed in gallic acid equivalents, GAE, using a gallic acid standard curve. Extracts were further diluted if the absorbance value measured above the linear range. Results were expressed as mg GAE x ·g−1 respective to dry weight (DW).

2.7. Determination of Total Flavonoids Content

Total flavonoid contents were estimated using the method described by other authors [63,64]. The extract (0.5 mL of 1 mg/mL) was mixed with 1.5 mL of methanol. To this mixture, 0.1 mL of 10% aluminum chloride was added, followed by 0.1 mL of 1 M potassium acetate and 2.8 mL of distilled water. The mixture was incubated at room temperature for 30 min. The absorbance was measured by a spectrophotometer at 420 nm. The results were expressed as milligrams quercetin equivalents (QE) per gram of extract (mg QE g−1 extract).

2.8. Antioxidant Activity of Orange Peels

2.8.1. DPPH Radical Scavenging Assay

The DPPH assay was carried out according to the method proposed by Alañon et al., 2011 [65] and Castro-Vazquez et al. [53]: “where 1,1-diphenyl-2-picrylhydrazyl radical was used as a stable radical. One hundred microliters of different dilutions of extracts were added to 2.9 mL of a 0.06 mM methanol DPPH radical solution. Methanol was used to adjust the zero and the decrease in absorbance was measured at 515 nm every minute for 25 min in a UV-vis spectrophotometer (Helios, Thermo Spectronic, Cambridge, UK). Only values between 20–80% of the initial absorbance of the radical DPPH were taken into consideration. Concentrations were calculated from a calibration curve in the range between 0.1–0.8 mM Trolox. Results were expressed in milligrams of Trolox per gram of dry weight”.

2.8.2. ABTS•+ Radical Scavenging Assay

The method used was the ABTS•+ decolorization assay in accordance with Alañon et al. 2011 [65] and Castro-Vazquez et al. [53]: “based on the ability of an antioxidant compound to quench the ABTS•+ relative to that of a reference antioxidant such as Trolox. A stock solution of ABTS•+ radical cation was prepared by mixing ABTS solution and potassium persulfate solution at 7 mM and 2.45 mM final concentration, respectively. The mixture was maintained in the dark at room temperature for 12–16 h before use. The working ABTS•+ solution was produced by dilution in ethanol (1:90 v/v) of the stock solution to achieve an absorbance value of 0.7 at 734 nm. An aliquot of 20 µL of diluted extract was added to ABTS•+ working solution. For the blank and standard curve, 20 µL of ethanol or Trolox solution was used, respectively. Absorbance was measured by an UV-vis spectrophotometer at 734 nm immediately after addition and rapid mixing (At = 0) and then every minute for 5 min. Readings at t = 0 min (At = 0) and t = 5 min (At = 5) of reaction were used to calculate the percentage inhibition value for each extract. A standard reference curve was constructed by plotting% inhibition value against Trolox concentration (0.1–0.8 mM). The radical scavenging capacity of extracts was quantified as milligrams of Trolox per gram of dry weight”.

2.8.3. FRAP Assay

The FRAP assay was performed as previously described by Castro-Vazquez et al. [53]: “this spectrophotometric assay measures the ferric reducing ability of antioxidants. The experiment was conducted at 37 °C and pH 3.6. In the FRAP assay, antioxidants present in the extract reduce Fe (III)-tripyridyltriazine complex to the blue ferrous form, with an absorption maximum at 593 nm. The assay was performed by means of an automated microplate reader (Tecan GENios Pro (Tecan Ltd., Dorset, UK)) with 96-well plates. Reagents included 300 mM acetate buffer pH 3.6; 40 mM hydrochloric acid, 10 mM TPTZ solution and 20 mM ferric chloride solution”. The working FRAP reagent was freshly prepared by mixing acetate buffer, TPTZ solution, and ferric chloride solutions in the ratio 10:1:1 and the mixture was incubated at 37 °C. Diluted extract (30 µL) and pre-warmed FRAP reagent (225 µL) were put into each well. The absorbance at time zero and after 4 min was recorded at 593 nm. The calculated difference in absorbance was proportional to the ferric reducing/antioxidant power of the extract. For quantification, a calibration curve of Trolox was prepared. The final results were expressed as milligrams of Trolox per gram of dried orange peel.

2.9. Formulation of Nanoemulsion Systems from Sanguina Peel Extracts

Among orange peels, the variety and the heat treatment that prove the highest antioxidant potential was selected in order to be formulated as a lecithin-stabilized nanoemulsion by the solvent displacement technique as previously proposed by Lozano et al. [66]. The selected prototype of orange peel, at the dried condition that provided the best antioxidant potential was chosen as a target for formulation studies and cell assays. Briefly, 63 µL of orange peel extracts was emulsified using 20 mg of lecithin kindly donated by Cargill (Barcelona, Spain), 0.25 mL of ethanol, and 4.75 mL of acetone (Sigma, Spain) under magnetic stirring. The aqueous phase was composed only by 5 mL MilliQ water. After emulsification, the formulations were rota evaporated to a final volume of 5 mL at 37 °C.

2.10. In Vitro Studies in Caco-2: Nanoemulsion Viability and Intracellular ROS Levels Measurements

2.10.1. Cell Culture

Caco-2 cells were cultured in DMEM supplemented with 1% (v/v) PEST, 1% (v/v) NEAA, 1% (v/v) L-glutamine, and 10% (v/v) heat-in-activated FBS in 75 cm2 flasks under an atmosphere of 10% CO2/90% air at 37 °C. The culture media was replaced every 2 days, and regular passaging was performed by trypsinization. Cells were used between passages x + 24 and x + 30.

2.10.2. Nanoemulsions Effect on Cell Viability

The effect of nanoemulsions on cell viability was studied in Caco-2 cells by the crystal violet assay. Firstly, 2 × 104 cells/well were seeded in 96-well plates and incubated at 37 °C for 24 h. Then, the medium was removed and different aliquots of nanoemulsions and extract dispersed in medium (3–95.5 μL/cm2) were added to the cells, which were further maintained at 37 °C for 24 h. After that period of incubation, the formulations were removed, 100 μL of a 0.5% (w/v) crystal violet staining solution was added to each well and further incubated at 37 °C for 30 min. Cells were washed twice with ultrapure water and left to dry at room temperature for 30 min. Finally, 100 μL of methanol was added to each well and maintained for 30 min with horizontal shaking. Optical density was measured at 570 nm with a plate reader, considering cells treated with DMEM and Triton-X 100 as negative and positive controls.

2.10.3. Intracellular ROS Levels Measurements

The effect of nanoemulsions on the intracellular ROS levels was studied in Caco-2 cells by the dichlorofluorescein (DCFH-DA) assay. Firstly, 2 × 104 cells/well were seeded in 96-well plates and incubated at 37 °C for 24 h. Then, the medium was removed and different aliquots of nanoemulsions and extract dispersed in medium (3–95.5 μL/cm2) were added to the cells, which were further maintained at 37 °C for 24 h. Then, cells were washed and 100 μL of DCFH-DA (10 μM) was added and further incubated at 37 °C for 60 min protected from light. After those incubations, cells were washed and 100 μL of H2O2 0.3% (v/v) was added to each well and incubated for 30 min at room temperature protected from light. Supernatants were collected and transferred to black flat-bottom 96-well plates (Cultek, Spain). The measurement of the fluorescent oxidized derivative of DCFH-DA was performed in a plate reader (BMG Labtech’s) using emission and excitation wavelengths of 475 and 125 nm, respectively. The treatments H2O2 and PBS were considered as positive and negative controls, respectively.

2.11. Statistical Analysis

Analysis of variance and multivariate analysis were performed using SPSS 15.0 for Windows statistical package. Differences between chemical data were established for significance at p ≤ 0.05 by the Student-Newman-Keuls test. Principal component analysis (PCA) was performed to rate the orange peel samples in groups according to their volatile compounds, phenolic composition, and antioxidant activity.

3. Results and Discussion

3.1. Volatile Compounds from Orange Peels

Methanol extracts from pressurized ASE isolation were used to quantify the volatile organic compounds (VOCs) by GC-MS. Sixty volatile components were identified in fresh and dried Navelina, Salustriana, and Sanguina peel extracts, among which were sesquitenenes, terpene oxides, terpenoids alcohols, monoterpenoid aldehydes, terpene hydroarbons, terpene esters, chain aldehydes, and C6-alcohols. Table 1 shows results and the relative standard deviation (RSD) expressed in percent and obtained by multiplying the standard deviation by 100 and dividing by the average of two analyzed samples.

Table 1.

Mean Concentration (μg. g−1 DW) and relative standard deviation (%) of volatile compounds in citrus peel extracts from Navelina (Citrus sinensis L. Osbeck cv. “Navelina”), Salustriana (Citrus sinensis L. Osbeck cv. “Salustriana”), and Sanguina (Citrus x sinensis var. “Sanguina”), fresh, oven-dried (50 °C, 70 °C), and freeze-dried (FD).

| KI | COMPOUNDS | Navelina Peel | Salustriana Peel | Sanguina Peel | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean Fresh | RSD | Mean FD | RSD | Mean Oven 50 °C | RSD | Mean Oven 70 °C | RSD | Mean Fresh | RSD | Mean FD | RSD | Mean Oven 50 °C | RSD | Mean Oven 70 °C | RSD | Mean Fresh | RSD | Mean FD | RSD | Mean Oven 50 °C | RSD | Mean Oven 70 °C | RSD | ||

| Sesquitenenes | |||||||||||||||||||||||||

| 1476 | α-copaene | 1.54 a | (7.76) | 1.71 a | (10.91) | 0.52 b | (8.32) | 0.38 b | (12.97) | 1.58 a | (14.91) | 1.2 a | (16.90) | 0.44 b | (0.59) | 0.34 c | (7.16) | 2.37 a | (2.13) | 2.92 b | (5.07) a | 1.26 c | (6.93) | 1.82 d | (5.75) |

| 1630 | γ-elemene | traces | 0.29 a | (11.78) | 0.26 a | (7.18) | 0.71 b | (7.52) | traces | 0.56 a | (8.13) | 0.36 b | (3.61) | 0.57 a | (5.61) | 0.33 a | (7.56) | 0.73 b | (8.15) | 0.13 c | (8.63) | 0.27 d | (10.80) | ||

| 1654 | β-farnesene | traces | 0.58 a | (9.82) | 0.24 b | (3.55) | 2.17 c | (15.98) | traces | 0.50 a | (0.77) | 0.25 b | (0.71) | 0.55 a | (16.94) | 0.27 a | (10.17) | 0.21 a | (5.82) | 0.24 a | (9.51) | 0.46 b | (13.48) | ||

| 1701 | valencene | 35.43 a | (0.98) | 36.67 a | (12.97) | 30.2 b | (7.82) | 13.31 c | (10.29) | 21.75 a | (5.06) | 27.45 b | (7.76) | 25.16 ab | (7.99) | 22.63 a | (7.99) | 20.54 a | (7.63) | 26.4 b | (9.38) | 5.86 c | (10.07) | 12.58 d | (8.63) |

| 1704 | germacrene D | 0.44 a | (0.00) | 0.81 b | (6.73) | 0.44 a | (5.08) | 0.12 c | (8.29) | 3.32 a | (20.20) | 3.37 a | (6.88) | 2.31 b | (12.91) | 2.04 b | (7.31) | 0.11 a | (6.15) | 0.38 b | (0.31) | 0.05 c | (1.36) | 0.21 d | (4.85) |

| 1723 | α-farnesene | 0.51 a | (0.34) | 0.87 b | (12.97) | 0.56 a | (0.28) | 0.42 c | (4.98) | 1.09 a | (0.29) | 0.88 b | (11.05) | 0.43 c | (7.88) | 0.31 d | (0.26) | 0.68 a | (0.98) | 3.22 b | (8.07) | 0.62 ac | (9.51) | 0.73 c | (10.16) |

| 1740 | δ-cadinene | traces | 0.5 a | (11.47) | 0.19 b | (6.86) | 0.62 a | (11.78) | traces | 0.36 a | (3.96) | 0.21 b | (4.56) | 0.26 b | (3.01) | 0.34 a | (5.66) | 0.91 b | (2.11) | 0.13 c | (10.97) | 0.65 d | (6.86) | ||

| 2016 | nerolidol | 2.06 a | (8.15) | 2.28 a | (11.55) | 0.42 b | (5.82) | 0.30 c | (6.86) | 0.99 a | (7.99) | 0.84 a | (3.91) | 0.64 c | (4.07) | 0.41 d | (5.35) | 0.66 a | (7.83) | 0.91 b | (6.82) | 0.41 c | (12.97) | 0.46 c | (2.77) |

| 2236 | β-sinensal | 11.8 a | (6.86) | 14.08 b | (7.44) | 5.69 c | (7.52) | 3.65 d | (7.52) | 3.19 a | (8.63) | 3.36 a | (2.00) | 2.6 b | (0.01) | 2.15 c | (0.28) | 5.17 a | (7.76) | 7.47 b | (5.70) | 0.35 c | (3.85) | 1.38 d | (0.98) |

| 2331 | α-sinensal | 10.95 a | (12.55) | 13.77 | (14.14) a | 4.91 b | (10.05) | 3.01 c | (10.05) | 4.32 a | (18.69) | 4.18 a | (18.21) | 1.86 b | (0.01) | 1.62 b | (11.39) | 4.32 a | (8.32) | 5.44 b | (3.33) | 0.73 c | (6.67) | 1.11 d | (8.07) |

| 2507 | nootkatone | 5.81 a | (7.82) | 6.16 a | (2.59) | 4.43 b | (7.56) | 2.86 b | (7.56) | 9.73 a | (1.22) | 11.03 b | (8.13) | 6.86 c | (0.78) | 4.03 d | (10.07) | 19.07 a | (5.70) | 27.75 b | (3.53) | 10.9 c | (9.59) | 13.21 d | (7.25) |

| 2083 | elemol | 3.93 a | (9.47) | 3.47 a | (9.38) | 0.81 a | (3.51) | 0.62 c | (4.98) | 1.82 a | (8.15) | 1.81 a | (13.48) | 1.81 a | (7.63) | 1.29 b | (7.63) | 1.3 a | (10.14) | 0.88 b | (8.13) | 1.65 c | (7.76) | 0.51 d | (0.77) |

| 2121 | γ-eudesmol | 1.12 a | (12.91) | 1.17 a | (3.55) | 0.25 b | (14.88) | 0.78 c | (7.52) | 0.67 a | (9.38) | 0.54 b | (6.67) | 0.51 b | (13.26) | 0.33 c | (13.26) | 0.21 a | (6.73) | 0.31 b | (0.01) | 0.32 b | (8.32) | 0.32 b | (4.07) |

| 2183 | δ-eudesmol | 2.15 a | (1.40) | 2.21 a | (9.38) | 1.17 b | (9.38) | 1.27 b | (2.28) | 5.05 a | (10.05) | 9.09 b | (7.88) | 5.09 a | (6.67) | 3.83 c | (6.67) | 7.81 a | (1.75) | 9.51 b | (2.77) | 4.68 c | (13.26) | 7.57 a | (7.16) |

| 2348 | (E)-farnesol | 1.33 a | (7.63) | 1.93 b | (3.63) | 1.4 a | (8.63) | 1.03 c | (8.07) | 1.58 a | (12.55) | 1.24 ab | (4.85) | 1.08 b | (0.01) | 0.68 c | (0.01) | 1.04 a | (7.52) | 1.62 b | (7.31) | 0.97 a | (12.49) | 1.02 a | (6.86) |

| Total | 76.57 | 86.5 | 51.49 | 31.25 | 55.09 | 66.41 | 49.61 | 41.04 | 64.22 | 88.66 | 28.3 | 42.3 | |||||||||||||

| Terpene oxide | |||||||||||||||||||||||||

| 1428 | (Z)-linalool oxide | 0.11 a | (7.83) | 0.21 b | (6.07) | 0.19 b | (4.47) | traces | 0.17 a | (8.44) | 0.44 b | (8.63) | 0.78 c | (5.14) | 0.51 b | (6.36) | 0.07 a | (10.88) | 0.60 b | (7.75) | 0.57 b | (3.40) | traces | ||

| 1430 | (Z)-limonene-oxide | 0.31 a | (4.98) | 0.64 b | (3.82) | 0.74 c | (0.77) | traces | 0.11 a | (6.73) | 0.79 b | (2.70) | 0.91 c | (7.63) | 0.42 c | (7.04) | 0.09 a | (8.32) | 0.32 b | (6.86) | 0.41 b | (5.82) | 0.20 c | (7.91) | |

| 1453 | (E)-linalool oxide | 0.16 a | (1.40) | 0.65 b | (6.87) | 1.24 c | (2.77) | traces | 0.25 a | (22.63) | 0.29 ab | (15.48) | 0.31 b | (6.96) | 0.01 c | (0.00) | 0.10 a | (14.14) | 0.27 b | (8.63) | 0.67 c | (5.08) | 0.18 ab | (6.82) | |

| Total | 0.58 | 1.50 | 2.17 | 0.03 | 0.53 | 1.52 | 2.00 | 0.94 | 0.26 | 1.19 | 1.65 | 0.39 | |||||||||||||

| Terpenoids alcohols | |||||||||||||||||||||||||

| 1541 | linalool | 66.79 a | (0.88) | 79.79 b | (7.86) | 81.02 b | (6.33) | 48.74 c | (2.24) | 32.52 a | (7.44) | 35.17 a | (14.76) | 45.12 b | (1.53) | 18.47 c | (6.90) | 63.90 a | (6.67) | 108.33 b | (3.24) | 80.96 | (1.36) | 24.52 | (6.99) |

| 1585 | α-terpineol | 32.08 a | (11.55) | 25.01 b | (7.33) | 7.81 b | (7.25) | 7.78 b | (7.44) | 17.61 a | (8.71) | 20.42 b | (7.91) | 7.61 c | (6.86) | 12.01 d | (6.86) | 34.72 a | (12.91) | 29.19 b | (7.52) | 7.00 | (7.99) | 5.86 | (1.13) |

| 1605 | p-menthadienol (I) | 7.35 a | (8.07) | 6.36 b | (5.14) | 13.13 b | (12.91) | 5.19 c | (4.98) | 5.62 a | (11.55) | 5.71 a | (7.75) | 7.76 c | (11.55) | 4.45 d | (7.63) | 8.26 a | (6.09) | 9.76 b | (8.82) | 11.41 | (4.02) | 2.37 | (10.29) |

| 1611 | p-menth-2-en-1-ol | 0.33 a | (14.98) | 0.35 a | (8.15) | 0.21 b | (13.64) | 0.69 c | (11.78) | 0.47 a | (7.88) | 0.37 b | (8.44) | 0.36 b | (4.98) | 0.37 b | (4.98) | 0.25 a | (7.82) | 0.36 b | (7.63) | 0.27 a | (8.57) | 0.09 | (8.32) |

| 1646 | p-menthadienol (II) | 8.94 a | (5.47) | 7.12 b | (7.63) | 7.70 b | (1.40) | 3.54 c | (12.97) | 4.90 a | (7.63) | 4.97 a | (1.16) | 4.12 b | (2.63) | 3.43 c | (8.44) | 6.08 a | (7.88) | 5.90 a | (9.68) | 5.62 ab | (7.63) | 5.19 b | (11.91) |

| 1667 | β-citronellol | 9.61 a | (2.52) | 8.66 b | (3.84) | 12.26 b | (7.44) | 7.64 c | (2.52) | 8.37 a | (0.75) | 8.26 a | (7.82) | 7.85 b | (0.75) | 6.41 c | (9.38) | 2.31 a | (7.56) | 2.77 a | (6.82) | 1.90 b | (9.85) | 5.13 c | (13.38) |

| 1786 | nerol | 14.48 a | (5.81) | 15.60 a | (8.63) | 10.26 b | (4.90) | 12.58 c | (7.63) | 7.46 a | (5.60) | 7.53 a | (7.04) | 7.99 b | (8.60) | 2.20 c | (13.45) | 5.78 a | (13.15) | 5.72 a | (4.07) | 1.38 b | (5.05) | 0.40 c | (7.31) |

| 1838 | geraniol | 14.46 a | (13.24) | 17.84 b | (7.56) | 7.13 b | (8.31) | 0.03 c | (0.00) | 8.97 a | (10.03) | 8.99 a | (7.52) | 5.88 b | (10.03) | 3.39 c | (15.98) | 8.60 a | (9.51) | 8.25 a | (13.26) | 1.46 b | (3.78) | 0.65 c | (5.70) |

| 1834 | (Z)-carveol | 2.28 a | (10.54) | 2.51 a | (4.13) | 2.42 a | (12.63) | 0.03 c | (0.00) | 2.77 a | (3.02) | 4.77 b | (1.94) | 1.53 c | (2.75) | 1.64 c | (7.56) | 1.10 a | (3.33) | 2.05 b | (3.85) | 1.70 c | (1.05) | 0.91 d | (1.91) |

| 1927 | limonyl alcohol | 0.73 a | (8.15) | 0.75 a | (8.07) | 0.59 b | (8.07) | 0.61 b | (7.63) | 0.58 a | (0.00) | 0.82 b | (2.25) | 0.62 a | (3.45) | 0.37 c | (6.99) | 0.21 a | (5.15) | 0.38 b | (4.67) | 0.20 a | (3.05) | 0.12 c | (6.86) |

| 1963 | p-mentha-dien-9-ol | 1.32 a | (9.51) | 1.73 ab | (9.31) | 1.98 b | (6.99) | 1.25 b | (8.63) | 3.58 a | (3.43) | 3.71 a | (6.50) | 2.64 b | (5.43) | 2.36 b | (5.82) | 0.63 a | (5.05) | 1.09 b | (5.14) | 0.61 a | (13.73) | 0.40 c | (7.52) |

| 1996 | perillyl alcohol | 2.04 a | (7.18) | 2.14 a | (0.03) | 2.14 a | (14.74) | 0.81 c | (6.86) | 1.34 a | (2.42) | 2.34 b | (7.52) | 0.79 c | (1.38) | 0.45 d | (9.51) | 0.49 a | (9.59) | 2.76 b | (8.44) | 0.70 c | (2.37) | 0.30 d | (2.87) |

| 2140 | eugenol | 0.39 a | (8.15) | 0.52 b | (3.61) | 0.38 a | (10.05) | 0.16 c | (8.15) | 1.03 a | (3.85) | 1.75 b | (7.52) | 0.98 a | (3.85) | 0.07 c | (5.70) | 0.27 a | (7.31) | 0.34 b | (7.12) | 0.25 a | (7.63) | 0.10 c | (12.97) |

| Total | 160.2 | 168.41 | 147.09 | 88.85 | 95.42 | 104.02 | 93.45 | 55.62 | 132.82 | 176.4 | 113.48 | 46.04 | |||||||||||||

| Monoterpenoid aldehydes | |||||||||||||||||||||||||

| 1468 | citronellal | 3.58 a | (6.33) | 3.99 a | (10.40) | 2.57 b | (7.76) | 0.00 c | 1.14 a | (5.82) | 1.87 b | (4.07) | 1.70 c | (0.71) | 0.00 d | 2.81 a | (0.60) | 3.19 b | (3.35) | 0.99 c | (8.82) | 0.00 d | |||

| 1664 | neral | 3.66 a | (4.95) | 2.88 b | (2.97) | 4.74 c | (1.26) | 7.15 d | (6.73) | 1.33 a | (3.30) | 2.84 b | (6.90) | 3.37 c | (7.45) | 4.11 d | (10.14) | 2.20 a | (2.16) | 4.29 b | (2.67) | 5.95 c | (9.51) | 9.94 d | (10.29) |

| 1712 | geranial | 5.61 a | (1.55) | 4.66 b | (6.73) | 3.74 c | (6.87) | 2.26 d | (5.82) | 3.19 a | (5.99) | 2.09 b | (7.63) | 1.37 c | (9.33) | 1.56 c | (7.63) | 3.60 a | (14.24) | 4.19 b | (11.41) | 7.83 c | (19.37) | 5.69 d | (0.02) |

| Total | 12.85 | 11.53 | 11.05 | 9.41 | 5.66 | 6.8 | 6.44 | 5.87 | 8.61 | 11.67 | 14.77 | 15.63 | |||||||||||||

| Chain aldehydes | |||||||||||||||||||||||||

| 1284 | octanal | 12.04 a | (6.73) | 9.98 b | (1.51) | 5.08 | (7.16) | 3.39 | (5.97) | 6.98 a | (8.38) | 7.17 a | (17.05) | 5.84 c | (7.31) | 2.77 d | (9.94) | 9.57 a | (14.76) | 8.70 b | (1.00) | 7.04 c | (2.00) | 2.33 d | |

| 1386 | nonanal | 2.58 a | (8.13) | 1.63 b | (6.09) | 1.52 b | (13.26) | 0.73 c | (7.56) | 2.00 a | (1.01) | 1.65 b | (3.19) | 1.88 ab | (4.86) | 1.15 c | (2.42) | 2.01 a | (7.63) | 2.10 a | (3.61) | 2.54 b | (2.16) | 0.05 c | |

| 1490 | decanal | 13.91 a | (7.31) | 12.22 b | (4.14) | 11.00 c | (6.09) | 7.00 d | (8.32) | 11.52 a | (3.31) | 11.00 a | (5.08) | 5.86 b | (1.02) | 3.86 c | (1.55) | 4.76 a | (7.63) | 3.44 b | (7.56) | 3.21 b | (5.98) | 0.34 c | |

| Total | 27.83 | 23.93 | 18.1 | 11.12 | 20.5 | 20.42 | 13.58 | 7.78 | 16.34 | 14.24 | 12.49 | 2.72 | |||||||||||||

| Terpene hydrocarbons | |||||||||||||||||||||||||

| 1018 | α- pinene | 13.49 a | (2.77) | 13.58 a | (1.48) | 21.97 b | (4.98) | 8.48 c | (8.03) | 11.12 a | (7.75) | 19.76 b | (3.31) | 21.85 c | (0.98) | 9.50 d | (0.98) | 17.57 a | (4.60) | 17.85 a | (3.05) | 11.58 c | (3.00) | 10.21 d | (10.81) |

| 1104 | β- pinene | 5.63 a | (4.52) | 6.36 b | (5.79) | 7.51 c | (2.76) | 5.20 d | (11.55) | 4.60 a | (8.13) | 5.80 b | (7.91) | 7.43 c | (7.18) | 2.00 d | (8.13) | 11.34 a | (7.56) | 9.64 b | (7.82) | 13.34 c | (11.22) | 1.61 d | (7.76) |

| 1119 | sabinene | 7.65 a | (13.34) | 9.47 b | (2.17) | 13.94 c | (8.32) | 4.84 d | (4.98) | 5.90 a | (10.07) | 7.14 b | (2.87) | 10.53 c | (7.99) | 3.10 d | (2.87) | 9.56 a | (3.97) | 11.84 b | (4.13) | 14.25 c | (6.73) | 3.69 d | (8.63) |

| 1209 | limonene | 1687.15 a | (4.98) | 1637.25 a | (1.59) | 2055.82 b | (7.31) | 986.05 c | (11.78) | 1677.04 | a (0.79) | 1700.36 b | (0.65) | 2005.28 c | (0.44) | 852.33 d | (7.83) | 2107.74 a | (3.65) | 2190.26 b | (0.72) | 2424.57 c | (8.32) | 925.92 d | (7.31) |

| 1237 | (Z)-b-ocimene | 0.31 a | (11.78) | 0.48 b | (7.16) | 0.75 c | (1.54) | 0.15 d | (3.61) | 0.23 a | (7.99) | 0.32 b | (0.77) | 0.43 c | (12.91) | 0.14 d | (0.77) | 0.45 a | (10.40) | 0.41 a | (6.90) | 0.59 b | (7.63) | 0.00 c | |

| 1254 | γ-terpinene | 3.19 a | (5.70) | 3.46 b | (5.95) | 3.77 c | (3.26) | 2.21 d | (1.40) | 2.08 a | (9.45) | 2.34 a | (8.47) | 3.37 c | (10.29) | 2.21 d | (7.45) | 3.14 a | (0.71) | 3.99 b | (1.98) | 2.72 c | (7.52) | 0.78 d | (10.92) |

| 1256 | (E) b-ocimene | 1.73 a | (3.33) | 2.28 b | (14.80) | 3.26 c | (1.40) | 1.59 d | (9.82) | 1.39 a | (8.71) | 1.69 a | (9.82) | 3.23 c | (7.12) | 0.76 d | (2.78) | 0.60 a | (1.94) | 0.49 b | (6.90) | 0.64 a | (0.26) | 0.41 b | (5.69) |

| 1269 | p-cymene | 0.73 a | (4.11) | 0.86b | (4.79) | 0.91 b | (3.51) | 0.69 c | (12.97) | 0.42 a | (9.04) | 0.46 a | (11.17) | 0.46 a | (9.61) | 0.20 d | (2.77) | 0.38 a | (3.31) | 0.40 a | (3.61) | 1.09 b | (7.25) | 0.25 c | (6.86) |

| 1289 | α-terpinolene | 2.55 a | (8.38) | 2.47 a | (10.14) | 3.01 b | (5.14) | 1.21 c | (12.32) | 2.50 a | (6.93) | 2.36 a | (8.22) | 3.28 b | (8.32) | 1.42 c | (8.32) | 3.83 a | (7.99) | 4.42 b | (7.44) | 3.15 c | (9.07) | 0.59 d | (8.62) |

| 1368 | alloocimene | 0.11 a | (8.13) | 0.11 a | (1.75) | 0.20 b | (17.91) | 0.10 c | (0.98) | 0.17 a | (3.55) | 0.15 a | (7.41) | 0.18 a | (14.93) | 0.07 d | (2.70) | 0.09 a | (8.47) | 0.12 a | (7.82) | 0.23 c | (3.13) | 0.08 a | (11.55) |

| 1427 | p-cymenene | 0.31 a | (7.99) | 0.66 | (6.86) | 1.68 b | (2.87) | 0.75 c | (7.41) | 0.23 a | (7.44) | 0.10 b | (7.44) | 0.62 c | (9.05) | 0.00 d | 0.35 a | (7.88) | 1.35 b | (6.40) | 1.48 b | (5.70) | 0.19 c | (3.61) | |

| 1521 | β-cubenene | 0.35 a | (7.52) | 0.69 b | (6.73) | 0.90 c | (7.16) | 0.42 d | (7.31) | 1.23 a | (3.33) | 0.54 b | (3.33) | 0.83 c | (7.63) | 1.28 a | (7.18) | 0.44 a | (13.26) | 0.41 a | (6.09) | 1.20 c | (6.93) | 0.28 d | (8.15) |

| 1578 | transCaryophyllene | 2.14 a | (6.86) | 2.96 b | (5.82) | 6.62 b | (2.59) | 1.77 c | (6.86) | 4.09 a | (11.62) | 4.45 ab | (4.60) | 4.77 b | (1.36) | 2.01 c | (6.09) | 2.75 a | (8.13) | 3.59 b | (1.57) | 7.50 c | (10.89) | 2.14 d | (9.38) |

| 1703 | β-selinene | 2.52 a | (0.36) | 3.30 b | (1.49) | 4.43 c | (7.21) | 0.30 d | (8.15) | 4.58 a | (10.72) | 4.13 a | (11.69) | 5.81 b | (6.44) | 2.39 c | (14.76) | 2.30 a | (3.26) | 2.90 b | (7.52) | 4.67 c | (4.65) | 1.62 d | (7.88) |

| Total | 1727.86 | 1683.49 | 2124.68 | 1013.76 | 1715.58 | 1749.1 | 2068.09 | 877.72 | 2190.64 | 2236.98 | 2487.17 | 947.84 | |||||||||||||

| Terpene Esters | |||||||||||||||||||||||||

| 1546 | linalyl acetate | 0.82 a | (6.86) | 0.64 b | (0.22) | 0.41 c | (8.32) | 0.00 d | 0.09 a | (12.91) | 0.11 a | (10.00) | 0.01 b | (1.00) | 0.00 c | 1.13 a | (13.65) | 0.89 b | (5.06) | 0.41 c | (4.98) | 0.29 d | (1.01) | ||

| 1570 | bornyl acetate | 0.48 a | (8.63) | 0.26 b | (6.99) | 0.24 b | (5.70) | 0.00 c | 0.38 a | (1.09) | 0.36 b | (6.53) | 0.34 a | (1.02) | 0.12 b | (14.76) | 0.19 a | (1.82) | 0.25 b | (1.00) | 0.01 c | (0.00) | 0.01 d | (0.00) | |

| 1644 | citronelly acetate | 0.23 a | (6.86) | 0.20 a | (10.05) | 0.12 b | (3.61) | 0.11 b | (9.82) | 0.16 a | (1.40) | 0.14 b | (1.40) | 0.00 b | 0.00 b | 1.41 a | (5.70) | 1.33 a | (6.99) | 1.41 a | (8.44) | 0.68 b | (2.15) | ||

| 1673 | terpinyl acetate | 3.80 a | (13.65) | 3.49 a | (13.26) | 1.08 b | (10.14) | 0.82 c | (12.97) | 1.36 a | (0.00) | 1.30 a | (0.00) | 1.16 b | (7.12) | 0.64 c | (6.73) | 3.22 a | (5.70) | 2.51 b | (2.63) | 0.45 c | (8.47) | 0.57 d | (8.13) |

| 1711 | geranyl acetate | 0.51 a | (4.30) | 0.49 a | (6.86) | 0.30 b | (10.14) | 0.17 c | (7.63) | 1.38 a | (7.42) | 0.49 b | (5.70) | 0.37 c | (8.71) | 0.27 d | (11.92) | 0.53 a | (10.07) | 0.55 a | (6.86) | 0.51 a | (7.75) | 0.26 b | (7.82) |

| 1742 | neryl acetate | 0.72 a | (12.55) | 0.77 a | (3.61) | 0.39 b | (3.64) | 0.23 c | (8.15) | 0.68 a | (2.46) | 0.66 a | (2.68) | 0.50 b | (0.00) | 0.32 c | (10.68) | 1.04 a | (3.92) | 1.09 a | (1.82) | 0.80 b | (2.90) | 0.34 d | (5.09) |

| Total | 6.56 | 5.72 | 2.54 | 1.39 | 4.05 | 3.08 | 2.39 | 1.36 | 7.72 | 6.38 | 3.59 | 2.15 | |||||||||||||

| C6 Alcohols | |||||||||||||||||||||||||

| 1350 | 1-hexanol | 10.21 a | (12.97) | 9.83 a | (0.31) | 1.04 b | (8.13) | 0.00 c | 2.76 a | (1.01) | 2.01 b | (1.36) | 0.76 c | (36.35) | 0.00 d | 1.73 a | (6.86) | 1.69 a | (9.68) | 0.67 b | (12.91) | 0.32 c | (8.63) | ||

| 1381 | (Z)-3-hexen-1-ol | 3.55 a | (0.98) | 3.39 a | (2.08) | 0.26 b | (10.07) | 0.00 c | 1.30 a | (8.19) | 1.07 a | (5.98) | 0.19 b | (0.00) | 0.00 c | 0.58 a | (8.71) | 0.52 a | (8.63) | 0.14 b | (4.98) | 0.00 c | |||

| Total | 13.76 | 13.22 | 1.30 | 0,00 | 4.06 | 3.08 | 0.95 | 0.00 | 2.31 | 2.11 | 0.81 | 0.33 | |||||||||||||

KI: Kovats index; a, b, c, d: Different letters in the same row denote significant difference according to the Student-Newman-Keuls test (p < 0.05).

In some cases, the formation of new sesquiterpene compounds after drying was observed. Thus, β-farnesene, γ-elemene, and δ-cadinene, absent in fresh Navelina and Salustriana peels (traces), appeared in dried samples (FD, OD-50 °C and OD-70 °C) as can be seen in Table 1. Similar findings were reported by other researchers [67,68,69], probably caused by reactions of oxidation, hydrolysis of glycosylated forms, or rupture of cell walls conditioned by the selected drying technique.

Regarding terpenoid alcohols, both fresh and dried orange peels displayed a wide number of these VOCs and outstanding concentrations of linalool, α-terpineol, nerol, and geraniol, mainly in Navelina peels (Table 1), allowing its differentiation as markers of Citrus sinensis L. Osbeck cv. “Navelina”. It is interesting to note that the global levels of terpenoids alcohols quantified in Navelina, Salustriana, and Sanguina peels remained practically unaffected between fresh and freeze-dried samples. However, the effects of drying at 50 °C on their individual terpenoids alcohols levels were variable (Table 1); thus, e.g., p-mentha-2.8-dien-1-ol (isomer I) and linalool significantly increased (p < 0.05) at OD-D-50 °C, attributed to the hydrolysis of the glycosidically form and releases of their aglycones [69,70]. After OD-70 °C treatment, most of the terpenoids alcohols significantly decreased (p < 0.05), caused by thermal degradation and oxidation reaction during drying, e.g., (Z)-carveol vary from 2.28 in fresh Navelina peel to 00.03 µg/g after 70 °C.

Monoterpenoid aldehydes were also affected by the drying conditions. Thus, the temperatures not only triggered the formation of some VOCs, they also caused the elimination of others like some monoterpenoids aldehydes (citronellal, perilla aldehyde), which occur in fresh Navelina and Sanguina peel extracts and were absent in samples oven-dried at 70 °C. The content of geranial at OD-50 °C and 70 °C tended to decrease while the content of neral tended to increase upon these treatments. This behavior was previously described [71] as isomerization of geranial, that is trans-isomer of citral into cis-isomer (neral) as consequence of the drying conditions.

The most interesting finding of the current experiment was the quite similar volatile profile found between fresh and FD orange peels. This fact denotes that the freeze-drying treatment retained as much as possible, better than oven-drying, the initial volatile composition of Navelina, Salustriana, and Sanguina peels. In some cases, freeze-drying even improve the total content that occurred in fresh samples, specifically for sesquitenenes, terpene oxide, and terpene alcohols (Table 1). These results can be explained based on the low processing temperatures applied that avoid the thermal degradation reactions retaining the volatile compounds.

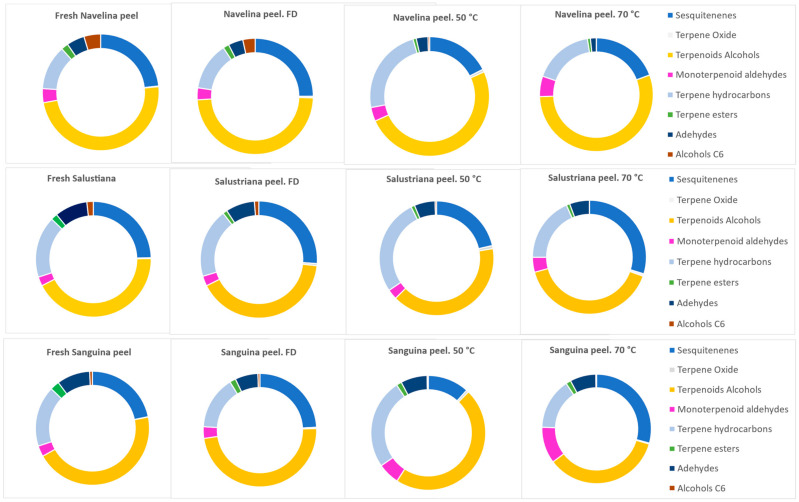

Regarding the amounts of the volatile compounds, terpene hydrocarbons was the chemical family of VOCs with the highest concentration, both in fresh and dried Navelina, Salustriana, and Sanguina peels. Limonene was the major aroma constituent (83.28–92.57%), according with several research focused on orange peels from Citrus sinensis [67,72].

Terpene hydrocarbons showed significantly higher levels (p < 0.05) in orange peels at OD-50 °C than in the fresh ones since they are categorized as nonpolar compounds. For instance, Salustriana peel showed 2068.1 µg/g and 1715.16 µg/g, respectively (Table 1). The increases in terpene hydrocarbons at OD-50 °C might have been caused by the release of bound volatiles (enzymatic or acid hydrolysis) during the drying process, since volatiles exist in free forms or bound to other molecules such as sugars forming glycosides [73]. Nevertheless, the oven-drying at 70 °C caused a significant decrease (p < 0.05) in the global levels terpene hydrocarbons (Figure 1) since drying at medium-high temperatures can cause stripping processes, oxidation, and thermal degradation reactions [74]. In particular, limonene at OD-70 °C decreased to 1000 µg/g in samples dried at 70 °C, even to 852.33 µg/g in Salustriana peels. The reduction of limonene content was also reported in previous research after the drying process at 60–70 °C [75], indicating that samples should not be dried at high temperature.

Figure 1.

Percentage (%) of every chemical family of VOCs respective to the total of volatile compounds, for every orange variety (Navelina, Salustriana, and Sanguina) and for every treatment: fresh, freeze-dried (FD), and oven-dried (50 °C, 70 °C).

It is of special note that the rich variety of sesquiterpene in fresh Navelina, Salustriana, and Sanguina peels ranged from 21.76 to 23.58% (Figure 1). An increase was observed of the total sesquiterpene in freeze-dried samples (p < 0.05) in comparison with their respective fresh extracts. For instance, Navelina peel showed 76.57 µg/g sesquiterpenes in fresh samples and 86.49 µg/g in freeze-dried peel (Table 1). This increase could be attributed to the breaking of the cells in which the compounds are stored, causing a more effective extraction [70]. In addition, sesquiterpenes have higher molecular weight and thus, they are less volatile and hardly removed from the plant material. However, they are susceptible to oxidation reaction for extended drying time or temperatures (Chua et al., 2019), which can explain the reduction of sesquiterpene amounts after to OD-50 °C and OD-70 °C.

To identify the potential volatile biomarkers that discriminate the three orange peel varieties studied, a factorial principal component analysis was applied. In relation to sesquiterpenes, Navelina fresh peel (Citrus sinensis L. Osbeck cv. “Navelina”) was characterized by its levels of valence (35.43 µg/g), α-sinensal (11.8 µg/g), and β-sinensal (10.95 µg/g) described in citrus matrices [76,77]. Salustriana peel (Citrus sinensis L. Osbeck cv. “Salustriana”) was identified based on its higher levels of Germecrene D (3.32 µg/g) and Sanguina peel (Citrus x sinensis var. “Sanguina”) focused on the amounts of nootkatone (19.07 µg/g), as can be seen in Table 1. All these compounds can be considered differential sesquiterpenes with a highly significant importance as potential specific biomarkers, quantified in concentrations 1.5–4-fold higher in their respective citrus species. These results are consistent with studies on the characterization of sweet orange peel (Citrus sinensis) [72,78], although it is the first approach, as far as the authors know, to separately differentiate Navelina, Sanguina, and Salustriana peels based on the sesquiterpene levels.

As concerns the C6-alcohols, 1-hexanol, and (Z)-3-hexen-1-ol, insignificant differences (p < 0.05) were observed between concentrations of fresh and FD samples from Navelina, Salustriana, and Sanguina peels, indicating that FD preserved these fresh aromas. Nevertheless, their amounts dropped by around 80% in the OD-50 °C sample and decreased (as far as disappearing) upon OD-70 °C, which indicates that C6-alcohols are more sensitive to the dehydration through oven-drying than to FD. For instance, 1-hexanol showed 10.21 µg/g in fresh Navelina peels, 1.04 µg/g in OD-50 °C, and 0.00 µg/g in samples OD-70 °C (Table 1).

Overall, results indicated that there were significant differences between the VOC profile of fresh and dried orange peels, based on the selected drying treatment. However, freeze-drying seems to be an extremely useful technique retaining the volatile compounds of fresh orange peels.

Previous studies have linked the volatile constituents and antioxidant activities of different citrus matrices as γ-terpinene, as well as terpinolene and geraniol, with a strong antioxidant activity in terms of DPPH•, ABTS•+ radical-scavenging activity; whereas limonene, which is a major component of many citrus peel extracts, has been described with little effect on radical-scavenging [79]. Thus, taking into account that these compounds occur in Navelina, Salustriana, and Sanguina peel extracts (representing 3–10% of its respective volatile group), this criterion could be useful to select or catgorize orange peel samples with antioxidant purposes.

In general, Figure 1 shows the percentage of every chemical family from Navelina, Salustriana, and Sanguina peels, and the effect of fresh/heat treatment.

3.2. Total Phenolic Content

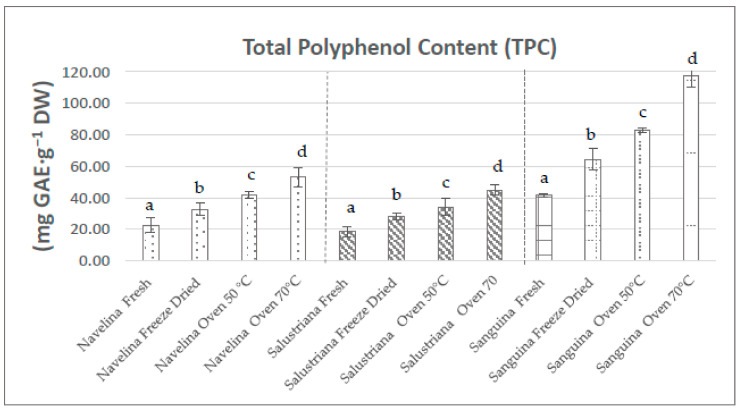

The total phenolic contents (TPC) of peel extracts from Salustriana (Citrus sinensis L. Osbeck cv. “Salustriana”), Navelina (Citrus sinensis L. Osbeck cv. “Navelina”), and Sanguina (Citrus x sinensis var. “Sanguina”) were analyzed in fresh, oven-dried at (OD 50–70 °C), and freeze-dried states. The classification of these orange peel extracts based on the highest TPC index was Sanguina > Navelina > Salustriana, as can be seen in Figure 2.

Figure 2.

Total phenolic contents of ASE extracts from Navelina, Salustriana, and Sanguina peels, fresh and after different drying treatments. a, b, c, d: Different letters in the same column denote a significant difference according to the Student-Newman-Keuls test, at p < 0.05. GAE—gallic acid equivalent.

The TPC levels were variable depending on the drying treatment. Thus, TPC of Navelina, Salustriana, and Sanguina peels extracts dried at 50 °C (30.50, 27.16, 64.36 mg GAE·g−1 DW, respectively) were significantly higher (p < 0.05) than those found in fresh peels (22.75, 19.55, 41.66 mg GAE·g−1 DW). These levels were enhanced with oven-drying at 70 °C, reaching 42.00, 31.27, 83.15 mg GAE·g−1 DW, respectively. Our results were similar to those reported by Jeong et al. [67], mentioning enhancements of TPC in Citrus unshiu peels as the heating temperature increased. Increases of TPC during drying at 70 °C from their precursors by non-enzymatic interconversion between phenolic molecules have also been reported [80].

At the same time, the highest levels of TPC were noted in freeze-dried (FD) extracts from Navelina, Salustriana, and Sanguina peels; they increased two/three-fold compared to their respective fresh peels (Figure 2). Our results were similar to those reported by Farahmandfar et al. [67] who reported remarkable increases in the TPC levels in FD-Navel peels (Citrus sinensis L. Osbeck) in comparison with those oven-dried at 45–60 °C.

Navelina, Salustriana, and Sanguina peels obtained by pressurized ASE extraction yielded TPC values 2–10-fold higher than levels reported in other orange peels varieties employing subcritical water extraction, ethanolic liquid isolation, and hot water extraction [35,44,81,82]. These findings prove that the tandem freeze-drying and pressure isolation (ASE) is probably the more suitable technique with regard to the extraction of phenolic compounds from orange peels.

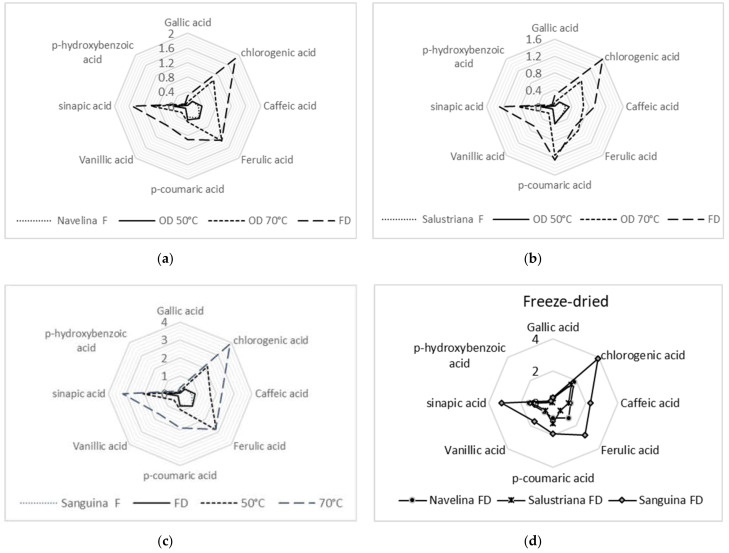

3.3. Phenolic Acids

The predominant phenolic acids of Navelina, Salustriana, and Sanguina peels were ferulic, sinapic, p-coumaric, caffeic, and chlorogenic acids, while gallic acid and p-hydroxy benzoic acids were the lower (Figure 3). On the whole, Sanguina peel exhibited highest amounts of phenolic acids mainly as ferulic acid (0.63 mg g−1), sinapic acid (0.94 mg g−1), p-coumaric acid (0.84 mg g−1), caffeic acid (0.66 mg g−1), and chlorogenic acid (0.36 mg g−1) (Table 2), in accordance with findings reported by Bocco et al. [83]. Chlorogenic acid, based on chemical structure, is highly linked with antioxidant potential and its presence can be of great relevance in the current extracts.

Figure 3.

Phenolic acids (mg g−1 DW) of Navelina (a), Salustriana (b), and Sanguina peels (c), fresh (F), after freeze-drying (FD), and after oven-drying (OD-50 °C, OD-70 °C). (d) shows the comparison between the three FD orange peels.

Table 2.

Mean values of phenolic acids (mg. g−1 DW) and relative standard deviation (RSD) in fresh extracts, oven-dried at 50 °C (OD-50 °C), oven-dried at 70 °C (OD-70 °C), and freeze-dried (FD).

| Phenolic Acids | Navelina Peel (Citrus sinensis L. Osbeck cv. “Navelina”) |

Salustriana Peel (Citrus sinensis L. Osbeck cv. “Salustriana”) |

Sanguina Peel (Citrus x sinensis var. “Sanguina”) |

|||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fresh | RSD | OD 50 °C | RSD | OD 70 °C | RSD | FD | RSD | Fresh | RSD | OD 50 °C | RSD | OD 70 °C | RSD | FD | RSD | Fresh | RSD | OD 50 °C | RSD | OD 70 °C | RSD | FD | RSD | |

| Gallic acid | 0.03 a | (2.40) | 0.03 a | (10.10) | 0.14 b | (6.24) | 0.29 c | (2.40) | 0.03 a | (10.48) | 0.04 a | (12.41) | 0.13 b | (9.88) | 0.29 c | (4.88) | 0.03 a | (6.73) | 0.03 a | (2.40) | 0.15 b | (3.87) | 0.40 c | (3.45) |

| p-Hydroxybenzoic acid | 0.02 a | (7.79) | 0.03 a | (9.43) | 0.07 b | (8.88) | 0.10 c | (7.44) | 0.02 a | (11.49) | 0.03 a | (10.48) | 0.06 b | (7.95) | 0.09 c | (13.70) | 0.05 a | (11.79) | 0.06 a | (9.43) | 0.14 b | (7.88) | 0.20 c | (7.44) |

| Vanillic acid | 0.07 a | (6.24) | 0.07 | (1.00) | 0.26 b | (8.32) | 0.73 c | (7.75) | 0.06 a | (9.99) | 0.06 a | (14.08) | 0.22 b | (8.64) | 0.64 c | (4.65) | 0.14 a | (6.24) | 0.15 a | (1.00) | 0.54 b | (8.32) | 1.54 c | (7.75) |

| Chlorogenic acid | 0.17 a | (8.32) | 0.19 a | (7.44) | 1.08 b | (7.24) | 1.94 c | (5.48) | 0.14 a | (12.31) | 0.17 a | (10.64) | 0.93 b | (7.83) | 1.67 c | (6.35) | 0.36 a | (8.32) | 0.40 a | (7.44) | 2.27 b | (7.24) | 4.08 c | (5.48) |

| Caffeic acid | 0.30 a | (4.71) | 0.38 a | (1.75) | 0.75 b | (8.54) | 1.02 c | (10.45) | 0.26 a | (4.54) | 0.31 a | (4.68) | 0.65 b | (6.46) | 0.90 c | (6.09) | 0.63 a | (4.71) | 0.85 a | (1.75) | 1.57 b | (8.54) | 2.14 c | (10.45) |

| p-Coumaric acid | 0.31 a | (8.40) | 0.38 a | (1.89) | 0.43 b | (3.29) | 0.89 c | (3.99) | 0.27 a | (9.92) | 0.29 a | (14.63) | 0.38 b | (5.42) | 0.75 c | (6.88) | 0.66 a | (8.40) | 0.67 a | (0.89) | 0.91 b | (3.29) | 1.87 c | (3.99) |

| Ferulic acid | 0.45 a | (2.37) | 0.46 a | (0.77) | 1.36 b | (1.57) | 1.38 c | (4.63) | 0.38 a | (5.89) | 0.38 a | (4.73) | 1.17 b | (2.27) | 1.22 c | (3.39) | 0.94 a | (2.37) | 0.97 a | (0.77) | 2.86 b | (1.57) | 2.90 c | (4.63) |

| Sinapic acid | 0.40 a | (3.54) | 0.41 a | (8.73) | 1.0 5 b | (8.80) | 1.62 c | (8.32) | 0.35 a | (5.00) a | 0.35 a | (10.64) | 0.91 b | (9.92) | 1.36 c | (5.35) | 0.84 a | (3.54) | 0.85 a | (8.73) | 2.20 b | (8.80) | 3.41 c | (8.32) |

| Total acids | 1.75 a | 1.94 a | 5.11 b | 7.94 c | 1.50 a | 1.63 a | 4.44 b | 6.92 c | 3.66 a | 3.98 a | 10.63 b | 16.54 c | ||||||||||||

a, b, c: Different letters in the same row denote a significant difference according to the Student-Newman-Keuls test, at p < 0.05. DW: dry weight basis.

Regarding heat treatment, fresh and OD-50 °C extracts from Navelina, Salustriana, and Sanguina peels displayed similar individual levels of phenolic acids, comparable with the results found by Deng et al. [84] in several citrus peels heating between 50–60 °C.

Sanguina peels showed the highest levels of ferulic acid, sinapic acid, and caffeic acid. The fresh Sanguina peels displayed 0.94, 0.84, and 0.63 mg g−1, respectively. Significant increases (p < 0.05) were noted after OD-70 °C (2.86, 2.20, 1.57 mg/g) and they were accentuated in FD samples (2.90, 3.41, 2.14 mg g−1, respectively) (Table 2); this fact supposes an increase by around 7–10 folds, compared with fresh Sanguina peels.

Our results suggest a reasonable release of phenolic compounds due to the heating temperature of oven-drying treatment, and an outstanding upward trend in FD extracts from Navelina, Salustriana, and Sanguina peels (Figure 3). Parallel findings reported increases in the phenolic acids’ free fraction of several dried citrus peels, at the same time that decreases in the glycoside bound forms [81,85,86].

The comparison of MAE, conventional solvent extraction, UAE, and ASE with data published in the literature showed that microwave assistant, ultrasound, and accelerated solvent has its own effects on the isolation of individual phenolic acids, total polyphenol content, flavonoids, and antioxidant activity of Citrus sinensis. Thus, values of TPC from Citrus sinensis peels using MAE extraction were 12.09 mg GAE g−1 DW [43] and 9.6 mg GAE g−1 DW using conventional methanol extraction [8]; however, with ASE extraction, in our optimized conditions, TPC values reached a ranged between 18.45 and 41.66 mg GAE g−1 DW for Navelina and Salustriana peels, respectively, revealing the suitability of accelerated solvent extraction by pressure (ASE).

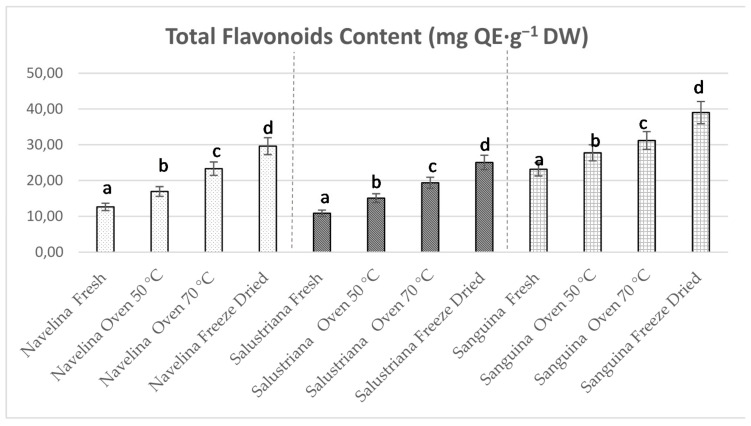

3.4. Total Flavonoids Content

The total flavonoid contents (TFC) of fresh orange peels varied between 12.64 (Navelina), 10.86 (Salustriana), and 23.14 mg QE·g−1 DW (Sanguina). Increases of TFC were noted in oven-dried peels, especially at 70 °C (p < 0.05) reaching 23.33, 19.37, and 31.19 mg QE·g−1 DW, respectively (Figure 4). This effect was previously quantified as two-fold higher in citrus peels dried between 70 and 100 °C in comparison with unheated peels [80,87]. Rafiq et al. [88] explained this TFC increase based on changes in the structure of flavonoids and the formation of low molecular weight phenolic compounds during drying.

Figure 4.

Total flavonoids contents (TFC) from pressurized extracts of Navelina, Salustriana, and Sanguina, both fresh and after drying treatments: oven-dried (50 °C), oven-dried (70 °C), and freeze-dried. QE–quercetin equivalent.

Our results revealed that freeze-dried samples showed the highest values of (p < 0.05) TFC displaying 29.61, 25.05, and 39.00 mg QE·g−1 DW in Navelina, Salustriana, and Sanguina peels, respectively (Figure 4). This conduct is probably due to the reduction of water content (concentrating the TFG), together with the low temperature during freeze-drying that preserved the flavonoids, avoiding their thermal degradation. Therefore, data suggest the suitability of FD treatment couple with pressurized ASE isolation to improve the total flavonoids of orange peel extracts that could be used for the reformulation of functional foods.

3.5. Individual Flavonoids of Orange Peel Extracts

The proposed ASE-LC-MS/MS method was applied to the isolation, analysis, and quantification of the individual flavonoids in Navelina, Salustriana, and Sanguina orange peels, allowing evaluating the impact of the drying treatments. The factors concerning pressurized ASE optimization were established in a previous experiment and comprised solvent type, extraction temperature, extraction time, and extraction cycles [53].

A total of ten flavonoids were quantified by HPLC-MS. Four glycosilated flavanones (FGs), namely hesperidin, narirutin, rutin, neohesperidin, and naringin; two flavonoid aglycones, specifically hesperetin and naringenin, and four polimethoxylated flavones (PMFs), namely sinensetin, quercetagenin, nobiletin, and tangeretin. The quantification was done based on the UV-data spectra and [M + H]+ [M-H ]− m/z (Table 3).

Table 3.

Spectral data of flavonoids in orange peel extracts.

| Tentative Identification | Retention Time (min) | UVmax (nm) | MS [M − H]− (m/z) | MS [M + H]+ (m/z) | Products Ions (m/z) |

|---|---|---|---|---|---|

| Rutin [89] | 11.43 | 256, 286, 351 | 611 | 300.8, 342.8 | |

| Narirutin [87,90] | 13.58 | 217, 284, 331 | 579 | 271, 151 | |

| Naringin [87,90] | 18.02 | 224, 283,331 | 579 | 459, 271 | |

| Hesperidin [87,90] | 20.19 | 225, 284, 328 | 609 | 301, 198 | |

| Naringenin [87,89,90] | 24.65 | 226, 284, 325 | 273 | 153 | |

| Hesperetin [89] | 26.57 | 225, 285, 329 | 303 | 285 | |

| Sinensetin [89,90] | 28.04 | 243, 264, 333 | 373 | 358, 343, 312 | |

| Quercetogenin [89] | 31.98 | 250, 272, 335 | 403 | 388, 373 | |

| Nobiletin [89,90] | 35.46 | 248, 268, 334 | 403 | 388, 373 | |

| Tangeretin [87,89,90] | 36.54 | 271, 322 | 373 | 358, 343, 325, 297 |

The highest individual flavonoid levels were observed in Sanguina followed by Navelina and Salustriana peel extracts. Hesperidin and narirutin were the predominant FGs in all the analyzed orange peels, mainly in fresh Sanguina peels with 202.32 mg g−1 and 47.83 mg g−1, respectively (Table 4). The levels of hesperidin and narirutin here obtained by pressurized extraction (ASE) resulted higher than those recently reported in blood Sanguinello (Citrus sinensis L. Osbeck) [90]) and also higher than those quantified in other orange peels using SWE, alkaline hot water, and MAE extraction [35,43,87,89,91].

Table 4.

Mean concentration of flavonoids (mg. g−1 DW) in Navelina, Salustriana, and Sanguina peels, both fresh and after drying treatment: oven-dried (50 °C), oven-dried (70 °C), and freeze-dried (FD).

| Navelina Peel (Citrus sinensis L. Osbeck cv. “Navelina”) |

Salustriana Peel (Citrus sinensis L. Osbeck cv. “Salustriana”) |

Sanguina Peel (Citrus x sinensis var. “Sanguina”) |

||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fresh | RSD | Oven 50 °C | RSD | Oven 70 °C | RSD | FD | RSD | Fresh | RSD | Oven 50 °C | RSD | Oven 70 °C | RSD | FD | RSD | Fresh | RSD | Oven 50 °C | RSD | Oven 70 °C | RSD | FD | RSD | |

| Flavonoids Rutin |

3.24 a | (0.24) | 2.62 b | (9.87) | 1.55 c | (0.45) | 3.11 a | (1.81) | 3.32 a | (2.21) | 2.62 b | (1.62) | 1.11 c | (12.49) | 2.98 a | (2.98) | 5.92 a | (3.21) | 3.94 b | (2.51) | 2.47 c | (7.18) | 5.37 a | (2.98) |

| Narirutin | 28.10 a | (3.11) | 21.56 b | (4.36) | 18.44 c | (11.92) | 27.87 a | (2.51) | 26.87 a | (3.25) | 19.61 b | (0.35) | 17.01 c | (7.75) | 23.92 d | (1.57) | 47.83 a | (3.25) | 39.18 b | (0.66) | 31.38 c | (2.53) | 42.57 d | (1.57) |

| Hesperidin | 124.73 a | (3.63) | 92.97 b | (4.21) | 84.22 c | (0.55) | 113.70 d | (2.73) | 124.00 a | (3.65) | 92.06 b | (0.52) | 92.23 c | (4.24) | 114.97 d | (2.75) | 202.32 a | (3.65) | 165.21 b | (3.81) | 135.49 c | (0.51) | 187.59 d | (2.75) |

| Neohesperidin | 11.62 a | (1.30) | 8.53 b | (3.84) | 7.02 c | (0.26) | 10.90 d | (0.03) | 10.39 a | (1.45) | 7.80 b | (4.87) | 6.79 c | (0.27) | 9.67 a | (5.03) | 18.49 a | (1.45) | 15.49 b | (0.80) | 13.87 c | (0.24) | 17.72 a | (9.03) |

| Naringin | 12.15 a | (2.08) | 7.25 b | (0.12) | 5.80 c | (1.35) | 10.40 d | (2.84) | 10.92 a | (2.32) | 6.57 b | (1.19) | 5.02 c | (0.18) | 10.14 a | (3.22) | 19.44 a | (2.32) | 12.70 b | (1.10) | 10.71 c | (0.15) | 16.32 d | (3.22) |

| Hesperetin | 5.55 a | (0.29) | 6.98 b | (0.93) | 8.87 c | (0.72) | 8.05 d | (2.76) | 4.61 a | (0.15) | 5.04 b | (1.19) | 7.53 c | (6.39) | 6.09 d | (2.91) | 8.21 a | (0.15) | 10.09 b | (0.78) | 12.51 c | (3.22) | 11.20 d | (2.27) |

| Naringenin | 3.77 a | (2.63) | 4.73 b | (5.54) | 7.42 c | (0.10) | 6.13 d | (2.08) | 3.64 a | (2.32) | 4.19 b | (0.62) | 6.93 c | (0.71) | 5.19 d | (1.70) | 3.57 a | (0.15) | 4.90 b | (0.87) | 6.48 c | (2.32) | 5.44 d | (3.22) |

| Sinensetin | 1.64 a | (4.94) | 1.61 a | (0.60) | 2.28 c | (4.44) | 2.05 d | (0.58) | 0.41 a | (12.66) | 0.38 b | (2.53) | 0.95 c | (3.87) | 0.82 d | (0.70) | 0.73 a | (11.66) | 0.69 a | (2.53) | 1.69 c | (3.87) | 1.46 d | (0.70) |

| Quercetogenin | 2.79 a | (3.47) | 3.35 b | (5.04) | 4.98 c | (0.14) | 4.26 d | (2.03) | 2.06 a | (12.56) | 3.02 b | (1.87) | 4.18 c | (6.12) | 3.70 d | (2.43) | 3.67 a | (12.56) | 3.04 a | (2.43) | 7.11 c | (0.17) | 6.36 d | (2.42) |

| Nobiletin | 8.53 a | (3.84) | 9.02 b | (0.21) | 11.91 c | (2.17) | 10.90 d | (0.03) | 7.95 a | (11.13) | 9.28 b | (0.84) | 12.83 c | (5.82) | 11.17 d | (2.64) | 16.51 a | (0.84) | 15.46 a | (1.90) | 26.40 c | (5.82) | 19.88 d | (2.64) |

| Tangeretin | 3.37 a | (1.54) | 4.23 b | (6.63) | 6.34 c | (2.48) | 5.53 d | (2.15) | 3.60 a | (0.32) | 4.00 b | (1.88) | 6.12 c | (4.85) | 5.04 d | (5.20) | 6.41 a | (0.32) | 7.12 b | (1.88) | 10.89 c | (4.85) | 8.96 d | (5.20) |

| TPC (mg GAE·g−1 DW) | 22.75 a | (10.88) | 30.50 b | (6.96) | 42.00 c | (10.10) | 53.29 d | (1.09) | 19.55 a | (3.26) | 27.16 b | (1.87) | 31.27 c | (10.27) | 45.09 d | (3.42) | 41.66 a | (1.17) | 64.36 b | (6.96) | 83.15 c | (1.45) | 117.15 d | (4.64) |

| TFC mg (QE·g−1 DW) | 12.64 a | (1.23) | 16.94 b | (1.04) | 23.33 c | (4.13) | 29.61 d | (6.96) | 10.86 a | (9.88) | 15.09 b | (3.12) | 19.37 c | (4.43) | 25.05 d | (7.25) | 23.14 a | (5.77) | 30.7 5 b | (3.45) | 35.19 c | (1.86) | 46.00 d | (0.44) |

a, b, c, d: Different letters in the same row denote a significant difference according to the Student-Newman-Keuls test, at p < 0.05. TPC total phenolic compounds. GAE—gallic acid equivalent; TFC—total flavonoids content; QE—quercetin equivalent.

Differences in PMF levels (p < 0.05) observed among sinensetin, quercetogenin, nobiletin, and tangeretin in fresh Navelina, Salustriana, and Sanguina peel were in the range 1.64–8.53, 0.41–7.95, and 0.73–16.51 mg g−1 (Table 4), respectively.

In effect, we noted significant differences among the individual flavonoid levels (FGs, aglycones forms, and PMFs) of fresh Navelina, Salustriana, and Sanguina peels that can be primarily attributed to factors such as orange variety, genetic details, cultivar, agroclimatic conditions, or geographical locations (studied in other research [92]). Nevertheless, our results were higher than those reported in the literature when other isolation techniques were used. In this sense, we therefore attribute these greater flavonoids contents to the suitable election of pressurized liquid extraction technique (ASE) improving the yield of FGs, aglycones, and PMFs by 2–5 times compared to data reported with other classical techniques.

Regarding drying treatments, it was observed that dried conditions modified the flavonoids profile of Navelina, Salustriana, and Sanguina peels extracts. The heating temperature impacted the FGs (rutin, narirutin, hesperidin, and naringin) generating decreases after heating, attributed to the cleaving of glycosylated bond fraction [93]. Therefore, for instance, hesperidin from Sanguina peels at OD-50 °C and OD-70 °C decreased at levels that vary from 92.23 to 114.97 mg g−1, respectively. The other FGs showed exactly the same behavior, as can be seen in Table 4.

The opposite evolution was noted in the levels of aglycones and PMFs (hesperetin, naringenin, sinensetin, quercetogenin, nobiletin, and tangeretin) of Navelina, Salustriana, and Sanguina peels, which experienced increases after OD in comparison with the fresh samples. Thus, Sanguina peel reached 12.51, 26.40, and 10.89 mg g−1 in peels oven dried at 70 °C, since heating treatment might release some low molecular weight phenolic compounds. Similar results and the same flavonoids evolution have been reported in orange peels dried at 70–100 °C using simply liquid extraction and subcritical water extraction under high Pressure [40,80,93,94].

With respect to freeze-drying, moderate decreases of the FGs fraction of Navelina, Salustriana, and Sanguina peels, with respect to the fresh ones, were noted. For example, rutin, narirutin, hesperidin, and naringin in FD-Salustriana peels displayed 5.17, 42.57, 187.59, and 16.32 mg g−1, respectively, which were very similar to those quantified in fresh samples (Table 4). It seems obvious that freeze-drying retains, to a large extent, the initial composition. Data are in a good agreement with those showed by Molina-Calle et al. [95] in lyophilized peels of eight different orange varieties.

Freeze-drying also affected the aglycones and PMFs levels from Navelina, Salustriana, and Sanguina, which significantly increased their levels (p < 0.05). The concentration of hesperetin, naringenin, sinensetin, quercetogenin, nobiletin, and tangeretin in freeze-dried samples was around twice that of the fresh peels. For instance, naringenin and nobiletin showed 3.77 and 3.3 mg/g, respectively, in fresh Navelina peel and reached 8.05 and 5.53 mg g−1 in FD-Navelina peel (Table 4). The comparison of results with the few data available in the literature were matched [87,96].

Considered all together, these results suggest that Navelina, Salustriana, and Sanguina peels are a good source of phenolic acids and free and bound flavonoids. Additionally, Sanguina peels were the main phenolic-rich extract, followed by Navelina and Salustriana peels.

Freeze-drying seems to be the most suitable drying technique to retain the initial composition. The evaluation of the two methods of water removal revealed that freeze-dying preserved the concentration of the flavonoids, while oven-drying (at 50 °C and 70 °C) produced significant decreases in the FGs (by oxidation reactions due to temperature exposure) and increases of aglycone forms and PMFs.

3.6. Effect of Drying Treatments on the Antioxidant Activity of Orange Peels

The antioxidant properties of Navelina, Salustriana, and Sanguina peel extracts were evaluated based on their ability to reduce free radicals formed during oxidation processes, using DPPH•, FRAP, and ABTS•+ assays. The effects of oven-drying temperatures (50 °C, 70 °C) and freeze-drying process were also studied, as shown in Table 5.

Table 5.

Antioxidant activity (mg trolox·g−1 DW) and relative standard deviations (RSD) for fresh and dried Navelina, Sanguina, and Salustriana orange peels.

| Navelina Peel (Citrus sinensis L. Osbeck cv. “Navelina”) |

Salustriana Peel (Citrus sinensis L. Osbeck cv. “Salustriana”) |

Sanguina Peel (Citrus x sinensis var. “Sanguina”) |

||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fresh | RSD | Oven 50 °C | RSD | Oven 70 °C | RSD | FD | RSD | Fresh | RSD | Oven 50 °C | RSD | Oven 70 °C | RSD | FD | RSD | Fresh | RSD | Oven 50 °C | RSD | Oven 70 °C | RSD | FD | RSD | |

| DPPH | 44.82 a | (11.94) | 56.30 b | (2.54) | 64.96 c | (4.43) | 71.57 d | (0.84) | 33.62 a | (11.94) | 42.22 b | (2.54) | 47.72 c | (4.52) | 53.68 d | (0.84) | 67.24 a | (11.94) | 80.45 b | (0.95) | 93.38 c | (1.53) | 107.36 d | (0.84) |

| FRAP | 26.89 a | (11.94) | 33.78 b | (2.54) | 42.92 c | (3.58) | 49.49 d | (6.16) | 18.83 a | (11.94) | 23.65 b | (2.54) | 30.04 c | (3.58) | 34.64 d | (6.16) | 38.73 a | (11.94) | 48.64 b | (2.54) | 63.36 c | (0.01) | 71.26 d | (6.16) |

| ABTS | 144.94 a | (2.44) | 213.62 b | (2.65) | 253.35 c | (1.95) | 313.07 d | (0.43) | 122.48 a | (0.56) | 159.08 b | (1.87) | 196.09 c | (0.01) | 239.85 d | (3.23) | 202.69 a | (0.61) | 283.48 b | (0.97) | 364.58 c | (5.54) | 569.23 d | (0.43) |

a, b, c, d: Different letters in the same row denote a significant difference according to the Student-Newman-Keuls test, at p < 0.05. DW—dry weight basis. FD—freeze-dried.

The first conclusion that can be drawn is the positive effect of freeze-drying in the antioxidant activity of the three orange peel extracts when they were compared with to fresh ones. Thus, for instance, fresh Navelina, Salustriana, and Sanguina peels extracts showed an initial DPPH value of 44.82, 33.62, and 67.24 mg trolox·g−1 DW, respectively, whereas freeze-dried samples displayed 71.57, 53.68, and 107.36 mg trolox·g−1 DW. This effect linked the freeze-drying process with an increase of redox-active metabolites and phenolic compounds, whcih play an important role in adsorbing and neutralizing free radicals. The same trend was observed for the ABTS and FRAP values in free and FD orange peels.

Similar results were corroborated by previous studies providing the outstanding antioxidant activity of ASE extracts from freeze-dried citrus peels compared with other drying treatments [67,97,98]. Therefore, it could be inferred that freeze-drying is the most efficient drying approach to preserving, even improving, the bioactive compounds and the antioxidant properties of orange peel extracts.

The DPPH values of oven-dried (50 °C, 70 °C) Navelina, Salustriana, and Sanguina peels increased after heat treatment, as can be seen in Table 5, mainly at 70 °C. Significant differences (p < 0.05) between fresh and oven-dried extracts were observed. For example, for Sanguina peel extracts, the temperature of 50 °C showed an increase of DPPH from 38.73 mg trolox·g−1 DW (fresh) to 48.64 mg trolox·g−1 DW (50 °C) and 63.36 mg trolox·g−1 DW (70 °C). The trend of these results was consistent with those reported for citrus extracts by other researchers [81,86] and should be attributed to the relationship between increases of dried temperatures and a higher generation of breakdown antioxidant products.

The ABTS•+ assay also revealed significant and highest values (p < 0.05) of free radical scavenging activity in FD orange peels extracts. It is worth noting that Sanguina freeze-dried peels reached 569.23 mg trolox·g−1 DW, whereas its fresh extracts just 202.69 mg trolox·g−1 DW.

The drying temperature displayed a profound effect on the antioxidant activity. The ABTS•+ activity values of Navelina, Salustriana, and Sanguina peels dried at 50 °C and 70 °C showed an increase when they were compared with fresh extracts, although the rise was less pronounced than in the case of the freeze-dried treatment. For instance, in oven-dried Sanguina peels, the ABTS•+ values ranged between 283.48 (50 °C) and 364.58 (70 °C) and 569.23 mg trolox·g−1 DW (Table 5). Our results were consistent with those reported by Xu et al. [99] and Jeong et al. [100] who reported significant increases (p < 0.05) in ABTS values and newly formed low molecular weight phenols in citrus peel extract after heat treatment in comparison with unheated peels. Therefore, data suggest that a proper heat treatment could be used to enhance the antioxidant capacity of citrus peel by-products. The higher levels of hesperidin and the rest of aglycone flavonoids and PMFs in oven dried samples at 70 °C, vs. 50 °C, also conditioned these results in the three orange peels studied.

Regarding FRAP chelating activity, once again, noteworthy increases in values (p < 0.05) for freeze-dried of Navelina, Salustriana, and Sanguina peels were observed. Data obtained vary from 26.89, 18.83, and 38.73 for fresh orange peels to 49.49, 34.64, and 71.26 mg trolox·g−1 DW for freeze-dried samples, respectively. This fact suggested that the freeze-drying treatment might produce changes not only for cellular modifications and dissociation or liberation of some phenolic compounds from biological structures, but also the alteration in their chemical structures which could make possible the conversion of insoluble phenols into more soluble forms.

The increase of FRAP values after oven-drying at 50 °C and mainly at 70 °C were observed in Navelina, Salustriana, and Sanguina peels as the temperature increased, which is undoubtedly related to their phenolic content [67]. The chelating activity values of samples dried at 70 °C increased around 1.6 times, reaching 42.92, 30.4, and 63.36 mg trolox·g−1 DW in Navelina, Salustriana, and Sanguina peels, respectively.

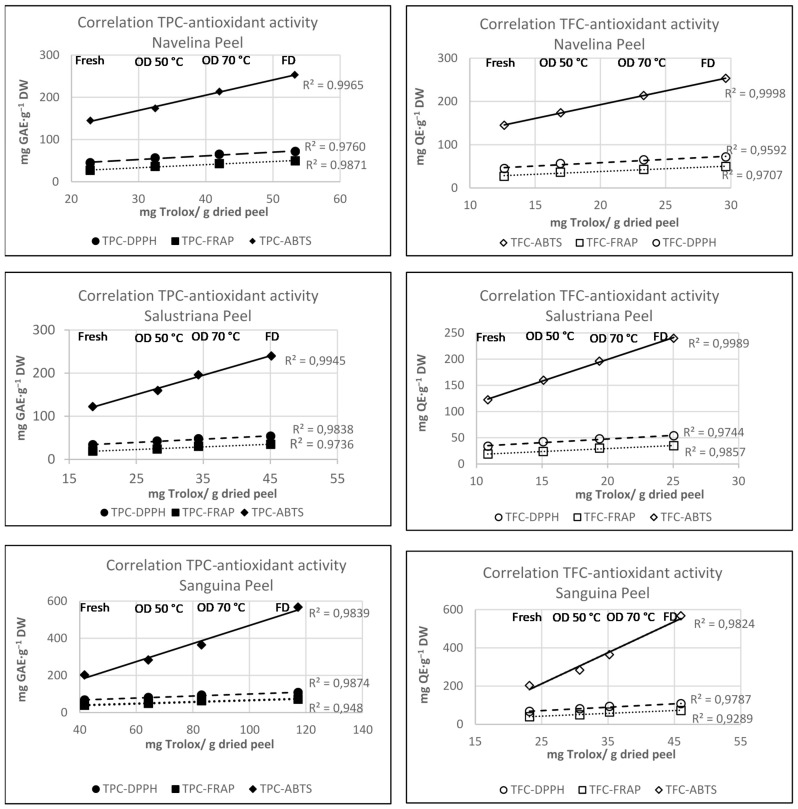

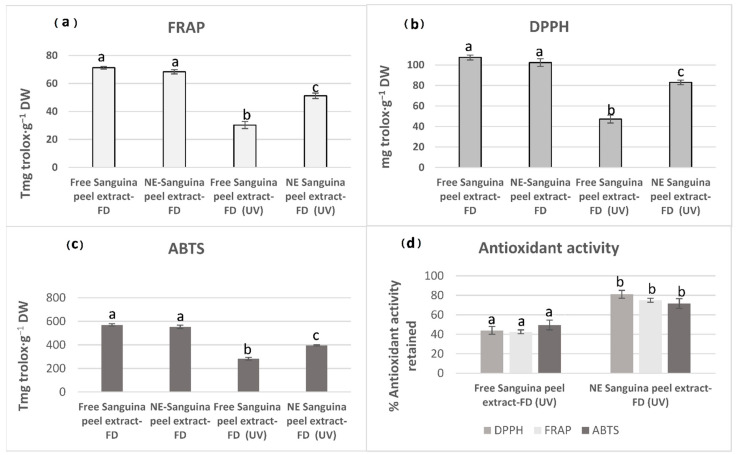

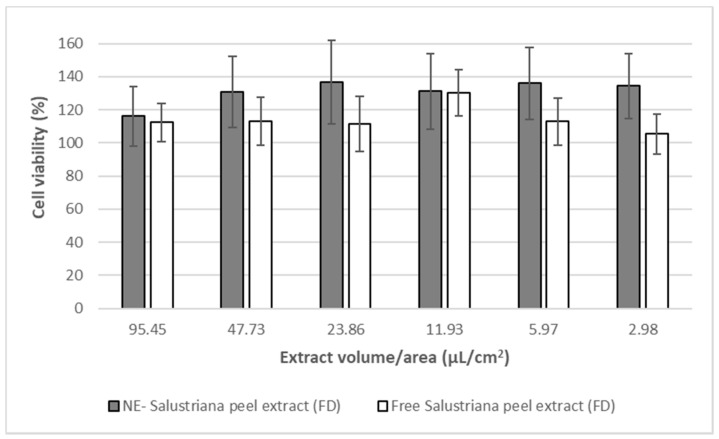

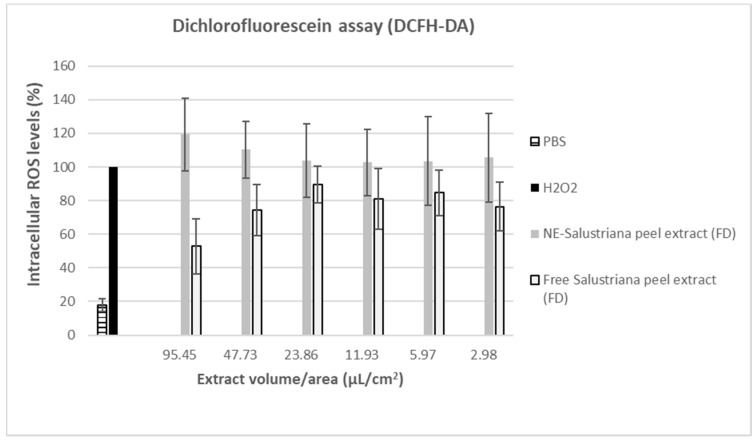

Taken together with the antioxidant activity values, it seems evident that freeze-dried Salustriana peels could be exploited in the food industry due to their richness in bioactive components that wield antioxidant properties. In the near future, it could be incorporated into a large number of applications as an antioxidant opportunity in circular economy for food industry.