Abstract

Environmental and social awareness are the key elements of the sustainable tire industry. End-of-life tire (ELT) waste flow is an important environmental problem worldwide since it produces severe air, water, and soil pollution issues. Significant advancements have been made in ELT management in the last few years. As a result, ELTs should not only be regarded as waste but also as a source of environmentally friendly materials. Besides, sound ELT management has vital importance for circular economy and sustainable development. Over the last decade, ELT management has attracted many researchers and practitioners. Unfortunately, a comprehensive review of the ELT management area is still missing. This study presents the first critical review of the whole ELT management area. It aims to present an extensive content analysis overview of state-of-the-art research, provide its critical analysis, highlight major gaps, and propose the most significant research directions. A total of 151 peer-reviewed studies published in the journals between 2010–2020 are collected, analyzed, categorized, and critically reviewed. This review study redounds comprehensive insights, a valuable source of references, and major opportunities for researchers and practitioners interested in not only ELT material flow but also the whole waste management area.

Graphical abstract

Keywords: Critical review, End-of-life tires, Waste management, Content analysis, Regulations review, Treatment review, Engineering applications, Network design

Introduction

Environmental and social awareness are becoming the key element of the sustainable tire industry. Vehicle tires are a source of pollution throughout their life cycle. End-of-life tires (ELTs1) are considered to be one of the most abundant as well as the most attractive waste from an economic point of view. Nearly one billion ELTs are generated worldwide annually and this waste flow is growing dynamically (Wang et al. 2019; Eurostat 2021). ELT waste flow constitutes more than 2% of the total amount of solid waste (Karaagaç et al. 2017). Only in the European market, more than 300 million passenger and truck tires are replaced annually (ETRMA 2019).

ELT waste flow is an important environmental problem worldwide since it produces severe air, water, and soil pollution issues. This waste flow is not biodegradable and belongs to the category of non-hazardous waste. Unfortunately, improper management of ELTs is still a common phenomenon in many economies in transition and developing economies. In fact, nearly one-half of ELT waste flow is disposed of in landfills without any treatment (Junqing et al. 2020). Landfilling of whole and shredded tires might be the most economically sound management option, but it should not be allowed since it presents a major threat to the environment and public health. Since 1999, ELT landfilling has been legally prohibited by the European landfill directive 1999/31/EC (EU. 1999). After that, in 2000, many policies were presented (e.g., 2000/76/EC, 2000/53/EC) which set out more detailed guidelines for ELT management (EU. 2000a, b). In the meantime, there were synchronizations with global regulations. The Waste Framework Directive (WFD) 2008/98/EC provided concepts and definitions related to ELT management (EU, 2008). According to WFD, management options are prevention, minimization, reuse, recycling, energy recovery, and disposal (Son et al. 2011). WFD was a significant step forward in all relevant aspects of waste management, including ELT as a group of end-of-life vehicle (ELV) parts. Based on these regulations, many countries around the world are in the process of developing their regulations to prolong the service life of tires and reduce their negative impact on the environment.

Sound ELT management has vital importance for circular economy and sustainable development. It requires an ecologically efficient and economically effective waste management scheme. ELT management depends on numerous entities (e.g., tire end-users, private and public companies, treatment facilities) and state-of-the-art technologies to convert waste into valuable products. Today, ELT management is a progressive and well-positioned research area. Besides, according to the reports published by the largest associations of tire producers and recyclers (e.g., ETRMA 2019; CRIA - China Rubber Industry Association 2020; JATMA 2020, 2021), significant advancements have been made in sustainable ELT management in the last few years. As a result, ELTs should not only be regarded as waste but also as a source of environmentally friendly materials.

ELT management has attracted many researchers and practitioners. However, to the best of our knowledge, there is no comprehensive review of the whole ELT management area. This study introduces the first critical review of the economic, environmental, and social issues of ELT management. It aims to present an extensive content analysis overview of state-of-the-art research published in the period 2010–2020, provide their critical analysis, highlight major gaps, and propose the most significant research directions. This critical review offers comprehensive insights, a valuable source of references, and major opportunities for researchers and practitioners interested in not only ELT material flow but also the whole waste management area.

The remaining part of the paper is organized as follows: Section 2 describes a review methodology. The results of the literature review are provided in Section 3. The discussion is given in Section 4. The last section presents the conclusions, major gaps, and significant research directions.

Review methodology

The content analysis is utilized to review the relevant literature. Only peer-reviewed journal papers are reviewed. The search engines, such as Web of Science, Scopus, Taylor and Francis Online, SpringerLink, Wiley Online Library, and Google Scholar, are used to explore the literature.

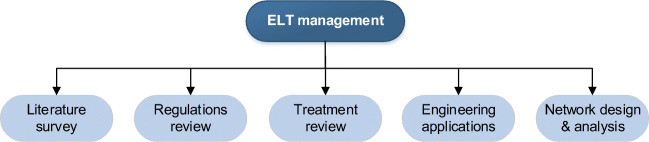

The relevant studies are classified into five categories as follows (Fig. 1):

Literature survey: Relevant state-of-art reviews are provided in this category. They are evaluated by taking into account their primary scope, coverage of the major categories of ELT management, and the number of reviewed papers.

Regulations review: As regulations play an essential role in ELT management, the regulations review studies are overviewed by considering their primary scope and focus, management regulation system, and subject area.

Treatment review: Publications that deal with treatment processes and material analysis are analyzed based on their primary scope, treatment type, and ELT application(s).

Engineering applications: Researches that explore or provide new applications/markets for the ELT industry from this category. They are surveyed based on their primary scope, considered treatment type, and ELT application(s).

Network design and analysis: Studies that are suggesting new methodologies and decision-making approaches for ELT management are grouped into this category. They are reviewed based on their primary scope and focus, considered aspects, and applied method(s).

Fig. 1.

The classification of ELT management studies

This classification aims to categorize the relevant studies and to make them more visible for researchers.

Results

The classification of 151 collected and analyzed researches generates the main framework of the review. Distribution is performed according to the focus of the problems analyzed in the research, i.e., by the field of ELT management to which these papers belong.

Literature survey

ELT management is becoming more and more interesting and challenging for researchers. Table 1 overviews relevant literature reviews regarding their scope.

Table 1.

The summary of the literature survey category

| Author(s) and year | Scope | Category | Reviewed papers | |||

|---|---|---|---|---|---|---|

| RL | TR | EA | NDA | |||

| Presti (2013) | ELTs in civil engineering | – | – | ✓ | – | 80 |

| Shu and Huang (2014) | – | – | ✓ | – | ~80 | |

| Thomas and Gupta (2016) | – | – | ✓ | – | 50 | |

| Wang et al. (2018) | – | – | ✓ | – | ~80 | |

| Li et al. (2019) | – | – | ✓ | – | 90 | |

| Siddika et al. (2019) | – | ✓ | ✓ | – | ~150 | |

| Yadav and Tiwari (2019) | – | – | ✓ | – | ~70 | |

| Du et al. (2020) | – | – | ✓ | – | 134 | |

| Milad et al. (2020) | – | – | ✓ | – | 110 | |

| Picado-Santos et al. (2020) | – | – | ✓ | – | 118 | |

| Roychand et al. (2020) | – | – | ✓ | – | ~130 | |

| Mokhtar et al. (2012) | Material properties | – | ✓ | – | – | ~60 |

| Williams (2013) | – | ✓ | ✓ | – | ~80 | |

| Danon et al. (2015) | Cost-effective thermochemical process | – | – | ✓ | – | 86 |

| Kumaravel et al. (2016) | – | – | ✓ | – | ~50 | |

| Czajczynska et al. (2017) | – | – | ✓ | – | 70 | |

| Martinez et al. (2019) | – | – | ✓ | – | ~60 | |

| Junqing et al. (2020) | – | ✓ | ✓ | – | ~120 | |

| Santos et al. (2020) | – | ✓ | ✓ | – | ~100 | |

| Quek and Balasubramanian (2012) | Fuel for gas turbines | – | – | – | ✓ | 65 |

| Oboirien and North (2017) | – | ✓ | – | ✓ | ~55 | |

| Sienkiewicz et al. (2017) | ELT management legislative | ✓ | – | – | – | ~100 |

| Uriarte-Miranda et al. (2018) | ✓ | ✓ | – | – | 62 | |

| Sienkiewicz et al. (2012) | Alternative fuels | – | – | ✓ | – | ~70 |

| Ramos et al. (2013) | Treatment comparison | – | ✓ | – | – | ~50 |

| Bharat and Dipak (2014) | LCA | – | ✓ | – | – | 44 |

| Saleh and Gupta (2014) | Tire derived carbons | – | – | ✓ | – | 115 |

| Rowhani and Rainey (2016) | Reuse and energy recovery methods | – | ✓ | ✓ | – | ~150 |

| Labaki and Jeguirim (2017) | – | ✓ | ✓ | – | 158 | |

| Iraola-Arreguia et al. (2019) | Demineralization | – | ✓ | – | – | ~200 |

| Mmereki et al. (2019) | Innovative treatment methods | ✓ | ✓ | – | – | 58 |

| Bockstal et al. (2019) | Recycling improvement | – | ✓ | – | – | ~120 |

| Lewandowski et al. (2019) | Reactor efficiency | – | ✓ | ✓ | – | ~150 |

| Our review | Whole ELT management area | ✓ | ✓ | ✓ | ✓ | 151 |

ELTs have very wide applications in civil engineering. Presti (2013) investigated the performances of pavements comprising bitumen from ELT recycling. Shu and Huang (2014) outlined the most frequent applications of recycled ELTs as asphalt paving mixtures and lightweight fillers. Rubberized concrete has good mechanical properties and is often an environmentally friendly material used in the construction industry (Thomas and Gupta 2016; Li et al. 2019; Siddika et al. 2019; Roychand et al. 2020). Wang et al. (2018) discussed the eco-efficiency when rubber is used in asphalt mixtures. Yadav and Tiwari (2019) provided an overview of ELT applications in construction for highway and railway embankments, the base material for roads, and as filling material behind a retaining wall. Milad et al. (2020) and Picado-Santos et al. (2020) reviewed ELT applications in asphalt mixtures. Du et al. (2020) investigated the low-temperature performance of asphalt mixtures.

A significant number of review papers is related to the field of pyrolysis as an increasingly common type of ELT treatment. Mokhtar et al. (2012) analyzed microwave pyrolysis for the conversion of materials to energy. In the same year, Quek and Balasubramanian (2012) and Oboirien and North (2017) pointed out the importance of the pyrolitic process for obtaining the gases used in gas turbines. Williams (2013) concluded that tire pyrolysis oil (TPO) is environmentally and economically advantageous to use in comparison to diesel. Martinez et al. (2013) found that pyrolysis represents an attractive thermochemical process, in the meantime. Thereafter, Danon et al. (2015) discussed oils obtained by ELT pyrolysis as chemical resources. Kumaravel et al. (2016) analyzed TPO as an alternative fuel for diesel engines. Similarly, Czajczynska et al. (2017) discussed the characteristics of TPO as a valuable energy source. In 2020, Junqing et al. and Santos et al. provided several studies. Junqing et al. (2020) analyzed carbon black from ELT pyrolysis. Santos et al. (2020) surveyed the feasibility to convert ELTs into chemical components as an alternative recycling method by focusing on TPO.

The European landfill directive 1999/31/EC has been the key driver for improving ELT management. Sienkiewicz et al. (2017) concluded that many countries established corresponding management systems or standards for increasing resource efficiency and reducing negative environmental impacts. As another legislation-based study from a different angle, Uriarte-Miranda et al. (2018) provided the legislative basis for empirical research regarding the assessment of reverse logistics (RL) processes in ELT management.

In today’s environmental conditions, ELTs should be treated not only as a pollutant but also as a valuable raw material (Sienkiewicz et al. 2012). Ramos et al. (2013) analyzed the efficiency, environmental friendliness, and economic viability of technologies for ELT treatment. Regarding ELTs as a group of ELV parts, Bharat and Dipak (2014) provided a review of applications of the life cycle analysis (LCA) methodology. Saleh and Gupta (2014) analyzed the cost-effectiveness of the utilization of ELTs for wastewater treatment. Later on, Rowhani and Rainey (2016) highlighted the importance of ELT recycling and reusing to sustainable environmental stewardship. Labaki and Jeguirim (2017) pointed out thermochemical processes as attractive and practicable ways for recovering energy and materials from ELTs. In 2019, several studies in the same scope were published. Iraola-Arreguia et al. (2019) found the demineralization was one kind of ELT pyrolysis for improving bio-oil quality. Mmereki et al. (2019) discussed an effective ELT management system from technical, environmental, economic, legal, and institutional aspects. Bockstal et al. (2019) analyzed physical and chemical processes for ELT recycling. Lewandowski et al. (2019) described various types of reactors for ELT pyrolysis.

Table 1 shows that the available review papers are focused only on one or two categories of ELT management. Most of the review papers are related to pyrolysis as chemical treatment and ELT applications in civil engineering. Besides, only a few review papers analyzed regulations and network design. Finally, to the best of our knowledge, there is no comprehensive review of the whole ELT management area.

Regulations review

In terms of worldwide recycling rates of ELTs, the EU takes first place in the list (Gigli et al. 2019). The EU already has appropriate regulations and organizations for ELT management. Besides, there are three different ELT management regulation systems worldwide:

Extended producer responsibility (EPR)—tire manufacturers and importers are responsible for ELT collection and treatment

Tax system (TS)—ELT collection and treatment are financed through consumer taxes

Free-market system (FMS)—local regulations define ELT collection and treatment

In Europe, EPR is the most common in ELT collection and treatment. Santini et al. (2011) found that ELT removal from vehicles needed to fulfill rigorous eco-efficiency targets of the Directive 2000/53/EC. Sohaney et al. (2012) provided analyses of ELT noise in the case of heavy trucks. Bravo and Brito (2012) considered that 5%, 10%, and 15% of the volume of natural aggregate can be replaced by aggregate derived from ELTs. Afterward, Uruburu et al. (2013) highlighted the strong role of non-profit organizations in ELT management. Elnour and Laz (2014) found that lawfully labeling tires could reduce ELT quantity. Hiratsuka et al. (2014) concluded that the Japan automobile tire manufacturer association gave voluntary contributions for the collection of ELTs. In addition to this, Niza et al. (2014) investigated the implementation of the EPR concept in Portugal. Zhang et al. (2016) analyzed legislative barriers and incentive measures to support local enterprises in pyrolysis initiatives. Rodrigues et al. (2016) presented an extended waste input-output model to assess the economic, environmental, and social impacts of the EPR system. Karaagaç et al. (2017) analyzed the degree of ELT recycling in Turkey. Park et al. (2018) concluded that the Colombian EPR system increased the number of ELTs collected over the last 5 years. Malyshkov et al. (2019) analyzed recycling standards for ELTs in Russia. Winternitz et al. (2019) found that the best recycling results were achieved with quantitative targets and clearly defined status of ELT management. Zorpas (2020) promoted the WFD strategies for improving the quality of living conditions, especially in urban areas.

Although EPR is dominant, some studies analyzed TS and FMS regulation systems. Samolada and Zabaniotou (2012) concluded that Greece had nevertheless adopted the EPR system despite the numerous benefits of TS. As a different approach, Sienkiewicz et al. (2012) described different organizational approaches for ELT management in the EU and some possible usages of ELTs as a source of raw materials or alternative fuels. Antoniou and Zabaniotou (2013) outlined general guidelines for EU member states related to ELT disposal. Zabaniotou et al. (2014) continued research to improve pyrolysis due to deficient market analysis, legislative barriers, economic instability, and public acceptance. Later on, Torreta et al. (2015) analyzed treatment and disposal schemes with ELTs in Italy and Romania. Alwaeli (2016) pointed out that Poland was the first European country to introduce an ELT management system, which was initiated by tire manufacturers and importers. Clar-Garcia et al. (2016) studied the European regulations devoted to the reduction of tire noise depending on the age structure of ELTs. Xie et al. (2016) concluded that tire manufacturers took measures to modify the structure of tires to avoid uneven wear. Godlewska (2017) analyzed increased imports of ELTs into Poland. Sienkiewicz et al. (2017) concluded that the establishment of the restrictive regulations, monitoring of improper warehousing, EPR, and TS had a pivotal role in the progress of ELT recovery. In 2018, Uriarte-Miranda et al. (2018) suggested an integrated model by considering regulations and policies in several countries and regions.

A comprehensive summary of the regulations’ review category is presented in Table 2. The table shows that most of the papers are related only to the treatment of ELTs. Besides, only a few papers took into account the strong connection between RL and ELT regulation. Finally, the papers are only focused on the economic and environmental components of sustainability, while the social component is completely neglected.

Table 2.

The summary of the regulations review category

| Author(s) and year | Scope | System | Focus | Subject area | ||||

|---|---|---|---|---|---|---|---|---|

| EPR | TS | FMS | COL | TRE | APP | |||

| Santini et al. (2011) | ELT recycling and recovery | ✓ | – | – | – | ✓ | – | Italy |

| Sohaney et al. (2012) | Noise from heavy trucks | ✓ | – | – | ✓ | ✓ | – | Europe |

| Bravo and Brito (2012) | ELT cement granulate | ✓ | – | – | – | ✓ | ✓ | Portugal |

| Uruburu et al. (2013) | ELT management | ✓ | – | – | ✓ | ✓ | ✓ | Spain |

| Elnour and Laz (2014) | ELT quantity reduction | ✓ | – | – | ✓ | ✓ | – | Saudi Arabia |

| Hiratsuka et al. (2014) | Recycling improvement | ✓ | – | – | – | ✓ | – | Japan |

| Niza et al. (2014) | ELT management | ✓ | – | – | – | ✓ | – | Portugal |

| Zhang et al. (2016) | ELT pyrolysis | ✓ | – | – | – | ✓ | – | Global |

| Rodrigues et al. (2016) | EPR system financing | ✓ | – | – | – | ✓ | – | Global |

| Karaagaç et al. (2017) | ELT quantity | ✓ | – | – | – | ✓ | ✓ | Turkey |

| Park et al. (2018) | Cost-effectiveness of EPR | ✓ | – | – | – | ✓ | – | Colombia |

| Malyshkov et al. (2019) | EPR and recycling standards | ✓ | – | – | ✓ | ✓ | – | Russia |

| Winternitz et al. (2019) | EPR system comparison for ELTs | ✓ | – | – | – | ✓ | – | Belgium, Italy, The Netherlands |

| Zorpas (2020) | Energy managing in TPO | ✓ | – | – | – | ✓ | ✓ | EU |

| Samolada and Zabaniotou (2012) | ELT pyrolysis | ✓ | ✓ | – | – | ✓ | ✓ | Greece |

| Sienkiewicz et al. (2012) | Alternative fossil fuels | ✓ | ✓ | ✓ | – | – | ✓ | EU |

| Antoniou and Zabaniotou (2013) | Features of ELT pyrolysis | ✓ | ✓ | ✓ | – | ✓ | ✓ | EU |

| Zabaniotou et al. (2014) | Pyrolisis improvement | ✓ | ✓ | – | – | ✓ | – | EU |

| Torreta et al. (2015) | ELT management schemes | ✓ | ✓ | ✓ | – | ✓ | – | Italy, Romania |

| Alwaeli (2016) | ELT recycling level analysis | ✓ | – | ✓ | – | ✓ | – | Poland |

| Clar-Garcia et al. (2016) | Noise and tire age relationship | ✓ | ✓ | – | – | ✓ | – | EU |

| Xie et al. (2016) | Tread depth | ✓ | ✓ | – | ✓ | ✓ | – | Global |

| Godlewska (2017) | ELT recycling | – | – | ✓ | – | ✓ | – | Poland |

| Sienkiewicz et al. (2017) | Regulations in ELT recovery | ✓ | ✓ | – | – | ✓ | – | EU |

| Uriarte-Miranda et al. (2018) | RL improvement in ELT management | ✓ | ✓ | ✓ | – | ✓ | – | Mexico, Russia, Japan, EU |

Treatment review

Inadequate ELT treatment creates major environmental issues. Besides, landfilling might be the most economically sound management option, but it should not be allowed since it presents a major threat to the environment and public health.

ELT treatment and improvement of environmental conditions are some of the most important concerns of sustainable business (Sadiktsis et al. 2012; Ghasemzadeh et al. 2020). In practice, four types of ELT treatment are applied: pyrolysis, recycling, retreading, and energy recovery.

Many researchers have focused on pyrolysis as an attractive ELT treatment. ELT pyrolysis is important for the circular economy since it can provide materials for the production of rubber from which tires are made. Abdul-Raouf et al. (2010) outlined that pyrolysis could be very appropriate for complex materials, such as tires. Sienkiewicz et al. (2012) and Williams (2013) noticed a growing interest in pyrolysis as a technology for producing TPO, char, and gas products. Due to the energy crisis and environmental degradation, Kandasamy and Gokalp (2014) analyzed energy recovery from not biodegradable waste, such as ELTs. Thereafter, Hita et al. (2016) claimed that ELT pyrolysis was the most environmentally friendly option for ELT treatment. Kordoghli et al. (2017) found that the temperature had an important impact on the gas quality. Cherbański et al. (2017) studied the kinetic reaction of ELT pyrolysis. Martinez et al. (2019) examined the performances of carbon black obtained by ELT pyrolysis. Wang et al. (2019) proposed a new protocol for high-value reusing of ELTs. In addition to these, Zhang et al. (2019) analyzed using carbon from ELT pyrolysis for wastewater treatment. Abdallah et al. (2020) found that the produced pyrolysis oil could replace conventional liquid fuels. Buadit et al. (2020) evaluated the potential environmental impacts of an ELT pyrolysis plant in Thailand by using the LCA method. For Sathiskumar and Karthikeyan (2019) and Junqing et al. (2020), pyrolysis is a promising thermochemical process to deal with ELT waste flow.

Recycling is a very common ELT treatment. Recycled ELTs are used in both engineering and non-engineering applications, from raw materials, through semi-finished products to packaging. Gupta et al. (2011a, b) and Derakhshan et al. (2017) pointed out the high potential of recycled ELTs for wastewater treatment applications. Ramarad et al. (2015) analyzed progress in ELT recycling with particular attention to the incorporation of waste tire rubber into polymeric matrices. Kardos and Durham (2015) investigated the properties of rubberized concrete. Depaolini et al. (2017) proved that older ELTs were less favorable due to their chemical composition. In the meantime, Tsai et al. (2017) analyzed ELTs as a supplement of conventional fossil fuel to attain a positive impact on environmental sustainability in Taiwan. Rashid et al. (2019) identified the great potential of using recycled ELTs in concrete as a low- and medium-strength material. Yamashita et al. (2020) analyzed the chemical reactions in the recycling of ELTs.

Retreading is one of the popular approaches for sustainable environmental stewardship of ELTs. This is a process of replacing the spent tread (outer layer of the tire) with a new one by vulcanization to prolong their life cycle exploitation. Retreading is especially beneficial for used truck tires since they could be processed three to four times (Dabić-Ostojić et al. 2014). This type of treatment can have significant environmental and economic sustainability effects (Abdul-Kader and Haque 2011). Bazan et al. (2015) found that retreading offers the most resource-efficient strategy for ELTs because it provided the possibility to save both material and energy. Ortíz-Rodríguez et al. (2017) found the strongest environmental impacts were associated with retreading and recycling of ELTs. Lonca et al. (2018) revealed that extending the lifetime through retreading and recycling improves the circularity of ELTs. Later on, Mrad and El-Samra(2020) analyzed different strategies for ELT management in Lebanon and concluded that retreading is the most economically, environmentally, and socially appropriate treatment.

Energy recovery is an attractive treatment commonly related to the combustion of ELTs in cement kilns. Feraldi et al. (2013) applied LCA to compare different ELT treatment options in the USA context. Aziz et al. (2018) concluded that TPO obtained from pyrolytic reactors could be used in industrial furnaces, power plants, and steam boilers.

The summary of the treatment review category is given in Table 3. As can be seen from this table, ELT pyrolysis and recycling are the most common treatment options. The waste hierarchy emphasizes the reuse and extension of the tire life cycle as a primary ELT management scheme. However, retreading is put into focus in only a few studies. On the other hand, economic efficiency is the primary comparison criterion in most studies. Sustainable ELT treatment should take into account the environmental, economic, and social dimensions of investigated waste flow.

Table 3.

The summary of the treatment review category

| Author(s) and year | Scope | Treatments type | Application(s) | |||

|---|---|---|---|---|---|---|

| PYR | REC | RET | ER | |||

| Abdul-Raouf et al. (2010) | Factors affecting prod. composition | ✓ | – | – | – | TPO, gas, char |

| Gupta et al. (2011a, b) | Recycled ELT usage | – | ✓ | – | – | Wastewater treatment |

| Feraldi et al. (2013) | Treatment option comparison | – | – | ✓ | ✓ | Civil engineering, fuel |

| Williams (2013) | Pyrolysis product characteristics | ✓ | – | – | – | TPO, gas, char |

| Kandasamy and Gokalp (2014) | ELT treatment improvement | ✓ | – | – | – | TPO, gas |

| Bazan et al. (2015) | Treatment cost analysis | – | – | ✓ | ✓ | Civil engineering |

| Kardos and Durham (2015) | ELT utilization improvement | – | ✓ | – | – | Civil engineering |

| Ramarad et al. (2015) | Polymer blends | – | ✓ | – | – | – |

| Hita et al. (2016) | TPO upgrading characteristics | ✓ | – | – | – | TPO, gas |

| Cherbański et al. (2017) | ELT pyrolysis kinetics | ✓ | – | – | – | TPO, rubber |

| Depaolini et al. (2017) | Recycled rubber characterization | – | ✓ | – | – | Rubber, playgrounds |

| Derakhshan et al. (2017) | Recycled ELT usage | – | ✓ | – | – | Wastewater treatment |

| Kordoghli et al. (2017) | Product quality | ✓ | – | – | – | TPO, gas |

| Ortíz-Rodríguez et al. (2017) | Management option comparison | – | – | ✓ | ✓ | Civil engineering, fuel |

| Tsai et al. (2017) | ELT recycling status | – | ✓ | – | – | TPO, gas, carbon black |

| Aziz et al. (2018) | Pyrolitic reactors characteristics | ✓ | – | – | – | TPO, char |

| Lonca et al. (2018) | Treatment environmental benefits | – | – | ✓ | ✓ | Civil engineering |

| Zhang et al. (2018) | Pyrolysis efficiency improvement | ✓ | – | – | – | TPO, carb. black, char |

| Martinez et al. (2019) | Carbon black production | ✓ | – | – | – | Carbon black |

| Rashid et al. (2019) | Rubberized concrete properties | – | ✓ | – | – | Civil engineering |

| Sathiskumar and Karthikeyan (2019) | ELT pyrolysis methods | ✓ | – | – | – | TPO, gas, char |

| Wang et al. (2019) | High-value temperature pyrolysis | ✓ | – | – | – | Carbon black, graphene |

| Zhang et al. (2019) | Pyrolytic carbon preparation | ✓ | – | – | – | Carbon black |

| Abdallah et al. (2020) | ELT pyrolysis products analysis | ✓ | – | – | ✓ | TPO, gas |

| Buadit et al. (2020) | Pyrolysis environmental impacts | ✓ | – | – | – | Energy |

| Junqing et al. (2020) | Pyrolysis efficiency improvement | ✓ | – | – | – | TPO, carbon black |

| Mrad and El-Samra(2020) | Management option comparison | ✓ | ✓ | ✓ | ✓ | Fuel |

| Yamashita et al. (2020) | Recycled tire properties | – | ✓ | – | – | – |

Engineering applications

Improper management of ELTs is still a common phenomenon. It produces serious air, water, and soil pollution issues. Fortunately, there are many environmentally friendly applications of ELT treatment products. Besides, ELT treatment can provide materials that have a wide range of applications from everyday life to commercial and industrial applications. As a result, it is of great interest to explore new applications/markets for the ELT industry.

In 2010, Edinçliler et al. (2010) found that processing techniques and ELT content significantly affect the mechanical properties of used tires-sand mixtures in soils. Fiksel et al. (2011) concluded that the usage of ELTs in civil engineering applications is an environmentally suitable alternative. In the years ahead, Centonze et al. (2012) and Guo et al. (2017) found that there are great possibilities to use steel and rubber from ELTs in civil engineering. Chyan et al. (2013) analyzed ELTs as pollutant removal material from the constructed wetland. Undri et al. (2013), Song et al. (2018), and Ma et al. (2020) analyzed characteristics of limonene as typical valuable chemical products of ELT pyrolysis. Torreta et al. (2015) concluded that ELT treatment has considerable ecological importance. Ayanoglu and Yumrutas (2016) claimed that lime TPO mixture had better results compared to gasoline and diesel fuels for diesel engines. Bičáková and Straka (2016) concluded that some pyrolysis products can serve as heating oil or a source for repairing asphalt surfaces. Fakhri (2016) found that the replacement of the sand by ELT particles in concrete pavement reduced water absorption. Derakhshan et al. (2017) showed the high potential of recycled ELTs for a variety of wastewater treatment applications. Hürdoğan et al. (2017) analyzed how to improve the effects of ELT pyrolysis. Machin et al. (2017) analyzed the energetic valorization of ELTs in Brazil in contexts of job creation, environmental footprint reduction, and electricity generation. Gnanaraj et al. (2018) promoted environmental sustainability through the use of ELTs in the battery industry. After 2018, several studies were published in the same scope. Antoniou and Zorpas (2019) found that ELT waste flow could be a valuable source for energy recovery. Brandsma et al. (2019) found some kinds of paraffin might end up in recycled products. Grioui et al. (2019) analyzed usage of olive oil in ELT pyrolysis for the production of upgraded pyrolytic oil as an alternative fuel. Uyumaz et al. (2019) showed that the TPO-diesel blend gave acceptable performances compared to diesel fuel. Karagoz et al. (2020b) investigated the optimal percentage of TPO in diesel fuel. Liu et al. (2020) provided a brief overview of the engineering properties and environmental effects of recycled ELTs. Narani et al. (2020) concluded that textile fibers from ELTs could enhance the geotechnical characteristics of the expansive soil. Toteva and Stanulov (2020) explored environmentally friendly applications of ELT pyrolysis.

Lately, ELT recycling has attracted more and more attention. Recycled tire rubber is being used in new tires, in tire-derived fuel, in civil engineering applications and products, in molded rubber products, in agricultural uses, recreational and sports applications, and rubber-modified asphalt applications. Thus, the benefits of using rubber-modified asphalts are being more widely experienced and recognized. The incorporation of tires into asphalt is likely to increase, as indicated by an increasing number of researches in this area.

In addition to many well-known, mostly engineering applications, there are many applications where whole, unprocessed ELTs are used. The most interesting and frequent ELT applications are boat protection (Abdul-Kader and Haque 2011), conveyor belts (Aziz et al. 2018), footwear industry (Machin et al. 2017; Aziz et al. 2018; Araujo-Morera et al. 2019), gardening (Fıglali et al. 2015; Singh et al. 2019; Zorpas 2020), lawn grounds (Symeonides et al. 2019), packing material (Thomas and Gupta 2015; Karaagaç et al. 2017; Heidari and Younesi 2020), playground flooring (Bravo and Brito 2012; Girskas and Nagrockienė 2017; Brandsma et al. 2019), thermal and acoustic isolation (Abdul-Kader and Haque 2011; Asaro et al. 2018; Araujo-Morera et al. 2019), vibration reduction on railway tracks (Sol-Sánchez et al. 2014), and wagon wheels (Girskas and Nagrockienė 2017).

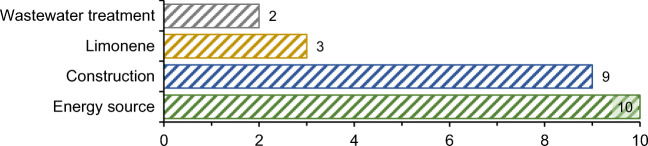

The engineering applications category is summarized in Table 4. As can be seen from this table, the most common engineering applications of ELTs are civil engineering and energy sources. ELT recycling is mainly associated with civil engineering applications even though recycled rubber could also be used in other industries. Besides, not enough emphasis is given to explore new fields of applications. Also, there are no researches on ELT applications in logistics activities (e.g., for logistics units in material flows).

Table 4.

The summary of the engineering applications category

| Author(s) and year | Scope | Treatment type | Application(s) | |

|---|---|---|---|---|

| Pyrolysis | Recycling | |||

| Edinçliler et al. (2010) | Embankment constructions | – | ✓ | Civil engineering |

| Fiksel et al. (2011) | Environmental benefits | – | ✓ | Civil engineering |

| Centonze et al. (2012) | Modified rubber concrete properties | – | ✓ | Concrete |

| Chyan et al. (2013) | Recycled ELT usage | – | ✓ | Wastewater treatm. |

| Undri et al. (2013) | Limonene production improvement | ✓ | – | Limonene |

| Torreta et al. (2015) | ELT management | – | ✓ | Civil engineering |

| Ayanoglu and Yumrutas (2016) | Sulfur amount, environmental protection | ✓ | – | TPO, fuel |

| Bičáková and Straka (2016) | Preparation process activities | ✓ | – | TPO, asphalt |

| Fakhri (2016) | Modified rubber concrete properties | – | ✓ | Concrete |

| Derakhshan et al. (2017) | Recycled ELT usage | – | ✓ | Wastewater treatm. |

| Guo et al. (2017) | Modified rubber concrete properties | – | ✓ | Concrete |

| Hürdoğan et al. (2017) | ELT pyrolysis effects | – | ✓ | Fuel |

| Machin et al. (2017) | Energetic valorization | ✓ | – | Civil engineering |

| Gnanaraj et al. (2018) | Anode in lithium-ion batteries | – | ✓ | Carbon black |

| Song et al. (2018) | Limonene production improvement | ✓ | – | Limonene |

| Antoniou and Zorpas (2019) | TPO in diesel fuel | ✓ | – | TPO, fuel |

| Brandsma et al. (2019) | Product characteristics | – | ✓ | Paraffines |

| Grioui et al. (2019) | ELT pyrolysis products | ✓ | – | TPO |

| Ma et al. (2020) | Limonene production improvement | ✓ | – | Limonene |

| Uyumaz et al. (2019) | Sulfur amount, environmental protection | ✓ | – | TPO, fuel |

| Karagoz et al. (2020b) | TPO in diesel fuel | ✓ | ✓ | TPO, fuel |

| Liu et al. (2020) | Recycled ELT applications | – | ✓ | Civil engineering |

| Narani et al. (2020) | Expansive soil characteristics | – | ✓ | Civil engineering |

| Toteva and Stanulov (2020) | Environmentally friendly applications | ✓ | ✓ | Energy source |

Network design and analysis

There are a significant number of studies that applied existing models or provided new methodologies to solve problems related to ELT management. In 2010, Sasikumar et al. (2010) developed the mixed-integer non-linear programming (MINLP) model for maximizing the profit of a multi-echelon reverse logistics network for retreading truck tires. Thereafter, Abdul-Kader and Haque (2011) presented an agent-basedmodeling and simulation approach for improving ELT retreading. Aranda et al. (2012) investigated environmentally friendly locations of ELT concept treatment plants.

De Souza and D’Agosto (2013) proposed a value chain analysis for RL supply chain management and explored the financial benefits of sending ELTs to the cement industry. Kannan et al. (2014) presented a decision-making framework to assess ELT management drivers in the Indian context. Dabić-Ostojić et al. (2014) introduced a model based on Bayesian belief networks for making tire retreading-related decisions. Dhouib (2014) used the fuzzy MACBETH to rank remanufacturing alternatives for ELTs.

In 2015, Bazan et al. (2015) presented an economic order quantity-based model for minimizing the costs of the tire retreading industry in Canada, which captured the costs for greenhouse-gasemissions and energy usage. Similarly, Radhi and Zhang (2015) developed MINLP models to simultaneously determine the optimal configuration of ELT remanufacturing networks and return quality decisions under uncertainty. Subulan et al. (2015) formulated a sustainable logistics network design model for tire closed-loop supply chains (CLSC).

Demirel et al. (2016) proposed a mixed-integer linear programming (MILP) model with different scenarios for the number of ELVs in the future. Pedram et al. (2016) presented the MILP model of a multi-echelon CLSC for the tire industry in Tehran, Iran. They used a simple scenario-based approach to represent uncertainties in demand, return rate, and quality of ELTs.

In 2017, Afrinaldi et al. (2017) used a multi-objective genetic algorithm (GA) to determine preventive replacement schedules for bus tires. Amin et al. (2017) formulated a single-objective MILP model for ELT remanufacturing for a real network in Toronto, Canada. Costa-Salas et al. (2017) analyzed the ELT recycling process according to waste collection, processing, and customer zones from a Colombian city. Simic and Dabic-Ostojic(2017) developed an interval-parameter chance-constrained programming model for optimizing long-term purchasing, retreading, and inventory planning in used tire management systems under multiple uncertainties. Simić et al. (2017) introduced an interval-parameter semi-infinitive programming model for used tire management and planning that can successfully handle real-life complex uncertainties.

Several studies dealt with network design and analysis issues of ELT management in 2018. Banguera et al. (2018) provided a MILP model for a reverse logistics network for used tires to meet the EPR national law in Chile. Ebrahimi (2018) developed a stochastic multi-objective programming model for the CLSC network design problem and took into consideration sustainability aspects and quantity discounts under uncertainty. Fathollahi-Fard et al. (2018) formulated a tri-level programming model based on the static Stackelberg game between manufacturers, distributors, and collectors to optimize location-allocation decisions in a tire CLSC. Hajiaghaei-Keshteli et al. (2018) modeled a CLSC of the tire industry as a two-stage stochastic program. Pereira et al. (2018) introduced a forecasting model to estimate the volume and time of used tire returns. Sahebjamnia et al. (2018) formulated a multi-objective MILP model to solve the tire CLSC problem by considering economic, environmental, and social dimensions. Saxena et al. (2018) developed a fuzzy multi-objective mixed-integer programming model to determine organizational and policy insights for a tire remanufacturing SC.

In 2019, Oyola-Cervantes and Amaya-Mier(2019) used the MILP approach to design an RL network for off-the-road tires discarded from the mining industry. Symeonides et al. (2019) compared existing ELT waste management strategies for Cyprus. Zang et al. (2019) conducted an economic analysis of ELT gasification by simulation processes in two types of gasification models: semi-empirical and one-dimensional kinetic models.

In the years ahead, Abdolazimi et al. (2020) proposed a three-objective MILP model for the selection of ELT suppliers for recycling plants based on the time delivery, total profit, and environmental impact. Ghasemzadeh et al. (2020) established MILP formulations for real-life CLSC applications in the Iranian tire industry. Nowakowski and Król (2020) assessed possible scenarios of ELT collection and transportation in Poland including their processing like cutting, baling, and packing. Yu et al. (2020) used the AHP method for investigating characteristics of rubberized asphalt mixtures.

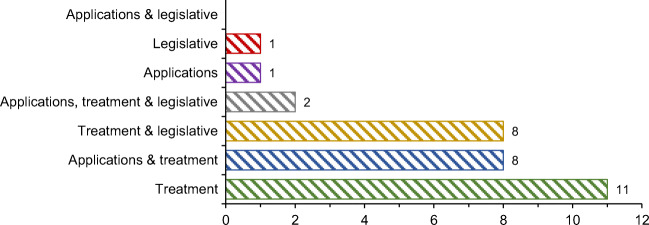

The review of the network design and analysis category is summarized in Table 5. The surveyed ELT management methodologies are rarely tailored for ELTs (Yadollahinia et al. 2018; Xiao et al. 2019; Karagoz et al. 2020a). Only one study took into account the third pillar of sustainable development. The others completely ignored the social aspect of ELT management. Also, the vast majority of the reviewed NDA studies neglected the multi-layer hierarchical nature of ELT management-related problems. Besides, only a few studies integrated legislation, treatments, and applications as three key elements of ELT management. Finally, the available methodologies and decision-making approaches are mostly related only to ELT treatment.

Table 5.

The summary of the network design and analysis category

| Author(s) and year | Scope | Goal function(s) | Method(s) | Focus | ||||

|---|---|---|---|---|---|---|---|---|

| Aspect | Type | |||||||

| Max | Min | LEG | APP | TRE | ||||

| Sasikumar et al. (2010) | Retreading facility locations | Profit | ✓ | – | MINLP | – | – | ✓ |

| Abdul-Kader and Haque (2011) | Remanufacturing and retreading | Profit, environmental | ✓ | ✓ | ABMS | ✓ | – | ✓ |

| Aranda et al. (2012) | ELT treatment plant locations | Distance | – | ✓ | CWA | ✓ | – | ✓ |

| De Souza and D’Agosto (2013) | RL for ELT | Cost | – | ✓ | VCA | – | ✓ | – |

| Kannan et al. (2014) | ELT management drivers | – | – | – | ISM | ✓ | – | – |

| Dabić-Ostojić et al. (2014) | Tire retreading | Distance | – | ✓ | BN | ✓ | ✓ | ✓ |

| Dhouib (2014) | ELT remanufacturing strategy | – | – | – | Fuzzy MACBETH | – | ✓ | ✓ |

| Bazan et al. (2015) | Tire RL inventory management | Cost | – | ✓ | EOQ | – | ✓ | ✓ |

| Radhi and Zhang (2015) | Remanufacturing production network | Profit | ✓ | – | MINLP | ✓ | ✓ | ✓ |

| Subulan et al. (2015) | Tire manufacturing CLSC | Profit, environmental | ✓ | ✓ | MILP, IFGP | – | – | ✓ |

| Demirel et al. (2016) | ELV reverse logistics network | Cost | – | ✓ | MILP | ✓ | – | ✓ |

| Pedram et al. (2016) | Tire management CLSC | Profit | ✓ | – | MILP | – | – | ✓ |

| Afrinaldi et al. (2017) | Tire replacement schedule | Profit, environmental | ✓ | ✓ | MOP, GA | – | – | ✓ |

| Amin et al. (2017) | Tire management CLSC | Profit | ✓ | – | MILP, DT | – | – | ✓ |

| Costa-Salas et al. (2017) | Tire recycling network | Profit, environmental | ✓ | ✓ | DES, MOP | – | – | ✓ |

| Simic and Dabic-Ostojic(2017) | Used tire management and planning | Profit | ✓ | – | IPCCP | – | – | ✓ |

| Simić et al. (2017) | Used tire management and planning | Profit | ✓ | – | IPSIP | – | ✓ | ✓ |

| Banguera et al. (2018) | RL for used tires | Cost | – | ✓ | MILP | ✓ | – | ✓ |

| Ebrahimi (2018) | Tire management CLSC | Cost, environmental, awareness | ✓ | ✓ | SMOP, ε-constrain | ✓ | – | ✓ |

| Fathollahi-Fard et al. (2018) | Tire management CLSC | Cost | – | ✓ | TLP, SA, VNS, KA, SFS | – | – | ✓ |

| Hajiaghaei-Keshteli et al. (2018) | Tire management CLSC | Cost, risk | – | ✓ | TSSP, PSO, GA | – | ✓ | ✓ |

| Pereira et al. (2018) | ELT quantity forecasting | – | – | – | TFM, ARIMA | – | – | ✓ |

| Sahebjamnia et al. (2018) | Tire management CLSC | Cost, environmental, social | – | ✓ | MOP, MILP, GA, SA, TAS, RDA, WWO | – | – | ✓ |

| Saxena et al. (2018) | Tire remanufacturing SC | Profit, coverage, flexibility, env. | ✓ | ✓ | FMOMIP | – | – | ✓ |

| Oyola-Cervantes and Amaya-Mier(2019) | Off-the-road tire RL | Profit | ✓ | – | MILP | – | ✓ | ✓ |

| Symeonides et al. (2019) | ELT strategy selection | – | – | – | SWOT | – | – | ✓ |

| Zang et al. (2019) | ELT gasification | Cost | – | ✓ | TCM | – | ✓ | ✓ |

| Abdolazimi et al. (2020) | Tire management CLSC | Delivery, profit, environmental | ✓ | ✓ | MOP, MILP, ε-constrain | – | – | ✓ |

| Ghasemzadeh et al. (2020) | Tire management CLSC | Profit, environmental | ✓ | ✓ | MILP, ε-constrain | – | ✓ | ✓ |

| Nowakowski and Król (2020) | ELT collection | – | – | – | AHP, PROMETHEE | ✓ | – | ✓ |

| Yu et al. (2020) | CRMA mixing sequence | – | – | – | AHP | – | ✓ | |

Discussion

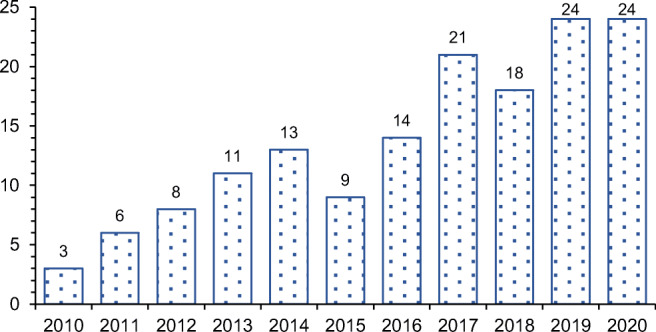

The annual distribution of researches in the ELT management area between 2010 and 2020 is given in Fig. 2. As can be seen from Fig. 2, there is a significant increase in the number of researches from 2017. Besides, over the last 2 years, almost one-third of the analyzed papers have been published. This indicates a growing interest in the ELT management area.

Fig. 2.

The distribution of papers per year across the period 2010–2020

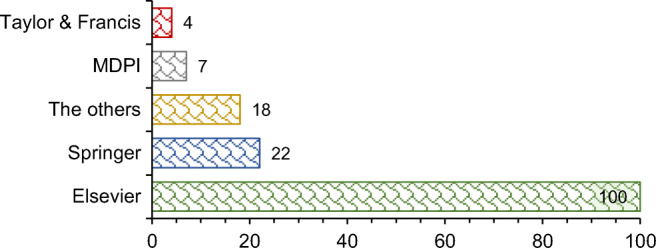

This presented critical review comprehensively analyzes state-of-the-art studies published by the world’s largest publishers. Figure 3 presents the distribution of the reviewed studies based on the publisher. The primary publisher for the ELT management research area is Elsevier with 100 publications and a 66.2% share. Twenty-two studies were published by Springer (14.6% share), seven studies were published by MDPI (4.6% share), and four studies were published by Taylor & Francis (2.6% share). The other 18 studies, which is less than 12% of the analyzed papers, were published by some other publishers such as ASME and SAGE.

Fig. 3.

The distribution of the reviewed studies based on the publisher

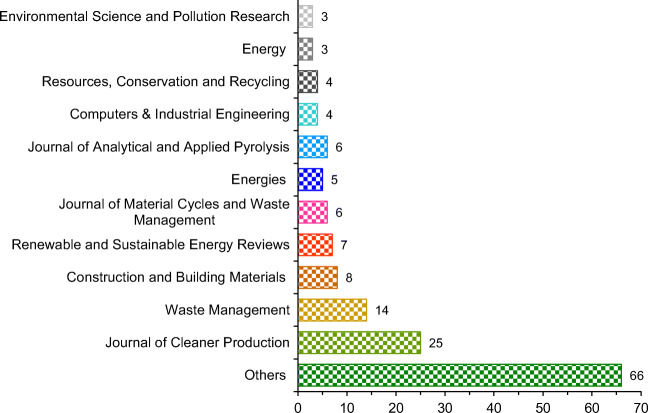

This research presents a comprehensive overview of 151 papers published in 69 peer-reviewed journals. Figure 4 depicts the distribution of the reviewed papers based on the source of publication. The largest number of papers were published in the Journal of Cleaner Production (25 publications) and Waste Management (14 publications), i.e., 25.8% of all collected papers. A significant number of contributions were also published in journals such as Construction and Building Materials (8 publications), Renewable and Sustainable Energy Reviews (7 publications), and Journal of Material Cycles and Waste Management (6 publications). The remaining 66 papers were published in 58 different journals.

Fig. 4.

The distribution of the reviewed studies based on the source of publication

The EU and Japan have the most developed regulations in the field of ELT management. However, only three papers investigated ELT management regulation systems on a global level (Table 2). Figure 5 presents the number and percentage of the regulations review papers based on the ELT management regulation system. EPR system is favored in almost all papers, as the most common regulation system for ELT management. A large number of studies (14 out of 24) advocates exclusively this system. This indicates the importance of the fact that tire manufacturers are increasingly taking responsibility when products end their service life. Such practice has positive effects on environmental, economic, and social sustainability.

Fig. 5.

The ELT management regulation system of the regulations review category

Figure 6 gives the distribution of the treatment review papers based on investigated ELT treatment. As can be seen from Fig. 6, pyrolysis is the most common type of ELT treatment since it is investigated in the majority of the treatment review papers. More than 80% (23 out of 29) of papers investigate recycling and/or pyrolysis, although in the waste hierarchy, extending the life of tires is an imperative of sustainable treatment. Besides, retreading is investigated in only five studies even though it is fully in line with the environmental, economic, and social dimensions of ELTs. These facts indicate that there are many challenges for future research in the treatment review category.

Fig. 6.

The distribution of the treatment review category by ELT treatment

After appropriate ELT treatment, certain materials are obtained which are later used as a substitute for raw materials. In almost all papers related to ELT management, their applications are analyzed, discussed, and evaluated. Figure 7 provides the distribution of the engineering applications category based on provided ELT waste flow applications. According to Fig. 7, 24 papers deal exclusively with applications, with ELTs being analyzed as an energy source in more than 41% of the engineering applications category, while 37.5% of this category prefers construction-related applications. These results are directly related to investigated ELT treatment, where pyrolysis and recycling are most commonly used.

Fig. 7.

The distribution of the engineering applications category

In a significant number of analyzed papers, optimization approaches are applied to improve ELT management. Figure 8 presents the number and percentage of the network design and analysis papers based on their research focus. From Fig. 8, it can be noticed that in 35.5% (11 out of 31) of the network design and analysis papers, the authors developed new methodologies and decision-making approaches that only deal with ELT treatment. In addition to treatment, legislation is also respected in 25.8% (8 out of 31) of papers. In most of the developed new methodologies and decision-making approaches, at least two key elements of ELT management are respected: most often applications and treatment as well as treatment and legislative. However, only two studies integrated applications, treatments, and legislation, as three key elements of ELT management. Based on these indicators, it can be outlined that the vast majority of network design and analysis papers failed to take into account all three key elements of ELT management.

Fig. 8.

The research focus of the network design and analysis papers

Conclusions

This study presents the first critical review of the ELT management area. Relevant peer-reviewed publications in the journal in the period 2010–2020 are collected, analyzed, categorized, and critically reviewed. As a result, an extensive content analysis overview of 151 state-of-the-art studies is provided.

There is a significant increase in the number of studies after 2017. Besides, almost one-third of the reviewed papers were published in the last 2 years. These indicators highlight the growing importance of ELT management. On the other hand, the reviewed studies were published in 69 peer-reviewed journals. The major publishers for the ELT management area are Elsevier (66.2% share) and Springer (14.6% share). The primary publication outlets are the Journal of Cleaner Production and Waste Management. The secondary publication outlets are Construction and Building Materials, Renewable and Sustainable Energy Reviews, and Journal of Material Cycles and Waste Management.

Most of the papers are related only to the treatment of ELTs. Pyrolysis and recycling are the most common ELT treatment options, while economic efficiency is the primary comparison criterion. The EU and Japan have the most developed regulations in the field of ELT management. From the regulation aspect, the EPR management system is most often implemented. This indicates that environmental awareness is becoming increasingly important in ELT management.

According to the performed review, the major gaps and significant research directions are as follows:

-

i.

Sustainable waste management should take into account the environmental, economic, and social dimensions of ELT material flow. The social dimension, as the third pillar of sustainable development, is mainly ignored in the available studies. Also, social indicators (i.e., affected population, customer satisfaction, health and safety practices, job opportunities and unemployment, local influence and development, occupational hazards, public awareness level, safety management, etc.) should be taken into account in future research efforts to generate comprehensive guidelines for relevant decision-makers.

-

ii.

Regulations play an essential role in ELT management. However, they have not been sufficiently respected in a significant portion of the previous studies. This negative trend is especially visible in the available network design and analysis research efforts. Future studies on new methodologies and decision-making approaches for ELT management should cover all three key elements of ELT management, i.e., legislation, treatments, and applications. Besides, future models need to be specifically tailored for ELTs.

-

iii.

Little has been done to investigate ELT management regulation systems on a global level. Also, the influence of EPR, TS, and FMS regulation systems on tire material circularity is missing. Besides, critical enablers and barriers for tire material circularity still have to be revealed.

-

iv.

The waste hierarchy emphasizes the reuse and extension of the tire life cycle as a primary ELT management scheme. Retreading is explored in only a few studies. It is on top of the waste management hierarchy. This insufficiently researched management scheme, which is fully in line with the environmental, economic, and social dimensions of ELTs, needs to be put into focus in future studies.

-

v.

ELT recycling is mainly associated with civil engineering applications even though recycled rubber could also be used in many other areas. New fields of applications of recycled ELTs have to be explored and well-documented to minimize ELT waste flow, e.g., innovative applications for thermal and acoustic isolation, vibration reduction, packaging as well as widespread utilization in the footwear industry and logistics activities.

-

vi.

Many studies in the literature deal with network design and analysis of ELTs; however, there are significant gaps in this scope. Only a few studies propose a strategic approach for the remanufacturing process of ELTs. In addition, very few studies focus on the social and environmental impacts of ELTs. Since uncertainty is one of the crucial factors in an effective network design process, there is no significant number of studies in the literature that takes uncertainty into account. As sustainability and resilience are key factors for the future of a realistic project, researchers can include these factors in future studies related to ELT management. Last but not least, reconcilement of conflicting goals in ELT optimization models could be an interesting topic to deal with for future researchers since economic, social, and environmental objectives tend to trade-off in waste management models.

-

vii.

Short- and long-term effects of external impact factors on the tire industry must be comprehensively assessed. Also, possibilities for increasing supply chain resilience should be extensively explored. Besides, a key challenge is to provide a set of alternative solutions that can serve as a rule of thumb for supply chain managers under medical crises, like the COVID-19(coronavirus) outbreak. To help researchers and practitioners in related future efforts, we introduce the novel concept of a “socially resilient supply chain”, where social resilience is defined as the ability of a sustainable supply chain to timely, eco-efficiently, and cost-effectively recover from social disruption events. It should be outlined that this research avenue deserves special attention.

The presented critical review provides comprehensive insights, a valuable source of references, and major opportunities for researchers and practitioners interested in not only ELT material flow but also the whole waste management area.

Acknowledgements

The authors are grateful for the valuable comments of the Editor-in-Chief and two anonymous reviewers, who helped to improve the manuscript greatly.

Abbreviations

- ABMS

Agent-based modeling and simulation

- AHP

Analytic hierarchy process

- APP

Application

- ARIMA

Autoregressive integrated moving average model

- BN

Bayesian network

- CLSC

Closed-loop supply chain

- COL

Collection

- CRMA

Crumb rubber modified asphalt

- CWA

Clarke-Wright algorithm

- DES

Discrete event simulation

- DT

Decision tree

- EA

Engineering applications

- ELT

End-of-life tire

- ELV

End-of-life vehicle

- EOQ

Economic order quantity

- EPR

Extended producer responsibility

- ER

Energy recovery

- EU

European union

- FMOMIP

Fuzzy multi-objective mixed-integer programming

- FMS

Free-market system

- GA

Genetic algorithm

- IFGP

Interactive fuzzy goal programming

- IPCCP

Interval-parameter chance-constrained programming

- IPSIP

Interval-parameter semi-infinitive programming

- ISM

Interpretive structural modeling

- KA

Keshtel algorithm

- LCA

Life cycle analysis

- LS

Literature survey

- MACBETH

Measuring attractiveness by a categorical based evaluation technique

- MCDM

Multi-criteria decision-making

- MILP

Mixed-integer linear programming

- MINLP

Mixed-integer non-linear programming

- MOP

Multi-objective programming

- NDA

Network design and analysis

- PROMETHEE

Preference Ranking Organization METHod for Enrichment of Evaluations

- PSO

Particle swarm optimization

- PYR

Pyrolysis

- RDA

Red deer algorithm

- REC

Recycling

- RET

Retreading

- RL

Reverse logistics

- RR

Regulations review

- SA

Simulated annealing

- SFS

Stochastic fractal search

- SMOP

Stochastic multi-objective programming

- SWOT

Strengths, weaknesses, opportunities, threats

- TAS

Tabu search

- TCM

Technical cost modeling

- TFM

Transfer function model

- TLP

Tree-level programming

- TPO

Tire pyrolysis oil

- TR

Treatment review

- TRE

Treatment

- TS

Tax system

- TSSP

Two-stage stochastic programming

- VCA

Value chain analysis

- VNS

Variable neighborhood search

- WFD

Waste Framework Directive

- WWO

Water wave optimization

Author contribution

Svetlana Dabic-Miletic: conceptualization; writing—review and editing; visualization; investigation; data curation; formal analysis.

Vladimir Simic: conceptualization; writing—review and editing; visualization; investigation; formal analysis.

Selman Karagoz: conceptualization; writing—review and editing; investigation.

Funding

Not applicable.

Data availability

All authors consent when it is published.

Declarations

Ethical approval

Not applicable.

Consent to participate

All authors consent.

Consent to publish

All authors consent when it is published.

Competing interests

The authors declare that they have no competing interests.

Footnotes

All abbreviations are provided in the Appendix.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Svetlana Dabic-Miletic, Email: cecad@sf.bg.ac.rs.

Vladimir Simic, Email: vsima@sf.bg.ac.rs.

Selman Karagoz, Email: selman.karagoz@ntu.ac.uk, Email: karagozselman@gmail.com.

References

- Abdallah R, Juaidi A, Assad M, Salameh T, Manzano-Agugliaro F. Energy recovery from waste tires using pyrolysis: Palestine as case of study. Energies. 2020;13(7):1817. doi: 10.3390/en13071817. [DOI] [Google Scholar]

- Abdolazimi O, Esfandarani MS, Salehi M, Shishebori D. Robust design of a multi-objective closed-loop supply chain by integrating on-time delivery, cost, and environmental aspects, case study of a tire factory. Journal of Cleaner Production. 2020;264:121566. doi: 10.1016/j.jclepro.2020.121566. [DOI] [Google Scholar]

- Abdul-Kader W, Haque MS. Sustainable tyre remanufacturing: an agent-based simulation modelling approach. International Journal of Sustainable Engineering. 2011;4(4):330–347. doi: 10.1080/19397038.2011.581392. [DOI] [Google Scholar]

- Abdul-Raouf ME, Maysour NE, Abdul-Azim AAA, Amin MS. Thermochemical recycling of mixture of scrap tyres and waste lubricating oil into high caloric value products. Energy Conversion and Management. 2010;51(6):1304–1310. doi: 10.1016/j.enconman.2010.01.007. [DOI] [Google Scholar]

- Afrinaldi F, Tasman AM, Zhang HC, Hasan A. Minimizing economic and environmental impacts through an optimal preventive replacement schedule: model and application. Journal of Cleaner Production. 2017;143:882–893. doi: 10.1016/j.jclepro.2016.12.033. [DOI] [Google Scholar]

- Alwaeli M. End-of-life vehicles recovery and recycling and the route to comply with EU directive targets. Environment Protection Engineering. 2016;42(1):191–202. doi: 10.5277/epe160114. [DOI] [Google Scholar]

- Amin SH, Zhang G, Akhtar P. Effects of uncertainty on a tire closed-loop supply chain network. Expert Systems with Applications. 2017;73:82–91. doi: 10.1016/j.eswa.2016.12.024. [DOI] [Google Scholar]

- Antoniou N, Zabaniotou A. Features of an efficient and environmentally attractive used tyres pyrolysis with energy and material recovery. Renewable and Sustainable Energy Reviews. 2013;20:539–558. doi: 10.1016/j.rser.2012.12.005. [DOI] [Google Scholar]

- Antoniou N, Zorpas AA. Quality protocol development to define end-of-waste criteria for tire pyrolysis oil in the framework of circular economy strategy. Waste Management. 2019;95:161–170. doi: 10.1016/j.wasman.2019.05.035. [DOI] [PubMed] [Google Scholar]

- Aranda UA, Ferreira G, Bribián ZI, Vásquez ZD. Study of the environmental performance of end-of-life tyre recycling through a simplified mathematical approach. Thermal Science. 2012;16(3):889–899. doi: 10.2298/TSCI120212129A. [DOI] [Google Scholar]

- Araujo-Morera J, Hernández Santana M, Verdejo R, López-Manchado MA. giving a second opportunity to tire waste: an alternative path for the development of sustainable self-healingstyrene–butadiene rubber compounds overcoming the magic triangle of tires. Polymers. 2019;11(12):2122. doi: 10.3390/polym11122122. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Asaro L, Gratton M, Seghar S, Hocine NA. Recycling of rubber wastes by devulcanization. Resources, Conservation and Recycling. 2018;133:250–262. doi: 10.1016/j.resconrec.2018.02.016. [DOI] [Google Scholar]

- Ayanoglu A, Yumrutas R. Production of gasoline and diesel like fuels from waste tire oil by using catalytic pyrolysis. Energy. 2016;103:456–468. doi: 10.1016/j.energy.2016.02.155. [DOI] [Google Scholar]

- Aziz MA, Rahman MA, Molla H. Design, fabrication and performance test of a fixed bed batch type pyrolysis plant with scrap tire in Bangladesh. Journal of Radiation Research and Applied Sciences. 2018;11(4):311–316. doi: 10.1016/j.jrras.2018.05.001. [DOI] [Google Scholar]

- Banguera LA, Sepúlveda JM, Ternero R, Vargas M, Vásquez ÓC. Reverse logistics network design under extended producer responsibility: the case of out-of-use tires in the Gran Santiago city of Chile. International Journal of Production Economics. 2018;205:193–200. doi: 10.1016/j.ijpe.2018.09.006. [DOI] [Google Scholar]

- Bazan E, Jaber MY, El Saadany AMA. Carbon emissions and energy effects on manufacturing–remanufacturing inventory models. Computers & Industrial Engineering. 2015;88:307–316. doi: 10.1016/j.cie.2015.07.002. [DOI] [Google Scholar]

- Bharat V, Dipak G. A literature review on life cycle analysis of tyre retreading. International Journal for Scientific Research & Development. 2014;2(9):46–50. [Google Scholar]

- Bičáková O, Straka P. Co-pyrolysis of waste tire/coal mixtures for smokeless fuel, maltenes and hydrogen-rich gas production. Energy Conversion and Management. 2016;116:203–213. doi: 10.1016/j.enconman.2016.02.069. [DOI] [Google Scholar]

- Bockstal L, Berchem T, Schmetz Q, Richel A. Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: a review. Journal of Cleaner Production. 2019;236:117574. doi: 10.1016/j.jclepro.2019.07.049. [DOI] [Google Scholar]

- Brandsma SH, Brits M, Groenewoud QR, van Velzen MJM, Leonards PEG, de Boert J. Chlorinated paraffins in car tires recycled to rubber granulates and playground tiles. Environment Science & Technology. 2019;53(13):7595–7603. doi: 10.1021/acs.est.9b01835. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bravo M, Brito J. Concrete made with used tyre aggregate: durability-related performance. Journal of Cleaner Production. 2012;25:42–50. doi: 10.1016/j.jclepro.2011.11.066. [DOI] [Google Scholar]

- Buadit T, Rattanapan C, Ussawarujikulchai A, Suchiva K, Papong S, Ma HW. Life cycle assessment of material recovery from pyrolysis process of end-of-life tires in Thailand. International Journal of Environmental Science and Development. 2020;11(10):493–498. doi: 10.18178/ijesd.2020.11.10.1296. [DOI] [Google Scholar]

- Centonze G, Leone M, Aiello MA. Steel fibers from waste tires as reinforcement in concrete: a mechanical characterization. Construction and Building Materials. 2012;36:46–57. doi: 10.1016/j.conbuildmat.2012.04.088. [DOI] [Google Scholar]

- Cherbański R, Wróblewski K, Molga E. Pyrolysis of waste tyres – the effect of reaction kinetics on the results of thermogravimetric analysis. Chemical and Process Engineering. 2017;38(3):363–377. doi: 10.1515/cpe-2017-0028. [DOI] [Google Scholar]

- Chyan J-M, Senoro D-B, Lin C-J, Chen P-J, Chen I-M. A novel biofilmcarrier for pollutant removal in a constructed wetland based on waste rubber tirechips. International Biodeterioration & Biodegradation. 2013;85:638–645. doi: 10.1016/j.ibiod.2013.04.010. [DOI] [Google Scholar]

- Clar-Garcia D, Velasco-Sanchez E, Campillo-Davo N, Campello-Vicente H, Sanchez-Lozano M. A new methodology to assess sound power level of tyre/road noise under laboratory controlled conditions in drum test facilities. Applied Acoustics. 2016;110:23–32. doi: 10.1016/j.apacoust.2016.03.018. [DOI] [Google Scholar]

- Costa-Salas Y, Sarache W, Überwimmer M. Fleet size optimization in the discarded tire collection process. Research in Transportation Business & Management. 2017;24:81–89. doi: 10.1016/j.rtbm.2017.08.001. [DOI] [Google Scholar]

- CRIA - China Rubber Industry Association, 2020. Gem set waste tire disposal goal. http://en.cria.org.cn/newsdetail/32083.html (accessed March 11, 2021).

- Czajczynska D, Krzyzynska R, Jouhara H, Spencer N. Use of pyrolytic gas from waste tire as a fuel: a review. Energy. 2017;134:1121–1131. doi: 10.1016/j.energy.2017.05.042. [DOI] [Google Scholar]

- Dabić-Ostojić S, Miljuš M, Bojović N, Glišović N, Milenković M. Applying a mathematical approach to improve the tire retreading process. Resources, Conservation and Recycling. 2014;86:107–117. doi: 10.1016/j.resconrec.2014.02.007. [DOI] [Google Scholar]

- Danon B, van der Gryp P, Schwarz CE, Görgens JF. A review of dipentene (dl-limonene) production from waste tire pyrolysis. Journal of Analytical and Applied Pyrolysis. 2015;112:1–13. doi: 10.1016/j.jaap.2014.12.025. [DOI] [Google Scholar]

- De Souza CDR, D’Agosto MDA. Value chain analysis applied to the scrap tire reverse logistics chain: an applied study of co-processing in the cement industry. Resources, Conservation and Recycling. 2013;78:15–25. doi: 10.1016/j.resconrec.2013.06.007. [DOI] [Google Scholar]

- Demirel E, Demirel N, Gökçen H. A mixed integer linear programming model to optimize reverse logistics activities of end-of-life vehicles in Turkey. Journal of Cleaner Production. 2016;112(3):2101–2113. doi: 10.1016/j.jclepro.2014.10.079. [DOI] [Google Scholar]

- Depaolini AR, Bianchi G, Fornai D, Cardelli A, Badalassi M, Cardelli C, et al. Physical and chemical characterization of representative samples of recycled rubber from end-of-life tires. Chemosphere. 2017;184:1320–1326. doi: 10.1016/j.chemosphere.2017.06.093. [DOI] [PubMed] [Google Scholar]

- Derakhshan Z, Ghaneian MT, Mahvi AH, Conti GO, Faramarzian M, Dehghani M, et al. A new recycling technique for the waste tires reuse. Environmental Research. 2017;158:462–469. doi: 10.1016/j.envres.2017.07.003. [DOI] [PubMed] [Google Scholar]

- Dhouib D. An extension of MACBETH method for a fuzzy environment to analyze alternatives in reverse logistics for automobile tire wastes. Omega. 2014;42(1):25–32. doi: 10.1016/j.omega.2013.02.003. [DOI] [Google Scholar]

- Du Z, Jiang C, Yuan J, Xiao F, Wang J. Low temperature performance characteristics of polyethylene modified asphalts - a review. Construction and Building Materials. 2020;264:120704. doi: 10.1016/j.conbuildmat.2020.120704. [DOI] [Google Scholar]

- Ebrahimi SB. A stochastic multi-objectivelocation-allocation-routing problem for tire supply chain considering sustainability aspects and quantity discounts. Journal of Cleaner Production. 2018;198:704–720. doi: 10.1016/j.jclepro.2018.07.059. [DOI] [Google Scholar]

- Edinçliler A, Baykal G, Saygili A. Influence of different processing techniques on the mechanical properties of used tires in embankment construction. Waste Management. 2010;30(6):1073–1080. doi: 10.1016/j.wasman.2009.09.031. [DOI] [PubMed] [Google Scholar]

- Elnour MG, Laz HA. Tire hazardous, disposal and recycling. Journal of Applied and Industrial Sciences. 2014;2(2):63–74. [Google Scholar]

- ETRMA. (2019). Erch 11, 2021).

- EU. (1999). Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste. Official Journal of the European Union L182, 1-19. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L:1999:182:FULL&from=EN (accessed March 11, 2021).

- EU. (2000a). Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on end-of-life vehicles. Official Journal of the European Union L269, 34-42. https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32000L0053 (accessed March 11, 2021).

- EU. (2000b). Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the incineration of waste. Official Journal of the European Union L221, 91-111. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32000L0076 (accessed March 11, 2021).

- Eurostat. (2021). End-of-life vehicles - reuse, recycling and recovery totals. https://ec.europa.eu/eurostat (accessed March 11, 2021).

- Fakhri M. The effect of waste rubber particles and silica fume on the mechanical properties of roller compacted concrete pavement. Journal of Cleaner Production. 2016;129:521–530. doi: 10.1016/j.jclepro.2016.04.017. [DOI] [Google Scholar]

- Fathollahi-Fard AM, Hajiaghaei-Keshteli M, Mirjalili S. Hybrid optimizers to solve a tri-level programming model for a tire closed-loop supply chain network design problem. Applied Soft Computing. 2018;70:701–722. doi: 10.1016/j.asoc.2018.06.021. [DOI] [Google Scholar]

- Feraldi R, Cashman S, Huff M, Raahauge L. Comparative LCA of treatment options for US scrap tires: material recycling and tire-derived fuel combustion. The International Journal of Life Cycle Assessment. 2013;18(3):613–625. doi: 10.1007/s11367-012-0514-8. [DOI] [Google Scholar]

- Fıglali N, Cihan A, Esen H, Fıglali A, Cesmeci D, Gullu MK, et al. Image processing-aided working posture analysis: I-OWAS. Computers & Industrial Engineering. 2015;85:384–394. doi: 10.1016/j.cie.2015.03.011. [DOI] [Google Scholar]

- Fiksel J, Bakshi BR, Baral A, Guerra E, De Quervain B. Comparative life cycle assessment of beneficial applications for scrap tires. Clean Technologies and Environmental Policy. 2011;13:19–35. doi: 10.1007/s10098-010-0289-1. [DOI] [Google Scholar]

- Ghasemzadeh Z, Sadeghieh A, Shishebori D. A stochastic multi-objective closed-loop global supply chain concerning waste management: a case study of the tire industry. Environment, Development and Sustainability. 2020;23:5794–5821. doi: 10.1007/s10668-020-00847-2. [DOI] [Google Scholar]

- Gigli S, Landi D, Germani M. Cost-benefit analysis of a circular economy project: a study on a recycling system for end-of-life tyres. Journal of Cleaner Production. 2019;229:680–694. doi: 10.1016/j.jclepro.2019.03.223. [DOI] [Google Scholar]

- Girskas G, Nagrockienė D. Crushed rubber waste impact of concrete basic properties. Construction and Building Materials. 2017;140:36–42. doi: 10.1016/j.conbuildmat.2017.02.107. [DOI] [Google Scholar]

- Gnanaraj JS, Lee RJ, Levine AM, Wistrom JL, Wistrom SL, Li Y, et al. Sustainable waste tire derived carbon material as a potential anode for lithium-ion batteries. Sustainability. 2018;10(8):2840. doi: 10.3390/su10082840. [DOI] [Google Scholar]

- Godlewska J. Recovery and recycling of waste tires in Poland. Procedia Engineering. 2017;182:229–234. doi: 10.1016/j.proeng.2017.03.173. [DOI] [Google Scholar]

- Grioui N, Halouani K, Agblevor FA. Assessment of upgrading ability and limitations of slow co-pyrolysis: case of olive mill wastewater sludge/waste tires slow co-pyrolysis. Waste Management. 2019;92:75–88. doi: 10.1016/j.wasman.2019.05.016. [DOI] [PubMed] [Google Scholar]

- Guo S, Dai Q, Si R, Sun X, Lu C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. Journal of Cleaner Production. 2017;148:681–689. doi: 10.1016/j.jclepro.2017.02.046. [DOI] [Google Scholar]

- Gupta VK, Gupta B, Rastogi A, Agarwal S, Nayak A. A comparative investigation on adsorption performances of mesoporous activated carbon prepared from waste rubber tire and activated carbon for a hazardous azo dye—Acid Blue 113. Journal of Hazardous Materials. 2011;186(1):891–901. doi: 10.1016/j.jhazmat.2010.11.091. [DOI] [PubMed] [Google Scholar]

- Gupta VK, Gupta B, Rastogi A, Agarwal S, Nayak A. Pesticides removal from waste water by activated carbon prepared from waste rubber tire. Water Research. 2011;45(13):4047–4055. doi: 10.1016/j.watres.2011.05.016. [DOI] [PubMed] [Google Scholar]

- Hajiaghaei-Keshteli M, Abdallahb KS, Fathollahi-Fard AM. A collaborative stochastic closed-loop supply chain network design for tire industry. International Journal of Engineering, Transaction A: Basic. 2018;31(10):1715–1722. [Google Scholar]

- Heidari A, Younesi H. Synthesis, characterization and life cycle assessment of carbon nanospheres from waste tires pyrolysis over ferrocene catalyst. Journal of Environmental Chemical Engineering. 2020;8(2):103669. doi: 10.1016/j.jece.2020.103669. [DOI] [Google Scholar]

- Hiratsuka J, Sato N, Yoshida H. Current status and future perspectives in end-of-life vehicle recycling in Japan. Journal of Material Cycles and Waste Management. 2014;16(1):21–30. doi: 10.1007/s10163-013-0168-z. [DOI] [Google Scholar]

- Hita I, Arabiourrutia M, Olazar M, Bilbao J, Arandes JM, Castaño Sánchez P. Opportunities and barriers for producing high quality fuels from the pyrolysis of scrap tires. Renewable and Sustainable Energy Reviews. 2016;56:745–759. doi: 10.1016/j.rser.2015.11.081. [DOI] [Google Scholar]

- Hürdoğan E, Ozalp C, Kara O, Ozcanli M. Experimental investigation on performance and emission characteristics of waste tire pyrolysis oil–diesel blends in a diesel engine. International Journal of Hydrogen Energy. 2017;42(36):23373–23378. doi: 10.1016/j.ijhydene.2016.12.126. [DOI] [Google Scholar]

- Iraola-Arreguia I, Van Der Gryp P, Görgens JF. A review on the demineralisation of pre- and post-pyrolysis biomass and tyre wastes. Waste Management. 2019;79:667–688. doi: 10.1016/j.wasman.2018.08.034. [DOI] [PubMed] [Google Scholar]

- JATMA. (2020). Tyre recycling - current status on ELT (end-of-life tyres) recycling. https://www.jatma.or.jp/english/tyrerecycling/report01.html ().

- JATMA. (2021). Tyre industry of Japan 2020. https://www.jatma.or.jp/media/pdf/tyre_industry_2020.pdf (accessed March 11, 2021).

- Junqing X, Jiaxue Y, Jianglin X, Chenliang S, Wenzhi H, Juwen H, et al. High-value utilization of waste tires: a review with focus on modified carbon black from pyrolysis. Science of the Total Environment. 2020;742:140235. doi: 10.1016/j.scitotenv.2020.140235. [DOI] [PubMed] [Google Scholar]

- Kandasamy J, Gokalp I. Pyrolysis, combustion, and steam gasification of various types of scrap tires for energy recovery. Energy Fuel. 2014;29(1):346–354. doi: 10.1021/ef502283s. [DOI] [Google Scholar]

- Kannan D, Diabat A, Shankar KM. Analyzing the drivers of end-of-life tire management using interpretive structural modeling (ISM) The International Journal of Advanced Manufacturing Technology. 2014;72(9-12):1603–1614. doi: 10.1007/s00170-014-5754-2. [DOI] [Google Scholar]

- Karaagaç B, Kalkan ME, Deniz V. End of life tyre management: Turkey case. Journal of Material Cycles and Waste Management. 2017;19(1):577–584. doi: 10.1007/s10163-015-0427-2. [DOI] [Google Scholar]

- Karagoz S, Aydin N, Simic V. End-of-life vehicle management: a comprehensive review. Journal of Material Cycles and Waste Management. 2020;22(2):416–442. doi: 10.1007/s10163-019-00945-y. [DOI] [Google Scholar]

- Karagoz M, Uysal C, Agbulut U, Saridemir S. Energy, exergy, economic and sustainability assessments of a compression ignition diesel engine fueled with tire pyrolytic oil− diesel blends. Journal of Cleaner Production. 2020;264:121724. doi: 10.1016/j.jclepro.2020.121724. [DOI] [Google Scholar]