Abstract

Novel types of an air purification system for improving indoor air quality (IAQ) and ventilation by reducing carbon dioxide (CO2) concentration were assessed in office buildings in India. This study provides an evaluation of a control system that reduces toxic gases in indoor spaces using the synthesized filter media. The reduction potential of CO2 levels of the control system, for different air handling unit (AHU) capacities, were compared. Experimental studies and in-situ evaluation has been done using the air purification system. Ventilation rates and CO2 concentration are monitored before and after the installation of the purification system. The results of the investigation indicated CO2 concentrations were reduced by more than 40% with the purification system. Fresh air intake to maintain the desired ventilation rates has been reduced to more than 50%, further reduce heat load. Ventilation flow rates were achieved with this air purification system. This system has the potential aspiration in controlling the CO2 levels in mechanically ventilated buildings. CO2 concentrations were brought down to permissible limits and maintained further without introducing fresh air into the system. Based on the results, assessment of the air purification system is a crucial and wide range of applicability in indoor environments to reduce cooling costs.

Keywords: Indoor air quality, Ventilation, Carbon dioxide concentration, Thermal comfort

Indoor air quality; Ventilation; Carbon dioxide concentration; Thermal comfort.

1. Introduction

During the last decades, indoor air quality (IAQ) has been widely considered a major concern as people spend 90 % of their time (De Giuli et al., 2012). Most of the time indoor air quality will be 5–10 % more polluted than ambient (Carslaw, 2007). The US Environmental Protection Agency (US-EPA) has ranked indoor air pollution (IAP) as among the top five environmental dangers. IAP is having a potential impact on health concerns to humans (Berglund et al., 1992; Nimlyat and Kandar, 2015). In 2012, the World Health Organization reported that 4.3 million premature deaths occurred due to undesired IAQ worldwide. Poor IAQ causes adverse health effects including respiratory symptoms, allergies, sensory irritation, asthma, sick building syndrome (SBS), cardiovascular diseases, headache, and fatigue (Dascalaki et al., 2008). PM and formaldehyde are classified as carcinogenic agents, cause lung cancer under chronic exposure (Herbarth et al., 2003; Reynolds et al., 2001). Children are more vulnerable to the risk associated with poor IAQ (Mendell and Heath, 2005; Suk et al., 2003). Improved IAQ and thermal comfort enhance the productivity of children and teachers in schools (Coley and Beisteiner, 2002; Faustman et al., 2000). Toxic gases and particulate matter (PM) concentrations were prominent concerning parameters in determining the risk associated with IAQ (Reche et al., 2014). Buildings with heating ventilation and air conditioning (HVAC) systems, desired suspended particulate matter levels have typically been achieved through the use of HEPA filters, non-thermal plasma air filters, and polytetrafluoroethylene (PTFE) multi-tube high efficiency membrane air filters (Jung and Kim, 2017; Sublett et al., 2010; Xu et al., 2021). Activated carbon fibers filters (ACF) and photochemical oxidation methods are capable of adsorbing indoor volatile organic compounds (VOC) (Mamaghani et al., 2017; Roegiers and Denys, 2021). Ionic liquids and porous materials have been used to remove inorganic gases (Yu et al., 2021). In general gaseous pollutants, removal can be separated into two types, adsorption and destruction processes. Oxidation techniques such as electrostatic precipitators, ozone generation, plasma driven oxidation, and photochemical oxidation (PCO) are known as destructive processes (Ongwandee and Kruewan, 2013; Zhong and Haghighat, 2015). Pollutants captured by a sorbent media by means of either physical or chemical binding is adsorption (Sublett et al., 2010). Each of these categories of control technologies has its limitations and significance in neutralizing the various indoor air pollutants.

In mechanically ventilated buildings, Carbon dioxide (CO2) is an indicator to ensure the ventilation rates, air exchanges, and air quality (McNabola et al., 2013; Persily, 2015). pollutants are spread throughout the spaces they serve (Haleem Khan and Mohan Karuppayil, 2012). According to the standards, the ventilation rate should be more than 10 l/s per person at below 800 ppm of CO2 concentration (Kapalo et al., 2014; Seppanen et al., 1999). Carbon dioxide (CO2) concentrations are often associated with occupants (Seppanen et al., 1999). In the recent past studies have assessed and reported that IAQ at high occupancy buildings has nonattainable (Hwang and Park, 2019). Maintaining desired air quality includes source control, improve ventilation, and air purification in indoors. Environmental factors and natural ventilation are considered to be important factors in determining IAQ (Nimlyat and Kandar, 2015). Improper maintenance, poor building design, and occupant activities resulting in vulnerable IAQ (da Costa Filho and Vilar, 2020). Chemical absorption of carbon dioxide from indoor air by aqueous solutions using cross-flow rotating packed bed (RPB) demonstrated the various parameters influencing the CO2 removal efficiency (Lin and Lin, 2013). The electric swing adsorption (ESA) method to remove CO2 concentration indicated that it is economical for higher concentrations i.e. mole fraction must be more than 0.15 (Lee et al., 2015). Smart ventilation systems (SVS) are used to control ventilation, CO2 sensor based demand control ventilation (DCV), infrared (IR) occupancy sensor based DCV, and constant air volume (CAV). Among these carbon dioxide (CO2) sensor based control strategies provide energy efficient ventilation and improved IAQ system (Carslaw, 2007; Lü et al., 2013). Several studies indicate that CO2 based DCV diminishes energy utilization (Chao and Hu, 2004; Lu et al., 2011). Many approaches are presented to implement DCV systems like proportional and exponential controls. The proportional control is optimal in energy saving as it was affected by the design ventilation rates based on CO2 equilibrium concentration under steady state conditions (Schell et al., 1998). With exponential control, CO2 concentration maintained much closer to the set point with PI or PID control (Lu et al., 2011).

To achieve desired indoor air quality and ventilation, controlling must be considered as important in reducing pollutant levels. Improved ventilation rate and indoor air quality save energy consumption compared to higher ventilation to obtain the desired IAQ (Ng et al., 2015). A sustainable and economical solution to improve indoor air quality (IAQ) and ventilation rate is an important area of interest in recent times. Previous studies have not been reported the increase in ventilation rates with air purification technologies and economical advantage. This article limits its scope to present, test results of an air purification system to control the toxic gas pollutants concentration and to achieve desire ventilation. Hence, it provides a safe, healthy, and productive environment with improved IAQ. In the present study, an attempt has been made to evaluate the performance of an air purification system to reduce indoor air pollution. Therefore, this study's objective is to evaluate a control system to improve indoor air quality, ventilation, and reduce cooling costs in mechanically ventilated buildings. The removal efficiency of an air purification system for inorganic air pollutants control (CO2, SO2, and NO2) in a laboratory scale. . The same air purification system has been tested on a laboratory scale and at office buildings of mechanically ventilated occupants to control CO2 and improve ventilation. The removal efficiency (RE) and air exchange ratio were assessed for different air handling unit (AHU) capacities. . Reduction of fresh air percentage into the AHU system was correlated with the amount of CO2 reduction. The advantage of the purification system in reducing the heat load and cooling cost of the AHU capacities was discussed.

2. Materials and methodology

2.1. Filter media

Two configurations of filter media samples have been synthesized for the present study to evaluate its performance. Filter granular media with 1–4 mm size, with bulk density 700–900 kg/m3, and specific surface area 200–225 m2/g was used for the present study. The granule size of media is chosen as optimum based on the pressure drop consideration. The pressure drop across the filter was 210–250 psi. Sample 1 5 % and sample 2 10 % NaOH doping on calcium silicate granules have been tested for the present study. Chemisorptions process of CO2 removal on the granular surface is as follows Eq. (1)

| (1) |

2.2. Laboratory testing

To study the filter media efficiency, an air purification system was tested in a sealed room of 1000 ft3 volume. The testing room was sealed to prevent the airflow for convective diffusion. Porous filter media sorbs the gaseous pollutants in the air, by chemisorptions. This experimental room was equipped with multi gas analyzers of Gray wolf make to monitor the concentration profiles of CO2, SO2, NO2, and O3. Each time a single pollutant source was introduced to test the filter media performance, the same experiment was conducted with the air purification system for each parameter. Monitoring data logged every five minutes. Several assumptions have been made for laboratory testing, a completely sealed room, no diffusion from boundaries, uniform concentration of pollutants throughout the room, no external factors are influencing the test conditions and the temperature remains constant for all experiments. Each experiment was done three times with each pollutant considered. Ozone (O3) concentration during the laboratory testing has been monitored.

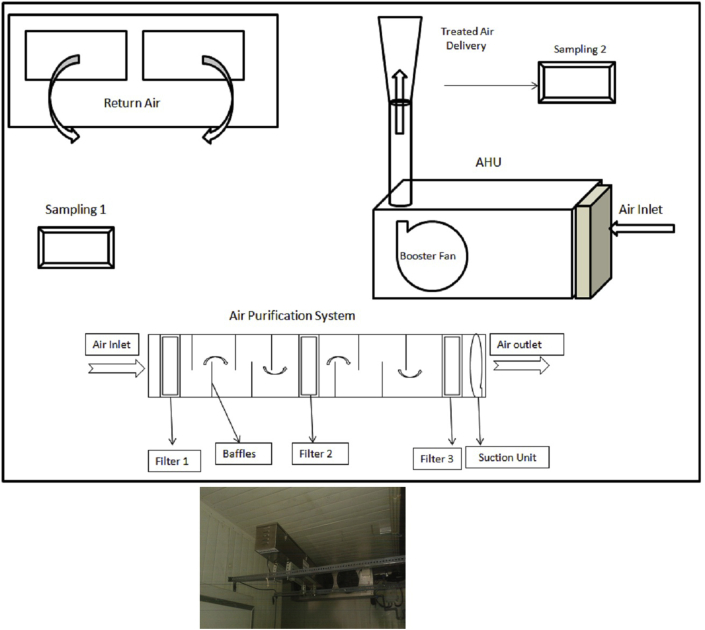

2.3. AHU testing

An air purification system of three filter layers in series in a rectangular chamber introduces in the air handling unit (AHU) room. The pressure drop across filters and required airflow rate were achieved with a suction fan in the airflow direction. Figure 1 presenting a schematic of AHU and arrangement of air purification system set up inside the AHU room for adsorbing the inorganic gaseous pollutants. For the present study selected office spaces consist of variable AHU- flow rates, cubic feet per minute (CFM), and occupants capacities to test the efficiency of CO2 adsorption. . Air purification system has been designed to use at variable AHU capacities in commercial and nonresidential buildings. During testing, fresh air inlets are closed. The specifications of study locations, occupants, and AHU capacities are mentioned in Table 1. Assuming CO2 concentrations are uniform inside the AHU room, no fresh air is introduced into the system. The number of occupants throughout the testing remains the same. Testing of the purification system has been done for three days (8 h) at each AHU. Air purification system was started with the AHU every time and continuously operated. During testing at each AHU, suction flow rate was arranged as 25% of the AHU capacity.

Figure 1.

Schematic of active filter bed installed in an HVAC system and CO2 sampling sites.

Table 1.

Specifications of the study area.

| Place of Cleaning | Capacity (CFM) | Occupants |

|---|---|---|

| AHU 1 | 10000 | 100–120 |

| AHU 2 | 15000 | 180–200 |

| AHU 3 | 25000 | 220–250 |

Circulation air gets cleaned upon partial treatment. As the air re-circulates through the system continuously CO2 levels indoors decrease with time. Air purification has two stages where the air purification mechanism takes place. In the first stage, contaminated air passes through the pre-filter, where the coarse particles get trapped from the air stream. After that, in the second stage, gaseous pollutants like CO2 will be removed from the gas stream.

2.3.1. Ventilation through air purification

To maintain the acceptable level of ventilation in buildings, periodically take the fresh air into the system. The parameter influencing the system to consider the rate of fresh air is CO2 concentration. In general 10–20 % of fresh air is taken into the system for maintaining permissible air quality in the building environment. The amount of fresh air into the AHU significantly influences the electric power consumption for cooling. The rate of air cleaning can be compensated using the ventilation rate. This is calculated using the rate equation

| (2) |

where n is the ventilation rate in the room through air filtration, Co is the CO2 concentration in indoor air, Csupply is the CO2 concentration in the supply air, C is the CO2 concentration after air purification.

Carbon dioxide increase in indoor space can be mathematically described as

| (3) |

where Ct is the CO2 concentration at the time t, [g/m3];

Csupply in the CO2 concentration in the supply air at the time t, [g/m3]; qCO2 is the carbon dioxide released from a human source, [g/s]; Q is the required ventilation airflow rate, [m3/s]; V is the room volume, [m3]; and t is the time, [s].

2.3.2. Analysis

| (4) |

Here Cr is the return air CO2 concentration, Cs is supplying air CO2 concentration, Co is the outside air CO2 concentration in ppm.

Heat load on the HVAC system to maintain the desired ventilation rate was calculated using sensible heat and latent heat burden cooling load.

| (5) |

| (6) |

Assumptions: Design factors like Bypass Factor = 0.15, Factor = 0.68.

Desired temperature = 24 °C, Total Heat load = Sensible heat load + Latent heat load.

Tonnage of refrigeration = heat load/12000, TR.

3. Results and discussions

3.1. Lab experimental results

An indoor air purification system has been tested in a closed controlled environment. An experimental testing room of ASHRAE standards was used for the performance evaluation of control technology. Null condition experiments have been conducted to test the concentration drop due to natural diffusion. Results indicated that the concentration drop due to natural diffusion was very limited. Data plotted to represents the average data of three similar experiments.

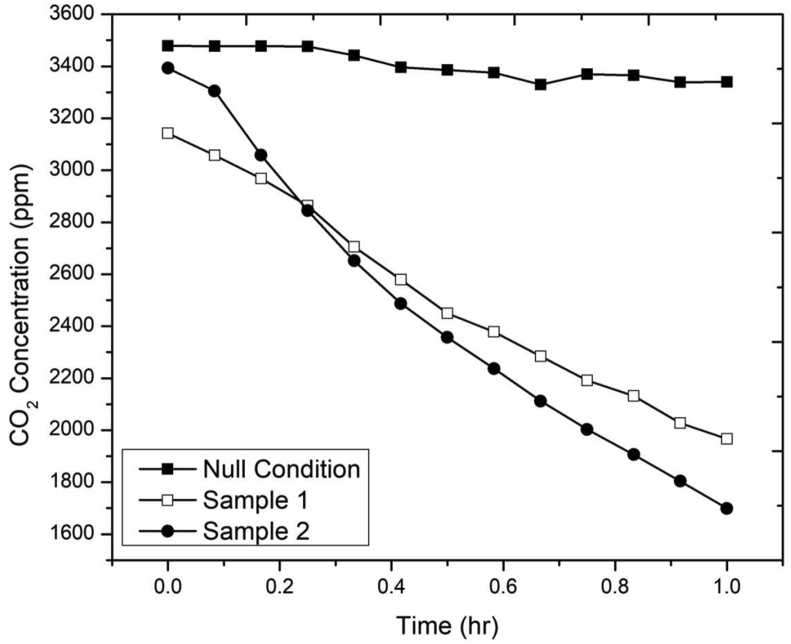

3.1.1. Carbon dioxide (CO2)

At null condition, the average CO2 concentration was observed to be 3404 ppm with an initial concentration of 3479 ppm (Figure 2). During null condition testing, the CO2 concentration drop was observed to be around 3 ppm per minute with the coefficient of determination was 0.85. Three experiments have been conducted with the purification system with each of the two sample filter media. It was reported that the concentration drop was 20 ppm and 30 ppm with the two sample conditions respectively. The coefficient of determination was observed to be 0.97 and 0.99.

Figure 2.

Measured CO2 concentration profile during testing room experiments.

From the experimental results, the reduction in CO2 concentration was assumed to be a first order reaction. The rate constant of CO2 adsorbed with the purification system was 0.69 min−1, and 0.5 min−1, for null condition i.e. without purification system rate constant was 0.05 min−1. The trends followed by CO2 concentration drop and rate constant were in good agreement with the samples tested. The efficiency of removal was observed to be 37% for first sample media and 49% for second sample media was observed.

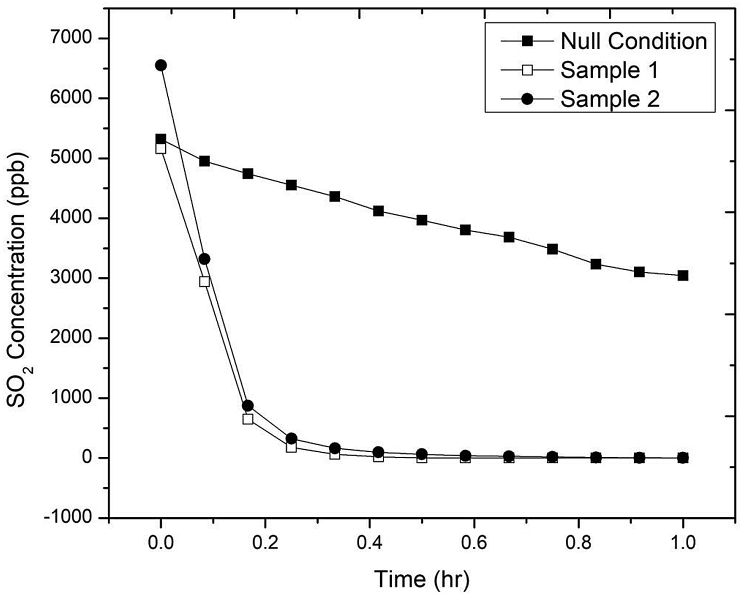

3.1.2. Sulfur dioxide (SO2)

The average SO2 concentration at null condition was observed to be 4028 ppb with an initial concentration of 5317 ppb (Figure 3). During the null condition, SO2 concentration drop was observed to be around 37 ppb per minute with the coefficient of determination 0.98. With the purification system, SO2 was completely absorbed within 30 min. More than 99% of removal efficiency was achieved with the two samples tested. Assuming first order reaction kinetics rate constant was found to be 0.24 min −1 and 0.12 min−1.

Figure 3.

Measured SO2 concentration profile during testing room experiments.

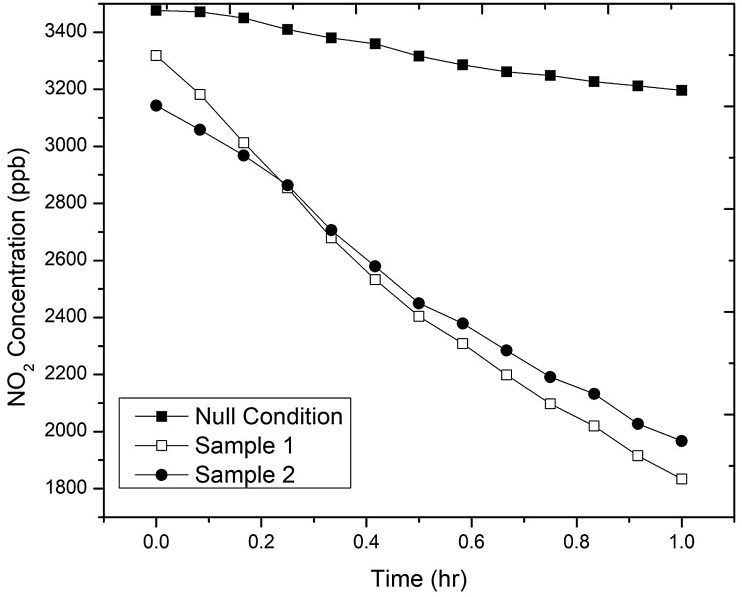

3.1.3. Nitrogen dioxide (NO2)

The average NO2 concentration was observed to be 3330 ppb with an initial concentration of 3476 ppb (Figure 4) during the null condition. Null condition testing NO2 concentration drop was observed to be around 5 ppb per minute with the coefficient of determination was 0.98. It was reported that the concentration drop was 25 ppb and 20 ppb with an air purification system for the two samples. The coefficient of determination was 0.97 and 0.99. The rate constant was found to be 0.008 min−1 and 0.01 min−1. The efficiency of removal was 44 % and 37 % for the first sample and second sample respectively.

Figure 4.

Measured NO2 concentration profile during testing room experiments.

3.2. Testing in AHU

3.2.1. AHU 1

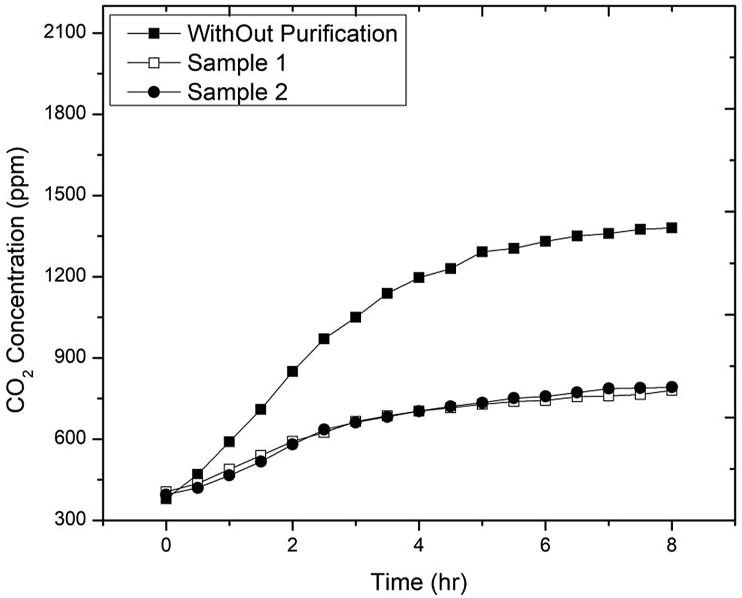

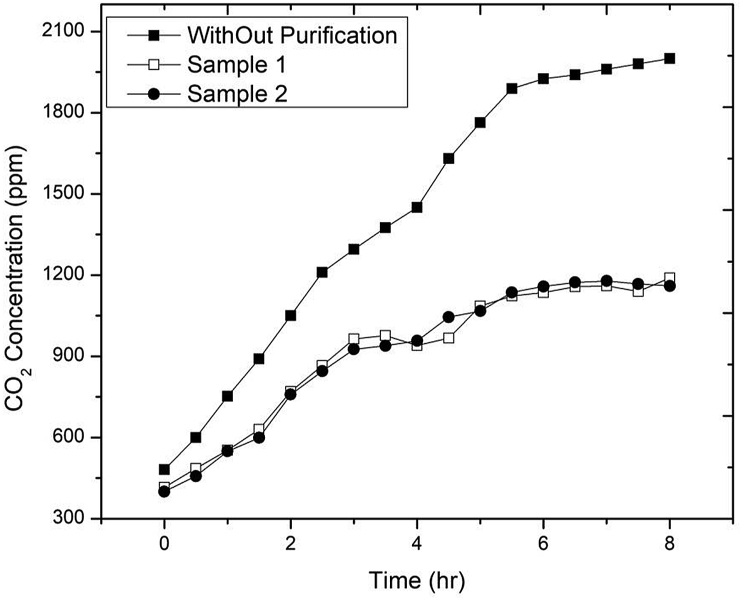

Different AHU capacities of mechanically ventilated buildings were selected for the performance evolution of the air purification system. Continuous monitoring of CO2 concentration with occupants has resulted in an average of 1060 ppm. The rate of increase in CO2 concentration was 144 ppm per hour. Average CO2 concentration was maintained at 655 ppm and 657 ppm (Figure 5). The rate of CO2 has decreased to 50 ppm and 56 ppm per hour with air purification.

Figure 5.

Measured CO2 concentration sampling at AHU 1.

Results with an air purification system in an AHU capacity of 10000 CFM found that the average air exchange was 24 % for two sample conditions, i.e. with the air purification system air quality achieved was the same as when it operated at 24 % of fresh air introduced (Figure 5). The efficiency of the CO2 removal was observed to be 40% with the control technology with two sample conditions. A statistical analysis reported that with the air purification system the supply air concentration was decreasing with the performance.

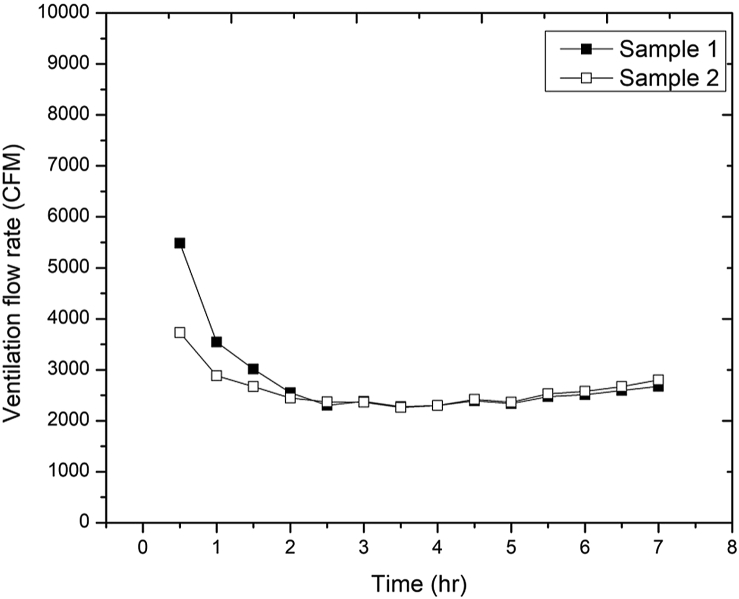

A decrease in CO2 concentration due to air purification indoors is represented as the rate ventilation airflow rate (Q) into the system. For the amount of CO2 adsorbed with air purification, the rate of ventilation airflow rate was calculated using Eq. (3). Assuming that number of occupants is 110, with CO2 exhalation mass flow rate as 10 mg/s per person and 10 air changes per hour. It can be observed from Figure 6, that the CO2 concentration remains constant after two hours. The ventilation flow rate of 2776 CFM can be achieved by using the air purification system. According to ASHRAE 62.1 standards, the minimum fresh air required per person in an office building is 5 CFM. With the air purification system ventilation rate per person was achieved to 25 CFM.

Figure 6.

Achieved ventilation flow rate for AHU 1.

3.2.2. AHU 2

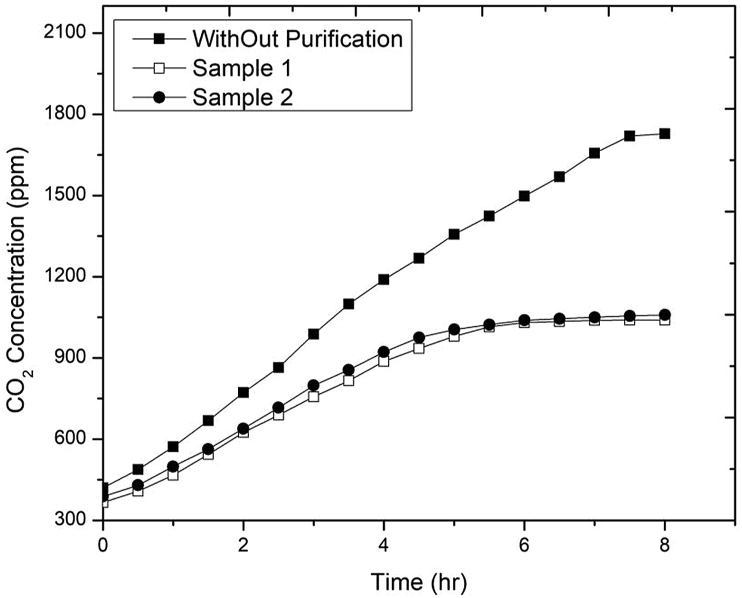

The average CO2 concentration in the 15000 CFM AHU was observed as 1134 ppm. The rate of increase in CO2 concentration was 174 ppm per hour. With the purification system, the average concentration was maintained at 808 and 828 ppm for the two sample conditions (Figure 7). With the purification system, the rate of CO2 concentration was controlled to 90 ppm per hour. The efficiency of removal of CO2 was observed to be 40% and 32 % with the samples tested. The statistical analysis indicated that with the control system, offset and amplitude of rising in CO2 concentrations were significantly varying.

Figure 7.

Measured CO2 concentration sampling at AHU 2.

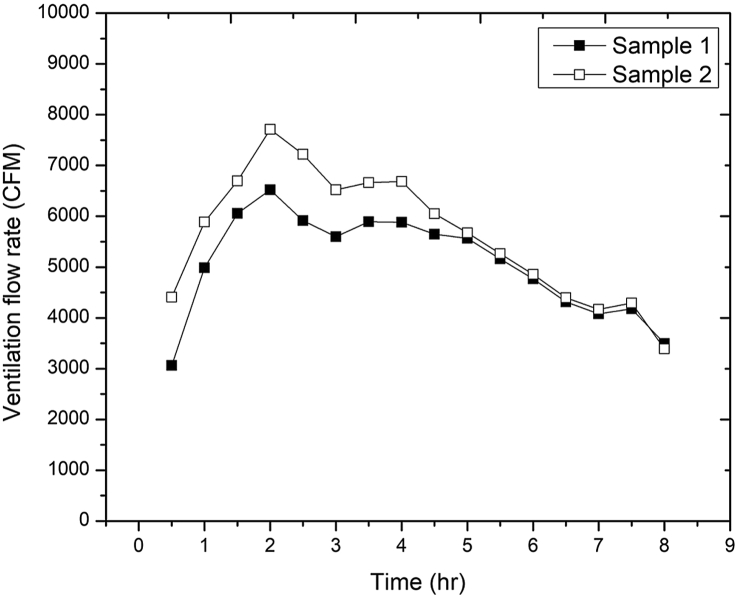

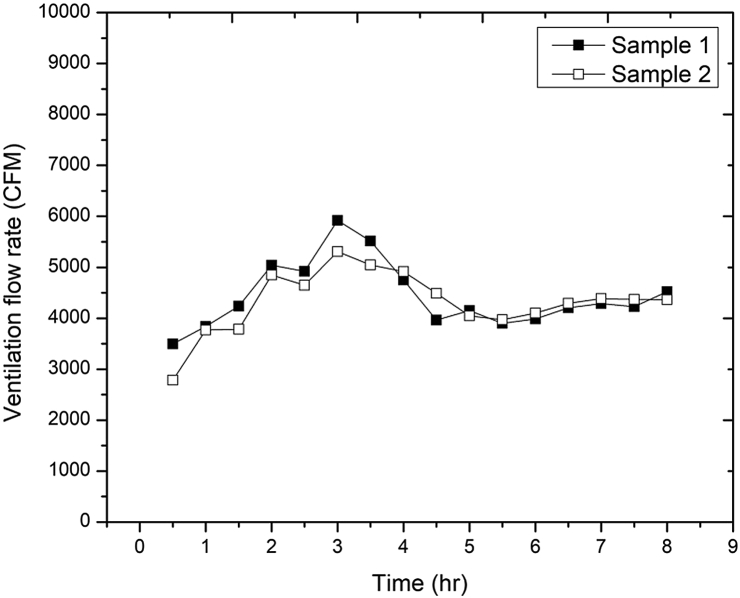

For 15000 CFM of AHU capacity the amount of CO2 adsorbed with air purification, the rate of ventilation air flow rate was calculated. Assuming that number of occupants is 190, with CO2 exhalation mass flow rate as 10 mg/s per person and 10 air changes per hour. It can be observed from Figure 8, that the CO2 concentration stabilizes after two hours of purification. The ventilation flow rate of 5175 and 5766 CFM can be achieved by using the air purification system for samples 1 and 2 respectively. By using a purification system ventilation rate per person was achieved to 27 CFM and 30 CFM.

Figure 8.

Achieved ventilation flow rate for AHU 2.

3.2.3. AHU 3

With the AHU of 20000 CFM capacity, it was found to have an average CO2 concentration of 1481 ppm. The rate of CO2 concentration was found to increase at 201 ppm per hour. With the air purification system, it was reduced to 946 and 944 ppm (Figure 9). The average increase in CO2 concentration was found to be 95 ppm and 100 ppm per hour with air purification. The rate of air exchange was found to be 14% with the control technology. The efficiency of CO2 removal was observed to be 34 % with the control technology.

Figure 9.

Measured CO2 concentration sampling at AHU 3.

With air purification in AHU 3, the ventilation flow rate was calculated by assuming that the numbers of occupants are 235, with the CO2 exhalation mass flow rate as 10 mg/s per person and 10 air changes per hour. It can be observed from Figure 10, that the CO2 concentration will stabilize after two hours of purification. The ventilation flow rate of 4434 CFM can be achieved by using the air purification system. With the purification system, the ventilation rate per person was achieved to 19 CFM.

Figure 10.

Achieved ventilation flow rate for AHU 3.

Since, during the AHU testing due to continuous CO2 source, it is difficult to determine the rate constants for the CO2 reduction. The dynamic rate constant for the time was calculated using the null condition as a reference. The rate constant values were shown in Table 2.

Table 2.

Rate constants.

| AHU 1 | AHU 2 | AHU 3 | |

|---|---|---|---|

| Sample 1 | 0.07 | 0.05 | 0.046 |

| Sample 2 | 0.06 | 0.044 | 0.04 |

Ventilation rate (n) that improved with the air purification system in AHU capacities tested was reported in Table 3.

Table 3.

Obtained Ventilation rate for AHUs tested.

| Ventilation rate (1/s) | AHU 1 | AHU 2 | AHU 3 |

|---|---|---|---|

| Sample 1 | 0.0024 | 0.0013 | 0.0012 |

| Sample 2 | 0.0022 | 0.0013 | 0.0011 |

The required fresh air intake to get the CO2 concentration achieved with the air purification system was calculated using Eq. (4), assuming outlet air CO2 concentration was 400 ppm. Results indicated that more than 50% fresh air flow has to be introduced to maintain the CO2 concentrations obtained with the purification system. The fresh air intake percentage of three AHU capacities has been reported in Table 4.

Table 4.

Percentage of reduced fresh air introduced into the system.

| Percentage of fresh air intake to the system (%) | AHU 1 | AHU 2 | AHU 3 |

|---|---|---|---|

| Sample 1 | 0.64 | 0.6 | 0.51 |

| Sample 2 | 0.63 | 0.48 | 0.54 |

This study of the performance of the air purification systems on indoor air quality improved ventilation, and reduced energy demand demonstrated the when the purification system was incorporated in the HVAC system cooling costs were cut down as heat load to achieve the desired ventilation rate was achieved. Though there was an increase in daily average CO2 levels in AHU, did not exceed relevant benchmarks and guidelines. Increasing the ventilation rate by more than 50% improved ventilating resulted in energy savings. The tonnage of refrigeration saved by using the air purification system was calculated, considering 10 % of the AHU capacity flow rate as fresh air intake and ambient temperature of 36.3 °C. This indicates that with air purification cooling cost reduced for the three AHU capacities of the present study indicated in Table 5. Further, the daily average CO2 concentration decreased using the control system, the ventilation rate is a potential strategy to maintain IAQ and save energy. As with demand control ventilation systems which reduced more than 8% up to 28 % electric consumption the present system also can be able to reduce the electric consumption for cooling purposes (Chao and Hu, 2004; Lu et al., 2011). The limitations of this study include the use of a single stage control with assumptions about ventilation rates, HVAC system operation, filtration, and CO2 source strengths. A constant emission rate was assumed but in reality, emissions may vary with temperature, humidity, and other factors.

Table 5.

Heat load reduced due to air purification.

| S No | Sensible Heat (Btu/hr) | Latent Heat (Btu/hr) | Total Heat Load | The tonnage of Refrigeration (TR) |

|---|---|---|---|---|

| AHU 1 | 6473.6 | 31292.92 | 37766.52 | 3.1 |

| AHU 2 | 9710.4 | 46939.38 | 56649.78 | 4.7 |

| AHU 3 | 16184 | 78232.3 | 94416.3 | 7.9 |

3.3. The benefit of CO2 filtration based ventilation system

CO2 based filtration system can poise and purpose of the traditional conflict between reducing ventilation to save energy to maintain the ventilation rates desired indoor air quality. The properly maintained CO2 based air purification system can provide the following benefits.

-

1.

CO2 based purification reduces the cooling cost when the space is completely occupied. The payback energy saving of the system can be less than two years.

-

2.

CO2 based purification can help to provide per person ventilation to ensure acceptable indoor air quality. This system helps ensure to meet the target ventilation rate per person based on actual occupancy.

-

3.

This is not particular about seasonality and outdoor air is coming from.

-

4.

A CO2 based purification system can be adjusted to maintain any ventilation rate between 15 CFM to 30 CFM.

-

5.

CO2 based purification can help improve thermal comfort conditions with extreme outdoor conditions. The reduced outdoor air intake in hot and humid climates helps in maintaining indoor humidity.

4. Conclusions

The performance of the two samples tested is not making any significant variation in controlling CO2, SO2, and NO2. It was found that reduction of acidic gases such as CO2, SO2, NO2 was significant in attaining the desired air quality levels indoors. The removal efficiency of CO2 is 43 ± 5%, SO2 is 99%, NO2 is 41 ± 4%, for the samples. With the AHU testing, it can be concluded that the amount of fresh air required maintaining the CO2 levels reduced to more than 50%. The desired ventilation rate is achieved in the office buildings as suggested by ASHRAE 62.1 standards with air purification system. The tonnage of the cooling system and cooling cost maintenance to achieve the desired temperature can be reduced. This can simultaneously reduce the operating cost and increase the performance of AHU systems. The two samples tested during this study did not make any significant variation in performance. The results of this study help treat indoor environments to achieve the desired IAQ at an economical rate. The data will be useful to identify and quantify the CO2 purification system performance evaluation in building environments. This study is useful in generating hypotheses for further studies on indoor air purification systems.

The scope of this study explains the significance of air purification system that improves the ventilation in mechanically ventilated buildings. It is important to maintain desired air quality and workplace comfortable. The future research area will be explored in the work and specifies the parameters within the study. The extent of filtration removal efficiency enhancement with different configurations of media developed.

Declarations

Author contribution statement

G S N V K S N SWAMY: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

This paper and the research behind it would not have been possible without the exceptional support of my supervisor, Prof.S.M.Shiva Nagendra. I would like to thank Air Ok Technologies, for providing the instrumentation facility. My sincere thanks to the R&D team members who worked with me on this project.

References

- Berglund B., Brunekreef B., Knoppe H., Lindvall T., Maroni M., Molhave L., Skov P. Effects of indoor air pollution on human health. Indoor Air. 1992;2:2–25. [Google Scholar]

- Carslaw N. A new detailed chemical model for indoor air pollution. Atmos. Environ. 2007;41:1164–1179. [Google Scholar]

- Chao C.Y.H., Hu J.S. Development of a dual-mode demand control ventilation strategy for indoor air quality control and energy saving. Build. Environ. 2004;39:385–397. [Google Scholar]

- Coley D.A., Beisteiner A. Carbon dioxide levels and ventilation rates in schools. Int. J. Vent. 2002;1:45–52. [Google Scholar]

- da Costa Filho B.M., Vilar V.J.P. Strategies for the intensification of photocatalytic oxidation processes towards air streams decontamination: a review. Chem. Eng. J. 2020;391:123531. [Google Scholar]

- Dascalaki E.G., Lagoudi A., Balaras C.A., Gaglia A.G. Air quality in hospital operating rooms. Build. Environ. 2008;43:1945–1952. [Google Scholar]

- De Giuli V., Da Pos O., De Carli M. Indoor environmental quality and pupil perception in Italian primary schools. Build. Environ. 2012;56:335–345. [Google Scholar]

- Faustman E.M., Silbernagel S.M., Fenske R.A., Burbacher T.M., Ponce R.A. Mechanisms underlying Children’s susceptibility to environmental toxicants. Environ. Health Perspect. 2000;108:13–21. doi: 10.1289/ehp.00108s113. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Haleem Khan A.A., Mohan Karuppayil S. Fungal pollution of indoor environments and its management. Saudi J. Biol. Sci. 2012;19:405–426. doi: 10.1016/j.sjbs.2012.06.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Herbarth O., Schlink U., Müller A., Richter M. Spatiotemporal distribution of airborne mould spores in apartments. Mycol. Res. 2003;107:1361–1371. doi: 10.1017/s0953756203008566. [DOI] [PubMed] [Google Scholar]

- Hwang S.H., Park W.M. Indoor air quality assessment with respect to culturable airborne bacteria, total volatile organic compounds, formaldehyde, PM10, CO2, NO2, and O3 in underground subway stations and parking lots. Air Qual. Atmos. Heal. 2019;12:435–441. [Google Scholar]

- Jung J.-S., Kim J.-G. An indoor air purification technology using a non-thermal plasma reactor with multiple-wire-to-wire type electrodes and a fiber air filter. J. Electrost. 2017;86:12–17. [Google Scholar]

- Kapalo P., Domnita F., Lojkovics J. Methodology for calculating the fresh air ventilation airflow rate based on CO2 concentration. Pollack Period. 2014;9:89–97. [Google Scholar]

- Lee T.S., Cho J.H., Chi S.H. Carbon dioxide removal using carbon monolith as electric swing adsorption to improve indoor air quality. Build. Environ. 2015;92:209–221. [Google Scholar]

- Lin C.-C., Lin H.-T. Removal of carbon dioxide from indoor air using a cross- flow rotating packed bed. Energy Proc. 2013;37:1187–1193. [Google Scholar]

- Lu T., Lü X., Viljanen M. A novel and dynamic demand-controlled ventilation strategy for CO2 control and energy saving in buildings. Energy Build. 2011;43:2499–2508. [Google Scholar]

- Lü X., Lu T., Viljanen M., Kibert C.J. A new method for controlling CO2 in buildings with unscheduled opening hours. Energy Build. 2013;59:161–170. [Google Scholar]

- Mamaghani A.H., Haghighat F., Lee C.-S. Photocatalytic oxidation technology for indoor environment air purification: the state-of-the-art. Appl. Catal. B Environ. 2017;203:247–269. [Google Scholar]

- McNabola A., O’Luanaigh N., Gallagher J., Gill L. The development and assessment of an aspiration efficiency reducing system of air pollution control for particulate matter in building ventilation systems. Energy Build. 2013;61:177–184. [Google Scholar]

- Mendell M.J., Heath G.A. Do indoor pollutants and thermal conditions in schools influence student performance? A critical review of the literature. Indoor Air. 2005;15:27–52. doi: 10.1111/j.1600-0668.2004.00320.x. [DOI] [PubMed] [Google Scholar]

- Ng L.C., Persily A.K., Emmerich S.J. IAQ and energy impacts of ventilation strategies and building envelope airtightness in a big box retail building. Build. Environ. 2015;92:627–634. [Google Scholar]

- Nimlyat P.S., Kandar M.Z. Appraisal of indoor environmental quality (IEQ) in healthcare facilities: a literature review. Sustain. Cities Soc. 2015;17:61–68. [Google Scholar]

- Ongwandee M., Kruewan A. Evaluation of portable household and in-car air cleaners for air cleaning potential and ozone-initiated pollutants. Indoor Built Environ. 2013;22:659–668. [Google Scholar]

- Persily A. Challenges in developing ventilation and indoor air quality standards: the story of ASHRAE Standard 62. Build. Environ. 2015;91:61–69. doi: 10.1016/j.buildenv.2015.02.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reche C., Viana M., Rivas I., Bouso L., Àlvarez-Pedrerol M., Alastuey A., Sunyer J., Querol X. Outdoor and indoor UFP in primary schools across Barcelona. Sci. Total Environ. 2014;493:943–953. doi: 10.1016/j.scitotenv.2014.06.072. [DOI] [PubMed] [Google Scholar]

- Reynolds S.J., Black D.W., Borin S.S., Breuer G., Burmeister L.F., Fuortes L.J., Smith T.F., Stein M.A., Subramanian P., Thorne P.S., Whitten P. Indoor environmental quality in six commercial office buildings in the midwest United States. Appl. Occup. Environ. Hyg. 2001;16:1065–1077. doi: 10.1080/104732201753214170. [DOI] [PubMed] [Google Scholar]

- Roegiers J., Denys S. Development of a novel type activated carbon fiber filter for indoor air purification. Chem. Eng. J. 2021;417:128109. [Google Scholar]

- Schell M.B., Turner S.C., Shim R.O. Application of CO2-based demand-controlled ventilation using ASHRAE Standard 62: optimizing energy use and ventilation. Build. Eng. 1998 [Google Scholar]

- Seppanen O.A., Fisk W.J., Mendell M.J. Association of ventilation rates and CO2 concentrations with health and other responses in commercial and institutional buildings. Indoor Air. 1999;9:226–252. doi: 10.1111/j.1600-0668.1999.00003.x. [DOI] [PubMed] [Google Scholar]

- Sublett J.L., Seltzer J., Burkhead R., Williams P.B., Wedner H.J., Phipatanakul W. Air filters and air cleaners: rostrum by the American academy of allergy, asthma & immunology indoor allergen committee. J. Allergy Clin. Immunol. 2010;125:32–38. doi: 10.1016/j.jaci.2009.08.036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Suk W.A., Murray K., Avakian M.D. Environmental hazards to children’s health in the modern world. Mutat. Res. Mutat. Res. 2003;544:235–242. doi: 10.1016/j.mrrev.2003.06.007. [DOI] [PubMed] [Google Scholar]

- Xu H., Jin W., Luo J., Wang F., Zhu H., Liu G., Yu Y., Lei C., Guo Y. Study of the PTFE multi-tube high efficiency air filter for indoor air purification. Process Saf. Environ. Protect. 2021;151:28–38. [Google Scholar]

- Yu M., Zeng S., Nie Y., Zhang X., Zhang S. Ionic liquid–based adsorbents in indoor pollutants removal. Curr. Opin. Green Sustain. Chem. 2021;27:100405. [Google Scholar]

- Zhong L., Haghighat F. Photocatalytic air cleaners and materials technologies – abilities and limitations. Build. Environ. 2015;91:191–203. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.