Abstract

In light of the maelstrom that global Supply Chains must struggle with, we contend that Systems Thinking in Supply Chain Management can be an enabling factor. Systems Thinking can support problem-solving in the reactive crisis mode that practitioners find themselves in, let alone when seeking ways to improve the end-to-end Supply Chain. This paper determines the prevalence of Systems Thinking methodologies within the literature and confirms if these contributions provide benefits to Supply Chain Management beyond the dyad through empirical research? Given the challenges of realising supply chain-wide progression, are these contributions supporting the discipline in pursuing industry advancement strategies? A systematic literature review methodology was employed, evaluating ninety-seven peer-reviewed papers regarding the breadth; from suppliers’ supplier to customers customer, and depth; from literature review to empirical research. Five research outcomes are identified, resulting in an established hypothesis. We argue that a positive correlation between Systems Thinking Maturity and Supply Chain Performance leads to a more significant opportunity to go beyond the dyad. The hypothesis led to a research construct that advocates the need to determine empirically whether a correlation exists between Systems Thinking Maturity and Supply Chain Performance.

Keywords: Systematic literature review, Systems thinking, Supply chain, Supply chain management

Introduction

Imagine a global health pandemic occurred, and the Systems of the World responded effectually. Impacts occur, a period of adjustment ensues; however, a level of confidence in the System remains. Within the broader Systems of the World, Sub-Systems are connected and can work through the adjustments to contend with the emerging variables from this wicked problem. The Supply Chain Sub-Systems are interconnected, with complete transparency and agility to shift the entire System towards the required position. Those within the Supply Chain System have clarity of the immediate and removed stakeholders and know the ramifications of decisions from those upstream to those at the receiving end. Whilst competitive, they focus upon what is suitable for the broader System. Efficient and holistic decisions are commonplace, with waste kept to a minimum, given actual demand and supply alignment. Those relying upon the Sub-System understand and see the Systems operating in real-time and trust that economic, societal, and environmental objectives are satisfied equally. Every day the World’s Supply Chain System continues to learn and adjust. Those depending upon it grow with more confidence and share resources as needed to ensure an equilibrium exists within their relative Systems. The Systems of the World manages the pandemic, returning to the normal state quickly, whilst implementing strategies to mitigate future instances.

The scenario above may sound like it belongs in a science fiction movie. However, it paints the picture of what a Systems Thinking utopia may look like compared to the world’s situation now. A Sub-System referred to in the above scenario is the World Supply Chains. This paper is concerned with the prevalence of Systems Thinking in the entire supply chain’s strategic management, henceforth called Supply Chain Management. Given the real-world maelstrom in which Supply Chains finds themselves, we contend that the postulated scenario is one all Supply Chain practitioners wish existed.

We seek to explore Systems Thinking’s position in Supply Chain Management, given the modern-day challenges we face to achieve a more developed position for the inevitable next black swan event (Taleb 2008). Advocating Systems Thinking, Jackson (2020) argues that Systems Thinking could have helped respond to COVID-19 in the UK, specifically the Systems Thinking frames of reference used to address some of the Supply Chain related challenges, e.g., personal protective equipment. Whilst not referring to Systems Thinking directly, Sarkis et al. (2020) takes a Systems view to critique the weaknesses in the Supply Chain and promote resilience measures, in addition to detailed lessons learnt from a post-COVID perspective (Sarkis 2020).

The Supply Chain functions as a System, from the extraction of raw materials to delivery to the ultimate end consumer. Those engaged are part of a broader system to deliver in full, on-time effectively. In recent times, the prominence of the Supply Chain has risen to near-celebrity levels (Esper 2021). Ideally, the entire supply chain system must operate in unison, via a seamless manner, to realise the consumers’ expectations. They expect the on-time delivery of toilet paper, let alone the supply of life-saving medication.

Examination of the System typically occurs at the point of crisis. This reactionary approach is typified per response to COVID-19, as Bhaskar et al. (2020) presented, calling for transformative reforms are those advocated by Mollenkopf et al. (2020). We contend that if actors know their Supply Chain system in terms of structure, process, and relationships, the ability of the Supply Chain to respond to wicked problems will be greater. The same is true in proactive instances, where Supply Chain actors seek to advance their collective System through initiatives. We assert that knowing about the System that constitutes one’s Supply Chain, from the supplier’s supplier to the customer’s customer, will provide additional benefits. Actors with Systems knowledge of the Supply Chain can respond more effectively to a crisis or have a greater ability to implement an advancement strategy.

Many advancement initiatives have contributed in this space, from Supply Chain Integration (Fawcett and Magnan 2002), Supply Chain Collaboration (Skjoett-Larsen et al. 2003), Supplier Networks (Dyer 1996), Supply Chain Ecology (Leigh and Li 2015), Dyads (Wilding et al. 2012) and Triads (Choi and Wu 2009). We recognise that many contributions in the literature have elements of Systems Thinking. However, there are limited examples where discrete Systems Thinking methodologies are employed to tackle the problems their Supply Chain faces, leading to this paper. We are not seeking to advocate one Systems Thinking methodology over another, or replace an existing Supply Chain strategy. Instead, we seek to determine the literature’s positions and aim to understand the impact these contributions have made to Supply Chain Management, leading to future research opportunities.

To set the foundation of Systems Thinking in Supply Chain Management, we seek evidence in the literature via a Systematic Literature Review (SLR). The intent is to systematically review extant literature to identify what has come before in the domain of Supply Chain Management through the application of Systems Thinking. In addition, we seek to understand the dominant focus or orientation? Finally, these positions will inform future research hypotheses that require empirical validation beyond this initial literature review.

Overview of Systems Thinking

When discussing Systems Thinking (ST), within the context of Supply Chain Management (SCM), there is a necessity to define the System in which we will view the Supply Chain: “A system is a whole consisting of two or more parts (1) each of which can affect the performance or properties of the whole, (2) none of which can have an independent effect on the whole, and (3) no subgroup of which can have an independent effect on the whole. In brief, then, a system is a whole that cannot be divided into independent parts or subgroups of parts” (Ackoff 1994, p. 175).

Many ST definitions exist within the literature, resulting in the absence of a central position, which seemingly has not changed since Rountree’s (1977) work. Table 1 provides definitions from several seminal contributors within the discipline, each with their unique position, yet several themes are present. Arnold and Wade (2015) presented various positions and applied a systems approach to categorise and provide a single definition. Whitehead et al. (2015) applied a systems thinking approach to establish a single definition in dissecting systems and thinking. Continuing with Ackoff, we have identified his definition of Systems Thinking as pertinent for this paper: “Systems thinking looks at relationships (rather than unrelated objects), connectedness, process (rather than structure), the whole (rather than just its parts), the patterns (rather than the contents) of a system, and context…” (Ackoff 2010, p. 6). From an SCM perspective, this definition aligns as for a Supply Chain to function as a System; it requires those in the Supply Chain to have working relationships for the fundamental objectives of the Supply Chain to be fulfilled. It needs to be connected, with an interweaving of processes to communicate amongst those in the Supply Chain to fulfil the end consumer’s fulfilment.

Table 1.

Systems thinking definitions

| Contributor | Definition | Reference |

|---|---|---|

| Richmond | Systems thinking is the art and science of making reliable inferences about behaviour by developing an increasingly deep understanding of underlying structure. | Richmond, p. 139, 1994 |

| Espejo | Systemic Thinking is an understanding of how the parts relate to each other and constitute larger wholes, that is, of self-organising processes. | Espejo, p. 210, 1994 |

| Systemic Thinking is understanding the interactive processes constituting wholes at multiple levels, that is, the recurrent conversations grounding shared constructs in a common reality. | ||

| Systemic Thinking is understanding how the System works, that is, understanding the mechanisms underlying the preceding processes. | ||

| Systemic Thinking is understanding the likely effects in the whole of local behaviors, and vice versa. | ||

| Systemic Thinking is understanding the language and emotions (i.e., conversations) most likely to produce stable, viable wholes. | ||

| Systemic Thinking is grounding purpose through shared distinctions and transforming these distinctions into interactive patterns enhancing people’s actions, making their action more effective. In other words, systemic Thinking is learning how to manage situational complexity. | ||

| Senge |

Systems thinking as a discipline for seeing wholes and a framework for seeing interrelationships rather than things, for seeing patterns of change rather than static snapshots. |

Senge, p. 68, 2006 |

| Forrester |

Systems thinking is coming to mean little more than thinking about systems, talking about systems, and acknowledging that systems are important. In other words, systems thinking implies a rather general and superficial awareness of systems. |

Forrester, p. 251, 1994 |

| Checkland | The process of systems that is to say: consciously organised thinking using systems ideas. | Checkland, p. 45, 1999 |

We argue that SCM lacks those seeing the whole Supply Chain rather than their isolated organisation, with a need to consider the entire System. Ackoff informs as to what we see as a need to change in today’s Supply Chain, being: “Thinking Systemically also requires several shifts in perception, which lead in turn to different ways to teach, and different ways to organise society.” (Ackoff 2010, p. 6). We argue that both Supply Chain academics and practitioners alike need to shift their perception from simply interfacing with the next in line and start considering the whole. Exploring questions like, what is the depth of our relationship, how are we connected, why do we communicate in the way we do? This paper seeks to understand the extant literature to start to form a position towards these questions.

An array of Systems Thinkers has influenced this paper and the questions we are seeking further insight over. Some have both summarised the historical evolution and contributed in their own right, such as Jackson (2019), Midgley (2003), Mingers (2014), Morgan (1997), and Senge (2006). Beer (1981) has influenced knowledge by considering the structure and control, Cybernetics, of the organisation with discipline defining initiatives such as, although not limited to, Project Cybersyn (Espejo 2014). Checkland’s (Checkland 1976) contribution is essential, given the inherent criticality of relationships across the Supply Chain, using the simple yet rich approach in his Soft Systems Methodology (Checkland and Scholes 1999). Forrester’s introduction of System Dynamics is of interest from a problem analysis perspective and causality, given the natural impact of any element in a Supply Chain and the actions’ subsequent outcomes (Forrester 1975). Luhmann (1996) has influenced communication questions and the transference of information across actors within the Supply Chain. Finally, Jackson’s System of System Methodologies (Jackson 2019) has guided an understanding of the context in which ST methodologies are best considered and utilised within the SLR section of this paper. We examine the prevalence of these methodologies across contributions within SCM, profiling the application of the ST methodologies in terms of the breadth of Supply Chain application and the depth of the research.

Supply Chain Context

The ST definitions and representation of the System align to a Supply Chain perspective, given the natural linkage of what a Supply Chain does, using the definition from Mentzer et al. (2001, p.4); “a supply chain is defined as a set of three or more entities (organisations or individuals) directly involved in the upstream and downstream flows of products, services, finance and/or information from a source to a customer.” This research is concerned with the management of the Supply Chain as defined by Mentzer et al. (2001, p.18) “the systemic, strategic coordination of the traditional business functions and the tactics across these business functions within a particular company and across businesses within the supply chain, for the purposes of improving the long-term performance of the individual companies and the supply chain as a whole”. Min et al. (2019) reiterates the earlier work of Mentzer et al. (2001) and expands to reflect the contemporary challengers of SCM, with the elements of a ‘central Supply Chain organisation as an essential facilitator, in addition to the ‘inter-organisational collaboration being at the centre of SCM.’

Adapted from Sadler (2007) is a Supply Chain represented via a Double-Bell Model (Fig. 1). This model depicts a conventional Supply Chain, from the supplier’s supplier to the customer’s customer. The Double-Bell Model is employed to articulate a typical scenario whereby a focal firm transforms the suppliers’ inputs into outputs to the customers. This model is for illustrative purposes, recognising the significant network of suppliers and customers in any one Supply Chain. In addition, this model provides a clear illustration of those within a system that revolves around a singular focal firm, taking the form as denoted in Lamming et al. (2000) and Harland et al. (2001). Orchestration typically originates from the demand side of the Supply Chain and progress to the final supplier at the dyadic level, as the organisation of the Supply Chain typically occurs between two entities as opposed to multiple, as promulgated in Choi and Wu (2009). The Supply Chain only functions when communication between the entities occurs, demand information flowing from the customer, and supply information from the suppliers. Effective communication is central to the Supply Chain for competitiveness, let alone survival, as outlined in Cao et al. (2010), with future software-based advances, e.g., IoT, blockchain, requiring a more significant presence of informatics to realise these new levels of operational competence (Bechtsis and Tsolakis 2018). Therefore, we contend the diagram in Fig. 1 depicts a conventional Supply Chain, with additions from a ST context, e.g., Systems Dynamics, that most practitioners are operating within, thus providing the opportunity to move beyond the convention and consider the Supply Chain from a Systems Theory perspective and expand the use of ST references in the Supply Chain. Besides meeting the requirements of the end-customer on a tactical level, e.g., supplying daily orders, the Supply Chain must compete with adjacent Supply Chains, e.g., those that support competing products, as presented in Li et al. (2006). Therefore, a key strategy to differentiate the Supply Chain is to achieve greater levels of integration across the wider Supply Chain.

Fig. 1.

Supply chain double bell model

The Challenge Integrating a System

Supply Chain Integration (SCI) stems from a systems perspective by Childerhouse and Towill: “optimisation of the whole achieves better performance than a string of optimised sub-systems” (Childerhouse and Towill, p. 4, 2011). SCI’s challenges denoted in Fawcett and Magnan (2002) cite apparent gaps in SCI’s success. Moreover, the presuppositions that the term Supply Chain Management (SCM) does not necessarily mean it prevails, e.g., managing the entire Supply Chain. A critical finding in Fawcett and Magnan (2002) is the lack of seeing the Supply Chain, with the Supply Chains entire System generally not known to those within the Supply Chain. Power (2005) advocates a holistic viewpoint and considers the systemic interactions in relationships from a system-wide perspective.

As Power argues, this is a substantial challenge that the theoretical promised benefits are in stark contrast to a fully integrated Supply Chain. Taking a broader empirical view, Bagchi et al. (2005) provide similar conclusions towards SCI, with outcomes limited to the dyad, with the inherent challenges associated with a fully integrated Supply Chain’s potential utopia. Expanding upon SCI’s challengers, in their empirical contribution, Childerhouse and Towill provide a clear understanding of what SCI is and more aptly detail the six arcs of integration upon the axis of supplier and customer integration (Childerhouse and Towill 2008). The struggle of SCI is recognised with a clear proposition that firms should organise their integration challengers before advancing outside their organisation’s walls. Given this research’s orientation, consideration turns to how Systems Thinking (ST) could aid individual firms in the Supply Chain to ‘see’ their internal systems and look to integrate further on the precondition they understand their System first. With the challenges of integrating the Supply Chain in mind, this work’s fundamental resolve is to ascertain if the ST contributions help Supply Chain practitioners advance their discipline?

Research Questions

Given the challenges the Supply Chain faces in reacting to a crisis or starting proactive strategies, this paper seeks to determine if the literature’s contributions provide sufficient insights to respond effectually? Accordingly, this research aims to address the following research questions:

What is the Prevalence of Systems Thinking in Supply Chain Management from a supply chain scope and research intensity perspective?

What insights into Systems Thinking utilisation across the Supply Chain have been established, given reactive crisis or proactive improvement instances?

Through the utilisation of Systems Thinking in Supply Chain Management, what contributions are made outside the focal firm to dyads and beyond?

Given that communication between humans and information systems is critical in the improvement of Supply Chains, to what extent can Systems Thinking augment the efficacy of such communication?

Methodology

This research utilises the Systematic Literature Review (SLR) approach of Tranfield et al. (2003) to systematically review the literature through a structured methodology. Parameters that confine the literature to a set of determinants are set, resulting in specific inferences. This SLR applies the defined steps of; establishing research questions, formulating a baseline sample of the literature, and synthesising the literature to yield several research outcomes. This approach enables the development of a hypothesis and a construct for future research. This research also integrates the SLR methodology propagated by Durach et al. (2017) that considers the Supply Chains characteristics. They suggest using a research framework to reflect the Supply Chains idiosyncrasies. Adapted from Durach et al. (2017), Table 2 charts the typical SLR steps by Tranfield et al. (2003) and extends to include the Supply Chain context by Durach et al. (2017).

Table 2.

SLR Approach applied to SCM

| # | Step | Steps in General SLR Guidelines (Tranfield et al. 2003) |

Steps in an SCM Review (Durach et al. 2017) |

|---|---|---|---|

| 1 | Define the Research Question |

- Justify review in terms of timeliness and relevance - Highlight contribution of SLR |

- Develop an initial theoretical framework regarding the phenomenon under study to refine it considering the SLR literature |

| 2 | Decide required characteristics of primary studies | - Craft inclusion and exclusion criteria | - Develop criteria for determining whether a publication can provide information regarding the theoretical framework |

| 3 | Retrieve sample of potentially relevant literature (“baseline sample”) |

- Decide search procedures - Define and apply keywords to retrieve a preliminary sample of primary studies.” |

- Find literature through structured and rigorous searches |

| 4 | Select pertinent literature (“synthesis sample”) | - Apply inclusion and exclusion criteria | - Conduct theoretically driven selection of literature to identify relevant studies according to inclusion/exclusion criteria |

| 5 | Synthesise literature |

- Apply coding schemes to extract pertinent information from the literature - Synthesise studies by summarising, integrating, or cumulating the different findings across the primary studies |

- Develop two data extraction structures based on aspects of the first theoretical framework - Integrate data to refine the theoretical framework, that is, figure out what works for whom, how, and under what circumstances - Develop narrative propositions that explain the mechanism, context (moderating conditions), and outcomes |

| 6 | Result Reporting | - Report results from the review | - Explain the refined theoretical framework and compare with initial theoretical assumptions |

Adapted from Durach et al. (2017)

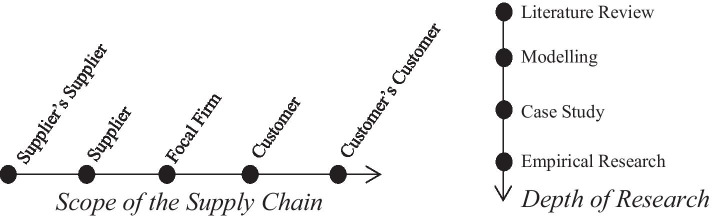

Research Framework

This paper utilises a research framework (Fig. 2) concerned with the Supply Chains breadth, where the extant literature evidence resides, and to what depth are the contributions making to the broader phenomena. First, an applied coding schema is determined to illustrate the relative points in the Supply Chain where the contributions reside, from the supplier’s supplier to customer’s customer. The second element relates to the intensity of the journal articles, extending from a literature review to empirical research. Then at further points of intersection, e.g., contributions that extend beyond the dyad and offer practical insights.

Fig. 2.

Research framework

Research Criteria

An established inclusion and exclusion criteria, Table 3 sets boundaries to limit the search returns. The inclusion criteria focus on the Supply Chain definition to provide context for the potential application of ST methodologies.

Table 3.

SLR criteria

| Inclusion Criteria | Exclusion Criteria | ||

|---|---|---|---|

| Supply Chain and alternative definitions | Covering the extent of Supply Chain and related definitions (e.g., Supply Chain Management, Logistics Management, Procurement, S&OP) | Title Only | Excluded are all other search elements besides title (TI) to understand the prevalence of Systems Thinking as a primary focus in the literature |

| Systems Thinking / Theory | Systems thinking and associated methodologies (e.g., Systems Dynamics, Soft Systems Methodologies, Viable Systems Model) | Conference, Opinion and Working Papers | Lacking empirical rigour and substantiation that could provide significant bias |

| Search Timeframe | Research published from 1956 (from the inception of General System Theory) to March 2020 | Non-English Based Publication | English only papers (unless translated) |

| Publication in peer-reviewed | The inherent quality of a peer review papers given as opposed to conference, opinion and working papers | Un-validated Journals | Unless validated through their presence in Scimago, Incites or ABCD journal ranking mechanisms |

Baseline Sample Selection

The initial two searches utilised several databases, e.g., EBSCOhost, Emerald Insight, Proquest & Scopus, and considered an array of Supply Chain Management and Systems Thinking related terms. The search strings utilised System Thinking methodologies from Jackson (2019) as detailed in the System of Systems Methodology (SOSM). The SOSM (Jackson 2019) encompasses methodologies consistent across the literature chronicled in Midgley (2003). The baseline search returned a vast array of articles relating to Supply Chain Management and Systems Thinking, with further refinement leading to 243 articles (Fig. 3). There is an increasing interest in Systems Thinking applications in Supply Chain Management, with Systems Dynamics being the predominant methodology employed within the literature.

Fig. 3.

Baseline sample

An initial interpretation of the prevalence of systems dynamics in SCM could be because the methodology has made its way into popular forms by Senge (2006) and Meadows (2008). However, there is a notable absence in other seminal contributors’ work, for instance, Soft Systems Methodology (Checkland 2000) and the Viable Systems Model (Beer 1984).

Synthesis of the Literature

The baseline search strings provided an initial ST position in SCM, providing a wide array of results. Whereas the final search string (Table 4) narrowed specifically to Supply Chain yet retained the methodology terms within the literature. After applying the criteria, the result yields 97 papers that fall into the established parameters listed in Appendix Table 5. Even with the revised search string, many papers were not included in the final review, as they returned results outside of the criteria or were unable to be validated.

Table 4.

Final search string

| Search | Search String | No. of Papers |

|---|---|---|

| 3 | Supply Chain* AND Systems Thinking* OR General Systems Theory* OR Operations Research* OR Systems Analysis* OR Vanguard Method* OR Systems Engineering* OR Systems Dynamics* OR Socio-Technical Systems Thinking* OR Viable System Model* OR Strategic Assumption Surfacing and Testing* OR Soft Systems Methodology* OR Interactive Planning* OR Team Syntegrity* OR Critical Systems Heuristics* OR Liberating Systems Theories* | 97 |

Table 5.

Systematic literature review - coding results

| Year | Author | Title | Journal | Methodology | Coding | |

|---|---|---|---|---|---|---|

| Supply chain scope | Research intensity | |||||

| 1993 | Towill, D. R. | System dynamics— background, methodology, and applications: Part 1: Background and methodology | Computing and Control Engineering Journal | System Dynamics | Level 4 | Level 1 |

| 1993 | Towill, D. R. | System dynamics— background, methodology, and applications: Part 2: Applications | Computing and Control Engineering Journal | System Dynamics | Level 4 | Level 3 |

| 1996 | Naim, M. M. | Methodology before technology | Manufacturing Engineer | System Dynamics | Level 3 | Level 1 |

| 1997 | Maloni and Benton | Supply chain partnerships: Opportunities for operations research | European Journal of Operational Research | Operations Research | Level 3 | Level 1 |

| 2001 | Sodhi and Mohan | Applications and opportunities for operations research in Internet-enabled supply chains and electronic marketplaces | Interfaces | Operations Research | Level 3 | Level 1 |

| 2003 | Spengler and Schroter | Strategic Management of Spare Parts in Closed-Loop Supply Chains-A System Dynamics Approach | Interfaces | System Dynamics | Level 3 | Level 3 |

| 2003 | Rubiano et al. | The effectiveness of using e-collaboration tools in the supply chain: an assessment study with system dynamics | Journal of Purchasing and Supply Management | System Dynamics | Level 3 | Level 2 |

| 2004 | Zhang and Dilts | System dynamics of supply chain network organisation structure | Information Systems and eBusiness Management | System Dynamics | Level 5 | Level 2 |

| 2004 | Y. Ge et al. | System dynamics modelling for supply-chain management: A case study on a supermarket chain in the UK: [1] | International Transactions in Operational Research | System Dynamics | Level 4 | Level 2 |

| 2005 | Amit et al. | Developing Indian grain supply chain cost model: a system dynamics approach | International Journal of Productivity and Performance Management | System Dynamics | Level 4 | Level 3 |

| 2005 | Akkermans and Dellaert | The rediscovery of industrial dynamics: the contribution of system dynamics to supply chain management in a dynamic and fragmented world | System Dynamics Review | System Dynamics | Level 1 | Level 1 |

| 2005 | Moon and Kim | Systems thinking ability for supply chain management | Supply Chain Management | Systems Thinking | Level 4 | Level 4 |

| 2005 | Georgiadis et al. | A system dynamics modeling framework for the strategic supply chain management of food chains | Journal of Food Engineering | System Dynamics | Level 2 | Level 3 |

| 2006 | Ashayeri, and Lemmes. | Economic value added of supply chain demand planning: A system dynamics simulation | Robotics and Computer-Integrated Manufacturing | System Dynamics | Level 3 | Level 3 |

| 2006 | Wu et al. | Using System Dynamics Approach to Construct a Performance Measurement Model for Pharmacy Supply Chain Management | Journal of International Technology and Information Management | System Dynamics | Level 3 | Level 2 |

| 2006 | Schwaninger and Vrhovec | Supply System Dynamics: Distributed Control in Supply Chains and Networks | Cybernetics and Systems | System Dynamics | Level 2 | Level 2 |

| 2007 | Caddy et al.. | Supply chains and their management: Application of general systems theory | Journal of Retailing and Consumer Services | General Systems Theory | Level 1 | Level 2 |

| 2007 | Vlachos et al. | A system dynamics model for dynamic capacity planning of remanufacturing in closed-loop supply chains | Computers and Operations Research | System Dynamics | Level 2 | Level 2 |

| 2007 | Sameer and Teruyuki | System dynamics study of the Japanese automotive industry closed loop supply chain | Journal of Manufacturing Technology Management | System Dynamics | Level 2 | Level 2 |

| 2007 | Özbayrak et al. | Systems dynamics modelling of a manufacturing supply chain system | Simulation Modelling Practice and Theory | System Dynamics | Level 1 | Level 2 |

| 2007 | Min et al. | Simulation study using system dynamics for a CONWIP-controlled lamp supply chain | International Journal of Advanced Manufacturing Technology | System Dynamics | Level 1 | Level 2 |

| 2007 | Kamath et al. | Capacity augmentation of a supply chain for a short lifecycle product: A system dynamics framework | European Journal of Operational Research | System Dynamics | Level 1 | Level 2 |

| 2008 | Georgiadis and Besiou | Sustainability in electrical and electronic equipment closed-loop supply chains: A System Dynamics approach | Journal of Cleaner Production | System Dynamics | Level 1 | Level 3 |

| 2008 | Everingham et al. | Operations Research Enhances Supply Chain Management at the US Coast Guard Aircraft Repair and Supply Center | Interfaces | Operations Research | Level 1 | Level 3 |

| 2008 | Rabelo et al. | Using system dynamics, neural nets, and eigenvalues to analyse supply chain behaviour. A case study | International Journal of Production Research | System Dynamics | Level 1 | Level 3 |

| 2009 | Bonett et al. | Using Confidence Intervals in Supply Chain and Operations Research | Journal of Supply Chain Management | Operations Research | Level 1 | Level 4 |

| 2010 | Campuzano et al. | Fuzzy estimations and system dynamics for improving supply chains | Fuzzy Sets and Systems | System Dynamics | Level 2 | Level 2 |

| 2010 | Georgiadis and Besiou | Environmental and economical sustainability of WEEE closed-loop supply chains with recycling: a system dynamics analysis | The International Journal of Advanced Manufacturing Technology | System Dynamics | Level 4 | Level 2 |

| 2011 | Towill and Childerhouse. | A systems engineering approach to supply chain auditing | Journal of Manufacturing Technology Management | Systems Engineering | Level 1 | Level 4 |

| 2011 | Rabelo et al. | Stability of the Supply Chain Using System Dynamics Simulation and the Accumulated Deviations from Equilibrium | Modelling and Simulation in Engineering | System Dynamics | Level 1 | Level 2 |

| 2011 | Kumar and Nigmatullin | A system dynamics analysis of food supply chains – Case study with non-perishable products | Simulation Modelling Practice and Theory | System Dynamics | Level 5 | Level 2 |

| 2011 | Janamanchi | Optimising Two-player Supply Chain Performance: A System Dynamics Simulation Study | Competition Forum | System Dynamics | Level 2 | Level 2 |

| 2011 | Ivanov et al. | Integrated supply chain planning based on a combined application of operations research and optimal control | Central European Journal of Operations Research | Operations Research | Level 1 | Level 1 |

| 2012 | Vimmerstedt et al. | Ethanol Distribution, Dispensing, and Use: Analysis of a Portion of the Biomass-to-Biofuels Supply Chain Using System Dynamics | PLoS One | System Dynamics | Level 3 | Level 1 |

| 2012 | Trappey et al. | System dynamics modelling of product carbon footprint life cycles for collaborative green supply chains | International Journal of Computer Integrated Manufacturing | System Dynamics | Level 3 | Level 2 |

| 2012 | Tavella et al. | Enhancing the Design and Management of a Local Organic Food Supply Chain with Soft Systems Methodology | International Food and Agribusiness Management Review | Soft Systems Methodology | Level 2 | Level 2 |

| 2012 | Tako et al. | The application of discrete event simulation and system dynamics in the logistics and supply chain context | Decision Support Systems | System Dynamics | Level 1 | Level 1 |

| 2012 | Lin and Shayo | Systems Dynamics Modeling for Collaboration and Information Sharing on Supply Chain Performance and Value Creation | Journal of International Technology and Information Management | System Dynamics | Level 1 | Level 2 |

| 2012 | Kumar and Chandra | U.S., Japan and EU auto industries’ closed loop supply chains: A system dynamics study | VINE Information and Knowledge Systems Management | System Dynamics | Level 2 | Level 2 |

| 2012 | Gu and Gao | Joint decisions for R/M integrated supply chain using system dynamics methodology | International Journal of Production Research | System Dynamics | Level 5 | Level 2 |

| 2013 | Das and Dutta | A system dynamics framework for integrated reverse supply chain with three way recovery and product exchange policy | Computers and Industrial Engineering | System Dynamics | Level 4 | Level 2 |

| 2013 | Campuzano-Bolarín et al. | An extension to fuzzy estimations and system dynamics for improving supply chains | International Journal of Production Research | System Dynamics | Level 2 | Level 2 |

| 2013 | Zhang and Zhang | The System Dynamics Analyses of Bullwhip Effect in China Processed Oil Supply Chain | Applied Mechanics and Materials | System Dynamics | Level 3 | Level 2 |

| 2013 | Teimoury et al. | A multi-objective analysis for import quota policy making in a perishable fruit and vegetable supply chain: A system dynamics approach | Computers and Electronics in Agriculture | System Dynamics | Level 2 | Level 2 |

| 2013 | Mula et al. | A system dynamics model for the supply chain procurement transport problem: comparing spreadsheets, fuzzy programming and simulation approaches | International Journal of Production Research | System Dynamics | Level 1 | Level 2 |

| 2013 | Lehr et al. | From waste to value - a system dynamics model for strategic decision-making in closed-loop supply chains | International Journal of Production Research | System Dynamics | Level 1 | Level 2 |

| 2013 | Janamanchi and Burns. | Control Theory Concepts Applied to Retail Supply Chain: A System Dynamics Modeling Environment Study | Modelling and Simulation in Engineering | System Dynamics | Level 1 | Level 2 |

| 2013 | Guo and Wang, | System Dynamics Model for VMI and TPL Integrated Supply Chains | Discrete Dynamics in Nature and Society | System Dynamics | Level 3 | Level 2 |

| 2014 | Böhme et al. | Systems engineering effective supply chain innovations | International Journal of Production Research | Systems Engineering | Level 1 | Level 4 |

| 2014 | Tian et al. | A system dynamics model based on evolutionary game theory for green supply chain management diffusion among Chinese manufacturers | Journal of Cleaner Production | System Dynamics | Level 1 | Level 2 |

| 2014 | Rodríguez et al. | New opportunities in operations research to improve pork supply chain efficiency | Annals of Operations Research | Operations Research | Level 1 | Level 1 |

| 2014 | Piewthongngam et al. | System dynamics modelling of an integrated pig production supply chain | Biosystems Engineering | System Dynamics | Level 1 | Level 4 |

| 2014 | Peng, Min:Peng, Yi:Chen, Hong | Post-seismic supply chain risk management: A system dynamics disruption analysis approach for inventory and logistics planning | Computers and Operations Research | System Dynamics | Level 2 | Level 3 |

| 2014 | Mendoza et al. | Using systems dynamics to evaluate the tradeoff among supply chain aggregate production planning policies | International Journal of Operations and Production Management | System Dynamics | Level 2 | Level 2 |

| 2014 | Hildbrand and Bodhanya | Application of the viable system model in a complex sugarcane supply chain | British Food Journal | Viable System Model | Level 2 | Level 2 |

| 2014 | Belbo and Talbot | Systems Analysis of Ten Supply Chains for Whole Tree Chips | Forests | Systems Analysis | Level 3 | Level 2 |

| 2014 | Afshar et al. | System Dynamics Analysis of a Blood Supply Chain System | Applied Mechanics and Materials | System Dynamics | Level 1 | Level 3 |

| 2015 | Blackburn et al. | Operations research in BASF’s supply chain operations | International Transactions in Operational Research | Operations Research | Level 1 | Level 3 |

| 2015 | Yuan and Zhang, Xiao | Recycler Reaction for the Government Behavior in Closed-Loop Supply Chain Distribution Network: Based on the System Dynamics | Discrete Dynamics in Nature and Society | System Dynamics | Level 4 | Level 2 |

| 2015 | Waller et al. | The Luxury Paradox: How Systems Thinking and Supply Chain Collaboration Can Bring Sustainability Into Mainstream Practice | Journal of Business Logistics | Systems Thinking | Level 1 | Level 1 |

| 2015 | Golroudbary et al. | System dynamics model for optimising the recycling and collection of waste material in a closed-loop supply chain | Simulation Modelling Practice and Theory | System Dynamics | Level 2 | Level 2 |

| 2015 | Behera and Prakash | Understanding Construction Supply Chain Management | Production Planning and Control | Soft Systems Methodology | Level 2 | Level 1 |

| 2016 | Ba et al. | Models for optimisation and performance evaluation of biomass supply chains: An Operations Research perspective | Renewable Energy: An International Journal | Operations Research | Level 1 | Level 1 |

| 2016 | Azadeh and Hamed | Biodiesel supply chain optimisation via a hybrid system dynamics-mathematical programming approach | Renewable Energy: An International Journal | System Dynamics | Level 4 | Level 2 |

| 2016 | Zhang and Yuan | The System Dynamics Model in Electronic Products Closed-Loop Supply Chain Distribution Network with Three-Way Recovery and the Old-for-New Policy | Discrete Dynamics in Nature and Society | System Dynamics | Level 4 | Level 2 |

| 2016 | Stindt et al. | How Transdisciplinarity Can Help to Improve Operations Research on Sustainable Supply Chains--A Transdisciplinary Modeling Framework | Journal of Business Logistics | Operations Research | Level 2 | Level 3 |

| 2016 | Puche et al. | Systemic approach to supply chain management through the viable system model and the theory of constraints | Production Planning and Control | Viable System Model | Level 3 | Level 2 |

| 2016 | Mehrjoo and Pasek | Risk assessment for the supply chain of fast fashion apparel industry: a system dynamics framework | International Journal of Production Research | System Dynamics | Level 1 | Level 2 |

| 2016 | Li et al. | A system dynamics simulation model of chemical supply chain transportation risk management systems | Computers and Chemical Engineering | System Dynamics | Level 1 | Level 2 |

| 2016 | Langroodi et al. | A system dynamics modeling approach for a multi-level, multi-product, multi-region supply chain under demand uncertainty | Expert Systems with Applications | System Dynamics | Level 1 | Level 2 |

| 2016 | Janamanchi and Burns | Performance metric optimisation advocates CPFR in supply chains: A system dynamics model based study | Cogent Business and Management | System Dynamics | Level 1 | Level 2 |

| 2017 | Demczuk and Padula | Using system dynamics modeling to evaluate the feasibility of ethanol supply chain in Brazil: The role of sugarcane yield, gasoline prices and sales tax rates | Biomass and Bioenergy | System Dynamics | Level 1 | Level 2 |

| 2017 | Bhushan | System dynamics modelling-based analysis of combating counterfeit drugs supply chain in India | International Journal of Emergency Management | System Dynamics | Level 3 | Level 3 |

| 2017 | Rao et al. | On the analysis of complex biological supply chains: From process systems engineering to quantitative systems pharmacology | Computers and Chemical Engineering | Systems Engineering | Level 1 | Level 1 |

| 2017 | Pan et al. | A system dynamic analysis of China’s oil supply chain: Over-capacity and energy security issues | Applied Energy | System Dynamics | Level 4 | Level 3 |

| 2017 | Miao et al. | System dynamics research of remanufacturing closed-loop supply chain dominated by the third party | Waste Management and Research | System Dynamics | Level 4 | Level 3 |

| 2017 | Mello et al. | Improving coordination in an engineer-to-order supply chain using a soft systems approach | Production Planning and Control | Soft Systems Methodology | Level 4 | Level 4 |

| 2017 | Hildbrand and Bodhanya | Exploring the complexity of sugarcane supply chains via systemic approaches | Kybernetes | Soft Systems Methodology | Level 3 | Level 4 |

| 2017 | Heidarzadeh et al. | Development of supply chain strategy in the Iranian automotive industry based on system dynamics and game theory | Scientia Iranica. Transaction E, Industrial Engineering | System Dynamics | Level 2 | Level 2 |

| 2017 | Ghisolfi et al. | System dynamics applied to closed loop supply chains of desktops and laptops in Brazil: A perspective for social inclusion of waste pickers | Waste Management | System Dynamics | Level 1 | Level 1 |

| 2018 | Elmasry and Größler | Supply chain modularity in system dynamics | System Dynamics Review | System Dynamics | Level 1 | Level 2 |

| 2018 | Barbosa-Póvoa et al. | Opportunities and challenges in sustainable supply chain: An operations research perspective | European Journal of Operational Research | Operations Research | Level 2 | Level 2 |

| 2018 | Zhao et al. | Enhancing Eco-Efficiency of Agro-Products’ Closed-Loop Supply Chain under the Belt and Road Initiatives: A System Dynamics Approach | Sustainability | System Dynamics | Level 3 | Level 3 |

| 2018 | Yan and Lifeng | A new trans-shipment policy in cluster supply chains based on system dynamics | RAIRO Recherche Operationnelle | System Dynamics | Level 2 | Level 1 |

| 2018 | Sandor et al. | System Dynamics of Polysilicon for Solar Photovoltaics: A Framework for Investigating the Energy Security of Renewable Energy Supply Chains | Sustainability | System Dynamics | Level 1 | Level 1 |

| 2018 | Saavedra et al. | Sustainable and renewable energy supply chain: A system dynamics overview | Renewable and Sustainable Energy Reviews | System Dynamics | Level 1 | Level 2 |

| 2018 | Gonul et al. | Impact of cloud-based information sharing on hospital supply chain performance: A system dynamics framework | International Journal of Production Economics | System Dynamics | Level 3 | Level 2 |

| 2019 | Cao et al. | System dynamics simulation for CO2 emission mitigation in green electric-coal supply chain | Journal of Cleaner Production | System Dynamics | Level 1 | Level 1 |

| 2019 | Alglawe et al. | Analysing the cost of quality within a supply chain using system dynamics approach | Total Quality Management and Business Excellence | System Dynamics | Level 1 | Level 3 |

| 2019 | Zhao et al. | System dynamics simulation-based model for coordination of a three-level spare parts supply chain | International Transactions in Operational Research | System Dynamics | Level 4 | Level 1 |

| 2019 | Susanty et al. | The performance of dairy supply chain in Indonesia: a system dynamics approach | International Journal of Productivity and Performance Management | System Dynamics | Level 4 | Level 1 |

| 2019 | Song et al. | Simulation of land green supply chain based on system dynamics and policy optimisation | International Journal of Production Economics | System Dynamics | Level 1 | Level 1 |

| 2019 | Singh et al. | Assessment of Supply Chain Flexibility Using System Dynamics Modeling | Global Journal of Flexible Systems Management | System Dynamics | Level 1 | Level 3 |

| 2019 | Rebs et al. | Impacts of stakeholder influences and dynamic capabilities on the sustainability performance of supply chains: a system dynamics model | Journal of Business Economics | System Dynamics | Level 1 | Level 1 |

| 2019 | Rebs et al. | System dynamics modeling for sustainable supply chain management: A literature review and systems thinking approach | Journal of Cleaner Production | Systems Thinking | Level 1 | Level 1 |

| 2019 | Poornikooabd Muhammad Azeem | System dynamics modeling with fuzzy logic application to mitigate the bullwhip effect in supply chains | Journal of Modelling in Management | System Dynamics | Level 3 | Level 2 |

| 2020 | Alamerew and Brissaud | Modelling reverse supply chain through system dynamics for realising the transition towards the circular economy: A case study on electric vehicle batteries | Journal of Cleaner Production | System Dynamics | Level 2 | Level 2 |

Result Reporting and Analysis

The final search string reaffirmed System Dynamics (SD) as the dominant methodology, representing 75% of all ST methodologies cited, Fig. 4. Over the preceding decade, the prevalence of ST in SCM increases, with SD being the primary research methodology. Figure 5 illustrates the results of the final search string, overlayed upon the composition of the Supply Chain.

Fig. 4.

Systems thinking methodologies

Fig. 5.

Literature positions across the supply chain

Only 3.1%, n = 3, of the journal articles provided research insights into the entire supply chain. Most of the journal articles were concerned with the focal firm or the focal firm and the immediate supplier or customer (Tier 1). This outcome denotes a significant orientation towards the focal firm, and at best, a dyadic relationship, with a lack of research undertaken beyond these points. 14.6% of all contributions reside between the focal firm and a Tier 1 supplier and Tier 1 customer.

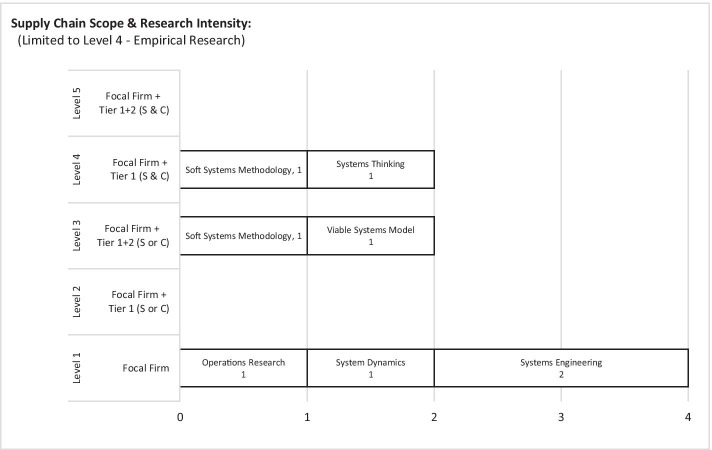

This section explores Supply Chain scope and research intensity by the coding schema illustrated in Fig. 6. Reviewing the literature from a Supply Chain scope perspective, we limit papers prevalent at Level 4: Focal Firm and Tier 1 Customer and Supplier, and Level 5: Supplier’s Supplier to Customer’s Customer. In this context, the first account of ST in SCM was Towill (1993a) and Towill (1993b) in applying SD at a Level 4 perspective. Towill’s Two-Part contribution provides both a framework and application that few in the literature have taken up. Zhang and Dilts (2004) explore a Supply Chain network using SD to model alternative structures. Ge et al. (2004) provide specific SD modelling in a supermarket setting, albeit limited to data modelling. Whilst the contributions of Georgiadis and Besiou (2010), Kumar and Nigmatullin (2011), Gu and Gao (2012), Das and Dutta (2013), Gang Yuan and Qing Zhang (2015), Azadeh and Arani (2016), Zhang and Yuan (2016), Zhao et al. (2019) and Susanty et al. (2019) extend beyond the dyad, with their outcomes applying SD modelling within a single area of concern across the Supply Chain. However, these contributions are limited in terms of research intensity and limited in their practical orientation. These contributions are in stark contrast to Towill (1993a) and Towill (1993b). They provided practical insights of understanding the Supply Chain by a holistic approach and did not apply SD in a mathematical modelling perspective.

Fig. 6.

Literature positions per supply chain scope and research intensity

In terms of research intensity, over two thirds, n = 72, of all articles are literature reviews and modelling, with SD being the primary methodology. This section is concerned with contributions beyond modelling, emphasising Level 3: Case Study and Level 4: Empirical Research. Most of this category’s contributions are limited to the focal firm with a small number, n = 3, at the dyad level. The standout contributions are limited to Childerhouse and Towill (2011) in their empirical research in the application of Systems Engineering (SE) in the deployment of a Quick Scan Audit Methodology (QSAM), applying QSAM to assess a Supply Chains health. Providing practical value, Böhme et al. (2014) also applied SE, using QSAM within the case of an engineer to order firm, realised insights through their empirical research. Operational Research (OR) featured in more significant proportions when considering intensity in isolation, with contributions through Everingham et al. (2008), Bonett and Wright (2009), Blackburn et al. (2015), Stindt et al. (2016), who provided several rich examples of OR ST methodologies in SCM, albeit limited to a focal firm or the immediate interfacing Tier. In contrast to the application of SD across a broader scope of the Supply Chain, Georgiadis et al. (2005) and Georgiadis and Besiou (2008) provides more significant insights and potential application within the industry.

Narrowing the analysis, Fig. 7 limits the contributions to those coded at Level 4 (empirical). Beyond the dyad, Soft Systems Methodology (Checkland) and Viable Systems Model (Beer) are the only methodologies mentioned with systems thinking referred to in general terms.

Fig. 7.

Empirical contributions. Supply chain performance

ST as an overarching ‘way of thinking’ is used by Moon and Kim (2005), whose work explores the ST capability of Supply Chain actors and its benefits to the SCM. This work is a rare contribution as far as the desire to explore ST as an archetype in managing a Supply Chain. In contrast, much of the reviewed literature is focused primarily on applying ST to a single organisational problem, with a limited discourse on applying the methodology to the broader SCM. Moon and Kim (2005) denote the ST abilities,’ referring to Sweeney and Sterman (2000), who promote a generic thinking capability at a more holistic level. Moon and Kim (2005) sought to understand the advantages that Supply Chain practitioners can obtain through the application of ST. Albeit limited to Systems Dynamics, Moon and Kim (2005) conducted tests, surveys, and simulations. They found a positive correlation between those who had ST capability and their Supply Chains performance, exemplified in their decisions relative to inventory positions. The implications for future research would be to expand the approach to include other methodologies, e.g., Soft Systems Methodologies, Viable Systems Model, to yield greater insight into the performance implications of applying ST in SCM.

In their application of Soft Systems Methodologies (SSM) in the shipbuilding process, from tender to commission, Mello et al. (2017) have sought improved levels of coordination across the shipbuilding Supply Chain. This contribution’s value lies in SSM utilisation in SCM, via the simplicity of the activity, yet the richness of the outcome by getting all the actors involved and aligned with proven practical benefits.

Beyond the single methodology, Hildbrand and Bodhanya (2017) applied a multi-methodology approach, utilising SSM and Viable Systems Model (VSM), which is the only application of multiple ST methodologies found in this SLR. Hildbrand and Bodhanya (2017) took a two-staged approach, with the first step of applying SSM to understand the sugar cane SCs complexity to make sense of the respective mess. This process of seeking out issues, debating, developing a model and actions to improve provided Hildbrand and Bodhanya (2017) the System’s context. The application of VSM enabled a System diagnosis that would articulate how the System could work, aside from the issues at play, e.g., trust and communication, which may undermine the System. The findings from this research supply a significant opportunity for Supply Chain practitioners to apply a multi-methodology approach that focuses on the System’s necessities, e.g., understanding the complexities and contextual elements via a rich picture.

The core themes across Moon and Kim (2005), Mello et al. (2017) and Hildbrand and Bodhanya (2017) are available benefits through the application of ST methodologies within SCM. In addition, their action research supplies a real opportunity for practical application, which contrasts much of the reviewed literature.

Discussion

This paper’s research outcomes provide insights into Systems Thinking (ST) prevalence within Supply Chain Management (SCM), with several results determined, informing a hypothesis and future research direction.

Research Outcomes & Hypothesis

This paper has determined the following research outcomes (RO):

Currently, Systems Thinking methodologies in Supply Chain Management primarily exist in the focal firm, extending to dyads in some instances.

Typically, contributions are limited to theoretical or conceptual modelling, employing Systems Dynamics as the dominant methodology in the literature. The orientation is towards a problem affecting the focal firm, with an extension to include the immediate supplier in some cases.

As the literature only uses a few Systems Thinking methodologies, a significant opportunity remains to publish knowledge of varied relevant methodologies. Supply Chain practitioners will benefit from the practical insights to employ single or multiple Systems Thinking methodologies to solve Supply Chain problems or implement improvements.

Few empirical contributions exist within the literature; such contributions employ alternative methodologies, e.g., Soft Systems Methodology and Viable Systems Model, rather than the dominant methodology.

Most of the literature orientates towards reacting to problems in the Supply Chain instead of proactively seeking strategic and collegiate improvements.

The literature is limited regarding communication enhanced by a Systems Thinking context, with a distinct absence of utilising frameworks to improve communication flows across the Supply Chain.

Providing empirically-based insights would help SCM pursue system-wide endeavours, in which practitioners can consider the whole Supply Chain from both strategic and tactical levels. In contrast to much of the extant literature, the work of Moon and Kim (2005), Mello et al. (2017) and Hildbrand and Bodhanya (2017) yield rich insights into the benefit of ST for SCM. We argue that Supply Chain practitioners require knowledge to apply ST’s principles to pursue initiatives. It is clearly challenging to advance beyond the dyad. Moreover, the absence of communication in the literature from a Systems Thinking context denotes a gap that undermines the ability to expand beyond dyadic relationships. Returning to Ackoff’s definitions, relationships and connectedness can only occur through communication. Communication as far as how are the actors firstly appreciating the challenges associated with communicating with partners, let alone methodologies to bring the collective Supply Chain together, via the means of communicating. Therefore, further research must address SCM’s challenge to promote practices to bring the ‘whole’ Supply Chain together through relationships and connectedness.

Given the research outcomes, we postulate a hypothesis:

H1: If there is a greater maturity of Systems Thinking within Supply Chain Management, we contend that Supply Chain performance will increase because an expansion beyond the focal firm is more likely to provide Supply Chain-wide achievements.

Future Research Directions

Considering the research outcomes and the above hypothesis, we contend there are further research opportunities to empirically determine the place of Systems Thinking within Supply Chain Management. We seek to identify a positive correlation between the application of Systems Thinking and Supply Chain Performance. Can Systems Thinking help Supply Chain practitioners in both reactive, problem-solving, and proactive improvement situations? This paper finds many contributions advocating Systems Thinking in Supply Chain Management, with an uplift in the contributions over the preceding decade. In response to the research outcomes, the research construct illustrated in Fig. 8 will guide the exploration of performance and maturity. We argue that there should be a positive correlation between higher Systems Thinking capability and Supply Chain Performance. Therefore, we seek empirical evidence regarding Supply Chain Performance (SCP) and Systems Thinking Maturity (STM) to test this hypothesis. Understanding these respective positions will inform whether there is a correlation between these two points, informing subsequent research and yield information to inspire future research.

Fig. 8.

Systems thinking & supply chain management research construct

In determining SCP, the literature will inform the construct in terms of established Supply Chain metrics, such as Beamon (1999), where we can contrast SCP with STM using approaches similar to Zailani (2005) or that of Cagliano et al. (2006). STM expands upon the earlier contributions, e.g., Moon and Kim (2005), that correlate Systems Thinking with Supply Chain Performance. In determining the method to establish STM, the Systems Thinking skills shared in Arnold and Wade (2017) provide practical insights. In addition, they provide insight that can be applied to understand empirical evidence from Supply Chain practitioners.

Conclusion

The research outcomes established in this paper are grounded in the literature, using a Systematic Literature Review by Tranfield et al. (2003) and Durach et al. (2017). The detailed analysis achieved by coding ninety-seven papers, Appendix Table 5, aligns with an established research framework. The positions are identified in terms of Scope, where in the Supply Chain the research resides, and the intensity or depth of the reviewed contribution. This paper reveals the limited occurrence of Systems Thinking within Supply Chain Management in terms of Scope. 42.7% of the reviewed literature is limited to the focal firm. In 14.6%, instances extend to the dyadic relationship with both a supplier and customer. In comparison, only 3% of the extant literature considers the supplier’s supplier to the customer’s customer.

Most of the contributions are theoretical or case modelling and apply Systems Dynamics. However, intersecting Scope beyond the dyad and set at the empirical level of research, System Dynamics is no longer the dominant methodology in this domain. Although methodologies such as Soft System Methodology and Viable Systems Model do feature at the empirical level, they are rarely employed across the literature.

Six research outcomes are determined, denoting an orientation towards a single methodology limited to the focal firm and dyads. Since the extant literature refers to a minimal array of Systems Thinking methodologies, an opportunity exists to expand Systems Thinking knowledge through alternate methodologies that can assist with structure, e.g., Viable Systems Model, and relationships, e.g., Soft Systems Methodology. The extant literature trends to react to problems within the Supply Chain rather than proactively seeking improvements to uplift performance. We identify a limitation as the literature does not use proactive methodologies to support the Supply Chain’s advancement, especially not coupling with existing Supply Chain improvement approaches.

The scarcity of multi-methodologies and the absence of mixed methodologies denote a limitation in the literature. Utilising a more extraordinary array of methodologies via the former approach could provide greater insight. We contend that multi-methodologies could provide a more significant opportunity to extract the actual value of Systems Thinking, given how such wicked challenges confront the contemporary Supply Chain. There are examples of empirical research by Moon and Kim (2005), Mello et al. (2017) and Hildbrand and Bodhanya (2017). All these propel the phenomenon forward, yet further contributions are needed to advance beyond the dyad and share a more significant array of existing methodologies, from a Systems Thinking context, communication in the literature is notably absent. For evolution to occur, the Supply Chain needs to transcend the extent to which they communicate between each other and across the entirety of the Supply Chain. Communication will be the intermediary in which the Systems Thinking methodologies will be diffused across the Supply Chain. The enabler to thinking as a System will be communication.

The established hypothesis questions the efficacy of present applications of Systems Thinking in Supply Chain Management, given the lack of empirical evidence. More is needed to determine if a positive correlation exists between the two disciplines. We infer that should a positive correlation exists, this will provide greater confidence in Supply Chain Management practitioners and academics to consider the broader application of Systems Thinking. Does a Supply Chain with more extraordinary Systems Thinking Maturity and End-to-End Scope understanding result in higher Supply Chain Performance? This question will guide future research.

We advocate a promotion of Systems Thinking in Supply Chain Management to pursue the utopian position of having the Systems of the World. Between now and the movement towards the realisation of this utopia across many years, we contend the World Supply Chains needs to collectively apply Systems Thinking to tackle the wicked problems of the day. This direction could achieve improved performance levels to attain sustainability across economic, environmental, and societal considerations. Organisations are struggling to respond to the current World pandemic. Pursuing Systems Thinking in times of relative calm would stand Supply Chains in good stead and provide an enabling factor when faced with an unprecedented crisis.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon request.

Appendix

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Ackoff RL. Systems thinking and thinking systems. Syst Dyn Rev. 1994;10:175–188. doi: 10.1002/sdr.4260100206. [DOI] [Google Scholar]

- Arnold RD, Wade JP. A complete set of systems thinking skills. Insight. 2017;20:9–17. doi: 10.1002/inst.12159. [DOI] [Google Scholar]

- Azadeh A, Arani HV. Biodiesel supply chain optimisation via a hybrid system dynamics-mathematical programming approach. Renew Energy. 2016;93:383–403. doi: 10.1016/j.renene.2016.02.070. [DOI] [Google Scholar]

- Bagchi PK, Chun Ha B, Skjoett-Larsen T, Boege Soerensen L. Supply chain integration: a European survey. Int J Logist Manag. 2005;16:275–294. doi: 10.1108/09574090510634557. [DOI] [Google Scholar]

- Beamon BM. Measuring supply chain performance. Int J Oper Prod Manag. 1999;19:275–292. doi: 10.1108/01443579910249714. [DOI] [Google Scholar]

- Bechtsis D, Tsolakis N. Trends in industrial informatics and supply chain management. Int J New Technol Res. 2018;4:91–93. doi: 10.31871/IJNTR.4.10.44. [DOI] [Google Scholar]

- Beer S. Brain of the firm: the managerial cybernetics of organization. Chichester: Wiley; 1981. [Google Scholar]

- Beer S. The viable system model: its provenance, development, methodology and pathology. J Oper Res Soc. 1984;35:7–25. doi: 10.1057/jors.1984.2. [DOI] [Google Scholar]

- Blackburn R, Kallrath J, Klosterhalfen ST. Operations research in BASF's supply chain operations. Int Trans Oper Res. 2015;22:385–405. doi: 10.1111/itor.12118. [DOI] [Google Scholar]

- Böhme T, Deakins E, Pepper M, Towill D. Systems engineering effective supply chain innovations. Int J Prod Res. 2014;52:6518–6537. doi: 10.1080/00207543.2014.952790. [DOI] [Google Scholar]

- Bonett DG, Wright TA. Using confidence intervals in supply chain and operations research. J Supply Chain Manag. 2009;45:26–33. doi: 10.1111/j.1745-493X.2009.03152.x. [DOI] [Google Scholar]

- Cagliano R, Caniato F, Spina G. The linkage between supply chain integration and manufacturing improvement programmes. Int J Oper Prod Manag. 2006;26:282–299. doi: 10.1108/01443570610646201. [DOI] [Google Scholar]

- Cao M, Vonderembse MA, Zhang Q, Ragu-Nathan T. Supply chain collaboration: conceptualisation and instrument development. Int J Prod Res. 2010;48:6613–6635. doi: 10.1080/00207540903349039. [DOI] [Google Scholar]

- Checkland P. Systems thinking, systems practice. Wiley Chichester; 1976. [Google Scholar]

- Checkland P. Soft systems methodology: a thirty year retrospective. Syst Res Behav Sci. 2000;17:S11–S58. doi: 10.1002/1099-1743(200011)17:1+<::AID-SRES374>3.0.CO;2-O. [DOI] [Google Scholar]

- Checkland P, Scholes J. Soft systems methodology: a 30-year retrospective. Citeseer; 1999. [Google Scholar]

- Childerhouse P, Towill DR (2011) A systems engineering approach to supply chain auditing. J Manuf Technol Manage

- Choi TY, Wu Z. Taking the leap from dyads to triads: buyer–supplier relationships in supply networks. J Purch Supply Manag. 2009;15:263–266. doi: 10.1016/j.pursup.2009.08.003. [DOI] [Google Scholar]

- Das D, Dutta P. A system dynamics framework for integrated reverse supply chain with three way recovery and product exchange policy. Comput Ind Eng. 2013;66:720–733. doi: 10.1016/j.cie.2013.09.016. [DOI] [Google Scholar]

- Durach CF, Kembro J, Wieland A. A new paradigm for systematic literature reviews in supply chain management. J Supply Chain Manag. 2017;53:67–85. doi: 10.1111/jscm.12145. [DOI] [Google Scholar]

- Dyer JH. Specialised supplier networks as a source of competitive advantage: evidence from the auto industry. Strateg Manag J. 1996;17:271–291. doi: 10.1002/(SICI)1097-0266(199604)17:4<271::AID-SMJ807>3.0.CO;2-Y. [DOI] [Google Scholar]

- Espejo R (2014) Cybernetics of governance: the Cybersyn project 1971–1973. Social Systems and Design. Springer

- Esper TL. Supply chain management amid the coronavirus pandemic. J Public Policy Mark. 2021;40:101–102. doi: 10.1177/0743915620932150. [DOI] [Google Scholar]

- Everingham K, Polaski G, Riedlin F, Shirk M, Deshpande V, Iyer AV. Operations research enhances supply chain management at the US coast guard aircraft repair and supply center. Interfaces. 2008;38:61–75. doi: 10.1287/inte.1070.0334. [DOI] [Google Scholar]

- Fawcett SE, Magnan GM. The rhetoric and reality of supply chain integration. Int J Phys Distrib Logist Manag. 2002;32:339–361. doi: 10.1108/09600030210436222. [DOI] [Google Scholar]

- Forrester JW. The collected works of jay W. Forrester. Wright-Allen Press; 1975. [Google Scholar]

- Gang Yuan X, Qing Zhang X (2015) Recycler reaction for the government behavior in closed-loop supply chain distribution network: based on the system dynamics Discrete Dynamics in Nature and Society, 2015

- Ge Y, Yang JB, Proudlove N, Spring M. System dynamics modelling for supply-chain management: a case study on a supermarket chain in the UK. Int Trans Oper Res. 2004;11:495–509. doi: 10.1111/j.1475-3995.2004.00473.x. [DOI] [Google Scholar]

- Georgiadis P, Besiou M. Sustainability in electrical and electronic equipment closed-loop supply chains: a system dynamics approach. J Clean Prod. 2008;16:1665–1678. doi: 10.1016/j.jclepro.2008.04.019. [DOI] [Google Scholar]

- Georgiadis P, Besiou M. Environmental and economical sustainability of WEEE closed-loop supply chains with recycling: a system dynamics analysis. Int J Adv Manuf Technol. 2010;47:475–493. doi: 10.1007/s00170-009-2362-7. [DOI] [Google Scholar]

- Georgiadis P, Vlachos D, Iakovou E. A system dynamics modeling framework for the strategic supply chain management of food chains. J Food Eng. 2005;70:351–364. doi: 10.1016/j.jfoodeng.2004.06.030. [DOI] [Google Scholar]

- Gu Q-L, Gao T-G. Joint decisions for R/M integrated supply chain using system dynamics methodology. Int J Prod Res. 2012;50:4444–4461. doi: 10.1080/00207543.2011.600344. [DOI] [Google Scholar]

- Harland CM, Lamming RC, Zheng J, Johnsen TE. A taxonomy of supply networks. J Supply Chain Manag. 2001;37:21–27. doi: 10.1111/j.1745-493X.2001.tb00109.x. [DOI] [Google Scholar]

- Hildbrand S, Bodhanya S. Exploring the complexity of sugarcane supply chains via systemic approaches. Kybernetes; 2017. [Google Scholar]

- Jackson MC. Critical systems thinking and the management of complexity : responsible leadership for a complex world. Hoboken: Wiley; 2019. [Google Scholar]

- Jackson MC. How we understand “complexity” makes a difference: lessons from critical systems thinking and the Covid-19 pandemic in the UK. Systems. 2020;8:52. doi: 10.3390/systems8040052. [DOI] [Google Scholar]

- Kumar S, Nigmatullin A. A system dynamics analysis of food supply chains–case study with non-perishable products. Simul Model Pract Theory. 2011;19:2151–2168. doi: 10.1016/j.simpat.2011.06.006. [DOI] [Google Scholar]

- Lamming R, Johnsen T, Zheng J, Harland C. An initial classification of supply networks. Int J Oper Prod Manag. 2000;20:675–691. doi: 10.1108/01443570010321667. [DOI] [Google Scholar]

- Leigh M, Li X. Industrial ecology, industrial symbiosis and supply chain environmental sustainability: a case study of a large UK distributor. J Clean Prod. 2015;106:632–643. doi: 10.1016/j.jclepro.2014.09.022. [DOI] [Google Scholar]

- Li S, Ragu-Nathan B, Ragu-Nathan TS, Subba Rao S. The impact of supply chain management practices on competitive advantage and organisational performance. Omega (Oxford) 2006;34:107–124. doi: 10.1016/j.omega.2004.08.002. [DOI] [Google Scholar]

- Luhmann N. On the scientific context of the concept of communication. Soc Sci Inf. 1996;35:257–267. doi: 10.1177/053901896035002005. [DOI] [Google Scholar]

- Meadows DH. Living in a world of systems. White River Junction, Vermont: Chelsea Green Pub; 2008. [Google Scholar]

- Mello MH, Gosling J, Naim MM, Strandhagen JO, Brett PO. Improving coordination in an engineer-to-order supply chain using a soft systems approach. Prod Plan Control. 2017;28:89–107. doi: 10.1080/09537287.2016.1233471. [DOI] [Google Scholar]

- Mentzer JT, Dewitt W, Keebler JS, Soonhoong M, Nix NW, Smith CD, Zacharia ZG. Defining supply chain management. J Bus Logist. 2001;22:1–25. doi: 10.1002/j.2158-1592.2001.tb00001.x. [DOI] [Google Scholar]

- Midgley G. Systems thinking. London: Sage; 2003. [Google Scholar]

- Min S, Zacharia ZG, Smith CD. Defining supply chain management: in the past, present, and future. J Bus Logist. 2019;40:44–55. doi: 10.1111/jbl.12201. [DOI] [Google Scholar]

- Mingers J. Systems thinking, critical realism and philosophy : a confluence of ideas. London: Routledge; 2014. [Google Scholar]

- Mollenkopf DA, Ozanne LK, Stolze HJ (2020) A transformative supply chain response to COVID-19. J Serv Manag

- Moon S-A, Kim D-J. Systems thinking ability for supply chain management. Supply Chain Manag: Int J. 2005;10:394–401. doi: 10.1108/13598540510624214. [DOI] [Google Scholar]

- Morgan G. Images of organisation. London: Sage; 1997. [Google Scholar]

- Sadler I. Logistics and supply chain integration. London: SAGE; 2007. [Google Scholar]

- Sarkis J. Supply chain sustainability: learning from the COVID-19 pandemic. Int J Oper Prod Manag. 2020;41:63–73. doi: 10.1108/IJOPM-08-2020-0568. [DOI] [Google Scholar]

- Sarkis J, Dewick P, Hofstetter JS, Schröder P. Overcoming the arrogance of ignorance: supply-chain lessons from COVID-19 for climate shocks. One Earth. 2020;3:9–12. doi: 10.1016/j.oneear.2020.06.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Senge PM. The fifth discipline : the art and practice of the learning organisation. London: Random House Business Books; 2006. [Google Scholar]

- Skjoett-Larsen T, Thernøe C, Andresen C (2003) Supply chain collaboration. Int J Phys Distrib Logist Manag

- Stindt D, Sahamie R, Nuss C, Tuma A. How transdisciplinarity can help to improve operations research on sustainable supply chains—a transdisciplinary modeling framework. J Bus Logist. 2016;37:113–131. doi: 10.1111/jbl.12127. [DOI] [Google Scholar]

- Susanty A, Bakhtiar A, Puspitasari NB, Susanto N, Handjoyo DKS (2019) The performance of dairy supply chain in Indonesia: a system dynamics approach. Int J Product Perform Manag

- Sweeney LB, Sterman JD. Bathtub dynamics: initial results of a systems thinking inventory. Syst Dyn Rev: J Syst Dyn Soc. 2000;16:249–286. doi: 10.1002/sdr.198. [DOI] [Google Scholar]

- Taleb NNA. The black swan : the impact of the highly improbable. London: Penguin; 2008. [Google Scholar]

- Towill DR. System dynamics-background, methodology and applications. 2. Applications. Comput Control Eng J. 1993;4:261–268. doi: 10.1049/cce:19930050. [DOI] [Google Scholar]

- Towill DR. System dynamics—background, methodology, and applications. Part 1: background and methodology. Comput Control Eng J. 1993;4:201–208. doi: 10.1049/cce:19930050. [DOI] [Google Scholar]

- Tranfield D, Denyer D, Smart P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br J Manag. 2003;14:207–222. doi: 10.1111/1467-8551.00375. [DOI] [Google Scholar]

- Wilding R, Wagner B, Miemczyk J, Johnsen TE, Macquet M (2012) Sustainable purchasing and supply management: a structured literature review of definitions and measures at the dyad, chain and network levels. Supply Chain Manag: Int J

- Zailani S. Supply chain integration and performance: US versus east Asian companies. Supply Chain Manag. 2005;10:379–393. doi: 10.1108/13598540510624205. [DOI] [Google Scholar]

- Zhang Y, Dilts D. System dynamics of supply chain network organisation structure. IseB. 2004;2:187–206. doi: 10.1007/s10257-004-0036-4. [DOI] [Google Scholar]

- Zhang X-Q, Yuan X-G (2016) The system dynamics model in electronic products closed-loop supply chain distribution network with three-way recovery and the old-for-new policy. Discret Dyn Nat Soc 2016

- Zhao Q, Chang R, Ma J, Wu C. System dynamics simulation-based model for coordination of a three-level spare parts supply chain. Int Trans Oper Res. 2019;26:2152–2178. doi: 10.1111/itor.12664. [DOI] [Google Scholar]