Abstract

The plastic system is burdened with many inefficiencies that have been exposed, and exacerbated, by the outbreak of the coronavirus (SARS-CoV2) pandemic in December 2019, widely known as COVID-19, and which threaten society's commitment to transition to a sustainable plastics economy. This perspective aims to depict the structural and systemic inefficiencies of the plastics system, and illuminate: (a) the vulnerability of the recycling sector to macroeconomic – particularly to oil price – shocks; (b) the economics of the recycling system; (c) the political dimensions of the plastics sector. It emphasises that is unwise to think about plastics recycling as an insular and linear problem, due to the complexity and interconnectedness of different parts of the plastic system that affect and are affected by the intertwined processes, stakeholders and values. That said, the transition to a sustainable plastics system requires an integrated, knowledge-based systems approach that interrogates the dynamics and causal-effect relationships of the interconnected challenges. This analytical scrutiny can indicate where interventions are needed in the plastics system towards creating transformational change.

Keywords: COVID-19, Virgin plastics production, Recycled plastics price, Plastics recycling, Recycling economics, Environmental policies

1. Introduction

Plastics are an extremely useful material (e.g. lightweight, cheap, durable, tough, resistant, easy to manufacture, etc.), lending their use in a plethora of applications, such as in packaging, automotive, agriculture, construction, and healthcare industries, with undisputable benefits over other materials (e.g. metals, glass) (Andrady and Neal, 2009). Notwithstanding, their many benefits, plastics have two major flaws; they are made from crude oil, and specifically from the liquid hydrocarbon stream (petroleum naphtha) produced via oil refinement, which goes against decarbonisation efforts, and they are awfully persistent materials in the environment. Therefore, the production of plastics amid the climate crisis on the one hand, and their improper disposal attributed to both deliberate and accidental releases into the environment, and plastic waste mismanagement on the other, has turned a useful material into a global menace.

The production of plastics has increased exponentially over the last decades, from 1.5 million metric tonnes (Mt) produced in 1950 to around 360 Mt in 2018, amounting to more than 8.3 billion (bn) metric tonnes of plastics produced worldwide (Zaman and Newman, 2021). The use of plastics in packaging applications remains consistently at around 40% of the total amount of plastics placed on the European market (PlasticsEurope, 2012, PlasticsEurope, 2018, PlasticsEurope, 2020). The single-use, short-lived nature of plastic packaging infers that these items are rapidly becoming waste in less than a year. Whereas the short life-span of plastic packaging constitutes an inefficiency that deems attention upstream in the plastics value chain, the reality that only a small fraction of it is actually being recycled downstream in the plastics value chain is alarming. A recent study in the UK revealed that less than 5% of the plastic packaging waste is being mechanically reprocessed into secondary material (i.e. recycling) (Iacovidou et al., 2020a). At global level only 9% of plastics ever produced (i.e. 6.9 bn tonnes) have undergone recycling (Geyer et al., 2017), and a large proportion of plastic waste is mismanaged. This denotes that plastic packaging waste is accumulated in the terrestrial and marine environment (e.g. river banks, rivers, beaches, parks and oceans), causing severe environmental damage, the extent of which has prompted global action (Iacovidou et al., 2020b). At present, efforts on reducing single-use, disposable plastics have gained traction with bans on plastics bags being implemented worldwide (Nielsen et al., 2019).

Since the outbreak of the coronavirus (SARS-CoV2) pandemic in December 2019, there has been a rejuvenated demand for plastics particularly in the health care sector and in personal protection equipment (PPE) equipment, such as gloves, medical masks, respirators, goggles, face shields, gowns, and aprons, to prevent the infection of healthcare and other workers, and contain the transmission of the virus in the general public (Wong et al., 2020). In spite of allegations that these measures are temporary, they harbour the risk of diverting our attention from achieving a sustainable plastics economy. The increase in demand for plastic packaging has exposed some the hidden dynamics between plastics production and recycling industries, and highlighted the vulnerability of the plastics recycling sector both to macroeconomic and political dimensions. With macroeconomic dimensions we refer to oil price fluctuations that are strongly correlated with economic activity (aside any external shocks such as conflicts in oil producing countries) and the growing demand for goods as an after-effect of rising living standards and growing population (American Chemistry Council, 2019). Political dimensions refer to the structures and/or affairs of government, the political agendas and discourse, policy making and regulatory and policy instruments used, that influence the interrelationships between political and economic processes. For instance, lobbying activities may influence policy decisions, which in turn can impact on how the economic system operates, and how the wealth that is produced within the economic system is distributed. Understanding these dynamics is important in gaining an insight into the future of plastic packaging. In this perspective, we explore how global political and economic system dynamics were affected by the pandemic, and how these have impacted on the plastics industry. We then explain what these changes mean for current and future efforts to reduce single-use plastics and what actions are needed to improve plastic waste recycling rates in an effort to promote sustainability in the plastics sector.

2. COVID-19 and its impact on the plastic system

The COVID-19 pandemic has led to a significant increase in the demand for, and the production of, plastics, particularly in the health care sector. The use of PPE has been essential in preventing the spread of the virus and the infection of healthcare and other workers, as well as in containing its transmission to the general public. It has been reported, that the production of face masks exceeded 100 billion in China alone in 2020, whereas the worldwide consumption of face masks and plastic gloves could be around 129 billion and 65 billion per month, respectively (Prata et al., 2020). In addition, consumers, under erroneous perceptions grew reluctant to purchase loose and ‘unprotected’ items, and as a result the retail sector grabbed the ‘opportunity’ to increase the use of single-use packaging (Klemeš et al., 2020, Prata et al., 2020). Plastic packaging has also experienced a marked increase in demand through the boom in online shopping and food-takeaway, which has led to an upsurge in the amount of plastic packaging used in the global system (Klemeš et al., 2020, Newburger and Lucas, 2020).

Whereas the surge in medical waste is likely to be of a short-term nature (i.e., until the COVID-19 situation simmers down), the accelerated shift towards e-commerce might lead to a permanent plateau of the production and use of single-use plastics in the economy. Characteristic of the impact of COVID-19 in the plastic system is the set-back on the bans on single-use plastic in several countries around the globe (Prata et al., 2020); all politically sanctioned with reference to COVID-19. Table 1 outlines some of the policy measures taken by governments around the world to rein in the use of single-use plastics and the set-backs caused as a result of the pandemic outbreak.

Table 1.

Targets set to ban single-use plastic across the globe and the way Covid-19 disrupted these measures, where relevant.

| Country | Fact | Planned for | Into effect on | References |

|---|---|---|---|---|

| NORTH AMERICA | ||||

| USA | Ban on the use of plastic carrier bags | Maine: April 22, 2020 | Maine: Jan. 15 2021 | (Bomey, 2020) |

| New York: March 1, 2020 | New York: Oct. 19, 2020 | (Gerken et al., 2020, New York State, 2020) | ||

| Philadelphia: July 2, 2020 | Philadelphia: Jan. 1, 2021 | (Cofrancisco, 2020) | ||

| Suspension of existing ban on the use of plastic carrier bag use | California: April 22, 2020 | California: June 21, 2020 | (Staub, 2020) | |

| Connecticut: March 26, 2020 | Connecticut: June 30, 2020 | (Day and Schatz, 2020) | ||

| Canada, Vancouver | Ban on plastic carrier bags | January 2021 | January 2022 | (Gul, 2020) |

| EUROPE | ||||

| UK | Ban on plastic straws, stirrers and cotton buds delayed | April 2020 | October 2020 | (Defra, 2020) |

| France | Ban on plastic carrier bags | 2016 | (Nielsen et al., 2019) | |

| Italy | Ban on plastic carrier bags | 2011 | (Nielsen et al., 2019) | |

| ASIA | ||||

| India | Ban on the single-use plastics | 2022 | Not yet decided | (Aravind, 2020) |

| Papa New Guinea | Ban on plastic carrier bags | 2005 | (Nielsen et al., 2019) | |

| New Zealand | Ban on plastic carrier bags | 2019 | (Nielsen et al., 2019) | |

| South Korea | Ban on plastic carrier bags and disposable single-use plastics (e.g. plastic dishes, straws and cups) | 2018 - Relaxed during Covid-19 for disposable plastic dishes, straws and cups | (Nielsen et al., 2019); (Tan, 2020) | |

| Oman | Ban on plastic carrier bags | 2018 | (Nielsen et al., 2019) | |

| Georgia | Ban on plastic carrier bags | 2017 | (Nielsen et al., 2019) | |

| Nepal | Ban on plastic carrier bags | 2016 | (Nielsen et al., 2019) | |

| Mongolia | Ban on plastic carrier bags | 2009 | (Nielsen et al., 2019) | |

| China | Ban (thin) /Pricing mechanism (thick) | 2008 | (Nielsen et al., 2019) | |

| Bangladesh | Ban on plastic carrier bags | 2002 (not fully enforced) | (Nielsen et al., 2019) | |

| AFRICA | ||||

| Gambia | Ban on plastic carrier bags | 2015 | (Nielsen et al., 2019) | |

| Burkina Faso | Ban on plastic carrier bags | 2015 | (Nielsen et al., 2019) | |

| Madagascar | Ban on plastic carrier bags | 2015 | (Nielsen et al., 2019) | |

| Ghana | Ban (on thin plastic carrier bags) | 2015 | (Nielsen et al., 2019) | |

| Ivory Coast | Ban on plastic carrier bags | 2014 | (Nielsen et al., 2019) | |

| Cameroon | Ban on plastic carrier bags | 2014 | (Nielsen et al., 2019) | |

| Mauritania | Ban on plastic carrier bags | 2013 | (Nielsen et al., 2019) | |

| Mali | Ban on plastic carrier bags | 2013 | (Nielsen et al., 2019) | |

| Malawi | Ban on plastic carrier bags | 2013 | (Nielsen et al., 2019) | |

| Rwanda | Ban on plastic carrier bags | 2008 | (Nielsen et al., 2019) | |

| Ethiopia | Ban on plastic carrier bags | 2008 | (Nielsen et al., 2019) | |

| Botswana | Ban (thin) / Pricing mechanism (thick) plastic carrier bags | 2007 | (Nielsen et al., 2019) | |

| Tanzania | Ban on plastic carrier bags | 2006 | (Nielsen et al., 2019) | |

| Eritrea | Ban on plastic carrier bags | 2004 | (Nielsen et al., 2019) | |

| South Africa | Ban (thin) / Pricing mechanism (thick) plastic barrier bags | 2003 | (Nielsen et al., 2019) | |

| CENTRAL / SOUTH AMERICA | ||||

| Bahamas | Ban on plastic carrier bags | 2020 | (Nielsen et al., 2019) | |

| Belize | Ban on plastic carrier bags | 2019 | (Nielsen et al., 2019) | |

| Panama | Ban on plastic carrier bags | 2018 | (Nielsen et al., 2019) | |

| Chile | Ban on plastic carrier bags | 2018 | (Nielsen et al., 2019) | |

| Colombia | Ban (thin) / Pricing mechanism (thick) plastic carrier bags | 2017 | (Nielsen et al., 2019) | |

| Haiti | Ban | 2012 | (Nielsen et al., 2019) | |

| Oceania | ||||

| Australian Capital Territory | Ban on single-use plastics | 2021 | (Burgess, 2020) | |

Shifting the safety issue to the forefront, the COVID-19 pandemic has also revealed a few, somewhat inconvenient, consumer misconceptions on how the virus is transmitted on different materials, firing an unsubstantiated trust in the use plastic packaging to protect them. These misconceptions have tactfully been exploited by lobbying groups and the plastic industry, who using anecdotal evidence that the virus might be lurking on the surface of the single-use plastics, they discouraged the reuse of the plastic bags and/or packages, and instead encouraged their disposal (Prata et al., 2020). Nonetheless, in spite of an increased opposition to single-use plastic bans among consumers, there have also been some encouraging signs of progress. It has been found that at least in some areas consumers have continued to be concerned about the sustainability of the packaging, even though one would have expected that strained budgets resulting from the economic consequences of the crisis would have made consumers more price-conscious, and hence, shift them away from the more expensive ‘green’ product line (Feber et al., 2020).

This has given riseto some interesting questions: are we expecting to see a permanent shift of consumer preferences toward ‘green’ and ‘sustainable’ products? If so, what are the underlying motives? Is it genuine concern about the environment, or, is it merely a form of consumer ‘greenwashing’ behaviour, i.e., consumers buying ‘green’ products to mentally offset environmentally unfriendly behaviour in other areas and/or for social approval? Notwithstanding, the importance of changing consumers perception and preferences, the price and quality of the packaging materials, is pertinent to the dynamics between the plastics production and recycling industries, as well as the functionality offered by the plastic packaging material. These dynamics cannot be overlooked, and instead be understood in their importance of driving production and recycling industries interests and influencing the future of plastic packaging. The following section explores these dynamics and explains how the COVID-19 has tampered with the balance that was (supposedly) achieved.

3. System dynamics of plastics production and management

Plastics are made from crude oil. The economic stagnation caused by COVID-19, has led to a reduction in global oil demand, which in turn has led a plunge in oil prices. In April 2020, the price of West Texas Intermediate (WTI) oil fall into negative territory having reached a historic drop, which has lowered the costs of plastic resins production (Worldwide, 2017, Klemeš et al., 2020). For the plastics production industry, falling oil prices translate into lower costs for plastic resins production. Hence, there is now a glut of virgin plastic resins produced, trading at very low prices. Even though production capacities and market fragmentation can significantly alter the relationship between the price of crude oil and recycled plastics (Angus et al., 2012), the low market price of virgin plastic resin has caused havoc to the plastics recycling industry.

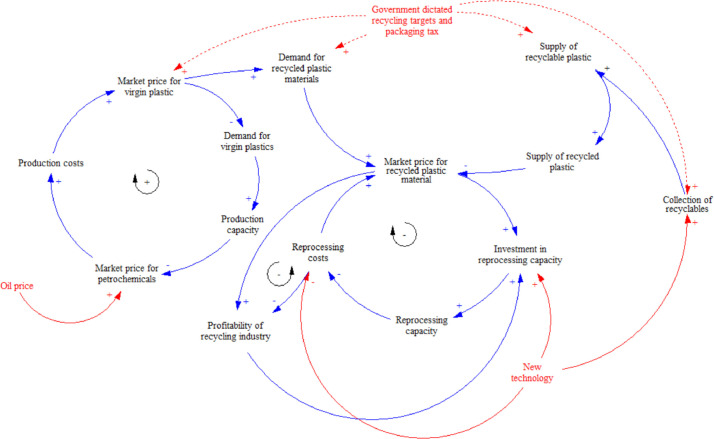

A decline in plastic resin prices makes the virgin plastic material more competitive vis-à-vis the recycled plastic resin, impacting directly the recycling sector that loses business to the plastics production industry as demonstrated by the cause-effect relationships depicted in Fig. 1 . Plastic production companies operate at much higher profit margins than recycling companies do. This means that they can (financially) survive a greater decline in plastic resin prices, particularly also, because the prices for the inputs to their plastic production processes, i.e. crude oil and energy more generally, move in the same direction. This means that even though the price of the output (i.e., plastic resin) declines, so does the cost of the inputs (i.e., crude oil and energy). In contrast, the plastics recycling industry is squeezed by the idiosyncratic dynamics of the recycling market, which make the supply of recycled plastic dangerously insensitive to market price signals. After all, the supply of recycled material is usually mandated by government policy rather than determined by price signals.

Fig. 1.

Casual loop diagram depicting the dynamics between oil price, plastics production and plastic waste recycling industries. RED font and arrows: exogenous variables that influence system dynamics; Dotted lines: denote uncertainty associated with the effect of the exogenous variable on the system dynamics.

For instance, a reduction in the demand for recycled plastic material could lead to a deterioration in the recycling companies’ profit margins. In turn, this could result in a lower price for the plastic packaging waste acquired from local authorities/ municipalities, and the waste collection and management companies. It could also lead to a potential reduction in the number of operating facilities, and a cut in jobs. Lower revenue for local authorities and waste management companies could have serious repercussions in the overall profitability of the recycling sector, and, hence, its willingness to make investments in new plants and technologies (see Fig. 1). This could effectively enhance the technological lock-in and delay changes required for improving the plastic waste recycling rates (Iacovidou et al., 2020a). For waste management and recycling companies to turn a profit and cover their costs, the tax payer would have to bear a greater share of those costs. However, such an option will not go down well in a post-COVID-19 environment that will be characterized by cash-strapped local-authorities and private individuals facing dire economic situations (Iacovidou et al., 2020a).

What's more, virgin plastic resin is not only in demand for its price alone. Quality is an important attribute that impedes the uptake of secondary plastic material, as the virgin material quality is undisputable (Iacovidou et al., 2019, Hahladakis and Iacovidou, 2018). As a result, the manufacturing industry has very little incentive to opt for the secondary plastic material when the virgin, high-quality material is cheaper, unless exogenous variables such as governmental interventions (policies, regulations and instruments), market stability and/or investment in new technologies and smart design of plastic packaging create a level playing field (see Fig. 1). For instance, delays in government interventions could see businesses reverting to the use of virgin plastic material as they would have little incentive to opt for the more expensive secondary material, influencing negatively the plastics recycling industry. This suggests that statutory plastic waste recycling targets are usually necessary to establish a viable collection and recycling system, which could, in tun, make several stakeholders legally obliged to participate in the recycling system andkeep pace with the collection and processing of plastic waste material regardless of the respective demand situation (Fig. 1) (Milios, 2018). This could render the supply of recycled plastic material only weakly contigent on the market price situation (Stromberg, 2004). The system would continue to produce recycled plastic material, even though, there is only an insufficient demand for it. This could result in further price deteriorations and consequently in eroding profit margins for the recycling sector. Likewise, the collection of recyclable plastics will continue to be implemented, on the one hand to demonstrate governments’ commitment to meeting recycling / recovery targets, and on the other hand to ensure the provision of a stable feedstock to the existing reprocessing facilities. That said, collection is an important link in the plastics value chain, and without it the recycling of plastic waste will stall. For example, where collection is not provided (e.g. remote areas, or poorly serviced regions in developing counties), it can disrupt the ability of local and national government to mitigate and prevent plastic pollution, and improve recycling rates. Effective recycling collection, supported by governmental interventions, could ensure the steady supply of recyclable waste materials (in this case plastics), and this in turn, could roll out investments in material recovery facilities and reprocessing infrastructure (Fig. 1).

For instance, in the UK the implementation of the Plastic Packaging Tax 2022, a new tax that mandates a minimum of 30% recycled material content in all plastic packaging placed on the market (including plastic packaging manufactured domestically, and those imported (filled, or unfilled) to the UK) (Gov.UK, 2020), and other policy measures (OECD, 2018), are anticipated to help raise the demand for recycled plastic material in the market. This, will subsidise the development of plastic processing infrastructure and new technologies (such as Internet of Things (IoT), and Big Data analytics) and create the conditions for the recycling industry to flourish. New technologies have the potential to influence positively consumers (via information apps that can support improvements in the collection of recyclable waste materials) and the recycling industry (via new sorting and purifications technologies that can improve the quality of the recycled plastic feedstock), and help to achieve cost competitiveness of the recycled plastic material in the market (Fig. 1). Nonetheless, this change can be associated with a high risk due to the sensitivity of the recycling system to sudden changing conditions, such as oil price, or a broader market uptake of bio-based alternatives. This could result in unintended knock-on effects, while external forces between competing interests could be adding more pressure to this dynamic (Iacovidou et al., 2020a). It is therefore not surprising that major consumer brand owners often miss their self-set targets – a phenomenon that can be characterised as “SET, MISS, REPEAT” – when it comes to the use of recycled plastic material in their product lines. They simply lack the proper economic incentives to do so (Brock, 2020).

The vulnerability of the recycling sector to macroeconomic drivers, such as volatility of oil prices, increased demand for goods, and price change, is not unique to the COVID-19 crisis. In 2014, plunging oil prices posed a severe threat to the economic viability of the recycling sector that has a long history of depending on government support (Brock, 2020). This vulnerability causes several undesirable effects, some of which are outlined below (and also depicted in Fig. 1):

-

■

creates uncertainty among stakeholders operating downstream of the plastics value chain, which disincentives investments in the recycling infrastructure (Stromberg, 2004);

-

■

increases the net-cost of recycling, putting further pressure on the public sector mid-stream of the plastics value chain, which is already strained due to the various stimulus programs to bolster the economy during the COVID-19 shock;

-

■

aggravates an already dire situation in the international oil markets that is largely caused by the shale gas (natural gas trapped within shale formations)/ oil revolution upstream of the plastics value chain; and the structural change of the economy away from fossil fuel powered to electric mobility (Brock, 2020).

The discovery of significant natural gas deposits in the United States and other countries has led to a significant increase in the supply of fossil fuels (PwC, 2013), with has been forecasted to play a significant role in the future energy supply. With the electrification of transport and heating gaining precedence, the sector's share of shale gas/ oil is projected to decline by 10% - 70% by 2050 according to the pace of transition (BP, 2020). Oil producers will therefore need to look for new market segments to sell their output. The plastics sector currently appears to be the economically most interesting outlet, due to ethane production, a gas liquid produced through natural gas fracking, and which is a key building block of plastics (Sicotte, 2020).

In the U.S., ethane production has revived the profitability of the plastics manufacturing sector, by lowering the cost of raw materials as ethane is “cheaper and chemically efficient than naphtha” (Sicotte, 2020). This has spurred investment into the plastics manufacturing sector, and since 2010, more than $200 billion have been invested in 333 plastic and other chemical projects to capitalise on the sudden abundance of these raw materials (Brock, 2020). These developments on ‘supply’ concur and feed into secular economic shifts and the development of a middle-class, consumer societies in emerging countries like China that are going to raise significantly the demand of affordable goods made of plastic, or contained in plastic packages (Dauvergne, 2018). This year alone, Exxon Mobil, Royal Dutch Shell and BASF have announced relevant investments in China worth a combined $25billion in order to tap into this rising demand in one of the world largest and most rapidly growing economies (Brock, 2020). An additional 176 new petrochemical plants are planned to be constructed globally within the next five years; nearly 80% of them will be located in Asia (Brock, 2020).

Global energy markets are expected to undergo a major transition over the next thirty years. Beyond Petroleum (formerly British Petroleum, BP), for instance, projects that oil's share of energy for transport will decline from the current >90% to <80% and possibly as low as 20% (BP, 2020). This means that oil producers need to strart looking for new market segments to sell their output. The aforementioned secular shift in consumer demand in developing countries and the associated growth in plastics demand, is strategically targetted by petrochemical companies. The expansion of the production capacities of plastics, thus, caters to the demand side by supplying the demanded plastic resin, while providing an outlet for the oil produced. Unsurprisingly perhaps, this situation has been exploited by various interest groups to deter the introduction of new legislation and measures aimed at the reduction of plastics production and consumption, halting, thereby, a shift towards sustainable and/or circular economy.

This effectively opens up the discussion on the relevance of political forces on system dynamics. Short-termism has threatened to pause long-term rational planning, as we've seen in the setbacks in plastic bans in several countries, whilst the political power of the petrochemical industry appears to impede policy reforms. Oil industry and plastic producers have a vested interest in pausing plastic bans that can curtail oil demand and plastic resin production, which in turn can jeopardise the oil industry's expectations that the plastic sector would pick up the demand that it is likely going to be lost due to transport electrification. Unsurprisingly therefore, producers try to use the various tools at their disposal to influence the political process (via lobbying organizations, political donations, etc.) to minimise any risks to their business. Moreover, producers have for decades been taking advantage of the results of (often commissioned) studies that highlight the limitations of bans, exploiting information gaps and ambiguities in regulations (Sicotte, 2020, Brock, 2020), such as it happened also recently with the uncertainty that surrounded the effectiveness of plastic packaging in preventing COVID-19 spreading. This kind of intended behaviours have led us to believe that the plastics industry is not refrained from the spreading of misinformation to further their agenda and protect their vested interests. In fact, plastic producers have miscommunicated the recyclability of plastics for decades, shifting the responsibility (and blame for the failure) of recycling to the consumer.

4. The future of recycling

The future of plastic waste recycling is pertinent to the dynamics of the production-management systems and is affected by exogenous variables such as oil price, delays in bans taking effect, implementation of policies that often try to deal with one problem (such as elimination of single-use plastic bags ban) whilst creating damaging consequences elsewhere in the system (e.g. replacement with bio-based, biodegradable alternatives) (Gerassimidou et al., 2021), or investment in new technologies, and new plastic packaging designs. These exogenous variable can either stimulate, or stallefforts on creating a stable market for recycled plastic material and increasing plastic recycling rates.

Therefore, the choice and implementation of policy instruments that can offer the most efficient means of meeting policy objectives is key to creating the enabling conditions for the recycling industry to flourish and improve plastic waste recycling rates (Iacovidou et al., 2020a). This is, however, a highly political process, where decisions are shaped by the competing interests of the petrochemical industry and plastic pellets / preform / component producers, products manufacturers, and brand owners, upstream of the plastics value chain (production), and reprocessors downstream of the value chain (management). On the one hand, the implementation of such policy instruments can influence positively the recycling industry and help to achieve cost competitiveness of the recycled plastic material in the market. On the other hand, it can be associated with a high economic and social risk due to the vulnerability of the recycling system to systemic upheavals, which could result in unintended knock-on effects. At the same time external forces between competing interests could be adding more pressure to this dynamic, favouring producers / manufacturers under the premise of promoting economic growth.

This emphasises that the future sustainability of the plastics system requires a paradigm shift, where the state-stakeholders relationships are scrutinised, the interconnectedness in the plastic system is underlined and an understanding of the complex cause-and-effect relationships is acquired as a means to create the knowledge and capabilities needed for supporting well-targeted and informed policy- and decision-making processes (Iacovidou et al., 2021, Cordier et al., 2021). Knowledge creation spans environmental, technological, economic, social, institutional, organisation aspects and requires the political tenacity of staying committed to addressing local, national and transboundary problems. This necessitates seeing complex value as a socially constructed point towards a dialogue over what is important to ‘preserve’, especially as transitions to sustainability are surging. Complex value refers to the measurable benefits (positive value) and impacts (negative value) in the environmental, economic, social and technical domains, as affected by political dimensions (Iacovidou et al., 2017). Selecting complex value can be difficult, and there is now an abundance of evaluation tools that diverge, depending on what types of values they measure; what data can be used; who participates and according to what role and competence; what results can be achieved. These include amongst others, life cycle assessment (LCA), environmentally extended input-output analysis (EEIOA), cost-benefit analysis (CBA), multi-criteria decision analysis (MCDA). Notwithstanding the power of these methods to evaluate different scenarios / options and provide (somewhat optimal) solutions, they are often limited by data (qualitative and quantitative) availability, the lack of in-depth insight, and ability to highlight important trade-offs and hidden aspects. This implies that a wider system-based evaluation of complex value, one that goes levels deeper in understanding and assessing a resource recovery system, such as the CVORR (Complex Value Optimisation for Resource Recovery) approach (Iacovidou et al., 2017), can help to identify where, and how, inefficiencies occur, where barriers exist and what changes ought to be implemented to transition to sustainable plastics systems. CVORR is a unique tool that offers a step-wise approach to help users (e.g., policy makers, decision-makers, practitioners) embrace all processes, structures and values involved in a resource recovery system (in this case, the entire plastics value chain). Firstly, CVORR guides users to mapping the material flows across the production, consumption and management stages, and include also the circularity potential and fate of mismanaged waste, which is followed by a mapping of the financial flows (monetary flows, ownership, trading, infrastructure, investments, costs, profits) attached directly and indirectly to material flows. The latter, highlights the stakeholders operating in the entire plastics system, and depicts their power dynamics that influence the capture, creation and /or dissipation of complex value. This type of analysis helps users cut through the sheer complexity of the plastics system, and provides multiple ways of viewing the plastic waste recycling problem depending on the scope of the analysis. This can help to identify and highlight hotspots of intervention that could, via a well-orchestrated effort of aligning varying views, needs and interests, ensure that targeted long-term strategies in the plastics system are not seriously impaired.

5. What needs to be done to remain on track?

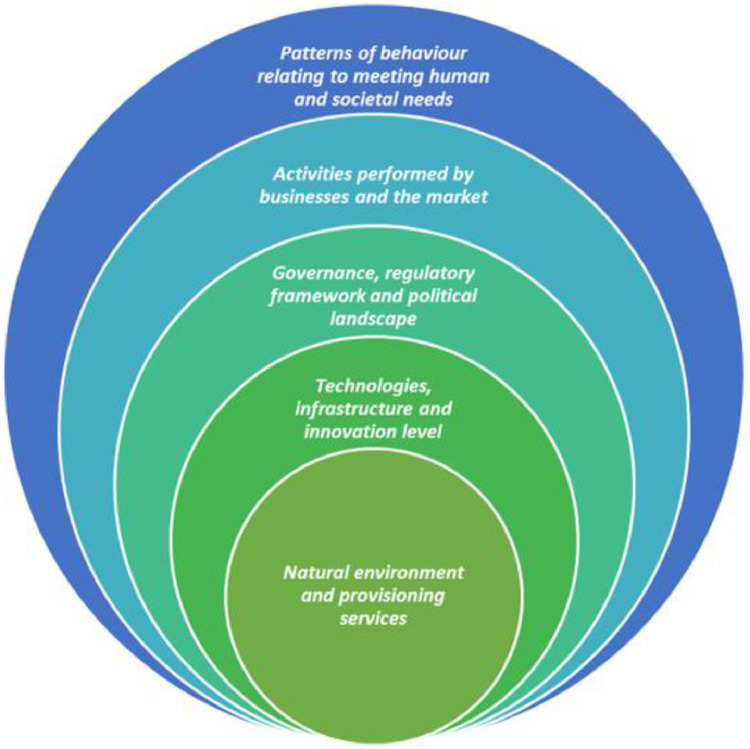

According to the CVORR approach there are five knowledge spheres or sub-systems, called the five levels of information, of which understanding can streamline the process of identifying the opportunities and barriers towards the sustainability of the plastics system. These five levels of information are mutually interacting with one another, and are interconnected. Their influence on the system is not independent, and thus, they all have to be viewed together to gain a good understanding of the system as a whole (Iacovidou et al., 2021). To be able to work through the five levels of information we arranged those in a concentric approach, illustrated in Fig. 2 , to indicate that the natural environment is at the core of any resource recovery system assessment, leading up to the patterns of behaviour which ‘embrace’ provisioning services and influence production-consumption, and therefore, management of plastics and plastic waste (Iacovidou et al., 2021). Each level of information makes clear recommendations of the type of changes needed to improve the sustainability of the plastics system. Whilst, the analysis is not restricted to the hierarchical order illustrated in Fig. 2, experience suggests that working from inside out (from, ‘natural environment’ to ‘patterns of behaviour’) helps to better conceptualise the problem and properly unpack the system's dynamics drivers and barriers (Iacovidou et al., 2020a).

Fig. 2.

The ‘Five levels of information’ framework used within CVORR to cut through the complexity of resource recovery systems and promote informed transitions to sustainability (from,Iacovidou et al., 2021). The concentric approach, working through it from inside-out, provides a comprehensive, structured way of unpacking the system's dynamics, drivers and barriers.

5.1. Natural environmental and provisioning services

Climate change is a primary area of concern in the plastics system, not only because of the plastics direct relationship with fossil fuel extraction and use, but also due to plastic waste contribution to environmental degradation and pollution. This highlights that plastic production and management processes can hardly avoid externalities. On the one hand, ecosystems will be changed through the process of extracting natural resources (crude oil) and turning it into inputs (i.e., plastic materials, components and products) to the economy. On the other hand, all inputs to the economic system will at some point become waste and will need to be managed properly to prevent environmental externalities, such as the global plastic pollution problem (Karasik et al., 2020). Aside the visible pollution caused by plastics, microplastics have also been found to impact the environment, the impact of which is currently under debate. For instance, Foley et al., (2018) suggest that microplastics impact on animals needs to be examined by looking at the relationship between effect size and concentration of microplastics that animals are exposed to (Foley et al., 2018)

The entire plastics waste management sector needs to become more transparent. To realise greater transparency in the system we need to improve and standardise the monitoring methods employed upstream (production) and downstream (management) of the plastics system, and to ensure that the processes used to coordinate data capture and availability are fit for purpose. This is by itself a complex task especially considering that the needs for, and potential of, achieving transparency can differ widely from one region to another, due to the pertaining political, economic, regulatory, organisational and social conditions. What's also important in improving transparency is a mandatory disclosure of reprocessing sector's compliance in meeting the quantity and quality standards of recycled plastic material, and of producers’ / manufacturers’ / brand owners’ tangible efforts to reduce, where possible, virgin plastic material use, and re-design plastics to improve their recyclability. Tracking the sources, pathways and/or destinations of plastic waste, particularly once they leave export countries’ ports, is needed to improve transparency on the end-of-life fate of plastic waste. Reliable data in this regard, are often difficult to come by, whilst the fate of the recycled (secondary) plastic produced remains underexplored. Similarly, the identification of all relevant stakeholders is often fraught with challenges, and risks, as a significant part of the plastic waste trade is illegal.

Transparency is not only needed on the processes involved in the plastics system, but also on the structures, or networks of stakeholders, who run the system, in order to shed light on their ability to collaborate effectively and productively in ensuring that solutions to improve transparency and the better management of plastics and plastic waste will become realised. For instance, improvements in transparency will help producers / manufacturers / brand owners gain a better understanding of their exposure to regulatory, reputational, etc. risks related to plastics, and the waste management industry identify inefficiencies in the recycling system and devise pathways to increasing the efficiency of their operations. Stakeholders such as government, businesses / investors, consumers, non-governmental organisations (NGOs) will be empowered to take necessary action and make informed decisions within their own operating spheres (i.e. political, economic, and social). Without transparency, companies and investors will only have a limited understanding of how they contribute to plastic pollution, and of their exposure to commercial, legal, and reputational risks; hence, growing reluctant to make changes in their current operating regimens. Likewise, governments and regulators will be hindered by the lack of insight when setting plastic pollution targets and reforming, drafting, and enforcing policies that must protect health, ecosystems; whilst consumers and civil society groups will struggle to understand how their contribution really impacts on the amount of plastics being produced and sold, and which end up polluting the environment.

5.2. Technologies, infrastructure and innovation level

The different types of plastic polymers placed on the market, and the way these are designed, which involves the use of labels, glues, inks, can negatively influence the sorting and reprocessing efficiency of plastic waste. This implies that the quality of the reprocessed resin might often be impaired; hence, be less competitive vis-à-vis the virgin resin. This highlights the complexity in the plastics systems and the need to simplify the techno- and socio-economic factors and processes that drive material flow (Iacovidou et al., 2020a). Improvements in the plastic waste recycling and mitigation of plastic pollution, require the collection and management of plastic waste via certain infrastructure.

For instance, the U.S. International Development Finance Corporation (DFC) announced that it would invest $2.5bn in infrastructure investments for reducing the discharge of plastic waste and marine debris into oceans and waterways under its new Ocean Plastics Initiative. The Ocean Plastics Initiative seeks to catalyse private sector investment in projects that advance the development of efficient waste management, recycling, and other infrastructure projects in developing countries (DFC, 2020). The UK appears to be on the same path, announcing plans to build plastic processing infrastructure in the UK to reduce exports (ENDS report, 2021). Unfortunately, though, not all countries have the financial resources to achieve these goals. Many developing countries lack the necessary infrastructure and the financial means required to attain it. Some 3.5 billion people around the world are estimated to lack access to formal waste management services (OECD, 2018, Plastics for Change, 2017). This situation is further aggravated by the fact that global solid waste generation is likely to increase by 70% by 2025 (Plastics for Change, 2017), putting municipalities under enormous pressure. Although many multi-lateral development funds such as The World Bank invest billions of US-dollars in waste management infrastructure, they are often ineffective in providing the appropriate funding where needed, especially for small-scale projects.

Tracking and tracing the flows of plastics and plastic waste, could highlight areas where global intervention is needed, and would support new funding schemes that cater for the requirements of the local waste management sector in different contexts (i.e., providing them with low-cost collection and treatment solutions while blending in with the formal and informal waste management networks that have emerged in various developing contexts). This could support people and their livelihoods in line with sustainable development goals, and would help governments assess compliance with waste management regulations in an effort to tackle fraudulence and illegalities in the system (Cordier et al., 2021). On the ground, data collection can be labour intensive and difficult, especially for plastic that leaks into the terrestrial and marine environment. New technologies, such as robots using artificial intelligence (Schmaltz et al., 2020), e-tracking and big data analytics could help to track, trace and streamline information / data on plastic flows across different spatial and temporal scales, and aid the development of a central platform to aggregate, analyse and disseminate data and diffuse the fragmentation in the plastics sector. This will help to monitor plastics trading and flows within economies, and realize the commitments of each country, and stakeholders, to alleviate plastic pollution; a process that should be overseen by a central institution that coordinates data collection and sets standards on data collection, data processing and reporting progress.

5.3. Governance, regulatory framework and political landscape

Politicians need to stay committed to their original pledges to transition to a more sustainable plastics economy. This requires tenacity in pushing forth the necessary (regulatory) measures, e.g. the planned tax on plastic packaging, and/or reforms in the Extended Producer Responsibility scheme (Prata et al., 2019, Iacovidou et al., 2020a, Raubenheimer and McIlgorm, 2018). The COVID-19 crisis should not be an excuse to delay such measures beyond any plausible necessity. Otherwise, societies risk to jeopardize the progress already made in the area. Even with the current schemes in place, increased vigilance is required to achieving recycling targets. Extended Producer Responsibility (EPR) regulations could maintain ongoing investment in the domestic plastic recycling sector, but further incentives might be required. A key action is that care must be taken to ensure that such developments within the recycling sector are not exploited by certain market participants for private gains. This warrants particular emphasis, not only with respect to the recycling sector, but the plastics value chain more generally.

In May 2019, most of the world's countries agreed to amend the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal, an international treaty that was designed to reduce the movements of hazardous waste between nations, and specifically to prevent transfer of hazardous waste from developed to developing countries, to include plastic waste as a regulated material. The Basel Convention as amended in May 2019 prohibits the transportation of plastic waste to just about every other country (i.e., it is “criminal traffic as soon as the ships get on the high seas”). The amendment followed a public outcry on taking responsibility for the management of plastic waste and advocate for restrictions in plastic waste exports, urging developed countries to increase their domestic reprocessing rates. As it is now more difficult, or in some cases (e.g., those that involve dirty, mixed plastic waste) illegal to ship plastic waste to developing countries, (more) plastic waste needs to be reprocessed domestically (Raubenheimer and McIlgorm, 2018). Policy measures will need to be developed to stabilise end-markets and create demand for recycled content, and responsible procurement policies (Raubenheimer and McIlgorm, 2018).

5.4. Activities performed by businesses and the market

To increase the economic viability of the recycling process and to facilitate the re-uptake of the recycled material into the value-chain, it is imperative to create markets where producers can economically source these materials. In other words, material sourcing platforms and the right institutional framework need to be created for primary and secondary resources markets to function well. There needs to be balance between what is placed on the market as virgin plastic materials, and how much it returns back as a secondary commodity. Plastics cannot be indefinitely recycled due to changes in resins properties (Iacovidou et al., 2019), which means that recyclers will still require a stable source of primary feedstock, to ensure the longevity and profitability of their business, as well as a stable demand for their product (Raubenheimer and McIlgorm, 2018). Market forces are, however, not sufficient to guarantee a smoothly running waste management system. For instance, the collection of plastic waste is, by its nature, subject to significant economies of density (OECD, 2018). That is, the lower the dispersion of the waste collection points (e.g., households), the lower the unit cost to provide the service. The service is thus generally most efficiently provided by a single firm (OECD, 2018).

Similarly, the geographic reach of collection and disposal of waste is generally limited by the high cost of transportation and proximity to infrastructure. This also favours a monopolistic market structure. It is key that governments are careful in the choice of theservice provision, as private companies might exploit the aforementioned economics to extract value disproportionally from the system. That is, workers and tax-payers might end up with a worse deal under private provision than state provision of these waste management services, while the private companies extract the value from the system. By ensuring transparency in the entire plastics value chain, inefficiencies that currently make recycling an uneconomical venture, as well as the illegalities in the system, will be revealed. In turn, this can help governments, and businesses to formulate the right strategies, and develop new business models that will help reduce their exposure to multiple risks, redefine their competencies and focus on innovation and new product design. However, solutions can vary depending on the context (developed vs developing) and market dynamics. The role of stakeholders involved in the plastics value chain, the way they are connected and the power dynamics between them, can shed light on the degree to which they influence global value chains, placing emphasis at the point on which the two ends of the plastics value chain connect.

5.5. Patterns of behaviour relating to meeting human and societal needs

Improving the sustainability of the production and management of plastics implies changes in the consumption stage. Without consumption there is no production, and in the case of plastics it is strongly advocated that consumption influences the pace of production. Therefore, to bring change, we need to reach out to consumers and understand their behaviour patterns, perceptions, and attitudes towards plastics, and the way these influence the production-management of plastic components and products, with emphasis on wastage / disposal.

Effective educational campaigns with respect to the plastics problem, and the measures required to tackle it, need to persevere as these were found to be effective tools in raising awareness and influencing (partly) behaviours (Heidbreder et al., 2019). But, information overload is also important to be considered (Melinat et al., 2014). To know the effect of one's own actions, one needs to know both the effect of the act itself – for example using plastics, disposing plastics, etc. – and how the plastics were produced. This is demanding and may often require one to source this information by themselves (depending on where they live and which collection regimes are offered by their local authority/ municipality), which makes it difficult even for the most engaged to ensure that they are well informed. Labelling has been used as a way to communicate better between consumers and producers and producers and recyclers. Understanding labels, however, is time consuming, often confusing and demands quite a lot of technical competence (Buelow et al., 2010).

Also to increase consumers’ participation rate in the recycling process and acceptance of certain policy measures, education, social norms and the sense of responsibility are important attributes (Issock et al., 2021). Social norms are particularly important to be understood when reaching out to people living in developing contexts, where more action is needed. Consumers worldwide need to be made aware of the impact of their actions, in order to grow a sense of responsibility towards future generations, as well as those living now, and change their behaviour. Unfortunately, a significant proportion of the world's population has little to no interest in contributing to such efforts due to personal beliefs and preferences, they may have no interest in recycling due to social norms, or they may be severely confounded by the complexities of the disposal/ sorting process (Sorkun, 2018, Abbott et al., 2013). This could be attributed to the lack of time or incentive/ interest to participate in the recycling process; to instructions that are often difficult to understand; discrepancies and changes to recycling regimes across different or same areas; or ideological beliefs enshrined in cultural norms (Iacovidou et al., 2020a, Iacovidou et al., 2021). Media and digital communication will have a central role to play in shaping public understanding and in promoting responsible environmental attitudes to consumption in the near future (Henderson and Green, 2020).

6. Conclusion

The COVID-19 pandemic has exposed the plastic recycling sector's vulnerability to macroeconomic shocks when the demand for recycled plastic plummeted in the wake of falling oil prices that made virgin plastic resin production cheaper. Before appropriate remedial action can be taken, it is important to adopt a system-based approach to gain a better understanding of the price dynamics and behaviour of the relevant stakeholders in the plastics system. This is an essential precautionary measure to shelter the plastic recycling sector from the current destabilizing price volatility, and to de-risk the entire plastic value chain. A systems-based approach can ensure that long-term strategies in the plastics system will not be seriously impaired. This translates into the following key actions:

-

•

Action 1: Take all processes, values and stakeholders involved in the plastics system into consideration (and include them as much as possible), and improve the ability to adequately monitor plastics and plastic waste flows and trading.

-

•

Action 2: Simplify the techno- and socio-economic factors and processes that drive the production and consumption of plastics, in alignment with the provisioning services for plastic waste management.

-

•

Action 3: Develop appropriate policy instruments and mechanisms (e.g., new funding, price-hedging and other insurance schemes) to cater for the requirements of the local waste management sector, and set the commitments of each country to alleviate plastic pollution.

-

•

Action 4: Monitor the legitimacy of services provided, and developments made within the plastics production and waste management sectors, making sure that these are not exploited by certain market participants for private gains. Transparency in the entire value chain is key to realising all proposed solutions. Without transparency, it is difficult to set the right targets, identify the right intervention points, formulate the right strategies, identify the responsible stakeholders (‘accountability’), and monitor progress.

The degree to which these actions can be implemented in different contexts, will vary depending on the political, economic, social, technological, institutional and environmental context. The absence of a central institution that coordinates and sets the standards / guidelines / principles for data collection, storage, processing and reporting; the lack of a central data management platform to aggregate, analyse and disseminate data across difference spatial and temporal scales; the fragmentation of the plastics sector and misalignment of targets and goals; the informal sector's role in improving plastics recycling performance, alongside the labour intensive nature of recycling in developing contexts, and what it means from a sustainable development perspective; the fuzziness on the trade / fate of recycled plastic (e.g. How is plastic waste processed to new material, and where? How is recycled plastic material re-introduced into the system, into which products and where does this take place?); the difficulties around data collection, trust and ownership aspects, and ability of nations to get access to technologies that help with this task; and power dynamics in global value chains, are only some of the challenges and hidden aspects that need to be further explored.

It is now the right time to re-build our system and bring together all stakeholders involved in the plastics value chain, to create a new attitude towards plastic production, use, and management. This will set us in the right trajectory towards a sustainable, circular plastics economy.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This research work was generously funded by the Oxford Martin School, University of Oxford, and Brunel University London. The authors would like to thank the Editor and Reviewers for their constructive input. The opinions expressed herein are the authors' alone.

Editor: Prof. Konstantinos Tsagarakis

References

- ABBOTT A., NANDEIBAM S., O’SHEA L. Recycling: Social norms and warm-glow revisited. Ecol. Econ. 2013;90:10–18. [Google Scholar]

- AMERICAN CHEMISTRY COUNCIL . IHS Markit Ltd.; 2019. Population Growth and Materials Demand Study.https://plastics.americanchemistry.com/IHS-Economic-Growth-and-Materials-Demand-Executive-Summary.pdf Available at: : American Chemistry Council (ACC) [Google Scholar]

- ANDRADY A.L., NEAL M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009;364:1977–1984. doi: 10.1098/rstb.2008.0304. [DOI] [PMC free article] [PubMed] [Google Scholar]

- ANGUS A., CASADO M.R., FITZSIMONS D. Exploring the usefulness of a simple linear regression model for understanding price movements of selected recycled materials in the UK. Resour. Conserv. Recycl. 2012;60:10–19. [Google Scholar]

- ARAVIND, I. 2020. Another pandemic: India's fight against single-use plastic falls victim to Covid, Available at:https://economictimes.indiatimes.com/news/politics-and-nation/maharashtra-moves-sc-to-put-on-hold-local-polls-for-6-months/articleshow/83942488.cms [Online]. The Economic Times, India. [Accessed].

- BOMEY, N. 2020. Plastic bag bans reversed: States, cities, stores are suddenly banning reusable bags during coronavirus.

- BP. 2020. Energy Outlook - Transport [Online]. bp p.l.c. Available: https://www.bp.com/en/global/corporate/energy-economics/energy-outlook/demand-by-sector/transport.html [Accessed].

- BROCK, J. 2020. A Reuters special report on "THE PLASTIC PANDEMIC" - COVID-19 trashed the recycling dream [Online]. Reuters Available: https://www.reuters.com/investigates/special-report/health-coronavirus-plastic-recycling/ [Accessed].

- BUELOW S., LEWIS H., SONNEVELD K. The role of labels in directing consumer packaging waste. Management of Environmental Quality: An International Journal. 2010;21:198–213. [Google Scholar]

- BURGESS, K. 2020. Coronavirus: ACT government delays single-use plastic ban, Australian Capital Territory (ACT) Politics [Online]. ACT Politics, Available at: https://www.canberratimes.com.au/story/6838799/act-single-use-plastic-ban-delayed-due-to-covid-19/ : The Canberra Times. [Accessed].

- COFRANCISCO, K. 2020. What's next for Philadelphia's Plastic Bag Ban [Online]. Available at: https://www.phila.gov/2020-04-21-whats-next-for-philadelphias-plastic-bag-ban/ : Department of Commerce, Office of the Mayor. [Accessed].

- CORDIER M., UEHARA T., BAZTAN J., JORGENSEN B., YAN H. Plastic pollution and economic growth: The influence of corruption and lack of education. Ecol. Econ. 2021;182 [Google Scholar]

- DAUVERGNE P. Why is the global governance of plastic failing the oceans? Global Environ. Change. 2018;51:22–31. [Google Scholar]

- DAY, R. L. & SCHATZ, L. B. 2020. Plastic Bag Fee Suspended Through May 15, 2020 [Online]. Available at: https://www.cttaxalert.com/2020/03/plastic-bag-fee-suspended-through-may-15-2020/ : CONNECTICUT STATE & LOCAL TAX ALERT, Shipman & Goodwin LLP. [Accessed].

- DEFRA. 2020. Ban on plastic straws, stirrers and cotton buds delayed due to coronavirus outbreak [Online]. Defra in the media, Available at: https://deframedia.blog.gov.uk/2020/04/16/ban-on-plastic-straws-stirrers-and-cotton-buds-delayed-due-to-coronavirus-outbreak/: Defra Press Office, UK government. [Accessed].

- DFC. 2020. DFC Announces New $2.5 Billion Ocean Plastics Initiative, Available at:https://www.dfc.gov/media/press-releases/dfc-announces-new-25-billion-ocean-plastics-initiative [Online]. U.S. International Development Finance Corporation, New York (NW), Washington, DC U.S. International Development Finance Corporation. [Accessed].

- ENDS REPORT. 2021. Defra plans for more UK plastic processing infrastructure, Available at:https://www.endsreport.com/article/1720724/defra-plans-uk-plastic-processing-infrastructure#:~:text=DEFRA%20is%20working%20with%20the,exports%2C%20according%20to%20the%20government.&text=She%20continued%20saying%20the%20government,exports%20to%20non%2DOECD%20countries. [Online]. ENDS report. [Accessed].

- FEBER D., GRANSKOG A., LINGQVIST O., NORDIGARDEN D. McKinsey & Company; 2020. The pandemic is reshaping their views about sustainable packaging materials in ways that will force the whole value chain to act quickly [Online]https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/sustainability-in-packaging-inside-the-minds-of-us-consumers [Accessed] [Google Scholar]

- FOLEY C.J., FEINER Z.S., MALINICH T.D., HÖÖK T.O. A meta-analysis of the effects of exposure to microplastics on fish and aquatic invertebrates. Sci. Total Environ. 2018;631-632:550–559. doi: 10.1016/j.scitotenv.2018.03.046. [DOI] [PubMed] [Google Scholar]

- GERASSIMIDOU S., MARTIN O.V., CHAPMAN S.P., HAHLADAKIS J.N., IACOVIDOU E. Development of an integrated sustainability matrix to depict challenges and trade-offs of introducing bio-based plastics in the food packaging value chain. J. Cleaner Prod. 2021;286 [Google Scholar]

- GERKEN M., SIMKO-BEDNARSKI E., GRANT B. The New York plastic bag ban is finally being enforced in businesses across the state. CNN US. 2020 https://edition.cnn.com/2020/10/19/us/new-york-plastic-bag-ban-trnd/index.html Available at: [Google Scholar]

- GEYER R., JAMBECK J.R., LAW K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017:3. doi: 10.1126/sciadv.1700782. [DOI] [PMC free article] [PubMed] [Google Scholar]

- GOV.UK 2020. Plastic Packaging Tax. In: CUSTOMS, H. R. (ed.). London, UK: © Crown copyright.

- GUL, M. 2020. Vancouver delays plastic-bag ban one year due to impact of COVID-19 on businesses [Online]. Available at: https://www.citynews1130.com/2020/12/10/vancouver-delays-plastic-bag-ban-one-year-due-to-covid-19-impact-on-businesses/: Citynews1130. [Accessed].

- HAHLADAKIS J.N., IACOVIDOU E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018;630:1394–1400. doi: 10.1016/j.scitotenv.2018.02.330. [DOI] [PubMed] [Google Scholar]

- HEIDBREDER L.M., BABLOK I., DREWS S., MENZEL C. Tackling the plastic problem: A review on perceptions, behaviors, and interventions. Sci. Total Environ. 2019;668:1077–1093. doi: 10.1016/j.scitotenv.2019.02.437. [DOI] [PubMed] [Google Scholar]

- HENDERSON L., GREEN C. Making sense of microplastics? Public understandings of plastic pollution. Mar. Pollut. Bull. 2020;152 doi: 10.1016/j.marpolbul.2020.110908. [DOI] [PubMed] [Google Scholar]

- IACOVIDOU E., EBNER N., ORSI B., BROWN A. Brunel University London, University of Leeds in collaboration with the Department for Environment, Food and Rural Affairs (DEFRA); London, UK: 2020. Plastic-Packaging How do we get to where we want to be? [Google Scholar]

- IACOVIDOU E., HAHLADAKIS J.N., PURNELL P. A systems thinking approach to understanding the challenges of achieving the circular economy. Environmental Science and Pollution Research. 2021;28:24785–24806. doi: 10.1007/s11356-020-11725-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- IACOVIDOU E., MARTIN V.O., JOBLING S. Department for Environment, Food and Rural Affairs (Defra; London, UK: 2020. Chapter 4 - Review of Sources and Pathways of Marine Plastic Pollution, Marine Plastic Pollution - Evidence Review. Contract number: ITT5345 /ME5436, Contractor: Environmental Sustainability Associates Ltd. [Google Scholar]

- IACOVIDOU E., MILLWARD-HOPKINS J., BUSCH J., PURNELL P., VELIS C.A., HAHLADAKIS J.N., ZWIRNER O., BROWN A. A pathway to circular economy: Developing a conceptual framework for complex value assessment of resources recovered from waste. J. Cleaner Prod. 2017;168:1279–1288. [Google Scholar]

- IACOVIDOU E., VELENTURF A.P.M., PURNELL P. Quality of resources: A typology for supporting transitions towards resource efficiency using the single-use plastic bottle as an example. Sci. Total Environ. 2019;647:441–448. doi: 10.1016/j.scitotenv.2018.07.344. [DOI] [PubMed] [Google Scholar]

- ISSOCK P.B.I., MPINGANJIRA M., ROBERTS-LOMBARD M. Trying to recycle domestic waste and feelings of guilt: a moderated mediation model applied to South African households. Sustainable Production and Consumption. 2021;27:1286–1296. [Google Scholar]

- KARASIK, R., VEGH, T., DIANA, Z., BERING, J., CALDAS, J., PICKLE, A., RITTSCHOF, D. & VIRDIN, J. 2020. Years of Government Responses to the Global Plastic Pollution Problem: The Plastics Policy Inventory. NI X.

- KLEMEŠ J.J., FAN Y.V., TAN R.R., JIANG P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renewable Sustainable Energy Rev. 2020;127 doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- MELINAT P., KREUZKAM T., STAMER D. Springer International Publishing; Cham: 2014. Information Overload: A Systematic Literature Review; pp. 72–86. [Google Scholar]

- MILIOS L. Advancing to a Circular Economy: three essential ingredients for a comprehensive policy mix. Sustainability Sci. 2018;13:861–878. doi: 10.1007/s11625-017-0502-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- NEW YORK STATE . Department of Environmental Conservation; 2020. Bag waste reduction law - Bring Your Own Bag New York - #BYOBagNY.https://www.dec.ny.gov/chemical/50034.html Available at: [Online]. New York State government. [Accessed] [Google Scholar]

- NEWBURGER E., LUCAS A. Plastic waste surges as coronavirus prompts restaurants to use more disposable packaging. CNBC. 2020 https://www.cnbc.com/2020/06/28/coronavirus-plastic-waste-surges-as-restaurants-use-more-disposable-packaging.html [Google Scholar]

- NIELSEN T.D., HOLMBERG K., STRIPPLE J. Need a bag? A review of public policies on plastic carrier bags – Where, how and to what effect? Waste Manage. (Oxford) 2019;87:428–440. doi: 10.1016/j.wasman.2019.02.025. [DOI] [PubMed] [Google Scholar]

- OECD 2018. Improving Plastics Management: Trends, policy responses, and the role of international co-operation and trade - A Background Report, Prepared by the OECD for the G7 Environment, Energy and Oceans Ministers. © OECD 2018.

- PLASTICS FOR CHANGE. 2017. Why are plastic recycling rates so low?

- PLASTICSEUROPE 2012. Plastics – the Facts 2012: An analysis of European plastics production demand and waste data for 2011. Produced by PlasticsEurope, EuPC (the European Plastics Converters), EuPR (the European Plastics Recyclers) and EPRO (the European Association of Plastics Recycling and Recovery Organisations). Brussels, Belgium: PlasticsEurope.

- PLASTICSEUROPE . PlasticsEurope; Brussels, Belgium: 2018. Plastics – the Facts 2017: An analysis of European plastics production, demand and waste data. Produced by PlasticsEurope (the Association of Plastics Manufacturers in Europe) and EPRO (the European Association of Plastics Recycling and Recovery Organisations) [Google Scholar]

- PLASTICSEUROPE . PlasticsEurope; Brussels, Belgium: 2020. Plastics – the Facts 2019: An analysis of European plastics production, demand and waste data. Produced by PlasticsEurope (the Association of Plastics Manufacturers in Europe) and EPRO (the European Association of Plastics Recycling and Recovery Organisations) [Google Scholar]

- PRATA J.C., SILVA A.L.P., DA COSTA J.P., MOUNEYRAC C., WALKER T.R., DUARTE A.C., ROCHA-SANTOS T. Solutions and Integrated Strategies for the Control and Mitigation of Plastic and Microplastic Pollution. International Journal of Environmental Research and Public Health. 2019;16:2411. doi: 10.3390/ijerph16132411. [DOI] [PMC free article] [PubMed] [Google Scholar]

- PRATA J.C., SILVA A.L.P., WALKER T.R., DUARTE A.C., ROCHA-SANTOS T. COVID-19 Pandemic Repercussions on the Use and Management of Plastics. Environ. Sci. Technol. 2020;54:7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- PWC . PricewaterhouseCoopers LLP; UK: 2013. Shale oil: the next energy revolution. [Google Scholar]

- RAUBENHEIMER K., MCILGORM A. Can the Basel and Stockholm Conventions provide a global framework to reduce the impact of marine plastic litter? Mar. Policy. 2018;96:285–290. [Google Scholar]

- SCHMALTZ E., MELVIN E.C., DIANA Z., GUNADY E.F., RITTSCHOF D., SOMARELLI J.A., VIRDIN J., DUNPHY-DALY M.M. Plastic pollution solutions: emerging technologies to prevent and collectmarineplastic pollution. Environ. Int. 2020;144 doi: 10.1016/j.envint.2020.106067. [DOI] [PubMed] [Google Scholar]

- SICOTTE D.M. From cheap ethane to a plastic planet: Regulating an industrial global production network. Energy Research & Social Science. 2020;66 [Google Scholar]

- SORKUN M.F. How do social norms influence recycling behavior in a collectivistic society? A case study from Turkey. Waste Manage. (Oxford) 2018;80:359–370. doi: 10.1016/j.wasman.2018.09.026. [DOI] [PubMed] [Google Scholar]

- STAUB, C. 2020. California reinstates bag ban and PCR requirements [Online]. Available at: https://resource-recycling.com/plastics/2020/06/24/california-reinstates-bag-ban-and-pcr-requirements/: Copyright 2021, Resource Recycling, Inc. [Accessed].

- STROMBERG P. Market imperfections in recycling markets: conceptual issues and empirical study of price volatility in plastics. Resour. Conserv. Recycl. 2004;41:339–364. [Google Scholar]

- TAN, A. 2020. South Korea undoes ban on disposable plastic utensils at cafes & restaurants due to Covid-19 [Online]. mothership, Available at: https://mothership.sg/2020/02/covid-19-south-korea-ease-ban-plastics/:mothership. [Accessed].

- WONG J., GOH Q.Y., TAN Z., LIE S.A., TAY Y.C., NG S.Y., SOH C.R. Preparing for a COVID-19 pandemic: a review of operating room outbreak response measures in a large tertiary hospital in Singapore. Can. J. Anaesth. 2020;67:732–745. doi: 10.1007/s12630-020-01620-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- WORLDWIDE, E. M. 2017. Falling crude oil prices likely to boost plastic, packaging sectors.

- ZAMAN A., NEWMAN P. Plastics: are they part of the zero-waste agenda or the toxic-waste agenda? Sustainable Earth. 2021;4:4. [Google Scholar]