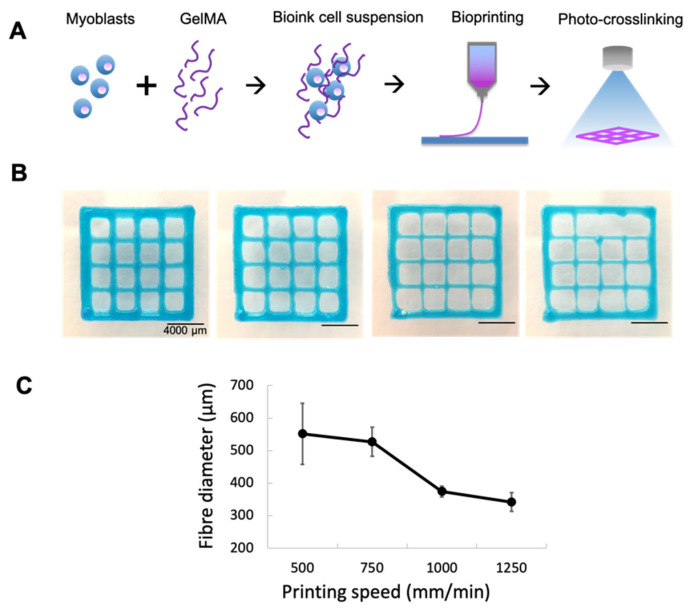

Figure 2.

Parametric study of fiber diameters. Constructs were printed with the smallest available CELLINK conical nozzle (27 G) at the minimum pressure required to initiate and maintain bioink flow (60 kPa). Blue food dye was used for the purpose of imaging. (A) Schematic of printing process. (B) Printing speeds were compared between 500, 750, 1000, and 1250 mm/min (left to right); 1000 mm/min produced the finest fibers without thread break-up. (C) Fibers were soaked in PBS overnight at 37 °C before diameters were measured. Error bars represent standard deviation.