Abstract

Implantable and ingestible biomedical electronic devices can be useful tools for detecting physiological and pathophysiological signals, and providing treatments that cannot be done externally. However, one major challenge in the development of these devices is the limited lifetime of their power sources. The state-of-the-art of powering technologies for implantable and ingestible electronics is reviewed here. The structure and power requirements of implantable and ingestible biomedical electronics are described to guide the development of powering technologies. These powering technologies include novel batteries that can be used as both power sources and for energy storage, devices that can harvest energy from the human body, and devices that can receive and operate with energy transferred from exogenous sources. Furthermore, potential sources of mechanical, chemical, and electromagnetic energy present around common target locations of implantable and ingestible electronics are thoroughly analyzed; energy harvesting and transfer methods befitting each energy source are also discussed. Developing power sources that are safe, compact, and have high volumetric energy densities is essential for realizing long-term in-body biomedical electronics and for enabling a new era of personalized healthcare.

Keywords: batteries, energy harvesting, energy transfer, implantable electronics, ingestible electronics

1. Introduction

1.1. Motivation

As the human life expectancy has increased, access to high-quality healthcare has become essential for ensuring a high quality of life.[1] This increase in lifespan is associated with a rising prevalence of disease, disability, dementia, and other ailments.[2] More than 60% of adults in the United States (US) have a chronic disease such as heart disease, cancer, stroke, and diabetes. Consequently, management of chronic conditions account for 75% of healthcare spending in the US.[3,4] ≈61 million adults (26%) in the US have some type of disability, such as a mobility impairment, a cognitive disability, hearing loss, or vision loss, and depend on the reliable assistance of one or more medical devices for the rest of their lives.[5] Worldwide, about three million people are living with a pacemaker and about 0.3 million people are living with a cochlear implant.[6,7] In order to lower the morbidity rate, it is important to monitor, intervene, and prevent diseases more effectively. Biomedical electronic devices have played a significant role in managing these medical demands. Developing energy-dense power sources is a major challenge for realizing the next generation of personalized biomedical electronics that are multifunctional, compact, and long-lived.

The energy requirements of biomedical electronic devices are highly dependent on their application and the complexity of the required electrical systems. Biomedical electronic devices can be divided into three main categories depending on their application: diagnostic, therapeutic, and closed-loop systems. Each category has a different degree of complexity in the electronic system, which will be discussed in Section 1.2. Diagnostic devices are used to monitor existing or potential medical conditions, to track disease progression and to evaluate the effects of any medical interventions. Diagnostic biomedical electronics are currently used to monitor the progression of diseases such as diabetes, cancer, hypertension, heart disease, stroke, respiratory disease, chronic kidney disease, arthritis, and obesity. Clinicians can also assess the efficacy of treatment through therapeutic drug monitoring or medication adherence monitoring; therapeutic prescriptions can then be altered to optimize efficacy. Furthermore, diagnostic electronic devices can collect clinical data from patients over an extended period of time without clinical consultations, which enables quicker, more efficient, and more accurate diagnoses and prognoses.

Therapeutic electronic devices enable potentially more efficient and effective therapeutic interventions than conventional treatment methods such as pill-type medications. For example, tissue/nerve stimulation is used to repair neurological dysfunction or to relieve pain by modulating the nervous system: examples include deep brain stimulation for Parkinson’s disease, gastric stimulation for gastroparesis, and peripheral nerve and spinal cord stimulation for chronic pain relief. Programmable drug pumps can increase medication adherence and maintain analyte concentrations within a targeted therapeutic window. Therapeutic efficacy can be optimized when the diagnostic and therapeutic devices are combined into a closed-loop system.

In a closed-loop system, diagnostic sensors monitor biomarkers related to a target disease and a central processing unit analyzes the measured data and adjusts the treatment accordingly. A closed-loop algorithm can achieve high therapeutic efficacy in pharmacologic treatment by maintaining the medication levels within a tight predetermined threshold; in electrical stimulation, closed-loop systems support stimulation in response to measured endogenous electrical activity. There are many medical treatments that can be enhanced by closed-loop medical devices: chemotherapy, anesthesia, opioids for postsurgical management of pain, methotrexate for control of rheumatoid arthritis, tacrolimus for post-transplant immunosuppression, phenytoin to control epileptic seizures, and the anticoagulant warfarin.[8] A well-recognized biomedical closed-loop electronic device is the type 1 diabetes glucose monitoring and insulin pump system, also known as an artificial pancreas, that continuously measures blood glucose levels and delivers the required insulin dose. Another closed-loop electronic medical device is a transgastric sensor and gastric stimulator, which is used to treat obesity. This implantable device detects food intake and triggers a gastric stimulator which makes a patient feel satiated.[9] Other examples of implantable biomedical closed-loop systems include closed-loop pacemakers, which treat cardiac arrhythmia, and closed-loop deep brain stimulators (DBS), which treat Parkinson’s disease. Table 1 summarizes clinical applications in which implantable/ingestible biomedical electronic devices are used.

Table 1.

Clinical applications that use implantable/ingestible biomedical electronic devices.

| Device category | Clinical application | Examples | Related diseases or medical conditions |

|---|---|---|---|

| Diagnostic | Pressure monitoring | Blood pressure monitoring | Hypertension[10,11] |

| Intra-cranial pressure (ICP) monitoring | Traumatic brain injury, brain tumor, chronic intracranial hypertension[12-15] | ||

| Intraocular pressure (IOP) monitoring | Glaucoma, ocular hypertension[16-18] | ||

| Intra-abdominal pressure (IAP) monitoring | Abdominal compartment syndrome (ACS), Intra-abdominal hypertension[19-21] | ||

| Bladder pressure monitoring | Neurogenic bladder dysfunction[22] | ||

| Temperature monitoring | Core body temperature monitoring | Infection, Thermoregulatory disorder[23,24] | |

| Glucose monitoring | Blood glucose level monitoring | Diabetes mellitus[25,26] | |

| Biomarker monitoring | Cortisol in blood, etc. | Psychiatric disorders[27-29] | |

| Gas monitoring | Gastrointestinal (GI) gas | Irritable bowel syndrome, Inflammatory bowel disease[30,31] | |

| Electrical signal monitoring | Electrogastrogram (EGG), Electrocardiogram (ECG) | Gastroparesis, heart failure[32-34] | |

| Medication adherence monitoring | Medication adherence monitoring | Disease treatment monitoring[35] | |

| Therapeutic drug monitoring | Chemotherapy, anticoagulants | Epilepsy, Anticoagulants, Immunosuppression, Cancer[36-38] | |

| Imaging | Wireless capsule endoscopy | GI bleeding, inflammatory disorder, precancerous tissues[39,40] | |

| Therapeutic | Electrical stimulation | Deep brain stimulation | Parkinson’s disease[41-43] |

| Electric nerve stimulation (spinal cord, vagus nerve, peripheral nerve, etc.) | Diabetic neuropathy, peripheral artery disease, chronic pain relief[44-46] | ||

| Gastric stimulator | Gastroparesis[47-50] | ||

| Drug delivery | To GI tract (e.g., IntelliCap) | ||

| To subcutaneous space (e.g., insulin injection) | |||

| Visual prosthesis | Retinal prostheses | Degenerative retinal diseases (Retinitis pigmentosa (RP)), Age-related macular degeneration (AMD))[51,52] | |

| Hearing assist | Cochlear implants | Hearing loss[53] | |

| Closed-loop | Cardiac assist | Pacemaker | Arrhythmia, heart attack, etc.[54-56] |

| Cardioverter defibrillator(ICD) | |||

| Ventricular assist device | |||

| Kidney assist | Implantable bioartificial kidney | Kidney failure[57,58] | |

| Closed-loop drug delivery | Blood glucose monitor-insulin pump | Diabetes mellitus[59] | |

| Chemotherapy | Cancer[60] | ||

| Anesthesia | Surgical process[61,62] |

Due to recent technological developments, the features available and implantation locations of biomedical electronic devices has increased substantially. Advances in wireless communication enable medical devices to be untethered when in the human body. Advances in minimally invasive or semi-invasive surgical implantation procedures have enabled biomedical devices to be implanted in locations where clinically important biomarkers and physiological signals can be detected; it has also enabled direct administration of medication or treatment to a target location. This leads to higher therapeutic efficacy and lower levels of patient discomfort. Nevertheless, a significant challenge arises when these electronic devices operate inside the body: power is a fundamental bottleneck. This is because the major functionalities of the device, such as diagnostic/therapeutic modalities, duty cycle, and operation lifetime, are often constrained by the amount of power that is available. Furthermore, additional features are constantly being added to biomedical electronic devices as a result of technological development. For instance, smartphones and internet of things (IoT) technologies facilitate physiological data collection; artificial intelligence (AI) algorithms provide advanced data analysis and personalized medical decision-making. As a result, the power demand for biomedical electronic devices is constantly increasing. Thus, technology related to powering devices is a major determinant in the ability to develop in-body biomedical electronics. Figure 1 shows the major milestones of implantable and ingestible electronic devices and relevant technologies to power these devices.

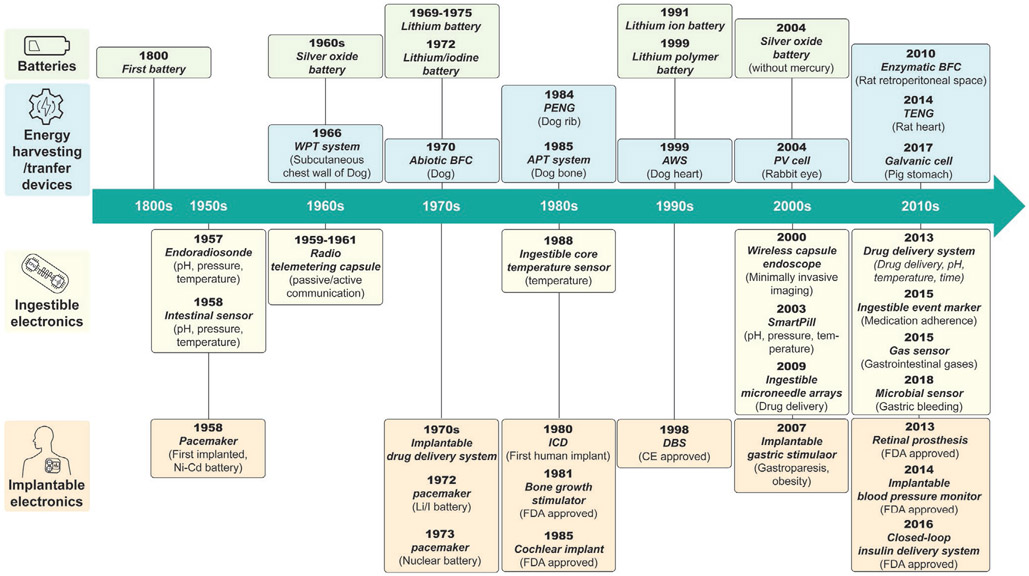

Figure 1.

Timeline of major milestones for implantable and ingestible electronic devices and technology for powering such devices. Listed are the years when batteries suitable to power biomedical devices were first commercialized,[63-69] in vivo experiments of energy harvesting and transfer devices first occurred,[70-78] ingestible electronics first appeared,[79,80] and implantable electronics first appeared.[81-89] (WPT: wireless power transfer, BFC: biofuel cell, PENG: piezoelectric nanogenerator, APT: acoustic power transfer, AWS: automatic wristwatch system, PV: photovoltaic, TENG: triboelectric nanogenerator).

1.2. Structure and Power Consumptions of Implantable and Ingestible Biomedical Electronic Devices

The power requirements of implantable and ingestible biomedical electronics are determined by their structure and components. This section discusses the functional blocks that are typically found in a biomedical electronic device and their power requirements.

1.2.1. Structure and Components of Biomedical Electronic Devices

Most biomedical electronic devices are composed of a common set of components, including a power unit, sensors, actuators, a signal processing and control unit, and a data storage unit (Figure 2). Implantable and ingestible devices that require a great deal of data manipulation or large quantities of data logging also need to be wirelessly connected to an external device so that data can be transmitted to an external receiver and signal processing, data storage, and display can be performed more efficiently. The power unit, which is composed of one or more energy sources as well as power management circuits, supplies electrical energy to the whole system. The sensors and actuators interface with the biomedical environment to record the external stimuli or generate appropriate medical interventions. The signal processing and control unit is the central processing unit that has many functionalities including input/output (I/O) operations, analog and digital signal conversion and processing, peripheral control, memory, and timing operations. This unit supervises the algorithm and operation of the entire system. Usually, a single mixed-signal microcontroller unit (MCU) is used for biomedical electronics since it enables all functionalities to be integrated onto a single chip that is small in size, requires little power, and is low in cost. The data storage unit can be integrated into a signal processing and control unit like memory is embedded onto an MCU, or it can be added as a separate memory unit if needed. The basic components of a wireless communication unit are a transmitter/receiver/transceiver and an antenna.

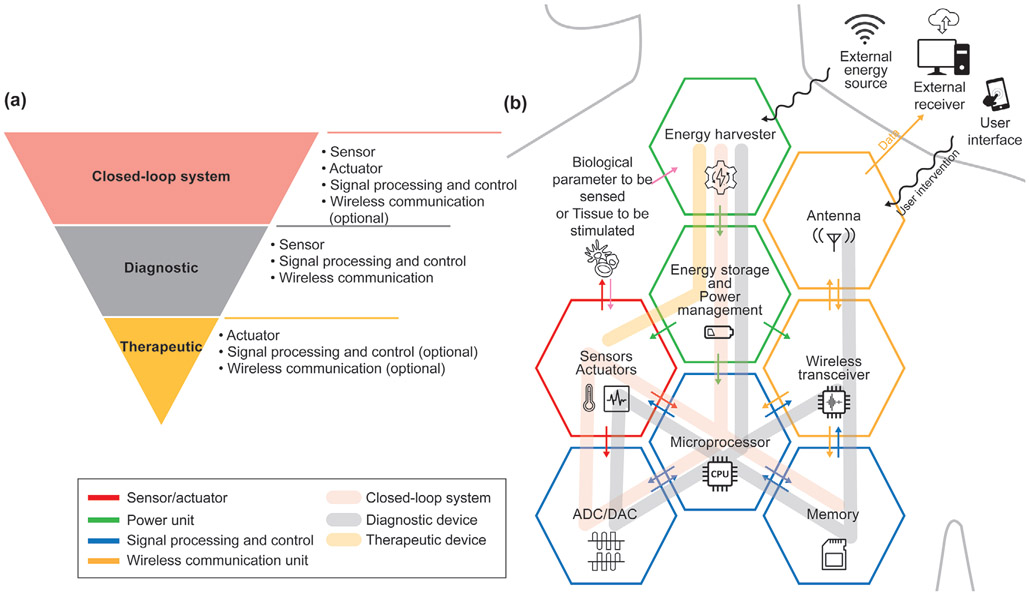

Figure 2.

a) The system configuration and b) the schematic of functional units of closed-loop, diagnostic, and therapeutic implantable/ingestible electronics.

The system complexity of each of the three biomedical electronic systems is shown in Figure 2. Therapeutic tools are usually the least complex systems and primarily require a controlled actuator. Control of the therapeutic devices can be achieved in one of three ways: wirelessly, by an external user for an on-demand application; by a microcontroller that has a pre-programmed algorithm that operates at a specific time and situation; or by environmental stimuli.[90-93] Microcontrollers and wireless communication units are optional components for therapeutic devices. However, systems composed of only actuators, which do not have computational elements and communication modules, can only implement simple on-off control. Adding a microcontroller and a radiofrequency (RF) communication module enables more sophisticated therapeutic procedures such as time-controlled drug delivery or feedback control. At the same time, these additional modules increase the power consumption of the devices and require the power management circuits to be more complex.[92]

A diagnostic device relies on different modules than a therapeutic device: sensors to collect biological information, a microcontroller to convert the analog inputs into digital data and perform signal processing, and a wireless communication module and/or additional on-board memory to transmit/store the processed data for further analysis.[80,94-98] Thus, a diagnostic device requires a more complicated circuit design than a therapeutic device. A closed-loop system has the most complex configuration since it must contain a sensor, an actuator, and a microcontroller. The microcontroller plays an important role in coordinating the sensory input with the output of the actuator. An RF communication module is an optional component in a closed-loop system. If the microcontroller unit in a closed-loop system, such as a pacemaker and artificial pancreas, does not require intervention from an external user to make a therapeutic decision, no communication component is needed.[99,100] However, if a system needs to be highly miniaturized and cannot incorporate a powerful microcontroller due to size and power consumption limitations, then having an RF communication module can shift the heavy computational load to a powerful external device.[101]

1.2.2. Power Requirements of Biomedical Electronic Devices

For implantable and ingestible devices, power requirements are a critical and often constraining parameter. There is a wide variety of biomedical devices that are currently used in clinical settings; these devices have a range of power requirements (Table 2). Among other factors, the functionality and longevity of the device are characteristics that need to be balanced with energy consumption. Devices that require relatively low power, such as pacemakers (10–30 μW) and artificial urinary sphincters (200 μW), can last for 8–12 years before they require a battery replacement or maintenance.[79,102] These devices can be implanted in the body and only require battery replacement surgery, a low risk and convenient procedure, approximately once every decade.

Table 2.

Power requirements of implantable and ingestible biomedical electronic devices.

| Implantable/Ingestible device | Power requirement | References |

|---|---|---|

| Deep brain stimulator (DBS) | 100 μW | [104,105] |

| Spinal cord stimulator | 1–10 mW | [104] |

| Intraocular pressure (IOP) monitor | 200 nW–200 μW | [106] |

| Retinal prosthesis | 250 mW | [107] |

| Cochlear implant | 100 μW–10 mW | [105,108,109] |

| Pacemaker | 10–30 μW | [79,102] |

| Implantable cardioverter defibrillator (ICD) | 50–500 μW | [105] |

| Implantable blood pressure monitor | Passive | |

| Wireless capsule endoscope | 5–30 mW | [110] |

| Medication adherence monitor | 1 mW | [35] |

| Gastric stimulator | 1–30 mW | [111] |

| Implantable drug delivery system | 100 μW–1 mW | [104,105,112] |

| Artificial urinary sphincter | 200 μW | [79,102] |

Similarly, for single-use devices, such as capsule endoscopes, batteries provide enough energy to power the devices for their entire lifetime. On the other hand, devices that consume higher amounts of power or operate over a longer time period cannot rely on simple primary batteries. Muscle stimulators and cochlear implants consume substantial amounts of energy and their batteries need to be recharged regularly. Devices with tight size constraints, such as retinal prostheses or brain implants, are not able to accommodate enough batteries within a single device. Implantable neurostimulators (INS), for example, consist of two parts: one is the network of implantable stimulating electrodes and the other is the external control unit. The external control unit is located in an infraclavicular or abdominal implant site outside the skull; it is connected to the electrodes through external connectors.[103] Different powering technologies, such as novel energy-dense batteries, energy harvesting techniques, and energy transfer techniques, can be used to continuously power the device or recharge its batteries which reduces the number of surgical procedures needed, minimizes infection risks, reduces the number of electrical components and connections needed, increases the device’s reliability, and lowers costs. Some transient electronic devices, such as medication adherence monitors, use biodegradable batteries or energy harvesting devices rather than conventional lithium (Li) batteries to perform their function.

The rest of this paper discusses three different powering methods for implantable and ingestible electronic devices: the use of batteries, energy harvesting, and energy transfer. In Section 2, we will review the fundamental principles and state-of-the-art technologies of batteries for biomedical electronics. In Section 3, we will cover the working principles and provide examples of energy harvesting systems, which scavenge naturally occurring energy from the human body. We will also thoroughly analyze the characteristics of each available energy source for devices implanted in or ingested into the human body in Section 3. In Section 4, we will review the energy transfer technologies which can deliver energy from outside the body to implanted or ingested devices.

2. Batteries to Power Biomedical Electronic Devices

Since the first pacemaker was implanted in 1958, batteries have been the main source of power for biomedical electronic devices. In this section, we will cover the history and the state of the art of battery technology for biomedical electronic devices. The important characteristics of batteries for biomedical applications will be discussed.

2.1. Important Characteristics of Batteries for Biomedical Electronic Devices

A battery is an electrochemical energy storage system which is composed of four main components: a cathode, an anode, the electrolyte, and a membrane separator. The electrochemical reactions between these components determine the characteristics of the batteries. When evaluating whether a particular battery is appropriate for a specific use, several parameters should be considered: nominal voltage, energy density and capacity, lifetime, and discharge profile. Energy density can be defined as either gravimetric energy density (specific energy), which is energy capacity in weight, or volumetric energy density, which is energy capacity in volume. For secondary or rechargeable batteries, cycle life and charging speed are two additional characteristics to consider. Other major characteristics to consider include the battery’s cost, its internal resistance, and the long-term effects of aging.

For biomedical applications, especially for implantable and ingestible electronic devices, the most significant parameters that should be considered are volumetric energy density and safety. Volumetric energy density is more important than specific energy because biomedical electronic devices often have size limitations but rarely have restrictions on their weight.[113] Safety factors to be considered include the battery’s risk of explosion and leakage, which could potentially lead to toxicity, reduced biocompatibility, and immunogenicity. The battery’s lifetime, its long-term stability and reliability, and the predictability of its performance are other important characteristics to consider for in-body applications. Indeed, the safety of implantable/ingestible batteries and battery-powered medical devices are generally regulated by government agencies such as the Food and Drug Administration (FDA, United States of America) and the European Medicines Agency (EMA, European Union). The standards set by the FDA and the EMA are meant to ensure the safe operation of primary and secondary batteries for medical devices under intended use and reasonably foreseeable misuse. FDA-recognized consensus standards for primary and secondary batteries include IEC 60086-4 (primary batteries—Part 4: safety of lithium batteries); IEC 60086-5 (primary batteries—Part 5: safety of batteries with aqueous electrolyte); UL 1642 (lithium batteries); and IEC 62133 (secondary cells and batteries containing alkaline or other non-acid electrolytes—safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications); IEC 62485 (safety requirements for secondary batteries and battery installations); UL 2054 (household and commercial batteries).[114-123] The standard IEC 60601-1 (medical electrical equipment—general requirements for basic safety and essential performance) also provides the general safety requirement of batteries for medical devices. The EMA has adopted “Regulation (EU) 2017/745 on Medical Devices (MDR)” and harmonized standards such as EN/IEC 60601-1 (EU-adopted version of IEC 60601-1) and EN/IEC 62133 (EU-adopted version of IEC 62133) to regulate the safety and performance of implantable medical devices and batteries[117,118,124-126]

2.2. Development of Battery Technologies for Biomedical Electronic Devices

As mentioned above, batteries that power biomedical electronic devices are required to meet specific standards in order to be sold in certain markets. In this section, a brief history and the state of the art of battery technology for implantable and ingestible biomedical electronic devices will be reviewed. Challenges facing battery technology for biomedical devices will be addressed as well as recent technological advances that attempt to resolve these issues.

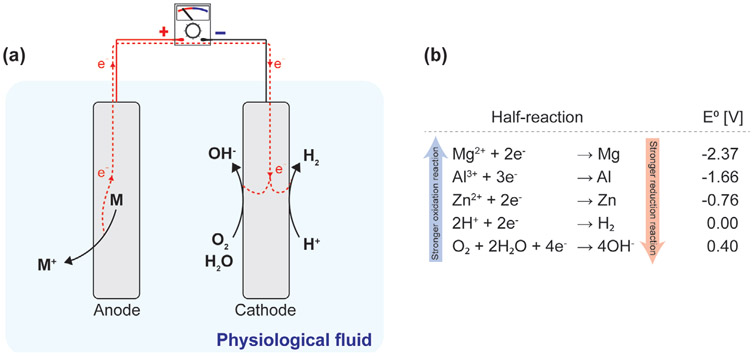

2.2.1. Batteries to Power Biomedical Electronic Devices

Lithium-Based Batteries for Biomedical Electronic Devices:

Since the development of lithium batteries and lithium-ion batteries (LIBs), they have been standard choices for on-board energy supplies in medical devices. Both types of batteries are made with Li metal, which has high theoretical energy densities of 2062 mAh cm−3 and 3862 mAh g−1; because of this, lithium-based batteries have a higher cell voltage and energy density than other battery chemistries.[127] Lithium-based batteries also have a flat, predictable, and reliable discharge profile, which is desirable in medical devices.[68,128] However, drawbacks include high manufacturing cost, moderate discharge current, safety issues, and limited recyclability.

Lithium and lithium-ion batteries share several common features; however, they exhibit quite different electrochemical characteristics. All lithium batteries have pure lithium metal as their anodes but they can have many types of cathodes, including iodine (Li/I2), manganese oxide (Li/MnO2), carbon monofluoride (Li/CFx), silver vanadium oxide (Li/SVO) or hybrid cathodes (Li/CFx–SVO).[105] Lithium batteries generally have a higher capacity and longer shelf life than lithium-ion batteries, but since pure lithium metal is highly reactive, damage to the batteries can pose a serious safety issue.[105,128]

LIBs use lithium-intercalated compounds as cathodes, which are more stable than pure lithium metal. Examples of commonly used cathode material in LIBs include lithium cobalt (Co) oxide (LiCoO2), lithium iron (Fe) phosphate (LiFePO4), lithium manganese oxide (LiMn2O4, Li2MnO3, or LMO), and lithium nickel (Ni) manganese cobalt oxide (LiNiMnCoO2 or NMC).[129] Lithium-ion batteries are rechargeable, which results in an extended lifetime compared to lithium batteries, which is especially useful for medical devices that have high power requirements. Using rechargeable batteries can significantly improve patient comfort because it reduces the frequency of battery replacement, which often needs to be done surgically. LIBs exhibit the highest battery capacity among existing rechargeable battery technologies, with no memory effect and a low self-discharge rate. Lithium-ion batteries are also safer than lithium batteries, but there are still some safety issues to be addressed. Physical damage, elevated temperatures or electrical abuse such as shorting the circuits and overcharging, can cause the batteries to experience a thermal runaway or explode. Also, if LIBs leak, their electrolytes are toxic to humans.[130] Adding a battery protection circuit is one way to keep LIBs within a safe operating range.

There is a long history of using lithium and lithium-ion batteries in implantable and ingestible biomedical devices.[131] A large portion of today’s commercial medical devices use lithium-based batteries as their on-board power source due to their reliability.[132] Lithium-based batteries have been used to power implantable devices such as pacemakers, neurostimulators, cochlear implants, implantable cardiac defibrillators, cardiac resynchronization devices, drug delivery systems, and bone growth generators.[102] Lithium-based batteries are also the preferred choice for hard-to-retrieve and single-use devices due to their high energy density. The most well-known biomedical devices that utilize lithium batteries as their power sources are cardiac pacemakers. Li/I2 batteries have been powering pacemakers since they were first developed in 1972 and are still used in pacemakers today due to their reliability and predictability.[167] Some applications that demand high power often utilize rechargeable lithium-ion batteries to increase the lifetime and reduce the size of the implant. For example, neurostimulators, which operate in the milliwatts power range, are one type of device that use secondary LIBs.[102]

Silver Oxide (AgO) Batteries for Ingestible Electronic Devices:

Other than lithium-based batteries, there are very few battery options for biomedical electronic devices on the market. Silver oxide batteries, which consist of an AgO/zinc (Zn) cathode/anode pair, have energy densities that are similar to or slightly lower than standard LIBs. One advantage of silver oxide batteries for implantable or ingestible medical devices is that they are not prone to thermal runaway.[133] Indeed, silver oxide batteries are preferred for on-board power supplies in ingestible electronics and they are the only type of battery that has been approved for clinical use to power capsule endoscopes.[80,110,133] However, the toxic metal and caustic electrolytes in silver oxide batteries can still be hazardous if the battery is retained or ruptured.[79]

There are other types of primary cells such as zinc-air batteries, which have the highest energy densities among all commercially available cells. However, these batteries are not suitable for in-body medical devices due to the lack of oxygen flow inside the body. Zinc-air batteries are used for hearing aids and in the external units of cochlear implants. Zinc carbon and alkaline batteries have low energy densities and are considered outdated technologies.

Non-Lithium-Based Rechargeable Batteries:

For rechargeable batteries in biomedical applications, there are not many viable alternatives to lithium ion batteries. Before the mid-1990s, nickel cadmium (NiCd) batteries had an overwhelming market share for rechargeable batteries due to their high current discharge rate, fast charging rate, and thermal stability.[134] However, since cadmium is toxic to humans and poses an environmental hazard, the sale of NiCd batteries has been restricted since 2006 by the EU battery directive.[124] Nickel metal hybrid (NiMH) batteries was developed as a substitute for NiCd batteries in 1990s.[134] NiMH batteries have a higher energy density and are less toxic than NiCd batteries but they also have a shorter cycle life and a shelf life. NiMH batteries are considered to be safer than lithium ion batteries under reasonable misuse such as physical, thermal, and overcharging stress. But they suffer from the same problems as NiCd batteries, such as memory effect, a high self-discharge rate, and the risk of explosion when overcharging. Lead acid batteries are the most economical rechargeable batteries for large power applications, but they have a low energy density and a short cycle life, are heavy, and contain hazardous lead, which make them unsuitable for biomedical devices. NiCd, NiMH, and lead acid batteries are still widely used in various types of devices, including industrial applications or motive power systems, but they are considered inferior to lithium ion batteries for implantable and ingestible biomedical devices in terms of both safety and performance.[135]

The major characteristics of the batteries introduced in this section are summarized in Table 3, which also lists the desirable characteristics of implantable and ingestible biomedical electronic devices.

Table 3.

Summary of battery technologies in biomedical field.

| Battery type | Rechargeability | Cathode material (+) |

Anode material (−) |

Voc [V] |

Gravimetric energy density [mWh g−1] |

Volumetric energy density [mWh cm−3] |

Cycle life | Self-discharge time | Safety | Application |

|---|---|---|---|---|---|---|---|---|---|---|

| Li | Nonrechargeable | I2, MnO2, CFx, SVO, SoCl2 | Li | 3.1–3.3 | 200–500 [136,137] | 500–1000 [137] | N/A | long (10 years) [128] | Risk of thermal runaway | Implantable electronics |

| Silver oxide | Nonrechargeable | Silver oxide | Zn | 1.6 | 150–250 [136] | 400–800 [136] | N/A | Long (5–7 years) | Free from thermal runaway, hazardous when ruptured | Ingestible electronics, Capsule endoscopy, insulin pump |

| Li-ion | Rechargeable | LiCoO2, LiFePO4, LiMnxOy, LiNiMnCoO2 | Graphite | 3.3–3.8 | 90–240 [136,139,140] | 200–700 [136,138] | 500–2000 [136] | Long (3 years) [128] | Protection circuit is mandatory, low toxicity[136] | Implantable electronics |

2.2.2. Efforts toward Current Challenges in Batteries for Biomedical Electronic Devices

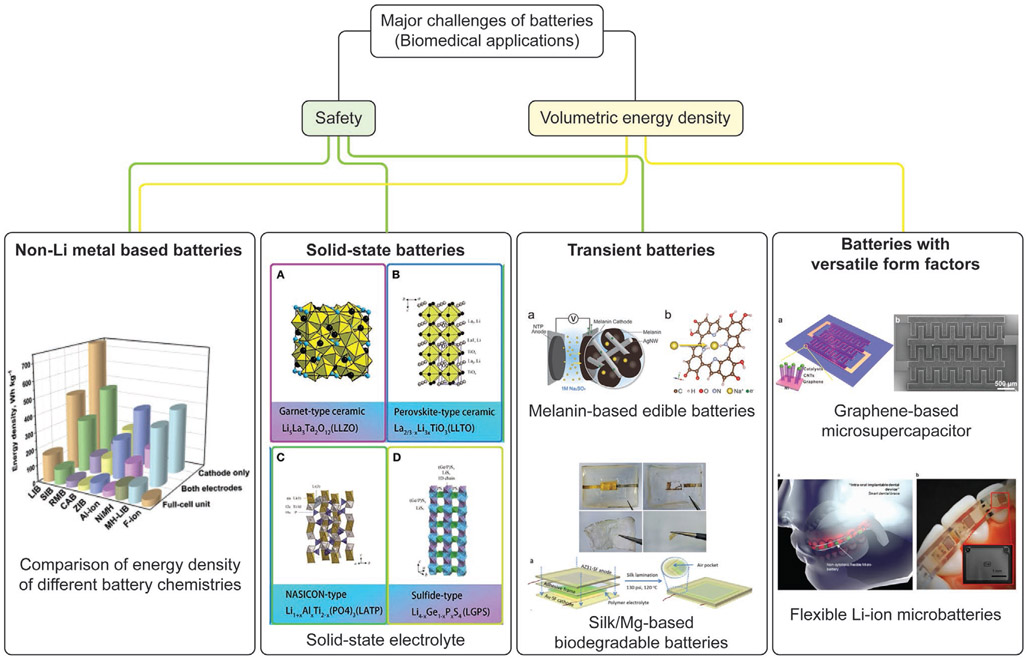

In the last few decades, new battery technology has led to increases in the performance, reliability, and lifetime of batteries. However, challenges remain, especially in terms of volumetric energy density and safety. Electronic miniaturization allows more functionalities to be added to devices, which increases power requirements. Recently, new material-based battery systems have been developed with higher energy densities. Also, battery components can be arranged in different geometric orientations in order to efficiently leverage the limited space in biomedical devices. Researchers have also been focused on developing electrolyte and electrode materials that are nonflammable, nontoxic, and biodegradable in order to improve the safety of batteries.

Rechargeable Batteries Based on Non-Lithium Metals:

To overcome the inherent danger of lithium-based batteries, there has been a lot of research that has focused on developing new battery technologies that are not based on lithium metals.[140] Alkali metals and alkaline earth metals such as sodium (Na), potassium (K), calcium (Ca), and magnesium (Mg) have been proposed as alternative materials to Li for batteries. In addition to being safer than Li, they are also less expensive and more abundant in nature. The raw materials which are essential in LIBs, such as Co, Ni, and Li, are limited in supply and would potentially increase the price of LIBs in the near future. [141,142] Alkali metals, including Li, Na, and K, are very reactive and electropositive monovalent metals, while alkaline earth metals, such as Ca and Mg, are divalent metals. Sodium-ion batteries (NIBs), potassium-ion batteries (KIBs), and calcium-ion batteries (CIBs) are some of the most promising alternatives to LIBs because they have high energy densities and are relatively safer. NIBs and KIBs can be manufactured using the same techniques as LIBs at room temperature due to the chemical–physical similarities of Na and K metals to Li metal.[143-145] CIBs use multivalent ions as charge carriers, which are capable of transferring multiple electrons per ion.[146] This means, in theory, that the energy capacities of CIBs have the potential to be doubled that of monovalent ion-based batteries. However, CIBs use different materials than LIBs for anodes and cathodes due to the difference between monovalent and multivalent ions.

Na and K, which are alkali metals, are two of the most abundant elements in the earth’s crust.[147] Na is the second alkali metal after Li; Li and Na share some chemical properties. NIBs are more common than KIBs, and high-temperature NIBs, such as the sodium-nickel chloride (ZEBRA) battery, have already been commercialized.[148] NIBs are considered safer than LIBs and are less prone to thermal runaway.[149] Potassium has a lower reduction potential than Na: the reduction potential of K is −2.93 V (vs standard hydrogen electrode, SHE) and Na is −2.71 V (vs SHE). With its lower reduction potential, KIBs can theoretically have higher working voltage and energy densities than NIBs. However, there is a fundamental limit on the energy densities that NIBs and KIBs can have. The theoretical energy densities of Na (1166 mAh g−1, 1131 mAh cm−3) and K (685 mAh g−1, 590 mAh cm−3) metals are small compared to Li (3862 mAh g−1, 2062 mAh cm−3).[127] Furthermore, the common cathode materials for LIBs would be easily disrupted in NIBs or KIBs, because the large radius of Na+ ions (0.102 nm) and K+ ions (0.138 nm) would cause large changes in the volume of the electrodes due to the frequent insertion and extraction of ions during the charge and discharge process.[150] This results in a low practical capacity, reduced performance, poor cyclability, and sometimes even electrochemical inactivity. Thus, the selection of host materials for the intercalation cathode in NIBs and KIBs is very limited.[140,151] Additionally, most NIBs and KIBs are only operational in high temperatures, which inhibit NIBs and KIBs from being used in biomedical applications. Even though there are some commercialized NIBs on the market, they are mostly developed for electromobility or large-scale energy storage and still have high manufacturing costs which make them just as expensive as LIBs.[152] Hence, understanding the structural and electrochemical properties of different electrode and electrolyte materials for NIBs and KIBs is important for developing fully functional batteries based on non-lithium metals for biomedical electronic devices.[151,153-157]

Calcium is the third alkaline earth metal, and is the fifth most abundant element in the earth’s crust.[147] The standard reduction potential of Ca (−2.87 V vs SHE) is similar to Li (−3.04 V vs SHE); the theoretical energy densities of Ca (1340 mAh g−1, 2072 mAh cm−3) is also similar to that of Li (3862 mAh g−1, 2062 mAh cm−3).[127,158] Calcium has a lower polarizing character than magnesium or aluminum, thus Ca2+ ions are more mobile in liquid. Compared to LIBs, CIBs are less toxic and less prone to thermal runaway.[159] However, the technology is still in its infancy: there are few actual prototypes and their operating temperatures are outside the range that is appropriate for medical applications. Recent efforts have focused on finding suitable Ca metal anodes, Ca intercalation cathodes, electrolytes that can allow CIBs to operate at room temperature, and steadily efficient compatible battery chemistries.[140,142,146,160] One hurdle to developing rechargeable CIBs for long-term applications is that passivation layers form at the Ca anodic surface during use. Passivation layers reduce the ability to reversibly plate and strip the Ca metal anode. Another challenge is developing an intercalation host material for the Ca cathode that is able to accommodate Ca ions, which, at 0.112 nm, are relatively large; only a few candidates have been proposed to date.[146,150]Ca2+ ions have a low diffusion rate and a high reduction potential which makes the development of suitable electrolytes for CIBs that operate at room temperature challenging.

There are other non-lithium based battery technologies that have the potential to be used in biomedical devices. For instance, potassium sulfur and sodium–sulfur batteries that do not use pure metal Na and K anodes can offer comparable or even higher energy densities than LIBs, but they do not have the same safety risks as pure alkali metal anodes.[161,162] Other candidates for next-generation, energy-dense, safe, and cost-efficient batteries for biomedical applications include magnesium batteries, aluminum ion batteries, nickel–zinc batteries, a silicon-based anode for LIBs, proton batteries, and graphite dual ion batteries.[163-173] However, most of these state-of-the-art battery technologies are being developed for large-scale applications, such as for energy grids or electric vehicles, and they do not reliably and efficiently operate at room temperature yet. Further research and efforts will be needed to achieve not only high volumetric energy density and safety, but also miniaturization, cost efficiency, and efficient operation at room temperature for biomedical applications.

Solid-State Batteries:

LIBs, like most other types of batteries, use liquid electrolytes, which are volatile, flammable, and toxic. As such, liquid electrolytes, which in LIBs consist of lithium salts in an organic solvent, are the reason LIBs can be hazardous, especially in biomedical applications. Aqueous electrolytes, which are water-based, are less hazardous than liquid electrolytes, but they limit the cell voltage and energy density.

Solid electrolytes exhibit number of advantages including reduced risk of thermal runaway and leakages. Solid electrolytes are also less flammable, more robust and flexible, and more resilient to shock, vibration, and high temperatures.[174] They have a slower self-discharge rate, a higher gravimetric energy density, and a more uniform output voltage than conventional liquid electrolytes. They eliminate the need for separators and other packaging restrictions, which enable flexible cell structure designs with various form factors.[175] As an example, the volumetric energy density of solid-state batteries can be significantly increased when they are made into the form of thin-film cells.[174] Solid-state primary or secondary batteries are already capable of meeting lifetime and power density requirements for low-power medical devices such as cardiac pacemakers.[175] Various kinds of materials have been investigated for use as solid-state electrolytes. They can be broadly classified by type: polymers, polymeric gels, ceramics, glassy materials, and hybrid composites.[176] The thickness of the electrolyte can range from hundreds of nanometers to hundreds of micrometers, depending on the fabrication method.[174] The most common solid-state electrolyte materials used in lithium-based batteries include oxide-type, sulfide-type, hydride-type, halide-type, borate or phosphate-type, thin film-type, and polymer-type.[176-178] For example, sodium superionic conductor (NASICON), lithium superionic conductor (LISICON), lithium phosphorus oxynitride (LiPON), and poly(ethylene oxide) (PEO) are some of the most well-known solid-state electrolytes for lithium-ion batteries.[177,178] One of the first solid-state electrolyte designs was a plastic-based lithium phosphorous oxy-nitride (LiPON or PLiON) glassy thin-film electrolyte; it was a conventional coin-type cell, which was flexible and easy to use.[68] For non-lithium based battery systems, ceramics are the most commonly used solid-state electrolytes.[179] Phosphates, such as NASICON, are the most promising solid-state electrolytes for sodium-ion batteries, and sulfide-based solid-state electrolytes are used in many solid-state battery systems.[174,180]

However, there are still many issues that are preventing the broad adoption of solid-state batteries in biomedical devices. One major problem is that solid-state electrolytes exhibit high ionic resistance in ambient temperatures, which causes their power density to decrease. In addition, it is not yet cost-effective to replace conventional liquid electrolyte-based LIBs with solid-state batteries: the manufacturing cost of the most common commercial solid-state battery, lithium polymer (LiPo) batteries, is 10% to 30% higher than standard LIBs. Solid-state batteries are not fully biocompatible or biodegradable, which can cause safety issues especially for biomedical applications. Other improvements needed for the wide-spread adoption of solid-state batteries in biomedical devices include increasing the cycle lifespan, preventing dendrite formation on the electrode/electrolyte interface, and increasing mechanical and chemical stability.[174,181-192]

Transient Batteries:

One safety hazard for LIBs, especially when used in implantable or ingestible biomedical devices, is the release of toxic materials upon accidental rupture. Since LIBs and other commercial batteries are not biodegradable, the devices can only be retrieved through invasive or semi-invasive surgical procedures, which can cause complications including patient discomfort and inflammation. To solve these issues, researchers have been developing biocompatible and/or biodegradable batteries for implantable and ingestible biomedical electronic devices.

In order for a battery to be fully biocompatible, all of its components, including the cathode, the anode, the electrolytes, and the packaging, must be made from nontoxic and biodegradable materials. The most promising materials for nontoxic transient anodes are biodegradable metals such as Mg and Zn, since they each possess a high theoretical energy density (Mg: 2200 mAh g−1, Zn: 820 mAh g−1) and excellent biocompatibility (maximum daily allowance Mg: 350 mg day−1, Zn: 40 mg day−1).[193-196]

Conventional Mg- or Zn-based primary batteries use silver chloride (AgCl), copper chloride (CuCl), or copper (Cu) as cathode materials which are nonbiodegradable and toxic. Biodegradable metals such as Fe, tungsten (W), or molybdenum (Mo) can serve as substitutes for conventional cathode materials.[197] Utilizing micro/nano-fabrication technology, metal electrodes can be formed into very thin films in order to increase surface area and power output of the battery, if necessary. Note that the redox reaction and degradation rate of the metal electrodes also increases as the surface area increases, so the battery should be designed to keep the amount of metal dissolved into the body within the maximum daily allowance. Moreover, any dissolvable metals being evaluated in the body should undergo rigorous testing in pre-clinical models prior to human translation.

Biocompatible electrolytes, such as a magnesium chloride (MgCl2) solution, can be used or physiological fluid itself can serve as the electrolyte with support material such as a biodegradable hydrogel or polymer. Biocompatible and degradable packaging made from for example polyanhydrides, polycaprolactone (PCL), or polylactic acid (PLA) could ensure the complete biodegradability, longevity, and stability of the batteries. In one study, a fully transient biodegradable Mg/Fe battery system with an MgCl2 electrolytic solution was fabricated using a MEMS process.[198] Its performance was sufficient to power transient implantable electronic systems, with an energy capacity of 0.7 mAh and a peak power output of 26 μW.

Biocompatible metals can still have the potential to induce adverse effects if the released amount exceeds the daily dose limitation. Other potential sources of electrode materials are biologically derived electrochemically active materials, such as natural melanin pigments and their synthetic analogs (“melanins”). Melanins can be used as both anodes and cathodes, depending on the reduction potential of the opposite electrode. One research group developed edible primary cells consisting of pre-oxidized melanin cathodes, benign ceramic-based anodes, and an aqueous sodium-ion electrolyte; the nominal voltage for these cells was 0.5 V and the nominal specific energy capacity was 25 mWh g−1.[79] Another group developed a biodegradable, flexible micro-supercapacitor that consisted of melanin drop-casted carbon paper electrodes operating in aqueous electrolytes. This supercapacitor had a power density of 5.24 mW cm−2, an energy density of 0.44 mJ cm−2, and a specific capacitance of 4.3 mF cm−2.[199] Both examples demonstrate that biologically derived materials have great potential to make fully biocompatible and biodegradable on-board energy supply and storage systems for implantable and ingestible electronic devices.

Batteries with Versatile form Factors:

Implantable and ingestible biomedical devices often have size and shape constraints. The dimensions and shape of ingestible electronic devices are especially limited due to the risk of GI obstruction and device retention.[80] Pill-shaped and round ingestible systems are normally used as a reference point when developing ingestible electronics, since they have a known safety profile:[80] the largest standard capsule (000) has a diameter of 9.91 mm and a locked length of 26 mm. Ingestible devices that are larger than these dimensions, such as the PillCam COLON capsule, which has a diameter of 11.6 mm and length of 33 mm, are sometimes unable to be passed out of the GI tract: the retention rate of the PillCam is 1.4% and it is often linked to obstruction of the GI tract.[200-204] In ingestible electronics, rigid batteries occupy more than half of the total volume of the device and are unable to provide power for more than several days.[80] Designing batteries with various shapes and sizes would reduce the overall size of these devices and reduce the risk of obstruction. Characteristics to consider when selecting batteries include their footprint (micro/large area batteries), thickness (thin film or bulk), mechanical properties (flexibility, bendability, rollability, stretchability, foldability), manufacturing methods (deposition, printing, coating), and technology (solid-state, lithium-polymer, carbon-zinc).

It is challenging to change the shape of bulky and rigid conventional batteries because they have composite electrodes and liquid electrolytes. There has been much research on new electrode and electrolyte materials for the purpose of developing flexible, low profile, or microsized batteries without compromising energy density. One major breakthrough for miniaturized battery (microbattery) and flexible battery technologies was the development of solid-state electrolytes, which was discussed previously. Using thin-film or 3D architecture techniques to overcome low ion conductivities, the thickness of these microbatteries can be reduced to a few micrometers. Typically, the electrodes of these microbatteries are composed of thin-film solid-state materials such as polymers, silicon, or carbon pillars; they can be fabricated by thick film technology or vapor deposition.[205-207] In some studies, nanocarbons, graphene, carbon nanotubes, or paper were combined with electrochemically active materials to make flexible electrodes.[208-211] Most of these flexible batteries are based on well-studied battery chemistry, such as lithium-ion, zinc-carbon, or lithium, but there have been efforts to make flexible batteries based on other battery chemistries, such as NIBs.[212]

There are a few microbatteries and flexible batteries that are already on the market. Commercial microbatteries available today are able to perform sufficiently well for several biomedical applications, including implantable orthodontic systems.[213] For example, the smallest lithium-ion microbattery on the market has a size of 1.75 × 2.15 × 0.02 mm3 (EnerChip, Cymbet Corporation).[214] However, the energy densities are very low (≈5 μAh) and typically only allow a few hours of active operation.[215] Flexible batteries are already widely used in various applications, such as smartphones, wearable healthcare devices, and skin patches; their capacity is comparable to conventional rigid LIBs. [216] One flexible lithium-ion polymer battery that was recently released to the market is the J.Flex battery by Jenax. This battery can be twisted, bent, and folded like paper and has a capacity of 30 mAh (27 × 48 mm, 2.3 mAh cm−2, 3.8 V), making it suitable for medical devices and consumer electronics.[217] The market size for flexible batteries was $98 million in 2020, and in 2025 it is expected to be $220 million.

There are also several academic groups that are researching ways to develop microbatteries with various shapes, sizes, and other physical characteristics. Kutbee et al. developed a biocompatible flexible LIB using the standard CMOS process; it had an unprecedented energy density of 200 mWh cm−3 (6 mWh cm−2), was lightweight at 236 μg for each microcell (2.25 mm × 1.7 mm × 30 μm), and was mechanically stable during 120 cycles of operation.[213] These batteries were integrated into an implantable orthodontic system with near-infrared (NIR) LEDs, which demonstrated the potential for flexible microbatteries to be used in biomedical microelectronic applications including medical implants, hearing aids, and wireless sensor networks.[213] Another group developed gel-based microbatteries that were safe, noncorrosive, and nonflammable and demonstrated that they could be used for low power ingestible and implantable devices.[218] The energy density of these gel-based microbatteries was 3.94 mAh cm−3, for a total capacity of 0.79 mAh, which is enough to power ingestible sensors requiring 4.69 mA for 168 h. (OCV 0.7 V, 7 mm × 7 mm)

Figure 3 summarizes the major challenges of developing batteries for implantable/ingestible biomedical electronic devices and corresponding examples of technology that address these issues.

Figure 3.

Current challenges of developing batteries for implantable/ingestible biomedical electronic devices and corresponding examples of technologies that address these issues. Reproduced with permission.[140] Copyright 2020, Elsevier. Reproduced with permission.[219] Copyright 2019, Frontiers Media S.A. Reproduced with permission.[220] Copyright 2016, Wiley-VCH. Reproduced with permission.[221] Copyright 2017, American Chemical Society. Adapted with permission.[222] Copyright 2017, American Chemical Society. Reproduced with permission[213] Copyright 2017, Springer Nature.

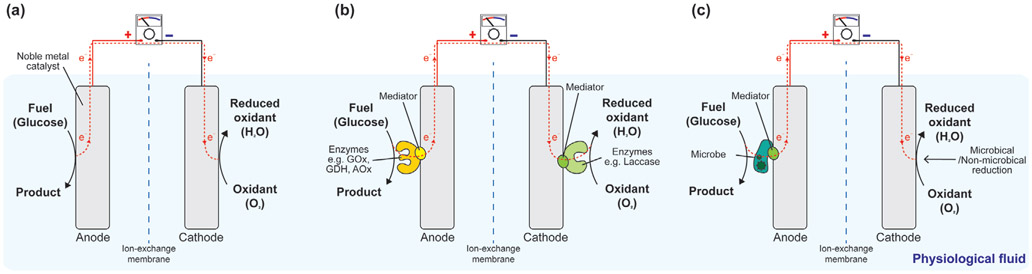

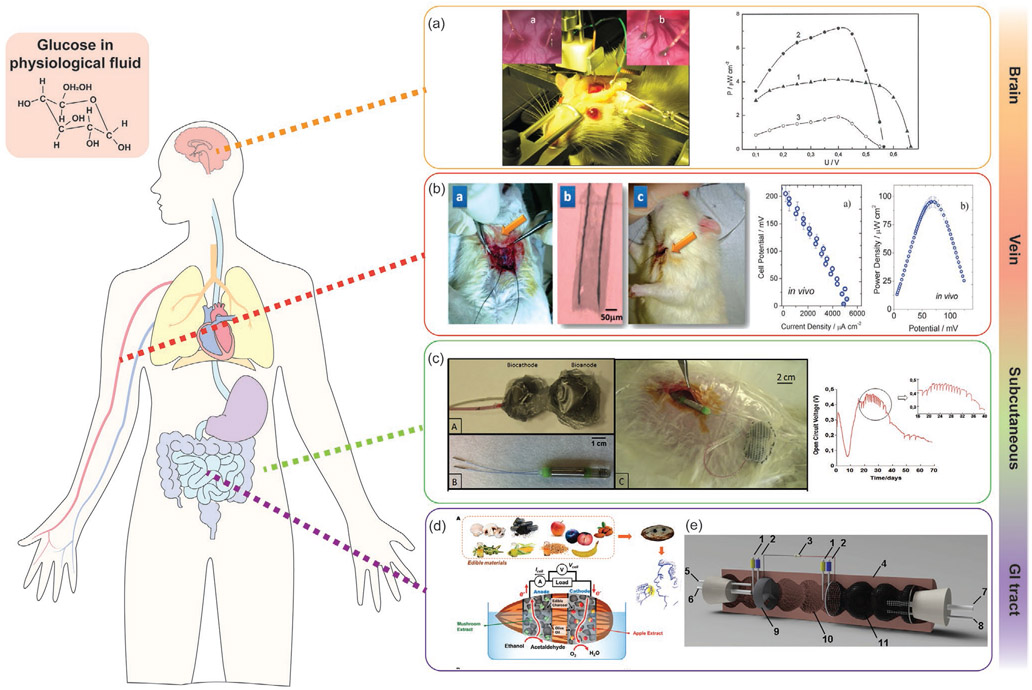

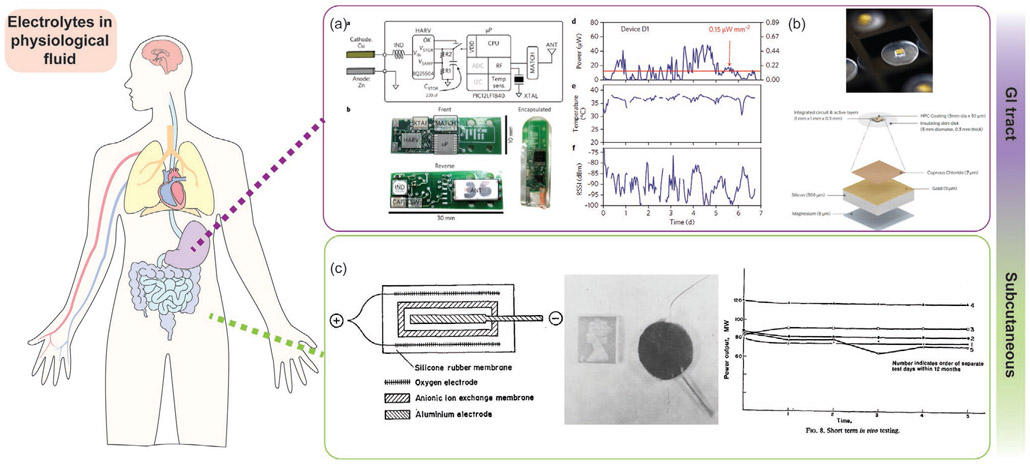

3. Energy Harvesting to Power Biomedical Electronic Devices

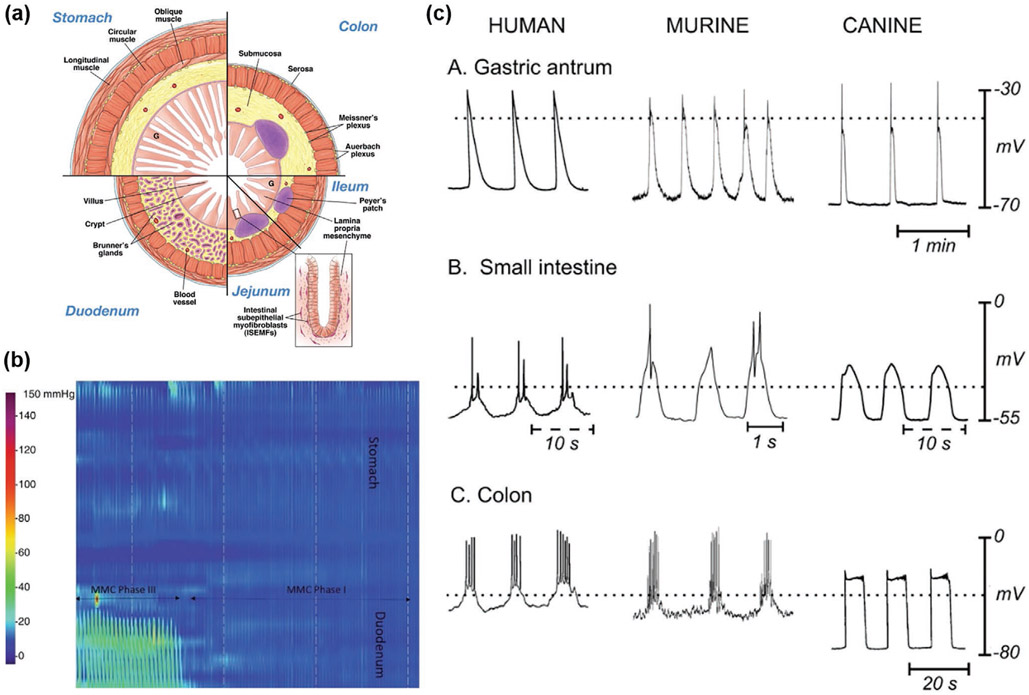

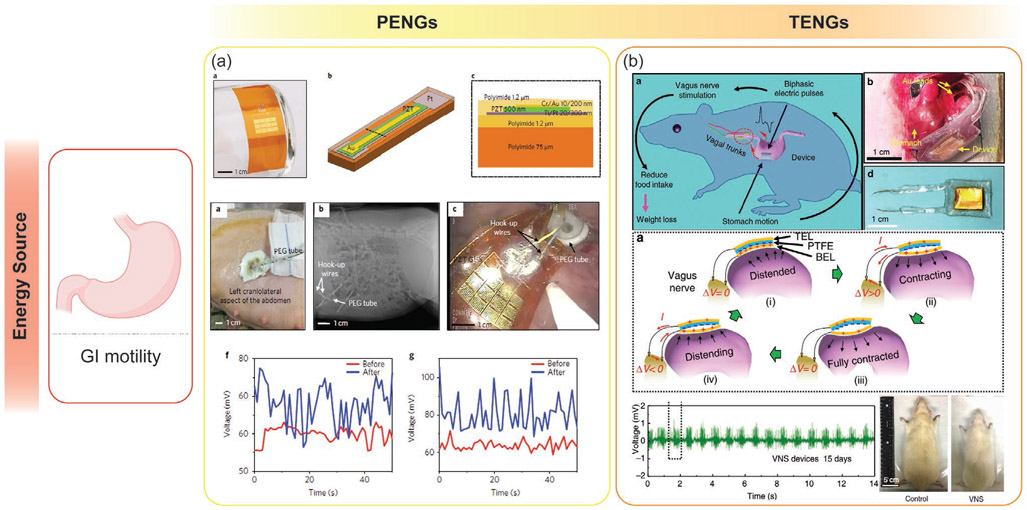

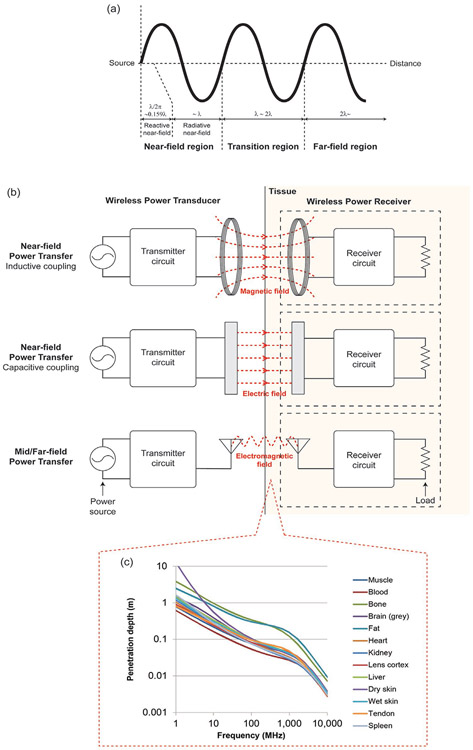

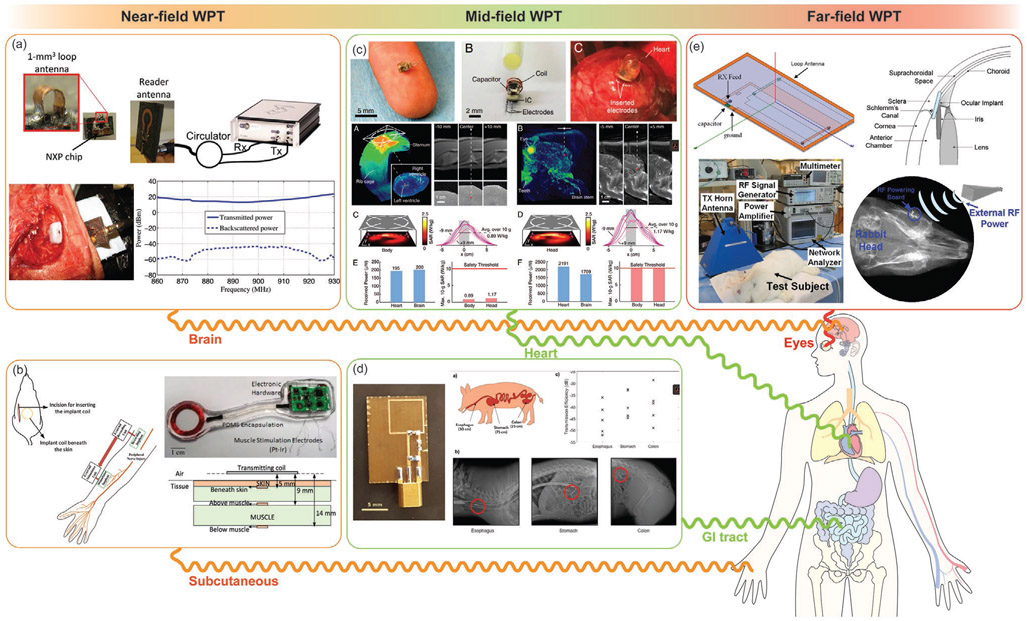

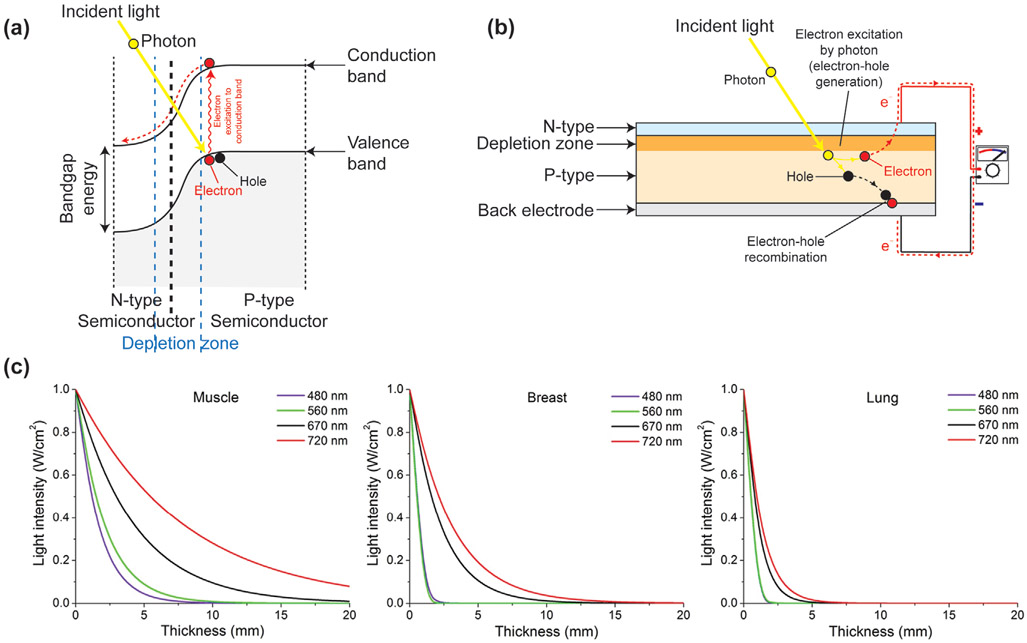

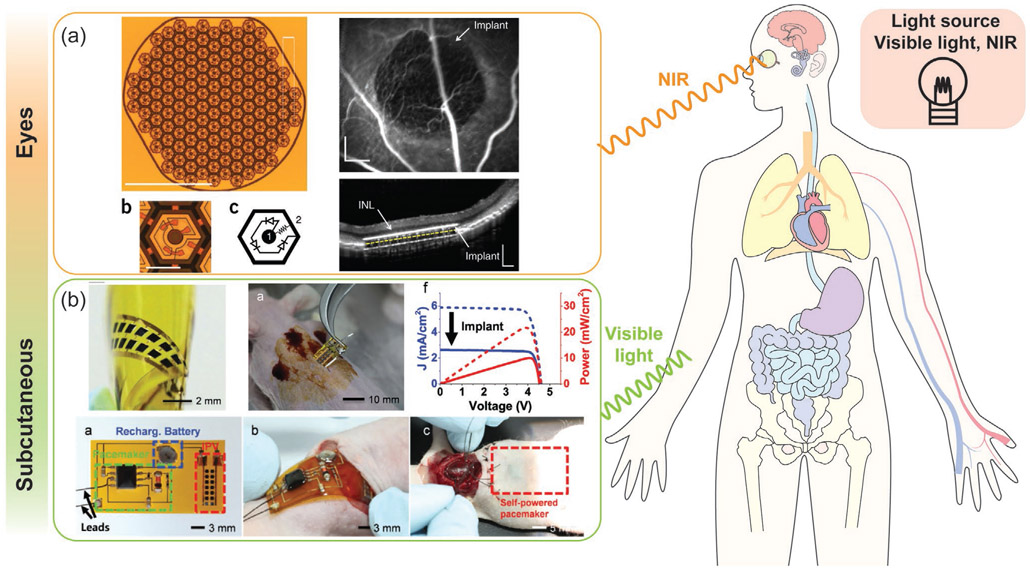

Different locations and organ systems in the human body have access to different types of energy sources, such as mechanical, chemical, and electromagnetic (EM) energies. Mechanical energy generally refers to the energy associated with the motion and position of an object. The contraction of muscles is a form of mechanical energy; most mechanical energy sources within the body are low in frequency (below 10 Hz). Ultrasound, which is a type of mechanical energy that can be produced artificially, has a frequency range between 20 kHz and 20 MHz. Chemical energy is potential energy stored in the bonds of chemical substances. This energy can be released by undergoing a chemical reaction. Molecules or ions that can act donate or accept electrons can be used as chemical energy sources; glucose, ethanol, and hydrogen ions are examples of electron donors or acceptors that are naturally found in the body.

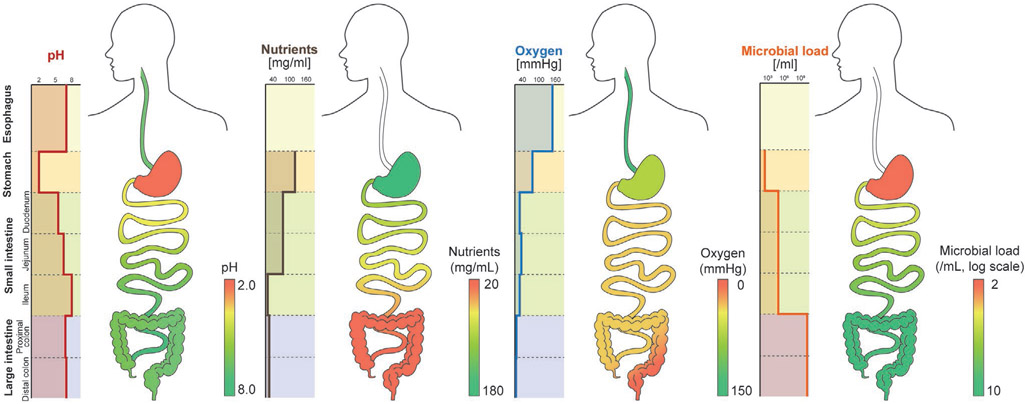

These energy sources can be classified into endogenous or exogenous energy sources based on how they are produced. Endogenous energy is naturally existing energy inside the body, while exogenous energy is artificially generated from human or external system activities. The circulatory system includes the endogenous mechanical energy of the heartbeat and blood flow and the chemical energy of blood glucose. The contraction and relaxation of the diaphragm generate mechanical energy in the respiratory system. In the GI tract, or digestive system, gastric motility can be a mechanical energy source. Endogenous chemical energy sources include glucose that is present in the brain’s cerebrospinal fluid (CSF) and the interstitial fluids. The pH gradients and nutrients present in GI fluid also possess chemical energy. Bioelectrical energy is another type of endogenous energy, which is a result of the electrochemical gradient found across cell membranes; it is actively maintained by energy (ATP)-consuming cell membrane ion pumps. In mammals, the largest direct current (DC) electrochemical potential can be found in the cochlear endolymphatic spaces, and ranges from 70 to 100 mV. Normally, part of these energies are used to operate and maintain the body, but a large portion of remaining energies are lost to the surroundings through heat or other types of energy. These energies can be collected and converted to electrical energy to power in-body electronics: this is called energy harvesting. If devices are implanted at the locations where there are no accessible endogenous energies, exogenous energies in the form of ultrasonic or electromagnetic waves can penetrate through the biological barriers and wirelessly deliver the energies to the devices: this is called energy transfer, which will be discussed in Section 4.

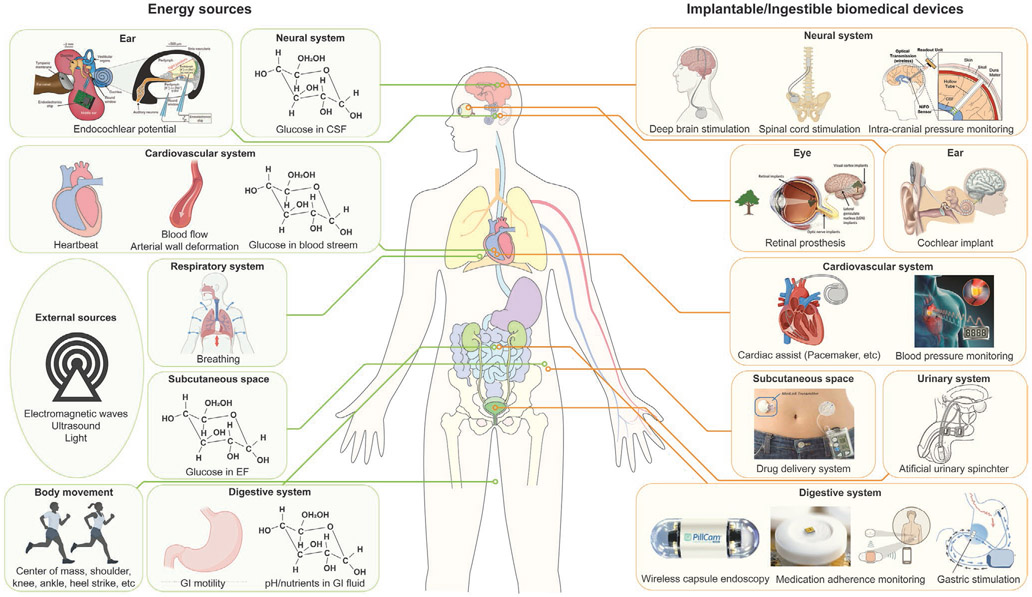

Figure 4 shows available energy sources present inside and outside the body as well as clinical applications that can be powered by these energy sources, and Table 4 summarizes the amount of energy available from the endogenous and exogenous energy sources shown in Figure 4. Employing suitable energy harvesting or transfer methods will empower sustainable ways to power in-body electronics.

Figure 4.

Energy sources available around the human body and biomedical devices that can be powered by these energy sources. Reproduced with permission.[223] Copyright 2012, Springer Nature. Adapted with permission.[224] Copyright 2011, IEEE. Reproduced with permission.[225] Copyright 2020, Elsevier. Reproduced with permission.[226] Copyright 2013, Elsevier. Reproduced with permission.[227] Copyright 2016, Elsevier. Adapted with permission.[228] Copyright 2010, SAGE Publications. Reproduced with permission.[229] Copyright 1996, Elsevier. Adapted with permission.[80] Copyright 2018, Springer Nature. Adapted with permission.[9] Copyright 2015, Springer Nature. Created with BioRender.com.

Table 4.

Amount of energy available from endogenous and exogenous energy sources.

| Type | Energy source | Available energy | References |

|---|---|---|---|

| Mechanical | Heartbeat | 0.93 W | [104] |

| Blood flow | 50–150 cm s−1 | [230] | |

| Breathing | 0.41 W | [104] | |

| GI motility | Table 8 | ||

| Center of mass | 20 W | [104] | |

| Shoulder | 2.2 W | [104] | |

| Knee | 36.4 W | [104] | |

| Ankle | 66.8 W | [104] | |

| Heel strike | 20 W | [104] | |

| Chemical | Blood glucose | 4.5 × 10−3–10 × 10−3 M | [231] |

| CSF glucose | 4 × 10−3–25 × 10−3 M | [232-234] | |

| GI pH | pH 1–8 | [235] | |

| GI nutrients | Table 10 | . | |

| Electromagnetic | EM wave | 10 mW cm−2 | [236] |

| Ultrasound | Average 10–1000 mW cm−2, max pulse 190 W cm−2 | [237] | |

| Bioelectric | Endocochlear potential | 70–100 mV | [223] |

3.1. Mechanical Energy Harvesting and Energy Sources

3.1.1. Mechanical Energy Harvesting Methods

Piezoelectric Energy Harvesters:

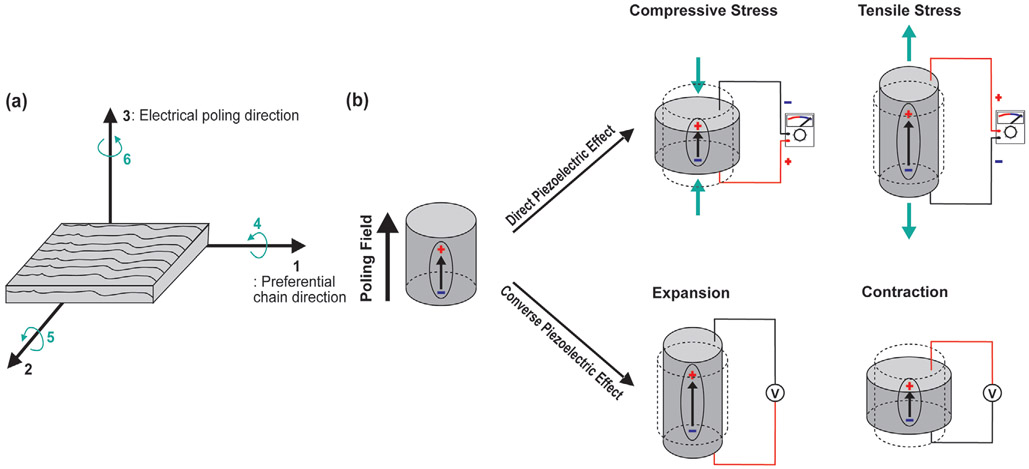

Piezoelectric effect is the phenomenon of conversion between mechanical vibration and electrical charges in piezoelectric materials such as quartz, topaz, cane sugar, zincblende, tourmaline, and Rochelle salt.[239] Applying an electrical voltage to a piezoelectric material will generate a change in its geometry—it will either expand or contract: this is called the converse piezoelectric effect. In addition, when a mechanical stress is applied to a piezoelectric material, it will generate an output voltage that is directly proportional to the amount of pressure applied: this is called the direct piezoelectric effect (Figure 5b).[239-241] Due to the direct piezoelectric effect, piezoelectric material-based energy harvesters, or piezoelectric nanogenerators (PENGs), can convert the mechanical energy present in small vibrations into electrical energy.

Figure 5.

The working principle and operation modes of the PENGs. a) Electrical poling direction and preferential chain direction of the piezoelectric materials. For instance, in poly(vinylidene fluoride) (PVDF), the polar axis (labeled as direction “3”) is the direction of the applied electrical poling field. The polymer stretch direction or the preferential direction of the aligned polymer chains is denominated as direction “1” and is perpendicular to the polar axis. the axis orthogonal to the stretch direction “1” is labeled as “2.” The shear planes of piezoelectricity are indicated by the directions “4,” “5,” “6,” and are perpendicular to the directions to “1,” “2,” “3,” respectively.[238] The direction of the applied mechanical stress relative to the polar axis largely affects the performance of the piezoelectric energy harvesting device. b) The schematics of direct and converse piezoelectric effects. The direct piezoelectric effect appears when a mechanical stress is applied to a material, and the electric charges are generated proportional to the applied mechanical stress. Before the external stress is applied, the centers of the positive and negative charges of each molecule coincide and the material is in a neutral net electrical polarization. When a mechanical stress is applied and deforms the structure of the material, the positive and negative charges inside of the molecule will be separated and this leads to the generation of dipolar moments. When a mechanical stress is reversed, the polarity of dipolar moments will be reversed. This polarization generates an electric voltage output, which is the transformation of the mechanical vibration applied to the material into useful electrical energy to power electronic devices. The converse piezoelectric effect occurs when the electric field is applied to the piezoelectric material. The external electric field will change the position of electrons and nuclei in each molecule and dipoles will be created. These dipoles will result in the polarization of the material and ultimately induce the deformation of the material. When the electrical field is removed or reversed, the electrons and nuclei will move back to their original position, and the material will return to their initial geometry.

The piezoelectric phenomenon is often associated with non-centrosymmetric crystalline materials: synthetic poly(vinylidene fluoride) (PVDF) and vinylidene fluoride (VDF) copolymers have some of the highest piezoelectric coefficients among polymeric materials.[240-242] Amorphous polymers can also be piezoelectric; however, their piezoelectric mechanism differs from that in semicrystalline polymers and inorganic materials. To exhibit piezoelectric activity, amorphous polymers must have dipoles present in their polymer chains that are able to rotate and align in the direction of the poling electric field. This process usually occurs when the temperature of the polymer is greater than its glass transition temperature (Tg), during which the polymer chains are adequately mobile so that their dipoles can align in the direction of the applied poling field. A partial orientation of the dipoles can be achieved by lowering the temperature below the Tg in the presence of an electric field, which gives rise to a remanent polarization in the direction of the electric field, and, consequently, induces piezoelectricity in the polymer.[243]

Due to the nature of the piezoelectric activity in amorphous polymers, electroactivity is only observed below Tg, when the chains are “frozen” and a cooperative movement of the backbone atoms in the polymer is restricted. Above Tg, there are cooperative and segmental movements of the polymer chains which cause depolarization to occur; as a result, amorphous polymers are not electroactive at these temperatures. In semicrystalline polymers like PVDF and its copolymers, the lock-in of the polymerization is supported by the crystalline lamellar structure of the polymer, and for that reason the piezoelectricity is stable above the Tg, and up to the Curie temperature (Tc).[243]

The piezoelectric effect can be quantified by the piezoelectric coefficients (dxy), which is defined as the ratio between the induced or applied electric polarization and the applied mechanical stress or induced strain of the piezoelectric material. The subscript letter “x” represents the direction of the applied mechanical stress or induced strain of the piezoelectric material, and “y” represents the direction of the induced or applied electric polarization. The axes to define the piezoelectric coefficients are shown in Figure 5a. The direct piezoelectric coefficients represent the amount of electric charge generated by the mechanical stress. A piezoelectric material with a higher piezoelectric coefficient will generate more electrical energy from the same mechanical stress.

Most of the piezoelectric materials that are commonly used for in-body applications can be categorized into the synthetic or natural polymers. Table 5 lists characteristic piezoelectric coefficients for the most commonly used synthetic polymers. Biological macromolecules like poly(lactic acid) (PLA) or poly(3-hydroxybutyrate) (PHB) are piezoelectric under shear deformation and have coefficients similar to those observed in bone (d14 = 0.7–10 pC N−1); this property has been explored for use in tissue engineering applications.[250,255] Furthermore, natural polymers and proteins can be used to create biocompatible energy harvesting devices, which are potentially biodegradable, for on-demand electronic power sources. Table 6 lists the piezoelectric coefficients of natural electroactive polymers.

Table 5.

The piezoelectric coefficients of most technologic synthetic polymers. Abbreviations: PVDF: poly(vinylidene fluoride), PVDF-TrFE: poly(vinylidene fluoride trifluorethylene), PLA: poly(lactic acid), PVC: poly(vinyl chloride), PAN: poly(acrylonitrile), PVDCN-VAc: poly(vinylidenecyanidevinyl acetate), (β-CN)APB/ODPA: nitrile substituted polyimide.

Table 6.

The piezoelectric coefficient of most biological macromolecules.

PENGs can be worn externally or implanted in the body; they can be used to convert small mechanical vibrations generated by the human body from activities such as walking, breathing, or fluxes in biofluids, into energy to power implantable medical devices.[265,266] The manufacturing process is easily scalable and often compatible with CMOS fabrication process. PENGs can also be used for flexible and stretchable devices.[267] The lifetime, reliability, and high energy density of piezoelectric materials make them ideal for use in implantable energy harvesting devices.

Triboelectric Energy Harvesters:

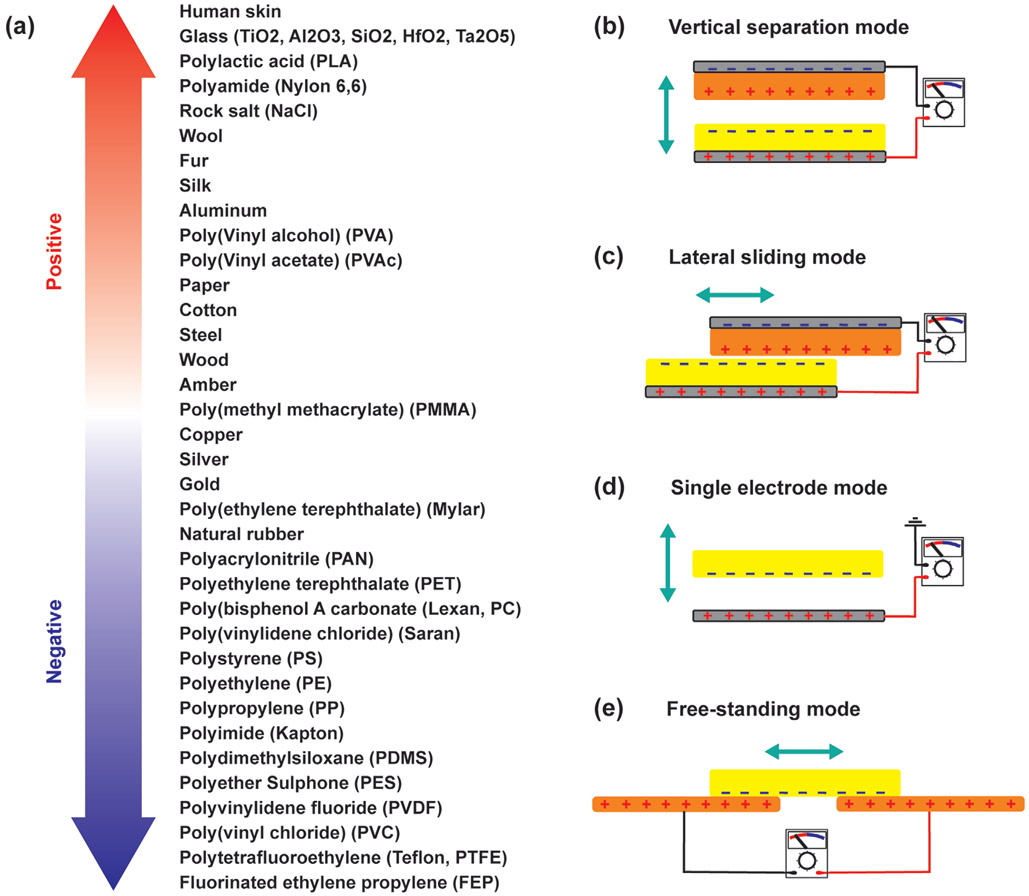

In triboelectric devices, electrostatic charges are generated when two different materials, which have electrically charged surfaces, are brought into contact. A typical triboelectric nanogenerator (TENG) consists of two thin films with opposite tribo-polarity; each film has an electrode attached to its back side. When the materials come into close contact, charges are transferred between the films leaving one side positive and the other negative; when the materials are separated, the transferred charges create a triboelectric potential. This potential then causes electrons to flow in the electrodes at the back side of the materials. The triboelectric series of the most common triboelectric materials used for biomedical applications is shown in Figure 6a.

Figure 6.

a) The triboelectric series of the common triboelectric materials used for biomedical applications.[270-275] b-e) The working principle and operation modes of TENGs.

There are four basic modes of operation for a triboelectric generator: vertical separation, lateral sliding, single electrode, and free-standing. In the vertical separation mode, two dissimilar dielectric surfaces face each other and the electrodes are located on the back sides of each surface (Figure 6b). When the dielectric surfaces are brought into physical contact, the surfaces accumulate opposite electrical charges. Separating the charged surfaces generates an electric field, which causes a potential difference across the electrodes. In the lateral sliding mode, two different dielectric surfaces are placed in contact with each other; the tangential movement of one surface with respect to the other changes the contact area of the charged surfaces which leads to transverse polarization along the sliding direction (Figure 6c). This polarization creates an electric potential, causing electrons to a flow between the two electrodes.[268,269]

The single electrode mode is similar to the vertical separation mode in the direction of relative motion, but the two moving parts are not electrically connected (Figure 6d). One of the moving parts is a dielectric layer and the other is an electrode. Separating the dielectric layer from the electrode generates an electric field which induces a current between the electrode and ground.[268,269] This mode is widely used for mobile applications like walking, where it is difficult to electrically connect dielectric materials to an external load.[268] Finally, in the free-standing mode, two identical electrodes coated with a dielectric material are in contact with a sliding dielectric surface, in which triboelectrification and electrostatic induction causes a cyclic movement of charges between the electrodes (Figure 6e).[268,269]

Wang and co-workers first developed TENGs in 2012 and demonstrated their ability to output high voltages and harvest energy from a variety of vibrational sources.[276-279] There are many advantages of using triboelectric generators including high output voltages, efficiency, simplicity in their structural design, high versatility in their design and fabrication, stability, and low environmental impact.[280-283] While PENGs are better at harvesting energy for high-frequency vibrations, TENG devices are more efficient at converting mechanical energy at frequencies below 4 Hz to electrical energy, which enables them to scavenge energy from the low frequency movement of the human body such as GI motility.[280,284] TENGs are a promising energy harvesting technology and could soon allow the conversion of mechanical energy from human motion, like walking, typing, and breathing, into useful electrical energy in order to power small electronic devices for various healthcare application.[285,286]

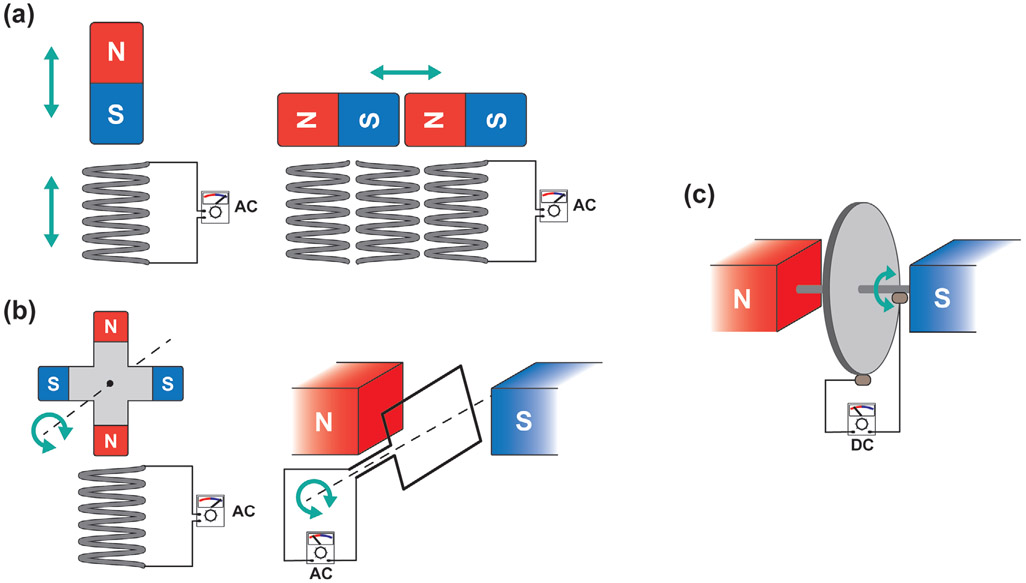

Electrical Generators:

An electrical generator is a device that converts mechanical energy to electrical energy; it consists of a coil of wire surrounded by an array of permanent magnets; an external mechanical force drives the relative movement between the coil of wire and the magnets (Figure 7). The magnetic flux experienced by the coil changes as either the coil or the magnets move, causing electrons to flow through the wire according to Faraday’s law.[287] The first electrical generator was developed by Michael Faraday and consisted of an electrically conductive disk that could be rotated between magnets to induce a current to flow through a wire (Figure 7c).[288] This type of homopolar generator, also called the Faraday disk, can generate DC without rectifiers or switches, while other types of electrical generator can produce only alternating current (AC). Today, there are many types of electrical generators but the basic principle is the same. The relative movement between the coils and magnets can be linear (Figure 7a) or rotation (Figure 7b), and movement can be induced by various types of motion such as vibrational, shaking, fluid flow, and swirling vortices.[289-291] The ability of an electrical generator to produce power from a variety of motion types would be especially advantageous when harvesting energy from human motion, which has many different modes and velocities.[7] Also, there is no mechanical contact between the moving parts of the device, which enhances the viability and durability of the system by reducing mechanical losses due to friction.[287] Efforts have been made to harvest energy from a variety of motions produced by the human body such as abdominal movement, body vibration, and walking.[292-294] However, the power output range of this type of generator is highly variable and depends on the size of the device; it is also less efficient for low frequency movements. Most electromagnetic induction energy harvesters are implemented for wearable devices,[294] and there are only few examples of implantable electromagnetic induction energy harvesters reported in the literature.

Figure 7.

The working principle of electrical generators. The electrical generators can be categorized by the type of relative motion between the magnets and coils: a) Linear or b) rotation. c) Homopolar generator or Faraday disk.

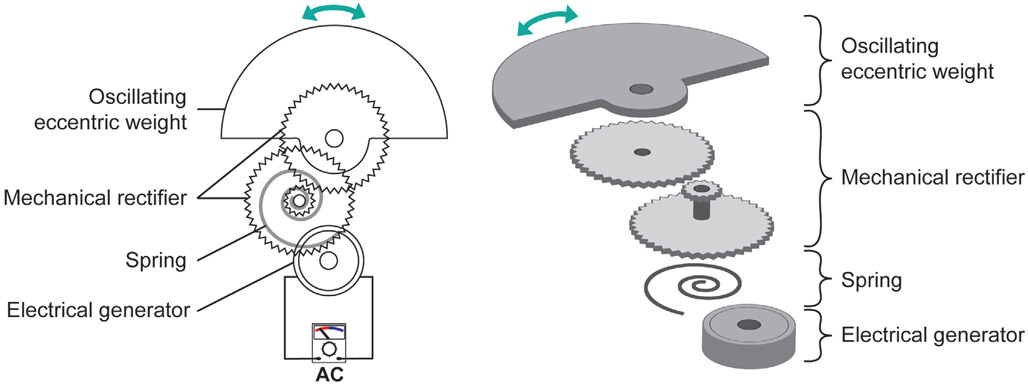

Automatic Wristwatch Systems (AWSs):

The AWS, also known as an automatic power-generating system, automatic generating system (AGS), or mass imbalance oscillation generator (MIOG), is a type of self-powered watch that uses wrist motion as the power source. Figure 8 shows the working principle of this device as a biomechanical energy harvester. When external movement causes an eccentric weight to oscillate, a mechanical rectifier transforms this oscillatory movement into a unidirectional rotation; this rotation winds a spring to temporarily store mechanical energy. When the torque reaches the detent torque of the generator, the spring unwinds which drives the electrical generator. This generates an electrical impulse with duration of a few milliseconds. When the spring is completely uncoiled, the whole process is repeated. The amount of energy produced by one electrical impulse depends on several parameters including spring stiffness, transmission gear ratio, and load resistance.[295] For example, the oscillation weight needs to be deflected about 2.5 rad in order to generate one electrical impulse, and the induced electrical impulse yields an average of 66.0 μJ (±10.7 μJ).[295] Furthermore, the energy conversion efficiency of an AWS is significantly affected by its coupling to a mechanical energy source: the original vibration of the mechanical energy source will be significantly dampened if the device is not tightly fixed to the mechanical energy source at the right tilting angle.[295] This system is commonly used in a wristwatch and the fabrication cost is relatively low. However, like an electrical generator, it is large and bulky compared to other mechanical energy harvesters. This is because it relies on a pendulum configuration which becomes insensitive to mechanical motion if the size is reduced. Researchers have used the energy transforming mechanism of the automatic wristwatch to harvest mechanical energy in vivo from cardiac contractions.[296]

Figure 8.

The working principle of AWSs.

3.1.2. Endogenous Mechanical Energy Sources and Corresponding Energy Harvesting Methods

Heartbeat and Blood Circulation in the Circulatory System:

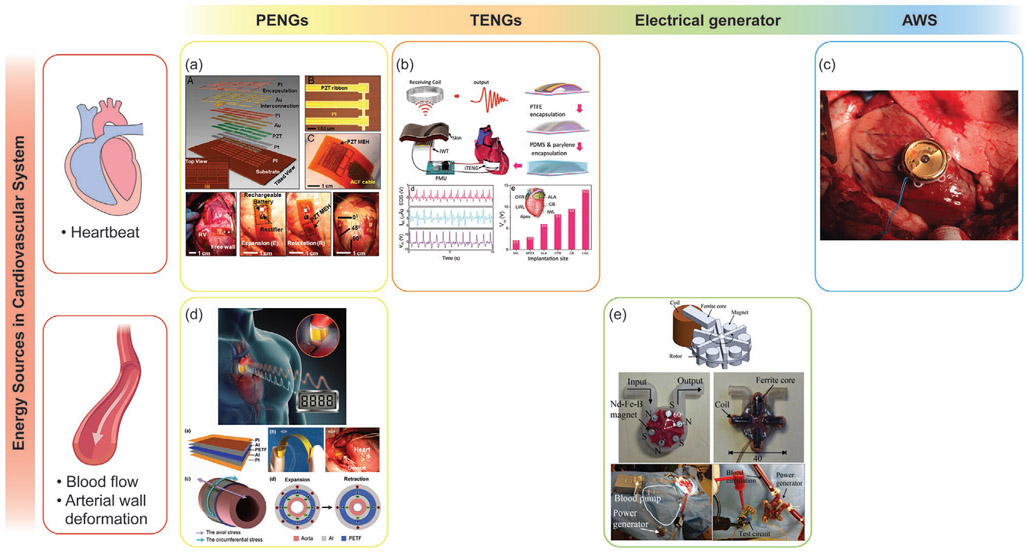

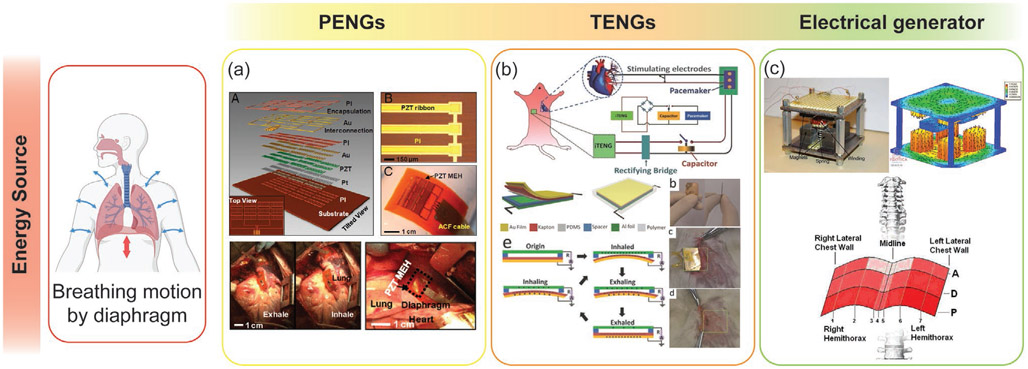

The circulatory system is responsible for transporting nutrients to and removing waste materials from cells in the body. From an energy harvesting perspective, the energy accessible in this system exists either in the form of mechanical energy from the contraction of the heart and the flow and pulses of blood, or in the form of chemical energy from the nutrients being transported in the circulatory system. The cardiac output power for an adult at rest is estimated to be around 0.93–1.4 W; the typical cardiac frequency, or intrinsic heart rate (IHR), for an adult at rest is 60–120 bpm.[297,298] The output power and frequency of a beating heart can vary depending on numerous factors including fitness and activity level, smoking status, cardiovascular health, metabolic health, ambient air temperature, body position, emotional state, body size, and medication use. The mechanical energy present in blood vessels depends on the dynamics of the blood flow. The cardiac cycle of the heart causes a cyclic change in blood pressure, which ranges from a maximum pressure while the heart is contracted, called systolic pressure, to a minimum pressure between contractions, called diastolic pressure. The systolic/diastolic blood pressure (SBP/DBP) range can vary depending on age, but the normal ranges are 90–120/60–80 mmHg for SBP/DBP.[299,300] The velocity of normal human blood flow, which can be measured by 4D flow MRI, varies with age, cardiac output, and anatomical site.[230] The average blood flow rate in the ascending aorta is 50–75 cm s−1 and peak systolic velocity can be up to 100–150 cm s−1.[230] Devices implanted close to the heart, such as pacemakers, implantable cardioverter defibrillators (ICD), or electrocardiogram (ECG) recorders, can potentially be powered from these mechanical energy sources. PENGs, TENGs, electrical generators, and automatic watch harvesters show promise in their ability to harvest energy from vibrational sources in the circulatory system.

One device, developed by Dagderiven et al., was able to harvest enough mechanical energy from the movement of the heart to continuously power a pacemaker; the monolithic and flexible system used lead zirconate titanate (PZT), a piezoelectric material, to harvest energy (Figure 9a).[301] Other piezoelectric materials are also being explored to convert the mechanical movement generated by the circulatory system into useful electrical energy. Piezoelectric ceramics like PZT and piezoelectric single crystals like PZN-PT and PMN-PT have high piezoelectric coefficients and electromechanical coupling factors; however, they contain lead, which is toxic and unsuitable in implantable energy harvesting applications.[302] Furthermore, they are brittle, which creates additional manufacturing challenges since PENG devices should ideally have some degree of flexibility so that they can be attached to soft tissues like the lungs or the heart without creating damage on either the devices or the organs. To overcome these obstacles, new scavenging devices based on piezoelectric polymers and polymer-based TENGs are being explored for energy harvesting applications to power the next generation of implantable medical devices.

Figure 9.

Examples of systems that harvest mechanical energy from the circulatory system. a) Adapted with permission.[301] Copyright 2014, National Academy of Science. b) Adapted with permission.[305] Copyright 2016, American Chemical Society. c) Reproduced with permission.[307] Copyright 2012, Springer Nature. d) Adapted with permission.[227] Copyright 2016, Elsevier. e) Adapted with permission.[309] Copyright 2016, IEEE.

Ouyang et al. developed an implantable TENG device that harvests energy from cardiac motion to power cardiac pacemakers (Figure 9b).[303] This TENG device was able to generate a maximum energy of 0.495 μJ from each cardiac cycle, which is enough to stimulate the heart to beat (the endocardial pacing threshold energy in humans is 0.377 μJ).[304] In another study, an implantable and biocompatible multilayered TENG attached to a porcine adult heart was able to achieve a maximum electrical output voltage of 14 V and a current of 5 μA from each heartbeat cycle.[305] This TENG device was able to power a cardiac monitoring system developed for a real-time remote health assessment. Another group developed a self-powered and multifunctional implantable TENG sensor made of electrodes, spacers, and triboelectric films packed with biocompatible polymer layers; this sensor was able to monitor multiple pathological and physiological parameters continuously and accurately. When tested in large-scale animals, the TENG sensor accurately monitored heart rate, detected arrhythmias, and measured respiratory rates and phases.[306]

Several studies have used automatic watch energy harvesting systems to harvest vibration energy from the heart. The first in vivo demonstration of such a system was realized in 1999 on the right ventricular wall of a mongrel dog.[74] More recent studies, which used computational and MRI-based analysis to optimize coupling between the heart motion and the AWSs, have led to higher energy conversion efficiencies and power outputs (Figure 9c).[295,307] The power output harvested by AWSs ranges from 16.7 to 44 μW and the approximate conversion efficiency is 16.8%.[74,295,307] Since the power consumption of a low-power cardiac pacemaker can be reduced to 8 μW, AWSs could power pacemakers by harvesting energy from the heart’s motion.[308]