Abstract

Biomass and fossil fuels are mostly used in rural areas of developing countries for cooking. These energy resources have negative impacts on the environment and human health mainly due to deforestation and greenhouse gas emissions. A cleaner and environmentally-friendly form of cooking is solar cooking using the sun's energy. Parabolic solar cookers perform better than other solar cookers such as box solar cookers since higher temperatures are achieved in a shorter duration. These higher temperatures allow most types of cooking processes such as; boiling, frying, roasting, and baking to be possible. The major problem with most conventional solar cookers is that cooking is not possible during off-sunshine periods. Integrating solar cookers with thermal energy storage (TES) makes cooking during off-sunshine periods possible. This paper presents a comprehensive review of parabolic solar cookers with TES which is a sustainable cooking solution for developing countries. Previous work on both parabolic trough and parabolic dish solar cookers with TES is presented. Solar cookers with storage are classified according to the two main types of TES technologies which are; sensible heat thermal energy storage (SHTES) and latent heat thermal energy storage (LHTES). The main conclusions of the review are that; parabolic dish solar cookers with TES are more common than parabolic trough cookers, more studies have been done using latent heat storage as compared to sensible heat storage, limited modelling work has been presented, most of the parabolic cookers used aluminum sheets as the reflecting material, large scale experimental studies are limited and fewer studies tackled the techno-economic and socio-economic aspects. The review also highlights research gaps on parabolic solar cookers with TES in terms of the modelling, combined TES (sensible and latent heat), different reflector materials, large-scale experimental setups, and techno-economic and socio-economic analyses. Other important aspects to consider for parabolic solar cookers with TES include; the choice of sensible or latent heat storage materials, environmental impact, types of food to be cooked, and social acceptance.

Keywords: Concentrating solar cooker, Latent heat, Sensible heat, Thermal energy storage, Parabolic dish cooker, Parabolic trough cooker

Concentrating solar cooker, Latent heat, Sensible heat, Thermal energy storage, Parabolic dish cooker, Parabolic trough cooker.

1. Introduction

Cooking is a vital method used by human beings to prepare food for survival, and it is responsible for a large amount of energy consumption in many countries. In developed countries such as the United States of America, cooking accounts for about 37 %–53 % of total energy consumption [1]. In developing countries located in Africa, Asia, and South America, a major part of the residential energy consumption is utilized for cooking. A study conducted by Karekezi [2] showed that about 80 % of Sub-Saharan African countries still utilize firewood, fossil fuels, biomass and electricity for cooking food, which results in huge amounts of greenhouse gas emissions and deforestation. This indicates that there is a need for alternative cooking methods that are environmentally friendly and use clean energy resources.

Although only about 14 % of the world's available renewable energy potentials is currently being utilized, the percentage utilization of renewables is projected to increase soon due to concerted global efforts to mitigate against global warming due to greenhouse gases emission [3]. Solar energy has gained prominence over recent years as an alternative energy source for developing countries. It is estimated that the solar radiation flux in the sunniest region of the earth is about 1 kW/m2, the total global solar radiation per day is about 7 kWh/m2, and the total amount of solar energy received on earth is approximately 1.8 × 1011 MW [4]. This is about 10 000 times larger than the present energy consumption rate from all other commercial energy sources. This indicates that solar energy can be exploited for a wide range of domestic energy requirements, especially cooking.

Solar collectors can be regarded as devices that help to concentrate/collect solar radiation by capturing and converting radiant energy from the sun into thermal or electrical energy. Solar collectors can be categorized into two groups namely; non-concentrated collectors (flat plate collector, evacuated tube collector, etc.) and concentrated collectors (parabolic dish, parabolic trough, etc.). Some of these collectors can be modified easily for solar cooking. A solar cooker is a solar collecting device that uses the energy from the sun to cook food. Although solar cookers are not a recent novel idea, they have undergone several modifications over the years [5]. However, there is still room for improvements in order to achieve higher efficiency, lower cost, greater portability, and further adaptability to different environmental conditions. The three main types of solar cookers are: solar box cookers, concentrated solar cookers, and indirect solar cookers, and these will be discussed in the next section.

1.1. Types of solar cookers

1.1.1. Solar box cookers

There are various types of solar box cookers or oven solar cookers that have been fabricated from previous studies [6, 7, 8]. A common solar box cooker consists of an insulated box with a transparent glass or plastic cover that allows solar radiation to pass through. Solar radiation is absorbed by the inner part of the solar box cooker while the transparent cover prevents solar radiant energy from leaving the interior of the box through the greenhouse effect [9]. In some solar box cookers, the interior of the box is painted black to maximize the absorption of solar radiant energy in order to increase the temperature of the cooking vessel placed inside. The insulated box is connected to reflectors which direct more solar radiation to the cooking vessel, thus increasing its cooking efficiency. Figure 1 shows different types of solar box cookers namely; (a) one without reflector, (b) one with a single reflector, (c) one with double reflectors, (d) one with three reflectors, (e) one with four reflectors, and (f) one with eight reflectors. One of the main reasons why solar box cookers are preferred over other types of solar cookers is that they have different types of uncomplicated designs. The appeal of solar box cookers over other types of solar cookers include the fact that they are easy to construct, they are user-friendly and safe to use, they require limited attention during operation, they utilize both the direct and diffusion components of solar radiation and no solar tracking is required [11]. However, the main disadvantages of solar box cookers are that they require longer cooking periods and cannot be used for roasting or frying food. Another reason is that they cannot cook during off-sunshine hours, and some solar box cookers are affected by prevailing weather conditions such as strong winds which result in slower cooking due to heat losses.

Figure 1.

Different types of solar box cookers: (a) without reflector, (b) with single reflectors, (c) with double reflectors, (d) with three reflectors, (e) with four reflectors and (f) with eight reflectors. The figure was reproduced from Ref. [10], with the permission of Elsevier Publishing.

Cooking with solar box cookers has been the most investigated, and well-documented solar cooking method [12, 13, 14, 15]. Solar box cooking experiments have been carried out at intermediate to high temperatures using different test loads and fluids to improve their thermal performance [16, 17, 18, 19, 20, 21].

1.1.2. Concentrating solar cookers

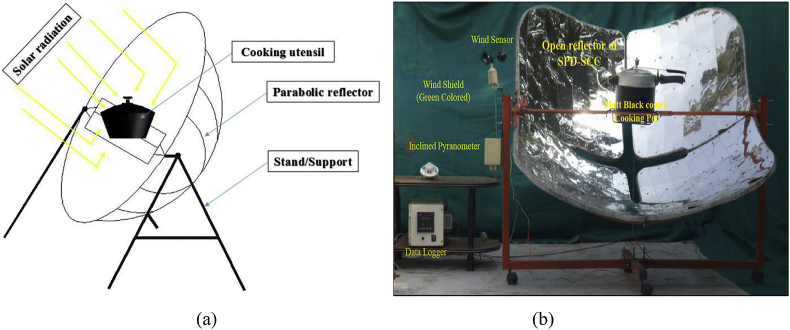

A category of solar cookers that are less popular but more efficient in terms of reaching higher cooking temperatures are the concentrating solar cookers [22]. A standard concentrating solar cooker is constructed with a framework stand to support the cooking vessel at the focal region and also the parabolic reflector. A tracking mechanism is used to position the concentrating solar cooker to face the sun. A solar optical mechanism is also used to direct and concentrate the incident solar radiation to a focal region which enables the attainment of higher temperatures at the focal region. For direct concentrating solar cookers, the cooking vessel is placed at the focal region of the parabolic reflector during cooking periods. One of the most popular direct concentrating solar cookers that is easy to construct and operate is the parabolic dish cooker. A parabolic dish cooker can achieve high temperatures of between 350 °C and 400 °C as compared to other types of concentrating solar cookers [23]. The main disadvantages of the parabolic dish cooker are that it requires constant tracking of the sun, constant attention to prevent the burning of foods and to avoid fire risks during operation. Figure 2 shows a schematic diagram of parabolic dish solar cooker, and a photograph of a square parabolic dish cooker.

Figure 2.

(a) A schematic diagram of a parabolic dish concentrating solar cooker, (b) a square parabolic dish solar concentrating cooker (SPD-SCC) with a pot. (a) was reproduced from Ref. [24], with the permission of Elsevier Publishing. (b) was reproduced from Ref. [25], with the permission of Elsevier Publishing.

Solar concentrating cookers have also been used for intermediate to high-temperature applications using different test fluids [25, 26, 27, 28, 29]. However, these studies do not consider the incorporation of thermal energy storage into these cookers for off-shine cooking.

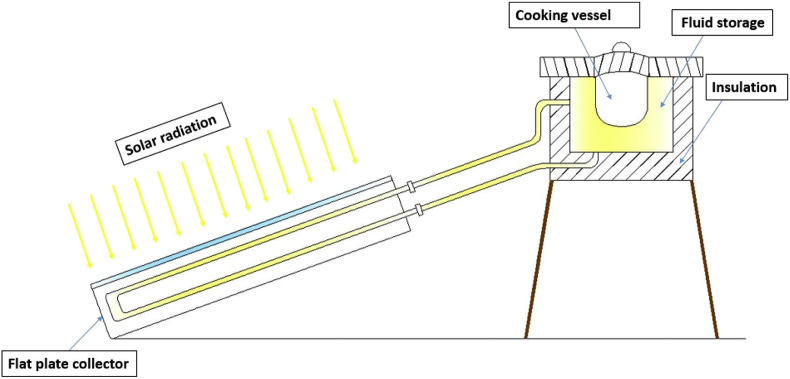

1.1.3. Indirect solar cookers

Indirect solar cookers use heat transfer fluids such as molten salts or thermal oils to absorb heat from the heat source (at the focal region of the reflector) and transfer the heat to the cooking vessel [30]. The indirect solar cooker is designed in such a way that the cooking vessel is placed separately from the collector. Solar collectors such as a parabolic trough collector/flat plate collector can be placed on a roof or outside a building, and the cooking vessel can be placed indoors. The challenge facing this type of cooker is the high rate of heat loss during the circulation of the heat transfer fluid. However, the main advantage of an indirect concentrating solar cooker is that it can be easily incorporated with a thermal energy storage system for off-sunshine cooking. Figure 3 shows a diagram of an indirect concentrating solar cooker using a flat plate collector. The main disadvantage is that indirect solar cookers are expensive to fabricate and maintain. Indirect solar cookers have been used for intermediate to high temperatures for various cooking applications such as cooking vegetables and frying meat [31, 32, 33, 34], using different test loads; and fluids such as sunflower oil and olive oil. Thermal energy storage integrated with indirect solar cookers makes them more versatile for operation during off-shine periods [35].

Figure 3.

A schematic diagram of an indirect solar cooker. The figure was reproduced from Ref. [24], with the permission of Elsevier Publishing.

1.2. Thermal energy storage for solar cookers

Simple solar cookers can be used only when the sun is available as they cannot operate at night, during cloudy days, or when it is raining. However, thermal energy storage (TES) offers a solution for this mismatch between solar energy supply and demand. Combining solar cookers with a TES system enables cooking during periods when the sun is not available. TES can be classified into three main categories which are sensible heat thermal energy storage (SHTES), latent heat energy storage (LHTES), and thermo-chemical thermal energy storage (TCTES). One of the main advantages of a TCTES is that it has high storage densities and heat losses are minimal, but the disadvantage is that it is reported to be expensive [36]. As a result of the expensive nature of TCTES, solar cookers with SHTES and LHTES have only been investigated because of their lower cost and simpler designs. In recent years, a lot of research have reported about SHTES and LHTES systems for solar cookers since these two types of TES systems are economically viable [1, 37, 38, 39, 40, 41, 42].

In a SHTES system, the TES material can store heat and release it as a consequence of the heat capacity of the heat storage material used as its temperature changes. This storage medium may either be in the solid or in the liquid phase. The main reasons why SHTES systems are favored or utilized often is because of their desirable thermal properties, cheapness, and availability. For a given SHTES material, the capacity for storing sensible heat will depend on its specific heat capacity and density [43]. The advantages of SHTES materials are that they are inexpensive and can be sourced locally. The major disadvantage of SHTES is that it requires a large amount of storage space because of the low thermal energy storage density of sensible heat storage materials. Unlike a SHTES material, a LHTES material stores both sensible heat and latent heat as it undergoes phase transition within a given temperature range. The solid-liquid transition is mostly utilized as the liquid-gas transition involves some complexities. The latent heat of fusion which is absorbed by a phase change material (PCM) as it transforms from the solid to the liquid phase and vice versa, presents a high TES density over a narrow temperature range during the nearly-isothermal transition. One of the main advantages of an LHTES system is that it uses a smaller volume of material to store thermal energy compared to SHTES due to its higher thermal energy storage density and large enthalpy. LHTES is however more expensive when compared to SHTES.

1.3. Previous recent reviews on solar cookers

In recent years, reviews on solar cookers have focused on different parameters such as tracking techniques, heat transfer enhancement technologies, thermal storage materials, cost-effective methods, location/country and size of the solar collectors to enhance the performance of solar cookers. Table 1 shows a summary of recent reviews on solar cookers.

Table 1.

A table summary of recent reviews on solar cookers.

| Author and Year | Title | Focus of study | Results |

|---|---|---|---|

| Lahkar and Samdarshi [44] 2010 | A review of the thermal performance parameters of box type solar cookers and identification of their correlations | The aim of the review was to compare the correlations of different performance parameters of solar box cookers. | It was found that none of the evaluated parameters were able to predict heat retention. |

| Saxena et al. [45] 2011 | A thermodynamic review on solar box type cookers | Diverse developments of solar box cookers were reviewed. | Results indicated that solar box cookers were safer to use, save money, and food cooked with solar box cookers was more nutritious. |

| Panwar et al. [46] 2012 | State of the art of solar cooking: An overview | A standard of testing solar cookers and thermal properties (such as energy and exergy) analyses were performed. | It was found out that utilizing solar cookers reduced carbon dioxide emissions. |

| Farooqui [47] 2014 | A review of vacuum tube based solar cookers with the experimental determination of energy and exergy efficiencies of a single vacuum tube based prototype | A review of the progress made with the development of vacuum tube-based solar cookers was presented. Also, energy and exergy analyses of a vacuum tube-based solar cooker were conducted. | The energy efficiency and exergy efficiency of the vacuum tube solar cooker were found to be 20–30%, and 4–6%, respectively. |

| Yettou et al. [48] 2014 | Solar cooker realizations in actual use: An overview | The review focused on the recent advances in the development of solar cooker technologies. | It found that the solar cooking technology has a potential to reduce the rate of energy consumption in the near future. |

| Harmim et al. [49] 2014 | Solar cooking development in Algerian Sahara: Towards socially suitable solar cookers. | The review focused on solar cooking in the Algerian Sahara environment. | It was found that the building an integrated solar cooker was easy to construct, and it was efficient even during the winter season. |

| Iessa et al. [50] 2017 | Unverified assumptions, overlooking of local needs and pro-solution biases in the solar cooking literature | A critical review was studied for solar cooking in Sub-Saharan Africa in order to reduce deforestation, improve health and empower women. | The review showed that solar cooking and its impact are not systematically tested, and may not be strong as claimed. |

| Herez et al. [24] 2018 | Review on solar cooker systems: Economic and environmental study for different Lebanese scenarios | The study focused on previous work done on the economic and environmental impact of solar cookers in Lebanon using different locations and economic backgrounds. | There was a reduction in the emission of carbon dioxide from homes, hotels and restaurants. On the economic aspect, it was found that the dependency on the solar cooker decreased the payback. |

| Hage et al. [51] 2018 | An investigation on solar drying: A review with economic and environmental assessment. | The aim of the study was to determine the role of main components of solar dryers, economic and environmental assessments and parameters affecting them. | When a certain percentage of time was utilized monthly, about $ 780 was saved monthly. |

| Indora and Kandpal [52] 2018 | Institutional cooking with solar energy: A review. | The aim of the study was to evaluate institutional solar cooking using parabolic dishes, scheffler dishes and the ARUN solar cooker. | The awareness of institutional solar cooking must be spread to potential users. |

| Elsheikh et al. [53] 2019 | Modeling of solar energy systems using artificial neural networks: A comprehensive review. | Artificial neural networks models were deployed to predict thermal parameters of solar systems such as solar cookers, solar dryers, etc. | Deploying artificial neural networks may save time and reduce costs. |

| Omara et al. [38] 2020 | Improving solar cookers performance using phase change materials: A comprehensive review. | The aim of this review was to study the feasibility of improving solar cookers when considering geometrical influence and different phase change materials. | Future work must include economic and environmental aspects using solid to liquid PCMs. |

| Arunachala and Kundapur [54] 2020 | Cost-effective solar cookers: A global review. | An investigation of cost-effective solar box cookers and other solar cookers was conducted on a global scale. | Thorough research must be conducted to improve the efficiency of low cost solar box cookers. |

| Devan et al. [55] 2020 | A comprehensive review on solar cookers with a sun tracking system. | An evaluation on solar cooking technology was done. | Installing a tracking system on parabolic dishes enhanced the performance of the solar cooker. |

| Khatri et al. [5] 2021 | Advances in the development of solar cookers for sustainable development: A comprehensive review. | The research focused on the effect of how the main components and heat transfer characteristics affect the overall efficiency. | Social and economic aspects can be improved with better policy implementations. |

| Gokul et al. [56] 2021 | A comprehensive review on solar cooker tracking techniques for performance enhancement | This review discussed tracking systems of solar cookers. | Thermal performance of the solar cookers improved when combined with a tracking system. |

It is evident that critical reviews on solar cookers with storage are rather limited, particularly on parabolic concentrating cookers with thermal energy storage which can perform most cooking processes such as boiling, frying and baking. Additionally, limited studies have reviewed the parameters that affect the performance of parabolic concentrating cookers with thermal energy storage.

1.4. Objective and justification

Solar cookers cannot operate during off-shine periods and besides, some cook relatively slower than conventional cookers. However, integrating solar cookers with TES systems such as SHTES and LHTES can overcome such drawbacks. This review aims to present and critically evaluate previous studies that analyzed the thermal performances of concentrating solar cookers that were coupled with different SHTES and LHTES systems. The review presents the results of different thermal performance parameters for solar concentrating cookers with TES systems. Solar concentrating cookers with heat storage are more attractive than the other types of cookers since they can perform most cooking processes such as baking, frying, roasting, and boiling. These cookers are also fast cookers that are reasonably priced. From this review, future work on solar concentrating cookers with TES will be suggested based on the shortcomings of previous studies.

2. Parabolic solar concentrating cookers with sensible heat thermal energy storage (SHTES)

2.1. Parabolic trough cookers with SHTES

A solar thermal-powered bakery oven was experimentally evaluated by Mishra et al. [57]. The system was proposed as a model of a combined solar and electrical powered bakery oven integrated with a solar parabolic trough collector. Duratherm 600 was used both as the heat transfer fluid and the thermal energy storage medium. A CFD analysis was done to analyze the heat transfer of the copper coils and airflow distribution in the oven. Results indicated that the maximum temperature in the storage tank was about 300 °C, while a temperature of about 168 °C was achieved inside the oven cavity. El Moussaoui et al. [58] experimentally evaluated a parabolic trough solar thermal cooker (PTSC) shown in Figure 4. A vacuum tube coupled with a parabolic trough reflector was used as the solar collector. A thermal oil was used both as the heat transfer fluid and the SHTES material. The vacuum tube and parabolic trough reflector were fitted to a solar thermal cooker which contained an insulated cooking box, a cooking vessel, and a storage container. Heat transfer models were developed to evaluate the operation period of the experimental setup, and cooking experiments were conducted. Results showed that potato chips took about 1 h to be cooked while the maximum temperature achieved inside the solar thermal cooker was about 198 °C.

Figure 4.

A parabolic trough solar thermal cooker (PTSC) with a cooking box containing thermal oil. The figure was reproduced from Ref. [58], with the permission of Elsevier Publishing.

An experiment to test the performance of a parabolic trough solar cooker for indoor cooking was reported by Asmelash et al. [59]. The experimental setup consisted of a parabolic trough with reflecting mirrors, a copper receiver pipe used to absorb sun rays, a cooking pot combined with fins, and a storage tank that stored thermal energy. Soya bean oil was used both as the heat transfer fluid and the heat storage medium. Experimental tests on the effects of the load and varying the diameter of the cooker were performed and analyzed. The results indicated that the maximum temperatures achieved under no-load conditions were about 191 °C for the absorber and about 126 °C for the cooking vessel. However, the maximum cooking efficiency achieved was about 6 %. Dianda et al. [60] reported an experimental investigation of a solar parabolic trough cooker. An indirect parabolic trough solar cooker named the “blazing tube” was used for cooking experiments. The blazing tube was made up of a transparent Pyrex glass vacuum tube, an aluminum parabolic trough reflector, an absorber tube that contained vegetable oil that was utilized as a heat transfer fluid and a heat storage medium, a cooking box that contained a cooking vessel and a storage container. Different cooking tests were performed, such as water heating, frying, and cooking rice, to determine the maximum temperature, the effect of the load, and the duration of the cooking time. The thermal efficiency and output power of the cooker were the parameters evaluated. The results indicated that when the solar radiation was about 930 W/m2, the maximum useful power was found to be 1000 W. The maximum efficiency achieved by the experimental setup during the day was about 55 %. Mohan and Vasanthakumar [61] analyzed the effectiveness of solar-assisted steam cooking using a parabolic trough collector. The experiment aimed to develop and analyze the performance of a solar-assisted steam cooking system using aluminum sheets and galvanized iron sheets as the reflector materials. The setup consisted of an insulated tank, a parabolic trough reflector, an absorber tube that contained water (the heat transfer fluid), and a steam cooker. Cooking experiments were conducted using variety of food items such as potatoes, carrots, onions, and beans. This was done to compare the nutritional quality of conventional and steam cooking. The second experiment was done to determine the performance of the steam cooker using different reflector sheet materials. The results showed that the maximum outlet temperature and the maximum cooking temperature achieved were 140.2 °C and 150 °C, respectively in the steam cooker.

Hassen et al. [62] investigated the performance of a solar-powered Injera baking oven for indoors cooking. A laboratory model contained an electrical heater that was used as the heat source, and it was coupled with a heat storage tank and a baking pan that was used to make Injera. A pump was used to circulate the heat transfer fluid (Shell Thermia B) during charging and discharging cycles. Baking and preheating experiments were done, and it took about 1 h to heat the oil, and 40 min to reach the required baking temperature. Results showed that 5 Injeras were baked in time intervals of 2 min for 10 min at temperatures of 220 °C. Goytom [63] modelled a solar thermal energy-powered Injera baking oven using a finite difference method. The model was aimed to predict the temperature distribution of an Injera baking pan during initial heating up and baking cycles using an unsteady state heat balance model. A parabolic trough was used to collect and reflect the solar radiation onto the receiver tube. An insulated storage tank containing the heat transfer fluid was coupled with a cooking pan. Thermia oil B was used as both heat transfer and storage medium, and a pump was used to circulate the heat transfer fluid in an experimental setup. Simulations were carried out in MATLAB to determine the efficiency of the Injera pan by varying the thickness of the pan. Results showed that there were reasonable heat-up and baking times when the pan thickness was set as 5 mm, and the oil temperature heated up to 300 °C.

A parabolic trough collector integrated with a cooking system was presented by Yilmaz et al. [64]. The system was composed of a parabolic trough solar collector array, a cooking system, a plate-type heat exchanger, an auxiliary heater, water heating tanks, and Fuchs Renotherm 320 was used as the heat transfer fluid. An analysis of the heat required to cook wheat using different system design arrangements was carried out. Results showed that the maximum cooking temperature attained was about 100 °C, and the energy required to cook a specified amount of wheat was determined by the energy value of the nominal solar radiation. Arunachala et al. [65] performed an analysis of a solar cooker for night cooking. The experimental setup was a self-circulating system composed of a compound parabolic trough collector, vacuum tubes, and an oil storage tank that was coupled with a cooker. Engine oil was used as the heat transfer fluid in the storage tank. Cooking experiments were done to determine the energy required for cooking, and rice was used as the cooking load. Results showed that the highest temperature reached by oil was about 110 °C, and it took less than an hour to cook 500 g of rice in the afternoon.

An investigation of a solar cooker with a parabolic trough concentrator was done by Noman et al. [66]. The parabolic trough collector was positioned at a fixed latitude to reflect maximum solar radiation to the absorber tube. The absorber tube was fabricated with black painted copper which was used as a receiver for the cooker. Water was used as both the heat transfer fluid as well as the heat storage material. The results showed that the maximum cooking temperature achieved in 4 h was about 53 °C at an ambient temperature of 31 °C and with the solar radiation being about 927 W/m2. Akayleh et al. [29] designed and developed a solar-based cooker with a mechanical sun tracking system. The experimental setup was composed of an automated sun tracking system, hot dish for baking bread, a control unit, a two pulleys connected to the gearbox and a parabolic trough. The objective of the experiment was to determine the efficiency of the solar cooker under various conditions. Baking experiments were carried out, the highest temperature achieved was found to be approximately 85 °C. Widjaja et al. [67] designed and simulated a concentrated solar thermal system with an integrated concrete storage for continuous heat supply. In this study a concentrated solar system for pasteurization was combined with concrete storage for process heating. The aim of the experiment was to compare a parabolic trough collector and compound parabolic concentrator with a concrete storage under different boundary conditions. Process heating experiments were carried out in four different countries, and the results showed that using a compound parabolic concentrator below 180 °C showed better performance as compared to the parabolic trough collector. Bade and Bandyopadhyay [68] proposed an energy model to determine the characteristics of thermal oil for cooking applications. An energy model based on a cooking system was developed, and therminol 55 was selected as the thermal oil. The proposed energy model was dynamic in nature and used the Euler method predict the temperature. The results showed that saving in fuel, and a possible payback period of 1.63 years. Abd-Elhady et al. [69] studied the thermal performance of solar cookers by using metallic wires and nanographene. The objective of the study was to improve the heat capabilities of the parabolic trough combined with the storage tank. The solar cooker operated on a thermosiphon mode using Mobil-Therm 605 as heat transfer fluid and storage medium. The results showed that adding nanographene particles contents up to 0.34 × 10−3 wt% to the heat transfer medium of solar cookers increased the heat transfer rate.

2.2. Parabolic dish cookers with SHTES

Agrawal and Yadav [70] experimentally investigated a parabolic solar cooker with a storage cooking pot. The experimental setup was composed of a solar cooker that was made up of a hollow-concentric cylindrical pot with sensible heat storage materials, a parabolic dish collector, and an insulator box. Experiments were conducted using different sensible heat storage materials such as sand, stone pebbles, iron grits, and iron balls to determine the thermal performance of the sensible materials. After the solar cooker was charged, it was transferred to the insulated box and loaded with food. Results showed that the food was cooked properly using sand, stone pebbles, and iron grits, and it was partially cooked when iron balls were utilized. Prasanna and Umanand [71] designed and optimized an energy transport system for a solar cooking application. The indirect system was composed of a paraboloid concentrating collector, and a heat storage tank that contained servo-thermal oil which was utilized as a storage medium and heat transfer fluid. Two pumps were used to circulate the heat transfer fluid during charging and discharging, and a heat exchanger was placed in the kitchen for cooking purposes. Simulations and experiments were performed using different pipe diameters to evaluate the overall energy transfer and the thermal performance of the proposed system. Results showed that cooking could be carried out at any time of the day, and the energy collected from the paraboloid concentrating collector was optimized by dynamically varying the flow rate.

Mawire et al. [72] simulated the energy and exergy of the charging of an oil–pebble bed thermal energy storage system for a solar cooker. The proposed system was composed of a parabolic dish concentrator coupled with an absorber coil, and a storage tank that contained oil that was used as a storage medium and heat transfer fluid. A load coil was coupled with a cooking vessel used for cooking applications. Energy balance equations were used to model the indirect solar cooking system. Energy and exergy analyses were carried out to predict the performance of the solar cooking system. Results indicated that a greater degree of thermal stratification and energy stored was achieved by constant temperature charging compared to constant flow-rate charging. Discharging simulations of a thermal energy storage (TES) system for an indirect solar cooker were done by Mawire et al. [34]. The conceptual setup was presented in [72]. The models were validated by experimental results, and reasonably good agreement was obtained between simulation and experiment. Two methods were utilized for discharging the TES system. The first method discharged at a constant flow-rate, while the second method discharged the TES system by varying the flow-rate to acquire the desired constant discharging temperature. The results showed that discharging the TES system at a constant flow-rate resulted in a higher rate of heat utilization.

An experiment on a portable solar cooker and a water heater was conducted by Badran et al. [73]. The experiment setup consisted of a parabolic dish collector, an absorber, a receiver, and a water storage tank as shown in Figure 5. The experimental setup had two modes of operation; which were the water heating mode and the cooking mode. During the water heating mode, the absorber was placed on the focal point of the dish to absorb heat and transport it to the storage tank. During the cooking mode, the collector was replaced by a cooking pot, and the pot lid was covered with polyurethane foam to reduce losses. Cooking and water heating experiments were done to determine the maximum efficiency and cooking power. Results showed that the boiling point of water was achieved under 1 h, and the maximum efficiency achieved was 77 %.

Figure 5.

A photograph of the experimental setup of a portable solar cooker and water heater. The figure was reproduced from Ref. [73], with the permission of Elsevier Publishing.

An evaluation of the thermal performance of the heat exchanger unit for a parabolic solar cooker for off-place cooking was done by Murty et al. [74]. The inclined cylindrical heat exchanger system contained an SK14 parabolic solar cooker, a lower cylindrical absorber, and an upper cylindrical vessel that contained a cooking pot with a lid. Soya oil was used as the heat transfer fluid and storage medium. Cooking experiments were conducted using different types and masses of food. Results indicated that the inclined convective heat exchanger could be utilized during non-shine periods, and the highest temperature recorded for food was around 85 °C. An evaluation of the thermal efficiency of a solar cooking unit was done using food and water. Results showed that high solar insolation decreased the cooking time to a minimum period. Craig and Dobson [75] compared a heat pipe, and a direct copper tube using a parabolic solar cooker for cooking applications. This experiment was aimed at investigating and optimizing heat collection from a parabolic dish collector to a solar cooker using a heat pipe and direct spiral copper tubes. Shell S2 oil was used as the heat transfer fluid. Parameters such as the cooking time, boiling characteristics and the overall heat utilization efficiencies were evaluated and analyzed. Results showed that both systems were satisfactory, but the spiral system was preferred over heat pipes because of the cost of production and the higher temperatures achieved when forced convection was employed. The spiral cooker took about 28 min to boil water, and the heat pipe took 30 min.

A parametric analysis of a parabolic solar cooking system with heat storage for indoor cooking was done by Mbodji and Hajji [76]. The experimental setup was an indirect solar cooking system that was composed of a concentrated solar parabolic dish, a receiver, a heat storage tank, a circulation pump, and a cooking section. Experiments and simulations were carried out to analyze the parameters of the solar cooking system. The results obtained showed that the daily maximum solar radiation increased the heat storage temperature by 4 °C. It was also found out that the maximum temperature on the surface of the plate was 81 °C which was sufficient for cooking. Senthil and Cheralathan [77] analyzed the thermal performance of solid and liquid energy storage materials in a parabolic dish solar cooker. The experiment was composed of a parabolic dish solar cooker, and the objective of the experiment was to test different sensible heat storage media such as pebbles, sand, and iron grits, steel balls, sunflower oil, olive oil, and coconut oil that were filled inside a storage tank. Water heating experiments were done to determine the thermal performance of each sensible heat storage medium. Results obtained indicated that sunflower oil was the best sensible heat storage material that showed better performance compared to other sensible heat storage materials, and the temperatures it achieved were sufficient for cooking during non-shine periods.

Nyahoro et al. [78] simulated the performance of thermal storage in a solar cooker. The proposed simulated system was an indirect solar cooker which consisted of a parabolic concentrator and a storage block that was coupled with a cooking pot. Mirrored reflectors were used to reflect sun rays to the bottom of a storage block which used granite and cast iron as the storage materials. A finite difference method was used to simulate the thermal performance of the thermal storage unit for solar cooking, and cooking during non-shine periods. Results indicated that cast iron obtained the highest temperature, and it also had shorter cooking periods and had fewer heat losses compared to granite. Lokeswaran and Eswaramoorthy [79] studied a solar parabolic dish cooker with porous media. The cooking utensil that contained metal copper chips was placed on the focal point. This experiment aimed to investigate the heat transfer enhancement of solar parabolic dish cookers using metal copper chips. Stagnation and cooking experiments were done with and without the metal copper chips. Results showed that the maximum temperature achieved was about 118 °C in 15 min with 85 g of eggs fried on the receiver with porous medium, whereas the temperature for the plain receiver was only 98 °C. Kedida et al. [80] analyzed the performance of a pebble bed thermal storage integrated with a concentrating parabolic solar collector for solar cooking. The experimental setup used air as the heat transfer fluid. The heat was transported from the receiver that was mounted on the parabolic dish to the thermal storage unit using the heat transfer fluid. A thermal storage unit was coupled with a cooking vessel. During the charging cycle, the cooking vessel was sealed with a cover plate to reduce heat losses, and during discharging a pot was placed on the cooking vessel. The experiment aimed to investigate the efficiency of a solar cooker using a 1D finite-difference computational model. Results obtained showed that during off-shine cooking periods, 5 L of water took 50 min to reach temperatures between 90 °C and 99 °C. The design and experimental investigation of a solar cooker with thermal energy storage was presented by Wollele and Hassen [81]. The experimental setup was composed of two joined parabolic dish collectors, and a solar cooker storage pot that was placed in between the parabolic dish collectors. Rock and engine oil were used as storage materials for the solar cooker storage pot. Charging and discharging experiments were conducted and water was used as the cooking load. The results showed that during discharging, the maximum temperature reached by water was 81.85 °C under 40 min.

An energy and exergy thermal analysis of a solar bakery unit was done by Ayub et al. [82]. The experimental system was composed of a Scheffler reflector, secondary reflector, a receiver, a PV module, and a baking chamber. Rocks were used as sensible heat material and they were placed in close contact with the receiver using air as the heat transfer fluid. Baking experiments were conducted using different food samples. Results showed that the baking temperature achieved was 180 °C, and it was also found out that the energy efficiency in the receiver increased with the baking time. The development and experimental analysis of a thermal oil-based roasting system were done by Raza et al. [83]. The continuous solar roaster was composed of a Scheffler concentrator, heat receiver, storage tank, and a roasting unit. was stored in the storage unit, and it was used to transfer heat from the heat receiver to the roasting unit. Roasting experiments were carried to investigate parameters such as feeding capacity, conveyor speed, and thermal oil flow rate for achieving a light, medium, and dark quality roasting of groundnuts. The results showed that the recommended time to roast light, medium and dark groundnuts was 14, 20, 29 min, respectively, at an average temperature of 180 °C.

Figure 6 shows a photograph with cooked food and a schematic diagram of a storage cooking pot that was made of stainless steel presented by Mawire et al. [84]. The storage cooking pot had an internal cavity in which the storage material was placed. Experiments were performed to compare two solar cooking storage pots combined with wonderbag slow cookers for off-sunshine cooking. The experiment consisted of two solar storage cooking pots, parabolic dish collectors, and wonderbags. Two similar storage cooking pots were experimentally evaluated and compared using parabolic dish solar cookers for solar cooking and wonderbag cookers for off-sunshine cooking. One storage pot had sunflower oil as the sensible heat storage material, and the other had erythritol as the phase change material (PCM). The results obtained showed that the sunflower oil cooking pot performed better during solar cooking periods taking 1.8–5.6 h with a maximum temperature range of 124–145 oC as compared to the erythritol PCM pot which took 3.8–6.6 h to cook with a maximum temperature range of 118–140 oC. During off-shine periods the erythritol PCM pot outperformed the sunflower oil pot, as it showed lower temperature drops of 0.1–9.7 °C as compared to the sunflower oil pot that showed temperature drops between 4.8-14.3 °C because of its latent heat of storage.

Figure 6.

(a) A photograph of a solar cooker pot with cooked chicken and chips (b) A labelled diagram of a solar cooking storage pot. The figure was reproduced from Ref. [84], with the permission of Elsevier Publishing.

A novel technique based on artificial intelligence for a solar bread cooker was presented by Nazari et al. [85]. A parabolic dish concentrator was used to reflect solar radiation to the solar cooker. The solar cooker was composed of a stand and cooking plate with an insulated lid. Experimental and numerical studies were carried out to analyze and evaluate the thermal performance of the experimental setup during baking periods. The results indicated that a dough ball weighing 200g attained a temperature of 180 °C in period of 20–25 min.

Table 2 shows a summary of different types of parabolic concentrators, and their applications related to cooking using different sensible heat storage materials.

Table 2.

A summary of parabolic solar concentrating cookers with sensible heat thermal energy storage (SHTES).

| Author | Type of concentrator | Application | Type of study | Storage material | Maximum cooking/storage temperature (oC) | Heat transfer fluid/Working fluid | Test load |

|---|---|---|---|---|---|---|---|

| Mishra et al. [57] | Parabolic trough | Baking | Experimental | Duratherm 600 | 168 | Duratherm 600 | Dough |

| El Moussaoui et al. [58] | Parabolic trough | Frying | Experimental | Thermal oil | 260 | Thermal oil | Potato chips(Fries) |

| Asmelash et al. [59] | Parabolic trough | Cooking | Experimental | Soya bean oil | 119 | Soya bean oil | Water, eggs and potatoes |

| Dianda et al. [60] | Parabolic trough | Cooking and frying | Experimental | Vegetable oil | ∼110 | Vegetable oil | Water, potato and mixed rice with ingredients |

| Mohan and Vasanthakumar [61] | Parabolic trough | Steam cooking | Experimental | Water | 150 | Water | Potatoes |

| Hassen et al. [62] | Parabolic trough | Baking | Experimental and Numerical | Shell Thermia-B oil | Shell Thermia-B | Injera (sour flatbread) | |

| Yilmaz et al. [64]. | Parabolic trough | Cooking and water heating | Experimental | Fuchs Renotherm 320 | 100 | Fuchs Renotherm 320 | Wheat |

| Arunachala et al. [65] | Compound parabolic collector | Cooking | Experimental and Numerical | Engine oil | 110 | Engine oil | Rice |

| Goytom [63] | Parabolic trough | Baking | Numerical | Thermia-B oil | 220 | Thermia oil B | Injera (sour flatbread) |

| Noman et al. [66] | Parabolic trough | Cooking | Numerical and Experimental | Water | Water | None | |

| Akayleh et al. [29] | Parabolic trough | Baking | Experimental | None | 85 | None | Dough |

| Widjaja et al. [67] | Parabolic trough and compound parabolic concentrator | Process heating | Numerical | Water | 75 | Steam | Milk |

| Bandyopadhyay [68] | None | Cooking and frying | Numerical | Therminol 55 | 202 | Therminol 55 | Vegetables and roti |

| Abd-Elhady et al. [69] | parabolic trough | Cooking | Experimental | Mobil-Therm 605 | 165 | Mobil-Therm 605 | None |

| Agrawal and Yadav [70] | Parabolic dish | Cooking | Experimental | sand, stone pebbles, iron grits and iron balls | 117 | None | Rice |

| Prasanna and Umanand [71] | Paraboloid concentrating collector | Cooking | Numerical | Servo-thermal oil | None | Servo-thermal oil | None |

| Mawire et al. [72] | Parabolic dish | Cooking | Numerical | Thermal oil | 200 | Thermal oil | None |

| Mawire et al. [34]. | Parabolic dish | Cooking | Experimental and Numerical | Thermal oil | 100 | Thermal oil | Olive oil and Water |

| Badran et al. [73] | Parabolic dish | Cooking | Experimental | Water | 100 | Water | Water |

| Murty et al. [74] | Parabolic dish | Cooking | Experimental | Soya oil | 85 | Soya oil | Oil, water and rice |

| Craig and Dobson [75] | Parabolic dish | Cooking and baking | Experimental | Shell S2 oil | 100 | Shell S2 oil | Water |

| Mbodji and Hajji [76] | Parabolic dish | Cooking | Experimental and Numerical | Synthetic oil SAE-40 | ∼85 | Synthetic oil SAE-40 | None |

| Senthil and Cheralathan [77] | Parabolic dish | Cooking | Experimental | Sunflower oil, sand, stone pebbles, iron grits, steel balls, coconut oil and olive oil | 100 | None | Water |

| Nyahoro et al. [78] | Parabolic concentrator | Cooking | Numerical | Granite and cast iron | 100 | None | Water |

| Lokeswaran and Eswaramoorthy [79] | Parabolic dish | Cooking and frying | Experimental | Waste metal chips | 118 | None | Eggs and water |

| Kedida et al. [80] | Parabolic concentrator | Cooking | Experimental and Numerical | Pebbles | 99 | Air | Water |

| Wollele and Hassen [81]. | Parabolic dish | Cooking | Experimental | Engine oil and rocks | 82 | None | Water |

| Ayub et al. [82]. | Scheffler dish | Baking | Experimental and Numerical | Rocks | 180 | Air | Variety of food |

| Raza et al. [83] | Scheffler dish | Roasting | Experimental and Numerical | Shell S2 oil | 180 | Shell S2 oil | Groundnuts |

| Mawire et al. [84] | Parabolic dish | Cooking | Experimental | Sunflower oil | 145 | None``` | Varieties of food |

| Nazari et al. [85] | Parabolic dish | Baking | Experimental and Numerical | None | 146 | None | Bread |

3. Solar concentrating cookers with latent heat thermal energy storage (LHTES)

3.1. Parabolic trough cookers with LHTES

An experimental investigation of a solar cooker during sunshine and off-sunshine hours using a thermal energy storage unit based on a parabolic trough collector was done by Saini et al. [86]. The experimental setup was composed of a parabolic trough that reflected solar radiation to an absorber tube. The collected heat was transferred to the cooker using a thermosiphon cycle. Water and engine oil were used as heat transfer fluids separately, and acetanilide was incorporated with the cooker and used as the storage medium. The results showed that the maximum temperature of the food was 75.9 °C, and it took 2 h to cook the food fully. Mussard and Nydal [87] experimentally investigated the charging of a heat storage tank coupled with a low-cost small-scale solar parabolic trough for cooking purposes as shown in Figure 7. The experimental setup was a self-circulating system that was composed of a parabolic trough and a storage tank. Two charging experiments were done using two different storage tank setups and TES materials. The main objective of the experiment was to store heat at the highest temperature to utilize it during off-shine periods for cooking purposes. The results obtained indicated that when the temperature was above 200 °C, it became difficult to collect heat energy without insulation on the receiver.

Figure 7.

A photograph of a parabolic trough cooker integrated with LHTES. The figure was reproduced from Ref. [87], with the permission of Elsevier Publishing.

An experimental investigation on improving the heat transfer of cascaded thermal storage systems using different fins was done by Beemkumar et al. [88]. The parabolic trough collector was used as a solar collector, with three storage tanks that contained Therminol-66 that was used as the heat transfer fluid. Encapsulated balls used as fins were filled with three different PCM (d-mannitol, d-sorbitol, and paraffin wax) and welded on the storage tanks. An analysis on different encapsulation shapes (rectangular, annular and pin fin) was done to determine the heat transfer rate. Results indicated that using an annular fin for encapsulation showed a higher heat transfer rate compared to others. The storage temperatures revealed that the solar cooking system had the potential of boiling and frying food. Mussard et al. [89] performed an experimental study of a solar cooker using heat storage in comparison with direct heating. A comparative experimental study of two solar cookers was done, and the surface of the storage unit was combined with a flat plate meant for cooking purposes. The first solar cooker was a parabolic dish cooker, and the second solar cooker was a prototype of a solar parabolic trough using a nitrate salt mixture storage unit. Cooking experiments such as boiling and frying were conducted to compare the performance of these two methods of heat extraction. The results obtained showed that cooking with heat storage using an optimized surface contact area was found to be competitive with standard solar cookers or other cooking devices.

An experimental and numerical investigation of a solar flat plate cooking unit for domestic applications was done by Kumaresan et al. [90]. The experimental setup was composed of a solar parabolic trough collector (PTC), a thermal energy storage (TES) tank, a parabolic trough cooking unit, and a positive displacement pump. Therminol 55 was used as the heat transfer fluid and D Mannitol was used as the phase change material. Cooking experiments were carried out, and dosa (an Indian pancake) was used as the cooking load. Parameters such as energy utilization, instantaneous heat transfer rate, and a detailed energy balance were analyzed and evaluated. Results showed that the maximum temperature reached was 167 °C, and it took 3.5 min to prepare 1 dosa. The experimental analysis of a solar cooker with a parabolic trough enhanced with a PCM-based thermal storage unit was presented by Kumar and Pandian [91]. The main components of the indirect solar cooker were a storage tank that was used to store heat energy, a heat transfer fluid, a manual tracking system, a parabolic trough collector, and a semicircular cooking oven. Stearic acid was used as the PCM storage medium. A heat transfer analysis of the experimental setup was carried out using various mass flow rates. Results showed that using a mass flow rate of 0.45 kg/s gave better energy extraction that could be utilized for cooking applications. The highest temperature achieved was approximately 120 °C in 3 h.

An evaluation of the thermal performance of a parabolic trough reflector with a PCM storage unit for different applications was presented by Abu-Hamdeh et al. [92]. The experimental components that were utilized were a parabolic trough reflector, a solar stove, an air blowing fan, and aluminum capsules that contain acetamide as a PCM. The PCM capsules were placed on the receiver of the parabolic solar reflector to absorb heat from the reflected sunlight. After the PCM melted completely, the capsules were removed from the receiver and transferred to the solar stove. Cooking experiments were done using rice, and the results showed that the cooking process took 60 min. The maximum cooking temperature achieved was approximately 90 °C with an airflow rate of 60 m3/h. A parametric study of a solar parabolic trough collector was conducted by Manikandan et al. [93]. A novel solar system was proposed, and it consisted of a parabolic trough collector that was combined with a TES unit and a cooking unit. Therminol 55 was used as the heat transfer fluid. A thermal analysis was done on parameters such as the mass flow rate, efficiency, useful energy, the concentration ratio of the collector, and the heat removal factor. The results showed that performance parameters such as thermal efficiency and the useful energy gain rate increased as the solar insulation increased, and this was evidence that it can be utilized for cooking and heating applications. Beemkumar et al. [88] performed a comparative experimental study on a parabolic trough collector integrated with a thermal energy storage system by using different reflective materials. The parabolic trough collector system was mainly composed of a parabolic trough collector, a storage tank that contained Therminol-66 oil which was used as the heat transfer fluid, D-mannitol, and a displacement pump to circulate Therminol-66 oil throughout the system. Two reflective materials (glass and stainless steel) were incorporated in the parabolic trough reflector. Experiments were conducted and various parameters were analyzed. Results obtained showed that the use of glass as reflective material showed better gain compared to stainless steel, and the maximum temperature achieved ranged from 220-230 °C.

An experimental and numerical study of a solar collector using phase change material as heat storage was done by Guerraiche et al. [94]. The aim of this experiment was to study the thermal performance of a solar collector combined with a thermal energy storage system. A small-scale parabolic trough was used to reflect solar radiation to the absorber; and the absorber contained a mixture of sodium nitrate and potassium nitrate that was used as PCM. Water was used as the heat transfer fluid, and it was stored in a storage tank. An experimental comparison of the absorber with and without PCM was done. The results showed that during heat retention the highest temperature achieved was 40 °C in a period of 1h:40 min to 2 h. Thermal performance of a coupled solar parabolic trough collector latent heat storage unit for solar water heating in large buildings was done by Lamrani et al. [95]. The experimental setup was composed of a shell and tube latent thermal energy storage system, a parabolic trough collector and a circulating pump. A thermal dynamic model was developed to evaluate thermal performance of the experimental system. Three phase change materials (RT-42, RT-55 and RT-65) were used as latent heat storage materials, and these were compared to determine the most suitable PCM. Results showed that using the mass flow rate of 1800 l/h, RT-55 showed better performance compared to RT-42 and RT-65. Furthermore, during daytime and nighttime, the system was able to produce hot water ranging from temperatures of 36–85 °C and 38–63 °C.

The thermal analysis of a solar dryer equipped with a parabolic trough solar collector (PTSC) and PCM using experimental and numerical methods was presented by Alimohammadi et al. [96]. The thermal performance of four fluids (Nano-fluid, engine oil, glycerin and water) used as heat transfer fluid was evaluated. Paraffin wax was used as the PCM, and air was used to transfer heat from the heat transfer fluid pipe to the drying chamber. Experiments and simulations were done using different heat transfer fluids. Results showed that engine oil reached around 80.4 °C, and it performed better compared to other heat transfer fluids.

3.2. Parabolic dish cookers with LHTES

The feasibility of incorporating phase change materials in a collapsible parabolic solar cooker was presented by Keith et al. [97]. The experimental setup consisted of a collapsible parabolic solar cooker with 12 panels, and a cooking vessel integrated with a PCM storage container. The PCM that was used was stearic acid. A comparison experiment with a commercial pot and a modified cooking vessel was done. Rice and pearled barley were used as the cooking loads. The results obtained showed that the cooking vessel integrated with a PCM reached a maximum average temperature of 57 °C for rice, and 59 °C for pearled barley, with cooking times of 131 min and 161 min, respectively. A solar-powered heat storage experiment for Injera baking in Ethiopia was presented by Tesfay et al. [98]. Two experimental setups were investigated and solar salt was used as the PCM. The first experimental setup was an electric-based system that was composed of an electric heating element and a solar salt storage tank coupled with a cooking vessel. The second experimental setup was similar to the first experimental setup and the difference was the pipeline system and a parabolic dish that was used to reflect solar radiation to the absorber tube. The objective of this experiment was to investigate the heat loss, cooking times, cooking temperatures, and temperatures of the PCM storage. Cooking experiments were carried out with Injera and nitrate salt mixtures were used as PCM. The results obtained showed that the useful latent energy and sensible heat stored were 374.4 kJ and 853 kJ, respectively. Results showed that cooking two Injeras and frying an egg took 32 min during non-shine periods.

Bhave and Kale [99] developed a thermal energy storage type of solar cooker for high-temperature cooking using a mixture of sodium nitrate and potassium nitrate as the PCM. A parabolic dish concentrator was used to direct solar radiation to the solar receiver as shown in Figure 8. The solar receiver was integrated with a cooking cavity and a PCM storage unit. Cooking experiments were carried out, and the results showed that the solar cooker was able to store heat at the PCM melting point of 220 °C in 110 min, with 0.2 kg of potatoes being fried in 17 min at night. Malik et al. [100] designed and fabricated a solar thermal energy storage system using potassium alum as the PCM. The parabolic dish collector's inner surface was made up of small pieces of glass and fiberglass. The heat transfer fluid (HTF) was composed of a mixture of ethylene glycol and water. Charging and discharging experiments were conducted and compared to simulation results. Results showed that thermal energy was stored for 7 h at a maximum temperature of 92 °C which was suitable for cooking and heating applications.

Figure 8.

A photograph of an experimental setup of a parabolic dish cooker combined with an insulated solar receiver/thermal energy storage. The figure was reproduced from Ref. [99], with the permission of Elsevier Publishing.

An enhancement of the uniform temperature distribution of a concentrated solar receiver integrated with phase change material was done by Senthil [101]. The parabolic dish reflector was a Scheffler dish with multiple mirrors, and it was used to reflect sunlight to the receiver. The receiver was a cylindrical container that contained a cooking vessel and PCM storage. Sodium nitrate and potassium nitrate were used as the PCMs, and charging experiments were done using an insulated receiver and a receiver without insulation. After charging, water was used as the cooking load. The results obtained showed that the receiver was able to store 30 MJ of energy at a temperature of 300 °C with water completely evaporating. Lecuona et al. [102] experimentally evaluated a portable parabolic dish cooker incorporating a heat storage unit based on PCMs. The experimental setup was composed of two cooking utensils that were combined with storage tanks, an insulated box used for off-shine periods, and a parabolic dish cooker that was used to reflect and direct sunlight to the cooking utensil. Erythritol and paraffin were suitable candidates that were chosen as PCMs because the melting temperatures are close to the boiling point of water. Results showed that the utensil was able to cook three meals for a family, and another finding was that at 100 °C, paraffin seemed to be better adapted for cooking than erythritol. A numerical study on coupling PCMs with a solar dish collector was done by Tao et al. [103]. The paraboloid solar collector was used to irradiate solar radiation to the receiver during sunshine periods. The receiver was composed of heat transfer tubes and PCM storage, and it was placed at the focal point of the paraboloid solar collector. 80.5%-lithium fluorine and 19.5 %-calcium fluoride was the PCM. A Monte Carlo ray-tracing method (MCRTM) and finite volume methods (FVM) models were used to study the heat transfer problem. Results showed that enhancing the PCM thermal conductivity was an efficient way to achieve a more uniform temperature field distribution in the PCM.

Senthil and Cheralathan [104] analyzed the effect of PCM in a solar receiver using a parabolic dish collector. A Scheffler parabolic dish solar concentrator was used to concentrate solar radiation to the receiver, and improve heat transfer in the receiver. The receiver was made up of fins and a storage container filled with magnesium chloride hexahydrate as the PCM. Experiments were carried out to analyze heat transfer from the receiver to the heat transfer fluid with and without PCM. Results obtained showed that integrating PCM in the receiver improved the energy efficiency of the parabolic dish solar concentrator by about 60–65 %, and decreased the time to reach the boiling point of water by about 20 % when compared with the receiver without PCM. An enhancement of the productivity of a parabolic dish solar cooker integrated with PCM was done by Senthil and Cheralathan [105]. The thermal performance of the solar cooker with PCM integrated into a cylindrical pot was investigated to determine the thermal conductivity and storage capability enhancement. Results indicated that the productivity of the cooker during off-sunshine hours was improved with PCM, and water reached its boiling point in 130 min. Tesfay et al. [106] studied solar cookers with latent heat storage for intensive cooking applications. The solar cooker experiment was composed of a parabolic collector with a receiver, a storage system where the baking plate was embedded with stainless steel steam pipes, and aluminum fins. Water was used as the heat transfer fluid and a nitrate salt mixture was used as the PCM. Baking experiments were carried out, and results indicated that Injera could be baked at lower temperatures (110–150 °C) than previously assumed (180–220 °C). An experimental investigation of a solar cooker based on a parabolic dish collector with a PCM thermal storage unit in Indian climatic conditions was done by Chaudhary et al. [107]. The solar cooker system consisted of a parabolic dish collector combined with a flat surface absorber, a hollow-spaced solar cooker, and an insulated wood box filled with glass wool. Acetanilide was used as the PCM, and it was filled in between the hollow space of the inner and outer wall of the solar cooker. Cooking experiments were conducted and water was used as the cooking load. The results showed that during the discharging process, the maximum temperatures of cooking load achieved for an ordinary solar cooker, a solar cooker with the outer surface painted black, and for a solar cooker with the outer surface painted black along with glazing were 52.2 °C, 84.3 °C, and 88.4 °C, respectively.

Yadav and Yadav [108] performed an experimental investigation of a novel solar cooker with a dual thermal storage unit based on a parabolic dish collector. The experimental setup consisted of a solar cooker that was integrated with a sensible heat storage unit (sand) and a latent heat storage unit (acetamide). The objective of the experiment was to evaluate the thermal performance of the solar cooker based on a parabolic dish collector with acetamide and sand as a dual thermal storage media for noon and evening cooking. Cooking was conducted during the daytime as well as in the evening with different cooking loads. Results showed that the rate of evening cooking was approximately 1.5–2 times faster as compared to noon cooking, and also the temperature of cooked food at 20:00 h was found to be in the range of 60.2–70.6 °C. An experimental design of a PCM-based solar cooker for both indoor and outdoor cooking applications was done by Rekha and Sukchai [109]. The experimental setup consisted of a parabolic dish collector used to reflect sunlight to the focal point, and a receiver that was made up of a cooking utensil combined with cylindrical tubes that contained PCM. The gap between the cooking utensil and cylindrical tubes of the receiver was filled with palm oil and salt hydrate was used as a phase change material. Performance parameters such as the heat loss factor, optical efficiency factor, and cooking power were calculated and analyzed with and without PCM in the receiver. The results obtained showed that the cooking power of the solar cooker with the PCM receiver was 125.3 W and 65.6 W without PCM in the receiver. The maximum temperature reached by the PCM solar cooker was approximately 100 °C. Bhave and Thakare [110] developed a solar thermal storage cum cooking device using magnesium chloride hexahydrate powder as the PCM. A parabolic dish concentrator was used to reflect solar radiation to the receiver. The receiver was integrated with cylindrical PCM tubes and a cooking cavity. Taurus Therm 500 was used as the heat transfer fluid in the cooking experiments. Cooking experiments were conducted with rice as a cooking load. Results showed that it took 30 min to cook 50 g of rice with 100 ml of water, and the maximum storage temperature was 129 °C.

Veremachi et al. [111] designed a PCM heat storage unit charged with a double reflector solar system. The system was composed of a primary parabolic dish reflector, a secondary plane mirror reflector, and a PCM heat storage unit that contained a mixture of sodium nitrate and potassium nitrate. This experiment aimed to evaluate the thermal parameters of the system. Charging experiments were conducted, and the results showed that the PCM in the storage unit melted at around 220 °C which was suitable for cooking or frying applications. Floess [112] developed a solar resource map for a stored solar cooker. A solar cooker named the “Sun Bucket” was used both as a cooking utensil and a PCM storage container. A combination of potassium nitrate salt and sodium nitrate salt was used as the PCM. A parabolic dish collector was used to reflect solar radiation to the solar cooker. Charging experiments were done under different environmental conditions. Parameters such as the heat transfer coefficient and rate were analyzed. Results showed that the combined PCM melted at a temperature of 334 °C which was suitable to cook a full range of foods that an electric stove could cook.

Performance analysis of a solar energy storage unit for cooking was done by Sreepathi et al. [113]. The experimental setup was composed of a “butterfly” parabolic collector and a storage cooking utensil that contained PCM. Oxalic acid was used as the phase change material. The experiment aimed at determining the peak temperature that could be attained. Water heating experiments and cooking experiments were conducted. Results obtained showed that the storage cooking utensil was able to store thermal energy for 3 h at a temperature of 65 °C. Panchal and Sadasivuni [114] investigated and performed an analysis of a Scheffler reflector solar cooking system integrated with sensible and latent heat storage materials. The experimental setup consisted of a Scheffler reflector, the solar cooker, the latent heat storage unit, a sensible heat storage unit, and an insulator box. Acetamide was selected as the latent storage material, rocks and sand were selected as the sensible storage material. A comparison experiment of acetamide-sand, acetamide-pebbles, and acetamide-iron balls was conducted to determine the thermal performance during off-shine periods. The results showed the maximum temperatures achieved by three materials were 95 °C, 82 °C, and 77 °C, respectively. The cooking process took 3 h achieving temperatures of 58 °C, 57 °C and 56 °C. Abreha et al. [115] did a study on numerical modelling and simulation of thermal energy storage for solar cooking using Comsol multiphysics software. A shell-and-tube heat exchanger-type storage system coupled with a PCM mixture of potassium nitrate and sodium nitrate was used to conduct numerical experiments. 19 heat transfer tubes were selected and integrated with four longitudinal fins. The maximum average temperature of 230 °C was achieved with the total energy ranging from 4.29 MJ to 10.17 MJ. A numerical and experimental analysis of a solar Injera baking cooker coupled with PCM storage was performed by Tesfay et al. [116]. The main components of the experimental setup were a parabolic dish concentrator, a receiver, a tracking mechanism, and an insulated storage tank that contained a mixture of potassium nitrate and sodium nitrate. Water was used as the heat transfer fluid, and Injera was used as the food load. The study determined which baking surface was optimum for baking Injera. Results showed that one Injera was baked at temperatures in the range of 110–150 °C under 3 min.

Thermal performance evaluation of a solar cooker with a latent and sensible heat storage unit for evening cooking was done by Yadav et al. [117]. The main experimental components consisted of a parabolic solar dish collector, a storage solar cooking vessel, and an insulation box. A combination of latent and sensible heat was used in the storage solar cooker. Acetamide was selected as the PCM and sand, iron grits, stone pebbles, iron balls were the selected sensible heat materials. The storage solar cooker was charged throughout the day, and in the evening the storage solar cooker was placed with food in an insulated box. Results showed that a combination of PCM-sand and PCM-stone pebbles stored more energy compared to other combinations. The maximum cooking temperatures that were achieved were 70 °C and 60 °C for a cooking process that took 4 h. Hosseinzadeh et al. [118] performed an experimental study of a nanofluid-based indirect solar cooker. The indirect solar cooker consisted of a parabolic dish collector, a cooking unit, a storage tank, and a pump. Behran thermal oil was used as the heat transfer fluid. The experiment aimed to investigate and compare Behran thermal oil and three other Behran thermal oil-based nanofluids. The three Behran thermal oil-based nanofluids that were considered were; Silicon dioxide-Behran thermal oil, Silicon carbide-Behran thermal oil, and Titanium dioxide-Behran thermal oil. The results obtained showed that Silicon carbide-Behran thermal oil out-performed other candidates, and it decreased the process of boiling 2 L of water by 17 min. An experiment on the effect of charging of PCMs in vertical and horizontal rectangular enclosures in a concentrated solar receiver was conducted by Senthil [119]. A parabolic concentrator was used to reflect the sun's rays to the receiver. The insulated receiver was composed of fins and a PCM used to store latent heat energy. Water was utilized as the heat transfer fluid, and it was used to transport latent energy from the receiver to the storage tank. A mixture of potassium nitrate and sodium nitrate was used as the PCM. An investigation on the effect of vertical and horizontal orientations was done. Results showed that after charging, the highest temperature achieved by the PCM receiver was approximately 315 °C in the vertical position and 297 °C for the horizontal position.

An experimental investigation on thermal performance of a cavity receiver integrated with short-term thermal energy storage for a solar parabolic dish concentrator was done by Thirunavukkarasu et al. [120]. A Scheffler dish integrated with solar grade mirrors was used to reflect solar radiation to the receiver. The receiver was composed of a double layer walled vessel filled with a salt mixture PCM (sodium nitrate and potassium). Water was used as the heat transfer fluid, and it was circulated from the storage tank to the receiver to absorb the heat with the help of a centrifugal pump. The aim of this experiment was to test the effect of the salt mixture integrated with the receiver and the thermal efficiency of the experimental setup. The results showed that the total thermal efficiency was 24.3 % for an average solar radiation of around 429 W/m2. An experimental investigation of solar nitrate salts as solar TES materials for potential cooking applications was done by Gabisa and Aman [121]. Potassium sodium nitrate salts were used as a latent storage material, and an electrical heater was used to simulate solar radiation. The aim of the experiment was to determine the thermal characteristics of the PCM. Experiments were carried out using two local meals, and the results showed 2.38 kWh was required for cooking two meals of five families. Foong et al. [122] investigated a small scale double-reflector solar concentrating system with high temperature heat storage. The main components of the experimental setup were a primary reflector (parabolic dish), a secondary reflector, and well insulated PCM heat storage unit. A combination of sodium nitrate and potassium nitrate was used as the storage heat material. Experiments were conduct to test and evaluate the thermal performance of the PCM heat storage during off-sunshine periods. Results showed that melting occurred after 2.5 h, and the maximum temperatures reached ranged from 230-260 °C.

Table 3 shows a summary of parabolic concentrating collectors using latent heat storage mostly for solar cooking applications.

Table 3.

A summary of parabolic solar concentrating cookers with latent heat thermal energy storage (LHTES).

| Author | Type of concentrator | Application | Type of study | Storage material | Maximum cooking/storage temperature (oC) | Heat transfer fluid/working fluid | Test load |

|---|---|---|---|---|---|---|---|

| Saini et al. [86] | Parabolic trough | Cooking | Experimental | Acetanilide | 76 | Water and engine | Rice and pulse |

| Mussard and Nydal [87] | Parabolic trough | Cooking and frying | Experimental and Numerical | Potassium nitrate and sodium nitrate | 200 | Duratherm 630 | Water and meat |

| Beemkumar et al. [88] | Parabolic trough | Heat storage | Experimental | D-mannitol, d-sorbitol, and paraffin wax | 300 | Therminol-66 | None |

| Mussard et al. [89] | Parabolic trough and parabolic dish | Cooking And frying | Experimental | Potassium nitrate and sodium nitrate | 130 | Therminol-66 | Meat |

| Kumaresan et al. [90] | Parabolic trough | Cooking | Experimental and Numerical | D-Mannitol | 167 | Therminol-66 | Dosa (thick pancake) |

| Kumar and Pandian [91] | Parabolic trough | Cooking | Experimental | Stearic acid | 120 | Waste engine oil and water | None |

| Abu-Hamdeh et al. [92] | Parabolic trough | Cooking and water heating | Experimental | Acetamide | 90 | Air | Rice |

| Manikandan et al. [93] | Parabolic trough | Cooking | Experimental and Numerical | D-Mannitol | 80 | Therminol 55 | None |

| Beemkumar et al. [88] | Parabolic trough | Heat storage | Experimental | D-mannitol, D-sorbitol and paraffin wax | ∼300 | Therminol-66 | None |

| Guerraiche et al. [94] | Parabolic trough | Heat storage | Experimental | Potassium nitrate and sodium nitrate | 120 | Water | None |

| Lamrani et al. [95] | Parabolic trough | Heat storage and water heating | Experimental | RT-55, RT-42 and RT-65 | 80 | Water | None |

| Alimohammadi et al. [96] | Parabolic trough | Dryer | Experimental and Numerical | Paraffin was | 80 | Engine oil | Slices of banana |

| Keith et al. [97] | Parabolic dish | Cooking | Experimental and Numerical | Stearic acid | 59 | None | Rice, lentil and pearled barley |

| Tesfay et al. [98] | Parabolic dish | Cooking | Experimental | Potassium nitrate and sodium nitrate | ∼237 | Steam | Eggs |

| Bhave and Kale et al. [99] | Parabolic dish | Cooking | Experimental | Potassium nitrate and sodium nitrate | 180 | None | Potatoes and rice |

| Malik et al. [100] | Parabolic dish | Cooking and heating | Experimental and Numerical | Potassium alum | 92 | Ethylene glycol and water | None |

| Senthil [101] | Scheffler dish | Cooking | Experimental | Potassium nitrate and sodium nitrate | 300 | None | Water |

| Lecuona et al. [102] | Parabolic dish | Cooking | Experimental and Numerical | Erythritol and paraffin | 170 | None | Water |

| Tao et al. [103]. | Paraboloid solar collector | Heat storage | Numerical | Lithium fluorine And calcium fluoride | 508 | Not sure | None |

| Senthil and Cheralathan [104] | Scheffler dish | Heat storage | Experimental | Magnesium chloride hexahydrate | 160 | None | None |

| Senthil and Cheralathan [105] | Parabolic dish | Cooking | Experimental | Paraffin wax | 90 | None | Water |