Abstract

Recently, many consumers have been adding plant-based beverages to their diets, due to different reasons. The addition of plant proteins to enrich these products in order to make them more nutritionally balanced has become a trend, mainly because of their lower prices and reduced environmental damage. Thus, the aims of the present patent review are to discuss the potential of, and challenges posed by, plant proteins to the beverage industry, as well as to check market trends, focused on raw materials and beverage types. Based on the results, pea, rapeseed, bean, peanut, chickpea, lentil, hempseed, sunflower seed, and cottonseed were among the most often addressed raw materials. Furthermore, this enrichment process is not limited to create products that mimic dairy, therefore expansion in plant proteins used to enrich carbonated beverages, sports drinks, or even juices is expected to happen. Thus, plant-derived proteins have been promising to high-quality beverage production, as well as to ensure food security, animal welfare, and low environmental impacts.

Subject terms: Nutrition; Science, technology and society; Sustainability

Introduction

Nowadays, plant-based beverage consumption has been gaining significant relevance. This segment has been projected to exceed US$26 billion by 2023, in the global market1. Environmental concerns and ethical awareness about animal welfare are factors often pointed out as motivation for the consumption of plant-based products, as well as a preference for a healthy lifestyle2. In fact, plant matrices tend to present a higher amount of fiber and phytochemicals, when compared to animal matrices. One more reason for the health-promoting effect of a plant-based diet is linked to the lifestyle as a whole, since those who opt for this diet are likely to be more conscious regarding food and exercise habits, and as a result, acquire protective factors against chronic diseases3. Moreover, the increasing incidence of individuals allergic to cow milk and intolerant to lactose mostly account for such consumption shift2.

A wide range of plant-based products is available in the market, mainly when it comes to milk analogs. In technological terms, milk analogs are aqueous extracts from milled plant material that resembles cow milk4. Soy-based beverages were the first of these products to become popular; however, they are currently facing rejection due to their allergenicity and genetic modifications5–8. At the same time, other plant sources have emerged as alternatives to soy-based beverages, as among them one finds almond, rice, oat, coconut, sunflower seed, and hempseed1. Because these raw materials are different from each other, the nutritional composition, appearance, and taste of final products can present considerable differences1,6. Regarding nutrients, for example, protein is a nutrient that tends to be missing in these beverages, and this issue can limit their acceptance by consumers8.

Indeed, people have been seeking protein-rich products9. According to Mintel, 30% of consumers would buy more milk substitutes if they had an extra protein appeal10. Plant source blends have been explored as the way to accomplish the nutritional adequacy and improvement of final products’ technological aspects11,12. However, the enrichment of products with proteins has become a major trend for this new beverage in the market, in order to make them even more nutritionally balanced9. Such enrichment can be applicable not only to milk replacers, but also to other sorts of beverages, such as fermented beverages, sports drinks, soft drinks, or even juices, in case appropriate technologies are applied to their production process.

Legumes, pulses, seeds, and nuts are often highlighted as great sources of plant protein, mainly oil industry by-products, like press-cakes, which are protein-rich, but yet poorly explored as food13,14. Leaves, aquatic plants, seaweed, and microalgae can also be used as raw materials for protein extraction. However, they require processing near the growing area, due to their high moisture and rapid deterioration15. When correctly combined, plant proteins are comparable to animal-based proteins, as they can provide all essential amino acids in adequate amounts16. It is also known that di and tripeptides can be absorbed by the gut, and, as well as animal proteins, plant proteins can be hydrolyzed in biopeptides which present health-promoting effects. Some of these benefits are17,18, for example, anticancer, antimicrobial, antioxidant, anti-inflammatory, antianemic, antithrombotic, antihypertension, antiobesity, antidiabetic, and immunomodulatory activities19,20. These biopeptides normally do not present bioactivity when encrypted in the parent protein, so the benefit only displays after the hydrolysis process21. Depending on the peptide, they can be obtained by natural digestion process or by food processing, using trypsin, pepsin, alkalase, and biological fermentation to create functional peptide ingredients22. Besides that, plant proteins account for costs lower than animal proteins; moreover, their production process is less damaging to the environment13. On the other hand, dealing with plant proteins can be challenging, since their functionality-related aspects, such as color and taste, remain an issue. Furthermore, even if the total amount of protein is high, the presence of limiting amino acids and antinutritional factors in plants ends up compromising the quality of the protein15.

But as the challenges related to plant proteins use have been overcome and their potential has been perceived, patenting mechanisms now play an important role. The existence of patenting mechanisms is crucial in the current technological world because it allows exclusivity to use an invention for a certain period of time. However, it happens in exchange for the disclosure of detailed information about the topic23. Any technical or functional aspect of products and processes can be patented, as long as they meet industrial applicability, novelty, inventiveness, and patentable subject matter criteria24. Plant proteins properties modifications, specific temperature, and pH conditions used in processes, isolation, and purifying methods, as well as the final product itself can be protected by patents25. More than working as a competitive instrument, patents are valuable sources of technological information23; therefore, the aims of the current patent review were to discuss the potential of, and challenges posed by, certain plant proteins to the beverage industry, as well as to check market trends focused on raw materials and beverage types.

Methodology

The search for patents was based on the International Patent Classification (IPC) system and carried out in “Espacenet” since this database gathers the largest number of open access patents. It is better to use a patent classification system rather than the “keyword” strategy alone because it ensures the selection of patents belonging to a specific field and technology. Patents published between January 2015 and June 2020 were herein selected in association with the IPC subgroup A23J1/14, which describes the technologies and applicability of protein compositions for foodstuffs obtained from leguminous, other vegetable seeds, press-cake, or oil-bearing seeds (Fig. 1).

Fig. 1. Definition of subgroup A23J1/14 based on the International Patent Classification (IPC).

Darker blue categories represent broader fields, whereas lighter blue categories concern more specific fields. Data source: World Intellectual Property Organization (WIPO). Elaborated by the authors.

Patents presenting duplicate or triplicated titles applied by the same authors and coming from different origins were excluded from the research as part of the screening. It is important taking into consideration that when duplicated or triplicated patents were excluded, the newest ones were maintained in the sample. Patents that were presented in title terms such as “soy”, “hybrid”, or “variety” were also excluded from the study. Soy was excluded given its growing rejection by consumers, mainly because of its allergenicity and genetic modifications8. Likewise, titles with the words “hybrid” and “variety” were also excluded, since they are related to the production of new plants based on genetic engineering, which is not the aim of the current study.

The full reading of the patents was carried out and the following eligibility criteria were established to exclude: (1) patents with an unavailable description or no translation into English or Portuguese; (2) duplicated or triplicated patents by the same authors, from different origins; (3) patents that used soy as preferable raw material; and (4) patents that used animal origin components as preferable raw material.

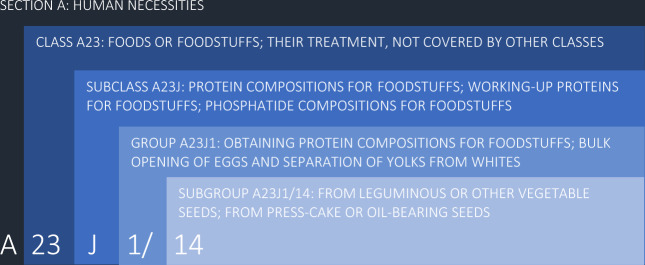

The keyword search was carried out in the descriptions by combining the following terms: “beverage” or “juice” or “drink” or ((“dairy” or “milk” or “yogurt”) and (“alternative” or “substitute” or “analog” or “replacer”)) in order to only select patents related to plant-based beverages. All surveyed patents were somehow related to plant proteins used as ingredient and/or supplement, and/or additives in the beverage industry, or even as a ready-to-consumption product (Fig. 2).

Fig. 2. Research methodology flowchart.

Patents’ identification followed by screening, and eligibility and inclusion criteria application.

Results and discussion

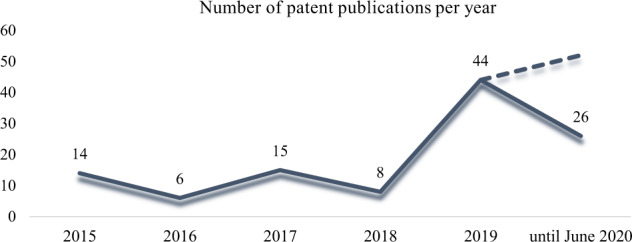

In total, 1036 patent applications were found from January 2015 to June 2020 in the IPC A23J1/14 subgroup. The final sample counted on 113 patents after screening and eligibility criteria application. By comparing the number of plant-based beverage applications in the last 5 years, it was possible seeing an increase in this number back in 2019: 44 patent applications (Fig. 3). Noteworthy, 26 patents were applied up to June 2019, and this finding is indicative of upward tendency estimated to the number of applications in the following years. Such an estimate can be confirmed by both the current plant-based beverage consumption trend1 and populations’ increased interest in protein-rich products9.

Fig. 3. Number of patent publications per year.

Solid line refers to the current number of filled patents over time; dashed line means the estimate for 2020 by taking into consideration the increasing number recorded in the previous year and in early 2020.

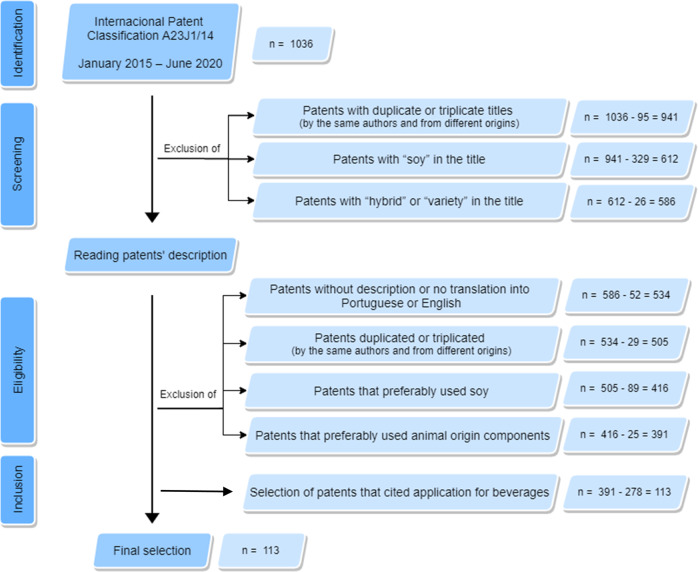

Patents were divided into three different groups, namely: “seeds and nuts”, “legumes and pulses”, and “other mixes”, since A23J1/14 subgroup is related to leguminous, vegetable seeds, press-cake, or oil-bearing seeds (Fig. 4). Based on the results, most patents are related to legumes and pulses using (45%), followed by seeds and nuts (36%), other mixes (18%), and patents that did not specify their raw materials (1%).

Fig. 4. Distribution of raw material groups and beverage types that can be produced.

Legumes and pulses examples are highlighted in orange; seeds and nuts, in blue; other mixes, in yellow; do not specify, in green; beverage types are expressed in light yellow. *Other mixes include patents that used “legumes and pulses” and/or “seeds and nuts” and/or other components, such as cereal, seaweed, and fungus.

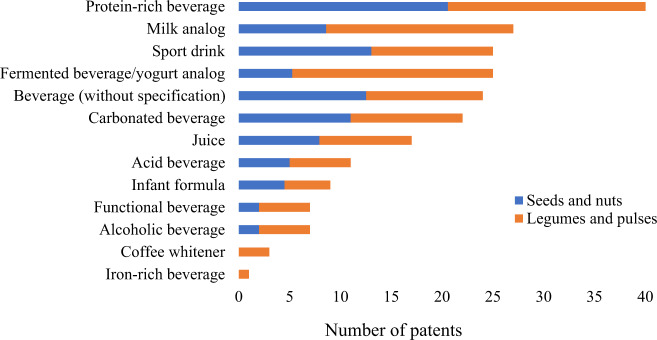

Most patents (n = 40) mentioned their applicability to protein-rich beverage production. This finding was expected due to the current demand for this category of product9 (Fig. 5). Milk analog (n = 27) and fermented beverage/yogurt analog (n = 25) come right in sequence, and it corroborated consumers’ increased interest in alternatives to dairy products1. Sports drink (n = 25), carbonated beverage (n = 22), juice (n = 17), and acid beverage (n = 11) were also often addressed in patents, and this finding meets the current need of using plant proteins at different pH ranges without compromising the features of final products.

Fig. 5. Number of patents based on beverage types and raw material groups.

Patents that have opted for seeds and nuts are represented in blue, whereas the number of patents that have used legumes and pulses is represented in orange. *The same patent can mention more than one beverage type as applicable.

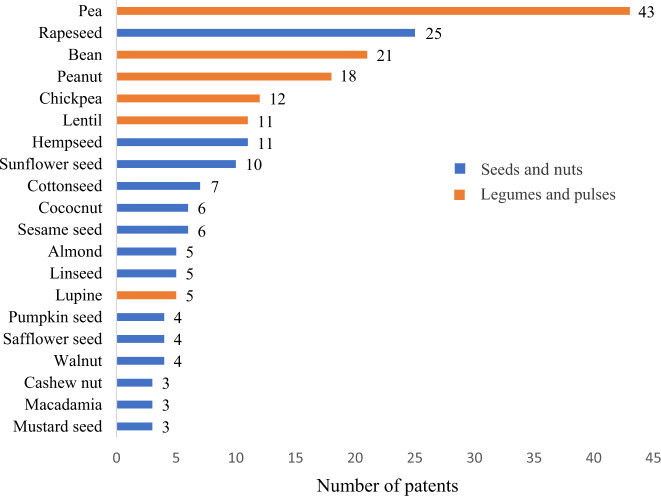

Figure 6 shows the preferable raw materials for patent applicants. It is important to point out that the sum of recorded results will be higher than the total number of patents selected for the current study if one takes into consideration that some patents used more than one raw material on its applicability. The most preferable raw materials chosen by patents applicants were pea, rapeseed, and bean.

Fig. 6. Number of patents by preferable raw materials for use.

Seeds and nuts are represented in blue, whereas legumes and pulses are represented in orange. *The same patent can use more than one raw material as preferable; **In total, 13 patents used other raw material types, such as cereal, seaweed, or fungus, besides using legumes, pulses, seeds, or nuts; ***Three (3) patents did not specify the used raw materials; ****Brazil nut, Camelina seed, Castor bean, Chia seed, Cocoa seed, Fenugreek, Ginkgo biloba seed, Pepper seed, Perilla seed, Physalis seed, Pistachio, Primula seed, Samara seed, Sea buckthorn seed, Snackegourd seed, Tamarind, Thistle seed, Tomato seed, Tung seed, Turnip seed, and Wisteria were cited as preferable raw material by one patent. *****Alfalfa, Broccoli seed, Camellia seed, Grape seed, Hazelnut, Moringa oleifera seed, and Locust bean were cited as preferable raw material by two patents.

Seeds and nuts

Seeds are of great economic and biological importance if one takes into account that they have a high oil and protein content, and large starch reserves. Nuts from trees are recommended as part of a healthy diet given their protein, phytochemicals, micronutrients, and unsaturated fat content14. Seeds and nuts can be the raw material for oil production, which is often extracted by cold pressing—this process generates a by-product known as “press-cake”; or it can also be extracted with organic solvents—in this case, the residue is called “meal”26. The global 2018/2019 oilseed production reached 600.47 million metric tons27, hence huge amounts of oil extraction by-products are available. Although press-cakes and meals are often discarded as waste or used as components for feed supplementation, they are good protein, fiber, and bioactive compound sources26,28. Moreover, because of the increasing demand of protein products, such waste types are a potential alternative source for protein extraction5. However, the oil extraction procedure often decreases protein solubility29 and it compromises its use in beverages. Thus, many of the herein-reviewed patents were related to methods applied to increase or preserve the solubility of proteins extracted from cakes and meals. Furthermore, depending on the raw materials, meals and press-cake often possess undesirable amounts of compounds that decrease protein digestibility, such as fibers and antinutritional factors5—such a matter is constantly discussed in most patents as well. Moreover, the preferable protein extraction methods were related to the protein precipitation using an alkaline, acid, or salted solution, followed by a specific filtration and drying technique (Table 1).

Table 1.

Patents that use seeds and/or nuts as preferable raw material.

| # | Preferable raw material | Publication number | Origin | Beverage type | Presentation form | Protein extraction methods and technologies applied | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Camellia seed | CN105053506 (A) | China | Protein-rich beverage | Powder |

- Low temperature basic/acid protein precipitation; - Spray drying. |

79 |

| 2 | Ginkgo biloba seed | CN104543328 (A) | China | Beverage (without specification), carbonated beverage, alcoholic beverage | Powder or liquid |

- Culture and fermentation; - Vacuum concentration; - Drying and milling. |

80 |

| 3 | Grape seed | US10335446 (B2); US2019000910 (A1) | United States of America | Juice | Powder or liquid | - Grinding pomace, centrifuge, and powder. | 81 |

| 4 | Hempseed | CN110250276 (A) | China | Protein-rich beverage | Liquid | - Formula composition. | 82 |

| 5 | Hempseed | WO2019213757 (A1) | World Intellectual Property Organization | Sports drink, infant formula | Powder or liquid |

- Alkalinization followed by isoelectric protein precipitation; - Ultrafiltering and microencapsulation. |

83 |

| 6 | Hempseed | US2015079235 (A1) | United States of America | Milk analog, juice, infant formula | Powder or liquid | - Formula composition. | 84 |

| 7 | Hempseed | CN108522780 (A) | China | Beverage (without specification) | Powder |

- Low-temperature physical squeezing extraction; - Physical superfine grinding. |

85 |

| 8 | Hempseed | CN110150391 (A) | China | Sport drink | Liquid |

- Basic/acid protein precipitation; - Formula composition. |

86 |

| 9 | Hempseed | BR112015001964 (A2) | Brazil | Sport drink, protein-rich beverage, carbonated beverage, acid beverage | Powder or liquid |

- Calcium salt protein precipitation; - Drying and diafiltration. |

87 |

| 10 | Moringa oleifera seed | CN110856518 (A) | China | Functional beverage | Liquid |

- Ethanol and aqueous extraction; - Vacuum drying. |

88 |

| 11 | Pepper seed | CN110463818 (A) | China | Protein-rich beverage | Powder |

- Alkaline protein precipitation; - Culture and fermentation; - Enzymolysis; - Spray drying. |

89 |

| 12 | Physalis seed | CN110432333 (A) | China | Beverage (without specification) | Powder | - Milling and baking the seeds. | 90 |

| 13 | Pumpkin seed | RU2590736 (C1) | Russian Federation | Milk analog | Powder |

- Natural antibiotic solution maceration; - Drying and milling. |

91 |

| 14 | Pumpkin seed | BRPI0110757 (B1) | Brazil | Beverage (without specification) | Powder or liquid | - Formula composition. | 92 |

| 15 | Rapeseed | AR097442 (A2) | Argentina | Sports drink, protein-rich beverage | Powder | - Basic/acid protein precipitation. | 93 |

| 16 | Rapeseed | BRPI0308380 (B1) | Brazil | Protein-rich beverage, fermented beverage/yogurt analog | Powder | - Drying the supernatant of a protein micelles dispersion | 94 |

| 17 | Rapeseed | BR112012008321 (A2) | Brazil | Sports drink, carbonated beverage, juice, alcoholic beverage | Powder or liquid | - Supernatant heat treatment or isoelectric precipitation extraction. | 95 |

| 18 | Rapeseed | US2020154732 (A1) | United States of America | Protein-rich beverage | Powder | - Basic/acid protein precipitation. | 96 |

| 19 | Rapeseed | CN107873944 (A) | China | Functional beverage | Powder |

- Enzymolysis; - Spray drying. |

97 |

| 20 | Rapeseed | WO2019234137 (A1) | World Intellectual Property Organization | Protein-rich beverage | Powder |

- Basic/acid protein precipitation; - Formula composition. |

98 |

| 21 | Rapeseed | BRPI0913429 (A2) | Brazil | Carbonated beverage, sports drink, juice, protein-rich beverage | Powder or liquid | - Supernatant heat treatment or isoelectric protein precipitation. | 99 |

| 22 | Rapeseed | BRPI0917301 (A2) | Brazil | Protein-rich beverage | Powder | - Basic/acid protein precipitation. | 100 |

| 23 | Rapeseed | BRPI0917304 (A2) | Brazil | Protein-rich beverage, carbonated beverage, sport drink | Powder |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

101 |

| 24 | Rapeseed | PL2323499 (T3) | Poland | Protein-rich beverage, acid beverage, carbonated beverage, sport drink | Powder |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

102 |

| 25 | Rapeseed | BRPI1012171 (A2); BRPI1012171 (B1) | Brazil | Protein-rich beverage, acid beverage, carbonated beverage, sport drink | Powder |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

103 |

| 26 | Rapeseed | BRPI0915489 (A2); BRPI0915489 (B1) | Brazil | Protein-rich beverage, carbonated beverage, acid beverage | Powder or liquid |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

104 |

| 27 | Rapeseed | BRPI0917295 (A2) | Brazil | Sports drink, protein-rich beverage, carbonated beverage, acid beverage | Powder |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

105 |

| 28 | Rapeseed | EP3481220 (A1) | European Patent Office | Beverage (without specification), fermented beverage/yogurt analog | Powder |

- Basic/acid protein precipitation; - Drying. |

106 |

| 29 | Rapeseed | WO2019110556 (A1) | World Intellectual Property Organization | Protein-rich beverage, fermented beverage/yogurt analog, juice, milk analog | Powder |

- Basic/acid protein precipitation; - Drying. |

107 |

| 30 | Rapeseed, mustard seed, broccoli seed, linseed, cottonseed, hempseed, safflower seed, or sesame seed | HUE033952 (T2) | Hungary | Protein-rich beverage, carbonated beverage, sport drink, milk analog, juice, infant formula | Powder |

- Organic solvent or aqueous extraction; - Basic/acid protein precipitation; - Drying. |

108 |

| 31 | Rapeseed, mustard seed, broccoli seed, linseed, cottonseed, hempseed, safflower seed, sesame seed | PL2498620 (T3) | Poland | Milk analog, protein-rich beverage, carbonated beverage, sports drink, juice, infant formula | Powder |

- Organic solvent or aqueous extraction; - Low g-force centrifugation. |

109 |

| 32 | Samara seed | CN104543326 (A) | China | Beverage (without specification) | Powder | - Supercritical carbon dioxide extraction. | 110 |

| 33 | Sesame seed | CN109430515 (A) | China | Fermented beverage/yogurt analog | Powder or liquid |

- Alkaline protein precipitation; - Fermentation; - Drying. |

111 |

| 34 | Sesame seed | CN110810687 (A) | China | Beverage (without specification) | Liquid |

- Enzymolysis; - Centrifugation. |

112 |

| 35 | Snake gourd seed | CN105192244 (A) | China | Beverage (without specification) | Powder or liquid |

- Cold-pressed technique; - Enzymolysis; - Centrifugation; - Ultrafiltration; - Concentration and desiccation. |

113 |

| 36 | Sunflower seed | HUE029430 (T2) | Hungary | Milk analog | Powder | - Heated pressed technique. | 114 |

| 37 | Sunflower seed | CN109354574 (A) | China | Milk analog | Powder |

- Supercritical carbon dioxide extraction; - Ethanol extraction; - Microwave extraction; - Ultrasonic extraction; - Basic/acid protein precipitation; - Spray drying. |

115 |

| 38 | Sunflower seed and/or cottonseed and/or rapeseed and/or coconut | CN110678083 (A) | China | Beverage (without specification) | Powder or liquid | - Formula composition. | 116 |

| 39 | Sunflower seed or rapeseed | RU2538147 (C1) | Russian Federation | Beverage (without specification) | Powder |

- Basic/acid protein precipitation; - Drying and granulation. |

117 |

| 40 | Thistle seed | CN109266432 (A) | China | Beverage (without specification) | Powder or liquid |

- Enzymolysis; - Centrifugation. |

118 |

| 41 | Walnut | CN209711374 (U) | China | Beverage (without specification) | Powder |

- Alkaline protein precipitation; - Centrifugation; - Spray drying. |

119 |

Based on the results, rapeseed was the most used seed, since it was the preferable raw material in 25 patents (Table 1). Rapeseed ranks second position of the major oilseed cultivated worldwide, it just loses its position to soybean30. Rapeseed and “canola” are the common names given to species Brassica napus L., Brassica rapa L., and Brassica juncea L; however, the name “canola” only refers to rapeseed varieties presenting less than 2% erucic acid and meal accounting for less than 30 μmol/g total glucosinolates. The crude protein in rapeseed meals ranges from 35 to 40%. At least 40 different protein fractions can be found in this total, but cruciferin, napin, and oleosin are the most investigated ones5. Cruciferin and napin are the main storage proteins, they account for 60 and 20% of the protein content in rapeseeds, respectively26. Oleosin presents structural proteins associated with oil components31. Although rapeseed has lower sulfur-amino acid levels5, canola meal has better amino acid profile than soybean. Nevertheless, canola proteins present many antinutritional factors, as among them glucosinolates, phenolics, phytates, as well as a large amount of fibers capable of compromising digestibility, color, taste, and physicochemical properties29. This finding explains some authors’ interest in patenting inventions that can solve these problem. Patents WO2019110556 (A1) and EP3481220 (A1) explain how to isolate inherently sweet rapeseed proteins presenting low content of antinutritional factors and high solubility, which can be used to reduce the amount of sucrose in beverages, and simultaneously increase protein content in the product. Likewise, BRPI0917295 (A2) provides rapeseed protein isolate that is soluble and stable not only in acid pH but also at higher temperatures. At the moment, Burcon® is the only manufacturer of high-purity canola protein in the world32,33, despite the potential of this raw material.

Hemp (Cannabis sativa L.) was the preferable raw material in 11 patents (Table 1). It is mainly cultivated for the industrial use of its seeds, fibers, oil, and meal34. At the moment, hemp is at the mainstream, since it is a sustainable crop that does not require fertilizers, herbicides, and pesticides35. Hemp can be legally cultivated for industrial purposes in most countries worldwide, when it has up to 0.3% of its main psychoactive compound: delta-9-tetrahydrocannabinol (THC)26. Hemp seeds are rich in phytosterols (ω-3 and ω-6) and have ~25% of proteins in its dry weight35. Approximately 65% of the total hemp protein comprises a single globular storage protein: edestin; on the other hand, the albumin fraction consists of 25% of storage proteins26. Although it has low lysine content15, hempseed protein contains all the essential amino acids and accounts for low amount of antinutritional factors, such as trypsin inhibitor; therefore, it presents high-degree digestibility35. Hempseed protein can be appropriate for athletes and infants, for example, given their quality. Patent BR112015001964 (A2) provides a hempseed protein that is completely soluble in acid beverages (lower than 4.4 pH), without the need of stabilizers or additives. Thus, it can be used for protein fortification in soft and sports drinks, as well as in other aqueous systems. Similarly, CN110150391 (A) disclosed a canned beverage for athletes made with hempseed albumins, which is even better absorbed by the organism than the whole hempseed protein. US2015079235 (A1) proposed hempseed protein using as the main ingredient in an alternative infant formula, which can be either powdered or liquid. Currently, Axiom Foods® and Good Hemp®, which offer products with 58 and 85% purity, respectively, are among the hempseed protein suppliers in the world36,37. Also, Manitoba Harvest® and LeanHemp® are brands focusing on the hempseed protein supplement segment38,39.

Ten patents used Sunflower (Helianthus annuus L) as preferable raw material (Table 1). This species is one of the most cultivated oilseed crops40; its seed meal can reach 40% protein content when it is mechanically extracted, and 50% protein content when the oil is extracted with organic solvents5. Approximately 85% of the total protein content in sunflower seeds is found in the form of storage proteins (11S helianthinin globulin and 2S albumins)26. Globulin content varies from 40 to 90%, whereas albumin rate ranges from 10 to 30% of the total protein found in seeds. It is possible observing differences in the ratio of these protein fractions since three different sunflower seed types are majorly cultivated—they are used for oil production, human and pet consumption, and ornamentation5. Despite its low lysine content, sunflower meal remains a good protein source, given its high digestibility and smaller number of antinutritional compounds41. Although sunflower seed proteins have low functionality, such a feature is closely linked to denaturation caused by heating at oil extraction, rather than to native proteins themselves. Moreover, phenolic compounds found in sunflower seeds, such as chlorogenic acid, can crosslink with proteins and change its color, functionality, and bioavailability. However, chlorogenic acid is also beneficial for human health40 and can be desirable when it is properly extracted from sunflower seed meal. Patent CN109354574 (A) improved a method by using supercritical carbon dioxide extraction to prepare chlorogenic acid and protein powder from sunflower seeds, in separate. This powder is an interesting raw material for making artificial milk and beverages due to its soft flavor. Similarly, FI128029 (B) addresses a sunflower seed protein with enhanced solubility and low phytate content. Its powder is a suitable ingredient for dairy alternatives. Following functionality improvements, BR112018070543 (A2) used enzymatic treatment, heating, fermentation, and pressure treatment to increase the techno-functional and organoleptic properties of sunflower seed protein, which is useful as a beverages’ supplement. Presently, Biotechnologies® is the only world sunflower seed protein producer whose product has more than 80% purity42; However, it is possible finding other suppliers whose products reach about 50% protein content, among them one finds Austrade Inc® and ETChem[®43,44.

Based on the results, cottonseed was the preferable raw material in seven patents (Table 1). Fiber is the most common product made out of cotton; however, cottonseed has great potential as protein source, for both animal and human consumption45. Cottonseed meal has ~30 to 50% total protein46. Arginine has the highest content (22–34%) of essential amino acids, whereas cysteine accounts for the lowest one (1–2%)47. Cottonseed meal is a good protein source for ruminants, but it is not appropriate without treatment for monogastric animals, including humans, who do not tolerate high fiber contents and antinutritive compounds, such as gossypol, phytin, and cyclopropane fatty acids46. In total, 80% of defatted cottonseed is used as substrate for edible mushroom crops or as fertilizer, but only 5 to 10% of it is used for animal feeding purposes, a fact that causes huge protein waste48. The appropriate extraction of these proteins from the meal is a feasible option to solve this problem. Patents HUE033952 (T2) and PL2498620 (T3) disclosed enhanced methods to produce high-quality protein concentrates and isolates from oilseed meals, including cottonseed, which has incredibly low fiber content and antinutritional factors. These concentrates and isolates are useful as powdered milk analog or to increase protein content of juices, soft drinks, sports drinks, and beverages in general. RU2018129466 (A) disclosed a method to extract cottonseed proteins that can fortify beverages as well. When it is compared to other patents, it also has the advantage of not presenting beany or grassy flavor notes. Nevertheless, so far, cottonseed protein suppliers in the market only provide to animal feeding, they still do not focus on human nutrition.

Legumes and pulses

Legumes are the most consumed staple food after cereals, since they are a low-priced source of nutrients, mainly of proteins; therefore, they are seen as “meat for poor men”14,15. In botanical terms, legumes belong to the family Leguminosae, which also comprises pulses. All pulses are legumes, although not all legumes are pulses. Based on the Food and Agriculture Organization definition, pulses are only dried edible leguminous presenting low oil content. Consequently, legumes harvested in green forms, such as green beans and green peas, are not included in this group. Furthermore, soybeans and peanuts, which are oil-rich, are also excluded from it. Lastly, crops used for sowing purposes, such as alfalfa and clover, are not pulses49. Pulses are good energy, fiber, vitamin, mineral, and bioactive compound sources, and besides, ~30% of pulses’ dry bases are proteins50. In addition to their nutritional importance, pulses have the good nitrogen-fixing capacity and are beneficial to soil fertility and the environment51. Some native pulses and legumes’ proteins are promising to the beverage industry due to their functional features, such as solubility, emulsifying, and foaming proprieties50. However, depending on the species and on the protein extraction method, beverages made with these proteins also show beany flavor, bitter taste, or sandy mouthfeel4,14,15 —these factors limit their acceptance by consumers. Another disadvantage of these proteins lies in the fact that different procedures must be followed in order to reduce antinutritional factors and nonprotein compounds from pulses and legumes. Although, isolate proteins extracted from legumes and pulses remain in the mainstream of researchers and patent applicants as they are an economical, ecological, nutritive, and gluten-free raw material used to enrich products50. Enzymolysis and protein precipitation using an alkaline, acid, or salted solution were the preferable protein extraction methods applied, commonly followed by a specific filtration and drying technique (Table 2).

Table 2.

Patents that use legumes and/or pulses as preferable raw material.

| # | Preferable raw material | Publication number | Origin | Beverage type | Presentation form | Protein extraction methods and technologies applied | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Alfalfa, lentil, bean, pea, lupine, locust bean, peanut, tamarind, wisteria, chickpea, fenugreek, or combinations thereof | US2019000112 (A1) | United States of America | Milk analog, fermented beverage/yogurt analog, protein-rich beverage, sports drink, infant formula | Powder or liquid |

- Basic/acid protein precipitation; - Salt protein precipitation; - Formula composition. |

120 |

| 2 | Bean and/or pea and/or chickpea and/or lentil | EP3573471 (A1) | European Patent Office | Milk analog | Powder |

- Enzymolysis; - Centrifugation; - Spray drying. |

121 |

| 3 | Black bean or pea | US2019133150 (A1) | United States of America | Protein-rich beverage | Powder or liquid |

- Freezing raw material; - Grinding. |

122 |

| 4 | Black-eyed pea | US2019239535 (A1) | United States of America | Acid beverage, carbonated beverage, protein-rich beverage, functional beverage, fermented beverage/yogurt analog | Powder or liquid |

- Wet grinding; - Basic/acid protein precipitation. |

123 |

| 5 | Broad bean | WO2020051622 (A1) | World Intellectual Property Organization | Protein-rich beverage | Powder |

- Milling; - Hydrating; - Filtrating; - Pasteurizing milk-like fluid. |

124 |

| 6 | Chickpea | JP2019520082 (A) | Japan | Milk analog | Powder |

- Basic/acid protein precipitation; - Ultrafiltration; - Evaporation. |

125 |

| 7 | Hyacinth bean | CN104774271 (A); CN104774271 (B) | China | Beverage (without specification) | Powder |

- Acidic protein precipitation; - Enzymolysis; - Centrifugation; - Drying. |

126 |

| 8 | Kidney bean, red bean, and peanut | KR102092404 (B1); KR20200013276 (A) | Republic of Korea | Milk analog | Liquid | - Formula composition. | 127 |

| 9 | Lentil | EP3209141 (A1); EP3209141 (B1) | European Patent Office | Beverage (without specification) | Powder or liquid | - Formula composition. | 128 |

| 10 | Lentil, chickpea, pea, or bean | WO2020061698 (A1) | World Intellectual Property Organization | Milk analog | Powder or liquid |

- Basic/acid protein precipitation; - Heating; - Drying. |

129 |

| 11 | Lentil, chickpea, pea, or bean | BR112015007140 (A2) | Brazil | Sports drink, protein-rich beverage, acid beverage, carbonated beverage, milk analog | Powder |

- Calcium salt protein precipitation; - Diafiltration and drying. |

130 |

| 12 | Lentil, chickpea, pea, or bean | KR20190087654 (A) | Republic of Korea | Protein-rich beverage | Powder |

- Calcium salt protein precipitation; - Drying. |

131 |

| 13 | Lentil, chickpea, pea, or bean | EP3586644 (A1) | European Patent Office | Protein-rich beverage, carbonated beverage, milk analog | Powder or liquid |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

132 |

| 14 | Lentil, chickpea, pea, or bean | JP2018110600 (A) | Japan | Protein-rich beverage, acid beverage, carbonated beverage, sport drink | Does not specify |

- Calcium salt protein precipitation; - Acidic protein precipitation; - Diafiltration and drying. |

133 |

| 15 | Lupine | CA2953644 (A1) | Canada | Milk analog, fermented beverage/yogurt analog | Liquid | - Supercritical carbon dioxide extraction. | 134 |

| 16 | Lupine | RU2555528 (C1) | Russian Federation | Fermented beverage/yogurt analog | Liquid |

- Acidic protein precipitation; - Enzymolysis; - Pasteurizing. |

135 |

| 17 | Mung bean | US2019191735 (A1) | United States of America | Protein-rich beverage, milk analog, fermented beverage/yogurt analog | Powder or liquid |

- Basic/acid protein precipitation; - Ultrafiltration. |

136 |

| 18 | Mung bean | JP6521257 (B2); JPWO2015105138 (A1) | Japan | Protein-rich beverage | Powder | - Formula composition. | 137 |

| 19 | Mung bean | JP6332266 (B2); JPWO2014156549 (A1) | Japan | Fermented beverage/yogurt analog | Gel | - Formula composition. | 138 |

| 20 | Mung bean | CN106261782 (A) | China | Fermented beverage/yogurt analog | Powder |

- Fermentation; - Drying. |

139 |

| 21 | Mung bean and/or chickpea and/or pea | CA2982280 (A1) | Canada | Milk analog | Liquid | - Formula composition. | 140 |

| 22 | Pea | MX2018012893 (A) | Mexico | Fermented beverage/yogurt analog | Liquid |

- Acidic protein precipitation; - Fermentation. |

141 |

| 23 | Pea | CA3067593 (A1) | Canada | Sports drink, carbonated beverage, juice, alcoholic beverage | Powder or liquid | - Formula composition. | 142 |

| 24 | Pea | WO2020007940 (A1) | World Intellectual Property Organization | Sport drink, protein-rich beverage, infant formula | Powder | - Formula composition. | 143 |

| 25 | Pea | FR3047151 (A1) | France | Protein-rich beverage, sport drink | Powder or liquid | - Formula composition. | 144 |

| 26 | Pea | BR112019022289 (A2) | Brazil | Protein-rich beverage, milk analog | Liquid |

- Basic/acid protein precipitation; - Drying. |

145 |

| 27 | Pea | CN107668314 (A) | China | Functional beverage | Powder |

- Enzymolysis; - Centrifugation; - Spray drying. |

146 |

| 28 | Pea | US2016316785 (A1) | United States of America | Fermented beverage/yogurt analog, juice, alcoholic beverage | Powder |

- Acidic protein precipitation; - Heating. |

147 |

| 29 | Pea | FR3070831 (A1) | France | Sports drink, protein-rich beverage, infant formula | Liquid | - Formula composition. | 148 |

| 30 | Pea | CN109907156 (A) | China | Functional beverage | Powder | - Enzymolysis. | 149 |

| 31 | Pea | MX2018010758 (A) | Mexico | Fermented beverage/yogurt analog, coffee whitener, protein-rich beverage | Powder or liquid |

- Basic/acid protein precipitation; - Pasteurizing; - Spay drying. |

150 |

| 32 | Pea | CO2020004049 (A2) | Colombia | Beverage (without specification) | Powder |

- Isoelectric protein precipitation; - Ultrafiltration. |

151 |

| 33 | Pea | CA3079976 (A1) | Canada | Protein-rich beverage, juice | Powder or liquid | - Enzymolysis. | 152 |

| 34 | Pea | US2019053517 (A1) | United States of America | Beverage (without specification) | Powder | - Enzymolysis. | 153 |

| 35 | Pea | CN109566747 (A) | China | Fermented beverage/yogurt analog | Liquid |

- Enzymolysis; - Basic/acid protein precipitation; - Fermentation. |

154 |

| 36 | Pea | BR112019018323 (A2) | Brazil | Acid beverage | Powder | - Acidic protein precipitation. | 155 |

| 37 | Pea | ES2676925 (T3) | Spain | Sport drink | Powder |

- Cetrifugation; - Ultrafiltration. |

156 |

| 38 | Pea | CN109907155 (A) | China | Functional beverage | Powder |

- Basic/acid protein precipitation; - Enzymolysis; - Spray drying. |

157 |

| 39 | Pea | EA030803 (B1); EA201691510 (A1) | Eurasian Patent Organisation | Carbonated beverage, juice | Does not specify | - Adsorbent resin extraction. | 158 |

| 40 | Pea | WO2020109741 (A1) | World Intellectual Property Organisation | Acid beverage, carbonated beverage | Powder |

- Enzymolysis; - Drying. |

159 |

| 41 | Pea | US2020100524 (A1) | United States of America | Fermented beverage/yogurt analog, milk analog, sports drink, carbonated beverage, acid beverage, protein-rich beverage | Powder |

- Basic/acid protein precipitation; - Enzymolysis; - Ultrafiltration. |

160 |

| 42 | Pea | CA3008464 (A1) | Canada | Milk analog, fermented beverage/yogurt analog | Powder or liquid |

- Acidic protein precipitation. - Enzymolysis; - Ultrafiltration. |

161 |

| 43 | Pea | CN111066944 (A) | China | Beverage (without specification) | Does not specify | - Formula composition. | 162 |

| 44 | Pea, lentil, chickpea, peanut, pinto bean, Great Northern bean, navy bean, red bean, black bean, kidney bean, broad bean, baby lima bean, pink bean, mayocoba bean, black-eyed pea, cranberry bean, white bean, rice bean, butter bean, or combinations thereof | US2017087209 (A1) | United States of America | Iron-rich beverage | Powder or liquid |

- Salt protein precipitation; - Enzymolysis; - Filtration. |

163 |

| 45 | Peanut | CN106260496 (A) | China | Beverage (without specification) | Powder |

- Basic/acid protein precipitation; - Drying. |

164 |

| 46 | Peanut | CN106367196 (A); CN106367196 (B) | China | Beverage (without specification) | Powder | - Formula composition. | 165 |

| 47 | Peanut | CN107927319 (A) | China | Juice | Liquid | - Enzymolysis. | 166 |

| 48 | Peanut | CN110140801 (A) | China | Juice | Powder or liquid |

- Enzymolysis; - Spray drying. |

167 |

| 49 | Peanut | US2020170279 (A1) | United States of America | Beverage (without specification) | Does not specify |

- Basic/acid protein precipitation; - Heating; - Enzymolysis; - Centrifugation. |

168 |

| 50 | Peanut | CN106333057 (A) | China | Milk analog | Powder |

- Low temperature basic/acid protein precipitation; - Spray drying. |

169 |

| 51 | Peanut | FR3072002 (A1); FR3072002 (B1) | France | Fermented beverage/yogurt analog | Gel | - Enzymolysis. | 170 |

Pea was the most used raw material in the herein assessed patents, it was the preferable raw material in 43 patents (Table 2). Pea is an ancient crop widely grown in different countries50. At the moment, pea stands out for its properties similar to those of soybean protein; therefore, it presents great potential to replace this protein, since soybean is often associated as allergenic13. Emulsification, foaming, and gelling are some of these properties, for instance14. Pea has 23 to 31% total protein, and 50 to 85% are globulins (legumin, vicilin, and convicilin), while 15 to 25% are albumins50. Arginine, phenylalanine, leucine, and isoleucine are among the essential amino acids commonly found in the globulin proteins, whereas tryptophan, lysine, threonine, cysteine, and methionine are found in the albumin ones52. Overall, the amino acid profile is well-balanced and the high lysine content is notable13. Even so, the bitter taste intrinsic to pea flour produced through dry milling can be transferred to final products. Patent CA3067593 (A1) disclosed methods to produce pea flour, concentrate or isolate with low nonvolatile flavor compound contents, specifically bound saponin, in order to solve this problem. This process consists of steam cooking and drying a raw pea slurry to produce a bitterless flour that can be used in beverages. Similarly, FR3070831 (A1) used sodium citrate and heating to partially or fully reduce the bitterness of pea protein compositions. Fermentation can also improve flavor; therefore, yogurt-like products are a good option to be made of pea protein, as proposed by CN109566747 (A). Pea protein has been consolidated in the market by world suppliers such as Roquette®, Burcon®, Axiom Foods®, AMCO Proteins®, Ingredion®, Cargill®, and Farbest[®53–59. Pea protein milk and yogurt are already available and provided by Ripple® and Siggi’s®, respectively60,61.

Based on the results, bean was the preferable raw material in 21 patents (Table 2). Common beans belonging to the family Leguminosae and to genus Phaseolus account for one-third of global pulses production62. There are more than 14,000 known different common bean cultivars. Peculiarities of local culture, agriculture, and history influence the mostly consumed beans. Variations on beans’ size, shape, and colors can occur, as well as on their composition and physicochemical features, but these differences tend to be nonsignificant63. Overall, dry beans are an important source of proteins—its protein rate ranges from 16 to 33%50. Albumins account for up to 10–30% of total protein content on dry weight basis, whereas globulins account for 45–70% of it52. Phaseolin and lectin are other important protein fractions found in beans50. Although the protein content in beans is significant, it shows some drawbacks, since beans have methionine as limiting amino acid and antinutritional factors are observed in them62. These factors can be removed from pulses through a simple fermentation process; consequently, it increases the quality of pulses’ proteins15. Patent JPWO2014156549 (A1) disclosed methods to produce a gel by adding alkali metal ions to mung bean protein and by fermenting it. The produced composition can be used as yogurt analog. Similarly, CN106261782 (A) used biological mung bean fermentation to separate protein, starch, fiber, and slurry, and to provide different products, such as instant tablet beverage and fermented drink. Once more, to reduce antinutritional factors, KR20190087654 (A) developed a bean protein presenting low phytic acid content by using calcium salt to precipitate it. At the moment, It is possible finding 80% purity mung bean and fava bean protein suppliers, as among them one finds ETProtein® and Atura®, respectively64,65. The brand Green Boy® also offers powdered proteins extracted from these same bean species66,67. Nancy’s® produces yogurts with different flavors, all made of fava bean protein68.

In total, 18 patents were related to peanut’s use as preferable raw material (Table 2). Peanut accounts for 11% of the global protein supply69; it has been gaining more popularity due to its resistance to climate changes8, as well as because it is a cheap source of high-quality protein. Deffated meal, which is a by-product by the peanut industry, has ~50–55% protein and balanced amino acid profile70; therefore, it can be easily used as raw material to produce protein isolates71. Peanut proteins are often classified as albumins and globulins. Arachin and conarachin are the main globulins, and both of them are rich in lysine, tryptophan, tyrosine, and phenylalanine69. Peanut protein is often nutritionally comparable to animal protein72, mainly after fermentation, since this process increases its l-lysine, l-methionine, and l-tryptophan contents1. However, its allergenicity69 and poor functional proprieties hamper peanut protein use by the food industry70. Different treatments, such as chemical, physical, or enzymatic methods, have been applied to expand peanut protein functionality. Patent CN106260496 (A) disclosed an improved ultrasonic treatment applicable to peanut protein that provides better solubility, higher yield, and efficiency, as well as environmental protection, when compared to the state of the art. FR3072002 (A1) addresses a stable gel that can be produced by improving peanut protein solubility followed by adding transglutaminase to it. This gel is highly useful to produce yogurts. According to CN106367196 (A), it is possible obtain peanut protein that presents stability in beverages by preventing its denaturation during the extraction process. High-purity peanut protein isolates or concentrates are not in the market yet; however, deffated peanut powder is already provided by ETChem® and Peanut Butter & Co®, for example73,74.

Based on the results, chickpea was the preferable raw material in 12 patents (Table 2). It is the second mostly produced legume worldwide and its protein amount ranges from 15 to 30%. Globulins (53 to 60%) and glutelins (19 to 25%) are the main protein fractions in chickpea, but albumins (8 to 12%), and prolamins (3 to 7%) are also relevant in it50. Although chickpea lacks sulfured amino acids52, it has low content of antinutritional factors and, consequently, high bioavailability of other essential amino acids14. Blend chickpea with other pulses that do not lack sulfured amino acids is an interesting solution to its limiting amino acids issue, so the quality of the protein in the final product increases significantly. Patent CA2982280 (A1) provided a method to produce an alternative to milk by using chickpea and/or pea protein as main ingredients. Moreover, the disclosed product has a smooth mouthfeel and does not necessarily need gum, emulsifier, or starch to be added to the formulation. On the other hand, EP3586644 (A1) and WO2020061698 (A1) focused on the production of pulse proteins, including chickpea. These proteins are stable both in hot and acid aqueous environments. Among chickpea proteins available in the market, finds the ones by Innovopro® and Atura®, which sell products with 70 and 80% protein contents, respectively75,76. The brand Green Boy® also has chickpea and other different plant-based proteins in its portfolio.

Other mixes

The group “other mixes” regards patents that used either seeds, nuts, legumes, pulses, cereals, seaweeds, fungus, or combinations of these elements. These combinations include blended products to reach a better amino acid score and to optimize the functional and sensorial features of final product. Such an outcome can be obtained through the interaction of proteins from different plant sources (Table 3).

Table 3.

Patents that use other mixes as preferable raw material.

| # | Preferable raw material | Publication number | Origin | Beverage type | Presentation form | Protein extraction methods and technologies applied | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Alfalfa and/or wheat | WO2019150144 (A1) | World Intellectual Property Organization | Sport drink | Powder |

- Heating - Microwave extraction; - Filtration. |

171 |

| 2 | Almond, cashew nut, Brazil nut, coconut, hazelnut, macadamia, peanut, walnut, or pistachio | CN110742128 (A) | China | Fermented beverage/yogurt analog | Liquid |

- Enzymolysis; - Centrifugation; - Fermentation. |

172 |

| 3 | Cashew nut and/or almond and/or peanut and/or pea and/or oat and/or wheat and/or quinoa | EP3429366 (A1) | European Patent Office | Milk analog | Liquid | - Formula composition. | 173 |

| 4 | Chia seed and/or pumpkin seed and/or hempseed and/or almond and/or macadamia and/or lentil and/or pea and/or chickpea and/or mung bean and/or rice | US2019225645 (A1) | United States of America | Sports drink, protein-rich beverage, infant formula | Does not specify | - Formula composition. | 174 |

| 5 | Does not specify | CN110637916 (A) | China | Fermented beverage/yogurt analog | Powder | - Fermentation. | 175 |

| 6 | Does not specify (Legume and/or seed and/or cereal and/or seaweed) | JP2017521498 (A) | Japan | Carbonated beverage, juice, milk analog, sports drink, functional beverage, fermented beverage/yogurt analog, alcoholic beverage | Powder or liquid |

- Heating; - Enzymolysis; - Nanofiltration; - Spray drying. |

176 |

| 7 | Does not specify (Legume and/or seed and/or seaweed and/or fungus | EP3634146 (A1) | European Patent Office | Protein-rich beverage, milk analog, coffee whitener, fermented beverage/yogurt analog, sport drink, juice | Powder or liquid |

- Ultrasonication; - Filtration. |

177 |

| 8 | Pea and coconut | US2019307143 (A1) | United States of America | Coffee whitener | Liquid | - Isoelectric protein precipitation or enzymolysis. | 178 |

| 9 | Pea and rice | CN111227101 (A) | China | Beverage (without specification) | Powder | - Formula composition. | 179 |

| 10 | Pea and/ or lupine and/or broad bean and/or rapeseed and/or turnip seed and/or sunflower seed | FI128029 (B) | Finland | Milk analog | Does not specify | - Formula composition. | 180 |

| 11 | Pea and/or rice and/or oat | FR3085826 (A3) | France | Beverage (without specification) | Powder | - Formula composition. | 181 |

| 12 | Pea and/or wheat and/or oat | WO2019228957 (A1) | World Intellectual Property Organization | Beverage (without specification), carbonated beverage, juice, alcoholic beverage | Powder or liquid | - Formula composition. | 182 |

| 13 | Pea or lupine or bean or chickpea or lentil or peanut or sunflower seed or rapeseed or camelina seed or linseed | BR112018070543 (A2) | Brazil | Milk analog, fermented beverage/yogurt analog | Powder |

- Organic solvent extraction; - Enzymolysis; - Heating; - Fermentation. |

183 |

| 14 | Pea or rice | BR112019019992 (A2) | Brazil | Infant formula | Powder or liquid |

- Enzymolysis; - Centrifugation; - Nanofiltration; - Pasteurizing; - Spay drying. |

184 |

| 15 | Pea, walnut, almond, cashew nut, hempseed, or rice | US2020060310 (A1) | United States of America | Milk analog, fermented beverage/yogurt analog, protein-rich beverage | Powder | - Formula composition. | 185 |

| 16 | Peanut and moringa oleifera seed | FR3019004 (A1); FR3019004 (B1) | France | Juice | Powder |

- Enzymolysis; - Heating; - Acidic protein precipitation; - Drying. |

186 |

| 17 | Peanut, rapeseed, sesame seed, linseed, sunflower seed, cottonseed, safflower seed, perilla seed, castor bean coconut, cocoa seed, almond, tung seed, sesame seed, primula seed, hazelnut, pumpkin seed, walnut, grape seed, sea buckthorn seed, tomato seed pumpkin seed, macadamia, oat, corn, rice, wheat, seaweed, or combinations thereof | CN107125430 (A) | China | Fermented beverage/yogurt analog | Powder or liquid | - Enzymolysis. | 187 |

| 18 | Rapeseed, sunflower seed, hempseed, safflower seed, cottonseed, linseed, sesame seed, mustard seed, peanut | RU2018129466 (A) | Russian Federation | Protein-rich beverage | Powder |

- Acidic protein precipitation; - Diafiltration; - Drying. |

188 |

| 19 | Sunflower seed, cottonseed, rapeseed, coconut, peanut | WO2020028446 (A1) | World Intellectual Property Organization | Protein-rich beverage | Powder | - Formula composition. | 189 |

| 20 | Sunflower seed, cottonseed, rapeseed, coconut, peanut, locust bean, or combinations thereof | US10645950 (B2); US2020060308 (A1) | United States of America | Beverage (without specification) | Powder or liquid | - Formula composition. | 190 |

| 21 | Wheat and/or barley and/or corn and/or pea and/or rice | JP6059659 (B2); JPWO2013027813 (A1) | Japan | Carbonated beverage, alcoholic beverage | Does not specify |

- Enzymolysis; - Fermentation. |

191 |

FR3085826 (A3) disclosed a powder ready to be reconstituted in water or plant-based milk. This process uses proteins from peas, rice, oats, or from their mixes. Similarly, EP3429366 (A1) divulges a replacement for dairy milk, which is made of peanut protein—but it can also be made of cashew nut, almond, pea, oat, wheat, quinoa, or of combinations of these elements.

In regard to functional improvements, CN111227101 (A) provided an instant powdered beverage that can be composed of pea and rice proteins, which shows excellent solubility in hot water (≥85 °C). JPWO2013027813 (A1) presented a beer-like product with increased foam stability that was produced with protease, transglutaminase, and with one or more proteins from wheat, barley, corn, pea, or rice.

Focusing on sensorial aspects, WO2019228957 (A1) described a method to mask undesirable notes from beverages made of pea, wheat, or oat protein when ethyl cyclohexanoate was used as additive. EP3634146 (A1) suggested the application of ultrasound and membrane filtration processes in proteins from legumes, seeds, seaweeds, or fungus to obtain a clean taste and neutral color product that can be used to enrich a wide range of beverages.

A huge variety of blended products has been introduced in the market. The supplier Burcon® developed a combination of pea and canola proteins, which is nutritionally and functionally better than when these proteins are used separated. The brand Orgain® offers a blend of deffated peanut powder, pea protein, pumpkin seed protein, and almond protein77, while Manitoba Harvest® commercializes a mix of pea and hemp proteins, which is ideal to be added to smoothies or nondairy milks78.

Conclusion

Plant proteins extraction to enrich plant-based beverages has recently emerged as solution to lack of this nutrient in these products. However, some other factors, such as poor solubility, off-flavor notes, limiting amino acids, and anti-nutrients remains an issue. Chemical, physical, biological, and enzymatic treatments were reported in patents to solve these problems. Among them, acidification, basification, heating, membrane filtration, centrifugation, ultrasonication, fermentation, or combinations thereof were frequently applied, with the specificity and uniqueness methodology of each patent. Moreover, it has been comprehended that each step of industrial processes, since protein extraction to its incorporation to final products, have huge influence on their nutritional, sensorial, and functional features. Pea, rapeseed, bean, peanut, chickpea, hempseed, sunflower seed, and cottonseed were the most addressed raw materials in the herein assessed patents. Protein blends also emerged as simple alternatives to improve amino acid profile, as well as the functional and sensorial aspects of beverages. Expansion in the use of plant proteins to enrich multiple categories of beverages is another tendency observed. These beverages include sport drinks, carbonated beverages, or even juices, not limited to products that mimic dairy. Briefly, research and development based on plant-based protein have been playing important role in the production of beverages by fulfilling the existing demands from vegetarians, lactose intolerants, and cow milk allergic individuals, but also by turning these products into a suitable option for a wide range of other consumers, such as infants, elderly, athletes, or those who chose a healthier lifestyle. Thus, plant proteins are a promising ingredient to create high-quality beverages, ensuring animal welfare, reducing environmental impact, and guarantying food security if proper technology is applied to them.

Acknowledgements

The icons bottle plant, milk analog, sport drink, lemon juice, infant formula, functional beverage, tamarind, lupin, beans, chickpea, walnut, pistachio, coconut, almond, fungus, seaweed, and cereal were made by Freepik; lentils and cocoa icons were made by Vitaly Gorbachev; pea icon was made by Darius Dan; peanut icon was made by Monkik; hazelnut icon was made by Eucalyp; protein-rich beverage and juice were made by Smashicons; yogurt analog icon was made by Wanicon; carbonated beverage icon was made by Iconixar; alcoholic drink icon was made by Srip from www.flaticon.com. Sunflower seed was made by Fengquan Li and cotton was made by Ale Estrada from https://thenounproject.com.

Author contributions

I.A.A., M.R.S., R.S., I.T.P. and J.d.C.d.C. conceived the study. All authors contributed to the study design. M.R.S. collected the data. C.T.A., I.A.A., R.S., I.T.P. and J.d.C.d.C. synthesized the patents applications included in the review. C.T.A. and J.d.C.d.C. created the tables and figures. C.T.A. and J.d.C.d.C. led the writing of this paper. I.A.A., M.R.S., R.S., I.T.P. and J.d.C.d.C. led the revision and editing of this paper.

Data availability

All data generated or analyzed during this study are included in this published article.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Tangyu M, Muller J, Bolten CJ, Wittmann C. Fermentation of plant-based milk alternatives for improved flavour and nutritional value. Appl. Microbiol. Biotechnol. 2019;103:9263–9275. doi: 10.1007/s00253-019-10175-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Aydar EF, Tutuncu S, Ozcelik B. Plant-based milk substitutes: bioactive compounds, conventional and novel processes, bioavailability studies, and health effects. J. Funct. Foods. 2020;70:103975. doi: 10.1016/j.jff.2020.103975. [DOI] [Google Scholar]

- 3.Wirnitzer, K. C. In Therapeutic, Probiotic, and Unconventional Foods Ch. 21 (eds Grumezescu, A. & Holban, A. M.) (Elsevier, 2018).

- 4.Mäkinen OE, Wanhalinna V, Zannini E, Arendt EK. Foods for special dietary needs: non-dairy plant-based milk substitutes and fermented dairy-type products. Crit. Rev. Food Sci. Nutr. 2015;56:339–349. doi: 10.1080/10408398.2012.761950. [DOI] [PubMed] [Google Scholar]

- 5.Arrutia F, Binner E, Williams P, Waldron KW. Oilseeds beyond oil: press cakes and meals supplying global protein requirements. Trends Food Sci. Technol. 2020;100:88–102. doi: 10.1016/j.tifs.2020.03.044. [DOI] [Google Scholar]

- 6.Sethi S, Tyagi SK, Anurag RK. Plant-based milk alternatives an emerging segment of functional beverages: a review. J. Food Sci. Technol. 2016;53:3408–3423. doi: 10.1007/s13197-016-2328-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Mintel Group LTDA. You heard it here first: the plant-based revolution. https://www.mintel.com/blog/food-market-news/you-heard-it-here-first-predicting-the-plant-based-revolution (2019).

- 8.Jeske S, Zannini E, Arendt EK. Past, present and future: the strength of plant-based dairy substitutes based on gluten-free raw materials. Food Res. Int. 2017;110:42–51. doi: 10.1016/j.foodres.2017.03.045. [DOI] [PubMed] [Google Scholar]

- 9.Banovic M, et al. Foods with increased protein content: a qualitative study on European consumer preferences and perceptions. Appetite. 2018;125:233–243. doi: 10.1016/j.appet.2018.01.034. [DOI] [PubMed] [Google Scholar]

- 10.Mintel Group LTDA. US sales of dairy milk turn sour as non-dairy milk sales grow 9% in 2015. https://www.mintel.com/press-centre/food-and-drink/us-sales-of-dairy-milk-turn-sour-as-non-dairy-milk-sales-grow-9-in-2015 (2016).

- 11.Vanga SK, Raghavan V. How well do plant based alternatives fare nutritionally compared to cow’s milk? J. Food Sci. Technol. 2018;55:10–20. doi: 10.1007/s13197-017-2915-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Rincon L, Botelho RBA, de Alencar ER. Development of novel plant-based milk based on chickpea and coconut. LWT. 2020;128:109479. doi: 10.1016/j.lwt.2020.109479. [DOI] [Google Scholar]

- 13.Graça C, Raymundo A, de Sousa I. Rheology changes in oil-in-water emulsions stabilized by a complex system of animal and vegetable proteins induced by thermal processing. LWT Food Sci. Technol. 2016;74:263–270. doi: 10.1016/j.lwt.2016.07.055. [DOI] [Google Scholar]

- 14.Qamar S, Manrique YJ, Parekh H, Falconer JR. Nuts, cereals, seeds and legumes proteins derived emulsifiers as a source of plant protein beverages: a review. Crit. Rev. Food Sci. Nutr. 2020;60:2742–2762. doi: 10.1080/10408398.2019.1657062. [DOI] [PubMed] [Google Scholar]

- 15.Schweiggert-Weisz U, Eisner P, Bader-Mittermaier S, Osen R. Food proteins from plants and fungi. Curr. Opin. Food Sci. 2020;32:156–162. doi: 10.1016/j.cofs.2020.08.003. [DOI] [Google Scholar]

- 16.Gorissen SHM, et al. Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids. 2018;50:1685–1695. doi: 10.1007/s00726-018-2640-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Clifton PM. Protein and coronary heart disease: the role of different protein sources. Curr. Atheroscler. Rep. 2011;13:493–498. doi: 10.1007/s11883-011-0208-x. [DOI] [PubMed] [Google Scholar]

- 18.Lin Y, et al. Plant and animal protein intake and its association with overweight and obesity among the Belgian population. Br. J. Nutr. 2011;105:1106–1116. doi: 10.1017/S0007114510004642. [DOI] [PubMed] [Google Scholar]

- 19.Banno A, et al. Identification of a novel cholesterol-lowering dipeptide, phenylalanine-proline (FP), and its down-regulation of intestinal ABCA1 in hypercholesterolemic rats and Caco-2 cells. Sci. Rep. 2019;9:19416. doi: 10.1038/s41598-019-56031-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Chan-Zapata I, Sandoval-Castro C, Segura-Campos MR. Proteins and peptides from vegetable food sources as therapeutic adjuvants for the type 2 diabetes mellitus. Crit. Rev. Food Sci. Nutr. 2020;0:1–10. doi: 10.1080/10408398.2020.1857331. [DOI] [PubMed] [Google Scholar]

- 21.Piovesana S, et al. Recent trends and analytical challenges in plant bioactive peptide separation, identification and validation. Anal. Bioanal. Chem. 2018;410:3425–3444. doi: 10.1007/s00216-018-0852-x. [DOI] [PubMed] [Google Scholar]

- 22.Montesano D, Gallo M, Blasi F, Cossignani L. Biopeptides from vegetable proteins: new scientific evidences. Curr. Opin. Food Sci. 2020;31:31–37. doi: 10.1016/j.cofs.2019.10.008. [DOI] [Google Scholar]

- 23.Ferreira AA, Guimarães ER, Contador JC. Patente como instrumento competitivo e como fonte de informação tecnológica. Gest.ão Produção. 2009;16:209–221. doi: 10.1590/S0104-530X2009000200005. [DOI] [Google Scholar]

- 24.Al Kassiri M, Čorejová T. Importance of patent and innovation in educational institutions. CBU Int. Conf. Proc. 2015;3:271–275. doi: 10.12955/cbup.v3.611. [DOI] [Google Scholar]

- 25.New Food Magazine. PBMAs are the plant-based proteins to watch out for. https://www.newfoodmagazine.com/article/128130/pbma/ (2020).

- 26.Kotecka-Majchrzak K, Sumara A, Fornal E, Montowska M. Oilseed proteins – Properties and application as a food ingredient. Trends Food Sci. Technol. 2020;106:160–170. doi: 10.1016/j.tifs.2020.10.004. [DOI] [Google Scholar]

- 27.USDA. Oilseeds: world markets and trade. https://downloads.usda.library.cornell.edu/usda-esmis/files/tx31qh68h/8w32r601z/1g05fb91f/oilseed-trade-05-10-2018.pdf (2018)

- 28.Gomes S, et al. Microencapsulated Brazil nut (Bertholletia excelsa) cake extract powder as an added-value functional food ingredient. LWT. 2019;116:108495. doi: 10.1016/j.lwt.2019.108495. [DOI] [Google Scholar]

- 29.Tan SH, Mailer RJ, Blanchard CL, Agboola SO. Canola proteins for human consumption: extraction, profile, and functional properties. J. Food Sci. 2011;76:R16–R28. doi: 10.1111/j.1750-3841.2010.01930.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Campbell L, Rempel CB, Wanasundara JPD. Canola/rapeseed protein: future opportunities and directions—workshop proceedings of IRC 2015. Plants. 2016;5:281–284. doi: 10.3390/plants5020017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Aider M, Barbana C. Canola proteins: composition, extraction, functional properties, bioactivity, applications as a food ingredient and allergenicity - A practical and critical review. Trends Food Sci. Technol. 2011;22:21–39. doi: 10.1016/j.tifs.2010.11.002. [DOI] [Google Scholar]

- 32.Supertein. https://burcon.ca/products/canola-proteins/supertein/ (2021).

- 33.Food in Canada. BurconCompany, merit functional foods, achieves first commercial production of canola protein. https://www.foodincanada.com/food-business/burconcompany-merit-functional-foods-achieves-first-commercial-production-of-canola-protein-148054/ (2021).

- 34.Vonapartis E, Aubin MP, Seguin P, Mustafa AF, Charron JB. Seed composition of ten industrial hemp cultivars approved for production in Canada. J. Food Compos. Anal. 2015;39:8–12. doi: 10.1016/j.jfca.2014.11.004. [DOI] [Google Scholar]

- 35.Mamone G, Picariello G, Ramondo A, Nicolai MA, Ferranti P. Production, digestibility and allergenicity of hemp (Cannabis sativa L.) protein isolates. Food Res. Int. 2019;115:562–571. doi: 10.1016/j.foodres.2018.09.017. [DOI] [PubMed] [Google Scholar]

- 36.Axiom Foods. Cannatein® hemp hearts protein. http://axiomfoods.com/cannatein-hemp-protein/ (2021).

- 37.Good Hemp Ingredients. White hemp seed protein isolate 85%. https://goodhemp-ingredients.com/ingredients/hemp-protein/white-hemp-seed-protein-isolate-85/ (2021).

- 38.Manitoba Harvest. Hemp yeah! Max protein unsweetened. https://manitobaharvest.com/products/hemp-yeah-max-protein-unsweetened (2021).

- 39.LeanHemp. Hemp protein is the best vegan protein. https://leanhemp.com/#1461725831070-43211078-316c (2021).

- 40.González-Pérez, S. Sunflower Proteins (Elsevier, 2015).

- 41.Murru M, Calvo CL. Sunflower protein enrichment. Methods and potential applications. OCL. 2020;27:1–14. doi: 10.1051/ocl/2020007. [DOI] [Google Scholar]

- 42.Bio Technologies LLC. Sunprotein. http://www.bio-t.pro/eng/products/food/sunprotein (2021).

- 43.Austrade Inc.—Sunflower Protein Supplier. Heliaflor® sunflower proteins. https://www.austradeinc.com/heliaflor/ (2021).

- 44.ETChem. Sunflower protein manufacturer sunflower kernels nutrition supplier. https://www.et-chem.com/sunflower-protein-manufacturer-sunflower-kernels-nutrition-supplier/ (2021).

- 45.Tsaliki E, Pegiadou S, Doxastakis G. Evaluation of the emulsifying properties of cottonseed protein isolates. Food Hydrocoll. 2004;18:631–637. doi: 10.1016/j.foodhyd.2003.11.001. [DOI] [Google Scholar]

- 46.Swiatkiewicz S, Arczewska-Wlosek A, Józefiak D. The use of cottonseed meal as a protein source for poultry: an updated review. Worlds Poult. Sci. J. 2016;72:473–483. doi: 10.1017/S0043933916000258. [DOI] [Google Scholar]

- 47.He Z, Zhang H, Olk DC. Chemical composition of defatted cottonseed and soy meal products. PLoS ONE. 2015;10:1–13. doi: 10.1371/journal.pone.0129933. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Zhang B, Cui Y, Yin G, Li X, Zhou X. Alkaline extraction method of cottonseed protein isolate. Mod. Appl. Sci. 2009;3:77–82. [Google Scholar]

- 49.FAO. Definition and classification commodities, 4. Pulses and derived products. http://www.fao.org/es/faodef/fdef04e.htm (1984).

- 50.Bessada SMF, Barreira JCM, Oliveira MBPP. Pulses and food security: dietary protein, digestibility, bioactive and functional properties. Trends Food Sci. Technol. 2019;93:53–68. doi: 10.1016/j.tifs.2019.08.022. [DOI] [Google Scholar]

- 51.FAO. About the international year of pulses. http://www.fao.org/pulses-2016/about/en/ (2016).

- 52.Boye J, Zare F, Pletch A. Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res. Int. 2010;43:414–431. doi: 10.1016/j.foodres.2009.09.003. [DOI] [Google Scholar]

- 53.Roquette. NUTRALYS® plant protein by Roquette. https://www.roquette.com/plant-protein (2021).

- 54.Burcon. Peazazz. https://burcon.ca/products/peazazz/ (2021).

- 55.Axiom Foods. Veg-o-tein neutral. http://axiomfoods.com/veg-o-tein-pea-protein-powder-neutral/ (2021).

- 56.AMCO Proteins. Plant Proteins. https://www.amcoproteins.com/plant-proteins (2021).

- 57.Ingredion. VITESSENCE® plant protein isolates. https://www.ingredion.com/na/en-us/ingredients/ingredient-product-families/vitessence-plant-protein-isolates.html (2021).

- 58.Cargill. Pea protein - North America. https://www.cargill.com/food-bev/na/pea-protein (2021).

- 59.Farbest Brands. Pea protein. https://farbest.com/ingredients/proteins/plant-proteins/pea-protein/ (2021).

- 60.Nutrition—a plant based milk company. https://www.ripplefoods.com/protein-shake/ (2021).

- 61.siggi’s. Icelandic yogurt—Vanilla plant based 24oz. https://siggis.com/categories/plant-based (2021).

- 62.Montoya CA, Lallès JP, Beebe S, Leterme P. Phaseolin diversity as a possible strategy to improve the nutritional value of common beans (Phaseolus vulgaris) Food Res. Int. 2010;43:443–449. doi: 10.1016/j.foodres.2009.09.040. [DOI] [Google Scholar]

- 63.Sathe SK. Dry bean protein functionality. Crit. Rev. Biotechnol. 2002;22:175–223. doi: 10.1080/07388550290789487. [DOI] [PubMed] [Google Scholar]

- 64.ETprotein. Mung bean protein 80% innovated by ETprotein, China supplier. https://www.etprotein.com/mung-bean-protein-manufacturer-china-supplier/ (2021).

- 65.Atura. Fava bean protein. https://aturaproteins.com/products/fava-bean-protein/ (2021).

- 66.Green Boy. Mung bean powder. https://www.greenboyproducts.com/products/mung-bean/ (2021).

- 67.Green Boy. Fava bean protein powder. https://www.greenboyproducts.com/products/fava-bean-protein-powder (2021).

- 68.Nancy’s. Oatmilk non-dairy yogurt. https://nancysyogurt.com/products/oatmilk-non-dairy-yogurt/ (2021).

- 69.Ghatak SK, Sen K. Peanut proteins: applications, ailments and possible remediation. J. Ind. Eng. Chem. 2013;19:369–374. doi: 10.1016/j.jiec.2012.09.009. [DOI] [Google Scholar]

- 70.Wu H, Wang Q, Ma T, Ren J. Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res. Int. 2009;42:343–348. doi: 10.1016/j.foodres.2008.12.006. [DOI] [Google Scholar]

- 71.Liu Y, Zhao G, Zhao M, Ren J, Yang B. Improvement of functional properties of peanut protein isolate by conjugation with dextran through Maillard reaction. Food Chem. 2012;131:901–906. doi: 10.1016/j.foodchem.2011.09.074. [DOI] [Google Scholar]

- 72.He XH, et al. Effects of high pressure on the physicochemical and functional properties of peanut protein isolates. Food Hydrocoll. 2014;36:123–129. doi: 10.1016/j.foodhyd.2013.08.031. [DOI] [Google Scholar]

- 73.ETChem. Peanut protein powder peanut protein content. https://www.et-chem.com/peanut-protein-powder-peanut-protein-content-manufacturer/ (2021).

- 74.Peanut Butter & Co. Peanut powder—Original. https://ilovepeanutbutter.com/products/peanut-powder-original (2021).

- 75.InnovoPro. First in the world launching of chickpea protein in vegan protein powder. https://innovopro.com/first-in-the-world-launching-of-chickpea-protein-in-vegan-protein-powder/ (2021).

- 76.Atura. Chickpea protein. https://aturaproteins.com/products/chickpea-protein/ (2021).

- 77.Orgain. Organic plant protein | Vegan plant protein powder. https://orgain.com/collections/protein-powder/products/organic-simple-plant-protein-powder (2021).

- 78.Manitoba Harvest. Hemp yeah! Plant protein blend unsweetened. https://manitobaharvest.com/products/hemp-yeah-plant-protein-blend-unsweetened (2021).

- 79.Long, J., Ning, F. & Ning, C. CN105053506 (A). Preparation method of tea seed cake dreg isolated protein. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20151118&CC=CN&NR=105053506A&KC=A (2015).

- 80.Zhang, Z. & Zhang, K. CN104543328 (A). Preparation method and application for fermented gingko cell protein concentrated solution. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20150429&CC=CN&NR=104543328A&KC=A (2015).

- 81.Hoang, K. US10335446 (B2); US2019000910 (A1). Methods of treating diseases using grape proteins. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20190103&CC=US&NR=2019000910A1&KC=A1 (2019).

- 82.Wang, M., Yang, J., Wang, Y. & Zhu, S. CN110250276 (A). Fructus cannabis protein beverage and preparation method thereof. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20190920&CC=CN&NR=110250276A&KC=A (2019).

- 83.Samaranayaka, A. G. P., Wanasundara, U. N., Ray, M. & Green, R. C. WO2019213757 (A1). Hemp protein and use for microencapsulation. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20191114&CC=WO&NR=2019213757A1&KC=A1 (2019).

- 84.Wright, J. & Sprague, D. US2015079235 (A1). Hemp-based infant formula and Methods of Making Same. (2015). Available at: https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20150319&CC=US&NR=2015079235A1&KC=A1. (2015).

- 85.Chen, Y. & Chen, Y. CN108522780 (A). Preparation method and application of industrial hempseed protein powder. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20180914&CC=CN&NR=108522780A&KC=A (2018).

- 86.Shi, J. et al. CN110150391 (A). Preparation method of sports type hemp kernel albumin beverage. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20190823&CC=CN&NR=110150391A&KC=A (2019).

- 87.Gosnell, B. & Schweizer, M. BR112015001964 (A2). Production of soluble protein products from hemp (‘H701’). https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20191217&CC=BR&NR=112015001964A2&KC=A2 (2019).

- 88.Xiao, D. CN110856518 (A). Technological method for comprehensive treatment of Moringa oleifera seeds, product and application thereof. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20200303&CC=CN&NR=110856518A&KC=A (2020).

- 89.Chen, H. CN110463818 (A). Extraction method of protein in chili pepper seed meal and application. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20191119&CC=CN&NR=110463818A&KC=A (2019).

- 90.Wang, N. & Zhou, Q. CN110432333 (A). Preparation method of physalis alkekengi seed polysaccharide protein brewing product for reducing blood sugar. https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&adjacent=true&locale=en_EP&FT=D&date=20191112&CC=CN&NR=110432333A&KC=A (2019).