Abstract

The use of single-use nitrile gloves has been on a sharp incline since the Coronavirus pandemic first started in late 2019. This led to a significant increase in the generation of this clinical waste that requires various recycling solutions to reduce its environmental impact from disposal or incineration. This paper explores its application in structural concrete by adding shredded nitrile gloves at 0.1%, 0.2%, and 0.3% of the volume of concrete. The compressive strength, modulus of elasticity, ultrasonic pulse velocity, and SEM-EDS analysis were undertaken to ascertain the effect of different concentrations of shredded nitrile gloves on the mechanical properties, quality of concrete, and its bond performance with the cement matrix. The results demonstrate that the inclusion of up to 0.2% of shredded nitrile gloves can provide ~22% improvement in the compressive strength of blended concrete composites at 28-days of curing. In comparison, the inclusion of 0.3% of shredded nitrile gloves shows improvements of ~20% in compressive strength at 28-days. The SEM-EDS analysis shows a very good bond formation between the nitrile rubber and the cement matrix with no gap identified in the interfacial transition zone (ITZ).

Keywords: COVID-19, Waste management, Surgical gloves, Nitrile rubber, Pandemic, Concrete, Mechanical properties

Graphical abstract

1. Introduction

COVID-19, a type of Coronavirus, has been instilling a worldwide pandemic that is continuing for most of 2021, bringing the ongoing list of environmental concerns that continue to grow daily (Boroujeni et al., 2021; Jaromír Klemeš et al., 2020a). In the early days of the pandemic, the World Health Organisation (WHO) introduced guiding principles around the use of personal protective equipment known as PPE. WHO has requested a 40% increase in the production of disposable PPE (Adyel, 2020). It has been reported that about 54,000 t of waste PPE were produced per day worldwide as of 22 November 2020 (Purnomo et al., 2021). The demand is expected to increase at a compounded annual rate of 10.6%–11.2% until 2027 at least (Patrawoot et al., 2021). This sharp increase in the utilisation rate of PPE is making its safe disposal very challenging. The single-use face masks and gloves forming the majority of PPE are now ending up in landfills or littering the streets (Jaromír Klemeš et al., 2020b; Saberian et al., 2021; Sangkham, 2020). PPE is being discarded along with other organic and inorganic waste and has also been found littering public places globally (Silva et al., 2020). Furthermore, COVID-19 related plastic has been observed in marine environments creating a potential new source of microplastics currently generated in our oceans (Anastopoulos and Pashalidis, 2021).

The majority component of this PPE waste is that of single-use surgical gloves that are made of PVC, rubber, nitrile, or neoprene, with healthcare settings preferring sterile nitrile gloves (Australia, 2020). Among various types of gloves, the use of nitrile gloves is proliferating (Patrawoot et al., 2021). With millions of contaminated gloves and other medical waste being generated daily that require safe disposal in landfills or incineration, they pose another environmental challenge for the community (Sangkham, 2020). Therefore, it becomes imperative for the research community to develop various recycling solutions that can increase the uptake of this clinical waste material.

Although the applications of different waste plastics for concrete have been extensively evaluated throughout numerous studies (Siddique et al., 2008; MolaAbasi et al., 2019; Ferdous et al., 2021; Kadam et al, 2021; Steyn et al, 2021), the adoption of plastic-based waste PPE for civil and construction have rarely been examined. There are only a few papers that do touch base on the applications of such plastic-based PPE. Saberian et al. (2021) evaluated the effects of single-use face masks for road constructions concluding that the addition of 1–2% shredded face masks to recycled concrete aggregates resulted in an increase in strength stiffness due to the face masks acting as a reinforcement role when binding with Recycled concrete aggregate (RCA). Also, based on the studies of Kilmartin-Lynch et al. (2021), the inclusion of shredded face masks to concrete provided a rise in compressive and indirect tensile strength when 0.2% of shredded single-use masks were applied to the concrete mix, noting the increase was due to the fibres being more densely spaced. Furthermore, Rehman and Khalid (2021) conducted studies on COVID-19 face masks for the amelioration of mechanical properties of fat clay, concluding that the face masks show a reasonable improvement in the unconfined compressive strength. Additionally, Abdullah and EL Aal (2021) conducted an assessment on the re-use of healthy COVID-19 personal protective materials on enhancing geotechnical properties for road construction and concluded that there was a decrease in maximum dry density; however, an increase was shown in the optimum moisture content that was directly proportional to the number of healthy face masks incorporated. To the best of the authors' knowledge, there is a lack of existing studies on the use of waste PPE and the inclusion of nitrile rubber gloves for concrete applications. Therefore, to address this research gap, an experimental study was undertaken to investigate the effect of the inclusion of 0.1, 0.2, and 0.3% of shredded nitrile gloves by volume of concrete. Compressive strength, Young's modulus, ultrasonic pulse velocity tests were undertaken in addition to the SEM-EDS analysis to ascertain its mechanical properties, quality of concrete, and its bond performance with the cement matrix.

2. Materials and experimental programme

2.1. Raw materials

The materials used in this experimental programme were general Portland cement (GPC) supplied by Eureka, 14 and 7 mm coarse aggregates (CA), fine aggregates (FA <2.36 mm), superplasticiser (Sika Plastiment 10), and nitrile gloves. Fine aggregates were oven-dried for a period of 48 h at a constant temperature of 110° Celsius to remove any excess moisture from the material.

Supplementary Fig. 1 outlines the particle size of aggregates as distribution curves that were utilised in the study, and Supplementary Table 1 shows the chemical composition of GPC. The XRF (X-ray fluorescence) results of GPC are presented in Supplementary Table 2, while the XRD (X-ray powder diffraction) outcomes of GPC are shown in Supplementary Fig. 2. XRF testing was undertaken using the Bruker AXS S4 Pioneer instrument. In addition, XRD testing was completed on oven-dried cement powder using Bruker AXS D4 Endeavour equipped with a lynx eye linear strip detector and Cu-Kα radiation. The instrument ran at a 40-kV voltage and 40-mA current. The cement was tested with a counting time of 1 s per step between a range of 5° and 70° 2-theta (2θ) with a step size of 0.01°.

Nitrile gloves that were both latex and powder-free conforming to ISO 374-1 (2016) and ISO 374-5 (2016) were used in this experiment. These gloves were stored in a sealed container for a 96-hour quarantine period, followed by undertaking the disinfection procedure. The disinfection procedure allowed the gloves to be washed and dried with hot soapy water before being cut to size. The isolation procedures were in accordance with studies conducted in the New England Journal of Medicine outlining how scientists found that SARS-CoV-2, the virus responsible for COVID-19, can be detected on plastics and stainless steel for up to 72 h after the application to the material (Van Doremalen et al., 2020). Following the isolation procedures is an extremely crucial part of the study; the quarantine and sanitization protocols help ascertain safe barriers when working with potential viruses and microbes to prevent accidental community transmission. It is worth mentioning that except for the isolation process, as one of the disinfection methods, other disinfection techniques on PPE have been analysed and reviewed for PPE by other scholars (Rowan and Laffey, 2021; Rowan and Moral, 2021). After the disinfection process, the gloves were cut into long strands using scissors before being cut into smaller pieces of approximately 5 × 15 mm. The size fractions were kept similar to the studies by Sharma and Bansal (2016) on waste plastics and Manjunath (2016) on e-plastic waste in concrete. Table 1 shows a breakdown of the physical properties of the nitrile gloves covering tensile strength, melting point, and other properties.

Table 1.

Physical properties of nitrile gloves.

| Physical properties | SHM | Standard |

|---|---|---|

| Specific gravity | 1.26 | ASTM D792-20 (2020) |

| Melting point (°C) | 167 | ASTM D7138-16 (2016) |

| Water absorption 24 h (%) | 14 | ASTM D570-98 (2018) |

| Tensile strength (MPa) | 2.73 | ASTM D638-14 (2014) |

| Tensile strength at break (MPa) | 2.71 | ASTM D638-14 (2014) |

| Elongation at break (%) | 103.55 | ASTM D638-14 (2014) |

| Rupture force (N) | 4.15 | ASTM D638-14 (2014) |

| Aspect ratio | 1:3 | – |

2.2. Mix designs

Four concrete mixes were utilised in total for investigating the samples combined with sterile shredded single-use nitrile gloves in proportions of 0%, 0.1%, 0.2%, and 0.3% of concrete volume. This series of inclusion by volume is consistent with studies by Kilmartin-Lynch et al. (2021), Sadiqul Islam and Gupta (2016), and Xu et al. (2020) experimenting in similar fields. Table 2 shows the mix designs containing different concentrations of shredded nitrile gloves. CM0 signifies the control mix (0% surgical gloves) compared to CM02 implying the mix contained 0.2% surgical gloves by volume.

Table 2.

Concrete mix designs.

| Material (kg/m3) | CM0 | CM01 | CM02 | CM03 |

|---|---|---|---|---|

| Cement | 420 | 420 | 420 | 420 |

| Coarse aggregate | 1260 | 1260 | 1260 | 1260 |

| Fine aggregate | 630 | 630 | 630 | 630 |

| Water | 210 | 210 | 210 | 210 |

| Superplasticiser (mL/m3) | 1260 | 1260 | 1260 | 1260 |

| Nitrile gloves | 0 | 3.70 | 5.55 | 7.41 |

2.3. Concrete mixing, casting, and curing

For concrete mixing, the dry materials were weighed and placed into the concrete mixer, and mixed together for a duration of 3 min. After the initial 3 min of dry mixing, the water/superplasticiser mix was gradually introduced into the cement/aggregate mix and thoroughly mixed for an additional 3 min. The wet concrete mix was then transferred into 100 mm Ø x 200 mm (H) cylindrical moulds for compressive strength, Young's modulus tests, and UPV test and vibrated for a period of 20 s to remove any excess voids and the trapped air present in wet concrete. Three replicates were cast for each mix design and were kept for the initial curing within the moulds for 24 h. Similar procedures were utilised in studies conducted by Kilmartin-Lynch et al. (2021), Sadiqul Islam and Gupta (2016), Moustafa and ElGawady (2015), and Su et al. (2015).

After initially curing for 24 h, the concrete specimens were taken out of their respective casting moulds and put into a curing tank with clean and fresh water to allow them to be cured for the rest of the 28 days at approximately 22 °C. Similar methods can be seen conducted by Zhao et al. (2012) and (Roychand et al., 2018). After curing for 28 days in water, the samples were removed from the curing tank and allowed to air dry before being prepared for testing. The tops of the compressive strength samples and Young's modulus samples were smoothened off using a concrete grinder. This process is undertaken to ensure a clean contact surface during testing.

2.4. Concrete testing

2.4.1. Compressive strength, Young's modulus, and ultrasonic pulse velocity test

Compressive strength test on the concrete samples was undertaken in accordance with AS 1012.9 (2014), using an MTS machine with a force of 157 kN/min applied directly to the concrete cylinders. Young's modulus test was undertaken following AS 1012.17 - 1997. Non-destructive Ultrasonic Pulse Velocity (UPV) test was undertaken on the concrete samples in accordance with ASTM C597-16 (2016) to evaluate the relative density, quality, and uniformity of concrete samples containing different concentrations of shredded nitrile gloves.

2.4.2. SEM-EDS analysis of the bond performance of nitrile rubber and the cement paste

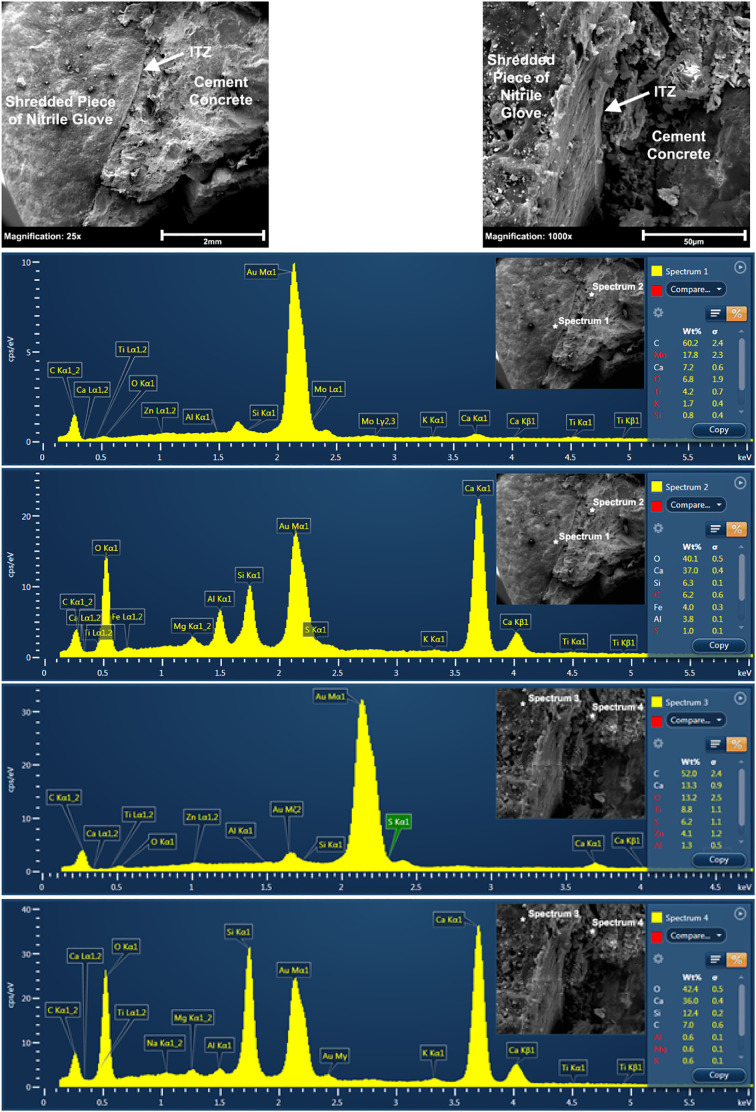

SEM-EDS analysis was undertaken on the concrete sample containing shredded nitrile gloves using FEI Quanta 200 SEM to ascertain its bond performance with the cement matrix. A small sample was cut out from the fractured exposed part of the flexural strength test sample. This sample was loaded onto the steel stub with carbon tape, followed by a gold coating to make it conductive for high-quality SEM images. The SEM images were taken at 25× and 1000× magnification levels. Since the images obtained with scanning electron microscopy are in greyscale, the EDS analysis was undertaken to correctly identify the shredded nitrile gloves from the cement paste based on the identified chemical composition. Since the samples were coated with gold, it was deconvoluted during the analysis to remove it from the percentage composition table of the individual spectrum.

3. Results and discussion

3.1. SEM-EDS analysis of the bond performance of nitrile rubber and the cement paste

Fig. 1 shows the SEM-EDS analysis of the bond performance of shredded nitrile gloves with cement matrix at 25× and 1000× magnification levels, respectively. A strongly bonded shredded piece of the nitrile glove was identified from Spectrum 1 from its high percentage of carbon content that is typical of organic compounds (nitrile rubber). A large number of the cement concrete particle bonded to the top surface of the shredded nitrile glove can be seen from a 25× magnification SEM image. Spectrum 2 shows high calcium, silicon, and oxygen concentrations that are typical of calcium silicate hydrate gel. Since Hydrogen, a low atomic weight element, cannot be identified by the EDS analysis, it is not shown in the analysis. From the SEM image, it is clearly evident that the shredded nitrile gloves provide a very good bond performance with the cement matrix. The second SEM image shows the magnified view (1000×) of the interfacial transition zone of the shredded nitrile glove and the cement matrix. The EDS Spectrums 3 is reflective of the shredded piece of the nitrile glove, and the Spectrums 4 is that of the cement matrix. The SEM image clearly shows a very close bond formation of the cement matrix with the vertical edge of the shredded nitrile glove. The overall analysis from Fig. 1 clearly reflects that the shredded nitrile gloves form a very strong bond with the cement matrix.

Fig. 1.

SEM-EDS analysis of the bond performance of shredded nitrile gloves with cement paste.

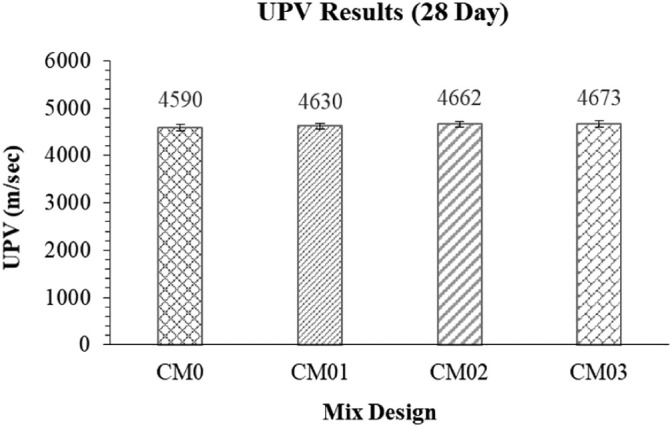

3.2. Ultrasonic pulse velocity (UPV)

UPV test is frequently used to determine the quality of concrete (Demirboğa et al., 2004), and as outlined by Jamle et al (2020), a UPV result greater than 4500 (m/s) is deemed to be concrete of excellent quality. Fig. 2 demonstrates the outcomes of the UPV test after 28-day curing. As outlined in Fig. 2, it can be seen that all mix designs from CM01 to CM03 had better results compared to that of the control mix. All samples from CM0 to CM03 fall into the category determined by Jamle et al (2020) as that of excellent quality. It can be seen in Fig. 2 that as the quantity of nitrile gloves increases between CM0 and CM03, so does the overall quality of the concrete present. Consequently, it can be determined that the inclusion of shredded nitrile gloves improves the overall quality of concrete. The increase in the quality of concrete is most likely due to the nitrile rubber aiding in limiting the formation of microcracks throughout the concrete matrix.

Fig. 2.

Ultrasonic pulse velocity results.

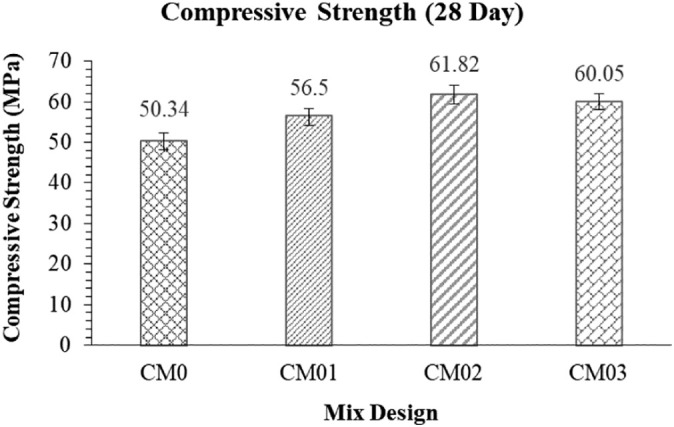

3.3. Compressive strength analysis

Fig. 3 outlines the compressive strength test results of the blended concrete composites containing different concentrations of the shredded nitrile gloves. The control mix shows a 28-day compressive strength of 50.34 MPa. The inclusion of shredded pieces of nitrile gloves increases the compressive strength with the increase in its concentration to the maximum concentration level of 0.2 vol%. With the further increase in shredded nitrile gloves, the compressive strength showed a small reduction in the compressive strength, reflecting 0.2 vol% to be the optimum concentration level. However, even at a 0.3% concentration level of shredded nitrile gloves, the CM03 concrete mix showed ~20% higher compressive strength compared to that of the control mix. Therefore, it can be implied that the inclusion of nitrile rubber from shredded single-use surgical gloves has a positive impact on the compressive strength of the concrete composites. This increase in the compressive strength can be attributed to (a) the strong bond formation (as observed in Fig. 1) between the shredded nitrile gloves and the cement paste and (b) the high tensile strength of the nitrile gloves that provides a crack bridging effect under direct stresses. Moreover, the improvement in the quality of the concrete composites as reflected in the ultrasonic pulse velocity test also aids in the improvement in the strength properties.

Fig. 3.

28-day compressive strength results.

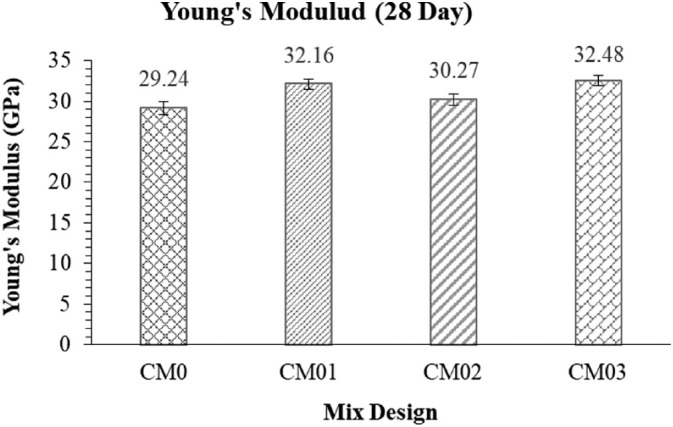

3.4. Young's modulus test analysis

Fig. 4 details the results of the 28-day cured Young's modulus test. It can be seen that there is no steady trend development and no direct correlation to the number of nitrile gloves present in the concrete against the modulus of elasticity; however, it can be noted that overall, the presence of the nitrile rubber in the concrete enhanced the modulus of elasticity against the control mix for all mixes. As outlined by Kilmartin-Lynch et al. (2021), the small variation between mixes can be regarded as a negligible change in the modulus of elasticity. Also, comparable results were shown by the study of Pesic et al. (2016) on the application of waste plastics in concrete, where the plastic fibres can be seen demonstrating no substantial effect on the elastic modulus of concrete. However, as also outlined in past studies by Kilmartin-Lynch et al. (2021), the failing presence of a developing trend similar to the compressive strength and UPV results can be put down to the low volume of single-use nitrile gloves present in the concrete mix. Although there is no significant trend being developed with the elastic modulus, it should be reiterated that all mixes showed an increase when compared to the control mix and all mixes fell within a suitable range for the modulus of elasticity. Therefore, with such a small variation to the overall value of the elastic modulus, it becomes apparent that the single-use nitrile gloves had little to no effect on the modulus of elasticity.

Fig. 4.

28-day Young's Modulus results.

4. Conclusion

This study outlined a series of experiments studying the effects of incorporating single-use shredded nitrile gloves and the underlying impacts they had on the mechanical properties, quality of concrete, and its bond performance with the cement matrix. This study proposes a potential solution to the PPE waste generated by the COVID-19 pandemic. From these sets of experiments, it can be concluded that:

-

1.

The SEM-EDS analysis showed very good bond formation between the shredded nitrile rubber gloves and the cement concrete with no gap identified in the interfacial transition zone, thus building the basis for an enhanced bridging effect allowing for advantageous results in the strength development of the concrete incorporated with nitrile rubber.

-

2.

The introduction of single-use nitrile gloves increased the overall results of UPV when related to the control mix, thus increasing the overall quality of the concrete. This is likely due to the nitrile gloves aiding in bond formation, limiting microcracks throughout the concrete compared to the control mix.

-

3.

Regardless of the developing trend of UPV results, all concrete mixes fell under the category of excellent concrete exceeding a speed of 4500 (m/s).

-

4.

A 0.2 vol% inclusion of shredded single-use nitrile gloves showed the best results, and the overall quality of the blended concrete composites was improved, as reflected by UPV test results.

-

5.

The presence of single-use nitrile gloves in concrete has the potential to show positive impacts on the mechanical properties of concrete.

-

6.

The compressive strength of the concrete composites containing shredded nitrile gloves increased with the increase in its concentration volume up to a maximum of 0.2%. However, even with the higher concentration of 0.3% of the shredded nitrile gloves, the blended concrete composite provided ~20% higher compressive strength compared to that of the control mix.

-

7.

The elastic modulus can be deemed unaffected showing small variations in the overall properties caused by the low volume of single-use nitrile gloves utilised in the mix design.

CRediT authorship contribution statement

Shannon Kilmartin-Lynch: Methodology, Validation, Investigation, Writing – original draft, Data curation, Formal analysis, Visualization. Rajeev Roychand: Writing – review & editing, Visualization, Investigation, Data curation, Formal analysis. Mohammad Saberian: Writing – review & editing, Formal analysis, Visualization. Jie Li: Writing – review & editing, Supervision, Resources, Validation, Project administration, Conceptualization. Guomin Zhang: Supervision, Resources, Visualization, Project administration.

Declaration of competing interest

With regards to the declaration of interest, we hereby confirm that there are no conflicts of interest associated with our paper.

Acknowledgements

The authors gratefully acknowledge the RMIT X-Ray Facility and RMIT Microscopy and Microanalysis Facility for providing training and access to the facilities. The authors would also like to acknowledge the generous support of the Lowitja Institute, Australia's national institute for Aboriginal and Torres Strait Islander health research.

Editor: Damia Barcelo

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.scitotenv.2021.151423.

Appendix A. Supplementary data

Supplementary material

References

- Abdullah G.M.S., EL Aal A.A. Assessment of the re-use of Covid-19 healthy personal protective materials in enhancing geotechnical properties of Najran’s soil for road construction: numerical and experimental study. J.Clean.Prod. 2021;320:1–13. doi: 10.1016/j.jclepro.2021.128772. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adyel T.M. Accumulation of plastic waste during COVID-19. Science. 2020;369:1314–1315. doi: 10.1126/science.abd9925. [DOI] [PubMed] [Google Scholar]

- Anastopoulos and Pashalidis, 2021 I. Anastopoulos I. Pashalidis J. J. O. M. L. 2021. Single-use surgical face masks, as a potential source of microplastics: do they act as pollutant carriers? 326, 115247. [DOI] [PMC free article] [PubMed]

- AS 1012.17 . Standards Australia; Sydney, NSW: 1997. Methods of Testing Concrete - Determination of the Static Chord Modulus of Elasticity and Poisson's Ratio of Concrete Specimen. (R2014) [Google Scholar]

- AS 1012.9 . Standards Australia; Sydney, NSW: 2014. Methods of Testing Concrete - Compressive Strength Tests- Concrete, Mortar, and Grout Specimens. [Google Scholar]

- ASTM C597-16 . ASTM International; West Conshohocken, PA: 2016. Standard Test Method for Pulse Velocity Through Concrete. [Google Scholar]

- ASTM D570-98 . ASTM International; West Conshohocken, PA: 2018. Standard Test Method for Water Absorption of Plastics. [Google Scholar]

- ASTM D638-14 . ASTM International; West Conshohocken, PA: 2014. Standard Test Method for Tensile Properties of Plastics. [Google Scholar]

- ASTM D7138-16 . ASTM International; West Conshohocken, PA: 2016. Standard Test Method to Determine the Melting Temperature of Synthetic Fibers. [Google Scholar]

- ASTM D792-20 . ASTM International; West Conshohocken, PA: 2020. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. [Google Scholar]

- Australia S.W. Safe Work Australia; 2020. Who should wear gloves to protect against COVID-19? [Online]https://www.safeworkaustralia.gov.au/covid-19-information-workplaces/industry-information/retail/gloves [Accessed 13/04 2021] [Google Scholar]

- Boroujeni M., Saberian M., Li J. Environmental impacts of COVID-19 on Victoria, Australia, witnessed two waves of coronavirus. Environ. Sci. Pollut. Res. 2021;28(11):14182–14191. doi: 10.1007/s11356-021-12556-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Demirboğa R., Türkmen İ., Karakoç M.B. Relationship between ultrasonic velocity and compressive strength for high-volume mineral-admixtured concrete. Cem. Concr. Res. 2004;34:2329–2336. [Google Scholar]

- Ferdous W., Manalo A., Siddique R., Mendis P., Zhuge Y., Wong H.S., Lokuge W., Aravinthan T., Schubel P. Recycling of landfill wastes (tyres, plastics, and glass) in construction – a review on global waste generation, performance, application, and future opportunities. Resour. Conserv. Recycl. 2021;173 [Google Scholar]

- ISO 374-1 . International Organisation for Standardisation; Geneva, Switzerland: 2016. Protective Gloves Against Dangerous Chemicals and Micro-organisms - Part 1: Terminology and Performance Requirements for Chemical Risks. [Google Scholar]

- ISO 374-5 . International Organisation for Standardisation; Geneva, Switzerland: 2016. Protective Gloves Against Dangerous Chemicals and Micro-organisms - Part 5: Terminology and Performance Requirements for Micro-organisms Risks. [Google Scholar]

- Jamleet al., 2020 S. Jamle N. Delmiya R. Singh J. J. O. X. a. U. O. A. & Technology, I. 2020. Efficient Use of UPV Meter: A Non Destructive Test of Concrete by Fragmentation Analysis. 1006-7930.

- Jaromír Klemeš J., Fan Y.V., Jiang P. The energy and environmental footprints of COVID-19 fighting measures – PPE, disinfection, supply chains. Energy. 2020;211 doi: 10.1016/j.energy.2020.118701. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jaromír Klemeš J., Fan Y.V., Tan R.R., Jiang P. Minimising the present and future plastic waste, energy, and environmental footprints related to COVID-19. Renew. Sustain. Energy Rev. 2020;127 doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kadamet al., 2021 A. M. Kadam P. P. Porwal Y. D. Gondil R. R. Khot P. P. Chavan P. T. Patil J. I. J. O. R. I. E., Science & Management 2021. Partial Replacement of Coarse Aggregate in Manufacturing of Waste Plastic Concrete Blocks. 4, 66-70.

- Kilmartin-Lynch S., Saberian M., Li J., Roychand R., Zhang G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021;296 doi: 10.1016/j.jclepro.2021.126460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Manjunath B.T.A. Partial replacement of E-plastic waste as coarse-aggregate in concrete. Procedia Environ. Sci. 2016;35:731–739. [Google Scholar]

- MolaAbasi H., Saberian M., Li J. Prediction of compressive and tensile strengths of zeolite-cemented sand using porosity and composition. Constr. Build. Mater. 2019;202:784–795. [Google Scholar]

- Moustafa A., Elgawady M.A. Mechanical properties of high-strength concrete with scrap tire rubber. Constr. Build. Mater. 2015;93:249–256. [Google Scholar]

- Patrawoot S., Tran T., Arunchaiya M., Somsongkul V., Chisti Y., Hansupalak N. Environmental impacts of examination gloves made of natural rubber and nitrile rubber, identified by the life-cycle assessment. SPE Polym. 2021;2(3):179–190. [Google Scholar]

- Pesic N., Zivanovic S., Garcia R., Papastergiou P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr.Build.Mater. 2016;115:362–370. [Google Scholar]

- Purnomo C.W., Kurniawan W., Aziz M. Technological review on thermochemical conversion of COVID-19-related medical wastes. Resour. Conserv. Recycl. 2021;167 doi: 10.1016/j.resconrec.2021.105429. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rehman Z.U., Khalid U. Re-use of COVID-19 face mask for the amelioration of mechanical properties of fat clay: a novel solution to an emerging waste problem. Sci. Total Environ. 2021;794 doi: 10.1016/j.scitotenv.2021.148746. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rowan N.J., Laffey J.G. Unlocking the surge in demand for personal and protective equipment (PPE) and improvised face coverings arising from coronavirus disease (COVID-19) pandemic – implications for efficacy, re-use and sustainable waste management. Sci. Total Environ. 2021;752 doi: 10.1016/j.scitotenv.2020.142259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rowan N.J., Moral R.A. Disposable face masks and reusable face coverings as non-pharmaceutical interventions (NPIs) to prevent transmission of SARS-CoV-2 variants that cause coronavirus disease (COVID-19): role of new sustainable NPI design innovations and predictive mathematical modelling. Sci. Total Environ. 2021;772 doi: 10.1016/j.scitotenv.2021.145530. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Roychand R., De Silva S., Setunge S. Nanosilica modified high-volume fly ash and slag cement composite: environmentally friendly alternative to OPC. J. Mater. Civ. Eng. 2018;30:04018043. [Google Scholar]

- Saberian M., Li J., Kilmartin-Lynch S., Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021;769 doi: 10.1016/j.scitotenv.2021.145527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sadiqul Islam G.M., Gupta S.D. Evaluating plastic shrinkage and permeability of polypropylene fiber reinforced concrete. Int. J. Sustain. Built Environ. 2016;5(2):345–354. [Google Scholar]

- Sangkham S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Stud.Chem.Environ.Eng. 2020;2 doi: 10.1016/j.cscee.2020.100052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharma R., Bansal P.P. Use of different forms of waste plastic in concrete – a review. J. Clean. Prod. 2016;112(1):473–482. [Google Scholar]

- Siddique R., Khatib J., Kaur I. Use of recycled plastic in concrete: a review. Waste Manag. 2008;28(10):1835–1852. doi: 10.1016/j.wasman.2007.09.011. [DOI] [PubMed] [Google Scholar]

- Silva A.L.P., Prata J.C., Walker T.R., Duarte A.C., Ouyang W., Barcelo D., Rocha-Santos T.J.C.E.J. Increased Plastic Pollution Due to COVID-19 Pandemic: Challenges and Recommendations. 2020;126683 doi: 10.1016/j.cej.2020.126683. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Steynet al., 2021 Z. Steyn A. Babafemi H. Fataar R. Combrinck J. C. & Materials, B. 2021. Concrete containing waste recycled glass, plastic, and rubber as sand replacement. 269, 121242.

- Su H., Yang J., Ling T.-C., Ghataora G.S., Dirar S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 2015;91:288–296. [Google Scholar]

- Van Doremalen N., Bushmaker T., Morris D.H., Holbrook M.G., Gamble A., Williamson B.N., Tamin A., Harcourt J.L., Thornburg N.J., Gerber S.I., Lloyd-Smith J.O., De Wit E., Munster V.J. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020;382:1564–1567. doi: 10.1056/NEJMc2004973. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xu H., Shao Z., Wang Z., Cai L., Li Z., Jin H., Chen T. Experimental study on mechanical properties of fiber-reinforced concrete: effect of cellulose fiber, polyvinyl alcohol fiber, and polyolefin fiber. Constr. Build. Mater. 2020;261 [Google Scholar]

- Zhao H., Sun W., Wu X., Gao B. Effect of initial water-curing period and curing condition on the properties of self-compacting concrete. Mater. Des. 2012;35:194–200. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material