Abstract

In recent decades, the production of H2 from biomass, waste plastics, and their mixtures has attracted increasing attention in the literature in order to overcome the environmental problems associated with global warming and CO2 emissions caused by conventional H2 production processes. In this regard, the strategy based on pyrolysis and in-line catalytic reforming allows for obtaining high H2 production from a wide variety of feedstocks. In addition, it provides several advantages compared to other thermochemical routes such as steam gasification, making it suitable for its further industrial implementation. This review analyzes the fundamental aspects involving the process of pyrolysis-reforming of biomass and waste plastics. However, the optimum design of transition metal based reforming catalysts is the bottleneck in the development of the process and final H2 production. Accordingly, this review focuses especially on the influence the catalytic materials (support, promoters, and active phase), synthesis methods, and pyrolysis-reforming conditions have on the process performance. The results reported in the literature for the steam reforming of the volatiles derived from biomass, plastic wastes, and biomass/plastics mixtures on different metal based catalysts have been compared and analyzed in terms of H2 production.

1. Introduction

The growing energy demand and the increasing awareness of the dependency on fossil fuels are promoting the use of alternative routes for the production of clean energy from sustainable raw materials and consumer society wastes. Currently, almost 80% of the global primary energy demand is supplied from crude oil, natural gas, and coal.1 Thus, the development of H2 technologies can help to alleviate the problems associated with global warming and climate change, promote sustainable development, and help to reduce CO2 emissions.

The current global H2 production is about 8 EJ/year, with around 96% being produced from fossil fuels. Thus, the actual sources whereby H2 is produced consist of natural gas (48%), oil (30%), coal (18%), and water electrolysis (4%) (see Figure 1a). This distribution shows that the current H2 generation is associated with the consumption of fossil fuels and the emission of CO2 in their production processes (mostly steam reforming processes). In addition, its consumption is largely carried out in the petrochemical industry for the generation of automotive fuels, which in turn are CO2 generators.

Figure 1.

Global current sources of H2 production (a), and H2 consumption sectors (b).

Almost all the H2 produced is used for the production of existing feedstocks, i.e., in refineries or in the production of ammonia for urea or other fertilizers or chemicals, such as methanol. Thus, the global H2 consumption is distributed as follows: (i) ammonia production for urea and other fertilizers (51%); (ii) refining, hydrocracking, hydrotreating (e.g., fuel desulfurization), biorefinery (31%); (iii) synthesis of methanol and derivatives (10%); (iv) processing, (e.g., rocket fuel, automotive fuel or semiconductor industry (5%); (v) production of other chemicals, (e.g., polymers, polyurethanes, fatty acids (1%); and (vi) liquified H2 for steel heat treating, metal welding and forming, blanketing gas, and glass production (1%). These results are summarized in Figure 1b.

The future of the H2 market is driven by the need to reduce CO2 emissions, which requires its production from alternative raw materials and renewable sources. Thus, in order to achieve the global target signed in the Paris Agreement in 2015, in which the aim was to limit the global temperature rise in this century to 2 °C, dramatic changes should be done in order to decrease CO2 emissions by 60% until 2050.2,3 In this scenario, the short-term implementation of H2 production processes from biomass and waste is gaining growing attention. Consequently, the development of technologies for obtaining H2 from biomass and waste, especially waste plastics, has deserved remarkable attention in the recent literature.4−10 Among them, thermochemical routes have proven a great potential and efficiency. These processes can be grouped into direct and indirect routes. Thus, the direct routes are classified as follows: (i) pyrolysis (catalytic pyrolysis and high temperature pyrolysis), (ii) steam gasification, (iii) supercritical water gasification, and (iv) the steam reforming of pyrolysis volatiles. The indirect routes are those involving intermediate steps to obtain liquid products (bio-oil or plastics pyrolysis oil) for their subsequent reforming (steam reforming and gasification).

Steam gasification has been widely studied in the literature for the valorization of biomass and waste plastics, since it can generate H2-rich syngas9,11,12 and the gaseous products can be directly used as fuel or intermediate products in the large scale chemical and fuel production.13,14 The main challenge of gasification processes involves the quality of the syngas and its tar content and, in fact, remarkable research efforts have been made to improve tar elimination processes.15−17 Thus, it is well-established that an optimized gasifier and a highly active catalyst can efficiently contribute to biomass tar elimination.18 Under suitable operating conditions and using appropriate catalysts, biomass steam gasification allows obtaining H2 productions in the 5–7 wt % range.19−22 The higher carbon and hydrogen content of waste plastics increases H2 production to values above 10 wt % when they are valorized by steam gasification.23−25

An alternative strategy to direct gasification proposed for syngas production is the one based on the gasification of pyrolysis oil, especially the one derived from biomass pyrolysis. This process involves the advantage of reducing the expensive transportation costs of the biomass and waste.26 Although the differentiation in the literature between bio-oil gasification and reforming is sometimes unclear and rather confusing, it has herein considered that bio-oil gasification is the process that requires higher temperatures (around 800–1400 °C) than reforming reactions and is carried out without catalysts or in the presence of primary mineral catalysts.8 Thus, the composition of the syngas obtained in the bio-oil gasification is similar to the one obtained in the biomass gasification, with higher H2 yields being attained in the gas product from bio-oil reforming. The production of H2 from bio-oil gasification is greatly influenced by the type of bio-oil used, reactor configuration, and operating conditions. Accordingly, H2 production values from 1.4 to 12.6 wt % have been reported in the literature.27−30

Bio-oil steam reforming is an indirect thermochemical route for H2 production from biomass.31,32 It should be noted that this strategy has been scarcely studied as a route for the upgrading of waste plastics. The bio-oil or liquid product from biomass pyrolysis has a higher energy density compared to biomass, leading to lower transportation costs and therefore allowing bio-oil valorization in centralized large scale catalytic conversion units. In spite of the operational problems associated with bio-oil handling and fast deactivation rate of the reforming catalyst, high H2 productions have been reported. Thus, values above 12 wt % by mass unit of the organic bio-oil have been obtained.33−36 The selection of suitable catalysts for oxygenate reforming has been extensively studied in the literature by using model compounds, the bio-oil aqueous phase, and raw bio-oil.37,38 Thus, although a wide range of base transition metals, such as Ni, Co, and Fe, and noble metals, such as Rh, Pt, Ir, and Ru, have been studied, Ni based catalysts are the most used ones because they strike a suitable balance between activity and cost.39,40 In addition, different supports and their modification with promoters have also been widely analyzed.12,41,42

An alternative and direct thermochemical conversion route for H2 production from biomass and waste is the strategy based on pyrolysis and in-line reforming of the volatiles, which has several advantages in comparison with the aforementioned routes. Thus, the integration of both reactors in the same unit allows selecting the optimum conditions in the pyrolysis and in-line reforming steps.43 Therefore, operation at lower temperatures than those in the gasification process and the use of highly active reforming catalysts lead to the avoidance of tar formation, reduce material costs, and prevent catalyst deactivation by sintering.44−46 Moreover, the direct contact of the reforming catalyst with the biomass and its impurities is avoided, given that they are retained in the pyrolysis reactor.47 In addition, this process has shown a remarkable capacity for H2 production. Concerning biomass conversion, values of around 10 wt % were obtained operating under optimum conditions and catalysts.40,48−53 The volatiles derived from biomass pyrolysis can be classified into two fractions: (i) bio-oil or liquid fraction (the condensable fraction at the outlet of the pyrolyzer), which is formed by a complex mixture of oxygenated compounds (phenols, ketones, saccharides, furans, acids, and alcohols) and water, and (ii) the non-condensable gaseous stream, which is mainly made up of CO and CO2 and, to a minor extent, by light hydrocarbons and H2. In the case of waste plastics, a wide range of conversions was reported depending on the polymer nature. Thus, polyolefins and polystyrene allow obtaining H2 production values higher than 30 wt %,43,46,54,55 whereas other polymers with lower carbon content, such as polyethylene terephthalate, lead to productions below 20 wt %.56 The volatile stream derived from polyolefins (PE and PP) pyrolysis under mild conditions was mainly formed by waxes (C21+) followed by hydrocarbons in the diesel fraction (C12–C20), with the yields of light oil (C5–C11) and gases being rather low. The products obtained in the pyrolysis of polystyrene (PS) are made up of aromatic hydrocarbons (styrene recovery being higher than 70%) and a small yield of light gaseous compounds. It is to note that no solid residue is formed in the pyrolysis of polyolefins and polystyrene, and therefore all the products that make up the volatile stream are fed into the reforming step. Conversely, a solid residue is obtained in the pyrolysis of PET, with the volatile stream being mainly composed of non-condensable gases (CO and CO2), oil (acetaldehyde), and a mixture of oxygenated compounds, which are solid at room temperature (mostly benzoic acid).

Therefore, H2 production by pyrolysis-reforming is highly dependent on the raw material. Furthermore, the volatile composition to be reformed affects the reaction mechanism as well as the catalyst deactivation rate.57

However, the development of the combined process of pyrolysis and in-line reforming is conditioned by the efficiency of the reforming catalyst. Thus, highly selective and active catalysts are required to enhance H2 production and ensure full conversion of pyrolysis volatiles and therefore avoid tar formation. Moreover, the complex nature of the volatile stream derived from the pyrolysis of biomass and waste plastics causes a fast deactivation rate.58 Thus, a remarkable research effort has been made in recent years to develop new catalysts and overcome the mentioned challenges. Accordingly, a wide variety of catalysts based on different supports, promoters, and active phases have been proposed in the literature. This review analyzes the development and application of these catalysts for the reforming of biomass and waste plastics. Moreover, a general overview on the combined process of pyrolysis and in-line reforming has also been included. The role played by pyrolysis and reforming conditions on process performance was briefly discussed, and technological aspects were also considered.

2. Pyrolysis and In-line Steam Reforming

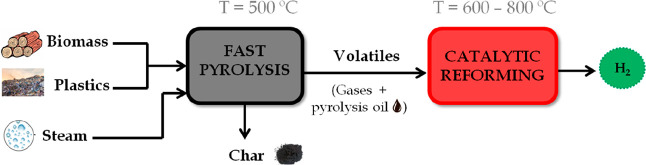

The pyrolysis-reforming strategy pursues H2 production by combining two reaction steps in a single process (see Figure 2). The aim of the pyrolysis step is to convert the solid feedstock into a volatile stream suitable for further transformation into a H2 rich gas in the subsequent catalytic reforming step. The composition and yields of the pyrolysis volatiles (gas and pyrolysis oil) depend on the pyrolysis conditions and feedstock characteristics. Moreover, a solid product or char can also be formed in the pyrolysis step, which is a valuable byproduct that is not fed into the reforming reactor. The pyrolysis step is usually performed at around 500 °C, as this is the minimum temperature to ensure full devolatilization of biomass and waste plastics.

Figure 2.

Scheme of pyrolysis-reforming of biomass/plastics.

The step of catalytic steam reforming of the pyrolysis volatiles is commonly carried out between 600 and 800 °C. This temperature range is conditioned by, on the one hand, the low reaction rate below 600 °C and, on the other hand, the catalyst instability due to metal sintering when operation is carried out at high temperatures. Different supported metallic catalysts have been used in this process, with Ni based ones the most common due to their suitable activity and low price. Steam partial pressure and catalyst space time also play a significant role in the performance of the reforming step and must be carefully considered.

In the following sections, the most relevant aspects involving the steps of pyrolysis and reforming are briefly discussed. Moreover, the main reactor designs used in this process are also presented and analyzed.

2.1. Pyrolysis Step

Pyrolysis is a thermochemical conversion process performed under inert conditions. Although pyrolysis is usually performed under a steam atmosphere, the mild conditions used for pyrolysis in the combined process of pyrolysis-reforming minimize the impact of steam in the pyrolysis mechanism44,50 when it is used as an inert carrier gas. Pyrolysis processes are often divided into three groups depending on the heating rate and gas residence time, namely, fast, intermediate, and slow pyrolysis.59,60 Thus, fast pyrolysis is usually conducted at moderate temperatures under very high heating rates (103–104 °C s–1) and short residence times (below 1 s). These conditions minimize secondary reactions leading to the non-condensable gas fraction and enhance the yield of primary products accounting for the liquid fraction. However, slow pyrolysis is characterized by long residence times and slow heating rates. It is to note that these conditions favor the formation of gas and solid products at the expense of the liquid one. Finally, intermediate pyrolysis conditions are halfway between those of fast and slow pyrolysis. In the processes involving pyrolysis and reforming, the most common fast pyrolysis reactors are fluidized and spouted beds, and their use is associated with the operation under a continuous regime.54,56,61,62 However, fixed bed reactors are used under slow pyrolysis conditions (below 40 °C min–1) and they operate in a batch regime.53,63,64

Thermal pyrolysis of biomass and waste plastics leads to wide and complex product distributions. The features of the obtained products are briefly mentioned below due to their impact on the subsequent reforming step. Biomass pyrolysis leads to three fractions, namely, gas, bio-oil, and char, with their yields depending on the pyrolysis conditions and original biomass composition. Although biomass has a variable composition in terms of cellulose, hemicellulose, lignin, sugar, protein and ash contents, some general features apply in all cases. Thus, the gases are mainly made up of CO and CO2, with minor contents of light hydrocarbons and H2. Bio-oil is the main product obtained in biomass pyrolysis, with its yield reaching 75 wt % under suitable processing conditions.59 The bio-oil is a complex mixture of oxygenated compounds, with phenols, ketones, saccharides, furans, acids, or alcohols being worth mentioning. Moreover, a significant amount of water is also formed in the biomass thermal degradation. The char is a carbonaceous material obtained as a byproduct in the pyrolysis-reforming process, which is not treated in the reforming step. However, it has several applications, as are those related to sorbents, fertilizers, catalyst supports, and soil amender.65,66

The type of waste plastic fully conditions the pyrolysis mechanism and the obtained product distribution. Accordingly, the product distribution obtained in the pyrolysis of each type of plastic waste deserves an individual description. Polyolefins, such as polyethylene (PE) and polypropylene (PP), are the most used plastics, whose thermal degradation takes place via a random radical scission mechanism leading to a wide product distribution from light gaseous hydrocarbons to heavy waxes. Furthermore, under suitable operating conditions, the yield of solid residue from these plastics is negligible.67,68 It should be noted that, under mild pyrolysis conditions, waxes and hydrocarbons in the diesel range are the prevailing products, with the yields of light oil and gases being low.69−71 However, the thermal degradation of polystyrene (PS) is a highly selective process. In fact, styrene recovery is above 90%, with the remaining products being other aromatics.72−74 Polyethylene terephthalate (PET) is a commodity plastic whose valorization by pyrolysis is challenging. Thus, the product distribution is a complex mixture of oxygenates (gaseous, liquid, and solid at room temperature) and a variable yield of solid residue.75,76 The yield of gas is higher than 40% and consists of CO and CO2, whereas the main heavy compounds are oxygenates of aromatic nature, such as benzoic acid. The co-pyrolysis of waste plastics and biomass is attracting increasing attention in recent years due to the interaction between their pyrolysis products and therefore the synergistic effects observed in their joint treatment.77 In spite of these interactions, the composition of the products is basically that corresponding to the contribution of the individual raw materials pyrolyzed.

2.2. Catalytic Steam Reforming Step

In the steam reforming step, the volatile stream from the pyrolysis step reaches the catalytic bed and reacts with steam on the catalyst active sites to yield a H2 rich gaseous product. The most relevant reactions in the reforming reactor are summarized in Table 1. These reactions can be divided into two groups, namely, heterogeneous catalytic reactions and secondary reactions in the gas phase. The first group includes the main desired reactions, which are promoted by the use of metallic catalysts. Steam reforming reactions convert oxygenates (eq 3) and hydrocarbons (eqs 4 and 5) into H2 and CO. These reactions are highly endothermic, and they are therefore favored at high temperatures. Moreover, CO can be further oxidized to CO2 by the water gas shift (WGS) reaction (eq 6), forming additional H2. This reaction is exothermic and is therefore hindered at high temperatures.

Table 1. Main Reactions Involved in the Reforming of the Volatiles Derived from Biomass and Waste Plastics.

| Bio-oil cracking: |

|

||

| Hydrocarbons (HCs) cracking: |

|

||

| Bio-oil steam reforming: |

|

||

| Methane steam reforming: |

|

||

| HCs steam reforming: |

|

||

| Water gas shift (WGS): |

|

||

| Interconversion: |

|

Secondary reactions include thermal cracking reactions of oxygenates (eq 1) and hydrocarbons (eq 2) and a wide variety of interconversion reactions (eq 7). These reactions are favored by severe operating conditions, i.e., high temperatures and long residence times. However, their impact is in general limited due to the competence with the much faster reactions promoted by the catalysts, i.e., steam reforming reactions. Thus, they only influence the final product composition when the process is performed under low conversion conditions (low space times or severely deactivated catalysts).

Apart from the conventional reforming under a steam atmosphere, the use of CO2 or dry reforming has been also proposed, especially when methane is used as the feedstock.78 Nevertheless, the low hydrogen content of biomass limits the interest of its valorization by dry reforming. However, the dry reforming of the volatiles derived from waste plastics leads to a significant H2 production.79 The oxidative steam reforming or oxygen co-feeding is a common strategy applied in catalytic steam reforming for the attenuation of the endothermicity of the process. Although the presence of oxygen in the reforming reactor contributes to reducing H2 production, it also has positive effects, such as the in situ combustion of the coke deposited on the catalysts and therefore, stability improvement.80

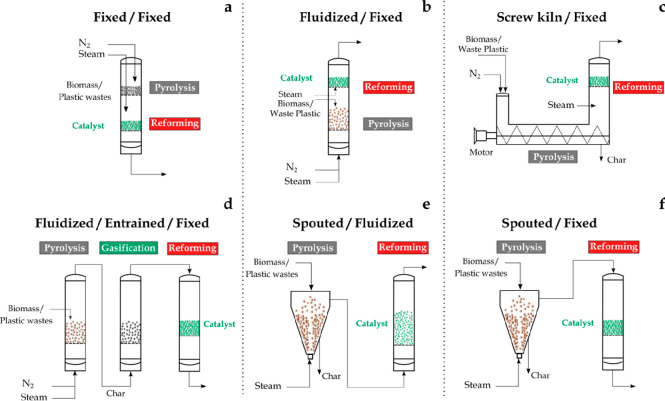

2.3. Pyrolysis-Reforming Reactor Configurations

A wide variety of reactor configurations has been proposed in the literature for biomass and waste pyrolysis and in-line reforming. Figure 3 summarizes the main reactor designs used. However, the majority of the studies were carried out in batch laboratory units, and they are therefore of a preliminary nature.9 Nevertheless, continuous operation regime is highly relevant in the pyrolysis-reforming process. Thus, continuous pyrolysis leads to a volatile stream of constant composition once steady state conditions have been attained. This fact not only allows for the extrapolation of the results to the conditions of industrial reactors but also eases the evaluation of catalyst performance as a pyrolysis stream with homogeneous composition throughout the time treated. Moreover, steady state conditions also allow for a better control of the process conditions and catalyst stability with time on stream.

Figure 3.

Reactor configurations for pyrolysis and in-line catalytic steam reforming of biomass and waste plastics: (a) fixed bed/fixed bed, (b) fluidized bed/fixed bed, (c) screw kiln/fixed bed, (d) fluidized bed/entrained flow/fixed bed, (e) spouted bed/fluidized bed, and (f) spouted bed/fixed bed. Adapted with permission from ref (8). Copyright 2018 Elsevier.

A combination of two fixed bed reactors for the pyrolysis and reforming steps has been widely used due to its simple design and operation as well as limited investment cost. The most common approach is the operation in a batch regime with the pyrolysis step being performed under slow pyrolysis conditions by using heating rates below 50 °C min–1.47,81−85 Thus, the pyrolysis volatiles formed throughout the heating process are transferred to the fixed bed reforming reactor, which operates under isothermal regime at the desired reforming temperature. The main shortcoming of this reactor configuration lies in its scaling up due to the poor heat transfer rate and complex control of operating conditions in the pyrolysis step. Besides, the use of a fixed bed reactor in the reforming step may involve operational problems related to bed blockage by coke deposition on the catalyst surface. Moreover, a two fixed bed configuration has also been used in the continuous regime for biomass86−89 and waste plastics43,90 valorization. It is to note that, in these studies, the continuous feed into the pyrolysis reactor leads to high heating rates. The use of fast pyrolysis reactors, such as fluidized and spouted beds, has also been proposed in the literature. These studies were carried out with a continuous biomass/plastic feed. The main advantages of these reactors are related to their suitable gas–solid contact features, high heat and mass transfer rates between phases and bed isothermicity. Fluidized bed reactors have limitations related to the feed and particle size in the bed, with defluidization being the main shortcoming, especially when plastic wastes are handled. The vigorous solid circulation movement in spouted beds allows handling coarse solids with irregular texture.91,92 The suitability of the conical spouted bed reactor has been proven in the pyrolysis of different residues, such as biomass, sewage sludge,93 tires,94 and plastics.75 In fact, a conical spouted bed reactor pilot plant (25 kg h–1) for biomass fast pyrolysis has been successfully operated.95 Thus, the pyrolysis in bubbling fluidized bed reactors was combined with the reforming of the volatiles in fixed49 and fluidized bed54,96 reactors. In the same line, the use of spouted beds in the pyrolysis step was also combined with fixed97,98 and fluidized bed99−101 reforming reactors. Moreover, Efika et al.102 used a screw kiln/fixed bed reactor configuration for the continuous biomass processing. Kuchonthara et al.103 studied biomass pyrolysis-reforming over a K2CO3/NiO/γ-Al2O3 catalyst in a batch reaction unit including a drop tube furnace and fixed bed for the pyrolysis and reforming steps, respectively.

It should be noted that the use of a fast pyrolysis reactor has practical advantages for the full scale operation in the pyrolysis-reforming process. Thus, it ensures an efficient conversion of biomass into volatiles with low yields of char59,104 and therefore increases the H2 production potential of the process. Moreover, these reactors are easy to operate and control in the continuous regime and allow for continuous char removal. In the same line, fluidized beds have advantages for the steam reforming process in relation to fixed beds. On the one hand, a better control of process conditions can be attained, which is essential in the case of temperature in this highly endothermic process. On the other hand, the pyrolysis-reforming process is greatly conditioned by the fast deactivation rate of the catalysts,8,9,105 and the use of a fluidized bed reactor allows implementing advanced catalyst regeneration strategies. Accordingly, a careful selection of the reactor design must be considered for full scale operation.

3. Reforming Catalysts

Although great effort has been devoted to the development of catalysts for the reforming of bio-oil model compounds, the studies conducted by feeding crude bio-oil are scarce. Similarly, few studies deal with the assessment of catalyst performance in the pyrolysis-reforming of plastic wastes. Therefore, knowledge on the performance of reforming catalysts under real process conditions, i.e., with a real pyrolysis volatile composition, is still limited. In fact, most of the studies have been carried out in batch-scale plants, and therefore further research effort is required in order to establish a suitable relationship between catalyst properties and their activity and stability in continuous large-scale plants.

Thus, this section deals with a brief introduction of heterogeneous catalysts, with special attention being paid to catalyst design (section 3.1) and the main causes and mechanisms of catalyst deactivation (section 3.2). Moreover, section 4 summarizes the aspects involving the catalysts used in the literature for biomass and plastic wastes pyrolysis and in-line reforming.

3.1. Catalyst Design

The design of a suitable catalyst for a specific process involves several challenges, as a wide range of features should be considered and optimized in order to achieve the desired performance. Accordingly, a large number of studies have been conducted on the reforming of bio-oil oxygenated compounds on commercial catalysts.50,106,107 However, the starting point for selecting possible materials and conditions for catalyst synthesis requires delving into the mechanisms of the process and the analysis and comparison of literature results.

3.1.1. Catalyst Components

The main components of a typical heterogeneous catalyst are as follows (Figure 4): (i) active phase, metal that provides active sites for the chemical reaction; (ii) support or carrier, high specific surface area oxide or carbon on which the active phase is dispersed and stabilized; and (iii) promoter, additive that improves catalyst properties, i.e., activity, selectivity, and catalyst life.

Figure 4.

Catalyst components.

Consequently, the selection of suitable catalytic materials is one of the most important factors for catalyst synthesis. Accordingly, given that active components are responsible for the main chemical reactions, the metal oxide selected as the active phase should promote reforming and WGS reactions in order to enhance H2 production in the reforming step. Ni-based catalysts have been widely used in the literature for CH4 and naphtha reforming108,109 as well as in the reforming of oxygenated compounds derived from biomass pyrolysis.110−112 Besides, other base transition metals, such as Co or Fe, and especially noble metals, such as Rh, Pt, Ir, and Ru, have been widely studied in the literature.113−115

Moreover, a suitable support must provide a high specific surface area, adequate pore distribution, mechanical strength, and good thermal stability. These two latter features are usually key factors in the steam reforming reactions.116 In addition, an ideal support should not have catalytic activity promoting secondary reactions leading to catalyst deactivation, as happens with Al2O3 support, which although is the most used support in reforming reactions, its acid properties promote coke deposition under reaction conditions and lead to catalyst deactivation.117,118 In this way, the support should facilitate the dispersion of the active phase and modulate catalyst activity.

The addition of the right promoter is an interesting option, since its incorporation into the catalyst enhances activity, selectivity, and stability. The promoters can be used for modifying both the active phase and the support and may therefore contribute to the following aspects: (i) improving thermal stability, as is the case of small amounts of SiO2 or ZrO2 into γ-Al2O3, which shift the phase transition from γ-Al2O3 to α-Al2O3 toward higher temperatures;119 (ii) hindering undesirable secondary reactions leading to catalyst deactivation by coke formation, which are attenuated by adding promoters with basic properties or capacity for gasifying the coke deposited during the reaction;120,121 and (iii) improving the dispersion of the active phase metal.12,122

3.1.2. Catalyst Properties

The design of reforming catalysts implies a compromise involving mechanical, physico-chemical, and catalytic properties. The balance of these interconnected properties is illustrated in Figure 5, with the relative significance of these features being greatly influenced by the process type, reactor design, process conditions, and economic factors. Thus, the selection of a suitable catalyst particle size leads to a good flow distribution and low pressure drop in the reactor for a catalyst having suitable mechanical strength and attrition resistance.

Figure 5.

Properties involving catalyst design.

High activity and selectivity are required for the catalysts, which are mainly influenced by the chemical components making up the catalyst but also by the preparation method and synthesis conditions. Both factors (catalytic materials and synthesis method) play a key role for attaining a proper specific surface area and ensuring a good dispersion of the metal active phase onto the support. In addition, the balance between porosity and mechanical strength should be considered, since a highly porous catalyst leads to a high activity at the expense of decreasing the mechanical strength.123

An active catalyst fulfilling the aforementioned requirements is not enough, but stability should also be considered. Thus, catalyst lifetime depends on its resistance to deactivation mechanisms, which in reforming reactions are mainly metal sintering and coke deposition. Therefore, although thermal stability and coke resistance are sensitive to process conditions, they are usually improved by adding a promoter.117,124

3.1.3. Synthesis Method

This section deals with the description of the usual catalyst synthesis methods in both the laboratory and industry for the preparation of heterogeneous catalysts. Thus, the preparation of an active catalyst can be carried out by different synthesis methods, and the properties obtained are strongly affected by each step in the preparation method and the quality of the raw materials.125

The significance of solid catalysts in large scale processes for the conversion of chemicals, fuels and pollutants is well-known. Moreover, the catalysts may be classified as follows: (i) unsupported (bulk) catalysts, (ii) supported catalysts, (iii) confined catalysts (ship-in-a-bottle catalysts), (iv) hybrid catalysts, and (v) polymerization catalysts, among others.126 However, with the aim of simplifying these groups, some authors have classified them according to the preparation procedure, as follows: (i) bulk catalysts or supports, in which the catalytic active phase is generated as a new solid phase; and (ii) impregnated catalysts, in which the active phase is introduced or fixed on a pre-existing solid by a process depending on the support surface.127 In addition, a third group was included by Hutchings and Védrine,128 i.e., (iii) mixed-agglomerated catalysts, in which the catalyst is an agglomerated mixture of an active substance and the support. However, this type of catalyst has been less frequently used in the literature.

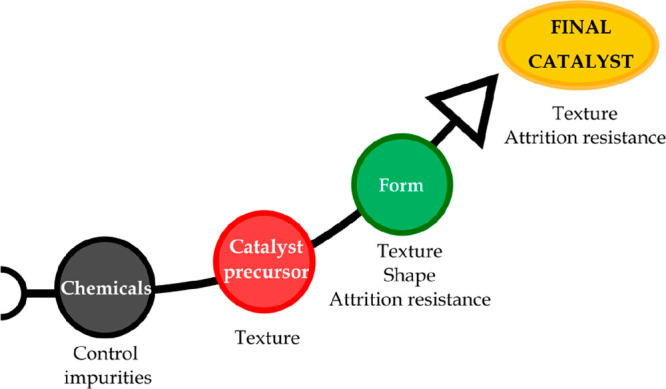

Generally, the catalyst must have certain features for each specific process, such as suitable texture (specific surface area, pore structure, and bulk density), attrition resistance, and shape, with the final properties being highly dependent on the preparation steps (Figure 6).

Figure 6.

Properties acquired by catalysts through the synthesis process.

The catalysts manufactured in industry involve the following steps:128 (i) precipitation or other synthesis processes, e.g., sol–gel, solid–solid, flame hydrolysis, vapor deposition; (ii) hydrothermal transformation; (iii) decantation, filtration, centrifugation; (iv) washing; (v) crushing and grinding; (vi) forming and/or shaping operations; (vii) calcination; (viii) impregnation; (ix) mixing; and (x) activation, reduction. Thus, a general scheme of catalyst preparation and formation is shown in Figure 7.

Figure 7.

General scheme for catalyst preparation and formation.129

As mentioned above, the catalysts may be classified into non-supported or bulk, supported, and mixed-agglomerated ones. The different types of catalysts and their preparation methods are briefly explained below.

3.1.3.1. Bulk Catalysts

Bulk catalysts are mainly made up of an active substance, although some inert binder is frequently added to ease the forming and/or shaping operation. The addition of this binder only influences the mechanical strength and should therefore be considered when operating under certain conditions in specific reactors. Accordingly, bulk catalysts can be used without binder addition, with the catalysts being prepared by high-temperature fusion.

Among the methods for preparing bulk catalysts, the following ones are worth mentioning: (i) precipitation, which is the most widely used for its simplicity and cost; (ii) sol–gel, which allows the preparation of aerogels or xerogels; (iii) hydrothermal synthesis; and (iv) flame hydrolysis.

3.1.3.2. Supported Catalysts

Supported catalysts have been widely used in both laboratory and large scale plants, given that they have certain advantages, such as: (i) high active phase dispersion, (ii) high mechanical strength and thermal conductivity, (iii) suitable catalytic properties by means of different metal–support interactions, and (iv) suitable for preparing bifunctional catalysts.

Moreover, some of the bulk materials previously described as unsupported catalysts can also be used as supports, with the most widely used being Al2O3, SiO2, TiO2 or ZrO2.126 Thus, the support can be synthesized following the different steps displayed in Figure 7. However, commercial preformed supports are usually considered more convenient, efficient, and economic,116 given that they already have the desired porous texture and mechanical strength.

Once the support with the optimum physical, chemical, and mechanical properties has been prepared or selected and stabilized with additives if required, the active phase is dispersed on the support by one of the following methods: (i) precipitation, (ii) adsorption, (iii) ion exchange, and (iv) impregnation. All these methods have certain advantages and disadvantages, and the selection of one or the other depends on the final features required for the catalyst. These methods are described below.

3.1.3.2.1. Precipitation

The aim of the precipitation method is to achieve the following reaction:

| 8 |

The choice of the salt precursor or the alkali depends on several factors, with the most influential being the possible detrimental effects on the final catalyst.116 Thus, the support, frequently powder, is slurried with enough amount of salt solution to reach the desired metal loading. Subsequently, enough alkali solution is added to cause precipitation, and the powder is then filtered or separated and washed to remove alkali ions, reagent anions, and an excess deposit on the outside of the particles. After washing, the excess of moisture is removed from the pores by drying, which is not a problematic step given that the active component is firmly anchored to the surface. The calcination step is then carried out to decompose the metal salt precursors into their oxidized form.

Moreover, the processes involved in the precipitation are as follows: (i) precipitation from bulk solutions or from pore fluids and (ii) interaction with the support surface. The precipitation takes place in three steps, supersaturation, nucleation, and growth, and depends on concentration, temperature, pH, and ripening.125,127 This method is usually preferred when loadings higher than 10–20% are required.

3.1.3.2.2. Adsorption

In this process, the support is exposed to metal salt solutions in which equilibrium amounts of salt ions are adsorbed following adsorption isotherms. Depending on the properties of the support surface, the adsorption can be cationic or anionic. This process is greatly influenced by the adsorption conditions, especially by the pH of the solution.126

The equilibrium reactions involved in the ionic adsorption (except for zeolites) are as follows:

| 9 |

| 10 |

Moreover, the support (as powder or particle form) is dehydrated and soaked into the solution for a suitable period of time, leading to a uniform active phase distribution, with the pores being properly filled during the soaking time. Likewise, drying and calcination steps are required.

Therefore, although this is an excellent method when low metal loadings are required, the amount of metal loading allowed until the saturation point is generally small (e.g., loadings of 2–3 wt % of Ni on Al2O3 are obtained).116

3.1.3.2.3. Ion Exchange

The catalyst synthesis by ion exchange is very similar to ionic adsorption. However, it involves the exchange of an ion by electrostatic interaction with the support surface by another ion species.125,127 The support containing ions A is plunged into an excess volume (compared to the pore volume) of a solution containing ions B, which gradually penetrate into the pores of the support, while ions A pass into the solution until equilibrium is reached, according to the following reaction:130

| 11 |

with s and z being the solution and the support, respectively. This is an adequate method for removing harmful agents and adding promoters and is considered as a promising alternative for the modification of catalytic materials.116

3.1.3.2.4. Impregnation

Impregnation is the simplest and most direct method to deposit the active phase onto the support. It implies the contact between a certain volume of active phase metal precursor and the solid support, with the solvent being removed in a subsequent drying step. This methodology allows improving the metal dispersion on the support, although the selection of the suitable metal salt precursor also plays a key role in the final dispersion.131

Depending on the volume of the solution, the impregnation may be classified as follows: (i) wet impregnation, in which an excess of solution is used, and (ii) incipient wetness impregnation, in which the volume of a solution with appropriate concentration is equal or slightly lower than the pore volume of the support.

In this method, the solubility of the precursor in the solution limits the maximum metal loading, although another impregnation step may be conducted after the drying or calcination step when higher metal loadings are required.

Furthermore, the drying process, which is necessary to crystallize the salt on the pore surface, may lead to irregular and uneven concentration, and this step should therefore be slow enough to form uniform deposits. Moreover, the calcination step, in which the salt precursor is converted into its oxide form, also plays a key role in the final metal dispersion.116

3.1.3.3. Physical Mixing

Mixed agglomerated catalysts are prepared by this method. These catalysts are prepared by physically mixing the active substances with a powdered support or support precursors in a ball mill. The final mixture is then agglomerated and activated.

The selection of a given preparation method and its synthesis steps condition the catalyst properties and therefore its overall performance in the pyrolysis-reforming step. In order to analyze their influence in detail, these studies should be performed under similar operating conditions. Although few research studies have investigated the influence the synthesis method and conditions have on the reforming step, the main studies are summarized and discussed in section 4.

3.2. Mechanism of Catalyst Deactivation

Over the last decades, the mechanisms and causes of catalyst activity decay have been widely analyzed in order to step further into the knowledge of catalysis, thereby establishing the basis for modeling deactivation processes, improving catalyst design, and preventing or slowing the degradation of the catalyst.116,123,129,132,133

The economic feasibility of a given catalytic process largely depends on the activity and catalyst lifetime, and although the catalyst activity decay with time is unavoidable, certain strategies may be developed in order to improve its performance during the reaction step. Thus, possible causes of catalyst deactivation and their mechanisms are described below.

The causes of catalyst deactivation can be ascribed to three main factors: (i) mechanical, (ii) thermal, and (iii) chemical. However, deactivation is not the consequence of a single mechanism, but usually their combination is responsible for the catalyst degradation. Table 2 shows the main causes of catalyst activity decay. As observed, the mechanisms may be classified as follows: (i) poisoning, (ii) coking and fouling, (iii) sintering, (iv) component volatilization, (v) inactive compound formation, (v) phase transformation, and (vi) particle failure or attrition.

Table 2. Causes of Catalyst Deactivation.

| Mechanism | Type | Result |

|---|---|---|

| Poisoning | Chemical | Loss of active sites |

| Fouling/coking | Mechanical/chemical | Loss of surface, plugging |

| Sintering | Thermal | Loss of surface |

| Component volatilization | Thermal/chemical | Loss of catalytic phases |

| Inactive compound formation | Thermal/chemical | Loss of catalytic phases and surface |

| Phase change | Thermal | Loss of surface |

| Particle failure | Mechanical | Bed channeling, plugging |

3.2.1. Poisoning

Poisoning is the strong chemisorption of reactants, products, or impurities on sites otherwise available for catalysis.134 The fact that a compound acts as a poison depends on the nature of the process and the adsorption strength of this compound to physically block the active sites. Besides, the poison can lead to the modification of the catalyst structure or formation of a compound.

Moreover, the decrease in catalytic activity as a consequence of poisoning can involve the following aspects: (i) physical blockage of the adsorption/reaction sites; (ii) electronic modification of the nearest metal atoms, thus hindering their capability to adsorb and dissociate the reactants; (iii) dramatic changes in the catalytic properties by rearranging the catalyst surface; (iv) blockage of reactant access; and (v) hindrance of surface diffusion of adsorbed reactants.123

Most of the compounds considered as poisons are contained in the feed in small quantities and deactivate the catalyst following a different mechanism from the main reaction. However, poisons can also be generated either in parallel or in a series of reactions, resulting in catalyst activity decay.116

The irreversibility of poisoning and catalyst regenerability are greatly influenced by the type of poison, the catalyst, and the process. Thus, the main poison of reforming catalysts is sulfur, which may be in the feed as an organic sulfur compound, at concentrations of up to 1500 ppm.135 However, the catalyst tolerance against poisons depends on the materials that make up the catalyst, with the best performance against poisoning deactivation having been reported for noble metal based catalysts.136,137

3.2.2. Fouling/Coking Deposition

The physical formation of species deposits from the fluid phase on the catalyst surface is the common mechanism of deactivation known as coking or fouling, although this latter term can also be associated with other types of deposition from the reactor material.138 Fouling leads to a loss of activity due to the blockage of active sites and/or pores and may involve the breakup of catalyst particles and reactor plugging.123

The consequences of carbon deposition are shown in Figure 8 and may be summarized as follows: (i) the coke deposited is strongly chemisorbed to the metal particle or physically adsorbed in a multilayer, hindering the access of reactants to the active sites; (ii) full deactivation of the metal particle due to its complete encapsulation by coke deposition; (iii) blockage of the support pores, hindering the access of the reactants to the active sites; and (iv) fracture of the support material due to the formation and growth of filaments, which may lead to reactor plugging.134

Figure 8.

Deactivation by carbon deposition.

The mechanisms of coke formation and its intrinsic nature are greatly influenced by the feed, the type of process, and its operating conditions. Moreover, the nature of this coke may evolve with time on stream. Thus, some authors have reported that the main coke precursors are aromatics and/or olefins, which by reactions of dehydrogenation, condensation, and oligomerization, lead to coke formation.138

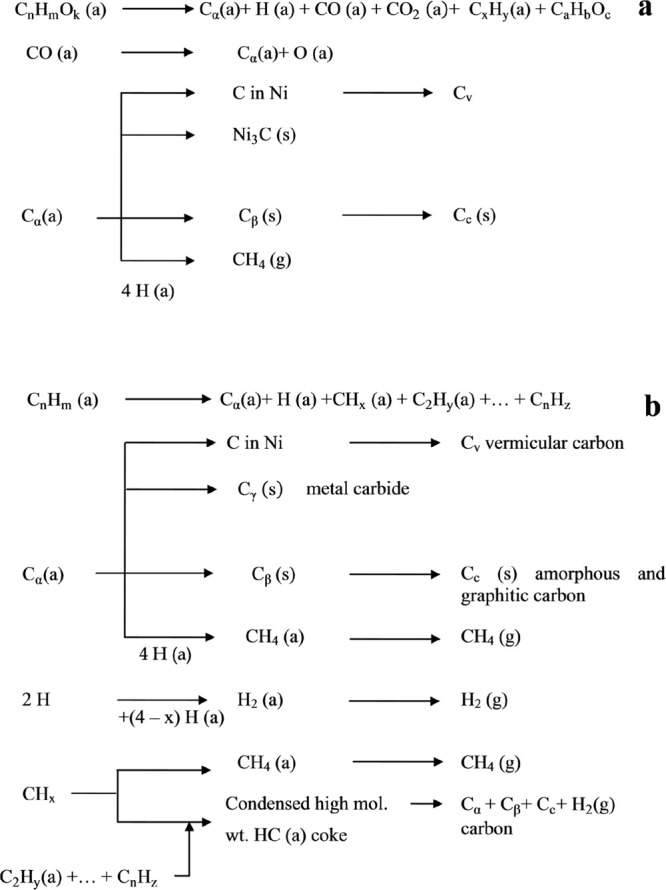

Several authors have studied the mechanisms of carbon deposition and coke formation on metal catalysts from carbon monoxide and hydrocarbons in steam reforming reactions.133,134,139 Accordingly, the mechanisms proposed by Bartholomew139 are presented in Figure 9.

Figure 9.

Mechanisms of coke formation and transformation during the reforming of oxygenates (CnHmOk) (a) and hydrocarbons (CnHm) (b). ((a), (g), and (s) refer to the adsorbed, gaseous, and solid states, respectively); gas phase reactions are not considered. Reproduced with permission from ref (139), Copyright 1982 Taylor & Francis Ltd. and ref (140), Copyright 2020 Elsevier.

As observed, the nature and morphology of the coke formed differs depending on the different reactions described above, with its formation and nature depending on the reaction conditions (Table 3).

Table 3. Carbon Species Formed According to the Aforementioned Mechanisms123.

| Structural type | Designation | Temp formed (°C) |

|---|---|---|

| Adsorbed, atomic (surface carbide) | Cα | 200–400 |

| Polymeric, amorphous films or filaments | Cβ | 250–500 |

| Vermicular filaments, fibers, and/or whiskers | Cv | 300–1000 |

| Nickel carbide (bulk) | Cγ | 150–250 |

| Graphitic (crystalline) platelets or films | Cc | 500–550 |

Furthermore, as mentioned above, the mechanism of catalyst deactivation and coke formation is greatly influenced by the feed. Thus, in the steam reforming of the volatiles derived from the pyrolysis of biomass and plastic wastes, the cracking of oxygenates (eq 1) and hydrocarbons, HCs (eq 2), respectively, should be taken into account.

Accordingly, Ochoa et al.141 analyzed the role oxygenates play in the catalyst deactivation in the steam reforming of bio-oil and distinguished between two types of coke: (i) encapsulating coke, with mainly aliphatic nature and oxygenates in its composition, since its precursors are mostly bio-oil oxygenates adsorbed on the metallic sites, and (ii) filamentous coke, with a higher ordering and carbonization in its structure, i.e., more polyaromatic and olefinic compounds, whose possible precursors are CO and CH4, largely contributing to a more severe catalyst deactivation. Likewise, the same authors evaluated the deactivation mechanisms of a Ni supported catalyst in the pyrolysis-steam reforming using HDPE as raw material.142 They reported that the mechanisms of coke formation follow two consecutive steps: (i) the formation of amorphous and encapsulating coke by condensation of promoters, and (ii) carbonization of adsorbed coke promoters leading to the formation of filamentous coke.

Thus, the formation of carbon deposits on metal oxides involves cracking reactions of the coke precursors, which are catalyzed by the acid sites, and may evolve to a more condensed coke by dehydrogenation and cyclization reactions.123

Several characterization techniques have been used in the literature in order to analyze catalyst and coke properties during the catalyst deactivation in the reforming step.140 Thus, Ochoa et al.143 conducted a detailed analysis of the evolution of catalyst deactivation in the biomass pyrolysis and in-line steam reforming. Thus, they determined coke content by TG-MS/TPO and analyzed its morphology by scanning and transmission electron microscopy (SEM and TEM), reporting its encapsulating nature as the main cause of catalyst decay.

SEM and TEM images have also been used in the pyrolysis-reforming of wastes plastics for analyzing the nature of the coke deposited. Thus, Barbarias et al.46 reported the presence of filamentous carbon in the reforming of HDPE pyrolysis volatiles, although no filamentous carbon was observed in the coke deposited when PS was used as the feedstock.

3.2.3. Sintering

The agglomeration and growth of the catalyst metal crystallites is the process known as sintering, which is influenced by several factors, such as temperature and the reaction medium, among others.135 Thus, high temperatures, typically above 500 °C, and the presence of steam promote the sintering phenomenon, leading to irreversible or difficult to reverse deactivation of the catalyst. Besides, the metal type and its dispersion on the support, the presence of promoters or impurities on the surface, and the textural properties of the support greatly influence the sintering rates.134

The influence of temperature on metal sintering has been correlated as follows:

| 12 |

| 13 |

where Tm is the melting point temperature in K. Accordingly, atomic particles on the surface, especially surface atoms weakly bound to defect sites, become mobile at temperatures above the Hüttig temperature, and bulk metal atoms acquire enough thermal energy to migrate within the crystallite at temperatures above the Tamman one.116,138

The mechanisms whereby metal particles increase in size may occur as illustrated in Figure 10, and they are summarized as follows: (i) atomic migration, which implies metal atom detachment from crystallites and their migration to the support surface, where they are finally captured by larger metal particles; (ii) migration of entire crystallites, forming larger particles by collision and coalescence; and (iii) spreading and splitting.123,134

Figure 10.

Deactivation by sintering.

The catalyst activity decay by sintering may lead to: (i) crystallite growth on the catalytic phase, decreasing the catalytic surface area, and (ii) collapse of the support and/or support pores, involving a loss of catalytic surface area and loss of support area.

Moreover, the support may also be subject to sintering involving the following processes: (i) surface diffusion, (ii) solid-state diffusion, (iii) grain boundary diffusion, (iv) evaporation/condensation of volatile atoms or molecules, and (v) phase transformations.123 These two latter processes are explained in the following sections.

3.2.4. Component Volatilization

The catalyst deactivation by direct volatilization of catalytic metals hardly plays a significant role in the catalyst activity decay, given that extremely high temperatures are required (normally, up to 1000 °C) for this process. On the contrary, the formation of volatile compounds, such as metal carbonyls, oxides, sulfides, and halides, which lead to a loss of catalytic material, can take place at moderate temperatures.123

Some examples of catalyst deactivation by component volatilization are found in the regeneration of molybdenum-containing catalysts in the hydrotreating process when temperatures of up to 800 °C are attained (Mo vaporizes at this temperature). It also applies in the naphtha steam reforming, although coke formation from heavier hydrocarbons is controlled in this process with potassium. Nevertheless, volatile KOH compound may be formed in the presence of steam, which accelerates coke formation.138

3.2.5. Inactive Compound Formation

A further chemical route leading to catalyst deactivation is the reaction between the vapor phase and the catalyst surface to produce inactive phases instead of strongly adsorbed species, which lead to a decrease in catalyst activity. Moreover, these reactions are usually promoted at high temperatures and can be easily detected by the X-ray diffraction (XRD) technique.

Accordingly, the reaction between the active phase of nickel with common supports, such as Al2O3 or SiO2 to form nickel aluminates or silicates, the formation of oxides with steam when cobalt or iron are used,116 or the oxidation, sulfidation, or carbidation of the metal active phase involve the loss of catalytic activity.134

3.2.6. Phase Transformation

Phase transformation is the consequence of the thermal degradation of the support and adversely affects physical or chemical catalyst properties. Thus, the support can be induced by thermal treatment to attain a phase modification, as in the case of the Al2O3 support, which can change from γ-Al2O3 to a transitional phase with lower specific surface area (δ-Al2O3, θ-Al2O3...) until reaching the most stable phase (α-Al2O3). Consequently, the supported catalyst surface area decreases, and therefore activity drops. Several authors have called this process support sintering.123 Moreover, the addition of small amounts of silica may contribute to control this phase change.131

3.2.7. Particle Attrition

The catalyst mechanical failure can arise from (i) granule, pellet, or monolithic crush when loading; (ii) attrition or reduction/breakup of the catalyst particle size forming fine particles, especially in fluidized bed reactors; and (iii) erosion of the catalyst particles when high fluid velocities are used.134 As a result, reactor plugging or channeling may occur, leading to an increase in pressure drop and non-uniform bed performance. Thus, thermal and coking effects promote other catalyst deactivation mechanisms.

In order to prevent catalyst attrition, the following alternatives have been proposed in the literature: (i) increasing strength by advanced catalyst synthesis methods, (ii) adding binders to improve strength and toughness, (iii) coating aggregates with porous but very strong materials, and (iv) inducing compressive catalyst stress by chemical or thermal tempering.123,134

4. Application of Metallic Catalysts in the Pyrolysis-Reforming Process

In recent decades, the development and study of a wide range of different metal catalysts has been approached in the literature for the reforming of oxygenates derived from biomass pyrolysis. However, most of these studies have been conducted by using model compounds144−146 or the aqueous fraction of the bio-oil.34,36,107 Similarly, the valorization of different waste plastics, namely, polyolefins (HDPE, LDPE, and PP), polystyrene (PS), polyethylene terephtalate (PET), and real world plastics recovered from municipal solid waste (MSW), or even the joint co-feeding of biomass and plastics mixtures, has attracted increasing attention in the two-step pyrolysis-reforming process in recent years due to the great versatility of this strategy.54,56,147,148 Furthermore, special attention has been paid to the design of a suitable reforming catalyst for the production of H2. This section reviews the catalysts used in the literature for the two-step processing of biomass, plastic wastes, and biomass/plastics mixtures, in which pyrolysis is carried out in the first step and in-line steam reforming of the volatiles in the second one.

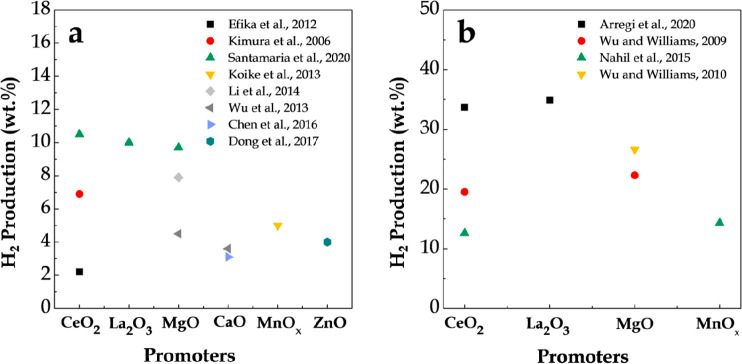

Accordingly, and with the aim of easing the comparison of the different catalysts, the following sections have been considered: (i) Ni/Al2O3 catalysts, which are the most widely used because Al2O3 support provides a high specific surface area, eases Ni dispersion, and confers mechanical strength and stability upon the catalyst149 (section 4.1); (ii) Ni supported on other materials, either on several metal oxides, such as SiO2, MgO, ZrO2, or TiO2 or on other types of supports, such as chars obtained from the fast pyrolysis of different biomasses, dolomite, chicken dropping (CD), or pig manure compost (PC), among others (section 4.2); (iii) Ni/Al2O3 catalysts modified with different promoters, such as CeO2, MgO or alkali compounds, which improve the properties of the bare catalyst and therefore enhance its activity or stability (section 4.3); and (iv) bimetallic and non-Ni based catalysts containing alternative active phases, such as Fe, Co, or Cu, or even noble metals, such as Rh, Pd, Ru, or Pt, which are generally more active than Ni (section 4.4).

Figure 11 shows the main components used as catalytic materials, namely, the active phase, promoter, or support, in the catalyst design for H2 production from the steam reforming of the volatiles derived from the pyrolysis of biomass, plastic wastes, and their mixtures. Thus, the suitability of these elements has been classified according to a color code, with green, yellow, and red being good, moderate, and poor performances, respectively.

Figure 11.

Main elements studied in the catalyst design for H2 production from the pyrolysis and in-line steam reforming process using biomass, plastic wastes, and biomass/plastic mixtures as feedstock. Adapted from ref (12). Copyright 2009 American Chemical Society.

4.1. Ni/Al2O3 Catalysts

Ni/Al2O3 catalysts (both commercial and prepared) have been widely studied in the literature on the reforming reactions.50,110,150,151 Thus, Ni has proven to be highly active on the reforming of the volatiles derived from biomass and plastic wastes pyrolysis as well as on methane steam reforming, WGS reaction, and ammonia decomposition.11,152,153 Moreover, its moderate cost made this metal an interesting option compared to other active phases, such as noble metals (Rh, Ru, Pd, Pt...). Similarly, Al2O3 is the most widely used support in reforming reactions, and its suitable properties (e.g., high specific surface area) allow an adequate Ni dispersion and provide stability and mechanical strength upon the catalyst, making this support suitable for fluidized bed reactor configurations.149 Nonetheless, catalysts supported on Al2O3 undergone a severe deactivation by carbon deposition, which is promoted by the acid properties of this support.100,117

Regarding the crystalline phases of the Al2O3 support, significant differences in the catalyst properties can be observed. Thus, the transition from γ-Al2O3 to α-Al2O3, which is usually formed at extremely high temperatures (>1200 °C) through intermediate crystal phases such as θ- and δ-Al2O3, leads to a remarkable decrease in the specific surface area of the support and therefore to a poorer active phase dispersion on the catalyst. Furthermore, the metal–support interaction is also influenced by the type of Al2O3 selected, and the reducibility of the metal catalyst is therefore modified, i.e., weaker interaction between metal and α-Al2O3 is obtained in comparison with γ-Al2O3, which is more likely to form a spinel phase.154 Besides, α-Al2O3 has proven to be attrition resistant when operating in fluidized bed reactors.155

Moreover, the acidity of the support is related to the crystalline phase of the Al2O3 support. Thus, the acid sites of γ-Al2O3 promote carbon deposition on the catalyst surface, which is the main cause of catalyst deactivation in reforming reactions.

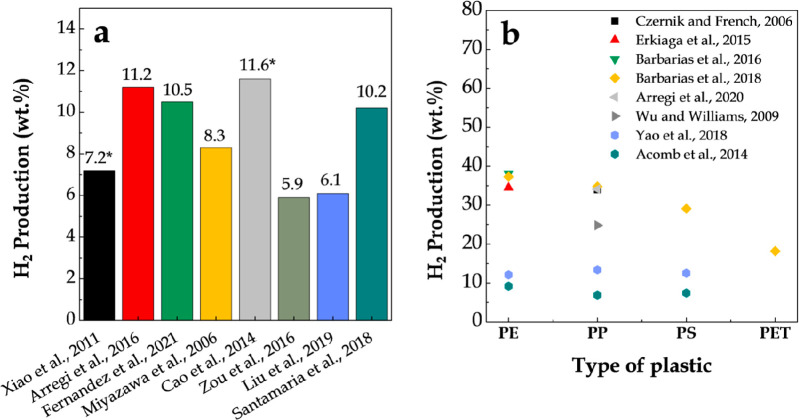

As mentioned before, the operating conditions, type of reactor configuration, and the catalyst selected in the pyrolysis-reforming strategy greatly influence the overall H2 production. Accordingly, Tables 4–6 summarize the main results reported in the literature for Ni/Al2O3 catalyst for the pyrolysis-steam reforming process of biomass, plastic wastes, and biomass/plastics mixtures. In regards to the use of biomass as raw material (Table 4), an extensive use of commercial catalysts has been reported in the literature. Xiao et al.61 carried out a parametric study in a two-step fluidized bed/fixed bed configuration, using wood chips and pig manure compost as feedstock and Ni/Al2O3 and Ni/BCC (brown coal char) as catalysts. Although Ni/Al2O3 undergoes gradual catalyst deactivation, mainly by carbon deposition, wood chip biomass leads to higher H2 productions compared to pig manure compost (7.2 and 5.0 wt %, respectively, on dry and ash free, daf).

Table 4. Ni/Al2O3 Catalysts Reported in the Literature for the Pyrolysis and In-line Steam Reforming of Biomass.

| Catalyst | Feed | Preparation methoda | Reactor configuration | Operating conditionsc | H2 conc. (vol %) | H2 prod. (wt %) | Ref. |

|---|---|---|---|---|---|---|---|

| 20Ni/Al2O3 | pine wood | commercial | fluidized/fixed (1–2 g min–1) | TP = 530–700 °C | 60.0 | 7.2b | Xiao et al.61 |

| TR = 550–710 °C | |||||||

| 20Ni/Al2O3 | pig manure compost | commercial | fluidized/fixed (1–2 g min–1) | TP = 530–700 °C | 56.2 | 5.0b | Xiao et al.61 |

| TR = 550–710 °C | |||||||

| 11Ni/Al2O3 | pine wood sawdust | commercial (G90 LDP) | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 66.0 | 11.2 | Arregi et al.50 |

| TR = 550–700 °C | |||||||

| S/C = 7.7 | |||||||

| 11Ni/Al2O3 | pine wood sawdust | commercial (G90 LDP) | spouted/fixed (0.75 g min–1) | TP = 500 °C | 64.5 | 10.5 | Fernandez et al.98 |

| TR = 600 °C | |||||||

| S/C = 7.7 | |||||||

| 10Ni/Al2O3 | wood sawdust | commercial | fixed/fixed (1 g) | TP = 300–600 °C | 38.1 | 2.2 | Olaleye et al.158 |

| TR = 800 °C | |||||||

| 20Ni/Al2O3 | sewage sludge | commercial | fixed/fixed | TP = 900 °C | 70.0 | 11.6b | Cao et al.156 |

| TR = 400–750 °C | |||||||

| 20Ni/Al2O3 | Japanese cypress | commercial | fixed/fixed (1 g) | T = 450 °C | 35.2 | 5.0b | Kannari et al.159 |

| 12Ni/Al2O3 | cedar wood | iwi | dual fixed bed (0.06 g min–1) | T = 550–650 °C | 60.1 | 8.3 | Miyazawa et al.89 |

| S/C = 0.5 | |||||||

| 20Ni/Al2O3 | wood pellets | iwi | screw-kiln/fixed (4 g min–1) | TP = 500 °C | 44.4 | 2.4 | Efika et al.102 |

| TR = 760 °C | |||||||

| 10Ni/Al2O3 | pine wood sawdust | wi | spouted bed/fluidized (0.75 g min–1) | TP = 500 °C | 64.2 | 10.2 | Santamaria et al.51,100 |

| TR = 600 °C | |||||||

| S/C = 7.7 | |||||||

| 3Ni/Al2O3 | pine sawdust | wi | entrained-flow/fixed (4 g min–1) | TP = 900 °C | 49.3 | 6.1 | Liu et al.160 |

| TR = 800 °C | |||||||

| 15Ni/Al2O3 | cellulose | wi | fixed/fixed (1.5 g) | TP = – | 5.9 | Zou et al.161 | |

| TR = 800 °C | |||||||

| 10Ni/Al2O3 | rice husk | iwi | fixed/fixed (2 g) | TP = 550 °C | 57.6 | 3.7 | Akubo et al.157 |

| TR = 750 °C | |||||||

| 10Ni/Al2O3 | coconut shell | iwi | fixed/fixed (2 g) | TP = 550 °C | 58.2 | 4.4 | Akubo et al.157 |

| TR = 750 °C | |||||||

| 10Ni/Al2O3 | sugar cane | iwi | fixed/fixed (2 g) | TP = 550 °C | 59.2 | 4.6 | Akubo et al.157 |

| TR = 750 °C | |||||||

| 10Ni/Al2O3 | palm kernel shell | iwi | fixed/fixed (2 g) | TP = 550 °C | 57.4 | 5.1 | Akubo et al.157 |

| TR = 750 °C | |||||||

| 10Ni/Al2O3 | cotton stalk | iwi | fixed/fixed (2 g) | TP = 550 °C | 58.0 | 4.1 | Akubo et al.157 |

| TR = 750 °C | |||||||

| 10Ni/Al2O3 | wheat straw | iwi | fixed/fixed (2 g) | TP = 550 °C | 54.1 | 3.3 | Akubo et al.157 |

| TR = 750 °C | |||||||

| 9Ni/Al2O3 | rice husk | wi | drop-tube fixed bed (120 mg) | T = 800 °C | 32.8 | 1.2 | Kuchonthara et al.103 |

| 10Ni/Al2O3 | pine wood | wi | fixed/nonthermal plasma (1 g) | TP = 600 °C | 0.8 | Blanquet et al.162 | |

| TR = 250 °C | |||||||

| steam = 2 g h–1 |

iwi, Incipient wetness impregnation; wi, wetness impregnation.

H2 production defined as gH2/100 gbiomass, daf (dry and ash free).

TP = pyrolysis temperature; TR = reforming temperature.

Table 6. Ni/Al2O3 Catalysts Reported in the Literature for the Pyrolysis and In-line Steam Reforming of Biomass and Plastic Mixtures.

| Catalyst | Feed | Preparation methoda | Reactor configuration | Operating conditionsb | H2 conc. (vol %) | H2 prod. (wt %) | Ref. |

|---|---|---|---|---|---|---|---|

| 11Ni/Al2O3 | pine wood sawdust HDPE 0, 25, 50, 75, 100 | commercial (G90 LDP) | spouted bed/fluidized (0.75 g min–1) | TP = 500 °C | 71.1 | 24.6 | Arregi et al.57 |

| TR = 700 °C | |||||||

| S/(B + P) = 4 | |||||||

| 10Ni/Al2O3 | rice husk (RH) PE 0, 25, 50, 75, 100 | wi | fixed/fixed (1 g) | TP = 600 °C | 46.0 | 4.4 | Xu et al.148 |

| TR = 800 °C | |||||||

| steam = 2 mL h–1 | |||||||

| 10Ni/Al2O3 | pine wood sawdust PP B/P = 80/20 | wi | fixed/fixed (2 g) | TP = 600 °C | 52.1 | 5.5 | Alvarez et al.147 |

| TR = 800 °C | |||||||

| Steam = 4.74 mL h–1 | |||||||

| 10Ni/Al2O3 | pine wood sawdust HDPE B/P = 80/20 | wi | fixed/fixed (2 g) | TP = 600 °C | 52.2 | 5.1 | Alvarez et al.147 |

| TR = 800 °C | |||||||

| steam = 4.74 mL h–1 | |||||||

| 10Ni/Al2O3 | pine wood sawdust PS B/P = 80/20 | wi | fixed/fixed (2 g) | TP = 600 °C | 49.2 | 4.0 | Alvarez et al.147 |

| TR = 800 °C | |||||||

| steam = 4.74 mL h–1 | |||||||

| 10Ni/Al2O3 | pine wood sawdust real plastics (RP) B/P = 80/20 | wi | fixed/fixed (2 g) | TP = 600 °C | 51.3 | 4.4 | Alvarez et al.147 |

| TR = 800 °C | |||||||

| steam = 4.74 mL h–1 | |||||||

| 10Ni/Al2O3 | HDPE-pine sawdust (5:5) | cp | fixed/fixed (0.5 g) | TP = 800 °C | 59.8 | 6.4 | Chai et al.166 |

| TR = 700 °C | |||||||

| steam = 5 mL h–1 | |||||||

| 10Ni/Al2O3 | PP-pine sawdust (5:5) | cp | fixed/fixed (0.5 g) | TP = 800 °C | 61.8 | 5.0 | Chai et al.166 |

| TR = 700 °C | |||||||

| steam = 5 mL h–1 | |||||||

| 10Ni/Al2O3 | PS-pine sawdust (5:5) | cp | fixed/fixed (0.5 g) | TP = 800 °C | 60.4 | 4.9 | Chai et al.166 |

| TR = 700 °C | |||||||

| steam = 5 mL h–1 |

wi, Wetness impregnation; cp, co-precipitation.

TP, Pyrolysis temperature; TR, reforming temperature.

Moreover, Arregi et al.50 studied H2 production by continuous fast pyrolysis (500 °C) of pine wood sawdust in a conical spouted bed reactor (CSBR) followed by in-line steam reforming of the pyrolysis vapors in a fluidized bed reactor. A commercial Ni/Al2O3 catalyst was highly active, with a H2 production of 11.2 gH2 100 gbiomass–1 at a reforming temperature of 600 °C, a space time of 20 gcat min gvolatiles–1, and a S/B ratio of 4. A similar H2 production was obtained by Fernandez et al.98 under the same operating conditions but using a CSBR and a fixed bed reactor for the pyrolysis and reforming steps, respectively. Despite this latter configuration led to lower catalyst deactivation, especially when low space times were used, the advantages of fluidized beds should be taken into account for further scalability of this strategy.

Furthermore, Cao et al.156 evaluated the performance of a commercial Ni/Al2O3 catalyst on the low-temperature catalytic reforming of volatiles and nitrogen compounds from sewage sludge (SS) pyrolysis in a two-step fixed bed reactor. They observed that although the results significantly depend on the operating conditions, a H2-rich gas stream with a content of 68.0 vol % and a H2 production of 11.6 wt % (daf) were obtained at 650 °C.

Besides, the synthesis of the Ni/Al2O3 catalysts has been analyzed in detail in the literature. Thus, Akubo et al.157 prepared a 10 wt % Ni based Al2O3 catalyst by incipient wetness impregnation and investigated the pyrolysis-catalytic steam reforming of six agricultural biomass waste samples (rice husk, coconut shell, sugar cane bagasse, palm kernel shell, cotton stalk, and wheat straw) in a two-step fixed bed reactor. The results for the different types of biomasses revealed that H2 production ranged from 3.3 wt % for wheat straw to 5.1 wt % for palm shell kernel. Efika et al.102 analyzed the performance of different prepared catalysts (Ni/Al2O3, Ni/CeO2-Al2O3 and Ni/SiO2) in a two-step continuous screw-kiln reactor, in which biomass pyrolysis (500 °C) and the subsequent catalytic steam reforming of the pyrolysis oils and gases was conducted (760 °C). They found that Ni/Al2O3 catalyst was the most effective one for H2 production, i.e., it allowed obtaining the highest H2 concentration of 44.4 vol %. Moreover, they characterized the coke deposited on this deactivated catalyst by SEM images and reported the presence of filamentous carbon. Santamaria et al.51,100 obtained a H2 production of 10.2 wt % in a CSBR-fluidized bed reactor configuration with pinewood sawdust being continuously fed at a rate of 0.75 g min–1 and using a 10Ni/Al2O3 catalyst prepared by the wet impregnation method.

Likewise, Ni/Al2O3 has been widely selected for waste plastic valorization by pyrolysis-reforming runs due to the aforementioned advantages, i.e., suitable activity, moderate cost, high specific surface area, good metal dispersion, and appropriate mechanical strength. Thus, Table 5 shows the main studies dealing with the pyrolysis-reforming of different waste plastics using Ni/Al2O3 as a reforming catalyst. The initial studies reported in the literature were performed by Czernik and French,54 who developed a continuous process consisting of two fluidized bed reactors. A commercial Ni reforming catalyst (C11-NK) used in industry for naphtha reforming was selected and PP was continuously fed at a rate of 1 g min–1. Operating at pyrolysis and reforming temperatures of 650 and 800 °C, respectively, these authors reported a H2 production of 34 wt %. A similar H2 production was reported by Erkiaga et al.,97 who conducted the continuous HDPE pyrolysis and in-line steam reforming in a bench scale plant consisting of a conical spouted bed and a fixed bed reactor for the pyrolysis and reforming steps, respectively, and using a commercial Ni based catalyst (G90-LDP). Under the optimum operating conditions, i.e., pyrolysis and reforming temperatures of 500 and 700 °C, respectively, and a S/C ratio of 3.1, they reported a H2 production of 34.5 wt %. However, due to the operational problems related to coke formation, Barbarias et al.44 conducted a parametric study in the same experimental unit but using a fluidized bed reactor instead of a fixed one. Thus, they reported a H2 production of 38.1 wt % at a reforming temperature of 700 °C and with a S/C ratio of 3.89. The good performance of this technology was further demonstrated in a later study on the valorization of different plastic wastes (PP, PET, and PS) and their mixtures.56 In this latter study, the highest H2 production was obtained with polyolefin plastics (37.3 and 34.8 wt % for HDPE and PP, respectively). However, a considerably lower H2 production was reported with PET (18.2 wt %), which is evidence of the high influence of the volatile composition and therefore of the plastic type selected.

Table 5. Ni/Al2O3 Catalysts Reported in the Literature for the Pyrolysis and In-line Steam Reforming of Plastic Wastes.

| Catalys | Feed | Preparation methoda | Reactor configuration | Operating conditionsb | H2 conc. (vol %) | H2 prod. (wt %) | Ref. |

|---|---|---|---|---|---|---|---|

| Ni/Al2O3 | PP | commercial C11-NK | fluidized/fluidized (1 g min–1) | TP = 600 °C | 70.0 | 34.0 | Czernik and French54 |

| TR = 850 °C | |||||||

| S/C = 4.6 | |||||||

| 11Ni/Al2O3 | HDPE | commercial (G90 LDP) | spouted/fixed (0.75 g min–1) | TP = 500 °C | 71.0 | 34.5 | Erkiaga et al.97 |

| TR = 700 °C | |||||||

| S/C = 3.1 | |||||||

| 11Ni/Al2O3 | HDPE | commercial (G90 LDP) | spouted/fluidized (0.6 g min–1) | TP = 500 °C | 72.7 | 38.1 | Barbarias et al.44 |

| TR = 700 °C | |||||||

| S/C = 3.9 | |||||||

| 11Ni/Al2O3 | HDPE | commercial (G90 LDP) | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 69.8 | 37.3 | Barbarias et al.56,99 |

| TR = 700 °C | |||||||

| S/C = 3.1 | |||||||

| 11Ni/Al2O3 | PP | commercial (G90 LDP) | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 70.1 | 34.8 | Barbarias et al.56 |

| TR = 700 °C | |||||||

| S/C = 3.1 | |||||||

| 11Ni/Al2O3 | PS | commercial (G90 LDP) | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 65.4 | 29.1 | Barbarias et al.46,56 |

| TR = 700 °C | |||||||

| S/C = 2.9 | |||||||

| 11Ni/Al2O3 | PET | commercial (G90 LDP) | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 63.6 | 18.2 | Barbarias et al.56 |

| TR = 700 °C | |||||||

| S/C = 4.3 | |||||||

| 11Ni/Al2O3 | HDPE 48 wt %; PP, 35 wt %; PS, 9 wt %; PET: 8 wt % | commercial (G90 LDP) | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 63.9 | 32.5 | Barbarias et al.56 |

| TR = 700 °C | |||||||

| S/C = 3.2 | |||||||

| 10Ni/Al2O3 | PP | wi | spouted/fluidized (0.75 g min–1) | TP = 500 °C | 70.8 | 34.1 | Arregi et al.55 |

| TR = 700 °C | |||||||

| S/C = 3.1 | |||||||

| Ni/Al2O3 (1:1 molar ratio) | PP | cp | fixed/fixed (1 g) | TP = 500 °C | 66.6 | 24.8 | Wu and Williams150 |

| TR = 800 °C | |||||||

| steam = 4.74 g h–1 | |||||||

| 10Ni/Al2O3 | PP | wi | fixed/fixed (1 g) | TP = 500 °C | 56.3 | 11.5 | Wu and Williams164 |

| TR = 800 °C | |||||||

| steam = 4.74 g h–1 | |||||||

| 10Ni/Al2O3 | PE | wi | fixed/nonthermal plasma (1 g) | TP = 500 °C | 0.9 | Aminu et al.165 | |

| TR = 250 °C | |||||||

| steam = 4 g h–1 | |||||||

| 10Ni/Al2O3 | HDPE | wi, cp, sg | fixed/fixed (1 g) | TP = 500 °C | 62.0 | 12.1 | Yao et al.63 |

| TR = 800 °C | |||||||

| steam = 6 g h–1 | |||||||

| 10Ni/Al2O3 | PP | wi, cp, sg | fixed/fixed (1 g) | TP = 500 °C | 59.4 | 13.4 | Yao et al.63 |

| TR = 800 °C | |||||||

| steam = 6 g h–1 | |||||||

| 10Ni/Al2O3 | PS | wi, cp, sg | fixed/fixed (1 g) | TP = 500 °C | 57.9 | 12.5 | Yao et al.63 |

| TR = 800 °C | |||||||

| steam = 6 g h–1 | |||||||

| 5 Ni/Al2O3 | PP | wi | fixed/fixed (1 g) | TP = 500 °C | 49.5 | 6.9 | Acomb et al.163 |

| TR = 800 °C | |||||||

| steam = 4.74 g h–1 | |||||||

| 5 Ni/Al2O3 | LDPE | wi | fixed/fixed (1 g) | TP = 500 °C | 53.1 | 9.2 | Acomb et al.163 |

| TR = 800 °C | |||||||

| steam = 4.74 g h–1 | |||||||

| 5 Ni/Al2O3 | PS | wi | fixed/fixed (1 g) | TP = 500 °C | 60.0 | 7.4 | Acomb et al.163 |

| TR = 800 °C | |||||||

| steam = 4.74 g h–1 |

wi, Wetness impregnation; cp, co-precipitation; sg, sol–gel; ie, ion-exchange.

TP = Pyrolysis temperature; TR = reforming temperature.

A two-step fixed bed configuration operating in batch mode has been widely used in the literature. Thus, the group headed by Prof. Williams investigated the effect of operating conditions, type of plastic, and catalyst synthesis method using a wide range of Ni-based catalysts.63,150,163 Thus, Ni/Al2O3 catalysts with different metal molar ratios (Ni/Al of 1:4, 1:2, and 1:1) synthesized by co-precipitation method were analyzed by Wu and Williams150 in the pyrolysis–reforming of PP at a pyrolysis temperature of 500 °C and a reforming one of 800 °C. They reported an increase in the potential H2 production from 48.8 to 57.7 wt % when the Ni/Al molar ratio was increased from 1:4 to 1:1, which corresponds to a rise in the H2 production from 20.9 to 24.8 g H2 per 100 gPP. Yao et al.63 investigated the influence the synthesis method has on the physicochemical properties and therefore on the catalyst activity for the production of H2 from pyrolysis-steam reforming of waste plastics (HDPE, PP, and PS). Accordingly, a Ni/Al2O3 catalyst was prepared by three different methods: co-precipitation, impregnation, and sol–gel. These authors observed that the catalyst prepared by the sol–gel method had higher specific surface area and fine nickel particle size with uniform dispersion, which led to higher H2 productions (12.1, 13.4, and 12.5 wt % for HDPE, PP, and PS samples, respectively).

Figure 12 compares the main results obtained in the literature for the steam reforming of the volatiles derived from the pyrolysis of biomass (Figure 12a) and different plastic wastes (Figure 12b) using Ni/Al2O3 as the reforming catalyst.

Figure 12.

Performance of Ni/Al2O3 catalyst on H2 production in the pyrolysis-reforming of biomass (a) and different types of plastics (b). Xiao et al., 2011;61 Arregi et al., 2016;50 Fernandez et al., 2021;98 Miyazawa et al., 2006;89 Cao et al., 2014;156 Liu et al., 2019;160 Santamaria et al., 2018;51 Czernik and French, 2006;54 Erkiaga et al., 2015;97 Barbarias et al., 2016;44 Barbarias et al., 2018;56 Arregi et al., 2020;55 Wu and Williams, 2009;150 Yao et al., 2018;63 and Acomb et al., 2014.163 * corresponds to H2 production on a daf (dry and ash free basis).