Abstract

The construction of biomimetic vasculatures within the artificial tissue models or organs is highly required for conveying nutrients, oxygen, and waste products, for improving the survival of engineered tissues in vitro. In recent times, the remarkable progress in utilizing hydrogels and understanding vascular biology have enabled the creation of three-dimensional (3D) tissues and organs composed of highly complex vascular systems. In this review, we give an emphasis on the utilization of hydrogels and their advantages in the vascularization of tissues. Initially, the significance of vascular elements and the regeneration mechanisms of vascularization, including angiogenesis and vasculogenesis, are briefly introduced. Further, we highlight the importance and advantages of hydrogels as artificial microenvironments in fabricating vascularized tissues or organs, in terms of tunable physical properties, high similarity in physiological environments, and alternative shaping mechanisms, among others. Furthermore, we discuss the utilization of such hydrogels-based vascularized tissues in various applications, including tissue regeneration, drug screening, and organ-on-chips. Finally, we put forward the key challenges, including multifunctionalities of hydrogels, selection of suitable cell phenotype, sophisticated engineering techniques, and clinical translation behind the development of the tissues with complex vasculatures towards their future development.

Keywords: Hydrogel, Vascularization, Vascular biology, Angiogenesis, Tissue regeneration, Drug screening, Vascularized tissue models

Graphical abstract

Highlights

-

•

The regeneration mechanisms of vascularization, including angiogenesis and vasculogenesis, are introduced.

-

•

We highlight the advantages of hydrogels as artificial microenvironments in fabricating vascularized tissues.

-

•

We discuss the utilization of hydrogel-based vascularized organs in tissue regeneration, drug screening, and organ-on-chips.

1. Introduction

Tissue engineering, aiming at constructing artificial tissues in vitro, offers significant potential to overcome the challenges associated with the shortage of organs caused by diseases, traumas, and population aging [1,2]. The engineered tissue constructs could act as effective tools to enhance the availability of transplantation in clinical therapy and provide realistic in vitro models for disease modeling and drug testing [3]. However, the current research states that it is highly challenging to fabricate versatile complex tissues or organs due to the inability of the engineered constructs to systematically replicating the in vivo organ composition and cellular microenvironments [3,4].

Basically, the tissues and organs rely on the transportation of nutrients, removing metabolic products, and delivery of oxygen via densely distributed vascular networks. The lack of such diverging vascular channels within the engineered constructs has become the major fundamental obstacle that limited the applicability of the fabricated biomimetic tissue or organs using various microfabrication approaches [5]. Moreover, the limited vessels in the engineered constructs in vitro sometimes have shown insufficient diffusion distance (within 100–200 μm from a supply vasculature), leading to cell death and the poor lifespan of the harbored cells in the tissue constructs [1,6,7]. Thus, the availability of integrated vascular networks has become an essential criterion during the development of large, solid, and functional organs in vitro, mimicking the in vivo environment [8]. To date, the formation of vascular networks in vitro was firstly reported by Folkman and colleagues in 1980 [9]. The capillary endothelial cells (ECs) were cultured in a two-dimensional (2D) tumor-conditioned medium, demonstrating the development of capillary tubes. Since then, research interests in engineering the vascularized tissue constructs have been increasing [[10], [11], [12]].

Further efforts by various research groups have evidenced that fully mimicking the physiological microenvironment in addition to the vascular networks is highly challenging as the in vivo conditions are too complex within native human tissues [3,4,13]. In addition, several critical issues in fabricating the well-defined constructs include the precise spatial arrangement of multiple cell types, the dynamic organizations of extracellular matrix (ECM), and complex interactions of cells within embedded ECM, requiring more in-depth research [14,15]. In general, ECM, a meshwork of polysaccharides and proteins, provides three-dimension (3D) supporting matrices simultaneously to conduct cell behavior and regulate organ functions, depending on the physiological needs during the stages of the organ analogs formation and tissue regeneration process [4,14]. The assemblies of ECM are regulated via reciprocate activities between various cell populations and their embedded microenvironments [[16], [17], [18]]. Notably, ECM mediates the crosstalk between the ECs and surrounding tissues, attributing to the retention of growth factors (GFs) in the cellular microenvironment [19,20]. These biochemical and biophysical interactions are highly dynamic within ECM surroundings, leading to the characterizations of various tissues [15,17,21]. Consequently, the biological functionalities and mechanical properties of the respective tissues determine the various ECM compositions [16,22]. Together, effective vascular networks and complex cellular environments are indispensable for vascularized tissue engineering strategy.

In tissue engineering, the designed 3D matrices based on biomaterials are regarded as an effective tool to provide a suitable microenvironment to predict cell activities, as well as orchestrate vascularized tissue formation [5,23,24]. Theoretically, the ideal scaffold materials would be the natural decellularized ECM (dECM), which could be harvested from the native tissues after acellular disposal treatment [25,26]. The predominant advantage of the dECM as scaffold materials is that it provides an integral cell growth microenvironment consisting of a variety of protein components, GFs, and other small molecules, which is essential in maintaining cell physiological functions [21,26,27]. In principle, all the potentially immunogenic components must be removed during the decellularization process while ensuring the preservation of the composition of natural ECM and raw ingredients [28,29]. However, inadequate decellularization, in some instances, may initiate strong inflammatory responses, resulting in the inhabitation of tissue remolding [25]. In addition, the content and composition of dECM obtained from different donors are varied based on similar decellularized protocols [30]. Consequently, the discontinuous decellularization and impossibility in scaling-up, along with the regulatory and ethical restrictions, restrict the therapeutic applicability of this dECM [28]. Owing to the drawbacks related to the applications of dECM scaffold materials, artificial ECM using various biomaterials has been explored over the past few years. In general, artificial ECM based on the biological scaffolds is derived from natural polymers, including polysaccharides and proteins, and synthetic matrices with biomimetic features [21,31]. Notably, it is widely acknowledged that the artificial ECM from natural polymers emerged as a promising alternative for large-scale production, manipulation, and compatibility [14,32]. In addition, multiple bioactive components, such as GFs and peptides, can be incorporated into the 3D artificial ECM, achieving the diffusion and immobilization of molecules at temporal and spatial gradients whenever necessary [19,33]. Moreover, adjustable mechanical properties and specific simulations of the tissues or organs based on artificial ECM can be achieved by varying scaffold materials [12,13,21]. However, it should be noted that the selection of biomaterials, cells, and biomolecules to reproducing the physiological conditions of the native tissue in vitro is critical towards the fabrication of vascularized tissue constructs, maintenance of tissue morphogenesis, as well as final achievement of organ homeostasis.

Among diverse biomaterials based on natural and synthetic origin, hydrogel materials have been demonstrated as an effective tool to serve as a 3D matrix for cells, specific factors, and drugs, attributing to their high permeability, water holding capacity, and excellent biocompatibility [34,35]. In addition to these advantages, hydrogels are often preferred over others as these soft polymeric materials resemble most of the soft tissues in the human body [[36], [37], [38]]. Moreover, significant advances in hydrogels have provided excellent opportunities both in engineering vascular analogs and vascularized tissues. The application of hydrogels in the human body was first reported in 1960 when Wichterle and Lim applied crosslinked poly (2-hydroxyethyl methacrylate)-based material as soft contact lens [39]. Subsequently, hydrogels were employed to encapsulate cells in 1980 [40]. Specifically, hydrogels consist of hydrophilic polymer chains embedded in a hydrated 3D environment, which allows a homogenous entrapment of multi-cell types to replicate tissue complexities [41,42]. In addition, molecules in hydrogel networks can diffuse through the interconnected pores, which satisfies the requirements of vasculature for the delivery of molecules from vessels to tissues [43,44]. Nowadays, hydrogels are widely investigated and applied for clinical therapy. To date, many researchers have reported the establishment of hollow vascular architectures based on hydrogels, ranging from micron to millimeter levels using various emerging techniques [45,46]. In addition, angiogenesis-related factors can be directly incorporated into the hydrogel to regulate the delivery of biological cues and accelerate vascular formation in the constructed tissue models. Above all, these perfusable tissue models based on hydrogels have shown great potential in modeling diverse pathological and physiological mechanisms of organs in vitro.

Considering the enormous potential of advanced hydrogels in engineering vascularized tissues, in this review, we first introduce the current main vascular formation mechanism, including angiogenesis and vasculogenesis. Further, the role of hydrogels in terms of physicochemical properties and intrinsic advantages is elaborately summarized towards the development of perfusable vascular architectures and subsequent vascularized tissue constructs. Finally, we discuss the applicability of these fabricated constructs in tissue transplantation, disease models for drug screening, as well as organ-on-chips (Fig. 1).

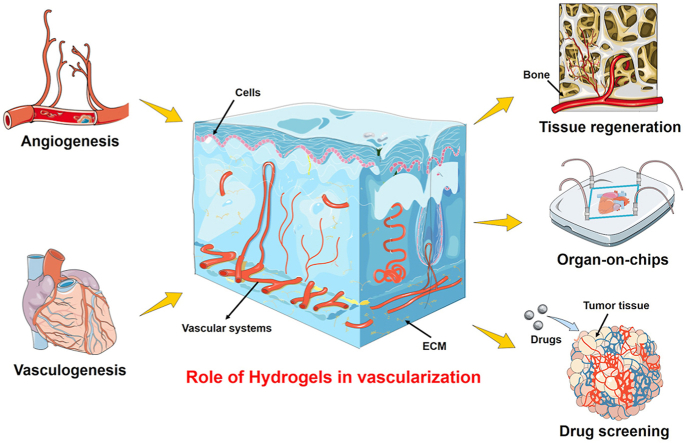

Fig. 1.

Schematic illustration of the vascularized tissues in hydrogels for tissue regeneration, organ-on-chips, and drug screening. Angiogenesis and vasculogenesis mechanisms of vascular formation are introduced both in the embryo stage and postnatal life, respectively. The enrichment of the effective vascular networks enables the delivery of nutrients and waste products for the recovery of organs upon severe damage. In addition, the emerging organ-on-chips approach provides excellent opportunities for incorporating vasculatures within chips for the stimulation of physiological 3D organoids. These target 3D organoids bridge the gap between clinical trials and in vitro drug screening.

2. Regeneration mechanism of vascular networks

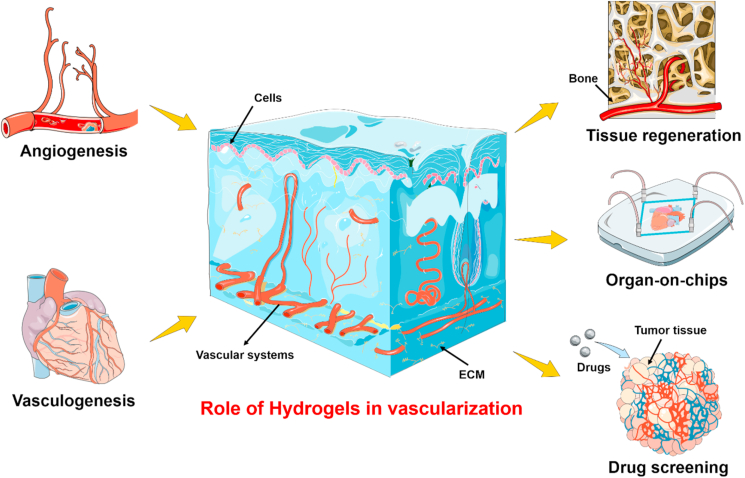

The vasculature is the major component of the systemic circulatory system distributed throughout the human body, branching vessels with diameters ranging from several micrometers to several millimeters (Fig. 2A) [[45], [46], [47]]. The arteries, compromising of hollow round channels (approximately 1 cm in diameter), branch into the smaller and thinner pipeline (100 μm −1 mm), and finally divide into a large number of capillaries (5–10 μm in diameter) for exchange of nutrients, waste products, and gases [48] (Fig. 2B). Although all the vasculatures are blood-carrying lumens, their heterogeneity in (1) physical properties, including thickness, geometries, wall components, and mechanical strength, and (2) physiological environments, including GFs, ECM compositions, and specific cell types, requires various fabrication methodologies and design criteria [[47], [48], [49]]. Considering the wide span of vascular diameters across several orders of magnitude and complex intertwined configurations, currently, several studies have been focused on the construction of the single-lumen structure over obtaining fully vascularized tissues to recapitulating the large vascular architecture with multiscale geometry allowing fluid flow with high pulsatile pressure [18,50,51].

Fig. 2.

(A) Schematic representation of functional vascular distribution in the human body. The vascular networks are organized into arteries (in red) and veins (in blue). The vasculatures comprise blood-carrying lumens. (B) The biochemical cues, including relevant cells and specific GFs, are expected to be integrated within the designed vascularized tissue constructs. (C) Vascularization mechanisms during (i) angiogenesis and (ii) vasculogenesis. Angiogenesis mainly relies on the sprouting of ECs to the fabricated constructs. Vasculogenesis primarily focuses on the differentiation and assembly of angioblasts and endothelial precursor cells (EPCs) into mature migrating ECs towards the repair region and subsequently forming the primitive vascular networks. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

To date, several advancements in developing hybrid engineering solutions and advanced fabrication techniques have been reported to enable the construction of microchannels and hollow microfibers towards imitating hollow vascular analogs [[49], [50], [51]]. In this vein, the human umbilical vein ECs (HUVECs) encapsulated in the hydrogel with a hollow structure showed good proliferation in culture, exhibiting a sign of the early maturation of the vessel tissue. For example, ECs within the microfibrous scaffolds migrate towards the peripheries of the microchannels to form a layer of confluent endothelium [49]. These endothelial beds were then seeded with cardiomyocytes to generate aligned endothelialized human myocardium capable of spontaneous and synchronous contraction. In addition, the wall thickness of the hollow structures could be controlled to some extent (179.4–314.9 μm) with various gauge combinations of co-axial nozzles. Although several efforts have been dedicated to fabricating such multiscale vascular hollow architectures, there are still quite a few challenges that must be overcome to form a mature, stable, and functional endothelium within the embedded engineering tissues [50,51].

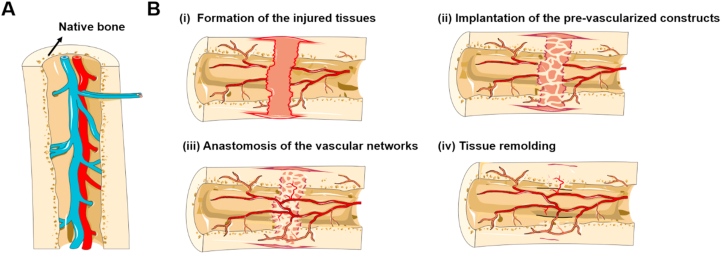

Although the perfusable vascular analogs have exhibited promising results towards the construction of various organs in vitro, the utilization of such biomimetic constructs in tissue regeneration upon clinical transplantation place high demands on the vascular alignment, which still remains limited for regeneration and implantation of large-scale engineered tissues, such as skeletal muscle, shin epithelium, liver, and other major organs [[52], [53], [54], [55], [56], [57], [58], [59], [60], [61]]. Indeed, capillaries are the places where blood and tissues exchange substances, including nutrition and waste products [62,63]. However, the large-scale vessels constructed in vitro cannot efficiently provide nutrients like microscale capillary beds. Moreover, the ideal oxygen and nutrient delivery require a dense capillary network within 100 μm from each other, which is not feasible for surgical anastomosis [48]. To address this goal, engineered microvasculature is expected to be emphasized in mimicking the dense capillary networks and endothelial barrier functionality. In principle, the newly formed capillaries within the engineered tissue constructs can enhance the spontaneous, surgical anastomosis of microvessels [50,51,62]. However, the fabrication of capillaries, as well as vascular tree-like networks within the engineered tissues, still remains a primary challenge in regenerative medicine. Consequently, fully comprehend the mechanisms of vascular formation and physiological environment of tissue counterparts in vivo are extremely required during the formation of the vascularized tissue constructs in vitro. In this section, we introduce two primary mechanisms for improving vascularization both in the embryo stage and postnatal life, including angiogenesis and vasculogenesis, respectively. (Fig. 2C).

2.1. Angiogenesis

The angiogenesis is mainly activated by the ingrowth and sprouting of existing primitive vessels from the adjacent host tissues into the transplanted grafts, which eventually form the host-originated vessel networks [5,64,65]. In general, there are two major steps during sprouting angiogenesis, including the initial ECs growth phase and subsequently stabilization stage [66,67]. At the beginning of the ECs proliferation, the degradation and permeability of the vascular basement membrane are improved. The subsequent direction of newborn vessels is defined by the gradients of angiogenic GFs that mediates ECs migration via the signaling pathway of EC surface proteins [19,33]. In the second stabilization phase, the recruitment of smooth muscle cells (SMCs) is stimulated, leading to the maturation of blood vessels [19,33]. Considering the necessary regulation mechanism of GFs on angiogenesis, some pre-vascularization through angiogenesis strategy populated GFs into the scaffolds in order to stimulate the capillary ingrowth [68,69]. However, from the overall process, the integration of capillary formed by ECs into host vasculature is relatively slow, and the rate of angiogenesis is approximately 5–17 μm/h, during which oxygen and nutrients are usually needed [68,69]. Consequently, tedious time span and cumbersome adjustment mechanism often lead to regeneration failure and final necrosis of the organ.

2.2. Vasculogenesis

The vasculogenesis process primarily focuses on the differentiation and assembly of angioblasts and endothelial precursor cells (EPCs) into mature migrating ECs towards the repair region and subsequently forming the primitive vascular network [70]. In the vasculogenesis strategy, ECs are always incorporated with targeted cells into the engineered hydrogel scaffolds in vitro to form pre-vascularization states [[71], [72], [73]]. In such cases, initially, the presence of ECs can stimulate the ingrowth of host vessels. Then, the formation of anastomosis of host vasculature and in vitro endothelial networks can be accelerated via the pre-existing endothelial networks in the engineered scaffolds [74]. Collectively, both of these strategies of angiogenesis and vasculogenesis place high requirements on the biophysical properties of scaffolds for cell delivery, biological cues transition, and perfusion with surrounding tissues.

3. Hydrogels as the artificial microenvironment

On the one hand, when designing vascular structures for large-volume blood transportation, the perfusion and structural integrity of the constructed blood vessels should be predominantly considered [50]. In this regard, the physical features of the vessels place high demands on the selection and design of suitable biological materials in terms of adjustable mechanical strength, stability of hollow structures, and orderly cell spatial distribution for the construction of perfusable vascular channels. Since vasculature is made of a single layer of ECs in native tissues, ECs are always employed to decorate the hollow biomimetic architectures, resulting in the formation of vascular analogs [75]. In this case, the hollow architectures of the scaffolds can be obtained firstly, and then the ECs are layout surrounded by the scaffold to mimic the blood vessel layer [1,45,76]. In another case, the cells can be initially distributed into the pre-solution of scaffold materials and then directly fixed in the perfusable architectures after shaping [45,50,62,77,78]. Despite the difference in the construction of blood vessels in vitro, the fabricated scaffolds in both instances can be utilized in transplanting, engineering functional tissues, and understanding correlates vascular disease [7,63,79].

On the other hand, while establishing branching vascular trees within the vascularized tissues, it is required to pay more attention to the construction of the capillary beds for the transportation of nutrients [80,81]. The key strategy of creating tissue and organ constructs with vascular components plays a crucial in offering the intrinsic functionalities [3,70,74,76]. In this vein, the combination of alternative cell types, controllable shaping of architectures, and tunable biochemical cues offer the merits in engineering designed tissue or organs [69,82]. Thus, increasing the versatility of the designed scaffold materials is extremely demanding, which faces some critical challenges, such as (1) compromising vasculatures with a microenvironment that is highly similar to native ECM, (2) integrating biochemical cues inside scaffold materials to regulate cell growth, as well as tissue morphogenesis, and (3) carrying the automated process for reliable and precise fabrication of scaffolds with designed geometry and features [12,13,46].

In this section, we summarize several advantages of hydrogel-based materials in fabricating perfusable vascular microchannels and vascularized tissue constructs (Table 1). Initially, we discuss the fundamental properties and shaping mechanism of the hydrogels. In addition, we briefly summarize the advantages and disadvantages of various hydrogel gelation mechanisms in terms of their application for vascularization tissues. Further, we emphasize the physiological environments, including suitable extracellular matrix (ECM) components, relevant cell types, and proper biochemical cues to better orchestrate the superiority of hydrogel-based materials for the development of vascularized tissues in vitro.

Table 1.

Significant hydrogel properties for vasculature.

| Hydrogel composition | Cell sources | Shaping mechanism | Advantages of shaping mechanism for vascularization | Significant hydrogel properties | Advantages for vasculature | Refs. |

|---|---|---|---|---|---|---|

| GelMA, gelatin | HUVECs | Thermal crosslinking and photocrosslinking | Smooth gel filament extrusion at sol-gel transition and rapid UV gelation for structural support | Natural sol-gel transition of the hydrogel systems; biocompatibility; porous structure | Formation of the interconnected tubular channels within well-defined 3D architectures; a confluent endothelial layer in the inner surface of the channels; in situ endothelialization of the channels | [75] |

| Alginate, gelatin | HUVECs | Ionic crosslinking and genepin penetration | Rapidly fixation of microrods architectures and inducing HUVECs migration | Rapidly crosslinking of alginate and controllable fixation of gelatin | Unique fabrication of HUVECs-laden microrods and regulation of HUVECs migration within hydrogel microrods; formation of new capillaries and organization of intensive vascular networks in mice after injection for 21 d | [78] |

| GelMA, HGSM | mBMSCs | Photocrosslinking and covalently crosslinking | Enhanced mechanical properties showing self-healing capability | Synthetization of host-guest supramolecular hydrogel (HGGelMA) with high compressive strength and an excellent stretching ability; about 400% water content; 5.25-fold compression modulus of the HGGelMA (0.63 MPa) than that of pure GelMA (0.11 MPa) | Higher expression level of blood vessel-related genes (SMA, CD31, and PDGF) in vivo than that of pure GelMA | [87] |

| GelMA, PEO | HUVECs, HepG2, and NIH/3T3 cells | Photocrosslinking and leaching | The hierarchical porous structures enhancing proliferation of HUVECs | Increased Yong's modulus of the GelMA-PEO with the increase of PEO concentration | 3- and 4-fold proliferation of HUVECs in the hierarchical porous GelMA than that of standard GelMA on 3 d and 7 d, respectively | [86] |

| GelMA, gelatin | HUVECs | Thermal crosslinking and photocrosslinking | Fabrication of pure-gelatin-based hollow structures for HUVECs encapsulation | Controllable gel point and pores diameters by adjusting gelatin and GelMA concentration, respectively | Long-term maintenance of hollow structures in culture medium | [50] |

| GelMA, NAGA, nanoclay | HUVECs | Photocrosslinking | Generation of a scalable large-length vascular-like microtube with variable outer and inner diameter | Marvelous mechanical properties with Young's modulus (≈21 MPa), a stretchability (≈500%), a tensile strength (≈22 MPa), an anti-fatigue performance (≈200 cycles), and a burst pressure (≈2500 mmHg) | Good permeability; formation of a complete single endothelial layer using HUVECs; the positive expression of various angiogenesis-related factors | [89] |

| GelMA, gelatin, HA | HUVECs, SMCs | Photocrosslinking | Spatial distribution of HUVECs and SMCs mimicking native vasculature | Adjustable tensile stress, Yong's modulus, and pore sizes | Development of heterogeneous bilayer tubular structures with HUVECs and SMCs laden on the luminal and outer surfaces, respectively | [92] |

| GelMA, alginate | HUVECs, DFs, and hKCs | Ionic crosslinking and photocrosslinking | Recapitulating native skin architectures by distributing HUVECs, DFBs, and KCs into three main layers | Increased compressive modulus and viscosity with an increase of alginate concentration | Higher secretion of Pro-Collα1 and lower levels of MMP-1 at 7.5% (w/v) GelMA concentration | [91] |

| Alginate, collagen | Keratinocyte, FBs | Cryogenic process (−30 °C) | Rapidly generation of vascular-like structures with core and shell at low temperature | Good structural stability; 7 times Young's modulus of the alginate/collagen scaffold than that of pure collagen, similar pore-structure, and cell viability | A hybrid scaffold with alginate core and collagen shell; the formation of granulation tissues and vascularization in vivo for 14 d | [100] |

| ELP | MSCs, HUVECs | Photocrosslinking | Adjustable crosslinking density mimicking stretchability of vasculature | Four times length after stretching; increased ELP concentration resulting in the increase in the crosslinking density | Maintenance of cell viabilities up to 7 d; limited cell spreading due to the lack of RGD peptide; no lymphocyte infiltration in vivo | [102] |

| PEGDA, GIA-PEGDA, RGD-PEGMA | HUVECs | Photocrosslinking | Biocompatible UV irradiation to HUVECs facilitating cell attachment | Enzymatic degradation of GIA modified PEG hydrogels; decrease in crosslinking density due to degradation | Initial HUVECs attachment at 4 h; elongation and reorganization of cells at 12 h; formation of capillary-like networks at 24 h | [80] |

| GelMA, PEG, SPELA | hMSCs, ECFCs | Photocrosslinking | Controllable release of angiogenic GFs using various UV curing polymers | Spatiotemporal release of BMP2 and VEGF using GF-grafted nanogel; the release kinetics of GFs depending on the PEG MW and lactide/glycolide ratio | Construction of osteogenic SPELA gel containing vasculogenic GelMA microchannels; increased vasculogenic and osteogenic differentiation of ECFCs and hMSCs | [135] |

| GelMA, alginate, PEGOA | hSMCs, HUCs, HUVECs | Ionic crosslinking and photocrosslinking | Direct extrusion of perfusable circumferentially multilayered tissues due to rapid ionic crosslinking | Significant increased mechanical strength compared with one or two-component hydrogels; alternative shapes and sizes without changing device | The spatial distribution of hSMCs and HUCs; creation of blood vessel tissue using hSMCs and HUVECs | [82] |

| GelMA | ECFCs, MSCs | Photocrosslinking | Adjustable physical properties at various UV exposure time for optimization of vascular luminal formation | Decreased degradation, increased elastic modulus, and viscous modulus with the increase of UV exposure time | Formation of ECGC-lined microvessels in vivo for 7 d after implantation, excessive GelMA crosslinking hindered luminal structures formation in vivo | [158] |

Abbreviations: CD31 - platelet endothelial cell adhesion molecule-1, DFS - dermal fibroblasts, ECFCs - human endothelial colony-forming cells, ELP - elastin-like polypeptides, GelMA - gelatin methacrylate, GIA - collagen type I-derived peptide, HepG2 - human hepatocellular carcinoma cells, HGGelMA - host-guest supramolecular GelMA hydrogel, HGSM - host-guest supramolecule, hKCs - human keratinocytes, hNDFs - human neonatal dermal fibroblasts, hSMCs - human bladder smooth muscle cells, HUCs - human urothelial cells, HUVECs - human umbilical vein endothelial cells, mBMSCs - mouse marrow mesenchymal stem cells, NAGA - N-acryloyl glycinamide, NIH/3T3 - mouse embryonic fibroblasts, PEGDA - poly(ethylene glycol) diacrylate, PDGF - platelet derived growth factor, PEG - poly(ethylene glycol), PEGOA - eight-arm poly(ethylene glycol) acrylate, PEO - poly(ethylene oxide), RGD - arginine-glycine-aspartate, SF - silk fibroin, SMA - smooth muscle actin, SPELA - lactide-chain-extended star polyethylene glycol.

3.1. Physical properties of hydrogels

3.1.1. Adequate pores within 3D hydrogel matrixes for mass transportation and molecules secretion

3.1.1.1. Tunable porous architectures for enhanced cell survival

Indeed, hydrogels provide sufficient pores within the 3D matrices which substantially facilitate the transportation of nutrients to cells and the removal of metabolic wastes within the engineered constructs [[83], [84], [85], [86]]. In addition, the essential architectural parameters, including pore size, pore interconnectivity, and surface area, are tunable to a considerable extent by altering the polymer concentration, molecular weight of the polymer, and shaping techniques. In our previous work, the pore diameters of the gelatin methacrylate (GelMA) hydrogels ranged from 22.22 ± 5.57 μm to 43.47 ± 15.36 μm with varied GelMA concentration ranging from 5 to 10% (w/v) of gel solution. In addition, the proliferation of HUVECs in the GelMA hollow microfibers was observed, inducing the formation of vessel-like structures [50]. In another instance, the GelMA was crosslinked through host-guest supramolecular (HGSM), in which the crosslinking density and the pore density were increased with the increase in the HGSM content [87]. However, the pore size showed a downward trend with an increase in the concentration of the HGSM.

Compared with the usual control over the superficial pores of the hydrogel by tuning the concentration, composition, and viscosity of the pre-gel solution, the hierarchical porous structures within hydrogel constructs have been successfully developed via the combination of two gel systems with low interfacial energy. Notably, a fully aqueous environment ensured the biocompatible environment for cell survival and mild mass exchange with the surrounding medium. In addition, the water-in-water system offered significant advantages towards regulating pore size in a wide range without the utilization of organic solvents, cell-unfriend porogens, and surfactants. Recently, Zhang's group designed a water-in-water formulation consisting of GelMA pre-gel solution as a continuous phase and poly (ethylene oxide) (PEO) solution as a “water-porogen” [86]. The hierarchical and interconnected pores were produced in the hydrogel structures upon photocrosslinking of GelMA and further leaching of PEO droplets. Notably, the encapsulated HUVECs exhibited three- and four-fold proliferation in the porous GelMA-PEO compared to the standard GelMA. In most recent research, the hierarchically macro-micro-nano porous cell-laden hydrogels constructs were uniquely developed based on their previous water-in-water systems, which could readily recover to their initial shapes after compression [84]. These novel findings ensure that the uniquely tailored pore-forming GelMA hydrogel systems are promising candidates in further engineering vascularized tissue regeneration.

3.1.1.2. Secretion of soluble molecules from porous hydrogel matrixes

In addition to the adjustment of the morphological properties, the multicellular and soluble molecules can be secreted from porous structures following precise dose and time intervals. This mass transportation behavior between tissues and cells mainly relies on the pore size of the surrounding gel [33,86,87]. Furthermore, the biochemical cues incorporated into hydrogel matrices can be employed as biochemical regulators of cell behavior. For example, Lee and coworkers provided a localized delivery system based on the alginate gels embedding recombinant human VEGF/poly (lactic-co-glycolic acid) (rhVEGF/PLGA) microspheres. The prevalent release of rhVEGF promoted HUVECs proliferation substantially, thus effectively enhancing angiogenesis in vivo [19]. In another example, Baker and colleagues generated the temporally and spatially defined VEGF gradients within 3D gelatin/collagen gels on the microfluidic chips, guiding the location and morphology of endothelial sprouting from the channels [33]. Accordingly, controlling the morphological properties of hydrogel can effectively mimic the in vivo cell surroundings and thus facilitating tissue morphogenesis.

3.1.2. Wide adjustment range of mechanical properties of hydrogels to emulating the multi-native tissues

3.1.2.1. Exceptional tensile stiffness and elasticity due to the employment of hybrid hydrogel systems

The mechanical properties of hydrogel materials are essential for the construction of vascularized tissues [[86], [87], [88], [89], [90], [91], [92]]. On the one hand, considering the degree of stiffness in various organs, the hydrogels offer the merits to emulate the multi-native tissue from extreme stiff vascularized bone (8–17 kPa) to the utmost soft brain (0.1–1 kPa) due to the controllable mechanical strength [93]. On the other hand, the hydrogel materials can be elastic and supportive, which meets the requirement not only for maintaining the hollow channels but also withstanding the hydraulic pressure while blood flowing in terms of fabrication of vascular analogs [45,67,79,[94], [95], [96]]. With an in-depth understanding of hydrogel polymerization principles and crosslinking mechanisms, the hydrogel has gradually evolved from original soft and low-stretchable material towards tough and highly elastic substrates [88,89].

Collagen and elastin, extensively existing in the natural ECM, are responsible for the tensile stiffness and elastic recoil properties of the tissues, respectively [15,63,[97], [98], [99], [100]]. In this vein, the engineered hydrogels derived from these natural proteins can provide exceptional strength and elasticity. Notably, the collagen-dense ECM is strictly controlled at the sub-cellular level to facilitate ECs migration during angiogenesis [98]. However, in most cases, the stiffness and other mechanical properties are still limited while using collagen or elastin solely [100]. For overcoming these deficiencies, several natural proteins or polysaccharides such as alginate, gelatin have been applied as an effective approach for enhancing the toughness and fracture energy of hydrogel [63,100]. For instance, Kim developed 3D hybrid scaffolds with outer collagen and inner alginate, exhibiting about seven times greater Young's modulus compared with the pure collagen scaffold. Furthermore, this engineered hybrid scaffold provided good granulation tissue formation and rapid vascularization between the dermis and the scaffold [100]. Moreover, regardless of hydrogel origins, researchers focused on the employment of hybrid hydrogels to improving the mechanical properties of the single hydrogel system. In a case, Eke and colleagues combined two independent networks, including GelMA and methacrylate hyaluronic acid (HAMA), to increase the compressive modulus (>6 kPa), which could be easily handled by surgical forceps without breaking [101]. In another case, Sultan and coworkers fabricated reinforced-hydrogel using GelMA and silk fibroin (SF). The increase of SF concentration resulted in an increase both in tensile stress and gelation time of the GelMA/SF hydrogels [90]. Besides, the addition of PEO into GelMA hydrogels also increased Young's modulus from 0.9 ± 0.3 to 1.4 ± 0.1 kPa, as the PEO concentration increased from 0.5% to 1.6% [86].

3.1.2.2. Tuning the strengthen by modifying the chain of hydrogel or relying on the nanomaterials

In addition to the direct entanglement of multiple polymer chains, modifying the chain of hydrogel or crosslinking sites is also practical for tuning the strength. Highly elastic and tough hydrogels could be synthesized by designing a polypeptide containing thiol residues without the incorporation of noncanonical amino acids. The crosslinking sites at the ends of the protein led to consistent molecular weight between the maintenance of excellent elastic properties of polypeptide and crosslinks. In addition, the inclusion of thiols from a pair of cysteine residues in the elastin-like polypeptide sequence allowed disulfide bond formation upon exposure to UV light [102]. As such, the engineered hydrogels showed four times the length before fracture. Rather than swelling-weaken property, most recently, liposomal membrane nanocarriers could be covalently embedded in hydrogel to regulate transmembrane transport. During the stretching process, the liposomes deformed and initiated the transmembrane diffusion of the encapsulated molecules, which trigger the formation of a new network from the preloaded precursor. In this vein, swelling-triggered self-strengthening could be achieved due to the tough nature of the double-network structure [103].

Another strategy relies on the employment of nanomaterials, such as carbon-based nanomaterials, polymeric nanoparticles, and inorganic nanoparticles to retort the mechanical properties of hydrogel scaffolds [89,[104], [105], [106]]. Most studies attained rigid polymer structures using these nanoparticles as physical fillers [89,104,105]. Yasmeen and colleagues demonstrated the incorporation of carbon nanotubes as nanofillers to enhance the mechanical properties of the chitosan/HA gels [104]. In another case, Shin and coworkers reported the carbon nanotube-reinforced GelMA hybrid scaffolds without affecting their porous structures [105]. These materials can either offer physical entanglement or covalent cross-linkage in the hydrogel networks [106,107]. Liang and colleagues demonstrated the physical interpenetration and covalent crosslinking between GelMA/N-acryloyl glycinamide (GelMA/NAGA) hydrogel networks and nanoclay, which could remarkably enhance the tensile strength, Yong's modulus, anti-fatigue performance, stretchability of the hydrogel, leading to the large-scale length microtubes and endothelialization of hydrogel microtubes after seeding with HUVECs [89]. In addition to the tailored mechanical performance, developing nanocomposite-based hydrogels with specific functionality, such as ion release, stimuli response, and electrical conductivity, provides enormous opportunities in developing advanced hydrogel systems [21,22,26,41,57,103,[108], [109], [110], [111], [112]]. Considering these advantages in both enhancing physical properties and facilitating cellular activities, the functional nano- or micro-composite hydrogels for engineering vascularized tissues will be further discussed in Section 3.2.3.

3.1.3. Controllable biodegradability of hydrogels for matching the rate of tissue regeneration

The degradability attribute of biomaterials in the physiological environment allows the scaffolds to gradually being absorbed and decomposed in the tissue. In some cases, a complete degradation seems not necessary, such as the regeneration of cornea and articular cartilage [17,110]. For such circumstances, the integration of native tissues and hydrogels along with a certain extent of degradation are preferred to give semi-permanent or permanent mechanical support. However, in most cases, the gradual and mild degradation of scaffold materials is required, while the poor degradation and prolonged presence of polymers at the site of transplantation sometimes may hinder the ingrowth of the native tissues [85]. Ideally, the rate of degradation is expected to match the rate of tissue regeneration. In addition, the by-product (polymer monomer and fragment) of the metabolic processes is anticipated to have a slight effect on cell survival [20,101,113].

In general, the degradation of hydrogel materials takes place mainly due to ion exchange, hydrolysis, and enzyme-induced process, along with the splitting of the 3D hydrogel networks [85]. Among others, the degradation of ECM-derived hydrogels involves enzyme induction, ECM proteins secretion, and subsequently, cells remolding, which can regulate the physiology-related processes, including cell migration, differentiation, as well as angiogenesis [16,17,25,26,55]. Although the degradation takes place physiologically and the by-products, such as glycolic acid, glucose, and lactic acid, are biocompatible, the control of degradation routing is still challenging. For example, the degradation of ionic-crosslinked hydrogels such as alginate is actually a reversed gelation process, comprising of exchange of divalent cations in alginate and eventual dissociation of ionic crosslinks, which is absolutely uncontrollable, especially in the cell culture medium containing abundant cations [59,100,[114], [115], [116]]. Moreover, the hydrolytic degradation process of polyethylene glycol (PEG) hydrogels from photopolymerization of poly (ethylene glycol) diacrylate (PEGDA) showed limited response to cell-secreted enzymes and cellular signals, leading to the relatively slow degradation rate both in vitro and in vivo [117]. Accordingly, considering the balance between the degradation process and tissue remolding, the degradability of hydrogels should be an alternative based on tissue demanding.

Considering these challenges, some of the synthetic hydrogels offer the merits towards the controllable degradation process due to the designed hydrolysable linkages [58,80,118]. Enzyme-sensitive peptide sequences could be incorporated into the hydrogel networks to instruct biodegradability. In a case, Zhu and colleagues reported the attachment of collagenase-sensitive GPQGIAGQ (GIA) sequence derived from collagen type I in the PEGDA chain, in which the authors observed the improved collagen sensitivity with a dependence on the concentration of collagenase [80]. Notably, the polymerized PEGDA hydrogel containing GIA and arginine-glycine-aspartate (RGD) peptides could induce the formation of capillary-like morphologies while seeding the HUVECs on the hydrogel surface, indicating that both biodegradability of scaffolds and the cell adhesion ability were essential in the organization of capillary-like networks. In another example, Hong fabricated a biomimetic adhesive hydrogel using synthetic GelMA and N-(2-aminoethyl)-4-(4-(hydroxymethyl)-2-methoxy-5-nitrosophenoxy) butanamide (NB) linked to the glycosaminoglycan (GelMA/HA-NB) hydrogel [118]. The progressive biodegradation was observed in vivo, in which the proportion of the implanted mass decreased from an initial 82.5 ± 5.5% at 7 d to 20.0 ± 5.0% at 56 d. Notably, the burst pressure of GelMA/HA-NB hydrogel (155 ± 27 mm Hg) was significantly higher than that of pure GelMA (31 ± 7 mm Hg), which allowed the hydrogel scaffold withstanding blood pressure. In some investigations, the adjustable biodegradation also enabled the programmed release of drugs, biomolecules, encapsulated cells, and GFs from the hydrogels, which could expand the application of hydrogel materials in tissue engineering [19,33,83,110].

3.2. Recreating physiological environments in vitro

The physiological environments of organs mainly include the relevant cell types and bioactive molecules [22,66,76,88,92,119,120]. Reproducing the appropriate physiological surroundings in vitro is of utmost importance to mimic the engineered constructs in vivo. In general, the natural ECM, comprising collagen, elastin, fibronectin/laminin, and glycoprotein, is the model for tailoring the cell-laden biomimetic scaffolds and delivery of signaling biomolecules [58,110,121,122]. Collagen and elastin primarily provide mechanical support for tissue growth [63,97,100]. In addition, fibronectin/laminin can be combined with cells and macromolecules in the ECM, which is essential in cell signaling [69,123]. The disrupted ECM equilibrium weakens the repository and regulatory effects of the extracellular space, leading to extended scar formation, as well as the loss of biological functionalities during tissue morphogenesis [16]. However, it should be noted that the understanding and simulation of the ECM components are fundamental requirements to engineer a biomimetic scaffold and display the complex multicellular interactions mimicking in vivo.

3.2.1. Incorporating ECM-mimetic bioactive cues

3.2.1.1. Incorporating cell adhesion peptides to improve cell-specific adhesion sites

Hydrogels provide advantages in terms of cell-specific adhesion and carrying of signal molecules due to their highly tunable linkages [19,33,117,122,[124], [125], [126], [127], [128]]. Although these hydrogels sometimes fail to offer ideal environments due to the lack of intrinsic biological activities of the natural chains such as PEG and alginate, ECM protein-derived cell adhesion peptides and angiogenic GFs can be incorporated into the hydrogel networks alternatively to overcome the inert nature and mimic ECM biological functionalities [[124], [125], [126],129]. Intrinsically, the essential properties, including cell adhesion and angiogenic factors, can be applied to simulate the physiological microenvironment effectively.

To date, numerous ECM-derived bioactive peptide sequences have been incorporated into the hydrogel networks to improve cell-specific adhesion sites [117,[124], [125], [126]]. Among various ECM-derived bioactive peptide sequences, fibronectin-derived RGD peptide is the most commonly used one for cell-adhesive modification [117,[124], [125], [126],129,130]. In addition, compared with the linear RGD sequence, the cyclic RGD can significantly improve the biological activity up to 240 times due to the enhancement of affinity to integrin αvβ3 [[124], [125], [126]]. Zhu and colleagues synthesized cyclic RGD peptide with a hydrophilic tail consisting of a linker of two lysine residues and a spacer of three serine residues, which could be conjugated with acryloyl-PEG-N-hydroxyl succinimide (Acr-PEG-NHS) and thus obtained cyclic RGD-PEGDA [129]. The cyclic RGD-PEGDA possessed not only excellent photopolymerization ability but also uniform distribution of cyclic RGD ligands, resulting in a significantly higher ECs population compared to the linear RGD-modified hydrogels. In another approach, GelMA, synthesized by collagen-derived gelatin and methacrylic anhydride, resembles the properties of ECM with adequate RGD motifs due to the employment of gelatin [131]. The RGD-rich property and design flexibility have made GelMA as one of the most commonly used photo-crosslinkable materials in engineering vascularized tissues, as well as tissue regeneration [50,110,111,131,132]. For instance, Chen and coworkers reported a novel aligned GelMA hydrogel scaffold for spinal cord regeneration [130]. From the platelet endothelial cell adhesion molecule-1 (CD31)-fluorescence analysis, it was observed that the density of vascular ECs in the implantation of GelMA scaffold was significantly higher than the implantation of gelatin scaffold, demonstrating a versatile method in triggering functional regeneration of the spinal cord.

3.2.1.2. Embedding angiogenic GFs within hydrogel matrices

GFs, ascribing to various polypeptides, transmit signals to modulate cellular activities via specific binding to the receptors on the surface of the target cells (Table 2) [19,33,127,133]. Since the dosage response, addition time, and gradient profile of GFs are extremely crucial for inducing cellular function and tissue revolution, the persistent stimulation with a fitting level of GFs is still an issue that needed to be resolved for the development of functional vascularized tissues in vitro [6,19,20,97,127,134]. Numerous attempts have been made in encapsulation the GFs into hydrogel matrixes through physical interactions (adsorption and complexation) [97], covalently attaching [134], and chemical modification by heparin due to the short half-lives in free forms [122,128]. In addition, the combined effects of multiple GFs other than individual GF have been widely investigated based on hydrogel systems [19,135,136]. These bioactive cues released from the scaffolds can facilitate rapid infiltration of host blood vessels. For example, the spatial and time-release of VEGF and bone morphogenetic protein-2 (BMP-2) was achieved via VEGF-grafted nanogels and BMP2-grafted nanogels [135]. Interestingly, the secretion of VEGF and BMP-2 from nanogels was independent of the protein size but dependent on the length of the degradable segment. In addition, BMP2-grafted nanogels and human marrow mesenchymal stem cells (hMSCs) were encapsulated in the lactide-chain-extended star polyethylene glycol (SPELA) hydrogel. VEGF-grafted nanogels, hMSCs, and ECFCs were encapsulated in GelMA hydrogel. The osteoblast-vascular niche was developed via embedding GelMA microchannels into the SPELA patterned hydrogel matrix. In another instance, three kinds of GFs, including VEGF, PDGF, and SDF-1, were secreted from hypoxia-inducible factor-1α (HIF-α)-mutated muscle-derived stem cells (MDSCs) to accelerate vascular ingrowth and neovascularization within heparin-coated GelMA/HAMA hydrogel scaffold [136]. Subsequently, the constructed GelMA/HAMA hydrogel scaffold was then implanted within mice to repair the injured cavernosum, demonstrating vascularization in cavernosa and repair of cavernous defects. Above all, the cooperation of multiple angiogenic factors holds great promise for engineering vascularized tissue and tissue regeneration.

Table 2.

Main GFs involved in the regeneration of vascular networks.

| GFs | Main function | Ref. |

|---|---|---|

| VEGF | The key regulator of angiogenesis during embryogenesis; promoting ECs migration, proliferation, vascular permeability, and degeneration of ECM through binding to the receptors with tyrosine kinase activity | [200,201] |

| bFGF | Inducing plasminogen activator and collagenase activity; a strong synergistic action with VEGF accelerating ECs migration | [202] |

| PDGF-B | Stabilizing and enclosing the channels of ECs, leading to the maturation of blood vessels | [203] |

| ANG-1 | Maintaining the interaction between ECs and surrounding supporting cells and the stability of blood vessel structure | [184] |

Abbreviations: ANG-1 - angiopoietin-1, bFGF - basic fibroblast growth factors, GFs - growth factors, PDGF-B - platelet-derived GF-B, VEGF - vascular endothelial growth factors.

3.2.2. Incorporation of multiple cell types

3.2.2.1. Involvement of proper ECs subtypes

The cell types, including the selection of proper ECs (HUVECs; human microvascular ECs, HMVECs; endothelial progenitor cells, EPCs; and embryonic stem cells, ESCs) and involvement of multiple supporting cells (pericytes; vascular SMCs, VSMCs; and FBs) for engineering vascularized tissue constructs in vitro must be considered carefully to maintain their growth effectively, thus guiding the vascularized tissue formation [133]. In terms of arteries or large blood vessels, vasculature is made of a single sheet of ECs that are tightly arranged on the interior surface of blood vessels. The ECs layer is then surrounded by one or more layers of VSMCs or connective cells, which finally be embedded into the connective tissues [94,123,137]. However, capillaries only consist of a single sheet of flattened ECs and scattered pericytes [94]. Moreover, in different organs, endothelium exhibits various architectures, molecular signatures, and barrier functions in tissue-specific phenotypic heterogeneity [138]. For instance, abundant neovascularization is desired in the injured tissues for supplying oxygen and nutrients, which could improve the regeneration effect following the damage. On the contrary, the dysregulated vasculatures may lead to serious pathogenesis, such as the most typical disease, cancer. Accordingly, the selection of different phenotypes of ECs and supporting cells needs to be considered carefully when designing the models of vascularized constructs [91].

In this vein, a wide variety of ECs subtypes are currently available, ranging from primary isolated ECs to cells differentiated from progenitor or stem cell populations. Among others, HUVECs remain the most prevalent choice due to the relatively easy accessibility and alleviation of immune rejection [78,126,139]. Notably, HUVECs specifically express vascular endothelial cadherin (VE-Cad) and CD31, which is helpful in effectively identify them as ECs [78,107,130]. In our previous study, CD31 and VE-Cad staining were operated both in vitro and in vivo, indicating the growth, maturation, and organization of HUVECs [23,78]. Similarly, EPCs, showing the possibility of differentiating into mature functional ECs, are characterized by the expression of hematopoietic progenitor cell antigen (CD34) and vascular endothelial growth factor receptor-2 (VEGFR-2) markers [140,141]. Moreover, the origins of EPCs (bone marrow, peripheral blood, and lipoaspirate tissue) make them prefer clinically relevant cell sources for engineering intra-organ vascular trees. HMVECs, varying in phenotype and morphology based on cell sources (dermal, lung, and uterine tissues), are suitable for tissue-specific vascularization, especially for the study on angiogenesis in the tumor microenvironment [142].

3.2.2.2. Supporting cells guiding the vascularized tissue formation using hydrogels

In addition to the proper ECs, various supporting cells should also be considered to sustain ECs growth [15,17,91,139,143]. For the construction of large blood vessels, SMCs act as vasodilators and vasoconstrictors, which help altering vascular mechanical strain and pulsatile flow of blood [82,92,139]. For instance, Bak and colleagues cocultured SMCs and HUVECs within thermo-responsive hydrogels [133]. Not only the VEGF expression was up-regulated in the coculture group, but also the tube length of capillaries and the number of arterioles were significantly increased after implantation for 4 weeks in mice compared with the injection of HUVECs or SMCs only. FBs are another type of vital supporting cells specifically for synthesizing and maintaining the ECM by secreting collagen [15,17,91]. Blinder and colleagues reported the coculture of HUVECs and neonatal human dermal FBs in a fibrin-based scaffold and showed the dynamics of neovascular formation [69]. Notably, the vascular morphogenesis was time-correlated with the deposition of an ECM-rich environment. In another example, Whisler and coworkers seeded HUVECs in fibrin gels and cultured them alongside human lung FBs within a perfusable microfluidic platform [123]. Interestingly, the sprouting vessels could maintain a stable morphology with the presence of FBs, while the nascent EC networks would rapidly degenerate without coculture of FBs, indicating the communications and interactions between HUVECs and FBs. Furthermore, the organ-specific supporting cells are varied among organs. Depending on the in vivo counterparts to be simulated, the selection of unique supporting cells should be considered to enhance the integration between the vascularized constructs or engineered vessels to the host vasculatures [1,3,28,52,76,94,144]. For instance, chondrocytes provide major supporting systems to facilitate cartilage formation in the bone tissue environment [145,146]. The blood-brain barrier depends on the extensive presence of pericytes and astrocytes [94,147]. Together, both the selection of ECs and coculture of ECs with supporting cells play vital roles in engineering vascularized tissue constructs and various organs.

3.2.3. Incorporation of tailored micro-, and nanomaterials in response to the demanding for cellular signals

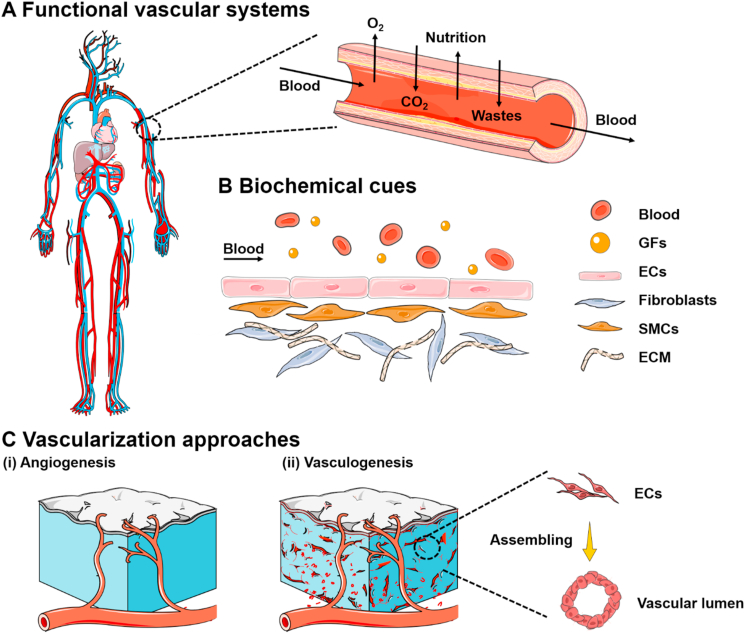

Since the growth of the vessel is an integral process involving numerous cues and GFs, the cooperation of various biometric signals into the engineered scaffolds can significantly govern the formation of vascular networks and effectively enhance the feasibility of vascularized tissues in vitro [22]. Hydrogels have been widely investigated as carriers of various hydrophobic or hydrophilic molecular cargos to target sites or injured tissues by releasing these biological cues in a programmed manner towards improving the angiogenesis process [6,19,97]. Initially, this conventional approach was applied to employing the hydrogels with different degradation rates as the desired sequential release platforms. However, these GF-supplemented scaffolds were troubled by the initial burst release of molecules from the hydrogel matrixes [148]. To overcome this challenge, the angiogenic factor-encapsulated polymeric particles were integrated within the hydrogel matrixes. For instance, Yonet-Tanyeri developed a non-degradable poly (ethylene glycol) dimethacrylate (PEGDMA) hydrogel patch, compromising VEGF121-contained poly (ethylene imine) (PEI)-PEGDA gel and VEGF165-laden PLGA microparticles (Fig. 3A) [149]. Initially, the PEI-PEGDA (Fig. 3A–i) could rapidly degrade due to cleavage of amino ester linkages between PEGDA and PEI (Fig. 3A–ii), leading to the immediate release of VEGF121 under degradation. Further, the VEGF165 was released from PLGA microparticles in a sustained fashion and then escaped from the PEGDMA patch (Fig. 3A–iii). Consequently, the sequential release of dual VEGF isoforms was achieved, demonstrating a more effective promotion of vascular sprouting and size expansion than releasing dual VEGF isoforms simultaneously or singular VEGF release (Fig. 3A–iv and v).

Fig. 3.

The design and application of (A) nanocomposite hydrogels and (B) micro composite hydrogels for angiogenesis and vasculogenesis. (A) Schematic illustration of the PEGDMA hydrogel patch (orange) in which PEI-PEGDA gels (green) are loaded in multiple micro-pockets and PLGA microparticles (violet) are embedded. (i) Representation of the chemical structure, (ii) bimodal hydrolytic degradation of the PEGDMA hydrogel patch, (iii) mechanism of the sequential molecular release from the PEGDMA hydrogel patch. Rapid VEGF121 (red) release with the degradation of the PEI-PEGDA gel and sustained VEGF165 (black) release from the PLGA microparticles, (iv) Quantified vascular density of chorioallantoic membrane (CAM), and (v) top view of the vasculature of CAM implanted with hydrogel patches. Sample 1 is the CAM implanted with a patch in which VEGF121 was loaded in the PEI-PEGDA gel, and VEGF165 was encapsulated in the PLGA particles embedded in the PEGDMA hydrogel. Sample 2 is the CAM implanted with the gel patch in which VEGF121 and VEGF165 were loaded in the PEI-PEGDA gel. Sample 3 is the CAM implanted with the gel patch in which VEGF121 and VEGF165 were loaded into the PEGDMA hydrogel. Reprinted with permission from Ref. [149]. Copyright 2013, Elsevier. (B) Inorganic strengthened hydrogel membrane for regenerative periosteum along with new vessels sprouting. (i) Fabricating amino-modified MBGNs and GelMA-MBGNs (G-MBGNs), (ii) pure GelMA and staining of CD31 at 8-week post-implantation, (iii) preparing GelMA/MBGNs and staining of CD31 at 8-week post-implantation, and (iv) preparing GelMA-G-MBGNs and staining of CD31 at 8-week post-implantation. The arrows indicate the new blood vessels. Reprinted with permission from Ref. [107]. Copyright 2017, America Chemical Society. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

In response to the demanding for various cellular signals in engineering tissue or organs in vitro, the focus of the researchers has been gradually shifted in recent times towards the development of composite gel systems using nanomaterials for the intended molecular delivery. These nanocomponents can physically or covalently be incorporated within the hydrogel bulk, leading to the nanocomposite hydrogel networks with exceptional physicochemical properties [106,107]. Moreover, the filler micro-and nanomaterials sometimes supply additional functionality, such as the promotion of electrical conductivity and facilitating tissue regeneration. As reported, a wide range of particulate forms, including inorganic nanoparticles, carbon-based nanomaterials, and metal nanoparticles, are combined to obtain such nanocomposite hydrogels [105,112,150,151]. In an example, the conductivity of electrical-conductive hydrogel using chemically reduced GO/GelMA (rGO/GelMA) was significantly higher than that of unreduced GO-incorporated GelMA (GO/GelMA) [106]. The incorporation of superparamagnetic iron oxide nanoparticles (SPIONs) in the star-shaped PEG with acrylate end groups could induce an ultrahigh magnetic response [151]. Silver nanoparticles enclosed into soft GelMA gels could accelerate wounding healing [111]. Conclusively, the employment of designed micro- or nano-materials is helpful in further expanding the applications of hydrogel systems in regenerating vascularized tissues.

3.3. Alternative hydrogel formation mechanisms

In most cases, cells are encapsulated into the hydrogels to develop tissues or organs in order to form a complex 3D culture environment [40,90]. Accordingly, the gelation processes and hydrogel solutions must be biocompatible. A variety of polymers, including natural and synthetic origins, can assemble of a liquid monomeric phase and be processed into hydrogels through self-assembly, thermos-condensation, chemical, and ultraviolet (UV)-irradiated photocrosslinking approaches, which appears the great versatility in physicochemical properties and gelation approaches of the hydrogel systems [[152], [153], [154]]. However, each shaping mechanism provides unique advantages and respective disadvantages towards the application of tissue engineering. Among others, the physical gelation approaches, such as thermo-response entanglement, are easy to achieve and reverse along with the limited tunable properties of hydrogels [83,108,113,133,155,156]. As for the prevalent chelation interactions, alginate is a prominent example to rapidly gel in the presence of divalent cations [59,100,[114], [115], [116],119]. The clipping process can occur in well-defined spaces, which facilitates the formation of distinctive tissue structures [78]. However, the lack of specific cell-binding motifs or receptors limits the enzymatic degradation of alginate under physiological conditions. In addition, potential calcium-related toxicities sometimes hamper the utilization of alginate [85,115,116]. Accordingly, in some cases, the removal of the alginate component was considered after gel shaping [137].

In recent years, UV-irradiation has been extensively used to initiate crosslinking [101,154,157]. During the shaping process of hydrogel, the mixed photo-initiators within hydrogel systems are excited by UV to create free radicals, which further interact with photo-curable macromers to stimulate crosslinking in the 3D polymeric networks [154]. Although the photocrosslinking approach has been widely utilized in building hydrogel systems, photoinitiation based on the presence of photo-initiators can lead to unforeseen toxicity issues to encapsulated cells [157,158]. In addition, the exposure time to UV light can affect the crosslinking density and thereby disturbing cell behavior. For example, Lin injected the GelMA solution containing human ECFCs and mesenchymal stem cells (MSCs) into mice to explore the effect of the degree of GelMA crosslinking to neovascularization in vivo [158]. They demonstrated that the cell spreading was progressively diminished by increasing the UV exposure time from 15 to 45 s. In addition, the cell viability was negatively affected beyond 300 s under UV exposure. Notably, they examined the application of UV light to modulate vascular morphogenesis in mice. The number of perfused blood vessels was significantly decreased from 374.7 ± 174.2 lumens mm−2 using 15 s UV exposure time to 145.1 ± 105.5 lumens mm−2 using 30 s UV exposure time, while no obvious blood vessels were observed in the GelMA hydrogels after 45 s exposure. Moreover, the morphology and lumen geometry of newly formed vessels were also larger using 15 s of UV irradiation (96.12 ± 10.5 mm2) compared with 30 s of irradiation (39.1 ± 5.3 mm2). In consideration of the benefits and limitations of various shaping approaches above, currently, several reports presented the integration of multiple hydrogel components and shaping mechanisms to enhance the physicochemical properties of the hydrogels [152,154]. Basically, the physical properties, such as viscosities of hydrogel aqueous solutions, swelling abilities, and mechanical properties after shaping, can be altered to some extent [100,116]. Furthermore, these multifunctional features of hydrogels also provide excellent opportunities for manipulating these hydrogels on various engineering techniques, including 3D printing, microfluidic spinning, and co-coaxial extrusion technology [[159], [160], [161]].

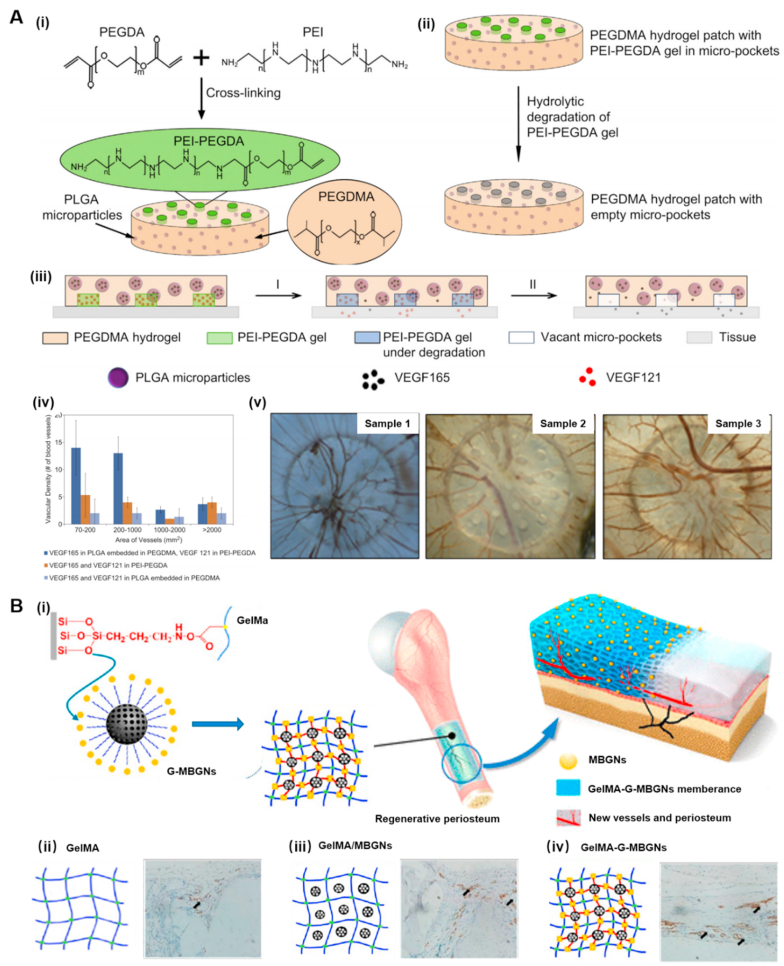

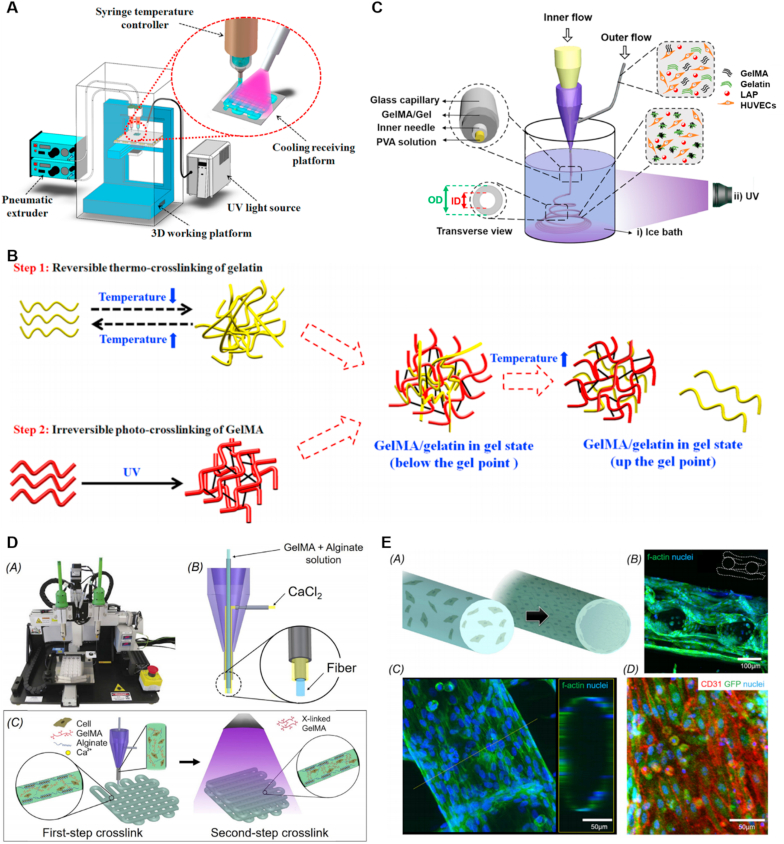

Nowadays, the majority of the combined gelation approaches rely on the combination of UV photocrosslinking with thermo-crosslinking or ion-crosslinking [50,78,132,162]. On the one hand, as for the thermo-crosslinking, thermal responsive polymers are directly entangled into the hybrid hydrogel solutions, and the most prevalent one is collagen-derived gelatin [50,132]. During the gelation process, successive reversible physical entanglement and the irreversible photocrosslinking of the hydrogel systems can be achieved (Fig. 4A) [132]. In the first step, the GelMA/gelatin bioinks were rapidly held under the gel point of gelatin, and in the second step, the gelatin was dissolved away after further stabilized by photocrosslinking without change of the scaffold geometry (Fig. 4B). Consequently, the blend of gelatin with GelMA could avoid the irregular filament shapes, time-consuming shaping process, and inadequate mechanical strength after printing at low GelMA concentration [132]. Notably, this blending hydrogel system based on gelatin could also cater to the microfluidic-based coaxial nozzle devices (Fig. 4C) [50]. In addition, the encapsulated HUVECs in the GelMA/gelatin gel exhibited excellent viability. The hollow structures of the constructed GelMA/gelatin microfibers were similar to blood vessels which could also be maintained after 10 d of cell culture. In addition to the natural polymers, the synthetic macromolecules, such as poly (N-isopropylacrylamide) (PNIPAAM) and polyacrylic acid (PAA), are also thermal responsive that can be utilized in vascularized tissue engineering [83,113,133,155].

Fig. 4.

(A) Schematic of the 3D bioprinting system: the temperature controller on the syringe regulated the viscosity of GelMA/gelatin bioinks; the cooling system under the receiving platform temporarily thermo-cross-linked gelatin in the bioinks; and the UV light permanently photo-crosslinked GelMA in the bioinks. (B) Two-step cross-linking of GelMA/gelatin bioinks. Reprinted with permission from Ref. [132]. Copyright 2018, ACS. (C) Schematic illustrating the setup for generating hollow GelMA/Gel microfibers by microfluidic coaxial biofabrication for cannular tissue engineering. Reprinted with permission from Ref. [50]. Copyright 2019, ACS. (D) Photograph of an Organovo bioprinter. Schematic of the coaxial needle where the bioink is delivered from the core and the ionic crosslinking CaCl2 solution is sheathed on the side. Schematic diagrams showing the two-step crosslinking process, where the alginate component is first physically crosslinked by the CaCl2 followed by chemical crosslinking of the GelMA component using UV illumination. Reprinted with permission from Ref. [49]. Copyright 2016, Elsevier.

On the other hand, alginate is another universally applied polymer for spontaneous physical gelation based on the chelation of polycarboxylates with Ca2+ or other divalent metal ions [59,100,[114], [115], [116],119]. Commonly, the gel formation takes place rapidly when the alginate contacts with calcium ions, leading to the precisely controlled anisotropic architectures and possibilities to prepare scaffolds of various shapes such as microrods [78], hollow microfibers [96], and helical structures [114]. In general, in the fabrication systems, the ionic solution of calcium ions and an aqueous solution of alginate were induced in dual syringe needles that were connected to the applicator, separately (Fig. 4D) [49]. During the bioprinting process, the bioink was extruded without clogging, following the firstly ionic crosslinking of the alginate component, and secondly, crosslinking of GelMA by UV exposure. In addition, the ECs could be encapsulated into the alginate/GelMA hydrogel to generate a perfusable vascular template after immigration (Fig. 4E). Accordingly, the alternative hydrogel formation approaches are significant to enhance manipulation flexibility.

4. Potential applications

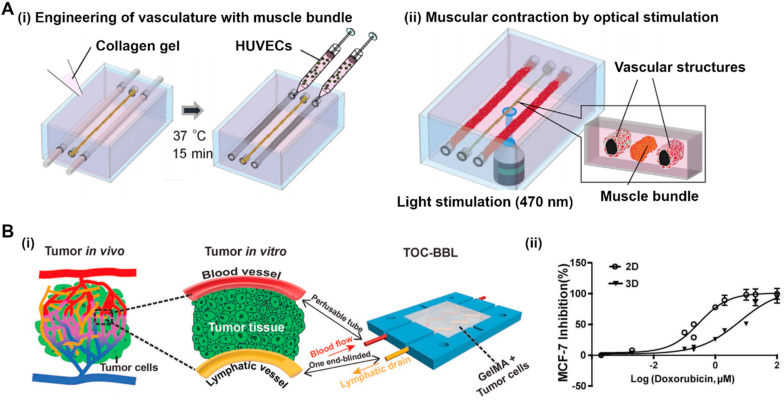

An impressive spectrum of cell biology, versatile hydrogels, and clinical pathology has enabled the formation of 3D tissue analogs with promoted vascularization. To date, an extensive study has demonstrated various organ types that can be mimicked by hydrogels, including but not limited to bone [77,95,[163], [164], [165]], kidney [[52], [53], [54]], liver [[55], [56], [57]], lung [160,166,167], muscle [[58], [59], [60], [61]], and brain [138,168]. Ultimately, the generation of these reproducible and accurate 3D organoids has extended the downstream translational applications, including tissue regeneration (Table 3), organ-on-chips (Table 4), and drug screening (Table 5). In this section, initially, we discuss the transplantation or injection of the vascularized organoids engineered by hydrogels for tissue repair. We further discuss the current applications of the hydrogel in organ-on-chips and drug development.

Table 3.

Construction of various organs with specific vascular morphology by hydrogel and its application in tissue regeneration.

| Hydrogel types | Cell sources | Organoid types | Vascular morphology/signals | Significant advantages of hydrogels | Major results | Ref. |

|---|---|---|---|---|---|---|

| GelMA, HAMA | HIF-1α mutated MDSCs | Corpus cavernosa | Ingrowth of vascularized tissue ingrowth and promotion of neovascularization | Similar multi-scale porous structure and Yong's modulus of hydrogel scaffolds to native corpus cavernosum | Heparin coating and secretion of VEGF, PDGF, and SDF-1 from MDSCs; restoration of the erectile and ejaculation function | [136] |

| GelMA | HDFs, HUVECs | Skin flap | Formation of HUVEC- tubes; increased density of microvessels in vivo | Controllable mechanical and degradation properties | Supporting for HUVECs proliferation and migration; a rapid formation of HUVEC-tubes | [157] |

| GelMA, gelatin | BMSCs | Spinal cord | Increased number of vascular ECs in vivo quantified by CD31 and synaptophysin staining | High elasticity and water content of the hydrogel scaffold | promotion of differentiation of BMSCs into neurons; formation of glial scar | [130] |

| GelMA, MBGNs | MC3T3-E1 | Periosteum | Formation of the initial circular lumen and further regular annular lumen by ECs after surgery for 4 and 8 weeks, respectively | Prolonged ion release, better mechanical strength, and more durable degradation time compared to pure GelMA | Fabrication of GelMA/MBGNs by physically mixture and GelMA-G-MBGNs by chemically modification, separately; quantified neovascularization GelMA-GMBGNs group > GelMA/MBGNs group > GelMA group > blank group at the same time after implantation | [107] |

| GelMA | BMSCs | Endochondral bone | GelMA architectures with interconnected microchannels in a diameter ranging from 265 to 1225 μm | Easy manipulating hydrogel architectures with hollow microchannels | Intensive vascular networks; enhanced vascularization within core regions of the microchannel GelMA templates; promotion of osteoclast/immune cell invasive and vascularization upon implantation | [95] |

| HAMA, GelMA | HUVECs, ADMSCs | Bone | Complex capillary-like networks in vitro; increased vessel density and area distribution of microvessels in vivo | Bioactive hybrid hydrogel solutions for differentiation of stem cells | Co-culture of HUVECs and ADMSCs within hydrogel coating improved vascularization in vitro, along with no significant effects on osteogenesis; functional anastomosis of capillaries in scaffold with the host vasculature | [163] |

| GelMA | HUVECs, hMSCs | Bone | 500 μm hollow channels within hard PLA scaffold; formation of capillary-like and lumen-like structures within biphasic constructs | Formation of biphasic constructs using hydrogel and delivery of angiogenic GFs within hydrogel matrixes | The formation of rounded morphologies of encapsulated cells within GelMA; enhanced osteogenic differentiation and vascularization due to the presence of BMP-2 peptide and VEGF peptide | [165] |

| Alginate, ceramic ink | HUVECs | Bone | Existing of about 500 μm hollow pipe in the middle of the strut | The regulation of HUVECs migration by ionic products in vitro | Promotion of bone marrow formation and bone marrow cavity reconnection | [96] |

| Alginate, gelatin | BMSCs | Bone | The positive expression of CD31 after injection for 3 weeks | Increased pore size with the increase of Mg particles within hydrogel | Development of in situ pore-forming injectable hydrogels | [85] |

Abbreviations: ADMSCs - adipose-derived mesenchymal stem cells, BMP-2 - bone morphogenetic protein-2, BMSCs - bone marrow mesenchymal stem cells, CD31 - platelet endothelial cell adhesion molecule-1, GelMA - gelatin methacrylate, GFs - growth factors, HAMA - methacrylate hyaluronic acid, HDFs - human dermal fibroblasts, hMSCs - human marrow mesenchymal stem cells, HUVECs - human umbilical vein endothelial cells, MC3T3-E1 - mouse embryonic osteoblasts precursor cells, MDSCs - muscle-derived stem cells, PDGF - platelet derived growth factor, VEGF- vascular endothelial growth factors.

Table 4.

Angiogenesis/vasculogenesis on-a-chip.

| Hydrogel types | Cell sources | Organoid types | Vascular morphology/signals | Major results | Ref. |

|---|---|---|---|---|---|

| Fibrin | HUVECs, lung FBs | Microvascular | Complex perfusable microvascular networks | Diseased vessel diameter by adding VEGF or increasing fibrinogen concentration | [123] |

| Fibrin | HUVECs, lung FBs, pericytes, hGMCs | Complex angiogenic sprouts and primary vessel network. | Spatially controlled co-culture of HUVECs with different cell types | Interconnected vasculogenic networks due to the co-culture of lung FBs; formation of a gradient of LF-secreted factors to induce angiogenic sprouting; simulation pericyte recruitment from interstitial tissue; mimicking of tumor vasculatures | [181] |

| Fibrin | HUVECs, hMSCs | Microvascular networks | Calculation of the size of microvascular networks, average vessel diameters, and length of branches for HUVECs only and co-culture condition | Generation of a non-interconnected microvasculature with the addition of TGF-β1; promotion of functional networks with the addition of Ang-1; reduction of mean vessel diameter and increased number of network branches with the presence of mural cells | [184] |

| Gelatin, fibrin | HUVECs, hMSCs, hNDFs | Osteogenic differentiation | HUVEC-lined vascular channel | The viability of hNDFs decreased at distance more than 1 mm from the embedded vasculature; differentiation of hMSCs to an osteogenic lineage | [186] |

| Collagen | HUVECs, NIH/3T3 | Vasculature | The confluent monolayers within the channels about 200 μm | Two endothelialized tubules within a stromal compartment; generation of spatially defined VEGF, bFGF, and phorbol myristate acetate gradients; investigations of invasion depth and sprouting morphology induced by GF gradients | [33] |

| PEGMA, PEGDA, GelMA, SPELA | HUVECs, MC3T3 | Microchannel networks | 150–1000 μm diameters of microchannel using various dispensing capillaries | Enhanced mass transport, differentiation, cellular viability within the constructs due to the presence of GelMA; proliferation of HUVECs at high GelMA concentration. | [187] |

| Collagen, gelatin | HUVECs, C2C12 cells | Vascularized muscle bundle | Microchannel at 500 μm in diameter | Formation of robust HUVEC-junction in 24 h; immediate HUVEC-sprouting with a muscle fiber; longer length of vessel sprouting in vascularized muscle bundle compared with the group without muscle bindle. | [188] |

Abbreviations: bFGF - basic fibroblast growth factors, C2C12 cells - mouse myoblasts, FBs - fibroblasts, GelMA - gelatin methacrylate, hGMCs - human glioblastoma multiforme cells, hMSCs - human marrow mesenchymal stem cells, hNDFs - human neonatal dermal fibroblasts, HUVECs - human umbilical vein endothelial cells, MC3T3 - mouse embryonic osteoblasts precursor cells, NIH/3T3 - mouse embryonic fibroblasts, PEGDA - poly(ethylene glycol) diacrylate, PEGMA - poly(ethylene glycol) dimethacrylate, SPELA - lactide-chain-extended star polyethylene glycol.

Table 5.

Modeling disease models by hydrogels with vasculatures for drug screening.

| Hydrogel types | Cell sources | Organoid types | Vascular morphology/signals | Major results | Ref. |

|---|---|---|---|---|---|

| GelMA, alginate | HUVECs, cardiomyocytes | Cardiac tissues | Migration of HUVECs and formation of a layer of confluent endothelium | The generation of aligned myocardium; dose-dependent responses of DOX towards HUVECs and cardiomyocytes | [49] |

| GelMA, PEGDA, alginate, PEGOA | MCF-7 cells, HUVECs, HLECs | Blood and lymphatic vessel pair | Perfusable blood vessels and lymphatic vessel with one blinded end | Adjusting levels of DOX diffusion using different combinations of lymphatic and blood vessels; increased IC50 value of DOX in 3D model | [51] |

| Gelatin, fibrin | ECFC-ECs, multiple tumor cell types (MCF-7, MDA-MB-231, SW620, SW480, and MNT-1) | Vascularized microtumors | Appearance of vessel-like fragments and complete networks within 3 d and 7 d, respectively | Enhanced angiogenic sprouting and vascular leakage in the vascularized microtumors with the presence of tumor cells; significant differences in IC50 for oxaliplatin between micro-tumors and 2D cultures | [198] |