Abstract

Objectives

The aim of this in vitro study was to investigate the torsional fatigue resistance of different rotary files in straight and curved positions at a simulated intracanal temperature.

Methods

Forty-eight size #25 files from ProTaper Universal (PTU), ProTaper Next (PTN) and ProTaper Gold (PTG) were tested for torsional resistance in both straight and curved (90 degrees) positions (n = 8 each). The experiment was conducted at a simulated intracanal temperature of 35 ± 1 °C. The torque gauge was reset before every use, and uniform torsional stress was applied by rotating the file clockwise at a speed of 40 rpm until fracture. Torque failure values were recorded, and fractured surfaces were tested using a scanning electron microscopy (SEM). Statistical analysis of the data was completed using one-way ANOVA and post-hoc test (LSD) in order to compare between the tested systems in each file position. Student’s t-test was also performed to compare between the two positions in each rotary system, and significance level was set at 5%.

Results

In the straight position, torsional resistance of PTN was significantly lower than that of PTU and PTG (p < 0.001), while the PTU and PTG had comparable results (p > 0.05). In the curved position, torsional resistance was found to be comparable among all systems (p > 0.05). Within each system, the curved position resulted in a significantly lower torsional resistance when compared to the straight position (p < 0.001). SEM examination revealed similar torsional failure behavior for all files tested under both positions.

Conclusions

Our study identified that placing files in a curved position was associated with a significant decrease in torsional resistance of all systems, and this necessitates reconsidering the torque settings proposed by the manufacturers. Whether these effects can be translated into in vivo studies remains to be investigated, and thus future studies are essential to provide confirming evidence.

Keywords: Curved position, Torsional resistance, ProTaper Gold, ProTaper Next, ProTaper Universal

1. Introduction

Endodontic files made of nickel-titanium (NiTi) alloy were introduced to the market with their superelastic behavior and shape memory property (Glossen et al., 1995, Del Fabbro et al., 2018) which make them superior to stainless steel files in cleaning and shaping the root canal system or removing the previous root canal filling in retreatment cases, especially in challenging root canal anatomy. The main factor for the improved characteristic of NiTi files is the reversible martensitic transformation. This transformation occurs due to a change between austenite and martensite phases which facilitates preparing curved root canals with safety, efficiency, and predictability (Kazemi et al., 2000, Perez et al., 2005). However, clinicians might encounter NiTi files fracture during root canal instrumentation which affects root canal treatment prognosis (Spili et al., 2005). File fracture might be caused by cyclic fatigue and/or torsional failure. The former occurs when compressive and tensile forces are repeatedly applied to the file while it is used in a curved canal in the area of greatest curvature until it fractures, while the latter takes place when the file tip is engaged in the canal while the rest of the file is rotating freely (Sattapan et al., 2000).

During root canal instrumentation, there are many factors that might generate stress on the file leading to fracture such as the handling technique, method of use, and complexity of the root canal anatomy. Moreover, the NiTi file performance under stress might be influenced by file design, alloy composition, and manufacturing process (Kuhn and Jordan, 2002, Miyai et al., 2006, Peters et al., 2007, Hieawy et al., 2015). The manufacturers of rotary systems strive to improve the mechanical characteristics of their products by developing new geometric design and/or thermo-mechanical manufacturing process (Cheung and Darvell, 2008, Shen et al., 2012). ProTaper Gold (PTG; Dentsply Sirona, Ballaigues, Switzerland) has been launched as the second generation of PTU with the same design and dimensions. However, both have different proprietary advanced metallurgy. Previous studies compared between PTG and PTU in relation to the resistance to cyclic fatigue and torsional failure and found that PTG had a higher resistance to cyclic fatigue yet lower resistance to torsional failure (Elnaghy and Elsaka, 2016, Elnaghy and Elsaka, 2017). Moreover, the same manufacturer introduced another NiTi system, named ProTaper Next (PTN), by using M-Wire technology with a unique design where the center of rotation is offset. The PTN files showed higher resistance to cyclic fatigue than PTU (Elnaghy, 2014).

It is worth mentioning that all previous torsional studies were performed while the file was held in a straight position. This might not reflect the reality of clinical practice where most root canals have some degrees of curvature. Therefore, conducting such type of experiments while the file is placed in curved position might be more informative on instruments' performance when used in vivo. Moreover, performing this experiment under simulated intracanal temperature shall show file performance inside the patient’s mouth. Thus, the aim of this in vitro study was to investigate the effect of torsional fatigue on PTU, PTN and PTG files in straight and curved positions at simulated intracanal temperature. The null hypothesis of this study is that there would be no difference in the torsional resistance between the two positions in each group and between the groups in each position.

2. Materials and methods

Forty-eight files with #25 tip size selected from PTU, PTN and PTG were tested in both, straight and curved positions (n = 8 each). File defects and irregularities were identified using a dental operating microscope (OPMI Zeiss Pico; Carl Zeiss MediTec, Dublin, CA), at a magnification of 13.6X.

A universal vise was used to hold the X-Smart Plus motor handpiece (Dentsply Sirona) with the mounted file above the torque gauge device (TT01; Mark-10 Corporation, Long Island, NY). The file’s apical 3 mm was firmly fixed using a stainless-steel pen vise. Then, the pen vise was attached to the torque gauge device in a way that placed the file in a vertical direction and oriented its tip apically toward the center of the gauge device for testing under straight position (Fig. 1.A).

Fig. 1.

Schematic drawings of the experimental set-up where the NiTi file was held in straight (A) or curved position (B).

In the curved position, the handpiece was moved 90 degrees in one plane while keeping the file tip toward the center of the gauge device. This created a curvature with 90 degrees angle and 2 mm radius, and the maximum tensile strain was generated 3 mm from the file tip (Fig. 1.B).

2.1. Torsional resistance test

The torque gauge was reset before every use, and uniform torsional stress from the motor was applied by rotating the file clockwise at a speed of 40 rpm until fracture. The readings of torque at failure were recorded.

During the experiment, the file was subjected to a hairdryer at a temperature of 35 ± 1 °C as confirmed by a thermocouple. The readings of torque at failure were recorded in real-time, and data were presented on a PC display using MESUR™ Lite software (Mark-10 Corporation, NY, USA).

2.2. Scanning electron microscopy

Two files from each subgroup were chosen for scanning electron microscopy (SEM) analysis to observe the topographic changes of the fractured surfaces. The files were cleaned by using absolute alcohol in an ultrasonic bath for 3 min to eliminate debris before the microscopic examination. They were dried at room temperature, and then each was mounted on a 15-mm metal stub vertically, by using a double-sided carbon type. The mounted sample was placed inside the SEM (6360LV Scanning Electron Microscope; JEOL, Tokyo, Japan) at 20 kV and 32-mm working distance. The SEM photomicrographs were captured at magnifications of 200X and 1000X.

2.3. Data analysis

Since the data were normally distributed (Shapiro-Wilk test; p > 0.05), they were analyzed statistically using one-way ANOVA and post-hoc test (LSD) to compare the tested systems in each file position. The two positions in each rotary system were compared using student’s t-test. All statistical analyses were performed using SPSS software version 22 (SPSS Inc., Chicago, IL, USA) at a 5% significance level.

3. Results

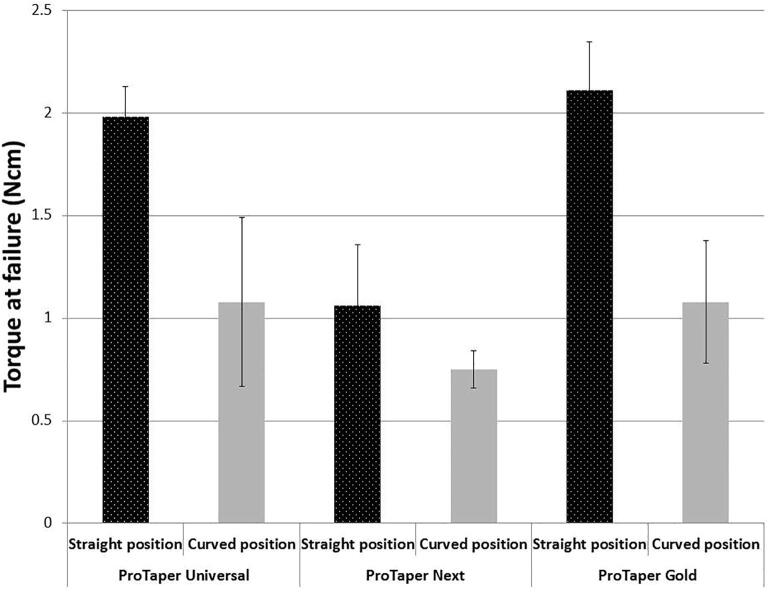

For all tested systems, placing the file in a curved position was found to reduce torsional resistance significantly (p < 0.001). In the straight position, torsional resistance of PTN was significantly lower than PTU and PTG (p < 0.001) while PTU and PTG were comparable (p > 0.05). In the curved position, torsional resistance was found to be comparable among the different systems (p > 0.05) (Fig. 2). Fractured segment length was found to be comparable, ranging from 3.3 mm to 3.8 mm in the tested systems in both positions (p > 0.05).

Fig. 2.

Torsional resistance data of the tested systems. Placing the file in a curved position was found to reduce torsional resistance significantly. In the straight position, torsional resistance of PTN was significantly lower than PTU and PTG while PTU and PTG were comparable. In the curved position, torsional resistance was found to be comparable among the different systems.

Under SEM, all tested files revealed similar behavior of torsional failure. Fractured cross-sectional surfaces exhibited typical features of failure, caused by torsion, with concentric abrasion patterns and a dimpled surface with micro-voids in the middle (Fig. 3).

Fig. 3.

Scanning electron microscopic images showing the fractured surfaces of PTU, PTN and PTG after torsional resistance failure in straight (a, c and e, respectively) and curved positions (b, d and f, respectively). Higher magnification showed typical features of torsional resistance failure (g and h).

4. Discussion

The aim of this study was to investigate the torsional performance of different rotary files from the same manufacturer under different positions. To the best of our knowledge, no study has investigated the file's torsional performance under a curved position. Compared to the straight position condition, placing the file in a curved position reduced the torsional resistance significantly in the tested systems. Thus, the null hypothesis was rejected.

Torsional fatigue is a mechanical property that occurs when the file gets twisted while the tip is locked in the canal. This behavior is highly seen in cases of narrow canals (Glossen et al., 1995, Sattapan et al., 2000). This property is usually studied according to the ANSI/ADA specifications (1989), in which the apical 3 mm of the file is secured, and the file shaft is allowed to rotate at 2 rpm speed. In this study, the file was secured at the same level and the speed was set at 40 rpm since the rotary file is operated at a higher speed than the hand file. Nonetheless, Ha et al. (2017) compared the torsional resistance of files rotated at 2 rpm with higher rpm values and found the performance of the rotary NiTi instruments were not affected by the rotational speed. Although the tested systems have identical features of fractured surfaces under SEM, the torsional resistance of PTN was significantly lower than that of PTU and PTG in a straight position which is in agreement with a previous study (Alqedairi et al., 2019). The PTN has less surface area than its corresponding file types in PTU and PTG at a 3 mm level (Alqedairi et al., 2019). Previous studies reported that an increase in the file's core diameter would enhance its resistance to the torsional stress (Xu et al., 2006, Kim et al., 2009, Baek et al., 2011, Pedullà et al., 2016, Goo et al., 2017). However, another study found that PTN had the highest torsional resistance, followed by PTU and PTG (Elnaghy and Elsaka, 2017). Moreover, Elnaghy and Elsaka (2016) found the torsional resistance of PTU and PTG to be higher than our findings. Also, Goo et al. (2017) studied the torsional failure of PTN and found its torsional resistance behavior higher than the present finding of the same file. These differences could be due to the study design, testing temperature and the level where the instrument was clamped and tested under torsion.

This study has shed light on the effect of canal curvature on the torsional performance of NiTi files. The curved position has reduced the torsional perfrormance in all tested groups, suggesting that canal curvature is an important predictor of torsional behavior. Several studies showed that the performance of NiTi alloy is affected by alloy transformation from the austenitic phase to the martensitic phase (Thompson, 2000, Miyai et al., 2006, Hayashi et al., 2007, Yahata et al., 2009). This transformation is induced by a change in stress and/or temperature. Although different geometric designs and manufacturing processes showed improved properties in previous studies (Cheung and Darvell, 2008, Shen et al., 2012), the present study showed that examining the NiTi file under the curved position reduced the torsional resistance of PTU, PTN, and PTG by 45%, 29%, and 49%, respectively, compared to the straight position. Deflecting the file to obtain a curved position would induce martensitic phase transformation by stress that leads to gradual defect accumulation. The defect is generated at the interface between martensite colonies which inhibits martensite to reform and reorient easily. This will facilitate crack growth and propagation and eventually leading to fracture at the maximum curvature area (Li et al., 2006). This might indicate the NiTi file will be more susceptible to torsional fatigue in curved canals. This shall make us reconsider the torque setting proposed by different manufacturers when preparing curved canals.

Laboratory studies have reported that changing the surrounding temperature affects file performance (Jamleh et al., 2016, Grande et al., 2017, Alfawaz et al., 2018, Elnaghy and Elsaka, 2018). Therefore, all the tested files were investigated under 35 ± 1 °C that simulates the intracanal temperature (de Hemptinne et al., 2015) which is clinically more relevant.

In this study, the pen vise was used to precisely secure the file in order to confirm the file clamping at 3 mm in all samples since slight changes in positioning can affect the torsional fatigue behavior of the tapered files. The fractured level was found to be close to the clamped level; in the range of 3.3–3.8 mm from the file tip in the groups with no significant difference, showing that the point of maximum stress was similar in each condition.

The fractographic examination is performed to show characteristics of the fractured surface that may indicate the crack direction and origin that has led to the file’s fracture (Shen and Cheung, 2013). The actual mechanism involved in the fracture process can be shown on the fractured surface (Del Fabbro et al., 2018). It is known that the failure caused by torsion demonstrates concentric abrasion patterns and a dimpled surface with microvoids on the fractured surface. The fractured surfaces of the tested files showed similar fractographic characteristics that were typical of torsional fatigue.

5. Conclusions

This study provided data on the torsional resistance of rotary files with different manufacturing processes in straight and curved positions at simulated intracanal temperature. Testing the file in curved position was associated with a significant decrease in the torsional resistance of all tested systems. Future torsional failure studies are highly recommended to mimic environmental conditions such as curved canals and intracanal temperature.

Authorship declaration

All authors have contributed significantly, and all authors are in agreement with the present manuscript.

CRediT authorship contribution statement

Ahmed Jamleh: Conceptualization, Investigation, Formal analysis, Validation, Funding acquisition, Writing - original draft, Writing - review & editing. Raghad Almedlej: Investigation, Validation. Rasha Alomar: Investigation, Validation. Nouf Almayouf: Investigation, Validation. Abdulmohsen Alfadley: Conceptualization, Formal analysis, Writing - review & editing. Khalid Alfouzan: Conceptualization, Formal analysis, Project administration, Writing - review & editing.

Declaration of Competing Interest

The authors declare no potential conflicts of interest with respect to the authorship and/or publication of this article.

Acknowledgements

This work was supported by a research grant (SP19/395/R) from King Abdullah international medical research center and National Guard Health Affairs, Riyadh, Kingdom of Saudi Arabia.

Footnotes

Peer review under responsibility of King Saud University.

References

- Alfawaz H., Alqedairi A., Alsharekh H., et al. Effects of sodium hypochlorite concentration and temperature on the cyclic fatigue resistance of heat-treated nickel-titanium rotary instruments. J. Endod. 2018;44(10):1563–1566. doi: 10.1016/j.joen.2018.07.009. [DOI] [PubMed] [Google Scholar]

- Alqedairi A., Alfawaz H., Abualjadayel B., Alanazi M., Alkhalifah A., Jamleh A. Torsional resistance of three ProTaper rotary systems. BMC Oral Health. 2019;19(1):124. doi: 10.1186/s12903-019-0820-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baek S.H., Lee C., Versluis A., Kim B., Lee W., Kim H. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 2011;37(9):1283–1286. doi: 10.1016/j.joen.2011.05.032. [DOI] [PubMed] [Google Scholar]

- Cheung G.S., Darvell B.W. Low-cycle fatigue of rotary NiTi endodontic instruments in hypochlorite solution. Dent. Mat. 2008;24(6):753–759. doi: 10.1016/j.dental.2007.09.004. [DOI] [PubMed] [Google Scholar]

- de Hemptinne F., Slaus G., Vandendael M., et al. In vivo intracanal temperature evolution during endodontic treatment after the injection of room temperature or preheated sodium hypochlorite. J. Endod. 2015;41(7):1112–1115. doi: 10.1016/j.joen.2015.02.011. [DOI] [PubMed] [Google Scholar]

- Del Fabbro M., Afrashtehfar K.I., Corbella S., et al. In vivo and in vitro effectiveness of rotary nickel-titanium vs manual stainless steel instruments for root canal therapy: systematic review and meta-analysis. J. Evid. Based. Dent. Pract. 2018;18(1):59–69. doi: 10.1016/j.jebdp.2017.08.001. [DOI] [PubMed] [Google Scholar]

- Elnaghy A.M. Cyclic fatigue resistance of ProTaper next nickel-titanium rotary files. Int. Endod. J. 2014;47(11):1034–1039. doi: 10.1111/iej.12244. [DOI] [PubMed] [Google Scholar]

- Elnaghy A., Elsaka S. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int. Endod. J. 2016;49(11):1073–1078. doi: 10.1111/iej.12557. [DOI] [PubMed] [Google Scholar]

- Elnaghy A., Elsaka S. Laboratory comparison of the mechanical properties of TRUShape with several nickel-titanium rotary instruments. Int. Endod. J. 2017;50(8):805–812. doi: 10.1111/iej.12700. [DOI] [PubMed] [Google Scholar]

- Elnaghy A., Elsaka S. Torsional resistance of XP-endo Shaper at body temperature compared with several nickel-titanium rotary instruments. Int.l Endod. J. 2018;51(5):572–576. doi: 10.1111/iej.12815. [DOI] [PubMed] [Google Scholar]

- Glossen C., Haller R., Dove S., del Rio C. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-flex endodontic instruments. J. Endod. 1995;21(3):146–151. doi: 10.1016/s0099-2399(06)80441-3. [DOI] [PubMed] [Google Scholar]

- Goo H., Kwak S., Ha J., Pedullà E., Kim H. Mechanical properties of various heat-treated nickel-titanium rotary instruments. J. Endod. 2017;43(11):1872–1877. doi: 10.1016/j.joen.2017.05.025. [DOI] [PubMed] [Google Scholar]

- Grande N., Plotino G., Silla E., et al. Environmental temperature drastically affects flexural fatigue resistance of nickel-titanium rotary files. J. Endod. 2017;43(7):1157–1160. doi: 10.1016/j.joen.2017.01.040. [DOI] [PubMed] [Google Scholar]

- Ha J.H., Kwak S.W., Kim S.K., Sigurdsson A., Kim H.C. Effect from rotational speed on torsional resistance of the nickel-titanium instruments. J Endod. 2017;43(3):443–446. doi: 10.1016/j.joen.2016.10.032. [DOI] [PubMed] [Google Scholar]

- Hayashi Y., Yoneyama T., Yahata Y., et al. Phase transformation behaviour and bending properties of hybrid nickel-titanium rotary endodontic instruments. Int. Endod. J. 2007;40(4):247–253. doi: 10.1111/j.1365-2591.2007.01203.x. [DOI] [PubMed] [Google Scholar]

- Hieawy A., Haapasalo M., Zhou H., et al. Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper Universal instruments. J. Endod. 2015;41(7):1134–1138. doi: 10.1016/j.joen.2015.02.030. [DOI] [PubMed] [Google Scholar]

- Jamleh A., Yahata Y., Ebihara A., et al. Performance of NiTi endodontic instrument under different temperatures. Odontology. 2016;104(3):324–328. doi: 10.1007/s10266-015-0214-5. [DOI] [PubMed] [Google Scholar]

- Kazemi R.B., Stenman E., Spångberg L.S. A comparison of stainless steel and nickel–titanium H-type instruments of identical design: torsional and bending tests. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2000;90(4):500–506. doi: 10.1067/moe.2000.108959. [DOI] [PubMed] [Google Scholar]

- Kim T.O., Cheung G.S., Lee J.M., Kim B.M., Hur B., Kim H.C. Stress distribution of three NiTi rotary files under bending and torsional conditions using a mathematic analysis. Int. Endod. J. 2009;42(1):14–21. doi: 10.1111/j.1365-2591.2008.01481.x. [DOI] [PubMed] [Google Scholar]

- Kuhn G., Jordan L. Fatigue and mechanical properties of nickel-titanium endodontic instruments. J. Endod. 2002;28(10):716–720. doi: 10.1097/00004770-200210000-00009. [DOI] [PubMed] [Google Scholar]

- Li U.M., Shin C.S., Lan W.H., Lin C.P. Application of nondestructive testing in cyclic fatigue evaluation of endodontic Ni-Ti rotary instruments. Dent. Mater. J. 2006;25(2):247–252. doi: 10.4012/dmj.25.247. [DOI] [PubMed] [Google Scholar]

- Miyai K., Ebihara A., Hayashi Y., Doi H., Suda H., Yoneyama T. Influence of phase transformation on the torsional and bending properties of nickel-titanium rotary endodontic instruments. Int. Endod. J. 2006;39(2):119–126. doi: 10.1111/j.1365-2591.2006.01055.x. [DOI] [PubMed] [Google Scholar]

- Pedullà E., Lo Savio F., Boninelli S., et al. Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. J. Endod. 2016;42(1):156–159. doi: 10.1016/j.joen.2015.10.004. [DOI] [PubMed] [Google Scholar]

- Perez F., Schoumacher M., Peli J.F. Shaping ability of two rotary instruments in simulated canals: stainless steel ENDOflash and nickel–titanium HERO Shaper. Int. Endod. J. 2005;38(9):637–644. doi: 10.1111/j.1365-2591.2005.00997.x. [DOI] [PubMed] [Google Scholar]

- Peters O.A., Roehlike J.O., Baumann M.A. Effect of immersion in sodium hypochlorite on torque and fatigue resistance of nickel-titanium instruments. J. Endod. 2007;33(5):589–593. doi: 10.1016/j.joen.2007.01.007. [DOI] [PubMed] [Google Scholar]

- Revised ANSI/ADA specifications No. 28 for root canal files and reamers, type K, and No. 58 for root canal files, type H (Hedstrom),1989. Council on Dental Materials, Instruments, and Equipment. J. Am. Dent. Assoc. 118:239–40. [PubMed]

- Sattapan B., Nervo G., Palamara J., Messer H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000;26(3):161–165. doi: 10.1097/00004770-200003000-00008. [DOI] [PubMed] [Google Scholar]

- Shen Y., Cheung G.S. Methods and models to study nickel-titanium instruments. Endod. Topics. 2013;29(1):18–41. [Google Scholar]

- Shen Y., Qian W., Abtin H., et al. Effect of environment on fatigue failure of controlled memory wire nickel-titanium rotary instruments. J. Endod. 2012;38(3):376–380. doi: 10.1016/j.joen.2011.12.002. [DOI] [PubMed] [Google Scholar]

- Spili P., Parashos P., Messer H. The impact of instrument fracture on outcome of endodontic treatment. J. Endod. 2005;31(12):845–850. doi: 10.1097/01.don.0000164127.62864.7c. [DOI] [PubMed] [Google Scholar]

- Thompson S.A. An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 2000;33(4):297–310. doi: 10.1046/j.1365-2591.2000.00339.x. [DOI] [PubMed] [Google Scholar]

- Xu X., Eng M., Zheng Y., Eng D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J. Endod. 2006;32(4):372–375. doi: 10.1016/j.joen.2005.08.012. [DOI] [PubMed] [Google Scholar]

- Yahata Y., Yoneyama T., Hayashi Y., et al. Effect of heat treatment on transformation temperatures and bending properties of nickel titanium endodontic instruments. Int. Endod. J. 2009;42(7):621–626. doi: 10.1111/j.1365-2591.2009.01563.x. [DOI] [PubMed] [Google Scholar]