Abstract

Objective

The goal of this study was to investigate the flexural strength, Young’s modulus and Weibull modulus of two heat-pressed and one CAD/CAM processed lithium disilicate (LD) ceramics.

Material and methods

A total of 45 specimens with dimensions 16 × 4 × 1.2 ± 0.2 mm were fabricated out of three LD ceramics. For heat-pressed LD specimens, acrylate polymer blocks were cut and divided into two groups (n = 15 per group); a GC LiSi Press LD group (LP) and an IPS e.max Press group (EP). Specimens for each group were pressed corresponding to the manufacturer’s recommendations. For the CAD-CAM Group (EC), IPS e.max CAD blocks were cut to obtain specimens (n = 15) to the desired dimensions. Flexural strength and Young’s modulus tests were executed using a universal testing machine. A one-way ANOVA and post-hoc Tuckey’s tests were applied to analyze the results (p ≤ 0.05).

Results

Regarding flexural strength, the EC group showed higher statistically substantial difference than the EP and LP groups (p = 0.001), while there was no pronounced difference between the EP and LP groups (p = 0.065). For Young’s modulus test, all the three tested groups had no statistically substantial difference (p = 0.798).

Conclusion

The IPS e.max CAD group had higher mechanical performance than the IPS e.max Press and GC LiSi Press groups.

Keywords: Lithium disilicate, Ceramics, CAD-CAM, Heat press

1. Introduction

Due to its esthetic appearance and favorable mechanical properties, dental ceramics have become the material of choice in restoring partial loss of the coronal tooth structure (Robert Kelly, 2004). Ceramics can be categorized based on their composition into polycrystalline, crystalline based with glass fillers, glass-based with crystalline fillers, and glass-based ceramics. Incorporation of crystals in ceramics is to enhance the mechanical properties while the glass matrix confers the esthetics merits (Teixeira et al., 2007, Vichi et al., 2011).

The most common example of the glass-based with crystalline fillers category is lithium disilicate (LD) glass ceramics. This material was introduced with a composition of 30% glass matrix and 70% highly interlocked needle-shaped LD (Li2Si2O5) crystals (Plengsombut et al., 2009). These crystals, which are randomly oriented within the matrix, have the major role in arresting the propagation of the crack, and then substantially increase the flexural strength of the LD (Holand et al., 2000, Höland et al., 2007, Huang et al., 2017). LD material is characterized by good mechanical and chemical properties, excellent esthetic outcomes, biocompatibility, and ease of fabrication (Dupree et al., 1990).

Heat pressing and computer-aided design and manufacturing (CAD/CAM) are the techniques available for fabrication of LD restorations. For the heat pressing technique, LDs are usually manufactured completely crystalized and offered in the form of ingots that under heating become viscous and pressed with a lost wax technique. For the CAD/CAM technique, the LDs are prepared by manufacturers in the form of partially crystalized (Li2SiO3) blocks that require firing after milling the restoration to reach the final crystallization stage (Li2Si2O5). The firing cycle improves the LD mechanical properties and the esthetic appearance (Bischoff et al., 2011, von Clausbruch et al., 2000, Wen et al., 2007). The crystallization process usually occurs in two main phases; nucleation and crystal growth (Huang et al., 2015). The final microstructure of the LDs includes highly interlocked crystals with dimensions of 5 µm in length and 0.8 µm in diameter (Denry and Holloway, 2010, Höland et al., 2006).

Various articles have investigated the mechanical properties of LD materials (Furtado de Mendonca et al., 2019, Lien et al., 2015, Zhang et al., 2014). Recently, (Furtado de Mendonca et al., 2019) assessed the flexural strength of CAD/CAM LD, hybrid polymer-infiltrated ceramic network materials, zirconia reinforced lithium silicate and hybrid high-performance polymer composite resin. They found that the LD significantly presented the highest flexural strength value. Another study investigated the flexural resistance of different heat pressed and CAD/CAM LD materials with various translucencies. They found that there was no substantial difference in the flexural strength between the heat pressable and CAD/CAM LD materials. The medium translucency groups had the highest flexural strength in both the heat pressable and CAD/CAD LD groups with values of 379.7 MPa and 397.46 MPa, respectively (Fabian Fonzar et al., 2017).

A newly introduced LD material, which is available in the market, has not been well investigated in the literature in terms of flexural resistance properties. Therefore, the goal of this study is to investigate the flexural strength, Young’s modulus and Weibull modulus of three different LD materials. The null hypothesis was that the flexural strength and Young’s modulus would not be substantially different among the three groups.

2. Materials and methods

2.1. Specimen preparation

This in vitro investigation was conducted to explore the flexural strength and elastic modulus of three LD materials using a total of 45 specimens. Three groups (n = 15, each group) were included. Specimens of two groups were fabricated using a heat pressing technique, and one group was made up of CAD/CAM technology (Table 1). For the heat pressing specimens, a total of 30 blocks of acrylate polymer material (IPS AcrylCAD, Ivoclar Vivadent, Schaan, Liechtenstein) were used and cut using a low-speed diamond saw with water coolant (ISOMET 5000 Linear Precision Saw, Buehler Ltd, IL, USA) to get 30 specimens with dimensions of 4.0 × 1.2 × 16.0 ± 0.2 mm (ISO6872, 2015).

Table 1.

The tested groups and materials used in this study.

| Tested Groups | Material | Manufacturer | Firing Temperature (°C) | Holding Time (min) | Composition | Shade | Patch Number |

|---|---|---|---|---|---|---|---|

| EP group | IPS e.max Press | Ivoclar Vivadent, Schaan, Liechtenstein | 910 | 15 | SiO2, Li2O, K2O, P2O5, ZrO2, ZnO | HT A1 | V20844 |

| LP Group | GC LiSi Press | GC Corp, Tokyo, Japan | 897 | 20 | SiO2, Al2O3, Li2O, K2O, ZrO2, Na2O, P2O5, ZrO2 | HT-E58 | 1,703,061 |

| EC group | IPS e.max CAD | Ivoclar Vivadent, Schaan, Liechtenstein | 850 | 7 | SiO2, Li2O, K2O, P2O5, ZrO2, ZnO, Al2O3, MgO | HT A1 | S44682 |

These specimens were then randomly distributed into two groups (n = 15). The LP group included specimens that were fabricated using GC LiSi Press LD ingots (GC Initial LiSi Press, GC Corp, Tokyo, Japan). In the second group (EP group), specimens were made using IPS e.max Press ingots (IPS e.max Press, Ivoclar Vivadent, Schaan, Liechtenstein). Sprueing for five specimens in each cycle was done using a 3-mm long, 3-mm diameter wax wire (wax wire, BEGO GmbH, Bremen, Germany) attached to the ring base (IPS Investment Ring System200 gr., Ivoclar Vivadent, Schaan, Liechtenstein). Specimens were kept 5 mm away from each other and at least 10 mm from the borders of the silicone ring. Investing, preheating, pressing of specimens were performed using a pressing furnace (Programat EP5010, Ivoclar Vivadent, Schaan, Liechtenstein) according to the manufacturers’ directions for each material (Table 1).

For the CAD group (EC group), blocks of lithium disilicates (IPS e.max CAD, Ivoclar Vivadent, Schaan, Liechten-stein) were used. Obtaining of specimens (n = 15) was performed by cutting the blocks using a low-speed water-cooled diamond saw (ISOMET 1000, Buehler, Lake Bluff, Illinois) into rectangular specimens with dimensions of 4.0 × 1.2 × 16.0 ± 0.2 mm. The final crystallization was applied following the manufacturer recommendations using a furnace (Programat P510, Ivoclar Vivadent, Schaan, Liechtenstein). The crystallization parameters included the firing temperature and the holding time for each LD ceramic material were mentioned in Table 1.

Finishing and polishing of all specimens were performed using #600, #1200, and #2400 grit carbide sandpapers under running water using a polishing machine (Struers, Ballerup, Denmark). The dimensions were verified using an electronic measuring device (extra large LCD screen digital caliper, Neiko tool) with an accuracy of 0.01 mm. Specimens were stored at the room temperature for 48 h.

2.2. Flexural strength

A three-point flexure test was applied to determine the flexural strength values of the tested groups using the equation FS = 3Fl/2bd2 following ISO 6872 (ISO6872, 2015). F was the fracture load, l pointed to the test span (14 mm), b was the specimen width, and d indicated the specimen thickness. Each specimen was loaded to fracture using a universal testing machine (Instron 8871; Instron Co., Norwood, MA, USA) with crosshead speed of 0.5 mm/min.

2.3. Young’s modulus

The Young’s modulus values were obtained from the slope of the most convenient region at the load deflection curve. The equation E = Fl3/4bh3d was used; where E is the Young’s modulus, F is the load to fracture value (N), l is the test span (14 mm), b is the width, h is the thickness of the bar shaped specimen, and d is the deflection related to the load (F) (ISO6872, 2015).

2.4. Weibull analysis

The variation in the flexural strength of each group was assessed using the Weibull modulus through the following equation (Lin et al., 2012):

P (σ) is the probability of failure; σ is the flexural strength at a given P (σ); σ0 represents the characteristic strength; m is the Weibull modulus, which is the slope of the ln (ln 1/1 − P) versus in σ plots.

2.5. Statistical analysis

Statistical data were analyzed by using SPSS-20.0, IBM product of Chicago, USA. Numeric data in terms of flexure strength (MPa) and Young’s modulus (GPa) were explored for normal distribution by using 1-sample Kolmogorov Smirnov Test. These data showed a normal distribution and were presented by mean and standard deviation. One-way analysis of variance (ANOVA) was applied to compare the means among the three groups and post-hoc Tuckey’s test to compare mean differences pairwise if a significant difference was attained among means (α = 0.05).

3. Results

Means and standard deviations (SD) of the three tested groups are shown in Table 2. This study included three groups (LP, EP, and EC). The normality test was conducted using One-Sample Kolmogorov-Smirnov test where all data showed normal distribution (Table 3). Each group had 15 specimens evaluated for flexural strength and Young’s modulus for the three LD materials. Regarding the flexural strength test, the EC group showed a higher statistically pronounced difference as compared to the EP and LP groups (p = 0.001), while there was no substantial difference between the EP and LP groups (p = 0.065) (Table 2). The LP group presented the lowest flexural strength mean value (203.54 MPa), and the EC had the highest value (364.64 MPa).

Table 2.

Flexural strength and Young’s modulus of the study’s groups.

| Parameters | LP (Mean ± SD)/ 95% Confidence Interval (L/U) |

EP (Mean ± SD)/ 95% Confidence Interval (L/U) |

EC (Mean ± SD)/ 95% Confidence Interval (L/U) |

P-value |

|---|---|---|---|---|

| Flexural strength [MPa] | 203.54 ± 38.68a | 249.59 ± 75.08c | 364.64 ± 66.51b,c | 0.001 |

| 182.12/224.96 | 208.01/291.17 | 327.81/401.47 | ||

| Young’s modulus [GPa] | 76.97 ± 7.20 | 79.77 ± 9.76 | 79.33 ± 17.39 | 0.798 |

| 72.98/80.96 | 74.37/85.17 | 69.70/88.96 |

Shows non-significant mean difference between group LP vs. EP (p = 0.065).

Shows significant mean difference between group LP vs. EC (p = 0.001).

Shows significant mean difference between group EP vs. EC (p = 0.001).

Table 3.

One-Sample Kolmogorov-Smirnov Test for Data Normal Distribution.

| One-Sample Kolmogorov-Smirnov Test | ||||

|---|---|---|---|---|

| Group | Fexural Strength (MPa) | Young's Modulus (GPa) | ||

| EC | N | 15 | 15 | |

| Normal Parametersa,b | Mean | 364.641687 | 79.32527 | |

| Std. Deviation | 66.5045646 | 17.392129 | ||

| Most Extreme Differences | Absolute | 0.141 | 0.150 | |

| Positive | 0.141 | 0.150 | ||

| Negative | −0.116 | −0.129 | ||

| Kolmogorov-Smirnov Z | 0.546 | 0.581 | ||

| Asymp. Sig. (2-tailed) | 0.926 | 0.888 | ||

| EP | N | 15 | 15 | |

| Normal Parametersa,b | Mean | 249.585947 | 79.76740 | |

| Std. Deviation | 75.0825673 | 9.763257 | ||

| Most Extreme Differences | Absolute | 0.197 | 0.106 | |

| Positive | 0.159 | 0.084 | ||

| Negative | −0.197 | −0.106 | ||

| Kolmogorov-Smirnov Z | 0.762 | 0.411 | ||

| Asymp. Sig. (2-tailed) | 0.607 | 0.996 | ||

| LP | N | 15 | 15 | |

| Normal Parametersa,b | Mean | 203.535507 | 76.97033 | |

| Std. Deviation | 38.6813675 | 7.203360 | ||

| Most Extreme Differences | Absolute | 0.078 | 0.163 | |

| Positive | 0.074 | 0.163 | ||

| Negative | −0.078 | −0.112 | ||

| Kolmogorov-Smirnov Z | 0.304 | 0.630 | ||

| Asymp. Sig. (2-tailed) | 1.000 | 0.822 | ||

Test distribution is Normal.

Calculated from data.

For Young’s modulus test, data showed that there was no statistically substantial difference between all three tested groups (p = 0.798), as shown in Table 2. The lowest elastic modulus value was shown in the LP group (76.97 GPa), while the highest value was shown in the EP group (79.77 GPa) (Table 2).

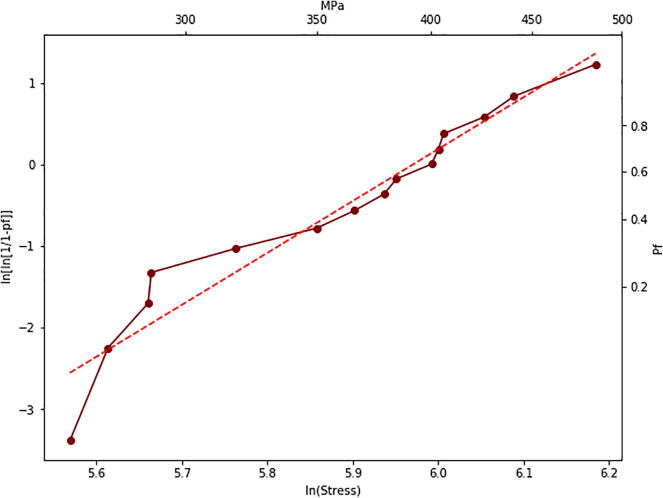

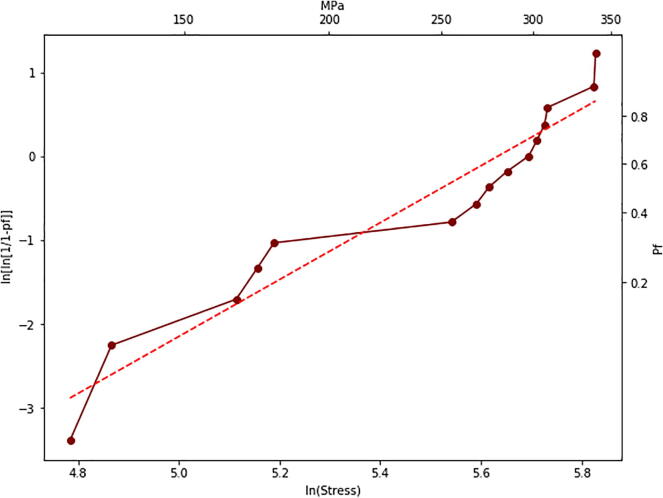

The statistical analysis of Weibull modulus and distribution is presented in Table 4 and Fig. 1, Fig. 2, Fig. 3. The EC group had the highest Weibull modulus value followed by the LP group and the least value was noticed in the EP group.

Table 4.

Weibull analysis of strength for the study’s groups.

| Tested Groups | m |

σ0.05 | |||

|---|---|---|---|---|---|

| Estimated | SE | 95% CI (Low) | 95% CI (High) | ||

| LP | 6.17 | 0.18 | 5.79 | 6.56 | 219.69 |

| EC | 6.36 | 0.46 | 5.37 | 7.35 | 392.79 |

| EP | 3.39 | 0.28 | 2.79 | 3.99 | 279.02 |

m value = Weibull modulus; σ0.05 = stress levels at 5% probability of failure.

Fig. 1.

Failure probability curve of Weibull modulus for LP group.

Fig. 2.

Failure probability curve of Weibull modulus for EC group.

Fig. 3.

Failure probability curve of Weibull modulus for EP group.

4. Discussion

Ceramic materials have evolved recently to convey the esthetic demands of dentistry. However, these materials are brittle in nature and risk fracture under the exertion of intraoral functional forces. The evolution of LDs has occurred to improve the mechanical properties and maintain the esthetic merits. This study was designed to evaluate the flexural strength and Young’s modulus of three different LD materials. The null hypothesis was partially accepted as the EC group presented a better substantial difference in the flexural strength test as compared to the EP and LP groups, while there was no significant difference between the tested groups in Young’s modulus test. Ohashi et al. (2017) investigated the mechanical properties of three heat pressing LDA materials, including GC LiSi LD. They found that LiSi did not differ significantly in biaxial flexural strength when compared to e.max Press. At the microstructure level, they claimed that LiSi SEM images showed small LD crystals, sized 1.0–1.5 μm, dispersed densely in the glass matrix. Differently, SEM images of E.max Press revealed larger LD crystals, sizes 1.0–4.0 μm. In agreement with Ohashi and colleagues’ study, the results of the present study exhibited no significant difference between GC LiSi (LP group) and e.max Press (EP group) in terms of the flexural strength test.

Despite the insignificance of the flexural strength values between LP and EP groups, the EC group had the highest value among the tested groups (364.64 MPa). Fabian Fonzar et al. (2017) compared the flexural strength of HT, MT, LT and MO translucency ingots of IPS E.max Press to IPS e.max CAD with the same translucency. They reported that there was no significant difference in the overall comparison between the CAD and Press main groups. However, the MT within the IPS e.max CAD groups presented a higher statistically significant difference in the flexural strength than the HT and MO. In addition, LT had a higher significant difference than the MO group. The results of Fabian Fonzar et al. (2017) study did not agree with the results of the present study, which may be a result of the different translucency materials used in both studies, where only HT translucency was used in this study. However, in Fabian Fonzar et al. (2017) study, the mean flexural strength value of HT translucency was higher in the IPS. e.max CAD than the IPS e.max Press, which is close to the present study’s results. Lupu and Giordano (2007) reported that HT of the CAD/CAM LD materials in the pre-crystallized phase includes fewer and larger lithium metasilicate crystals. Nevertheless, it could be noticed that the flexural strength values of IPS. e.max CAD and the IPS e.max Press were varied in different studies which could be attributed to the difference in the composition and the processing technique. Furthermore, the crystallization of IPS e.max Press is yielded and controlled industrially while the crystallization of IPS. e.max CAD accomplished in two phases. The first phase formulated by the manufacturer where the lithium metasilicate (Li2SiO3) crystals are yielded and the second phase completed in the dental laboratory by heat treatment where lithium metasilicate transform into lithium disilicate (Li2Si2O5) crystals (Zheng et al., 2008).

Fraga et al. (2017) assessed the impact of machining of different CAD/CAM ceramics on their flexural strength and the surface roughness. They found that polishing ceramics after machining dramatically improved their flexural strength. In the present study, all specimens were machined and then polished to mimic the clinical scenario following the manufacturer recommendations. Another study evaluated the mechanical properties of different CAD/CAD lithium silicate ceramics as received from the manufacturers and after heat treatment. Authors reported that the average value of the flexural strength of e.max CAD LD was significantly higher than the other groups (327.8 ± 14) (Alves et al., 2019). This could be referred to the reduction in the amorphous phase after heat treatment and the substantial transformation of lithium metasilicate (Li2SiO3) crystals into lithium disilicate (Li2Si2O5) crystals as well (Alves et al., 2019).

The ceramic blocks are usually provided in a partially crystallized status to be easily milled while containing LD (Li2Si2O5) and lithium metasilicate (Li2SiO3) crystals. After complete crystallization in the heat treatment, the HT LD crystals exhibited layered clusters in the glossy matrix. The orientation of these clusters usually occurs in different directions, which may result from crack deflection. Furthermore, once the LD is subject to external stress, the crack could be initiated in the glass matrix. LD crystals deflect the crack and subsequently impede further crack propagation. Another mechanism has been proposed by Borom et al. (1975) stating that the increase in the strength of LD could refer to the mismatch in thermal expansion after the final crystallization procedure between the glass matrix and LD crystals. Young’s modulus test revealed no pronounced difference among the tested groups. However, the EC and EP groups showed higher elastic modulus than the LP group. These results could be attributed to the percentage of LD crystals in the three ceramic materials that resisted the specimens’ deformation under the applied load. Lawson et al. (2016) evaluated the elastic modulus of various CAD/CAM materials including e.max CAD. They reported that e.max CAD had the highest value of elastic modulus. Lien et al. (2015) evaluated the effect of the flexural strength and the elastic modulus of the e.max CAD processed at different thermal stages. They reported that the temperature range (750–840 °C) and a protracting holding time (820–840 °C) for 14 min increased the elastic modulus values significantly as compared to the manufacturer’s recommended temperature range (820–840 °C), while the flexural strength showed no significant differences between the two heating stages.

The Weibull analysis was carried out in the present study to explore the variation in the flexural strength due to defects or flaws, which may evolve within the materials internal structure. A higher value of Weibull modulus suggests less defects and cracks and subsequently greater reliability of data while lower value suggests more defects and flaws in the material structure (Della Bona et al., 2003, Robin, 2002). The results of the present study showed that higher values (m) were obtained for EC (6.36) and LP groups (6.17) while the EP had the lowest value (3.39). This variation could be attributed to the difference in the composition and the processing technique among the three materials (Elsaka and Elnaghy, 2016, Lin et al., 2012).

The clinical use of the three ceramic materials could be defined based on ISO 6872 specifications (ISO6872, 2015). In the present study, the flexural strength mean values of GC LiSi LD and IPS e.max Press were above 100 MPa and below 300 MPa, thereby both materials fulfill the ISO requirements for Class 1 and 2. Accordingly, they are recommended for anterior or posterior single-unit prostheses. On the other hand, the value of e.max CAD was above 300 MPa and below 500 MPa. Therefore, it should be categorized in class 3 where it is recommended for anterior or posterior single-unit prostheses and three-unit prostheses not including molar restoration.

The present study assessed the flexural strength and Young’s modulus of three LD materials, including a recently introduced ceramic material (GC LiSi Press). However, this study has some limitations, including that it did not mimic the complexity of the oral cavity, such as occlusal forces, the range of intraoral temperature, the role of saliva and the buffering system, and the effect of acidic drinks and food on the ceramic materials. Furthermore, in-vitro studies are recommended to assess the fracture toughness, the hardness, tensile strength, the effect of artificial aging on the mechanical properties of LD ceramics and the bond strength of the GC LiSi Press LD ceramics. In addition, clinical trial studies are recommended to investigate the ability of this material to perform successfully in the oral cavity.

5. Conclusions

Considering the limitations of the present study, the following conclusions were obtained:

-

–

The IPS e.max CAD group presented a significantly higher flexural strength mean value than the IPS e.max Press and GC LiSi Press groups.

-

–

There was no statistically significant difference in the Young’s modulus between the three tested groups.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

Author would like to acknowledge the Deanship of Scientific Research, Imam Abdulrhamn Bin Faisal University for providing a research grant used for this study (Grant No. 2015062). Authors would like to thank Mr. Intisar Siddiqui for helping in the statistical analysis and Mr. Fahad AlOtaibi in the mechanical testing.

Footnotes

Peer review under responsibility of King Saud University.

References

- Alves M.F.R.P., Simba B.G., Campos L.Q.B., Ferreira I., Santos C. Influence of heat-treatment protocols on mechanical behavior of lithium silicate dental ceramics. Int. J. Appl. Ceram. Technol. 2019;16(5):1920–1931. doi: 10.1111/ijac.13257. [DOI] [Google Scholar]

- Bischoff C., Eckert H., Apel E., Rheinberger V.M., Höland W. Phase evolution in lithium disilicate glass–ceramics based on non-stoichiometric compositions of a multi-component system: structural studies by 29Si single and double resonance solid state NMR. PCCP. 2011;13(10):4540. doi: 10.1039/c0cp01440k. [DOI] [PubMed] [Google Scholar]

- Borom M.P., Turkalo A.M., Doremus R.H. Strength and microstructure in lithium disilicate glass-ceramics. J. Am. Ceram. Soc. 1975;58(9–10):385–391. doi: 10.1111/j.1151-2916.1975.tb19004.x. [DOI] [Google Scholar]

- Della Bona A., Anusavice K.J., DeHoff P.H. Weibull analysis and flexural strength of hot-pressed core and veneered ceramic structures. Dent. Mater. 2003;19(7):662–669. doi: 10.1016/S0109-5641(03)00010-1. [DOI] [PubMed] [Google Scholar]

- Denry I., Holloway J. Ceramics for dental applications: a review. Materials. 2010;3(1):351–368. doi: 10.3390/ma3010351. [DOI] [Google Scholar]

- Dupree R., Holland D., Mortuza M. A MAS-NMR investigation of lithium silicate glasses and glass ceramics. J. Non-Cryst. Solids. 1990;116(2–3):148–160. doi: 10.1016/0022-3093(90)90687-H. [DOI] [Google Scholar]

- Elsaka S.E., Elnaghy A.M. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent. Mater. 2016;32(7):908–914. doi: 10.1016/j.dental.2016.03.013. [DOI] [PubMed] [Google Scholar]

- Fabian Fonzar R., Carrabba M., Sedda M., Ferrari M., Goracci C., Vichi A. Flexural resistance of heat-pressed and CAD-CAM lithium disilicate with different translucencies. Dent. Mater. 2017;33(1):63–70. doi: 10.1016/j.dental.2016.10.005. [DOI] [PubMed] [Google Scholar]

- Fraga S., Amaral M., Bottino M.A., Valandro L.F., Kleverlaan C.J., May L.G. Impact of machining on the flexural fatigue strength of glass and polycrystalline CAD/CAM ceramics. Dent. Mater. 2017;33(11):1286–1297. doi: 10.1016/j.dental.2017.07.019. [DOI] [PubMed] [Google Scholar]

- Furtado de Mendonca A., Shahmoradi M., de Gouvêa C.V.D., De Souza G.M., Ellakwa A. Microstructural and mechanical characterization of CAD/CAM materials for monolithic dental restorations. J. Prosthodontics. 2019;28(2):e587–e594. doi: 10.1111/jopr.12964. [DOI] [PubMed] [Google Scholar]

- Höland W., Apel E., van ‘t Hoen C., Rheinberger V. Studies of crystal phase formations in high-strength lithium disilicate glass–ceramics. J. Non-Cryst. Solids. 2006;352(38–39):4041–4050. doi: 10.1016/j.jnoncrysol.2006.06.039. [DOI] [Google Scholar]

- Holand W., Schweiger M., Frank M., Rheinberger V. A comparison of the microstructure and properties of the IPS Empress®2 and the IPS Empress® glass-ceramics. J. Biomed. Mater. Res. 2000;53(4):297–303. doi: 10.1002/1097-4636(2000)53:4<297::AID-JBM3>3.0.CO;2-G. [DOI] [PubMed] [Google Scholar]

- Höland Wolfram, Rheinberger V., Apel E., van’t Hoen C. Principles and phenomena of bioengineering with glass-ceramics for dental restoration. J. Eur. Ceram. Soc. 2007;27(2–3):1521–1526. doi: 10.1016/j.jeurceramsoc.2006.04.101. [DOI] [Google Scholar]

- Huang S., Huang Z., Gao W., Cao P. Trace phase formation, crystallization kinetics and crystallographic evolution of a lithium disilicate glass probed by synchrotron XRD technique. Sci. Rep. 2015;5(1):9159. doi: 10.1038/srep09159. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huang S., Li Y., Wei S., Huang Z., Gao W., Cao P. A novel high-strength lithium disilicate glass-ceramic featuring a highly intertwined microstructure. J. Eur. Ceram. Soc. 2017;37(3):1083–1094. doi: 10.1016/j.jeurceramsoc.2016.10.020. [DOI] [Google Scholar]

- ISO6872 . International Standardization Organization, ISO; 2015. Dentistry-ceramic materials; p. 6872. [Google Scholar]

- Lawson N.C., Bansal R., Burgess J.O. Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent. Mater. 2016;32(11):e275–e283. doi: 10.1016/j.dental.2016.08.222. [DOI] [PubMed] [Google Scholar]

- Lien W., Roberts H.W., Platt J.A., Vandewalle K.S., Hill T.J., Chu T.-M.G. Microstructural evolution and physical behavior of a lithium disilicate glass–ceramic. Dent. Mater. 2015;31(8):928–940. doi: 10.1016/j.dental.2015.05.003. [DOI] [PubMed] [Google Scholar]

- Lin W.-S., Ercoli C., Feng C., Morton D. The effect of core material, veneering porcelain, and fabrication technique on the biaxial flexural strength and Weibull analysis of selected dental ceramics. J. Prosthodontics. 2012;21(5):353–362. doi: 10.1111/j.1532-849X.2012.00845.x. [DOI] [PubMed] [Google Scholar]

- Lupu M., Giordano R. Flexural strength of CAD/CAM ceramic framework materials. J. Dent. Res. 2007;88:224. [Google Scholar]

- Ohashi K., Kameyama Y., Wada Y., Midono T., Miyake K., Kunzelmann K.-H., Nihei T. Evaluation and comparison of the characteristics of three pressable lithium disilicate glass ceramic materials. Int. J. Develop. Res. 2017;7:16711–16716. [Google Scholar]

- Plengsombut K., Brewer J.D., Monaco E.A., Davis E.L. Effect of two connector designs on the fracture resistance of all-ceramic core materials for fixed dental prostheses. J. Prosthetic Dentistry. 2009;101(3):166–173. doi: 10.1016/S0022-3913(09)60022-6. [DOI] [PubMed] [Google Scholar]

- Robert Kelly J. Dental ceramics: current thinking and trends. Dent. Clin. North Am. 2004;48(2):513–530. doi: 10.1016/j.cden.2004.01.003. [DOI] [PubMed] [Google Scholar]

- Robin C. Weibull parameters of composite resin bond strengths to porcelain and noble alloy using the Rocatec system. Dent. Mater. 2002;18(5):389–395. doi: 10.1016/S0109-5641(01)00062-8. [DOI] [PubMed] [Google Scholar]

- Teixeira E.C., Piascik J.R., Stoner B.R., Thompson J.Y. Dynamic fatigue and strength characterization of three ceramic materials. J. Mater. Sci. - Mater. Med. 2007;18(6):1219–1224. doi: 10.1007/s10856-007-0131-4. [DOI] [PubMed] [Google Scholar]

- Vichi A., Louca C., Corciolani G., Ferrari M. Color related to ceramic and zirconia restorations: a review. Dent. Mater. 2011;27(1):97–108. doi: 10.1016/j.dental.2010.10.018. [DOI] [PubMed] [Google Scholar]

- von Clausbruch S.C., Schweiger M., Höland W., Rheinberger V. The effect of P2O5 on the crystallization and microstructure of glass-ceramics in the SiO2–Li2O–K2O–ZnO–P2O5 system. J. Non-Cryst. Solids. 2000;263–264:388–394. doi: 10.1016/S0022-3093(99)00647-X. [DOI] [Google Scholar]

- Wen G., Zheng X., Song L. Effects of P2O5 and sintering temperature on microstructure and mechanical properties of lithium disilicate glass-ceramics. Acta Mater. 2007;55(10):3583–3591. doi: 10.1016/j.actamat.2007.02.009. [DOI] [Google Scholar]

- Zhang P., Li X., Yang J., Xu S. Effect of heat treatment on the microstructure and properties of lithium disilicate glass-ceramics. J. Non-Cryst. Solids. 2014;402:101–105. doi: 10.1016/j.jnoncrysol.2014.05.023. [DOI] [Google Scholar]

- Zheng X., Wen G., Song L., Huang X.X. Effects of P2O5 and heat treatment on crystallization and microstructure in lithium disilicate glass ceramics. Acta Mater. 2008;56(3):549–558. doi: 10.1016/j.actamat.2007.10.024. [DOI] [Google Scholar]