Abstract

The present study investigates potential nanomaterial releases and occupational health risks across the lifecycle of nano-enabled building materials (NEBMs), namely, insulations and coatings. We utilized real-world degradation scenarios of a) sanding (mechanical), b) incineration (thermal), and c) accelerated UV-aging (environmental) followed by incineration. Extensive physicochemical characterization of the released lifecycle particulate matter (LCPM) was performed. The LCPM2.5 aerosol size fraction was used to assess the acute biological, cytotoxic and inflammatory effects on Calu-3 human lung epithelial cells. RNA-Seq analysis of exposed cells was performed to assess potential for systemic disease. Findings indicated that release dynamics and characteristics of LCPM depended on both the NEBM composition and the degradation scenario(s). Incineration emitted a much higher nanoparticle number concentration than sanding (nearly 4 orders of magnitude), which did not change with prior UV-aging. Released nanofillers during sanding were largely part of the matrix fragments, whereas those during incineration were likely physicochemically transformed. The LCPM from incineration showed higher bioactivity and inflammogenicity compared to sanding or sequential UV-aging and incineration, and more so when metallic nanofillers were present (such as Fe2O3). Overall, the study highlights the need for considering real-world exposure and toxicological data across the NEBM lifecycle to perform adequate risk assessments and to ensure workplace health and safety.

Keywords: nanofiller, engineered nanomaterials, coatings, insulations, sanding, incineration, UV-aging/weathering, exposure and risk assessment

Graphical Abstract

1. INTRODUCTION

Nanotechnology applications are rapidly increasing across the industrial and consumer sectors[1–6] with a significant fraction invested in the building and construction industry to enhance material properties, conserve energy expenditure and incorporate greener and environmentally sustainable structural materials.[7,8] Applications of nano-enabled building materials (NEBMs) include but are not limited to paints and coatings,[8–10] insulation materials,[11,12] flame retardants,[13] thermoplastic components,[14] and multifunctional concrete and glass structures,[15–17] and incorporate a wide variety of engineered nanomaterials (ENMs).[18] It has been forecasted that the global value of nano-enabled products (NEPs), nano-intermediates, and nanomaterials will reach US$ 125 billion by 2024.[7]

Although the economic value and the societal benefit of nanotechnology in the construction sector are immense, very little is known about potential exposures to ENMs that may occur over the useful lifecycle of NEBMs. Occupational workers engaged in various construction/renovation/demolition-related activities may be exposed to aerosolized particulate matter (dust) released from the destructive manipulation of the NEBMs, a significant fraction of which may be inhalable and may contain the ENMs originally embedded in the NEBM matrices.[8] These released LCPM (lifecycle-associated particulate matter) particles can be generated from various lysis scenarios that NEBMs might go through during their use or end-of-life disposal phase, such as mechanical degradation (sanding, drilling, cutting, grinding, etc.), thermal degradation (incineration, combustion during accidental fires, etc.) and environmental degradation (exposure to sunlight, rain, ambient temperature fluctuations, etc.).[19,20,29,30,21–28] The released LCPM may be a combination of pure matrix fragments, ENMs embedded or protruding from matrix fragments, and freely released ENMs that may have been significantly physicochemically transformed during the lysis scenario(s). In addition, LCPM particles may be accompanied by the release of several gaseous species and semi-volatile organic co-pollutants adsorbed to PM, depending on the specific lifecycle scenario, such as during thermal decomposition (TD).[31–33] A significant fraction of the LCPM may be inhalable fine particles (PM2.5) containing a mixture of carbonaceous and metallic species, with potential for adverse environmental health implications.[34]

Major knowledge gaps exist with respect to understanding exposures across the lifecycle of NEBMs, release mechanisms, and the properties of released LCPM. Both public health risk assessors and the industry are struggling with the fact that most of the ENM hazard data focus on pristine (raw) ENMs rather than impacts associated with worker/consumer use of NEPs, their disposal, and potential ENM release and transformations across the lifecycle.[35] This knowledge gap is highlighted in the latest National Institute for Occupational Safety and Health (NIOSH) Nanotechnology Research Plan for FY2018–25, where one of the strategic goals is to characterize emissions and particles generated from NEPs and evaluate their acute and chronic toxicity during workplace scenarios such as cutting, grinding, sanding, and spraying.[36] Importantly, there is a lack of exposure data assessing the LCPM release profiles across the lifecycle of NEBMs and critically, to answer the question of nano-related occupational health and safety risks to the workers involved in handling, usage, technical manipulation, and disposal of the NEBMs.

Recently, to address the lack of standardized methodologies and exposure generation platforms to investigate the end-of-life scenario via TD of NEPs, we developed a versatile Integrated Exposure Generation System (INEXS)[37] that enables controlled parametric studies under different TD operational conditions such as the final temperature, heating rate, oxygen concentration and aerosol residence time. The INEXS platform was recently used to investigate the TD of several industrially-relevant thermoplastic nanocomposites and nanocoatings, widely used in the built environment.[31,38–41] Interestingly, it was observed that the matrix-embedded inorganic nanofillers such as iron oxide (Fe2O3) and titanium dioxide (TiO2) were released in trace amounts in the aerosol PM but the carbonaceous nanofillers such as CNTs (carbon nanotubes) were completely combusted at high TD temperatures. The released LCPM physicochemical properties, such as the mean aerosol size and the overall chemical composition, were strongly influenced by the NEP matrix and modulated by the nanofiller chemistry and weight loading in the matrix. The dominant fraction of the TD LCPM particles consisted of organic carbonaceous compounds (>99 wt%). The bulk of the inorganic nanofiller mass (>99%) was retained in the residual ash as agglomerated nanoparticles. We observed synergistic chemical interactions between the released inorganic nanofillers (such as Fe2O3) and the semi-volatile polycyclic aromatic hydrocarbon (PAH) co-pollutants (byproducts of combustion) to form higher molecular weight and more toxic and carcinogenic PAHs, illustrating nanofiller-specific effects on released LCPM chemistries and hence potential environmental health implications. The bioactivity and cytotoxicity of the released LCPM were found to be significantly associated with both the host polymer matrix and the nanofiller chemical composition.

In this study, the main objective was to investigate the potential occupational health and safety implications of an industrially relevant panel of NEBMs consisting of in-house synthesized nano-enabled acrylic-based coatings with inorganic or organic nanofillers, and commercially procured nano-enabled insulation materials. Three distinct categories of lifecycle lysis scenarios were used: a) sanding (a form of mechanical degradation representing the NEBM use phase during the lifecycle), using an existing standardized sanding platform,[42] b) incineration (or thermal degradation) under standard industrial waste incinerator conditions (representing the NEBM end-of-life/disposal phase), utilizing our recently developed INEXS platform,[37] and c) accelerated UV-aging (simulating outdoor environmental weathering over several years) in an ISO (International Organization for Standardization)-standardized UV-exposure chamber,[26] followed by incineration in the INEXS platform. The roles of the NEBM matrix/embedded nanofillers and the specific lifecycle degradation scenario(s) in determining the released LCPM dynamics and physicochemical/morphological (PCM) properties and potential acute toxicological implications were assessed. The novelty of our study lies in the utilization of NEBMs of direct industrial relevance and application for the various realistic lifecycle degradation and occupational exposure scenarios in which workers may be exposed to unintentionally released LCPM. More importantly, the synergistic effects of combined, sequential lysis scenarios resembling real-world disintegration of NEBMs such as environmental (UV) aging over a lifetime followed by thermal degradation at the end-of-life on nanofiller release dynamics and subsequent occupational health risks were assessed.

2. MATERIALS AND METHODS

2.1. Panel of NEBMs

Table 1 summarizes the list of industrially relevant NEBMs that were utilized for our lifecycle investigations, along with their known chemical compositions. The panel consists of two families of NEBMs, namely, nano-enabled coatings (NECs) that were synthesized in-house and two commercially available insulation blankets that were provided in-kind through a local construction workers’ union (code-named for anonymity: INS1 and INS2). The NECs consisted of an acrylic copolymer matrix containing an alumina-passivated non-nano white TiO2 pigment in a defined proportion and the nanofiller at a defined weight loading, which was then applied on a pure quartz substrate at ~100 μm thickness. Two different kinds of nanofillers were utilized, each at 1.5 wt% loading in the coating matrix, namely, Fe2O3 (iron oxide) and DPP-Red (organic pigment of the chemical substance diketopyrrolopyrrole). A coating with an identical matrix but without any nanofiller was also formulated to act as the control coating for all NECs. The corresponding assigned codes for the coatings were ACR, Fe-ACR, and DPP-ACR. Technical details on the synthesis of the NECs have been provided in the Supporting Information (SI) file. The corresponding codes for the generated LCPM2.5 (aerodynamic size fraction less than 2.5 µm) from the insulations and coatings during the different lifecycle scenarios were assigned by prefixing the appropriate symbol before the NEBM code name (last column in Table 1), i.e., “M” for mechanical degradation (sanding), “I” for incineration, and “UV” for aging by UV light exposure.

Table 1.

List of NEBMs utilized in the study – family (source), material code, material description, composition, investigated lifecycle scenarios and released LCPM2.5 code

| Family of building material | Material Code | Material Description | Composition | Lifecycle scenarios investigated | Released LCPM Code |

|---|---|---|---|---|---|

| Coatings (source: Synthesized at BASF labs, Germany) | ACR | Acrylic polymerbased matrix (applied on pure quartz substrate at ~100 µm thickness) | Matrix = Acrylic (~52–53 wt%) + alumina-passivated non-nano TiO2 pigment (~42–43 wt%) | Incineration | I_ACR |

| UV-Aging followed by Incineration | I_UV_ACR | ||||

| Fe(s)- | Acrylic matrix | Matrix + 1.5 wt% | Incineration | I_Fe(s)-ACR | |

| ACR | with iron oxide nanofiller | Fe2O3 nanofiller of mean size ~37 nm | UV-Aging followed by Incineration | I_UV_Fe(s)ACR | |

| Fe(L)ACR | Acrylic matrix with iron oxide nanofiller | Matrix + 1.5 wt% Fe2 O3 nanofiller of mean size ~150 nm | Incineration | I_Fe(L)-ACR | |

| DPP-ACR | Acrylic matrix with *DPP-Red organic nanofiller | Matrix + 1.5 wt% DPP-Red nanofiller of mean size ~43 nm | Incineration | I_DPP-ACR | |

| UV-Aging followed by Incineration | I_UV_DPP-ACR | ||||

| Insulations (source: local construction workers union in Boston, MA) | INS1 | Cryogenic insulation blanket | **Trimethylated Silica (40 – 50%), Fibrous Glass (10 – 20%), Polyethylene Terephthalate (10 – 20%), Magnesium Hydroxide (<5%), Aluminum (<5%) | Sanding | M_INS1 |

| Incineration | I_INS1 | ||||

| INS2 | Hightemperature insulation blanket | **Trimethylated Silica (40–50%), Fibrous glass (textile grade) (40–50%), Titanium Dioxide (1–5%), Aluminum Trihydrate (1–5%) | Sanding | M_INS2 | |

| Incineration | I_INS2*** |

DPP Red (aka Pigment Red 254): Organic pigment with an IUPAC name of 3,6-bis(4-chlorophenyl)-2,5-dihydropyrrolo[3,4-c]pyrrole-1,4-dione, molecular formula C18H10Cl2N2O2 and CAS No. 84632–65-5

Obtained from the material safety data sheet (MSDS) provided by the manufacturer

Negligible PM2.5 collected due to lack of thermal degradation of the material, even at temperatures higher than 850 °C

2.2. PCM characterization of NEBMs

2.2.1. Nanofillers in NECs:

Detailed PCM characterization of the Fe2O3 and DPP-Red nanofillers used in the synthesis of NECs was conducted using a variety of analytical techniques such as scanning and transmission electron microscopy with energy-dispersive X-ray spectroscopy (S/TEM-EDX) to assess nanofiller morphology, size, and surface elemental composition; Brunauer-Emmett-Teller (BET) method to measure nanofiller specific surface area (SSA); inductively coupled plasma mass spectrometry (ICP-MS) to measure elemental concentrations in the nanofiller; X-ray powder diffraction (XRD) to assess crystallinity and purity of the nanofiller; X-ray fluorescence (XRF) for bulk elemental analysis of the nanofiller; and X-ray photoelectron spectroscopy (XPS) to determine surface elemental composition. Further characterization details are described in the SI.

2.2.2. PCM characterization of pristine insulation materials:

In order to address the critical question of whether the commercially procured insulations are indeed nano-enabled, extensive PCM characterization was performed. Small rectangular sections of the materials across the entire thickness of the insulation blankets were cut out to prepare samples for analysis. The morphology and surface elemental composition were assessed through SEM/TEM/EDX to look for the presence of nanoparticles and their surface chemical composition, and the bulk elemental composition of the insulations was quantified with ICP-MS.

2.3. Lifecycle degradation scenarios investigated on NEBMs

2.3.1. Sanding:

The two insulations were mechanically degraded in a sanding setup described in detail in Neubauer et al.[42] Figure S1 shows the schematic of the sanding chamber setup. Briefly, sanding on the insulation blankets was conducted inside a 0.15 m3 aerosol chamber equipped with a drilling machine (Bosch, GBS 21–2 RCT Professional) and flushed by particle-free air from a HEPA (High Efficiency Particulate Air) filter before the experiment. The drilling head was equipped with a sanding support (disc of diameter 115 mm, sanding paper with grit size 80, Starcke GmbH & Co.KG). The insulation sheets to be investigated were mounted onto a fixed holder which did not rotate during the experiments. A contact force of 17 N was applied by using a spring with a diameter of 4 mm. The rotational frequency of the disc was maintained at 1330 rpm during each sanding operation that lasted 60 s. Triplicate sanding experiments were performed for each insulation. The real-time monitoring of the concentration and size of the released aerosol was performed using the TSI SMPS 3080 (Scanning Mobility Particle Sizer), allowing detection and quantification of airborne nanoparticles between 10 nm and 300 nm. Furthermore, the released aerosol was monitored using the TSI OPS 3330 (Optical Particle Sizer), allowing for size-resolved quantification of larger particles between 0.3 and 10 μm. The released particles were sampled onto gold filters (APC, 25 mm diameter, 0.2 μm pore size) for subsequent SEM/EDX analysis. The chamber was kept closed during the whole experiment. After sanding, the collected dusts at the bottom of the chamber were retrieved and stored in plastic containers. It is worth noting that the sandpaper abrasive was silicon carbide, which is an extremely hard material (compared to the soft insulation blankets) and contains no metals. Therefore, it is not expected to degrade and release particles during sanding and hence interfere in the elemental analysis of the sanded dusts.

The size fractionation of the collected sanded dusts was done by re-aerosolization of the dusts using the TSI Fluidized Bed Aerosol Generator 3400A (Figure S2) followed by collection of the PM2.5 size fraction using the 30 L/min Harvard Compact Cascade Impactor (CCI), as described previously.[43] The bead purge flow in the fluidized bed was adjusted to 2 L/min and the bed flow to 15 L/min. The sampling was performed for at least 2–3 h in order to collect at least a few mg of PM2.5 for PCM and toxicological characterization. The PM2.5 size fraction was collected on PTFE (Polytetrafluoroethylene or Teflon) membrane disc filters (47 mm diameter, 2 μm pore size, Pall Corporation, NY). The PM>2.5 size fraction was collected on rectangular polyurethane foam (PUF) substrates. Gravimetric analysis of the collected size fractions (PM2.5 and PM>2.5) was performed to obtain the mass-size distributions of the aerosolized sanded PM from the insulations. During size-fractionated sampling, the aerosol number concentration and particle size distribution were also measured using the TSI APS 3321 (Aerodynamic Particle Sizer).

2.3.2. UV-aging:

Three coatings (as applied on quartz substrates), namely, ACR, Fe(s)-ACR, and DPP-ACR were weathered under ISO4892 standardized aging protocol with 60 W/cm2 UV intensity (integrated across the wavelength range of 300 to 400 nm).[44] The specimen aging was performed in a stand-alone equipment (Suntest XLS+), where the specimens were covered by a UV-transparent borosilicate glass to prevent any loss of fragments for a period of 3 months, which roughly corresponds to two years of outdoor weathering.[26] The weathering was performed on triplicate coating samples for each coating type.

2.3.3. Incineration:

The coatings (pristine and UV-aged) and the insulations were thermally decomposed using the INEXS platform[37] (Figure S3) at the standard incineration conditions, i.e., 850 °C, 20.9 vol% O2, and a heating rate of 20 °C/min starting from room temperature. The maximum temperature was reached in 40 min and was held constant for 10 min to ensure maximum degradation, resulting in a total 50 min of incineration time. The mass of each coating incinerated was ~100 mg whereas ~500 mg each of the insulations was used for incineration. A higher amount is used for the insulations due to a higher amount of incombustible metal content of the insulations to collect enough released particles for PCM and toxicological analysis. The released aerosol during TD was monitored in real-time using the TSI SMPS 3080 for the concentration and size of nanoparticles (~5–300 nm mobility size) and using the TSI APS 3321 for the larger particles (0.5–20 μm aerodynamic size). The released aerosol was also size-fractionated and collected in the Harvard CCI[43] throughout the incineration time (50 min) to collect the PM2.5 aerodynamic size fraction on Teflon membrane disc filters for further PCM and toxicological characterization. Gravimetric analysis of the collected size fractions (PM2.5 and PM>2.5) was performed to obtain the mass-size distributions of the incineration PM from the coatings and insulations. The amount of residual ash remaining after incineration was weighed after each experiment to calculate the residual ash yields (mass %) from the coatings and insulations.

2.4. PCM characterization of released LCPM

2.4.1. Sanding LCPM:

The bulk size sanding dusts from insulations collected on the gold filters were analyzed for shape and surface elemental composition using SEM/EDX and TEM to detect the presence of released nanoscale fragments and their composition. Furthermore, the collected insulation dusts were analyzed for the quantitative mass concentration of 55 elements (metals/non-metals) using ICP-MS to determine their bulk elemental composition. Further details on ICP-MS are described in the SI text.

2.4.2. Incineration LCPM:

The collected PM2.5 size fraction during incineration of coatings and insulations was analyzed for the concentration of 55 elements (metals/non-metals) using ICP-MS to determine the quantitative release of metals in the LCPM. To assess the release of the organic nanofiller DPP-Red, XPS analysis was performed on the incineration PM2.5 from the DPP-Red containing coatings to look for chlorine (Cl), the unique characteristic element in the DPP-Red molecule (C18H10Cl2N2O2). Further details are described in the SI text.

In addition, to assess the chemical composition of the evolved gaseous species during the thermal decomposition of the insulation materials, thermogravimetric analysis (TGA) (NETZSCH TG 209 F1 Libra) coupled with Fourier transform infrared spectroscopy (FTIR) and gas chromatography-mass spectrometry (GC-MS) was employed. Further details on this analysis are described in the SI text.

2.5. LCPM extraction and colloidal characterization

The sanding and incineration LCPM2.5 collected on Teflon filters in the CCI was extracted into a concentrated aqueous stock suspension using the previously developed SEDD (sampling, extraction, dispersion, and dosimetry) methodology by the authors.[45] A dispersion of the LCPM in water was then achieved by delivering the critical sonication energy to the suspension to reduce the agglomerate size, per previously established dispersion protocols.[46,47] Dispersed stock solutions in deionized endotoxin-free water were diluted to 100 µg/mL in the EMEM (Eagle’s Minimum Essential Medium) + 10% FBS (fetal bovine serum) cellular media and vortexed for 30 s. LCPM suspensions in pure water and cellular media were then characterized for various colloidal parameters using dynamic light scattering (DLS, Malvern Zetasizer Nano ZS), which provides the intensity-averaged hydrodynamic diameter, zeta potential, polydispersity index, and specific conductance of the particles in suspension.

2.6. Cell culture and exposure

As inhalation exposures of the workers to the released LCPM from NEBMs are a concern in the occupational setting, the human lung epithelial cell line Calu-3 purchased from the American Type Culture Collection (ATCC HTB-55, Manassas, VA) was used and cultured in EMEM culture media (ATCC, Manassas, VA), supplemented with 10% (FBS), 100 U/mL of penicillin G and 100 μg/mL streptomycin and grown at 37°C in 5% CO2.

Cells were seeded in 96 or 24 well plates at a density of 0.5 × 106 cells/mL in 100 µL or 600 µL growth medium for a single well of a 96 or 24-well plate respectively and were treated for 24 hours. Two administered doses of the LCPM were utilized for the basic cytotoxicity assays (20 and 75 µg/mL), whereas the higher dose of 75 µg/mL was administered for the acute inflammatory biomarker assessment. The selected cellular doses were derived from experimentally obtained LCPM exposure data and simulation of lung-deposited LCPM dose using the Multiple Path Particle Dosimetry Model (MPPD, v3.04)[48–50] (calculation details described in the SI). Appropriate controls, including culture medium and the LCPM dispersion vehicle control, and the comparator material mild steel welding fume (MS-WF) particles (obtained from Dr. J.M. Antonini, NIOSH) were utilized in all cellular toxicological experiments. MS-WF particles, with a count mean diameter of 1.22 μm, were generated as described previously.[51,52] Cellular exposures of all LCPM materials and controls were performed in at least triplicates (triplicate administered doses to cells) in order to be able to perform a robust statistical analysis of the observed cellular responses.

2.7. Cell viability assay

Lactate dehydrogenase (LDH) in the supernatant of 24 h treated cells in a 96-well plate was measured using the Pierce LDH assay kit (Sigma Aldrich, St. Louis, MO, USA) according to the manufacturer’s instructions. Untreated cells were used to measure spontaneous LDH release and lysed cells, using 150 μL 10X lysis buffer 45 min prior to the end of incubation, were used to measure maximum LDH release. Apical supernatant from each well was transferred to a 1.5 ml tube and 50 μL of supernatant from each tube was then added in triplicate wells in a new 96-well plate. Fifty μL of the reaction mixture was added and mixed using a multichannel pipette. Plates were incubated at room temperature for up to 30 min protected from light, and the reaction was stopped by adding 50 μL of stop solution. Absorbance was measured at 490 nm (A490) and 680 nm (A680). To calculate LDH activity, A680 values were subtracted from A490 values to correct for instrument background. To correct for particle/medium interference/background, LDH activities from no-cell controls were subtracted from test well LDH activities. Percent cytotoxicity was calculated by subtracting spontaneous LDH release values from treatment values, dividing by total LDH activity (Maximum LDH activity – Spontaneous LDH activity), and multiplying by 100.

2.8. Metabolic activity assay

PrestoBlue metabolic activity (cell viability) assay was performed after 24 h exposure using cells cultured and exposed in a 96-well plate. PrestoBlue® cell viability reagent (ThermoFisher Scientific, Waltham, MA, USA) was used according to the manufacturer’s instructions. Cells treated with lysis buffer for 1 h at 37°C were used as positive controls for inhibition of metabolic activity. Briefly, the supernatant was removed from each test wells, the wells were washed 3 times with 300 μL of PBS (Phosphate Buffered Saline) and 100 μL of 10% PrestoBlue reagent was added to each test well. Plates were then incubated at 37 °C for 15 min, and fluorescence was measured at 560 nm (excitation)/590 nm (emission). Percent metabolic activity was reported as normalized on the response from the negative control/untreated cells (100%).

2.9. Oxidative stress/reactive oxygen species (ROS) assay

ROS analysis was performed after 6 h treatment in a 96-well plate. Production of ROS was assessed using the CellROX® green reagent (Thermo Fisher Scientific, Waltham, MA, USA) according to the manufacturer’s instructions. Cells treated with 100 μM menadione for 1 h at 37°C were used as positive controls for ROS generation. Briefly, media was removed from each test well, the wells were washed 3 times with 200 μL PBS, 100 μL of working solution (CellROX Reagent) was added in each well, and plates were incubated for 30 min at 37 °C. The supernatant was removed, and wells were then washed 3 times with 200 μL PBS. Fluorescence was measured at 480 nm (excitation)/520 nm (emission). Percent ROS generation was reported as normalized on the maximum ROS generation from the positive control as 100%.

2.10. Inflammatory response assessment

The supernatants from cells exposed to the higher dose (75 μg/mL) LCPM for 24 hours were collected and shipped on dry ice for cytokine and chemokine assessment using the Human Cytokine Array / Chemokine Array 48-Plex (HD48) assay (Eve Technologies, Calgary, AB). The samples were prepared according to Eve Technologies’ protocol. Briefly, the supernatants from each well were transferred in new 1.5 mL tubes, centrifuged at 3000 × g for 10 min to remove debris, and transferred to a new 1.5 mL tube. Then 75 μL of supernatant from each sample were aliquoted in new 0.5 mL tubes and stored at −80 °C until shipment. The remaining supernatant was aliquoted and frozen at −80 °C for additional experiments.

The 48-plex consisted of soluble CD40 ligand (sCD40L), Epidermal Growth Factor (EGF), Eotaxin, Fibroblast Growth Factor (FGF-2), FMS-like tyrosine kinase 3 ligand (Flt-3L), Fractalkine, granulocyte-colony stimulating factor (G-CSF), granulocyte monocyte-colony stimulating factor (GM-CSF), Growth-Related Oncogene (GRO)-α, Interferon (IFN)-α2, Interferon gamma (IFNγ), Interleukin-1α (IL-1α), IL-1ra, IL-1β, IL-2, IL-3, IL-4, IL-5, IL-6, IL-7, IL-9, IL-10, IL-12 (p40), IL-12 (p70), IL-13, IL-15, IL-17A, IL-17E, IL-17F, IL-18, IL-22, IL-27, IFN-γ-inducible protein 10 (IP-10), monocyte chemotactic protein 1 (MCP-1/CCL2), MCP-3, macrophage- colony stimulating factor (M-CSF), Macrophages derived chemokine (MDC/CCL22), monokine induced by gamma interferon (MIG), macrophage inflammatory protein 1α (MIP-1α), MIP-1β, Platelet derived Growth Factor (PDGF)-AA, PDGF-AB/BB, Regulated on Activation, Normal T-cell Expressed and Secreted (RANTES), Transforming growth Factor (TGF)-α, tumor necrosis factor α (TNFα), TNFβ and vascular endothelial growth factor (VEGF)-A.

2.11. RNA-Seq transcriptomic profiling

Total RNA was extracted from the higher dose (75 μg/mL) LCPM-exposed cells after 24 h using the miRNeasy kit (Qiagen) according to the manufacturer’s instructions and used for RNA-Seq transcriptional profiling to detect broad toxicological effects of LCPM exposure and possible systemic disease mechanisms at play. Three samples for each LCPM exposure group were obtained.

2.11.1. RNA-Seq library preparation and sequencing:

Polyadenylated mRNAs were selected from total RNA samples using oligo-dT-conjugated magnetic beads on an Apollo324 automated workstation (PrepX PolyA mRNA isolation kit, Takara Bio USA). Entire poly-adenylated RNA samples were immediately converted into stranded Illumina sequencing libraries using 200bp fragmentation and sequential adapter addition on an Apollo324 automated workstation following manufacturer’s specifications (PrepX RNA-Seq for Illumina Library kit, Takara Bio USA). Libraries were enriched and indexed using 12 cycles of amplification (LongAmp Taq 2× MasterMix, New England BioLabs Inc.) with PCR (polymerase chain reaction) primers which included a 6bp index sequence to allow for multiplexing (custom oligo order from Integrated DNA Technologies). Excess PCR reagents were removed using magnetic bead-based cleanup (PCR Clean DX beads, Aline Biosciences). RNA integrity was checked with a 2200 TapeStation (Agilent Technologies), and after libraries were created, they were quantified by QPCR (Kapa Biosystems). Libraries were pooled and sequenced on one lane of a HiSeq 2500 high output v3 flow cell using single end, 50 bp reads (Illumina).

2.11.2. RNA-Seq data analysis:

RNA-Seq data was analyzed using the RAVED (Reproducible Analysis and Validation of Expression Data) pipeline (https://github.com/HimesGroup/raved).[53] Briefly, quality control (QC) metrics for raw reads were obtained with FastQC[54] (v.0.11.7). Reads for each sample were aligned with STAR software (Spliced Transcript Alignment to a Reference, v. 2.5.2b) to reference Homo sapiens build 38 UCSC (University of California, Santa Cruz) file (hg38) genome obtained from the Illumina, Inc. iGenomes resource.[55] Additional QC parameters were obtained to assess whether reads were appropriately mapped: Bamtools (v.2.3.0)[56] was used to count/summarize the number of mapped reads, including junction spanning reads, and the Picard Tools (v.1.96; http://picard.sourceforge.net) RnaSeqMetrics function was used to compute the number of bases assigned to various classes of RNA, according to the hg38 refFlat file available as a UCSC Genome Table. For each sample, HTSeq (v.0.6.1) was used to quantify genes based on reads that mapped to the provided hg38 reference files.[57] The DESeq2 R package (v. 1.26.0) was used to measure the significance of differentially expressed genes between the treatment and control samples for the provided 12 treatments and create plots of the results.[58] The reported adjusted p-values are false-discovery rate corrected according to the procedure in DESeq2 that accounts for the large number of comparisons made. An adjusted p-value <0.05 was considered significant. The Gene Set Enrichment Analysis (GSEA) R package fgsea (v.1.12.0) was used to perform enrichment analysis using gene sets from Reactome and KEGG (Kyoto Encyclopedia of Genes and Genomes) pathway annotations downloaded from Molecular Signatures Database (MSigDB) (v.6.2), and pathways with gene number >15 and <500 were included for analysis.[59,60] P-values for enriched pathways were based on the distribution of enrichment scores following 10,000 permutations, and subsequently, q-values were obtained using the Benjamini-Hochberg approach. Pathways with a q-value <0.05 were considered significant. Pathways with p-values < 0.005 were collapsed using the collapsedPathways function in fgsea to reduce the number of pathways with highly overlapping sets of genes.

2.12. Statistical analysis

The sanding, incineration, and cellular exposure experiments were all performed in triplicates. The real-time aerosol characteristics (particle number concentrations and aerosol size distributions) were averaged across the triplicate experiments and the resulting aerosol data analysis was performed in the TSI Aerosol Instrument Manager software (AIM, v9.0). In the LDH release and metabolic activity assays, statistical analysis was performed on an average of 6 samples for each exposure condition. ROS assay statistical analysis was performed on an average of 4 samples for each exposure condition. Fold-changes>20% were deemed to be statistically significant. The cytokine/chemokine data were presented as the mean ± standard error of mean (SEM) of 3 samples (n=3) and statistical significance was reported with respect to the negative control (culture media). Statistical analyses for all toxicological data were performed on GraphPad© Prism using one-way ANOVA (analysis of variance) tests and corrected for multiple comparisons (with Dunnett’s test).

3. RESULTS

3.1. PCM characterization of NEC nanofillers

The detailed PCM properties of the nanofillers used in the synthesis of the NECs, i.e., iron oxide (Fe2O3) and DPP-Red, are summarized in Table S1 and described further in the SI text. Briefly, the TEM-measured average primary particle diameters of the utilized nanofillers Fe2O3 (small), Fe2O3 (large), and DPP-Red were 37 nm, 150 nm, and 43 nm, respectively. Figure S4A depicts the images of the synthesized NECs after being applied on the quartz plates, showing the characteristic color shades of the different nanofillers.

3.2. Commercial insulation materials: are they nano-enabled building materials?

The photographed images of the INS1 and INS2 insulation blankets are shown in Figure S4(B-C). Prior to investigating the various lifecycle scenarios and associated occupational health implications of the insulation materials, an important question needed to be addressed as to whether these commercial insulations (INS1, INS2) are indeed nano-enabled materials containing nanoscale particles that are intentionally incorporated into their matrices. Figure S5 shows the SEM/TEM images of INS1 and INS2 at different magnifications and the corresponding EDX surface elemental surveys of the observed nanoparticles on the material surface. Morphologies of both materials look similar with irregularly shaped flaky fragments with rounded edges lying on the top of or in the empty space between straight, smooth fibrous structures. The fragments span a size range from tens of microns down to the nanoscale size (<100 nm), providing evidence for the presence of nanoscale materials in the insulations (encircled in red in the images). The EDX elemental composition of the nanoparticles shows the presence of elements expected in accordance with the manufacturer provided MSDS (material safety data sheet) compositions (Table 1) of INS1 and INS2, as well as several other heavy metals not described in the MSDS (Figure S5; INS1: O, Si, C, Al, Mg, Zr, Cr, Fe, Co, Ca, Sn; INS2: O, Si, C, Al, Sn, Mg, Ca, Zr, Cr, Fe), indicating the presence of nanoscale metals/metal oxides in the insulation materials. It is not known whether these nanoscale particles were intentionally incorporated during the industrial manufacture of the insulations to impart certain functional properties or they were unintentionally introduced into the insulation fabric during the fibrous silica aerogel synthesis from raw materials containing trace amounts of these heavy metals. Nevertheless, it is clear that the insulations INS1 and INS2 can be classified as NEBMs containing a mixture of nanoscale heavy metals or metal oxide particles.

Furthermore, the ICP-MS analysis (Figure S6) of the bulk insulation samples confirms the presence of various metals including transition metals in significant concentrations (INS1: Si (18.8 wt%), Ca (3.87 wt%), Al (2 wt%), Mg (0.69 wt%), B (0.34 wt%), Na (0.14 wt%), Ti (0.1 wt%), Fe (0.06 wt%), S (0.04 wt%), Sr (0.03 wt%), K (0.02 wt%), Zr (0.01 wt%); INS2: Si (16 wt%), Ca (12.5 wt%), Al (5.5 wt%), Fe (1.34 wt%), B (0.91 wt%), Mg (0.54 wt%), K (0.35 wt%), Na (0.22 wt%), Ti (0.16 wt%), S (0.09 wt%), Sr (0.08 wt%), P (0.04 wt%), Ba (0.02 wt%), Zr (0.01 wt%), Mn (0.01 wt%)). The total metal content of the bulk insulation materials is found to be quite high at 26.1 wt% for INS1 and 37.8 wt% for INS2, which points to a possible intentional use of such metallic nanoparticles to enhance the mechanical and thermal properties of the insulations. The mass concentrations of the remaining measured elements for both INS1 and INS2 are summarized in SI Excel File 1.

3.3. Sanding of NEBMs: released LCPM characteristics

In this section, the real-time released aerosol characteristics during the mechanical degradation via sanding of insulation materials INS1 and INS2 under predefined operational conditions are summarized as well as the subsequent PCM characterization of the collected sanded dusts to assess whether nanomaterials embedded in the insulations are released into the air during sanding of NEBMs.

3.3.1. Real-time LCPM monitoring:

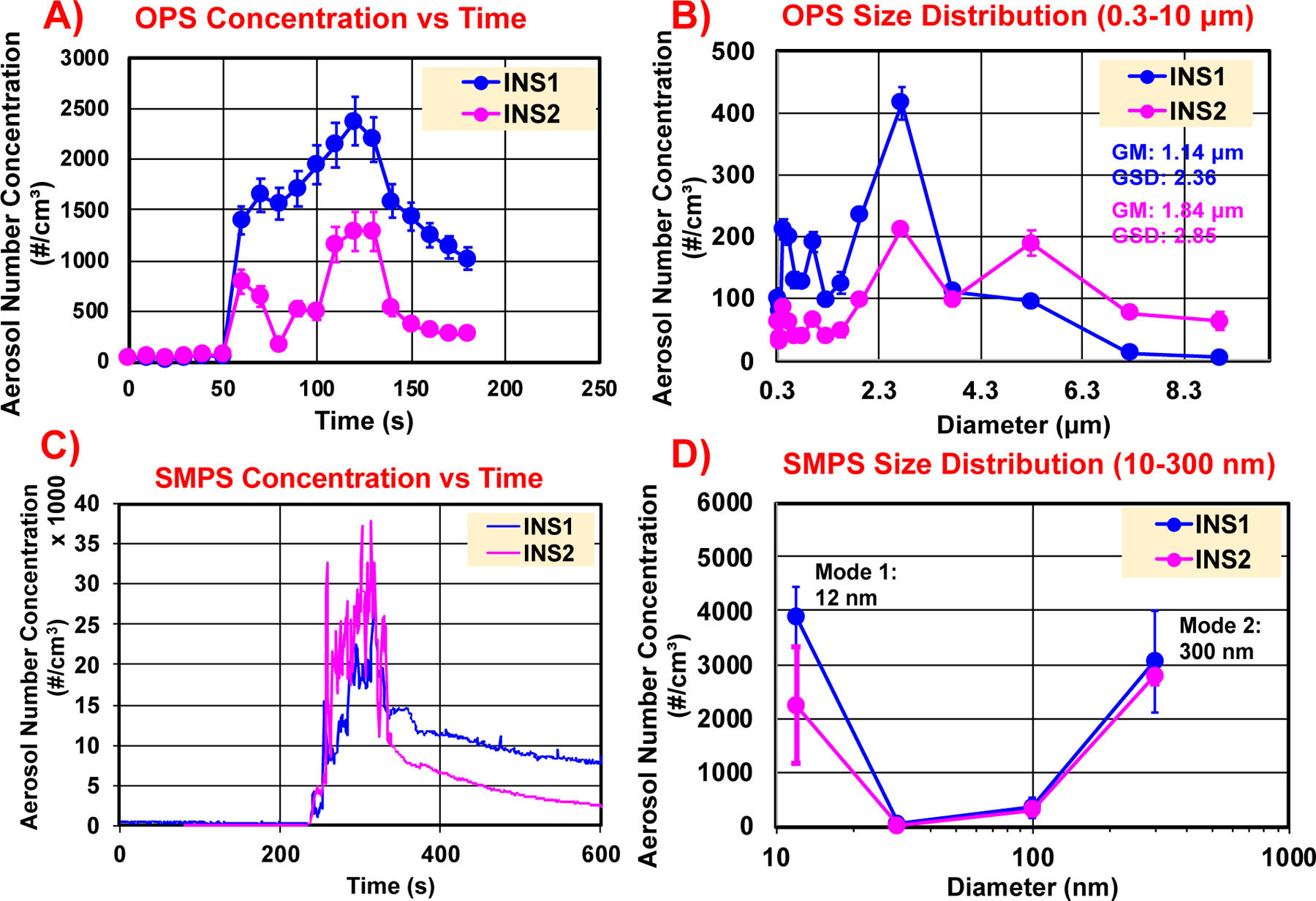

Figure 1 shows the real-time evolution of the aerosol number concentration in the sanding chamber during the sanding operations on INS1 and INS2 using the OPS (Figure 1A, aerodynamic sizes 0.3–10 μm) and SMPS (Figure 1C, mobility sizes 10–300 nm) instrumentation, as well as the real-time OPS aerodynamic size distributions (Figure 1B, sizes 0.3–10 μm) and SMPS mobility size distributions (Figure 1D, sizes 10–300 nm) of the released LCPM from INS1 and INS2 captured at the timepoints of maximum particle number concentration. It is clear from both real-time instruments that the particle number concentration increases significantly as sanding progresses with respect to the background levels (before sanding) and reaches a peak ~60s after the start of sanding, which also is the sanding duration employed, and falls off to background levels gradually after the peak when sanding stops. The peak OPS particle number concentration reaches ~2,500 particles/cm3 for INS1 versus ~1,500 particles/cm3 for INS2. On the other hand, the peak SMPS nanoparticle number concentration reaches ~37,000 particles/cm3 for INS2 versus ~30,000 particles/cm3 for INS1. Although the peak number concentrations differ slightly between the two insulations, the particle generation curve over time appears to be similar between both materials for the larger particles and the nanoparticles. The OPS number-size distributions of the insulations are slightly different (Figure 1B), with the geometric mean aerodynamic particle diameter and geometric standard deviation of 1.14 μm (σg = 2.4) for INS1 having a single large peak, whereas it is 1.84 μm (σg = 2.85) for INS2, which shows a bimodal distribution with two smaller peaks. The SMPS nanoparticle size distribution of released sanding LCPM shows two prominent modes at 12 nm and 300 nm for both insulations (Figure 1D).

Figure 1.

Real-time released aerosol investigations using TSI OPS (0.3–10 μm) and SMPS (10–300 nm) for the sanding of insulations, INS1 and INS2. A) OPS time trace of particle number concentrations; B) OPS size distributions at the maximum concentration timestamp; C) SMPS time trace of particle number concentrations; and D) SMPS size distributions at the maximum concentration timestamp

The insulation sanding dusts were also re-aerosolized using the TSI fluidized bed chamber and the resulting aerosol particle number concentration as a function of aerodynamic diameter was measured (Figure S7). The mean geometric aerodynamic diameter of the larger particles is 1.17 μm (σg = 1.88) for INS1 whereas 1.13 μm (σg = 1.65) for INS2, showing that the aerosolized sanding dust consists of both micron-sized and submicron-sized particles, consistent with real-time OPS measurements from the sanding chamber.

The gravimetric analysis of the time-integrated and size-fractionated sanded PM shows nearly 63–67% by weight of particles in the PM2.5 size fraction whereas the remaining mass fraction (33–37 wt%) belongs to particles larger than 2.5 μm aerodynamic size (data not shown), indicating that majority of the sanded LCPM of the insulations by mass lies in the inhalable size fraction.

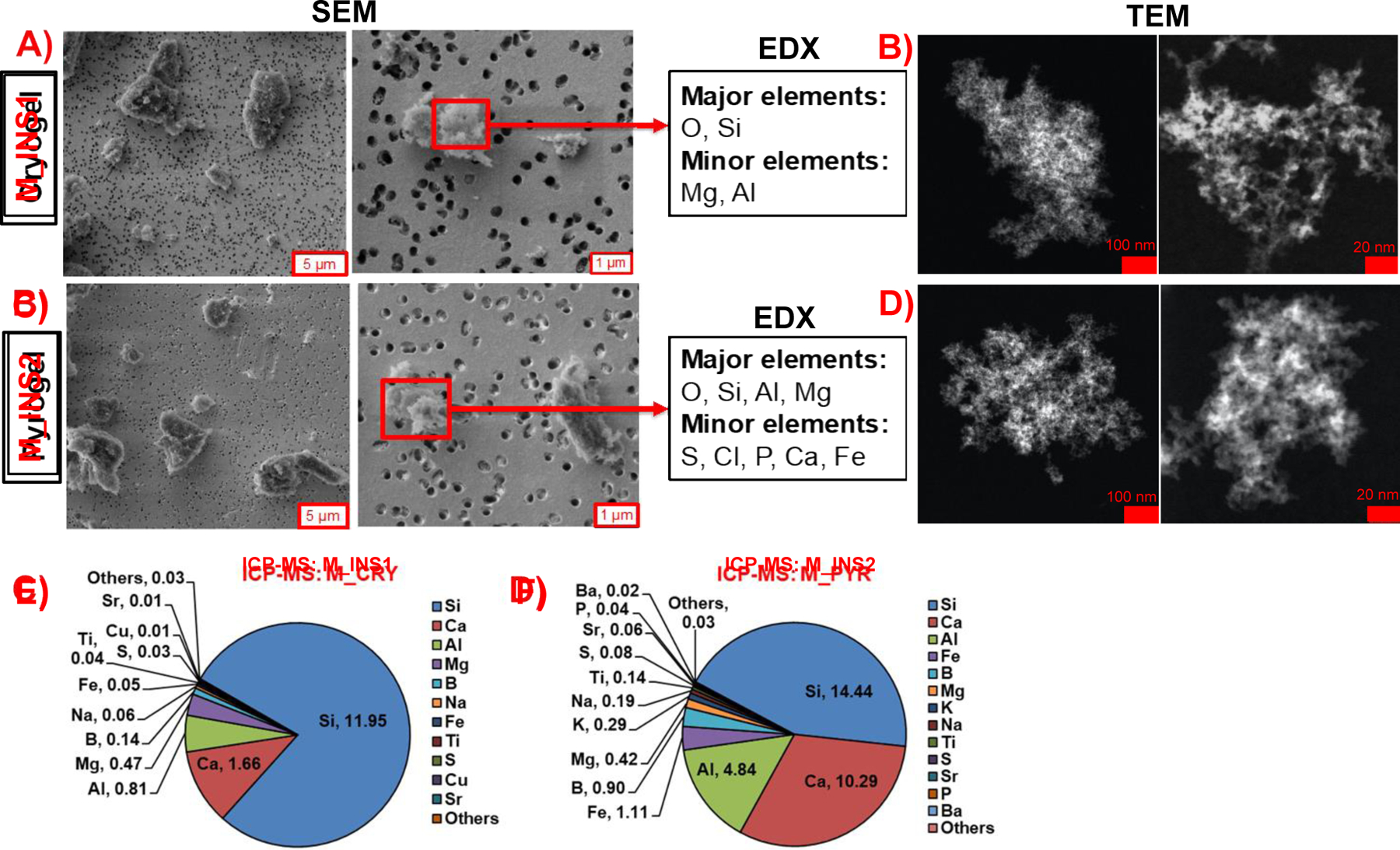

3.3.2. Morphology and elemental composition of released LCPM:

Figure 2 shows the SEM/TEM images at different magnifications along with the EDX elemental information on the total sanded dust collected from INS1 (Figure 2A-B) and INS2 (Figure 2C-D). The corresponding EDX spectra on the insulation dusts are shown in Figure S8. The micrographs show the presence of several micron-sized random-shaped fragments along with a few submicron aggregates for both materials in the SEM images, as well as nanoscale (<100 nm) structures in the TEM images. Elemental mapping of the submicron aggregates reveals the presence of the characteristic elements (including transition metals) of the pristine insulation materials (as indicated in the MSDS and PCM characterization of the insulations described in the previous section) in the released LCPM, suggesting the presence of released nano-metals in the sanded dusts. The major elemental species observed for the INS1 sanded dust are O and Si, whereas the minor species are Mg and Al. For the INS2 sanded dust, the major elements observed are O, Si, Al, and Mg, and the minor ones are S, Cl, P, Ca, and Fe.

Figure 2.

Released sanding dust physicochemical and morphological characterization for insulations INS1 and INS2. SEM/EDX and TEM on sanding dust from A, B) INS1and C, D) INS2. ICP-MS bulk elemental composition on the sanding dust of E) INS1 and F) INS2.

The bulk elemental compositions of the collected sanded dust of INS1 and INS2 were also measured using ICP-MS (Figure 2E-F). A high mass fraction of total metal content is observed for both dusts, with INS1 sanded dust containing 15.3 wt% total metals, whereas for INS2 sanded dust it is much higher at 32.9 wt%. The quantitative mass percentages of the various prominent elements measured in the sanded dust from INS1 are Si (11.95 wt%), Ca (1.66 wt%), Al (0.81 wt%), Mg (0.47 wt%), B (0.14 wt%), Na (0.06 wt%), Fe (0.05 wt%), Ti (0.04 wt%), S (0.03 wt%), Cu (0.01 wt%), and Sr (0.01 wt%), whereas those from INS2 are Si (14.44 wt%), Ca (10.29 wt%), Al (4.84 wt%), Fe (1.11 wt%), B (0.90 wt%), Mg (0.42 wt%), K (0.29 wt%), Na (0.19 wt%), Ti (0.14 wt%), S (0.08 wt%), Sr (0.06 wt%), P (0.04 wt%) and Ba (0.02 wt%). Mass concentrations of the remaining metals in both sanded dusts are tabulated in SI Excel File 1.

3.4. Incineration of NEBMs: released LCPM characteristics

In this section, we present the real-time released aerosol characteristics, PCM properties of released LCPM, time-integrated and size-fractionated collected LCPM data, and residual ash yields from the incineration of the insulation materials and the NECs (unaged and UV-aged), under the predefined thermal decomposition conditions, to identify factors affecting nano-release dynamics and LCPM PCM properties during the incineration of NEBMs. In more detail:

3.4.1. Incineration of insulation materials

3.4.1.1. Real-time LCPM monitoring:

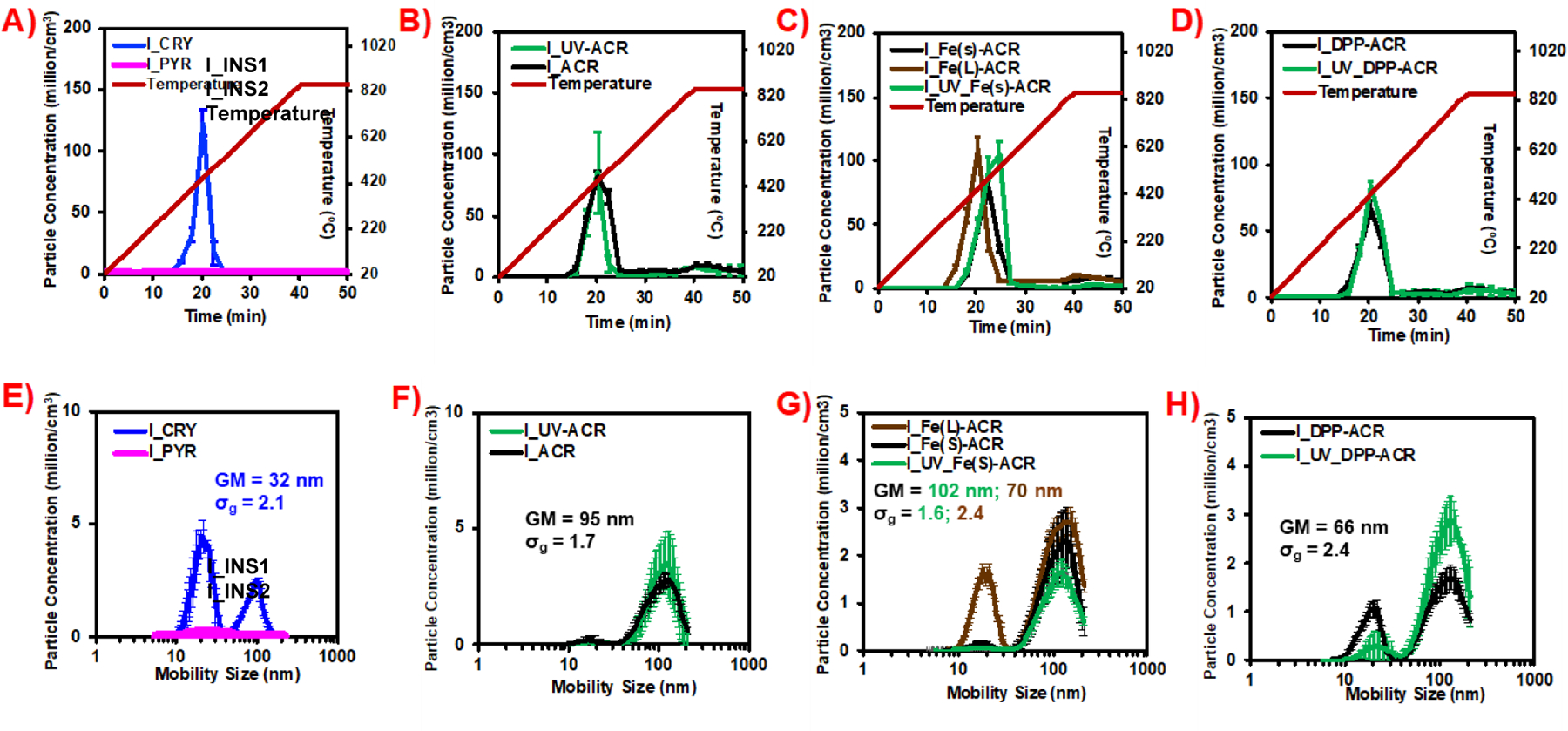

Figure 3A shows the real-time evolution of SMPS-measured nanoparticles (mobility size: 5–250 nm) number concentration with respect to time during the incineration of the insulation materials INS1 and INS2. Correspondingly, Figure 3F presents the SMPS-measured nanoparticle size distributions (snapshots at the timepoint of maximum particle number concentration) during incineration of the insulations. During the incineration, the temperature increases linearly with time starting from the room temperature at the pre-defined heating rate of 20 °C/min up to a maximum of 850 °C until ~40 min and staying constant for 10 min before the furnace begins to cool off. For the insulation materials, only the INS1 appears to undergo thermal degradation with the aerosol generation beginning around 15 min (~400 °C) and the peak emitted particle number concentration reaching ~150 million particles/cm3 around 20 min (~450 °C), followed by a rapid decrease in particle concentration. Comparatively, the insulation INS2 does not generate significantly more particles than the baseline, suggesting a lack of thermal degradation of the material even at the high final temperature of 850 °C, although mass loss of the insulation was observed and was accompanied by release of several decomposition gaseous byproducts and volatile organic compounds (described in subsequent sections). The INS1-emitted incineration PM exhibits a bimodal nanoparticle size distribution with peaks at 22 nm and 102 nm, with an overall geometric mean mobility diameter of 32 nm (σg = 2.1).

Figure 3.

Real-time released aerosol investigations using TSI SMPS 3080 during incineration of insulations and coatings (w, w/o UV-aging). (A, E) PNC over time, mobility size distribution of INS1, INS2; (B, F) PNC over time, mobility size distribution of ACR, UV_ACR; (C, G) PNC over time, mobility size distribution of Fe(s)_ACR, UV_Fe(s)_ACR, Fe(L)_ACR; (D, H) PNC over time, mobility size distribution of DPP_ACR and UV_DPP-ACR. PNC: particle number concentration; GM: geometric mean mobility diameter; σg: geometric standard deviation.

Real-time PM monitoring using the APS for the larger particles (aerodynamic size: 0.5–20 μm) was also performed for the incinerated insulations, however, the peak number concentrations observed are nearly four orders of magnitude lower than the SMPS-measured nanoparticle concentrations (~15,000–25,000 particles/cm3) with the observed geometric mean aerodynamic size between 1.2–1.5 μm (data not presented). No significant emitted particles compared to the baseline are detected in the APS during the incineration of the INS2 insulation, similar to the SMPS measurements, confirming that the INS2 insulation did not disintegrate thermally.

3.4.1.2. Elemental composition of released PM2.5:

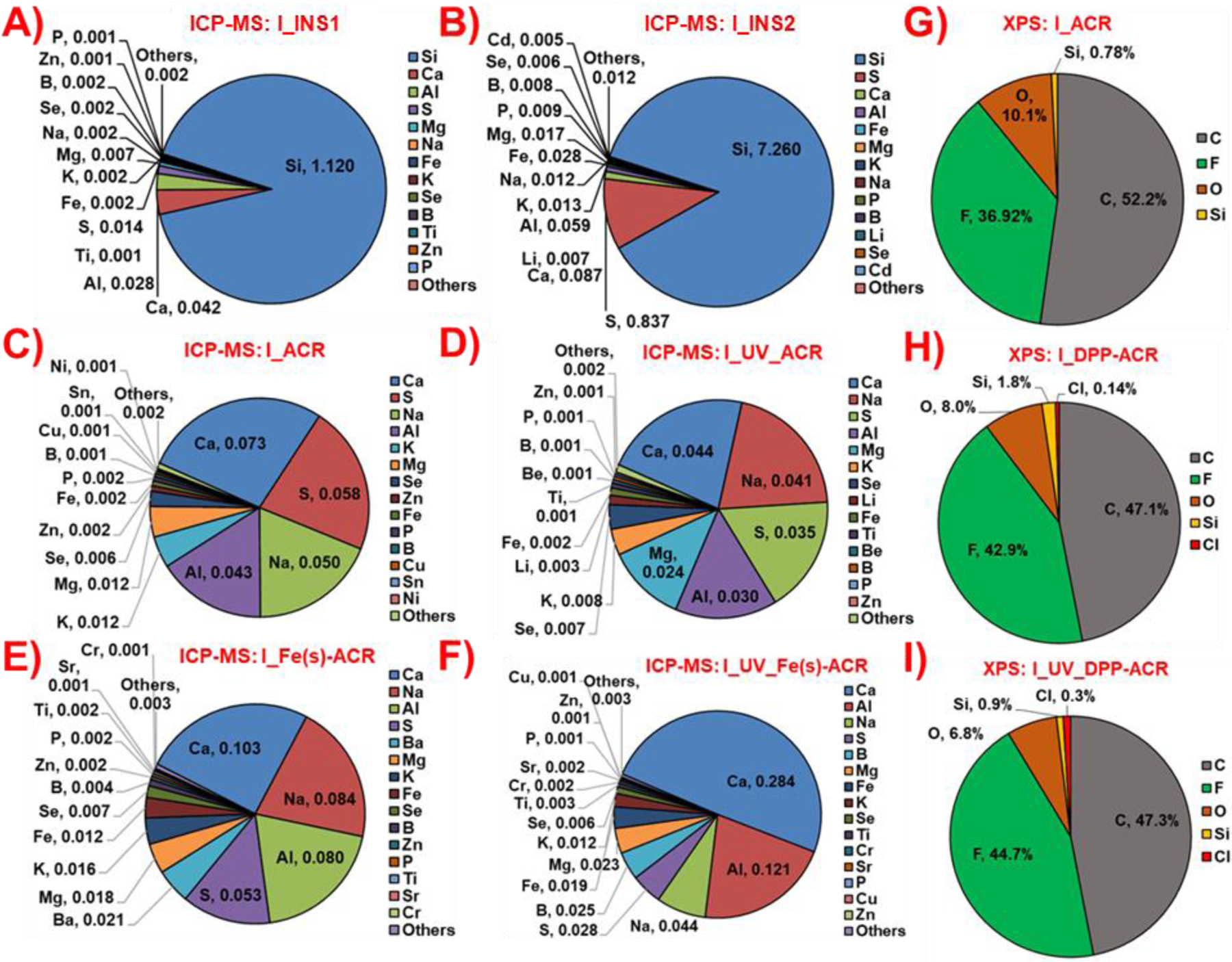

The released and collected PM2.5 from the incineration of the insulations were analyzed for their bulk elemental composition using ICP-MS to determine the potential release of the nanoscale metal/metal oxides in the pristine insulations into the airborne PM. Figure 4A-B shows the quantitative mass percentage concentrations of the ICP-MS-determined metals in the incineration PM2.5 from the insulations (INS1, INS2).

Figure 4.

Released LCPM2.5 bulk elemental composition for incineration of insulations A) INS1 and B) INS2 using ICP-MS; incineration of coatings C) ACR, D) UV_ACR, E) Fe(s)-ACR and F) UV_Fe(s)-ACR using ICP-MS; and LCPM2.5 surface elemental composition for incineration of coatings G) ACR, H) DPP-ACR and I) UV_DPP-ACR using XPS.

The total metal concentration measured in I_INS2 is 8.4 wt%, significantly higher than in I_INS1 (1.2 wt%), mostly dominated by the high concentration of Si in I_INS2 (7.3 wt%) compared to I_INS1 (1.1 wt%). Both I_INS1 and I_INS2 are found to contain several other metals in trace-level concentrations (<0.1 wt%), including but not limited to Ca, Al, Mg, Na, Fe, K, Se, Ti, Zn, and Cd (Figure 4A-B, SI Excel File 1), providing evidence of release of the inherent metallic nanoparticles in the insulations into the incineration aerosol PM.

3.4.1.3. Evolved gas chemical analysis:

Figures S9-12 summarize the chemical spectral information obtained from FTIR (absorbance vs. wavenumber) and GC-MS (intensity vs. retention time) on the evolved off-gases during the thermal decomposition of INS1 (snapshot around 523 °C) and INS2 (snapshot around 612 °C), respectively in the TGA. The spectra identify a mixture of aliphatic (including alicyclic) and aromatic compounds, with alcohol, aldehyde, and ketone functional groups in the gaseous off-stream. Common gaseous species identified for both insulations included significant traces of cyclohexene, 4-hexen-1-ol, and benzaldehyde, and a large mixed peak corresponding to unidentified halogenated compound(s). Additionally, for INS1, α-methylstyrene (a monomer for the poly(α-methylstyrene) (PAMS) synthetic polymer) is identified, thus pointing to the presence of this hydrophobic polymer in INS1.[61] In contrast, for INS2, additional volatile organics namely, formaldehyde, hexamethylcyclotrisiloxane, and cis-cyclooctene are identified. The presence of hexamethylcyclotrisiloxane as a decomposition byproduct indicates the presence of organosilicon polymers such as polydimethylsiloxane in the INS2 matrix.[62] Furthermore, the presence of the cyclic olefin (cis-cyclooctene) fragment suggests the presence of corresponding polyoctenamers as the hydrophobic additive in the INS2 matrix.[63]

3.4.2. Incineration of NECs

3.4.2.1. Real-time LCPM monitoring:

Figure 3B-D shows the real-time evolution of SMPS-measured nanoparticles (mobility size: 5–250 nm) number concentration with respect to time during the incineration of the unaged/UV-aged NECs. Correspondingly, Figure 3(F-H) presents the SMPS-measured nanoparticle size distributions (snapshots at the timepoint of maximum particle number concentration) during incineration of the NECs. Incineration of the NECs (both unaged and UV-aged) shows similar particle generation profiles with time, with nanoparticle number concentrations reaching their maximum at ~20–22 min (~450–490 °C) after the start of incineration. No significant differences are observed in the peak nanoparticle number concentrations between the unaged NECs and the corresponding UV-aged NECs, for either the ACR, Fe(s)-ACR, or DPP-ACR coatings. However, the Fe2O3 nanofiller containing coatings (Fe(s)-ACR, Fe(L)-ACR, UV_Fe(s)-ACR) show a slightly higher peak particle number concentration at ~100 million particles/cm3 compared to the ACR/UV_ACR and DPP-ACR/UV_DPP-ACR coatings, which show maximum nanoparticle emission at ~75 million particles/cm3. Similarly, the SMPS mobility size distributions of the released aerosol are similar between the unaged and UV-aged NECs and were bimodal in all cases. The observed geometric mean mobility diameters for the incineration LCPM from coatings are 95 nm (σg = 1.7), 102 nm (σg = 1.6), and 66 nm (σg = 2.4), for ACR/UV_ACR, Fe(s)-ACR/UV_ Fe(s)-ACR, and DPP-ACR/UV_DPP-ACR coatings, respectively. The incineration LCPM from the unaged coating with the larger size of Fe2O3 nanofiller (Fe(L)-ACR) shows a significantly different geometric mean diameter at 70 nm (σg = 2.4) compared to the NEC with the smaller Fe2O3 nanofiller (geometric mean = 102 nm, σg = 1.6).

The APS-measured real-time aerosol number concentrations and aerodynamic size distributions for the NECs were quite similar to the insulations, with nearly four orders of magnitude lower particle number concentration (~104 particles/cm3) than the SMPS-measured nanoparticles and mean aerodynamic particle sizes close to 1 µm (data not presented).

3.4.2.2. Elemental composition of released PM2.5:

The released and collected PM2.5 from the incineration of the unaged/UV-aged NECs were also analyzed for their bulk elemental composition using ICP-MS to determine the potential release of the nanoscale metal/metal oxides in the pristine NECs into the airborne PM. Figure 4C-F shows the quantitative mass percentage concentrations of the ICP-MS-determined metals in the incineration PM2.5 from the NECs (except for the DPP-Red containing coatings for which XPS was performed on the PM2.5).

Interestingly, the total metal concentrations measured in the incineration PM2.5 from coatings are significantly lower than those observed for the insulation materials (Figure 4C-F, SI Excel File 1). The observed weight concentrations of the total metals in incineration LCPM from unaged and UV-aged coatings are I_ACR (0.27 wt%), I_UV_ACR (0.2 wt%), I_Fe(s)-ACR (0.41 wt%), I_UV_Fe(s)-ACR (0.57 wt%), and I_Fe(L)-ACR (0.24 wt%). Prominent elements detected in the released PM2.5 include but are not limited to Ca, Al, Mg, Na, S, B, K, Fe, and Ti. One of the critical questions to be addressed is whether the metal oxide nanofiller (Fe2O3) in the acrylic coating matrix is released into the aerosol during incineration. Examining the concentration of Fe metal in the incineration LCPM from the Fe2O3-containing coatings, the mass concentration of Fe is I_Fe(s)-ACR (0.012 wt%), I_UV_Fe(s)-ACR (0.019 wt%), and I_Fe(L)-ACR (0.005 wt%), which is ~2–9 times higher than for the control acrylic matrix-only coatings, I_ACR (0.002 wt%) and I_UV_ACR (0.002 wt%), indicating probable release of the Fe2O3 nanofiller in PM2.5, although the exact physicochemical and morphological state of the released Fe is not investigated here.

In addition, to assess the possible release of the organic nanofiller (DPP-Red) from the incineration of DPP-ACR/UV_DPP-ACR, XPS analysis on the released PM2.5 was performed to detect the presence of the signature element (chlorine, Cl) that is part of the molecular structure of DPP-Red (C18H10Cl2N2O2) organic nanofiller. Figure 4G-I shows the surface elemental atomic composition of the incineration PM2.5 from the ACR, DPP-ACR, and UV_DPP-ACR coatings. The high elemental concentrations of carbon (C: ~47–52 atomic %) and oxygen (O: ~7–10 atomic %) reflect the presence of a substantial concentration of carbonaceous and organic compounds in the released particles from the incineration of coatings. Importantly, I_DPP-ACR and I_UV_DPP-ACR show the presence of a tiny atomic percentage of Cl in the PM at 0.14% and 0.3% respectively, while no Cl is observed for I_ACR, indicating that DPP-Red could be partly released in the aerosol during incineration, although most of it could have been oxidized and its physicochemical composition might have significantly transformed at the high incineration temperatures involved.

3.4.3. Incineration LCPM mass-size distributions and PM/residual ash yields

The mass-aerodynamic size distributions of the size-fractionated and collected PM in the Harvard CCI during the incineration of the insulations and NECs for two size fractions, PM2.5 and PM>2.5 were analyzed (data not shown). Consistent with data from previous studies,[41] a majority of the PM mass (80–87 wt%) is contained in the aerodynamic size fraction below 2.5 μm (PM2.5), indicating that most of the released particles by weight during incineration are fine, inhalable particles. A minuscule amount of incineration PM is collected from INS2, as is expected from its real-time APS and SMPS aerosol measurements, that did not show significantly more released particle number concentration compared to the baseline.

The mass percentage yields of the generated and collected PM2.5 and the remaining residual ash after incineration with respect to the starting quantity of the pristine insulations/coatings are summarized in Table S2. It can be observed that the NECs yield a higher quantity of the released PM2.5 (~5–7 wt% of starting material) than the insulation INS1 (~0.61 wt%), whereas INS2 has a negligible PM2.5 yield (~0.02 wt%). Conversely, as expected from mass balance, the insulations leave behind a much higher percentage of the residual ash (~89 wt% for INS1; ~99 wt% for INS2) than the coatings (~42–45 wt%).

The instantaneous TGA data on the mass loss of insulations as a function of temperature ramp-up are plotted in Figure S13 for INS1 and Figure S14 for INS2. Consistent with the gravimetric analysis on the residual ash collected in the INEXS platform, the TGA data also indicate a higher total mass loss of the insulation INS1 (10.2 wt%) compared to INS2 (5.3 wt%) over the entire temperature regime up to 800 °C, thus yielding corresponding residual ash amounts of 89.8 wt% and 94.7 wt% respectively of the starting insulation weights.

3.5. Colloidal characterization of LCPM2.5 particles

Table S3 summarizes the detailed colloidal properties of the collected PM2.5 particles from the sanding and incineration of the insulations and coatings, that were dispersed in deionized water at their critical sonication energy at t=0 and then diluted in culture media (EMEM + 10% FBS) at t=0 and t=24 h (to indicate the colloidal stability of the dispersed particles in cellular media over 24 h). The LCPM dispersions in the culture medium appear to be mostly stable with minimal changes over 24 h in the zeta-average intensity-weighted hydrodynamic diameter (dH, nm), the polydispersity index (PdI), and the zeta potential (ζ, mV) of the particles. In more detail:

3.5.1. Colloidal characteristics of insulation LCPM:

For the insulation materials, it can be observed that the sanded LCPM displays a higher average dH and a moderately more negative ζ than the incineration LCPM, although all LCPM suspensions are polydisperse. For example, in the culture medium at 24 h, M_INS1 and M_INS2 display an average dH of 436 nm (PdI = 0.3) and 418 nm (PdI = 0.5) respectively and an average ζ around −10 mV, whereas I_INS1 has a much lower dH at 85 nm (PdI = 0.2) and a ζ around −8 mV. Since a negligible amount of incinerated PM2.5 particles were released and therefore collected from INS2, there was no colloidal characterization performed for these particles.

3.5.2. Colloidal characteristics of NEC LCPM:

The incinerated LCPM from NECs displays different hydrodynamic sizes depending on the nanofiller type and prior UV-aging of the NEC. For example, I_ACR, I_Fe(s)-ACR, and I_DPP-ACR show average hydrodynamic diameters in culture medium (at 24 h) of 100.6 nm, 55.1 nm, and 20.6 nm respectively, indicating the effect of the nanofiller type on the LCPM colloidal size. In addition, the hydrodynamic diameter of I_Fe(L)-ACR (with larger Fe2O3 nanofiller size) is 142.5 nm, which is higher than that of I_Fe(s)-ACR at 55.1 nm. The hydrodynamic diameters of the incinerated LCPM from the corresponding UV-aged NECs are different from the unaged NECs. The I_UV_ACR, I_UV_Fe(s)-ACR, and I_UV_DPP-ACR have hydrodynamic diameters of 19 nm, 78 nm, and 70 nm, respectively. The zeta potentials of the NEC LCPM in culture media stay in a narrow range between −13 mV and −8 mV. The PdI of the NEC LCPM in media ranged from 0.2–0.7 indicating that the particle suspensions are polydisperse.

In comparison, the comparator MS-WF particles have the largest hydrodynamic size at 1002 nm, PdI of 0.2, and a zeta potential of −11 mV in culture medium after 24 h.

3.6. In vitro toxicity assessment of LCPM2.5 particles

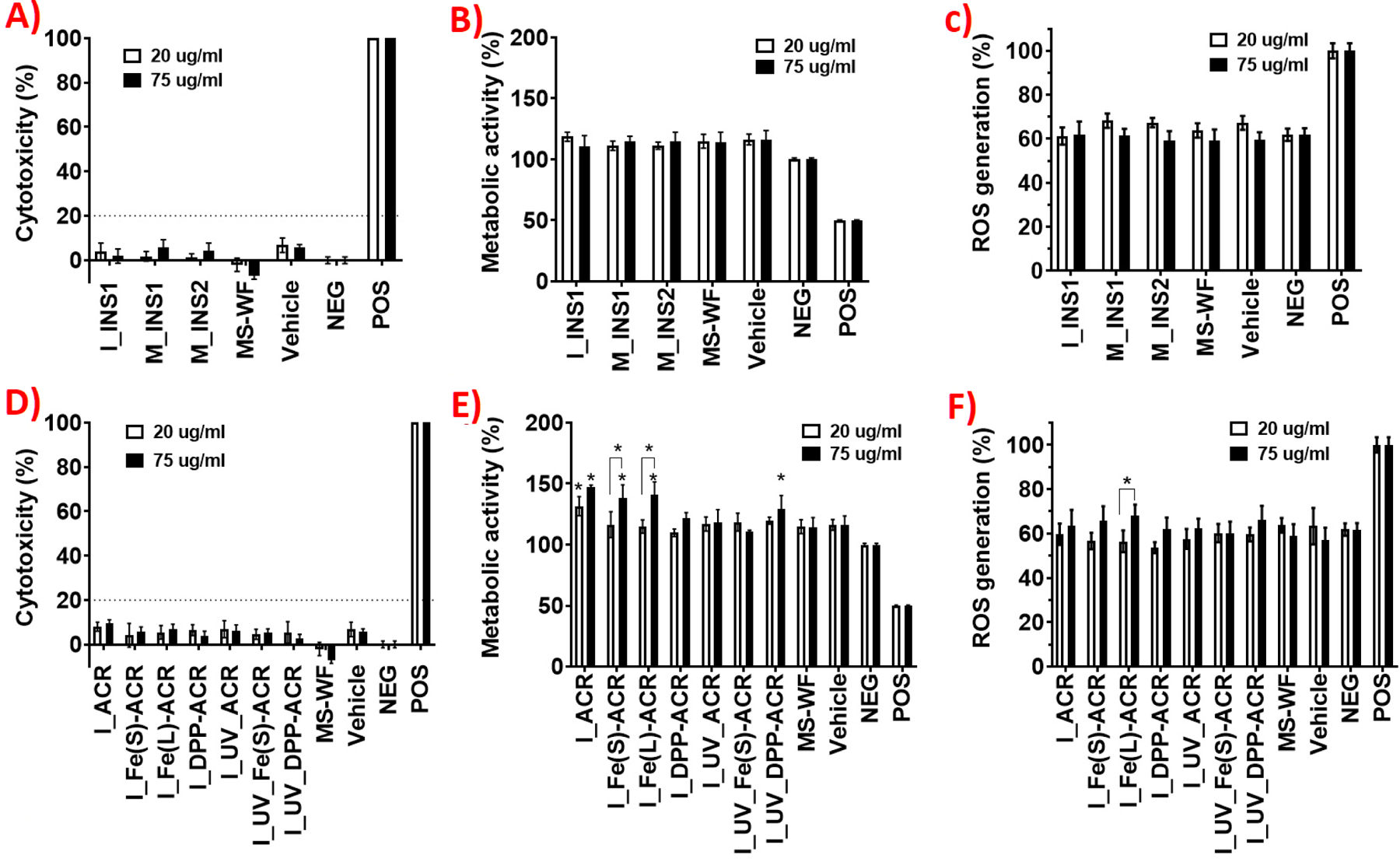

Here we describe the results of the cytotoxicity assessment of the LCPM2.5 obtained from the sanding and incineration of the insulations and coatings on the Calu-3 human lung cell line, using the assays for the endpoints of cellular viability (LDH release), metabolic activity and oxidative stress at the two administered LCPM doses of 20 and 75 µg/mL. In more detail:

3.6.1. Cytotoxicity of insulation LCPM:

Figure 5 (A, B, C) shows the results for the LDH release, metabolic activity, and ROS production in the exposed cells for the sanding and incineration LCPM of the insulation materials, namely, M_INS1, M_INS2, and I_INS1, at the two doses. As described earlier, collected incineration LCPM2.5 from INS2 was negligible and therefore not included in the cytotoxicity investigations. Neither of the LCPM samples induced significant LDH release or changes in metabolic activity after 24 h or increase in ROS production after 6 h in the treated cells at either dose, compared to the negative control and the vehicle control, indicating that the released PM from the sanding or incineration of these insulation materials is not cytotoxic, at the investigated doses. Furthermore, the comparator material, i.e., MS-WF does not exhibit any cytotoxic response at the studied doses as well.

Figure 5.

Acute in vitro cytotoxicity assessment of insulation (top row) and coating (bottom row) LCPM2.5 during various lifecycle scenarios in human lung epithelial cells (Calu-3) at 2 doses of 20 and 75 µg/mL: (A, D) LDH release at 24 h; (B, E) metabolic activity at 24 h; (C, F) ROS at 6 h. Statistical analysis was performed on an average of 6 samples (LDH and metabolic activity) oand 4 samples (ROS) for each condition; fold-changes >20% were deemed to be statistically significant.

3.6.2. Cytotoxicity of NEC LCPM:

Figure 5 (D, E, F) shows the cytotoxicity assay results for the incineration PM2.5 from both the unaged and the prior UV-aged NECs. None of the incineration LCPM induces significant LDH release at 24 h compared to the negative or vehicle controls at both doses, indicating no effect on the cellular viability of the lung epithelial cells. However, statistically significant increases in metabolic activity of the exposed cells compared to the untreated cells after 24 h is observed at the lower administered LCPM dose (20 µg/mL) for I_ACR (+31%, p<0.05) and at the higher administered LCPM dose of 75 µg/mL for I_ACR (+47%, p<0.05), I_Fe(s)-ACR (+38%, p<0.05), and I_Fe(L)-ACR (+41%, p<0.05), indicating a dose-dependent effect on the metabolic activity of the exposed lung epithelial cells. However, the corresponding incineration LCPM from UV-aged ACR, Fe(s)-ACR, and Fe(L)-ACR did not exhibit any effect on cellular metabolic activity. In addition, increased cellular metabolic activity at the higher dose is observed for I_UV_DPP-ACR (+29%, p<0.05), but not for I_DPP-ACR, suggesting the modulating effect of prior UV-aging on the subsequent incinerated PM bioactivity in the case of DPP-Red nanofiller. The incineration LCPM from unaged/aged NECs does not increase oxidative stress after 6 h in the exposed cells compared to the negative or vehicle controls, however, a small dose-dependent but statistically significant increase in ROS production was observed for I_Fe(L)-ACR at 75 µg/mL compared to 20 µg/mL (p<0.05).

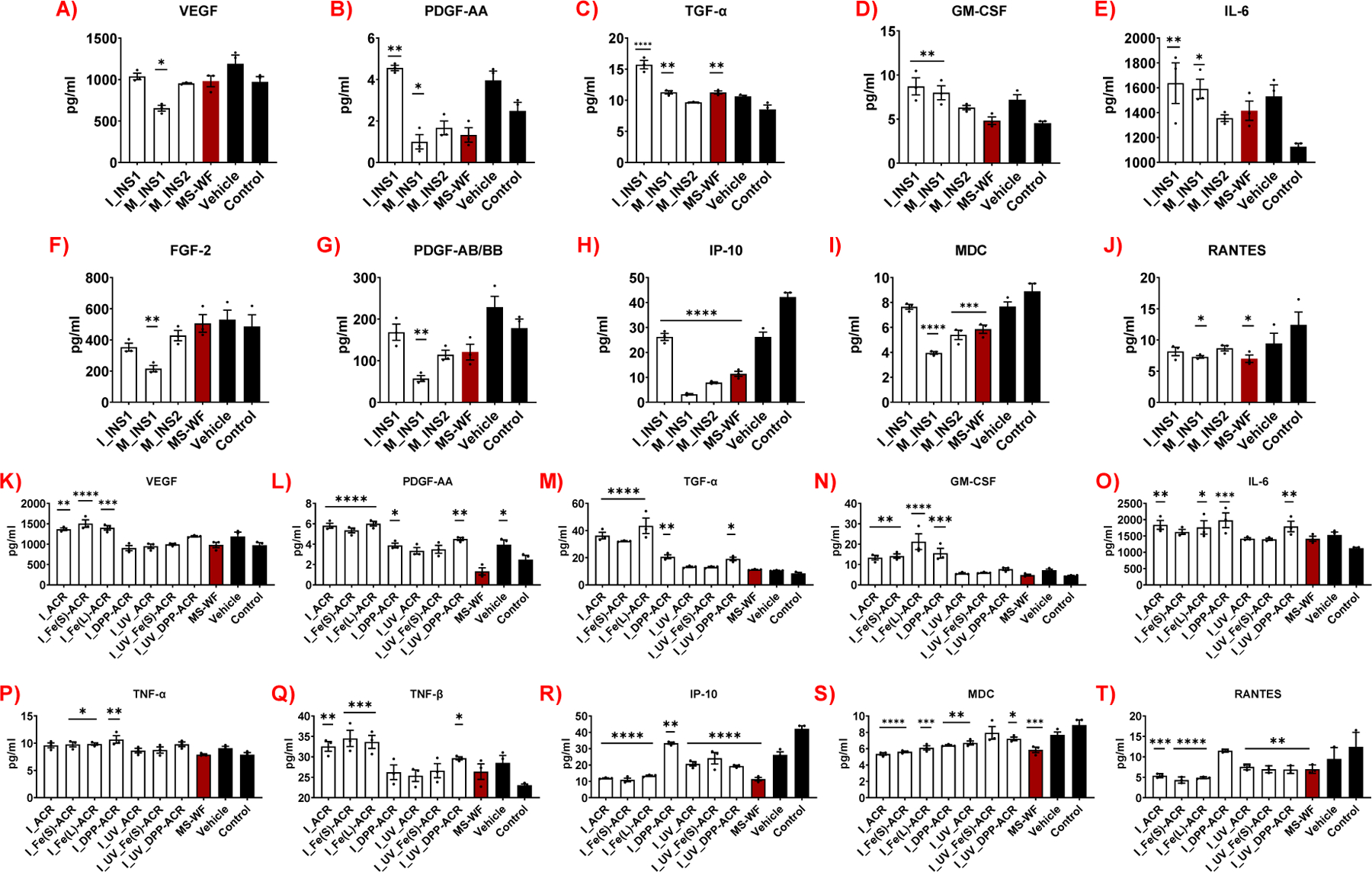

3.7. In vitro inflammatory response assessment of LCPM2.5 particles

The supernatants of the exposed lung epithelial cells at the higher LCPM administered dose of 75 µg/mL after 24 h were also analyzed for a diverse panel of inflammatory cytokines and chemokines to assess the in vitro acute inflammatory response to the various LCPM exposures.

3.7.1. Inflammatory response to insulation LCPM

3.7.1.1. Sanding LCPM from insulations:

Figure 6 (A-J) shows the concentrations of selected biomarkers measured in the cellular supernatants from exposures to the sanding LCPM from INS1 and INS2, in addition to the negative and vehicle controls and the comparator material MS-WF. Exposure to M_INS1 results in the significant upregulation or downregulation of several inflammatory biomarkers, compared to the negative control. Biomarkers that are significantly enhanced are TGFα (p<0.01), GM-CSF (p<0.01), IL-6 (p<0.05) (Figure 6C-E), and MCP-1 (p<0.0001) (Figure S15F) whereas those that are significantly suppressed are VEGF-A (p<0.05), PDGF-AA (p<0.05), FGF-2 (p<0.01), PDGF-AB/BB (p<0.01), IP-10 (p<0.0001), MDC (p<0.0001), RANTES (p<0.05) (Figure 6A, B, F-J), IL-4 (p<0.01), and GROα (p<0.05) (Figure S15D, E). In contrast, exposure to M_INS2 increases the secretion of only one biomarker, i.e., MCP-1 (p<0.05) (Figure S15F), and significantly suppresses the release of two biomarkers, namely, IP-10 (p<0.0001) and MDC (p<0.001) (Figure 6H, I). The comparator MS-WF exposure significantly enhances the release of TGFα (p<0.01) (Figure 6C) and IL-18 (p<0.001) (Figure S15A), while significantly suppressing IP-10 (p<0.0001), MDC (p<0.001), and RANTES (p<0.01) (Figure 6H-J).

Figure 6.

Acute 24-h inflammatory cytokine and chemokine assessment of coating (A-J) and insulation (K-T) LCPM2.5-exposed lung epithelial cells at the higher administered dose of 75 µg/mL (only selected biomarkers shown out of the 48). Data are the mean ± SEM of 3 samples (n=3). *p<0.05, **p<0.01, ***p<0.001, ****p<0.0001, versus negative control.

3.7.1.2. Incineration LCPM from insulations:

Incineration LCPM from the insulation INS1 significantly upregulates several biomarkers including PDGF-AA (p<0.01), TGF-α (p<0.0001), GM-CSF (p<0.01), IL-6 (p<0.01) (Figure 6B-E), IL-1α (p<0.05), and IFNγ (p<0.01) (Figure S15B-C), while strongly suppressing only the biomarker IP-10 (p<0.0001) (Figure 6H). The inflammatory response assessment was not able to be performed for the incineration LCPM of insulation INS2 due to its lack of thermal decomposition and therefore no collection of released LCPM, as also mentioned earlier.

3.7.2. Inflammatory response to NEC LCPM

Figure 6 (K-T) shows the biomarker levels as a result of exposures to the incineration LCPM from the NECs (both unaged and UV-aged prior to incineration), along with the employed controls. Compared to the negative control, I_ACR significantly promotes the release of VEGF-A (p<0.01), PDGF-AA (p<0.0001), TGF-α (p<0.0001), GM-CSF (p<0.01), IL-6 (p<0.01), and TNFβ (p<0.01) (Figure 6K-O, Q), whereas the corresponding LCPM from I_UV_ACR does not increase the release of any cytokine. However, both I_ACR and I_UV_ACR strongly suppress the secretion of IP-10 (p<0.0001 for both), MDC (p<0.0001, p<0.01, respectively), and RANTES (p<0.001, p<0.01, respectively) (Figure 6R-T), while only the I_ACR suppresses GROα (p<0.001) and MCP-1 (p<0.01) (Figure S15K, L). The incineration LCPM from the Fe2O3 nanofiller containing acrylic coatings shows consistent upregulation/downregulation of biomarkers between the two Fe2O3 nanofiller sizes. Similar to I_ACR, both I_Fe(s)-ACR and I_Fe(L)-ACR display a strong enhancement of the biomarkers VEGF-A (p<0.0001, p<0.001, respectively), PDGF-AA (p<0.0001), TGFα (p<0.0001), GM-CSF (p<0.01, p<0.0001, respectively), and TNF-β (p<0.001) (Figure 6K-N, Q). Additionally, unlike I_ACR, both I_Fe(s)-ACR and I_Fe(L)-ACR significantly upregulate TNF-α (p<0.05) (Figure 6P), whereas I_Fe(s)-ACR alone promotes IL-4 secretion (p<0.05) (Figure S15J). Both I_Fe(s)-ACR and I_Fe(L)-ACR induce a strong suppression of IP-10 (p<0.0001), MDC (p<0.0001, p<0.001 respectively), RANTES (p<0.0001), (Figure 6R-T), GROα (p<0.05, p<0.01 respectively), and MCP-1 (p<0.05 for both) (Figure S15K, L), similar to I_ACR. However, the incineration LCPM from the UV-aged Fe(s)-ACR coating does not enhance the secretion of any inflammatory biomarkers but decreases the release of only two biomarkers, IP-10 (p<0.0001) and RANTES (p<0.01) (Figure 6R, T). Similar to I_ACR, I_Fe(s)-ACR and I_Fe(L)-ACR, the incineration LCPM from both unaged and UV-aged DPP-Red containing coatings, I_DPP-ACR and I_UV_DPP-ACR, significantly upregulate the biomarkers PDGF-AA (p<0.05, p<0.01, respectively), TGF-α (p<0.01, p<0.05, respectively), and IL-6 (p<0.001, p<0.01, respectively) (Figure 6L, M, O). Additionally, I_DPP-ACR, but not I_UV_DPP-ACR, stimulates the release of GM-CSF (p<0.001) and TNF-α (p<0.01) (Figure 6N, P). In contrast, I_UV_DPP-ACR, but not I_DPP-ACR, enhances the release of TNF-β (p<0.05) (Figure 6Q). Furthermore, unlike I_ACR, I_Fe(s)-ACR and I_Fe(L)-ACR, I_DPP-ACR significantly promotes the secretion of additional cytokines, namely, IL-18 (p<0.01), IL-1α (p<0.001), and IFNγ (p<0.05) (Figure S15G-I). Both I_DPP-ACR and I_UV_DPP-ACR suppress the release of IP-10 (p<0.01) and MDC (p<0.01), while RANTES is inhibited only in cells treated with I_UV_DPP-ACR (p<0.01) (Figure 6R-T).

As for the remaining cytokine and chemokine levels, they either did not reach detectable levels in the supernatant (sCD40L, G-CSF, IFNα2, IL-2, IL-3, IL-7, IL-9, IL-12 (p70), IL-17A, IL-17E, IL-17F, MIP-1α, MIP-1β) or did not markedly differ between the various LCPM exposure groups (EGF, Eotaxin, Flt-3 ligand, IL-1β, IL-1ra, IL-5, IL-8, IL-10, IL-13, IL-15, IL-22, IL-27, MCP-3, M-CSF, MIG) (data not shown).

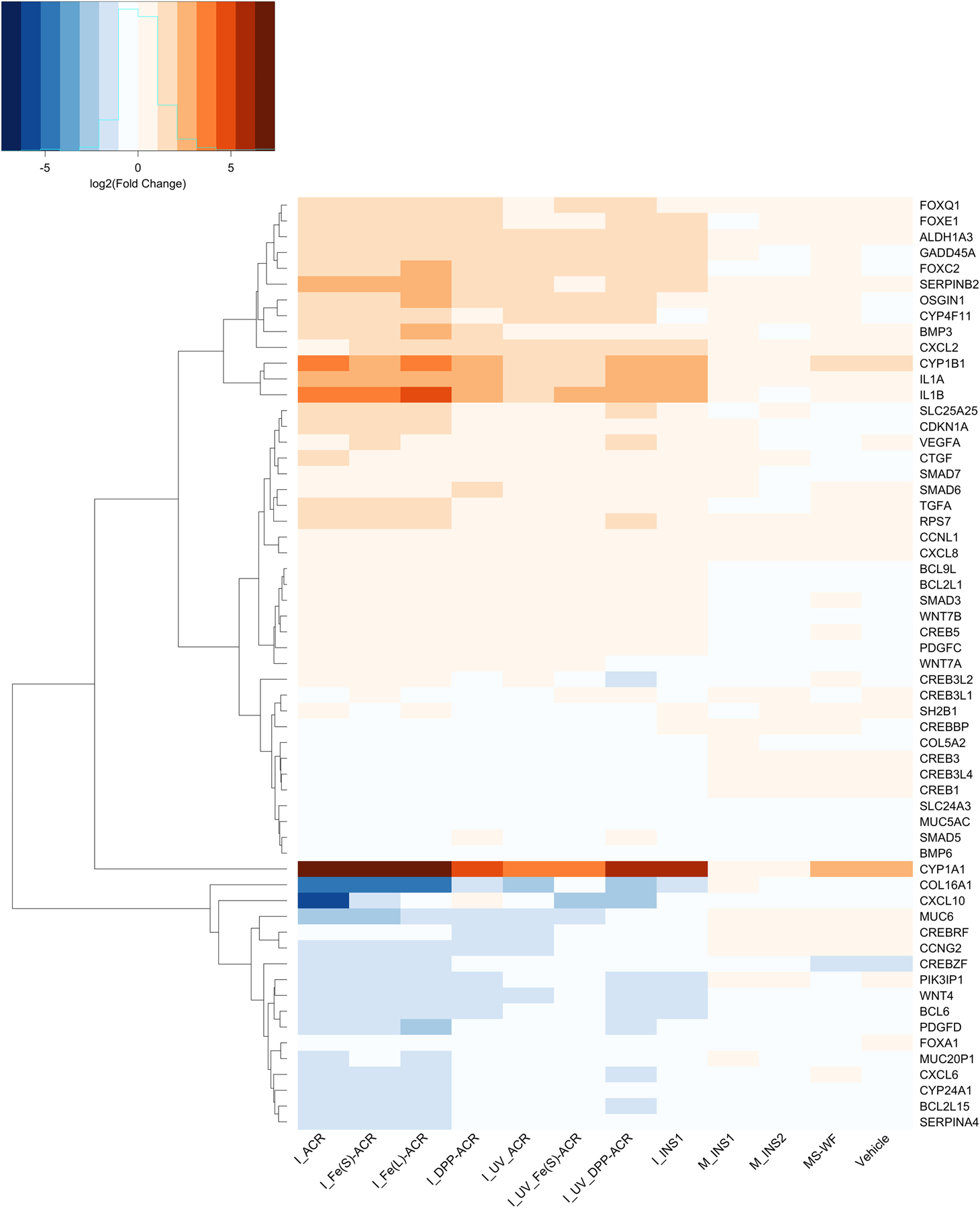

3.8. RNA-Seq transcriptomic profiling of LCPM2.5-exposed Calu-3 lung epithelial cells

Differential expression results for genes with adjusted p<0.05 and magnitude Log2Fold change >1 for comparisons involving each LCPM2.5 material versus the negative control samples are listed in the SI Excel File 2. Figure 7 shows the heatmap of a selected subset of 60 genes related to inflammation, cellular metabolism, carcinogenesis, DNA repair and collagen production.

Figure 7.

Heatmap of differential expression results for 60 selected genes from the Calu-3 lung epithelial cell RNA-Seq analysis corresponding to various coating and insulation LCPM2.5 exposures at the higher administered dose of 75 µg/mL versus the negative control (culture medium). Shades of red indicate upregulation (Log2Fold change > 1), while shades of blue indicate downregulation (Log2Fold change < −1) of the genes, compared to the negative control.

3.8.1. Transcriptomic profiling of insulation LCPM-exposed cells:

Compared to the negative control, incineration LCPM from INS1 (I_INS1), as well as MS-WF, increased the expression of genes involved in chemical carcinogenesis, such as CYP1A1 (FC (Log2Fold change) 5.8) and CYP1B1 (FC 3.08). Moreover, compared to the control, I_INS1 enhanced the expression of genes involved in inflammation, such as IL1A (aka IL-1α; FC 2.34), IL1B (aka IL-1β; FC 2.61), and CXCL2 (FC 1.51); cell cycle regulation, such as CDKN1A (FC 0.72); and DNA repair, such as GADD45A (FC 1.34), and I_INS1 decreased the expression of genes involved in collagen deposition such as COL5A2 (FC −1.43). In contrast, sanding LCPM M_INS1 or M_INS2 did not induce significant changes of pathways or gene expression compared to MS-WF and the control. GSEA results showed that I_INS1 affected mostly pathways related to cell cycle (normalized enrichment score [NES] 2.31) and semaphorin interactions (NES −2.18); M_INS1 affected peptide chain elongation (NES 2.00) and developmental biology (NES −4.88); and M_INS2 affected mitotic prometaphase (NES 2.53) and metabolism of proteins (NES −4.28) (SI Excel File 3).

3.8.2. Transcriptomic profiling of NEC LCPM-exposed cells:

Notably, the expression of genes involved in drug metabolism and chemical carcinogenesis such as CYP1A1 and CYP1B1 is upregulated in cells treated with all NEC incineration LCPM and MS-WF, compared to control (Figure 7). Moreover, compared to the control, the incineration LCPM from NECs, regardless of UV-aging, upregulates several genes involved in carcinogenesis (i.e., FOXC2, FOXE1, ALDH1A3, OSGIN1), inflammation and angiogenesis (i.e., CXCL2 (GRO-α), IL1A (IL-1α), IL1B (IL-1β), SERPINB2, TGFA (TGF-α), CXCL8, BMP6), cell cycle regulation (i.e., CDKN1A), collagen production (i.e., COL16A1), and cellular metabolism (i.e., SLC24A3, SLC25A25). Some genes involved in inflammation and angiogenesis are downregulated (i.e., CXCL6, PDGFD, BMP3), as well as genes correlated with a negative cell cycle regulation and carcinogenesis (i.e., CCNG2, WNT4). Interestingly, all the NEC LCPM except I_DPP_ACR also downregulate IDO1 gene expression. Overall, UV-aging of NECs decreases the magnitude of effect of the LCPM on the up- or down-regulation of the genes.

GSEA shows that compared to the control, I_ACR, I_Fe(s)_ACR, I_DPP-ACR, I_UV_ACR, I_UV_Fe(s)-ACR and I_UV_DPP-ACR alter pathways related to the metabolism of proteins (translation, metabolism of mRNA, peptide chain elongation, signal-recognition particle (SRP) dependent cotranslational protein targeting to membrane, NES <−3.8). I_ACR also significantly alters the pathways assembly of the pre-replicative complex (NES −2.43) and p53 independent G1-S DNA damage checkpoint (NES −2.27). I_DPP-ACR alters the JAK-STAT signaling pathway (NES 2.14). I_Fe(s)_ACR affects cell cycle (NES −4.34) while I_Fe(L)_ACR alters the pathway related to cell respiration, i.e., respiratory electron transport (NES −2.79). Enriched pathways are summarized in SI Excel File 3.

4. DISCUSSION

The primary motivation of our investigation was to assess the potential health and safety implications of occupational inhalation exposures to released particulate matter during multiple lifecycle lysis scenarios of NEBMs during their use phase, environmental weathering, and end-of-life disposal. We focused on two industrially relevant and highly functional classes of building materials, i.e., in-house synthesized NECs with the choice of both inorganic nanofiller (Fe2O3) and organic nanofiller (DPP-Red), and the commercially marketed insulations INS1 and INS2, that we confirmed to be nano-enabled (containing various nanoscale metals/metal oxides) through extensive PCM characterization. The mechanical degradation lifecycle scenario, namely, high-speed sanding, was applied on the insulation blankets under well-controlled operational parameters to assess possible nano-release, physicochemical properties of the released aerosol PM, and its potential toxicological implications for exposed workers. Similarly, we applied the end-of-life thermal decomposition scenario on the insulations and NECs, and further investigated the combined, synergistic effects of sequential lifecycle scenarios by conducting accelerated UV-light weathering of the NECs followed by end-of-life incineration, to answer fundamental questions about the potential airborne release of nanofiller and the important factors (both material-related and lifecycle-specific) governing the released aerosol characteristics and its bioactivity and potential adverse health implications. Here, we discuss the findings of our investigation in a systematic way to address these missing knowledge gaps in the existing literature on the occupational safety of NEBMs. Furthermore, we evaluate if the results to date require further acute/chronic toxicity validation studies on NEBMs and emphasize the importance of including realistic lifecycle exposure and toxicological data as part of occupational risk assessment approaches for advanced building materials.

4.1. Insulation materials: factors governing LCPM release dynamics, physicochemical composition, and in vitro biological effects.

4.1.1. Role of matrix in released LCPM characteristics:

Our findings point to the strong influencing role of the insulation matrix in determining the released LCPM number concentration, size, and chemical composition, for a given lysis scenario. Comparing two different insulation matrices, INS1 and INS2, the sanded LCPM had slightly different peak aerosol number concentrations and geometric mean optical sizes for the two materials (Figure 1). The total metal contents of the sanded LCPM, M_INS1 (15.3 wt%) and M_INS2 (32.9 wt%) (Figure 2E-F), also were in line with the total metal concentrations of the corresponding pristine bulk insulations INS1 (26.1 wt%) and INS2 (37.8 wt%) (Figure S6), suggesting that the matrix composition governs the sanding LCPM chemistry, and the released metallic nanoparticles are largely encapsulated within the sanded matrix fragments. Similarly, INS1 and INS2 matrices behaved drastically different during the incineration scenario. TD of INS1 led to a high emitted aerosol number concentration (~108 particles/cm3, Figure 3A) and a PM2.5 aerosol yield of 0.6 wt% (Table S2), whereas INS2 underwent minimal or no TD at all, as evident from no change in aerosol concentration from the baseline and a very low measured PM2.5 yield of 0.02 wt%. The higher combustibility of the INS1 insulation compared to INS2 is likely attributed to the presence of a significant concentration (10–20 wt%) of the thermoplastic polyethylene terephthalate (PET) in the INS1 matrix, as disclosed in the manufacturer-provided MSDS composition for INS1 (Table 1). On the other hand, there is no combustible carbon-based polymer in the INS2 as per the MSDS, but only silica-based and metallic ingredients, thus explaining its excellent thermal resistance even at 850 °C. Although the TGA-GC-MS spectra of evolved volatile compounds from INS2 points to the presence of siloxane (-Si-O-Si-), siloxy (R3-Si-O-), or methylsilyl (R3-Si-) functional groups in the INS2 matrix, these organosilicon compounds can act as flame retardants and suppress the thermal decomposition of the INS2 matrix.[64] The chemical composition of the incineration LCPM from INS1 and INS2 also differed significantly (Figure 4A-B), with a higher released metal content in I_INS2 (8.4 wt%) than I_INS1 (1.2 wt%), in line with the higher metal content of the pristine INS2 (37.8 wt%) compared to INS1 (26.1 wt%). This indicates that even though the INS2 matrix did not sufficiently thermally degrade, the incineration process resulted in some of the nanoscale metals/metal oxides incorporated in the matrix to escape into the released aerosol PM. Thus, the physicochemical makeup of the insulation matrices played a critical role in determining the extent of airborne nano-release and therefore the elemental composition of the released incineration LCPM. Our previous TD investigations with nano-enabled thermoplastics also highlighted the important role of the polymer matrix in governing the total released LCPM number concentrations and the overall LCPM chemical composition. For example, in terms of organic/elemental carbon content, the TD LCPM consisted of 99 wt% organic carbonaceous compounds for a given matrix irrespective of the nanofiller type or its weight loading in the polymer matrix.[37,39] The released LCPM nanoparticle number concentration and the mean aerosol size during TD also differed significantly between the investigated polymer matrices (polyethylene (PE), polypropylene (PP), polycarbonate (PC), and ethyl-vinyl acetate (EVA)), confirming that the bulk matrix degradation during the lysis scenarios contributes the most to the LCPM release dynamics.[37,39,65]

4.1.2. Effect of lifecycle lysis scenario on released LCPM characteristics: