Abstract

Additive manufacturing, enabling rapid prototyping and so‐called on‐demand production, has become a common method of creating parts or whole devices. On a 3D printer, real objects are produced layer by layer, thus creating extraordinary possibilities as to the number of applications for this type of devices. The opportunities offered by this technique seem to be pushing new boundaries when it comes to both the use of 3D printing in practice and new materials from which the 3D objects can be printed. However, the question arises whether, at the same time, this solution is safe enough to be used without limitations, wherever and by everyone. According to the scientific reports, three‐dimensional printing can pose a threat to the user, not only in terms of physical or mechanical hazards, but also through the potential emissions of chemical substances and fine particles. Thus, the presented publication collects information on the additive manufacturing, different techniques, and ways of printing with application of diverse raw materials. It presents an overview of the last 5 years’ publications focusing on 3D printing, especially regarding the potential chemical and particle emission resulting from the use of such printers in both the working environment and private spaces.

Keywords: 3D printer, additive manufacturing, chemical hazards, emission, particulate matter, volatile organic compounds

Abbreviations

- ABS

acrylonitrile butadiene styrene

- AF

additive fabrication

- ALM

additive layered manufacturing

- AM

additive manufacturing

- APS

aerodynamic particle sizer

- ASA

acrylonitrile styrene acrylate

- ASM

size‐selective aerosol spectrometer

- ASTM

American Society for Testing and Materials

- CAD

computer‐aided design

- CJP

ColorJet printing

- CPC

condensation particle counter

- DLP

digital light processing

- DMA

differential mobility analyzer

- DMLS

direct metal laser sintering

- ELPI

electrical low‐pressure impactor

- ER

emission rate

- Fab Lab

fabrication laboratories

- FDM®

fused deposition modeling

- FFF

fused filament fabrication

- FMPS

fast mobility particle sizer

- GC

gas chromatography

- HDPE

high‐density polyethylene

- HIPS

high‐impact polystyrene

- HPLC

high‐performance liquid chromatography

- IAQ

indoor air quality

- ICP

inductively coupled plasma

- ISO

International Organization for Standardization

- LENS

laser engineered net shaping

- LOD

limit of detection

- LOM

laminated object manufacturing

- LOQ

limit of quantification

- MJF

direct metal laser jet fusion

- MJM

MultiJet modeling

- MS

mass spectrometry

- NCA

nanoclasters

- NIOSH

National Institute for Occupational Safety and Health

- NPs

nanoparticles

- OPC

optical particle counter

- PA

aliphatic polyamides (also known as nylon)

- PC

polycarbonate

- PEEK

polyether ether ketone

- PETG

copolymer of poly(ethylene terephthalate)

- PLA

polylactic acid

- PM

particulate matter

- PPSU

poly(phenyl sulfone)

- PSM

particle size magnifier

- PSU

polysulfone

- PWPC

particulate wood polymer composite

- R&D

research and development

- RC

rapid casting

- RM

rapid manufacturing

- RP

rapid prototyping

- RT

rapid tooling

- SFF

solid free‐form fabrication

- SLA

stereolithography

- SLS

selective laser sintering

- SMPS

scanning mobility particle sizer

- TD

thermal desorption

- TMSN

tetramethyl succinonitrile

- TPE

thermoplastic elastomers

- TPU

thermoplastic polyurethane

- TVOC

total volatile organic compounds

- UCPC

ultrafine condensation particle counter

- UFPs

ultrafine particles

- ULTRAT

acrylonitrile butadiene styrene +0–3% polycarbonate

- VOCs

volatile organic compounds

Practical Implications.

3D printing technology provides users with extraordinary opportunities both in terms of practical applications and the use of materials with exceptional parameters.

The novelty and variety of AM developments cause them to be monitored with user safety and appropriate precautions considered, especially since most of them are still in the experimental phase.

Ultrafine particles and volatile organic compounds released into the air during the operation of 3D printers, depending on the technology applied, the materials, and their additives as well as the process conditions, may pose a health risk to the user.

More research on emission and potential exposure‐related health hazards during additive manufacturing especially in technologies other than FDM® should be conducted and the principles of emission testing should be clearly defined to enable comparison of the obtained results.

1. INTRODUCTION

Additive manufacturing (AM) is an attractive innovative technology that is increasingly used in many areas of the world's economy. Originally, it was just one method of rapid prototyping, used for both the designing of forms and the prototypes themselves. In addition to improving the quality of objects created by 3D printers (three‐dimensional printers), it has also become a method of producing complete forms, including toys, clothes, sweets, and even medical prostheses or implants. Commonly known as 3D, additive manufacturing is an extremely promising technology that offers many new opportunities not only for science, medicine, architecture, and industry but also for any other kind of business. 1 , 2 , 3 , 4 , 5 , 6 The advantages of this technique most often refer to greater structural efficiency, geometric freedom, better customization, reduction of consumption, and waste of the materials used. 3D introduces opportunities for functionally graded materials and prestressing, but also for fast repairs and enhancements of the products already available on the market. It also streamlines and speeds up the design‐build process and improves the accuracy and safety on site. 7 , 8 The potential of this technology in the area of reducing costs, waste, and transport should also be emphasized. 9 The additive manufacturing used today in almost every sector of the economy, still significantly broadens the spectrum of users and is becoming increasingly useful for amateurs, such as homemakers or students. This technology has been also significantly developed last years to create low‐cost, high‐performance printers, and revolutionary tools as well as new materials for creating three‐dimensional objects. The range of materials and their combinations used for AM is constantly growing, 10 , 11 thus allowing to produce items in a way that is not possible or hard to obtain with conventional manufacturing approaches.

AM plays an important role in the Industry 4.0, because of its ability to create customizable products and reduce cost for low‐ and medium‐batch sizes and its material reuse capabilities. 12 Although 3D printing is still used primarily in research and development (R&D), company departments that are working on new solutions using this technology are validating their ideas without involving other departments. Such types of printers are becoming widely used also for small‐scale production. Rapid manufacturing creates opportunities to produce on‐site replacement parts for the machinery and production lines as well as the finished parts mounted in the products. However, on a larger scale, use of 3D printing is not a common solution yet. In order to be profitable on an industrial scale and to be able to compete or coexist with traditional production techniques, the process should be faster and cheaper. 13 Therefore, scientists, engineers, and designers are working on reducing the limitations of 3D printing and moving such devices to the factories, thus switching from the rapid prototyping to the production of various types of items. 13

At the same time, similar to other new technologies, application of 3D printing devices can pose risks which the user must be aware of and which are related not only to the processes and technologies used, but also to the specific working environment in which the printing takes place. The aim of this work was to review the current state of the art in the field of additive manufacturing and to find possible risks associated with its application. The authors focused on the potential emission of hazardous chemicals and particles during the process of printing and compared the data from various studies on the emitted agents.

2. METHODS

The authors conducted a literature review covering mainly last five years (2016–2020), although several earlier examples were included. The interest in the topic of 3D printing is enormous and constantly growing. It should be emphasized that the number of publications when entered as a keyword “additive manufacturing”, only in the science direct browser in 2020 exceeded 17,770, and in 2021, there are already 804 publications. However, majority of the emerging publications deal with issues such as materials used in AM, their manufacturing and technology improvements, or life cycle assessment. Papers not pertaining to 3D printing that show up as a result were not evaluated further.

The searches, carried out by the authors, included both principle of the technique itself and introduction to the additive manufacturing technology with its practical applications, as well as the related potential risks for the user. The main searching concerned the emission of chemical substances such as volatile organic compounds and fine or ultrafine particles during the operation of this type of printers and their potential impact on the health of people working with them. The authors have reviewed the literature using different browsers, such as the Web of Science, Science Direct, PubMed, and Google Scholar. The web search was carried out using the option to find title/keywords/abstract with the specific word or combination of words.

The exemplary keywords introduced into the web browser were the following: additive manufacturing, 3D printing (and their alternative names), 3D printer, emission, hazards, volatile organic compounds, particles, particulate matter, fine or ultrafine particles, nanoparticles, occupational exposure, and the combinations of the presented keywords, for example, emission +3D printing, ultrafine particles +additive manufacturing, and VOCs emission +3D printing. Each of the printing technologies included in the review (e.g., stereolithography, SLA, FDM®) was also used as a keyword or in a keyword combination with AM or 3D printing. The basic rule for the selection was that the article must be in English and represent either research paper or review. Then, the publications were selected according to the assumptions made concerning the particular chapters in this publication to describe the additive manufacturing process, its technologies, materials used, and applications, but also possible hazards they can pose to the user. In total, over 170 papers were taken into consideration and described in the separated sections of the presented review.

3. 3D PRINTING RULES

3D printing is considered as a process of creating three‐dimensional, physical objects based on a computer model. 14 This process is referred to as three‐dimensional, spatial printing and consists of creating an object by applying successive layers of the applied material. This technology, commonly named 3D printing, is also known as additive or generative manufacturing. The International Organization for Standardization and ASTM International consider these terms to be the same, while NIOSH places 3D printing in an area it defines as “a family of technologies used to build objects (usually layer by layer) from a computer‐assisted design computer file”. 15 In a consequence of attempts to standardize the terminology, 7 , 16 additive manufacturing has been adopted for all the processes of making parts from 3D models and materials. 17 Seven key groups of the AM technologies have been distinguished: binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat polymerisation. 7 , 16 Additive fabrication (AF), additive layered manufacturing (ALM), rapid casting (RC), rapid manufacturing (RM), rapid prototyping (RP), rapid tooling (RT), and solid free‐form fabrication (SFF)—all these terms are alternative names for 3D printing technology used in the literature. 7 For the practical considerations, the printing technique itself can be divided into two separate technical processes, that is, the melting technique—used in highly advanced industry—and the extrusion technique—less specialized and used mainly on the consumer market and as a part of experiments in the additive manufacturing. Each 3D printer is practically designed for the use with specific types of materials, and their number increased significantly over the last 10 years. Hence, such materials as ceramic fibers, steel, glass, and even wood are also used nowadays and will be described further in the article. In AM printers, initially the virtual project is created and stored using a computer program with 3D modeling software and/or a 3D scanning device. All 3D printers are integrated with computer‐assisted design (computer‐aided design) CAD software dedicated to this technology. Based on the image generated by the computer, the raw material is applied in layers through a controlled thermal, chemical, or photochemical process, thus creating a precise 3D image replica.

3.1. Printing technologies

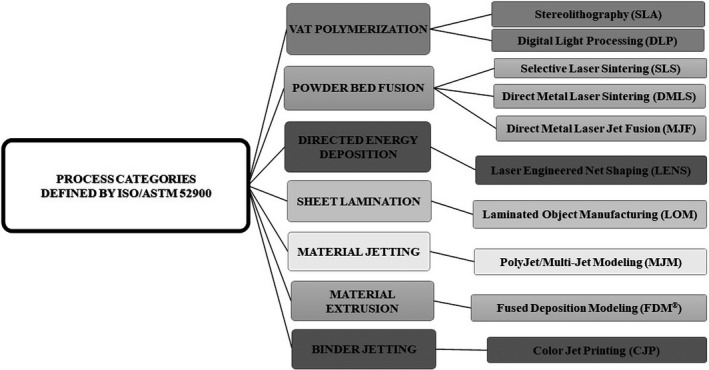

The principle of 3D printers’ operation depends on the technology of application and curing the material from which three‐dimensional elements are being made. 18 The process seven categories defined by ISO/ASTM 52900 17 are represented by different technologies, from which the most important and popular types include the following: stereolithography (SLA) and digital light processing (DLP), fused deposition modeling (FDM®), selective laser sintering (SLS) or direct metal laser sintering (DMLS) and direct metal laser jet fusion (MJF), laser engineered net shaping (LENS), laminated object manufacturing (LOM), PolyJet/ MultiJet Modeling (MJM), and ColorJet Printing (CJP). 11 , 19 , 20 Their classification is presented in Figure 1, and the technologies are briefly described below to introduce to the issue of printing.

FIGURE 1.

AM process categories and technologies

The printing method, included in the material extrusion process that allows for printing from thermoplastics, is called fused deposition modeling (FDM®), fused filament fabrication (FFF), or molten polymer deposition. 21 This is the most widely used AM printing technology so far. 16 The differences between FDM® and FFF are demonstrated in detail as they generally work the same way. The materials used for 3D printers in this technology are filaments rolled on a coil. The material is pressed through an extruder nozzle, heated to its melting temperature, and deposited on a platform layer by layer till the final fabrication of the object. FDM® prints are characterized by their side surface with a noticeable layout of layers, which in fact can be reduced by finishing with acetone or minimizing the height of printing layer. The advantage of FDM® over traditional processing is that objects can be printed without any geometrical limitations, damaged objects can be easily replaced, and the technique is cost‐effective. 22 In this technology, so‐called support materials are used (later dissolved, melted, or detached from the printed product) in order to provide the physical scaffolding necessary to print or to obtain special structures. 16

3D printing in SLS technology consists of sintering successive layers of material in powder form, using laser light. 23 This technology is a compromise between fairly low‐cost FDM® technology and cost‐effective SLA resin prints, but the time of printing is slightly longer compared to both of them. SLS combines the benefits of high printing precision and capability, is effective in prototyping elements with complex geometry, and is one of the few technologies that do not need to use support structures. Solvent‐free nature, availability of thermoplastic polymer (currently used in hot melt‐extrusion process), and minimal/no post‐processing stage are some of the features of the SLS printing process. 24 The common defects related to the direct metal laser sintering can be listed as porosity, distortion, and delamination, as well as the so‐called “balling phenomenon”. 25 SLS process is capable of producing parts from a wide variety of materials, including polymers and blends of polyamides with fillers and nylon in powder form with appropriate gradation, glasses, ceramics, and metals. 16 The prints are composed of powder materials based on plastics (polyamides), which can be enhanced with glass or carbon fiber or aluminum. There have been reports on the use of SLS and thermoplastic pharmaceutical grade polymers for manufacturing medicines. 26 However, ceramic parts prepared by SLS still show some defects, including low density and poor mechanical properties. 27

Other powder bed fusion method, direct metal laser sintering (DMLS) is utilizing a laser beam of high‐power density for melting and fusing the metallic powders. 28 , 29 Because of poor surface quality post‐processing operations are required. 29 , 30 DMLS and selective laser melting (SLM) are functionally the same and both can produce strong and functional metal parts directly. The difference concerns higher energy density level in case of SLM. Selective laser melting involves the fabrication of relatively complex 3D metallic parts with precise dimensional accuracies by following the principle of layer‐by‐layer melting. 31 SLM enables the free‐forming of a near‐full dense metal lattice structure at a fine resolution without any need for additional tooling. 32 Despite the relatively high cost of production, the execution of some geometries in this technology is economically justified, as many activities cannot be performed manually even with the highest quality equipment. 33 It should be emphasized that 3D printing from metals is becoming more and more popular production method. Moreover, for this type of printing, even titanium, aluminum, or stainless steel can be applied.

Vat polymerization technologies make use of a liquid photopolymer resin which is able to solidify under a light source. 20 , 34 Stereolithography is known as an optical fabrication, or photo‐solidification, and the prints are made of light‐curing resin, a liquid material that changes its physical state to solid under the influence of a UV laser. 28 , 35 3D resin prints are very precise (even the smallest details are maintained) perfectly reproduce the digital model and have a smooth side surface. Its weakness is low mechanical strength of the prints in comparison with other technologies. Resins used in this technique may have however the increased mechanical properties (strength) and flexibility due to the possible additives. DLP is similar to SLA, as it cures photosensitive materials (photopolymers) but using the digital light projector screen. Both these technologies have undergone a huge evolution last years and are forging ahead as mass manufacturing technologies.

ColorJet Printing (CJP) is a binder jetting technology that uses a core and a binder to create high‐resolution full‐color models. It uses an inkjet print‐head to deposit the droplets of a liquid binder onto the powder particles in a powder bed and selectively glue them together. 36 , 37 The “raw material” is plaster powder, which is bound by colored glue. CJP cannot be used for functional prototypes, since abrasion is too high and the material is relatively fragile. Compared to, for example, powder bed fusion, the advantage of the binder jetting method is not employing the heat (eg, laser) during the build process, which prevents the creation of residual stresses in the parts.

MultiJet Printing (MJP) is used to create components in high resolution and in a short time. Prints are made of photosensitive resins, thermoplastics, and wax, making "postprinting" a simple and fast process. Liquid materials are deposited from inkjet print‐heads onto a build platform and subsequently solidify through photopolymerization, cooling, etc. 36 , 38 PolyJet and MultiJet Modeling (MJM), representing the material jetting differ only in the type of support material, that is, gel‐like water‐soluble materials or paraffin wax, respectively. Printers working with this technology are user‐friendly. However, in comparison to SLS technology, the printouts have poor mechanical strength. Therefore, the MJP is primarily used for prototyping rather than functional printing.

The directed energy deposition represented by laser engineered net shaping (LENS) uses computer‐controlled lasers that weld air‐blown streams of metallic powders into custom parts and production molds in a matter of hours. This technique produces shapes similar enough to the final product that there is no need for rough machining. One of the purposes of LENS is to make small batches of high‐density parts or molds. 39 Laminated object manufacturing (LOM) is a sheet lamination, a technique of printing a 3D object by stacking and laminating thin sheets of material together. 36

3.2. Materials used in 3D printers

The choice of material to be used in the 3D printing process fundamentally defines the properties of the finished item. 40 The most extensively used polymer materials for various AM techniques are photosensitive resins, thermoplastic powders and filaments, and viscous polymer inks. 11 The literature review shows that the optical (eg, absorption), thermal (eg, melting and crystallization behavior), or rheological (eg, viscosity and relaxation dynamics) properties of polymeric materials can be adapted to any process and AM application. 10

Certain materials are clearly assigned to the technologies described above. Thus, thermoplastics are mostly used in FDM® technology and include, for example, acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high‐impact polystyrene (HIPS), thermoplastic polyurethane (TPU), aliphatic polyamides (PA, also known as nylon), and polyether ether ketone (PEEK), also polycarbonate (PC), high‐density polyethylene (HDPE), poly(phenyl sulfone) (PPSU) or resistant to UV, heat, and frost acrylonitrile styrene acrylate (ASA). 16 The raw material itself may however consist not only of the main components, but also of various additives including dyes, flame retardants, UV stabilizers, antioxidants, or plasticizers. 41 These additives may also include some ceramics or metals. 42 The most common and most extensively applied in FDM® technology are PLA and ABS. The polylactic acid valued for its low melting point, non‐toxic, non‐irritation, and biocompatibility 43 , 44 under certain conditions is not free from harmful emissions to health issues, especially if melted at temperatures over 200°C. 45 PETG, a copolymer of poly(ethylene terephthalate) with ethylene glycol, is known mainly as a material for food packaging. The combination of these two substances results in a thermoplastic with properties different from those of ordinary PET in beverage bottles. Nylon, in turn, is suitable for the creation of highly loaded structural elements; however, it unwillingly absorbs moisture from the air. Natural composites can also be used in FDM® for biomedical applications. Recently, such biomaterials as bio‐macromolecules polymerized polyvinyl chloride (BPVC) and others were used to print some personal protective equipment, for example, bio‐cellular face shield during the COVID‐19 pandemic. 46 , 47 , 48 Natural polymers, such as cellulose or natural rubber, are known for their friendly behavior toward the biological environment and can be used with SLA, FDM®, or LOM. 28 FFF uses filament as a feed material, SLA applies liquid resins, while SLS and directed energy deposition technologies make use of powder materials. For powder‐based AM technologies, support materials are not necessary since the unsintered powders serve such purpose properly. 16 Polymer powders are mainly based on polyamides, although as reviewed by Tan and col., 11 thermoplastic elastomer (TPE) powders have also gained significant attention. TPE can undergo repeated melting and crystallization cycles, allowing them to be processed, for example, by SLS. For instance, PA12 is a material with increased chemical resistance, allowing to produce elements with good mechanical properties, and matt, rough surface. 49 , 50 A mixture of powdered polyamide and aluminum (alumide) is also used. Other materials applied in AM on an industrial scale are synthetic plastics polysulfone (PSU) and poly(phenyl sulfone) (PPSU) but their processing requires respective safety measures. A summary of available powdered materials being used in AM was presented by Mostafaei and colleagues 37 and concerned iron, nickel, cobalt, and their alloys. Also ceramics such as alumina (Al2O3), tricalcium phosphates, or ceramic composites can play an important role as biomaterials to fabricate, for example, bones or teeth. The use of metals is currently considered as the fastest growing segment of the rapid manufacturing industry. Stainless steel, Co–Cr alloy, CP–Ti, Ti–6Al–4 V, NiTi, Inconel, gold, silver, copper, Al, and their alloys are most widely used metal powders, nowadays. 28 Metal additive manufacturing exhibits a huge potential in terms of the design flexibility and the optimization of the lattice structure design features. 32 , 51 , 52 Laser powder bed fusion and directed energy deposition are the most common AM methods to process steels. 53 In the 3D printing process, metals are combined with petroleum‐based synthetic materials. The high temperatures at which this bonding takes place require appropriate safety and material handling measures. Cermets, a category of materials including ceramic and metallic phases, that possess the combined properties of both phases are also in use. 54

The resins, applied mainly in SLA/DLP technologies, are selected on the basis of their properties, but also their compatibilities with the equipment. 34 There are currently several resin curing technologies, for example, using a laser, LCD screen, or projector and thus the raw materials differ in terms of, for example, polymerizing light wavelength. Among the available resins, their basic types concern classical resins, engineering materials where particular emphasis is placed on the strength of the printed elements and their mechanical properties (eg, resistance to hits or increased temperatures) as well as biocompatible resins adapted for medical and dental applications. Continuous development is ongoing on the functional resins with enhanced bioactivity, dielectricity, conductivity, magnetism, etc. Special types of resins with properties that push the boundaries of standard 3D printing materials are also in use. 55

In case of inks used in the inkjet technology, special attention should be paid to their properties. According to Shen and Naguib, 38 the ink compositions, such as volatility, hydration, surface tension, chemical stability, abrasion, and electrical properties that deviate from the specifications of the printhead, shorten its life. A wide variety of ink materials have been developed for applications such as biomedical devices, energy storage devices, and flexible electronics. Viscous inks have been gaining increasing attention because of their versatility and potential use for multi‐material part fabrication, which is particularly favorable for printing soft materials and cells for biomedical applications. A remarkable example of 3D application is bioprinting based on the production of additives from materials containing living cells. These materials, often referred to as bioink, are based on cytocompatible hydrogel precursor formulations, which gel in a manner compatible with different bioprinting approaches. 56

The search for newer materials modifications is leading to high‐performance, flexible, biocompatible and continuous polymer fiber‐reinforced composites for engineering applications. Fused deposition modeling, selective laser sintering or stereolithography, and inkjet 3D printing are most common techniques for the preparation of polymer matrix composites. FDM® and SLS are used to develop particulate wood polymer composites (PWPCs) by amalgamating the wood particles with the polymer matrix. 57 Wang et al 58 presented an overview on 3D printing techniques of polymer composite materials, their properties, and performance of 3D printed parts as well as their potential applications in the fields of biomedical, electronics, and aerospace engineering. Recent developments in the use of conductive materials that can be printed in AM, enabling the development of mass‐produced electrochemical sensors of varying geometries were reviewed by Hamzah and col.. 59 Many companies are working on the reuse of previously useless materials for filament production. 60 A new task is also an application of carbon nanofibres and other nanomaterials. 61 , 62 Wu et al 16 has brought more than just commercially available materials as well as research activities related to recent progress on high‐performance polymer nanocomposites used in various AM techniques. It is anticipated that in the nearer future, all kinds of nanomaterials will be widely used on an industrial scale. New type of an intelligent material may react to differences in temperature, pressure, or light intensity after production. 63 Metamaterials, applied to AM technologies, are designed to have properties beyond the normal interactions in the mechanical, acoustic, and optical domains. 64 It is therefore necessary to monitor the introduction of these high‐tech materials and to take care of safety issues, as most of them are still in the experimental phase.

3.3. Practical applications of rapid manufacturing

Due to the additive manufacturing, the usually long, time‐consuming and expensive process of making prototypes and models can be replaced, depending on the needs, by the selected additive technique. It is also possible to produce spare parts that can be carried out on‐site, thus modifying the role of suppliers in the production lines. 12 To date, many review papers have been devoted to practical applications of 3D printing, for example, in medicine, 65 , 66 , 67 , 68 , 69 construction, 7 , 70 , 71 or even customized food fabrication. 72 , 73 , 74 Examples of successful use of 3D printing technology were found also in the textile industry, 75 furniture sector, 76 and environmental applications in air, water, and energy. 77

The use of 3D printing in design and research has many benefits, including shorter prototyping period, increased speed of detection of design errors, possibility of multiple tests; and very fast improvement, enhancement, and optimization of the prototypes. Precision, accuracy, and exact copy of the model being created are of great importance here. Due to the wide range of materials available in additive manufacturing techniques, the R&D departments have an extensive scope of expertise in their projects and product development. FDM® is recommended for the companies starting their adventure with 3D printing or these with specific requirements that the technology can meet. FDM® is mainly dedicated to conceptual modeling for prototypes as well as preparing models by architectural and design offices. With 3D printing, making architectural models and patterns is simple, fast, and cheap. Very complicated geometries, bold designs, but also standard realizations can be quickly transferred from the area of design and visualization to a specific model in the appropriate scale. The architectural industry uses virtually all printing techniques, both FDM® and SLS or DLP and SLA. AM provides structural flexibility and the possibility to use almost any kind of material, so today it is even possible to print energy‐efficient and inexpensive houses. 78

Till now, the most widely in the world, 3D printing is used in the aerospace industry. 79 , 80 This industry makes use of AM not only for interior and cockpit equipment parts, but recently also for parts used in aircraft engines. The aviation industry uses mainly SLS and metal powder printing techniques, but there is no shortage of prototyping projects using DLP and SLA. SLS printers are used wherever the strength of the printed components goes along with the precision. 23 Therefore, SLS printing is used in the automotive, aerospace, heavy industry, robotics, and all R&D departments where the quality of the printout is important and the prototype is not just a visualization.

The 3D printing market currently offers numerous solutions and many materials dedicated to the medical and pharmaceutical industry. 81 , 82 In medicine, due to the extraordinary accuracy of model mapping and completely smooth printing surfaces, the DLP, DMLS, and SLA techniques are used, in which light‐sensitive materials are being printed. Making such precise models in a short period of time is not possible with the traditional techniques used so far. Apart from stomatology, 83 3D printing is used in surgery (eg, reconstruction surgeries) or in research such as cell multiplication. 84 Pharmaceutical three‐dimensional printing makes it possible to create custom‐made medicinal products of virtually any shape and size from a computer‐aided design model. 23 Medical 3D printing is growing and serves to aid physicians in the diagnosis, therapeutic planning, and the treatment of patients with complex diseases. 66 The scaffolds of high demand for regenerative medicine can be printed with additive manufacturing. 85 Considering bioprinting, this enables the generation and transplantation of tissues, including multilayered skin, bone, vascular grafts, tracheal splints, heart tissue, and cartilaginous structure. 56 According to Morris, 86 if a transplant has to be performed, the three‐dimensional biological printing could save thousands of lives without the need to involve the donor.

The jewelry industry requiring extreme precision employs a wide range of materials, in terms of both properties and colors. 3D printing is used here both for the production of models and forms from which the actual jewelry is being made, and also for direct small series production. DLP, SLA, and FDM® technologies work best here, and occasionally, metal printing is being used. DLP is also an ideal technology for injection and thermal molding of the plastics. It offers a number of benefits for the footwear industry and completely replaces traditional manufacturing for hearing aids market.

In the automotive industry, prototypes or models of parts and design elements are prepared with rapid prototyping, both small in size and entire dashboards, engine blocks, bumpers, mirrors, etc. All of the techniques described in this paper with the printing from metals are actually working in the automotive industry. The technology is used by all of the world market leaders as well as by small companies dealing with tuning, renovation, and individual projects.

In addition, the use of 3D printing takes place even in food product development. 87 , 88 Jetting‐based methods are the most common for 3D printing of edible items. 89 In this case, it is essential to use appropriate 3D printers that would ensure the sanitary (both microbiological and chemical) quality of these products and enable control of the structure and texture of foods. 3D printing has already attracted great ecological attentions in energy efficiency, material saving, and emission reduction for better sustainability. 90 Moreover, AM can be considered as a recycling tool to reuse thermoplastic waste materials, 91 which can significantly increase the value and potential of subsequent applications.

4. IDENTIFICATION OF POTENTIAL RISKS ASSOCIATED WITH 3D PRINTING

AM is being introduced to an increasing number of workplaces that intend to benefit from its opportunities. The possibilities of this technology seem to be unlimited and the advantages presented in the previous section were perceived by an increasing number of users. However, this technology is also a potential health and safety challenge. Not only is the variety of printing processes and the use of both familiar and new materials increasing, but depending on where and for what purpose the process is used, risks are emerging.

Despite the potential to eliminate certain types of hazards present during traditional manufacturing processes, such as exposure to oil mist resulted from metalworking fluid, reduction or elimination of the toxic chemicals often used in conventional manufacturing processes 92 or other common hazard, which is, for example, noise, AM processes may create new health problems. 93 While many forms of 3D printing exhibit some similarities to the existing technologies, changes in materials, instrumentation, applications, and work organization can create potentially new risks. The challenges facing occupational safety and health experts can resemble those of nanotechnology, where the mix of old and new processes, new environments, and the speed of changes affect hazard characterization and risk assessment. According to Roth et al, 42 the established AM process categories (Figure 1) can serve as a basis for identifying risks, including those arising from the organization of the workplace, workforce, and related technologies. These categories are defined by AM feedstock materials, the feedstock form (its phase liquid, solid, or powder), processes (the mechanical forces and energies used to bind the materials), and the machine architecture. Thus, exposure to the 3D printer user may be caused by generation of fine and ultrafine particles, heat and hot surfaces (burn hazards), mechanical hazards from the moving parts, high voltage, or heating sources used (eg, production of ionizing radiation by electron beams). 42 , 94 , 95 Examples of directed energy deposition bonding strategies (laser, electron beam, or plasma arc) present potential burn hazards and may pose such risks as eye damage, exposure to ionizing radiation, or electric shock. Safety of the electrical machinery itself, the possibility of shock or mechanical injury during maintenance and malfunctioning must be taken into account during routine operations. Ferraro et al 96 also lists the potential electrical hazards concerning the electromagnetic phenomena emitted by the machine or electrostatic produced by, for example, powder flowing in the powder bed fusion/sintering machines. Potential hazards also concern ergonomic during loading, unloading, and maintenance of AM tools. Depending on both the feedstock material, forms, and the binding mechanism, potential AM user's hazards cover: inhalation exposure to volatile organic compounds (VOCs) and particle emissions generated during the printing or post‐printing processes, dermal exposure to the applied feedstock and processing materials (polymers, resins, powders, solvents, binders, etc.) but also the possibility of fire or explosion (eg, airborne powders) and harmful physical agents depending on the heat energy (eg, laser radiation, ultraviolet radiation, or ionizing radiation) etc. In addition, AM can also be unusually fatiguing or stressful for its users in a work environment. This can be posed not only, due to the pace of innovation in this type of technology coupled with the lack of suitably skilled workers, but also to the irregular, long on‐call hours during printing and thus the sense of job security. 42 Moreover, the differences in the machine architecture between different process categories may result in significant risk differences.

Thus, risks associated with three‐dimensional printing, depending on the process category, include exposure of workers to the chemicals used or their potentially hazardous emissions during the printing process. A wide range of feedstock materials like epoxy resins, cyanoacrylates, polycarbonates, acrylates, elastomers, and polyamides introduced for AM may pose a potential risk due to their health effects. If the operator comes into contact with these chemicals through inhalation of fumes or accidental spills on the skin, inhalation exposure, acute skin reactions, or eye irritation and allergies may occur. 93 , 97 Nanomaterials in 3D technology are found in feedstock for printers, added for their physicochemical or microbiological properties, but can also be created during the 3D printing process. 98 Therefore, inhalation and dermal exposure to nanomaterial by‐products released from 3D printers may occur in numerous industries. Metals, used mainly in directed energy deposition, may be toxic or sensitizing. It should be noted that even if the feedstock materials themselves can pose a threat to the printer's user, even more so chemical vapors (eg, styrene, acrylonitrile, or carbonyl compounds such as formaldehyde,) emitted during the operation of the printers. Many VOCs are known irritants with carcinogenic/reproductive toxicity potentials. Excessive exposure to volatile organic compounds that can be emitted during different AM processes can lead to eye, nose, and throat irritations, headache, or loss of coordination. Biological materials (ie, cells for engineered‐tissue generation) can be printed causing potential exposure to aerosols generated in the process. 39 The risk of dermal exposure to powders (mainly in such processes as powder bed fusion and binder jetting), resins, and solvents (eg, in vat photopolymerization and material jetting) is also possible. The risk of allergic reactions leading to contact dermatitis 99 can be associated with epoxy resins, used in the process of stereolithography as well as in the surface treatment of the printed objects. Other chemicals, used in post‐processing and surface treatment can also be hazardous, including those used to dissolve support structures in some technologies, for example, in SLA. 93 According to Rejeski et al, 1 in addition to the use of uncommon raw materials and new processes, threats caused by working in atypical conditions are increasingly common. Chan et al 100 conducted a preliminary survey among employees of 17 companies using 3D printing for prototyping, educational institutions, and public libraries in Canada. 59% (out of 46 employees surveyed) reported respiratory symptoms at least once a week. There was also a link between working for more than 40 hours a week using 3D printers and recognizing symptoms such as asthma and allergic rhinitis. The case study described by House et al 101 also indicates that employees using 3D printers may experience respiratory problems (including asthma). Studies on rats in a chamber exposed to aerosols emitted from AM machines using ABS reported acute hypertension and microvascular dysfunction, suggesting that health effects have been observed in animals at sufficient exposure levels. 102 Also Farcas et al 103 have demonstrated that FFF could induce toxicological effects in human small airway epithelial cells (SAEC). Furthermore, common plastics applied for 3D printing are considered as new threats to the environment. 104 The authors found that leachate plastic with stereolithographic printing causes developmental toxicity in zebra finches. Exposure to plastic leachates causes oxidative stress and caspase‐dependent apoptosis.

It should be noted, however, that the 3D printing hazard literature is heavily focused on inhalation hazards associated with the emission of particles and potentially harmful chemicals.

5. EMISSIONS FROM 3D PRINTING DEVICES

Due to such an increasing usage of 3D printers and past experience with laser printer emissions, the characterization of 3D printer hazards and potential emissions is necessary in order to assess human exposure and possible health impacts. 105 3D printers are able to generate potentially harmful concentrations of fine and ultrafine particles (UFP) and chemicals in the printing and post‐printing processes used to produce the finished product.

The materials entering the machine, as already mentioned, can be hazardous, releasing vapors and gases that may be more dangerous, for example, when heated to higher temperatures during printing. This risk will depend on the technical requirements of the printed object, its material, and the printing method itself. The applied materials in most of AM processes are heated, extruded, and/or melted using energy sources. 106 Simultaneously, previous research on the thermal treatment of plastics, that are currently the most common materials used in AM, even at moderately high temperatures (eg, 170–240°C) indicated the emission of volatile organic substances. 45 There are number of reports in specialist literature indicating that 3D printers can emit high levels of volatile organic compounds during the printing process. 107 , 108 Although they are mainly concerned with FDM® technologies, it should be emphasized that inhalation exposure to VOCs is possible in almost any of AM technology due to the feedstock materials used and their additives. Heating of feedstock materials creates the potential for volatilization of the material's components or by‐products resulting from its thermal decomposition. For example, photopolymer resins (applied in vat photopolymerization) may include volatile or toxic elements and compounds such as antimony, acrylates, and epoxies. If not even the material itself, the precursor or binder used (eg, in binder jetting technologies) may become a source of such emissions. In case of powder bed fusion, the powdered base material might become aerosolized during printing or post‐processing. 109 Finally, the finished product may be hot enough to emit volatile compounds. Thus, to determine the possible effects of these emissions, the role of material being used in the process of printing, its physical state, and the properties (eg, in case of technologies using powder—their characteristics such as morphology, particle size distribution), printing process parameters (eg, layer thickness, print orientation, and speed, drying time), sintering (temperature and holding time), and post‐processing should be considered. 37

Ultrafine particles (UFPs) or nanoparticles (NPs) generated during the 3D printing process have been associated with adverse health effects. 100 , 110 The significance of ultrafine particle emission is under growing suspicion in its relationship to inflammatory, pulmonary, and cardiovascular effects. 111 , 112 , 113 , 114 Ultrafine particles (below 100 nm) can penetrate the blood and biological membranes, and as a result can be translocated to different human internal organs, causing negative health effects. 115 , 116 , 117 , 118 The toxic effect of PM is believed to be associated with particles of aerodynamic diameter less than 10 μm. According to many authors, the particles with diameters below 2.5 μm (PM2.5) or up to 0.2 μm are considered to cause oxidative stress and inflammatory reactions. On the other hand, the chemical composition of particles is also important to understand their potential health impact. Therefore, caution should be taken when operating the 3D printing instruments inside unvented or unfiltered indoor environments due to their large emissions of UFPs. 119 Due to the fine metal powders and high temperatures involved, the printing process is likely to generate particulate matter (PM). 120 3D printers can emit particles even smaller than those from laser printers. Results of Zisook and his col. 109 pilot‐scale study indicated that airborne emissions associated with AM operations are variable, depending on printing and parts handling processes, raw materials, and ventilation characteristics. In the presented review of recent publications on emissions, the emissions of chemicals and fine and ultrafine particles are discussed separately.

5.1. Chemical substances emitted during the additive manufacturing

Despite many different 3D printing technologies, material extrusion (represented by FDM®) is the best recognized at the moment, as evidenced by the number of publications on the possible emission of gaseous thermal by‐products harmful to the human body released during the operation of the printer. Some of the studies described in the literature concerned emission measurements carried out during the operation of printing machines in the test chambers, 102 , 106 , 121 some in the air of specific workplaces or indoors. 122 , 123

Davis and others 124 conducted research in a chamber (cubic capacity of 1 m3) on five commercially available stationary FFF type 3D printers from various manufacturers, using twenty different filaments. The authors identified 216 individual VOCs in the air samples, which may indicate a wide range of chemical formulations currently available for 3D printer filaments. Their studies overall showed top emitting individual VOCs were filament material monomers (eg, styrene (276 µg/h) from ABS and HIPS (281 µg/h), lactide (111 µg/h) from PLA, and caprolactam (1750 µg/h) from nylon), while the most common carbonyl compounds were formaldehyde, acetaldehyde, and benzaldehyde. The authors have also found a relationship with the nozzle temperature estimating that VOC emissions decreased with the decrease of temperature. Although Azimi and others 21 declared no apparent relationship between total volatile organic compound (TVOC) emission rates and either bed or nozzle temperatures (as opposed to UFP emission), ding and colleagues 125 noted that VOC emissions from FDM® printer start at the beginning of the glass transition and peak during the fiber liquefaction. As two main mechanisms of creating VOCs, the authors considered the initial growth of emission during liquefaction and relatively constant distribution of products in the liquid phase. Another factor influencing the emission rate mentioned by the authors was a heat‐up rate. Their studies have shown that low heat‐up rate had the potential to inhibit the formation of styrene, the ABS monomer. 125 In material extrusion technology, the release of volatile chemicals can result not only from thermal degradation of the polymer itself but also from the presence of chemical additives that can be easily decomposed. 126 Thus, it can be noticed that significant differences in VOC emissions when using the same type of filaments but from various manufacturers are caused by the presence of additives such as plasticizers, fillers, dyes, flame retardants, UV stabilizers, antioxidants, or cyclosiloxanes (D3‐D6) that can be used as lubricants in a 3D printer. 124 According to Wojtyła et al, 41 the presence of additives may affect VOC emissions either directly (thermal decomposition of additives) or indirectly (by affecting the thermal stability of the main polymeric component). It was verified also by Gu and others 127 who indicated that the presence of semi‐volatile organic compounds deposited on the particles resulted not only from the raw materials used (in this case thermoplastics) but above all from the additives to these materials. The best‐known FDM® filaments have been quite well analyzed in terms of potential emissions when used for printing. An example of such a polymer can be ABS, 22 which sold by different manufacturers may differ due to the admixtures used. In accordance with Unwin et al, 128 ABS can decompose into its components: butadiene, acrylonitrile, and styrene at 400°C, but usually 3D printing with this material takes place at much lower temperatures. In most of the studies, however, the main substance emitted from the printers with application of ABS was styrene 22 , 41 , 121 although in different quantities. Other VOCs identified during additive manufacturing with this material were as follows: acrylonitrile, acetonitrile, methyl methacrylate, propylene glycol, methyl styrene, cumene, cyclohexanone, ethylbenzene, toluene, butanol, and acetone. 41 Many authors tried to identify the potential sources of the emitted substances. For example, tetramethyl succinonitrile (TMSN) and 2,4‐di‐tert‐butylphenol were considered polymerization by‐products and polymerization stabilizers, ethylbenzene came as a styrene degradation product, 2 cumene (in the study of several ABS types) might come from the decomposition of dicumen, commonly added as a flame retardant. 129 The presence of methyl methacrylate (MMA) might result from the addition of inoculated latex rubber (to ABS or HIPS) to increase their impact strength. 130 Gu et al 127 identified also phthalates (diethyl phthalate (DEP), di‐n‐butyl phthalate (DnBP) and diisobutyl phthalate (DiBP)) during printing with ABS, HIPS, PETG, and ASA, describing them as typical plasticizers; and bisphenol A as a monomer of polycarbonate. It should be emphasized that additives of this type are also added in other 3D technologies, for example, to raw plastic resin to give the final product specific desired properties.

Part of the research concerning the emissions from 3D printers described in the literature is based on the research of filaments themselves 41 but also products printed in this technology. Yi and col. 131 conducted research in a steel chamber (0.6 m3) during printing with two toys using ABS and PLA filaments in different colors. The study determined both TVOC emission levels (from <LOD to 590 µg VOC/g printing) and the emission rate for ABS (4393–5793 µg/h) and PLA (<LOD to 617 µg/h). With ABS, the highest concentrations were measured for styrene (2216 µg/m3), ethylbenzene (647.3 µg/m3), and ethanol (187.5 µg/m3). The concentration of substances such as acetaldehyde, acetone, benzene, isopropyl alcohol, or toluene did not exceed 34 µg/m3. In case of PLA, the highest concentrations were for ethanol (73.9 µg/m3) and isopropyl alcohol (62.5 µg/m3). Emissions varied depending on the color of the filament and between individual toys with the same color. In these studies, the extruder nozzle conditions (diameter, temperature) significantly influenced the particle and TVOC emissions. In addition, eight of the nine tested combinations of the color of the filament/toy showed the presence of metals, Si in an emission range of 15 to 107 ng/g print, and 3 combinations of Fe (127–3168 ng/g printout); Co (0.03–0.005 ng/g printout), Mn (1.6–92.3 ng/g printout), Mo (0.04–0.26 ng/g printout), Pb (0.13–1.2 ng/g printout), Sn (0.17–0.24 ng/g printout), and Sr (0.10–0.95 ng/g printout). Filaments may include ceramic or metallic particles as precursors to creating pure parts of these materials. 42

Wojtyła and col. 97 tested the possible emissions without the printer, by heating the ABS, PLA, PET, and nylon filaments to 200–250°C for 10 minutes in the laboratory conditions. Air samples from the heated samplers were taken with a gas‐tight syringe and introduced directly onto the gas chromatograph column followed by the GC‐MS analysis. Their studies confirmed previously described consideration, as the main emitted component of the ABS copolymer was styrene, together with butadiene and ethylbenzene. In case of nylon, these were propylene glycol and cyclopentanone. PET emitted toluene, formaldehyde, acetaldehyde, ethylene, and acetone. In PLA, the main contaminant was methyl methacrylate (less isobutanol and cyclohexanone). For ABS, the calculated total emission reached 0.50 μmol/h of printing. In further studies of the authors, 41 commercially available filaments ABS (6 types), HIPS (3 types), and Carbon Car (3 types) were heated to 210–270°C in the laboratory conditions for 20 minutes. Simultaneously, tests were carried out with a 3D printer in a glass gas‐tight chamber with a total volume of 250 l. During the printing process, an increase in the concentration of styrene, ethylbenzene, α‐methylstyrene, and acrylonitrile was noted. The printing of the object from the ABS pillar led to higher emissions (almost twice) compared to HIPS. The increase in VOCs concentration was almost linear for all contaminants and both pillars.

Concerning AM technologies other than material extrusion (represented mainly by FDM®), they were much less frequently subjected to tests determining the emission of harmful chemicals during printing operations. One of them is the work of Afshar‐Mohajer and colleagues, 19 who presented the Binder Jetting method as a source of emission of fine particles and volatile organic compounds. Damanhuri et al 49 described total VOC emissions (at 0.5 ppm) influenced by the sintered powder temperature during operation of SLS 3D printer using virgin polyamide nylon powder. In other study of this author, 50 TVOC concentration from recycling powder was slightly higher during the post‐printing phase confirming the influence of the powder cake and PA12 temperature from the printing process. The stereolithography process utilizes photosensitive liquid resins, which might cause hazardous gaseous emissions due to the volatilization process as well as additive manufacturing production activities. 132 Stefaniak, Bowers et al 133 assumed the average TVOC emission efficiency was significantly higher for DLP compared to SLA printers, which the authors referred to differences in light sources and resin curing principles. Moreover, they indicated vat polymerization chemistry as highly complex due to the analysis of bulk resins, emitted particles, and built objects. They found this process category (vat polymerization) printers emitted nanoscale particles containing potential carcinogens, sensitizers, and reactive metals as well as carbonyl compound vapors. Several elements were quantified in the bulk resin (Al, Cr, P, and Ti) and in the printed objects (Al, Ca, Cr, Fe, Ni, P, Ti, and Zn) using ICP‐MS. Väisänen et al 122 also described the emissions from different technologies. During vat polymerization manufacturing, they have detected mainly methyl methacrylate (27–136 μg/m3), 2‐butenoic acid methyl ester (55–63 μg/m3), and 4‐methyl‐2‐pentanone (3–76 μg/m3). The authors have noticed TVOC concentration at slightly elevated level at the beginning of the manufacturing process, and the concentrations of several VOCs greatly elevated during post‐processing of manufactured objects (4‐methyl‐2‐pentanone (8,139 μg/m3), isopropanol (1,658 μg/m3), and tetrahydro‐2‐furanylmethyl pivalate (442 μg/m3)). Concentrations of formaldehyde and acetone were equal to 12 μg/m3 and 136 μg/m3, respectively. During powder bed fusion process manufacturing, TVOC concentrations were not increased relating to the background level. Dominant compounds were in this case formaldehyde (40 μg/m3), cyclododecanone (1–32 μg/m3), n‐butyl ether (18–23 μg/m3), and decamethylcyclopentasiloxane (2–26 μg/m3). The multi‐jet fusion emission resulted in higher mean TVOC concentration (1,114 μg/m3) comparing to most manufacturing methods in their study. The highest concentration level compounds were 2‐pyrrolidinone (549–564 μg/m3), triethylene glycol (201–211 μg/m3), and alpha‐pinene (49–56 μg/m3). Acetone, formaldehyde, and butanone were detected with concentrations of 41 μg/m3, 18 μg/m3, and 14 μg/m3, respectively. 122 These discrepancies may be due to differences in AM machine manufacturers and model types, raw materials, but also room sizes or ventilation indicators. 109

To understand the potential health impact from the printing process emission, the chemical composition of particles should be also considered. Graff with col. 134 demonstrated the exposure to particles during the manufacture of metallic powder consisting mainly of chromium, nickel, and cobalt during selective laser melting operations. Also Ljunggren and col. 135 examined metal exposure in an AM facility using selective laser melting by gravimetric analyses of particles and biomonitoring of workers proving that elevated metal exposure (nickel, chromium, and cobalt) in urine may be lowered after the employees have taken appropriate protective measures.

Several examples of the studies measuring chemical mainly VOC emissions during AM processes are presented in Table 1 and cover among others also methods of air sampling and the techniques used to determine TVOCs and the identified chemicals.

TABLE 1.

Examples of chemical substances determination in air samples taken during 3D printing

| Materials used | Applied sampling | Monitoring method or analytical methods | MAX concentration or emission tvoc | Identified chemical compounds /max concentration or emission | References |

|---|---|---|---|---|---|

| BINDER JETTING 3D PRINTING (3DP) | |||||

|

zp®150 a zb®60 b zbond®90 c |

TVOC: ‐ | real‐time photoionization detector |

1725 µg/m3 |

VOC: not identified | 19 |

| MATERIAL EXTRUSION FFF/FDM | |||||

| ABS, PLA, HIPS nylon, laybrick laywood polycarbonate, nylon‐based plasticized copolyamide thermoplastic elastomer (PCTPE), polyester resin filament (T‐Glase) |

TVOC: ‐ VOCs: Tenax‐GR sorbent tubes |

real‐time photoionization detector TD/GC/MS |

Nylon: 200 μg/min |

propylene glycol/‐ 2‐ (2‐butoxyethoxy) ethanol/‐ 2‐ethoxy−1‐pronanol/‐ ethylbenzene/‐ 2‐ethyl−2‐hexanal/‐ hexanal/‐ acetophenone/‐ caprolactam/180 μg/min styrene /110 μg/min lactide/ 5 μg/min |

21 |

|

ABS, ULTRAT, ASA, HIPS, PETG, GLASS, PCABS ESD |

TVOC: Quartz fiber filters, VOC: Samplers with: Tenax® TA, Carbotrap®, Carbograph 5TD |

GC/MS TD‐GC‐MS |

ABS BLUE: 17.3 μg/min GLAS: 0.2 μg/min ULTRAT: 40.5 μg/min |

ASA Blue: Caprolactam/59 ng/m3 4‐tert‐Butylphenol/33 ng/m3 2,4‐Di‐tert‐butylphenol/28 ng/m3 Diethyl phthalate/19 ng/m3 Lauryl acrylate/30 ng/m3 Tris‐(2‐chloroethyl)‐phosphate/59 ng/m3, Diisobutyl phthalate/26 ng/m3 methyl palmitate/80 ng/m3 Di‐n‐butyl phthalate/18 ng/m3 Bisphenol A/ 424 ng/m3 Triphenylphosphine oxide/71 ng/m3 Tris(2,4‐di‐tert‐butylphenyl) phosphate/207 ng/m3 ULTRAT: Styrene/26.3 µg/min Benzaldehyde/1.7 µg/min Acetophenone/0.8 µg/min Ethylbenzene/1.4 µg/min toluene/3.9 µg/min acrylonitrile /1.1 µg/min |

127 |

|

PET, PLA, PLA woodfill, Flex silicon based filament, Nylon, ABS, PE |

TVOC: Tenax sorbent tubes ALDEHYDES: samplers with silica gel modified with 2,4‐DNPH |

TD‐ GC‐ FID and MS HPLC‐DAD |

ABS: 0.46 mg/m3 |

VOCs: not identified PLA: Formaldehyde/0.036 mg/m3 Acetaldehyde/0.014 mg/m3 |

138 |

|

ABS, PC, ultem (polyetherimide) |

TVOC: ‐ ALDEHYDES: TD tubes with a multi‐bed sorbent METALS: NRD sampler |

real‐time photoionization detector TD‐GC‐MS, ICP‐MS |

ABS: 17.7 mg/m3 |

VOCs: not identified ABS: Acetone/7.2 mg/m3 Al, Cr, Cu, Fe and Ti (respirable fraction)/ <0.01 mg/m3 |

137 |

|

ABS, PLA, PVA, HIPS, PCABS, nylon, Bronze‐PLA PETT |

TVOC:‐ VOCs: trisorbent thermal desorption tube |

real‐time photoionization detector TD‐GC‐ MS |

PLA:1.1×10−2 μg/cm3 |

PCABS: Styrene/ 21.2 μg/min α‐methylstyrene/21.5 μg/min PLA acrylic acid dimer (1,4‐dioxane−2,5‐dione, 3,6‐dimethyl‐)/11.0 μg/min PVA Glycerine/14.2 μg/min triethanoloamine/4 μg/min Nylon Caprolactam/26.1 μg/min |

106 |

|

ABS PLA |

Aldehydes: silica gel modified with 2, 4‐DNPH BTEX: carbon tubes Phthalates: XAD−2 resin TVOC: ‐ |

HPLC‐UV/Vis GC‐MS GC‐MS real‐time photoionization detector |

PLA: 387.43 μg/m3 |

ABS Acetaldehyde/31.9 ppb isovaleraldehyde/90.8 ppb ethylbenzene/11.5 ppb Toluene/ 3.7 ppb DEP/2.2 ppb DEHP/1.4 ppb PLA: formaldehyde /155.9 ppb toluene/16.2 ppb m‐and p‐xylene/1.3 ppb, DBP/2.7 ppb DEHP/1.4 ppb |

140 |

|

ABS ABS‐CNT d |

System for Thermal Diagnostic Studies (STDS) | GC‐MS | ABS‐CNT: 300 μg/g filament |

ABS Styrene/168 μg/g 2‐phenyl−2‐propanol/23.2 μg/g ethylbenzene/9.5 μg/g, isopropylbenzene/5.1 μg/g CNT Styrene/150.9 μg/g Tetramethylsuccinonitrile (TMSN)/10.5 μg/g 2,4‐di‐tert‐butylphenol/45.4 μg/g α‐methylstyrene/15.6 μg/g acetophenone/17.9 μg/g |

170 |

|

ABS PLA |

VOC: canister Carbonyl compounds: water impingers TVOC: ‐ |

GC‐MS GC‐MS real‐time photoionization detector |

ABS: 3552 μg/h |

ABS Acetaldehyde/16.3 μg/m3 Ethanol/67.2 μg/m3 Acetone/62.4 μg/m3 Isopropyl alc/213 μg/m3 Toluene/1.4 μg/m3 Ethylbenzene/7.3 μg/m3 m,p‐xylene/3.1 μg/m3 styrene/252.1 μg/m3 PLA Acetaldehyde/5.5 μg/m3 Ethanol/103.3 μg/m3 Acetone/31.8 μg/m3 Isopropyl alc/1582.8 μg/m3 Toluene/1.9 μg/m3 |

102 |

|

ABS PLA |

TVOC:‐ Organic substances: Tenax TD sorbent Tubes PAH: glass fiber filters, connected to an XAD−2 adsorbent tube Ozone |

real‐time photoionization detector TD‐GC‐MS. GC‐MS Miniaturized UV‐ absorption monitor |

ABS: 520 µg/m3, PLA: 770 µg/m3, |

ABS styrene/260 µg/m3 fluoranthene/0.033 µg/m3 pyrene/0.027 µg/m3 PLA methyl methacrylate/290 µg/m3 fluorantene/0.031 µg/m3 pyrene/0.028 µg/m3 |

123 |

|

ABS PLA |

Chemical Composition | ACSM Aerosol Chemical Speciation Monitor | data not available |

ABS Acrylonitrile/‐ 1,3‐butadiene/‐ Styrene/‐ PLA lactic acid/‐ lactide/‐ |

121 |

|

ABS PLA |

TVOC: Tenax TA Aldehydes: silica gel modified with 2, 4‐DNPH |

TD/GC/ FID HPLC/UV |

data not available |

PLA Lactide/30 ng/L Nonanal/10 ng/L decanal/12 ng/L acetic acid/7 ng/L benzoic acid/5 ng/L acetaldehyde/ 4 ng/L |

139 |

|

bio‐based PC, PLA, ABS, fossil PC |

TVOC:‐ Formaldehyde |

Portable detection device |

PLA: 0.792 mg/m3, ABS: 1.304 mg/m3, Fossil PC: 0.448 mg/m3, Bio PC: 0.080 mg/m3 |

VOCs: not identified PLA Formaldehyde/0.167 mg/m3 ABS: Formaldehyde/0.250 mg/m3 Fossil PC: Formaldehyde/0.072 mg/m3 Bio PC: Formaldehyde 0.015 mg/m3 |

171 |

|

ABS, PLA |

TVOC:‐ VOC: Tenax TD tubes passive samplers TraceAir® Aldehydes: water impingers Metals: NRD samplers |

real‐time photoionization detector TD/GC/MS GC‐MS ICP‐MS |

PLA: 3.1× 104 µg/min |

ABS Acetone/457 µg/m3 Isopropyl alc./4637 µg/m3 Benzene/8.2 µg/m3 Hexane/7.7 µg/m3 |

126 |

|

ABS pro Easy Wood Carbon Filament |

VOC: Tenax TA Aldehydes: silica gel modified with 2, 4‐DNPH |

TD/GC/MS HPLC/UV |

Easy Wood: 322 µg/m3 |

Easy Wood: Propylene glycol/34 µg/m3 (Butoxyethoxy)ethyl acetate/70 µg/m3 Lactide/56 µg/m3 Benzaldehyde/4 µg/m3 Furfural/19 µg/m3 |

122 |

| VP VAT PHOTOPOLYMERIZATION | |||||

|

VarseoWax CAD/Cast Formlabs Grey& Castable |

VOC: Tenax TA Aldehydes: silica gel modified with 2, 4‐DNPH |

TD/GC/MS HPLC/UV |

VarseoWax CAD/Cast: 427 µg/m3 |

VarseoWax CAD/Cast: Methyl methacrylate/136 µg/m3 2‐butenoic acid methyl ester/63 µg/m3 4‐methyl−2‐pentanone/76 µg/m3 Isopropanol/14 µg/m3 Acetone/136 µg/m3 Formaldehyde/12 µg/m3 Nonanal/8 µg/m3 Decanal/10 µg/m3 |

122 |

|

resin e‐shell 600 LS 600 M |

TVOC:‐ | real‐time photoionization detector | 1774.15 µg/m3 | VOCs: not identified | 132 |

|

Formlabs Alchemy Universal XYZ Printing Spot ‐HT Hard and Tough |

TVOC:‐ Aldehydes: impingers Metals: ‐ |

real‐time photoionization detector GC‐MS ICP‐MS |

DLP: 1931.2 µg/g printed SLA: 322 µg/g printed |

VOCs: not identified Acetone/26 ppb, benzaldehyde/12.7 ppb, 4‐oxopentanal /0.07 ppb Al, Ba, Fe, Mg, Na, P, S, Si, Zn |

133 |

| POWDER BED FUSION | |||||

| Polyamide 2200 |

VOC: Tenax TA Aldehydes: silica gel modified with 2, 4‐DNPH |

TD/GC/MS HPLC/UV |

105 µg/m3 |

n‐butyl eter/23 µg/m3 cyclododecanone/32 μg/m3 n‐butyl ether/23 μg/m3 decamethylcyclopentasiloxane/26 μg/m3 Ethanol/6 µg/m3 Acetic acid/9 µg/m3 Alpha‐pinene/17 µg/m3 Formaldehyde/40 μg/m3 Nonanal/15 µg/m3 |

122 |

| Polyamide nylon (PA12) virgin powder |

TVOC Formaldehyde |

real‐time photoionization detector Formaldemeter |

0.5 ppm |

VOCs: not identified Formaldehyde/0.05 ppm |

50 |

| MATERIAL JETTING ‐ MJ | |||||

| Visijet M2R‐CL |

VOC: Tenax TA Aldehydes: silica gel modified with 2, 4‐DNPH |

TD/GC/MS HPLC/UV |

2872 µg/m3 |

4‐isopropyl benzyl alcohol/8 µg/m3 Hexadecane/16 µg/m3 Toluene/61 µg/m3 Ethylbenzene/34 µg/m3 o‐Xylene/102 µg/m3 2‐Furanpropanoic acid/162 µg/m3 Isobornyl acrylate/2076 µg/m3 |

122 |

|

TangoBlack+ VeroClear Support |

VOC:TD tubes |

real‐time photoionization detector TD/GC/MS |

4,5 × 104 µg /min |

acetaldehyde 14–214 mg/m3) ethanol 10.6 mg/m3 ozone (26.3 µg/m3) acetone benzene ethanol toluene m,p‐xylene |

168 |

| MULTIJET FUSION—MJF | |||||

| Polyamide 12 |

VOC: Tenax TA Aldehydes: silica gel modified with 2, 4‐DNPH |

TD/GC/MS HPLC/UV |

1151 µg/m3 |

Triethylene glycol/211 µg/m3 2‐methyl butane/21 µg/m3 Decane/20 µg/m3 Toluene/31 µg/m3 Ethylbenzene/19 µg/m3 Styrene/31 µg/m3 p‐Xylene/33 µg/m3 2‐Pyrrolidone/564 µg/m3 Acetone/41 μg/m3, Formaldehyde/18 μg/m3, Butanone/14 μg/m3 |

122 |

zp®150 ‐ composite powder (80% plaster, 10% vinyl polymer and 10% carbohydrate by weight).

zb®60 ‐ binder solution (20% humectant, 5% polymer and 75% water by weight).

zbond®90 ‐ color bond (composed of cyanoacrylate and hydroquinone) as infiltrator.

CNT – carbon nano tubes.

The results shown in Table 1 indicate VOC emissions in individual publications were presented in different units, in either concentration (ppb, ng/l, mg/m3, etc.) or emission rate (mg/min), but also under different process conditions (chamber/no chamber, sampling, and analysis of air samples for the determination of volatile and semi‐volatile organic compounds). However, the aim of this review was to gather as many examples of such measurements as possible and thus to obtain data on potential exposure of people operating 3D printers. So far, there are some gaps in the literature data on emissions and exposure associated with working with 3D printers. Although exposure may occur during material processing 136 or after processing of manufactured parts, only a few studies include data related to these tasks, as confirmed by Zisook and col.. 109 Another important issue is different ways to calculate, for example, TVOC value from the results of an analysis, making published TVOC data often not comparable. The problem is not only the lack of guidance on which compounds should be considered in the procedure for calculating TVOC values as their sum, 45 but also the conditions under which the measurements were conducted, which can significantly affect the final result. 97 Bravi and col. 45 assumed that such differences may arise from the influence of the analytical system including the adsorbent used for sampling, the sampling rate and volume, and the separation and detection system. In order to determine VOCs, the authors of the reviewed studies used different measuring and analytical methods, starting from real‐time photoionization detectors 20 , 123 , 137 or other portable detection devices till canisters 101 or Tenax sorbent sampling tubes followed by TD/GC‐MS. 124 , 138 , 139 Carbonyl compounds were mostly sampled onto sorbent tubes filled with silica modified with 2,4‐dinitrophenylhydrazine and determined with HPLC–UV 139 , 140 or water impingers analyzed further by GC‐MS. 102 , 141 In a few studies, also phthalates content was measured by sampling with XAD tubes followed by GC‐MS analysis. 140 Metals were taken mainly to MCE filters, which were mineralized with nitric and hydrochloric acid and determined by ICP‐MS. 126

5.2. Particle emission during additive manufacturing

In the literature on the subject, many studies concern potential particle emissions in the 3D printing process. The significant majority of the data presented relates to FDM® technology.

Various testing devices are used to determine the number concentration of particles and they enable counting particles in a wide range of dimensions. 142 Investigations using a condensation particle counter (CPC), a scanning mobility particle sizer (SMPS), and an optical particle counter (OPC) to determine the number concentration of particles in the 7 nm to 25 mm diameter range (7–300 nm for SMPS and 0.3–25 mm for CPC and OPC) showed that large particles (OPC data) accounted for less than 1% of total particle count emissions. 143 This outcome is consistent with other studies that have shown that 99% of the particles were smaller than 100 nm in size. 2 , 111 , 123 , 140 , 144 The micron‐scale particles were observed sporadically in the microscopic images by Yi and col.. 145 They conducted measurements in the test chamber using the ELPI Classic impactor and scanning mobility particle sizer (SMPS) and stated that particle sizes during 3D printing ranged from several tens to several hundred nanometers. Average particle concentration (106–1010 particles/g printing) and sizes (30–300 nm) were similar during 3D printing for both home and 3D printers used in the workplaces. Poikkimäki and others 146 studied aerosol molecules from nanoclasters (NCA), that is, particles in the size range below 3 nm. NCA emission rates were between 9 and 48% of total emissions depending on the combination of filament material and nozzle temperature used. The research shows that most of the nanoparticles emitted from 3D printers are agglomerated. Youn et al 144 investigated the single spherical particles in the 50–150 nm range, which were probably generated during melting of the filament. They found that most 10–20 nm particles agglomerate and form agglomerates of about 100 nm. The studies show that 3D printer particles form irregularly shaped aggregates or branch chain aggregates of nanoscale primary particles. 103 , 131 SEM images also demonstrate nanoscale‐cluster particle, compact irregular particle, discrete spherical particle, flake‐like particle, or submicron‐scale compact particles. 103 , 131 , 133

In accordance with Sittichompoo and col., 147 local temperature and concentration of volatile organic material emitted from the filament play an important role in the number of created particles, while printing time and air exchange rate influence particle size, morphology, and emission rate. Particle formation and growth are thought to be due to aerosol dynamic processes of vapor nucleation resulting in new particle formation, vapor condensation onto existing particles, and particle–particle interactions through coagulation. 143 , 144 , 145 , 148

The concentration of particles emitted by 3D printing changes at different stages of the process. Zhang and col. 141 conducted research in a 1 m3 stainless steel chamber. The printer was placed in the middle of the chamber, and the measurements were carried out from at least 15 minutes before the start of printing until 2 hours after its completion. At the beginning of printing, the concentration of particles increased to a maximum of 2 × 105 – 1 × 106 particles/cm3 for 20 nm particles. Then, the total number concentration decreased while their size increased. After 30 minutes to 2 hours of printing (depending on the applicable filament), the total number concentrations, as well as the particle sizes, reached a level, which remained constant until the end of printing. After the end of printing, the number concentration decreased mainly due to dilution by a continuous supply of clean air into the chamber and the settling of particles on surfaces. The authors explained that the observed increase in average particle size may be due to settling of the smallest particles on surfaces and coagulation between small and large particles. In turn, in a study by Azimi and col., 21 particle concentrations increased rapidly as soon as printing began, remained at this level for 10–20 minutes, and then decreased, but were higher than the background concentration. The release of most of the particles during the early stages of the FDM® printing was documented in various investigations. 111 , 125 , 149 , 150 Yi and col. 145 measured particle concentrations before (~1 h), during (~14 min), and after printing (~1 h). A few minutes after the start of printing, the particle number concentration increased rapidly to a maximum value of about 3×105 particles/cm3 and decreased about 100 minutes after printing was completed. The average geometric diameter of the particles was 34.7 ± 1.4 nm. In turn, Stabile and colleagues 151 noted an increase in concentration during printing to a maximum value reached approximately at the end of the printing process (about 1.10 × 105 particles/cm3) and a decrease in concentration at the end of printing, which was the source of the particles.

The size and dynamics of particle emissions varied greatly depending on the printer, material, shape of the printed item, nozzle, and temperature. The results demonstrated a significant difference in particle emissions between filaments. Kim and col. 140 showed that ABS and PLA filaments emit particles in the size range 10–420 nm, with most particles being less than 100 nm and ABS printing leads to 33–38 times more particles than PLA printing. The higher emission for ABS (> 106 particles/cm3) compared to PLA was also observed in the studies of Sigloch et al 152 and Byrley et al 148 Manoi et al 153 explained this fact by the high melting temperature of ABS. In the study by Mendes et al2, the emission of nanoparticles remained insignificant during the first minute of the printing process, that is, during the mechanical movement of the component and the heating. The emission started when the extruder reached its working temperature (eg, >200°C). Characteristic is a sudden increase in particle concentration at the beginning of printing, followed by a slight decrease until it stabilizes during the printing period. Jeon with col. 154 conducted an assessment of the temperature impact on the intensity of particulate emissions during FDM® printing using different types of filaments. They found that particle emissions increased as the temperature increased from 185 to 290°C. For all the filaments, the emission rate (ER) at the highest temperature was recorded 100–10,000 times higher than the emission rate at the lowest temperature. Stabile and col. 151 estimated the particle emission was affected strongly by the extrusion temperature. In fact, the ERs increase as the extrusion temperature increases.