Abstract

Three-dimensional food printing offers the possibility of modifying the structural design, nutrition, and texture of food, which may be used for consumers with special dietary requirements such as dysphagic patients. One of the food matrices that can be used for liquid delivery to dysphagic patients is food foams. Foams are widely used in different food products to adjust food density, rheological properties, and texture. Foams allow the food to stay in the mouth for sufficient time to provide hydration while minimizing the danger of choking. Our work studies the foam properties and printability of both egg white foams and eggless foams with a strong focus on their foaming properties, rheological properties, printability, and suitability for dysphagic patients. Food hydrocolloid, xanthan gum (XG), is added to improve foam stability and rheological properties so that the inks are printable. Rheological and syneresis properties of the pre-printed foam inks are examined. The texture profile and microstructure properties are studied post-printing. International dysphagia diet standardization initiative tests are carried out to assess the inks’ potential for dysphagic diets. Inks with XG performed better with minimal water seepage, better foam stability, and excellent printability. This suggests that hydrocolloids lead to more stable food foams that are suitable for 3DFP and safe for hydration delivery to dysphagic patients.

Keywords: Additive manufacturing, 3D food printing, Dysphagia, Hydrocolloids, Food foams’, Food inks

1. Introduction

With the introduction of Industry 4.0, additive manufacturing has been growing in focus as it opens up many possibilities for smart production. It has progressed from a mere prototyping tool to a practical manufacturing solution[1,2]. The improvements in design, materials, hardware, and controller software of additive manufacturing printers have resulted in time- and cost-efficient parts, opening up additive manufacturing to various applications for mass customization.

With the advances of three-dimensional (3D) printing technology, many different industries are increasingly utilizing 3D printing for manufacturing, such as aerospace[3], construction[4], dentistry[5], and regenerative medicine[6,7]. In the recent decade, there has been a rising interest in 3D food printing (3DFP)[8,9]. 3DFP provides benefits that include structural design of the food[10], customized nutrition[11], modified food texture[12], and reduced need for skilled cook[13]. For example, it can be used for designing diets for individuals with special nutritional requirements such as dysphagic patients[14] or athletes[15]. 3DFP may also target prosumers such as high-end restaurants in producing aesthetically beautiful meals and products[16].

Foams are a type of food that consists of a liquid or continuous phase in which air bubbles are dispersed[17]. They are widely applied to food products such as ice creams, mousse, and baked goods[18,19]. The primary purposes for foam products are food density and caloric density reduction, modification of texture, and improved rheological properties[20]. Foams are also used to enhance sensory features, such as enhanced texture and flavors of food. More importantly, food foams are used to deliver liquid in a more easy-to-swallow form, especially for dysphagic patients[21]. For example, the aeration of water or milk into foams changes their texture and improves nutrients delivery to dysphagic patients. These foods could stay in the mouth for a certain duration, thereby providing prolonged hydration for dysphagic patients[22].

The main characteristics of food foams are foaming ability, foam stability, and water leakage[23]. The foaming ability dictates how much the volume increases after foaming, and the foam stability measures how long the foam maintains its shape without disintegrating. The water leakage (syneresis) determines the ability of the foam to hold its shape. This provides an early indication if the printed part is able to sustain its shape. The criteria for the ideal ink for food foam should be decently high foaming ability, high foam stability of more than an hour (sufficient time for printing), and low/no syneresis. Foaming ability indicates whether the food matrix is suitable for the creation of food foam. One of the most widely studied food foams is egg white (EW) food foam. It is the most commercially used foaming ingredient due to its high foaming ability and its ability to create an irreversible semi-stable foam[24]. Most of the foam-based food, such as meringues, pavlova, macarons, and mousse, are made from EW food foams[25,26]. 3D printing of EW foam was demonstrated by Kouzani et al., achieved through printing a pavlova using an EW foam-based batter[27]. However, the foam stability and rheological properties, which were key properties to the printability of foams, were not characterized and controlled. Food foams have yet to be studied in depth for 3DFP. Without the characterization of foam properties and rheological properties, it is unclear if these foams are suitable for patients with dysphagia. Therefore, there is a need to study the foam inks for 3DFP.

Foam stability is a unique aspect of food foam that is different from other types of food matrices and strongly influences printability. Unlike other food matrices, the thermodynamic instability causes the disintegration of foams, and it is vital to ensure that the foam remains stable while undergoing printing. Therefore, it is crucial to increase the foam stability for 3DFP purposes with additives such as hydrocolloids[28,29] while ensuring that the texture meets the standard of the dysphagic diet set by the international dysphagia diet standardization initiative (IDDSI) framework. In addition, food foams generally have a lower viscosity, making them harder to print than other food matrices.

In this study, we used EW and alternative food ingredients, Methocel F50 and Foam Magic, which are commercial products available to create food foams. The hydrocolloid included in this study is xanthan gum (XG). XG is a thickener that is commonly used in food products, such as mayonnaise and ice cream[30]. XG provides high viscosity even at low concentrations[31]. Its highly shear-thinning properties[32] make it an ideal choice as a thickener to improve the printability of low-viscosity food foams and enhance the stability of foams[33]. XG was added to the foaming agent to formulate printable food foam inks. The foam properties, such as foaming ability, foam stability, foam density, and syneresis, were studied to provide an in-depth understanding of how the foam properties affect the printability of the respective foam inks. The rheological properties, printability, microstructures, and texture profiles of the food foams were characterized extensively in this study. IDDSI[34] tests were also conducted to examine the suitability of the foam inks for hydration to dysphagic patients.

2. Materials and method

2.1. Formulation of foam inks

The materials used were commercially available pasteurized eggs from a local supermarket (N & N Egg Story, Singapore), Foam Magic from Modernist Pantry (SKU:1214-25), Methocel F50 from Modernist Pantry (SKU:1056-50), XG from Diabetic Food Delivery Singapore - Better4U.sg and Honeydew Extract Powder from RunDeKang BioTechnologies.

For the egg-based foams, the EW were separated from the egg yolks and weighed. They were then beaten using an electronic whip (Kenwood, 800W) for 5 min to foam. 12.5 wt% of honeydew extract powder was then added, and the mixture was whipped for another minute.

For eggless foams, 2 wt% of Foam Magic and/or 2 wt% Methocel F50 were added to water, and the mixture was beaten using an electronic whip for 5 min. Foam Magic is a proprietary formulation of maltodextrin, methylcellulose, and XG designed to create foams when whipped with either a hand blender or iSi whipper. Methocel F50 is a food-grade hydroxyl propyl methylcellulose (HPMC).

The pH of EW is approximately 9.2 in the normal state. The EW used in Inks 1 and 2 were not treated; therefore, Ink 1 has a pH close to pure EW’s (Table 1). The presence of XG brought down the pH of Ink 2. The pH of XG in an aqueous solution is 7 which brought down the overall pH of the solution. Tap water was used to produce Inks 3 – 5. The pH of tap water was tested to be approximately 8.40. Therefore, the pH of Inks 3 – 5 is approximately similar to that of tap water.

Table 1.

Formulation for each foam ink

| Sample | Ingredients | pH |

|---|---|---|

| Ink 1 | • Egg white 87.5 wt% • Honeydew extract 12.5 wt% |

9.19 |

| Ink 2 | • Egg white 85.5 wt% • Honeydew extract 12.5 wt% • Xanthan gum 2 wt% |

8.91 |

| Ink 3 | • Methocel F50 2 wt% • Water • Honeydew extract 12.5 wt% |

8.33 |

| Ink 4 | • Foam Magic 2 wt% • Water • Honeydew extract 12.5 wt% |

8.16 |

| Ink 5 | • Methocel F50 2 wt% • Foam Magic 2 wt% • Water • Honeydew extract 12.5 wt% |

8.20 |

2.2. Foaming characteristics

(1) Foaming ability

The foams were prepared at room temperature by whipping 50 mL of respective suspensions in a 500-mL beaker using a multi-quick hand blender (Kenwood, 800W) at a constant turbo speed for 5 min. The foaming ability, which is also known as the overrun, is the percentage of volume increase after the whipping process. Three replicates were used for each type of foam, and the averages from the results were reported.

(2) Foam stability

Foam stability was characterized by the half-life of the foam, which was measured as the time required to lose 50% of the volume of the foam. Three replicates of 30 mL of foams were placed in a 50-mL Falcon tube. The volume of the foam was recorded over time to determine the time required for the volume of the foam to reduce to half. Only the volume of the foam, not including the volume of the liquid formed as foams burst, was measured in this study.

(3) Foam density

The foams were prepared as mentioned in part (1) of section 2.2. Then, 50 mL of each foam ink was placed in a 50-mL Falcon tube and weighed using an electronic balance. Each ink was measured in three replicates. The average density was calculated by dividing the average mass from the volume of 50 mL.

(4) Syneresis of foam inks

Syneresis was analyzed by placing 0.2 g of the foam ink at the center of a piece of Whatman Grade 4 filter paper. The foams were spread evenly to cover a circle of 1 cm in radius. The filter paper was left to stand for 30 min to allow the liquid to spread before the filter paper was photographed. The area covered by the fluid was measured using a Python program that detects the edge of the foam inks and the edge of the spread fluid. An 1 × 1 cm2 red square was included in the photograph as a reference for image analysis. Each sample was carried out in replicates of three.

2.4. Rheological characterization of the foams

The rheological properties of the foam inks were tested using an oscillatory rheometer (Discovery Hybrid Rheometer DHR-3, TA Instruments, Delaware, USA). The measurements were conducted using stainless steel parallel plates with a diameter of 40 mm and a truncation gap of 500 μm. Viscosity shear-thinning tests were performed on the foam inks by applying a stepwise shear ramp rate from 0.001 s−1 to 100 s−1. Stress sweep measurements were carried out with a logarithmically increasing shear stress at a constant frequency of 1 Hz from 0.1 to 2000 Pa to study the viscoelastic properties of the inks. A recovery test was done to mimic the three phases the ink experienced – before extrusion, during extrusion, and after extrusion from the nozzle. A multiple stepped flow ramp (peak hold) test was conducted wherein the initial shear rate of 0.1 s−1 – 0.2 s−1 was applied for 20 s, followed by a rapid increase in shear rate from 0.2 s−1 to 200.0 s−1 in 1 s. The shear rate was held at 200.0 s−1 for 5 s before reducing the shear rate from 200.0 s−1 to 0.1 s−1 in 1 s and held for 20 s.

2.5. 3D printing of foams

Wiiboox Sweetin 3D Food Printer (Wiiboox, China), an extrusion-based 3D food printer, was used to print the 3D samples of different foam inks. The nozzle size used for these experiments was 1.5 mm. The foams were printed into a six-pointed star with a length and width of 3 cm and a height of 0.5 cm to assess its printability. The star was used to assess if the ink was able to handle sharp curves. Three replicates were printed with each foam ink. Photographs of the printed samples were taken after the printing and assessed visually. The first three prints of the inks were rated visually from 1 (poorest) to 5 (best) on two categories, self-supporting structure and shape, with a maximum total score of 10. The smallest observation for each category was given a score of 1.

The foams were printed at a print speed of 25 mm/s with an initial layer thickness of 0.8 mm and subsequent layer thickness of 1 mm. The fill density was set to 80% with a flow of 80%.

2.6. Scanning electron microscopy (SEM)

The micromorphological structure of the printed parts was observed by using SEM. All samples were gold-coated with 10 mA current using JEOL JFC-1600 Auto Fine Coater machine. The images were viewed and taken under 10 – 13 kV condition under a JEOL JSM-5600LV SEM.

2.7. Texture profile analysis

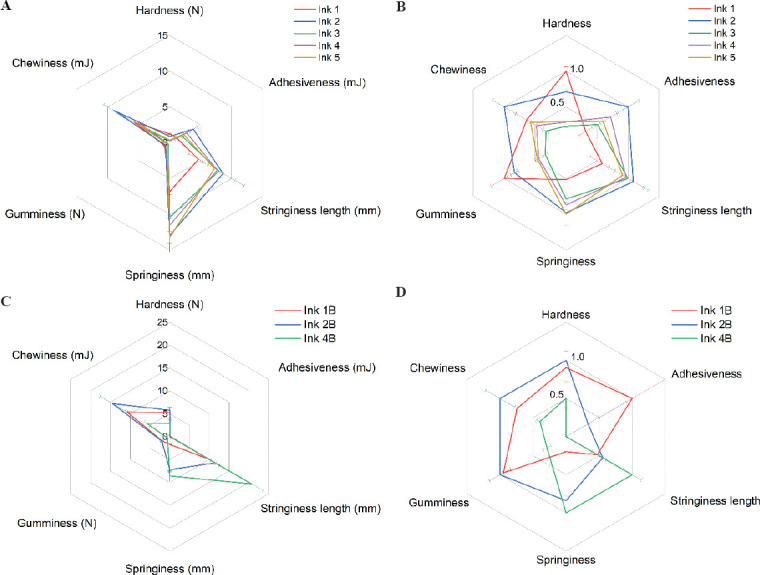

Texture Pro CT V1.3 Build 15 (Brookfield Engineering Labs, Inc) was used for double-cycle compression tests to obtain force-time curves. The foams were prepared and filled into a 20-mm deep tray of aluminum foil for testing. Both as-printed and baked foam inks were tested. The baked foam samples were printed and baked at 70°C for 2 h before being tested at the height of 20 mm. The test parameters were as follows: Block probe with a trigger load of 5 g, pre-test, test and return speed at 2.0 mm/s, and the compressive strain was set to 45% for two cycles. Each ink was tested in triplicates. Hardness, chewiness, adhesiveness, gumminess, stringiness, and springiness were measured. The averages of the three replicates were represented in a radar graph. They were also normalized to the highest value obtained among the food inks and represented in another radar graph for ease of comparison.

2.8. Data analysis

Data were plotted by using the OriginLab software. The results were analyzed using unpaired student’s t-test with n = 3. The significance of the results is denoted on top of the columns where * represents P ≤ 0.1, **P ≤ 0.01, ***P ≤ 0.001, and ****P ≤ 0.0001. The results were compared within the groups of EW and non-EW inks on whether XG affects the properties of food foams. The first group (EW-based) was compared between Inks 1 and 2, and the second group (HPMC-based) was compared between Ink 3 and Inks 4,5.

3. Results and discussion

3.1. Foam properties

(1) Foaming ability of the inks

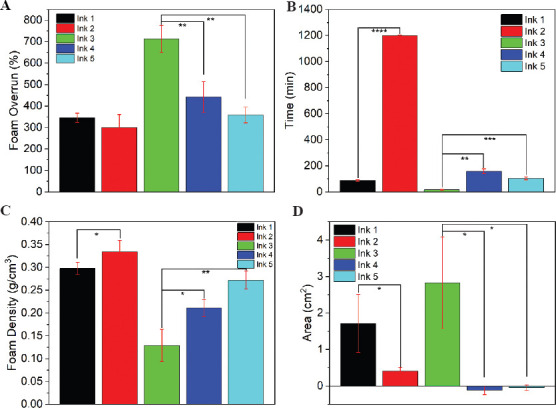

Both EW[23] and HPMC[35] are known to have excellent foaming abilities. The overrun quantitatively measures the foaming ability of each foam ink. Figure 1A shows that all the food ink formulations can foam more than 300% of their original volume.

Figure 1.

Foam properties (A). The foaming ability of each foam ink based on their overrun. (B) The foam stability of each foam ink. (C) The density of each foam ink. (D) The syneresis results of each ink. *P ≤ 0.1, **P ≤ 0.01, ***P ≤ 0.001, ****P ≤ 0.0001 for the t-test results (n=3).

Ink 1 is based on EW, and Ink 3 is based on methylcellulose without the addition of hydrocolloids. They were able to foam more than their counterparts with added XG. The inclusion of XG makes the foam denser and more sticky, thus less able to hold more air bubbles. The reduced foaming ability may be attributed to the increase in density, as seen from the difference between Inks 3 and 4. While Ink 5 contains Methocel F50, a component present in Ink 3 which is able to foam to a massive extent of over 700% of its original volume, it has an overrun that is even lower than Ink 4. While inks with XG have reduced overrun, the overall increase in Methocel F50 and Foam Magic mass, contributing to the increase in density that made it difficult to hold the air bubbles without bursting too. The EW foam ink generally has a lower overrun compared to the eggless foams.

(2) Foam stability of the inks

The foam inks’ stability is a critical factor as the food inks have to retain the foams after being printed. The viscosity of the continuous fluid phase is one of the main factors affecting foam stability[36]. The higher viscosity of the continuous fluid phase delays the movement of the liquid through the network of films that enclose the air bubble, hence slowing the formation of larger bubbles and the liquid drainage.

As shown in Figure 1B, the foam inks without XG have much poorer foam stability. The significant difference in the half-life of foams shows that XG plays an important role in foam stability for both groups (EW and HPMC). Ink 3 with only HPMC is unable to retain the foam for more than 15 min. The poor foam stability is due to the lack of foam stabilizer in the mixture. HPMC generally stabilizes the hydration layer when it is heated and sets into a gel at a specific temperature. However, this ink was prepared at room temperature. Therefore, while it was able to foam, it was unable to retain the foam and stabilize the foam at room temperature. As for the EW-based Ink 1, it has the foam stability of over 80 min. While its stability is not as high as inks that contain XG, it is stable enough to be printed within a certain duration immediately after preparation. EW contains globulins that facilitate foam formation, and also contains ovomucin that stabilizes the foam[37]. During the whipping, the EW proteins adsorb at the interface of air bubbles and the liquid through the hydrophobic areas. The partially unfolded proteins (denatured through whipping) stabilize the protein films formed. The foam collapses when large gas bubbles grow at the expense of tiny bubbles. These films counteract the growth of the large bubbles, thus stabilizing the foam. However, the EW foams, without additives, tend to destabilize too[28].

Inks with the inclusion of XG have a significant improvement in foam stability of more than 1000% in terms of half-life. With the use of Foam Magic which has a proprietary mix of HPMC and XG, Inks 4 and 5 have a foam stability of 158 min and 104 min, respectively. An inclusion of 2 wt% of XG in the EW-based foam allows Ink 2 to have long half-life of 1200 min. XG is widely used as a food thickener. It thickens the inks and retains the liquid phase in foam structures against gravitational force[29]. The fixation of the liquid phase due to the presence of XG makes it harder for small bubbles to grow into larger bubbles, which stabilize the foams. However, the increase in density also makes it harder for the foams to form, resulting in a lower overrun.

(3) Foam density

The EW foams (Inks 1 and 2) are generally denser than the HPMC foams. The HPMC forms a light foam as a result of the large overrun. The XG increases the density as shown in Figure 1C, where there is a slight increase in density from Ink 1 to Ink 2 and from Ink 3 to Ink 4. The density affects the foaming ability inversely; as discussed previously, the overrun is lower when the density is higher. Ink 5 has a higher density than Ink 3 and 4 as it contains more HPMC, thus making it more difficult to be aerated and leading to a denser foam.

(4) Water retention

Syneresis refers to the undesired leakage of water from food. This study investigates the ability of the foam ink to retain water. In the case of foams, the spreading of water affects the integrity of the printed structures, causing the print to spread and collapse due to instability. In this study, the amount of water leakage from the foam inks was obtained by measuring the area wetted on a piece of filter paper.

Inks that do not have XG (Inks 1 and 3) had a large amount of spreading compared to the inks containing XG (Figure 1D), and the difference was statistically significant. The spreading was caused by both foam instability and lack of ability to retain water. XG thickened the foams by increasing the viscosity of the liquid phase and forming a hydrogel phase[31]. This prevented water from spreading on the filter paper, greatly reducing water spreading of Inks 2, 4, and 5. Without XG, while Ink 1 had the protein films to hold the air bubbles and water migrated to the filter paper due to strong capillary force. Likewise, for Ink 3, water between the air bubbles migrated from the food ink to the filter paper. Over time, the area of wetting increased when the foam collapsed. For Inks 4 and 5, XG prevented the water from leaking onto the filter paper. Over time, water evaporated, thus resulting in a slight shrinkage of the area of the foam.

3.3. Rheological properties of the inks

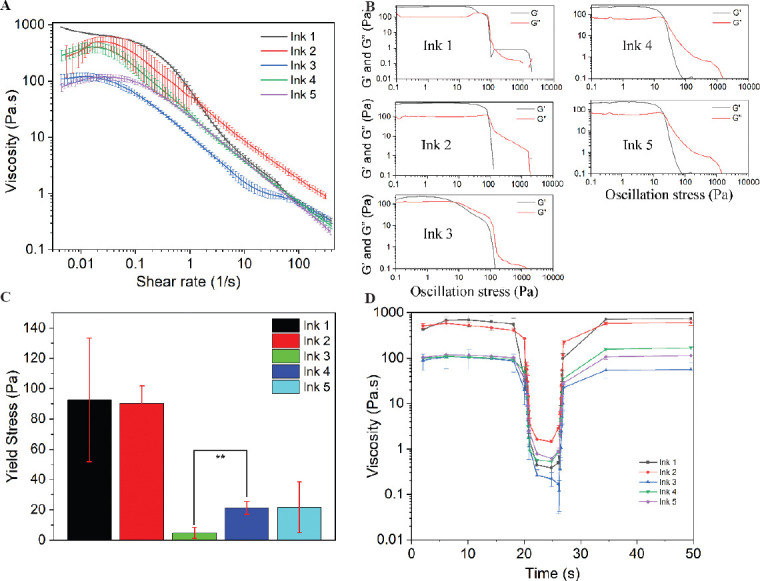

All the five inks displayed a shear-thinning or pseudoplastic property (Figure 2A). Shear-thinning properties were preferred for extrusion printing as they suggested that the food ink could be easily extruded and held its shape after extrusion. The printability and self-supporting structure depended on the viscosity and yield stress, respectively[33]. The low viscosity of the inks allowed them to be printed easily through extrusion. When the shear rate increased, the viscosity of the ink decreased, allowing the ink to flow out smoothly. The EW inks (Inks 1 and 2) had a higher viscosity than the HPMC inks (Inks 3 – 5), which accounted for the slightly better foam stability explained in part (2) of Section 3.1. As XG allowed the liquid phase to form a hydrogel-like phase with increased viscosity, Ink 3 had the lowest viscosity compared to the ones with XG. While XG generally increases the viscosity of the foam inks, similar to the comparison between XG containing HPMC inks (Inks 4 and 5) and non-XG containing HPMC ink (Ink 3) the viscosity of Ink 2 was lower than that of Ink 1.

Figure 2.

Rheological properties of the foam inks. (A) Flow ramp study of each foam ink. (B) Stress sweep of each ink in triplicates. (C) Yield stress of each foam ink. (D) Peak hold study of each ink simulating before, during, and after extrusion printing. *P ≤ 0.1, **P ≤ 0.01, ***P ≤ 0.001, ****P ≤ 0.0001 for the t-test results (n = 3).

All foams displayed characteristics of linear viscoelasticity at low oscillation frequencies, where storage modulus (G’) was higher than loss modulus (G”) (Figure 2B). Having a G’ that was higher than the G” in the linear viscoelastic range also suggests that the ink has the potential to form gel-like self-supporting structure after it was printed[33]. In the non-linear range, the G’ fell below G”, indicating a more liquid-like behavior. The foams tend to flow like liquids, and are easier to extrude.

The average yield stresses of the inks are displayed in Figure 2C. Yield stress determined the ability to form a self-supporting structure[33]. Higher yield stress allowed better self-supporting ability. The EW inks (Inks 1 and 2) have higher yield stresses than the HPMC inks (Inks 3-5). This suggests that they can undergo higher stress before plastic deformation. This allowed Inks 1 and 2 to form better self-supporting structures and higher leniency under the pressure used for the extrusion of the inks during printing. Ink 3 exhibited low yield stress <10 Pa. This suggests that the foam from Ink 3 might not survive the pressure from extrusion printing. Ink 4 has significantly higher yield stress than Ink 3 (P < 0.01). XG does not significantly change the yield stress of egg-based foam inks but shows a significant effect in eggless foams. Inks 1 and 5 have significant errors due to the poorer foam stability, which caused some foam to collapse in later tests, changing the rheological properties slightly.

Figure 2D shows the peak hold study of the inks. Under low a shear rate from 0.1 to 1 s−1, all the inks gradually reduced their viscosities, which is in line with the flow ramp study that depicts the inks as shear thinning. When the inks experienced a spike in shear rate, the viscosity dropped drastically. This suggests that the viscosities of the foam inks reduced during printing, and inks flowed effortlessly out of the nozzle, allowing smooth printing. Once the shear stress was removed, simulating the shear rate after printing, the viscosities of the inks recovered quickly. This implies that the inks were able to return to their original rheological properties after printing and held their structures.

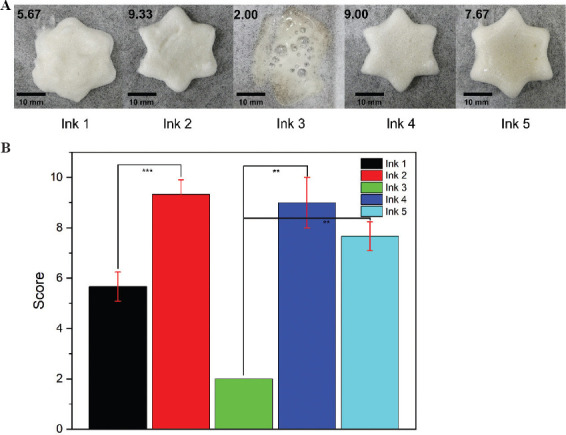

3.4. Printability of the inks

The printability is dependent on the rheology and the stability of the inks. Out of all the inks, Ink 3 was not printable at all as shown in Figure 3 where the printed ink was a pool of liquid and it has an average printability score of 2. The foam stability, as described earlier, was very low for Ink 3 as it collapsed too quickly. While in the foam stability test, the half-life of Ink 3 was 15 min under atmospheric pressure, the stability within the syringe and during printing was lower due to significantly higher pressure. Therefore, Ink 3 was extruded as a liquid instead of foams. This was also seen in Ink 1 (Figure S1 (283.2KB, pdf) ). While it was printable in the first print and was able to form self-support structures, the foam bubbles grew in size in the cartridge and became unstable in the subsequent second and third print. Even though the viscosity of Ink 1 was the highest amongst all the inks, but its stability was not high enough. This was also observed in Ink 5. While the first print was good, it was less able to self-support and spread more in the later prints. The best prints were from Inks 2 and 4 with scores of approximately 9, where they consistently presented good self-supporting structures in three consecutive prints.

Figure 3.

(A) Six-pointed star (first) prints with Inks 1 – 5 with the average score in each frame. (B) The printability scores for each ink. *P ≤ 0.1, **P ≤ 0.01, ***P ≤ 0.001, ****P ≤ 0.0001 for the t-test results (n = 3).

Supplementary Figure 1 shows that some inks are printable, they do not maintain the same performance throughout the different prints. As seen in Ink 1, the bubbles of the ink grew and reduced the printability of the ink. This shows that the printability of a cartridge of Ink 1 decreases over time. This is also visible in Ink 5 where the prints are not consistent. The third print was less able to retain a self-supporting shape.

The effect of XG on the printability of the inks within the EW and HPMC groups was compared. The first three prints of the inks were rated visually from 1 (poorest) to 5 (best) on two categories, self-supporting structure and shape fidelity. The printability of inks with XG shows significant improvement regardless of the base ingredients. XG is an important factor to achieve a good printable structure for the foam inks.

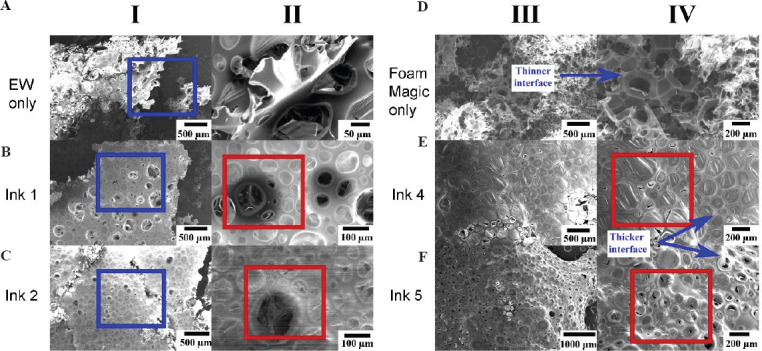

3.5. Microstructure of the baked inks

The scanning electron micrographs in Figure 4 show the microstructure of the EW foams and the HPMC foams. Only the printable inks (i.e. Inks 1, 2, 4, and 5) were assessed. The pure EW or Foam Magic only foam samples were included for comparison.

Figure 4.

Microstructure of foam inks after baking for 1 h at 70°C. (A) Control 1: Egg white only foam. (B) Ink 1. (C) Ink 2. (D) Control 2: Foam Magic only foam. (E) Ink 4. (F) Ink 5.

Comparing the foam formed by EW and by Foam Magic only (Figure 4A & D), the EW foam had a microstructure with thicker films between each bubble. It also explains why the EW inks were denser than the HPMC inks.

Comparing the EW only foam to Inks 1 and 2, the baked EW foam was flakier and had more disconnected sections as shown in the blue boxes in column I for A, B, and C. The honeydew extract, which contained a large portion of small polysaccharide[38], seemed to increase the adhesiveness of the liquid phase of the foams. Even after the foams were baked, most bubbles retained their shapes for Inks 1 and 2. In Inks 1 and 2, thin films covered most of the bubbles. More bubbles were intact in Ink 2 than Ink 1 (red boxes of B and C in column II); suggesting that the XG kept the foams from collapsing, especially at elevated temperature during baking, and the gas bubbles tend to grow larger. Furthermore, in Ink 2, the films over the bubbles were more wrinkled, suggesting that the liquid phase with XG was stretched when hydrated to prevent the bubbles from bursting and the foam from collapsing.

Comparing Control 2 to Inks 4 and 5, the pores in Control 2 were larger and exhibited a thinner layered interface between pores pointed out in blue arrows in column IV. Most of the bubbles in Control 2 were torn or burst after being dehydrated by baking. The honeydew extract increased the adhesion between each bubble and thickened the interfaces. In Ink 4, the film over the larger bubbles was intact, whereas the film over smaller bubbles was torn slightly as seen in column IV (Figure 4E). In comparison, Ink 5 had more burst or torn bubbles than Ink 4. Ink 5 also showed more small- and medium-sized bubbles than Ink 4 as shown in the red box in column IV. This could be attributed to the higher density of Ink 5, which made it harder for foam formation and reduced its ability to trap air.

3.6. Texture profile of foam inks

From Figure 5A, all the inks have relatively low hardness and gumminess ranging from 0 to 2 N. The adhesiveness of all inks is below 5 mJ. Adhesiveness helps increase the ability of the foam to self-support. A good combination of slightly higher hardness and good adhesiveness of Ink 2 as well as Inks 4 and 5 resulted in better printability than inks without XG, such as Inks 1 and 3. While Ink 1 had a higher hardness, it had poor adhesiveness. Hence, while it could be extruded, it was unable to maintain a good shape, resulting in poor printability. Ink 5 had a lower adhesiveness than Inks 2 and 4 but higher than Ink 1. This explains the better printability of Ink 5 than Ink 1 as it can retain shape better than Ink 1.

Figure 5.

Texture profile of the foam inks in (A) absolute values, (B) normalized values and its baked samples (B represents baked), (C) absolute values, and (D) normalized values.

While Inks 1, 2, 4, and 5 were all printable and retained their shapes after baking, Ink 5 could not maintain the height of 20 mm after baking and collapsed. Hence, it was not included in the texture profile analysis in the baked form (B is added to the ink names to differentiate baked samples). After baking, all the printed inks became meringue-like after dehydration by baking. This increased the hardness as reflected in Figure 5C. The chewiness of the printed inks increased too. However, the springiness and adhesiveness reduced. The other parameters remained similar. The lack of water made the inks less sticky and leads to a fall in adhesiveness and springiness. In absolute values, Ink 2B and Ink 4B had similar performance to Ink 1B. This suggests that the XG added to EW foam increases printing performance. Furthermore, the use of HPMC inks as a replacement for EW foams does not significantly affect the textural performance due to the similar texture profiles.

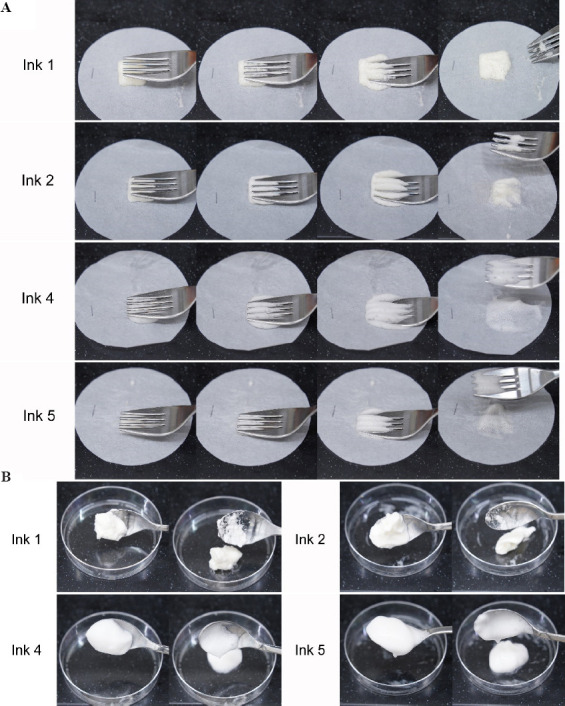

Considering that foams are to be consumed by dysphagic patients as a safe way of hydration, IDDSI tests, including the fork pressure test (Figure 6A) and the spoon tilt test (Figure 6B), was carried out. These two tests were recommended test in the IDDSI framework for food of level 4-5 (pureed, minced, and moist). The results are shown in Figure 6. The fork pressure tests food hardness. Inks 2, 4, and 5 show a clear indent pattern, suggesting that they are soft enough to be consumed by dysphagic patients. For the spoon tilt test, the spoon was tilted and flicked once to check if the inks slid off the spoon. It is used to determine the adhesiveness and cohesiveness. According to the framework, the food is considered safe for consumption by dysphagic patients as long as the spoon is visible after flicking, even though a thin food film may remain on the spoon[34]. Most inks allow a large portion of the inks to slide off the spoon, except Ink 5, suggesting that most inks would not stick to the oral cavity. Out of all the inks, Ink 2 had the best performance.

Figure 6.

IDDSI tests. (A) Fork pressure test on a 20 × 20 × 10 mm3 sized 3D-printed samples of the foam inks. (B) Spoon tilt test on the foam inks.

3.7. Demonstration of 3D-printed food foam

Out of the three inks tested for textural properties, Inks 2 and 4 had better printability. Both inks were used to print various 3D structures. The structures were created without overhang or with only small overhang due to the lack of support. The four structures printed were an octopus, lobster, turtle, and hammerhead shark, as shown in Figure 7.

Figure 7.

Demonstration of 3D food foam printing. (A) Top profile of the 3D printed structures of an octopus, lobster, turtle and hammerhead shark (from left to right) using Ink 2. (B) Top profile of the 3D printed structures of an octopus, lobster, turtle, and hammerhead shark (from left to right) using Ink 4.

The lighter Ink 4 provided better and smoother prints than Ink 2, (Figures 7A and B), with the octopus head bearing clunks and a smooth spherical shape as shown in Figure 7A and B. However, these 3D structures were larger than the prints used in the printability test. The lower foam stability is visible in the one printed by Ink 4. The surface of the prints was getting moist and shrank over time. The lobster and octopus were printed first. Hence, the surfaces were getting watery and causing them to lose their structure ahead of all the other prints. This suggests that the printed parts of Ink 4 had an even lower storage time than the foam stability test’s time, as the printing process reduces the stability due to higher pressure. It should be served or baked once printed. Ink 2 was able to produce stable structures with a half-life foam stability of 30.6 h at room temperature. When refrigerated, it was possible to be stored longer. Ink 2 also performed better in the spoon tilt test. These properties suggest that Ink 2 is ideal as food foam for hydration delivery.

Most meringues are produced with EW and sugar. The presence of honeydew powder was to enhance the taste and flavor of the foams. Similar fruit extract powders such as strawberry and papaya could be used to achieve similar results. Fruits provide a sweet taste that replaces sugar as a flavor enhancer[39]. These foams can function as a flavor and sensory booster in addition to mere water delivery systems to dysphagic patients.

4. Conclusions

The structures in Figure 7 show that 3D printing can provide more creative and esthetically pleasing, and complex structures of food foams by computer-aided design (CAD) designs and a 3D food printer. Silicone molds cannot accomplish the shaping of foams because it is almost impossible to de-mold the foam. 3DFP with foam allows artists to freely express their ideas and designs using food, enhancing visual appeal of the food, hence, elevating palatability. Moreover, 3DFP provides a simple way of modifying the food texture, giving chefs more freedom to work with the different food and cooking methods. However, food foams are volatile and delicate to work with due to the instability of foams. In this study, the foam properties of the foam inks (with and without XG) proposed were investigated. The inclusion of XG in this study stabilized food foams for high printability. XG provided additional foam stability, which aided in producing better prints and permitted longer storage of the printed food, as displayed by Inks 2 and 4. The texture properties were also studied to understand the difference between the EW foam and HPMC foam and their XG counterparts. The improvements to the EW ink provide an alternative approach to creating artisan meringues. In this case of 3DFP, the sugar is replaced with fruit extract to provide a fruity and sweet taste. Several 3D shapes were printed with the optimal Inks 2 and 4 to demonstrate the 3D printing of food foams. This form of 3DFP may also be used as a flavor and visual enhancer as foams are widely used for dish plating. Vegans do not consume egg-based products, so the eggless Ink 4 may be an alternative to EW in creating 3D-shaped meringues and icing. The excellent performance of Inks 1, 2, and 4 in the IDDSI tests shows that these food foams (without baking) are well suited for medical applications such as hydration for dysphagic patients as EW consists of mainly 90% of water[40] and the formulation in Ink 4 has approximately 87% of water. This study has shown the possibility of 3DFP of stable food foams and their applications for hydration delivery for dysphagic patients. In the future, robotic arm-based printers may be used over cartesian printers as they allow both printings of the foam and assembling the foams in 3D, using a similar concept by Awa Taccino machine from Takara Tomy[41].

Funding

Authors would like to thank National Additive Manufacturing Innovation Cluster (Project ID 2019048) and Singapore University of Technology and Design (SUTD) Growth Plan, Healthcare Sector Thrust 3-3 3DFP (SGPHCRS1907) for the funding support. This work is also supported by Singapore Centre for 3D Printing, which is funded by the Singapore National Research Foundation under its Medium-Sized Centre funding scheme

Conflicts of interest

The authors declare no known conflict of interest.

Author contributions

A.Y.L., A.P., and Y.Z. conceptualized the idea. Y.Z. and C.K.C. supervised the project. A.Y.L., Y.Z., and A.P. planned the experiments. A.Y.L., K.P., and C.P.L. carried out the experiments. A.Y.L. wrote the manuscript. J.A., M.H., U.X.T, C.H.L., C.P.L., C.K.C., G.W., and Y.Z. discussed the results, and reviewed and edited the manuscript. All authors contributed to the final manuscript.

References

- 1.Haleem A, Javaid M. Additive Manufacturing Applications in Industry 4.0:A Review. J Ind Inf Integr. 2019;4:1930001. [Google Scholar]

- 2.Chua CK, Fai K. Rapid Prototyping:Principles and Applications. 5th ed. Singapore: World Scientific Publishing Co Inc; 2017. 3D printing and Additive Manufacturing:Principles and Application. [Google Scholar]

- 3.Najmon J, Raeisi S, Tovar A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. Amsterdam, Netherlands: Elsevier; 2019. https://doi.org/10.1016/b978-0-12-814062-8.00002-9. [Google Scholar]

- 4.Ahmed ZY, Bos FP, van Brunschot MC, et al. On-demand Additive Manufacturing of Functionally Graded Concrete. Virtual Phys Prototyp. 2020;15:194–210. https://doi.org/10.1080/17452759.2019.1709009. [Google Scholar]

- 5.Khorsandi D, Fahimipour A, Abasian P, et al. 3D and 4D Printing in Dentistry and Maxillofacial Surgery:Printing Techniques, Materials, and Applications. Acta Biomaterialia. 2021;122:26–49. doi: 10.1016/j.actbio.2020.12.044. https://doi.org/10.1016/j.actbio.2020.12.044. [DOI] [PubMed] [Google Scholar]

- 6.Ng WL, Chua CK, Shen YF. Print Me An Organ!Why We Are Not There Yet. Progress in Polymer Science. 2019;97:101145. https://doi.org/10.1016/j.progpolymsci.2019.101145. [Google Scholar]

- 7.Ng WL, Chan A, Ong YS, et al. Deep Learning for Fabrication and Maturation of 3D Bioprinted Tissues and Organs. Virtual Phys Prototyp. 2020;15:340–58. [Google Scholar]

- 8.Chua CK. Publication Trends in 3D Bioprinting and 3D Food Printing. Int J Bioprint. 2020;6:257. doi: 10.18063/ijb.v6i1.257. https://doi.org/10.18063/ijb.v6i1.257. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Voon SL, An J, Wong G, et al. 3D Food Printing:A Categorised Review of Inks and their Development. Virtual Phys Prototyp. 2019;14:203–18. [Google Scholar]

- 10.Severini C, Azzollini D, Albenzio M, et al. On Printability, Quality and Nutritional Properties of 3D Printed Cereal Based Snacks Enriched with Edible Insects. Food Res Int. 2018;106:666–76. doi: 10.1016/j.foodres.2018.01.034. https://doi.org/10.1016/j.foodres.2018.01.034. [DOI] [PubMed] [Google Scholar]

- 11.Lee CP, Karyappa R, Hashimoto M. 3D Printing of Milk-based Product. RSC Adv. 2020;10:29821–8. doi: 10.1039/d0ra05035k. https://doi.org/10.1039/d0ra05035k. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Derossi A, Caporizzi R, Paolillo M, et al. Programmable Texture Properties of Cereal-based Snack Mediated by 3D Printing Technology. J Food Eng. 2021;289:110160. https://doi.org/10.1016/j.jfoodeng.2020.110160. [Google Scholar]

- 13.TomaševićI, Putnik P, Valjak F, et al. 3D Printing as Novel Tool for Fruit-Based Functional Food Production. Curr Opin Food Sci. 2021;41:138–45. https://doi.org/10.1016/j.cofs.2021.03.015. [Google Scholar]

- 14.Pant A, Lee AY, Karyappa R, et al. 3D Food Printing of Fresh Vegetables Using Food Hydrocolloids for Dysphagic Patients. Food Hydrocolloid. 2021;114:106546. https://doi.org/10.1016/j.foodhyd.2020.106546. [Google Scholar]

- 15.Godoi FC, Prakash S, Bhandari BR. 3d Printing Technologies Applied for Food Design:Status and Prospects. J Food Eng. 2016;179:44–54. https://doi.org/10.1016/j.jfoodeng.2016.01.025. [Google Scholar]

- 16.Baiano A. 3D Printed Foods:A Comprehensive Review on Technologies, Nutritional Value, Safety, Consumer Attitude, Regulatory Framework, and Economic and Sustainability Issues. Food Rev Int. 2020;2020:1–31. https://doi.org/10.1080/∳9129.2020.1762091. [Google Scholar]

- 17.Perez AA, Sánchez CC, Patino JM, et al. Foaming Characteristics of ?-Lactoglobulin as Affected by Enzymatic Hydrolysis and Polysaccharide Addition:Relationships with the Bulk and Interfacial Properties. J Food Eng. 2012;113:53–60. https://doi.org/10.1016/j.jfoodeng.2012.05.024. [Google Scholar]

- 18.Mardani M, Yeganehzad S, Ptichkina N, et al. Study on Foaming, Rheological and Thermal Properties of Gelatin-free Marshmallow. Food Hydrocolloid. 2019;93:335–41. https://doi.org/10.1016/j.foodhyd.2019.02.033. [Google Scholar]

- 19.Licciardello F, Frisullo P, Laverse J, et al. Effect of Sugar, Citric Acid and Egg white Type on the Microstructural and Mechanical Properties of Meringues. J Food Eng. 2012;108:453–62. https://doi.org/10.1016/j.jfoodeng.2011.08.021. [Google Scholar]

- 20.Żmudziński D, Ptaszek P, Kruk J, et al. The Role of Hydrocolloids in Mechanical Properties of Fresh Foams Based on Egg White Proteins. J Food Eng. 2014;121:128–34. doi: 10.1007/s11483-013-9320-5. https://doi.org/10.1016/j.jfoodeng.2013.08.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.de Villiers M, Hanson B, Moodley L, et al. The Impact of Modification Techniques on the Rheological Properties of Dysphagia Foods and Liquids. J. Texture Stud. 2020;51:154–68. doi: 10.1111/jtxs.12476. https://doi.org/10.1111/jtxs.12476. [DOI] [PubMed] [Google Scholar]

- 22.Belardi L. Bringing Dignity Back to Modified Meals. United States: Intermedia Group; 2014. [Google Scholar]

- 23.Alavi F, Emam-Djomeh Z, Mohammadian M, et al. Physico-chemical and Foaming Properties of Nanofibrillated Egg White Protein and its Functionality in Meringue Batter. Food Hydrocolloid. 2020;101:105554. https://doi.org/10.1016/j.foodhyd.2019.105554. [Google Scholar]

- 24.Gharbi N, Labbafi M. Influence of Treatment-induced Modification of Egg White Proteins on Foaming Properties. Food Hydrocolloid. 2019;90:72–81. https://doi.org/10.1016/j.foodhyd.2018.11.060. [Google Scholar]

- 25.Li X, Li J, Chang C, et al. Foaming Characterization of Fresh Egg White Proteins as a Function of Different Proportions of Egg Yolk Fractions. Food Hydrocolloid. 2019;90:118–25. https://doi.org/10.1016/j.foodhyd.2018.12.014. [Google Scholar]

- 26.Özer C, Ağan C. The Influence of Aging Egg on Foaming Properties of Different Meringue Types. J Culin Sci Technol. 2020;2020:1–10. https://doi.org/10.1080/15428052.2020.1790073. [Google Scholar]

- 27.Kouzani AZ, Adams S, Oliver R, et al. 3D Printing of a Pavlova. 2016 IEEE Region 10 Conference (TENCON) 2016:2281–5. https://doi.org/10.1109/tencon.2016.7848435. [Google Scholar]

- 28.Ptaszek P, Kabziński M, Ptaszek A, et al. The Analysis of the Influence of Xanthan Gum and Apple Pectins on Egg White Protein Foams Using the Large Amplitude Oscillatory Shear Method. Food Hydrocolloid. 2016;54:293–301. https://doi.org/10.1016/j.foodhyd.2015.10.010. [Google Scholar]

- 29.Dabestani M, Yeganehzad S. Effect of Persian Gum and Xanthan Gum on Foaming Properties and Stability of Pasteurized Fresh Egg White Foam. Food Hydrocolloid. 2019;87:550–60. https://doi.org/10.1016/j.foodhyd.2018.08.030. [Google Scholar]

- 30.Milani J, Maleki G. Hydrocolloids in Food Industry. IntechOpen: 2012. DOI: 10.5772/32358. Available from: https://www.intechopen.com/books/food-industrial-processes-methods-and-equipment/hydrocolloids-in-food-industry . [Google Scholar]

- 31.Sworn G. Xanthan Gum. In: Phillips GO, Williams PA, editors. Handbook of Hydrocolloids. 2nd ed. Sawston, United Kingdom: Woodhead Publishing; 2009. pp. 186–203. [Google Scholar]

- 32.Saha D, Bhattacharya S. Hydrocolloids as Thickening and Gelling Agents in Food:A Critical Review. J Food Sci Technol. 2010;47:587–97. doi: 10.1007/s13197-010-0162-6. https://doi.org/10.1007/s13197-010-0162-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Jiang H, Zheng L, Zou Y, et al. 3D Food Printing:Main Components Selection by Considering Rheological Properties. Crit Rev Food Sci. 2019;59:2335–47. doi: 10.1080/10408398.2018.1514363. https://doi.org/10.1080/10408398.2018.1514363. [DOI] [PubMed] [Google Scholar]

- 34.IDDSI Framework Testing Methods 2.0, (2021) [Last accessed on 2021 Mar 01]. Available from: https://www.iddsi.org .

- 35.Karlsson K, Schuster E, Stading M, et al. Foaming Behavior of Water-soluble Cellulose Derivatives:Hydroxypropyl Methylcellulose and Ethyl Hydroxyethyl Cellulose. Cellulose. 2015;22:2651–64. https://doi.org/10.1007/s10570-015-0669-0. [Google Scholar]

- 36.Renpu W. Measures for Putting a Well into Production. In: Renpu W, editor. Advanced Well Completion Engineering. Gulf Professional Publishing. 3rd ed. Vol. 8. 2011. pp. 417–523. https://doi.org/10.1016/b978-0-12-385868-9.00011-7. [Google Scholar]

- 37.Belitz HD, Grosch W, Schieberle P, editors. Food Chemistry. Berlin, Heidelberg: Springer Berlin Heidelberg; 2009. Amino Acids, Peptides, Proteins; pp. 8–92. https://doi.org/10.1007/978-3-662-07279-0_2. [Google Scholar]

- 38.Simandjuntak V, Barrett DM, Wrolstad RE. Cultivar and Maturity Effects on Muskmelon ( Cucumis melo) Colour, Texture and Cell Wall Polysaccharide Composition. J Sci Food Agric. 1996;71:282–90. https://doi.org/10.1002/(sici)1097-0010(199607)71:3 <282:aid-jsfa576>3.0.co;2-5. [Google Scholar]

- 39.Hutchings SC, Low JY, Keast RS. Sugar Reduction without Compromising Sensory Perception. An Impossible Dream? Crit Rev Food Sci. 2019;59:2287–307. doi: 10.1080/10408398.2018.1450214. https://doi.org/10.1080/10408398.2018.1450214. [DOI] [PubMed] [Google Scholar]

- 40.Réhault-Godbert S, Guyot N, Nys Y. The Golden Egg:Nutritional Value, Bioactivities, and Emerging Benefits for Human Health. Nutrients. 2019;11:684. doi: 10.3390/nu11030684. https://doi.org/10.3390/nu11030684. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Moynihan T. This Gadget Fires Foamy 3-D Pandas into your Lattes 2014 [Google Scholar]