Abstract

Objective:

To evaluate the material composition, mechanical properties (hardness and elastic modulus), and scratch resistance of the coating of four commercialized esthetic orthodontic archwires.

Materials and Methods:

The coating composition of esthetic archwires was assessed by Fourier-transform infrared spectroscopy (FTIR). Coating hardness and elastic modulus were analyzed with instrumented nano-indentation tests. Scratch resistance of coatings was evaluated by scratch test. Coating micromorphologic characteristics after scratch tests were observed in a scanning electron microscope. Statistical differences were investigated using analysis of variance and Tukey post hoc test.

Results:

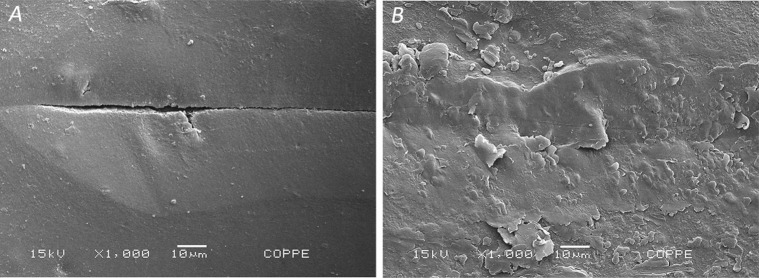

The FTIR results indicate that all analyzed coatings were markedly characterized by the benzene peak at about 1500 cm−1. The coating hardness and elastic modulus average values ranged from 0.17 to 0.23 GPa and from 5.0 to 7.6 GPa, respectively. Scratch test showed a high coating elasticity after load removal with elastic recoveries >60%, but different failure features could be observed along the scratches.

Conclusion:

The coatings of esthetic archwires evaluated are probably a composite of polyester and polytetrafluoroethylene. Delamination, crack propagation, and debris generation could be observed along the coating scratches and could influence its durability in the oral environment.

Keywords: Composition, Nano-mechanical properties, Scratch resistance, Esthetic archwires

INTRODUCTION

Esthetic accessories have been a requirement for many patients seeking orthodontic treatment. The development of materials with acceptable esthetics for the patient and optimal technical performance for the orthodontist has been an extremely essential goal.1 With the improvement in physical, mechanical, and optical properties of esthetic brackets this problem has been partially solved. However, most archwires are still made of metal, such as stainless steel and nickel titanium.

Manufacturing methods have been developed to improve the esthetics of orthodontic wires, making them less visually perceptible with good color stability and clinical performance. Metallic archwires coated with inorganic or polymeric materials are indeed the existing solution to such an esthetic problem.2 Materials used in archwire coatings are probably plastic resin materials such as synthetic fluorine-containing resin or epoxy resin composed mainly of polytetrafluoroethylene (PTFE Teflon) to simulate tooth color.3 The coating is applied by a deposition process using compressed air as a transport medium for the atomized Teflon that plates the base wire. This process includes some surface pretreatment of the wire to obtain a strong adhesion between the epoxy coating and the substrate.4

The literature contains different claims concerning esthetic coated archwires. A study of coating adherence and sliding properties showed that the coating decreased friction between archwires and brackets.5 Some authors have experienced difficulties with these coated archwires, claiming that they do not have acceptable color stability and that the coating layer tends to split, thereby exposing the underlying substrate metal.6,7 The surface quality of archwires affects the area of surface contact and influences the esthetic result, the corrosion behavior, and the biocompatibility.7 However, despite these problems with the coating, these wires continue to be marketed and used in clinical practice, which shows the need for esthetic archwires with structural characteristics at least comparable to the conventionally used stainless steel and nickel titanium archwires.

Limited information about composition, durability, and manufacturing process of material coating is given by the manufacturers. Among the available techniques for characterizing thin polymer films, Fourier-transform infrared (FTIR) spectroscopy is useful and provides valuable quantitative and qualitative analysis of polymer and plastic materials, detecting functional groups and characterizing covalent bonding information. For coating durability, scratch tests allow comparison of the scratch resistance and deformation of materials with different compositions and surface textures with good reproducibility.8,9

However, little information is available in the orthodontic literature evaluating coating composition as well as its integrity and tribologic properties of esthetic coated archwires. Therefore, the aims of this research were to investigate the material composition, mechanical properties (hardness and elastic modulus) at low loads, and the scratch resistance of the coating of esthetic orthodontic archwires.

MATERIALS AND METHODS

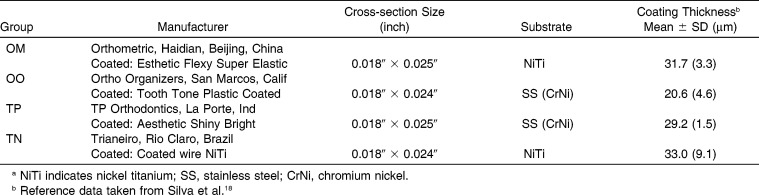

Four commercially available brands of esthetic coated archwires (conventional stainless steel and nickel titanium archwires) were evaluated (OM, OO, TP, TN, see Table 1 for descriptions). As the methods used for the present study are inappropriate tools for analyzing rounded surfaces, only wires with a rectangular cross section were investigated. A sample-size calculation was performed, based on a pilot study to detect a 10% difference in the nano-mechanical properties tested with a test power of 85% and level of significance of 5%. It showed that at least three specimens of 20-mm-long per group in each test would be necessary. Before the analyses, samples were immersed in distilled water and placed in an ultrasonic cleaning bath (Cristófoli LTDA, Campo Mourão, Brazil) for 5 minutes. Excess water on the surfaces was removed with tissue paper, and samples were allowed to dry in air. In order to perform the nano-indentation analysis and scratch tests, each wire segment was fixed on a glass slide with its labial surface facing up.

Table 1.

Commercially Available Coated Archwires Used in This Studya

Coating Composition—Infrared Analysis

For the FTIR spectroscopy analysis three samples of each brand were prepared. Each sample was made by placing 10-mm-long wire segments together and uniting their juxtaposed ends with metallic ligature and utility wax. The esthetic coating surface of every wire segment was facing the same direction, and the total width of each sample had to be at least 7 mm, so that its coating composition could be properly analyzed. The composition of the coating of esthetic archwires was investigated by microattenuated reflection (micro-ATR) FTIR spectroscopy. The samples were pressed against the diamond reflective element of a micro-ATR accessory attached to a spectrometer (Nicolet 6700 model, Thermo Scientific, Waltham, Mass). The spectra were record for the 4000–650 cm−1 range with 4 cm−1 resolution. A PTFE FTIR spectrum was used as reference.10

Nano-indentation Tests

Hardness (H) and elastic modulus (E) of the coatings were measured by instrumented indentation tests using the Nanoindenter G200 equipment (MTS Agilent, Santa Clara, Calif) following the Oliver-Pharr method.11 Tests were carried out using a Berkovich diamond tip. A total of 28 indents, 100 µm spaced from each other, were performed on each sample under five cycled loads with 2.0 mN maximum load, 10 second loading time and 15 second peak hold time. A fused-silica sample with known properties (E = 73.0 GPa) was used for the tip's area calibration. Poisson's ratio of 0.2 was used in the calculations.11

Scratch Tests

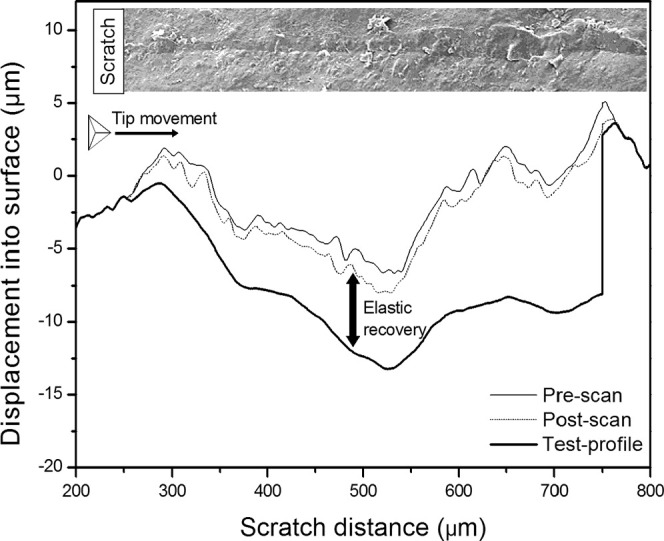

Scratch tests were carried out on the coatings using the G200 equipment (MTS Agilent). The experiments were performed in air at room temperature and 55% relative humidity. A diamond tip with the Berkovich geometry was displaced in the knife-face position. Initially, the tip traveled on the sample under the normal load of 0.05 mN to perform the pre-scan (original profile). Then, the scratch test was carried out by applying ramping loads from 0.0 up to 500 mN, 50 µm/s scratch velocity, and 250 µm to 750 µm length. At the end of the test, the tip was displaced again on the formed scratch under the load of 0.05 mN to scan the residual depth after scratching (post-scan). The elastic recovery (ER) of the coatings was estimated by the difference between the maximum penetration depth (scratch-test profile) and the residual one (or post-scan profile) at load (position) of 200, 300, 400, and 450 mN, as shown in Figure 1. Five scratch tests per sample were performed at different locations along the 20 mm wire length. In this study, the time-dependent scratch behavior caused by different relaxation characteristics among samples was not taken into account.

Figure 1.

Example of a scratch test performed on the TP sample using ramping loads from 0 to 500 mN. The SEM image shows the scratch formed after load removal. The parameter elastic recovery is indicated by the arrow.

Surface micromorphologic characteristics of the coating labial surface after scratch tests were observed by scanning electron microscopy (SEM) using a Jeol microscope (JSM 6460 LV, Peabody, Mass) working at 15 kV. The images were recorded at 200× and 1000× magnification.

Statistical Analyses

A standard software package (SPSS version 17.0, Chicago, Ill) was used for data analysis. The Kolmogorov-Smirnov test was applied to verify the normality in the results, and descriptive data were calculated for hardness, elastic modulus, and elastic recovery. The coating hardness and elastic modulus for each group were submitted to a one-way analysis of variance with a Tukey post hoc test to identify intergroup differences. The level of statistical significance was set at 5%.

RESULTS

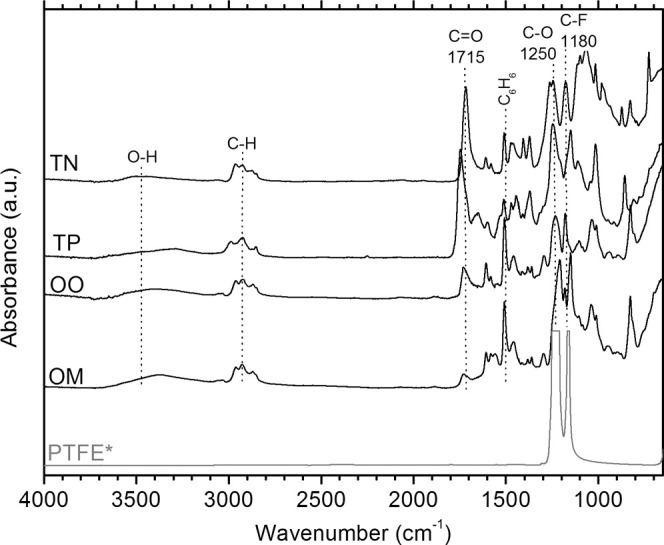

Coating FTIR spectra of esthetic archwires are shown in Figure 2. All spectra have a broad absorption region at 3600–3100 cm−1 related to O–H stretching vibrations; the peaks at 3000–2800 cm−1 are associated with C–H stretching vibrations. The peak at 1745–1715 cm−1 is related to the aromatic carbonyl (C = O) absorption. The peak located at about 1500 cm−1 may be due to the benzene ring vibration. The region in the 1300–1000 cm−1 range indicates C–O stretching vibrations.10 Such characteristics strongly suggest that the five coatings are polyester-like materials.

Figure 2.

Coating FTIR spectra esthetic orthodontic archwires compared with a reference PTFE sample.

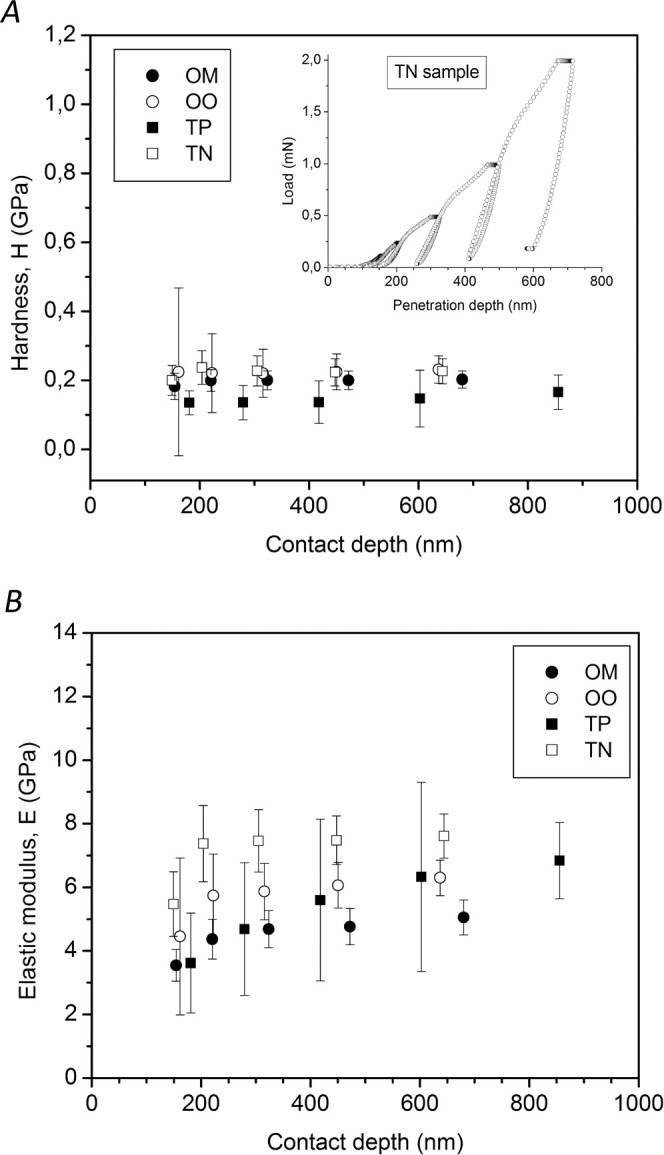

Coating hardness (H) and elastic modulus (E) of esthetic archwires obtained by nano-indentation tests are shown in Figure 3. As the hardness did not notably change with respect to the contact depth, the average H values obtained for 2.0 mN load were chosen for statistical comparison. The same is valid for the elastic modulus results. The intergroup comparisons using a Tukey post hoc test for coating hardness and elastic modulus of esthetic archwires are displayed in Table 2. For all groups, average H values varied in the 0.20–0.23 GPa range, except the TP group, which was slightly lowered (∼0.17 GPa). Furthermore, average E values ranged from 5.0 to 7.6 GPa. The TP and TN groups showed the highest elastic modulus, and the OM group had the lowest. For both hardness and elastic modulus, the TP group presented the greatest variation.

Figure 3.

Nano-indentations: coating hardness (A) and elastic modulus (B) of esthetic orthodontic archwires. The insert in (A) shows a typical load-displacement curve obtained for TN samples (five load-unload cycles).

Table 2.

Coating Hardness and Elastic Modulus (2.0 mN load) of Esthetic Archwires and Intergroup Comparison Using a Tukey Post Hoc Test

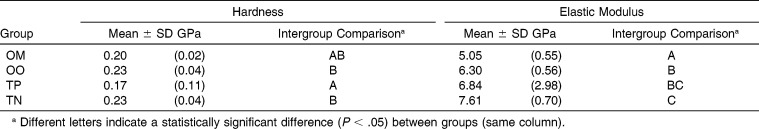

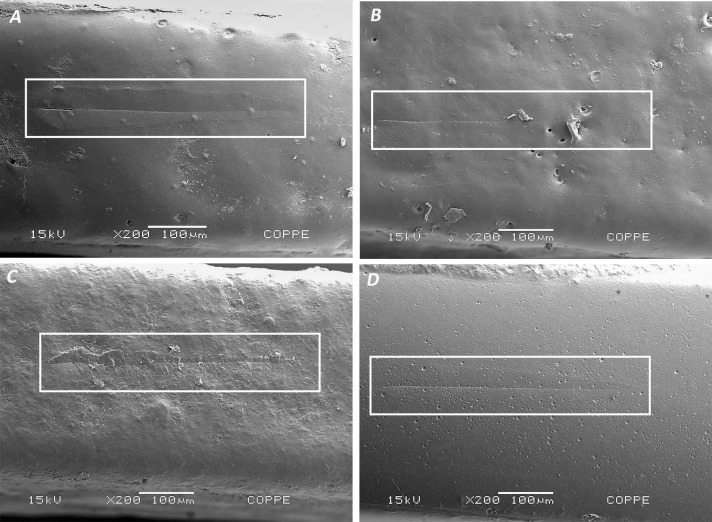

Representative SEM images of the scratched surfaces of different esthetic coated archwires are shown in Figure 4. Most of the specimens were characterized by small coating delamination and irregularities over some points produced during the scratch tests. The TN group presented the smoothest surface appearance (Figure 4D), and the TP group was the most damaged (Figure 4C). Also, small crack formation (or nucleation) could be observed at the end of the scratch for the OM samples (Figure 4A). The OO group seemed to be the least damaged (Figure 4B). Figure 5 displays a closer view of the scratches formed on both OM and TP samples by SEM.

Figure 4.

Photomicrographs of scratches formed on the samples after scratch tests. (A) OM group, (B) OO group, (C) TP group, and (D) TN group. Original magnification at 200×.

Figure 5.

Photomicrographs of scratches formed on the samples after scratch tests. (A) Cracks on the OM group and (B) debris on the TP group. Original magnification at 100×.

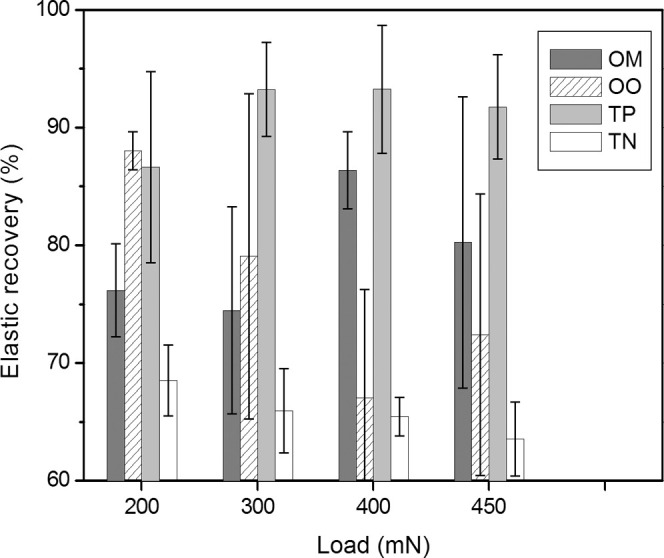

Because of the viscoelastic behavior shown by polymers, high elasticity was observed after load removal, as indicated in Figure 1. Four different loads were chosen for elastic recovery calculations: 200, 300, 400, and 450 mN. Figure 6 plots the elastic recoveries obtained for all coatings. In general, TP samples presented the highest values, and the TN group showed the lowest.

Figure 6.

Coating elastic recovery of esthetic orthodontic archwires. Calculation derived from load-displacement curves at 200, 300, 400, and 450 mN loads.

DISCUSSION

The surface topography of an orthodontic wire is an essential functional property known to influence its mechanical and tribologic properties, esthetic appearance, corrosion behavior, and biocompatibility.12 A great variation in the type and number of surface defects on the labial side of each sample and between different samples of as-received wires could be observed (Figure 4). Clinically, a rough surface encourages greater plaque accumulation and influences its friction properties, corrosion behavior, and biocompatibility.13

After scratch tests, damage to the sample surfaces showed distinct appearances, which may depend on many factors, such as coating composition, thickness. and manufacturing process. Specific information about the coating production process and composition is not readily available. Thus, it is useful to attempt to characterize the chemical composition of the polymers, in particular because end-use properties of the archwires are strongly dependent not only on the raw materials used for their synthesis but also on the polymerization process.14 Nevertheless, this investigation revealed a large number of irregularities on as-received esthetic archwires and described some characterization of coating by FTIR spectroscopy.

Previous studies have shown that FTIR spectroscopy is an effective technique to characterize optically thick polymer specimens.15 This method has been used to determine the different functional groups present in the minerals and resins in dental composites.15 No reports describing the characterization of tooth-colored coatings in esthetic archwires could be found in the literature. The FTIR results (Figure 2) indicate that all analyzed coatings are polyester-based materials that are markedly characterized by the benzene peak at about 1500 cm−1. Besides the C–O stretching vibrations (1300–1000 cm−1), pure PTFE presents two main absorption peaks (fluoride) at around 1220 and 1160 cm−1 related to C–F stretching vibrations (Figure 2). Thus, these coatings could also have PTFE in their compositions once the C–F stretching peaks overlap the polyester C–O stretching vibrations. In fact, the TN sample is a composite of polyester and PTFE, according to private communication with its manufacturer.

The hardness and elastic modulus values correspond to the coating rather than the coating substrate composite, once the maximum contact depths were <10% of the coating thicknesses. The large variation for hardness and elastic modulus observed for TP samples at shallow depths could also be associated with its irregular surface (Figure 4C) instead of the analyzed volume bulk (physicochemical features). Concerning the general mechanisms of scratch tests on polymers, elastic modulus is an important parameter that can affect the scratch depths. Polymers with E < 1.0 GPa are usually the most influenced by elastic modulus, thereby presenting deeper scratch penetrations.16 Our scratch results, therefore, must not be correlated to the elastic moduli solely, as all of the E values are in the same range and at least fivefold higher than 1.0 GPa (Table 2). Despite being polyester plus PTFE composite coatings, all of the differences for H and E could probably have been caused by structural and chemical composition variation.

Figure 4 shows the scratches formed on the coatings after load removal from the scratch tests. In all cases, the initial scratch cannot be visualized until a certain point (from left to right) where damage begins to be more visible. However, the OM samples presented some cracks formed on the valley of the scratches, which were more evident at higher loads (Figure 5A). Even so, debris did not detach from the coating, as observed for TP group (Figure 5B). From the point of view of surface wear, these findings suggest that both the OO and TN groups were the most resistant to scratching compared with the OM and TP groups. In the case of archwire coatings, cracking is undesirable because it can play an important role in further corrosion and wear (or damage) mechanisms in the oral environment.

Elastic recovery may be considered a useful parameter to infer depth recovery after load releasing to rank different coatings. It compares the initial penetration curves with the residual penetration ones from the scratch tests (Figure 1). The initial penetration depth is related to the viscoelastic deformation imposed by the sliding tip. The residual penetration depth curves reflect the residual plastic and any prolonged viscoelastic deformation. The difference between initial penetration depth and residual penetration depth curves at any given load is the scratch recovery (or simply elastic recovery). High elastic recovery is sometimes more desirable than shallower depth penetrations (or scratch harder material) depending on its application. If a coating has a high elastic recovery, it could be more suitable to cover esthetic metallic archwires because no considerable wear would be seen. A high recovery is indicative of elastic strain, whereas a lower recovery suggests significant plastic (permanent) deformation.17 In Figure 6, all samples showed elastic recovery values greater than 60% for the four analyzed loads. These values are in the same range found for many different polymers submitted to scratch tests with different loads and geometry tips.16

In general, the TP samples had the highest elastic recoveries, and the TN samples the lowest (Figure 6). It is interesting to note that TP samples had the most damaged surfaces in terms of debris generation. In contrast, the TN samples presented net surfaces with notable low elastic recoveries after scratch tests (Figures 4 and 6). As a matter of fact, the relation among viscoelastic recovery and material properties (e.g., hardness, elastic modulus, tensile strength) is not well established.16

Some studies have reported that in clinical conditions the coating layer tends to crack and detach, thereby exposing the underlying substrate metal.7,18 Probable factors influencing the coating integrity are associated with surface roughness, deposition method (synthesis and fabrication process) used, material stability, and coating-substrate adhesion strength. As manufacturers provide little information about the manufacturing processes and raw materials used, more studies evaluating coating quality and adhesion mechanisms to metallic substrate are necessary. Limitations of this research include few studies in the literature with which to compare our results; therefore, conclusions are based mainly on these present findings. Therefore, the demand for knowledge of surface properties of commercially available and currently used coated archwires is evident and the permanent development of these materials is urgent.

CONCLUSIONS

The as-received coatings of esthetic archwires showed an irregular and rough surface.

The FTIR spectroscopy strongly suggests that the coating material of esthetic archwires evaluated is a composite of polyester and PTFE.

The average coating hardness and elastic modulus values ranged from 0.17 to 0.23 GPa and 5.0 to 7.6 Gpa, respectively.

All groups presented elastic recoveries greater than 60% but had different failure features, such as delamination, crack propagation, and debris generation along the coating scratches.

ACKNOWLEDGMENT

This work was partially supported by CNPq and CAPES Brazilian agencies.

REFERENCES

- 1.Hammad SM, Al-Wakeel EE, Gad el S. Mechanical properties and surface characterization of translucent composite wire following topical fluoride treatment. Angle Orthod. 2012;82:8–13. doi: 10.2319/030811-168.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Elayyan F, Silikas N, Bearn D. Mechanical properties of coated superelastic archwires in conventional and self-ligating orthodontic brackets. Am J Orthod Dentofacial Orthop. 2010;137:213–217. doi: 10.1016/j.ajodo.2008.01.026. [DOI] [PubMed] [Google Scholar]

- 3.Ramadan AA. Removing hepatitis C virus from polytetrafluoroethylene-coated orthodontic archwires and other dental instruments. East Mediterr Health J. 2003;9:274–278. [PubMed] [Google Scholar]

- 4.Clocheret K, Willems G, Carels C, Celis JP. Dynamic frictional behaviour of orthodontic archwires and brackets. Eur J Orthod. 2004;26:163–170. doi: 10.1093/ejo/26.2.163. [DOI] [PubMed] [Google Scholar]

- 5.Husmann P, Bourauel C, Wessinger M, Jager A. The frictional behavior of coated guiding archwires. J Orofac Orthop. 2002;63:199–211. doi: 10.1007/s00056-002-0009-5. [DOI] [PubMed] [Google Scholar]

- 6.Silva DL, Mattos CT, Araújo MV, Ruellas ACO. Color stability and fluorescence of different orthodontic esthetic archwires. Angle Orthod. 2013;83:127–132. doi: 10.2319/121311-764.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Elayyan F, Silikas N, Bearn D. Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod. 2008;30:661–667. doi: 10.1093/ejo/cjn057. [DOI] [PubMed] [Google Scholar]

- 8.Palaniappan S, Celis JP, Van Meerbeek B, Peumans M, Lambrechts P. Correlating in vitro scratch test with in vivo contact free occlusal area wear of contemporary dental composites. Dent Mater. 2013;29:259–268. doi: 10.1016/j.dental.2012.10.007. [DOI] [PubMed] [Google Scholar]

- 9.Jadret V, Zahouani H, Loubet JL, Mathia TG. Understanding and quantification of elastic and plastic deformation during scratch test. Wear. 1998;218:8–14. [Google Scholar]

- 10.Cui X, Zhong S, Xu J, Wang H. Synthesis of polytetrafluoroethylene/polyacrylate core-shell nanoparticles via emulsifier-free seeded emulsion polymerization. Colloid Polym Sci. 2007;285:935–940. [Google Scholar]

- 11.Oliver W, Pharr G. Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res. 2004;19:3–20. [Google Scholar]

- 12.Daems J, Celis JP, Willems G. Morphological characterization of as-received and in vivo orthodontic stainless steel archwires. Eur J Orthod. 2009;31:260–265. doi: 10.1093/ejo/cjn104. [DOI] [PubMed] [Google Scholar]

- 13.Eliades T, Athanasiou AE. In vivo aging of orthodontic alloys: implications for corrosion potential, nickel release, and biocompatibility. Angle Orthod. 2002;72:222–237. doi: 10.1043/0003-3219(2002)072<0222:IVAOOA>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 14.Tirrell M. Chemical engineering of polymers: production of flexible, functional materials. Chem Eng Sci. 1995;50:4123–4141. [Google Scholar]

- 15.Skrtic D, Antonucci JM, Eanes ED, Eidelman N. Dental composites based on hybrid and surface-modified amorphous calcium phosphates. Biomaterials. 2004;25:1141–1150. doi: 10.1016/j.biomaterials.2003.08.001. [DOI] [PubMed] [Google Scholar]

- 16.Xiang C, Sue H, Chu J, Coleman B. Scratch behavior and material property relationship in polymers. J Polym Sci B Polym Phys. 2001;39:47–59. [Google Scholar]

- 17.Lin-Gibson S, Sung L, Forster AM, Hu H, Cheng Y, Lin NJ. Effects of filler type and content on mechanical properties of photopolymerizable composites measured across two-dimensional combinatorial arrays. Acta Biomaterialia. 2009;5:2084–2094. doi: 10.1016/j.actbio.2009.01.043. [DOI] [PubMed] [Google Scholar]

- 18.Silva DL, Mattos CT, Simao RA, de Oliveira Ruellas AC. Coating stability and surface characteristics of esthetic orthodontic coated archwires. Angle Orthod. 2013;83:994–1001. doi: 10.2319/111112-866.1. [DOI] [PMC free article] [PubMed] [Google Scholar]