Abstract

Objective:

To measure the slot dimensions of an entire series of metal orthodontic brackets.

Materials and Methods:

Ten bracket series approximating five complete sets of brackets each were imaged and measured. Descriptive statistics were generated.

Results:

Slot dimension varied significantly from series to series as well as within the series themselves. About one-third of the brackets would not accommodate a full-size wire, and 15% to 20% are 0.001 inches or larger than the nominal advertised size.

Conclusion:

The clinician is unlikely to have on hand complete sets (upper and lower 5-5) of ideal brackets and should both expect and be able to be accommodate tooth movement through wire bending in three planes of space to overcome any bracket deficiencies.

Keywords: Brackets, Mechanics

INTRODUCTION

Contemporary orthodontists have a variety of methods to move teeth. When traditional brackets are the treatment of choice, there are dozens of brands with an almost endless variety of wings, slots, ligation features, and first-, second-, and third-order prescriptions. They can be mixed and matched in either the 0.018-inch or 0.022-inch size, depending on preference.

Despite the near universal use of brackets in orthodontic treatment, there are few scientific studies of the bracket slot's tolerances, which are especially important when using a preadjusted appliance. “The brackets and tubes for an edgewise appliance must be precisely manufactured so that the internal slot dimensions are accurate to at least 1 mil (1 mil = 0.001 inches).”1 Bennett stated, “Oversize slots undermine the whole basis of preadjusted edgewise, which is intended to minimize wire bending.”2 Bennett further stated that there should be a reasonable expectation that the appliance accuracy should be exactly as claimed in advertising brochures. While theoretical tooth positions or prescription values may be debated, few have questioned whether a specific bracket or bracket series is even capable of moving the tooth to the desired position. Dentists appear to be relying more on the advice of peers and the opinions of experts, as scientific data are considered valuable only 42% of the time when selecting dental products.3 Past bracket studies that are frequently cited that deal with bracket slot dimension and shape were limited to either relatively small sample sizes and/or the inclusion of just a single tooth-specific bracket (ie, upper left central) from a bracket series. This may or may not be representative of all the other individual tooth brackets in the series. In a metal injection molded bracket series, for example, each specific tooth is manufactured from a separate and unique mold.

Cash et al.4 measured the slots of five upper left central 0.022-inch brackets from 11 bracket series representing six different manufacturers. They reported that all bracket systems were oversized with a range of 5% to 24%. Four systems had parallel slot walls, five systems converged from the base to the top of the slot, and two systems showed diverging slot walls.

Kusy and Whitley5 measured three brackets (unspecified as per tooth) from 24 unique bracket series from eight different companies.2 Their sample included brackets manufactured from four different materials and included three different slot sizes 0.018, 0.0185, and 0.022 inches. They reported that 15% of the brackets were smaller than reported and slot sizes exceeded the nominal value by as much as 16% and 8% (in the cases of nominal 0.018-inch and 0.022-inch slots, respectively). Finally, they underscored the need for the practitioner to know the exact dimension of the bracket in order to avoid compromising treatment mechanics.

Bhalla et al.6 measured five upper left central 0.022-inch self-ligating brackets from each of six different bracket series that represented four different manufacturers. They reported the brackets to be between 5% and 15% larger than the nominal values and that slot walls diverged from the base to the top of all the brackets. It was noted that brackets from the same manufacturer may vary in size as well.

Major et al.7 measured 30 upper right central 0.022-inch stainless steel self-ligating brackets from three manufacturers. They reported slot heights from 2% smaller to 3% over the nominal size. Parallel, divergent, and convergent walls were reported. The authors cautioned that one cannot assume a consistent slot shape. It is clear from these studies that there is considerable variation in the slot tolerances when measuring a single bracket from a bracket series.

The purpose of this study is to measure the slot dimensions of entire series of metal orthodontic brackets and provide descriptive statistics of their measurements. This should give the clinician a much better appreciation of the capabilities and limitations of various bracket systems than a sample consisting of only a single bracket from the series.

METHODS AND MATERIALS

In this study, the following bracket series were evaluated: A-Company 0.022 inch (manufactured circa 1985), Ormco Damon Q 0.022 inch (Ormco Corp, Orange, Calif), Unitek Victory 0.022 inch and 0.018 inch (Unitek, Monrovia, Calif), GAC In-Ovation 0.022 inch (GAC, Bohemia, NY), Opal Avex 0.022 inch and 0.018 inch (Opal Orthodontics by Ultradent, South Jordan, Utah), SPEED 0.022 inch (Strite Industries, Cambridge, Ontario, Canada), and American Orthodontics Masters 0.022 inch and 0.018 inch (American Orthodontics, Sheboygan, Wis). The bracket series consisted of 100 brackets each, representing five cases of upper and lower second premolar to second premolar, except for Speed (n = 99), A-Company (n = 96), and Damon (n = 78) due to only partial sets of lower incisors and second premolars (Table 1). The methods used to manufacture the various brackets were obtained verbally through company representatives or from published sales literature.

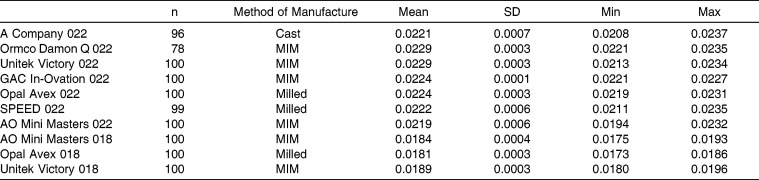

Table 1.

Bracket Series and Their Characteristics

A Clark Microhardness Tester-Model CM-700 and a Clark Instrument Automatic Reading System-Model CM-AR90 were used to image, scale and, measure each bracket. A Knoop/Vickers microhardness tester has two basic components: (1) a device that (in a very controlled fashion) forms small indents on the surface of specimens and (2) a very accurate measuring microscope. For this study, only the measuring microscope capability of the microhardness tester was used. The microhardness tester that was used has multiple objectives providing total magnifications between 50× and 500× and filars (measuring lines) that can be set to provide greater than 1-µm resolution.

The brackets were placed on a microscope slide using rope wax with the slots oriented vertically so that the line of view with the measuring microscope was parallel to the slot axis (Figure 1). The slide was then placed on the microscope table and the slot and light adjusted until a sharp, well-focused image was viewed on the screen and digitally captured (Figure 2).

Figure 1.

Orienting the bracket onto the microscope slide with rope wax.

Figure 2.

Digital view of the bracket slot properly oriented and focused on the microscope table.

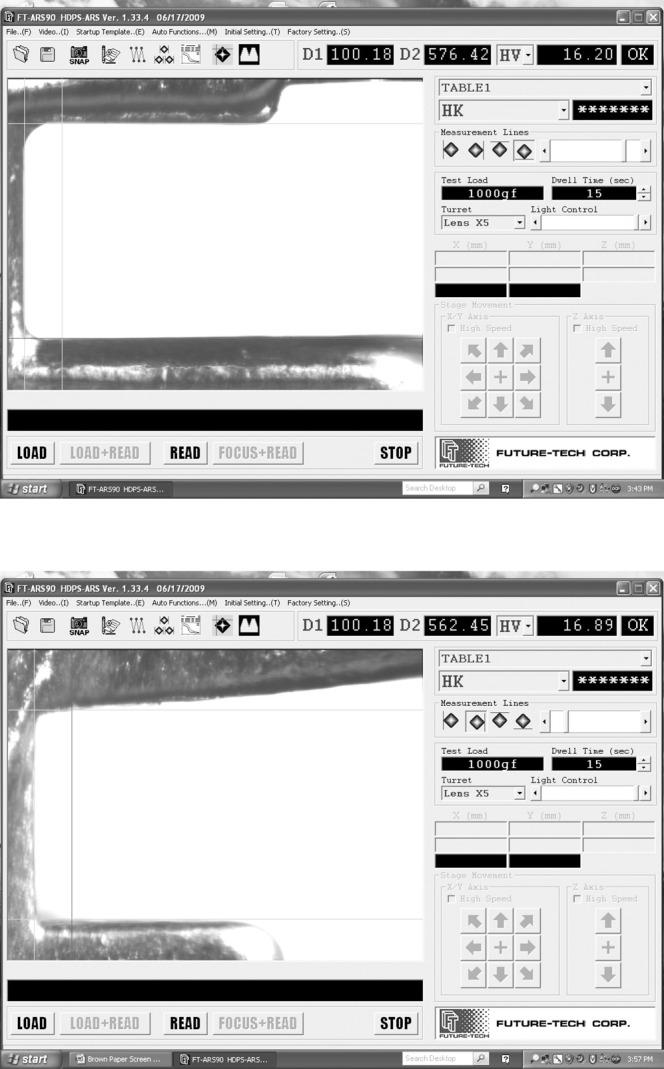

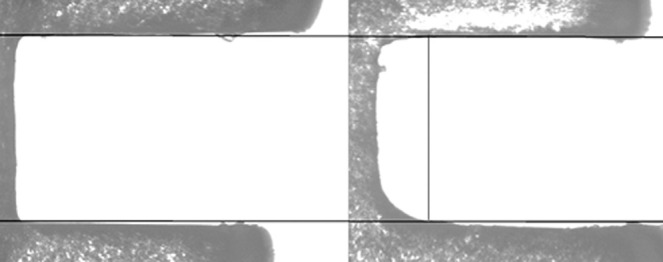

Figure 3 shows two screenshots from the Automatic Reading System showing a bracket with rounded internal line angles and another with a divergent slot. The digitally imaged bracket is automatically scaled and loaded into the measuring software. To compensate for both rounded and defective corners as well as excess material, the initial vertical filar was placed at the deepest portion of the bracket base approximating the middle of the slot. The second vertical filar was then moved and set at a distance of 100 µm down the slot. At 100 µm down the slot, the horizontal filars were moved until the first contact was made along this distance and the bracket wall. The vertical slot dimension was then recorded. Observers were able to measure the brackets with a correlation coefficient of .947.

Figure 3.

Two screenshots showing the vertical filars set at the base of the bracket and 100 µm apart down the slot. The horizontal filars are set perpendicular to the second vertical filar where it intercepts the bracket walls. The top screenshot depicts a bracket with rounded internal line angles and the lower screenshot a bracket with a divergent slot.

RESULTS

Table 1 shows the bracket's characteristics and descriptive statistics of the measurements, while Figure 4 shows a graphic representation of the vertical slot dimensions. For 0.018-inch slots, the Opal Avex, a milled bracket, was on average closest to the accepted nominal value, being 0.0001 inch oversized. It also had the smallest range and similar standard deviation as the Unitek Victory.

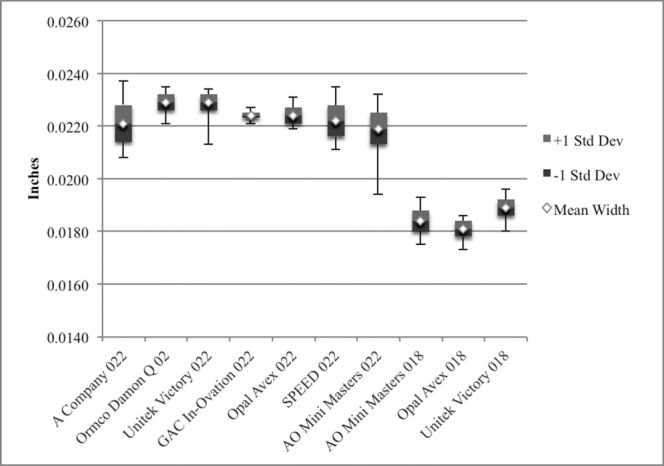

Figure 4.

Graphic representation of the vertical slot dimensions.

For 0.022-inch slots, the closest average sizes were American Orthodontics Mini Masters, a metal injection molded bracket, that was 0.0001 inch undersized, and the A-Company bracket, a cast bracket, that was 0.0001 inch oversized from the accepted nominal value. The GAC In-Ovation, while oversized, had the smallest standard deviation and range of any bracket in the sample, while the A-Company had the largest standard deviation and the American Orthodontics Mini Masters the largest range of any bracket in the sample.

DISCUSSION

This sample of about five cases per bracket series indicates that torque issues as a function of vertical slot dimension remain problematic. Compounding the problem are the internal line angles, the orientation of the walls relative to the base, and presence of various size and topography of asperities.

Alexander8 has put the clinical torque problem in a simple perspective. “It should be understood that for every 0.001 inch of freedom between the archwire and vertical bracket slot, approximately 5 degrees of effective torque is lost.” This would obviously assume 90° interior line angles, parallel and smooth bracket walls, and accurate and geometrically correct arch wire sizes.

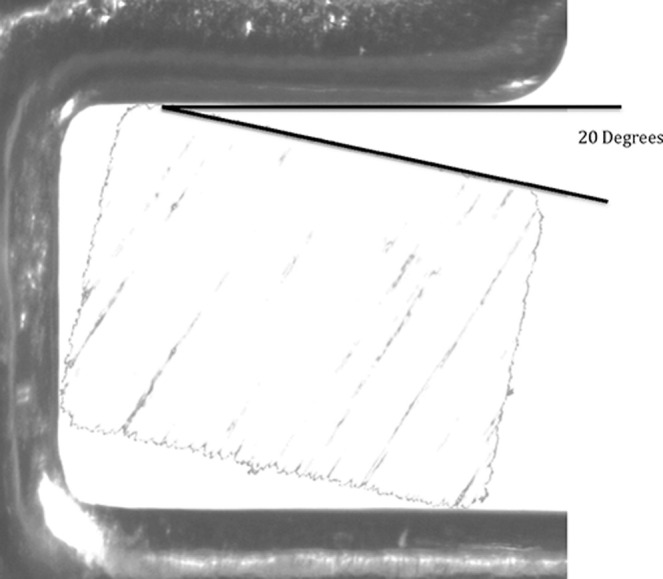

This implies that a 0.019-inch thickness archwire in a 0.022-inch straight wire bracket with a typical 12° of torque in the prescription would produce no effective torque. Figure 5 is a cross section of a 0.019- × 0.025-inch archwire, scaled and superimposed into a 0.022-inch bracket from the sample. It should be emphasized that these are nominal values from the manufacturer.

Figure 5.

Depiction of a cross section of a polished 0.019- × 0.025-inch archwire that was imaged and scaled into the 0.022-inch slot of a bracket from our samples showing ±20° of slot play. Similar examples could be found in 0.018-inch slots as well.

Considering all 0.022-inch brackets that were measured in this study and assuming the walls were completely parallel and smooth, 36% of the slots would not be large enough to insert a full-size wire and 15% would be larger than 0.023 inches. For the 0.018-inch sample, 31% would not accommodate a full-size wire, and 20% would be larger than 0.019 inches.

Brackets with single-digit torque values or single-digit differences in their respective prescriptions likely offer little if any advantage over a standard edgewise bracket or different bracket prescription, respectively. A recent study determined that the ability of clinicians to distinguish the posttreatment effects of brackets with 12° vs 17° of upper incisor torque was essentially no better than chance.9 A direct comparison of manufacturing techniques is difficult as the actual processes and feed stocks remain proprietary. All bracket series contained some brackets manufactured at the nominally advertised values.

In general, this study confirms the findings of the other cited studies that measured brackets of the same series and manufacturer. An examination of the images in our sample would also confirm a general slot shape (parallel walls, converging walls, or diverging walls) as well as quality of the bracket base to wall line angles as reported, with exceptions as noted.

Cash et al.4 reported the 0.022-inch slot Unitek Victory and Ormco Damon series to both be oversized (4.6% or 0.0221 inches and 16.86% or 0.0224 inches, respectively), with the Victory bracket diverging toward the top of the slot and the Damon bracket converging.4 Both the Unitek Victory and Ormco Damon brackets in the current sample were oversized and with the same general slot shapes. Cash et al.4 cautioned clinicians that the preadjusted bracket and wire systems may not produce the three-dimensional control required to produce an acceptable result.

The 0.018-inch Unitek Victory was reported by Kusy and Whitley5 to be oversized at 0.0183 inches (n = 3) vs 0.0189 inches in the current study.5

Both the In-Ovation and Speed brackets were considerably oversized, as reported by Bhalla et al.6 (0.02385 and 0.02311 inches, respectively), with the In-Ovation bracket being the most consistent. In the current sample, the brackets were closer to nominal means. This study confirmed the speculation by Bhalla et al.6 that brackets from the same manufacturer may vary (Figure 6).

Figure 6.

A right and left central incisor bracket from the same series. Not only would the same full-size wire not fit into the slot, a first-order discrepancy would also be introduced, due to a rounded lower corner on the right bracket.

Major et al.7 reported the Speed brackets to be slightly undersized at the base 0.556 mm (0.0219 inches) with “pronounced rounding” and “large fillets” where the base meets the wall and slight convergence. Such bases-to-wall issues were also present throughout this sample. For Major et al., the GAC In-Ovation measured 0.564 mm (0.0222 inches) at the base and “most closely resembles a trapezoidal shape.” The Damon Q's base was reported at 0.572 mm (0.0225 inches), with the “highest measured manufacturing tolerance” among the three tested and “nearly 90-degree corners.” While there are examples of Damon Q brackets in the current sample with 90° corners, the great majority have large rounded internal line angles.

Manufacturing defects occurred both as a single anomaly as well as throughout the entire tooth-specific set of brackets in a series. While the correct bracket position is a given, continuously rebonding a straight wire bracket for more optimal tooth position may or may not achieve the desired result. In some cases, one would simply be rebonding a similarly defective bracket, and in others, the tooth position could potentially become even less optimal. Figure 7 shows one ideal set, although slightly oversized, of central, lateral, and canine brackets that have square corners, parallel walls, and are free from asperities.

Figure 7.

An ideal set of anterior straight wire brackets.

“Most orthodontists prefer a particular bracket system. It is important to know the system used in treatment and why it was chosen.”10 The clinician is unlikely to have on hand complete sets (upper and lower 5-5) of ideal brackets that would consistently work as “claimed in the brochure.” “It is necessary to avoid the mind-set that all brackets [bracket prescriptions, bracket series, and specific tooth brackets] are more-or-less the same.”11 One should both expect and be able to be accommodate tooth movement through wire bending in three planes of space to overcome any bracket deficiencies.

CONCLUSIONS

The actual slot size and shape of an orthodontic bracket are likely to vary both larger and smaller from the advertised nominal value within a bracket series.

Using conventional wire sizes and a straight wire approach, some brackets marketed as preadjusted clearly are not able to produce a torqueing tooth movement without additional wire bending.

Manufacturing anomalies may occur in a single bracket, throughout the sets of specific tooth brackets, or generally throughout an entire bracket series.

REFERENCES

- 1.Proffit W. Contemporary Orthodontics. 4th ed. St. Louis, Mo: Mosby Elsevier; 2007. [Google Scholar]

- 2.Bennett J. Fundamentals of Orthodontic Treatment Mechanics. 1st ed. London, UK: LeGrande Publishing; 2014. [Google Scholar]

- 3.King G. Biomedicine in orthodontics: from tooth movement to facial growth. Orthod Craniofac Res. 2009;12:53–58. doi: 10.1111/j.1601-6343.2009.01437.x. [DOI] [PubMed] [Google Scholar]

- 4.Cash A, Good S, Curtis R, McDonald F. An evaluation of slot size in orthodontic brackets—are standards as expected. Angle Orthod. 2004;74:450–453. doi: 10.1043/0003-3219(2004)074<0450:AEOSSI>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 5.Kusy R, Whitley J. Assessment of second-order clearances between orthodontic archwires and bracket slots via critical contact angle for binding. Angle Orthod. 1999;69:71–80. doi: 10.1043/0003-3219(1999)069<0071:AOSOCB>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 6.Bhalla N, Good S, McDonald F, Sherriff M, Cash A. Assessment of slot sizes in self-ligating brackets using electron microscopy. Aust Orthod J. 2010;26:38–41. [PubMed] [Google Scholar]

- 7.Major T, Carey J, Nobes D, Major P. Orthodontic bracket manufacturing tolerances and dimensional differences between select self-ligating brackets. J Dent Biomech. 2010:1–6. doi: 10.4061/2010/781321. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Alexander R. The 20 Principles of the Alexander Discipline. Chicago, Ill: Quintessence Publishing; 2008. [Google Scholar]

- 9.Moesi B, Dyer F, Benson P. Roth versus MBT: does bracket prescription have an effect on the subjective outcome of pre-adjusted edgewise treatment. Eur J Orthod. 2013;35:236–243. doi: 10.1093/ejo/cjr126. [DOI] [PubMed] [Google Scholar]

- 10.English JD, Briss BS, Jamieson SA, et al. Common errors in preparing for and completing the American Board of Orthodontics clinical examination. Am J Orthod Dentofacial Orthop. 2011;139:136–137. doi: 10.1016/j.ajodo.2010.11.005. [DOI] [PubMed] [Google Scholar]

- 11.Bennett J. Fundamentals of Orthodontic Bracket Selection. 2nd ed. London, UK: LeGrande Publishing; 2010. [Google Scholar]