Abstract

3D printing has been widely used for the personalization of therapies and on-demand production of complex pharmaceutical forms. Recently, 3D printing has been explored as a tool for the development of topical dosage forms and wound dressings. Thus, this review aims to present advances related to the use of 3D printing for the development of pharmaceutical and biomedical products for topical skin applications, covering plain dressing and products for the delivery of active ingredients to the skin. Based on the data acquired, the important growth in the number of publications over the last years confirms its interest. The semisolid extrusion technique has been the most reported one, probably because it allows the use of a broad range of polymers, creating the most diverse therapeutic approaches. 3D printing has been an excellent field for customizing dressings, according to individual needs. Studies discussed here imply the use of metals, nanoparticles, drugs, natural compounds and proteins and peptides for the treatment of wound healing, acne, pain relief, and anti-wrinkle, among others. The confluence of 3D printing and topical applications has undeniable advantages, and we would like to encourage the research groups to explore this field to improve the patient’s life quality, adherence and treatment efficacy.

Keywords: additive manufacturing, wound dressing, FDM, skin disorders, film, patch, 3D-printing

1. Introduction

Skin is the largest organ in the human body and plays an important role in emotional and physical welfare [1,2]. The skin covers the whole-body surface, being the first defense against xenobiotic entrance [3]. Due to its extension, it has been considered as a drug application site for local, but also for systemic aims. It is widely known that certain substances can passively diffuse through the skin and produce both, local and, less commonly, systemic effects, but this feature is limited to a few drugs [4].

Skin diseases are a problem for the world population as one-third of the population is affected by these disorders [5]. Still, skin diseases are the fourth most common cause of human infirmity and represent a major problem in the United States healthcare system [5,6]. Moreover, wound treatment, especially chronic wounds, represents an important health care burden, with global care costs varying from $13 to $15 billion annually [7]. Consequently, novel technologies for the treatment of skin diseases and injuries are highly encouraged.

Nowadays, topical products are a lot more complex, varying from simple solutions and creams to multiphase, nanotechnology and assisted technologies [4]. In this scenario, 3D printing is a promising alternative to develop and produce biomedical and pharmaceutical products aiming at the treatment of skin disorders and skin injuries. This technology allows the design and control of specific desired properties, porosity, pore size, roughness, functional groups, size, shape, swelling, degradability profile, drug loading and drug release profile [8,9,10]. Fundamentally, these properties can provide similarities to the skin’s native environment and provide better conditions for diseases/injury treatment.

3D printing has emerged in the past years as an innovative and versatile platform for the development of new healthcare solutions. Although it is a well-consolidated technology in other industries, such as automotive and aeronautics, in the pharmaceutical and biomedical fields it is still new and with a promising path ahead [8]. The first drug produced by 3D printing and approved by the Food and Drug Administration (FDA) was only in 2015, highlighting its innovative potential [11]

3D printing has been well explored in oral drug delivery to produce the most diverse drug release profiles and customizations [12]. Different approaches have been proposed for controlled [13], sustained [14], or fast [15] release of drugs and for the production of the so-called polypills with different drug release profiles [16]. Orodispersible films, chewing tables, and implants are just some other pharmaceutical dosage forms that have been explored by the wide range of 3D printing possibilities [12,17].

Regarding skin applications, the use of 3D printing tools for improving skin drug delivery with systemic and local applications is an emerging area of research, which is in exponential growth. 3D printing has been recently used to produce microneedles, aiming, mainly, for transdermal applications [18]. Moreover, with the improvement of the printing techniques and, therefore, with cell bioprinting, e.g., the printing of cells, these systems have been intensively explored for skin tissue engineering [19]. Yet, some disadvantages can be cited, as the use of cells relies on strict regulatory control [19,20]. Despite all these skin applications, 3D printing for topically applied local drug delivery systems onto the skin and wound dressing without cells is still a modest but highly promising research field.

There are excellent reviews that cover 3D printing and its applications on the skin, as transdermal drug delivery [21] and bioprinting [22,23,24]. However, to the best of our knowledge, none of them were dedicated to discussing the association of 3D printing and pharmaceutical topical skin products for drug delivery and dressings. In this review, we mainly focus on the applications of 3D printing in topical drug delivery with a local therapeutic aim and for plain dressing. Accordingly, this work provides an updated review of the aforementioned association in the treatment or prevention of skin diseases. Therefore, we first discuss the topical route and main 3D printing techniques applied to this field and thereafter, based on the literature research performed, a discussion of the studies that comprise 3D printing and topical skin application. Lastly, challenges and perspectives are discussed, followed by a brief conclusion.

2. Topical Delivery

Topical administration refers to the application of formulations on the superficial area of the skin for the local treatment of diseases or injuries [25]. Site-specific drug delivery can target several skin sites, such as stratum corneum (SC), viable epidermis, dermis, pilosebaceous unit, hypodermis and deeper tissues [26]. The main advantages of this delivery route are patient acceptance; its painless and noninvasive properties; improvement in drug skin bioavailability; better pharmacological and physiological response; and minimum systemic toxicity and drug exposure to non-desired sites [25]. In this article, we will focus on localized skin active ingredient delivery, which implies targeting specific skin layers, while reducing systemic absorption.

Skin active ingredient delivery requires a complex understanding of the skin structure, physiology, skin disease, drug, and vehicle characteristics. There are some intrinsic skin factors that can affect active ingredient delivery across the skin, such as the skin barrier function, provided mainly by the stratum corneum, skin hydration, anatomical site, pathological effects, age, ethnicity and gender, among others [27]. Hydration is also an important factor that influences penetration, as well hydrated areas provide better permeation conditions [28].

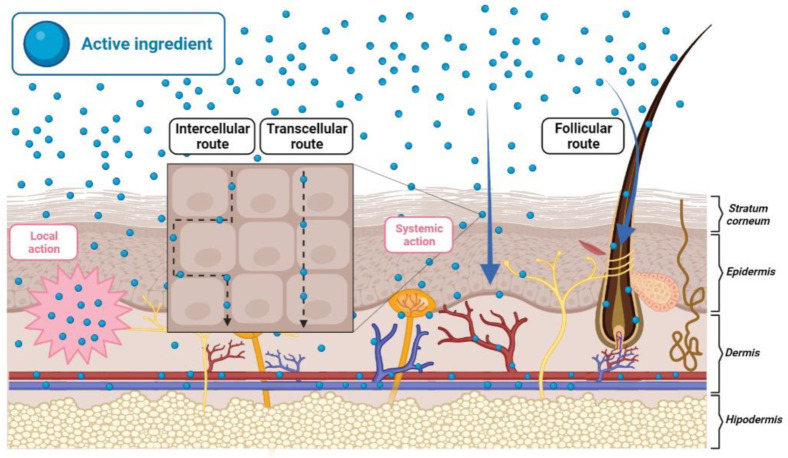

The therapeutic effect of the topically applied formulations relies on the following three steps: i. Release of the active ingredient from the formulation/dosage form; ii. Partition and distribution of the drug within the skin barrier, the SC, and permeation/diffusion through the SC; iii. Partitioning and diffusion from the SC to the viable epidermis and/or dermis, where the active ingredient should produce the desired pharmacological effect [29,30]. The passage of drugs into the skin or through the skin involves three potential routes (Figure 1): the transcellular route, which is related to the drug transport through the lipid matrix and corneocytes of the SC; the intercellular route, in which the drug diffuses between the lipid matrix and the corneocytes; and the transappendageal route, in which the drug is transported through the hair follicles, sebaceous glands or sweat glands [26,31].

Figure 1.

Skin layers and drug delivery routes for systemic and local action.

The vehicle containing the active ingredient and its characteristics, such as formulation type (e.g., emulsions; gels; alcoholic, hydrophilic, or lipophilic properties), concentration of the components, presence of permeation enhancers (surfactants and chemicals that can interact with the stratum corneum and make it more permeable), pH, viscosity, and charge can also importantly influence drug delivery rates and their permeability [27,31]. In addition, occlusive formulations will always improve drug permeability through an increase in skin hydration [27]. Therefore, when designing the ideal formulation, it is important to understand all the variables affecting the active ingredient penetration and permeation across the skin [32]. The vehicle should also be designed and manufactured according to the disease and skin area to be treated [33,34].

Nowadays, semisolid formulations are preferred for dermatological use. Powders and solutions show important disadvantages for topical drug delivery, such as low retention time on the skin, thus leading to a transient drug release and therapeutic effect. Semisolid, or even solid, formulations provide a more adequate permanence of the active ingredient onto the skin and are able to prolong its release. Therefore, different types of pharmaceutical formulations have been developed and produced to be applied onto the skin, such as ointments, emulsions, gels, patches, films, among others [35].

One of the major drawbacks in active ingredient skin delivery is the barrier function of the SC. To effectively diffuse through the skin, molecules must fulfill a set of requirements, such as being small molecules (<~500 Da), an adequate partition coefficient (log 1–3) and ionization degree [36,37]. Unfortunately, a great range of pharmaceutically interesting molecules does not fulfill these criteria, such as peptides, proteins and vaccines, making the delivery across the skin a difficult process [36].

Some approaches have been proposed to increase site-specific drug delivery, such as including penetration enhancers, use of supersaturated systems, prodrugs, nanocarriers, physical and mechanical methods (e.g., microneedles, abrasion, stretching) and electrical methods (e.g., iontophoresis, electroporation) [38]. Some of them will be discussed further in this review.

In addition to the use of drug-loaded devices, sometimes it is necessary to use non-medicated dressings for wound healing processes. In this case, more complex dressings, that can offer ideal conditions for the wound healing process, are being explored [39]. Importantly, these dressings can be individually customized to preserve patient anatomy and needs, thus ensuring good efficacy and acceptable aesthetic aspects.

The ideal wound dressing should provide some features, such as mechanical protection of the wound; protection against infections and microorganisms; oxygen permeability; control of the humid environment; excess exudate removing; be easily peeled off from the wound; biodegradable, biocompatible; non-toxic; and cost-acceptable [39,40]. Nonmedical dressing can be composed of a wide range of materials, as hydrocolloids, alginates, chitosan and hydrogels, among others [39,41].

The current trend is to replace traditional dressings, such as cotton or gauze, which do not have any therapeutic effect, with technological and individualized dressings, providing a more personalized therapy [12,41]. Over the course, the wound dressing can be divided into three categories: bioactive; passive or inert; and interactive [42]. Bioactive dressings are characterized by the gradual release of bioactive molecules. Inert or passive dressing are common materials that provide covering and protection of the wound against pathogens from the external environment, acting mainly as a physical barrier. Interactive wound dressing can influence the wound surface and afford benefits to the healing process. They are able to influence the wound environment and can reduce exudates, prevent infections, form granulation tissue and re-epithelialize and even facilitate debris removal [42,43]. Another classification used relies on their complexity, divided into traditional dressings (e.g., gauze), modern (e.g., films and foams) and advanced dressings (e.g., medicated modern dressing and tissue-engineered substitutes) [44,45].

Some of the commercially available skin dressings include TegadermT™, DermaView II™, DuoDERM®, ALGISITE◊ M, Exuderm™ LP, TegasorbMR, AquaFlo™, etc., and they vary from films, hydrogels, hydrocolloids, etc., [46]. Although these commercial dressings hold great properties and advantages, some of them still present limitations, such as high cost and low adhesion to the lesion surface, which may lead to additional injury upon replacement of the dressing [47]. In this review, we will discuss wound dressing and how 3D printing can benefit this therapeutic approach.

3. 3D Printing Techniques

Three-dimensional printing (3D-printing) is an additive manufacturing method that allows the production of objects layer-by-layer based on a digital file, using computer-aided design (CAD) or imaging techniques, such as magnetic resonance imaging or scan [48,49,50]. The digital file is converted to stereolithography (.stl) file format, which is interpreted by the printer software. Thus, the translation of a digital file into a physical object allows the manufacture of personalized and individualized objects [51].

3D printing was introduced to the market approximately three decades ago and has impacted significantly in many industrial fields. Nowadays, this technology benefits from the possibility of creating prototypes quickly and being cost-effective. The reality is that 3D printing is only limited by the power of imagination and the features of the available printers and techniques [50].

More recently, 3D printing has shown that it can be used in healthcare and that it has a high potential to improve existing therapies. In this area, it can be applied from printing personalized prostheses, implants, and cells to products containing drugs or nanomaterials [8,50]. Supporting the concept of personalized medicine, 3D printing came to disrupt some previously well-established concepts. There is a trend to complement the “one-size-fits-all” concept, promoted by large-scale manufacturers, going ahead also with the personalization of therapies. This is driven by the proposition that one dose may not suit everyone, as the dose can vary with weight, age, disease, and genetics [49,50]. In view of this, personalized therapy aims to meet the individual needs of each patient or group of patients, and thus promote better therapy.

Different 3D printing technologies are currently available for several applications [8]. The different 3D printing techniques are characterized by unique properties, regarding resolution, output volume, cost-efficiency, biocompatibility, among others, which can influence the final printing objective [52]. Therefore, 3D printing techniques can be divided into seven categories: material jetting, material extrusion, vat photopolymerization, powder bed fusion, binder jetting, sheet lamination and directed energy deposition [51]. As there are great reviews focusing on the 3D printing techniques for pharmaceutical applications, as fused deposition modeling (FDM) [53], semisolid extrusion (SSE) [10], inkjet printing [54], stereolithography [55], and powder bed fusion [56], here, only a brief overview of the most used techniques in the pharmaceutical field will be discussed.

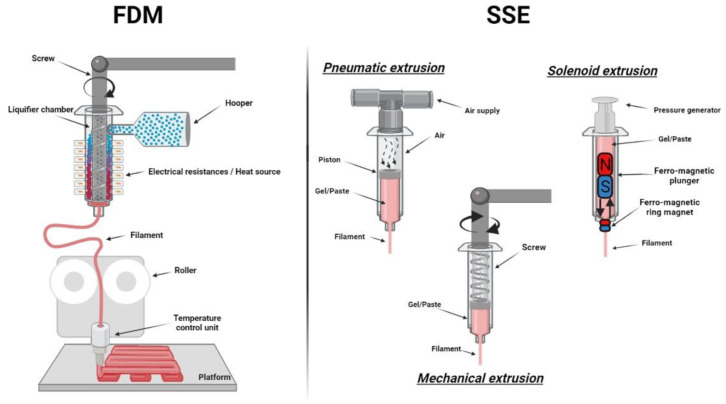

The extrusion-based system includes mainly FDM and SSE (Figure 2) [57]. Among them, FDM is one of the most employed techniques in the pharmaceutical and biomedical fields, owing to its low cost and efficiency. This is a thermo-based technique, so thermoplastic materials are widely used, due to their low melting point, an important parameter in FDM. Solid polymeric filaments are placed in the printer, and by temperature control, it melts during extrusion. Subsequently, the material hardens before another layer is laid onto the previous one, to create a new structure [58]. Moreover, SSE is also largely used in the pharmaceutical and biomedical fields for the development of semisolid structures and formulations. SSE is also known as robocasting, cold extrusion-based printing, hydrogel-forming extrusion, melting extrusion, melting solidification printing process, thermal extrusion, direct ink writing, hot-melt pneumatic extrusion, melting extrusion, micro-extrusion, pressure assisted micro syringe (PAM). This technique relies on the extrusion and deposition of gels or pastes, being the nature of the material that differs from FDM and what makes it important also for bioprinting applications [10]. There are three main SSE mechanisms: pneumatic, mechanical, or solenoid-based systems, and they vary from the use of pressurized air to mechanical force and electrical pulse, respectively (Figure 2). While FDM requires high temperature, SSE can be used at low temperature. However, during SSE printing, a post-printing process is often required, as a drying process or cross-linking phase [10,57].

Figure 2.

Extrusion based techniques, fused deposition modeling (FDM) (left) and semisolid extrusion (SSE) mechanisms (right).

Laser techniques, as SLA and digital light processing (DLP), is based on photopolymerization that use light irradiation to build 3D solid structures. Compared to other technologies, these methods offer several advantages including greater feature resolution, a smoother surface finish and avoidance of drug thermal degradation [55,59]. Jetting techniques, such as inkjet, electrohydrodynamic jet (EHD) and binder jet printing, are also used in pharmaceutical approaches. The EHD technique was developed from electrospinning and provides layer-by-layer deposition of aligned fibers, while inkjet printing includes all systems that place small liquid drops on a substrate [60,61,62]. Binder jet printing is based on the agglomeration of powdered material, layer by layer [60] and has been reported as the most successful 3D printing technology since it was used to print Spritam, the first 3D printed medicine approved by the FDA [51].

In addition to the aforementioned, 3D printing can be applied in mold production of pharmaceutical dosage forms [63]. The solvent casting method has been used to prepare polymeric films for tissue engineering, drug delivery, or coating procedures, and is based on the deposition of polymeric solutions in a 3D-printed mold to create a structure with the negative shape of the mold after solvent evaporation [64].

Encouraged by the development of 3D printing technology, a great range of polymers are arising to achieve diverse requirements of biomedical applications [58]. Basically, polymers, ceramics and hard metals can be used [65]. Polymers are widely used in pharmaceutical dosage forms [12] and biodegradable scaffolds [66]. The polymers used in the biomedical field meet medical standards, such as biocompatibility and are very versatile, allowing their use in more than a single technique [67]. Understanding the rheology of the polymer and how drugs can affect printability is important for efficient 3D printing [57].

Natural polymers, i.e., chitosan, collagen and alginate are ideal for biomedical applications, even though they can have poor mechanical strength [68]. FDM has still limited materials suitable for printing due to the use of high temperatures during the process, and because thermoplastic polymers are preferred. The main polymers reported for this technique are PVA (poly(vinyl alcohol)), PLA (polylactic acid) and EVA (Ethylene Vinyl Acetate) [69]. Moreover, PCL (polycaprolactone) [70,71] and polymethacrylates, as Eudragit® [72] are being well explored in the pharmaceutical field due to their versatility. On the other hand, some 3D printing technologies, i.e., SLA, lack a great range of materials available, once most of them are not recognized as safe (GRAS) [53]. In addition to the main polymers, other excipients can be necessary for successful 3D printing and adequate mechanical properties, such as plasticizer, antioxidant, insoluble or soluble filler, lubricant, among others [70,72,73,74].

4. Review Methodology

In this review, Web of Science, Pubmed and Scopus were used as databases for the literature search, up to 30 of September of 2021. The keywords used were: ((3D print*) and (skin or topical or dermal) and (drug* or scaffold* or film* or patch* or wound dressing or dressing* or mat or bandage)) and (3D print* and wound dressing). Only experimental articles that met the following inclusion criteria were included: use of 3D printing technology for pharmaceutical or biomedical products aiming topical skin applications. The exclusion criteria were transdermal (aiming systemic circulation); skin grafts; product implantation on the skin; bioprinting (cell printing); cell-laden scaffolds prior in vivo studies; articles that have not yet demonstrated practical topical applicability; review articles and access to the full text of the papers not available. Potential articles identified during the reading that fulfill the inclusion criteria were also added. Although the use of cell-laden scaffolds and bioprinting are the main topics found in the database research, 3D printing of products without cells for dermatological use seems to be still an emerging research area, but with great potential ahead. Applying the inclusion and exclusion criteria described above, 66 articles were comprised in this review.

5. 3D printing for Topical Skin Applications

According to the literature, 3D printing is a promising tool to develop personalized dressing and drug dosage forms in the manufacture of biomedical/pharmaceutical products for topical use.

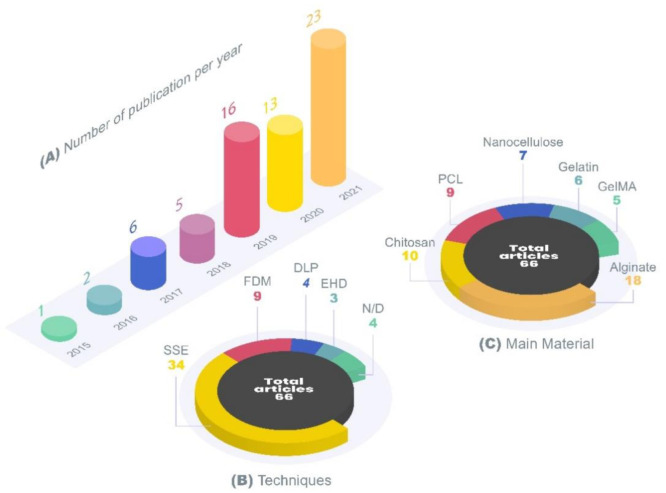

An exponential growing interest in this field can be evidenced by the increasing number of published articles per year. Approximately 79% of the included articles were published in the last 3 years (2019, 2020 and 2021), highlighting the potential alliance between 3D printing and topical skin application (Figure 3).

Figure 3.

Main characteristics of the studies included in this review: (A) number of publications per year using 3D printing for topical skin applications; (B) number of records of the most employed 3D printing techniques; (C) number of records of the most employed materials; DLP, digital light processing; EHD, electrohydrodynamic jet; FDM, fused deposition modeling; GelMA, gelatin-methacryloyl; N/D, not clearly defined (according to the description described by the authors, it was not possible to categorize it in this review); PCL, polycaprolactone; SSE, semisolid extrusion.

Regarding the 3D printing techniques, extrusion-based were the most widely used technology, representing approximately 76% of the techniques applied. Among these techniques, SSE appears in an important number of articles published, indicating the relevance of this 3D printing method for skin applications. This technology holds great advantages in the use for the formulation of topical systems, as it allows the use of a great range of polymers. In addition, it is able to create the most diverse therapeutic approaches and does not need high-temperature ranges nor implies laser use. Additionally, SSE allows hydrogel dressings printing, which are systems with high water content and can be used to treat several skin conditions, such as acne, cellulite, burn wounds to mycosis and psoriasis [75]. They provide moisture retention, skin hydration and thus, an optimal environment for wound healing and the treatment of other skin diseases [75]. Another advantage is the possibility to easily load antimicrobials, biological signaling and pain relief molecules, among others, into these 3D-printed hydrogel systems [10,75]. Hydrogels are an interesting option for topical treatment, and their use in the production of 3D printed products comprised a significant portion of the studies included in this review.

Different printing techniques require different polymeric materials, leading to a high diversity of materials used to produce these 3D products. It is important to note that most articles used more than one material for the 3D printing and Figure 3C represents the number of records of the most reported materials. Alginate was the most used material, followed by chitosan and its derivatives, PCL, nanocellulose, gelatin and gelatin-methacryloyl (GelMA) (Figure 3). Alginate is a very versatile polymer and is already widely used in dressings on the market. It is a natural polymer that has good biocompatibility, biodegradability, swelling and absorption properties, and is also associated with promoting the healing process [76]. Throughout the article, some advantages and disadvantages of alginate, chitosan, PCL, gelatin and nanocellulose will be discussed.

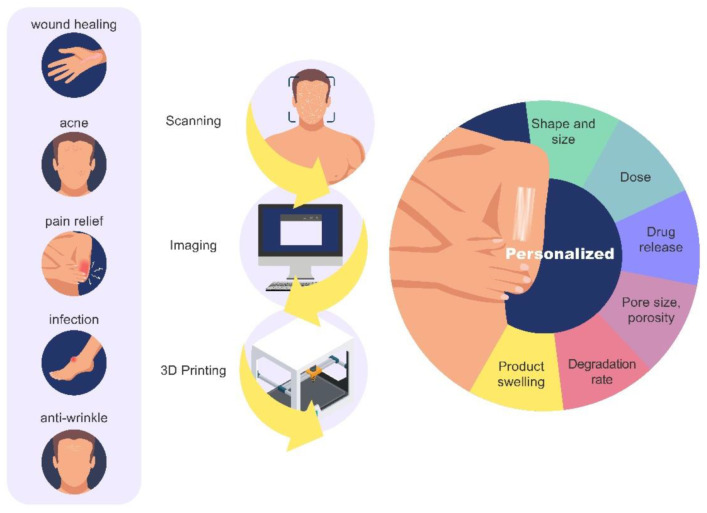

3D printing can be used for customizing dressings and patches, based on the individual anatomical needs of each patient, with the aid of virtual scanning. In addition, several properties can be targeted, ranging from porosity, fluid absorption, and degradation characteristics to more complex drug release profiles and dose characteristics. Several dermatological disorders can benefit from 3D printing, such as acne, infection, pain resolution, scarring, among others. Figure 4 summarized the main applications and advantages of 3D printing for topical skin products.

Figure 4.

Main applications and advantages of 3D printing for topical skin products.

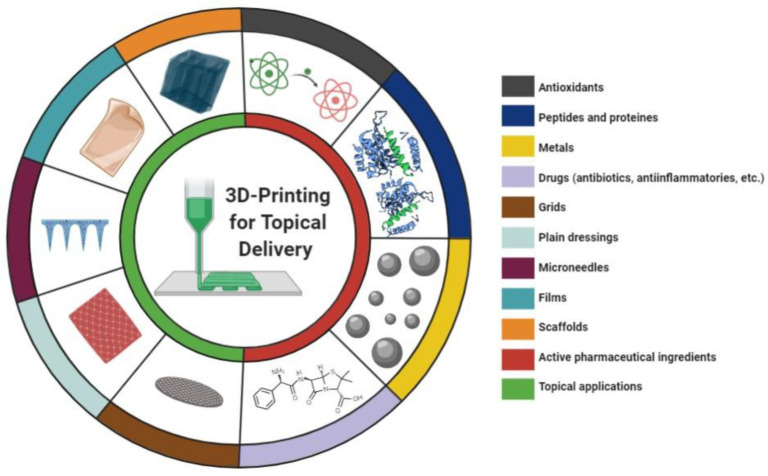

Different topical 3D printed products and types of active ingredients were described in the studies (Figure 5), demonstrating the wide range of 3D printing possibilities for skin applications. Dermatological approaches to treat or prevent skin disorders may include the use of plain dressing for wound healing purposes or dosage forms containing active ingredients. Here, for an easy-to-read format, this paper was divided into two main topics: “Plain Dressings” and “Active Ingredients Delivery”.

Figure 5.

3D printed products (left side of the circle) and types of active ingredients (right side of the circle) previously proposed for topical skin applications.

5.1. Plain Dressings

Although the formulation of drug delivery systems has been an important strategy for the treatment of skin disorders, many wound healing treatments can be designed as non-medicated/plain dressing. 3D printing can address several limitations of conventional wound dressings by tailoring its mechanical and physical properties and providing a better wound healing environment. Most articles presented in this section used the SSE printing technique probably because of its aforementioned advantages. Based on the data acquired, alginate and nanocellulose are the most explored polymers for this purpose. In addition, hydrogel scaffolds seem to be the best alternatives for conventional wound dressing, due to their ability to keep a humid environment, allow oxygenation, promote proliferation, protect the injury from contamination and also because it can be easily removed [77,78]. In this scenario, this section will focus on passive and interactive wound dressing/skin substitutes, and on the discussion of how 3D printing can influence the development of this kind of skin product. Table 1 summarizes the articles regarding plain wound dressings.

Table 1.

3D-printed plain dressings.

| 3D Printing Technique | Main Material | Application | Printed Form | Reference |

|---|---|---|---|---|

| SSE | Nanocellulose | Wound dressing | Grid | [79] |

| SSE | Alginate and gelatin | Recover full-thickness skin wounds | Scaffold | [80] |

| Jet dispensing (micro-jetting system) | Alginate | Robotically deposited bioprinting hydrogel directly onto moving human hand | Hydrogel | [81] |

| SSE | Gellan gum | Wound dressing or cartilage replacement | Scaffold | [82] |

| n/d | ABS | Burn wound healing | Artificial skin | [83] |

| Extrusion based | Chitosan | Skin tissue regeneration and diabetic wound healing | Scaffold | [84] |

| SSE | PEGMA-sodium acrylate-PEGDA and kaolin | Absorbent and hemostatic wound dressing | Dressing | [85] |

| SSE | Nanocellulose | Wound healing, regeneration and tissue repair | Hydrogel scaffold | [86] |

| SSE | Alginate and nanocellulose | Wound dressing devices | Grid wound dressing | [87] |

| SSE | Xylorhamno uronic acid and gelatin | Skin repair and wound healing | Hydrogel scaffold | [88] |

| SSE | Alginate and cellulose nanofibrils | Wound dressing | Hydrogel dressing | [89] |

| SSE | Chitosan and sodium alginate | Skin regeneration | Skin construct/membrane | [90] |

| SSE | PVA and sodium alginate | Bilayered polymeric carriers for wound care | Mats | [91] |

| Cryogenic free-form extrusion | Decellularized small intestinal submucosa | Skin tissue engineering | Scaffold | [92] |

| SSE | Nanocellulose and GelMA | Wound healing | Scaffold | [93] |

| EHD e SSE | PLGA and sodium alginate | Deep wound healing | Membrane scaffold | [94] |

| SSE | Gelatin and cellulose nanocrystals decorated with nitrogen-doped carbon dots | Skin wounds | Hydrogel dressing | [95] |

| Extrusion-based direct-write | PCL and functionalized polyesters | Wound healing | Scaffold dressings | [96] |

| Hybrid extrusion | Alginate, CMC and PCL | Tissue engineering and wound dressing | Scaffold | [97] |

| SSE | GelMA | Wound healing and skin repair | Scaffold | [98] |

| FDM | PVA, PU and PCL | Wound dressing | 3D lattices | [99] |

| n/d | CMC and ε-polylysine | Skin wound repair | Hydrogel dressing | [100] |

| Cryogenic extrusion-based | Chitosan and bioactive glass | Wound healing | Scaffold | [101] |

n/d, not clearly defined (according to the description described by the authors, it was not possible to categorize it in this review); ABS, acrylonitrile butadiene styrene; CMC, carboxymethyl cellulose; EHD, electrohydrodynamic; FDM, fused deposition modeling; GelMA, gelatin methacrylate; PCL, polycaprolactone; PEGDA, poly(ethylene glycol) diacrylate; PEGMA, poly(ethylene glycol) methacrylate; PLGA, poly (lactic-co-glycolic acid); PU, polyurethane; PVA; Poly(vinyl alcohol); SSE, semisolid extrusion;.

Among the polymers used alone or in combination with other biocompatible polymers widely used for dressing applications, we will briefly discuss the most described and their main characteristics:

5.1.1. Algae-Derived Biomaterials

Alginate is a biocompatible polymer that enhances cell proliferation and facilitates the absorption of wound exudates. It has been widely explored in the development of approaches to promote wound healing [76]. Despite its advantages, it also presents some drawbacks. Polysaccharide hydrogels can suffer from bad mechanical properties. Based on that, Milojevic and coworkers (2021) developed a hybrid 3D printed method by alternating the deposition of stiff thermoplastic polymer, PCL, and softer hydrogels, alginate/carboxymethyl cellulose. The hybrid scaffold demonstrated macroporous scaffolds with improved mechanical and physicochemical properties, which showed desired architecture. Compared to the hydrogel, the degradability of the hybrid scaffold was significantly delayed (from 2 days to more than 30 days), which is an important property to observe when designing wound dressings. Compared to PCL scaffolds without the hydrogel layer, the hybrid scaffolds showed higher swelling values, once the hydrogels add hydrophilic groups to the scaffolds. Mechanical strength values were between those shown by the scaffolds containing pure PCL and pure hydrogels, which could be attributed to their hybrid composition. Besides, the authors suggested that by adjusting the mass ratios of soft polymers and PCL a fine control of the mechanical properties could be provided, being an interesting approach for the development of personalized dressings [97].

Liu and coworkers (2016) evaluated the effect of 3D printed gelatin-alginate scaffolds in skin injury healing in mice. In this study, injury closing, and wound healing were enhanced with the scaffold’s application compared to the control. Wound healing was faster (around 2 days), showing decreased necrosis and hemorrhage, and formation of thinner crusts. In addition, the treatment with gelatin-alginate scaffolds promoted granulation tissue formation and angiogenesis; allowed good healing with less accumulation of keratinized substances and increased the strength and tensility of the injury [80].

Apart from the polymers, the combination of different techniques has been assayed to improve the mechanical strength and produce dressing materials with personalized layers. In the light of it, Palo and coworkers investigated a way to combine two different techniques to produce a bilayer carrier. These dosage forms were prepared by solvent casting (SC) combined with 3D printing (SSE) or electrospinning (called by the author’s SC/3D and SC/NF, respectively). SC/3D carriers were prepared with PVA and sodium alginate and were able to absorb liquid without cytotoxicity. Skin bioadhesion using simulated wound fluid demonstrated the decrease in the adhesiveness of SC/NF carriers compared to SC/3D carriers or solvent casting films, which impact the dermal use (non-adherent dressing is preferred). Additionally, SC/NF carriers were demonstrated to be the best physical structure for cell proliferation and adhesion. An additional inkjet 3D printing step was evaluated to explore the deposition of aqueous ink droplets on these carriers, aiming to use a drug solution for drug delivery in the future. However, the droplet distribution was uneven in SC/3D carriers, while a uniform distribution was obtained in SC/NF carriers. Even so, the use of inkjet printing can be an important alternative to provide specific doses of drugs, such as antibiotics, to facilitate wound healing or improve the treatment of other dermatological diseases [91].

As discussed before, 3D printing allows the development of the most diverse dressing structures and architectures. Among the wide range of wound dressing configuration and properties, asymmetric wound dressing has gained space in the research field lately. Of note, these materials have the outstanding ability to mimic dermal and epidermal layers of the skin. The external layer often provides a dense matrix with low porosity and small pores, exhibiting, also, a hydrophobic character. These characteristics act as protection against external factors, such as bacterial infection, mechanical stability and radiation [47,102]. On the other hand, the internal layer provides hydrophilic materials with loose structure, high porosity and large pores. This layer is involved with cell adhesion, migration and proliferation, as well as wound exudate absorption [47,102]. 3D printing can be an interesting alternative for the design and production of this asymmetric wound dressing due to its feasibility in the personalization and production of the most diverse complex structures.

In this context, Miguel and coworkers (2019) developed an asymmetric 3D printed construct for skin tissue engineering purposes. The external dense layer was composed of PCL and a silk sericin electrospun membrane, acting as a protective skin barrier, whereas the internal layer was composed of 3D printed alginate and chitosan hydrogel to provide an ideal environment for cell proliferation and migration. The top layer exhibited excellent mechanical properties, similar to human skin, and the bottom layer had adequate wettability, porosity and cell supporting properties [90]. Wang et al. (2019) have also explored this kind of bilayered printed form. They developed a bilayer scaffold with PLGA and alginate hydrogel for deep wound healing. The structure mimicked the skin structure, since the top layer (PLGA) and the bottom layer (alginate), simulated the epidermis and dermis, respectively. This pharmaceutical form was printed by two different techniques: (1) electrohydrodynamic jet (EHD) printing for the PLGA layer, followed by (2) SSE, for alginate hydrogel layer, which was crosslinked with calcium ions to prevent degradation. The use of PLGA blocked S. aureus penetration into the structure, like the epidermis’ role. Alginate promoted cell adhesion and proliferation as long as the wound environment was moist, a condition guaranteed by PLGA layer protection. The scaffold accelerated the wound healing process, which was completed by day 12, promoting angiogenesis and deposition of collagen I and III [94].

Other algae-derived biomaterials are being explored in 3D printing and wound healing. Xylorhamno-uronic acid, extracted from ulvacean macroalgae, was modified by methacrylation and further photo-crosslinked to produce xylorhamno-uronic acid hydrogels. The hydrogel was successfully printed by SSE with the controlled fabrication of 3D structures. The 3D printed form showed excellent cytocompatibility with human dermal fibroblasts, making this novel 3D printed scaffold a promising alternative for wound healing applications [88].

5.1.2. Nanocellulose

Nanomaterials derived from cellulose are known as nanocellulose and can be categorized into cellulose nanocrystals, cellulose nanofibers and bacterial nanocellulose. These materials have advantages, such as biodegradability, renewability, biocompatibility, and mechanical strength [103].

During the SSE technique, due to the limited mechanical properties of hydrogel inks, sometimes it is not possible to print multiple layers, as the structure collapses. Thus, cellulose nanofibrils can be an interesting strategy to improve the printability of hydrogels, since they present a shear-thinning and rapid consolidation behavior [89]. Moreover, cellulose nanofibrils are a promising material for wound dressing, as they have excellent characteristics, including bacterial growth inhibition, high water absorption, adequate mechanical properties and can form translucent structures [89,104]. In this context, different pre-treatments of nanocelluloses (2,2,6,6-tetramethylpyperidine-1-oxyl-TEMPO nanocellulose and C-Periodate nanocellulose) were evaluated in terms of 3D printability and antibacterial effect for wound dressing materials. Overall, C-Periodate nanocellulose ink formed a more solid structure, and TEMPO nanocellulose tended to collapse, which could be attributed to its low consistency. Besides, these materials inhibited bacterial growth, revealing a promising property for dressing materials [79]. More recently, Chinga-Carrasco et al. (2019) explored Sugarcane Bagasse source of cellulose nanofibrils and confirmed its non-cytotoxic potential. Cellulose nanofibrils ink presented an adequate shear thinning behavior and were successfully 3D printed by SSE to form an object with a grid design. The authors also combined the cellulose nanofibrils with alginate and cross-linked them with Ca2+. However, the alginate addition to the ink had its print fidelity reduced. Even so, the cross-linking reduced the 3D printed grid area [87].

Similarly, Espinosa and coworkers (2019) explored 3D printed hydrogels with porous structures containing TEMPO cellulose nanofibrils and alginate for wound healing purposes. SSE technique was successfully applied, and the hydrogels exhibited important water absorption capability, demonstrating the suitability of these materials for wound dressing materials [89]. Besides the aforementioned studies, Chekni et al. (2020) reported a sensing nanocolloidal hydrogel with an antibacterial effect using cellulose nanocrystals and carbon dots. The dual functionality of the hydrogel dressing is based on the ability to absorb Fe3+ by the nanofibrillar network of the hydrogel, depriving the bacteria of this ion, and thus inhibiting its growth. Once the Fe3+ is absorbed on the surface of the carbon dots, its photoluminescence is quenched, promoting a sensing capability. Hydrogel patches were successfully and readily 3D printed by SSE on a 3M Tegaderm film and could be used to cover the wound, allowing a sensing capability of Fe3+ absorption, without the need for unnecessary changes of dressing that can lead to pain and can impact the healing outcome [95].

5.1.3. Chitosan

Based on its hemostatic and antimicrobial properties, chitosan has also been a highly explored polymer for wound dressing applications, being already available in the market, as HemCon™ bandage [105]. Similarly, chitosan has been widely used in pharmaceutical 3D printing with the most diverse purposes [106], including wound dressing. Intini et al. (2018) explored 3D printed chitosan-based scaffolds by an innovative extrusion-based 3D printing technique for the treatment of diabetes wounds in a rat model. The scaffolds showed good biocompatibility, cytocompatibility and no cytotoxicity against human fibroblast cells and keratinocytes, which were able to attach and colonize the printed form. In vivo tests suggested that these 3D printed forms were as effective in wound healing as the conventional available alternatives. However, no sign of infection was observed in the 3D printed chitosan scaffold group, while the group treated with the commercial one showed infection in the wound [84]. More recently, a blend of chitosan and bioactive glass were proposed to fabricate porous dressing structures to accelerate wound healing. Cryogenic extrusion-based 3D printing was used to rapidly cool the solution below the freezing point. Different bioactive glass concentrations were evaluated, and they had no influence on morphology and water absorption. However, above a concentration of 20%, there was a decrease in the tensile strength and elongation rate. In addition, bioactive glass concentration has impacted the antibacterial effect, cell proliferation and migration, as higher concentration led to better performance. In vivo studies in rats demonstrated that the highest bioactive glass concentration (30%) exhibited better wound closure and collagen deposition, compared to the other groups (positive group, negative group and scaffold containing 20% of bioactive glass) [101].

5.1.4. Synthetic Polymers

Synthetic polymers, compared to natural polymers, have the advantages of homogeneous physiochemical properties and tend to be more chemically and mechanically stable and possess lower cost, which are important points in 3D printing [107]. Synthetic polymers are also employed together with natural polymers, as shown in Section 5.1.1 by Milajovic and coworkers and discussed in Section 5.1.1, with the aim to modify the hydrophobicity and biodegradability of the structures.

Nun and coworkers (2020) combined two different techniques to prepare wound dressings, comparing extrusion-based 3D printed and electrospun dressing. Four synthesized polyesters were blended with PCL with the aim to investigate the influence of polymer composition and thread size in wound healing outcomes. Compared to the control (no dressing), neither the thread size nor the polymer composition affected the normal healing outcome. On the other hand, all dressings improved wound closure compared to polymeric materials commonly used in the literature. Thread size affects angiogenesis and epidermal thickness. Compared to the 3D printed and the control groups, groups treated with electrospun dressing showed an increase in epidermis thickness. On the other hand, 3D printed dressing increased angiogenesis, probably as a result of their larger pore size [96].

The possibility of polymer synthesis based on the desired properties is another great advantage of synthetic polymers. Based on that, Streifel and coworkers (2018) proposed hydrogel foams of synthetized PEGMA-sodium acrylate-PEGDA copolymer, since these gels are extremely absorbent, and further incorporated with kaolin, a hemostatic aluminosilicate. There are products on the market, such as QuikClot Combat Gauze (QCCG, Z-Medica, Wallingford, Connecticut, EUA, composed of kaolin, which is able to address hemostatic activity. However, this product suffers from low fluid absorption potential and may be difficult to remove from the skin. The proposed gels were produced by the high internal phase emulsion technique and showed good viscosity and shear thinning behavior for 3D printing. The hydrogels showed cytocompatibility with human dermal fibroblasts, high fluid absorption and good hemostatic activity, revealing the feasibility of this multifunctional material to prevent several hemorrhages. Furthermore, these 3D printed gels have demonstrated high fidelity to the design and hierarchical porosity [85].

3D printing can also be used to create a dressing with no intrinsic activity attributed, but to aid as a physical top layer. Chuan and coworkers (2018) reported the printability of ABS curved skin, fitting the exact area of the human wound. The approach comprised the use of 3D printed ABS artificial skin and the addition of a hydrocolloid gel composed of agar-agar and crushed eggshells. This gel composed the inner layer of the artificial skin to provide a natural adhesiveness, as well as keep the wound cool. Data demonstrated a short drying time with good adherence to human skin for a long time. Besides, after the 3D printed skin was peeled off, no adhesive marks or stains were observed, which could be of great value for burn wounds [83].

5.1.5. Other Polymers

However, despite all these results, one important concern in wound healing treatment is the material ability on minimizing the complex microenvironment of the natural extracellular matrix (ECM) [108,109]. Commonly available polymers, natural or synthetic, lack on this task. To overcome this issue, decellularized extracellular matrices are becoming promising materials, as they maintain the structural proteins of ECM, as glycoproteins, glycosaminoglycans and biologically active networks [108]. However, decellularized matrices have some disadvantages since membranes or gels of these materials have limitations to form three-dimensional porous structures. In this sense, 3D printing at low temperatures becomes an approach to circumvent the problem. Based on that, scaffolds composed of decellularized small intestinal submucosa were 3D printed by novel cryogenic bioprinting assisted by free-form extrusion and were proposed as a new strategy for skin tissue engineering applications. Addressed by the limitation of 3D printing of decellularized materials, the novel printing technology developed by the authors consists of a 3D robot platform, a pneumatic dispensing system and a cryogenic stage. The scaffolds were successfully printed and demonstrated great mechanical properties, allowing the maintenance of the porous structure, which could support cell growth. Even so, pore size had impacted the mechanical properties once the increase of pore size led to a decrease of young’s modulus. In vitro experiments demonstrated that the 3D printed scaffold could accelerate the production of ECM proteins and also cell proliferation [92].

In the current scenario, the data discussed here evoke great possibilities of 3D printing in skin injuries and wound healing. Interactive dressing can be developed by 3D printing with the manipulation of the most diverse materials, providing multifunctional properties to accelerate the healing process. There is a trend in the use of polymers and materials that have intrinsic activities, such as antibacterial activity, fluid absorption capacity, hemostatic activity, among others. This can provide several advantages for the development of interactive dressings and can significantly impact the quality of life of patients. Still, 3D printing also allows the production of inert dressings, which can be easily associated with another pharmaceutical strategy.

In addition, it must be highlighted that some studies have put some effort into the development of dressings combining two distinct techniques, either two different 3D printing techniques on the same dressing, or different techniques, such as 3D printing combined with electrospinning. This interesting trend can give some new insights for future research.

Despite all the promising outcomes, 3D printing has limitations regarding the printing technique and the polymers used, as limited printability and low mechanical properties. Here several approaches to improve the mechanical properties of these dressings were discussed, which cover the use of polymeric blends, the addition of nanofibers, extrusion at freezing temperatures and hybrid 3D printing techniques.

Even though there are still few studies on the development of plain dressing by 3D printing, this technology holds a promising future regarding the feasibility of complex structures, a wide range of polymers and personalization of wound dressing and skin substitutes. On the other hand, progress in the optimization of printing properties to improve the performance of the materials and to produce customized therapeutic skin dressing has been observed in the last few years, which highlights the potential application of 3D printing and the perspectives of further studies in this area.

5.2. Active Ingredients Delivery

Cutaneous topical treatment with active ingredients may be required by some skin conditions, as injuries, inflammation, or infections, among others. Some factors can compromise patient adherence to topically applied treatments, including complex treatment regimes, misunderstanding of side effects and disease, drug affordability, non-aesthetic approaches, and formulation properties (smell, spreadability, bad organoleptic properties, discoloration and messiness of the delivery system during use). Dose inaccuracy can also be a problem, as conventional formulations do not allow precise control of drug dose and release. Therefore, maintaining treatment adherence can become a challenge for both, the patient and the physician, and compared to oral administration, may lead to more time-consuming and complicated treatments [110].

Other concerns about topical skin delivery are allergic reactions and the high frequency of dose applications, which could be overcome through innovative technologies [28]. Based on this scenario, new topical cutaneous drug delivery systems that can provide more precise doses and drug release rates, targeting specific skin areas, and be focused on the patient’s needs, would be very much appreciated.

3D printing allows the production of complex formulations containing active ingredients for the development of new pharmaceutical dosage forms, considering tailor-made-dosage forms for individual differences. This new technology can produce customized shapes, size, porosity, and a number of layers of dressing/mats/devices while allowing a precise personalization of active ingredients dose and release profiles [111,112].

Active ingredients can be incorporated in 3D printed products by different approaches, which depend on the 3D technique, the materials and the properties of the active ingredients: pre-printing (e.g., blended with polymers prior the filament production by HME [113] or together with the polymers ink prior SSE [9] or SLA [113]) or post-printing (e.g., soaking the 3D structure on a drug solution or suspension [70]). In any case, as will be discussed in the following sections, an active ingredient can be also placed outside the 3D printed product and/or can be infused or injected into the structure when desired.

The incorporation method can also provide different drug release profiles and drug loading values, which can be used as a strategy to modulate drug delivery [114,115]. Most of the studies discussed here incorporated the active ingredient in the materials before the 3D printing process.

Table 2 summarizes the studies concerning 3D printed products for active ingredient delivery across the skin. In the following sections, we will discuss different methods and 3D printing applications for topically and localized active ingredient delivery to the skin, focusing on its release properties. We will present the active ingredients following the sequence: drugs; peptides and proteins; metals; and natural compounds.

Table 2.

3D-printed products for topical delivery of active ingredients.

| 3D Printing Technique | Main Materials |

Active Ingredient |

Active Incorporation Method | Application | Printed Form | Reference |

|---|---|---|---|---|---|---|

| FDM | NF, FLPA and PCL. | Salicylic acid | Preprint: solvent casting prior filament fabrication by hot melt extrusion | Anti-acne personalized patch | Patch/mask | [113] |

| SLA | PEGDA and PEG | Preprint: dispersion in the polymer | ||||

| DLP | 3DM-Castable resin | Diclofenac | * | Trigger finger treatment | Microneedle | [116] |

| FDM | PCL | Zinc, copper and silver | Preprint: solvent casting prior filament fabrication by hot melt extrusion | Antimicrobial personalized wound dressings | Dressing | [112] |

| EHD | PCL and PVP | Tetracycline | Preprint: blended in the ink | Tetracycline loaded patches for personalized drug delivery | Patch | [117] |

| SSE | Alginate and CMC | Sodium diclofenac and lidocaine | Preprint: blended in the ink | Pain-relieving scaffolds for wound healing applications | Scaffold | [9] |

| n/d | PLLA and gelatin | Platelet rich fibrinogen | Postprint: blended in the 3D printing powder | 3D printed scaffolds for chronic wounds | Scaffold | [118] |

| SSE | PEGDA, mineral oil and Kolliphor® P188 | Gallium maltolate | Postprint: soaking method | Hydrogel wound dressing with antimicrobial agent | Hydrogel dressing | [119] |

| FDM | Lignin, PLA and castor oil | Tetracycline | Preprint: blended with polymers prior hot melt extrusion for filament fabrication | Drug loaded meshes with antioxidant activity for wound dressing application | Mesh | [120] |

| Curcumin | * | |||||

| Jet dispensing | Chitosan | Fluorescein sodium | Preprint: blended in the ink | Films for wound healing applications | Film | [121] |

| MEW | PCL | Milk proteins (whey protein and lactoferrin) | Preprint: blended in the ink | Milk proteins loaded scaffold for deep skin tissue regeneration | Scaffold | [122] |

| SSE | Chitosan and pectin | Lidocaine hydrochloride | Preprint: blended in the ink | Hydrogel dressing loaded with local anesthetic for wound dressing | Hydrogel scaffold | [123] |

| SSE | PDMS | Silver nanoparticles | Preprint: blended in the ink | Wound dressing with silver nanoparticles and oil infusion for wound healing activity | Dressing membrane | [124] |

| SSE | GeLMA | PDGF-BB | Preprint: blended in the ink | Skin-inspired bilayer scaffold for diabetic wound healing | Scaffold | [125] |

| Silver nanoparticles | Postprint: impregnation | |||||

| FDM | PLA | Silver nanoparticles | * | Antibacterial Superporous Hydrogels Wound Dressing | Porous dressing templates | [126] |

| Melt extrusion | PCL-PPSu block copolymers | Silver | Preprint: polymer impregnation prior printing | Scaffold with antimicrobial properties for skin tissue engineering | Scaffold | [127] |

| SSE | Pectin and manuka honey | Chitosan and β-cyclodextrin/propolis extract inclusion complexes | Preprint: blended in the ink | Bio-active dressing patch for ulcers and wound healing applications | Patch | [128] |

| SSE | Sodium alginate | Propolis | Preprint: blended in the ink | Propolis-sodium alginate scaffolds for wound healing applications | Scaffold | [129] |

| SSE | Alginate and starch | Rhodamine B | Preprint: blended in the ink | Topical hydrogel patch for drug delivery | Hydrogel patch | [111] |

| FDM | Resin VeroClear, and Tango black | BSA, VEGF, cefazolin | * | Wound bandage with miniaturized needle array for wireless actively delivery of drugs | Miniaturized needle array | [130] |

| SSE | Sodium alginate and PEG | Satureja cuneifolia extract | Preprint: blended in the ink | 3D printed loaded scaffold for diabetic wound treatment | Scaffold | [131] |

| SSE | Alginate and methylcellulose | Manuka honey, aloe vera gel and eucalyptus essential oil | Preprint: blended in the ink | Hydrogel loaded with bioactive components for wound healing applications | Hydrogel film | [132] |

| DLP | 3DM-Castable resin | Acetyl-hexapeptide-3 | * | Microneedle patch with different geometries and curvature for anti-wrinkle peptide delivery | Microneedle patch | [133] |

| SSE | PLGA | Mupirocin | Preprint: blended in the ink | 3D printed scaffold to cover piercing studs for preventing piercing infections | Scaffold | [134] |

| DLP | Keratin | Halofuginone | Postprint: impregnation | Keratin loaded scaffold for burn wounds healing | Scaffold | [135] |

| SSE | Sodium polyacrylate | Cryptotanshinone niosome | Preprint: blended in the ink | Cryptotanshinone loaded niosome for topical delivery in acne treatment | Hydrogel | [136] |

| SSE | Cellulose nanocrystals and chitosan methacrylamide | VEGF, BSA, silver nanoparticles and gentamicin | Preprint: blended in the ink | 3D-printed multifunctional wound dressing | Hydrogel | [137] |

| EHD | Bacterial cellulose and PCL | amoxicillin, ampicillin, and kanamycin | Preprint: blended in the ink | Antibiotic patches for local transdermal delivery in wound healing applications | Patch | [138] |

| FDM | PLA | Cu-CDs | Postprint: soaking method | Nanocomposite containing PLA/HA/chitosan/Cu-CDs/rosmarinic acid for wound healing applications | Scaffold | [139] |

| N/D | Chitosan and alginate | Epidermal Growth Factor | Postprint: solution was embedded or directly dropped in the scaffolds | Multifunctional dressings for local release of therapeutic adjuncts | Scaffold | [140] |

| Material jetting | VeroClear RGD810 and TangoBlack FLX973 resins | Fetal bovine serum, VEGF and rhodamine B | Postprint: by filling the microneedles | Microneedle arrays for drug delivery applications | Microneedles patch | [141] |

| Freeze-deposition | Chitosan | α-tocopherol | Preprint: blended in the ink | Active dressings for chronically infected wounds | Scaffold | [142] |

| Cryogenic extrusion based | Mesoporous bioglass, sodium alginate and decellularized small intestinal submucosa | Exosomes | Postprint: exosome solution was wrapped in the scaffold | Hydrogel scaffold for diabetic wound healing | Hydrogel scaffold | [143] |

| FDM | PCL | Gold nanoparticles | Postprint: soaking method |

Scaffold loaded with gold nanoparticles for skin regeneration | Scaffold | [144] |

| DLP | Vinyl pyrrolidone and PEGDA | Acetyl-hexapeptide-3 | Preprint: blended in the polymers resin | Personalized microneedle patch for anti-wrinkle peptide delivery | Microneedle patch | [145] |

| SSE | Polyacrylamine and gelatin | Silver nanoparticles | Preprint: blended in the ink | Printable inks with antibacterial and anti-UV properties | Scaffolds | [146] |

| SSE | Starch and N, O-carboxymethyl chitosan | Mupirocin | Preprint: blended in the ink | Hybrid biomaterial ink for 3D printed wound dressings | Scaffold | [147] |

| SSE | Methylcellulose, alginate, PNIPAAm | Octenisept® (octenidine dihydrochloride and 2-phenoxyethanol) | Postprint: soaking method | Thermoresponsive 3D printed hydrogel loaded with antimicrobial agent for wound healing applications | Hydrogel dressing | [148] |

| FDM | VeroClear resin | VEGF | * | Miniaturized needle array for VEGF intradermal delivery for wound healing application. | Miniaturized needle array | [149] |

| SSE | Alginate | Bacteriophage nanoparticles | Preprint: blended in the ink | Bacteriophage-based antibacterial wound dressing | Hydrogel dressing | [150] |

| SSE | GelMA and gelatin | VEGF and ZnO | Preprint: blended in the ink | Smart wound scaffold with antibacterial active | Hydrogel patch | [151] |

| Hot melt extrusion-based | PLLA | Neomycin | Postprint: soaking method | Neomycin loaded mats for wound healing applications | Mats | [152] |

| SSE | Chitosan methacrylate | Lidocaine hydrochloride and levofloxacin | Preprint: blended in the ink | Wound dressing for thermal burns | Hydrogel dressing | [153] |

| SSE | Sodium alginate and GelMA | Tea polyphenols | Postprint: soaking method | Hydrogel with antibacterial and antioxidant activities for wound healing and treating | Hydrogel scaffolds | [154] |

* Active ingredients are not incorporated into the 3D printed product itself; n/d, not clearly defined (according to the description described by the authors, it was not possible to categorize it in this review); BSA, bovine serum albumin; CMC, carboxymethyl cellulose; Cu-CDs, copper carbon dots; DLP, digital light processing; EHD, electrohydrodynamic; FDM, fused deposition modeling; FLPA, Flex ecoPLA™; GelMA, gelatin methacrylate; HME, hot melt extrusion; MEW, melt-electrowriting; NF, Ninja Flex®; PCL, polycaprolactone; PDGF-BB, platelet derived growth factor-BB; PEG, poly(ethylene glycol); PEGDA, poly(ethylene glycol) diacrylate; PEGMA, poly(ethylene glycol) methacrylate; PLA, polylactic acid; PLLA, poly-l-lactic acid; PMDS, polydimethylsiloxane; PNIPAAm, poly(N-isopropylacrylamide); PPSu, poly(propylene succinate); PVP, polyvinylpyrrolidone; SLA, stereolithography; SSE, semisolid extrusion; VEGF, vascular endothelial growth factor; ZnO, zinc oxide.

5.2.1. Drugs

Several skin pathologies imply the use of pharmacological drugs for efficient treatments [155]. Acne [156], psoriasis [157], skin infections [158] are some examples that often require topically applied and skin localized drug delivery. A variety of drugs are intended for topical use against these conditions, such as antibiotics and antifungals, for skin infections; topical corticosteroids, for skin inflammations; topical retinoids, for acne treatment; and local anesthetics, as lidocaine, for dermal anesthesia. A great range of skin diseases can be treated with topically applied drugs, thereby avoiding the systemic side effects [35]. These drug classes have been further evaluated to obtain versatile and personalized delivery dosage forms by using additive manufacturing.

Maver and coworkers (2018) developed a pain-relieving wound-dressing combining a 3D printing technique and electrospinning. Diclofenac sodium and lidocaine, a nonsteroidal anti-inflammatory and a local anesthetic, respectively, were loaded in dressings produced by SSE with alginate and carboxymethylcellulose. The drugs were added before the 3D printing process, what did not significantly affect the printability of the hydrogels. Lidocaine and diclofenac sodium showed a sustained release from the 3D printed hydrogels over a period of 48 h. Approximately 25–30% of the drugs were released immediately, followed by a fast release until reaching about 75–80% (350 min), and by a further slower release phase in the next hours (up to 48 h). Besides, the release profile was similar for both drugs, indicating that it was not affected by the drug’s chemical composition. Electrospun drug-loaded fibers exhibited a faster drug release, as 93% of diclofenac and 78% of lidocaine were released within the first 30 min. Therefore, the authors proposed combining both techniques in one wound dressing. The first layer was composed of lidocaine-loaded electrospun fibers, which would trigger immediate pain relief, and the second layer was composed of diclofenac 3D-printed hydrogel, continuing pain relief for 2 days [9].

One year later, Long and coworkers (2019) designed a 3D printed chitosan-pectin hydrogel loaded with lidocaine for wound dressing. Chitosan has important advantages for skin applications, as it is bioadhesive, biocompatible, biodegradable and non-toxic, and shows antimicrobial, antioxidant, hemocompatible and hemostatic activity [20,159]. The authors prepared hydrogel scaffolds by SSE followed by lyophilization. To provide the best wound environment, the scaffolds showed a high swelling ratio and water absorption, highlighting their ability to absorb exudates and retain wound moisture. Bioadhesion strength indicated great self-adhesion onto the skin. Wound dressing should be self-adhesive but easy and painless to remove. Different drug concentrations were evaluated, and all formulations showed a fast drug release within the first hour, followed by a sustained release behavior. This release profile was attributed to the lidocaine entrapment within the polymers [123].

Chitosan films were also proposed by Hafezi and coworkers (2019), using the jet-dispenser 3D printing technique. Fluorescein sodium was used as a model drug, along with genipin, as a crosslinker molecule with anti-inflammatory and antibacterial activity, and PEG and glycerol, as plasticizers. In vitro mucoadhesion studies showed their ability to adhere to a model mucosal surface, in which the plasticizer could play an important role, as films containing PEG hydrated better, leading to a higher detachment force. The high adhesion reinforced the potential of these chitosan films to stay longer when applied to the skin wound surface, therefore, contributing to better patient compliance. For the release studies, fluorescein sodium was used as a model drug. Approximately 67% of fluorescein sodium was released within the first hour, which was in agreement with the swelling study, which showed fast hydration in the first 15 min [121].

The use of protein-based biomaterials has been vastly spreading in biomedicine, tissue engineering [160] and drug delivery [161] and becoming an important natural alternative to synthetic polymers. These materials are interesting in drug delivery because they have low toxicity, are water-holding, able to emulsify and are abundant in nature [162]. Besides, protein structures can enhance cell attachment and migration [163]. All these features sustain their use on topical dressings for skin diseases, such as burn wounds.

Navarro and coworkers (2020) successfully developed a keratin scaffold loaded with halofuginone for burn wound healing treatment. Halofuginone is an FDA-approved inhibitor of collagen I synthesis and prevents the accumulation of abnormal fibrillar collagen, which is associated with fibrosis and wound contracture. The DLP technique was used to fabricate keratin-based scaffolds, followed by lyophilization and gamma irradiation sterilization. Noteworthy, the results showed that lyophilization, sterilization and further rehydration prior to in vivo use, can lead to changes in the crosslinked network, in the dimensions of the samples and/or loss of mass. In vivo, the porcine burn wound model showed that 3D printed halofuginone-loaded scaffolds were non-inferior to the treatments in the literature, and do not hamper the healing processes. However, the 3D printed scaffolds were the only group to significantly demonstrate improvement in healing from day 30 to day 70, which could be an indicator of more organized dermal healing after-burn. As concluded by the authors, this treatment is slower, however, improves healing [135].

Wound infections can be an important issue during the wound healing process, as they may delay the healing progress and impact negatively on pain and life quality [164]. Singh et al. (2021) designed and characterized FDM 3D printed neomycin PLA mats for wound covering and antibiotic delivery. The PLA mats were printed and soaked in molten PEG or in molten PEG containing neomycin for the drug load mats. Three different molecular weights of PEG were evaluated (400Da, 6kDa and 20kDa). Results showed that the higher the molecular weight of PEG, the lower the total drug cumulative release over a 3-week period. Additionally, coating with PEG 400 Da exhibited great mechanical properties, evidenced by the formation of a flexible mat, with sufficient porosity, making it suitable for dermal/bandage-like wound covering [152].

In the same context, mupirocin, a topical antibiotic, loaded in 3D printed scaffolds were proposed to cover piercing studs and prevent infection. The bioabsorbable PLGA “biopierce” was designed to stay in the human tissue for up to two weeks and release the drug during this period to prevent infection and allow wound healing. The antibacterial assay demonstrated bacterial inhibition over 14 days, showing the efficacy of the 3D printed product. This study brings new insight into drug-eluting wound dressings [134].

Stimulus-responsive systems for the delivery of therapeutic drugs are another interesting approach for topical treatments. In this context, Niziol et al. (2021), proposed a thermoresponsive hydrogel loaded with Octenisept®, an antimicrobial agent composed of octenidine dihydrochloride and 2-phenoxyethanol, for wound healing applications. SSE was employed for the fabrication of these hydrogel-based dressings composed of poly(N- isopropylacrylamide) (PNIPAAm) precursors, sodium alginate and methylcellulose. The swelling hydrogel and drug release profiles were dependent on the temperature. The highest the temperature, the lowest the swelling ratio and the highest the OCT release [148].

Another research group has developed single-step EHD printing for rapid tailored dosage forms containing antibiotics for wound healing. Amoxicillin, ampicillin, and kanamycin were individually mixed with bacterial cellulose and PCL to fabricate 3D printing patches. The complete drug release took 14 days, with an initial burst release, followed by a slow-release phase. Interestingly, the kinetic releases fit Fick’s law of diffusion, regardless of the solubility of the antibiotic. In addition, the antibacterial assay demonstrated that all patches were effective against gram-positive and gram-negative bacteria. This study provides a versatile approach for the development of wound dressing with antimicrobial drugs [138].

To investigate the influence of 3D printed parameters on fiber deposition and alignment and to evaluate the influence of the composition of the patch material and the print-void geometry on drug release, Wang and coworkers (2017) developed 3D printed film patches via EHD technique. Films were composed of PCL or PCL-PVP loaded with an antibiotic (tetracycline). Drug release from PCL patches was slower than from PCL-PVP patches, probably due to the higher hydrophobic property of PCL. In addition, the pore size had an important influence on tetracycline release, in which patches with lower pore sizes values (200 × 200 μm2) showed a relatively slower release (65.4 ± 1.6%) compared to patches with higher pore sizes of 500 × 500 μm2 (72.1 ± 2.9%), in the first 24 h. For all samples, after this burst release, a slow and steady release was observed until the fifth day. The authors showed that both matrix composition and pore size can be tailored, based on the aimed drug release profile, providing appropriate drug concentration and release to inhibit bacterial infection [117].

Tetracycline was also used by Dominguez-Robles and coworkers (2019), in addition to a model compound, curcumin. Lignin, a natural biopolymer with antioxidant properties, blended with PLA and castor oil, was used to prepare 3D printed filaments by HME. Tetracycline was incorporated with lignin in the filament and the FDM technique was applied to produce the 3D-printed meshes. Even so, due to the printer configuration, a two-nozzle FDM was used to combine the mesh with a printed PVA film (as the second layer). Finally, a curcumin film, produced with hydroxypropyl methylcellulose (HPMC), was placed on the top of the 3D-printed mesh. The mesh dimensions affected the curcumin release rate, and so the meshes might be designed according to the patient’s healing needs [120].

Despite many studies on this area aimed at wound healing applications, there are still many other skin diseases and possibilities to explore by using 3D printing techniques in the development of therapeutic approaches for skin delivery. Bom and coworkers (2020) developed a drug delivery system for topical application, based on alginate-pregelatinized starch. Semisolid extrusion was chosen as the 3D printed technique, and the process parameters were evaluated by a Quality by Design approach. The addition of starch led to an increase in the size and the number of open pores, which can influence the drug release. In the in vitro rhodamine B release, alginate-starch patches demonstrated a higher burst effect than alginate alone, which was explained by the starch swelling properties. After 360 min, alginate-starch patches released 90.46% vs. 71.51% of the alginate patches. According to the authors, these data pave the way for future drug delivery strategies for topical skin delivery [111].

Moreover, the alliance of 3D printing and nanotechnology has been widely explored in the biomedical area in the last years and can improve pharmaceutical dosage forms [8]. Nanotechnology plays a prominent role in developing more complex drug release profiles, and in targeting specific pharmacological therapy [165]. Wang et al. (2020) explored 3D printed hydrogel loaded with cryptotanshinone (CPT) niosomes for topical therapy of acne. The 3D printed hydrogels (blank hydrogel, CPT loaded hydrogel and CPT niosomes loaded hydrogel) demonstrated good bioadhesion, gel strength and extrusion. Furthermore, in vitro release showed that CPT niosomes loaded hydrogel were able to control drug release, even up to 96 h. It exhibited a lower release (61.5%) compared to the CPT-loaded hydrogel (78.6%). Skin permeation and skin deposition experiments demonstrated, respectively, significantly higher rates of transdermal flux and skin deposition of CPT from 3D printed niosomes-loaded hydrogels. These results highlighted the feasibility of 3D printing to incorporate nanostructures (niosomes) for enhanced topical drug delivery. Moreover, the in vivo anti-acne assay was promising, showing an anti-acne effect without skin irritation and holding great potential for novel personalized acne treatments [136]. However, as highlighted by Santos and coworkers (2021), the association of nanotechnology and 3D printing for topical use must be carefully evaluated to avoid toxicity and systemic absorption of the drugs [8].

Among the most important advantages of using 3D printing in the pharmaceutical field is the possibility of personalization, especially for topical products where it is possible to design the product, based on the patient’s needs. Goyannes and coworkers (2016) explored the potential of 3D printing to produce personalized nose-shape anti-acne devices loaded with salicylic acid by two different 3D printing techniques: FDM and SLA. Salicylic acid was blended with the FDM polymers (Flex EcoPLA—FPLA—and PCL) and the filaments were produced by hot-melt extrusion. Thermal degradation of the drug was observed during the extrusion because of the high temperatures used. An FPLA-salicylic acid filament was efficiently printed as a nose-shape mask instead of a PCL-salicylic acid filament, which was not possible to print. For the SLA printing, the drug was mixed with both polymers (PEGDA and PEG) before solidification by the laser beam. There was no drug degradation, and the printing resolution was better than by FDM technique. Drug diffusion from 3D printed circular-shaped devices produced by SLA exhibited a faster release profile than those prepared by FDM. According to the authors, SLA printing is a promising technology to produce personalized anti-acne devices and could allow specific dosage, shape, and size [113].

From the data discussed above, 3D printing has demonstrated outstanding positive points in producing complex and customized drug delivery systems for topical skin delivery. The burgeoning area is an important technology that can provide better therapeutic results for skin diseases, although it still needs to be explored more. There is still a gap in the evaluation of drug permeation and penetration across the skin. Moreover, considering the site-specific/local drug action, it is extremely important to ensure that no systemic absorption of the drug will occur by the application of the proposed 3D printed products.

5.2.2. Peptides and Proteins

Topically applied proteins and peptides for the treatment of skin disorders have also become an important research field in the last years [166]. These macromolecules are relevant for the local treatment of several skin diseases, and increasing their site-specific delivery is an important goal to be achieved [26]. However, peptides and protein delivery through the skin suffer from inefficient penetration and permeation. This limitation results in reduced efficacy and wastage, caused by the inadequate/insufficient drug concentration at the site of action [133]. Some approaches have been proposed to improve their skin delivery, such as the use of microneedles (MN).

MN are a very explored alternative for the delivery of these molecules and are normally referred to as transdermal systems, but they can also represent a strategy for localized site-specific drug delivery [26,167]. The fine control of the microneedle length and arrays allow the targeting of ingredient actives to the epidermis or the dermis, producing minimal systemic effects [26,133]. The use of 3D printing to produce MN enables their customization, such as distribution and depth of needles and also the drug release rate [18]. Remarkably, this technology provides continuous one-step manufacturing and cost-efficiency [18,52]. Its use to improve the skin delivery of peptides and proteins for local treatment will be discussed in this section.

Acetyl-hexapeptide-3 (AHP-3) is a small topically applied anti-wrinkle peptide, with good efficacy and safety characteristics, but its permeation across the skin is limited due to its high molecular weight and hydrophilicity. Lim et al. (2020) developed a 3D printed personalized microneedle patch as a “poke and patch” approach for AHP-3 solution delivery. Although the authors referred to transdermal delivery, this strategy was proposed to promote the local effect of AHP-3. DLP technology was used to fabricate MN with different geometries and curvatures, and later to fabricate a personalized MN patch for the periorbital eye region. 3DM-castable resin was used as the main material. MN geometries with different curvatures were produced in order to analyze the relationship between different MN dimensions and their effect on mechanical strength and skin penetration efficiency. The author’s hypothesis was that each curvature would have its own optimized MN geometry. However, the results showed the same optimized geometry for all three curvatures (MN height of 800 μm; tip diameter of 100 μm, interspacing of 800 μm and base diameter of 400 μm). In vitro drug delivery demonstrated that the optimized personalized curved MN patch for the eye region provided approximately 45x higher AHP-3 delivery through the skin, compared to a flexible commercial MN patch [133].