Abstract

In the native vasculature, flowing blood produces a frictional force on vessel walls that affects endothelial cell function and phenotype. In the arterial system, the vasculature's local geometry directly influences variations in flow profiles and shear stress magnitudes. Straight arterial sections with pulsatile shear stress have been shown to promote an athero-protective endothelial phenotype. Conversely, areas with more complex geometry, such as arterial bifurcations and branch points with disturbed flow patterns and lower, oscillatory shear stress, typically lead to endothelial dysfunction and the pathogenesis of cardiovascular diseases. Many studies have investigated the regulation of endothelial responses to various shear stress environments. Importantly, the accurate in vitro simulation of in vivo hemodynamics is critical to the deeper understanding of mechanotransduction through the proper design and use of flow chamber devices. In this review, we describe several flow chamber apparatuses and their fluid mechanics design parameters, including parallel-plate flow chambers, cone-and-plate devices, and microfluidic devices. In addition, chamber-specific design criteria and relevant equations are defined in detail for the accurate simulation of shear stress environments to study endothelial cell responses.

1 Introduction

The vascular endothelium is the cellular monolayer located at the interface between flowing blood and the vessel wall. Playing a dynamic role, the endothelium actively adapts to preserve structural and functional homeostasis through the maintenance of anticoagulant properties, regulation of vessel permeability and vasomotion, and response to pathological disease processes associated with inflammation, wound healing, and cardiovascular diseases [1]. All of these properties are known to be influenced by biochemical and biomechanical stimuli that determine the pathology within the hemodynamic environment of the vasculature [2]. Endothelial cells (ECs) respond to tangential fluid shear stress and circumferential wall stretch forces via a variety of mechano-receptors and mechano-transducers, regulating various pathways that maintain vascular tone and homeostatic function [3,4]. Thus, the flow-sensitive mechanisms through which ECs respond to various (patho)physiological flow environments have been a continuous area of study within the field [5,6].

Wall fluid shear stress is defined as the frictional force blood (fluid) flow exerts on vessel walls and is expressed in units of force per area (dynes/cm2, where 1 dyne/cm2 = 0.1 Pa) [7]. Flow patterns in the human arterial system, as described in Table 1, are complex and can vary both spatially and temporally, causing variations in wall shear stress. Overall, the mean physiological shear stress level is normally maintained by instantaneous vasomotor changes to average between 10 and 20 dynes/cm2 but is highly dependent on the local fluid dynamics of the vessel [8–11]. In general, flow patterns in the arterial system can be categorized as either laminar unidirectional pulsatile or oscillatory shear flow. Unidirectional pulsatile shear stress occurs in straight arterial regions at 10–60 dynes/cm2. These regions experience flow in ordered, laminar patterns (fluid flows in parallel streamlines with no disruption between layers) of a pulsatile function that is dependent on the cardiac cycle, yielding mean positive shear stress [12]. Regions with fully developed (the velocity profile is not dependent on the axial location) unidirectional pulsatile flow with sufficiently high mean fluid shear stresses are known to induce an athero-protective EC phenotype and protect against the localization of cardiovascular disease [13,14]. This physiological flow is frequently simplified to steady laminar flow for in vitro EC flow experiments [12]. ECs exposed to steady laminar flow become elongated and align parallel to the direction of fluid flow (Fig. 1(b)), which is mediated by integrins [15], the cytoskeleton, primary cilia [16], and glycocalyx components, such as syndecan-1 and heparan sulfate [17,18]. Shear stress for fully developed steady Poiseuille flow in straight, circular vessels of constant cross-sectional area is directly proportional to the velocity of blood flow ( ) and inversely proportional to the vessel radius ( ) to the third power

| (1) |

Table 1.

Description of flow patterns within various in vivo locations

| Flow description | Velocity | Wall shear stress | In vivo locations | ||

|---|---|---|---|---|---|

| Laminar < 1400 | Steady | Positive or negative (directional) | Constant, unidirectional | Constant | Rare–capillary |

| Pulsatile | Unidirectional | Transient, mean positive flow–frequency ranges generally below 10 Hz | Low, transiently changing between positive and negative | Arteries, arterioles | |

| Oscillatory | Reversing | Low, positive and negative | Branching, bends | ||

| Turbulent > 1400 | Chaotic | Unpredictable | >95% stenosis | ||

Fig. 1.

![Representative images of endothelial cell morphology under static and laminar flow conditions. Immunofluorescent images are stained for microtubules and nuclei. (a) Endothelial cells under 24 h of static culture exhibit a nonaligned, cobblestone morphology. (b) Endothelial cells exposed to 24 h of 12.5 dynes/cm2 unidirectional laminar wall shear stress exhibit an aligned and elongated morphology. The flow study [14] was performed in a PPFC with dimensions of 7.62 cm × 2.54 cm × 250 μm. Fluid viscosity was 1 cP. Flow direction is horizontal. Scale bars indicate 50 μm.](https://cdn.ncbi.nlm.nih.gov/pmc/blobs/25cf/8628846/ecede2f1f0bd/bio-20-1480_020801_g001.jpg)

Representative images of endothelial cell morphology under static and laminar flow conditions. Immunofluorescent images are stained for microtubules and nuclei. (a) Endothelial cells under 24 h of static culture exhibit a nonaligned, cobblestone morphology. (b) Endothelial cells exposed to 24 h of 12.5 dynes/cm2 unidirectional laminar wall shear stress exhibit an aligned and elongated morphology. The flow study [14] was performed in a PPFC with dimensions of 7.62 cm × 2.54 cm × 250 μm. Fluid viscosity was 1 cP. Flow direction is horizontal. Scale bars indicate 50 μm.

where is the viscosity of blood [19]. Thus, small changes in greatly influence the magnitude of shear stress which ECs experience.

In contrast, oscillatory shear stress, which occurs with forward and reversing flow patterns, is found at arterial bifurcations, branch points, regions of high curvature (±4 dynes/cm2), and within stenotic arteries (30–40 dynes/cm2) [20]. These regions are characterized by a low shear stress magnitude and complex changes in the flow direction. These disturbed flow conditions fail to align and elongate ECs, which is seen in athero-protective hemodynamic conditions, and result in a cobblestone morphology (Fig. 1(a)). ECs experiencing disturbed flow, which is associated with low, oscillatory shear stress, have a pro-inflammatory phenotype and contribute to the pathogenesis of cardiovascular diseases [21,22].

Gaining insight into the direct effects of flow patterns, fluid shear stress magnitudes, and blood vessel geometry can deepen the understanding of EC responses to mechanical forces. Many flow chamber models have been designed to study these factors independently in vitro, including parallel-plate flow chambers, cone-and-plate viscometers, and microfluidic devices. Flow chamber device design is critical in shaping flow patterns, inducing the correct shear stress magnitude, and other flow parameters to accurately simulate in vivo (patho)physiology of ECs. This review discusses design criteria and device modifications for in vitro flow devices for the study of hemodynamic forces on vascular EC structures and functions.

2 Parallel-Plate Flow Chambers

The most commonly used in vitro device to study the combined effects of physical and chemical stimuli to advance the understanding of mechanical cues on ECs is the parallel-plate flow chamber (PPFC) [23]. Simple in design and operation, PPFCs have several advantages in their use over other flow chamber applications. Wall shear stress (SS) over a cell monolayer is well-defined due to the uncomplicated rectangular geometry of the chamber, allowing for the application of constant SS in physiological ranges for a defined time period (Fig. 2(a)). Different flow patterns can also be induced to study various physiological effects on an EC monolayer, including elongation and alignment [24], adhesion [25], and gene and protein expression [26]. This versatile tool enables researchers to grow cells under flow conditions, recover cells after a flow study for further experiments or subsequent data analyses, continually sample the fluid medium for secreted metabolites [27], study real-time cellular interactions and changes using live imaging apparatuses, and to directly fix cells once experiments are concluded, making studies easily reproducible. While the fluid can be continuously sampled for secreted molecules, fresh media can also be circulated to control cytokine influences. However, one limitation of PPFC devices used for experiments with downstream sampling is that the temporal resolution of the measurement depends on the flow rate and sampling frequency, which limits the sensitivity for detecting molecules that are produced in small quantities or have short half-lives. Representative optical images of PPFCs within literature can be viewed within references [28–31].

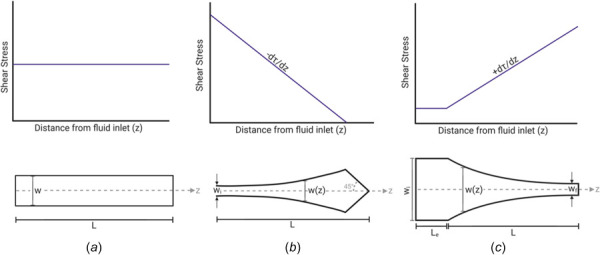

Fig. 2.

Characterization of PPFCs with variable width modifications. (a) The plain PPFC has a constant width (w) along the length of the chamber. This produces a constant shear stress for the entire chamber length (L). (b) As the width of the fluid channel increases from the inlet to the outlet, a constant, negative SSG is generated along the center axis of the channel. At the chamber inlet of width wi, the shear stress is at its maximum and linearly decreases to zero at the outlet of the chamber. (c) As the width of the fluid channel decreases from the inlet to the outlet, a constant, positive SSG is generated along the center axis of the channel. The entrance region of length Le and width wi produces a constant shear stress with fully developed laminar flow. As the width decreases along length L, a positive, uniform SSG is produced along the center axis of the channel. The width of the channel outlet is defined as wf.

2.1 Steady Laminar Flow in Parallel-Plate Flow Chambers.

Wall shear stress at the cellular monolayer within a PPFC can be derived through the simplification and rearrangement of the Navier–Stokes equations and continuity equations [32–34]. Given the assumptions of an incompressible, Newtonian fluid in fully developed laminar flow, shear stress (SS) between two stationary parallel-plates can be described as

| (2) |

where is the pressure gradient parallel along with the plates, is the fluid viscosity, is the fluid velocity, and is the height position with respect to the bottom plate ( ) [33]. After integrating with respect to the chamber height position twice and applying the no-slip boundary condition, the velocity profile between plates can be described as a parabolic function of the height position [33,35,36]

| (3) |

In two-dimensional Poiseuille flow, SS can be expressed as a function of PPFC geometry and flow rate ( ) of the fluid by integrating over the total height ( ) and width of the chamber [23,33,35,37–41]

| (4) |

in which is the wall SS at the EC monolayer. This equation is valid for Newtonian fluid in fully developed laminar flow within a chamber with a high aspect ratio ( ), where ; therefore, a chamber must be designed with a wide fluid channel with a short distance between the top plate and ECs. To ensure at least 85% of the monolayer is exposed to a homogeneous SS, the aspect ratio must be a value equal to or greater than 20 [33,36]. The initial design of a PPFC can be achieved by defining the required SS for the study, the fluid (media) viscosity, and chamber width and height to calculate the volumetric fluid flow rate required for the study.

To ensure ECs are experiencing purely laminar flow, one must consider the values of the Reynolds number ( ) and entry length ( ) at the monolayer. Physiologic arterial flow is typically between one hundred and several thousand, and, generally, a < 1400 is considered laminar [33,42,43]

| (5) |

In the equation above, is defined as fluid density. This equation can also be expressed in terms of the hydraulic diameter of the chamber [44]

| (6) |

To eliminate any possible entry effects of the flow profile, the EC monolayer must be placed beyond the entrance length of the flow. The entrance length is the length from the fluid inlet into the chamber to fully developed laminar flow and is a function of [37,44]

| (7) |

The criteria of Eqs. (5)–(7) must be met for the in vitro device to accurately simulate steady-state laminar flow. PPFCs can be initially designed using the equations in this section to estimate design criteria. Chamber specifications can be further refined through computational fluid dynamic (CFD) simulations to validate that the monolayer is experiencing fully developed, steady-state laminar flow. CFD models can also be used to calculate and/or confirm fluid velocity, pressure, SS, and other hemodynamic phenomena [45]. Generally, dimensions determined by numerical solutions should fall within 5% of CFD values for an optimal chamber design.

2.2 Linear Shear Stress Modifications

2.2.1 Variable Width PPFCs.

While plain PPFCs expose cells to a constant, homogeneous SS, many studies have modified the chambers to generate a varying SS along the length of the fluid channel [46]. Using the standard rectangular cell seeding area, the generation of different SS values is done by changing either the flow rate, the fluid viscosity, or the chamber height between the two plates, which require separate experiments and can require disassembling of the device [37]. One PPFC modification to enable the study of multiple SS values for a single cell source within a single experiment is to create a PPFC with tapered channel width. This PPFC design adaptation has a uniform height (h w,L) across the channel with an increasing, variable width, which is typically created by modifying the lower gasket (Fig. 2(b)). Based on Hele–Shaw stagnation flow theory, as the channel width increases along the chamber length from the fluid inlet to the outlet, a constant SS gradient of a linearly decreasing magnitude is generated [47]. In a tapered channel, SS is a function of axial distance (z) from the inlet and creates a stagnation point proximal to the fluid outlet. The increasing width of the channel along the centerline (z-axis) can be determined by

| (8) |

where is the total length of the fluid channel and is the width of the fluid inlet [48]. Thus, for a constant flow rate and height, SS diverges linearly along the center of the channel with respect to distance from the inlet [49]

| (9) |

Pressure drop ( ) across the channel can be calculated using [46]

| (10) |

Therefore, chamber designs with an increasingly tapered channel allow for the time-efficient study of a single cell source under a wide SS range for each experimental run.

Conversely, channels can also be inversely tapered by decreasing the width in the flow direction from the fluid inlet to the outlet, creating a converging PPFC [50]. As the channel width decreases along the chamber length from the fluid inlet to the outlet, a constant SS gradient (SSG = ) of a linearly increasing magnitude is generated (Fig. 2(c)). Both the SS and the shape of the variable side walls are a function of axial distance from the inlet and have been derived from the plane-Poiseuille solution by Lu et al. [23].

In a PPFC with a constant height, the variable decreasing width of the channel can be determined by

| (11) |

where is the width of the fluid outlet [23]. Thus, for a constant flow rate and negligible wall effects, SS increases linearly along the center of the channel with respect to distance from the inlet

| (12) |

The constant positive SSG across the channel can then be determined by

| (13) |

2.2.2 Variable Height PPFCs.

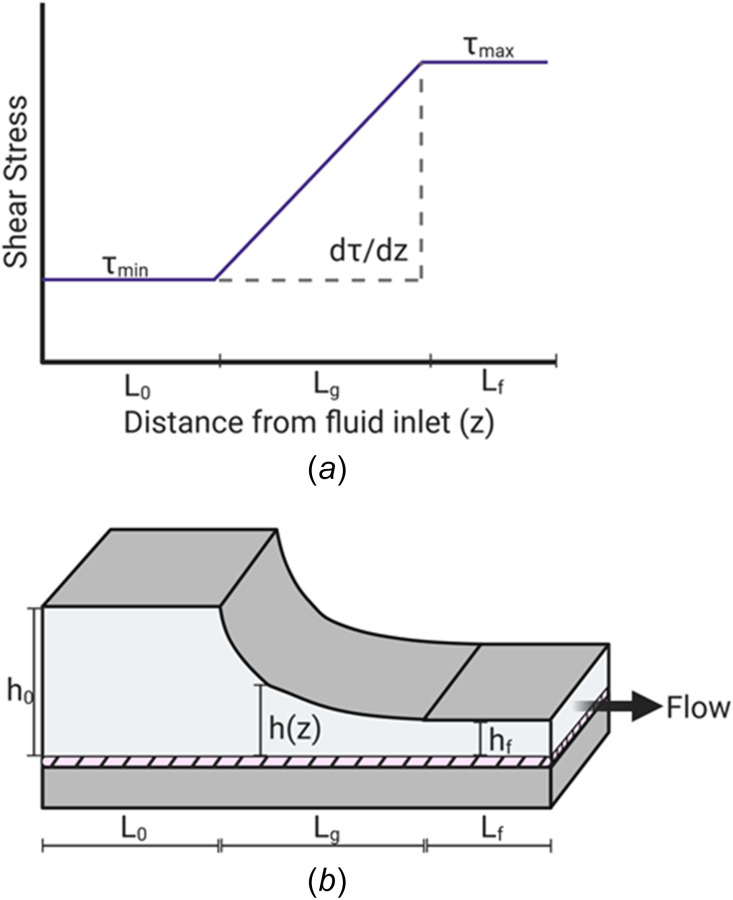

Another modification of the PPFC to generate a uniform SSG is made by tapering the top plate to have a variable height along the channel length [39]. Tapering of the top plate allows for the generation of three distinct experimental regions: (1) an entrance region with a minimum SS along the length L0, (2) a positive, constant SSG region of length Lg, and (3) an exit region with a maximum SS of length Lf (Fig. 3(b)). Because the chamber is variable in height, the constant heights at the inlet and outlet are denoted as h0 and hf, respectively, and the channel height along the gradient region is defined as a function along the chamber length

| (14) |

Fig. 3.

Characterization of the modification of tapering of the top plate. (a) The modification of producing a variable height of the PPFC by tapering the top plate forms three distinct experimental regions along the distance from the fluid inlet. As the fluid flows into the entrance, the height of the chamber is at its maximum, h0. This generates a constant, minimum shear stress along the entrance length, L0. As the height decreases, a positive, uniform SSG is generated for the gradient length of Lg. Shear stress reaches its maximum along the exit region of Lf at the minimum height of hf. (b) Schematic diagram of the modification of the tapering of the top plate. The hatched region represents the endothelial monolayer.

This flow chamber generates a uniform linear increase in SS along the constant gradient region (Fig. 3(a)) where SS and the SSG are, respectively, given by

| (15) |

| (16) |

Minimum and maximum SS values depending on the chamber design can be calculated as follows:

| (17) |

| (18) |

Another way to design a chamber with a uniform linear SS range is by defining the required values for minimum SS, maximum SS, and the SSG. Using the experimental criteria, the dimensions of the chamber can be designed using the equations below:

| (19) |

| (20) |

2.3 Parallel-Plate Flow Chamber Modifications for High Shear Stress Gradients.

It is speculated that low SS magnitudes and high SSGs play an important role in the pathogenesis of atherosclerosis due to the localization of atherosclerotic plaques in regions where ECs are exposed to low, disturbed flow, which creates temporal and spatial SSGs [23]. Flow separation (divided fluid streamlines due to adverse pressure gradients) and reattachment (divided streamline attaches to forward flow) cause SSGs large in magnitude, resulting in distinct regions of confluent EC monolayers mimicking both disturbed and physiologic flow regions in vivo [22]. Large positive SSGs with low SS magnitudes have also been shown to lower EC density, which promotes cell dysfunction in regions prominently located to arterial blockages and at vessel bifurcations and results in areas of atherogenesis, arteriovenous fistulae, stenoses, and collateral arteries [51,52]. While these areas of complex flow have been highly studied, areas of high SS magnitudes (>30 dynes/cm2) and high SSGs have been studied much less [53]. These hemodynamic conditions are located in areas with the complex flow that stimulate outward remodeling due to an increase in flow rate, such as aneurysm initiation, proximal to stenoses or other arterial blockages, and arteries upstream of arteriovenous fistulae [53]. These complex geometries induce flow impingement, generating both large positive and negative SSGs. Even though these regions are much less studied, their clinical relevance remains of interest. This section will briefly touch on the design of (1) high SSG chambers for the generation of high SS magnitudes, (2) the design of a vertical backward-facing step, and (3) radial impinging flow for the study of high SSGs with low SS magnitudes.

2.3.1 High SSG Chambers.

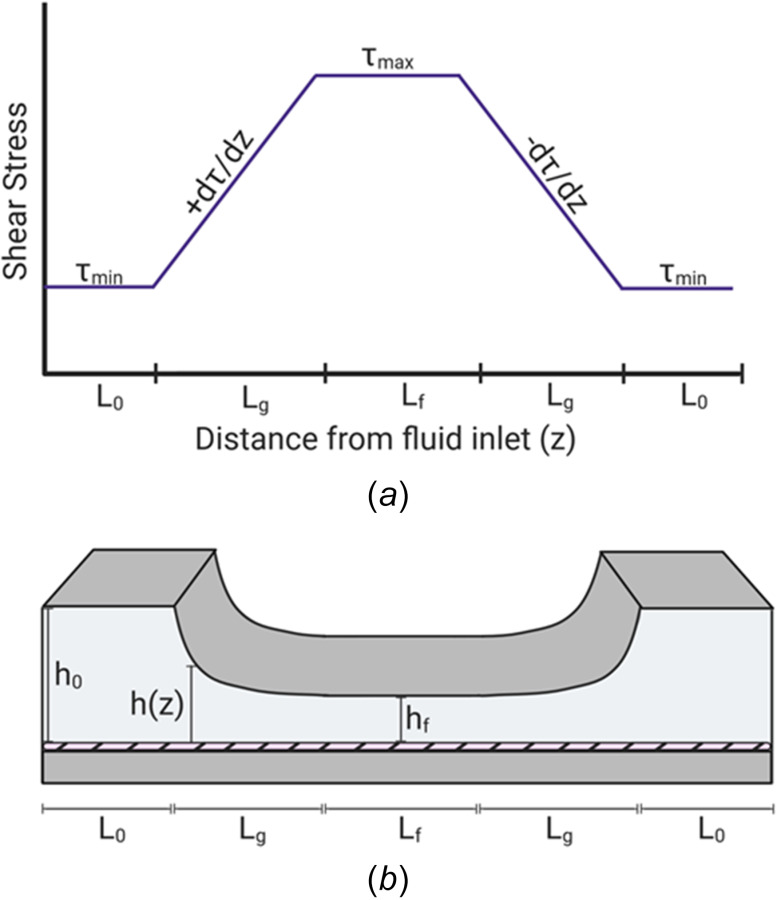

High SSG chambers (Fig. 4(b)) can be designed to produce a gradient along the channel through the variation in height of the top plate [40]

| (21) |

Fig. 4.

Characterization of the SSG chamber. (a) The modification of a variable height of the top plate of the PPFC forms four distinct experimental regions. Shear stress is either at its minimum or maximum values when the top plate is at its maximum height along the entrance length L0 or at its minimum height along the length Lf, respectively. Constant SSGs are formed along the varying height of the converging or diverging regions of equal lengths of Lg. The converging and diverging regions will generate either a uniform, positive SSG or a uniform, negative SSG, respectively. (b) Schematic diagram of a SSG chamber. As the fluid flows from the entrance region of height h0 and length L0, the shear stress at the monolayer is at a constant minimum. As the height of the top plate decreases, a converging region with a uniform, positive SSG is generated along the length Lg. As the height reaches a constant minimum of height hf, the shear stress at the monolayer is a constant maximum along the length Lf. As the height of the top plate increases, a diverging region with a uniform, negative SSG is generated along the length Lg.

where the channel height profile is a function of distance along the channel length, beginning at the initial height, at

| (22) |

Equation (22) allows the chamber to produce two regions with a constant SSG of opposite signs. In total, this chamber forms four regions of SSG values: two regions of SSG absence, a region of SSG convergence, and a region of SSG divergence. The ECs will be exposed to two uniform SS values of different magnitudes in the SSG absent regions, while the converging and diverging regions will generate SS ranges for one positive, uniform SSG and one negative, uniform SSG (Fig. 4(a)). In addition, the SSGs in these sections are constant and of similar magnitude but opposite in sign. This allows the two gradient regions to be directly compared to study shear effects attributed to only the sign of the SSG. The SS values in these regions of variable height will range directly between the maximum and minimum SS values. Modifications of PPFCs to produce a constant SSG are useful for distinguishing between the effects of an SSG from other aspects of disturbed flow patterns that also produce SSGs, such as flow separation, recirculation, and reattachment. However, it is important to note that results from constant SSG devices are not strictly dependent on the magnitude of SS values. ECs within a monolayer transmit force to neighboring cells via intercellular junctions and paracrine signaling. SSG devices cause these shear differences between neighboring cells, and studies have raised the possibility that SS differences between two cells might induce changes in gene expression due to intercellular junction interactions [50,54]. Therefore, the interpretation of results found from SSG devices should be further verified by experiments with single SS values.

2.3.2 Vertical Backward-Facing Step Modification.

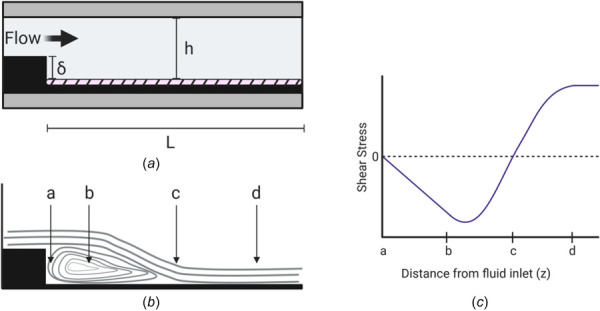

ECs exposed to disturbed flow with a low, oscillatory SS coupled with a large SSG generally exhibit disease-prone phenotypes [55,56]. Disturbed flow conditions have been shown to increase cell loss, migration, proliferation, and monocyte adhesion [40,57]. These disturbed flow regions also reduce responses of cell morphology, orientation, cytoskeletal orientation, and anti-infammatory gene expression, often resulting in EC dysfunction [40]. The flow patterns exhibited in these environments are similar to those at arterial bifurcations and bends, e.g., flow separation, recirculation, and reattachment [42]. This complex flow system can be replicated in vitro with a vertical backward-facing step (Fig. 5(a)) [23]. Able to model inhomogeneous flow dynamics, an adequate vertical backward-facing step expansion chamber design can provide a well-defined laminar recirculation region downstream of the step without transitioning to turbulent flow (irregular flow patterns of individual fluid particles resulting in chaotic eddies and flow instabilities).

Fig. 5.

Characterization of the vertical backward-facing step PPFC modification. (a) Schematic diagram of the vertical backward-facing step modification where δ is the vertical height of the step, h is the total height between plates, and L is the total length distal to the step. (b) Schematic of the flow patterns induced by the vertical backward-facing step. Distal to the step, four regions along the length of the chamber are formed: a, the stagnant area with impinging flow; b, the laminar recirculation eddy; c, the flow reattachment point; and d, fully developed laminar flow. (c) Wall shear stress characterization in each of the four regions along the lower plate of the chamber. No shear stress occurs within the stagnation area or reattachment point. Negative values correspond to fluid flowing back toward the step within the recirculation eddy in the retrograde direction.

A vertical step expansion (i.e., 90 deg alignment to the channel axis) forms four specific flow regions along the length of the chamber: a stagnant flow area, a recirculation eddy, a point of flow reattachment, and a fully developed laminar flow area (Fig. 5(b)) [58]. The recirculation eddy causes an increasing velocity in the retrograde direction, which progressively decreases near the wall of the step. Approaching the step, upward curved streamlines carry fluid away from the lower surface of the chamber and toward the reattachment area. Thus, the eddy is characterized by negative SS values between the step and reattachment point (Fig. 5(c)). At the reattachment region (stagnation point), SS is approximately zero with steady flow fluctuating between the forward and retrograde directions with a large magnitude SSG [59,60]. This type of flow is also defined as “impinging flow.” At the initiation of experiments, the sudden onset of flow moves the reattachment point away from the vertical step in a developmental phase, lasting approximately a few hundred milliseconds [61,62]. If the flow is pulsatile, the reattachment point will shift forward and backward with each cycle [63]. Downstream of the reattachment point, SS becomes increasingly positive along the length of the chamber with constant, steady flow [64]. Disturbed flow occurs in both the stagnant flow and reattachment regions (Fig. 5(b), points a and c, respectively), whereas ECs are exposed to laminar flow in opposite directions within the recirculation eddy and the fully developed laminar flow regions (Fig. 5(b), points b and d, respectively). ECs in each region can be studied to determine the differential effects of each flow profile.

A well-defined, two-dimensional laminar recirculation eddy is highly reliant on adequate design of the vertical expansion step because the flow dynamics are dependent on the dimensions of the chamber. Two gaskets can be used to easily form the vertical step in the standard PPFC. The first gasket will help develop laminar flow before the step, which will aid in the characterization of the step-induced recirculation. The second gasket will form the step itself. Vertical height ( ) can be altered by using various gasket material thicknesses or multiple gaskets. It is imperative that the height is large enough to sufficiently generate disturbed flow in the region close to the step, but that the chamber can still develop laminar flow farther along the channel for direct comparisons. Thus, the vertical step height can be designed by the knowledge that the length of the recirculation region increases nonlinearly with an increasing expansion ratio ( ) [65]. For a two-dimensional laminar recirculation eddy with , an expansion ratio ranging between 1.25 and 4 is recommended [66]. It is important to note that sidewall effects are more prominent for smaller expansion ratios [67]. In addition to a vertical step, the effects of flow separation and recirculation eddies on ECs can also be designed with a gradual change in hydraulic diameter of the fluid channel [68]. This design alteration is capable of modeling the recirculation region directly downstream of an eccentric stenosis and can aid in accurately simulating physiological stenosis-induced blood flow conditions and their effect at the apex on ECs [69]. In general, because of the design of either the 90 deg backward-facing step or gradual change in hydraulic diameter, these PPFC expansion modifications are considered to have two-dimensional recirculation eddies.

Three-dimensional flow profiles can be generated with a backward-facing step expansion chamber where the step is aligned oblique (i.e., < 90 deg) to the chamber axis. Step angle characterization of the resulting flow pattern has been performed through dye visualization methods. Watkins et al. have demonstrated direct effects of the angle, flow velocity, and Reynolds number on the pitch on the newly generated eddy, width of the stagnant flow area, and clearance time of the fluid medium [70]. The design of an oblique backward step can allow for the study of higher dimensional, complex flows that are commonly found in large vessels, nonplanar bifurcations, and fluid interactions with vessel walls. Vertical backward-facing step chambers can also be combined with pulsatile and oscillatory flows to further study ECs under (patho)physiologically relevant flow patterns.

2.3.3 Radial Impinging Flow Chambers.

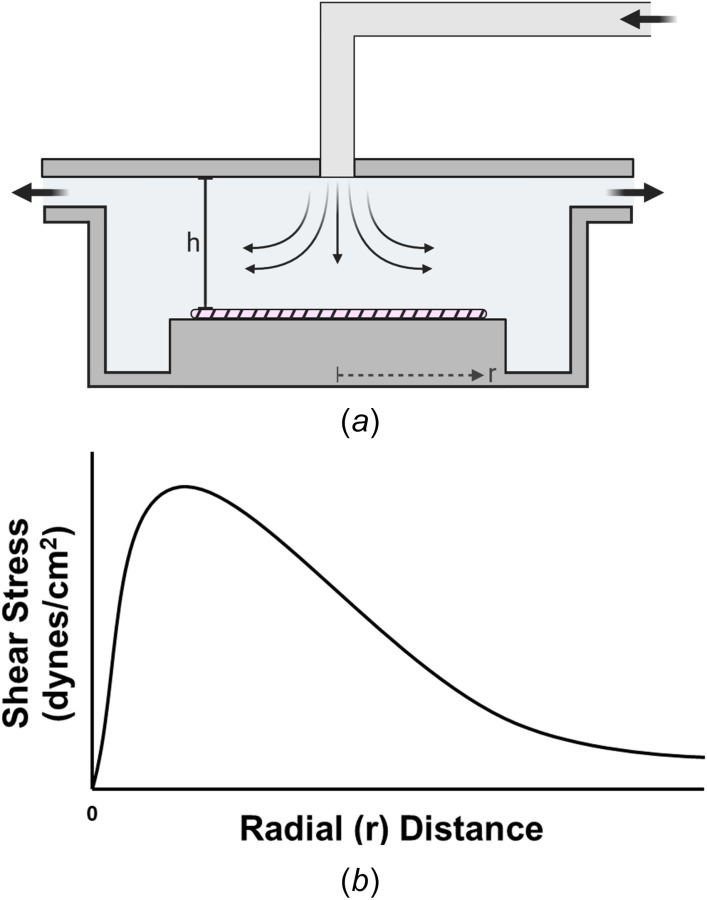

Hemodynamics at apices of arterial bifurcations are also subjected to disturbed flow. At these regions, blood flow impinges at the apex and locally accelerates downstream, forming a region at the center of the impingement that experiences flow stagnation characterized by a low SS and high SSG [71]. ECs in vitro can be studied under these circumstances by use of a radial impinging flow chamber, in which an incoming fluid impinges on the opposite wall of the chamber and flows radially outward. This device consists of two stationary, parallel disks separated by a small height . A central pipe (typically tubing or a blunt needle) forms a T-shaped inlet to the center of the top plate and directs flow outward from the center at a constant flow rate to flow radially over a substrate seeded with ECs (Fig. 6(a)). Radial impinging flow chambers offer several advantages to study ECs under disturbed flow: (1) this axisymmetric flow technique applies a large range of SSs (typically 10–200 dynes/cm2) to a monolayer in a single experiment due to the geometry of the device, (2) sterility issues are largely decreased due to no moving parts within the device, and (3) direct visualization and monitoring of cells by live imaging is possible if disks are made of transparent materials. These devices are commonly utilized to experimentally study cellular adhesion [72], EC migration [73,74], local heat and mass transfer principles [75,76], and ligand-receptor bond affinities [77].

Fig. 6.

Characterization of the radial impinging flow chamber. (a) Schematic diagram of the radial impinging flow chamber. Disturbed flow is created by fluid flowing downward from a height onto the surface of the cellular monolayer, shown by the hatched region. (b) Schematic of the wall shear stress profile at the monolayer. Wall shear stress is spatially dependent on both the initial height/geometry of the inlet and the radial distance from the stagnation point of the impinging flow. For each flow system, the exact magnitude and values of the SS produced beyond the stagnation point should be computed with CFD simulations.

Wall SS generated in a radial impinging flow chamber can be modeled as a nonlinear function

| (23) |

where viscous SS generated by axisymmetric flow at the center of the chamber is accounted for in the first term. The second term is a correction to account for inertial effects that are formed near the sharp-edged inlet and will decrease with an increasing radial position. The design of these flow chambers should minimize the inertial effects to be less than 5% of the viscous forces by either modifying the geometry of the inlet [78] or adjusting the volumetric flow rate [79]. The radius of the inlet should be a function of the chamber height of to minimize flow disturbances [80,81]. One also needs to ensure that the tubing that forms the inlet is sufficiently rigid and long to produce fully developed flow before entering the chamber.

If one assumes laminar axisymmetric flow and neglects any entrance effects, the SS equation reduces to only the first viscous term [82]

| (24) |

From this equation, average fluid velocity and, therefore, wall SS decrease radially with distance from the stagnation point as the cross-sectional area increases. Most radial flow configurations operate under laminar flow , for If one goes above the critical Reynolds number, turbulence can form. This effect usually occurs at small radii or with an incorrectly set volumetric flow rate

| (25) |

Because these inertial effects will always be present, investigators should decrease parameters, such as , to minimize entry effects [83]

| (26) |

This equation shows that at larger radial positions, an increased volumetric flow rate, or increased gap height, the inertial effects become significant. However, the exact flow patterns and SS values around the stagnation point will depend on the Reynolds number and the specific geometry of the inlet and chamber height. Therefore, for regions not accurately described by the approximate numerical solution, CFD simulations must be performed to determine the SS values of the flow system as a function of radial distance from the inlet [83,84]. A schematic of the overall wall SS profile produced by impinging flow chambers is shown in Fig. 6(b).

2.4 Unsteady Flow in Parallel-Plate Flow Chambers.

While the majority of experimental studies have been performed under steady, unidirectional (nonreversing) flow in PPFCs, it is critical to expand in vitro studies to include more physiologic flow conditions. In their native environment, ECs experience unsteady, pulsatile flow due to the rhythmic nature of pressure applied by the cardiac cycle. In long, straight arterial sections of the vessel wall, blood flows in ordered, laminar patterns of pulsatile fashion where the flow rate is time-variant but always forward in direction [12]. In this hemodynamic environment, ECs experience pulsatile SS with fluctuations in magnitude that yield a positive mean SS. In vitro studies have shown that both nonreversing and reversing pulsatile flow with positive mean SS stimulates many of the same EC responses as steady flow, but there can be some modulation effects [85–87]. Conversely to a steady flow, nonreversing pulsatile SS with mean SS above 10 dynes/cm2 has been shown to elongate EC morphology, increase cellular stiffness, and decrease EC proliferation [88], while others have shown that a frequency of 1 Hz enhances prostacyclin (PGI2) by 2.5 fold [89], suppresses monocyte chemoattractant protein-1 expression [90], increases histamine metabolism [91], and transiently increases the proto-oncogene mRNA level of c-fos [86]. These studies collectively suggest pulsatile flow causes changes in EC functions due to the basic mechano-sensory interactions induced by flow rather than the transient elevation of SS magnitude during the cardiac cycle.

Arterial branches and bifurcations are subject to periodic flow recirculation zones, which expose ECs to time-reversing, oscillatory flow. These flow patterns can result in periodic flow reversal with a time-averaged SS of approximately zero [92–94]. It has been shown that the regulation of EC function can either be identical to or different than a steady flow, depending on the mean SS value, due to the dynamic ability of ECs to discriminate among and respond to different forms of unsteady flow. Immediately after the onset of flow, unidirectional, steady flow induces pro-inflammatory and proliferative regulation pathways, such as nuclear factor-κB, reactive oxygen species production, and monocyte chemoattractant protein-1 expression [90,95]. However, with prolonged exposure to steady or pulsatile SS, as the cells align, these pathways are transiently downregulated [96]. In contrast, oscillatory flow patterns sustain the activation of these pathways, and ECs do not undergo cytoskeletal remodeling, retaining a cobblestone morphology in response to the dynamic nature of the fluid behavior [97]. Compared to an elongated morphology, cobblestone ECs are more permeable to macromolecules and have increased monocyte adhesion. Importantly, the degree of intimal wall thickening has been correlated to hemodynamic characteristics of low shear, as seen in oscillatory regimes [98,99]. These studies suggest that oscillatory flow regimes have higher inflammatory responses and can ultimately result in atherogenesis due to the continuous changes in flow magnitude and direction [96,100–102]. Therefore, PPFCs have been modified to further produce pulsatile, oscillatory, and disturbed flow patterns.

Blood behaves in a Newtonian fashion in arteries with shear rates greater than 100 s−1 [103]. In vivo, blood pressure and flow are unsteady due to the cyclic nature of the heart alternating between systole and diastole. Acting as a natural physiologic pump, the cardiac output from the heart drives blood in the same direction as the decreasing pressure gradient within the cardiovascular system. Thus, flow and, therefore, SS are subjected to unsteady, pulsatile conditions with each cardiac cycle [104]. While the nature of the physiologic waveform differs at various regions of the vasculature, many experimental and computational studies have modeled in vivo blood flow profiles as a simple sinusoidal waveform [105,106]. For this arterial model, the hemodynamic conditions of the fluid velocity, rate of flow, and the viscous drag can be calculated if the pressure gradient is known for a cylindrical geometry with a rigid wall by using the Womersley theory [94], which also determines the unsteadiness of the flow profile.

The nature of unsteady flow can be described by the Womersley number ( ). This dimensionless parameter describes the ratio between the pulsation flow frequency with respect to viscous effects, where larger values correspond to increased unsteadiness [107]

| (27) |

In the equation above, is the angular frequency defined as , and is the kinematic viscosity of the fluid. When unsteady flow effects are negligible, i.e., inertial forces are small compared to viscous forces and the fluid velocity responds instantaneously to changes in the pressure gradient ( 1), the fluid behaves in a quasi-steady manner, and, thus, the steady equations in Sec. 2.1 can be used to approximate chamber design specifications for pulsatile and oscillatory SS when the following conditions are met:

| (28) |

| (29) |

where is the oscillating boundary layer thickness, and is the flow frequency [108]. The Poiseuille relationship has been shown to be 97% accurate for quasi-steady regimes [109]. When the Womersley number is equal to or greater than one, the quasi-steady approximation for the flow profile becomes ineligible due to the relationship between the volumetric flow rate and SS becoming time-dependent. At , the velocity profile maintains Poiseuille shape, but the oscillatory phase lag with respect to the pressure gradient begins to develop. As 1, both the phase lag and the deviation in the fluidic behavior from the quasi-steady behavior increase and become more unsteady. The amplitude of the oscillations will also vary with an increasing [110]. SS has further been derived for unsteady flow in a rigid tube with an approach similar to Womersley's solution [111] and by the use of heat transfer principles [112]. However, many investigators do not report the methods used to calculate SS under unsteady flow regimes for studies performed in PPFCs [113].

For quasi-steady flow of an incompressible, Newtonian fluid through a narrow rectangular channel, as such in a PPFC, SS can generally be derived from the Navier–Stokes equation for fluid under sinusoidal oscillating conditions

| (30) |

where and are the steady component and the oscillating component, respectively [108]. The fluid velocity is of the form

| (31) |

where A and B are real functions of further defined by Loudon et al. [110]. The integration of Eq. (31) over the interval results in the induced average velocity as a function of the amplitude and the phase lag of the average velocity

| (32) |

Oscillatory SS is directly proportional to the local velocity gradient at the cellular monolayer

| (33) |

where . Therefore, a dynamic velocity will result in a changing SS at the bottom plate. SS on the ECs will also vary sinusoidally with time at the same frequency as the oscillating pressure gradient

| (34) |

Here, is the relative amplitude of the wall SS, and is the phase lag with respect to the imposed pressure oscillation. Both of these constants are functions dependent upon the distance from the EC monolayer [114].

Stability of oscillations in the fluid profile can be determined by the Reynolds number based on the Stokes thickness . For , the oscillating flow will remain stable. At the range , the flow transitions between laminar and turbulent states over a single period. Above a value of , the flow regime becomes fully turbulent [115,116]. In addition to determining the stability of the unsteady flow, studies have shown that pulsatile flow in a PPFC can increase the entrance length of the fluid by 15% or more [117]. Therefore, it is important to fully characterize the flow in the channel using CFD simulations to either validate or determine the experimental conditions the cellular monolayer is experiencing.

While many studies investigate endothelial responses to unsteady flow, typically only sinusoidal oscillations at fundamental frequencies are studied. However, these simplified models do not fully mimic realistic physiological flow profiles, and results may not be representative of in vivo responses. While mean SS influences endothelial signaling and flow topology, the rate of shear development has been shown to affect endothelial responses, such as nitric oxide production [118]. Therefore, the reproduction of realistic arterial waveforms is recommended to fully investigate EC responses in vivo. The reproduction of arterial waveforms requires four or more harmonics and can be formed by a computer-controlled pump. The flow loop parameters, such as wall displacement (compliance in tubing), pressure, and velocity of the pulse wave, must also be considered when designing each study and require an understanding of the individual role of each of these parameters to the unsteady flow profile [119]. Literature device designs for PPFCs under multiple flow conditions and modifications and the studies' data analysis methods can be found in Tables 2 and 3, respectively.

Table 2.

Summary of designs for literature PPFC systems

| System | Type of flow | Type of cell | Time (hr) | Shear stress (dynes/cm2) | Length (mm) | (mm) | Width (mm) | Height (mm) | Aspect ratio | Pump type | Ref. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plain | Steady | HUVECs | 15 | 8 | 13.5 | 75.18 | 0.07 | 25.15 | 0.13 | 198 | Peristaltic | [33] |

| 2 | 8.4 | n.s.b | 85 | n.s.b | 25 | 0.3 | 83.3a | Constant Flow | [120] | |||

| 6 | 12 | n.s.b | 80 | n.s.b | 38 | 0.5 | 76a | n.s.b | [121] | |||

| BAECs | 24 | 10, 30, and 85 | 60 | 50 | 0.75 | 13 | 0.25 | 52 | Peristaltic | [36] | ||

| HMEC-1 | 24 | n.s.b | n.s.b | 75 | n.s.b | 38 | Variant | Variant | Peristaltic | [122] | ||

| HSVECs | 6 | 0.2–40 | 363a | 32 | 7 | 27 | 0.5 | 54a | Peristaltic | [123] | ||

| Rat aortic ECs | 6 | 10.4 | 0.133 | 75.3 | 0.238a | 35.2 | 0.330 | 106.67a | Peristaltic | [124] | ||

| Human aortic ECs | n.s.b | 120 | 2000 | 150 | 100 | 4 | 1 | 4a | Pulsatile | [125] | ||

| Porcine aortic ECs | 6 | 1.13 and 11.5 | 100 and 900 | 22.5 | 94 | 17.5 | 1.8 | 9.72 | Peristaltic | [126] | ||

| Rat EPCs | 24 | 5–20 | 0.0317–0.127 | 57.5 | 25.36 × 10−5–10.16 × 10−4 | 12.4 | 0.2 | 62a | Peristaltic | [127] | ||

| Human and Porcine EPCs | 48 | 15 and 100 | 13.9–234 | 70 | 0.1–2.5 | 19 | 0.166–0.267 | 114.5–71.2a | Peristaltic | [44] | ||

| Oscillatory | HUVECs | 6 | −195 to 70.19 | 1 | 50 | n.s.b | 12 | 0.5 | 24a | Peristaltic | [28] | |

| Porcine aortic ECs | 6 | 39.1–40.3 | 2750 | 22.5 | 198 | 17.5 | 1.8 | 9.72 | Peristaltic | [126] | ||

| Pulsatile | Human aortic ECs | n.s.b | 3.1–107 | 1000 | 150 | 100 | 4 | 1 | 4a | Pulsatile | [125] | |

| Porcine aortic ECs | 6 | 10.7 | 230–1260 | 22.5 | 94 | 17.5 | 1.8 | 9.72 | Peristaltic | [126] | ||

| Vertical-Step | Disturbed | HUVECs | 0.083 | −3 to 6 | 24–60 | 8 | n.s.b | 19 | 1.399 | 13.6 | Syringe | [128] |

| 0.333 | 1–7 | 100 | 45 | 15 | 10 | 0.5 | 20a | Double Syringe | [129] | |||

| BAECs | 0.083–0.05 | 0–13.5 | n.s.b | 30 | n.s.b | 22 | 1 | 22a | Peristaltic | [130] | ||

| 24 | 167 | 267 | 76.2 | 30 | 19.05 | 0.635 | 30a | Peristaltic | [131] | |||

| SSG | Steady | BAECs | 24 and 36 | 35–284 | 780–848 | 100 | n.s.b | 22 | 1–3 | 7.33–22a | Peristaltic | [40] |

| HCtAECs | 24 | 20–60 | 1510 | 16 | n.s.b | 12 | 0.20–1.11 | 10.8–60a | Peristaltic | [39] |

Values that have been calculated by the author with the information presented within the reference article listed.

Values were not stated (n.s.) in the reference article listed and were unable to be calculated by the author.

Table 3.

Analysis methods of various PPFC studies

| System | Type of flow | Type of cell | Analysis method |

|---|---|---|---|

| Plain | Steady | BAECs [36] | Atomic force microscopy [33] |

| HMEC-1 [122] | |||

| HSVECs [123] | |||

| Human aortic ECs [125] | |||

| Human & Porcine EPCs [44] | |||

| HUVECs [33,120,121] | |||

| Porcine aortic ECs [126] | |||

| Rat aortic ECs [124] | |||

| Rat EPCs [127] | |||

| Chemiluminescence [44] | |||

| Fluorescent microscopy [33,44,121,123] | |||

| MTT assay [127] | |||

| Nitric oxide assay [127] | |||

| Phase contrast microscopy [36,123,126,127] | |||

| Reverse transcription polymerase chain reaction (RT-PCR) [121,122,124] | |||

| Western blot [120] | |||

| μ-PIV [124,125] | |||

| Oscillatory | HUVECs [28] | Fluorescent microscopy [28] | |

| Pulsatile | Human aortic ECs [125] | μ-PIV [125] | |

| Vertical-step | Disturbed | BAECs [130,131] | Dye injections [130] |

| ELISA [131] | |||

| HUVECs [128,129] | Flow cytometry [129] | ||

| Fluorescent microscopy | |||

| Immunocytochemistry [130] | |||

| Phase contrast microscopy [128–131] | |||

| RT-PCR [129] | |||

| Western blot [129] | |||

| SSG | Steady | BAECs [40] | Fluorescent microscopy [39,40] |

| Phase contrast microscopy [40] | |||

| HCtAECs [39] |

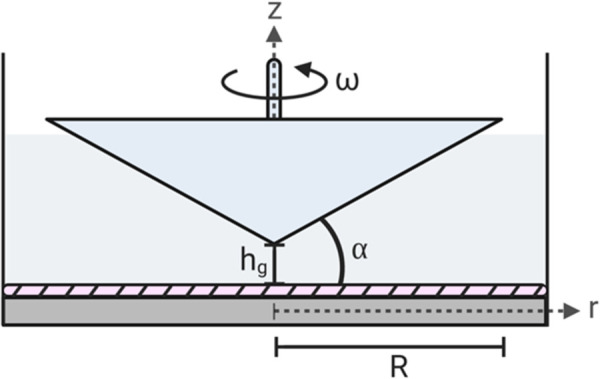

3 Cone-and-Plate Devices

Cone-and-plate apparatuses are another way to induce wall SS on endothelial monolayers. Initially, these Couette flow devices were introduced to solve the limitation of the PPFC's inability to study SS on suspended cells [132]. In more recent studies, these devices have been used to study SS influence without the hydrostatic pressure gradient effects introduced by fluidic pumps on the seeded monolayer. For these purposes, cone-and-plate devices (CPDs) position an inverted, rotating cone above a stationary flat plate. The flat plate can be designed to either house several coverslips or directly be a replaceable tissue culture dish (Fig. 7). Representative optical images of CPDs have been included in many literature articles [133–135]. The rotation of the cone forces the fluid medium between the cone and plate to flow azimuthally in concentric circles and, thus, produce SS on the flat, bottom plate seeded with ECs [17,136]. This apparatus is able to achieve a laminar SS range between 0.01 and 100 dynes/cm2 and a turbulent SS range from 2 to 200 dynes/cm2, with the minimum values dependent upon the fluid's physical properties and the physical chamber parameters [17]. CPDs have several advantages over PPFCs: (1) entrance and exit length effects are nonexistent, (2) the laminar, homogeneous flow profile is independent of hydrostatic pressure gradients, (3) small dimensional changes of the device do not have large effects on the SS produced, (4) the operating fluid volume is small, making the detection of metabolites easier, and (5) they have the ability to produce both laminar and turbulent flow in a single device. However, these systems have their own limitations: (1) continuous sampling of the fluid requires further modifications, (2) accumulation of secreted molecules can occur within the operating fluid and could affect cell behavior if there are autocrine effects, (3) significant fluid evaporation can occur due to exposure to the open environment, requiring the continuous addition of fresh medium for long-term studies, and (4) live visualization of cells during the study is not possible unless transparent materials are used in device fabrication.

Fig. 7.

Schematic diagram of a cone-and-plate device depicting the flow domain and critical design parameters. The hatched region is the endothelial monolayer. As shown, α is the angle between the cone's surface and bottom plate, ω is the angular velocity of the cone, hg is the height gap, R is the total radius of the cone, r is the radial distance from the apex of the cone, and z is the coordinate orthogonal to the bottom plate, typically the cone's axis.

3.1 Shear Stress Calculations.

Assuming a constant, low angular velocity , the radial flow caused by centrifugal forces (secondary flow) is negligible, and SS across the surface of the bottom plate is defined as [137]

| (35) |

where is the coordinate normal to the plate and is the radial distance from the cone's apex. With a sufficiently small cone angle ( = 0.5–3 deg), the tangent function may be replaced solely by , resulting in a constant SS along the stationary plate [17]

| (36) |

If a gap exists between the cone apex and the bottom plate , the SS becomes spatially dependent (Fig. 8(a)) [138]

| (37) |

Fig. 8.

![Characterization of shear stress effects in a cone-and-plate device. (a) Wall shear stress at the monolayer is spatially dependent on the gap height between the cone and plate. With a gap height of zero, the plate experiences a constant shear stress along the radial distance from the apex of the cone, as calculated by Eq. (36) from Sdougos et al. [137]. As the gap height increases, the magnitude of the spatially dependent shear stress decreases, as calculated by Eq. (37) from Sucosky et al. [138] for the gap heights of 0.001 cm, 0.010 cm, and 0.100 cm. (b) Effect of the effective Reynolds number on wall shear stress at the monolayer as calculated by Eq. 38. When Rẽ < 1, the flow is primary and produces no secondary flow effects. An Rẽ between 1 and 4 develops secondary flow effects and becomes fully turbulent at values greater than 4. All equations were calculated with μ = 3.5 cP, ω = 2.49 rad/s, and α = 0.5 deg.](https://cdn.ncbi.nlm.nih.gov/pmc/blobs/25cf/8628846/0e55550f813f/bio-20-1480_020801_g008.jpg)

Characterization of shear stress effects in a cone-and-plate device. (a) Wall shear stress at the monolayer is spatially dependent on the gap height between the cone and plate. With a gap height of zero, the plate experiences a constant shear stress along the radial distance from the apex of the cone, as calculated by Eq. (36) from Sdougos et al. [137]. As the gap height increases, the magnitude of the spatially dependent shear stress decreases, as calculated by Eq. (37) from Sucosky et al. [138] for the gap heights of 0.001 cm, 0.010 cm, and 0.100 cm. (b) Effect of the effective Reynolds number on wall shear stress at the monolayer as calculated by Eq. 38. When < 1, the flow is primary and produces no secondary flow effects. An between 1 and 4 develops secondary flow effects and becomes fully turbulent at values greater than 4. All equations were calculated with μ = 3.5 cP, ω = 2.49 rad/s, and α = 0.5 deg.

SS can also generally be defined by the ratio of the viscous and inertial forces within the system, as shown by Fig. 8(b) [64,137,139]

| (38) |

where is the effective Reynolds number. This unitless parameter describes the flow regime induced by the system and is defined through the -theorem as

| (39) |

where is the total radius of the cone, is the gap height between the cone and plate, and a correction factor of 1/12 is included to coincide with literature values [139–141]. It is important to note that is locally dependent and ranges from 0 at the cone apex to a maximum at . Thus, it is possible to have laminar, transitional, and turbulent flows within the fluid at a single steady rotational rate. When , the flow is governed solely by viscous forces, and the radial flow velocity of the secondary flow is zero everywhere, inducing uniform SS over the entire plate surface. The flow produced is essentially axisymmetric, laminar, and tangential, which is termed primary flow. As becomes larger, the centrifugal forces become more significant, and secondary flow begins to develop in the range of . Here, the laminar fluid no longer flows in concentric circles and becomes three-dimensional. Turbulence first forms at the outer boundary and spreads inward with an increasing rotational speed. These secondary flow effects were first observed by Cox through the use of a dye visualization technique [141]. At these larger values of the effective Reynolds number (but still within the laminar flow range), SS at the surfaces of the plate and cone , respectively, become [137]

| (40) |

| (41) |

Regions with turbulence do not have a uniform SS. At , the flow is fully turbulent [138,143,144]. It is important to note that two values of and have been reported as the transition from laminar to turbulent flow due to the development of secondary effects.

3.2 Experimental Device Design.

Devices to produce primary laminar flow require minimal with a small cone angle. The use of a minimal produces a uniform SS on the cellular monolayer at a lower angular velocity. However, the requirement of a small cone angle magnifies the error in the cone positioning [33]. Literature values of are usually of the order of deg. Typical commercial devices are designed with and deg and cm, approximately [137]. In addition to a small cone angle, the cone axis (z-axis) must be closely aligned so that it is perpendicular to the plate, otherwise eccentric and pulsatile effects can form. Another aspect to consider is that the fluid must only fill the space between the plate and the cone or else an additional torque from fluid shearing can be developed [132]. Surfaces exposed to the study must also be biocompatible to reduce cell activation or damage. Importantly, these devices have a nonideal flow pattern near the outer boundary, and one should organize subsequent data analyses with this in mind. Literature designs of CPDs and their associated data analysis methods can be found in Table 4.

Table 4.

Cone-and-plate device designs

| Type of flow | Type of cell | Time (hr) | Shear stress (dynes/cm2) | Cone angle (deg) | Motor type | Analysis methods | References |

|---|---|---|---|---|---|---|---|

| Steady | HUVECs | 2 and 6 | 2.2 | 2.5 | Stepper | RT-PCR Immunoblot Fluorescent microscopy |

[145] |

| 48 | 8–10 | 0.5 | Brushless | Phase contrast microscopy | [134] | ||

| 0.5 | 12 | 1 | n.s.a | Fluorescent microscopy | [146] | ||

| 1–24 | 2–20 | 1 | n.s.a | RT-PCR ELISA Immunoblot |

[147] | ||

| 1 | 0–20 | 2 | DC Servo | Fluorescent microscopy | [148] | ||

| 12–36 | 5–20 | 0.5 | n.s.a | Western blot Phase contrast microscopy Flow cytometry |

[149] | ||

| 0.5–4 | 30 | 0.5 | n.s.a | Northern blot | [150] | ||

| BAECs | 1 | 15 | 0.5 | n.s.a | Western blot | [151] | |

| Pulsatile | HUVECs | 24 | −8.9 to 3.7 | 1 | n.s.a | RT-PCR ELISA Immunoblot |

[147] |

| 24 | 13.3–43.7 | 1 | n.s.a | RT-PCR ELISA Immunoblot |

[147] | ||

| 48 | 12–23 | 0.5 | Brushless | RT-PCR Phase contrast microscopy Fluorescent microscopy |

[133] | ||

| Oscillatory | HUVECs | 2 and 6 | 2.2–3.4 | 2.5 | Stepper | RT-PCR Immunoblot Fluorescent microscopy |

[145] |

| Human and rat aortic ECs | 24 | ±5 | 0.5 | Stepper | RT-PCR Western blot Phase contrast microscopy |

[152] | |

| Disturbed | HUVECs | 0.5 | −5 to 12 | 1 | n.s.a | Fluorescent microscopy | [146] |

Specifications were not stated (n.s.) in the reference article listed.

3.3 Device Modifications.

CPDs can undergo several modifications to induce various flow regimes. Production of turbulent flow or the alteration of SS magnitude can be accomplished by either increasing the rotational speed of the cone, increasing , or by increasing the viscosity of the fluid medium by adding dextran, gelatin, or polyvinylpyrrolidone. The device itself can be also altered for the ability to induce various flow regimes. CPDs used for studying the effect of mechanotransduction on cellular signaling generally fail to quantify and/or control the unsteady portion of the flow. For example, at the onset of flow, a lack of consideration of the time-dependent development of the flow profile could potentially lead to a mischaracterization of the effects of imposed flow regimes on cellular responses. Blackman et al. described the use of a microstepper motor modification to establish control of the dynamic fluid environment, allowing for quantification and control of the unsteady portion of the flow [153]. They later utilize this modification in a dynamic flow system to reproduce arterial waveforms segmented into discrete time steps [154]. In addition, the disturbed flow has been shown to be induced through a simple modification of the bottom plate similar to a vertical facing step for PPFCs by DePaola et al. [22]. Pulsatile and oscillatory flows can be induced by either positioning the cone oblique to the plate (i.e., not perpendicular) [155,156] or by bidirectional rotation of the cone [145], respectively. CPDs can also be modified for direct flow or cell visualization by using transparent materials, such as plexiglass [139,157].

4 Microfluidic Devices

While conventional macroscale devices have been widely used to generate mechanical forces, they require a large fluidic volume and many cells for culture. Additionally, these systems produce unstable SSGs [158] and lack the capacity to capture the full range of effects of complex in vivo models. To account for these insufficiencies, microfluidic devices have recently become an essential tool to study microcirculation systems at diameters comparable to human arterioles (∼90 μm) [159]. These devices can replicate physiologically relevant dimensions and lengths while holding the advantages of requiring minimal reagents (1–10−12 μL), shortened residence times, higher throughput, the ability for in situ quantification, and highly customizable geometries. Various micromodels of endothelial processes can also be developed at the microscale, with previous literature including devices for cell adhesion and detachment kinetics [160], blood-brain barrier function [161,162], tumor angiogenesis [163], nanoparticle permeability [164], and vascular permeability [165,166]. While microfluidic devices are highly customizable, representative optical pictures can be viewed within literature articles [167–171].

Due to scaling law effects, fluid behavior at the micron-level widely differs from behavior at the macroscale. It is imperative that the dimensions of microfluidic devices are not scaled-down from a conventional system design, making the appropriate construction and design of microfluidic devices essential to perform effective experiments. Dominant forces to leverage in device design due to the micron-length scale include laminar flow, diffusion, fluidic resistance, a large surface area to volume ratio, and surface tension [172]. By utilizing scaling laws, these devices provide the opportunity to integrate multiple mechanical cues and enable precise environmental control to accurately simulate physiologically relevant characteristics.

4.1 Shear Stress Calculations.

SS in a microchannel can range between 0.7 and 130 dynes/cm2 and is calculated as [173,174]

| (42) |

Therefore, given the same average velocity, SS will increase as the height of the channel decreases [175]. The exact equation will depend largely on the channel geometry and will need to be calibrated if there are various microdevices of differing height dimensions used in a study [158]. The simplest method to calculate SS in a microfluidic device is by using the planar Poiseuille model. For a parallel-plate configuration with an infinite aspect ratio, the wall SS and pressure drop across the channel, respectively, are

| (43) |

| (44) |

This method was adopted by Lu et al. for the design of two microfluidic devices with a large aspect ratio to simultaneously study cell detachment dynamics under multiple flow conditions [176]. In addition to Eq. (43), the Purday approximation can be used to calculate SS in the center of a microchamber [177,178]

| (45) |

In the equation above, and are empirical parameters related to the channel's aspect ratio. The empirical parameters were calculated by Young et al. for an aspect ratio less than three using , and [179]. Purday's approximation is valid for a fully developed laminar flow regime within a rectangular microchannel and has been shown to strongly correlate with experimental results [179]. The flow rate in a microchannel is given by where is the fluidic resistance within the channel. Resistance for a circular geometry can be calculated by the equation [172]

| (46) |

while a rectangular microchannel geometry with low or high aspect ratios have resistances, respectively, of

| (47) |

| (48) |

On the microscale, resistance can be a vital design parameter for the automatic modulation of the flow rate, and, therefore, SS, through individual parts of the device [180].

The Reynolds number for flows in long, straight microchannels of a constant cross section can be calculated with [181]

| (49) |

Because of the small scale of the chamber dimensions, flow within a microfluidic device will be exclusively laminar. The length of entrance effects in microchannels is approximated below. For a low Reynolds number approaching zero , it is predicted that the entrance length will be approximately 0.6 in length [182,183]

| (50) |

However, many microfluidic devices do not have a constant cross-sectional geometry, and, therefore, fluid dynamic parameters cannot be easily calculated by the methods described in this section. Because many microfluidic devices can easily be custom built for specific applications, the majority of experimental studies model the flow behavior using CFD analyses [184–186].

4.2 Device Design Considerations.

While many advantages come with the utilization of microfluidic devices, there are several design considerations that need to be accounted for with the initial fabrication. One needs to consider: (1) the choice of the device material, (2) the geometry and dimensions of the microchannels for the intended study, (3) pumping techniques and the method of controlling the fluid flow rate, and (4) external connections and their implications. The majority of devices are fabricated through soft lithography methods and use polydimethyl siloxane (PDMS) as the bulk material. PDMS is an excellent substrate material for experimental cell studies because the surface can easily be modified [187], and the geometry it uptakes can be specifically designed according to the intended application. In addition to the ease of fabrication, the material is characterized by a high gas permeability and optical transparency, giving the ability for real-time visualization. However, because of the hydrophobic nature of PDMS, the surface may cause unwanted adsorption of hydrophobic proteins or particles [188]. This can result in the loss of molecules or a significant decrease in molecule concentration during long-term recirculation of the fluid. While PDMS is highly utilized for device fabrication, microfluidic devices have been increasingly used by multiple groups to house three-dimensional (3D) hydrogels with more physiologic substrates, such as 3D extracellular matrices [189–192]. By designing 3D platforms to study cellular behavior on the micron-scale, both the 3D effects of flow are accounted for, and a more representative physiological environment can be utilized. Other microfluidic device fabrication methods and surface materials have been reviewed extensively elsewhere [163,193,194].

Due to the scale, the small hydraulic diameter used in microfluidic devices results in a significant pressure loss across the channel. This effect can be reduced by the use of a super hydrophobic surface as a coating or acting as the channel wall. The hydrophobicity introduced produces a mixed no-slip no-shear condition at the wall, comparatively reducing the pressure drop [195]. In addition to affecting the pressure drop, the inner surface of the fluid channel also provides the area for cell adhesion. Therefore, the fabrication material needs to be biocompatible. Cell seeding in micro-environments has been reviewed previously by Young et al. [196]. An important factor for data collection after applied SS is because the amount of cells cultured within the device is small, analysis of mRNA or proteins by either RT-PCR, enzyme-linked immunosorbent assay (ELISA), immunohistochemistry, or immunoblotting methods is difficult. New methods, such as single cell RNAseq, hold promise for these devices. Current major analysis approaches coupled with microfluidics can be broadly categorized as optical, electrochemical, or mass spectrometry [197].

The microscale also prohibits mixing within the fluid due to the low Reynolds number, enabling the study of responses to chemical gradients. Compared to macroscale devices that have the ability to produce mixing from turbulence, the laminar flows present in microchannels will not mix except by diffusion, which is governed by Brownian motion. Because diffusion is a dominant force, cells within the device may be inadvertently exposed to varying concentrations of nutrients, growth factors, or cell signaling molecules. Thus, microfluidic geometries may result in differing cellular responses depending on the position, and this mechanism has been widely used to study chemotactic, durotactic, and haptotactic responses to steady chemical gradients that cannot be captured in conventional macroscale devices [198].

The precise control of fluidic pumping is a critical consideration in device functionality, and much progress has been made in recent years to refine pumping techniques for microfluidic applications. Broadly, microfluidic pumps can be categorized as nonmechanically (i.e., electric field driven or passive flow [199]) or mechanically (e.g., Braille pins [200], syringe pumps [201,202], piezoelectric pumps [203], etc.) controlled. These methods have been extensively reviewed elsewhere for microdevices [204–208]. The method of pumping and controlling the fluid flow rate also influences how the device is externally connected to other components needed for operation. By increasing the number of connections, the potential for fluid leakage and contamination also becomes greater. In addition to the technique of media delivery to the cells, the consistent operation of pumps can lead to the formation of bubbles within the system. The development of bubbles can cause several consequences including inadequate supply of media, damage of cells at the gas–liquid interface, or obstruct fluid flow to certain areas of the device. Therefore, the prevention of bubble formation is critical and can be accomplished by either flushing the device either at a high-pressure flow or with a liquid characterized by a low surface tension before studies, utilization of a bubble trap, or by operating the device under a high-pressure flow for the duration of the experiment. As an alternative to pump-driven flow in microfluidic devices, gravity-driven perfusion flow, which is driven by a hydraulic head, has been implemented in microfluidic devices to help circumvent pump limitations [209,210].

5 Commercial Devices

While many in vitro flow chambers have been custom designed, an increasing number of commercial flow devices have been made available, with PPFCs and microfluidic devices being the most common on the current market (Table 5). In selecting a commercial PPFC, several aspects should be considered, including but not limited to: ease of sterilization, size of cell seeding area, the range of applied SS, imaging and/or analysis considerations, sealing mechanisms of the chamber, and overall cost. Commercial PPFCs are frequently supplied with the top and bottom chamber plates, precut silicone gaskets of varying thicknesses, and a length of tubing to fit the inlet and outlet chamber ports. PPFCs have a wide variety of applications in replicating (patho)physiologic flow regimes to study cellular phenomena, ranging from cellular adhesion under flow to effects of different flow regimes on cellular junctional proteins [25,191]. The use of microfluidic devices has expanded rapidly, as recently reviewed by Volpatti and Yetissen [130], which presents the current commercial market for microfluidic devices, the challenges it faces, and future directions microfluidic commercialization may take. Miniaturization and 3D printing manufacturing have allowed the design of complex microfluidic devices for many applications [211].

Table 5.

Commercially available flow chamber devices

| Manufacturer | Product | Base model price (USD) | Flow width (mm) | Flow depth (μm) |

|---|---|---|---|---|

| Applied Bio-Physics | ECIS flow system-single channel | $329 | 5.00 | 360 |

| SCIS flow system- Y channel | $329 | 5.00 | 600 | |

| Ibidi | μ-Slide I Luer | $200 | 5.00 | 200 |

| 400 | ||||

| 600 | ||||

| 800 | ||||

| IBI Scientific | Convertible flow cell | $122 | 24.00 | 8000 |

| IBI 3-channel flow cell | $171 | 4.00 | 1000 | |

| Glycotech | 31-001 circular flow chamber | $675 | 2.50 | 127 |

| 254 | ||||

| 5.00 | 254 | |||

| 10.00 | 254 | |||

| 31-010 rectangular flow chamber | $625 | 10.00 | 127 | |

| 254 | ||||

| Warner Instruments | (PFC-1) Pro-flow shear flow chamber | $1098 | 10.40 | 250 |

| RC-30 or RC-31 | $1360–$1461 | 4.00 | 125 | |

| 250 | ||||

| 375 | ||||

| 17.00 | 125 | |||

| 250 | ||||

| 375 |

The use of commercial devices inherently carries several advantages. Experimental studies become more repeatable with a commonly available commercial device. This also gives investigators the ability to compare and contrast studies from other groups if the same device and flow environment are used, thereby enabling meta-analyses and the potential extraction of meaningful results from a larger dataset across repeated experiments. The major disadvantage to widely available commercial devices is that they are generally designed for simple flow environments across a wide variety of applications, which is in contrast to custom-made chambers whose design is modified to the specific requirements of a specific experimental study.

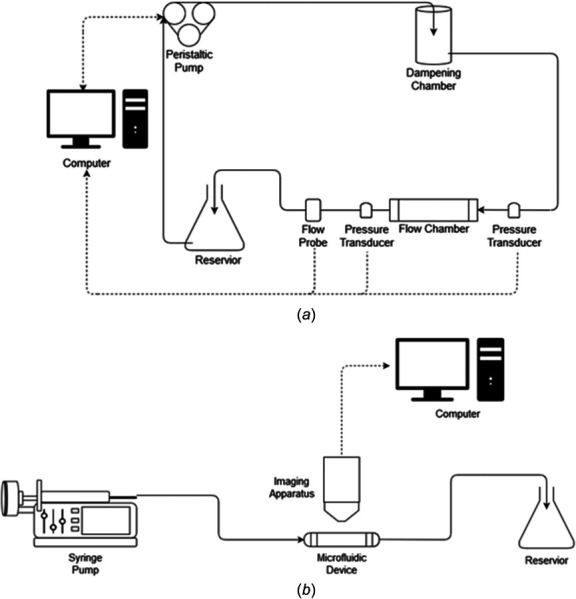

6 Fluid Driving Systems

The performance of the flow chamber device is also dependent upon the design of the flow loop system. Typically, systems consist of a pump as a mechanical driving force, a digital flowmeter placed distal to the chamber outlet, one or more pressure transducers, a computer and software to monitor the flow environment, and an adequate number of connector ports and length of tubing to link all components to the flow loop (Fig. 9). While the entire system loop is specific to the experiment, the most critical aspect one needs to consider is the pump as a fluidic driving force. When choosing a pump, several factors must be considered to meet experimental requirements: (1) fluid capacity, (2) control of the fluid profile and/or range of flow rates, (3) directionality, (4) size if needed to fit inside an incubator, and (5) overall cost [212]. Various types of pumps offer recirculating or single pass flow and the ability to be easily integrated with the device. The most common pumps are peristaltic and syringe pumps.

Fig. 9.

Process flow diagrams of fluid driving systems. (a) Process flow diagram for systems utilizing a peristaltic pump. Typically, fluid flow is driven from a reservoir by the pump. As the fluid exits the pump, it enters a dampening chamber, which minimizes pulsatile effects generated by the peristaltic pump. The fluid then flows through the flow chamber back to the reservoir, completing the flow system. Flow rate is monitored by a computer through a flow probe located downstream of the chamber. Pressure transducers can also be placed on either side of the flow chamber to monitor the pressure drop across the device. If changes are needed to the required flow rate, the computer will alter the angular velocity of the pump's rotor to produce the desired flow profile and shear stress for the study. (b) Process flow diagram of systems utilizing a syringe pump. Typically, a syringe loaded with fluid is mounted on a pump motor. The motor then pushes fluid from the syringe by a speed previously designated by the user. The fluid flows through the microfluidic device and into a discard reservoir. Real time imaging over the length of the study is collected by an imaging apparatus and is recorded by a computer.

6.1 Peristaltic Pumps.

The peristaltic pump, otherwise known as a roller pump, is the most common fluid driving system for both macro- and microdevices. This positive displacement pump drives fluid movement through the system loop by a process called peristalsis. This driving method utilizes flexible tubing placed on a rotor that houses multiple rollers (typically 3–4). As the rotor rotates, the tubing is alternatively compressed and released by the rollers, which actuates a fixed amount of fluid flow per rotation through mechanical action. However, because of the induced compression pattern, peristaltic pumps result in pulsatile flow. Pulsatility of the fluid can be minimized for studies requiring steady flow by the addition of a dampening chamber located downstream of the pump and proximal to the flow chamber. It is also important to note that for studies using whole blood as the recirculating fluid, the continued application of high shear stresses due to tube compression can result in the initiation of pump-induced platelet aggregation [213].

Peristaltic pumps offer several advantages over other types. Because of their size, they are able to generate high flow rates and handle large volumes of fluid. The rotor can also rotate either in a specified direction, producing pulsatile or steady flow, or in both directions, providing the ability to generate a more complex oscillatory flow. Their enclosed recirculation also reduces the volume of culture medium required. However, for long-term studies, the medium must be buffered with CO2 either within the chamber by the use of a gas-permeable material or by using a CO2-independent medium for a short time period [214]. In addition, systems are relatively inexpensive and have the ability to be sterilized, allowing them to be placed within an incubator. The likelihood of contamination is also minimal due to the fluid being in contact with only the inner surfaces of the tubing and not the pump itself.

When designing the flow system for use with a peristaltic pump, several factors should be considered. The first design parameter to be specified is the inner diameter of the tubing. For a given angular velocity of the rotor, as the inner diameter increases, the flow rate will also increase. Second, the flow rate is dependent on both the angular velocity of the pump's rotor and the inner diameter of the tubing. As the angular velocity increases for a given tube diameter, the flow rate will also increase. The last consideration is the pulsatility of the system. As the flow rate, length of tubing, the angular velocity of the rotor, and fluid density increase, more pulsation will occur. Therefore, for studies requiring steady flow, one should design the flow chamber to generate the required SS with a lower flow rate and include a dampening chamber to the flow loop, as described above, to reduce the pulsation. In addition, shorter lengths of tubing should be used, especially if the system needs to fit within an incubator.

In addition to a steady flow, this pump system is also used to simulate pulsatile and oscillatory flow conditions for the investigation of physiologic arterial pressure profile effects. For these unsteady flow conditions, two adjustments can be made to a peristaltic pump: (1) variation in the angular velocity of the stepping motor in one cycle, and (2) decreasing the gap size between the rollers and the roller bed of the pump head [215]. Generally, binary computer code will automatically vary the angular velocity. Flow pulsatility can also be simulated by adjusting the ratio of air to liquid in a compliance-adjustment chamber [216,217]. Setups using compliance-adjustment chambers usually place them after the flow probe within the system loop.

Systems with a peristaltic pump may be controlled by computer software systems, such as matlab or labview. These programable systems can monitor and record the flow rate and pressure over the time of the experiment by using flow probes and pressure transducers. Flow probes should be placed distal to the device to ensure the cellular monolayer is experiencing the correct flow rate. The software typically utilizes the flow probe to alter the pump's angular velocity to stabilize the flow rate to a user-defined value through a positive feedback loop (Fig. 9(a)).

6.2 Syringe Pumps.