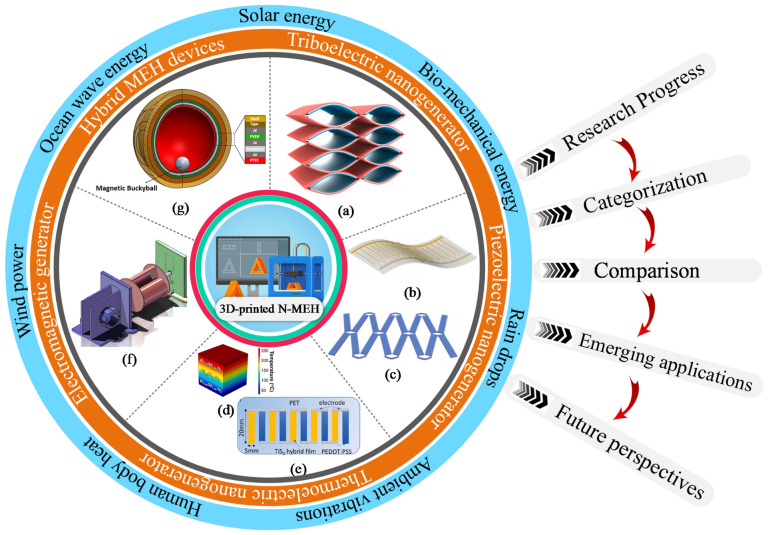

Graphical Abstract

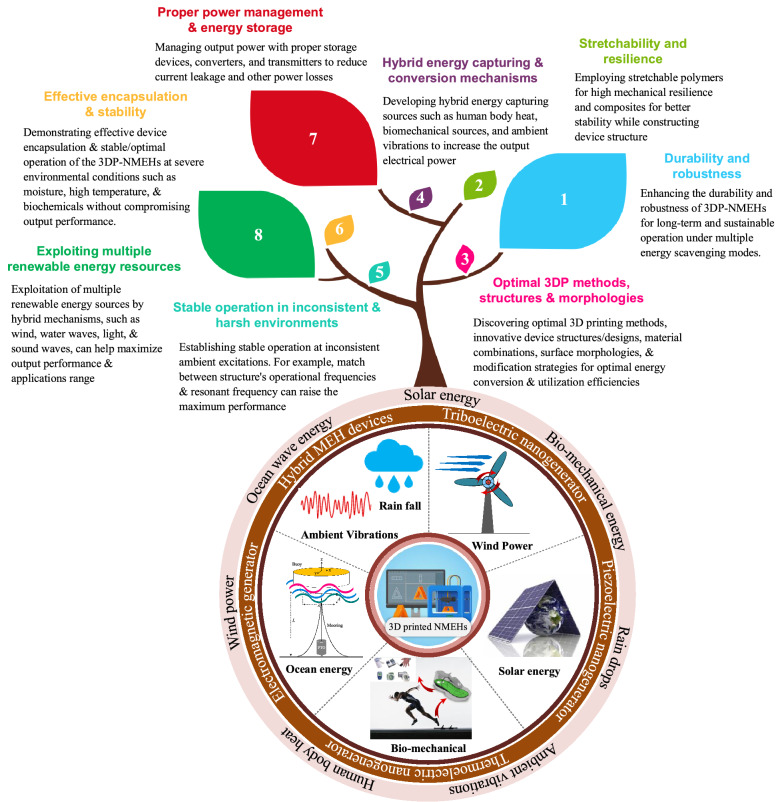

Additively manufactured nano-MEH systems are widely used to harvest energy from renewable and sustainable energy sources such as wind, ocean, sunlight, raindrops, and ambient vibrations. A comprehensive study focusing on in-depth technology evolution, applications, problems, and future trends of specifically 3D printed nano-MEH systems with an energy point of view is rarely conducted. Therefore, this paper looks into the state-of-the-art technologies, energy harvesting sources/methods, performance, implementations, emerging applications, potential challenges, and future perspectives of additively manufactured nano-mechanical energy harvesting (3DP-NMEH) systems. The prevailing challenges concerning renewable energy harvesting capacities, optimal energy scavenging, power management, material functionalization, sustainable prototyping strategies, new materials, commercialization, and hybridization are discussed. A novel solution is proposed for renewable energy generation and medicinal purposes based on the sustainable utilization of recyclable municipal and medical waste generated during the COVID-19 pandemic. Finally, recommendations for future research are presented concerning the cutting-edge issues hurdling the optimal exploitation of renewable energy resources through NMEHs. China and the USA are the most significant leading forces in enhancing 3DP-NMEH technology, with more than 75% contributions collectively. The reported output energy capacities of additively manufactured nano-MEH systems were 0.5–32 mW, 0.0002–45.6 mW, and 0.3–4.67 mW for electromagnetic, piezoelectric, and triboelectric nanogenerators, respectively. The optimal strategies and techniques to enhance these energy capacities are compiled in this paper.

Supplementary Information

The online version contains supplementary material available at 10.1186/s40580-021-00289-0.

Keywords: Nano-energy, Energy harvesting, Renewable energy, Sustainability, 3D printing, Challenges

Highlights

The current technology evolution and advancements in 3DP-NMEHs were evaluated.

Categorization and comparison of 3DP-NMEHs were performed in terms of inputs and energy conversion.

The emerging applications of 3DP-NMEHs were discussed briefly.

The potential challenges confronted by 3DP-NMEHs and respective recommendations were summarized.

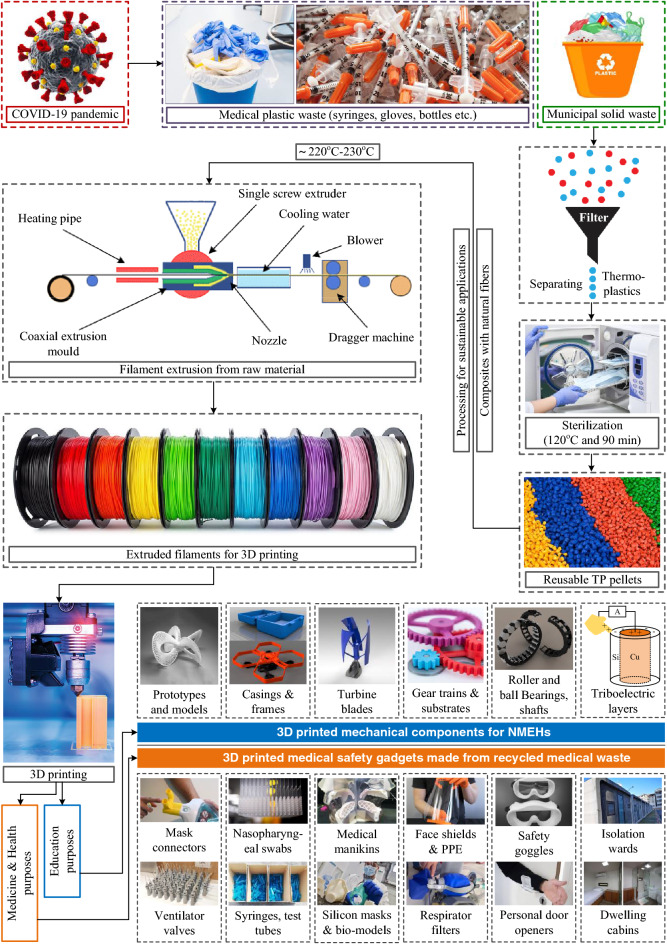

Sustainable use of recyclable waste generated during the COVID-19 pandemic was proposed.

Supplementary Information

The online version contains supplementary material available at 10.1186/s40580-021-00289-0.

Introduction

In recent years, the robust advancement in the miniaturized and diversely functionalized microelectronic systems caused the development of smart nano-devices such as watches, health monitoring sensors, phones, and wearable gadgets. This has changed our lifestyle by enabling us to interact with others and confront disasters and diseases through self-powered nano-energy devices [1, 2]. Although the energy output of nano-devices is minimal compared to conventional energy powerplants and other resources [3, 4]. However, it has stimulated the development of self-powered gadgets and sensors for personal use with a wide range of applications. Harvesting energy using standalone nano-devices to provide clean and affordable energy to everyone is also a promising contribution to fulfilling Sustainable Development Goals (SDG 7) under the 2030 sustainability agenda implemented by United Nations [5, 6].

The growth of rapid manufacturing technologies has revolutionized the perception of nano-mechanical energy harvesting in the past decade [7]. Low-power nano-mechanical energy harvesting (3DP-NMEHs) systems [8] have been extensively employed for innovative electronic applications such as biomedical health monitoring sensors, pacemakers, watches, cell phones, self-powered wireless sensor nodes, self-powered water desalination, ocean navigation, surveillance, and structural monitoring [9].

Batteries are restricted by low energy densities, uncertain/limited lifetime, bulky size, hazardous chemicals, risks of overcharging, and expensive recycling/replacement/recharging; henceforth, various studies have been conducted to harvest energy directly from renewables [10], including wind [11], ocean waves [12], solar irradiations [13, 14], raindrops [15], biomechanical motions, bodily heat, sound [16] and railway vibrations [17] through various compact, cheap, and easily replaceable energy conversion technologies such as electromagnetic, piezoelectric, triboelectric, thermoelectric and pyroelectric nanogenerators [18], for powering wireless sensor networks [19] anywhere and anytime.

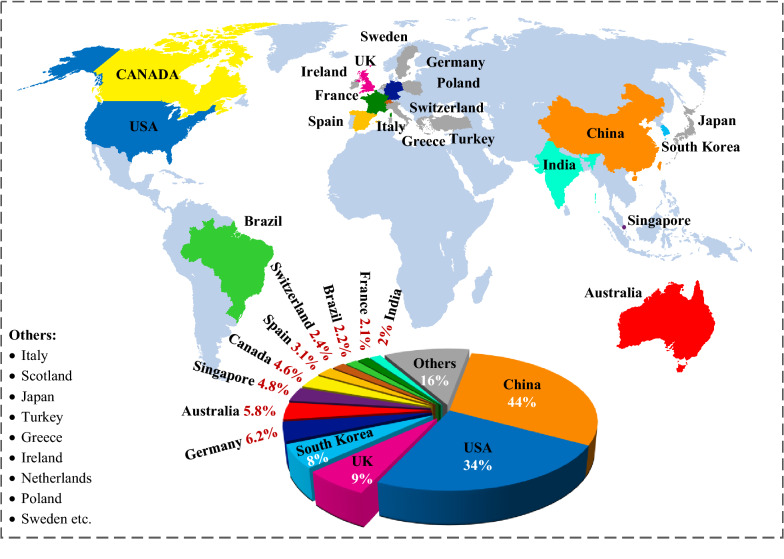

Additive manufacturing has advantages of accurate patterning, architectural customization, easy implementation, optimal mechanical resilience [20], lower environmental impact [21], sustainable/flexible production, faster speed, high-fabrication compatibility, less human intervention [22], relief from post-treatment, and minimal wastage/usage of materials [23, 24], over conventional manufacturing. With these benefits, 3D-printed structural frames [25], casings, shells, blades [26], substrates [27], piezoelectric [28], and triboelectric materials [29] have been widely utilized in nanogenerators. Moreover, it enables the use of biodegradable and recyclable materials for the fabrication of NMEH devices. Figure 1 shows the flourishment of 3D printed nano MEH mechanisms in various countries. China and the USA are on the top of the list with 44% and 34% contributions, respectively, holding more than half of the publications on the 3DP-NMEHs.

Fig. 1.

Contribution of the most prolific countries in the flourishment of 3D-printed mechanical energy harvesting systems

Tol et al. [30] developed a 3D-printed phononic crystal lens for elastic wave energy harvesting. The design parameters, including aperture size and gradient coefficient, were optimized numerically under plane wave excitation to achieve optimal performance. Lee et al. [27] demonstrated a 3D-printed hybrid coaxial TENG inspired by a crank engine to harvest large current from the ambient rotational motions at high frequencies. The prototype revealed an energy conversion efficiency of 17% at optimal output performance. Lu et al. [31] constructed a bidirectional gear transmission TENG using 3D printing to harvest energy from ambient vibrations to power a digital thermometer. The design parameters, including flywheel mass and the triboelectric film size, were optimized for optimal energy harvesting. The proposed design developed a short-circuit current of 14 μA, an open-circuit voltage of 450 V, and an output energy of 2.4 mJ.

Han et al. [26] developed a 3D printed miniature NMEH to harvest wind energy. The maximum output power from the device was 0.31 W at a 7% of maximum energy conversion efficiency. In another previous study, a 3D printed grating disk type NMEH device was presented as a power source for wireless electronic systems to harvest wind energy by Seol et al. [25]. The prototype developed a short-circuit current of 18.9 μA, an open-circuit voltage of 231 V, and maximum output power of 2.2 mW.

In a previous study, a ship-shaped hybridized nanogenerator was demonstrated for energy harvesting from water waves. The model produced a peak output power of 9 mW at a resistive load of 100 Ω, sufficient for powering self-powered positioning and seawater self-desalination. The experimental investigation demonstrated that the desalination rate could reach up to 30% in 180 min. Other demonstrated applications for the proposed MEH system include driving radio-frequency emitters for wireless positioning systems in ocean and rescue systems. Gao et al. demonstrated a 3D printed hybrid blue energy harvester based on a rotating gyro structure [32]. The proposed device was validated as a self-powered tracking system for an autonomous underwater vehicle in addition to an inertial sensor for marine equipment. Similarly, 3D printed NMEH systems, and solar energy trees have been developed for solar energy harvesting applications.

A 3D printed flexible triboelectric nanogenerator was demonstrated as a blue energy harvester and self-powered electro-Fenton degradation system for wastewater treatment by methylene blue degradation [29]. The peak density of output power, short circuit current, and an open-circuit voltage obtained from the prototype were 6 Wm−2, 2 mA, and 610 V, respectively. It was revealed that the methylene blue degradation efficiency could reach up to 98% within approximately an hour. Yuan et al. [33] developed a 3D-printed piezoelectric nanomechanical energy harvesting device for self-powered sensor applications. The PENG generated a maximum voltage of 74 V and power density of 478 μWcm−2. The potential applications for the proposed NMEH were self-powered artificial skin and tactile sensors. Zhou et al. proposed a 3D-printed stretchable PENG with a non-protruding kirigami structure for wearable electronic devices [34]. The prototype PENG could be stretched up to > 300% strain and was suggested for application as a self-powered gait sensor.

Yang et al. [35] constructed a thermoelectric generator (TEG) using multi-material 3D printing. The device could generate a peak output power density of 260 mWcm−2 and an efficiency of 9% at a temperature difference of 236 °C. A flexible thermoelectric device composed of a p-type and n-type organic superlattice film deposited onto the flexible PET substrate was developed for low-temperature applications [36]. The power factor of 210 μW m−1 K−2 was achievable at ambient room temperature. At ∆T = 70 K, a peak power density of approximately 2.6 Wm−2 was recorded for the proposed TEG. Han et al. [26] demonstrated a 3D printed miniature electromagnetic (EMG) NMEH driven by wind speed. The peak output power of 0.3 W at an energy conversion efficiency of 7% was achieved experimentally from the prototype. A 3D printed hybrid 3D activity inertial sensor was developed based on the combination of EMG, TENG, and PENG nanogenerators that could be used in inertial sensing in 6 different directions [37]. The structure consisted of magnetic buckyballs captured inside a 3D–printed spherical casing. The inner walls of the shell were deposited with layers of aluminum, PTFE, and PVDF films, whereas wire coils surrounded the outer surface. The sensor performed effectively in state monitoring of human activities and motion recognition applications. Moreover, the prototype could sense the x, y, and z components of the acceleration during linear motion and yaw, roll and pitch components of angular velocity during rotational motion.

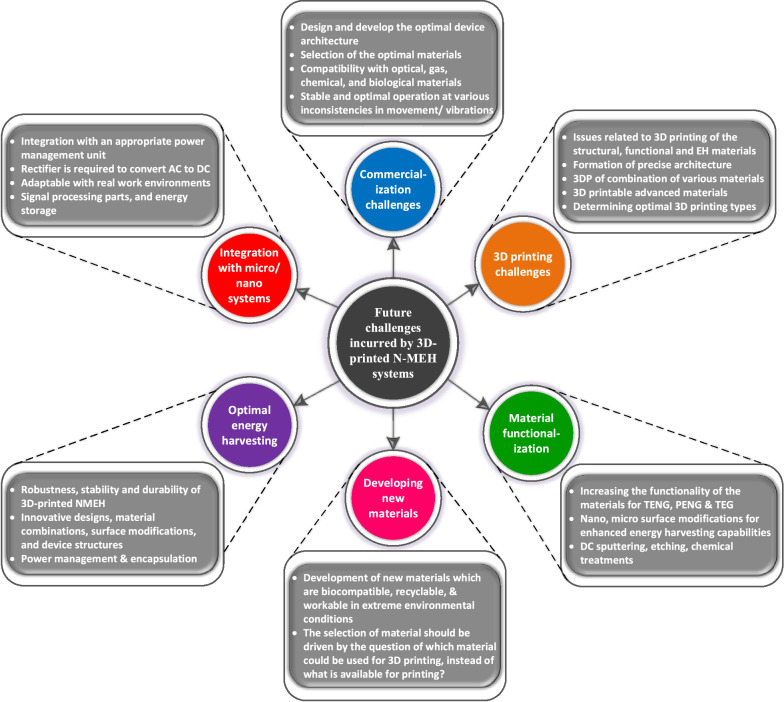

Despite many advantages related to NMEHs, some challenges still need to be addressed. For example, efforts are required to employ advanced and simpler methods to modify the surface morphology of the materials for optimal nanopatterning to improve the surface work function and output power. Unfortunately, most printable polymers are unsuitable for implementation in biomedical implants, encapsulations, and wearable electronics. In addition to a few 3D printing methods currently used in developing NMEHs, demonstrating new optimal 3D-printing techniques to develop intelligent nanogenerator structures and materials is crucial. Furthermore, prototyping of integrated nanogenerators and functional accessories such as implants, sensors, and actuators is challenging [38]. Due to the unavailability of favourable processes and materials, fabrication of the coil spools and permanent magnets used in electromagnetic (EMG) generators is not currently achievable through rapid prototyping techniques. In addition, the requirement of bulky gear mechanisms for enhancing speed to maximize output power also hinders the assembly of compact EMGs [39]. Due to their high-temperature processing, it is complicated to 3D print rare-earth dielectric materials for piezoelectric nanogenerators (PENG) [40]. Triboelectric nanogenerators are highly compatible with rapid prototyping technology; however, it is restricted by the wear of the modified surface morphology caused by friction and adhesion of the printed nanopatterns [9]. In this regard, significant efforts are needed to develop optimal fabrication procedures and novel materials for fabricating nano-MEH devices.

A comprehensive study focusing on in-depth technology evolution, applications, problems, and future trends of specifically 3D printed nano-MEH systems with an energy point of view is rarely conducted. Therefore, this paper looks into the technologies, energy harvesting sources/methods, performance, implementations, emerging applications, potential challenges, and future perspectives of additively manufactured nano-mechanical energy harvesting (3DP-NMEH) systems. The prevailing challenges concerning renewable energy capacities, optimal energy scavenging, power management, material functionalization, sustainable manufacturing strategies, new materials, commercialization, and hybridization were highlighted. For sustainable energy generation and medicinal purposes, a strategy is proposed for sustainable applications of recyclable municipal and medical waste generated during the COVID-19 pandemic. Finally, recommendations for future research are presented concerning the significant issues hurdling the optimal exploitation of renewable energy resources through NMEHs.

Nano-mechanical energy harvesting (NMEH)

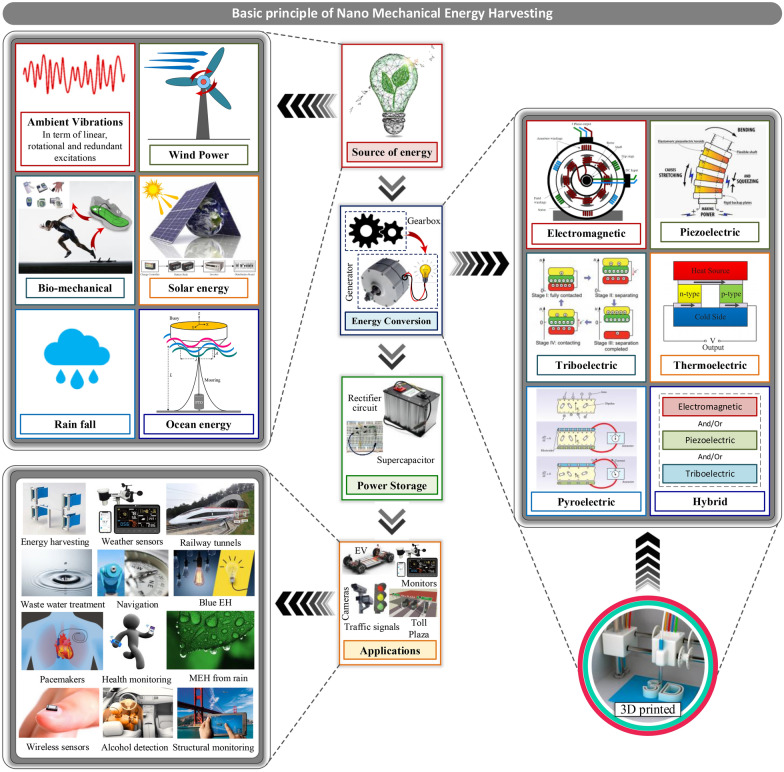

Harnessing energy from the ambient energy resources in the environment is an adequate substitute for the battery-based operation for low-power and self-powering devices. Besides, utilizing the harvested power near the energy source can eliminate the need for long transmission cables and power storage systems. Recently it has been revealed that micro/nano energy harvesting systems such as triboelectric, electromagnetic, piezoelectric, and electrostatic transducers can provide electrical power reaching from a few tens to hundreds of μW [8]. Figure 2 shows the layout of nano-mechanical energy harvesting with various ambient sources, 3DP-based manufactured energy conversion technologies, and potential applications reviewed in this study. The process consists of four modules.

-

I.

Source of perturbation or ambient energy

-

II.

Energy conversion mechanism

-

III.

Post-processing and power storage

-

IV.

Suitable applications

Fig. 2.

Schematic of nanomechanical energy harvesting along with various energy sources, energy conversion methods and potential applications

The most frequently used energy sources are wind, solar irradiation [41], ocean waves, human motion, raindrops [15], and ambient vibrations. The energy captured by these ambient sources can be transformed into useful form through several energy conversion phenomena such as electromagnetic, piezoelectric, triboelectric [42], thermoelectric, pyroelectric, and hybrid systems. Various studies have employed 3D printing for the development of structural components [25] of energy conversion devices such as turbine blades [26], casings, substrates [27], piezoelectric materials [28], solar energy trees, nano-structures for triboelectric nanogenerators, and many others. A few applications of NMEH are powering wearable devices, wireless sensor networks, navigation devices, wastewater treatment, charging mobile phones, biomedical healthcare systems, lighting LED, weather sensors, structural health monitoring, and cloud-based data transfer systems [8]. The output power can be post-processed before utilization, using complex rectifying and power management circuits. Batteries and supercapacitors are widely used to store harvested energy.

However, potential challenges still exist, such as the development of printing materials, printing of nanostructures, surface modifications, matching ambient vibration frequencies, scalability, usage location, energy conversion rate, and mass production. In addition, the significance of choosing a suitable battery, supercapacitor, or energy storage system must not be underrated. The impedance and capacity of the energy storage device must match the pulsed output of the NMEH device. Table 1 shows the distribution, significance, and performance of nano-mechanical energy harvesting systems over various sources of MEH and categorization with respect to output power. Table 2 elaborates the features and characterization of some previously developed nano-MEH systems to harvest renewable energy from natural resources such as wind, ocean, and solar energy.

Table 1.

Distribution and significance of nano-mechanical energy harvesting systems over various renewable energy sources of MEH and categorization concerning output power

| Source | Nano | References | Energy conversion | Input | Output | Efficiency |

|---|---|---|---|---|---|---|

| Road profile | ✓ | [43] | Piezoelectric EH structure | 2–4 mm, 5–10 Hz | 3 mW | – |

| × | [44] | Chessboard sliding plate on the road | – | 66 W | 62.4% | |

| × | [45] | Piezoelectric MEH using road bump | 10–30 km/h, 38–53 kg | 4.1 W | 13% | |

| × | [46] | High-efficiency MEH paver | 80 kg | 12 W | 50% | |

| ✓ | [47] | MEH from multi-directional vibration | 5 km/h | 1.4 mW | – | |

| Railway track vibrations | × | [48] | Electromagnetic energy convertor | 1–2 Hz, 6 mm | 6.5 V | 56% |

| ✓ | [49] | Thermoelectric EH using railway track | – | 317 mW | 60% | |

| ✓ | [50, 51] | Smart railway monitoring system | 10–30 Hz | 548 mW | – | |

| × | [52] | Vibration EH using multi-frequencies | 5.6 Hz | 1.5 W | – | |

| × | [53] | The electromagnetic based EH from the railroad | - | 10–100 W | 74% | |

| Shock absorber vibrations | × | [54] | MEH from hydraulic shock absorber | 5–25 mm, 1–5 Hz | 397 W | 50% |

| × | [55] | Electromagnetic shock absorber EH for railway cars | 2–4 mm, 2–4 Hz | 1.2 W | 68% | |

| × | [56, 57] | Regenerative mechanism for shock absorber | 5–10 mm, 1–3 Hz | 0.5 W | 84% | |

| ✓ | [58] | Self-powered sensor nodes for freight rail transport | 80 km/h | 263 mW | 65% | |

| × | [59] | Energy regenerative shock absorber based MEH | 2.5–7.5 mm, 1–2.5 Hz, | 4.3 W | 55% | |

| Ocean wave | × | [60] | Ocean-wave based energy harvesting mechanism | Wave height of 0.2 m | 63 W | – |

| × | [61] | The floating WEC | 0.8 m, 0.76 Hz | – | 39% | |

| × | [62] | WEC with power take-off mechanism | 8 mm, 3 Hz | – | 67% | |

| ✓ | [63] | Oscillating buoy as WEC | 15 mm, 1.2 Hz | 3 V | 57% | |

| × | [54] | Hydraulic energy regeneration from shock absorbers | 72 km/h | 397 W | 50% | |

| Wind energy | ✓ | [64] | Piezoelectric EH from wind energy | 6.5 m/s | 25 mW | – |

| ✓ | [65] | Wind EH using fibre composites | 7.5 m/s | 0.53 mW | – | |

| ✓ | [66] | High-performance piezoelectric EH for wind energy | 2.1 m/s | 1.2 mW | – | |

| ✓ | [67] | A rotational piezoelectric wind energy harvester | 14 m/s | 160 V, 2566 μW | – | |

| ✓ | [68] | Vibro-impact dielectric wind EH | 4 m/s | 0.72 mW | – | |

| Bio-mechanical energy | ✓ | [69] | Scavenging energy from human motion | 5 Hz | 9 mW | 8% |

| ✓ | [70] | Electromagnetic EH from human movements | 9 km/h | 85 mW | 92% | |

| ✓ | [71] | MEH for ultra-low frequency vibrations | 4 Hz | 5.3 mW | – | |

| × | [72] | A human motion-based vibration energy harvester | 4.8 km/h | 5.1 W | – | |

| ✓ | [73] | Biomechanical energy harvesting pavement | 30 Hz | 300 mW | – |

Table 2.

Features and characterization of some previously developed nano-systems to harvest renewable energy from natural resources (wind, ocean and solar resources)

| Energy conversion | Mechanism | Input | Output | Advantages () and disadvantages (↓) |

|---|---|---|---|---|

| Electromagnetic generators (EMG) | Portable wind energy harvester based on S-rotor and H-rotor | 5–12 m/s | 108 mW, 23.2% |

() powers the monitoring sensors in railway tunnels () uses hybrid S-rotor and H-rotor |

| Double-Skin Façade system for harvesting wind energy | 3–8 m/s | 1110 W/m2 |

() low turbulence and uniform flow due to cavity (↑) provides a wide range of angles for incident wind |

|

| Galloping, vortex shedding, flutter, and aerodynamic instability | 2–6 m/s | 1 W |

(↑) based on wake galloping (↑) a simpler mechanism for structural health monitoring system (↑) powers wireless sensors |

|

| Piezoelectric nanogenerators (PENG) | The flutter of a flexible piezoelectric membrane | 9 m/s | 5 mW/cm3 |

(↑) simple inverted flag orientation (↑) Self-aligning capability (↑) can operate in low-speed regimes |

| Vortex-induced vibration-based piezoelectric EH | 1–1.4 m/s | 0.6 mW |

(↑) facilitates Y-shaped attachments on bluff body (↑) provides an enhanced energy harvesting efficiency |

|

| MEH is composed of permanent magnets, rotor, piezoelectric stack, and flexure mechanism | 100 rpm | 0.2 mW |

(↑) simple and compact design (↑) optimal performance with a larger power output |

|

| Pyroelectric (PEG)/ Thermoelectric generators (TEG) | Flexible vortex generator or turbulator | 1–25 m/s | 3 W/cm2 |

(↑) Flexible structure with un-interrupted energy output (↓) possesses low pyroelectric coefficient |

|

Harvesting solar and wind energies using thermal oscillations through sustainable PEG |

2.5–5.3 m/s | 421 W/cm3 |

(↑) provides high power density (↓) power density depends on the intensity of the solar irradiations and wind speed |

|

| Triboelectric nanogenerators (TENG) | A rotary TENG based on mechanical deformation of multiple plates | 15 m/s | 39 W/m2 |

(↑) facilitates the application of polymer nanowires (↑) can be used as a self-powered wind speed sensor |

| TENG-based windmill composed of nanopillar-array architectured layers | 14–15 m/s | 568 V, 26 μA |

(↑) simple and cheap fabrication (↑) high output and optimal performance (↑) high stability |

|

| Pendulum-based TENG using a pendulum structure with high energy conversion efficiency | 2 m/s, 2 Hz | 56 V |

(↑) superior durability (↑) ultrahigh sensitivity (↑) long-time operation (↑) energy harvesting from wave and wind |

The references of the research papers cited in this table are provided in the Additional file 1

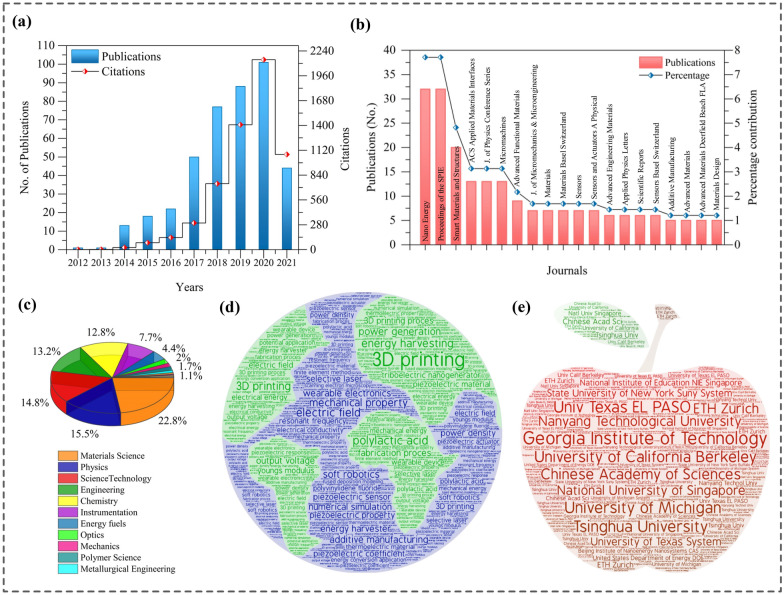

Advancements in 3D printed Nano-MEH systems

Figure 3 signifies the technology evolution pathways of 3D printed mechanical energy harvesting systems in terms of bibliometric parameters such as publication growth, top contributing research areas, frequently investigated keywords, and the most prolific journals and institutions globally. The published literature, including original research articles, were obtained from Web of Science and investigated in CiteSpace software to visualize the specialties. It can be observed in Fig. 3a that the number of publications on 3DP-NMEHs was ignorable till 2013 and dramatically increased after 2013, reaching above a hundred in 2020. The number of citations drastically grew after 2016. Nano Energy, Proceedings of the SPIE, and Smart Materials & Structures were the top three most prolific journals contributing to the advancement of 3DP-NMEHs research, as shown in Fig. 3b. The highly dynamic research areas involved in the flourishment of the research are Materials Science, Physics, Science & Technology, Engineering, and Chemistry (Fig. 3c). The most frequently studied keywords related to the domain are 3D printing, energy harvesting, mechanical modulations, polylactic acid (PLA), triboelectric nanogenerator (TENG), and piezoelectric nanogenerators (PENGs) (Fig. 3d). The institutions publishing the most significant publications in the 3DP-NMEH research field are the Georgia Institute of Technology, University of California Berkeley, Nanyang Technological University, Chinese Academy of Sciences, and Univ Texas EL PASO, as shown in Fig. 3e.

Fig. 3.

Research progress in 3D printed MEH systems a Growth in publications and citations related to 3D printed MEH devices, b leading journals in the flourishment of 3DP nano MEH research, c significant research areas of the published literature, d the most influential keywords in the study of 3D-printed nano MEH systems, e the most prolific institutions contributing to the enhancement of nano MEH research, Results were obtained from postprocessing of the data, retrieved from Web of Science using search keywords {TOPIC: ((“3D Printed” OR “3DP” OR “3D printing”)) AND TOPIC: ((“energy convertor” or “Triboelectric” OR “Piezoelectric” OR “Thermoelectric” or “nanogenerator” OR “Nano-energy harvester” OR “Biomechanical energy” OR “human movements” OR “Nano energy” or “Mechanical energy” OR “Energy harvesting” OR “linear generator” OR “Energy harvester” OR “Electromagnetic generator”)), Refined by: Document types: (Article or Review) and Research domains: (Science & Technology) and Languages: (English), Timespan: 2010–2021. Databases: WOS, CSCD, DIIDW, KJD, MEDLINE, RSCI, SCIELO}

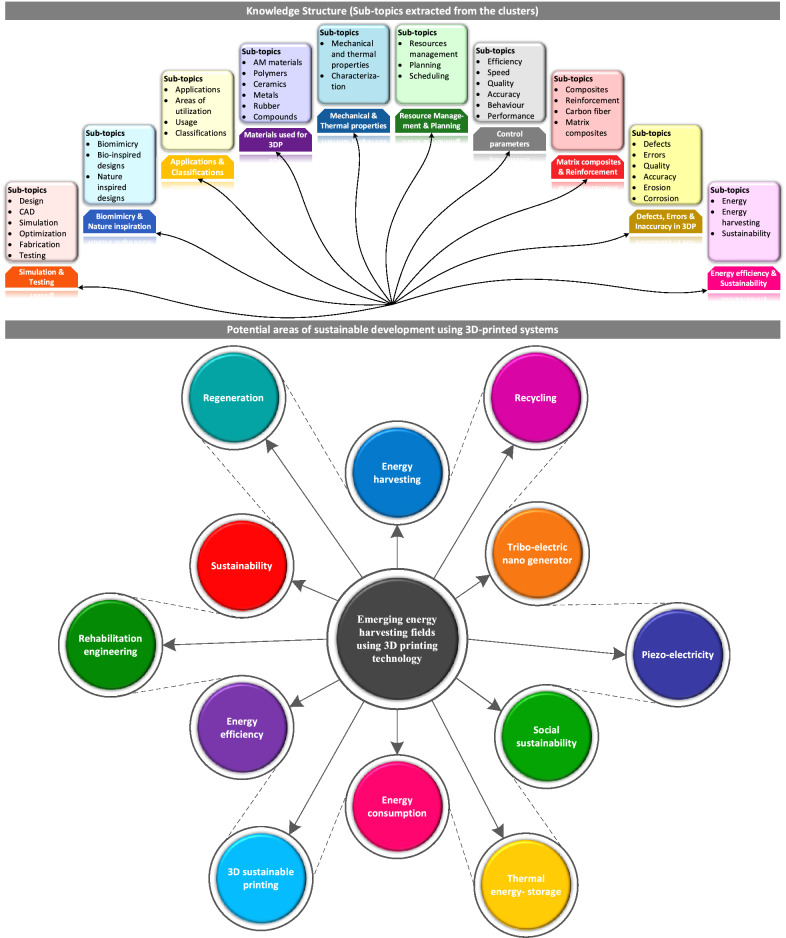

Potential areas of sustainable energy development using 3D printed devices

To determine the inter-disciplinary research fields where 3D printed components are being extensively used, a simulation study was conducted using CiteSpace software based on the literature retrieved from Web of Science databases. A knowledge structure was developed after detailed analyses to evaluate the network of these research domains, as shown in Fig. 4. It can be noticed that “sustainable energy” and “energy harvesting” are among the top ten research fields related to 3D printing. It shows the emerging significance of 3D printing in developing mechanical energy harvesting (MEH) mechanisms. In addition, the emerging fields of MEH using 3D printed components are mapped in Fig. 4. Numerous devices have been reported to be fabricated using the integration of 3D printed parts to harvest energy from various sources such as human activities [31] and joint movements, wind [26], ocean waves, sound [16], rain droplets, and other ambient vibrational energy sources [30]. The wind and ocean energy harvesting devices have been commonly fabricated using 3D printed substrates, structural frames, conductive electrodes [74], blades [75], rotors, printed electronics [76, 77], shells, and casings. Additive manufacturing facilitates the utilization of biodegradable and reusable materials for the manufacturing of nano-MEH systems. Moreover, the portability of the small and compact 3D-printed mechanisms has inspired the concept of nano-energy. However, the application of 3D printed parts in the development of medium to large-scale mechanical energy harvesting systems has been rarely reported. In future MEH research, significant efforts are required to optimize the printing materials and printing techniques to develop durable, reliable, renewable, and mechanically and thermally strong functional components for large power-extracting (greater than 1 Watt) MEH systems such as blue EH, wind turbines, regenerative shock absorbers, wave energy converters and railway-vibrations based MEHs.

Fig. 4.

Energy harvesting as a prominent domain in 3D-printing research and significant areas of MEH using 3D-printed devices

Resources and methods of 3D-printed Nano-MEH systems

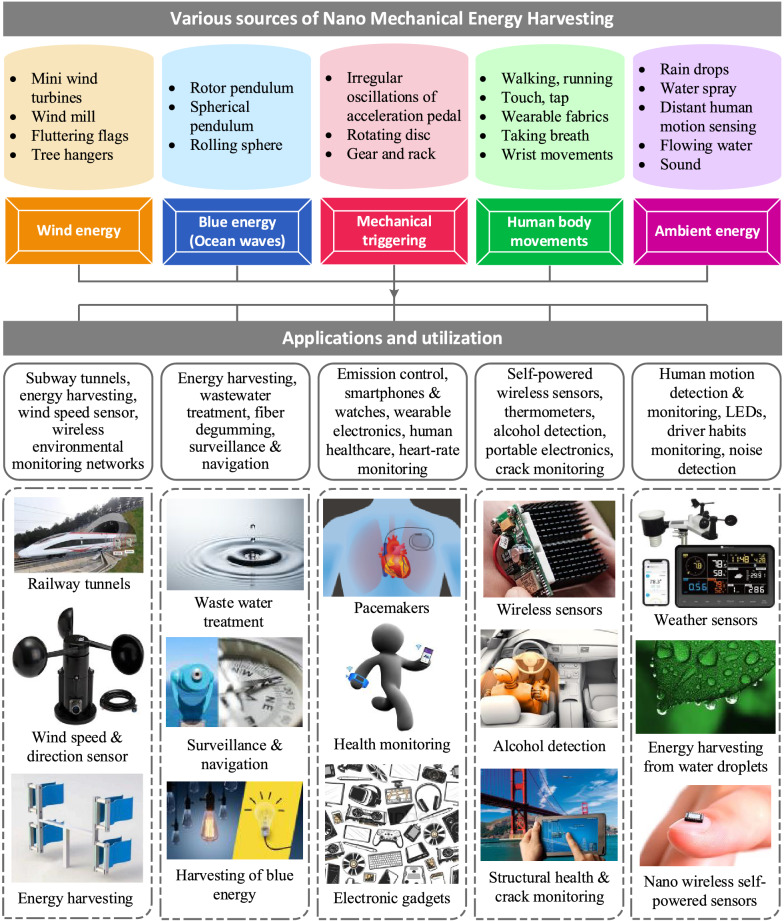

Renewable energy sources

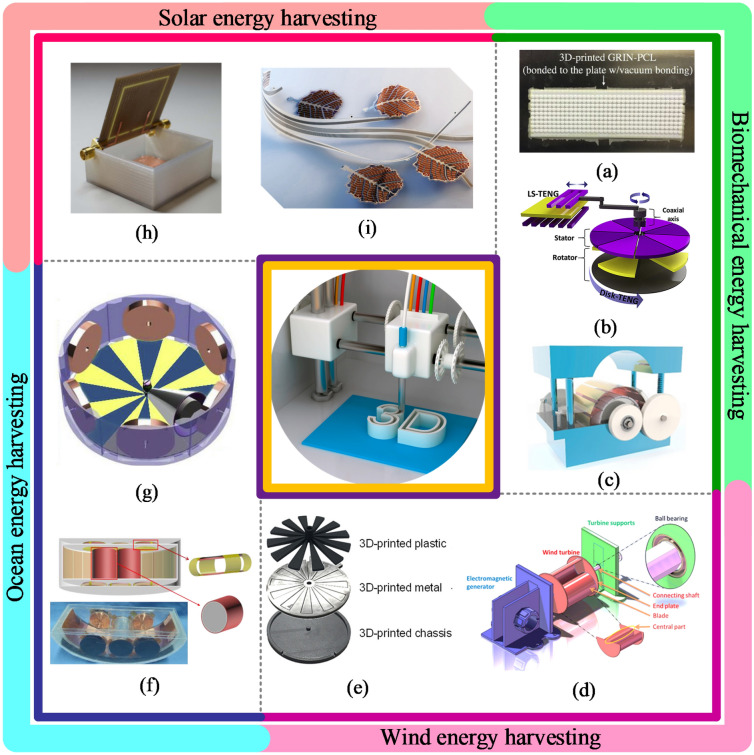

The 3D printed nanomechanical energy harvesting systems can be categorized based on energy sources and energy conversion methods. Figure 5 shows significant energy sources used to harvest mechanical energy, such as ocean waves, wind, solar energy, biomechanical triggering, and ambient vibrations in the environment. Tol et al. [30] developed a 3D-printed phononic crystal lens for elastic wave energy harvesting, as shown in Fig. 5a. The design parameters, including aperture size and gradient coefficient, were optimized numerically under plane wave excitation to achieve optimal performance. Lee et al. [27] demonstrated a 3D-printed hybrid coaxial TENG inspired by a crank engine to harvest large current from the ambient rotational motions at high frequencies, as illustrated in Fig. 5b. The prototype revealed an energy conversion efficiency of 17% at optimal output performance. Lu et al. [31] constructed a bidirectional gear transmission TENG using 3D printing to harvest energy from ambient vibrations to power a digital thermometer, as shown in Fig. 5c. The design parameters, including flywheel mass and the triboelectric film size, were optimized for optimal energy harvesting. The proposed design developed a short-circuit current of 14 μA, an open-circuit voltage of 450 V, and an output energy of 2.4 mJ.

Fig. 5.

Various sources of MEH through 3D-printed MEH devices a 3D-printed phononic crystal lens for elastic wave energy harvesting [30] b 3D-printed hybrid coaxial TENG inspired by a crank engine [27] c Bidirectional gear transmission triboelectric nanogenerator fabricated using 3D printing [31] d 3D printed miniature electromagnetic energy harvester driven by airflow [26] e All 3D printed grating disk type TENG [25] f ship-shaped hybridized nanogenerator [78] g triboelectric-electromagnetic rotating gyro structured blue energy harvester [32], h Solar energy harvester with a 3-D printed package [84] i 3D printed solar energy trees (Image credits: alternative-energy-news.info/) (Images are re-used with the permission of the publisher)

Han et al. [26] developed a 3D printed miniature NMEH to harvest wind energy, as shown in Fig. 5d. The maximum output power from the device was 0.31 W at a 7% of maximum energy conversion efficiency. A 3D printed grating disk type NMEH device was presented as a power source for wireless electronic systems in a previous investigation to harvest wind energy by Seol et al. [25], as given in Fig. 5e. The prototype developed a short-circuit current of 18.9 μA, an open-circuit voltage of 231 V, and maximum output power of 2.2 mW.

A ship-shaped hybridized nanogenerator was developed in a previous study for energy harvesting from water waves [78], as shown in Fig. 5f. The model produced a peak output power of 9 mW at a resistive load of 100 Ω, sufficient for powering self-powered positioning and seawater self-desalination. The experimental investigation demonstrated that the desalination rate could reach up to 30% in 180 min. Other demonstrated applications for the proposed MEH system include driving radio-frequency emitters for wireless positioning systems in ocean and rescue systems. Gao et al. demonstrated a 3D printed hybrid blue energy harvester based on a rotating gyro structure [32], as shown in Fig. 5g. The proposed device was validated as a self-powered tracking system for an autonomous underwater vehicle in addition to an inertial sensor for marine equipment.

Organic solar cells have limited applications due to low energy conversion efficiencies compared to their inorganic counterpart. It is due to the short-range light absorption, low charge mobility, and electrical conductivity of the prevailing organic materials. Carbon nanomaterials, including graphene and carbon nanotubes, are characterized by high mobility, electrical conductivity, and unique optical characteristics, making them suitable for organic solar cell applications [79]. Moreover, graphene-based energy storage devices have also been employed for power management of these nano-devices [80]. Recently developed colloidal quantum dots (CQDs) have revolutionized photovoltaics, and the resultant devices are capable of cheaper solution processes and a tunable bandgap [81]. Organic and metallic monovalent cations-based perovskite solar cells are newly developed solar devices that are less toxic than lead-based solar cells [82]. The new 3D printed NMEH systems and solar energy trees [83] developed for solar energy harvesting applications are shown in Fig. 5h, i.

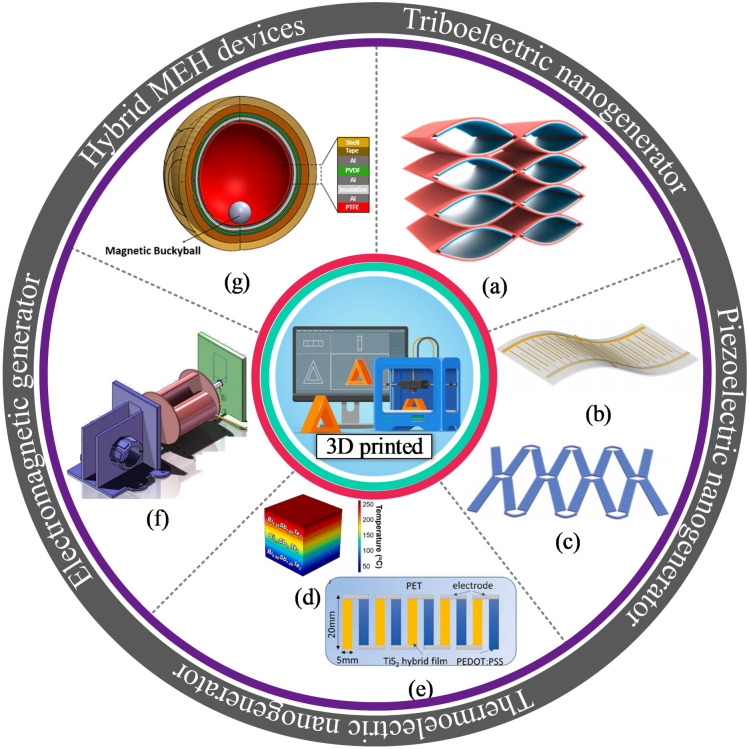

Energy harvesting methods

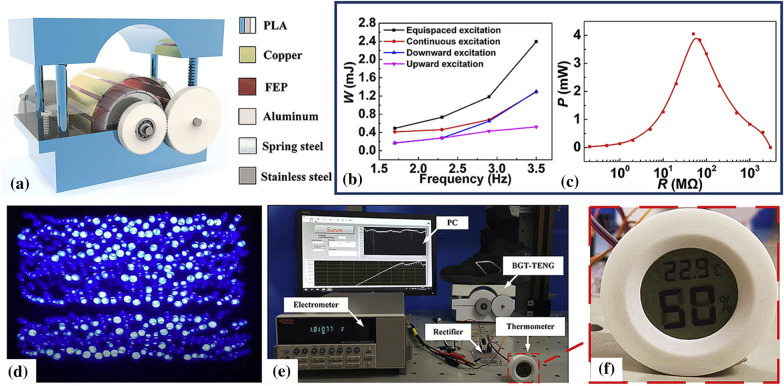

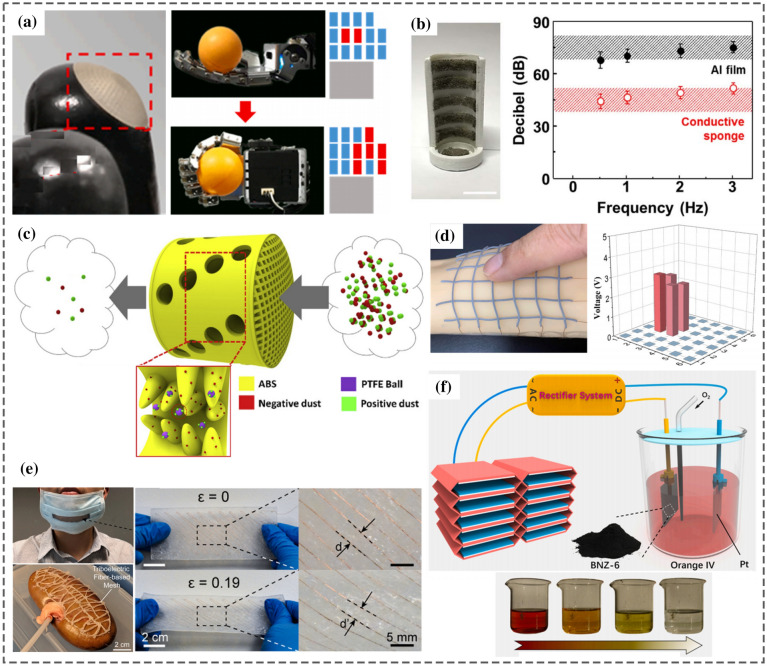

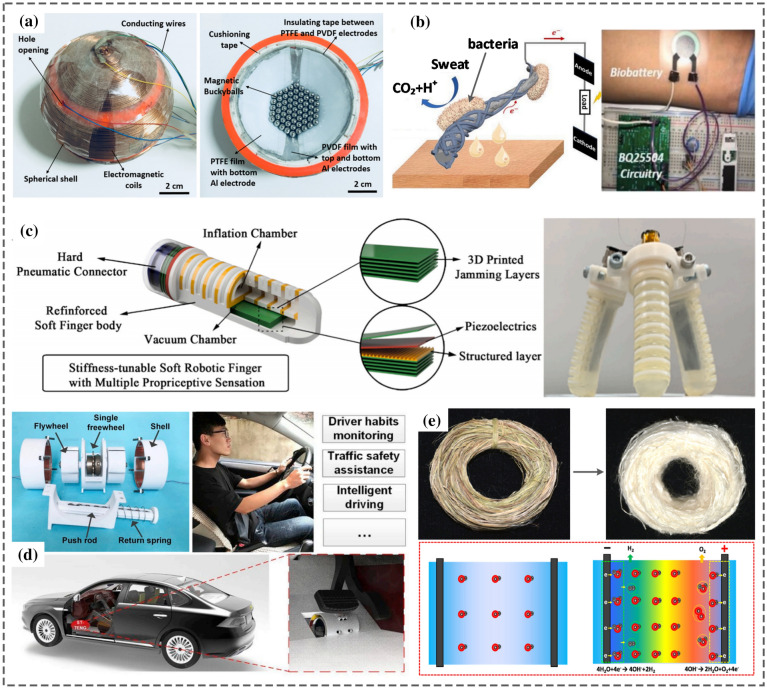

The energy conversion methods primarily utilized for 3DP-NMEH systems include electromagnetic, piezoelectric, triboelectric, thermoelectric, and hybrid combinations, as shown in Fig. 6. A 3D printed flexible triboelectric nanogenerator was demonstrated as a blue energy harvester and self-powered electro-Fenton degradation system for wastewater treatment by methylene blue degradation [29], as shown in Fig. 6a. The peak density of output power, short circuit current, and an open-circuit voltage obtained from the prototype were 6 Wm−2, 2 mA, and 610 V, respectively. It was revealed that the methylene blue degradation efficiency could increase up to 98% within approximately an hour.

Fig. 6.

Classification of 3D printed energy harvesting devices based on working principle a 3D printed flexible triboelectric nanogenerator as a self-powered electro-Fenton degradation system [29] b 3D-printed piezoelectric device for self-powered sensor application [33] c 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure [34] d 3D printed BiSbTe thermoelectric generator [35] e Thermoelectric device composed of a p-type and n-type organic superlattice film deposited onto the flexible PET substrate [36] f 3D printed miniature electromagnetic energy harvester driven by airflow [26] g 3D printed hybrid 3D activity inertial sensor based on EMG, TENG and PENG nanogenerators [37] (Images are re-used with the permission of the publisher)

Yuan et al. [33] developed a 3D-printed piezoelectric nanomechanical energy harvesting device for self-powered sensor applications, as shown in Fig. 6b. The PENG generated a maximum voltage of 74 V and power density of 478 μWcm−2. The potential applications for the proposed NMEH were self-powered artificial skin and tactile sensors. Zhou et al. proposed a 3D-printed stretchable PENG with a non-protruding kirigami structure for wearable electronic devices [34], as shown in Fig. 6c. The prototype PENG could be stretched up to > 300% strain and was suggested for application as a self-powered gait sensor.

Yang et al. [35] constructed a thermoelectric generator (TEG) by multi-material 3D printing, as shown in Fig. 6d. The device could generate a peak output power density of 260 mWcm−2 and an efficiency of 9% at a temperature difference of 236 °C. A flexible thermoelectric device composed of a p-type and n-type organic superlattice film deposited onto the flexible PET substrate was developed for low-temperature applications [36], as shown in Fig. 6e. The power factor of 210 μW m−1 K−2 was achievable at ambient room temperature. At ∆T = 70 K, a peak power density of approximately 2.6 Wm−2 was recorded for the proposed TEG.

Han et al. [26] demonstrated a 3D printed miniature electromagnetic (EMG)-based NMEH driven by wind speed, as shown in Fig. 6f. The peak output power of 0.3 W at an energy conversion efficiency of 7% was achieved experimentally from the prototype. Figure 6g highlights a 3D printed hybrid 3D activity inertial sensor based on the combination of EMG, TENG, and PENG nanogenerators [37]. The structure consisted of magnetic buckyballs captured inside a 3D–printed spherical casing. The inner walls of the shell were deposited with layers of aluminum, PTFE, and PVDF films, whereas wire coils surrounded the outer surface. The sensor performed effectively in state monitoring of human activities and motion recognition applications. Moreover, the prototype could sense the x, y, and z components of the acceleration during linear motion and yaw, roll, and pitch components of angular velocity during rotational motion.

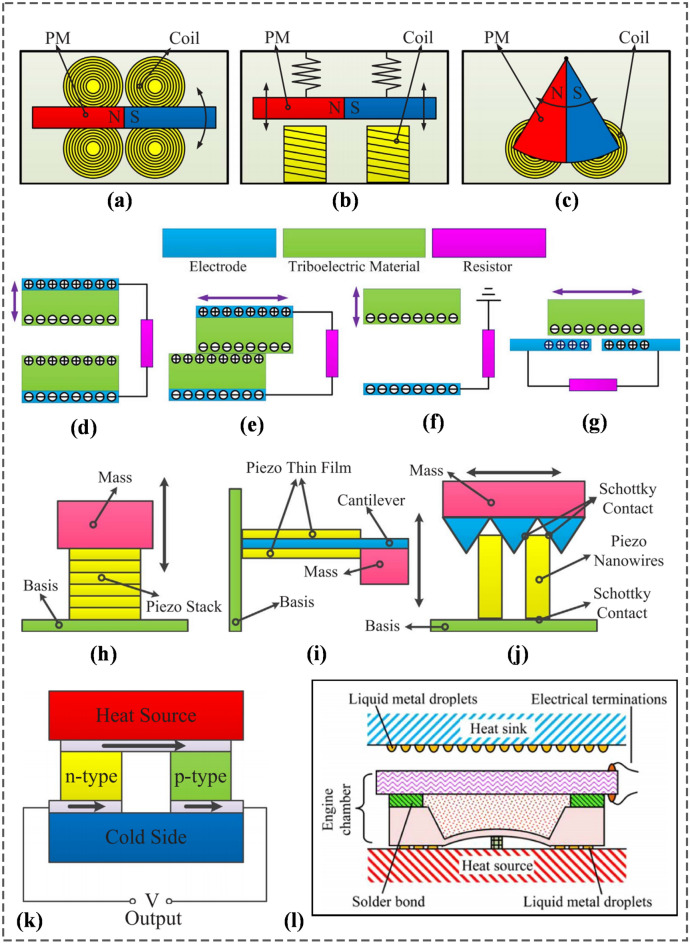

Electromagnetic energy harvesters

Electromagnetic generator (EMG) based NMEH devices work on the principle of Faraday’s law of electromagnetic induction, a relationship between the induced electromotive force across the coil and time rate of change of the magnetic flux through the coil. The relative motion between the rotor coils and surrounding magnets induces a current in the external circuit. The coils and magnets can be fixed or movable. In Fig. 7a–c, three different working layouts of EMGs are illustrated [39] based on the types of mechanical motions involved.

Rotation-based EMGs—are miniaturized electromagnetic generators that convert the continuous rotational motions of the magnets or armature into electrical output, as shown in Fig. 7a.

Oscillatory EMGs—are based on the oscillatory motions between the magnets and coils for energy conversion, as shown in Fig. 7b.

Hybrid EMGs—utilize an imbalanced structure to harvest energy from chaotic or random vibrations by converting rectilinear motion into rotational motion, as shown in Fig. 7c.

Fig. 7.

Working modes of electromagnetic energy harvesters: a rotational, b oscillatory and c hybrid; working modes of triboelectric nanogenerators d vertical contact-separation mode, e in-plane contact-sliding mode, f single-electrode mode and g freestanding mode working modes of piezoelectric energy harvesters: h d33 working mode, i d31 working mode and j piezotronic working mode; k schematic diagram of a thermoelectric nanogenerator l schematic of the micro pyroelectric energy harvester [39] (Images are re-used with the permission of the publisher)

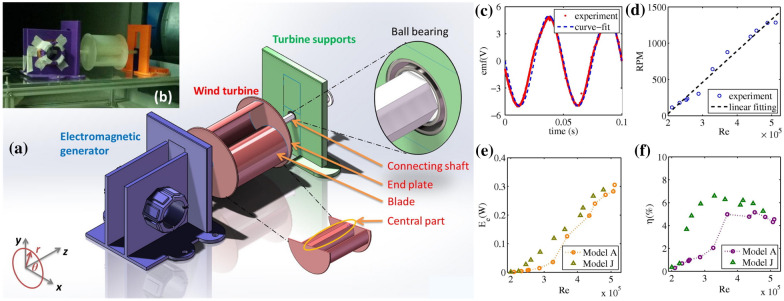

3D printing of conventional EMG-based MEH devices is challenging due to the unavailability of favourable printing processes and materials. For example, 3D printing of the coil spools and permanent magnets used in electromagnetic generators is not achievable currently. In addition, several factors such as low output voltage, high output current, unavoidable coil losses, and the requirement of bulky gear mechanisms for enhancing speed to maximize output power levels add to the difficulty of 3DP-based development of micro/nanoscale EMG MEH devices. Many researchers have conducted efforts to develop miniature structures for EMG-based MEHs. Han et al. [26] developed a 3D printed miniature electromagnetic energy harvester driven by airflow, as shown in Fig. 8a, b. The maximum output power from the device was 0.31 W at a 7% of maximum energy conversion efficiency, as shown in Fig. 8c–f. The rotational speed of the turbine and output power was increased with increasing Reynolds number (Re). However, the optimal energy conversion efficiency was restricted by friction with the increase in the rotating speed of the turbine. The proposed 3D printed EMG-based wind-driven MEH system was demonstrated as an efficient strategy to harvest renewable wind energy and can be used to supply power to HVAC ventilation systems and household electronic appliances. Gao et al. demonstrated a 3D printed EMG blue energy harvester based on a rotating gyro structure [32]. The proposed device was validated as a self-powered tracking system for an autonomous underwater vehicle in addition to an inertial sensor for marine equipment.

Fig. 8.

a CAD model of the air-driven 3D printed EMG energy harvester, b prototype for the experimental testing in the wind tunnel c output voltage with time d RPMs with Reynolds number (Re) e output power with Re f energy conversion efficiency with Re [26] (Images are re-used with the permission of the publisher)

Triboelectric nanogenerators

Triboelectric nanogenerator (TENG), working on the principle of electrostatic induction and contact electrification, has excellent potential in nanoscale energy harvesting applications. Owing to the high energy conversion efficiency, low fabrication cost, and optimal output power density, triboelectric nanogenerators are widely used for MEH from wind [85], water waves [86], human motion [87, 88], and ambient vibrations [89]. Various techniques have been utilized, such as spin coating [90], etching [91], and electrospinning, to improve the frictional effect of the triboelectric materials. This is accomplished by developing the micro or nanostructures on the surface to enhance the effective frictional contact areas between the TENG surfaces. 3D printing facilitates high material-usage efficiency to fabricate objects from complex CAD models in a shorter period. Therefore, it has been widely employed to manufacture casings, blades, shells, tubular components, structural frames, nano-patterns, surface modifications, and friction materials. TENG holds exceptional compatibility with 3D printing technology for the following reasons:

Most of the materials used for the development of TENGs are compatible with 3D printing. For example, the structural supports are made of plastics, the triboelectric materials are mostly polymers, and the electrodes are conductors, and all of these can be fabricated through 3DP.

The manufacturing requirements of TENGs are compatible with the 3D printing process as there is no need for vacuum apparatus or high-temperature treatment after fabrication. Moreover, the device performance is not compromised by 3DP.

3DP facilitates accurate and simple structural control, which is advantageous for TENG fabrication. For instance, the dampers and springs can easily be 3D printed, and interdigitated configurations can be 2D printed, improving EH performance.

3D printing offers customization in design considering the optimization of various complicated structural parameters

Due to frictional contact between two materials with different electronegativities, opposite charges accumulate at the contact surfaces and remain for a long time even after the separation of the surfaces. If the triboelectric materials are integrated with electrodes connected to an external circuit, the cyclic separation and contact of triboelectric surfaces develop a charge on the surfaces, causing an alternating electric current in the circuit. It is due to the electrostatic induction and varying equivalent capacitance between the surfaces. In Fig. 7d–g, four different working modes of TENGs [92] are shown as described below,

Vertical contact-separation mode—is based on the cyclic contact and separation between the two horizontal triboelectric surfaces [93], as shown in Fig. 7d.

In-plane sliding mode—is based on the rotational or sliding motions between the two planar contacting surfaces. The change in the out-of-contact area causes the generation of AC output in the external circuit [94], as shown in Fig. 7e,

Single electrode mode—consists of a moving object (acting as an electrode) and the other electrode connected to the ground [95], as shown in Fig. 7f. Due to electrostatic screening, the current induced across the electrode is not very effective [96]; however, it has found wide applications due to the mobility of the triboelectric layer.

Free-standing mode—eliminates electrostatic screening and utilizes the movement of a single triboelectric layer relative to the other two under-placed externally connected electrodes [97], as shown in Fig. 7g.

Lu et al. [31] demonstrated a bi-directional gear-transmission mechanism for TENG that could harvest mechanical energy during an entire stroke of excitation. The proposed design achieved 2.4 mJ with short-circuit current and open-circuit voltage of 14 μA and 450 V. Both and were observed to be increased with increasing the length of the triboelectric film but were limited to a certain magnitude due to resulting contact of the films with two adjacent metallic electrodes at larger film lengths. Maximum output energy was obtained at an optimal film length of 45 mm, and film installation angle of 30°. Figure 9a shows the proposed design of the 3DP-TENG, and the output energy and power trends are shown in Fig. 9b, c. The 3D printed TENG device was demonstrated to power 375 LEDs and a commercial thermometer, as shown in Fig. 9d, f. The testing facility used to evaluate the performance of TENG is shown in Fig. 9e. A linear motor (J-5718HBS401, Yisheng, China) was used to excite the TENG, and the output performance of the TENG was analyzed with a programmable electrometer (6514, Keithley, USA) integrated with a data acquisition module (PCI-6259, National Instruments, USA).

Fig. 9.

a 3D printing assisted bi-directional gear transmission TENG b output energy c instantaneous power output with varying external resistances d powering 375 LEDs e experimental setup f output power of the TENG used to run a thermometer [31] (Images are re-used with the permission of the publisher)

In contrast, LabVIEW software was employed to record the output electrical signals. Significant efforts in developing TENG-based 3D printed NMEH systems are summarized in Table 3 regarding working conditions, materials, output characteristics, and energy applications. Some common applications of 3D printed TENG nano-devices include wearable electronics, self-powered healthcare monitoring sensors, thermometers, sustainable removal of methylene blue (MB) emissions, sensors for subway tunnels, wireless sensor nodes, thermo-hygrometers, smartwatches, temperature/vibration sensors, biomechanical applications, driver habits-monitoring, and road condition analysis.

Table 3.

Triboelectric nanogenerator based 3D printed energy harvesting devices, their output energy capacities and applications

| Energy harvesting devices | Source of excitation | Excitations | Materials | Output | Applications |

|---|---|---|---|---|---|

| Wrist-wearable TENG device | Human wrist-motions | ≤ 5 Hz | ABS, PLA | 0.118 mW/cm3 | Self-powered healthcare monitoring sensors |

| Bidirectional gear transmission based TENG | The motion of the human foot | 3.5 Hz | PLA | 4 mW | Thermometers |

| Elastic TENG based self-powered electro-Fenton system | Reciprocation by hand | 2–5 Hz | Acrylic | 1.95 W/m2 | Sustainable removal of methylene blue (MB) emissions |

| Hybrid coaxial TENG | Rotary motion | 100–400 rpm | ABS, acrylic | 846.4 W | Small toys |

| Wind-driven hybrid TENG nanogenerator | Slow speed wind | 6 m/s | PLA | 245 mW | Subway tunnel |

| Freestanding kinetic-impact-based TENG | Human motions | 5 Hz | PLA | 102.29 mW | Thermo-hygrometers, smartwatches |

| Flexible TENG for vibration energy harvesting | Vibrations | 6 Hz | Acrylic | 608.5 mW/m2 | Portable and wearable sensors |

| 3D-printed silicone-Cu fiber-based TENG | Human motion | ≤ 5 Hz | Si elastomer | 31.39 mW/m2 | Biomechanical applications |

| Integrated flywheel & spiral spring TENG | Human foot motion | ≤ 5 Hz | PLA | 38.4 mJ | LEDs |

| Low-frequency resonant TENG nanogenerator | Manual vibrations | 18 Hz | ABS | 2.61 mW | Vibration sensors, recharging batteries |

| Novel sweep-type TENG | Rotary motion | 1.2 m/s | PLA | 400 V, 15 μA | Driver habits-monitoring |

| Mechanical frequency regulator based TENG | Human and windmill | 10–50 Hz | PLA | 17 V, 6.5 mA | Wireless node sensors |

| Water droplet vibrations based TENGs | Vibrations | 1–30 Hz | ITO glass | 7.55 μW | Self-powered electronic systems |

| Origami-tessellation-based TENG | Ambient excitations | 3–16 Hz | Nylon | 26.16 μW | Energy harvesting on road pavement |

| Galloping TENG based on two flexible beams | Wind energy | 1.4–6 m/s | ABS, PET | 200 V, 7 μA | Outdoor electric devices |

| Direction-switchable TENG | Human joint motions | 5–15 cm/s | PLA | 5 V, 10 μA | Temperature sensors |

| Rotary cam-based TENG | Rotary motion | 300–1000 rpm | PLA | 3.5 mW | Commercial and industrial applications |

| Nanopillar-array architectured TENG | Wind energy | 14–15 m/s | PLA | 568 V, 25.6 μA | Wind energy harvesting |

The references of the research papers cited in this table are provided in the Additional file 1

EMG electromagnetic generator, TENG triboelectric nanogenerator, ABS acrylonitrile poly-butadiene styrene, PLA polylactic acid, ITO Indium tin oxide

Piezoelectric nanogenerators

Piezoelectricity describes the reversible interaction between electrical and mechanical states in specific materials. It refers to the development of electric potential across output terminals under applied mechanical stress [98]. The inverse piezoelectric effect is the indication of mechanical strain due to the applied electric field. Based on the working principle, PENGs can be categorized into three types: (1) the mode, (2) the mode, and (3) piezotronic mode, as shown in Fig. 7h–j. In mode, as shown in Fig. 7h, piezoelectric stacks are composed of various thin films connected mechanically in serial and electrically in parallel with each other. The piezoelectric layers are oriented in a specific manner to achieve an optimal voltage under the minimal strain (0.1%) for piezoelectric materials. Finally, the layers are integrated to make different stacks which effectively enhance the amount of accumulated charge. The piezoelectric stacks are placed on cantilever supporting structures in working mode, as shown in Fig. 7i. Various structures, including cymbals, bimorphs, and unimorphs, have been investigated as effective piezoelectric transducer structures. In the piezotronic layout, the Schottky barrier is provided between the electrodes and nanowires to control the electric flow, as shown in Fig. 7j.

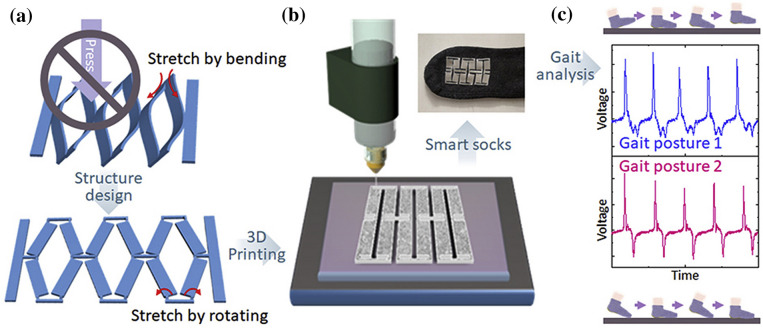

Zhou et al. [34] developed an all 3D printed piezoelectric nanogenerator (PENG) using a non-protruding kirigami-like structure as shown in Fig. 10a. Figure 10b describes the 3D printing of the PENG, and Fig. 10c demonstrates the mounting of the PENG device on a sock with adhesive. It was observed that in normal stamping (casual walking), there is only one (> 0) peak and two (< 0) peaks. Whereas, when the toes are fixed on the ground, and only the heel is stamped, then one (> 0) peak and one (< 0) peak is obtained. Experimental results proved that the 3D printed PENG could detect various gait postures and pace frequencies, which could be a promising solution for detecting steppage gait and slap gait caused by some neurological ailments. Park et al. [99] developed stretchable nanocomposite-based PENG to harvest energy from the minute biomechanical motions inside the human body for self-powered wearable electronics and sensitive piezoelectric sensors. Significant contributions to piezoelectric-based 3D printed nano energy harvesting systems are highlighted in Table 4 regarding working conditions, materials, output characteristics, and applications. Some typical materials used in 3D printing of PENGs are photocurable resins, PVDF-TrFE [33], piezoelectric inks [100], and acrylic [37]. The typical applications of PENGS include energy focusing, ultrasonic sensing, self-powered conformal sensors, haptic sensing of a robotic hand, external stress stimulation, self-powered tactile sensors, artificial skin, gait sensors, body motion sensor, multi-axis rotation and acceleration inertial sensing, telemedicine applications, anthropomorphic grippers, flexible electronics, and force sensor applications.

Fig. 10.

a 3D printed PENG with the kirigami structure b fabrication of 3D-printed PENG c output voltage of the printed PENG-integrated socks under different foot-stamping postures [34] (Images are re-used with the permission of the publisher)

Table 4.

Piezoelectric nanogenerator based 3D printed energy harvesting devices, their output energy capacities and applications

| Energy harvesting devices | Source of excitation | Excitations | Materials | Output | Applications |

|---|---|---|---|---|---|

| Piezoelectric ceramics for MEH | Vibrations | – | Photocurable resin | 0.301 V | Energy focusing, ultrasonic sensing |

| Piezoelectric BNNTs nanocomposites | Biomechanical energy | 10 Hz | Photocurable resin | 24 mV/kPa | Conformal sensors, haptic sensing of robotic hand |

| 3D-printed PVDF-TrFE piezoelectric film | Finger and wrist joints | 0.5–4 Hz | PVDF-TrFE | 73.5 V | External stress stimulation, tactile sensors, artificial skin |

| Stretchable kirigami piezoelectric nanogenerator | Vibrations from magnetic shaker | 5 Hz | Piezoelectric ink | 1.4 μW/cm2 | Self-powered gait sensor |

| Stretchable piezoelectric nanogenerator | Vibrations from magnetic shaker | 5 Hz | 3D printable ink | 0.29 V | Body motion sensor |

| 3DAIS | 3D vibration, rotation & human motion | 2.5 Hz | Acrylic | 0.19 µW | Multi-axis rotation and acceleration inertial sensing, telemedicine applications |

| Stiffness-tunable soft robotic gripper | Finger bending | 1 mm/s | FLX9760, RGD8530 | 3 V | Anthropomorphic grippers |

| Ceramic-polymer composite | Universal testing machine | 100 Hz | Grid-composite | 270 mV | Flexible electronics, force sensors |

The references of the research papers cited in this table are provided in the Additional file 1

BNNTs Boron nitride nanotubes, PVDF-TrFE Poly (vinylidene fluoride-co-trifluoroethylene), 3DAIS 3D activity inertial sensor

Energy harvesting from heat

Energy harvesting from human body heat depends on the temperature change of the body and involves two types of mechanisms: the thermoelectric generators (TEGs) and the pyroelectric generators (PEGs). TEG is developed on the principle of thermoelectric conversion and converts the temperature difference across the device into an electrical signal [101], whereas PEG relies on the temporal temperature variations of the device. TEG is a thermocouple made of two different conductors in which two junctions are maintained at high temperature and low temperature , respectively. As a result, an open-circuit voltage directly proportional to the temperature difference ∆T is developed across the output terminals. Generally, a TEG is composed of many thermocouples comprising p-type and n-type doped elements [102]. The thermoelectric elements are integrated so that they are thermally connected in parallel and electrically connected in series. The basic schematic of a TEG is shown in Fig. 7k.

The pyroelectric generator (PEG) generates pyroelectric current due to a change in polarization orientation due to temperature fluctuations [103]. The basic schematic of a PEG is illustrated in Fig. 7l. A PEG based on a liquid–gas phase-change fluid and a temperature-dependent operational frequency [104] was demonstrated to achieve an output power of 40 mW at a ∆T of 80 K, as shown in Fig. 7l.

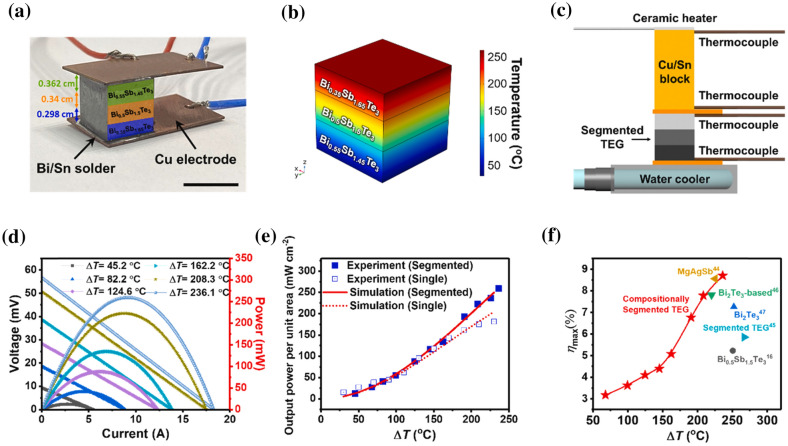

Yang et al. [35] designed a novel TEG using a multi-material 3D printing method and composition-persuaded BiSbTe material. The TEG could achieve a peak power density of approximately 259 mW/cm2 and an energy conversion efficiency of approx. 9% at a temperature difference of 236 °C. Figure 11a shows that a TEG with the p-type leg was manufactured by integrating the copper electrodes with the legs with Bi/Sn solder. Figure 11b shows the temperature distribution along the chipped TEG from the numerical study. The test scheme for experimental measurement of ΔT across the Sn/Cu block is shown in Fig. 11c. With an increase in the temperature difference, the voltage was increased to be maximum at 57 mV, as shown in Fig. 11d. The power density also directly relates with ΔT, and a peak power density of 259.3 mW/cm2 was observed experimentally (Fig. 11e). From Fig. 11f, it can be noticed that the maximum efficiency of almost 9% was achieved at the maximum temperature difference (236 °C). It was demonstrated that the efficiency obtained from the proposed TEG was higher than the previously reported TEGs. Some significant contributions in developing thermoelectric and pyroelectric-based 3D printed nano energy harvesting systems are presented in Table 5, along with working conditions, printable materials, output characteristics, and applications. The common applications of heat energy harvesting are wearable electronics, self-powered sensors, and microelectronic applications.

Fig. 11.

a A 3D printed compositional three-block BiSbTe thermoelectric generator b temperature gradient along the TEG layers evaluated by simulations c testing schematic to experimentally measure the output power and energy conversion efficiency of TEG d the output power and voltage of the proposed TEG at varying temperature difference e comparison of the simulated and experimentally measured power densities of the TEG as a function of the applied temperature difference f trend of energy conversion efficiency with ΔT [35] (Images are re-used with the permission of the publisher)

Table 5.

Thermoelectric generator based 3D printed energy harvesting devices, their output energy capacities and applications

| Energy harvesting devices | Source of excitation | Materials | Performance | Applications | |

|---|---|---|---|---|---|

| Flexible thermoelectric power generator | Electric heater | 30 K | TE materials | 80 mV | Wearable electronics |

| Segmented thermoelectric generators | Ceramic heater | 236 °C | BiSbTe-based viscoelastic inks | 8.7% | Self-powered sensors |

| Conformal cylindrical thermoelectric generators | Hot water flowing through alumina pipe | 39 °C | Bi2Te3-based inks | 1.62 mW | – |

| 3D printed SnSe thermoelectric generators | Thermoelectric tester | 772 K | Tin selenide (SnSe) | 20 µW | Solar cell applications |

| A flexible and stretchable organic thermoelectric device | Heating controller | 75 K | Polyurethane/CNT nanocomposites | 19.8 ± 0.2 µV/K | – |

| Shape-controllable thermoelectric devices | Heating rod | 54.6 K | Bi2Te3/(PVP) composites | 0.68 mW | – |

|

Self-healing and stretchable 3D-printed TE device |

Body temperature | 7 K | PEDOT: PSS | 12.2 nW | Flexible electronics |

|

Thick printed TE generator |

Microelectronic heat sink | 40 °C | Bi2Te3-based TE ingot | 10 W/cm2 | Microelectronic applications |

The references of the research papers cited in this table are provided in the Additional file 1

SnSe Tin selenide, CNT carbon nanotubes, PVP polyvinylpyrrolidone, TE thermoelectric, PEDOT: PSS poly(3,4-ethylenedioxythiophene) doped with polystyrene sulfonate

Hybrid 3DP-NMEH mechanisms

Various energy conversion systems such as EMG, TENG, PENG can be integrated for maximum energy harvesting from various ambient energy sources, such as wind, solar energy, ocean waves, body heat, and biomechanical energy. Usually, PENGs and TENGs are hybridized with other energy harvesters due to their structural multiplicity and flexibility. PENG-EMG and TENG-EMG hybrids are the most popular combinations for nano/micro-scale self-powering applications. Various hybrid energy harvesting systems have been reported to be fabricated through 3D printed structures, parts, substrates, blades, frames, shells, and casings [26, 78, 105].

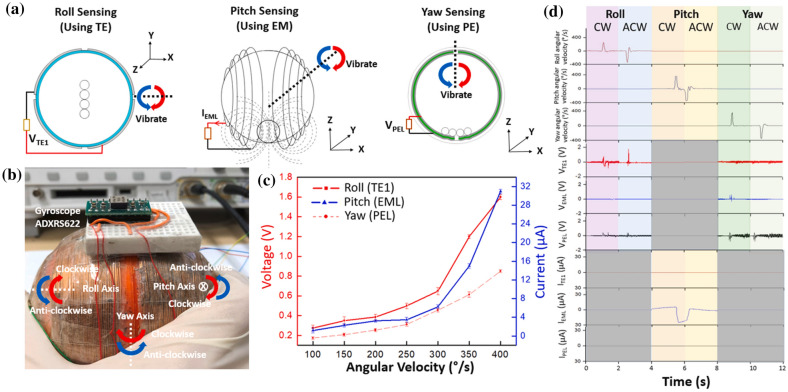

Koh et al. [37] demonstrated the applications of a 3D printed hybrid EMG-TENG-PENG nanodevice in multi-axis acceleration/rotation inertial sensing and telemedicine. A spherical and symmetrical self-powered 3-dimensional sensor was proposed to record and measure the inertial movements in six directions. Figure 12a illustrates the application of TENG voltage in roll-sensing, EMG current in pitch-sensing, and PENG voltage in yaw-sensing. The prototype of the mechanism integrated with a gyroscope is shown in Fig. 12b. The variation of output current and voltage with angular velocity in yaw, roll, and pitch motions is plotted in Fig. 12c whereas, Fig. 12d shows the profiles of angular velocities and output voltage from the hybrid EMG-TENG-PENG sensor for anticlockwise and clockwise roll, yaw and pitch movements. The hybrid NMEH system could harvest energy using hybrid energy-conversion modules and be integrated into different human body parts for healthcare monitoring applications. Some significant contributions in developing hybrid 3D printed nano energy harvesting systems in terms of test conditions, printed materials, output characteristics, and applications are accessible in Table 6. Some recently reported common applications of hybrid nano-devices include wearable electronics, healthcare monitoring sensors, multi-axis acceleration & rotation inertial sensing, telemedicine applications, Internet-of-Things, HVAC (heating, ventilating, and air conditions) ventilation exhaust systems, self-functional tracking system, seawater self-desalination, and self-powered positioning.

Fig. 12.

a Illustration of the application of TENG voltage in roll-sensing, EMG current in pitch-sensing and PENG voltage in yaw-sensing b prototype of the 3DAIS integrated with gyroscope c output current and voltage variation with angular velocity in yaw, roll, and pitch motions d profiles of angular velocities and output voltage from the hybrid EMG-TENG-PENG sensor for anticlockwise and clockwise roll, yaw and pitch movements, [37] (Images are re-used with the permission of the publisher)

Table 6.

TENG, PENG, TEG and EMG based 3D printed hybrid MEH devices, their output energy capacities and applications

| Energy harvesting devices | Source of excitation | Excitations | Materials | Output | Applications |

|---|---|---|---|---|---|

| Hybrid EMG-TENG wrist-wearable device | Human wrist-motions | 5 Hz | ABS, PLA | 0.118 mW/cm3 | Wearable healthcare monitoring equipment |

| Hybrid EMG-TENG-PENG 3DAIS device | 3D vibration, rotation & human motion | 2.5 Hz | Acrylic | 0.19 µW | Inertial sensing |

| Hybrid EMG-TENG wind-driven nanogenerator | Slow speed wind | 6 m/s | PLA | 245 mW | Subway tunnel monitoring sensors |

| Hybrid EMG-TENG device resonating at low frequency | Manual vibrations | 18 Hz | ABS | 2.61 mW | Vibration study |

|

Hybrid TENG-EMG-PENG energy harvester |

Hybrid step-servo motor | 45 rpm (0.75 Hz) | ABS | 712 μW, 31 mW, 6.4 μW | – |

| Solar & electromagnetic Energy harvesting System | Solar irradiance | 100 mW/cm2 | PLA | 93 mW | Internet-of-Things |

| 3D printed miniature EMG device driven by airflow | Wind energy, wind tunnel | – | ABS | 0.305 W | HVAC (heating, ventilating, and air conditions) ventilation exhaust systems |

| Hybrid EMG-TENG rotating gyro structured blue EH | Blue energy | 1.2 to 2.3 Hz | White resin | 14.9 mW (EMG) 4.1 μW (TENG) | Self-powered and self-functional tracking system |

| Ship-shaped hybridized nanogenerator (SHNG) | Blue energy (linear motor) | 2 Hz | PLA | 800 µW (TENG) 9 mW (EMG) | Seawater self-desalination and self-powered positioning |

The references of the research papers cited in this table are provided in the Additional file 1

EMG electromagnetic generator, TENG triboelectric nanogenerator, PENG piezoelectric nanogenerator, 3DAIS 3D activity inertial sensor, ABS acrylonitrile poly-butadiene styrene, PLA polylactic acid, EH energy harvester

Comparative assessment

A comprehensive comparative analysis was performed regarding advantages, disadvantages, strategies for effective energy harvesting, optimal locations for biomechanical energy harvesting, range of power output on nano-scale, and potential challenges of EMG, TENG, and PENG devices, as given in Table 7.

Table 7.

Comparison of nanomechanical energy harvesting methods in terms of pros and cons, performance, techniques for efficient utilization, and challenges

| Comparison/ types | Electromagnetic | Piezoelectric | Triboelectric |

|---|---|---|---|

| Pros |

No requirement of contacts [106] No requirement of voltage source [106] Smaller mechanical damping [106] Higher current [107] Operation is durable and robust [107] Lower impedance [108] |

Smaller mechanical damping [106] No need for a voltage source [106] Higher capacitance [107] No requirement of mechanical stoppers [106] High energy density [106] High output voltage (2–10 V) [106] |

Flexibility in device structure [109] Higher power density [110] Can operate at lower frequencies [109] Easy to fabricate with nanoscale size [109] High energy conversion efficiencies [110] |

| Cons |

Low efficiency at low frequency [107] Difficult miniaturization [111] High coil losses [112] Lower efficiency [112] Complex integration [106] Lower output voltage [106] |

Low current and high impedance [108] Incompatible for CMOS process [111] Poor coupling at microscale [106] Difficult to integrate [106] Requirement of special piezoelectric materials [112] Can be self-discharged at lower frequencies [111] |

Durability is not good [110] The mechanism is not fully understood [110] High voltage and low current [109] Challenging to be integrated [110] Electrostatic charge accumulation |

| Strategies for effective energy harvesting |

Frequency up-conversion [113] Sprung eccentric rotor [114] Elimination of spring [115] Spring clockwork mechanism [116] Induce non-linearity [117] |

Induce non-linearity [118] Proper circuit management [119] Frequency up-conversion [120] Use a double pendulum system [121] |

Development of core–shell structure [122] Design an ultrathin and flexible structure [123] To use single-electrode mode Use liquid metal electrode [124] Use of air-cushion mechanism [124] |

| Optimal locations for biomechanical energy harvesting |

Center of gravity of upper body [125] Wrist movements [126] Knee movements [127] Feet motion [128] Legs and arms [113] |

Movements of arms and legs [121] Human feet [129] Palms and fingers [130] |

Relaxation and contraction of lung and cardiac muscles [131] Human skin [132] Clothes [133] Hand tapping [132] |

| Range of power output on nano-scale | 0.5‒32 mW [113, 128, 134] | 0.0002‒45.6 mW [121, 135, 136] | 0.3‒4.67 mW [133] |

| Challenges |

Difficult miniaturizing [137] Difficulties in integration [138] Design of flexible system [139] |

Toxicity of piezoelectric materials Ultralow frequencies of human motions [140] Requirements of complex human movements [141] Rigidity and brittleness of Piezoelectric materials [142] |

Need of surface modifications Humidity challenges The inflexibility of the electrode [143] Biocompatibility [144] Washability [122] |

Recent 3DP methods in fabricating NMEHs

Among various additively manufacturing approaches, as per ASTM F2792 standards, such as material extrusion, binder jetting, directed energy deposition, powder bed fusion, inkjet 3D printing, vat-photopolymerization, and laminated object manufacturing, the researchers have employed material extrusion and digital light processing (an advanced version of stereolithography) for fabricating 3DP-NMEHs. Recently, nanoimprint lithography has also been utilized for the low-cost fabrication of nano-devices [145]. Some optimal 3D printing methods, printing parameters, and 3D printers involved in fabricating 3DP-NMEHs are given in Table 8.

Table 8.

Optimal 3D printing methods, printing parameters and 3D printers involved in fabricating novel structures of 3DP-NMEHs

| Sr | Structure/shape | Printing approach | 3D printer company | Printing parameters | Applications |

|---|---|---|---|---|---|

| 1 | Hierarchical and porous structures | FDM | HTS-300, Fochif Tech., pressure-controlled direct ink printer |

Deposition speed of 2.8 mm s−1, extrusion speed of 0.008 mm s−1, filament diameter of 0.85 mm, and micro-nozzle diameter of 0.80 mm |

Wearable electronics |

| 2 | Circular-shaped structures | FDM | Shining, Einstart-p, 3D printer | Uniform material extrusion from needle | Voiceprint recognition sensor |

| 3 | Square-shaped structures | FDM | 30 M Hyrel 3D, USA 3D printer | Nozzle inner diameter of 0.5 mm | Self-healing/ stretchable conductor |

| 4 | Cubical shape | Hybrid UV based 3D printing | 3D printer equipped with automatic UV curing, pressure-injection, and ink extrusion along with precision positioning platform | UV-based curing and printing precision of 1 μm | Ultra-flexible 3D printed TENG |

| 5 | Cylindrical structures | FDM |

Makerbot Industry, USA, Replicator 2X 3D printer |

Printing speed 90 mms−1 with plate temperature of 110 , using a raft to improve the adhesion between the plate and 3D printed parts |

Noise-canceling |

| 6 | Hollow circular-shaped tubes | FDM | – | 3D-printed circular tube of 1.1 cm inner dia and 1.2 cm outer dia |

Human biomechanical energy harvesting |

| 7 | Lamellar porous constructions | DIW | – | An 840 μm dia cylindrical nozzle to print CNF ink through DIW printer | Multifunctional sensors |

| 8 | Biomimetic-villus shaped structure | DLP | Master Plus J 845 DLP printer from Carima, Korea | – | Dust filter |

| 9 | Grating disk-like structure | FDM, SLM | ProX DMP 320 from 3D Systems, metal 3D printer | 3D printing in argon gas with a 245 W laser, with 60 μm layer thickness, 82 μm side step, and 1250 mm s−1 mark speed | Sustainable energy harvesting |

| 10 | Sponge | FDM | Z300, Beijing Huitianwei Technology Co., Ltd, China, 3D FDM printer | Nozzle size of approx. 10 μm | Energy harvesting applications |

| 11 | Zigzag design | FDM |

FDM printer Z300, Beijing Huitianwei Technology Co., Ltd, China |

Material extrusion with 0.1 mm layer height | Mechanical energy harvesting |

| 12 | Hierarchical morphological structures | DIW | – | Parallel printing direction with 0.2 mm tip diameter | Mechanical energy harvesting |

The references of the research papers cited in this table are provided in the Additional file 1

FDM fused deposition modelling, DIW direct ink writing, SLM selective laser melting, UV ultraviolet

Material extrusion

The material extrusion, also known as fused deposition modelling (FDM), has been widely used to fabricate 3DP NMEHs due to its high speed, cheaper materials, large-volume printing capability, and a wider range of functional materials. Moreover, FDM facilitates faster solidification, the usability of various thermoplastics, exceptional chemical characteristics, easy removal of supporting members, excellent heat resistance and high mechanical strengths. Shihua et al. [146] used the material extrusion to develop spongy micropatterns on TENG films made of polyamide and PDMS polymers. It was revealed that the FDM-based fabrication of thermosetting materials, for instance, PDMS, was easier than other printing approaches. The TENG was developed in the following stages: firstly, a CAD model made by Siemens PLM Software, Unigraphics NX 10, was sliced through a Cura, Ultimaker software. The required surface morphologies and properties were analyzed to develop the machine code and loaded into the 3D printer (version Z300, Beijing Huitianwei Technology Co., Ltd, China). The 3D printed specimen was 120 mm long, 100 mm in width, 0.1 mm in height, and 0.3 mm thick. The sponge-like structure made through FDM was characterized by a larger contact area and induced charge.

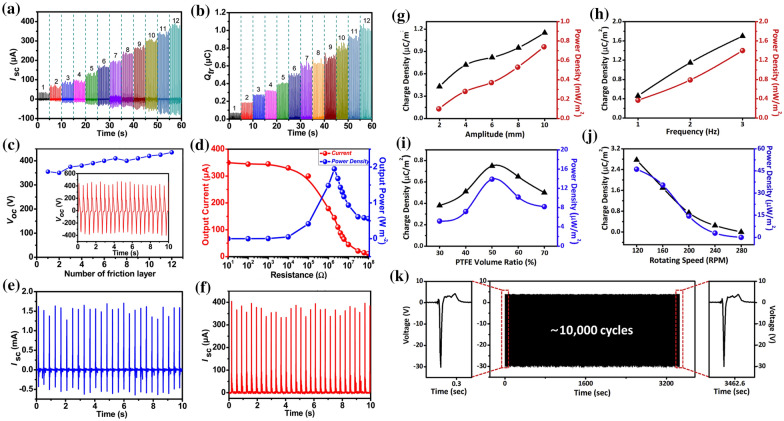

Similarly, M. Tian et al. [147] demonstrated the fabrication of thermoplastic elastomer filaments on thin copper films by FDM printing. The Cu films were integrated with the polytetrafluoroethylene film to enhance the nanodevice’s structural resilience and increase the triboelectric charge accumulation. The proposed device exhibited a short-circuit current of 375 μA and a maximum power density of 2 Wm−2 and could efficiently power the EF pollution degradation system. The output performance of the 3DP-NMEH in terms of accumulated charge, short-circuit current, open-circuit voltage, and output power are shown in Fig. 13a–f. It was revealed that a higher short-circuit current and induced charges were achieved with increasing friction layers on the triboelectric material. Connecting the friction layers in parallel caused a significant increase in open-circuit voltage.

Fig. 13.

Output performance characteristics of the 3DP-TENG proposed by Tian et al. [147]: a short-circuit current, b induced charge c open-circuit voltage with twelve different pairs of fraction layers, d output current and power density with the external resistance e, the transformed short-circuit current, and f rectified short-circuit current [147]. Electrical performance of the 3DP-NMEH proposed by Hong et al. [148] under various test conditions: The induced charge density and powder density under the vertical operational mode and various: g amplitudes (2–10 mm) h frequencies (1–3 Hz), charge and powder densities achieved by the device under rotational working mode and various: i Teflon volume ratios (30–70%) j speeds (120–280 RPMs) k durability test under vertical operational mode over 10,000 operational cycles [148] (Images are re-used with the permission of the publisher)

Digital light processing (DLP)

DLP, the advanced development of stereolithography, employs a light projector for photoreactive curing of the material and has been excessively utilized for precise printing of the resins onto the 3DP-NMEHs substrates. DLP-based printing facilitates fast solidification of resins upon exposure to bright light. Moreover, it consumes less material, minimizes waste, and eliminates the additional use of powder [9]. Hong et al. [148] demonstrated applying a DLP Master Plus J 845 machine to print a commercially available ABS photopolymer onto a Teflon film. The cylinder-shaped structures of 38 mm height and 42 mm diameters were developed consequently. A silver paste was adsorbed on the outer surface of the ABS substrate, and a dust filter was also demonstrated. The unique structure made by DLP facilitated a smooth flow of the air through the device’s proximity. The proposed 3DP-NMEH device generated a peak power density of 1.4 mW/m2 in vertical operational mode and 13.9 μW/m2 in rotational mode. The device’s output performance optimization for the vertical and rotational working modes is shown in Fig. 13g–k. In the vertical operational mode, with an increase in the amplitude along the z-axis, an effective increase was observed in the charge and power densities of the device, making the freestanding working mode more feasible for optimal energy harvesting. On the other hand, the output current increased directly with the input excitation frequencies. The output power was enhanced at the PTFE powder’s 50% volume ratio in the rotational working mode.

Benefits and drawbacks related to 3D printing of NMEHs

The benefits and drawbacks of 3D printing of nano-mechanical energy harvesting systems are presented in Table 9.

Table 9.

Benefits and challenges related to 3D-printing of the nano MEH systems

| Benefits | The accurate pattern-making ability for architectural customization of the nanogenerators. The tiny-structured patterns allow easy implementation and mechanical resilience to electronics |

| Lower power consumption and environmental impact. Facilitates long-term sustained production | |

| Provides faster speed and high-fabrication compatibility | |

| Less human intervention is required in the printing of the parts and post-treatment | |

| Abatement of waste materials and overall material usage | |

| 3D printing is a safe, sensitive, and flexible fabrication facility | |

| Excellent chemical attributes characterize the printed objects | |

| FDM printing gives heat resistance and good mechanical strength to the prototypes | |

| Facilitates easy and manual removal of the supporting elements, i.e., water-soluble wax at the end of the printing process | |

| Fast solidification of the printed components on various substrates | |

| Exceptional printing accuracy and resolution | |

| Limitations | The complex integration of functional polymers |

| To achieve and maintain the tiny gap required between triboelectric polymer surfaces is challenging | |

| The formation of precise macro/nano dimensional architectures is yet to be studied | |

| The combination of various materials for 3D printed TENGs is problematic | |

| The development of integrated systems comprising of nanogenerators and functional devices and simultaneous handling of multiple printing materials is still challenging | |

| 3D printed nano MEH systems are needed to be biocompatible and integrated with biological tissues | |

| End-of-life recyclability/biodegradability of the 3D-printed components is a critical concern to reduce impacts on the environment and the human body | |

| For complex models, the printing time is often high | |

| Digital light processing (DLP) demands more light sources, for instance, arc lamps during printing | |

| A liquid crystal display is employed at the entire 3D-printed deposit during a single layer of the DLP | |

| In 3D printing of fabrics, it is challenging to develop appropriate CAD modeling in order to facilitate the simulation of the draping of the textile across a curved surface | |

| 3D-printed textiles are not strong enough and tend to break easily due to the conventional textiles' lesser flexibility. Hence, they are not very suitable for day to day textile applications |

The references of the research papers cited in this table are provided in the Additional file 1

The commonly achieved length scales, capacities, and printing techniques currently observed in rapid prototyping of nano-mechanical energy harvesting mechanisms are enlisted in Table 10.

Table 10.

The capacities, length scales and printing methods of recently demonstrated 3DP-NMEHs

| Sr. No | Size/Length scale | Printing technique | Output performance | References | ||

|---|---|---|---|---|---|---|

| Current (μA) | Voltage (V) | Power (W/m2) | ||||

| 1 | 3 cm × 3 cm | FDM | 6.14 | 306 | ~ 237 | [146] |

| 2 | 3 cm × 3 cm | DIW | 190 | 170 | ~ 185 | [149] |

| 3 | – | DLP | 2.3 | – | ~ 46 | [148] |

| 4 | – | FDM | 0.9 | 90 | ~ 45 | [150] |

| 5 | – | FDM | 0.26 | 0.1 | ~ 0.5 | [24] |

| 6 | 4 cm × 3.5 cm | FDM | 375 | 410 | ~ 2 | [147] |

| 7 | 4 cm × 1.5 cm | FDM | 7.6 | 103 | ~ 7 | [151] |

| 8 | 3.2 cm × 3.2 cm | DIW | 0.94 | 55.8 | ~ 29 | [152] |

| 9 | 3 cm × 3 cm | FDM | 4 | 100 | ~ 40 | [153] |

Optimal 3D printing methods for NMEH functional parts

Seol et al. [25] developed 3D printed electrodes, casing, and triboelectric parts for a sustainable energy device that could implement an ideal resource utilization. The Titanium Grade 23 powder was used to 3D print metal blades for a triboelectric nanogenerator using a ProX DMP 320 metal 3D printer from 3D Systems. The printing was optimally accomplished using an 82 µm sidestep, 1250 mm/s speed, 60 µm layer thickness under an argon environment, and laser power of 245 W. The printed blades were thermally treated to relieve internal stresses and prevent surface oxidation using a 1216 FL CM furnace with a Furnace 3504 temperature controller in an inert environment and an argon flow rate of 30 psi. Finally, the heat-treated metal blades were processed through a Millport 2 milling machine equipped with a Walter F4033 Milling Cutter to obtain a smooth surface. The blades were detached from the base using an electrical discharge machine. The all-3D-printed TENG could generate an RMS short-circuit current of ~ 19 μA, the open-circuit voltage of 231 V, and power of 2.13 mW and be demonstrated as a sufficient power supply for wireless electronic sensors.