Abstract

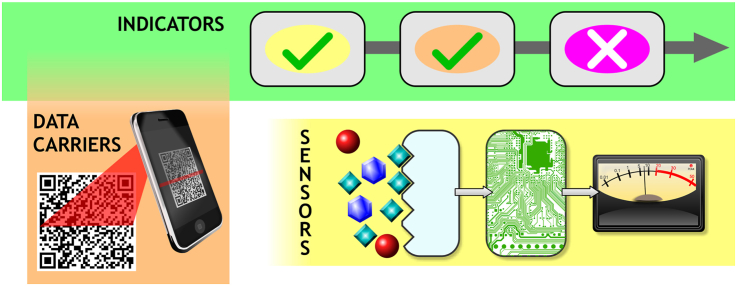

Intelligent food packaging is usually designed to monitor the state of the food itself and/or the environment around it, as well as the interactions between them, providing customers with information on food quality and/or safety through a variety of signals. They involve indicators (which inform by direct visual changes about specific properties related to food quality) and sensors (which detect specific analytes by using receptors, transducers, and signal processing electronics). A third type of intelligent packaging is known as data carriers, which are not typically used for information on food quality, but rather to track the movement of food along the food supply chain. In this graphical review, the basic mechanisms of intelligent food packaging systems are presented, as well as their main applications, with particular emphasis on those focused on food quality monitoring.

Keywords: Intelligent packaging, Food safety, Biosensors, Sensing devices, Colorimetric indication

Graphical abstract

Highlights

-

•

Mechanisms and applications of intelligent food packaging systems are addressed.

-

•

Indicators and sensors monitor state of food and/or its surrounding environment.

-

•

Indicators inform by visual changes about properties related to food quality.

-

•

Chemical sensors convert chemical information into a quantifiable signal.

-

•

Data carriers track movement of food along the food supply chain.

1. Introduction

Intelligent (or responsive) food packaging systems are those that include tools to monitor the packaged food and/or the surrounding environment. Thus, they typically generate information about the food quality and/or safety in real time, not depending on inaccurate expiration dates, thus helping not only to prevent illnesses resulting from the consumption of unsafe food, but also preventing the huge food waste derived from early food recall(Yousefi et al., 2019).

Differently from active packaging (which involves some mechanism to actually improve food stability, such as removal of deleterious agents or release of components that prolong food stability), intelligent packaging systems usually do not directly extend food shelf life, but they rather convey information about food quality to the stakeholders of the food supply chain (Ghaani et al., 2016).

This graphical review is focused on the basic mechanisms of intelligent food packaging systems, as well as their main applications for food industries.

2. Main mechanisms of intelligent packaging

Intelligent packaging systems rely on three main technologies, namely: indicators, data carriers, and sensors.

2.1. Indicators

Indicators basically inform the consumers about any property related to food quality. As shown in Fig. 1, they are typically based on indication about the actual conditions to which the food has been exposed and/or its actual quality status. Although most indicators are based on colorimetric dyes, there also those based on other mechanisms, such as fluorescent dyes (Kiryukhin et al., 2018).

Fig. 1.

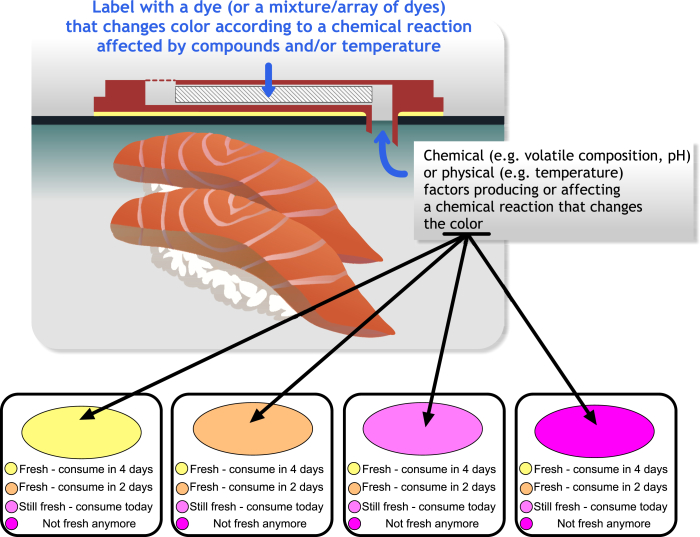

Scheme of a typical indicator for food freshness.

The information provided by such systems are related to the presence/absence or concentration of a target chemical, or to the extent of a reaction, as a result of their interaction with food components (Ghaani et al., 2016; Kalpana et al., 2019). The most common types of indicators related to food packaging are based on temperature and freshness.

2.1.1. Temperature indicators

Most deteriorative changes in foods are temperature-dependent, and that is why temperature control is so important for food stability, mainly for refrigerated and frozen products. Temperature abuse (including temperature fluctuations) in frozen foods along the food distribution chain may not only negatively affect food texture (causing e.g. emulsion disruption in emulsion-based foods, and cell damages in frozen-thawed foods), but it also allows microbial growth, particularly of psychrotrophic microorganisms.

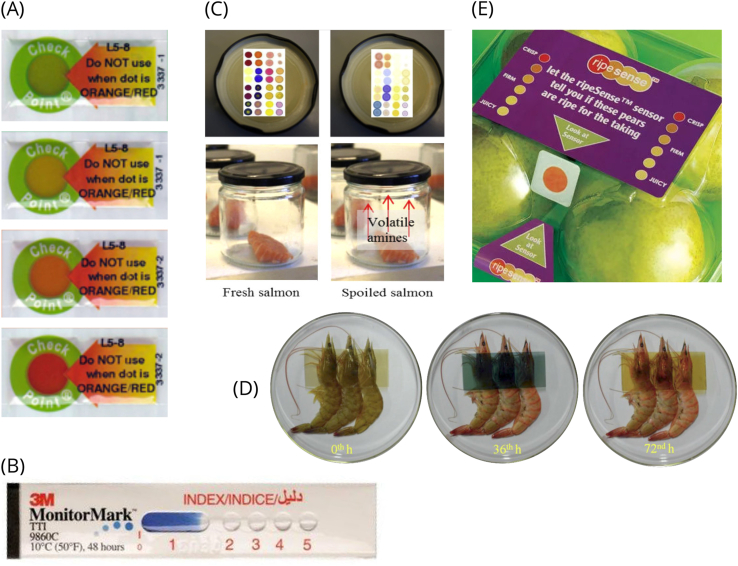

Since temperature indicators are based on temperature changes, they are indirect indicators of food quality, i.e., they provide information about an extrinsic factor in food changes (temperature abuse) rather than the changes themselves. Information on temperature abuse is useful to warn consumers about e.g. potential microbial growth, protein denaturation or emulsion breaking. Temperature indicators are classified as critical temperature indicators (CTI, which indicate whether a critical temperature value has been reached along storage) and time-temperature integrators (TTIs, which provide information on the full temperature history of the food product along the food supply chain). They are based on temperature-induced mechanical, chemical, enzymatic or microbiological changes, and the information is usually expressed as a visible (and irreversible) response such as mechanical deformation or color development (Fig. 2A and B) (Ghaani et al., 2016). There are also the thermochromic systems, which provide temperature indication based on reversible changes, thus useful rather for assessing real-time temperature for sensory purposes (e.g. for cold beverages) than information on food stability.

Fig. 2.

Examples of indicators: (A) VitsabTM L5-8 Smart TTI Seafood Label (Vitsab International AB, Sweden); (B) TTI Monitor MarkTM (3M, USA); (C) fish freshness indicator based on volatile amines (Reprinted from Morsy et al., 2016, with permission from Elsevier); (D) pH indicator for shrimp, based on anthocyanins (Reprinted from Liu et al., 2019, with permission from Elsevier); (E) fruit ripeness indicator ripeSenseTM, based on aroma volatiles released by the fruit (Ripesense Ltd., NZ).

2.1.2. Freshness indicators

Freshness indicators are direct food quality indicators, since they provide information on microbiological and/or chemical changes responsible for food spoilage (Kalpana et al., 2019). Freshness indicators for meat products, for example, may be based on biogenic amines (Sørensen et al., 2018) or hydrogen sulfide (H2S, released during meat spoilage) (Zhai et al., 2019). In seafood, the total volatile basic nitrogen content (volatile amines), primarily composed of dimethylamine (DMA), trimethylamine (TMA) and ammonia, is frequently used to assess microbial degradation (Morsy et al., 2016). The indicators may be based on the detection of volatiles in the headspace of food packaging, such as Ag nanoparticles to detect H2S in meat (Zhai et al., 2019), and an array of chemo-sensitive compounds for volatile amines in fish (Fig. 2C) (Morsy et al., 2016).

Microbial or chemical deteriorative changes may also be indirectly monitored by evaluating the resulting pH changes (Fig. 2D), which may derive from organic acids produced from microbial growth or carbonic acid from CO2 dissolution, being an effective way to identify microbial spoilage (Yousefi et al., 2019). Actually, most freshness indicators are based on pH-sensitive dyes, which may be synthetic (e.g. bromocresol green, methyl red) or natural (e.g. anthocyanins, betalains, curcumin) (Wu et al., 2021). Although synthetic dyes are usually cheaper, more stable and with more intense colors, natural food-grade colorants (e.g. anthocyanins) have received more attention, due to their biodegradability, and the overall perception by consumers (not always correct or scientifically based) of natural compounds as being healthier and safer than synthetic ones (Alizadeh-Sani et al., 2020).

The term ‘freshness’ may also refer to fruit ripeness. For such indicators (such as RipeSenseTM, commercially available for pears, and in development for other fruits – http://www.ripesense.co.nz/, accessed on July 13th, 2021 – Fig. 2E), the indicated degree of ripeness is based on the release of aroma compounds or ethylene by the fruit on ripening (Kalpana et al., 2019). An indicator of apple ripeness was based on the release of aldehydes and its reaction with NaOH, consuming OH− and changing the color of methyl red (Kim et al., 2018).

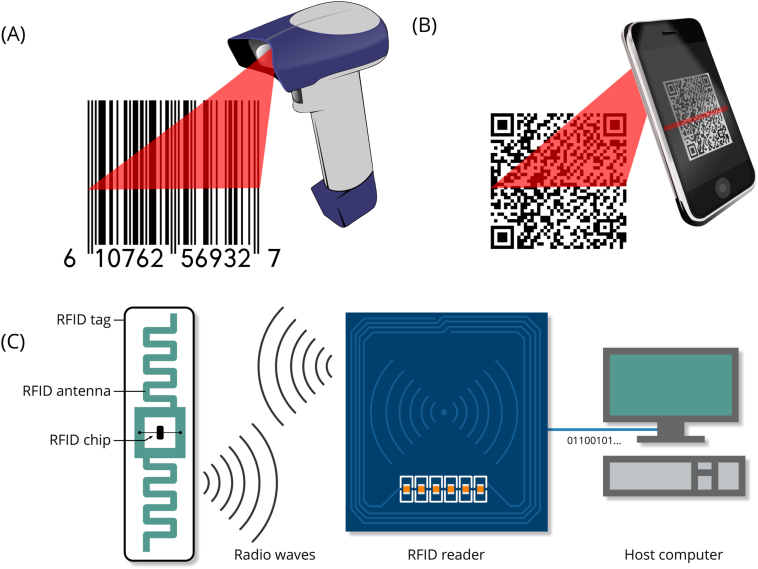

2.2. Data carriers

Data carriers, including barcodes and radiofrequency identification tags (RFID), are specifically intended to help follow the movement of food products along the food supply chain, being generally not used to collect information on food quality status, but rather to enable automatization, traceability, theft prevention and counterfeit protection (Ghaani et al., 2016). The main data carriers in food packaging are barcode labels and radiofrequency identification (RFID) tags. A barcode is a machine-readable pattern of parallel bars and spaces (for 1-D barcodes, Fig. 3A) or an array of dots and spaces (for 2-D barcodes, Fig. 3B) arranged to represent hidden encoded data, the information being decoded by an optical scanner that conveys it to a system where it is stored and processed (Ghaani et al., 2016; Sohail et al., 2018). An RFID system (Fig. 3C), more advanced and convenient, is based on wireless communication between a tag attached to the product and an interrogator. The main components of an RFID system (Fig. 3C) are: an RFID antenna for communication linked to a chip for unique identification and data storage, a reader (interrogator) for wave emission and reception upon backscattering from the tag, and a host computer/cell phone for data saving and processing (Bibi et al., 2017).

Fig. 3.

Examples of data carriers: (A) 1-D barcode; (B) 2-D barcode; (C) RFID tag and its components.

2.3. Chemical sensors

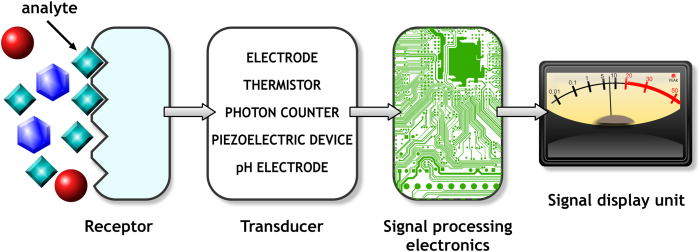

Chemical sensors can rapidly detect specific analytes by transforming a chemical information into a quantifiable output signal proportional to that measurement, which is then processed by proper electronics and software (Ghaani et al., 2016). Chemical sensors are constituted by the following main components (Fig. 4): a receptor (the sensing part, represented by a sampling area where the surface chemistry takes place), a transducer (the measuring part, such as an electrode, which transforms the physical or chemical information into a useful signal), the signal processing electronics, and (usually) a signal display unit (Ghaani et al., 2016).

Fig. 4.

Components of a sensor. (Adapted from Ghaani et al., 2016, with permission from Elsevier).

The receptor of a chemical sensor interacts chemically with the analyte, and the transducer converts the chemical information into a measurable signal. Chemical sensors are usually classified according to the transduction principles as electrical, electrochemical, optical, and gravimetric (Teodoro et al., 2021). Chemical sensors have been proposed, for example, to quantify gases generated by food deterioration, such as a capacitive sensor to quantify NH3, TMA, ethanol, and H2S emitted from chicken meat spoilage (Senapati and Sahu, 2020). In another approach, a hybrid chemiresistor sensor was developed to convert radio-frequency identification tags into wireless sensors to be potentially employed in smart packaging to monitor biogenic amines released from chicken, beef and fish (Andre et al., 2021). Electrochemical sensors have also been proposed to quantify potentially toxic additives or monomers migrated from packaging materials into food (or their toxic products generated upon contact with the food), including primary aromatic amines produced from isocyanate monomers of polyurethane adhesives (Ghaani et al., 2018) and bisphenol-A (BPA, which may play some role in endocrine disorders) migrated from polycarbonate bottles and epoxy resins (Karthika et al., 2021).

Biosensors constitute a specific type of chemical sensors in which the receptor is combined with some biological material (e.g. enzymes, antigens, antibodies, and nucleic acids) specific to the target analyte and a transducer that converts the biological signals into a quantifiable electrical response (Yam et al., 2005). Biosensors are especially useful, for example, when it comes to the detection of specific microbial species in food, particularly pathogenic microorganisms (Ghaani et al., 2016). Intelligent devices have been created with surfaces functionalized with antibodies that respond to microbial metabolites, e.g. aflatoxins (Costa et al., 2017), or antigens on the surface of pathogenic microorganisms, e.g. Escherichia coli (Lamanna et al., 2020). Many of the recent developments involve nanomaterials as the active layer of the sensor devices, owing to their special optical and electrical properties as well as their large surface area, which are able to amplify the detection signal (Caon et al., 2017). Other examples of nanosensors applicable to food packaging include a black phosphorene-based one for voltammetric detection of ochratoxin A (a mycotoxin that may be found in wine, coffee, etc.) (Xiang et al., 2018), and an electrochemical sensor based on MoWS2 nanoparticles for the determination of Sudan I (a potentially carcinogenic azo dye that have been banned in several countries as a food colorant) and BPA (Ghazanfari et al., 2021). Although nanomaterials have remarkably enhanced the transduction mechanisms and detection sensitivity towards several targets (including bacteria, allergens, antibiotics and toxins), challenges related to integration of sensing technology into food packaging, improved selectivity, large-scale manufacture with reproducibility and improvement and removal of matrix effects due to the food complex composition (Mustafa and Andreescu, 2020) are current bottlenecks to be overcome.

3. Final remarks

The intelligent packaging technologies (especially those related to sensors) are mostly still underexplored in market applications, not only for economic reasons (some devices have significant costs), but also because of a number of challenges in translating them to the real world, where, in contrast to the controlled conditions of a laboratory, the presence of a myriad of components may interfere with the functionality of the sensing devices. Moreover, some intelligent devices are required to be placed inside the packaging (i.e. in contact with the food), so their use must conform to the food safety legislation, which may is also be a limitation. Additionally, the sensing properties of some devices may be diminished during food storage, e.g. by oxidation or any other chemical reaction that might lead to degradation, which would impair their actual effectiveness. So, those challenges should be addressed in order to translate some systems into actual food applications.

On the other hand, intelligent devices have great potential to revolutionize food packaging in many aspects, benefitting consumers (in terms of food quality and safety assurance) but also manufacturers and retailers (who could answer legally and financially for the outcomes from any spoiled or hazardous products reaching consumers’ fridges and tables). Particularly for food quality and safety, it does not make sense to keep relying on estimated expiration dates (which are based on predictions established over probable storage conditions and probable outcomes) in an era when the information technology has advanced so much over all aspects of life. Intelligent packaging technologies are tools that enable consumers to rely on more accurate current information about the state of food quality/safety.

However, advances on the widespread use of intelligent packaging may also be hampered by e.g. inappropriate suppliers in the food supply chain (who may have the habit of turning off refrigerators and freezers on off hours to save on the energy bill). Neophobia by some consumers could also be a factor to negatively impact the acceptance of intelligent food packaging systems. On the other hand, once consumers understand the benefits of those systems for their own safety, they may be more confident about their reliability, and even demand that they are adopted, which may balance any eventual resistance.

CRediT authorship contribution statement

Henriette M.C. Azeredo: Conceptualization, Writing – original draft. Daniel Souza Correa: Writing – review & editing.

Declaration of competing interest

The authors declare that they have no conflict of interest regarding the publication of this article.

Acknowledgements

The authors acknowledge the financial support from Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP, 2018/22214–6), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), MCTI-SisNano (CNPq/402287/2013–4), and Rede Agronano-EMBRAPA from Brazil.

References

- Alizadeh-Sani M., Mohammadian E., Rhim J.-W., Jafari S.M. pH-sensitive (halochromic) smart packaging films based on natural food colorants for the monitoring of food quality and safety. Trends Food Sci. Technol. 2020;105:93–144. doi: 10.1016/j.tifs.2020.08.014. [DOI] [Google Scholar]

- Andre R.S., Ngo Q.P., Fugikawa-Santos L., Correa D.S., Swager T.M. Wireless tags with hybrid nanomaterials for volatile amine detection. ACS Sens. 2021;6:2457–2464. doi: 10.1021/acssensors.1c00812. [DOI] [PubMed] [Google Scholar]

- Bibi F., Guillaume C., Gontard N., Sorli B. A review: RFID technology having sensing aptitudes for food industry and their contribution to tracking and monitoring of food products. Trends Food Sci. Technol. 2017;62:91–103. doi: 10.1016/j.tifs.2017.01.013. [DOI] [Google Scholar]

- Caon T., Martelli S.M., Fakhouri F.M. In: 18 - New Trends in the Food Industry: Application of Nanosensors in Food Packaging. Grumezescu A.M.B.T.-N., editor. Academic Press; 2017. pp. 773–804. [DOI] [Google Scholar]

- Costa M.P., Frías I.A.M., Andrade C.A.S., Oliveira M.D.L. Impedimetric immunoassay for aflatoxin B1 using a cysteine modified gold electrode with covalently immobilized carbon nanotubes. Microchim. Acta. 2017;184:3205–3213. doi: 10.1007/s00604-017-2308-y. [DOI] [Google Scholar]

- Ghaani M., Cozzolino C.A., Castelli G., Farris S. An overview of the intelligent packaging technologies in the food sector. Trends Food Sci. Technol. 2016;51:1–11. doi: 10.1016/j.tifs.2016.02.008. [DOI] [Google Scholar]

- Ghaani M., Pucillo F., Olsson R.T., Scampicchio M., Farris S. A bionanocomposite-modified glassy carbon electrode for the determination of 4,4′-methylene diphenyl diamine. Anal. Methods. 2018;10:4122–4128. doi: 10.1039/C8AY01376D. [DOI] [Google Scholar]

- Ghazanfari Z., Sarhadi H., Tajik S. Determination of Sudan I and bisphenol A in tap water and food samples using electrochemical nanosensor. Surf. Eng. Appl. Electrochem. 2021;57:397–407. doi: 10.3103/S1068375521030066. [DOI] [Google Scholar]

- Kalpana S., Priyadarshini S.R., Maria Leena M., Moses J.A., Anandharamakrishnan C. Intelligent packaging: trends and applications in food systems. Trends Food Sci. Technol. 2019;93:145–157. doi: 10.1016/j.tifs.2019.09.008. [DOI] [Google Scholar]

- Karthika P., Shanmuganathan S., Viswanathan S., Delerue-Matos C. Molecularly imprinted polymer-based electrochemical sensor for the determination of endocrine disruptor bisphenol-A in bovine milk. Food Chem. 2021;363:130287. doi: 10.1016/j.foodchem.2021.130287. [DOI] [PubMed] [Google Scholar]

- Kim Y.H., Yang Y.J., Kim J.S., Choi D.S., Park S.H., Jin S.Y., Park J.S. Non-destructive monitoring of apple ripeness using an aldehyde sensitive colorimetric sensor. Food Chem. 2018;267:149–156. doi: 10.1016/j.foodchem.2018.02.110. [DOI] [PubMed] [Google Scholar]

- Kiryukhin M.V., Lau H.H., Goh S.H., Teh C., Korzh V., Sadovoy A. A membrane film sensor with encapsulated fluorescent dyes towards express freshness monitoring of packaged food. Talanta. 2018;182:187–192. doi: 10.1016/j.talanta.2018.01.085. [DOI] [PubMed] [Google Scholar]

- Lamanna L., Rizzi F., Bhethanabotla V.R., De Vittorio M. Conformable surface acoustic wave biosensor for E. coli fabricated on PEN plastic film. Biosens. Bioelectron. 2020;163:112164. doi: 10.1016/j.bios.2020.112164. [DOI] [PubMed] [Google Scholar]

- Liu J., Wang H., Guo M., Li L., Chen M., Jiang Suwei, Li X., Jiang Shaotong. Extract from Lycium ruthenicum Murr. incorporating κ-carrageenan colorimetric film with a wide pH–sensing range for food freshness monitoring. Food Hydrocolloids. 2019;94:1–10. doi: 10.1016/j.foodhyd.2019.03.008. [DOI] [Google Scholar]

- Morsy M.K., Zór K., Kostesha N., Alstrøm T.S., Heiskanen A., El-Tanahi H., Sharoba A., Papkovsky D., Larsen J., Khalaf H., Jakobsen M.H., Emnéus J. Development and validation of a colorimetric sensor array for fish spoilage monitoring. Food Control. 2016;60:346–352. doi: 10.1016/j.foodcont.2015.07.038. [DOI] [Google Scholar]

- Mustafa F., Andreescu S. Nanotechnology-based approaches for food sensing and packaging applications. RSC Adv. 2020;10:19309–19336. doi: 10.1039/D0RA01084G. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Senapati M., Sahu P.P. Meat quality assessment using Au patch electrode Ag-SnO2/SiO2/Si MIS capacitive gas sensor at room temperature. Food Chem. 2020;324:126893. doi: 10.1016/j.foodchem.2020.126893. [DOI] [PubMed] [Google Scholar]

- Sohail M., Sun D.-W., Zhu Z. Recent developments in intelligent packaging for enhancing food quality and safety. Crit. Rev. Food Sci. Nutr. 2018;58:2650–2662. doi: 10.1080/10408398.2018.1449731. [DOI] [PubMed] [Google Scholar]

- Sørensen K.M., Aru V., Khakimov B., Aunskjær U., Engelsen S.B. Biogenic amines: a key freshness parameter of animal protein products in the coming circular economy. Curr. Opin. Food Sci. 2018;22:167–173. doi: 10.1016/j.cofs.2018.05.014. [DOI] [Google Scholar]

- Teodoro K.B.R., Sanfelice R.C., Migliorini F.L., Pavinatto A., Facure M.H.M., Correa D.S. A review on the role and performance of cellulose nanomaterials in sensors. ACS Sens. 2021;6:2473–2496. doi: 10.1021/acssensors.1c00473. [DOI] [PubMed] [Google Scholar]

- Wu D., Zhang M., Chen H., Bhandari B. Freshness monitoring technology of fish products in intelligent packaging. Crit. Rev. Food Sci. Nutr. 2021;61:1279–1292. doi: 10.1080/10408398.2020.1757615. [DOI] [PubMed] [Google Scholar]

- Xiang Y., Camarada M.B., Wen Y., Wu H., Chen J., Li M., Liao X. Simple voltammetric analyses of ochratoxin A in food samples using highly-stable and anti-fouling black phosphorene nanosensor. Electrochim. Acta. 2018;282:490–498. doi: 10.1016/j.electacta.2018.06.055. [DOI] [Google Scholar]

- Yam K.L., Takhistov P.T., Miltz J. Intelligent packaging: concepts and applications. J. Food Sci. 2005;70:R1–R10. doi: 10.1111/j.1365-2621.2005.tb09052.x. [DOI] [Google Scholar]

- Yousefi H., Su H.-M., Imani S.M., Alkhaldi K.M., Filipe C.D., Didar T.F. Intelligent food packaging: a review of smart sensing technologies for monitoring food quality. ACS Sens. 2019;4:808–821. doi: 10.1021/acssensors.9b00440. [DOI] [PubMed] [Google Scholar]

- Zhai X., Li Z., Shi J., Huang X., Sun Z., Zhang D., Zou X., Sun Y., Zhang J., Holmes M., Gong Y., Povey M., Wang S. A colorimetric hydrogen sulfide sensor based on gellan gum-silver nanoparticles bionanocomposite for monitoring of meat spoilage in intelligent packaging. Food Chem. 2019;290:135–143. doi: 10.1016/j.foodchem.2019.03.138. [DOI] [PubMed] [Google Scholar]