Summary

Nowadays, wearable devices mainly exist in the form of portable accessories with various functions, connecting various kinds of terminals like mobile phones to form various wearable systems. In a wearable system, the wearable power supply device is the key component as energy dispenser for all devices. Nanosheets, a kind of two-dimensional material, which always displays a high surface-to-volume ratio and thus is lightweight and has remarkable conductive as well as electrochemical properties, have become the optimal choice for wearable power supply devices. The development and status of nanosheet-based wearable power supply devices including nanosheet-based wearable batteries, nanosheet-based wearable supercapacitors, nanosheet-based wearable self-powered energy suppliers are introduced in this article. Besides, the future opportunities and challenges of wearable devices are discussed.

Subject areas: Applied sciences, Engineering, Devices

Graphical abstract

Applied sciences; Engineering; Devices

Introduction

With the rapid development of computer technology, sensors, and communication technology at home and abroad, miniaturization and rapid operation meet the requirements of wearable devices on people (Li et al., 2021), so a variety of wearable devices gradually appear in the eyes of the public, gradually emerging in the fields of medical care, education, military, and daily life and show extremely important research value and application potential (Almusawi et al., 2021; Beniczky et al., 2021; Faruk et al., 2021; Huifeng et al., 2020). With the maturity of wearable technology, various wearable devices have poured into the lives of ordinary people on a large scale.

Power supply devices are always the key components of integrated wearable systems, which guarantees wearable systems to keep operating uninterruptedly, continuously, and for a long term (Gao et al., 2021). Consequently, the wearable power supply device is required to be flexible, durable, safe, and with high energy density (He et al., 2021). To meet all these requirements, nanosheets, a kind of two-dimensional (2D) nanomaterial with excellent physical and mechanical properties including ultra-thin thickness, high flexibility, stretchability, and excellent adhesion have triggered great research enthusiasm and become the optimal material for wearable power supply device due to these remarkable characteristics (Kim et al., 2021; Liang et al., 2018; Nie et al., 2020; Zhong et al., 2019). Especially, the extremely large surface-to-volume ratio of the nanosheets provides the miniaturization of wearable power supply devices and greatly increases the capability of power storage and supply for wearable power supply devices (Jin et al., 2020; Zhou et al., 2021) considering that nanosheets bring numerous electrocatalytic sites and thus catalyze the electrochemical reaction at the electrode. A large number of nanosheets, e.g., graphene analogues (GA), including graphene oxide (GO) nanosheets, reduced graphene oxide (rGO) nanosheets, and graphdiyne nanosheets, and transition metal element nanosheets, including MoSe2 nanosheets, Ru-Ni nanosheets, MoS2 nanosheets, ZnO nanosheet, and organic nanosheets like PLLA nanosheets, have been produced by researchers (Careta et al., 2021; Guo et al., 2019; Liu et al., 2021; Yang et al., 2019a, 2019b; Yu et al., 2019; Zhang et al., 2018b, 2021) since the first-developed nanosheets, graphene, was reported in 2004 (Novoselov et al., 2004). Among nanomaterials, nanosheet materials display the highest possible specific surface area (Mohammadpour and Majidzadeh, 2020), which brings better performance in power supply applications. Besides the higher surface area over zero-dimensional (0D) nanoparticles and distinct kinds of one-dimensional (1D) nanomaterials, nanosheets can act as the nanoplatform to be decorated/combined with 0D and 1D nanomaterials or be coated on other nanomaterials so that three-dimensional nanostructures with unique and better properties can be obtained to meet more requirements.

In this review, the wearable power supply devices based on nanosheets are divided into three classifications: nanosheet-based wearable batteries, nanosheet-based wearable supercapacitors, and nanosheet-based wearable self-powered energy suppliers. The nanosheets applied in such three classifications of nanosheet-based wearable power supply devices are summarized. In addition, on the basis of the related literature, the perspective and future research trend of the nanosheet-based wearable power supply devices are also discussed in this review.

Nanosheet-based wearable batteries

Next-generation electronic devices need portable, continuous, and stable power supplies for charging. Among all wearable power supply devices, wearable batteries possess satisfactory cyclic stability, are lightweight, and have prominent energy density, all of which make the wearable batteries one of the optimal wearable power supply devices to charge next-generation electronic devices such as wearable sensors, touch screens, roll-up displays, as well as implantable medical devices. Besides, wearable electronic devices with broad applications (e.g., organic light-emitting diode [LED] devices, integrated circuits, and photodetectors) are always applied under constant deformation and large mechanical strain. To supply energy to such stretchable electronic devices, nanosheet-based batteries are gradually applied as power supplies thanks to the stability of electronic properties. Moreover, thanks to the application of nanosheet materials, wearable batteries can be more lightweight.

The development of graphene nanosheets has ushered two-dimensional (2D) nanomaterials into the limelight for energy conversion and storage devices (Tan et al., 2017; Xu et al., 2013; Zhang, 2015). Particularly, as the thickness of 2D nanosheets reduces into a few unit-cell layers, some physical and chemical properties (e.g., bandgap, wettability, in-plane transport) will become distinct from their bulks or rigid and thick nanosheets, and these changes may affect their electrochemical properties for ion transport and storage (Wu et al., 2014).

Up to now, a variety of metal oxide nanosheets (e.g., V2O5, MnO2, SnO2, Co3O4, Fe2O3) have been successfully fabricated and explored as cathode/anode materials for different types of batteries, including lithium-ion batteries (LIBs), sodium-ion batteries, metal-sulfur batteries, and metal-air/oxygen batteries (Mei et al., 2018; Sun et al., 2016; Wu et al., 2014). Among them, the Li-ion battery is the market-leading one for energy storage applications, especially for power batteries in stationary power plants and electric/hybrid vehicles as well as consumer batteries in electronics (Pan et al., 2018). Therefore, the investigation toward wearable Li-ion batteries (LIBs) based on nanosheets has become a focused area (Manthiram, 2017).

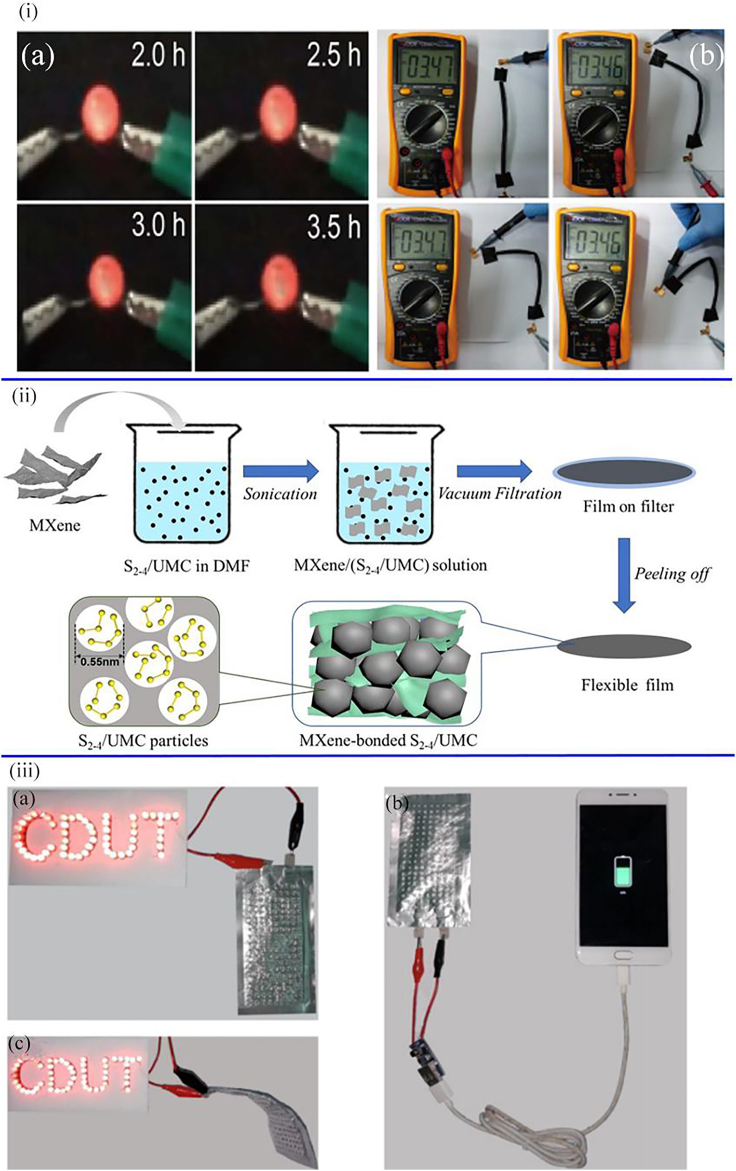

For instance, Hoshide et al. fabricated a flexible Li-ion fiber battery based on the most used LIB material, titanium oxide, but processed into nanosheets by a wet-spinning process (Hoshide et al., 2017). The titanium oxide nanosheets are stacked regularly and hybridized with reduced graphene oxide, another kind of nanosheets, to obtain a novel current collector with high efficiency. The application of nanosheets and the unique stacking structure enable the wearable battery with prominent battery performances including cyclic behaviors, linear densities, and rate capabilities, as well as remarkable mechanical properties, and provide a novel and promising way for the advanced wearable energy storage systems. By applying LiMn2O4 as the cathode, the device exhibits a high working voltage from 3.9 to 4.2 V and a LED of 60 mW can be powered continuously for no less than 5 hours by only a 10-cm hybrid fiber (Figure 1i). After 200 cycles at 0.0085 mA, the capacity retention is more than 70%. Besides the TiO2 nanosheets, molybdenum disulfide (MoS2) nanosheets and gallium chalcogenide (GaX) nanosheets can also be the basic material for wearable LIBs, which demonstrate the great potential of LIBs in future wearable device applications (Lu et al., 2020; Zhang et al., 2017a). As the market-leading batteries, the production technique of LIBs is mature and achieves low cost. Although the energy density and cyclic behavior of the LIBs are not as good as other kinds of batteries, LIBs are the optimal choice to be first applied as the energy supply components in distinct wearable electronic devices for commercialization.

Figure 1.

Wearable Li batteries based on nanosheets

(i) (a) The Li-ion battery with the ability to continuously light a lamp for no less than 5 h. (b) Voltage output when bending and recovering (Hoshide et al., 2017).

(ii) Schematic showing the fabrication procedure of the flexible MSC film (Zhao et al., 2019b).

(iii) Photos illustrating (a, c) the digital LEDs (b) and a mobile phone powered by the lithium-oxygen battery (Long et al., 2019).

However, the energy density of the LIBs is insufficient at 200–250 Wh kg−1, which prevents the batteries from further applications (Wu and Cui, 2012; Yin et al., 2018). Therefore, alternative batteries are needed for the development of wearable devices. Li-sulfur battery with an excellent energy density of 2,600 Wh kg−1 is a promising candidate for the next generation of wearable batteries as it is also environmentally friendly and low cost (Peng et al., 2017). In the work of Zhao et al., conventional cyclo-S8 was replaced by S2-4, small sulfur molecules, to eliminate the shuttle effect, which is the most significant hindrance for the practical application of lithium-sulfur batteries (Zhao et al., 2019b). MXene nanosheets are applied as the flexible backbone and conductive binder and combined with S2-4/carbon composite to develop a small-sulfur electrode (Figure 1ii). Encouraged by the MXene nanosheets and the S2-4/carbon composite, the wearable power supply device is found to have excellent electrochemical properties, including a high capability of 1,029.7 mAh g−1 at 0.1 C and satisfactory cyclic behavior (after 200 cycles, the capability maintains 946.7 mAh g−1 with 91.9% retention). Meanwhile, while at 2 C current density, the capability of the electrode is still 502.3 mAh g−1. In this work, the MXene nanosheets are applied as the flexible backbone and conductive binder, which provides a new strategy for Li-sulfur batteries to be practically applied in wearable device areas and achieve flexibility together with excellent performance. As a result, this MXene-based Li-sulfur battery can be widely applied in wearable electronic devices with the requirements of high energy density and capacity like wearable VR/AR glasses and Google glasses. Except for the Li-sulfur battery, the rechargeable lithium-oxygen battery is also an optimal alternative for wearable applications resulting from its much higher density energy of 3,500 Wh kg−1 than the LIB (Khetan et al., 2015). Long et al. designed a Li-O2 battery based on CuCo2S4 nanosheets as an electrode with satisfactory efficiency (Long et al., 2019) (Figure 1iii). The free-standing CuCo2S4 nanosheets play a significant part in the increase of catalytic properties and the deliberately designed structure further improves the performance. As a result, the Li-O2 battery possesses the enhanced capability of 9,673 mAh g−1 at 100 mA g−1, the improved cycle life of 164 cycles and yield lower overpotential of 0.82 V and satisfactory performance under distinct bending and twisting cases. The prominent capability enables the battery to be the wearable power supply device toward the large-energy consumption like smartphones.

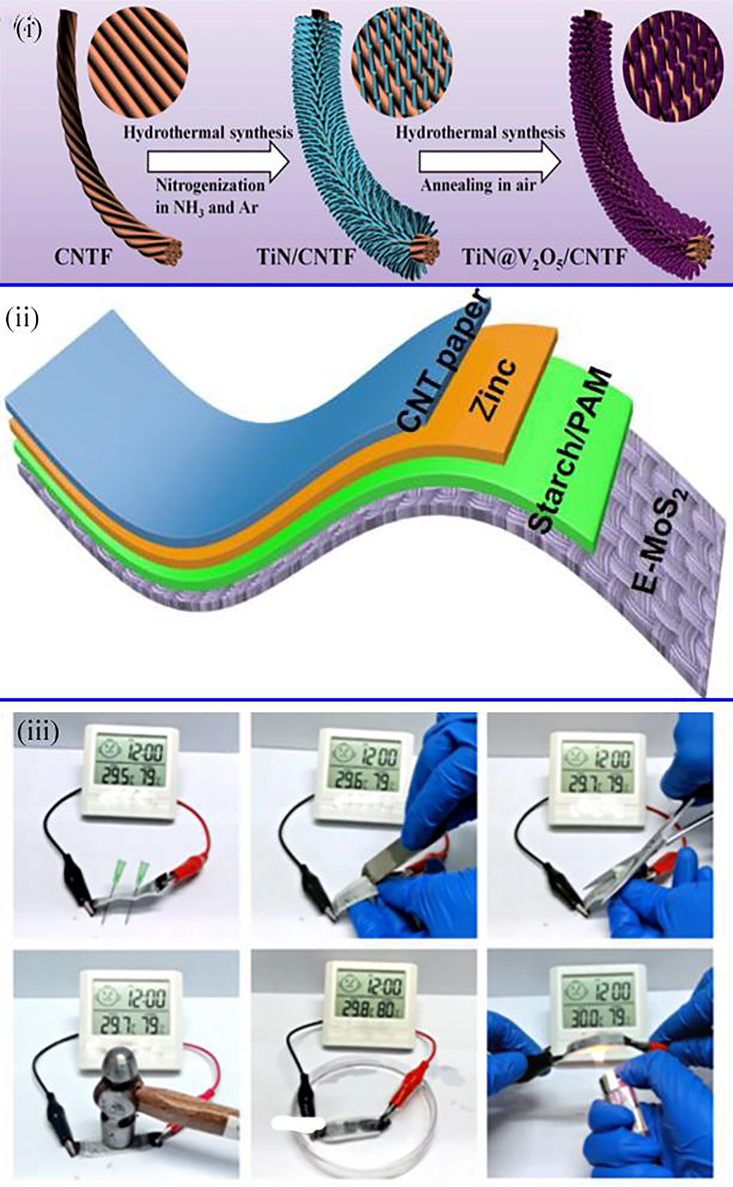

Lithium is not an abundant element and dozens of alarmists regard it as the next gold in the next century (Song et al., 2018). In addition, the leading market battery, the LIB, is not environmentally friendly, especially when used for less than a thousand cycles (Larcher and Tarascon, 2015). As a result, the earth-abundant multivalent cations (Mg2+, Ca2+, Zn2+, Al3+) attract extraordinary attention to develop polyvalent metal-ion batteries (Blanc et al., 2020). Among them, Zn-ion batteries are investigated most and possess well-developed techniques because Zn is abundant and safe and has large volumetric capacity compared with other elements (Rajput et al., 2018). V2O5 is a welcome material for energy devices because of the low cost of vanadium and high theoretical capacity (De Juan-Corpuz et al., 2019). For instance, a wearable chargeable Zn-ion battery based on V2O5 nanosheets was reported to be developed by Li et al. (2019b). The V2O5 nanosheets are decorated with titanium nitride (TiN) nanowires as (TiN)@V2O5 three-dimensional nanostructures. Such hierarchical core-shell heterostructure was deposited on carbon nanotube fibers (CNTFs) to form the binder-free cathode (Figure 2i). Benefit from the TiN nanowires and layered V2O5 nanosheets, the cathode shows great energy storage properties, a large rate capability of 486.8 mAh g−1 (1.11 mAh cm−2) at 10 mA cm−2, and a large capacity of 636.0 mAh g−1 (1.45 mAh cm−2) at 0.5 mA cm−2. Besides, the wearable aqueous Zn-ion batteries deliver a large energy density of 373.0 Wh kg−1 (283.5 mWh cm−3), large capacity of 532.9 mAh g−1 (405 mAh cm−3), large capacity retention of 90.6%, and remarkable cyclic performance of more than 3,500 cycles. As a result, this power supply device is a promising choice for applications with the requirements of mildly high power consumption and charge-discharge for thousands of times, e.g., wearable sensors and even epidermal sensors for continuous monitoring. Especially, the energy density (373.0 Wh kg−1) of such battery is nearly twice higher than the standard of blade electric vehicles in China (125 Wh kg−1), which illustrates that such Zn-ion device can fit almost all standards of all electronic devices. More significantly, the unique materials applied, (TiN)@V2O5 structures, endow the Zn-ion battery with integration and flexibility characteristics. Furthermore, V2O5 nanosheets can grow on the titanium substrate (Javed et al., 2020) or be combined with N-doped carbon (NC) nanowall arrays (He et al., 2019) to form the electrode of wearable Zn-ion batteries and improve the energy storage performance of Zn-ion batteries. Bedsides the V2O5, MoS2 nanosheet is also a promising candidate for energy storage and conversion applications as the layered structure enables MoS2 with dramatic ion intercalation capability (Zhang et al., 2021). In the study of Li et al., MoS2 nanosheets expanded inter-layer spacing (E-MoS2) was first demonstrated as the encouraging cathode materials for rechargeable Zn-ion batteries (Li et al., 2019a). The E-MoS2 nanosheet electrode manifests a prominent energy density of 148.2 Wh kg−1, desirable cyclic ability over 600 cycles with large capacity retention (98.6%), and a decent capacity of 202.6 mAh g−1 (Figure 2ii). With the assistance of the novel starch/polyacrylamide (PAM)-based polymer electrolyte showing outstanding conductivity of Zn ion, the MoS2 nanosheet-based battery displays satisfactory performance even under distinct huge deformations and paves the way for applications in wearable devices that need large deformations in a prospective view, for example, the wearable sensors mounted at elbow or knee. The high energy density of 148.2 Wh kg−1 is slightly better than the standard of blade electric vehicles in China (125 Wh kg−1), which illustrates that such Zn-ion device is a great choice for the miniaturization of electronic devices. In addition, Zhao et al. reported a MnO2−x nanosheet-based Zn-ion battery and combined it with perovskite solar cells to fabricate a self-powered and flexible waistband system (Zhao et al., 2021). By the lithium treatment to expand the interlayer spacing of MnO2 nanosheets and combined with the carbon cloth (CC), the MnO2−x@CC was first developed. Even with large mass loading of more than 25.5 mg cm−2, the MnO2−x@CC electrode has outstanding cycle stability up to 5,000 cycles, much improved rate performance, and a specific capacity of 3.63 mAh cm−2 at the current density of 3.93 mA cm−2. More importantly, the Zn-ion battery achieves ultrahigh safety under various severe conditions and a wide range of temperatures and has been applied to power a wearable smart bracelet. However, the low energy density (5.11 mWh cm−2) and the low capacity prevent such Zn-ion battery from commercialization, and after further research toward this MnO2−x nanosheet-based Zn-ion battery, it shows great potential in applications of self-powered electronic devices that need thousands of charge-discharge cycles.

Figure 2.

Wearable Zn-ion batteries based on nanosheets

(i) Schematic diagram showing the fabrication process of TiN@V2O5 NWAs on a CNTF (Li et al., 2019b).

(ii) Schematic diagram illustrating the structure of the flexible battery based on starch/PAM polymer electrolyte. (Li et al., 2019a).

(iii) Safety experiments of the battery under various conditions, including soaking, hammering, cropping, burning, puncturing, and cutting (Zhao et al., 2021).

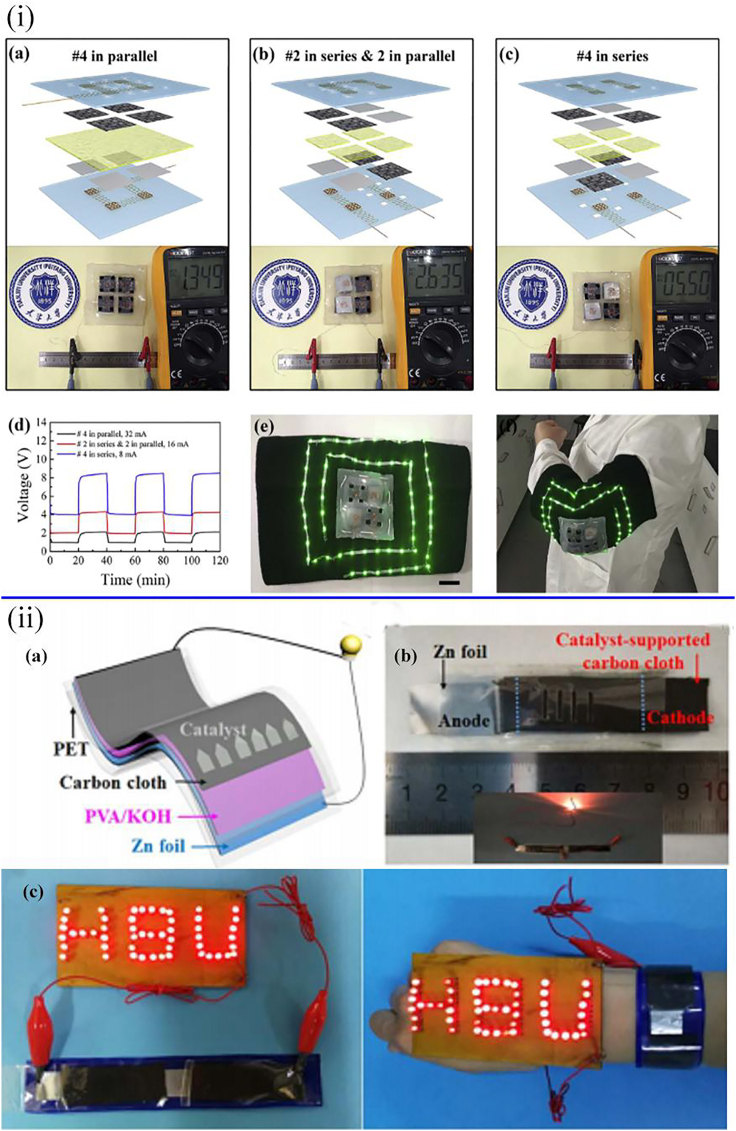

Metal-air batteries are regarded as the optimal candidate for wearable battery applications as the energy density of metal-air batteries is much higher than that of the market-leading batteries, LIBs, and even several times larger than the threshold energy density of LIBs (Li and Lu, 2017; Zubi et al., 2018). Among the metal-air batteries, Zn-air and Li-air batteries are the most promising ones. As the Li is not abundant and has a safety hazard, Zn-air batteries show great potential for the alternative of Li-air batteries (Chi et al., 2021; Yu et al., 2020, 2021). For example, Qu et al. conducted a Co3O4 nanosheet-based Zn-air battery array fabricated by an integrated electronic system in a layer-by-layer 2 × 2 structure. The Zn-air battery manifested stable electrochemical behaviors under 100% strain and could be discharged at bending and high-frequency dynamic stretching conditions. After being rearranged of the electrode array, the flexible Zn-air battery array could generate a broad range of voltage from 1 to 4 V. The above-mentioned properties have made it capable for an experiment to power a green light band with 60 LEDs (Figure 3i) (Qu et al., 2017). Flexible Zn-air batteries (FZABs) hold remarkable potential in powering flexible electronics in other researches as well. Zhang et al. prepared a flexible Zn-air battery that is assembled with CoNi alloy/NCNSAs/CC-800. 3D hierarchical nanostructure enabled the Zn-air with a significant mechanical cycle ability (charge/discharge cycles at flat and folded states with a low voltage gap of 0.66 V), a high energy density (98.8 mW cm−2), as well as a high capacity (879 mAh g−1). Two series of Zn-air batteries were assembled to power an “HBU” indicator consisting of 51 red LEDs, which indicated the Zn-air battery was a prominent candidate for electrochemical energy conversion and storage (Figure 3ii) (Zhang et al., 2020). For such Li-air and Zn-air batteries, their poor cyclic behaviors of more than 20 and 40 cycles, respectively, are the most significant hindrance for their commercialization. Further research is needed for these two batteries to be applied practically. In addition, the construction of a chargeable Zn-air battery device consisting of RuO2 and N-doped carbon nanosheets with a liquid electrolyte and BN/C catalyst was proposed by Zhao et al. (2020) The proposed battery exhibited a peak power density of ∼115 mW cm−2, a good performance in an open-circuit potential of 1.36 V, and excellent durability (1,000 cycles in 14 days operation). The battery can also be charged under different bending states. Therefore, such wearable Zn-air battery based on N-doped carbon nanosheets displays a great future for application in wearable electronic devices with the need of mildly high capacity as well as energy density and large deformations like wearable sensors mounted at the neck, elbow, or knee. Apart from these works with distinct nanosheets, many other nanosheets including reduced graphene oxide nanosheets and zeolitic imidazolate framework nanosheets (Li et al., 2018b; Zhao et al., 2019d) have been applied to be the basic materials for Zn-air batteries, which demonstrates that Zn-air batteries are the most attractive ones for the future wearable batteries.

Figure 3.

Wearable Zn-air batteries based on nanosheets

(i) (a-c) Exploded view of the layout of the various layers in the Zn-air battery array structure (# 4 in parallel, # 2 in series & 2 in parallel, and # 4 in series), with open-circuit voltages of 1.35, 2.6, and 5.5 V, respectively. (d) Charge-discharge curves of the three types of such arrays at a current density of 2 mA cm−2, with each cycle being 40 min. (e) Photograph of a Zn-air battery array (# 4 in parallel) sewn on clothes to light a LED band (scale bar, 2 cm). (f) Photograph of the array (# 4 in parallel) being stretched and bent by body movement (Qu et al., 2017).

(ii) (a) Schematic illustration showing components of FZABs, and (b) photograph. (c) Photographs of an “HBU” indicator including 51 red LEDs, which obtain power through a wearable bracelet with two-series FZABs (Zhang et al., 2020).

Besides Li-based and Zn-based batteries, Kong et al. found that quasi-solid-state Nickel-Fe batteries (QSS-NFBs) demonstrated an ultrahigh energy density and excellent cycling stability as well. The QSS-NFB was fabricated by 3D printing. With the compressible feature, the QSS-NFB is expected to be applicable in next-generation stretchable electronics (Kong et al., 2020). Another flexible Ni-Fe battery based on NiCoP nanosheets was also listed in the work of Yang et al. with negligible capacity loss, significant capacity, and high energy density (Yang et al., 2020). The prominent charge-discharge cyclic behaviors of over 10,000 cycles and 4,000 cycles, respectively, for such two Ni-Fe batteries demonstrate an excellent promise in the use of technological gadgets that need a large number of charging-discharging times. The low capacity and energy density of the Ni-Fe battery of Yang et al., however, preclude its commercialization and practical application and more work is urgently required.

Nanosheet-based wearable supercapacitors

Together with nanosheet-based batteries, nanosheet-based supercapacitors, particularly stretchable all-solid-state supercapacitors, make great contributions to wearable electronics as well due to the rapid charge-discharge rates, high power density, and excellent cycling stabilities (An and Cheng, 2018; Augustyn et al., 2014; Brezesinski et al., 2010). In addition, tens of thousands of cycle life together with the application of the nontoxic aqueous electrolytes in supercapacitors make the supercapacitors more suitable for wearable electronic devices with the requirements of the long-term application and environmental friendliness. However, although the high cyclic behavior, the power density of supercapacitors is relatively lower than that of the traditional batteries, which greatly prevents the supercapacitors from further application of wearable devices (Muralee Gopi et al., 2020). Therefore, nanosheet materials with a high surface-to-volume ratio and thus more energy storage and electrocatalyst sites are applied to address this problem.

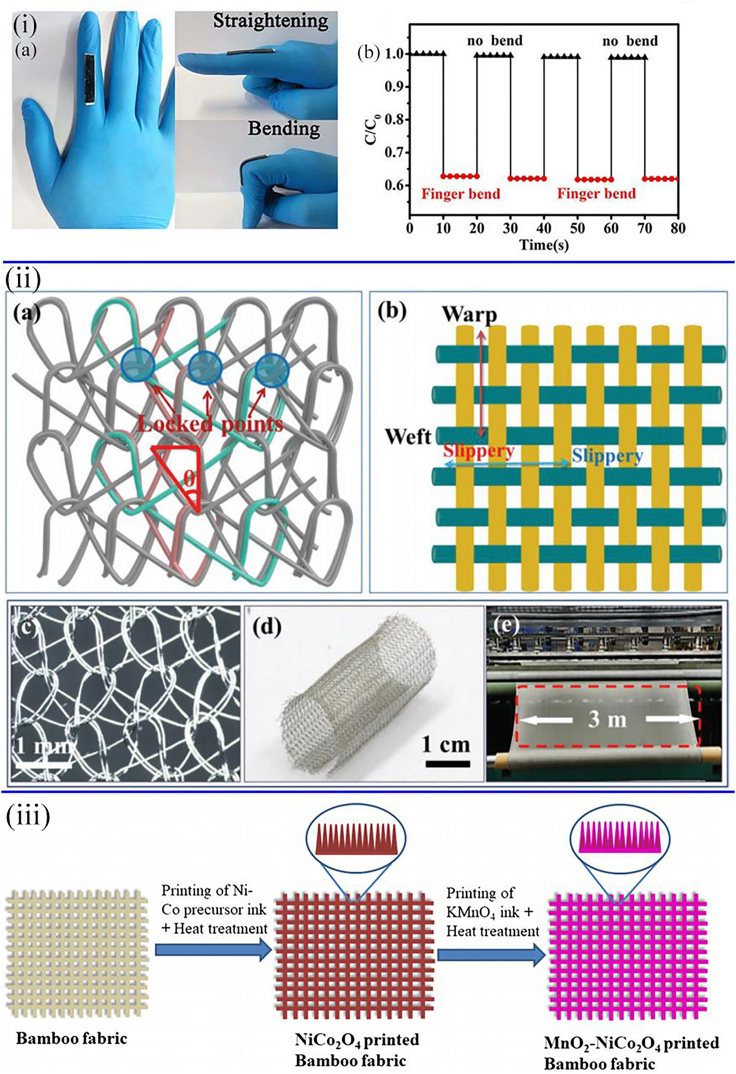

For instance, Song et al. prepared a solid-state supercapacitor electrode by decorating Ni(HCO3)2 nanosheets to flexible PVA/carbon nanotube (Song et al., 2019). The prepared device with remarkable stretchable and bendable ability exhibited an instant response to the finger bending with the capacitance variation of more than 35% (Figure 4i), which proved the potential of composite nanomaterials as wearable devices and the potential of the device as the wearable sensors at fingers. Besides the Ni(HCO3)2 nanosheets, which can improve the electrochemical performance of the supercapacitors, NiCO2S4, and NiCO2O4 nanosheets as battery-type materials are the potential Faradaic redox materials owing to their ability to offer improved electrochemical performance, excellent redox activity, and outstanding capacity values (Conway, 2013). For example, Shao et al. conducted a stainless-steel meshes (SSMs)-based supercapacitor that was obtained by covering CoS2 nanowires onto NiCo2S4 nanosheets in situ (Shao et al., 2020). The SSM-based supercapacitor manifested prominent performances with respect to a remarkable tensile recovery (≤40% elongation), high energy density (60.2 Wh kg−1 at 800 W kg−1), and high stability (≈76.4% capacity retention at 30% strain for 1,000 stretching cycles). The highly flexible supercapacitor was sewn on the elbow of a garment to power a LED, which demonstrated its high applicability to wearable electronics like wearable sensors or electric light installed on the elbow of a garment (Figure 4ii). In the work of Sundriyal et al., MnO2–NiCo2O4, and rGO were applied as the positive and negative electrodes, respectively, to form a solid-state supercapacitor (Sundriyal and Bhattacharya, 2020). The formed supercapacitor was fabricated by a replicable printing process with different metal oxide inks on the bamboo fabric substrate. Notably, the supercapacitor showed remarkable electrochemical performances under various mechanical deformation conditions including a finger bending test, which demonstrated its excellent mechanical strength and flexibility (Figure 4iii). The ink-printed technique endows the solid-state supercapacitor with various shapes and paves the way for the future self-design of wearable power supply devices. Moreover, Zhao et al. and Wang et al. also reported the wearable supercapacitors based on NiCo2S4 nanosheets and NiCo2O4 nanosheets, respectively (Wang et al., 2014; Zhao et al., 2019c), which demonstrates the great potential of NiCo2S4 nanosheets and NiCo2O4 nanosheets in the field of wearable power supply.

Figure 4.

Wearable solid-state supercapacitors based on nanosheets

(i) (a) Photographs of the supercapacitor fixed onto the index finger; (b) cyclic stability of supercapacitor (Song et al., 2019).

(ii) Schematic illustration showing (a) SSM together with (b) the stainless-steel plain cloth. (c) SEM image of SSM. (d) Image of a hollow tube of SSM under the size of 3 cm × 3 cm at natural state. (e) SSM knitted applying a modified Raschel warp knitting machine (Shao et al., 2020).

(iii) Schematic diagram illustrating the construction of printed MnO2–NiCo2O4 electrode over the bamboo fabric (Sundriyal and Bhattacharya, 2020).

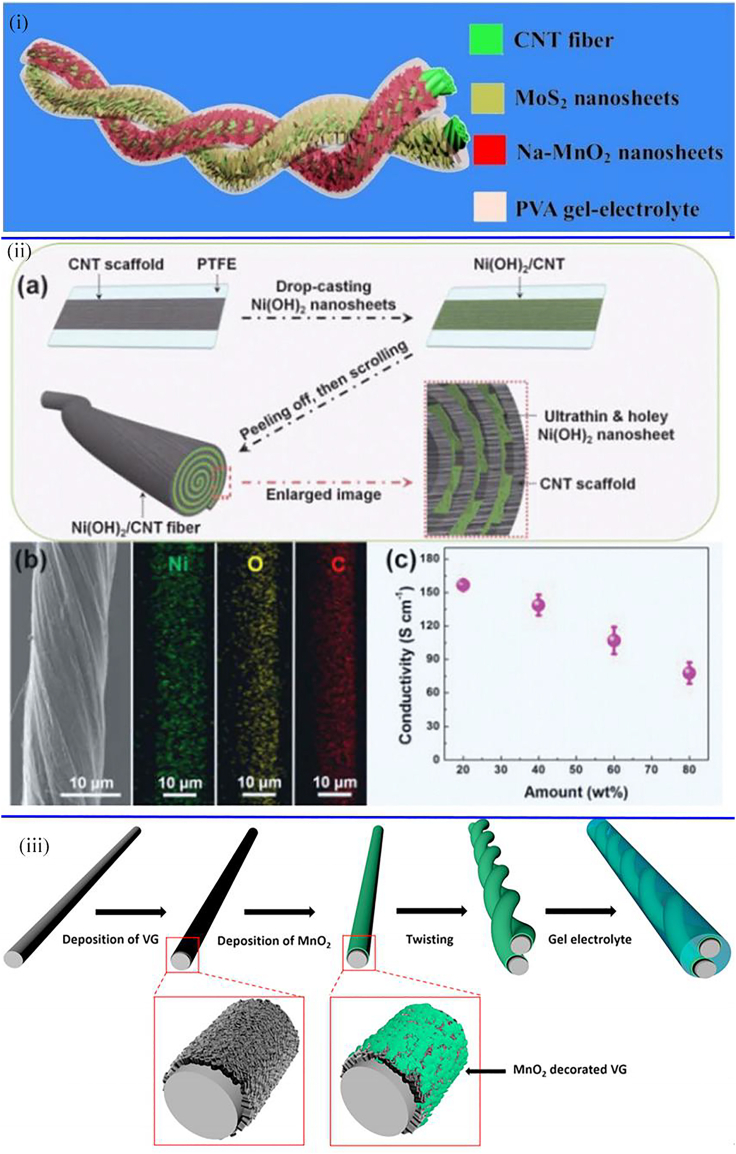

Fiber-shaped supercapacitors are more intriguing owing to their better flexibility and smaller volume and thus have easier wearability compared with the conventional solid-state supercapacitors (Li et al., 2020; Lim et al., 2017b; Liu et al., 2015; Yu et al., 2016; Zhao et al., 2019a). In the research of Zong et al., a fiber-shaped asymmetric supercapacitor (FASC) based on carbon nanotube fibers (CNTFs), MoS2, and MnO2 nanosheets was developed (Zong et al., 2018). The MnO2 nanosheets are doped with Na and grown on the carbon nanotube fibers to form the positive electrode, while MoS2 nanosheets-coated carbon nanotube fibers are applied as the negative electrode. Thanks to the unique design of electrodes, such fiber-shaped supercapacitors manifest an excellent specific capacitance (265.4 mF cm−2) and a high operating potential window of up to 2.2 V (Figure 5i). However, the poor energy density (178.4 μWh cm−2) of such fiber-shaped supercapacitors hinders them from commercialization and only the wearable electronic devices with low-power consumption like a wearable electronic watch can apply such fiber-shaped supercapacitor. Besides, reported by Li et al., MnO2 nanosheets can also be combined with single-wall carbon nanotubes (SWCNTs) to form the electrode of a wearable capacitor with an ultrahigh energy density of 10.4 mWh cm−3, the excellent volumetric capacitance of 74.8 F cm−3, as well as outstanding cyclic stability of more than 5,000 cycles, all of which illustrate a bright future for application in distinct kinds of wearable electronic devices, especially in the wearable devices with the need for high capacity as well as cyclic behaviors like Google glass. (Li et al., 2018a). In addition, Shi et al. facilely synthesized the Ni(OH)2 nanosheets, the average thickness of which is 2 nm, and after that embedded the nanosheets on the carbon nanotubes to develop the electrode of a fiber capacitor (Figure 5ii) (Shi et al., 2018b). The Ni(OH)2 nanosheets/carbon nanotubes nanostructure not only enables the electrode with superior rate performance, as well as an excellent volumetric capacitance (335.9 F cm−3 at the current density of 0.8 A cm−3), but also endows the hybrid supercapacitor with satisfactory mechanical stability after repeated bending experiments for 5,000 bending-unbending cycles, an outstanding energy density (5.8 mWh cm−3), as well as a dramatic specific capacitance (24.8 F cm−3). The excellent cyclic behavior in the bending experiment illustrates that the hybrid supercapacitor can be applied in wearable devices that need to bend thousands of times, e.g., wearable sensors worn on the elbow or knee. Moreover, MnO2 and vertical graphene nanosheets were applied as the basic materials for a fiber-shaped supercapacitor, which was constructed by Zhou et al. (2021). After growing the vertical graphene nanosheets (VGNs) on ductile nickel wires, MnO2 was deposited on the nanostructure of VGNs/NiWs (Figure 5iii). With the help of the solid-state electrolyte consisting of sodium sulfate and carboxymethylcellulose, a moldable supercapacitor can be developed by the two electrodes. Result from the synthesis of MnO2 as well as the VGNs, the supercapacitor delivers a high areal power density (5 mWh cm−2), areal energy density (7.7 mWh cm−2), and areal capacitance up to 56 mF cm−2. The following bending and twisting tests also illustrate the great mechanical properties of such supercapacitor as there is little loss of performance after molding into various shapes by twisting and bending and show great potential of such supercapacitor in practical application of wearable sensors worn on the elbow, neck, or knee.

Figure 5.

Wearable fiber-shaped supercapacitors based on nanosheets

(i) A detailed illustration of the FASCs (Zong et al., 2018).

(ii) (a) Schematic of the development of the Ni(OH)2/CNT nanostructure. (b) Scanning electron microscopy (SEM) images as well as EDS mapping of the hybrid fiber of Ni(OH)2/CNT. (c) The conductivity of the Ni(OH)2/CNT nanofiber structure with various loads of the nanosheets with 20, 40, 60, and 80 wt%, respectively (Shi et al., 2018b).

(iii) Schematic illustration of construction procedure of the fiber-shaped supercapacitors (Zhou et al., 2021).

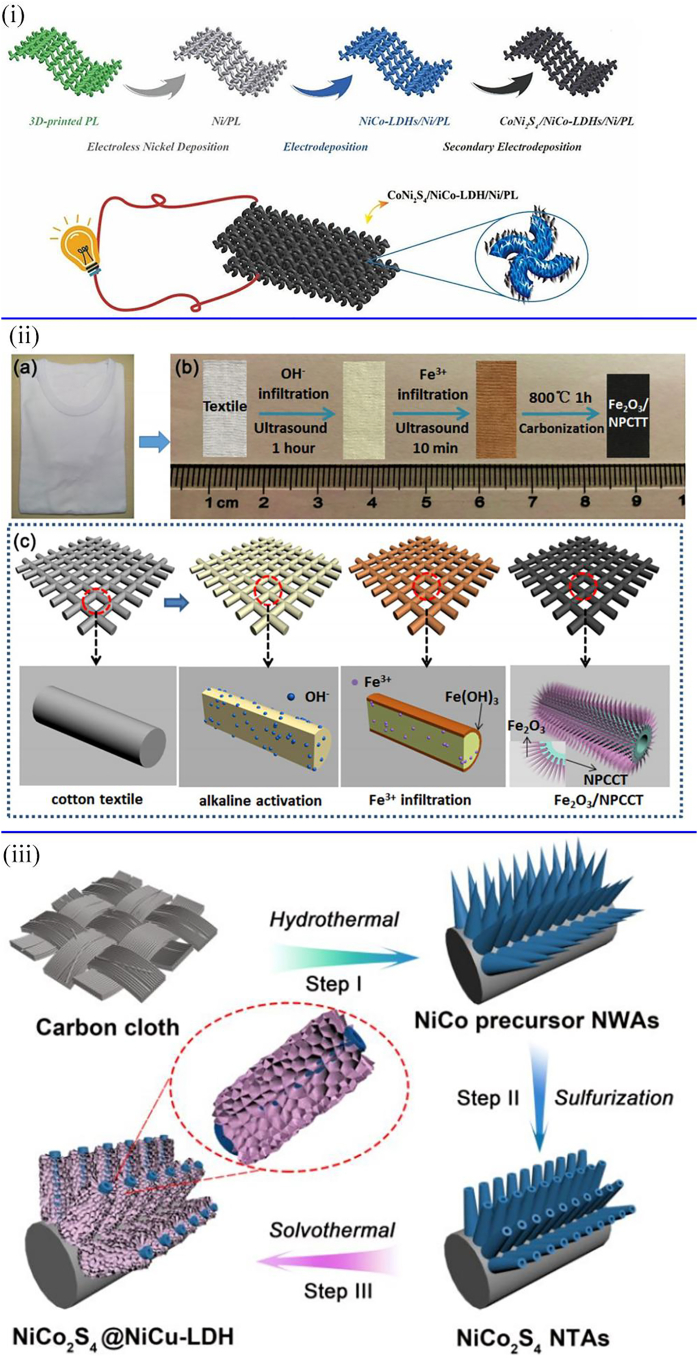

The development of wearable nanosheet-based supercapacitors is still immature. Although some researches have not progressed to the point of wearability, they have delivered great potential in wearable electronic devices. Chang et al. combined 3D printing with electrodeposition to print a CoNi2S4/NiCo-LDHs nanocomposites-based supercapacitor (Figure 6i) (Chang et al., 2020). The combined stretchable symmetric supercapacitor exhibited a superior capacitance of 28.71 F cm−3 and satisfactory stability in stretching and bending cycles. The above properties are highly comparable with previously reported stretchable supercapacitors. The relatively low energy density of 0.582 mWh cm−3 indicates there should be further research toward such stretchable supercapacitors. In the work of Ding et al., homogeneously distributed α-Fe2O3 nanobelt arrays were reported to fabricate a stretchable and flexible electrode (Figure 6ii) (Ding et al., 2020). In the experiments, the reported supercapacitor possessed a great stretchability and excellent flexibility together with a high specific areal capacitance. This study opens a new way to the designing method of next-generation wearable electronics. In addition, Huang et al. fabricated a facile hierarchical NiCo2S4@NiCu−LDH nanotube/nanosheet hybrid supercapacitor on carbon cloth by a solution-based strategy in multistep. The NiCo2S4@NiCu−LDH had a volumetric energy density up to 2.7 mWh cm−3, a power density of 21.3 mW cm−3, and long-term cycling robustness over 2000 cycles. This work exhibited the possibility of designing and fabricating nickel-based LDHs as supercapacitors toward highly efficient and durable soft energy storage devices (Figure 6iii) (Huang et al., 2020). Furthermore, a carbon nanosheet-based large-area supercapacitor was proposed by Jun et al. The exceptional mechanical stability of the capacitor was confirmed. As a result, only an approximate 15% increase in the electrical resistance was measured under a tensile strain of 100%. The initial resistance was fully recovered after release, which met requirements for wearable electronics (Jun et al., 2018). Besides, lots of other materials have been applied in constructing nanosheet-based supercapacitors such as MoS2 nanosheets on spindle-like α-Fe2O3, Cu@Ni@NiCoS nanofibers network based on Ni-Co-S nanosheets, and carbon nanotube-MnO2 nanocomposite film based on MnO2 nanosheet, which are reported by Man et al., Soram et al., and Wang et al., respectively (Man et al., 2020; Soram et al., 2020; Wang et al., 2019).

Figure 6.

Nanosheet-based supercapacitors showing great potential in wearable applications

(i) Schematic diagram illustrating the fabrication process of 3D-printed stretchable CoNi2S4/NiCo-LDHs/Ni/PL electrode as well as the construction procedure of the supercapacitor (Chang et al., 2020).

(ii) (a) Photo of a cotton T-shirt for sale; (b) digital photographs of the color changes of a piece of pristine cotton textile cut from the T-shirt before (left) and after alkaline activation, Fe3+ infiltration, and the resulting Fe2O3 nanobelts/NPCTT; (c) schematic illustration of fabrication procedure of the Fe2O3/NPCTT. The schematic illustrations below present detailed changes of the surface layer for a single fiber and the features of the grown nanostructures at various steps (Ding et al., 2020).

(iii) Schematic diagram showing the various production stages of NiCo2S4@NiCu-LDH nanostructure on carbon cloth (Huang et al., 2020).

Nanosheet-based wearable self-powered energy suppliers

Keeping up with the developments of batteries and supercapacitors, the use of self-powered energy suppliers is indispensable for generating wearable electronics (Alam and Ramakrishna, 2013; Buscema et al., 2013). In the past decade, triboelectric nanogenerators (TENGs) and piezoelectric nanogenerators (PENGs) have gained massive attention owing to their exceptional capability to transfer mechanical energy to electric power (Gao et al., 2017; Karan et al., 2016; Kim et al., 2014; Ku et al., 2017; Seung et al., 2017; Tsai et al., 2017; Zhou et al., 2018).

PENGs have become a hot research field for nanosheet-based self-powered energy suppliers owing to their unique merits of mechanical-electrical energy conversion capability, lightweight, low cost, and easy manufacturing, which can harvest various types of mechanical energy by utilizing the piezoelectric effect.

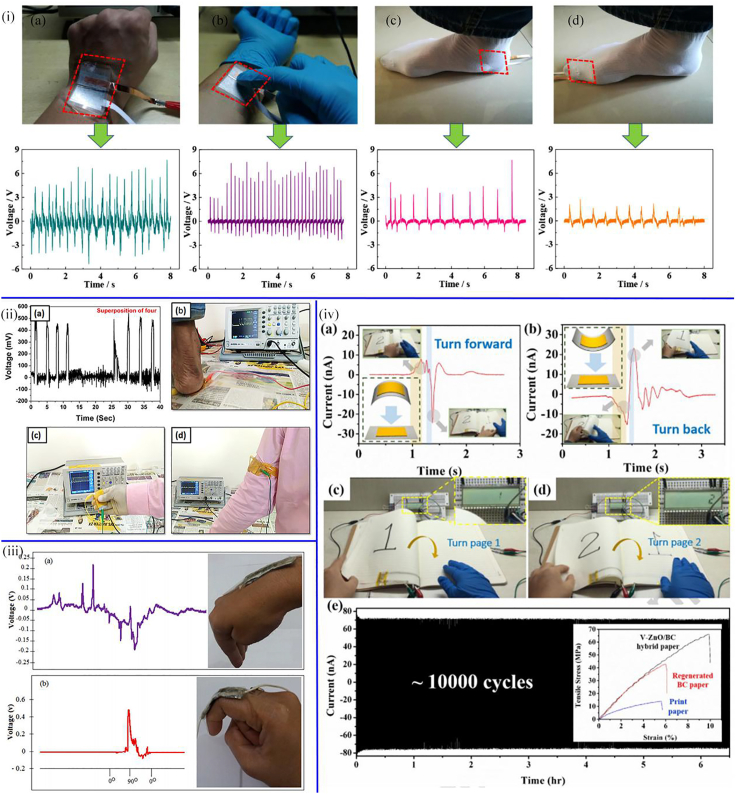

By applying nanosheets as the alternative to conventional materials, the power production performance of PENGs increases dramatically. For example, in the work of Shi et al., a PENG with high output and good flexibility was proposed (Shi et al., 2018a). The proposed PENG was fabricated by using electrospun nanocomposite fiber mats comprising graphene nanosheets, barium titanate (BT) nanoparticles, and poly(vinylidene fluoride) (PVDF). The open-circuit voltage generated by the PENG can reach as high as 11 V under a loading frequency of 2 Hz and a strain of 4 mm with no obvious decline of the open-circuit voltage. In addition, the PENG generated a peak voltage as high as 112 V during a finger pressing-releasing process, which can light up 15 LEDs and drive an electric watch. The PENG can also be activated by movements of different parts of the human body including wrist bending, finger tapping, and foot stepping by heel and toe (Figure 7i). As a result, the PENG can provide the power for the wearable devices mounted at various body parts including finger, feet, elbow, and knee. Moreover, Tsai et al. applied vertically oriented graphene nanosheets to grow and transfer the aligned single-crystalline GaN nanorods (NRs) so that a transparent flexible PENG with an output current of 1.2 mA and an ultrahigh output voltage of more than 8 V can be obtained (Tsai et al., 2018).

Figure 7.

Wearable piezoelectric nanogenerators based on nanosheets

(i) Photographs together with voltage output produced through human motions for (a) wrist bending, (b) finger tapping, together with foot stepping by (c) heel as well as (d) toe (Shi et al., 2018a).

(ii) (a) Voltage output of four nanogenerators connected in series, (b)–(d) photog of the experiments of foot pressure, bending, muscle stretching, respectively, for the nanogenerator in real time (Manjula et al., 2020).

(iii) (a) Wearable PENG deposited at the wrist joint and its corresponding output signal. 10 (b) Wearable PENG attached onto finger joint and its electrical output signal (Rafique et al., 2021).

(iv) Current output signal (a) while the page turning forward and (b) turning back. (c-d) The ability of the LCD screen to connect with the PENGs while turning the page. (e) After releasing or bending for 10,000 cycles, the current output remains stable. The inset image illustrates the break strength of the V-ZnO/BC film compared with the print paper as well as the regenerated BC paper (Zhang et al., 2018a).

Applied most, ZnO nanosheets are the most promising material for PENGs because ZnO nanosheets not only display outstanding biological compatibility compared with other materials for piezoelectricity, environmental friendliness, pyroelectricity, as well as excellent piezoelectricity (Theerthagiri et al., 2019; Yang et al., 2012) but also can be produced by the one-step process (Zhang et al., 2017b), all of which make the ZnO nanosheets the most applied in PENGs (Manjula et al., 2020; Rafique et al., 2021; Wang et al., 2018; Zhang et al., 2018a). For instance, in the work of Manjula et al., a flexible PENG based on ZnO nanosheets was fabricated (Figure 7ii) (Manjula et al., 2020). On a flexible Al substrate with a low growth temperature of 80°C, a one-step, facile, and cost-effective synthesis hydrothermal method was applied to prepare the Zn nanosheet networks. The wearable device can output 100 mA for a single device and 400 mA for four devices connected in series. A reasonable output voltage is obtained and the simple production method used illustrates a bright future of ZnO nanosheets for wearable nanogenerators. In addition, Wang et al. reported a two-stage preparation process of 2D ZnO nanosheets (Wang et al., 2018). With the assistance of the ZnO nanosheets, the current output of the PENG increased from ∼40 nA to ∼0.15 μA compared with the conventional PENG based on one-dimensional nanowires under the same compressive load of 1 kgf. Besides, it is demonstrated that, with the thinner of the nanosheets, the output performance of the PENG becomes better. In the work of Rafique et al., by doping Br into the ZnO nanosheets through a simple hydrothermal process on nanoporous anodic aluminum oxide (AAO) template, the output voltage of the PENG based on ZnO nanosheets can reach 8.82 V at a frequency of 6 Hz (Figure 7iii) (Rafique et al., 2021). Besides, vanadium can also be doped into ZnO nanosheets to improve the performance of the wearable PENGs based on ZnO nanosheets, and in the work of Zhang et al., the output voltage of the wearable device can reach 1.5 V (Figure 7iv) (Zhang et al., 2018a). Although the output voltage and output current are relatively lower for these ZnO nanosheet-based PENGs, these researches pave the way for the wide application of wearable PENGs based on ZnO nanosheets in the piratical energy harvest field with the development of techniques.

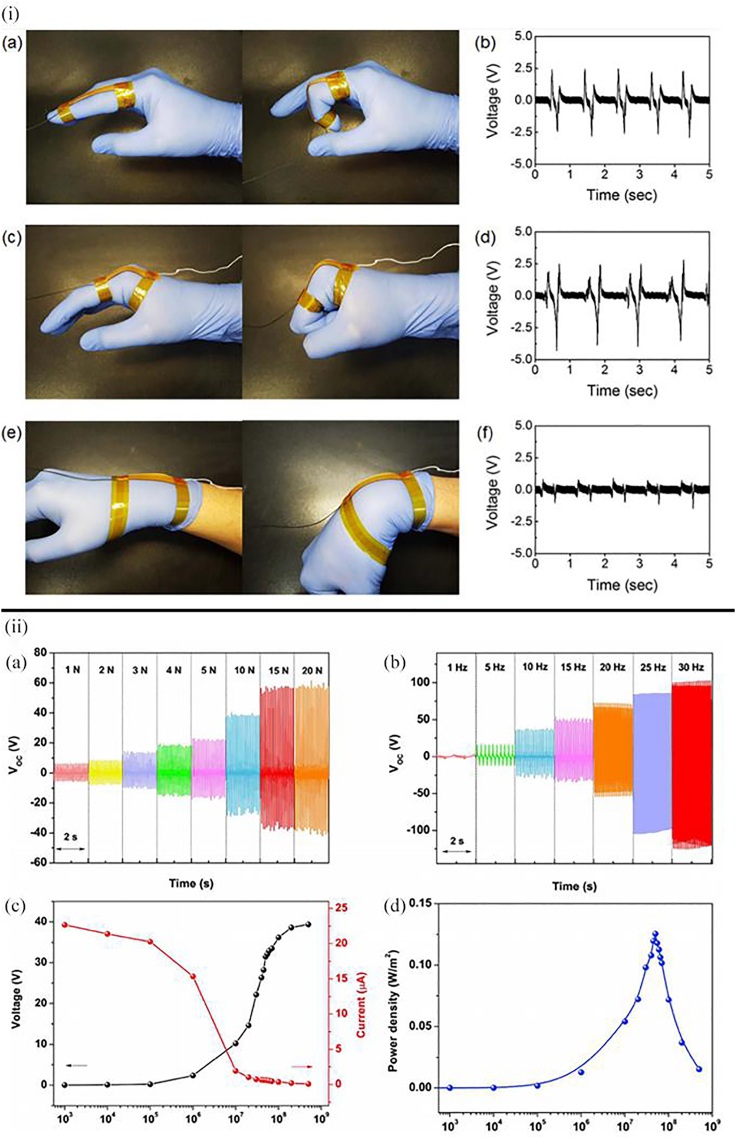

TENGs are developed on the basis of the coupling mechanism between the electrostatic as well as the triboelectric charge to achieve energy production and this energy is one of the most common power in our surrounding environments (Zhou et al., 2020). The features of ease to access, satisfactory power density, and low cost lead to the wide application in the power supply industry (Kang et al., 2019; Liu et al., 2019). For instance, Lim et al. conducted a highly durable TENG that was based on gold-nanosheet (AuNS) electrodes (Lim et al., 2017a). It was found that the novel design of the AuNS electrodes highly improved the mechanical flexibility, enabling one to achieve the remarkable output stability of the AuNS electrode-based TENG. The conducted AuNS-TENGs are successfully employed in the self-powered human-motion detection for wearable electronics and exhibit ultrahigh voltage output of up to 98.9 V and output stability up to 10,000 cycles (Figure 8i). Moreover, in the study of Lan et al., MoS2 nanosheets were wrapped by the silver nanowires (AgNWs) to form a high conductive nanocomposite (Lan et al., 2019). Thanks to such unique structure, the composite film exhibits outstanding conductivity as well as flexibility and enables the stretchable triboelectric nanogenerator (sTENG) formed by such nanocomposite with ultrahigh output voltage up to 95.8 V at a 30 Hz frequency with the 2.5-cm2 contact area, output stability more than 10,000 cycles, which is similar to TENG in the work of Lim et al., and prominent stretchability for 50% (Figure 8ii). The stretchability of the sTENG is so high that such sTENG illustrates great potential for application in smart cloth or smart shoes. MXene nanosheets with outstanding mechanical and hydrophilic properties (Yang et al., 2019c) are also a reasonable basis material for TENG. By integrating the poly(vinyl alcohol) (PVA) with MXene nanosheets for the electrospinning nanofibers, a kind of novel flexible all-electrospun TENG based on MXene nanosheets was fabricated (Jiang et al., 2019). Owing to the high biocompatibility and triboelectricity, silk fibroin (SF) is applied as the electrospinning nanofibers. As a result, the MXene-based nanogenerator manifests a remarkable output voltage of 117.7 V, extremely high durability of 124,000 cycles, as well as peak power density of 1,087.6 mW m−2, all of which enable such MXene-based nanogenerator with deep potential for applications in all kinds of wearable electronic devices. Surprisingly, reported by Shi et al., the application of graphene nanosheets and polyvinylidene fluoride (PVDF) in TENG can obtain a dramatic peak power density of ∼130.2 W m−2 and output voltage of ∼1511 V (Shi et al., 2021).

Figure 8.

Wearable triboelectric nanogenerators based on nanosheets

(i) Optical images and output as the function of voltage responses to the repeated bending/relaxation of the triboelectric nanogenerator that was attached onto the (a, b) index finger, (c, d) knuckle, and (e, f) wrist, respectively (Lim et al., 2017a).

(ii) Output voltage of stretchable triboelectric nanogenerator with the size of 1 cm × 2.5 cm. (a) Output VOC of stretchable triboelectric nanogenerator at various forces under a fixed 10 Hz frequency. (b) Output VOC of stretchable triboelectric nanogenerator at distinct frequencies under a fixed force of 10 N. (c) Voltage and current output under various load resistances related to stretchable triboelectric nanogenerator. (d) Output power density under different resistances of the external loads (Lan et al., 2019).

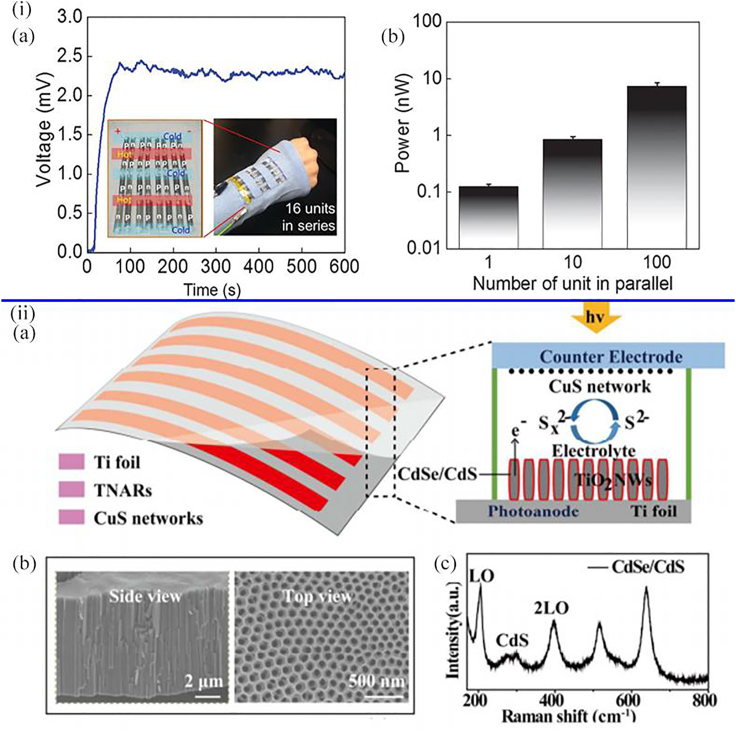

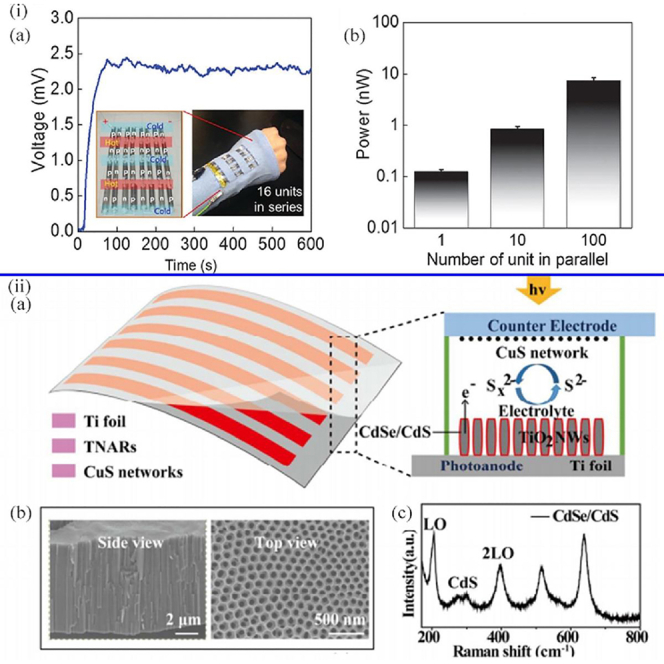

Besides nanogenerators that are mounted on mechanical energy conversion (PENGs and TENGs), nanosheet-based thermoelectric generators are competitive as well to power wearable devices. This is because the human body is a stable power source (about 36.5°C) to assist attaching devices to produce direct current (DC) electric power (Liu et al., 2017; Ma et al., 2016; Meng et al., 2010). Oh et al. demonstrated an intrinsically stretchable and foldable thermoelectric generator that is based on chemically exfoliated 1T-transition metal dichalcogenide (TMDC) nanosheets (NSs). The conducted thermoelectric generator was able to constantly produce an output power up to 38 nW at Δ60 K. After 100 bending cycles and 100 stretching cycles of 50% strain, the thermoelectric device stably sustained its performance. A thermoelectric generator for a glove-type wristband has proved its compatibility in wearable applications (Figure 9i) (Oh et al., 2016). Moreover, Kim et al. constructed a multi-stacked metal dichalcogenide (TMD) nanosheet-based thermoelectric generator. The constructed generator possessed a high thermoelectric power factor of 47 μW K−2 m, which is capable of powering wearable devices (Kim et al., 2019). The commercialization of thermoelectric generators still needs a lot of further work. However, thermoelectric generators hold the brightest future as the power supply is stable and consistent compared with PENGs and TENGs.

Figure 9.

Wearable thermoelectric generators and solar cells based on nanosheets

(i) A wearable thermoelectric generator for a glove-type wristband. (a) Output voltage generated from the heat of a human wrist at room temperature. The inset photos represent the device configuration and the operating situation. (b) Output power produced from 16 units in series with multi-stacked units in parallel (Oh et al., 2016).

(ii) (a) Schematic illustrating the QDSCs based on CuS TCEs; (b) SEM images of the side view and the top view of the TNARs on Ti foil; (c) Raman spectra of the CdSe/CdS co-sensitized TNARs (Xu et al., 2017).

Wearable power supply devices can also benefit from flexible solar cells. As solar energy is an abundant, green, and inexhaustible energy resource, it has attracted great interest, especially in the wearable industry. Xu et al. presented a flexible quantum-dot solar cell (QDSC) based on CuS-nanosheet networks, which is highly transparent and flexible (Xu et al., 2017). The networks are applied as the counter electrode, and the sheet resistance of the networks is 50 Ω sq-1 at 85% transmittance. CuS nanosheet networks are applied as prominent catalysts for reducing polysulfide (S2−/Sx2−) electrolytes, as well as conducting films in order to collect electrons from external circuits (Figure 9ii). As a result, this QDSC displays a high power conversion efficiency of 3.25% and satisfactory stability after bending for 500 cycles. It is believed that this CuS nanosheet-based solar cell with high flexibility, transparency, conductivity, and catalytic activity will be widely employed in wearable electronic devices like solar vests to supply power for every wearable electronic device. In the work of Arbab et al., a wearable all-carbon dye-sensitized solar cell (C-DSSC) was constructed (Arbab et al., 2020). The carbon front electrode demonstrates great sheet conductivity and 50% light transmittance, while the counter electrode dip-coated with graphene oxide nanosheet displays a decreasing charge transfer resistance of 0.79 Ω cm2 and outstanding electrocatalytic activity. C-DSSC's sustainable design achieves a 6 ± 0.5% efficiency with a high photocurrent density of 18.835 mA cm2. The enhanced charge mobility, reduced internal resistance, and improved interfacial electrode contact of C-DSSC are credited with its superior performance. Resulting from the application of graphene oxide nanosheet, C-DSSC is 3 mm thick so that no stiff glass is required in the dye-sensitized solar cell. There are still many obstacles to overcome, such as improving mechanical strength and electrical conductivity. Therefore, additional work has to be done in order to expand the use and achieve the commercialization of nanosheet-based wearable solar cells.

Conclusion and perspective

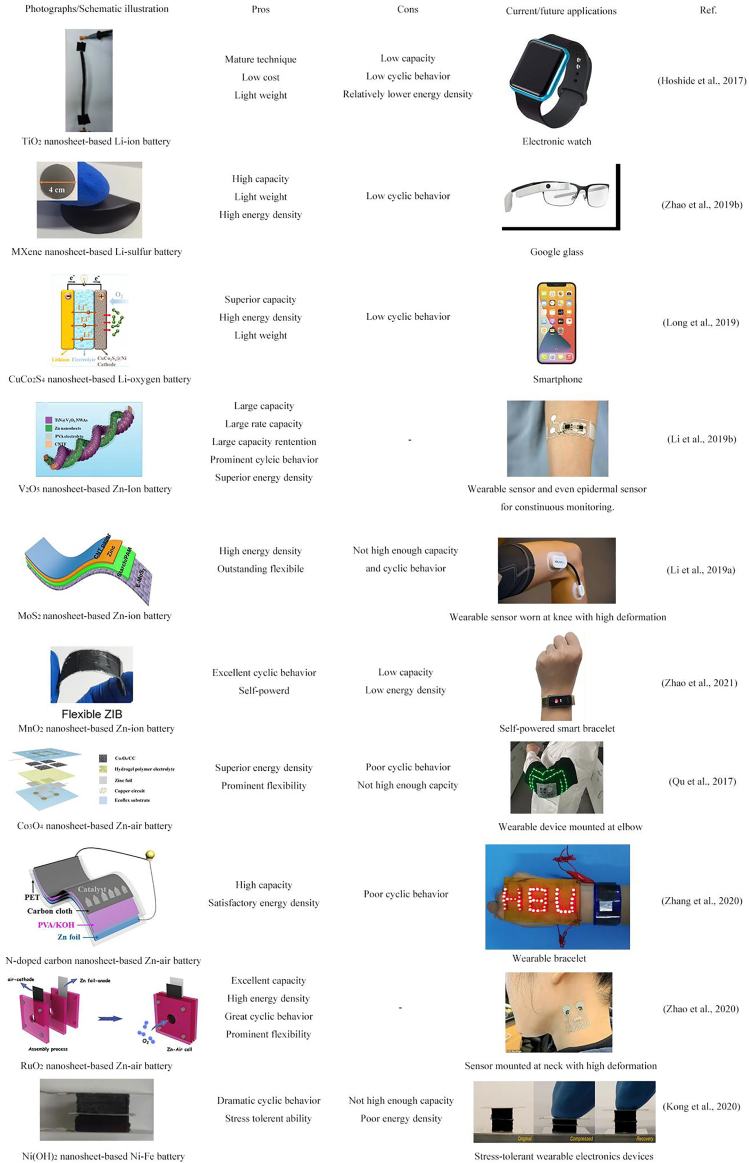

In this review, three common and popular wearable power supply devices based on nanosheet materials are introduced, which are nanosheet-based wearable batteries, nanosheet-based wearable supercapacitors, and nanosheet-based wearable self-powered energy suppliers. The specific researches toward these three kinds of nanosheet-based wearable power supply devices and their comparison are tabulated in Tables 1, 2, and 3. Besides, three figures (Figures 10, 11, and 12) illustrating the development and science problem of nanosheet-based power supply devices, advantages/disadvantages, as well as the current/potential applications are included to offer a concise and clear overview of each device.

Table 1.

Comparison among the nanosheet-based wearable batteries based on different nanosheets

| Classification of nanosheet-based wearable batteries | Nanosheet materials | Modification/functionalization/fabrication | Capacity/specific capacity | Cyclic behaviors and capacity retention | Energy density | Ref |

|---|---|---|---|---|---|---|

| Li-ion batteries | Titanium oxide | Hybridized with reduced graphene oxide | 89 mAh g−1 at 0.0425 mA | After 200 cycles at 0.0085 mA, the capacity retention is more than 70% | – | Hoshide et al. (2017) |

| Li-Sulfur batteries | MXene | Combined with S2–4/carbon composite | 1,029.7 mAh g−1 at 0.1 C | After 200 cycles with 91.9% retention | – | Zhao et al. (2019b) |

| Li-air batteries | CuCo2S4 | – | 9,673 mAh g−1 at 100 mA g−1 | Over 164 cycles | – | Long et al. (2019) |

| Zn-ion batteries | V2O5 | Decorated with titanium nitride (TiN) nanowires as a (TiN)@V2O5 three-dimensional nanostructure | 532.9 mAh g−1 | Cyclic performance of more than 3,500 cycles and capacity retention of 90.6% | 373.0 Wh kg−1 | Li et al. (2019b) |

| MoS2 | Expending the layer spacing of MoS2 nanosheets to get E-MoS2 nanosheets | 202.6 mAh g−1 | Over 600 cycles with a capacity retention of 98.6% | 148.2 Wh kg−1 | Li et al. (2019a) | |

| MnO2 | Using lithium treatment to expand the interlayer spacing of MnO2 nanosheets and combined with the carbon cloth (CC) | 3.63 mAh cm−2 at the current density of 3.93 mA cm−2 | Up to 5,000 cycles | 5.11 mWh cm−2 | Zhao et al. (2021) | |

| Zn-air | Co3O4 | An integrated electronic system in a layer-by-layer 2 × 2 structure | 595 mAh g−1 | More than 20 cycles | 573 Wh kg−1 | Qu et al. (2017) |

| N-doped carbon | CoNi alloy nanoparticles and carbon nanotubes decorated N-doped carbon nanosheet arrays on carbon cloth (CoNi alloy/NCNSAs/CC) | 879 mAh g−1 | Over 40 cycles | 98.8 mW cm−2 | Zhang et al. (2020) | |

| RuO2 | N-doped carbon | 802 Wh kg−1 at 5 mA cm−2 | 1,000 cycles | 115 mW cm−2 | Zhao et al. (2020) | |

| Nickel-Fe batteries | Ni(OH)2 | 3D printed | 268.3 mAh g−1 | 91.3% capacity retentions after 10,000 cycles | 28.1 mWh cm−3 at a power of 10.6 mW cm−3 | Kong et al. (2020) |

| NiCoP | Hydrothermal synthesis and pursuant gas phosphating process | 0.294 mAh cm−2 at 2 mA cm−2 | 89% after 4,000 cycles | 235.6 μWh cm−2 | Yang et al. (2020) |

The cyclic behaviors refer to the charging-recharging cycles.

Table 2.

Comparison among the nanosheet-based wearable supercapacitors based on different nanosheets

| Classification of nanosheet-based wearable power supply devices | Nanosheet materials | Modification/functionalization/fabrication | Capacity/specific capacity | Cyclic behaviors with capacity retention | Energy density | Ref |

|---|---|---|---|---|---|---|

| Supercapacitors | Ni(HCO3)2 | Decorating Ni(HCO3)2 nanosheets to flexible PVA/carbon nanotube | – | 85.5% capacitance retention after 2,000 cycles | – | Song et al. (2019) |

| NiCo2S4 | Covering CoS2 nanowires onto NiCo2S4 nanosheets in situ | 168.3 mAh g−1 at 1 A g−1 | 80% capacity retention after 6,000 charge-discharge cycles | 60.2 Wh kg−1 at 800 W kg−1 | Shao et al. (2020) | |

| Depositing on activated carbon cloth | 2392 F g−1 | 85.1% even after 10,000 cycling test | 30.1 Wh kg−1 | Zhao et al. (2019c) | ||

| Fabricated on carbon cloth by a facile multistep solution-based strategy | – | 2,000 cycles | 2.7 mWh cm−3 | Huang et al. (2020) | ||

| NiCo2O4 | Printing MnO2 on the nanosheet-based substrate | – | 93.1% after 5,000 cycles at 50 mA cm−2 | 37.8 mW cm−3, | Sundriyal and Bhattacharya (2020) | |

| Growing on Ni wire | – | 78% at 0.1 mA after 5,000 cycles | 1.44 mWh cm−3 | Wang et al. (2014) | ||

| MnO2 | Doped with NA | 265.4 mF cm−2 | 92.2% after 5,000 cycles at 1 mA cm−2 | 178.4 μWh cm−2 | Zong et al. (2018) | |

| Combined with single-wall carbon nanotubes (SWCNTs) | 74.8 F cm−3 | 94% capacitance retention over 5,000 cycles | 10.4 mWh cm−3 | Li et al. (2018a) | ||

| Ni(OH)2 | Embedded the nanosheets on the carbon nanotubes | 24.8 F cm−3 | 93.8% over 3,000 cycles | 5.8 mWh cm−3 | Shi et al. (2018b) | |

| VGNs | After VGNs growing on ductile nickel wires, MnO2 was deposited on the nanostructure of VGNs/NiWs | 56 mF cm−2 | 80% of its original value after 2,000 cycles | 7.7 mWh cm−2 | Zhou et al. (2021) | |

| MnO | Integrated with NPCTT | – | 86.2% after 5,000 cycles | 176 μWh cm−2 | Ding et al. (2020) | |

| CoNi2S4 | Combined 3D printing with electrodeposition | 28.71 F cm−3 | 92.2% after 5,000 cycles at 500 mA cm−3 | 0.582 mWh cm−3 | Chang et al. (2020) |

The cyclic behaviors refer to the charging-recharging cycles. VGN, vertical graphene nanosheet; NiW, Ni wire; NPCTT, nanoporous carbon tube textile.

Table 3.

Comparison among the nanosheet-based wearable self-powered energy suppliers based on different nanosheets

| Classification of wearable self-powered energy suppliers | Nanosheet materials | Modification/functionalization/fabrication | Output voltage | Output current | Cyclic behaviors | Ref. |

|---|---|---|---|---|---|---|

| Piezoelectric nanogenerators (PENGs) | Graphene | Using electrospun nanocomposite fiber mats comprising graphene nanosheets, barium titanate (BT) nanoparticles, and poly(vinylidene fluoride) (PVDF) | Peak voltage is 112V | – | Over 1,800 cycles for stretch test | Shi et al. (2018a) |

| Applied vertically oriented graphene nanosheets to grow and transfer the aligned single-crystalline GaN nanorods (NRs) | More than 8 V | 1.2 mA | – | Tsai et al. (2018) | ||

| ZnO | On a flexible Al substrate with a low growth temperature of 80°C using synthesis hydrothermal method to prepare the Zn nanosheet networks | 100 mV for a single device | – | – | Manjula et al. (2020) | |

| Two-stage preparation process of 2D ZnO nanosheets | 35 mV | 0.15 μA under the load of 1 kgf | – | Wang et al. (2018) | ||

| Doping Br into the ZnO nanosheets | 17.78 V | 8.89 μA cm−2 | – | Rafique et al. (2021) | ||

| Doping vanadium into ZnO nanosheets | 1.5V | 80 NA | Over 10,000 cycles for bend test | Zhang et al. (2018a) | ||

| Triboelectric nanogenerators (TENGs) | Au | Au nanosheets embedded into both PDMS matrix and micropyramid-patterned PDMS | 98.9 V | – | Over 10,000 cycles in stretch test | Lim et al. (2017a) |

| MoS2 | MoS2 nanosheets were wrapped the silver nanowires (AgNWs) | 95.8V at a 30 Hz frequency | – | Over 10,000 cycles for stretch test | Lan et al. (2019) | |

| MXene | Integrating the poly(vinyl alcohol) (PVA) with MXene nanosheets | 117.7 V | – | 124,000 cycles for contact test | Jiang et al. (2019) | |

| Graphene | Based on polyvinylidene fluoride (PVDF) via graphene nanosheets incorporation in conjunction with electrospinning technology | 1511 V | 189 mA m−2 | 80,000 cycles for contact test | Shi et al. (2021) | |

| Nanosheet-based thermoelectric generators | Metal dichalcogenide (TMDC) | Chemically exfoliated | – | – | Over 100 cycles for stretch test | Oh et al. (2016) |

| Adding highly conducting single-wall carbon nanotubes | – | – | More than 10,000 cycles for stretch test | Kim et al. (2019) | ||

| Nanosheet-based solar cells | CuS | ITO (indium tin oxide)-free and Pt-free flexible quantum-dot solar cells (QDSCs) were assembled into a typical sandwich structure | – | – | 500 cycles for bending test | Xu et al. (2017) |

Figure 10.

Overview of each nanosheet-based battery including advantages/disadvantages and current/future applications

Figure 11.

Overview of each nanosheet-based supercapacitor including its benefits and drawbacks, as well as present/potential uses

Figure 12.

Overview of each nanosheet-based self-powered energy supplier including advantages/disadvantages and current/future applications

Nanosheets, a class of two-dimensional materials, manifest a high surface-to-volume ratio, and thus more conducive and electrocatalyst sites. Therefore, the conductivity of distinct kinds of nanosheets is always high and the application of nanosheet can minimize the size of wearable power supply devices. Nanosheets possess the highest possible specific surface area among nanomaterials and are the key materials to form the 3D nanostructures, both of which make nanosheets the optimal basic materials for power supply applications. By applying nanosheets as the basic materials for wearable power supply devices and combining nanosheets with plenty of zero-dimensional nanoparticles, one-dimensional nanowires, nanotubes, as well as nanorods to form three-dimensional nanostructures, the power storage and supply performance of all wearable power supply devices will dramatically increase.

The nanosheet-based wearable batteries exhibit satisfactory cyclic stability, lightweight, and better energy density than other power supply devices like supercapacitors. As a result, the nanosheet-based wearable batteries are the optimal choice for the application that need less charge-discharge times and long-term duration for one time use, e.g., wearable smart watches and earphones, as well as the application with the requirement of large power consumption like Google glasses and VR/AR glasses. However, safety is a crucial issue for wearable nanosheet-based batteries considering that they are always mounted on human skin. Therefore, supercapacitors with nontoxic aqueous electrolytes can act as an alternative choice. Although the energy density of the nanosheet-based wearable supercapacitors is lower than that of batteries, the charge-discharge cyclic behaviors of nanosheet-based wearable supercapacitors are much better than those of nanosheet-based wearable batteries and the charging time is faster, which makes nanosheet-based wearable supercapacitors more suitable for the electronic device applications with shorter duration for one time and the requirements of multiple uses, e.g., wearable sensors. The limited energy density for nanosheet-based wearable batteries and supercapacitors can be modified by combining them with nanosheet-based self-powered energy suppliers including TENG, PENG, thermoelectric generators, and solar cells. The power obtained by self-powered energy suppliers is not continuous and the energy harvested is always not enough, both of which lead to the limited application of the nanosheet-based self-powered energy suppliers toward the wearable electronic devices with low-energy consumption and long internal time between uses.

To be specific, LIBs are the market-leading classification of distinct batteries. Zn-based batteries based on nanosheets also attract great attention, as compared with Li, Zn is abundant, safe, and environmentally friendly. Besides Li-based and Zn-based batteries, other batteries, e.g., Ni-Fe batteries, are also attempted to achieve wearability owing to their high cycling stability. When it comes to the nanosheet-based wearable supercapacitors, NiCo2S4 nanosheets and NiCo2O4 nanosheets are the most applied nanosheet materials for the wearable solid-state supercapacitors owing to their prominent electrochemical performance, redox activity, and capacity values. Compared with conventional solid-state supercapacitors, fiber-shaped supercapacitors are more intriguing owing to their better flexibility and smaller volume and are thus easier for wearability. The applied nanosheets include MoS2 nanosheets, MnO2 nanosheets, Ni(OH)2 nanosheets, and vertical graphene nanosheets. TENGs and PENGs are the most widely applied self-powered energy suppliers. For wearable PENGs, ZnO nanosheets and graphene are the two of the welcome basic nanosheet materials, whereas for wearable TENGs, researchers select Au nanosheets, MoS2 nanosheets, MXene nanosheets, and graphene nanosheets as the basic nanosheet materials. Besides nanogenerators that work by mechanical energy conversion, there exist some researches toward thermoelectric generators based on nanosheets, e.g., dichalcogenide (TMDC) nanosheets. The nanosheet-based wearable solar cell is another hot research target for self-powered energy suppliers as solar energy is an abundant, green, and inexhaustible energy resource. However, the mechanical strength and electrical conductivity of nanosheet-based wearable solar cells need further improvement to be commercialized.

From a prospective view, nanotechnology is enabling the development of devices on a scale ranging from one to a few hundred nanometers. At the scale, the novel nanosheets show new properties and behaviors not observed at the microscopic level. In the future, with the development of wearable power supply devices based on nanosheets, networks of nanodevices with the ability of biomedicine, environmental protection, entertainment, homeland security, and beyond will play a significant role in almost every field of our society. Moreover, researchers will develop more nanosheet materials with better properties to make the nanosheets more suitable in power supply applications. As for the wearable batteries based on nanosheets, the technique should be improved and novel nanosheet materials used should be developed to improve the cyclic behaviors and capacity retention, while energy density needs to be enhanced for the wearable supercapacitors. Among the wearable power supply devices, wearable self-powered energy suppliers based on nanosheets hold the brightest future as by means of application of wearable self-powered energy suppliers, the wearable devices can be self-powered and thus low cost, facile, and environmentally friendly. Furthermore, with the development of technology, wearable batteries and supercapacitors can be applied together with wearable self-powered energy suppliers to store the extra energy not used by wearable devices. The combination of wearable nanosheet-based batteries/supercapacitors and self-powered energy suppliers is expected to be the future development trend as self-powered, consistent, and sufficient power supply devices are badly required for all types of wearable/unwearable electronic devices and the realization of the Internet of Things. This field will be the focus of a vast number of studies.

However, there are still some challenges that need to be overcome for the practical application of wearable power supply devices. First of all, nanosheet materials are quite expensive, which prevents the nanosheet-based power supply device from further commercialization. To solve this problem, novel nanosheets with low cost and satisfactory properties should be built and a one-step, facile, and low-cost nanosheet production process should be developed. In addition, the energy storage of nanosheet-based batteries and supercapacitors is limited. The frequent charge or replacement will bring inconvenience for users. Therefore, improving the energy capacity and combining it with wearable self-powered energy suppliers were optimal solutions. The power supply of wearable self-powered energy suppliers based on nanosheets is unstable, which also indicates that the combination of wearable nanosheet-based batteries, supercapacitors as well as self-powered energy suppliers must be the future trend. Besides, the power supply of the self-powered energy suppliers needs to be improved a lot to make it possible for applications with large power consumption.

Acknowledgments

This research was funded by the National Natural Science Foundation of China (No. 51805469), the Natural Science Foundation of Zhejiang Province of China (No. LQ20E090008), and Science and technology plan project of drug regulatory system of Zhejiang province (No. 2020016).

Author contributions

S.Z. and C.L. did most writing for the manuscript and literature studying. S.M. assisted partially in writing and literature searching. C.Y. and J.B. provided the guidance and framework of the study. Q.X. and W.Y. supervised the manuscript process.

Declaration of interests

The authors declare no conflict of interest.

References

- Alam H., Ramakrishna S. A review on the enhancement of figure of merit from bulk to nano-thermoelectric materials. Nano Energy. 2013;2:190–212. [Google Scholar]

- Almusawi H.A., Durugbo C.M., Bugawa A.M. Innovation in physical education: teachers’ perspectives on readiness for wearable technology integration. Comput. Educ. 2021;167:104185. [Google Scholar]

- An T.C., Cheng W.L. Recent progress in stretchable supercapacitors. J. Mater. Chem. A. 2018;6:15478–15494. [Google Scholar]

- Arbab A.A., Ali M., Memon A.A., Sun K.C., Choi B.J., Jeong S.H. An all carbon dye sensitized solar cell: a sustainable and low-cost design for metal free wearable solar cell devices. J. Colloid Interf. Sci. 2020;569:386–401. doi: 10.1016/j.jcis.2020.02.078. [DOI] [PubMed] [Google Scholar]

- Augustyn V., Simon P., Dunn B. Pseudocapacitive oxide materials for high-rate electrochemical energy storage. Energ Environ. Sci. 2014;7:1597–1614. [Google Scholar]

- Beniczky S., Wiebe S., Jeppesen J., Tatum W.O., Brazdil M., Wang Y., Herman S.T., Ryvlin P. Automated seizure detection using wearable devices: a clinical practice guideline of the international league against epilepsy and the international federation of clinical neurophysiology. Clin. Neurophysiol. 2021;132:1173–1184. doi: 10.1016/j.clinph.2020.12.009. [DOI] [PubMed] [Google Scholar]

- Blanc L.E., Kundu D., Nazar L.F. Scientific challenges for the implementation of Zn-Ion batteries. Joule. 2020;4:771–799. [Google Scholar]

- Brezesinski T., Wang J., Tolbert S.H., Dunn B. Ordered mesoporous alpha-MoO3 with iso-oriented nanocrystalline walls for thin-film pseudocapacitors. Nat. Mater. 2010;9:146–151. doi: 10.1038/nmat2612. [DOI] [PubMed] [Google Scholar]

- Buscema M., Barkelid M., Zwiller V., van der Zant H.S.J., Steele G.A., Castellanos-Gomez A. Large and tunable photothermoelectric effect in single-layer MoS2. Nano Lett. 2013;13:358–363. doi: 10.1021/nl303321g. [DOI] [PubMed] [Google Scholar]

- Careta O., Fornell J., Pellicer E., Ibanez E., Blanquer A., Esteve J., Sort J., Murillo G., Nogues C. ZnO nanosheet-coated TiZrPdSiNb alloy as a piezoelectric hybrid material for self-stimulating orthopedic implants. Biomedicines. 2021;9:352. doi: 10.3390/biomedicines9040352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chang P., Mei H., Tan Y., Zhao Y., Huang W., Cheng L. A 3D-printed stretchable structural supercapacitor with active stretchability/flexibility and remarkable volumetric capacitance. J. Mater. Chem. A. 2020;8:13646–13658. [Google Scholar]

- Chi X., Li M., Di J., Bai P., Song L., Wang X., Li F., Liang S., Xu J., Yu J. A highly stable and flexible zeolite electrolyte solid-state Li-air battery. Nature. 2021;592:551–557. doi: 10.1038/s41586-021-03410-9. [DOI] [PubMed] [Google Scholar]

- Conway B.E. Springer; 2013. Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications. [Google Scholar]

- De Juan-Corpuz L.M., Corpuz R.D., Somwangthanaroj A., Nguyen M.T., Yonezawa T., Ma J., Kheawhom S. Binder-free centimeter-long V2O5 nanofibers on carbon cloth as cathode material for zinc-ion batteries. Energies. 2019;13:31. doi: 10.3390/ijms21093113. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ding Y., Tang S., Han R., Zhang S., Pan G., Meng X. Iron oxides nanobelt arrays rooted in nanoporous surface of carbon tube textile as stretchable and robust electrodes for flexible supercapacitors with ultrahigh areal energy density and remarkable cycling-stability. Sci. Rep. 2020;10:11023. doi: 10.1038/s41598-020-68032-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Faruk M.O., Ahmed A., Jalil M.A., Islam M.T., Shamim A.M., Adak B., Hossain M.M., Mukhopadhyay S. Functional textiles and composite based wearable thermal devices for Joule heating: progress and perspectives. Appl. Mater. Today. 2021;23:101025. [Google Scholar]

- Gao J., Shang K., Ding Y., Wen Z. Material and configuration design strategies towards flexible and wearable power supply devices: a review. J. Mater. Chem. A. 2021;9:8950–8965. [Google Scholar]

- Gao S.Y., Chen Y., Su J.Z., Wang M., Wei X.J., Jiang T., Wang Z.L. Triboelectric nanogenerator powered electrochemical degradation of organic pollutant using Pt-free carbon materials. Acs Nano. 2017;11:3965–3972. doi: 10.1021/acsnano.7b00422. [DOI] [PubMed] [Google Scholar]

- Guo S., Yang D., Zhang S., Dong Q., Li B., Tran N., Li Z., Xiong Y., Zaghloul M.E. Development of a cloud-based epidermal MoSe2 device for hazardous gas sensing. Adv. Funct. Mater. 2019;29:1900138. [Google Scholar]

- He B., Zhou Z., Man P., Zhang Q., Li C., Xie L., Wang X., Li Q., Yao Y. V2O5 nanosheets supported on 3D N-doped carbon nanowall arrays as an advanced cathode for high energy and high power fiber-shaped zinc-ion batteries. J. Mater. Chem. A. 2019;7:12979–12986. [Google Scholar]

- He W., Fu X., Zhang D., Zhang Q., Zhuo K., Yuan Z., Ma R. Recent progress of flexible/wearable self-charging power units based on triboelectric nanogenerators. Nano Energy. 2021;84:105880. [Google Scholar]

- Hoshide T., Zheng Y., Hou J., Wang Z., Li Q., Zhao Z., Ma R., Sasaki T., Geng F. A flexible lithium-ion fiber battery by regularly stacking two-dimensional titanium oxide nanosheets hybridized with reduced graphene oxide. Nano Lett. 2017;17:3543–3549. doi: 10.1021/acs.nanolett.7b00623. [DOI] [PubMed] [Google Scholar]

- Huang J.J., Xie J.L., Wang L., Zhang J., Wang P.J., Sun P.H., Yao Z.J., Yang Y.F. Boosted electrochemical performance of honeycomb-like NiCu-LDH nanosheets anchoring on NiCo2S4 Nanotube arrays for flexible solid-state hybrid supercapacitors. Energ Fuel. 2020;34:13157–13166. [Google Scholar]

- Huifeng W., Kadry S.N., Raj E.D. Continuous health monitoring of sportsperson using IoT devices based wearable technology. Comput. Commun. 2020;160:588–595. [Google Scholar]

- Javed M.S., Lei H., Wang Z., Liu B.-t., Cai X., Mai W. 2D V2O5 nanosheets as a binder-free high-energy cathode for ultrafast aqueous and flexible Zn-ion batteries. Nano Energy. 2020;70:104573. [Google Scholar]

- Jiang C., Wu C., Li X., Yao Y., Lan L., Zhao F., Ye Z., Ying Y., Ping J. All-electrospun flexible triboelectric nanogenerator based on metallic MXene nanosheets. Nano Energy. 2019;59:268–276. [Google Scholar]

- Jin X., Gu T.-H., Lee K.-G., Kim M.J., Islam M.S., Hwang S.-J. Unique advantages of 2D inorganic nanosheets in exploring high-performance electrocatalysts: synthesis, application, and perspective. Coord. Chem. Rev. 2020;415:213280. [Google Scholar]

- Jun J.H., Song H., Kim C., Choi I.S., Jeong Y., Lee J.H. Carbon-nanosheet based large-area electrochemical capacitor that is flexible, foldable, twistable, and stretchable. Small. 2018;14:1702145. doi: 10.1002/smll.201702145. [DOI] [PubMed] [Google Scholar]

- Kang H., Kim H.T., Woo H.J., Kim H., Kim D.H., Lee S., Kim S., Song Y.J., Kim S.-W., Cho J.H. Metal nanowire–polymer matrix hybrid layer for triboelectric nanogenerator. Nano Energy. 2019;58:227–233. [Google Scholar]

- Karan S.K., Bera R., Paria S., Das A.K., Maiti S., Maitra A., Khatua B.B. An approach to design highly durable piezoelectric nanogenerator based on self-poled PVDF/AlO-rGO flexible nanocomposite with high power density and energy conversion efficiency. Adv. Energy Mater. 2016;6:1601016. [Google Scholar]

- Khetan A., Luntz A., Viswanathan V. Trade-offs in capacity and rechargeability in nonaqueous Li-O2 batteries: solution-driven growth versus nucleophilic stability. J. Phys. Chem. Lett. 2015;6:1254–1259. doi: 10.1021/acs.jpclett.5b00324. [DOI] [PubMed] [Google Scholar]

- Kim J.Y., Oh J.Y., Il Lee T. Multi-dimensional nanocomposites for stretchable thermoelectric applications. Appl. Phys. Lett. 2019;114:043902. [Google Scholar]

- Kim Y., Lee K.Y., Hwang S.K., Park C., Kim S.W., Cho J. Layer-by-layer controlled perovskite nanocomposite thin films for piezoelectric nanogenerators. Adv. Funct. Mater. 2014;24:6262–6269. [Google Scholar]

- Kim Y., Samuel E., Joshi B., Park C., Lee H.-S., Yoon S.S. Flexible metallized carbon nanofibers decorated with two-dimensional NiGa2S4 nanosheets as supercapacitor electrodes. Chem. Eng. J. 2021;420:130497. [Google Scholar]

- Kong D.Z., Wang Y., Huang S.Z., Zhang B., Lim Y.V., Sim G.J., Alvarado P.V.Y., Ge Q., Yang H.Y. 3D printed compressible quasi-solid-state nickel-iron battery. Acs Nano. 2020;14:9675–9686. doi: 10.1021/acsnano.0c01157. [DOI] [PubMed] [Google Scholar]

- Ku N.J., Liu G.C., Wang C.H., Gupta K., Liao W.S., Ban D.Y., Liu C.P. Optimal geometrical design of inertial vibration DC piezoelectric nanogenerators based on obliquely aligned InN nanowire arrays. Nanoscale. 2017;9:14039–14046. doi: 10.1039/c7nr04689h. [DOI] [PubMed] [Google Scholar]

- Lan L., Yin T., Jiang C., Li X., Yao Y., Wang Z., Qu S., Ye Z., Ping J., Ying Y. Highly conductive 1D-2D composite film for skin-mountable strain sensor and stretchable triboelectric nanogenerator. Nano Energy. 2019;62:319–328. [Google Scholar]

- Larcher D., Tarascon J.M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015;7:19–29. doi: 10.1038/nchem.2085. [DOI] [PubMed] [Google Scholar]

- Li G.-X., Hou P.-X., Luan J., Li J.-C., Li X., Wang H., Shi C., Liu C., Cheng H.-M. A MnO2 nanosheet/single-wall carbon nanotube hybrid fiber for wearable solid-state supercapacitors. Carbon. 2018;140:634–643. [Google Scholar]

- Li H., Yang Q., Mo F., Liang G., Liu Z., Tang Z., Ma L., Liu J., Shi Z., Zhi C. MoS2 nanosheets with expanded interlayer spacing for rechargeable aqueous Zn-ion batteries. Energy Storage Mater. 2019;19:94–101. [Google Scholar]

- Li Q., Zhang Q., Liu C., Zhou Z., Li C., He B., Man P., Wang X., Yao Y. Anchoring V2O5 nanosheets on hierarchical titanium nitride nanowire arrays to form core–shell heterostructures as a superior cathode for high-performance wearable aqueous rechargeable zinc-ion batteries. J. Mater. Chem. A. 2019;7:12997–13006. [Google Scholar]

- Li X., Chen X., Zhao Y., Deng Y., Zhu J., Jiang S., Wang R. Flexible all-solid-state supercapacitors based on an integrated electrode of hollow N-doped carbon nanofibers embedded with graphene nanosheets. Electrochimica Acta. 2020;332:135398. [Google Scholar]

- Li X., Lu Y., Fu X., Qi Y. Building the internet of things platform for smart maternal healthcare services with wearable devices and cloud computing. Fut. Gener. Comput. Syst. 2021;118:282–296. [Google Scholar]

- Li Y., Lu J. Metal–air batteries: will they be the future electrochemical energy storage device of choice? ACS Energy Lett. 2017;2:1370–1377. [Google Scholar]

- Li Y., Zhong C., Liu J., Zeng X., Qu S., Han X., Deng Y., Hu W., Lu J. Atomically thin mesoporous Co3 O4 layers strongly coupled with N-rGO nanosheets as high-performance bifunctional catalysts for 1d knittable zinc-air batteries. Adv. Mater. 2018;30:1703657. doi: 10.1002/adma.201703657. [DOI] [PubMed] [Google Scholar]

- Liang X., Long G., Fu C., Pang M., Xi Y., Li J., Han W., Wei G., Ji Y. High performance all-solid-state flexible supercapacitor for wearable storage device application. Chem. Eng. J. 2018;345:186–195. [Google Scholar]

- Lim G.-H., Kwak S.S., Kwon N., Kim T., Kim H., Kim S.M., Kim S.-W., Lim B. Fully stretchable and highly durable triboelectric nanogenerators based on gold-nanosheet electrodes for self-powered human-motion detection. Nano Energy. 2017;42:300–306. [Google Scholar]

- Lim L., Liu Y., Liu W., Tjandra R., Rasenthiram L., Chen Z., Yu A. All-in-one graphene based composite fiber: toward wearable supercapacitor. ACS Appl. Mater. Inter. 2017;9:39576–39583. doi: 10.1021/acsami.7b10182. [DOI] [PubMed] [Google Scholar]

- Liu C., Zhang B., Chen W., Liu W., Zhang S. Current development of wearable sensors based on nanosheets and applications. Trac Trends Anal. Chem. 2021;143:116334. [Google Scholar]

- Liu L., Yu Y., Yan C., Li K., Zheng Z. Wearable energy-dense and power-dense supercapacitor yarns enabled by scalable graphene-metallic textile composite electrodes. Nat. Commun. 2015;6:7260. doi: 10.1038/ncomms8260. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Y., Pharr M., Salvatore G.A. Lab-on-skin: a review of flexible and stretchable electronics for wearable health monitoring. Acs Nano. 2017;11:9614–9635. doi: 10.1021/acsnano.7b04898. [DOI] [PubMed] [Google Scholar]

- Liu Z., Li H., Shi B., Fan Y., Wang Z.L., Li Z. Wearable and implantable triboelectric nanogenerators. Adv. Funct. Mater. 2019;29:1808820. [Google Scholar]

- Long J., Hou Z., Shu C., Han C., Li W., Huang R., Wang J. Free-standing three-dimensional CuCo2S4 nanosheet array with high catalytic activity as an efficient oxygen electrode for lithium-oxygen batteries. ACS Appl. Mater. Inter. 2019;11:3834–3842. doi: 10.1021/acsami.8b15699. [DOI] [PubMed] [Google Scholar]

- Lu W., Yu P., Jian M., Wang H., Wang H., Liang X., Zhang Y. Molybdenum disulfide nanosheets aligned vertically on carbonized silk fabric as smart textile for wearable pressure-sensing and energy devices. ACS Appl. Mater. Inter. 2020;12:11825–11832. doi: 10.1021/acsami.9b21068. [DOI] [PubMed] [Google Scholar]

- Ma Y.J., Jang K.I., Wang L., Jung H.N., Kwak J.W., Xue Y.G., Chen H., Yang Y.Y., Shi D.W., Feng X., et al. Design of strain-limiting substrate materials for stretchable and flexible electronics. Adv. Funct. Mater. 2016;26:5345–5351. doi: 10.1002/adfm.201600713. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Man P., Zhang Q.C., Zhou Z.Y., Chen M.X., Yang J., Wang Z., Wang Z.X., He B., Li Q.L., Gong W.B., et al. Engineering MoS(2)nanosheets on spindle-like alpha-Fe(2)O(3)as high-performance core-shell pseudocapacitive anodes for fiber-shaped aqueous lithium-ion capacitors. Adv. Funct. Mater. 2020;30:2003967. [Google Scholar]

- Manjula Y., Rakesh Kumar R., Swarup Raju P.M., Anil Kumar G., Venkatappa Rao T., Akshaykranth A., Supraja P. Piezoelectric flexible nanogenerator based on ZnO nanosheet networks for mechanical energy harvesting. Chem. Phys. 2020;533:110699. [Google Scholar]

- Manthiram A. An outlook on lithium ion battery technology. ACS Cent. Sci. 2017;3:1063–1069. doi: 10.1021/acscentsci.7b00288. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mei J., Liao T., Sun Z. Two-dimensional metal oxide nanosheets for rechargeable batteries. J. Energy Chem. 2018;27:117–127. [Google Scholar]