Abstract

Natural biopolymers, polymeric organic molecules produced by living organisms and/or renewable resources, are considered greener, sustainable, and eco-friendly materials. Natural polysaccharides comprising cellulose, chitin/chitosan, starch, gum, alginate, and pectin are sustainable materials owing to their outstanding structural features, abundant availability, and nontoxicity, ease of modification, biocompatibility, and promissing potentials. Plentiful polysaccharides have been utilized for making assorted (nano)catalysts in recent years; fabrication of polysaccharides-supported metal/metal oxide (nano)materials is one of the effective strategies in nanotechnology. Water is one of the world’s foremost environmental stress concerns. Nanomaterial-adorned polysaccharides-based entities have functioned as novel and more efficient (nano)catalysts or sorbents in eliminating an array of aqueous pollutants and contaminants, including ionic metals and organic/inorganic pollutants from wastewater. This review encompasses recent advancements, trends and challenges for natural biopolymers assembled from renewable resources for exploitation in the production of starch, cellulose, pectin, gum, alginate, chitin and chitosan-derived (nano)materials.

Keywords: Polysaccharides, Sustainable nanomaterials, Wastewater treatment, Degradation, Organic dyes, Heavy metals, Pollutants

1. Introduction

Water is one of the world’s foremost environmental stress concerns; the supply of safe, affordable drinking and/or clean water is a massively challenging proposition throughout the world. Rapidly escalating environmental contamination of natural resources is an emerging issue in recent years that needs to be tackled on priority basis for sustaining the earth and its inhabitants for future generations. Indeed, resources of freshwater are limited and they are deteriorating fast due to the discharge of untreated or inadequately-treated wastewaters. Traditionally, coagulation/flocculation, ion exchange, floatation, reverse osmosis, oxidation, adsorption, membrane separation, ultra-filtration, sedimentation, electro-precipitation, and advanced oxidation processes are mainly resorted to as the accessible technologies in treating waste-water. Conventional methods of wastewater treatment and purification cannot possibly yield the desired extent of purification to attain accurate or cost-effective discharge standards (Khoramzadeh, Nasernejad, & Halladj, 2013; Nasrollahzadeh, Sajjadi, Dasmeh, & Sajadi, 2018; Yargıç, Şahin, Özbay, & Önal, 2015).

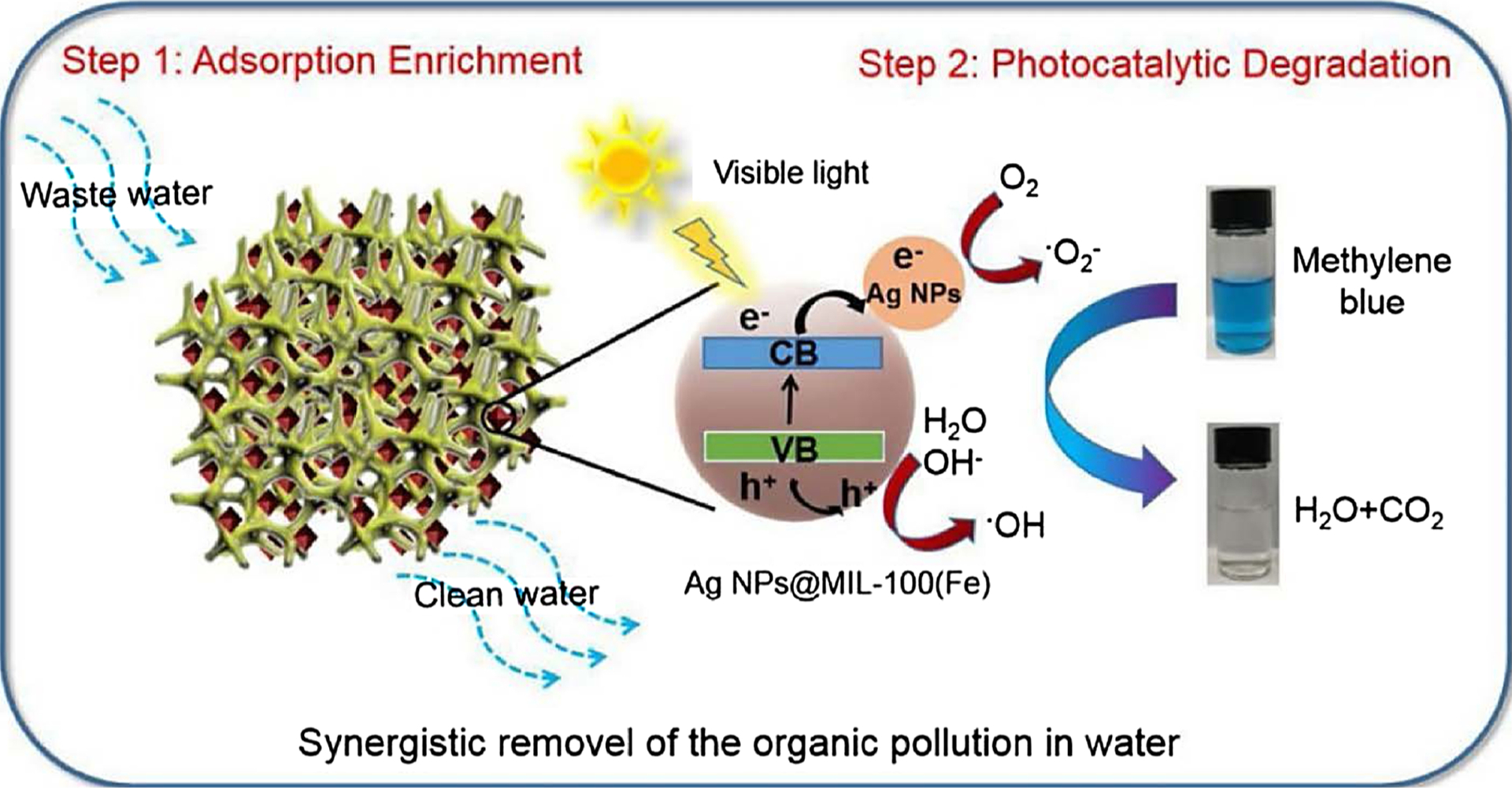

Beyond the stoichiometric use of reagents, catalysis is one of the most important foundation of “green chemistry” with novel processing systems and deployment of assorted novel catalysts with many benefits in terms of product selectivity, process utilization, energy reduction as well as the utilization of safer materials and alternative reaction media/conditions. Novel wastewater treatment approaches such as UV photolysis/photocatalysis, activated carbon adsorption, ozonation, and perovskite adsorption, among others can be utilized for the degradation of pharmaceutically active compounds, metal ions, and toxic dyes (Cai et al., 2018; Garba, Xiao et al., 2019; Garba, Zhou, Zhang, & Yuan, 2020; Karnib, Kabbani, Holail, & Olama, 2014; Xu, Nasrollahzadeh, Sajjadi et al., 2019). Interestingly, the expensive energy-intensive commercially-activated carbons applied for this goal can be effectively replaced by renewable alternatives and low-cost biosorbents that are based on natural biopolymers (Crini, 2006; Xu, Nasrollahzadeh, Sajjadi et al., 2019). In general, the development of ‘greener’ and eco-friendly treatment technologies must be perceived as a key element for the industries dealing with toxic, hazardous and chemically laden wastewater (Atarod, Nasrollahzadeh, & Sajadi, 2015; Hatamifard, Nasrollahzadeh, & Lipkowski, 2015; Hatamifard, Nasrollahzadeh, & Sajadi, 2016; Iravani & Varma, 2020a; Khodadadi, Bordbar, & Nasrollahzadeh, 2017; Khodadadi, Bordbar, & Nasrollahzadeh, 2017; Maryami, Nasrollahzadeh, Mehdipour, & Sajadi, 2016; Nasrollahzadeh, Bagherzadeh, & Karimi, 2016; Nasrollahzadeh, Sajadi, & Maham, 2016; Omidvar, Jaleh, & Nasrollahzadeh, 2017; Sharma, Zboril, & Varma, 2015; Sivan et al., 2019; Varma, 2014; Zhang, Yu et al., 2018; Zhang, Hou et al., 2018).

Among the greener technologies, the synthesis of natural (nano) catalysts with lower costs, and enhanced efficiency has been a focus area for the treatment of wastewater pollutants as exemplified by nanoscale filtration procedures and the adsorption of pollutants by metal/metal oxide based nanoparticles (NPs) (Ai, Yue, & Jiang, 2012; Crini, 2006; Meng, Zhu, Choi, Park, & Oh, 2011; Nasrollahzadeh, Baran et al., 2020; Nasrollahzadeh, Sajjadi, Dasmeh et al., 2018; Xu, Nasrollahzadeh, Sajjadi et al., 2019; Zhang, Sèbe, Rentsch, Zimmermann, & Tingaut, 2014). The utilization of nanostructures with unique features namely large surface area, significant chemical reactivity, cost-effectiveness, and lower power consumption, can meaningfully exploit multifunctional nanosystems that enable particle retention and removal/elimination of pollutants.

Over the decades, the accessibility of synthetic polymers derived from gas, petroleum, and nonrenewable carbon sources is diminishing as researchers are exploring more readily available and sustainable alternatives, namely, natural biopolymer-derived materials from renewable resources. Natural biopolymers are polymeric organic molecules acquired from renewable resources (alga, plants, microbial biomass and animals) comprising monomeric parts that are bonded covalently to form larger molecules (Baran & Nasrollahzadeh, 2020; Den, Sharma, Lee, Nadadur, & Varma, 2018; Hebbalalu, Lalley, Nadagouda, & Varma, 2013; Iravani & Varma, 2020b; Mohazzab et al., 2020; Motahharifar, Nasrollahzadeh, Taheri-Kafrani, Varma, & Shokouhimehr, 2020; Nasrollahzadeh, Shafiei, Nezafat, & Bidgoli, 2020; Nasrollahzadeh, Issaabadi, & Varma, 2019). They represent a highly promising option for the generation of sustainable materials owing to their extraordinary structural and physical features, safety, availability, and economics; biocompatibility and the biodegradability of these natural resources can enhance their utilization as nanocatalysts and nanosorbents. Low-cost biopolymers such as polysaccharides are diverse in size, structure, and molecular chains, making them attractive candidates for stabilization and immobilization and the reduction of NPs; biopolymer-based (nano) catalysts can be immobilized on their uniquely featured reactive groups to enhance (nano)catalytic efficiency and stability (Crini, 2005; Kumar, 2000; Oladoja, Adelagun, Ahmad, Unuabonah, & Bello, 2014; Xu, Nasrollahzadeh, Sajjadi et al., 2019; Xu, Nasrollahzadeh, Selva, Issaabadi, & Luque, 2019). The salient advantageous features for the utilization of polysaccharide supports include the release of nanostructures during operations, the prevention of aggregation, the ease of recovery of catalytic materials, and importantly, improving the photocatalytic efficiency compared to the conventional slurry systems.

Pollution generated by dyes, heavy metals, nitroarenes, and pesticides in water/wastewater is a global major problem; in particular, the dye effluents are identified as largest class of industrial colorants and significant threat to aquatic environments as the discarded dyes seriously affect humans and flora/fauna (Albukhari, Ismail, Akhtar, & Danish, 2019; Khan et al., 2016; Sajjadi et al., 2020). Toxic dyes/nitroarenes are hazardous, biologically and chemically stable, non-biodegradable and water soluble organic contaminants that are responsible for a diversity of human diseases e.g. kidney failure, skin irritation, nervous system damage, liver disease, etc. (Chamjangali, Bagherian, Javid, Boroumand, & Farzaneh, 2015; Dai et al., 2009; Mazaheri, Ghaedi, Azqhandi, & Asfaram, 2017; Nasrollahzadeh, Nezafat, Gorab, & Sajjadi, 2020). The main sources of contamination from dyes have their origin in diverse industries, namely coloration of textiles, inks, paints, paper, plastics, dye sensitized solar cells, energy transfer cascades, display devices, light emitting diodes, laser welding processes, as well as food and/or cosmetic dyes which are particularly derived from azo dyes (Sannino, Vaiano, Sacco, & Ciambelli, 2013; Singh & Arora, 2011). Textile dye effluents are generally present as a mixture of several dyes in diverse percentages depending on the factory schedule, and the extent of dye fixation on a fabric (Yaseen & Scholz, 2018). Consequently, the removal of such admixed dyes (in diverse concentration levels and mixing ratios) in wastewaters is extremely vital. The development/improvement of novel eco-friendly treatment approaches should be considered as a critical element for the industries generating toxic and hazardous chemical-laden wastewater.

Generally, polysaccharide derivatives showed high removal efficiency of both inorganic (e.g. heavy metal ions) and organic (e.g. dyes, nitroarenes, and pesticide formulations) pollutants via adsorption, reduction/degradation and coagulation/flocculation methods (Kanmani, Aravind, Kamaraj, Sureshbabu, & Karthikeyan, 2017; Sajjadi, Nasrollahzadeh, & Tahsili, 2019; Sivan et al., 2019). Among these, adsorption can be considered as a good option for the removal of the hazardous organic contaminants, since it can be simply deployed thus avoiding the formation of various toxic intermediates, which gets generated while treating novel organic contaminants in aqueous solutions (Ertas & Uyar, 2017; Ghaedi et al., 2012; Liu et al., 2020). The utilization of biopolymer-based adsorbents is not only restricted to the removal of heavy metals, dyes and nitro compounds, but extends to a range of toxic contaminants including pharmaceuticals (Amouzgar & Salamatinia, 2015), hydrocarbons (Xu, Yong, Lim, & Obbard, 2005), pesticides (Sahithya, Das, & Das, 2015), phosphates (An, Jung, Zhao, Lee, & Choi, 2014), nitrates (Rajeswari, Amalraj, & Pius, 2016), fluo-rides (Jagtap, Yenkie, Labhsetwar, & Rayalu, 2011), perchlorates (Sayed & Jardine, 2015), and radioactive ions (Lu et al., 2016), etc.

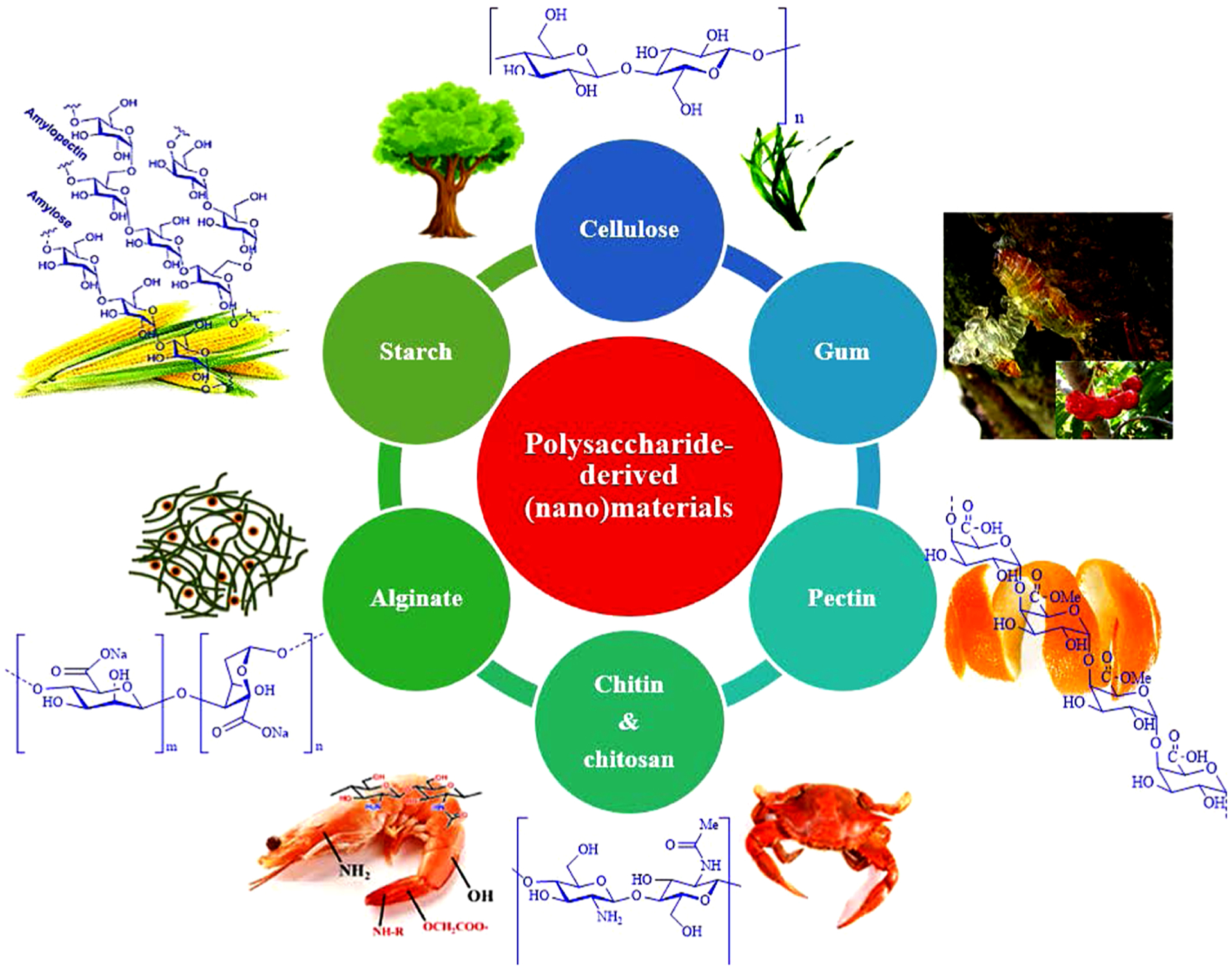

Polysaccharides are sustainable and environmental-friendly organic biopolymers naturally engineered by living organisms and comprise the repeat unit of monosaccharides (Cn(H2O)n). In this respect, chitin/chitosan, cellulose (Ahmad, Ahmed, Swami, & Ikram, 2015; Olivera et al., 2016; Xu, Nasrollahzadeh, Sajjadi et al., 2019), starch (Yusof & Kadir, 2016), pectin (Sharma, Naushad, Pathania, & Kumar, 2016), alginate (Swain, Patnaik, & Dey, 2013; Xu, Nasrollahzadeh, Sajjadi et al., 2019), guar gum (Kee, Mukherjee, & Pariatamby, 2015) and xanthan gum (Kee et al., 2015; Pi et al., 2016) are important examples of sustainable and environmental-friendly organic biopolymers (Fig. 1). Among the polysaccharides, after cellulose (most abundant biopolymer on earth), chitosan, the second most abundant biopolymers have been preferred for broad ranging environmental appliances (Ahmad et al., 2015; Olivera et al., 2016; Xu, Nasrollahzadeh, Sajjadi et al., 2019). Herein, this paper sums up the recent advances in the remediation and elimination of aqueous pollutants and noxious contaminants using some of the most abundant natural biopolymer resources, namely chitin/chitosan, starch, gum, alginate, pectin, and cellulosic (nano)materials.

Fig. 1.

Sustainable and environmental-friendly organic polysaccharides.

2. Polysaccharide derived (nano)catalysts for water treatment

Recently, polysaccharide derived (nano)catalysts have been investigated as heterogeneous and novel catalysts with excellent catalytic prowess for the water treatment. Different applications of polysaccharide derived (nano)catalysts in water treatment are summarized in this section.

2.1. Cellulose-based nanomaterials

2.1.1. Chemistry and properties

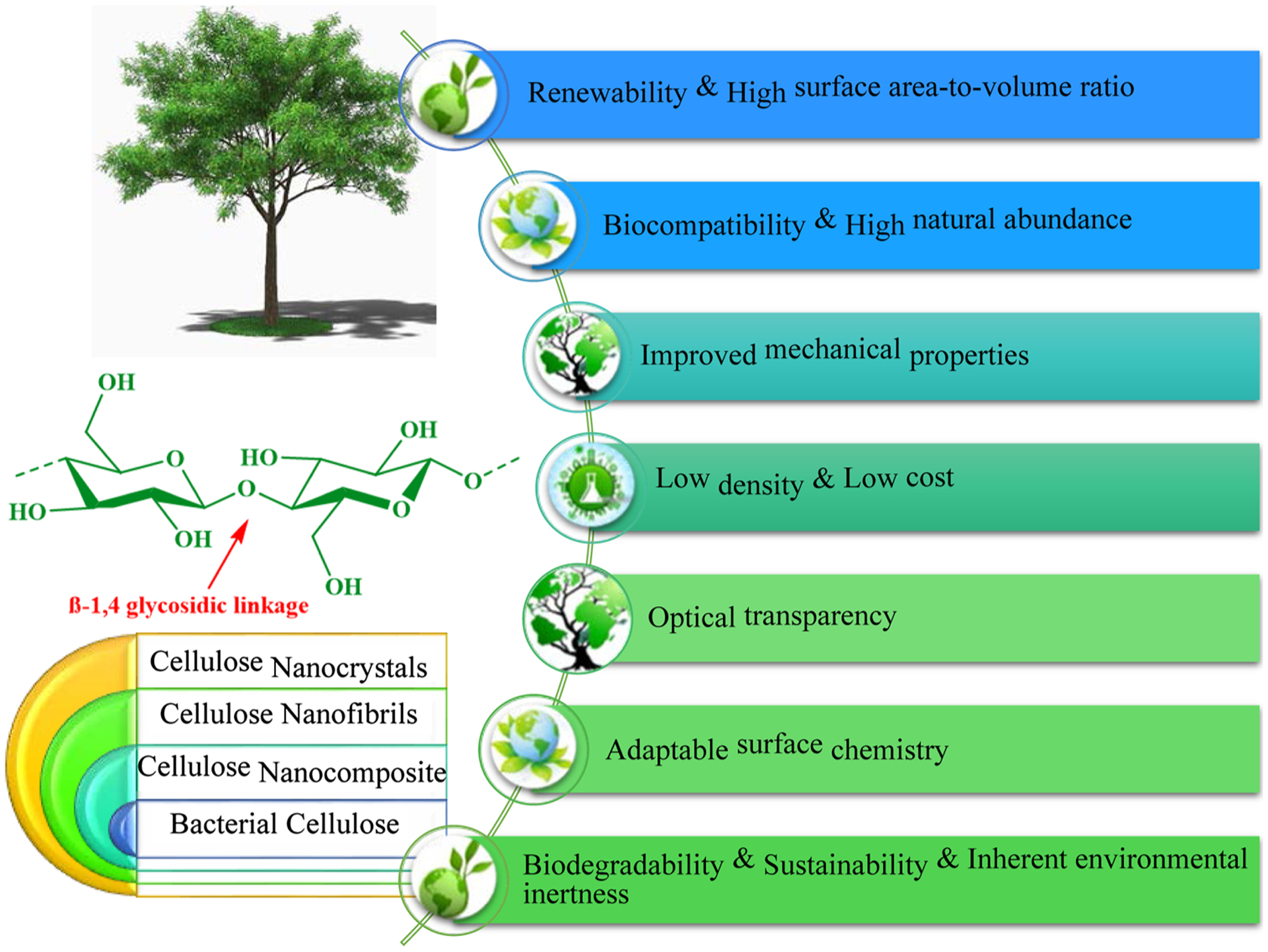

Cellulose-based materials for example, cellulose nanofibrils (CNFs) and nanocrystals (CNCs) have found numerous applications in medicine, bioplastics, barrier films, biomedicine, pharmaceutics, electronics, nanocomposites, membranes, supercapacitors, and cosmetic products. These nanomaterials have garnered substantial interest for deployment as (nano)sorbents because of their unique properties (Fig. 2) (Moon, Martini, Nairn, Simonsen, & Youngblood, 2011; Ray & Shipley, 2015; Trache, Hussin, Haafiz, & Thakur, 2017); cellulose-based adsorbents and their use in water and wastewater treatment have been reviewed (Table 1) (Mohammed, Grishkewich, & Tam, 2018).

Fig. 2.

Significant properties and attributes of cellulosic nanomaterials.

Table 1.

Cellulosic nanomaterial-based adsorbents for the removal of pollutants in water.

| Cellulosic nanomaterial-based adsorbents | Contaminants | Ref. |

|---|---|---|

| β-Cyclodextrin modified CNCs@Fe3O4@SiO2 superparamagnetic nanorods | Procaine, imipramine | (Chen, Berry, & Tam, 2014) |

| PEG modified CNCs | Acetaminophen, sulfamethoxazole, N, N-diethyl-meta-toluamide | (Herrera-Morales et al., 2017) |

| Pristine CNCs | Chlorpyrifos | (Moradeeya et al., 2017) |

| Dialdehyde functionalized CNCs | Creatinine | (Huang, Liu, Sun, & Fatehi, 2016) |

| Poly(acrylic acid) modified poly (glycidylmethacrylate) grafted CNCs | Trypsin | (Anirudhan & Rejeena, 2012) |

| Poly(methacrylic acid-co-vinyl sulfonic acid) grafted magnetic CNCs | Hemoglobin, immunoglobulin G | (Anirudhan & Rejeena, 2013) |

| Aminopropyltriethoxysilane modified, hydroxyl-carbonated apatite modified and Epoxy modified CNFs | Hydrogen sulphide | (Hokkanen, Repo, Bhatnagar, Tang, & Sillanpää, 2014) |

| Carbonated hydroxyapatite modified CNFs | Phosphate, nitrate | (Hokkanen, Repo, Westholm et al., 2014) |

| UiO-66/polydopamine/bacterial cellulose | Aspirin, tetracycline hydrochloride | (Cui et al., 2020) |

| Carboxy methyl cellulose/citric acid aerogel | Nitrate, nitrite, phosphate | (Darabitabar, Yavari, Hedayati, Zakeri, & Yousefi, 2020) |

While the materials have shown demonstrative effectiveness in separating and eliminating various contaminating materials, the environmental influences of modified cellulose nanomaterials should be assessed; their non-toxicity and biodegradability attributes, though suitable for wastewater treatment, need stability evaluation. Sizeable amounts of cellulose nanomaterials are needed for remedial applications, thus their cost, feasibility of access, and life cycle considerations for the large scale manufacturing of these materials must be considered (Shatkin, Wegner, & Neih, 2013) although cellulosic nanomaterials have environmental advantages over activated carbon derived from charcoal. Biochar (obtainable from plant biomass) with its similarity to activated carbon has less functionality than cellulose nanomaterial. Cellulosic nano- and microfibers with suitable dimensions and strength have been used to generate membranes for water management. Membranes have been prepared as pristine cellulose nanomaterial mats as well as from cellulose nanomaterials incorporated into assorted polymer matrices such as cellulose triacetate, polypyrrole, poly(vinylidene fluoride), poly (ethylene oxide), poly(ether sulfone), poly(vinyl alcohol), poly(acrylonitrile), and poly(3-hydroxybutyrate) (Carpenter, de Lannoy, & Wiesner, 2015); they can be applied in membrane distillation, nanofiltration, hemodialysis, microfiltration, and ultrafiltration. The presence of cellulose nanomaterials within polymer matrices can noticeably change the membrane characteristics. For instance, better membrane tensile strength, surface hydrophilicity, superior permeability, resistance to biofouling, and enhanced selectivity can be attained by adding cellulose nanomaterials which are highly biocompatible and eco-friendly and ideally suited for pharmaceutical, biomedical and environmental applications of these nanocomposite membranes (Carpenter et al., 2015; Yin & Deng, 2015); challenge being the application of polymer-cellulose nanocomposites realizing uniform and homogeneous dispersing within polymer matrices (Xie, Mai, & Zhou, 2005). Homo-aggregating cellulose nanomaterials destructively influence the amorphous and semi-crystalline polymers by upsetting the polymer solutions homogeneity (Varma, 2016).

2.1.2. Applications for water treatment

2.1.2.1. Removal of oil and organic solvents.

Cellulose is an ideal adsorbent due to its low-cost and abundance relative to commercial ion exchange sorbents. Although unmodified cellulose lacks certain properties to be applied as an effective adsorbent, namely variable physical stabilities and low heavy metal adsorption capacities (O’Connell, Birkinshaw, & O’Dwyer, 2008), among others; thus, surface engineering via chemical modification have been studied in recent years. Modified cellulose nanomaterials matrices can be applied for the sorption of organic contaminants; inherently hydrophilic cellulose nanomaterials are modifiable to enhance their affinity for hydrophobic materials. The surface modification of cellulosic nanomaterials can be attained by insertion of both, the organic and inorganic groups as has been exemplified via the atomic layer placement of titanium dioxide (TiO2) NPs onto cellulose nanomaterial aerogels (Korhonen, Kettunen, Ras, & Ikkala, 2011); TiO2 veneer formed a low-energy surface on the fibers to generate nanocellulose-based material which has both, the oleophilic and hydrophobic properties and they could absorb oil and diverse organic solvents from the water’s surface with 20–40 g/g and 80–90 % vol/vol capacity. Jiang and Hseih achieved better sorption capabilities of model organic solvents ranging from 139–345 g/g by vapor phase deposition of triethoxyl(octyl)silane on CNFs aerogels (Jiang & Hsieh, 2014). The addition of hydrophobic silanes to cellulose nanomaterials transformed them into water-repellant and oleophilic materials which could eliminate oil from the top or below the surface of water; heterogeneous catalyst could be reused 6 times. Wang, Yadav et al. (2014) and Wang, Zhang et al. (2014) prepared hydrogels with graphene oxide embedded in the nanocellulose matrix. After the H2 gas reduction, the graphene oxide-cellulose nanomaterials composites could sorb cyclohexane and dimethylformamide (DMF).

Other hazardous atmospheric volatile organic compounds (VOCs), namely, phenol, toluene and xylenes are of health concern owing to their low solubility and volatility that adversely effects the environment and human health (Al Momani, 2007); toluene, an ingredient utilized in adhesives, paints, detergents, and inks, is a typical VOC in water (Zeng et al., 2009). Rezaee, Pourtagi, Hossini, and Loloi (2016) reported that TiO2 NPs impregnated on the microbial cellulose (MC) surface (MC/TiO2) could degrade toluene in air at ambient temperature under UV-irradiation conditions with maximum photodegradation abilities towards toluene pollutants being 87.79 % and 76.87 % after 40 min irradiation with UVC and UVA, respectively.

2.1.2.2. Removal of pesticides.

Pesticides are major organic pollutants in water bodies that are generally treated using assorted techniques such as photocatalytic degradation, aerobic degradation, ozonation, ultrasound combined with (photo)Fenton treatment, advanced oxidation processes, electrodialysis, reverse osmosis, adsorption, etc. (Ahmad et al., 2010; Hladik, Roberts, & Bouwer, 2005; Salman, Njoku, & Hameed, 2011). Based on target organisms, the main classes of pesticides are herbicides, fungicides, and insecticides, with herbicides accounting for approximately 46 % of the total pesticide (4.1 million tons) use worldwide (Mojiri et al., 2020). 2,4-Dichlorophenoxyacetic acid (2,4-D), one of the oldest herbicides and a common type of pesticide utilized broadly in the agricultural industry, is an organochlorine compound commercially accessible since 1945 (Kanmani et al., 2017). Nevertheless, pesticides are widely used in agriculture, industry and households, and they pose a risk to ecosystems and human health. Salman et al. (2011) reported that the maximum allowable concentration of 2,4-D in affordable drinking water is 100 μg L−1. Due to its endocrine disrupting and plant hormone activities, 2,4-D (well-known plant growth regulator) has been listed as one of the top 10 bestselling pesticides (Wang, Ge et al., 2013). The 2, 4-D accumulation in agricultural products and natural environment not only can cause serious contamination to the environment/ecosystem, but also jeopardizes public safety, human health, and economic advancement; indeed, it is associated with the occurrence of human cancer, endocrine disruption, etc. (Smith, Smith, La Merrill, Liaw, & Steinmaus, 2017). In yet another attempt, Zhang, Zhao et al. (2019) and Zhang, Ma et al. (2019) described a facile and novel method to prepare fluorescent microfluidic paper chips (paper@QDs@MIPs) by depositing fluorescence signal material, CdTe quantum dots (QDs) onto cellulose paper as a base material, and studied the ability of the resulting paper@QDs@MIPs in rapid detection of pesticide 2,4-D.

2,4-Bis(isopropyl amino)-6-(methylthio)-s-triazine or prometryn (Pr), a colorless crystal, nonionic and hydrophobic herbicides pose a serious threat to the environment as well as human/animal’s health (Plakas & Karabelas, 2009). In this context, Garba, Zhou, Lawan, Zhang, and Yuan (2019) synthesized a copper modified microcrystalline cellulose (Cu@MCC) by a facile synthesis and deployed it as an effective composite adsorbent for Pr herbicide adsorption from synthetic waste-water; good adsorption capacity of 97.80 mg g−1 at ambient temperature was discerned with sufficient stability for 6 sequential adsorption-desorption runs. In another study, a facile and novel process was developed for embedding triolein into cellulose acetate sphere as a sustainable and efficient composite adsorbent for removing lipophilic pollutants (Liu, Dai, Qu, & Ru, 2005); adsorbent could be used for the effective removal of two organochlorinated pesticides (OCPs) of low concentrations from water. In addition, a novel class of recoverable CdS@x%SCNF (x = 5, 10, 15, 20, 50) bionanocomposites was attained by depositing cadmium sulfide NPs on a matrix of biomass-derived silanized cellulose nanofibers via a solvothermal methodological route (Gupta, Kumar, Tikoo, Kaushik, & Singhal, 2020), and used for the adsorptive detoxification of pesticide (organophosphate insecticide chlorpyrifos) and textile dye (MB and safranin O) contaminants from wastewater. The as-synthesized CdS@10 %SCNF bionanocomposite exhibited maximum adsorption capacities for all the contaminants and could be reused up to six adsorptive runs.

Cellulose composites and metal organic frameworks (MOFs) are promising adsorption candidates as they combine the high adsorption capacities of MOFs and the sustainability of cellulose-based (nano)materials. Abdelhameed, Abdel-Gawad, Elshahat, and Emam (2016) selected Cu-BTC MOFs for the adsorption of 14C-ethion as an organo-phosphorus insecticide pollutant. Cu-BTC@cotton was fabricated via a facile method by an interaction of Cu in MOF and cellulose functional groups; indeed, the ethion molecule can bind with adsorbent by forming chemical bonds with Cu-BTC (copper-benzene-1,3,5-tricarboxylic acid) and cotton fabrics (chemisorption). As a result, the maximum sorption capacity of as-prepared composite reached 182 mg g−1 and the ethion removal percent exceeded 97 %. After recovering five times, the Cu-BTC@cotton adsorption efficiency was still retained and surpassed 85 %. Interestingly, Gan et al. (2019) extracted carbon nanofiber (CCNF) from abundant cellulosic source via electrospinning and pyrolysis treatment strategy and coated CoFe2O4 on it via a hydrothermal method to generate a novel catalyst for the activation of peroxymonosulfate (PMS). The appliance of CoFe2O4/CCNF nanocomposite activated PMS has been illustrated in the degradation of dimethyl phthalate (DMP), a classical organic pesticide pollutant, in wastewater. Besides, the catalyst could be easily reused in catalytic degradation reactions for 5 cycles with an insignificant loss in catalytic performance.

2.1.2.3. Removal of heavy metal ions.

As aforementioned, there has been a growing ecological and global public health concern associated with wastewater contamination by heavy metals. Heavy metals represent any naturally occurring element that has a high atomic weight or a high density (5 times higher than that of water) and are toxic/hazardous even at very low concentration (Huang, Liu, Zhang, Wu, & Tang, 2017; Sajjadi et al., 2019; Varghese, Paul, & Latha, 2019; Yadav & Xu, 2013); numerous heavy metals are summarized in Table S1. One of the common heavy metals is chromium [Cr(VI)] that finds diverse applications in leather tanning, pigment production, stainless steel manufacturing, and is detrimental to the human health. Simultaneous exposure to several heavy metals can generate a toxic effect, which is either additive/synergistic or antagonistic. Yu, Tong, Ge, Wu et al. (2013) and Yu, Tong, Ge, Zuo et al. (2013) reported that applying succinic acid groups onto CNCs considerably accelerated the binding efficiency to Pb2+ and Cd2+ in water; transformation of the carboxylic acid groups to sodiated carboxylates improved their ability to eliminate toxic metal ions from solutions. Researchers have established the capability of COO-amended CNFs to sorb Ni2+, Cd2+, Pb2+ and Cr3+, with competences 3–10 % greater than original CNFs (Srivastava, Kardam, & Raj, 2012). Besides, the catalyst could be easily separated and reused for 5 times. On the other hand, cysteine usage offered appended thiol functionalities to effectively bind Cr(VI) and Pb(II) (Yang et al., 2014). The amine group mobilization on the surface of CNCs enabled more than 98 % elimination of anionic chromate comprising Cr6+ in the concentration range of 12.5 mg g−1 (Singh, Arora, Sinha, & Srivastava, 2014). Moreover, the catalyst could be recycled and reused at least five times without any noticeable decrease in catalytic activity.

Bacterial cellulose (BC) possesses numerous advantages such as high purity and crystallinity, favorable biocompatibility, low density, high porosity, durable mechanical properties, high absorption capacity, low-cost, and three dimensional interconnected structures with ultrafine nanofibers (Brandes, Carminatti, Mikowski, Al-Qureshi, & Recouvreux, 2017; Campano, Balea, Blanco, & Negro, 2016; Chawla, Bajaj, Survase, & Singhal, 2009; Qiu & Netravali, 2014; Shao, Liu, Liu, Wang, & Zhang, 2015). The high crystallinity of BC endows it with excellent physico-chemical stabilities (Fang, Zhou, Deng, Zheng, & Liu, 2016), and its hydrophilicity originating from its abundant hydroxyl groups makes it suitable catalyst support for deployment in water bodies (Costa, Gonçalves, Zaguete, Mazon, & Nogueira, 2013; Thiruvengadam & Vitta, 2013). Bacterial nanocellulose (BNC) is another family member of natural biopolymers and renewable raw materials, similar to nanoscale forms of cellulose, i.e. CNCs and CNFs that display tremendous potential for environmental and water treatment as highlighted recently (Mahfoudhi & Boufi, 2017; Voisin, Bergström, Liu, & Mathew, 2017; Wang, 2019). For the water purification application, Ma, Lou, Chen, Shi, and Xu (2019) reported a BC@zeolitic imidazolate framework-8 (ZIF-8) composite aerogel with low density below (<0.03 g cm−3), large surface area, and hierarchical porosity, which displayed prominent heavy metal adsorption performance and recyclability superior to original ZIF-8 NPs (1.2 times).

Magnetite NPs have been simply incorporated into the cellulose nanomaterial structure for their controlled retrieval through magnetic separation (Zhou, Wu, Lei, & Negulescu, 2014; Zhou, Fu, Zhang, Zhan, & Levit, 2014). Zhu et al. (2011) prepared CNFs encompassing magnetite NPs trapped inside the fibers via the growth media of CNFs making bacteria during their generation; a low energy pathway for altering cellulose nanomaterials is a major advantage although extended time for growth and up-scaling challenges may hamper the commercialization process. Bacteria-originated CNFs has been applied for removing the heavy metals (e.g. Pb2+, Mn2+, and Cr3+) and the fabricated catalyst could be recovered and reused for three cycles without noticeable drop in catalytic activity.

2.1.2.4. Removal of dyes.

Organic dyes are complex organic pollutants exemplified by cationic, anionic and/or nonionic properties that originate from several industrial sources e.g. textile, printing, pulp and paper, rubber leather tanning and cosmetic industries for coloring various products; toxic pigments and dyes are notable environmental afflictions in various parts of the world that need to be eliminated (Crini, 2006; Nasrollahzadeh, Sajjadi, Maham, Sajadi, & Barzinjy, 2018; Rafatullah, Sulaiman, Hashim, & Ahmad, 2010). It has been estimated that ~1.6 million tons of toxic dyes are generated each year and ~10–15% of aforesaid volume is released as wastewater. Various cationic dyes are eliminated deploying CNCs and CNFs modified with anionic moieties as adsorbent materials or catalysts. Carboxylation of cellulose-based nanomaterials is one of the most investigated procedures for enhancing their sorption capacity. He et al. (2013) investigated the adsorption characteristics of carboxylated nanocelluloses fabricated via a single-extraction step hydrolysis process. Carboxylated or COO-modified CNCs are prepared through an ammonium persulfate (APS) hydrolysis of microcrystalline cellulose, in which carboxyl groups could be introduced on their surface during the cellulose hydrolysis. Adsorption studies conducted for a cationic dye e.g. methylene blue (MB) confirmed that the carboxylate groups bind to positively charged dyes; the adsorption capacity of MB onto CNCs approached a balance (0.32 mmol g−1) at 22 °C after 10 min. The MB desorption from CNCs by ethanol was vastly efficient with more than 90 % dye removal up to seven desorption cycles. Similarly, Yu, Zhang, Lu, and Yao (2016) described a facile and single-step method to prepare carboxylated CNCs by deploying HCl/citric acid hydrolysis of the microcrystalline cellulose which has been utilized for the adsorption of MB; nearly complete UV degradation of methyl blue by the COO-modified CNCs, was observed after 4 h, and with an increased rate compared to other types of CNCs prepared using acids like sulfuric acid and formic acid. This result is attributed to the surface modification of carboxylated CNCs wherein additional carboxyl groups could effectively serve as a binding site for the dyes.

Zhou et al. prepared porous hydrolyzed polyacrylamide (HPAM)/CNC nanocomposite hydrogels via facile thermal treatment, and studied their activities for MB dye adsorption in aqueous solutions (Zhou, Wu et al., 2014); synergy between CNCs and HPAM can effectively increase the removal of toxic MB via the improvement in swelling properties wherein enhanced adsorption capacity for toxic dye can be attained by increasing CNCs content (~20 wt.%), raising HPAM and decreasing the pH of the prepared solution. Generally, porosity and the availability of the hydroxyl groups on surfaces of CNCs and/or CNFs can provide an outstanding mechanical template and support for nanocatalysts, thus ensuring good dispersion of NPs and stability of nanocatalysts (Mohammed et al., 2018; Xu, Nasrollahzadeh, Sajjadi et al., 2019; Zeng, Liu, Cai, & Zhang, 2010).

In another study, the fabrication of a novel CoPc@BC by covalent immobilization and decoration of amino cobalt phthalocyanine (CoPc) onto BC nanofibers has been described (Chen & Huang, 2015); ensuing nanocatalyst could be successfully deployed in the ≥90 % destruction of Rhodamine B (RhB) dye in water/wastewater using H2O2 as an oxidant within 3 h. An effective approach was disclosed by Yang et al. (2011) for growing cadmium sulfide NPs and stabilizing them through coordination effects with the bacterial CNFs via hydrothermal reaction; CdS/BCNFs hybrid composites were affirmed as robust recoverable photocatalysts for the 82 % MO degradation after 90 min exposure to visible light irradiation. The nanocomposite could be reused 5 times with no remarkable decrease of catalytic activity/efficiency. In another development, Zhang, Yu et al. (2018) and Zhang, Hou et al. (2018) prepared BC@TiO2 nanocomposite by immersing well-preserved 3D interconnected porous BC blocks into a solution of titanium source that exhibited tremendous potential as MO adsorbent. Furthermore, a novel class of robust and highly scalable polydopamine (PDA)/BNC hybrid membrane has been prepared by Derami et al. (2019) which could be effectively used for the adsorptive removal of organic dyes (rhodamine 6 G, MB, and MO) from contaminated water.; the membrane catalyst was separated and reused 10 times with no detectable decrease of the catalytic performance.

After the capture of toxic pollutants, the ability to isolate and separate them from the nanosorbent or nanocatalyst and especially the reuse of such nanomaterials are some key issues in producing and designing sustainable treatment systems. The development of novel and recoverable CNCs is of paramount importance in numerous research areas such as remediation of toxic pollutants via adsorption and degradation process, however, the recovery of nanosorbents (or nanocatalysts) can limit their practical utilization on large-scale remediation processes. One of the straightforward procedures for the fabrication of reusable adsorbents is the incorporation of pristine nanocellulose (CNCs and/or CNFs) into various nanocomposite hydrogels or polymers that can be easily recycled using sieves, filtration, and magnets, etc. These materials could also be packed within columns and applied in wastewater remediation operations. In this context, a novel class of recoverable microgel comprising pristine CNCs and amphoteric poly(vinyl amine) (PVAm) has been reported by Jin and co-workers (Jin, Sun, Xu, & Xu, 2015), which can be utilized for the adsorptive removal of anionic dyes. The protonation of amine functionalities on the microgel particle’s surface organized positively charged microgels under an acidic pH medium wherein the electrostatic attraction among negatively charged sulfate groups and protonated amine promote the adsorption of anionic dyes into/onto microgels surface.

Besides, active NPs for photocatalytic destruction of pollutants has been introduced by placing TiO2 particles on CNFs via controlled surface hydrolysis strategy (Sun, Yang, & Wang, 2010); significant ultra violet degradation of methyl orange (MO) could be detected within 20 min, that was 20 % faster compared to the rate attained with TiO2 alone. Likewise, Snyder, Bo, Moon, Rochet, and Stanciu (2013) fabricated hybrid gold/TiO2- and silver/TiO2-cellulose CNF composites which eliminated MB ~75 % and 70 %, respectively, after one hour via photocatalytic degradation and adsorption. Notably, the mechanical strength of the CNF films can be augmented by addition of metallic NPs thus rendering them recyclable and imparting them additional durability.

A variety of cellulose-based nanosorbents deployed for the elimination of dyes and heavy metals are presented in Table 2.

Table 2.

Organic dyes and heavy metal ions adsorption onto assorted cellulose-related nanosorbents.

| Cellulose-based nanosorbent | Contaminant | Max. adsorption capacity (mg g−1) or removal percent | T. (K)/pH | Ref. |

|---|---|---|---|---|

| Pristine CNFs | Ag(I) | 34.35 mg g−1 | 298/5.45 | (Liu et al., 2014) |

| Pristine CNCs | 15.45 mg g−1 | 298/6.39 | ||

| Pristine CNCs from sludge | Cu(II), Fe(III) | 25.5, 1.85 mg g−1 | 298/3.5–4.5 | (Liu, Borrell et al., 2015) |

| Pristine CNCs from bioethanol | 30.15, 4.35 mg g−1 | |||

| Pristine CNCs | MB | 118 mg g−1 | 298/9.0 | (Batmaz et al., 2014) |

| TEMPOa oxidized carboxylated CNCs | 769 mg g−1 | |||

| Pristine CNCs | Crystal violet (CV) | 185.19 mg g−1 | 303/6.0 | (Qiao et al., 2015) |

| Maleic anhydride grafted CNCs | 243.90 mg g−1 | |||

| Pristine CNFs | MB | 122.2 mg g−1 | 293/9.0 | (Chan, Chia, Zakaria, Sajab, & Chin, 2015) |

| Phosphorylated CNFs from sludge | Cu(II) | 72.75 mg g−1 | 298/3.5–4.5 | (Liu, Borrell et al., 2015) |

| Phosphorylated CNCs from sludge | 72.8 mg g−1 | |||

| Sodium substituted succinic anhydride-amended CNCs | Pb(II), Cd(II) | 465.1, 344.8 mg g−1 | 298/5.5, 6.5 | (Yu, Tong, Ge, Wu et al., 2013) |

| Succinic anhydride-modified CNCs | 367.6, 259.7 mg g−1 | |||

| Succinic anhydride modified CNCs | Cr(III) | 2.88 mg g−1 | 298/6.5 | (Singh et al., 2014) |

| Acrylamide modified CNCs | Cr(VI) | 2.77 mg g−1 | 298/2.5 | |

| Carboxylated CNFs | Cu(II) | 135 mg g−1 | 298/6.2 | (Sehaqui et al., 2014) |

| Carboxylated CNFs | 167 mg g−1 | 298/6.5 | (Ma et al., 2012) | |

| Fe-Cu@CNC | Pb(II) | 93.98 % | – | (Chen, Yu, Deutschman, Yang, & Tam, 2020) |

| Sulfonated CNFs | Au(III) | 57 and 60 mg g−1 | 295/3.26 | (Dwivedi, Dubey, Hokkanen, & Sillanpää, 2014) |

| Electrosterically stabilized CNCs | Cu(II) | 185 mg g−1 | 298/4.0 | (Sheikhi, Safari, Yang, & Van De Ven, 2015) |

| CHAb modified CNFs | Ni(II), Cd(II) | 99.33 %, 99.30 % | 298/5.0 | (Hokkanen, Repo, Westholm et al., 2014) |

| 2-Mercaptobenzamide altered itaconic acid attached magnetite CNCs | Hg(II) | 240.0 mg g−1 | 303/8.0 | (Anirudhan & Shainy, 2015) |

| Magnetic CNC@Zn-benzene-1,3,5-tricarboxylic acid | Pb(II) | 558.66 mg g−1 | 298.2/- | (Wang, Ouyang, Yang, & Omer, 2017) |

| TEMPO oxidized CNFs modified by PEI | Cu(II) | 52.32 mg g−1 | 303/5.0 | (Zhang, Zang, Shi, Yu, & Sheng, 2016) |

| Amino functionalized CNCs | Acid red GR | 555.6 mg g−1 | 298/4.7 | (Jin, Li, Xu, & Sun, 2015) |

| Au@BSA NCs loaded CNC-ALG hydrogel beads | Hg(II) | 26 mg g−1 | 298/7.0 | (Mohammed, Baidya et al., 2016) |

| Poly(itaconic acid/methacrylic acid) embedded CNCs/bentonite nanocomposite | Co(II) | 350.8 mg g−1 | 303/6.0 | (Anirudhan, Deepa, & Christa, 2016) |

| FeNP modified CNFs | As(V) | 241.8 mg g−1 | 293/2.0 | (Hokkanen, Repo, Lou, & Sillanpää, 2015) |

| Carboxylated CNFs/PVA hybrid aerogels | Hg(II), Pb(II), Cu(II), Ag(I), | 157.5, 110.6, 151.3, 114.3 mg g−1 | – | (Zheng, Cai, & Gong, 2014) |

| Carboxylated CNFs/magnetic chitosan hydrogel beads | Pb(II) | 171.0 mg g−1 | 298/4.5 | (Zhou, Fu et al., 2014) |

| CNCs/HPAMc nano-hydrogels (by casting) | MB | 326.08 mg g−1 | 298/5.0 | (Zhou, Wu et al., 2014; Zhou, Fu et al., 2014) |

| CNCs/HPAM nano-hydrogels (by electrospinning) | MB | – | 298/6.5 | (Zhou, Lee, Dooley, & Wu, 2013) |

| MnO2 coated CNFs | MB | 99.8 % | 298/9.6 | (Wang, Yadav et al., 2014; Wang, Zhang et al., 2014) |

| D-CNCs/PVAmd microgels | Congo red 4BS, reactive light-yellow K-4G, acid red GR | 869.1, 1250.9, 1469.7 mg g−1 | 298/3.5 | (Jin, Sun et al., 2015) |

| CNC@polydopamine | MB | 2066.72 mg g−1 | 298/10.0 | (Wang, Zhang et al., 2020) |

| Cellulose nanocrystals | Victoria Blue 2B, methyl Violet 2B, rhodamine 6 G | 98 %, 90 %, 78 % | r.t./5.01 | (Karim, Mathew, Grahn, Mouzon, & Oksman, 2014) |

| CMC/GOCOOHe microbeads | MB | 180.32 mg g−1 | 298/10.0 | (Eltaweil, Elgarhy, El-Subruiti, & Omer, 2020) |

| Ag, Au, Pt NPs- and Ag@Au, Ag@Pt NPs-CNF | 4-nitrophenol (4-NP) | – | r.t./- | (Esquivel-Pena et al., 2020) |

| CTABf modified CNC | CR | 448.43 mg g−1 | 298/7.5 | (Ranjbar, Raeiszadeh, Lewis, MacLachlan, & Hatzikiriakos, 2020) |

| CNC-ALG hydrogel bead | MB | 255.5 mg g−1 | – | (Mohammed, Grishkewich, Waeijen, Berry, & Tam, 2016) |

| CNF-GnPg aerogel | MB, CR | 1178.5, 585.3 mg g−1 | – | (Yu, Hu, Dichiara, Jiang, & Gu, 2020) |

| CMC/g-C3N4/ZnO | Methyl violet | 96.43 mg g−1 | 298/8.0 | (Sharma et al., 2020) |

| G-C3N4/CNCs-H hydrogel | MB | 232.558 mg g−1 | r.t./7.0 | (Wang, Li et al., 2020) |

| M3D-PAA-CCNh | MB | 332 mg g−1 | – | (Samadder et al., 2020) |

| Carboxylated cellulose fabric filter | MB, Pb(II) | 76.92, 81.30 mg g−1 | 298/5.0 | (Li, Ma, Venkateswaran, & Hsiao, 2020) |

| PAETMACi-g-CNC | Neutral reactive blue 19 (RB 19) | >80 % | 298/7.0 | (Jiang, Lou, Hua, Deng, & Tian, 2020) |

| Cellulose-modified La0.9Sr0.1FeO3 | CR | 38.46 mg g−1 | r.t./4.0 | (Ali & Al-Oufi, 2020) |

| MBCNF/GOPAj | Malachite green (MG) | 270.27 mg g−1 | 298/7.0 | (Arabkhani & Asfaram, 2020) |

| BCk@CdS nanocomposite | MB | 10.92 mg g−1 | 293/- | (Qian, Xu, Yue, Wang, & Liu, 2020) |

| CNF-Fe(0)@FeS | MB, CR | 200.0, 111.1 mg g−1 | 298/7.0, 5.0 | (Sankararamakrishnan, Singh, & Srivastava, 2020) |

| CNF/PEIl/Ag NPs aerogel membrane | 4-NP, MB, CR | 96 %, 99.2 %, 96.4 % | – | (Zhang et al., 2020) |

| TOCN/CGGm hydrogel | Cu(II), MO, thioflavin T | 498.5, 134.3, 430.2 mg g−1 | – | (Dai et al., 2020) |

| D-ZSMn/CNF, Cu- and Fe- ZSM/CNF | Rhodamine 6B, Reactive blue 4 | 34.36, 9.22 and 16.55 mg g−1 | r.t./≥ &≤7.0 | (Lakhane, Mahabole, Bogle, Khairnar, & Kokol, 2019) |

| CA-PANI/β-CDo nanofiber | MB | 49.51 mg g−1 | 298/8.0 | (Ali, El-Aassar, Hashem, & Moussa, 2019) |

| IDA@CMC-PBQp microbeads | CV | 107.52 mg g−1 | 298/8.0 | (Omer, Elgarhy, El-Subruiti, Khalifa, & Eltaweil, 2020) |

| PEI-Pt@BCq membrane | Acid black ATT | 1157.9 mg g−1 | 298/5.2 | (Huang et al., 2020) |

| α-Fe2O3 nanodisk/bacterial cellulose membrane | Orange II (OII), MO, Rhodamine B (RhB), MB, CV, MG | – | – | (Zhu et al., 2018) |

| PMPC/BNCr nanocomposite | MB, MO | 4.44 ± 0.32, 4.56 ± 0.43 mg g−1 | – | (Vilela, Moreirinha, Almeida, Silvestre, & Freire, 2019) |

| MoS2-graphene-CFPs | MB | 485.4 mg g−1 | 298/7.0 | (Gopalakrishnan, Singh, & Badhulika, 2020) |

| hPEIt modified cellulose-based bioadsorbent | Cationic bright yellow M-7 G, anionic reactive yellow X-RG, nonionic disperse brown S-3RL | 571.43, 970.87, 581.40 mg g−1 | r.t./- | (Chen et al., 2018) |

| PANi/BC mat | Cr(VI) | – | 298 ± 2/1–5 | (Jahan, Kumar, & Verma, 2018) |

| CMC-Ni-BC | MB, 2-NP | >95 %, >90 % | – | (Kamal, Ahmad, Khan, & Asiri, 2019) |

| BC/PDA/TiO2 | RhB, MB, MO | 100 %, 99.5 %, 95.1 % | – | (Yang et al., 2020) |

| BC/NiHCFu membrane | Cs(I) | 175.44 mg g−1 | 298/6.0 | (Zhuang & Wang, 2019) |

| BC-ACv | MB | 505.8 mg g−1 | – | (Khamkeaw, Jongsomjit, Robison, & Phisalaphong, 2019) |

| ZIF-67/BC/CHw aerogel | Cu(II), Cr(VI), active red X-3B | 200.6, 152.1 mg g−1, 100% | 298/6.0 | (Li, Tian et al., 2020) |

| Cellulose acetate-ceria/zirconia@Cu° NPs | Mixture of 4-NP-MB, 4-NP-RhB & 4-NP-MB-RhB | – | – | (Khan et al., 2020) |

| Cellulose/Ag3PO4 | Mixture of industrial fertilizer effluent + RhB dye | 52 % and 86 % | – | (Tavker, Gaur, & Sharma, 2020) |

2,2,6,6-Tetramethyl-1-piperidinyloxy.

Carbonated hydroxyapatite.

Hydrolyzed polyacrylamide.

Polyvinylamine.

Carboxymethyl cellulose/carboxylated graphene oxide.

Cetyltrimethylammonium bromide.

Cellulose nanofibrils-graphene nanoplates.

Polyacrylic acid-magnetic 3D crosslinkers-carboxylated cellulose nanocrystal.

Poly acryloyloxyethyltrimethyl ammonium chloride.

Magnetic bacterial cellulose nanofiber/graphene oxide polymer aerogel.

Bacterial cellulose/cadmium sulphide.

Poly(ethylene imine).

TEMPO-oxidized cellulose nanofibers/cationic guar gum.

De-aluminated ZSM-5 zeolite.

Cellulose acetate-polyaniline/β-cyclodextrin.

Iminodiacetic acid@carboxymethyl cellulose-p-benzoquinone.

Polyethylenimine caged platinum nanomaterials@bacterial cellulose.

Poly(2-methacryloyloxyethyl phosphorylcholine)/bacterial nanocellulose.

Cellulose filter paper.

Hyperbranched polyethyleneimine.

Nickel hexacyanoferrates loaded bacterial cellulose.

Activated carbon.

Zeolitic imidazolate framework-67/bacterial cellulose/chitosan.

2.1.2.5. Removal of other pollutants.

Non-biodegradable nitrophenols are extremely hazardous, and carcinogenic and are responsible for several ailments in humans; their removal from water/wastewater is of utmost importance. They have numerous applications in diverse industries e.g. synthesis of anilines as a crucial feedstock to produce pharmaceuticals, dyes, explosives, resins, agrochemicals and synthetic polymers, among others (Crini, 2006; Nasrollahzadeh, Sajjadi, Dasmeh et al., 2018; Rafatullah et al., 2010) and are on the list of regulated materials. Shi et al. synthesized CNCs-supported gold NPs with a quick swelling rate and superior catalytic prowess to catalyze the aqueous sodium borohydride (NaBH4)-mediated reduction of pollutant, 4-nitrophenol (4-NP) (Scheme S1) with turnover frequency value and maximum rate constant of 641 h−1 and 0.0147 s−1, respectively (Yan et al., 2016); synthesis was accomplished via electrospinning and thermal treatment of polyethylene glycol, CNCs and HAuCl4 at 80 °C for 60 min wherein CNCs and polyethylene glycol act as support and reductant, respectively.

Additionally, cellulosic nanomaterials can be applied for the passive nanoremediation of reactive NPs where they act as scaffolds or particle-stabilizers. These NPs are often altered by using polymers to prevent aggregation; though, these surface-bound stabilizers cover the surface of reactive particle and may hinder the degradation and sorption of targeted materials (Yu, Tong, Ge, Zuo et al., 2013). Nata, Sureshkumar, and Lee (2011) reported one-pot simple solvothermal approach by incorporating the aminated iron oxide particles in bacterial cellulose nanofibers (BCNFs) for the remediation of arsenic; hardy CNF template prohibited the aggregation of particles and simplified the amine modification of magnetite particles. Therefore, ensuing materials demonstrated extremely superior arsenic elimination capacity (36.49 mg g−1) than the bare iron oxide-based adsorbents and the nanocomposite could be reused 5 times with a minimal catalytic activity impairment. In one of the studies, Ma, Hsiao, and Chu (2012) demonstrated the capability of CNFs for eliminating radioactive uranyl ions () from solutions; ions coordinated to the carboxylate groups of TEMPO-oxidized CNFs removed more than 167 mg/g, which was 2–3 times more than traditional adsorbents including hydrogels, montmorillonite, silica and polymer particles.

Polyethylene glycol (PEG) modified CNCs composites have been prepared for adsorbing pharmaceutical compounds, including sulfa-methoxazole, acetaminophen, and N,N-diethyl-meta-toluamide (DEET) in aqueous media. Such cellulose-based nanocomposite can be applied for eliminating the hydrophobic drugs from water; PEG-functionalized CNCs could facilitate the interaction between the cellulose nano-crystals and drugs. Such composite have been prepared via carboxylation of CNCs surface via 2,2,6,6-tetramethyl-1-piperidinyloxy oxidation, tailed by covalent appendage of hydrophilic polyether diamine of molecular weight of 600 g mol−1 using sodium salt of N-(3-dimethylaminopropyl)-N′-ethyl-carbodiimide/N-hydroxysulfosuccinimide (Herrera-Morales et al., 2017).

2.2. Chitin/chitosan-based nanomaterials

2.2.1. Chemistry and properties

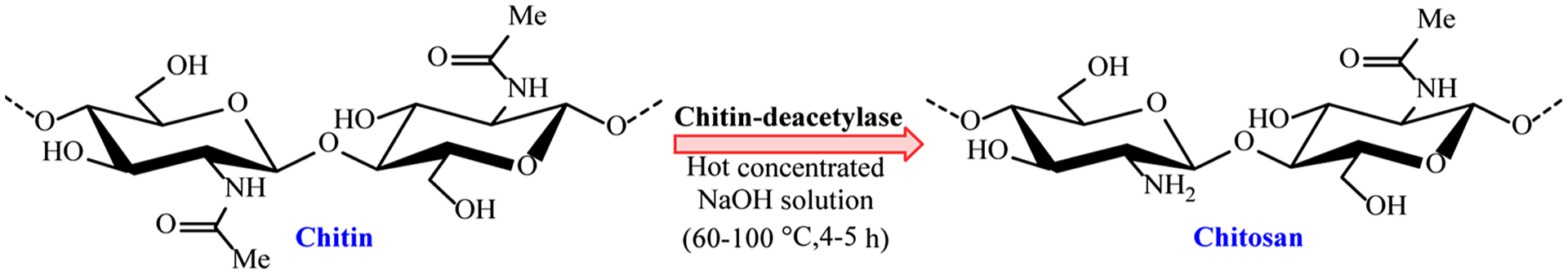

After cellulose, chitin and chitosan are the next most abundant bio-polymers in nature. Chitosan is a renewable and biodegradable carbohydrate and is essentially, N-deacetylated chitin, the main constituent of insect cuticles and crustaceous shells, built up from linear aminopolysaccharide of glucosamine (Fig. 3). Bioconversion of chitin into chitosan via enzymatic N-deacetylation could be achieved with chitindeacetylase. The hydrophilic functional groups, including hydroxyl and amino groups, present in chitosan cannot change its hydrophobic nature enough to allow its use for adsorption and modification (Wang & Zhuang, 2017). In general, chitin/chitosan as a biogenic raw material is of specific significance because of its abundance, high adsorption capacity and ease of modification; chitosan has been deployed in biocatalysis, wastewater treatment, drug/gene delivery, agricultural/industrial use, and cell/enzyme immobilization (Bagheri, Roostaie, & Baktash, 2014; Dotto & Pinto, 2017; Rangel-Mendez, Monroy-Zepeda, Leyva-Ramos, Diaz-Flores, & Shirai, 2009; Xu, Nasrollahzadeh, Sajjadi et al., 2019).

Fig. 3.

Deacetylation of chitin for the preparation of chitosan.

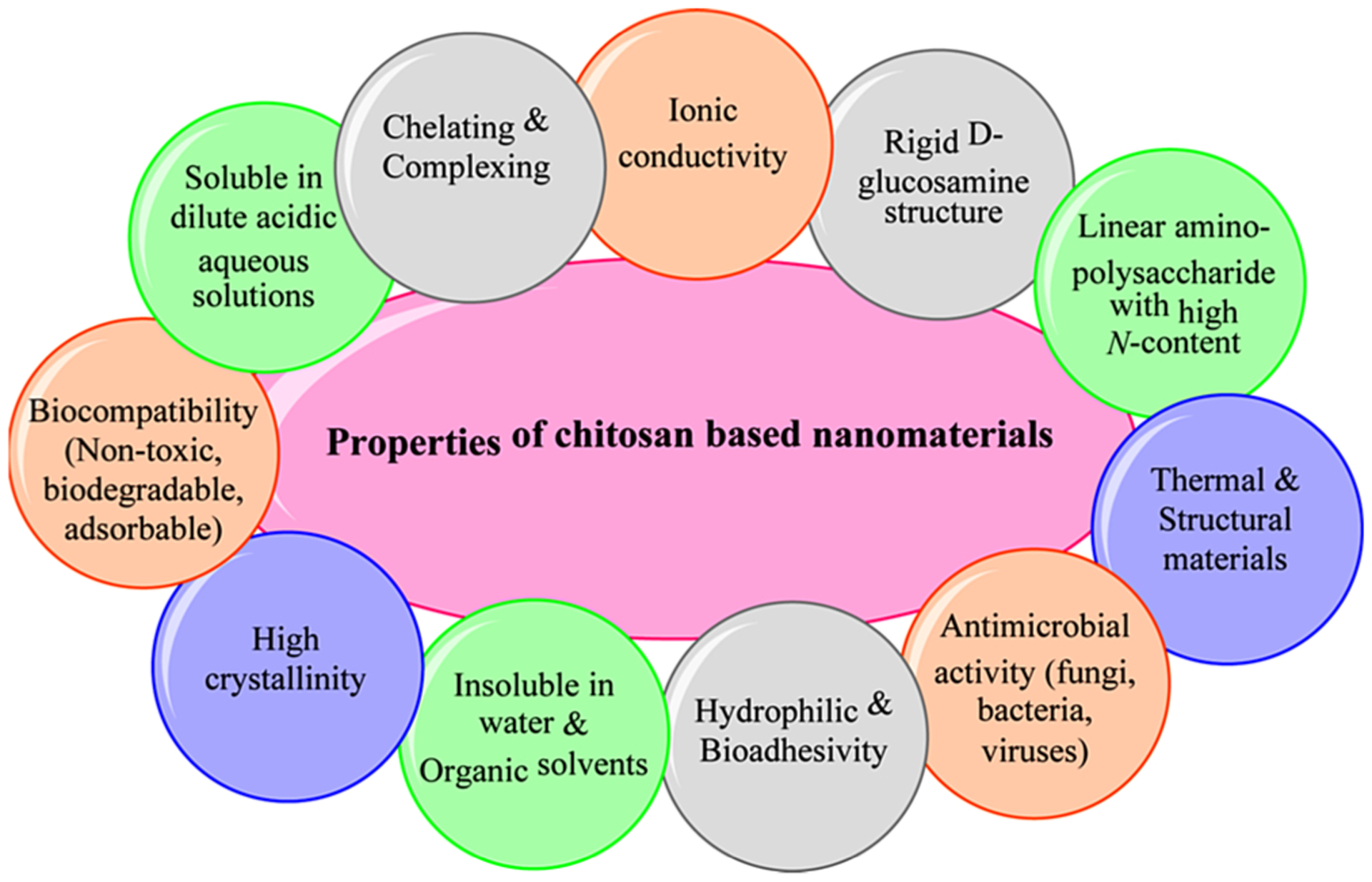

Chitosan-based nanomaterials have garnered significant interest as they are utilized as nanosorbents and nanocatalysts because of their distinctive physicochemical properties (Fig. 4). The presence of N-acetamido functionality is responsible for the formation of various inter/intra-molecular hydrogen bond between linear structures of chitin. Indeed, the extended hydrogen bonded chitin chains does limit their solubility in solvents, and therefore, their processing and novel appliances have been under scrutiny for the preparation of sustainable nanomaterials. Their application as eco-friendly, low-cost, sustainable and renewable resources for the synthesis of chitin/chitosan-based nanocatalysts and for the assembly of potable and safe water systems are under rigorous investigation (Crini, Morin-Crini, Fatin-Rouge, Deon, & Fievet, 2017; Krajewska, 2001; Xu, Nasrollahzadeh, Sajjadi et al., 2019).

Fig. 4.

Essential physicochemical properties of chitosan.

2.2.2. Applications for water treatment

2.2.2.1. Removal of heavy metal ions.

Coagulation and flocculation of ionic substances and charged particles in wastewater has efficiently been performed with the aid of natural polymers, while diminishing the dependability on synthetic polyelectrolytes (Zemmouri, Drouiche, Sayeh, Lounici, & Mameri, 2013). Chitin, chitosan and their derived molecules have been exploited as natural and eco-friendly coagulants/flocculants to eliminate various charged particles such as dyes and metal ions from wastewater (Kanmani et al., 2017; Sami, Khalid, Iqbal, Afzal, & Shakoori, 2017). Chitosan and its derivatives present a cationic character in acidic media that facilitates their dissolution and enable ion-exchange interactions or electrostatic attraction with various anionic characters, while, the non-protonated amino groups in neutral media expedite complexation of metal ions and organic molecules. Polyvinyl alcohol-chitosan and PEG-chitosan composites have been investigated by Rajeswari et al. (2016) to remove aqueous nitrate ions with a adsorption capacity of > 35.03 and 50.68 mg g−1, respectively, while the preparation of carboxymethyl chitosan (Borsagli, Mansur, Chagas, Oliveira, & Mansur, 2015) and goethite/chitosan nano-composites (goethite NPs 10~60 nm) (Rahimi, Moattari, Rajabi, & Derakhshan, 2015) were selective towards the complexation of Cd2+/Cr6+ and Pb2+, respectively. Wang, Chen, Yuan, Sheng, and Yu (2009) reported a highly water-soluble chitosan-based flocculant by grafting it with (2-methacryloyloxyethyl) trimethyl ammonium chloride (grafting percentage >236.4 %) for the treatment of pulp mill waste-water; as-prepared flocculant revealed a more notable flocculation capacity and performance than that of polyacrylamide.

Considerable endeavors have been explored to ameliorate the experimental processes towards capacitive deionization (CDI) using a diversity of conducting polymers (e.g. polypyrrole) in view of their ion-exchange property and doped process (Abdi, Nasiri, Mesbahi, & Khani, 2017; Fang, Jiang, Luo, & Geng, 2018). Besides, the synergistic effect of polypyrrole and chitin/chitosan was described to improve the stability of polypyrrole material because of its −COOH and –NH2 (Huang et al., 2013). For example, Zhang, Xue, Li, Dai, and Zhang (2019) reported a polypyrrole(PPy)/CS/CNT nanoelectrode (34.57 nm) with various mass ratios of PPy and CS via in-situ polymerization for the adsorption of copper ion from water/wastewater by CDI process (Fig. S1); high adsorption competence of 16.83 mg g−1 for the Cu2+ removal was attained by this nanocomposite. The result of 100 cycles CV test shows that the specific capacitance of PPy/CS/CNT composite electrode decreased 13.1 % after 100 cycles, but only 3.4 % after the last 50 cycles, which indicated that this composite electrode has a good stability after 50 cycles.

The stabilization of various NPs has been achieved via their impregnation on organic renewable supports by preparation of nano-composite as shown by Chen, Cao, Quinlan, Berry, and Tam (2015) where the amino functionalization on surface of organic supports under mild conditions greatly diminished the agglomeration of metal/metal oxide NPs. The adsorption capacity of chitin/chitosan-supported NPs as nanocatalysts or nanosorbents could be further improved by a fusion of NPs and natural polymers culminating in promising natural polymer-based nanocomposites (Qiu, Ma, & Hu, 2014). Low-cost natural polymers, such as chitin/chitosan, has largely been applied as highly effective catalytic support in the heterogeneous catalysis field owing to its inherent functional groups (Murugadoss & Chattopadhyay, 2007; Wang, Zhu et al., 2017); reactive amino group-bearing chitosan has become an ideal support compared to other biopolymers. Environmental applications of bio(nano)composites of chitin/chitosan formed by combining them with diverse nanostructures, namely iron oxide (Fe3O4), titanium dioxide (TiO2), etc. have recently been reported (Anaya-Esparza et al., 2020; Li, Xiao, & Qin, 2010). For example, a novel nano-TiO2-enabled CS beads crosslinked with copper were prepared that could achieve the (photo)oxidation of toxic arsenite (As(III)) to a less-toxic and more easily adsorbed arsenate (As(V)) in UV light as well as the selective adsorption of As(III) and As(V) in presence of phosphate (Pincus, Melnikov, Yamani, & Zimmerman, 2018), which serves as a strong adsorption competitor and inhibitor of As removal in such protocols.

2.2.2.2. Removal of dyes.

Chitosan-based nanomaterials have been examined to adsorb or remove dye molecules wherein hydroxyl groups are effectively exploited in the dye adsorption, while the amine groups profoundly remain as a most active group and influences other biopolymer activities. Gibbs, Tobin, and Guibal (2003) have shown that by diminishing the acetylation degree of chitosan increases the relative proportions of amine groups available for protonation, thus favoring the adsorption of dyes like Acid Green 25. However, the alteration in these adsorption features is not proportional to the deacetylation or acetylation degree, but it varies with the nature of dyes (Saha, Ichikawa, & Fukumori, 2006) and also the repartitioning of acetyl groups in the macromolecular chains (Rinaudo, 2006), depending largely on the preparative process. Gopi and co-workers have reported the efficient wastewater treatment by using multifunctional bio-hybrid aerogels based on CNFs decorated with chitin nanocrystal (CNC) (Fig. S2a) (Gopi et al., 2017). A rare semi-square CNCs (20–100 nm) and wire-like CNFs (60–120 nm) were initially extracted from shrimp shells and corn husks, respectively (Fig. S2b). Hybrid bio-aerogels (neat AR, AR1 or AR2) were prepared with varying percentages of CNCs (0, 1% or 2%) and decorated on the CNFs via an eco-friendly freeze-drying procedure. This mixture comprised CNFs aqueous solution with well-dispersed CNCs that was frozen at about −70 °C in the dry ice-isopropanol and finally freeze dried at −88 °C under vacuum for at least 4 days. The higher amount of CNCs can lead to better alignment, organization and morphology of nanofibers in AR2, and higher crystallinity, in addition, the nanofibers orientation of AR2 mimicked the multilayer maple seed structure (Fig. S2b). The AR2 aerogel showed considerable adsorption capability for the remediation of dyes (MB and rhodamine 6 G) from aqueous solutions (Fig. S2c); the electrostatic interactions among positively charged dyes and negatively charged CNCs decorated AR2 with acetamide-enriched groups favored the dye adsorption. Besides, the hybrid bio-aerogels could be reused 5 times with no noticeable loss in activity/efficiency.

Marrakchi, Khanday, Asif, and Hameed (2016) developed a reinforced chitosan with sepiolite as an additive and epichlorohydrin as a crosslinker to fabricate crosslinked chitosan/sepiolite composites for the removal of reactive orange 16 and MB from aqueous solutions; attained maximum adsorption capacity of modified chitosan for MB and reactive orange 16, being 40.99 mg g−1 and 190.97 mg g−1, respectively, at initial dye concentration of 100 mg L−1 and adsorbent dosage of 1 g L−1 at 30 °C for 30 h. The adsorption processes were best explained using pseudo-second-order kinetics and Freundlich model that provided a finer explanation of the adsorption process for both the organic dyes. The functioning of this crosslinked chitosan composite was superior to what has been reported in earlier studies (37.04 mg g−1) (Xie, Li, Chi, & Wu, 2013), (11.94 mg g−1) (Yao et al., 2014) and (24.690 mg g−1) (Zeng et al., 2015) for the removal of MB. In addition, the elimination of Acid Red-2 from textile wastewater by a glutaraldehyde crosslinked magnetic chitosan nanocomposite has been investigated (Kadam & Lee, 2015); it could effectively adsorb 91.6 % textile pollutant, while iron oxide could adsorb only 16.4 %. This improved performance of magnetic chitosan nanocomposite in view of the available free amino and hydroxyl groups and 96 % pollutant removal with 100 % recovery bodes well for its practical uses.

Moreover, the combination of Fe3O4 and chitin/chitosan can afford fascinating magnetic support towards hassle-free separation of nano-catalysts. Chang and Chen (2005) designed carboxymethylated chitosan-conjugated magnetic nanosorbents (~13.5 nm) for the elimination of anionic dyes from aqueous solutions; excellent adsorption efficiencies were attained (1471 and 1883 mg g−1) for acid green 25 and crocein orange G, respectively.

2.2.2.3. Removal of other pollutants.

The adsorption of pesticides onto low-cost materials could help effectively remediate contaminated waters; particularly, nanomaterials, nanosorbents and polysaccharide-based adsorbents display high performance in eliminating pesticides from water bodies as exemplified by chitin and chitosan towards the biosorption of pesticides. Indeed, the presence of hydroxyl groups in chitin/chitosan determined its conformation and also the stereochemistry of chemical transformations and kinetics. In this respect, chitosan removed more than 90 % of oxadiazon (herbicide) from aqueous solutions (Arvand et al., 2009) wherein strong binding of oxadiazon to the chitosan was observed (chemisorption). Moreover, 76.2 % of atrazine (herbicide) could be removed (with a maximum adsorption capacity of 17.92 mg g−1) from aqueous solutions by chitosan/modified sepiolite (Liu, Chen, Cui, & Liu, 2015).

Modified chitosan nanomaterial matrixes can be applied for the biosorption of organic/inorganic contaminants; sustainability of chitosan and its derivatives can be boosted by mixing with reinforcement and/or supporting matrixes like crosslinkers and polymers. This entails the presence of at least two reactive sites or functional groups in linkers to suitably transform the chitosan by producing bridges amongst their polymeric chains and/or neighboring molecules (Xing, Ju, Yang, Xu, & Qian, 2013). The used crosslinkers for buttressing chitosan namely glutaraldehyde, silicate, tripolyphosphate, starch, polyvinyl alcohol and cellulose must enable the flow of organic/inorganic contaminants towards the charged particles of the supported chitosan and concomitantly ensuring the physicochemical stability of chitosan (Xing et al., 2013). To ensure the adsorption competence close to the parent chitosan, the use of various additives like alginate (Nadavala, Swayampakula, Boddu, & Abburi, 2009), polyethylenimine, chloroacetic acid and Fe3O4 is deemed necessary. The adsorption efficiency depends on numerous factors such as the adsorbent characteristics, the degree of crosslinking, crystallinity and the stiffness of the chitosan linkages, and the chemistry of pollutant (Alaba et al., 2018). Mi, Shyu, Chen, and Lai (2002) reported a novel protocol for the synthesis of bundle-like porous chitosan beads via a phase inversion wet process; this chemically modified chitosan could absorb anti-inflammatory drug such as indomethacin.

Chitin/chitosan-supported metal/metal oxide NPs have displayed high performances for removing pollutants from water/wastewater; indeed, the synergistic effects of chitin/chitosan and nanostructures can improve (nano)materials in terms of antimicrobial, UV blocking, and magnetic properties. In this context, Mujeeb Rahman et al. (Mujeeb Rahman, Muraleedaran, & Mujeeb, 2015) studied the antimicrobial properties of ZnO NP reinforced chitosan nanocomposites which could be utilized as photocatalytic and/or natural antimicrobial agents; superior antimicrobial activities against gram-negative and gram-positive bacteria (E. coli and S. aureus) was observed compared to chitosan itself. Utilizing the well-developed preparative procedures for chitin/chitosan-based (nano)materials, multifunctional chitosan/TiO2 (nano)composite photocatalysts could be easily attained owing to the miscibility between CS and hydrophilic TiO2 NPs (Wiaącek, Gozdecka, & Jurak, 2018).

In one study, TiO2 NPs (1% w/v) were embedded in two different matrixes, viz. chitosan and polyvinyl alcohol-chitosan blend (PVA-CS), through a precipitation procedure using an alkali/solvent medium (Neghi, Kumar, & Burkhalov, 2019) where the nanocomposites/blends exhibited high metronidazole (MNZ) removal efficiency (76.1 % and 63.7 % in PVA-CS-TiO2 and CS-TiO2 systems, respectively) from aqueous solutions under UV irradiation as compared to the TiO2 NPs suspension alone. As a result, PVA-CS-TiO2 showed enhanced stability than CS-TiO2 in an aqueous solution at different pH values and could be reused under UV exposure up to 15 cycles as an effective photocatalyst without significant loss of catalytic performance. In a recent study, Shoueir et al. (Shoueir, Kandil, El-hosainy, & El-Kemary, 2019) reported an efficient visible-light photocatalyst by stacking a layer of nano-structured Au@TiO2 on a chitosan fiber substrate; the as-prepared plasmonic fiber displayed catalytic activities in visible light for the degradation of various water pollutants (MB, MNZ, and carbofuran (CBN)) and for the Cr(VI) reduction (~98.9 %) in presence of citric acid (pH = 1) within 21 min. The plasmonic fiber photocatalyzed the degradation of MB within 12 min under visible irradiation using a low catalyst dosage of 1 × 10−3 g L−1, with an efficiency of 98.8 %. In the case of MNZ and CBN, the degradation reaction times were longer, namely 260 min and 130 min, respectively, which could be improved by deploying H2O2 in these systems, when the photocatalytic degradation degree of MNZ reached 96 % and 98.3 % for CBN.

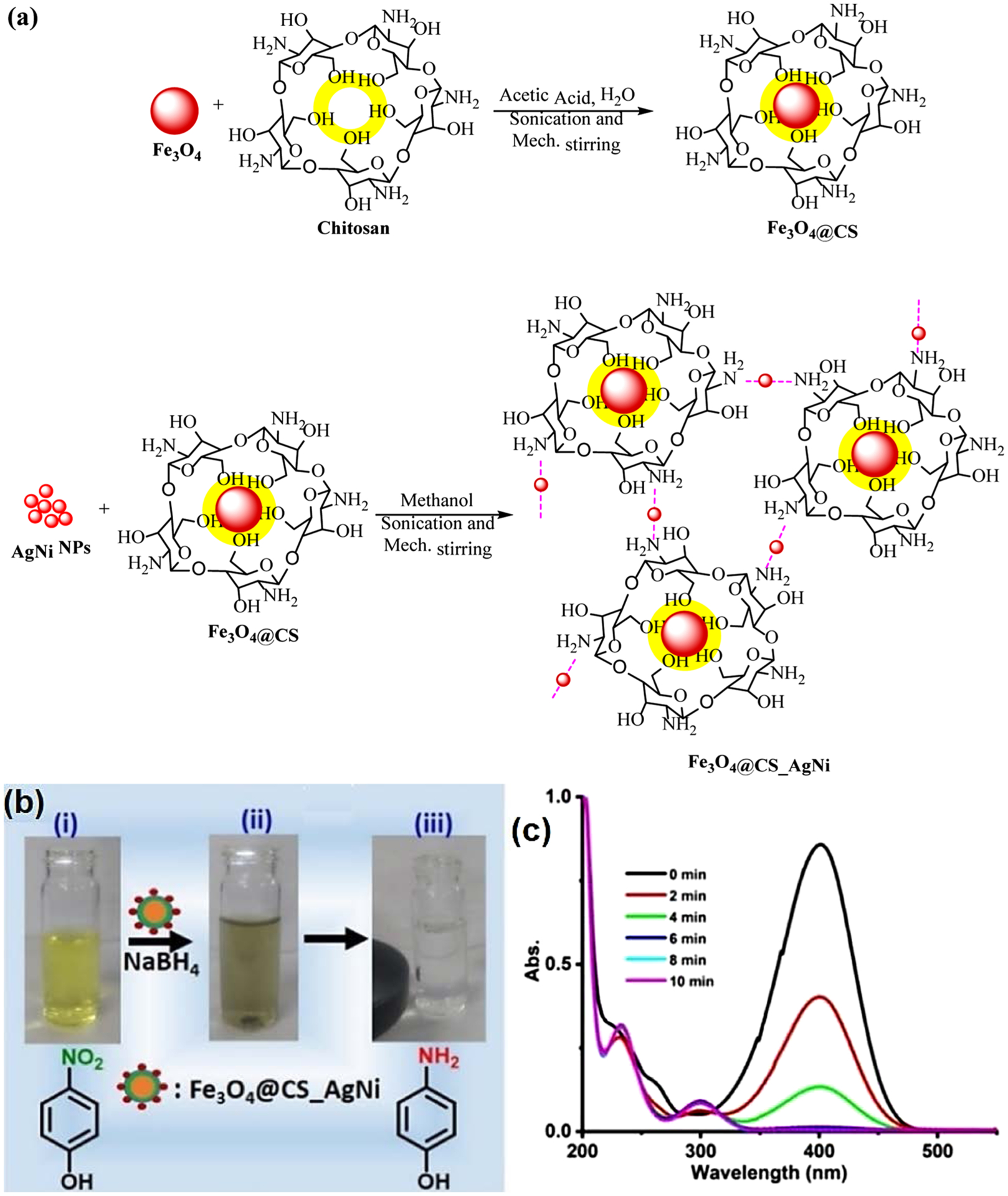

Additionally, by designing the core/shell structures, the surface functionalities of the natural polymers could be made easily available to metal/metal oxide NPs (Ghosh Chaudhuri & Paria, 2012). In this regard, Antony et al. (Antony, Marimuthu, & Murugavel, 2019) developed a facile and novel approach for anchoring bimetallic AgNi NPs (20~25 nm) on Fe3O4@chitosan core/shell support (Fe3O4@CS_AgNi) as a heterogeneous retrievable nanocatalyst (Fig. 5); magnetic nanocomposite has been applied for the rapid and nearly quantitative reduction of 4-nitrophenol (4-NP) using NaBH4 within 10 min under ambient conditions. Furthermore, the heterogeneous nanocatalyst could be simply recovered/separated using an external magnet and reused seven times.

Fig. 5.

Preparation of Fe3O4@CS_AgNi nanocomposite, (b) Color changes observed during 4-NP reduction; (i) bare 4-NP, (ii) 4-NP + magnetic nanocomposite + NaBH4, (iii) easy separation of magnetic nanocomposite via a magnet after the complete 4-NP reduction, (c) time dependent evolution illustrating the 4-NP reduction to 4-AP catalyzed by Fe3O4@CS_AgNi nanocomposite. Reproduced with permission from Ref. (Antony et al., 2019).

Applications of wide ranging chitin/chitosan-based nanomaterials for the removal of water contaminants and toxic pollutants such as various dyes, heavy metals and pharmaceutical materials are summarized in Table 3.

Table 3.

Various chitin and chitosan-based nanomaterials used for water/wastewater treatment.

| Chitin and chitosan-based nanomaterials | Contaminants | Ref. |

|---|---|---|

| Chitosan films containing urea modified TiO2 | MG | (Pérez-Obando et al., 2019) |

| CS/MCM-41/nano-γ alumina | MB | (Teimouri, Ghased, Nasab, & Habibollahi, 2019) |

| Chitosan clay nanocomposites | Cu(II) | (Azzam et al., 2016) |

| Chitosan-polyethyleneimine-graphene oxide nanocomposite membrane coating | Cr(VI) and Cu(II) | (Bandara, Nadres, & Rodrigues, 2019) |

| Carboxymethyl chitosan coated nano zerovalent iron beads | Cr(VI) | (Xie et al., 2018) |

| Chitosan modified with polyhexamethylene biguanide | Cr(VI) | (Aslani, Kosari, Naseri, Nabizadeh, & Khazaei, 2018) |

| Chitosan/organic rectorite-Fe3O4 composite microspheres | Cu(II) and Cd(II) | (Xie et al., 2015) |

| Nano-ZnO/chitosan microspheres | MO | (Zhong, Zhong, Huo, Yang, & Li, 2020) |

| Attapulgite/CoFe2O4@SiO2-chitosan/EDTA | Cd(II) | (Wang, Ran et al., 2020; Wang, Zhou et al., 2020) |

| Polymaleic acid-chitosan microspheres | Cd(II) | (Yu et al., 2017) |

| Cu@chitosan-silica nanoparticles | 1,1-Dimethylhydrazine | (Wang et al., 2019) |

| Chitosan-coated fly ash | Cr(VI) | (Wen, Tang, Chen, & Gu, 2011) |

| Polyvinylidene fluoride/chitosan/dopamine | MB and orange G | (Zhang, Li et al., 2019) |

| Bilayer amino-functionalized cellulose nanocrystals/chitosan composite | Diclofenac sodium | (Hu et al., 2019) |

| Zinc ferrite-CS, Nickel ferrite-CS, Cobalt ferrite-CS | Fluoride | (Kumar, Dosanjh, & Singh, 2019) |

| Chitosan-magnetite nanocomposite | Cr(VI) | (Bavasso, Vuppala, & Cianfrini, 2019) |

| Chitosan-4-nitroacetophenone/CuO-CeO2-Al2O3 and Chitosan-4-nitroacetophenon/CuO-CeO2-Fe2O3 | Red 60 | (Mohamed et al., 2019) |

| Fe3O4-chitosan micro- and nanoparticles | Bromothymol Blue | (Akın Sahbaz, Yakar, & Gündüz, 2019) |

| MIL-100(Fe) and nano-Fe3O4 onto the chitosan | Sb(III) | (Xiong et al., 2020) |

| Nano titanium oxide/chitosan/nano-bentonite | Levofloxacin and Ceftriaxone | (Mahmoud, El-Ghanam, Mohamed, & Saad, 2020) |

| Chitosan/cerium oxide/iron oxide nano-composite | Cr(VI) and Co(II) | (Farokhia, Parvareha, & Moravejia, 2019) |

| Chitosan supported ZnO and Ce-ZnO nano-flowers | Malachite green | (Saad et al., 2020) |

| Chitosan nano zerovalent iron activated carbon composite beads | Cu(II) | (Sikdera et al., 2019) |

| Salicylaldehyde functionalized chitosan NPs | Cu(II), Cd(II) and Pb(II) | (Hussain, Musharraf, Bhanger, & Malik, 2020) |

| 2D Ag-TiO2/γ-Al2O3/Chitosan nano-composite | Nitrate | (Zarei et al., 2020) |

| Chitosan/silver nanoparticle/copper nanoparticle/carbon nanotube multifunctional nano-composite | Cu(II), Cd(II) and Pb(II) | (Alsabagh, Fathy, & Morsi, 2015) |

| Zirconium chitosan composite | Cr(VI) | (Zhang, Xia, Teng, Liu, & Zhang, 2013) |

| Wet-spun nanoTiO2/chitosan nanocomposite fibers | Free fatty acids | (Bao et al., 2019) |

| MnFe2O4 impregnated chitosan-microspheres | MB | (Jyothi et al., 2019) |

| Humic acid modified magnetic chitosan NPs | Uranium | (Basu, Saha, Pimple, & Singhal, 2019) |

| Pd NPs@Fe3O4/CS-AG microcapsules | 4-NP | (Baran & Nasrollahzadeh, 2019) |

| Chitosan-zirconium phosphate nanostructures | Reactive blue-21, Reactive Red 141, Rhodamine-6 G | (Bhatt, Ageetha, Rathod, & Padmaja, 2019) |

| Chitosan grafted thin film nanohydrogel | Cr(VI) | (Sethy, Pradhan, & Sahoo, 2019) |

| Nanoscale zero-valent iron loaded chitosan | U(VI) | (Zhang, Zhao et al., 2019; Zhang, Ma et al., 2019) |

| Functionalized chitosan clinoptilolite nanocomposites | Nitrate | (Yazdi, Anbia, & Salehi, 2019) |

| Chitosan coated magnetic NPs | Cu(II) | (Zhou, Nie, Branford-White, He, & Zhu, 2009) |

| Nickel oxide/chitosan nano-composite | Zn(II) | (Abdolmohammad-Zadeh, Ayazi, & Naghdi, 2019) |

| Magnetic β-cyclodextrin-chitosan/graphene oxide | MB | (Fan, Luo, Sun, Qiu, & Li, 2013) |

| Magnetic graphene/chitosan | Acid Orange 7 | (Sheshmani, Ashori, & Hasanzadeh, 2014) |

| Carboxymethyl chitosan coated Fe3O4 NPs | Direct Red 16 | (Zinadini et al., 2014) |

| CS/β-CD/Nano-ZnO composite | CR | (Yan, Zhang, & Li, 2018) |

| Ag2O/TiO2 modified chitosan | MO | (Zhao, Tao, Xiao, & Su, 2017) |

| NiFe2O4 nanocomposite grafted chitosan | Cr(VI) | (Zhang, Wu, & Fan, 2019) |

| Thiocarbohydrazide chitosan gel | Cr(VI) | (Li et al., 2017) |

| 3,5-Dinitrosalicylic acid/chitosan/MnFe2O4 | MB | (Shoueir et al., 2018) |

| Chitosan zinc oxide nano-beads | MB and safranin | (Roshitha, Mithra, Saravanan, Sadasivam, & Gnanadesigan, 2019) |

| Chitin/chitosan nano hydroxyapatite composite | Cu(II) | (Gandhi, Kousalya, & Meenakshi, 2011) |

| Chitin powder | Ag(I) | (Songkroah, Nakbanpote, & Thiravetyan, 2004) |

| Chitosan gel beads | Ag(I) | (Zhang, Helleur, & Zhang, 2015) |

| Chitosan/triethanolamine composite | Ag(I) | (Zhang et al., 2012) |

| Thiol-functionalized chitin nanofibers | As | (Yang et al., 2015) |

| Chitosan-coated biosorbent | As | (Boddu, Abburi, Talbott, Smith, & Haasch, 2008) |

| Fly ash coated by chitosan | As | (Adamczuk & Kołodyńska, 2015) |

| Chitin | Au | (Côrtes, Tanabe, Bertuol, & Dotto, 2015) |

| Chemically modified chitosan | Au | (Donia, Atia, & Elwakeel, 2007) |

| Chitosan derivative | Au | (Wang et al., 2012) |

| Glycine crosslinked chitosan resin | Au | (Wang et al., 2012) |

| Chitosan films | V | (Cadaval, Dotto, Seus, Mirlean, & de Almeida Pinto, 2016) |

| Ti-doped chitosan bead | V | (Liu & Zhang, 2015) |

| Protonated chitosan flakes | V | (Padilla-Rodríguez et al., 2015) |

| N-citryl chitosan | V | (Mujeeb, Alikutty, & Muraleedharan, 2014) |

| Chitin networks | U | (Schleuter et al., 2013) |

| Amidoximated chitosan polyacrylonitrile | U | (Xu et al., 2015) |

| Chitosan/bentonite composite | U | (Anirudhan & Rijith, 2012) |

| Magnetic chitosan resin | U | (Zhou, Shang, Liu, Huang, & Adesina, 2012) |

| Chitosan saturated montmorillonite | Pb(II) | (Hu, Zhu, Cai, Hu, & Fu, 2017) |

| Modified chitosan/CoFe2O4 particles | Pb(II) | (Fan et al., 2017) |

| Thiosemicarbazide-modified chitosan | Pb(II) | (Li, Zhang, Li, Wang, & Ali, 2016) |

| Magnetic chitosan/clinoptilolite/magnetite | Pb(II) | (Javanbakht, Ghoreishi, Habibi, & Javanbakht, 2016) |

| Magnetic chitosan | Hg(II) | (Kyzas & Deliyanni, 2013) |

| Coarse chitin | Hg(II) | (Barriada, Herrero, Prada-Rodríguez, & de Vicente, 2008) |

| Raw chitin and surface-modified chitin | Co(II) | (Dotto, Cunha, Calgaro, Tanabe, & Bertuol, 2015) |

| Chitosan polymethacrylate nanoparticles | Co(II) | (Shaker, 2015) |

| Modified chitosan resin | Co(II) | (Monier, Ayad, Wei, & Sarhan, 2010) |

| Cellulose acetate/chitosan/single walled carbon nanotubes/Fe3O4/TiO2 | As(V), Cr(VI), MB, CR | (ZabihiSahebi et al., 2019) |

| Titanium dioxide/chitosan/poly(lactide-co-caprolactone) composite membrane | Cu(II) | (He et al., 2019) |

| Molecularly imprinted polymer (MIP) chitosan-TiO2 nanocomposite | Rose Bengal | (Ahmed, Abdelbar, & Mohamed, 2018) |

| TiO2(KH-570)-g-(chitosan-glycidyl methacrylate) | Toluene, Pb(II) | (Chen, Song, Huang, & Wang, 2019) |

| TiO2 doped chitosan microspheres supported on cellulose acetate | MO | (Shi, Zhang, Ma, Xiang, & Li, 2019) |

| Chitosan tripolyphosphate/TiO2 nanocomposite | Reactive orange 16 | (Abdulhameed, Mohammad, & Jawad, 2019) |

| Schiff’s base cross linked chitosan-glutaraldehyde TiO2 nanoparticles | Reactive red 120 | (Jawad, Mubarak, & Abdulhameed, 2020) |

| Hybrid crosslinked chitosan-epichlorohydrin/TiO2 nanocomposite | Reactive red 120 | (Jawad, Mubarak, & Abdulhameed, 2020) |

| Chitosan ethylene glycol diglycidyl ether/TiO2 nanoparticles | Reactive orange 16 | (Abdulhameed, Jawad, & Mohammad, 2019) |

| TiO2 supported 3D printed chitosan scaffolds | Amoxicillin | (Bergamonti et al., 2019) |

| Hybrid chitosan-TiO2/ZnS | Aromatic amines, carboxylic acids | (Jbeli, Ferraria, do Rego, Boufi, & Bouattour, 2018) |

| Crosslinked magnetic EDTA/chitosan/TiO2 | Phenol, Cd(II) | (Alizadeh, Delnavaz, & Shakeri, 2018) |

| 2D Ag-TiO2/γ-Al2O3/chitosan | Nitrate | (Zarei et al., 2020) |

| Chitosan-AgCl/Ag/TiO2 | Toluidine, salicylic acid, 4-aminomethyl benzoic acid | (Jbeli, Hamden et al., 2018) |

| Chitosan beads | Tartrazine, amido black, CR | (Mincea, Patrulea, Negrulescu, Szabo, & Ostafe, 2013) |

| Chitosan films | Mixture of Diclofenac and Ketoprofen | (Rizzi et al., 2019) |

2.3. Starch-based (nano)materials

2.3.1. Chemistry and properties

Starch, a natural, abundant, renewable, biocompatible and biode gradable biopolymer is present in sundry plants as a reserve carbohydrate and is commonly found in many parts of plants such as stalks, roots, and crop seeds; main sources being cassava, wheat, rice, maize or corn, and potatoes, among others. Starch granules have a 3D architecture with crystallinity in the range of 15–45 % and comprise d-glucose units with bio-macromolecules including amylopectin, branched (1→6) α-d-glucan, amylose, and linear (1→4)-linked α-d-glucan (Visakh, Mathew, Oksman, & Thomas, 2012; Zobel, 1988). Microcrystalline starch, starch nanocrystal, starch crystallite, and hydrolyzed starch all embody the crystalline part of the starch generated via hydrolysis (Le Corre, Bras, & Dufresne, 2010); modes for preparing crystalline and amorphous starch nanostructures with varying morphologies and crystallinities are shown in Fig. S3.

The mixing of fibrous clays with natural polymers is an appealing alternative for removing pollutants from water. Biopolymers e.g. guar gum or starch can be combined with polyacrylic acid (PAA) and polyacrylamide (PAAm) to develop eco-friendly and biodegradability superabsorbents (Li, Liu, & Wang, 2005). Generally, the incorporation of clays has boosted water absorption rate and water absorbency of these catalytic systems as noted for the starch/g-PAAm and guar gum-g-PAA (Ruiz-Hitzky et al., 2013). For example, the effect of sepiolite modification with cationic starch on the physical properties such as increased Young’s modulus of the composites obtained as a reinforced starch film was investigated (Chivrac, Pollet, Schmutz, & Avérous, 2010).

Among the naturally occurring polymers, starch polysaccharides; especially starch nanocrystals, have been increasingly utilized as ideal supports to afford environmentally benign and practical catalyst systems due to their high surface area, high abundance, non-toxicity, low cost, renewability, and biocompatibility (Ghaderi, Gholinejad, & Firouzabadi, 2016; Gholinejad, Saadati, Shaybanizadeh, & Pullithadathil, 2016; Herreros-López et al., 2016). Nanocrystalline starch is ideal for the reinforcement of a biopolymer compared to amorphous or amorphous starch (Angellier, Molina-Boisseau, & Dufresne, 2005; Jenkins, Cameron, & Donald, 1993). Functionalized natural starches can generally be attractive supports for various colloidal metal NP-based catalysts owing to their abundance, biocompatibility, and biodegradability.

2.3.2. Applications for water treatment

2.3.2.1. Removal of organic pollutants.

The modified starch had significantly greater water binding capacities than native starch and their amylase digestibility decreased as their degree of crosslinking increased (Jyothi, Moorthy, & Rajasekharan, 2006); for example, epichlorohydrin is the most familiar crosslinking agent that can be utilized for natural polysaccharides. Guo, Li, Liu, Meng, and Tang (2013) synthesized a crosslinked porous starch by crosslinking corn starch with epichlorohydrin and then hydrolyzing it with α-amylase, ensuing catalyst could be successfully utilized in MB adsorption from water with a maximum adsorption capacity from Langmuir isotherm model being 9.46 mg g−1 at 293 k.

(Photo)catalysts, often deployed for (photo)degradation of environmental contaminants, are commonly metal oxide/metal acid salts of n-type semiconductors, including TiO2, Fe2O3, ZnO, etc; (Rostami--Vartooni, Nasrollahzadeh, Salavati-Niasari, & Atarod, 2016; Wang, Wang et al., 2018; Wang, Li et al., 2018) relatively inexpensive TiO2 NPs have been extensively studied as environmentally friendly (photo) nanocatalysts owing to their nontoxicity, and stability (Al-Harbi, Kosa, Abd El Maksod, & Hegazy, 2015; Hassan, Chen, Liu, Zhu, & Cai, 2014; Rostami-Vartooni et al., 2016). Starch as a biodegradable and renewable raw material, offers additional sustainability/stability to the nano-particles similar to graphene (Doustkhah & Rostamnia, 2016; Ye, Hao, Liu, Li, & Xu, 2017) and carbon nanotubes (Ihsanullah, 2019). The modification of starch can be accomplished easily because of its hydroxyl groups which have strong bonding with diverse functional groups and are amenable to easy chemical transformation. Guo, Wang, Zheng, and Jiang (2019) investigated the photodegradation and adsorption of cationic golden yellow X-GL/cationic yellow 28 dye from water/wastewater by TiO2 NPs (~10 nm) loaded onto the crosslinked carboxymethyl starch (CCMS) surface (TiO2 NPs/CCMS) as a novel biosorbent by the sol-gel technique (Fig. S4); TiO2 NPs/CCMS was reused for four successive cycles.

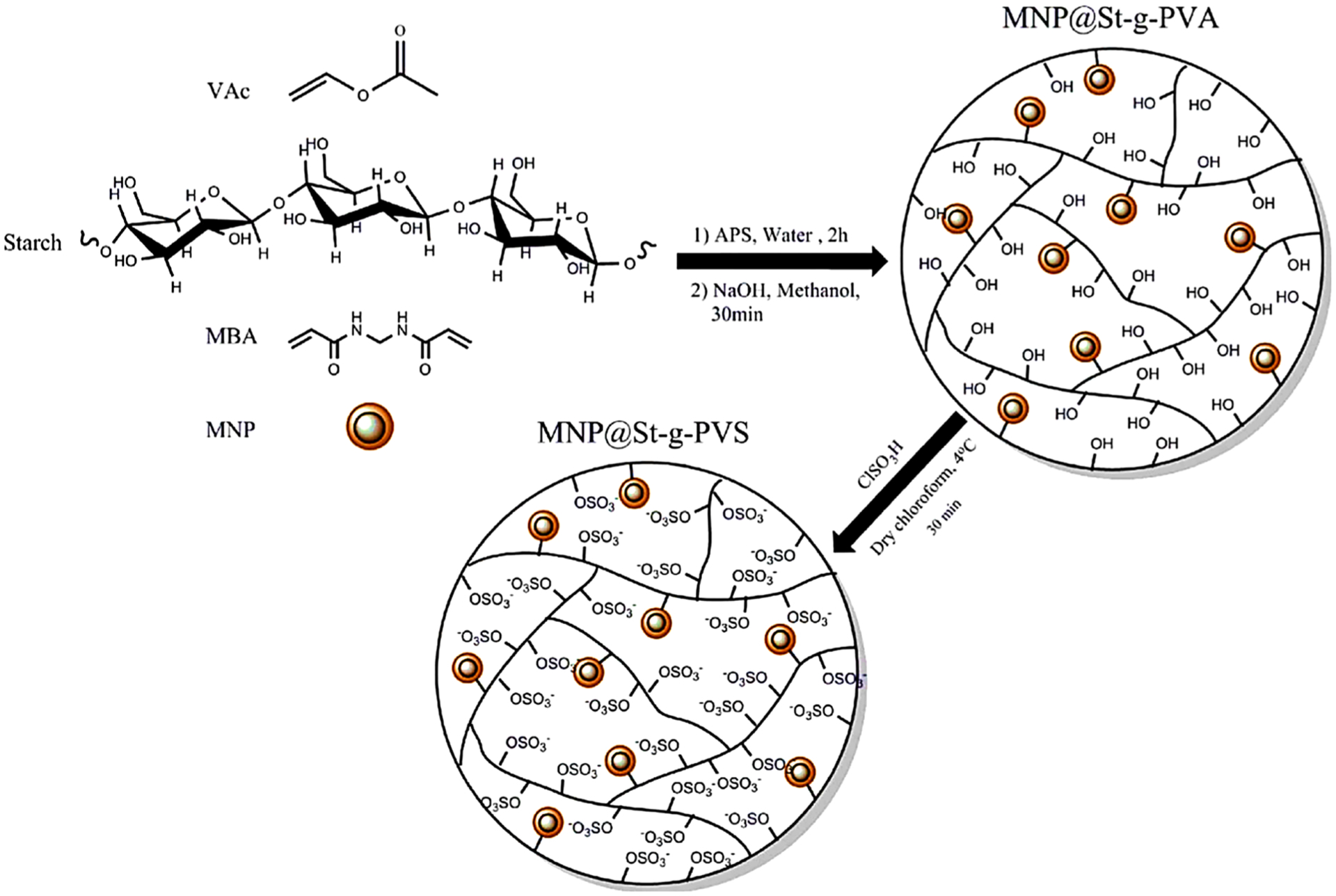

Negatively charged starch can efficiently adsorb various cationic dyes (Huang, Chang, Lin, & Dufresne, 2014; Pourjavadi, Abedin-Moghanaki, & Tavakoli, 2016). In a related study, Guo, Wang, Zheng, and Jiang (2019) prepared crosslinked cationic starch from corn starch and 3-chloro-2-hydroxypropyl trimethylammonium chloride and epichlorohydrin as cationic etherification and crosslinked agents, respectively. Crosslinked cationic starch was applied to eliminate reactive golden yellow SNE dye from aqueous solutions and its maximum adsorption capacity was found to be 208.77 mg g−1 at 308.15 K. Besides, Pourjavadi et al. (2016) functionalized magnetic crosslinked starch materials with PVA modified by chlorosulfonic acid based vinyl acetate copolymerization onto crude starch (sulfation of its hydroxyl groups) to generate MNPs@Starch-g-poly(vinyl sulfate) nanocomposite (Fig. 6). It can effectively eliminate cationic dyes such as MG and MB from water; excellent adsorption capacities of 567 and 621 mg g−1, respectively, were demonstrated and up to 90 % of MB and MG dyes could be removed from the solution by the regenerated adsorbent even after five cycles of adsorption-desorption.

Fig. 6.