Abstract

Ultrasound as an eco-friendly green technology has been widely studied in food processing. Nevertheless, there is a lack of publications regarding the application of ultrasound in food processing using large-scale reactors. In this paper, the mechanisms and the devices of multi-frequency power ultrasound (MFPU) are described. Moreover, the MFPU applied in enzymolysis of protein, and washing of fruits and vegetables are reviewed. The application of MFPU can improve the enzymolysis of protein through modification on enzyme, modification on substrate materials, and facilitation of the enzymatic hydrolysis process. The ultrasound treatment can enhance the removal of microorganisms, and pesticides on the surface of fruits and vegetables. Furthermore, the reactors of ultrasound-assisted enzymolysis of protein, and washing of fruits and vegetables on the industrial scale are also detailed. This review paper also considers future trends, limitations, drawbacks, and developments of ultrasound application in enzymolysis and washing.

Keywords: Ultrasonication, Enzymolysis, Washing, Pesticide, Microorganism, Industrial-scale

1. Introduction

Food processing transforms agricultural produce into ready to eat items for humans through different unit operations. Throughout the processing operations and keeping the product safe for human consumption, processes must be shelf-stable without altering the desired taste, aroma, and delicacy [1]. Modern industrial food processing and preservation started with canning in the eighteenth century, and now the twenty-first century has become the inevitable part of the human food chain. The fundamental food processing operations (heat exchange in different forms and stages, drying, fermentation, packaging, evaporation, mixing, sorting/separation, forming, pumping and others) in different food systems (fruits and vegetables, dairy, meat, and cereals) have become more efficient with the combined technologies and application of computer and information technology [2], [3].

The ultrasound technology has transformed food processing manufacturing with its extensive use in numerous processes among the technologies applied in the food processing industry. This sustainable technology itself is a rapid, low-cost, non-thermal, non-destructive technology with many advantages: rapid processes, enhanced process efficiency, elimination of process steps, better quality product and retention of the volatile profile, sensory quality, and aesthetical characteristics of food products, leading to improved shelf-life [4], [5]. Traditionally, most food processing unit operations involve applying energy-intensive heat application or chemical treatment to control or inhibit the foodborne pathogens from making food safe for consumption without imparting secondary pollution. Due to the strategic mechanical and/or chemical effect, this novel application of ultrasound in food processing has been proved to be an efficient way to improve shelf-life, remove the microbial load, enhance fermentation output, clean pesticide, and enhance drying rate with better quality and nutrition retention, better emulsification, crystallization, filtration, efficient thawing, and many others [2], [6], [7], [8].

Different ultrasonic frequency ranges, transducer orientation, and application medium have been used in food industries according to the processing requirements or applicability [7], [9]. Historically, single-frequency ultrasonic reactors are commonly used in different ultrasonication, but in recent decades combining different ultrasonic frequencies reported to be more efficient in many food processing applications [1], [2], [10]. A series of multiple frequencies has been reported to be effective and efficient in different unit operations [11], [12], [13], [14]. Successful research has led to developing industrial-scale application of multi-frequency power ultrasound on protein enzymolysis, and fruits and vegetables cleaning system at the Institute of Food Physical Processing at Jiangsu University, Zhenjiang, China, which will be described below. It has been reported that multi-frequency generator systems have grated benefits because they can produce different cavitation bubble sizes, amplify the numbers of cavitation bubbles, and reduce the thickness of the boundary layer near the adjacent surface [15]. These effects result in the more effective exclusion of smaller particles while cleaning fruits and vegetables. Similarly, these cavitation benefits also help in removing microorganisms [5], [16], [17], [18], enzymolysis [19], [20], [21], [22], [23], protein modification [24], [25], [26], [27], [28]. Moreover, a large number of publications mainly focus on the application of ultrasound technology in food processing using lab-scale equipment. The equipment of multi-frequency power ultrasound on large industrial scale is seldom reported.

Therefore, this review article summarizes the current use and possible applications of multi-frequency power ultrasonic systems in the selected food processing industry including enzymolysis of protein, and washing of fruits and vegetables, to enhance or improve the efficiency of the unit operations and sketch the potential commercial application for large scale reactors.

2. Background of ultrasound

2.1. Principles of power ultrasound in food processing

When a violinist plays the violin, sound waves are generated through the vibration of the violin's strings. This sound wave is transmitted to human ears and is called music. In fact, all sound waves are similar to them. It is a process in which mechanical vibration propagates in the medium in the form of longitudinal waves.

Ultrasound is a process of propagation of mechanical vibration in a medium. The effect of ultrasound and medium can be divided into thermal, mechanical and cavitation mechanisms [29]. In the food processing process, ultrasonic waves act on food materials through various physical and chemical effects produced by the mechanisms. The thermal mechanism of ultrasonic waves means that when ultrasonic waves propagate in the medium, their vibration energy is absorbed by the medium and converted into heat energy, which increases the temperature of the medium [30]. The heat generated is directly proportional to the absorption coefficient of the medium, the ultrasonic intensity and duration. The mechanical mechanism of ultrasound means that after ultrasound acts on the medium, the particles in the medium will enter a state of vibration with this mechanical wave, thereby enhancing the movement of the particles in the liquid medium and accelerating the mass transfer [29]. In this process, the propagation form of ultrasonic mechanical energy, the particle displacement, vibration velocity, acceleration and sound pressure of the wave process are all related to the ultrasonic self-effects [31].

The cavitation mechanism of ultrasound is a very complex and important process. Ultrasonic waves propagate in the liquid medium in a cycle of alternating positive and negative pressures. When the ultrasonic intensity is strong enough and under negative pressure, the original integrity structure of the liquid itself will be destroyed, and bubbles will be generated. At this time, the gas initially dissolved in the liquid will enter the bubbles. As time goes by, the bubbles will gradually increase. When the sound pressure becomes positive pressure, it shrinks due to the tension on the bubble surface. At this time, the gas in the bubble re-enters the liquid. However, as the surface area of the bubble shrinks, the volume of gas diffused into the liquid is reduced. When the next cycle of alternating positive and negative pressure comes, the volume of gas entering the bubble is always higher than that in the returning liquid. After multiple cycles, the volume of the bubble will become larger and larger, until the bubble cannot withstand the pressure of the internal gas and rupture, thereby releasing energy[32]. The effects of bubble growth, contraction, rupture and a series of physical disturbances produced by ultrasonic waves in liquid media are called cavitation effects [33].

The cavitation effect can be divided into stable cavitation and transient cavitation effect according to whether the cavitation bubble bursts or not, [34], [35]. The bubbles in the stable cavitation effect will produce a series of acoustic effects when they propagate in the liquid medium. The micro-jet is one of them. The occurrence of micro-jet is due to the violent circular motion of bubbles, which causes vortexes to be generated around the bubbles in the liquid medium [36]. The violent disturbance generated by the stable cavity can improve the mass transfer and heat transfer efficiency, and the effect achieved is unmatched by ordinary mechanical stirring [37]. In addition, the stable cavitation effect can induce cell membrane deformation. If the cell is placed in a stable cavitation effect environment, its structure will be destroyed. This is due to the significant velocity gradient difference between the surface of the cavitation bubble and the liquid medium. The unbalanced force produced by this gradient difference causes cell destruction [38].

The transient cavitation effect means that the ultrasonic cavitation bubble will expand rapidly under higher sound pressure [39]. When its volume reaches a critical point, the oscillating frequency of the bubble just coincides with the ultrasonic frequency, the bubbles will burst quickly during the compression stage, and a large amount of energy will be released. The burst of a cavity bubble will generate instantaneous high temperature (above 5000 K) and high pressure (70–100 MPa) around it [40]. Under such instantaneous high temperature and violent pressure changes, it will cause chemical changes both inside the cavity and the liquid medium around the bubble, such as the generation of primary and secondary free radicals [41], the formation of nitrogen dioxide from the interaction between the dissolved nitrogen and oxygen in the medium, causing the decrease of pH [42], and the pyrolysis of organic substances [43], [44], etc.

2.2. Application of ultrasound in food processing

Ultrasound has a frequency range of 18 kHz to 10 MHz [45]. According to the frequency range of ultrasonic waves, ultrasonic waves can be divided into high-frequency and low-frequency ultrasound [2]. The frequency of the former ranges over 1 MHz, which is mainly used for food non-destructive testing, quality evaluation, and process control to ensure the quality and safety of food. The frequency of the latter ranges from 18 to 100 kHz, which is mainly used in food processing, such as extraction [46], enzymolysis of protein [11], modification of starch [14], sterilization [47], inactivation of enzymes [48], washing [49], [50], osmotic dehydration [13], freezing [51], [52] and thawing [53].

Fig. 1 shows the analysis results of ultrasound application in “Food Science Technology”. There were 4068 articles based on the keywords of “Ultrasound, or Ultrasonic, or Sonication” in the web of science (WoS) database (2017 to 2021) with the subject classification “Food Science Technology”. The overlay visualization (Fig. 1A), and the ranking of institutions (Fig. 1B) were obtained using the software VOSviewer (Version 1.6.17) and the WoS system, respectively. As shown in Fig. 1A, extraction, protein, storage, and determination were the main research hotspots in recent five years. The emerging trend of hotspots including protein, shelf life, modification, mechanism, vitro was also shown in the Fig. 1A. The research spots of “ultrasound” and “protein” mainly include extraction, enzymatic hydrolysis, modification, and peptides. Fig. 1B exhibits the ranking of institutions by the number of published papers in “Food science technology”. The Jiangsu University has the most publications (179), followed by Jiangnan University (145), South China University of Technology (91), Islamic Azad University (82), and Zhejiang University (74). Eight institutions of top ten are Chinese.

Fig. 1.

Analysis results of ultrasound application in “Food Science Technology” in recent years (2017–2021) (A) Overlay visualization; (B) Ranking of institutions by the number of published papers.

2.3. Ultrasonic devices

The cavitation effect plays a decisive role in the application of ultrasonic wave. Ultrasonic cavitation is a complex physical and chemical process. The formation and collapse of cavitation bubbles depend on ultrasonic parameters, fluid viscosity, system flow rate, gas content, system temperature, and other conditions [54]. Generally, not all cavitation bubbles can generate a significant cavitation effect for ultrasonic cavitation [55]. The bubble nucleus can grow to the cavitation bubble, producing cavitation effect only under selecting suitable conditions. Under this condition, the cavitation bubbles oscillate, grow, contract, and collapse. Then the physical and chemical interactions and extreme physical environment of high temperature and high pressure occur in the tiny space around the cavitation bubble, which provides conditions for the application of ultrasonic in the field of food processing [56], [57], [58], [61].

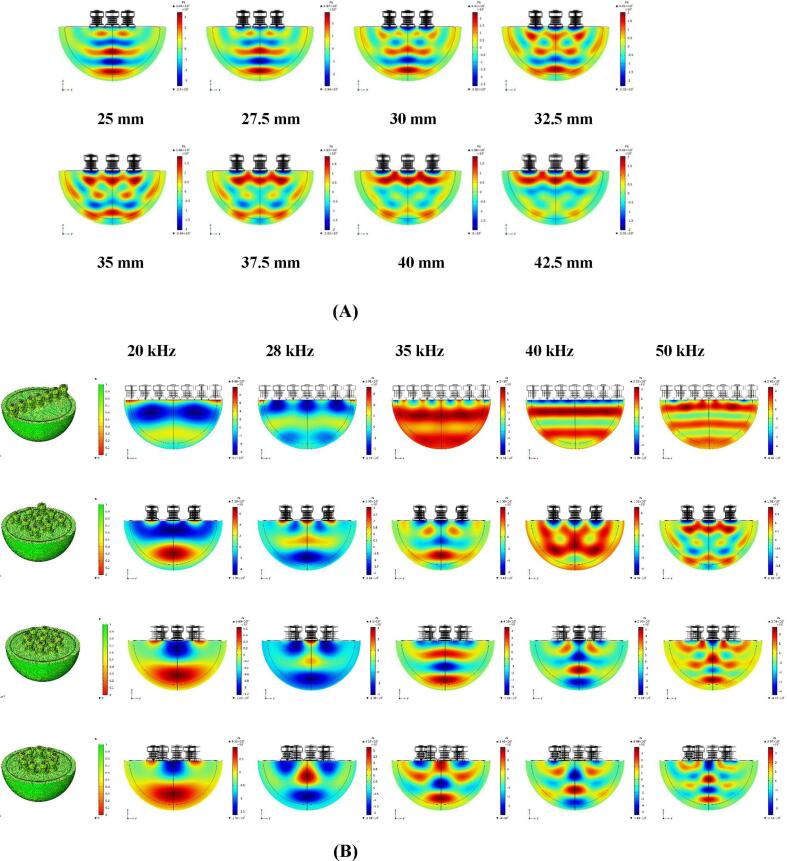

The ultrasonic parameters greatly affecting the cavitation effect mainly include ultrasonic frequency, intensity, ultrasonic transducers’ design. The ultrasonic frequency plays a crucial role in the yield of sonochemical reactions [59]. However, a single-frequency ultrasonic cleaning tank (bath) and ultrasonic cell crusher (probe) are widely used in research work worldwide. There are widespread problems such as excessive ultrasonic power and uneven sound field distribution of sound field caused by standing wave formation, which is far from playing the role of ultrasound in food processing. It seriously restricts the theoretical research, technical development, and industrial application of ultrasonic technology. Ding et al. [55] evaluated the effect of different ultrasonic frequencies (20, 28, 35, 40, and 50 kHz) on the cavitation effect using a numerical simulation model to realize the acoustic field’s distribution visualizing. Fig. 2 showed the acoustic field distribution in the Z direction at frequencies of 20, 28, 35, 40, and 50 kHz. The apparent effects of the standing wave in the acoustic field at every frequency could be observed, resulting in the uneven distribution of the sound field.

Fig. 2.

Distribution of acoustic field with the frequency of 20, 28, 35, 40, and 50 kHz in the Z-direction.

Moreover, it was also found that spacing of transducers (Fig. 3A) and arrangement of transducers (Fig. 3B) are two important factors affecting the distribution of sound field [60]. As shown in Fig. 3A, when the spacing of transducers was 25.0 mm and 27.5 mm, the acoustic side lobes were less and the acoustic energy was more concentrated. Reducing the spacing of transducers could effectively inhibit the formation of acoustic side lobes. With the increase of transducer spacing, the number of side lobes in the acoustic field increased, and the absolute sound pressure decreased due to the dissipation of sound energy radiation. In addition, the distribution of the sound field became more and more uneven due to the narrowing of the width of the main lobes. The results from Fig. 3B show that no obvious sound pressure distribution law can be observed in the arrangements of transducers under different frequencies. The absolute sound pressures in linear arrangements of transducers for 40 and 50 kHz were higher than others. Circular and ring arrangements of transducers were more likely to produce standing waves, thereby causing the uneven distribution of the sound field. Compared to circular and ring arrangements, the linear and rectangular arrangements exhibited a more even sound field distribution.

Fig. 3.

Distribution of acoustic field in Z-direction of spacing of transducers in 50 kHz (A), and the arrangements of transducers (B) Spacing between of is 25 mm, 27.5 mm, 30 mm, 32.5 mm, 35 mm, 37.5 mm, 40 mm and 42.5 mm, respectively.

In order to solve the poor ultrasonic effect problem and fewer cavitation events resulting from the uneven distribution of sound field, the research team (at the Institute of Physical Food Processing, School of Food and Biological Engineering at Jiangsu University, Zhenjiang, Jiangsu, China.) developed multi-mode multi-frequency power ultrasonic techniques including sweeping and fixed frequency ultrasound, pulse and continuous ultrasound, single- and multi-frequency ultrasound, and multi-frequency ultrasound in sequential and simultaneous working modes. Accordingly, a great many multi-mode multi-frequency power ultrasonic devices have been designed independently (Fig. 4). These devices have been successfully used in many fields of food processing, such as extraction [61], thawing [62], maturation [63], drying [13], [64], degradation [14], blanching [65], sterilization [47], enzymolysis including modification on enzyme [66], modification on substrate materials [67], and treatment on enzymatic hydrolysis process [15], washing including pesticide removal [50], microorganism reduction [5], and quality retention [68].

Fig. 4.

Schematic diagrams of lab-scale multi-frequency power ultrasonic devices in the School of Food and Biological Engineering, Jiangsu University. [A. Cup-type single frequency counter current ultrasonic device (20, 28, 35, 40, and 50 kHz); B. Dual-frequency sweeping ultrasonic device (22, 28, 33, 40, and 68 kHz;); C. Cup-type dual-frequency counter current ultrasonic device (20, 28, 35, 40, and 50 kHz); D Hexagonal tri-frequency ultrasonic device (20, 28, 35, 40, 50 and 60 kHz); E. Cylindrical five frequency counter current ultrasonic device (20, 28, 35, 40, and 50 kHz); F. Slit type six frequency ultrasonic device (20, 23, 25, 28, 33, and 40 kHz).

3. Application of power ultrasound in enzymolysis of protein

Protein provides the essential amino acids for the growth and metabolism of the human body and has many specific metabolic functions related to physiologically active substances [69]. Nevertheless, many proteins have low bioavailability due to structural defects in their molecules or are rich in anti-nutritional factors, and food processing and heat treatment, which cannot be completely digested and absorbed by the human body. At present, enzymatic hydrolysis is the most commonly used method to improve the functional properties of proteins [67], [70]. However, traditional enzymatic hydrolysis technology has shortcomings including low reaction efficiency, long enzymolysis time, low substrate conversion rate, low product activity and product yield [71], [72]. Ultrasonic technology is widely used in the intensive research of enzymatic hydrolysis reaction due to its advantages of short action time, simple operation, easy control, and low temperature rise [73].

3.1. Ultrasound-assisted enzymolysis in three ways

The main applications of ultrasound in enzymatic hydrolysis focus on three aspects: ultrasonic modification on enzyme [39], ultrasonic modification on substrate materials [74], and ultrasonic treatment on enzymatic hydrolysis process [75].

3.1.1. Ultrasonic modification on enzyme

An enzyme is a protein, and its activity is determined by the state and degree of exposure of the active centre existing on the enzyme molecule. Many biochemical reaction processes can be activated under the application of ultrasound with the participation of enzymes. When ultrasound is applied to the enzyme molecule, the energy released can cause the conformation of the enzyme molecule to change, thereby affecting the change of catalytic activity [39]. Reasonable conformational changes can increase enzyme activity, while irrational or destructive changes reduce enzyme catalytic activity [15].

Generally speaking, the proper intensity of ultrasonic irradiation can make the conformation of the enzyme forward and improve the enzymes’ activity and the substrates’ conversion rate [76]. Ultrasonic treatment under low intensity can increase in the energy of enzyme molecules and the temperature of the medium, causing slight changes in the conformation of enzyme molecules. This makes the ultrastructure of enzyme molecules more flexible and reasonable, and thus exhibits higher catalytic activity [77]. Nevertheless, under the application of high-intensity ultrasound, the energy of the enzyme molecule is further increased, and the conformation tends to be unreasonable, which causes the catalytic activity of the enzyme molecule to be hindered [70].

The effects of ultrasound on the Alcalase were investigated by Ma et al [66]. It was found that the activity of Alcalase was the highest under the ultrasonic power of 80 W for 4 min. At the ultrasonic parameters, the activity was increased by 5.8% compared to without ultrasound. The mechanism can be attributed to the slight increase in the number of tryptophan on the enzyme surface, an increase in the number of α-helix by 5.2% and a decrease in the number of the random coil by 13.6%. These alterations caused the Alcalase exhibit more regularity and flexibility, which favoured the improvement of Alcalase activity.

Kadkhodaee & Povey [78] investigated the effect of ultrasound on the inactivation of Bacillus α-amylase. The results show that ultrasound could lead to protein denaturation, thus enhancing the inactivation of Bacillus α-amylase. The temperature and sonotrode radiating area were the two factors affecting the inactivation rate. The inactivation rate assisted by ultrasound was 24.5 times higher than that without ultrasound application. The mechanism can be attributed to the generation of OH free radicals and shearing force resulting from the ultrasound cavitation effects.

Yang et al [70] studied the extraction effect of peptides from the bovine bone using ultrasound-assisted enzymolysis. The results showed that the extraction yield significantly increased with the ultrasonic power of 1–400 W/L. When the power increased to 800 W/L, the yield of peptides significantly decreased. The triple-helical protein structure was broken and the enzyme structure was destroyed under improper ultrasonic parameters, thereby leading to the enzyme inactivation.

3.1.2. Ultrasonic modification on substrate materials

In addition to the modification of the enzyme, ultrasound pretreatment has been successfully applied to change the structure of substrate materials and improve the substantial enzymolysis efficiency of protein [74]. Many researchers confirmed that ultrasound pretreatment could change the substrate material, making the substrate easier to be enzymatically digested compared to the non-sonication treatment [79], [80], [81]. Besides, the ultrasound treatment of protein prior to enzymolysis can facilitate the substantial reaction and promote the release of peptides during enzymatic hydrolysis (Table 1).

Table 1.

Summary of representative studies on the effects of ultrasound in enzymolysis of proteins.

| Sample matrix | US devices | US conditions | Main Results | Ref./Year |

|---|---|---|---|---|

| Oat-Isolated Protein | Fig. 1A | Frequency: 20 kHz; Power: 250–1250 W. | Under the best conditions of ultrasound pretreatment, the hydrolysis rate and the ACE inhibitory activities of peptides were significantly (P < 0.001) increased by 32.1 and 53.8 %, respectively compared to the samples without ultrasonic pretreatment. | [98]/2015 |

| Wheat gluten (WG) | Fig. 1A | Frequency: 20 kHz; Power density: 200 W/L. | The counter flow ultrasound (CFU) pretreatment resulted in significantly (P < 0.05) higher value compared with control, the ACE inhibitory activity was increased by 29.8 % and the value of IC50 was decreased by 36.92 %. | [99]/2015 |

| Sodium caseinate (NaCas) | Fig. 1A | Frequency: 20, 28, 35, 40, and 50 kHz; Power density: 0–500 W/L. Modes: Mono-frequency | Ultrasound significantly (p < 0.05) increased the degree of hydrolysis (DH), conversion rates of protein, ACE inhibitory. ultrasound successfully improved enzymolysis of NaCas and release more ACE inhibitory activity due to the increases in specific surface area of protein molecule. |

[100]/2017 |

| Rapeseed protein (RP) | Fig. 1B | Frequency: 22, 28, 33, 40, and 68 kHz; Power density: 20–70 W/L; Modes: Mono-, and Dual-frequency | After DFU assisted-enzymolysis, the yield of soluble solids content, including protein, peptides and totalsugar in hydrolysate increased by 64.61%, 40.88% and 23.60%, respectively. The DH increased by 74.38% with DFU assisted-enzymolysis. | [15]/2016 |

| Defatted wheat germ protein (DWGP) | Fig. 1B | Frequency: 22, 28, 33, 40, and 68 kHz; Power: each one was 600 W; Power density: 40–100 W/L; Modes: Mono-, and Dual-frequency | Under the dual-fixed frequency ultrasound mode of 28/40 kHz, the ACE inhibitory activity of DWGP hydrolysate was the highest with its value of 74.75% (increased by 62.30% compared to control). | [101]/2017 |

| Zein protein | Fig. 1B | Sweeping frequency: 40 ± 2 kHz; Power density: 100 W/L; Modes: Mono-frequency | Ultrasonic pretreatment significantly increased the degree of hydrolysis (DH) of zein and the ACE-inhibitory activity of zein hydrolysates by 19.37 and 133.76%, respectively. | [102]/2018 |

| Rapeseed protein | Fig. 1C | Frequency: 20, 28, 35, 40, and 50 kHz; Power density: 150–200 W/L. Modes: Mono-, and Dual-frequency | Sequential dual-frequency ultrasound (SDFU) pretreatment remarkably increased rapeseed protein enzymolysis efficiency compared to the samples without SDFU pretreatment. This higher efficiency of enzymolysis was attributed to the significant decrease in the kinetic and thermodynamic parameters KM and Ea. | [103]/2018 |

| Rapeseed meal protein concentrate | Fig. 1C | Frequency: 20, 28, 35, 40, and 50 kHz; Power density: 150–200 W/L. Modes: Mono-, and Dual-frequency | Ultrasound could be considered as a promising pretreatment technology for preparing enzymatic hydrolysates with high bioavailability and thus realize the maximum utilization of rapeseed meal protein. | [67]/2021 |

| Sunflower-meal protein (SMP) | Fig. 1C | Frequency: 20, 28, 35, 40, and 50 kHz; Power density: 220 W/L. Modes: Mono-, and Dual-frequency | Ultrasonication could facilitate the releasing/unfolding of hydrophobic amino acids from SMP over nonsonicated samples during enzymolysis with high antioxidative capacity. Dual-frequency ultrasound pretreatment enhanced SMP-enzymolysis efficiency at different substrate and enzyme concentrations, temperature, and pH. |

[104], [105]/2018, 2019 |

| Rice protein (RP) | Fig. 1D | Frequency: 20, 28, 35, 40, 50 and 60 kHz; Power: each one was 300 W; Power density: 100 W/L; Modes: Mono-, Dual- and Tri-frequency. | Ultrasound frequencies and working modes were of great effect on the ACE inhibitory activity of RP. Sequential TFU of 20/35/50 kHz produced the highest increase in ACE inhibitory activity. |

[86]/2017 |

| Corn gluten meal (CGM) | Fig. 1E | Frequency: 20, 23, 25, 28, 35, and 40 kHz; Power density: 100 W/L. Modes: single-, duple-, triple-, quadruple, quintuple and sextuple frequency. | With a sequential duple-frequency of 20/40 kHz showing the most signifcant effect, the maximum value of enzymolysis effciency and protein dissolution rate were 15.99% and 61.69%, respectively. | [106]/2021 |

| Corn gluten meal (CGM) | Fig. 1F | Frequency: 20 (fundamental one), 23, 25, 28, 35, and 40 kHz; Power density: 60–200 W/L. Modes: Dual-frequency | Ultrasonication had considerable impact on the conformation of CGM and consequently improved the susceptibility to alcalase proteolysis. Dual-frequency slit ultrasound (DFSU) pretreatment played a critical role in improving the enzymolysis efficiency of CGM due to the alterations of the molecular conformation and production of more protein fragments with well-distributed size. |

[107]/2020 |

Jia et al [82] reported the effect of mono-frequency ultrasound pretreated defatted wheat germ protein (DWGP) on the enzymatic preparation of ACE-inhibitory peptides. An ultrasonic cell crusher with a flat tip probe (2 cm) at different power levels 0–1800 W was applied. The ultrasound was carried out in mono-frequency mode (20 kHz). Compared to non-ultrasound pretreatment, the average value of apparent breakdown rate constant (kA) of DWGP hydrolysis pretreated by ultrasound increased by 22.2%, and the apparent constant analogous to the Michaelis–Menten constant (kM) decreased by 13.0%. The ACE-inhibitory activity of DWGP hydrolysate increased by 21.0–40.7% after ultrasonic pretreatment, resulting from the release of peptides from DWGP during the process of enzymolysis. In addition, an increase in the surface hydrophobicity of DWGP and disperse in the protein tissue could be observed after ultrasound pretreatment using the ANS fluorescence spectra and SEM analysis. This was in favor of the hydrophobic amino acids release. A similar result was also reported by Zhou et al. [83] in the mono-frequency ultrasound pretreatment of corn gluten meal proteins with the frequency of 20 kHz and a power of 1000 W.

Frequency, power and duration are three important ultrasonic parameters that affect the ultrasonic modification on substrate materials. Ultrasonic frequency has a substantial impact on the efficiency of the sonochemical reaction [84]. Ren et al. [85] comparatively studied the effect of ultrasound pretreatments of zein with different frequencies including sweeping frequency ultrasound (SFU) and fixed frequency ultrasound (FFU) on enzymatic preparations of ACE-inhibitory peptides. Compared to the control, SFU and FFU improved the degree of hydrolysis (DH) by 11%. Nevertheless, there was no significant difference in DH between SFU and FFU. For the ACE-inhibitory activity, SFU and FFU at 22 and 40 kHz were significantly higher than the control, while those at 28 kHz had no significant difference. Moreover, the ACE-inhibitory activity of SFU is greatly higher than that of FFU. The increase in α-helical content (3.4%), and decreases in β-sheet, β-turns, and random coils (24.4%) indicated that SFU pretreatment enhanced the release of ACE-inhibitory peptides from zein by changing the secondary structure and loosening the protein.

Jin et al. [72] investigated the multi-frequency power sweeping ultrasound (MPSU) pretreatment on the kinetics and thermodynamics of corn gluten meal (CGM). The MPSU were sweeping dual-frequency ultrasound with 28 ± 2 kHz and 68 ± 2 kHz frequencies. It is found that MPSU pretreatment remarkably improved the hydrolyzed protein concentration compared to traditional enzymolysis. Besides, a decrease in kM value by 26.1% and an increase in kA value by 7.3% after MPSU pretreatment indicated that MPSU pretreatment increased the affinity between enzyme and CGM.

Yang et al. [86] studied the multi-frequency power ultrasound (MFPU) pretreatment in different frequencies and working modes on the degree of hydrolysis of rice protein (RP). The MFPU includes mono-, dual- and tri-frequency ultrasound. The latter two MFPU can work in simultaneous and sequential working modes. The results showed that tri-frequency ultrasound in sequential working mode (20/35/50 kHz) had the highest ACE inhibitory activity compared to other ultrasound frequencies and working modes. It indicated that the frequency selection of ultrasound pretreatment of RP is essential for preparing ACE inhibitory peptides.

3.1.3. Ultrasonic treatment on enzymatic hydrolysis process

The reasons why ultrasound can promote the enzymolysis reaction mainly include increasing the contact area by reducing the particle size, increasing the contact probability between the enzyme and the substrate by enhancing mass transfer, and promoting the effective combination through the influence on the conformation of the enzyme and the substrate [87]. It is challenging to explore the mechanism of ultrasound irradiation promoting enzymolysis efficiency because the action system mixes with enzymes, proteins and hydrolysates [15]. An immobilized enzyme can be applied to investigate the mechanism, as it can be separated out from the system after enzymolysis [75].

Wang et al. [15] used sweeping dual-frequency ultrasound (SDFU) to promote enzymolysis on rapeseed protein by immobilized Alcalase. The DH increased by 75.38% with SDFU assisted-enzymolysis under the optimal parameters. The yield of protein, peptides and total sugar in the hydrolysate increased by 64.61%, 40.88% and 23.60%, respectively. The decrease in a-helix (10.7%) and random coil content (4.5%), and increase in the β-chain (2.4%) indicated the change in the secondary structure of the enzyme after ultrasound treatment from the analysis of CD. The SEM also exhibited that ultrasound treatment increased the degree of surface roughness of Alcalase. It can be concluded that the improvement of hydrolysis by DFU assisted-enzymolysis was achieved by enhancing the solid solubility, changing the molecular structure of protein and increasing the surface area of the immobilized enzyme. Similar results were also found by Qu et al [75] in the immobilized enzymolysis of corn gluten meal under tri-frequency ultrasound.

In summary, ultrasound can improve the efficiency of enzymatic hydrolysis from three aspects: enzyme processing, substrate processing, and enzymatic hydrolysis processing. Whether the ultrasound promotes or inhibits the enzymatic hydrolysis reaction of protein is affected by various factors such as enzyme types and characteristics, ultrasonic parameters including power, frequency, and durations. Therefore, choosing the appropriate ultrasound parameters is the key to promoting the enzymatic hydrolysis reaction [88].

3.2. Reactors of ultrasound-assisted enzymolysis of protein on the industrial scale

The industrial-scale continuous multi-frequency power ultrasonic equipment for enzymolysis of protein at the Institute of Food Physical Processing, School of Food and Biological Engineering (Jiangsu University, Zhenjiang, Jiangsu, China) shown in Fig. 5 was built in 2018. This processing line includes the anterior and back-end process. The former is comprised of an enzymatic hydrolysis tank, continuous membrane reactor, and dual-frequency ultrasonic reactor. The latter includes filtration, vacuum concentration, and spray drying. The enzymatic hydrolysis tank can be loaded with 500 L. During the enzymatic hydrolysis process, the pH of the reaction mixture is automatically controlled by a regulator. The tank is connected to the membrane reactor and ultrasonic reactor. The mixture can be treated by dual-frequency ultrasound in the sequential or simultaneous working mode under the frequency of 20 and 40 kHz and the power level of 2 kW. According to the time of enzyme adding, the reaction can be divided into ultrasonic modification on substrate materials and ultrasonic treatment on enzymolysis process. Then the mixture will be pumped to the continuous membrane reactor. The mixture with a small particle size will pass through the membrane and go to the next unit, while that with a big particle size that can not pass the membrane will flow back to the tank. The filtration lines can be divided into micro-, ultra-, and nanofiltration. The proper filtration line will be selected according to the terminal desired particle size of the enzymolysis liquid. After filtration, the vacuum concentration and spray drying will carry out to obtain the final powder products. Since the reactor was built, it was successfully applied to produce peptides from rapeseed protein, wheat gluten, defatted wheat germ protein, zein protein, rice protein (RP), and donkey-hide gelatin, etc.

Fig. 5.

An industrial-scale continuous multi-frequency power ultrasonic equipment for enzymolysis of protein at the Institute of Food Physical Processing, School of Food and Biological Engineering at Jiangsu University, Zhenjiang, Jiangsu, China.

4. Application of power ultrasound in the washing of fruits and vegetables

4.1. Ultrasound-assisted washing

Ultrasound-assisted washing has been successfully adopted in small- to medium-scale cleaning of fruits and vegetables, metal parts, glasses, plastics, medical tools, jewellery, and laboratory equipment. Nowadays, domestic use ultrasound-assisted vegetable cleaners can be purchased from the market. The enhancement process is principally triggered by cavitation, where strong convective currents, acoustic streaming, microstreaming, microjets, shock waves, and heating occurs [89], [90]. The combination of physical and chemical impact in an ultrasonication system, removal of pesticide and microorganism from the surface of fruits and vegetables can be carried out. Therefore, a large scale ultrasonic cleaning system could potentially benefit the food, pharmaceutical, and biological processing industry over traditional heat or chemical-based cleaning. Sustainable and environment-friendly technologies like ultrasound treatment could save processing time and energy and improve shelf-life and product quality [91], [92].

4.1.1. Microorganisms removal

Power ultrasound is a well-studied method that hinders or inactivates certain microorganisms' growth (bacteria, yeasts, molds, and viruses). The application of ultrasound has great potential as a nonthermal treatment for food preservation, enhancing shelf-life with the food's original organoleptic properties. Bacteria, yeasts, and molds are mainly responsible for food spoilage. Ultrasonic parameters (frequency, power, and sonication period) directly affect the bacteria, yeast, and mold [93]. For different food systems, ultrasound with electrical current, slightly acidic water, ozone could be adopted to achieve better results. Alenyorege et al. reported that multiple-frequency combinations (20–60 kHz) in different modes (in sweeping, sequential, or simultaneous) are more effective in the removal of Listeria innocua than single frequency [4]. Furthermore, the product quality, shelf-life, nutritional and flavour profile also retain better with multi-frequency treatment for leafy vegetables. Ultrasound-assisted microbe removal could be a promising and result-oriented novel technique that can be used without causing any loss of nutrients and product quality.

4.1.2. Pesticide removal

Pesticides have been playing a crucial role in agricultural production in feeding the growing population worldwide, but widespread and excessive use in the fields and discharge from the manufacturing industries have also contributed to alarming environmental concerns. Applying ultrasound or combining it with other methods for cleaning post-harvest fruits and vegetables has been reported to be an efficient, cost-effective, fast, energy-saving, and green food processing technique [94], [95], [96]. In special contrast to fresh-cut fruits and vegetables, salad items, and minimally processed vegetables, there is a potential alternative to conventional heat or chemical-based rapid cleaning processes that reduce wastewater [97]. Quite a few research groups' works on the possible application of different ultrasonic modes (frequency, power, or combining with other methods) could be used to achieve high-quality products. It has been reported that, for the removal of pesticides from lettuce leaves, a combination of 20, 40 and 60 kHz in a sequential manner works better for removing abamectin, alphamethrin, and emamectin benzoate [7]. Table 2 summarizes the recent research suggesting the potential industrial application of ultrasound-assisted cleaning (pesticides and microbes) and l systems of fruits and vegetables and their outcome in recent years. Even though the ultrasound-assisted cleaning systems do not use chemicals, the wastewater from the cleaning system needs to be handled according to a safe handly procedure to the environment.

Table 2.

High impact research related to the application of ultrasound in cleaning or extraction of pesticides (2018-till the date).

| Mode of Ultrasound | Objective | Effects of ultrasound and recommendation | Reference |

|---|---|---|---|

| Pulsed electric field and ultrasound | Microbial load and bioactive compounds of grapefruit juice | Reduced microbial load as combined pulsed electric fields (PEF) with ultrasound. Improved the antioxidant activity, total phenolics, flavonols, flavonoids, lycopene, and total carotenoids. PEF + ultrasound also improves the quality of grapefruit juice and has the potential for industrial scale. | [108] |

| Ultrasound-assisted extraction | Extraction and determination of pesticides in fruit and vegetable. | Due to the application of ultrasound, the relative recovery ranged improved. | [109], [110], [111] |

| Combined ultraviolet and ultrasound treatments | Design of modern pasteurization methods | The integration of ultraviolet and ultrasound processes into the pasteurization process limits microbial activity at lower temperatures and time than the conventional pasteurization process. | [112] |

| Ozone and ultrasound | Effect of ultrasound in disinfecting and decontaminating strawberry | A positive effect of ozone with ultrasound on disinfecting and decontaminating with extended shelf-life. | [113] |

| Frequency-based ultrasound | Effect of multi-frequency based ultrasound on the removal efficiency and impact of ultrasound on leafy vegetable cleaning. | Triple-frequency (20, 40, and 60 kHz) removed 92.31, 89.36, and 95.25% abamectin, alphamethrin, and emamectin benzoate in sequential mode, respectively, after 8 min of ultrasonication with the most negligible change in product quality. | [7] |

| Ultrasound with electrolyzed water | Effects of ultrasound and dipping in electrolyzed water on quality and shelf life of the refrigerated chicken breast | Sonication for 30 min increased the tenderness of the samples. The combination of ultrasound and acidic electrolyzed water treatment reduces microbial counts without changing the lipid oxidation and color parameters. | [114] |

| Ultrasound and malic acid treatment | Compare the impact of ultrasound in inactivating Salmonella typhi, Shigella dysenteriae, Listeria monocytogenes, and Shigella flexneri and | The combination of US treatment and 1% malic acid reduced the initial bacterial value (7.2–7.6 log CFU/ml) to 5, 4.6, 3.5, and 3.8 log CFU/ml of Salmonella typhi, Shigella dysenteriae, Listeria monocytogenes, and Shigella flexneri, respectively. | [115] |

| Ultrasound with steam | Removal of surface contaminants from fruits, vegetables, and meats. | Short-time heating with ultrasound lowers the microbial (E. coli) load. | [116] |

| Ultrasound and 80 ppm nisin-ultrasound | Ultrasound on total aerobic bacteria, yeast, and mold; physical and nutritional quality of fresh carrot juice. | Nisin-assisted ultrasound has the best result in hindering total aerobic bacterial. Ultrasound had no apparent effect on the yeast and mold in the studied condition. Nisin-assisted ultrasound also retained the best product quality. | [117] |

| Supercritical carbon dioxide combined with high-power ultrasound | Study the effect of ultrasonic treatment on microbial inactivation and product quality. | Ultrasound-assisted method reduced microbial load significantly, improved shelf-life with the best product quality of the dry-cured ham. | [118] |

| Low-intensity electrical current and ultrasound | Effect of studied methods on reduction of pesticide residues from lettuce | 1400 mA and ultrasound (24 kHz) at 10 min could remove 92.57, 81.99 and 93.09% of captan, thiamethoxam and metalaxyl residues. | [94] |

| Remove pesticide residues from tomatoes. | Based on the synergistic effect of combining low-intensity electrical current and ultrasound, it has been proposed that the studied method has a great potential for industrial-scale application for removing pesticides from vegetables. | [119] | |

| Airborne ultrasound | Effect of airborne ultrasound on microbial inactivation and physicochemical properties. | Airborne acoustic technology is an effective technology for microbial inactivation with the most negligible impact on product quality. | [120] |

| Ultrasonic pretreatment (20–25 kHz, 300 W) | Effect of ultrasonic pre-treatment on microbial transglutaminase crosslinking on the gel properties of the soybean-whey mixed protein. | For the ultrasound treated sample, the polypeptide chain expanded and gelling properties significantly improved. | [121] |

| Ultrasonic treatment (output intensity of 0, 150, 300, and 450 W) | Effect of ultrasonic treatment on soy-whey mixed protein. | Ultrasonic treatments change the secondary structure of the gel with a regular and uniform network. | [122] |

| Ultrasound (40 kHz) | Effect of ultrasound on the physicochemical characteristics of cherry tomatoes. | Silver nanoparticles with ultrasound significantly reduced microbial load without affecting quality parameters. | [123] |

| Ultrasound (20 kHz) | Effect of ultrasound on probiotic goat milk yogurt | Sonication for 6 min enhanced the apparent viscosity and consistency, reducing tyramine and total biogenic amine. | [124] |

| Ultrasound-assisted matrix solid-phase dispersion | pesticide extraction from fruits and vegetables | An efficient, simple, cheap, robust, and environmentally friendly ultrasound-assisted method was developed for extracting different pesticides. | [125] |

| Ultrasound combined with carbon | Effect of ultrasound with carbon dots coating on the microbial and physicochemical quality of fresh-cut cucumber. | Ultrasound treatment combined with carbon dots coating successfully improves microbial and product quality with the best flavor profile. | [126] |

| Ultrasound (20 kHz) | Ultrasound treatment on microbial loads and the quality of modified atmospheric packaged fresh-cut cucumber. | Ultrasound treatment for 10 min inhibited microbial growth and reduced weight loss, firmness, total soluble solids, and color change. | [127] |

| High-intensity ultrasound | Effect of ultrasound on microbial transglutaminase-catalyzed tofu gel | The application of ultrasound improved the water holding capacity and a dense, homogenous, and stable network structure. | [128] |

| Pulsed electric field and high-power ultrasound | Effect of ultrasound and Pulsed electric field combined method on E. coli, A. niger and B. pumilus, | Studied method inactivated vegetative bacteria or fungal spores in emulsions with limited inactivation for bacterial spores. | [129] |

| High-intensity ultrasound (0, 200, 400 and 600 W) | Effect of different ultrasonic power levels on microbial inactivation on prebiotic whey beverage. | The optimal condition could improve beverage kinetic stability, avoid phase separation, and decrease particle size and denaturation of whey proteins. | [130] |

| Ultrasound and warm water | Ultrasound-assisted warm water treatment for kale seeds to inactivate microorganisms. | Ultrasound-assisted warm water treatment significantly reduced the E. coli counts in the seeds. The germination rates of the samples were above standard. | [131] |

| Ultrasound (20, 40, and 60 kHz) | Ultrasound-assisted treatment for ultrafiltered feta-type cheese | Microbial load (E. coli, S. aureus, P. chrysogenum, and Cl. sporogenes) reduced and improved the acidity of ripened cheese. | [132] |

| Benzoic acid and ultrasound | Effect of combination of benzoic acid and ultrasound in microbial sterilization. | The combined effect of benzoic acid and ultrasound for 5 min significantly reduced the number of viable cells E. coli and P. fluorescens | [133] |

| Ultrasound | Plackett-Burman design and response surface method to optimize ultrasonic cleaning of pesticide residues with different methods. | Ultrasonic cleaning conditions in a sink has a positive effect on food safety. | [134] |

| Ultrasound, thermosonication, and thermosonication combined with nisin. | Effect of ultrasound, thermosonication, and thermosonication combined with nisin in sterilizing grape juice. | Thermosonication and thermosonication combined with nisin have great potential application value that can ensure microbial safety and improve grape juice quality. | [135] |

| Aqueous ozone and ultrasound | Effect of aqueous ozone and ultrasound treatment on strawberry. | Ozone and ultrasound treatment for 3 min could reduce bacterial load (98%) and pesticides residues (98–99%) and delay in fungal decay by 4 days. | [136] |

| Ultrasonic dishwasher | Ultrasonic dishwasher to remove difenoconazole, azoxystrobin, thiamethoxam, abamectin and tebuconazole pesticides from rape and grape. | Removal rates between 14.7% and 59.8% on rape and between 72.1% and 100% on grapes. | [89] |

| Ultrasonic power | Removals of chlorothalonil, pyrazophos, and carbendazim residues form pakchoi by ultrasonic treatment and effect of ultrasound on leafy vegetable quality. | Ultrasonic power is a dominator for the maximum removal of studied pesticides and product quality of Chinese cabbage. | [137] |

| ultraviolet-assisted ultrasound | Nonthermal sterilization of mango juice with regards to microbial growth and quality changes. | Ultraviolet-assisted sonication (10 min, 600 W) improved carotenoids (43.72 to 75.15%, relative content) and carotenes (increased 49.04% to 95.15%). | [93] |

| Ultrasound (20 kHz, 750 W) | Production of low-fat mayonnaise without preservatives | Ultrasound treatment worked as a substitute for benzoate-sorbate preservatives, reduced total bacterial count, and lower pH. | [138] |

4.2. Reactors of ultrasound-assisted washing of fruits and vegetables on the industrial scale

The industrial-scale multi-frequency power ultrasonic equipment for cleaning fruits and vegetables at the Institute of Food Physical Processing, School of Food and Biological Engineering (Jiangsu University, Zhenjiang, Jiangsu, China) shown in Fig. 5 was built in 2019. Fig. 6A shows the multi-frequency power ultrasonic conveyor belt cleaning equipment. The production capacity of this equipment for leafy vegetable is over 2000 kg/h. Six ultrasonic vibration boxes with different frequencies (20, 28, 33, 40, 68, and 80 kHz) are placed in series on the conveyor belt cleaning tank. The transducers are arranged evenly in the box and the power of each box is 2 kW. It can operate under multi-frequency multi-mode ultrasound controlled by PLC. This equipment can be applied to the root, stem, leafy vegetables, and fruits to remove sediment, microorganism, and pesticide. The multi-frequency power ultrasonic centrifugal cleaning equipment is shown in Fig. 6B. Six arc-shaped ultrasonic vibration boxes with different frequencies (20, 28, 35, 40, 50, and 66 kHz) are placed at the bottom of the cylindrical tank. During the washing process, the basket with fruits and vegetables can be put inside the equipment. The sediment, microorganism, and pesticide can be removed through centrifugal forces and ultrasonic treatment. This equipment is especially suitable for washing fragile leafy vegetables, such as lettuce, Chinese green vegetables, and chives.

Fig. 6.

An industrial-scale continuous multi-frequency power ultrasonic equipment for cleaning of fruits and vegetables at the Institute of Food Physical Processing, School of Food and Biological Engineering at Jiangsu University, Zhenjiang, Jiangsu, China. (A. Multi-frequency power ultrasonic conveyor belt cleaning equipment, B. Multi-frequency power ultrasonic centrifugal cleaning equipment).

5. Conclusion and future trends

Many researchers have been working on ultrasonic technology in food processing for many years and it is found that ultrasound is an advanced eco-friendly non-thermal technology. This paper reviewed the fundamental principles of ultrasound for food processing and the influences of multi-frequency power ultrasound (MFPU) treatment on the enzymolysis of protein, and washing of fruits and vegetables. The literature showed that MFPU pretreatment improved the enzymatic hydrolysis of protein, and facilitated the washing of fruits and vegetables. Meanwhile, the reactors of ultrasound-assisted enzymolysis of protein and washing of fruits and vegetables were also exhibited. It should be emphasized that several drawbacks limit the development of ultrasound-assisted enzymolysis of protein and washing of fruits and vegetables, which were listed as follows:

For the research on improving the enzymolysis characteristics of the ultrasonic pretreatment of protein, most of the work focused on the activity changes of the proteolysis products before and after the ultrasonic pretreatment and the corresponding changes in the structure of the protein substrate. There are still some shortcomings in controlling the process of ultrasonic pretreatment and functional evaluation of products, mainly including:

-

(1)

There is a lack of monitoring of protein structure and activity of enzymatic hydrolysis products during ultrasonic pretreatment, and information on the dynamic changes of various indicators of protein structure during ultrasonic pretreatment. In addition, which protein has the greatest impact on enzymatic hydrolysis products, and the relationship between the various structural changes are still unclear. The specific quantitative relationship between the degree of protein denaturation and the improvement of its enzymatic properties is still unclear.

-

(2)

For the process control and parameter optimization of peptides prepared by enzymatic hydrolysis, the methods of time-sharing sampling and ex-situ determination are still used. It requires cumbersome procedures such as sampling from the reactor, enzyme inactivation, and centrifugation. The workload is extensive and accurate results cannot be obtained because the reaction site is left, and in-situ monitoring cannot be achieved. To establish the in-situ intelligent monitoring system for enzymatic hydrolysis process and ultrasonic pretreatment process, it is necessary to develop the corresponding software system and intelligent instrument control system based on the established spectral prediction model, which can be applied to the in-situ spectral instrument to realize intelligent control of the terminal of enzymatic hydrolysis.

-

(3)

The peptide products from different varieties of substrate materials and with different molecular weights after ultrasonic enzyme hydrolysis determine their functional properties, physiological activity, and bioavailability, such as improving immunity, anti-cancer, fall blood pressure, lipid-lowering, and anti-ageing diseases. The physiological activity and bioavailability of peptides from different varieties of substrate materials by different ultrasonic treatments needed to be investigated and evaluated in the future.

Most research on improving the washing effect focus on removing pesticides, loosely attached dirt or foreign material, and microorganisms before and after the ultrasonic treatment. There are still some drawbacks in ultrasonic washing, mainly including:

-

(1)

In the washing processing of fresh-cut vegetables, especially leafy vegetables, ultrasound irradiation can destroy the tissue and cells of leafy vegetables, which affects the integrity of the vegetable shape. Thus, specific studies on optimizing ultrasonic parameters for each leafy vegetables need to be carried out.

-

(2)

During industrial ultrasound manufacturing, triggered noise can be hazardous to the auditory system of line workers, especially when exposed to it frequently. Therefore, overall noise levels must be maintained at levels acceptable to human hearing systems, which may increase the cost of ultrasound equipment.

-

(3)

The establishment cost for new technology is a big challenge from the economic and technical perspectives.

CRediT authorship contribution statement

Baoguo Xu: Conceptualization, Writing – review & editing. S.M. Roknul Azam: Conceptualization, Writing – review & editing. Min Feng: Writing – review & editing. Bengang Wu: Writing – review & editing. Weiqiang Yan: Writing – review & editing. Cunshan Zhou: Supervision. Haile Ma: Supervision.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

This work was supported by the National Natural Science Foundation of China (No. 31801561), China Postdoctoral Science Foundation (Grant No. 2019T120401), and 2020 Provincial Policy Guidance Program (Subei Science and Technology Project, SZ-HZ202002). The authors are grateful for the support provided by Jinan City Science & Technology Innovation Project of Ten Agricultural Characteristic Industries.

References

- 1.Guiné R.P.F., Florença S.G., Barroca M.J., Anjos O. The duality of innovation and food development versus purely traditional foods. Trends in Food Science & Technology. 2021;109:16–24. [Google Scholar]

- 2.Bhargava N., Mor R.S., Kumar K., Sharanagat V.S. Advances in application of ultrasound in food processing: A review. Ultrasonics Sonochemistry. 2021;70 doi: 10.1016/j.ultsonch.2020.105293. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Chen J., Zhang M., Xu B., Sun J., Mujumdar A.S. Artificial intelligence assisted technologies for controlling the drying of fruits and vegetables using physical fields: A review. Trends in Food Science & Technology. 2020;105:251–260. [Google Scholar]

- 4.Alenyorege E.A., Ma H., Ayim I., Aheto J.H., Hong C., Zhou C. Reduction of Listeria innocua in fresh-cut Chinese cabbage by a combined washing treatment of sweeping frequency ultrasound and sodium hypochlorite. LWT - Food Science and Technology. 2019;101:410–418. [Google Scholar]

- 5.Alenyorege E.A., Ma H., Ayim I., Lu F., Zhou C. Efficacy of sweep ultrasound on natural microbiota reduction and quality preservation of Chinese cabbage during storage. Ultrasonics Sonochemistry. 2019;59 doi: 10.1016/j.ultsonch.2019.104712. [DOI] [PubMed] [Google Scholar]

- 6.Gallo M., Ferrara L., Naviglio D. Application of Ultrasound in Food Science and Technology: A Perspective. Foods. 2018;7 doi: 10.3390/foods7100164. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Azam S.M.R., Ma H., Xu B., Devi S., Stanley S.L., Siddique M.A.B., Mujumdar A.S., Zhu J. Multi-frequency multi-mode ultrasound treatment for removing pesticides from lettuce (Lactuca sativa L.) and effects on product quality. LWT - Food Science and Technology. 2021;143 [Google Scholar]

- 8.Wang Y.Y., Yan J.K., Ding Y., Ma H. Effects of ultrasound on the thawing of quick-frozen small yellow croaker (Larimichthys polyactis) based on TMT-labeled quantitative proteomic. Food Chemistry. 2022;366 doi: 10.1016/j.foodchem.2021.130600. [DOI] [PubMed] [Google Scholar]

- 9.Inui A., Honda A., Yamanaka S., Ikeno T., Yamamoto K. Effect of ultrasonic frequency and surfactant addition on microcapsule destruction. Ultrasonics Sonochemistry. 2021;70 doi: 10.1016/j.ultsonch.2020.105308. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Li S., Zhang R., Lei D., Huang Y., Cheng S., Zhu Z., Wu Z., Cravotto G. Impact of ultrasound, microwaves and high-pressure processing on food components and their interactions. Trends in Food Science & Technology. 2021;109:1–15. [Google Scholar]

- 11.Xu B., Yuan J., Wang L., Lu F., Wei B., Azam R.S.M., Ren X., Zhou C., Ma H., Bhandari B. Effect of multi-frequency power ultrasound (MFPU) treatment on enzyme hydrolysis of casein. Ultrasonics Sonochemistry. 2020;63 doi: 10.1016/j.ultsonch.2019.104930. [DOI] [PubMed] [Google Scholar]

- 12.Xu B., Chen J., Azam S.M.R., Feng M., Wei B., Yan W., Zhou C., Ma H., Bhandari B., Ren G., Duan X. Flat dual-frequency sweeping ultrasound enhances the inactivation of polyphenol oxidase in strawberry juice. Journal of Food Measurement and Characterization. 2021 [Google Scholar]

- 13.Xu B., Chen J., Sylvain Tiliwa E., Yan W., Roknul Azam S.M., Yuan J., Wei B., Zhou C., Ma H. Effect of multi-mode dual-frequency ultrasound pretreatment on the vacuum freeze-drying process and quality attributes of the strawberry slices. Ultrasonics Sonochemistry. 2021;78 doi: 10.1016/j.ultsonch.2021.105714. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Xu B., Ren A., Chen J., Li H., Wei B., Wang J., Azam S.M.R., Bhandari B., Zhou C., Ma H. Effect of multi-mode dual-frequency ultrasound irradiation on the degradation of waxy corn starch in a gelatinized state. Food Hydrocolloids. 2021;113 [Google Scholar]

- 15.Wang B., Meng T., Ma H., Zhang Y., Li Y., Jin J., Ye X. Mechanism study of dual-frequency ultrasound assisted enzymolysis on rapeseed protein by immobilized Alcalase. Ultrasonics Sonochemistry. 2016;32:307–313. doi: 10.1016/j.ultsonch.2016.03.023. [DOI] [PubMed] [Google Scholar]

- 16.Arghavani-Beydokhti S., Rajabi M., Asghari A. Coupling of two centrifugeless ultrasound-assisted dispersive solid/liquid phase microextractions as a highly selective, clean, and efficient method for determination of ultra-trace amounts of non-steroidal anti-inflammatory drugs in complicated matrices. Anal Chim Acta. 2018;997:67–79. doi: 10.1016/j.aca.2017.10.005. [DOI] [PubMed] [Google Scholar]

- 17.Cheng Y., Donkor P.O., Ren X., Wu J., Agyemang K., Ayim I., Ma H. Effect of ultrasound pretreatment with mono-frequency and simultaneous dual frequency on the mechanical properties and microstructure of whey protein emulsion gels. Food Hydrocolloids. 2019;89:434–442. [Google Scholar]

- 18.Kollath A., Andreeva D.V. Use of high-intensity ultrasound for production of antimicrobial and self-cleaning surfaces. Food Preservation. 2017:229–264. [Google Scholar]

- 19.Yu X., Bao X., Zhou C., Zhang L., Yagoub A.E.A., Yang H., Ma H. Ultrasound-ionic liquid enhanced enzymatic and acid hydrolysis of biomass cellulose. Ultrasonics Sonochemistry. 2018;41:410–418. doi: 10.1016/j.ultsonch.2017.09.003. [DOI] [PubMed] [Google Scholar]

- 20.Dabbour M., He R., Mintah B., Xiang J., Ma H. Changes in functionalities, conformational characteristics and antioxidative capacities of sunflower protein by controlled enzymolysis and ultrasonication action. Ultrason Sonochem. 2019;58 doi: 10.1016/j.ultsonch.2019.104625. [DOI] [PubMed] [Google Scholar]

- 21.Gligor O., Mocan A., Moldovan C., Locatelli M., Crișan G., Ferreira I.C.F.R. Enzyme-assisted extractions of polyphenols – A comprehensive review. Trends in Food Science & Technology. 2019;88:302–315. [Google Scholar]

- 22.Musa A., Ma H., Gasmalla M.A.A., Sarpong F., Awad F.N., Duan Y. Effect of multi-frequency counter-current S type ultrasound pretreatment on the enzymatic hydrolysis of defatted corn germ protein: Kinetics and thermodynamics. Process Biochemistry. 2019;87:112–118. doi: 10.1039/c9fo01531k. [DOI] [PubMed] [Google Scholar]

- 23.Ding Y., Wang Y., Qu W., Ren X., Lu F., Tian W., Quaisie J., Azam S.M.R., Ma H. Effect of innovative ultrasonic frequency excitation modes on rice protein: Enzymolysis and structure. LWT - Food Science and Technology. 2022;153 [Google Scholar]

- 24.Zhang Z.-H., Peng H., Ma H., Zeng X.-A. Effect of inlet air drying temperatures on the physicochemical properties and antioxidant activity of whey protein isolate-kale leaves chlorophyll (WPI-CH) microcapsules. Journal of Food Engineering. 2019;245:149–156. [Google Scholar]

- 25.Zhang Z., Wang Y., Li Y., Dai C., Ding Q., Hong C., He Y., He R., Ma H. Effect of alkali concentration on digestibility and absorption characteristics of rice residue protein isolates and lysinoalanine. Food Chemistry. 2019;289:609–615. doi: 10.1016/j.foodchem.2019.03.085. [DOI] [PubMed] [Google Scholar]

- 26.Wen C., Zhang J., Zhang H., Duan Y., Ma H. Effects of divergent ultrasound pretreatment on the structure of watermelon seed protein and the antioxidant activity of its hydrolysates. Food Chemistry. 2019;299 doi: 10.1016/j.foodchem.2019.125165. [DOI] [PubMed] [Google Scholar]

- 27.Mintah B.K., He R., Dabbour M., Xiang J., Agyekum A.A., Ma H. Techno-functional attribute and antioxidative capacity of edible insect protein preparations and hydrolysates thereof: Effect of multiple mode sonochemical action. Ultrasonics Sonochemistry. 2019;58 doi: 10.1016/j.ultsonch.2019.104676. [DOI] [PubMed] [Google Scholar]

- 28.Huang L., Ding X., Li Y., Ma H. The aggregation, structures and emulsifying properties of soybean protein isolate induced by ultrasound and acid. Food Chemistry. 2019;279:114–119. doi: 10.1016/j.foodchem.2018.11.147. [DOI] [PubMed] [Google Scholar]

- 29.Wen C., Zhang J., Zhang H., Dzah C.S., Zandile M., Duan Y., Ma H., Luo X. Advances in ultrasound assisted extraction of bioactive compounds from cash crops – A review. Ultrasonics Sonochemistry. 2018;48:538–549. doi: 10.1016/j.ultsonch.2018.07.018. [DOI] [PubMed] [Google Scholar]

- 30.Qiu L., Zhang M., Chitrakar B., Bhandari B. Application of power ultrasound in freezing and thawing Processes: Effect on process efficiency and product quality. Ultrasonics Sonochemistry. 2020;68 doi: 10.1016/j.ultsonch.2020.105230. [DOI] [PubMed] [Google Scholar]

- 31.Thompson L.H., Doraiswamy L.K. Sonochemistry: Science and Engineering, Ind.eng.chem.res. 1999;38:1215–1249. [Google Scholar]

- 32.Zheng L., Sun D.W. Ultrasonic Assistance of Food Freezing Emerging Technologies for. Food Processing. 2005:603–626. [Google Scholar]

- 33.T.J. Mason, Power ultrasound in food processing-The way, Ultrasound in food processing, (1998) 105.

- 34.E.R. G . Blackie Academic and International; London: 1998. Ultrasound: a new opportunity for food preservation. [Google Scholar]

- 35.Zhang P., Zhu Z., Sun D.-W. Using power ultrasound to accelerate food freezing processes: Effects on freezing efficiency and food microstructure. Critical Reviews in Food Science and Nutrition. 2018;58:2842–2853. doi: 10.1080/10408398.2018.1482528. [DOI] [PubMed] [Google Scholar]

- 36.Zheng L., Sun D.W. Innovative applications of power ultrasound during food freezing processes : a review. Trends in Food Science & Technology. 2006;17:16–23. [Google Scholar]

- 37.Ensminger D. Battelle, Acoustic and electroacoustic methods of dewatering and drying. Drying Technology. 1988;6:473–499. [Google Scholar]

- 38.Hughes D.E., Nyborg W.L. Cell Disruption by Ultrasound Streaming and other activity around sonically induced bubbles is a cause of damage to living cells. Science. 1962;138:108–114. doi: 10.1126/science.138.3537.108. [DOI] [PubMed] [Google Scholar]

- 39.Wang D., Yan L., Ma X., Wang W., Zou M., Zhong J., Ding T., Ye X., Liu D. Ultrasound promotes enzymatic reactions by acting on different targets: Enzymes, substrates and enzymatic reaction systems. International Journal of Biological Macromolecules. 2018;119:453–461. doi: 10.1016/j.ijbiomac.2018.07.133. [DOI] [PubMed] [Google Scholar]

- 40.Ashokkumar M., Grieser F. Single bubble sonoluminescence–a chemist's overview, Chemphyschem A European Journal of Chemical Physics & Physical. Chemistry. 2004;5:439–448. doi: 10.1002/cphc.200300926. [DOI] [PubMed] [Google Scholar]

- 41.Ashokkumar M., Lee J., Kentish S., Grieser F. Bubbles in an acoustic field: an overview. Ultrasonics sonochemistry. 2007;14:470–475. doi: 10.1016/j.ultsonch.2006.09.016. [DOI] [PubMed] [Google Scholar]

- 42.Supeno P. Kruus, Sonochemical formation of nitrate and nitrite in water. Ultrasonics sonochemistry. 2000;7:109–113. doi: 10.1016/s1350-4177(99)00043-7. [DOI] [PubMed] [Google Scholar]

- 43.Dibbern E.M., Farah Jean-Jacques T., Suslick K.S. Formation and characterization of polyglutamate core-shell microspheres. Journal of the American Chemical Society. 2006;128:6540–6541. doi: 10.1021/ja058198g. [DOI] [PubMed] [Google Scholar]

- 44.Toublan F.J., Boppart S., Suslick K.S. Tumor targeting by surface-modified protein microspheres. Journal of the American Chemical Society. 2006;128 doi: 10.1021/ja0544455. [DOI] [PubMed] [Google Scholar]

- 45.Xu B., Zhang M., Bhandari B., Cheng X. Influence of power ultrasound on ice nucleation of radish cylinders during ultrasound-assisted immersion freezing. International Journal of Refrigeration. 2014;46:1–8. [Google Scholar]

- 46.Kumar K., Srivastav S., Sharanagat V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrasonics Sonochemistry. 2021;70 doi: 10.1016/j.ultsonch.2020.105325. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Wahia H., Zhou C., Fakayode O.A., Amanor-Atiemoh R., Zhang L., Taiye Mustapha A., Zhang J., Xu B., Zhang R., Ma H. Quality attributes optimization of orange juice subjected to multi-frequency thermosonication: Alicyclobacillus acidoterrestris spore inactivation and applied spectroscopy ROS characterization. Food Chemistry. 2021;361 doi: 10.1016/j.foodchem.2021.130108. [DOI] [PubMed] [Google Scholar]

- 48.Jiang Q., Zhang M., Xu B. Application of ultrasonic technology in postharvested fruits and vegetables storage: A review. Ultrasonics Sonochemistry. 2020;69 doi: 10.1016/j.ultsonch.2020.105261. [DOI] [PubMed] [Google Scholar]

- 49.Roknul Azam S.M., Ma H., Xu B., Devi S., Siddique M.A.B., Stanley S.L., Bhandari B., Zhu J. Efficacy of ultrasound treatment in the removal of pesticide residues from fresh vegetables: A review. Trends in Food Science & Technology. 2020;97:417–432. [Google Scholar]

- 50.Roknul Azam S.M., Ma H., Xu B., Devi S., Stanley S.L., Bakar Siddique M.A., Mujumdar A.S., Zhu J. and effects on product quality. 2021. Multi-frequency multi-mode ultrasound treatment for removing pesticides from lettuce (Lactuca sativa L.) p. 111147. [Google Scholar]

- 51.Xu B.-G., Zhang M., Bhandari B., Sun J., Gao Z. Infusion of CO2 in a solid food: A novel method to enhance the low-frequency ultrasound effect on immersion freezing process. Innovative Food Science & Emerging Technologies. 2016;35:194–203. [Google Scholar]

- 52.Xu B., Azam R.S.M., Wang B., Zhang M., Bhandari B. Effect of infused CO2 in a model solid food on the ice nucleation during ultrasound-assisted immersion freezing. International Journal of Refrigeration. 2019;108:53–59. [Google Scholar]

- 53.Xu B., Chen J., Yuan J., Azam S.R., Zhang M. Effect of different thawing methods on the efficiency and quality attributes of frozen red radish. Journal of the Science of Food and Agriculture. 2021;101:3237–3245. doi: 10.1002/jsfa.10953. [DOI] [PubMed] [Google Scholar]

- 54.Fan D., Huang L., Li B., Huang J., Zhao J., Yan B., Zhou W., Zhang W., Zhang H. Acoustic intensity in ultrasound field and ultrasound-assisted gelling of surimi. LWT – Food Science and Technology. 2017;75:497–504. [Google Scholar]

- 55.Ding Y., Ma H., Wang K., Azam S.M.R., Wang Y., Zhou J., Qu W. Ultrasound frequency effect on soybean protein: acoustic field simulation, extraction rate and structure, LWT – Food Science and Technology. 2021;145:111320. [Google Scholar]

- 56.Chandrapala J., Oliver C., Kentish S., Ashokkumar M. Ultrasonics in food processing. Ultrasonics Sonochemistry. 2012;19:975–983. doi: 10.1016/j.ultsonch.2012.01.010. [DOI] [PubMed] [Google Scholar]

- 57.Priego-Capote F., Luque de Castro M.D. Analytical uses of ultrasound I. Sample preparation, TrAC Trends in Analytical Chemistry. 2004;23:644–653. [Google Scholar]

- 58.Shirsath S.R., Sonawane S.H., Gogate P.R. Intensification of extraction of natural products using ultrasonic irradiations—A review of current status. Chemical Engineering and Processing: Process Intensification. 2012;53:10–23. [Google Scholar]

- 59.Preece K.E., Hooshyar N., Krijgsman A.J., Fryer P.J., Zuidam N.J. Pilot-scale ultrasound-assisted extraction of protein from soybean processing materials shows it is not recommended for industrial usage. Journal of Food Engineering. 2017;206:1–12. [Google Scholar]

- 60.K. Wang, Numerical simulation of ultrasound-assisted extraction based on multi-physical field coupling, in, Jiangsu University, 2019.

- 61.Zhang L., Hu Y., Wang B., Xu X., Yagoub A.E.A., Fakayode O.A., Ma H., Zhou C. Effect of ultrasonic pretreatment monitored by real-time online technologies on dried preparation time and yield during extraction process of okra pectin. Journal of the Science of Food and Agriculture. 2021;101:4361–4372. doi: 10.1002/jsfa.11076. [DOI] [PubMed] [Google Scholar]

- 62.Wang Y.-Y., Yan J.-K., Tayyab Rashid M., Ding Y., Chikari F., Huang S., Ma H. Dual-frequency sequential ultrasound thawing for improving the quality of quick-frozen small yellow croaker and its possible mechanisms. Innovative Food Science and Emerging Technologies. 2021;68:102614. [Google Scholar]

- 63.Wang Z., Li T., Liu F., Zhang C., Ma H., Wang L., Zhao S. Effects of ultrasonic treatment on the maturation of Zhenjiang vinegar. Ultrasonics Sonochemistry. 2017;39:272–280. doi: 10.1016/j.ultsonch.2017.04.020. [DOI] [PubMed] [Google Scholar]

- 64.Xu B., Sylvain Tiliwa E., Yan W., Roknul Azam S.M., Wei B., Zhou C., Ma H., Bhandari B. Recent development in high quality drying of fruits and vegetables assisted by ultrasound: A review. Food Research International. 2021:110744. doi: 10.1016/j.foodres.2021.110744. [DOI] [PubMed] [Google Scholar]

- 65.Guo Y., Wu B., Guo X., Liu D., Wu P., Ma H., Pan Z. Ultrasonication and thermosonication blanching treatments of carrot at varying frequencies: Effects on peroxidase inactivation mechanisms and quality characterization evaluation. Food Chemistry. 2021;343 doi: 10.1016/j.foodchem.2020.128524. [DOI] [PubMed] [Google Scholar]

- 66.Ma H., Huang L., Jia J., He R., Luo L., Zhu W. Effect of energy-gathered ultrasound on Alcalase. Ultrasonics Sonochemistry. 2011;18:419–424. doi: 10.1016/j.ultsonch.2010.07.014. [DOI] [PubMed] [Google Scholar]

- 67.Ruan S., Xiong J., Li Y., Huang S., Wang X., Ma H. Improvement in enzymolysis efficiency and bioavailability of rapeseed meal protein concentrate by sequential dual frequency ultrasound pretreatment. Process Biochemistry. 2021;102:240–249. [Google Scholar]

- 68.Taiye Mustapha A., Cunshan Z., Amanor-Atiemoh R., Tahany A.A.A., Hafida W., Haile M., Yanhui S. Efficacy of dual-frequency ultrasound and sanitizers washing treatments on quality retention of cherry tomato. Innovative Food Science and Emerging Technologies. 2020;62:102348. [Google Scholar]

- 69.Daniel T. Digestibility Issues of Vegetable versus Animal Proteins: Protein and Amino Acid Requirements—Functional Aspects. Food and nutrition bulletin. 2013;34:272–274. doi: 10.1177/156482651303400225. [DOI] [PubMed] [Google Scholar]

- 70.Yang L., Guo Z., Wei J., Han L., Yu Q.-L., Chen H., Chen Y., Zhang W. Extraction of low molecular weight peptides from bovine bone using ultrasound-assisted double enzyme hydrolysis: Impact on the antioxidant activities of the extracted peptides. LWT – Food Science and Technology. 2021;146 [Google Scholar]

- 71.Jian J., Haile M., Weiwei W., Min L., Bei W., Wenjuan Q., Ronghai H., Owusu J., Yunliang L. Effects and mechanism of ultrasound pretreatment on rapeseed protein enzymolysis. Journal of the Science of Food and Agriculture. 2016;96:1159–1166. doi: 10.1002/jsfa.7198. [DOI] [PubMed] [Google Scholar]

- 72.Jin J., Ma H., Qu W., Wang K., Zhou C., He R., Luo L., Owusu J. Effects of multi-frequency power ultrasound on the enzymolysis of corn gluten meal: Kinetics and thermodynamics study. Ultrasonics Sonochemistry. 2015;27:46–53. doi: 10.1016/j.ultsonch.2015.04.031. [DOI] [PubMed] [Google Scholar]

- 73.Cui P., Yang X., Liang Q., Huang S., Lu F., owusu J., Ren X., Ma H. Ultrasound-assisted preparation of ACE inhibitory peptide from milk protein and establishment of its in-situ real-time infrared monitoring model. Ultrasonics Sonochemistry. 2020;62 doi: 10.1016/j.ultsonch.2019.104859. [DOI] [PubMed] [Google Scholar]

- 74.Umego E.C., He R., Ren W., Xu H., Ma H. Ultrasonic-assisted enzymolysis: Principle and applications. Process Biochemistry. 2021;100:59–68. [Google Scholar]

- 75.Qu W., Qu R. Sehemu, Masoud T., Zhang B., Song L., Yang X., Ren H.Ma. Immobilized enzymolysis of corn gluten meal under triple-frequency ultrasound. International Journal of Food Engineering. 2018;14:20170347. [Google Scholar]

- 76.Yu Z.-L., Zeng W.-C., Lu X.-L. Influence of ultrasound to the activity of tyrosinase. Ultrasonics Sonochemistry. 2013;20:805–809. doi: 10.1016/j.ultsonch.2012.11.006. [DOI] [PubMed] [Google Scholar]

- 77.Feng H., Barbosa-Canovas G.V., Weiss J. Springer; New York: 2010. Ultrasound technologies for food and bioprocessing. [Google Scholar]

- 78.Kadkhodaee R., Povey M.J.W. Ultrasonic inactivation of Bacillus α-amylase. I. effect of gas content and emitting face of probe. Ultrasonics Sonochemistry. 2008;15:133–142. doi: 10.1016/j.ultsonch.2007.02.005. [DOI] [PubMed] [Google Scholar]

- 79.Li S., Yang X., Zhang Y., Ma H., Qu W., Ye X., Muatasim R., Oladejo A.O. Enzymolysis kinetics and structural characteristics of rice protein with energy-gathered ultrasound and ultrasound assisted alkali pretreatments. Ultrasonics Sonochemistry. 2016;31:85–92. doi: 10.1016/j.ultsonch.2015.12.005. [DOI] [PubMed] [Google Scholar]

- 80.Ren X., Wei X., Ma H., Zhou H., Guo J., Mao S., Hu A. Effects of a dual-frequency frequency-sweeping ultrasound treatment on the properties and structure of the zein protein. Cereal Chemistry. 2015;92:193–197. [Google Scholar]

- 81.Cunshan Z., Jiali H., Xiaojie Y., ElGasim A., Yagoub A., Yanyan Z., Haile M., Xianli G., Yarley Otu P.N. Heat and/or ultrasound pretreatments motivated enzymolysis of corn gluten meal: hydrolysis kinetics and protein structure. LWT – Food Science and Technology. 2017;77:488–496. [Google Scholar]

- 82.Jia J., Ma H., Zhao W., Wang Z., Tian W., Luo L., He R. The use of ultrasound for enzymatic preparation of ACE-inhibitory peptides from wheat germ protein. Food Chemistry. 2010;119:336–342. [Google Scholar]

- 83.Cunshan Z., Haile M., Qingzhi D., Lin L., Xiaojie Y., Lin L., Chunhua D., Yagoub A.E.G.A. Ultrasonic pretreatment of corn gluten meal proteins and neutrase: effect on protein conformation and preparation of ACE (angiotensin converting enzyme) inhibitory peptides. Food and Bioproducts Processing. 2013;91:665–671. [Google Scholar]

- 84.Qu W., Ma H., Jia J., He R., Luo L., Pan Z. Enzymolysis kinetics and activities of ACE inhibitory peptides from wheat germ protein prepared with SFP ultrasound-assisted processing. Ultrasonics Sonochemistry. 2012;19:1021–1026. doi: 10.1016/j.ultsonch.2012.02.006. [DOI] [PubMed] [Google Scholar]

- 85.Ren X., Ma H., Mao S., Zhou H. Effects of sweeping frequency ultrasound treatment on enzymatic preparations of ACE-inhibitory peptides from zein. European Food Research and Technology. 2014;238:435–442. [Google Scholar]