Abstract

The restructuring of global value/supply chains gained increasing attention as the unprecedented COVID-19 echoed around the world. Yet, the COVID-19 related theory-driven, large scale quantitative, and empirical studies are relatively scarce. This study advances the extant literature by empirically investigating how do firms in the global food value chains (GFVCs) re-imagine their businesses structure in response to the COVID-19—becoming more resilient and competitive to the current pandemic and similar future events. We leverage a unique data of 231 senior managers of the Australian GFVCs and examine their firms’ response strategies. Drawing upon key insights from the dynamic capability view, we find that GFVCs’ competitiveness is achieved when exposure to COVID-19 shocks elicits dynamic capabilities—readiness, response, recovery—and these capabilities work jointly and sequentially to cultivate resilience. A key finding of this study is that firms with domestic plus global value chain partners are more resilient than those having only global business partners. This finding implies that excessive reliance on offshoring sometimes becomes lethal, especially amid unexpected and prolonged global shocks and, therefore, companies should strike a balance between domestic and global business partners to remain competitive. These findings offer important contributions to theory, practice, and UN sustainable development goals.

Keywords: COVID-19, Global value chains, Resilience, Competitiveness, Dynamic capabilities, Food industry

1. Introduction

The concept of the global value chain, often used interchangeably with the global supply chain, refers to the entities and activities involved in the production and distribution of goods and services across geographies with superior customer value. The ongoing shocks caused by the Novel Coronavirus (COVID-19) pandemic have exposed the level of vulnerabilities, preparation, and missing links in today’s extended and globally dispersed value chains. Many of the statistics demonstrate that COVID-19 has inflicted massive shocks and disrupted between 78% and 95% of organisations participating in value chain networks (NAM, 2020, Van Hoek, 2020). This indicates that conventional supply chain resilience strategies are important but not enough to deal with the prolonged shocks caused by the COVID-19. As such, there is now a burgeoning literature to reimagine supply chain resilience (SCRes) capabilities—keeping in view the COVID-19 outbreak. However, most of the existing literature is based on small scale qualitative case studies, analytical modelling, atheoretical studies, conceptual frameworks or authors’ personal views on the potential impact of the shocks and resilience to COVID-19—thus calling for more theory-driven quantitative and empirical research.

Among other challenges, a major transformation associated with the COVID-19 outbreak is related to its influences on the changing nature of strategic industries’ perceptions globally (e.g., Arslan et al., 2021). For example, the food/agriculture sector and its value chains became extremely exposed, especially when the domestic and global travel restrictions came into effect. Many businesses in the value chains have been exposed to COVID-19 induced labour shortages, border closures, unavailability of transportation services, resulting in food demand and supply fluctuations, lack of cash, facilities’ shutdown and others. Since businesses in the contemporary food value chains are tangled within large and extended networks (Ali and Gurd, 2020, Ali and Govindan, 2021), food supply and demand disruptions in one country or part can have massive trickle down and cascading effects in various parts of the world. Given the rising challenges of food availability and security amid COVID-19 shocks, SCRes has been stressed as being extremely important in the specific context of the food industry (Hobbs, 2021, Ker, 2020).

While SCRes has been conceptualised in several ways by different scholars, the elements of responsiveness, readiness and recovery have been increasingly emphasised by previous studies (e.g., Chowdhury and Quaddus, 2016, Han et al., 2020, Iftikhar et al., 2021). Correspondingly, in this paper, we operationalise SCRes with these three elements, given that these constitute key parts of a system’s resiliency. Despite considerable studies on SCRes during the pandemic (Chowdhury et al., 2021, Ivanov and Dolgui, 2020, Remko, 2020), there is still a visible gap for empirical research concerning the role of different elements of SCRes in response to COVID-19 shocks within the larger value chain networks. Specifically, the degree of exposure to COVID-19 shocks from demand, supply and production sides and its influences on resilient capabilities (readiness, responsiveness, and recovery) has not been systematically addressed in the context of global food value chains (GFVC). Nonetheless, the food sector is considered highly vulnerable to external shocks and the impact of COVID-19 has amplified the food security risk associated with today’s long-stretched food chains (Ali et al., 2021, Ali et al., 2021, Garnett et al., 2020).

Our study fills the current knowledge void in the literature by examining the Australian GFVCs’ response strategies. Historically, the Australian food and agriculture industry has been one of the most significant industries of the country. The gross value added by the industry is estimated to be around A$67 billion, alongside export valued at an estimated A$48.23 billion in 2020 (ABARES, 2021). Around two-thirds of Australian food products are exported to various countries of the world. The firms in the Australian GFVC are amongst the major suppliers of premium quality food to about 40 countries across the globe (Ali and Gölgeci, 2020, Ali and Aboelmaged, 2021). However, in the wake of the current pandemic, these value chains have been grappling with several upheavals, for example, border closures, disrupted port operations, strict quarantine measures, which triggered formidable challenges of stock piling, food supply shortages and price manipulation (Australian Food & Grocery Council, 2019).

Prior research suggests that cultivation of dynamic capabilities becomes crucial for firms to respond to external shocks, and it is in such a context that scholars have highlighted their role in enhancing firm's performance (e.g., Ambrosini et al., 2009, Barreto, 2010, Teece et al., 1997, Giannoccaro and Iftikhar, 2020). As such, grounded in the dynamic capability view (DCV) (Teece et al., 1997, Teece, 2007), this study aims to specifically theorise and analyse how does exposure to COVID-19 shocks influence firms’ dynamic capabilities, and how do these capabilities affect GFVC’s competitiveness?

Based on the empirical analysis of primary data collected from 231 senior managers of the Australian food industry, our paper contributes to the extant SCRes and food value chains’ literature in several ways. First, we provide a systematic account of the shocks caused by the COVID-19 on GFVC’s competitiveness. Second, we recognise the important mediating mechanisms that trigger dynamic capabilities or key elements of SCRes through which the exposure to COVID-19 drives the competitiveness of GFVCs. Drawing upon the DCV, we elucidate that the sustained competitive advantage of GFVCs is translated by the firms’ dynamic capabilities (abilities to integrate, build, and reconfigure internal and external competencies) that are effectively cultivated in response to the COVID-19 shocks. Third, the current literature on the key elements of SCRes is somewhat fragmented. That is, some studies suggest that only response elements are important to deal with the current pandemic (Leite et al., 2021, Paul and Chowdhury, 2020), while other propose response and recovery as crucial elements (Gunessee and Subramanian, 2020, Ivanov and Dolgui, 2020). Still others have suggested readiness and recovery elements (Deaton and Deaton, 2020, Mollenkopf et al., 2021). This existing inconsistency could create confusion amongst practitioners for the deployment of scarce resources to deal with the daunting threats of COVID-19. To this end—we characterise the readiness, response and recovery as firms’ key dynamic capabilities which build SCRes and maintain competitiveness amidst the COVID-19 pandemic. Going further, we corroborate that the competitiveness of firms in GFVC is achieved when all three capabilities (readiness, response, and recovery) are deployed together, and they work in a sequential manner (readiness to response to recovery) in response to COVID-19 shocks. We have presented (see Section 4.2, practical implications) a robust set of strategies to realise these three capabilities and become resilient to the current pandemic and similar future disruptions. Fourth, we recognise that, amidst COVID-19 crises, the companies, that retain both domestic plus global food value chain networks, are more resilient and competitive compared to those having only global value chain networks. In essence, we suggest that managers reinvigorate their business plans ensuring trade with both domestic plus international partners to avoid the risk of complete supply–demand disruptions and business shutdown triggered by cross border upheavals amid global disasters, such as the ongoing COVID-19 pandemic.

The rest of the paper is organised as follows. Section 2 presents theoretical background and hypotheses followed by a discussion of research methodology in Section 3. Section 4 provides discussion and implications. The paper concludes with the presentation of limitations, and future research directions in Section 5.

2. Theoretical background and hypotheses

2.1. COVID-19 shocks and food value chains

Given the fierce cost competition and subsequent offshoring initiatives, contemporary value chains have evolved into globally dispersed and interconnected supply and demand networks with profound interdependencies (Islam & Polonsky, 2020). The unprecedented outbreak of COVID-19 has exposed the vulnerabilities of such interdependent global value chains (Magnani et al., 2019, Gereffi, 2020). The unanticipated shocks, such as border closure, labour shortage, social distancing, lockdowns, production failures, have disrupted and dismantled production and distribution operations of several organisations both from the manufacturing and service sectors. For example, the Fortune magazine reported that the pandemic disrupted about “94% of the Fortune 1000 companies” including suppliers, manufacturers and customers (Fortune 2020).

While all industry sectors and value chains have been affected by COVID-19-inflicted risks, GFVCs were found to be more vulnerable because of the complex supply chain networks, uncertainty associated with volatile demand patterns, higher labour dependency, seasonal food production systems, and long lead times. A simple supply or value chain is composed of suppliers, food processors/manufacturers and customers. As such, the main COVID-19 related shocks to the global food value chain can be mapped under three major categories—including supply-side shocks, production shocks, and demand-side shocks. The choice of these three types of shocks could capture major challenges that global value chains encountered (Hobbs, 2020, Ponte et al., 2019). For instance, supply-side shocks cover issues, such as loss of key suppliers, unstable quality of supplies, unstable quality of product supplies, and poor logistics performance of supplier (Brusset and Teller, 2017, Chen et al., 2013; Liu et al., 2017; Wagner & Bode, 2008). Production-side shocks encompass threats of production failure, high variability in production, and shortage of skilled workers (Chen, Sohal, & Prajogo, 2013; Kumar et al., 2017). Demand-side shocks—include risks of fluctuation in demand, hoarding behaviours and panic buying (Hobbs, 2020, Brusset and Teller, 2017, Liu et al., 2018). The existing research on global value chains has established that supply, production and demand are interlinked (Gereffi et al., 2005; Milberg & Winkler, 2013). Hence, a disruption from any of these three sides can cause a domino effect (particularly amidst the COVID-19), interrupting operations in the entire GFVC. Managing such shocks is, therefore, crucial, otherwise organisations and their value chain members may not be able to continue their business operations in the wake of the disruption.

2.2. COVID-19 shocks and dynamic capability view

Supply chain disruptions are inevitable, and disruptions may arise from many sources such as natural disasters, strategic failure, operational disruptions, and demand and supply uncertainty. Disruptions have a multifarious impact on supply chain processes and, as a result, change in routines and capabilities becomes essential to maintain competitiveness. For instance, the recent COVID-19 shocks caused unforeseen disruptions such as supply shortage, demand uncertainty, production plant shut down and delay in distribution. The DCV (Teece et al., 1997) has been found an appropriate lens to study how firms integrate resources and deploy capabilities in response to supply chain shocks or risks (Jajja et al., 2018). The DCV asserts that in the wake of an uncertain business environment (e.g., COVID-19 shocks), organisations strive to develop dynamic capabilities (capacities of sensing, seizing and reconfiguration) to maintain competitive advantage (Eisenhardt & Martin, 2000; Teece, 2007, Teece et al., 1997). Prior studies on supply chains (e.g., El Baz and Ruel, 2021, Jajja et al., 2018, Chowdhury and Quaddus, 2017) have utilised the DCV to study the connections between uncertain/risky business environment, dynamic capabilities and a firm’s competitive advantage. As such, we suggest that the DCV as an appropriate framework to examine whether and how the presence of COVID-19 shocks (uncertain and disruptive environment) elicits firms to develop SCRes related dynamic capabilities, and thereby maintain the competitiveness of GFVCs. It is in such a context that the development of dynamic capabilities has been suggested to be crucial for firms to maintain their competitive advantages (cf. Khan and Lew, 2018, Teece, 2014).

2.3. COVID-19 shocks and global food value chains competitiveness

Competitiveness of the global value chains has been an increasingly researched concept (e.g., Hernández & Pedersen, 2017; O'Connor et al., 2018, Koval et al., 2019), since it was brought mainstream by the seminal work of Michael Porter (e.g., Cho & Moon, 2013). In past research, several factors associated with the competitiveness of global value chains have been discussed (e.g., O'Connor et al., 2018, Koval et al., 2019). However, the exposure to COVID-19 shocks introduced novel challenges to maintaining the competitiveness of global value chains. While all global value chains were exposed to COVID-19, the existing scholarships suggest that global food value chains were amongst the most affected entities (Hobbs, 2020, Sharma et al., 2020, Sharma et al., 2020). This is because food value chains produce and distribute highly demanded food commodities, are considered more labour intensive, trade perishable products and possess seasonal production systems (Ali et al., 2017). When the COVID-19 pandemic induced issues related to the drastic changes in demand, labour shortage, transport disruption, and border closure, etc. (e.g., Hobbs, 2020, Saarinen et al., 2020), in addition to closed borders (e.g., Weersink et al., 2021). These shocks negatively impacted the competitiveness of several firms in the value chains that was not well-prepared in response to the COVID-19 outbreak in early 2020 (Hobbs, 2021, Saarinen et al., 2020). Alternatively, following the COVID-19 shocks, numerous progressive firms quickly developed and utilised new set of capabilities to maintain their competitiveness (Hobbs, 2021, Sharma et al., 2020, Sharma et al., 2020). These new capabilities included, but are not limited to, alternative supply routes for the food products (e.g., Perdana et al., 2020, Yu et al., 2019), dedicated shipments, use of omnichannel, use of domestic suppliers (e.g., Thilmany et al., 2021, Dubey et al., 2020), re-adjustments in delivery schedules and stocking up strategies (e.g., Goddard, 2020). According to the DCV (Teece, 1997, 2007), competitiveness is positively affected when firms adapt to new practices in response to threats or changing conditions (e.g., COVID-19 shocks). Correspondingly, we assert that exposure to COVID-19 would positively influence the competitiveness of firms in global food value chains. Thus, we hypothesise that:

H1: Exposure to COVID-19 shocks has a positive influence on global food value chain competitiveness.

2.4. COVID-19 shocks and supply chain resilience

In today's increasingly turbulent business landscape, business continuity requires the cultivation of SCRes amidst the unforeseen shocks (Jia et al., 2020). SCRes is defined as “the adaptive capability of the system to prepare for, respond to, and recover from disruptions and continue operations in a normal or even better than pre-disruptive state” (Ponomarov & Holcomb, 2009, p. 131). Drawing upon the DCV (Ambrosini et al., 2009, Teece et al., 1997, Teece, 2007, Teece, 2014), prior research suggests SCRes as a vital “dynamic capability” (Gölgeci and Kuivalainen, 2020, Golgeci and Y. Ponomarov, 2013). For instance, Teece (2007) characterise dynamic capabilities as the distinct skills and competencies of sensing, seizing, and reconfiguring in a risky business environment. Firms need to deploy such capabilities to sustain their competitive advantage in dynamic environments (e.g., Khan and Lew, 2018, Teece, 2014).

Sensing is an essential dynamic capability for organisations, which helps them to quickly identify changes in the environment and exploit resources to maintain operational fitness over time (Teece, 2007, Barreto, 2010). Extant research (Chowdhury and Quaddus, 2016, Prayag et al., 2018, Conz and Magnani, 2020) note that the readiness element of SCRes encompasses multi-dimensional capabilities—such as multi-skilled workers, buffer capacities, swift coordination, and excess production capacities. As such, we assert that the readiness element of SCRes as a dynamic capability (sensing). We further contend that the COVID-19 related shocks work as a trigger for firms to invest in such capabilities in order to mitigate external shocks.

Seizing is another dynamic capability allowing to seize resources for strong resistance to uncertainties (Teece, 2007). The response capability of SCRes can be considered seizing capability, as it seizes resources to resist and deactivate an event, as soon as it is detected—thus continuing the business operations in a normal way (Ali & Gölgeci, 2019). For example, Ponomarov and Holcomb (2009), and Chowdhury and Quaddus (2017) also note that response capability is an essential dynamic capability for organisations in a supply chain allowing them to capture opportunities or tackle threats for gaining competitive advantage. Aligned with the prior scholarly works (Ponomarov and Holcomb, 2009; and Chowdhury and Quaddus, 2017), we argue that the presence of COVID-19 shocks positively influences firms’ response related dynamic capabilities, so they can respond to such shocks effectively, and can quickly and effectively recognise, gather and interpret information, enact flexible operations, extend payable, and switch to telework.

Finally, reconfiguring is a dynamic capability, allowing to rearrange resources and regain stability (Teece, 2007, Chowdhury and Quaddus, 2017). In this outlook, recovery capability can be deemed (reconfiguring) as a dynamic capability (Chowdhury and Quaddus, 2017). The recovery capability of a system helps it to regain stability, concentrate on the continuation of operations, and minimise the long-term impact (Chen et al. 2019). It enables firms to absorb shocks and quickly rebound through collaboration with internal (supply chain partners) and external stakeholders (e.g., government agencies and NGOs) (Ali et al., 2018). Prior research has offered evidence on the role of exposure to crisis and shocks in triggering new capabilities (recovery) to regain normality in a limited time (e.g., Sawyer & Harrison, 2019). Overall, in light of the DCV, it is logical to expect that exposure to COVID-19 shocks could elicit dynamic capabilities of readiness, response and recovery elements in GFVC. Based on the above discussion, we hypothesise that:

H2: Exposure to COVID-19 shocks positively influence firms’ readiness (H2a), response (H2b), recovery (H2c) capabilities in global food value chains.

2.5. Supply chain resilience and global food value chains competitiveness

Competitive advantage is the firms’ ability to maintain a distinct position in the industry (Porter, 1985). It is a key element that differentiates a firm from its competitors. Return on investment, customer satisfaction, timely delivery, and growth in market share is amongst the crucial measure of a firm’s competitiveness (Feurer and Chaharbaghi, 1994, Li et al., 2006, Yang et al., 2013). The current COVID-19 shocks have exposed the level of vulnerabilities and competitiveness of various firms in the globally dispersed food value chains. Businesses are exposed to a multitude of external shocks including, inter alia, demand volatility, labour shortage, transport service and supply distortion, supply disruption and facilities shutdown. Under such circumstances, the competitiveness of firms in a value chain is defined by their key capabilities of readiness, response and recovery from unexpected shocks (e.g., COVID-19) and continue operations in a normal fashion. Readiness capability allows a firm to early detect risks and build, integrate and reconfigure resources to avoid disruption (Ali & Golgeci, 2019). On the other hand, response capabilities aim to resist shocks and minimise losses, when a risk materialises. While recovery capabilities support the firms to quickly resume normal operations by reconfiguring resources (Leite et al., 2021, Paul and Chowdhury, 2020). In light of the dynamic capabilities (Teece 2007), we contend that readiness, response and recovery capabilities are firms’ dynamic capabilities that could positively influence global food value chains amidst the COVID-19 crises. Thus, we suggest that:

H3: Readiness (H3a), response (H3b), and recovery (H13c) capabilities positively influence global food value chains’ competitiveness.

2.6. The mediating role played by supply chain resilience

Along with philosopher Plato’s proclamation “necessity is the mother of invention,” we assert that COVID-19 shocks opened the eye of decision-makers to hone resilience capability to stay competitive. Recent scholarship suggests that SCRes is often triggered in response to supply chain risks thereby maintaining a system’s competitiveness by reducing disruptions (El Baz and Ruel, 2021, Jajja et al., 2018). However, past studies (before COVID-19) continue to debate the different phases or elements of SCRes. Some studies suggest that response and recovery as an appropriate set of elements to be resilient to disruptions, for example: capacity to react and recover to a normal state (Rice & Caniato, 2003); the capability to and speed at which a system recovers from risks and disruption (Peck, 2007); the ability to absorb disruption and return to stable condition (Blackhurst et al., 2011, Wu et al., 2013); “the ability to simultaneously restore some processes and change—often radically—others” (Craighead et al. 2020, p. 838).

Another stream of research implies that, in the face of risks, readiness and response phases come into play to reduce disruption secure competitive advantage, for instance: the ability to proactively plan and design supply chain network and recover quickly (Ponis & Koronis, 2012). Given the implication of risk readiness in managing disruptions, Das and Lashkari (2015) proposed a proactive approach to supply chain risk management (SCRM) planning through risk readiness and resiliency metrics and asserted that a resilient supply chain (SC) should be able to inhibit the impacts of foreseeable and preventable disruptive factors by employing proactive operational measures. In fact, inadequate readiness to handle disruptions and lack of ability to predict the impact of disruptions reduce firms' capability to take pre-emptive operative measures and make them less responsive to situational demand, ultimately impacting resiliency, profitability, and competitiveness of firms’ supply chains. Such impacts were evident during high-profile disruptions such as the global economic recession (Juttner & Maklan 2011) and COVID- 19 crisis (Ivanov & Dolgui, 2020). In a similar vein, the DCV literature (e.g. Teece, 2007, Chowdhury and Quaddus, 2017) proclaimed that, during disruptive events, readiness capabilities such as sensing and identifying disruptive factors, disaster preparedness, visibility, and building backup capacity are salient for maintaining operational fitness and managing performance. Thus, organisations need to possess capabilities to adapt and respond to external shocks and crises (e.g., Dixon et al., 2014).

The third stream of research assumes three phases or elements—including readiness, response and recovery, for example, adaptive capacity to prepare, respond and recover back (Ponomarov & Holcomb, 2009), proactive and reactive resilience capability such as readiness, response and recovery mechanisms to manage disruptions and improve performance (Chowdhury & Quaddus, 2017). Chowdhury and Quaduus (2017) and Ponomarov and Holcomb (2009) shed light on the dynamic capability of firms and their supply chains in enhancing proactive and reactive capabilities by orchestrating readiness, response, and recovery capabilities. The DCV (Teece 2007) echoed that sensing, seizing, and reconfiguration/transformation capabilities are linked because a firm's ability to sense have implications on seizing and navigating threats by combining and reconfiguring specific resources for managing situational demand to maintain evolutionary fitness and remain competitive. Teece’s view of sensing, seizing and reconfiguration capabilities can be commensurate with the readiness, response and recovery capabilities of a supply chain (Chowdhury & Quaddus, 2017) which are interdependent and does not function in isolation.

Since most studies in the face of the COVID-19 draw upon previous scholarship, the confusion on essential elements or phases of SCRes continues to propagate, for instance: response (Leite et al., 2021, Paul and Chowdhury, 2020); response and recovery (Gunessee and Subramanian, 2020, Ivanov and Dolgui, 2020); readiness and recovery (Deaton and Deaton, 2020, Mollenkopf et al., 2021). The ongoing debate, without empirical support, could cause confusion among practitioners for the deployment of scarce resources to deal with daunting threats of COVID-19. Specifically, this could significantly influence firms in global food value chains that are dominated by resource-scarce SMEs. The above discussion leads us the following set of hypotheses:

H4: Exposure to COVID-19 shocks has a significant influence on global food value chains’ competitiveness through response and recovery capabilities.

H5: Exposure to COVID-19 shocks has a significant influence on global food value chains’ competitiveness through readiness and recovery capabilities.

H6: Exposure to COVID-19 shocks has a significant influence on global food value chains’ competitiveness through readiness, response and recovery capabilities (sequentially).

3. Research methodology

Consistent with the research questions, a quantitative research method with an online survey tool was utilised for primary data collection. A widely accepted procedure was adopted to structure the survey questionnaire and sampling (Dillman, 2011). We used the “stratified random sampling technique” to ensure that the population is evenly sampled (Madow, 1953). The data was collected from senior-level managers of the Australian global food value chains (the firms having global operations).

3.1. Constructs and measures

To justify the validity, measurement items and latent constructs were adapted from the previous literature. The “COVID-19 shocks (CS)” was assessed as a higher-order construct with three associated sub-constructs: supply-side shocks (SS) (Brusset and Teller, 2017, Chen et al., 2013; Liu et al., 2017; Wagner & Bode, 2008); production shocks (PS) (Chen, Sohal, & Prajogo, 2013; Kumar et al., 2017); demand-side shocks (DS) (Brusset and Teller, 2017, Liu et al., 2018, Wagner and Bode, 2008). A typical supply chain is composed of a supplier, producer and buyer and, as such, analysis of these three types of risks allows this study to map almost all critical sources of risk along the entire value chain. Exposure to risks and disruptions can drive SC resilience mechanisms—causing firms to prepare, resist, adapt and recover from crises and return to a normal or even better state. To test this, SCRes construct was measured through three main elements: Readiness (Ali et al., 2018, Chowdhury and Quaddus, 2017, Chowdhury et al., 2019, Jüttner and Maklan, 2011, Prayag et al., 2018); response (Chowdhury and Quaddus, 2016, Chowdhury and Quaddus, 2017, Chowdhury et al., 2019, Yu et al., 2019); recovery (Altay et al., 2018, Chowdhury and Quaddus, 2017, Dubey et al., 2020; Dubey et al., 2019; Yu et al., 2019). The outcome variable—global food value chain competitiveness (GFVCC)—was measured with six items drawn from the past literature (Feurer and Chaharbaghi, 1994, Li et al., 2006, Yang et al., 2013).

All items were measured on a 5-point Likert scale. The items for supply chain risks were measured with a rating of not at all (1) to a very great extent (5); while all other items were assessed at a rating of strongly disagree (1) to strongly agree (5).

3.2. Pre-tests

While most items were validated by previous research, the adapted measurement items, along with new items—was subject to content validity and reliability in the context of this study. To ensure content validity—the items and constructs were discussed with 5 senior managers and two academics who hold extensive practical and theoretical knowledge about the topic. Based on their feedback, three minor amendments were then made to the questionnaire: the wording and sequence of the items associated with the construct of supply-side shocks and production shocks were improved to make them clearer in the context of global food value chains; the directions for completing the questionnaire were further elaborated. The instrument was then pilot tested with a group of 62 respondents. The reliability of measurement items and associated constructs were evaluated where Cronbach’s alpha value was much higher than the 0.7 threshold (Hair, Anderson, Babin, & Black, 2010). The respondents who participated in the pre-test were not included in the final survey and subsequent study.

3.3. Data collection

A survey link was created in Qualtrics and distributed amongst 923 senior-level managers of firms from the Australian food industry on 10 March 2021. These firms were amongst the major food (dairy and meat, fruits, nuts and vegetables, beverages, and wheat) producers and distributors to both international and domestic markets (see Table 1 ) with a total worth of over A$40 billion, annually (Australian Agriculture Trade, 2020). The contacts of respondents were obtained from three main sources: companies’ websites, industry associations and purchasing from a registered broker. With four follow up emails, we received 231 valid responses—resulting in a response rate of 25 percent. The final sample of 231 respondents satisfies the minimum requirement of five observations per parameter (Bentler and Chou, 1987, Bollen, 1989).

Table 1.

Sample characteristics.

| Parameter | Percent of the total sample |

|---|---|

| Food Industry’s sub-sectors | |

| Dairy and meat | 30.74 |

| Fruit, nuts and vegetables | 25.54 |

| Beverage | 22.94 |

| Wheat | 20.78 |

| Position of respondents | |

| Operations manager | 29.00 |

| Managing director | 23.81 |

| Director | 19.05 |

| General manager | 15.14 |

| CEO | 13.00 |

| Firm size | |

| Small (<19 employees) | 42.86 |

| Medium (20–199) | 57.14 |

| Business network | |

| International only | 44.16 |

| International plus domestic | 55.84 |

The sample characteristics (see Table 1) reveal that most of the respondents held senior management or leadership positions. The firm size data reveals that respondents belonged to small (<19 employees) and medium-sized firms (20–199 employees). The industry sector breakdown indicates that our sample covered four major industry sub-sectors within the Australian food industry. Overall, the data suggest heterogeneity in the sample.

3.4. Common method bias and non-response bias

The common method bias (CMB) could be a serious problem with a survey study based on a single informant per company. Therefore, multiple techniques/methods should be applied to make sure that a study is free or comes with negligible CMB issues. To overcome the CMB, we applied two ways to test CMB. First, Harmon’s single factor test was used where the “average variance extracted” by any individual construct or variable was found much smaller than the cutoff value of 50% (Harman, 1976). Doing so, we performed factor analysis where we fixed the number of factors extracted to ‘1’. As a result, only 1 factor emerged which explained the 15% variance. If this factor explains more than 50% variance, there is a risk of CMB (Harman, 1976). Second, we used ‘respondent character’—a theoretical unrelated variable—as a maker variable, like past research in the field (Gu, Yang, & Huo, 2021). The marker variable was evaluated with three items: possesses a lot of friends, sense of talking with others, and a cheerful person. The statistical results indicated that the marker variable has non-significant correlation with each of the principal variables: supply-side risk (r = 0.29), production risk (r = 0.21), demand-side risk (r = 0.19), readiness (r = 0.22), response (r = 0.31), recovery (r = 0.18), global value chain competitiveness (r = 0.24). Thus, a non-significant relationship between the marker variable and any of the principal variables would indicate no CMB (Craighead et al., 2011, Williams et al., 2010). The Confirmatory Factor Analysis (CFA) was employed where no correlation between the marker variable and any other variable was found.

Non-response bias occurs when there is a significant variation in data across the early vs. late respondents of a survey. In this study, we compared the responses from early respondents (1 5 7) to the late respondents (74) using an independent sample t-test. The data suggest insignificant variance amid the means of two datasets; thus, “non-response bias” was not detected in our sample (cf. Mentzer & Flint (1997).

Given the potential endogeneity issue, the explanatory factors possibly correlated with error terms due to unintentional elimination of a factor—and therefore the estimate of a model can be biased (Damali et al., 2016). Thus, we took the necessary steps to address the potential endogeneity bias. First, endogeneity may occur due to reverse causality between IV and DV; that is DV causes IV (Antonakis et al., 2014, Damali et al., 2016). Our hypotheses are grounded in theory (the DCV) which does not support reverse causality – GFVCC cause change/predict COVID-19 shocks. Second, given that CMB can lead to endogeneity issues (Antonakis et al., 2014, Guide and Ketokivi, 2015), we made sure that there was no CMB issue in this study, as elaborated in prior discussion. Third, endogeneity can result from no-response bias (Damali et al., 2016), which has already been addressed in the previous section. Four, while the cross-sectional nature of the study reduces the likelihood of causality, the questionnaire items were derived from literature and written with common items that sought to elicit time-ordered responses (Damali et al., 2016). Fourth, we followed the suggestions of Antonakis et al., (2014) to avoid possible endogeneity problems by including control variables.

3.5. Measurement model evaluation

Before the structural model, the measurement model should be tested. To test the measurement model, all latent variables were covaried and the test was run using AMOS 26. The results suggested acceptable model fit indices (Hair et al., 2010, Hu, 1999) including “x2/df = 1.732, CFI = 0.915, GFI = 0.913, AGFI = 0.922, TLI = 0.893, IFI = 0.917, TLI = 0.921, RMSEA = 0.029, RMR = 0.035, p < 0.001”. As shown in Table 2 , factor loading for each item exceeds 0.50 (Hair et al., 2010), thus ensuring the item reliability. Furthermore, values of both Cronbach’s alpha (α) and composite reliability were much higher than the cutoff value of 0.70 (Hair et al., 2010, Nunnally, 1978), confirming the constructs’ reliability.

Table 2.

Construct and item reliability.

| Construct and item | Factor loading | AVE | CR | α |

|---|---|---|---|---|

| Supply-side shocks | ||||

| SS1: Loss of key suppliers. | 0.88 | 0.69 | 0.86 | 0.87 |

| SS2: Unstable quantity of supplies. | 0.82 | |||

| SS3: Unavailability of transportation services. | 0.84 | |||

| SS4: Unstable quality of product supplies. | 0.77 | |||

| Production side shocks | ||||

| PS1: Shortage of skilled workforce for production. | 0.86 | 0.71 | 0.87 | 0.91 |

| PS2: Production failure and food waste. | 0.79 | |||

| PS3: Delays in production time and delivery. | 0.85 | |||

| PS4: Issues with production quality. | 0.87 | |||

| Demand-side shocks | ||||

| DS1: Panic buying; drastic change in demand. | 0.81 | 0.66 | 0.84 | 0.86 |

| DS2: Hoarding behaviour. | 0.89 | |||

| DS3: Inaccurate demand forecasting. | 0.79 | |||

| DS4: Insufficient or distorted demand information. | 0.76 | |||

| COVID-19 shocks | ||||

| CS1: Supply side shocks, | 0.83 | 0.7 | 0.83 | |

| CS2: Production side shocks, | 0.81 | |||

| CS3: Demand side shocks, | 0.88 | |||

| Readiness | ||||

| Rdns1: Our firm proactively switched to remote work and ensured workers safety and well-being. | 0.73 | 0.63 | 0.77 | 0.85 |

| Rdns2: Our firm organised the excess stock and minimised unnecessary expenses to deal with unanticipated shocks. | 0.74 | |||

| Rdns3: Our firm proactively trained workforces to deal with potential uncertainties. | 0.93 | |||

| Rdns4: Our firm has backward and forward integration. | 0.77 | |||

| Rdns5: Our firm implemented omnichannel. | 0.76 | |||

| Response | ||||

| Resp1: Our firm has effectively responded to the unexpected shocks of the pandemic. | 0.71 | 0.61 | 0.77 | 0.84 |

| Resp2: Our firm maintained close coordination with government and industry bodies for support. | 0.67 | |||

| Resp3: Our firm extended payables and expedited receivables. | 0.91 | |||

| Resp4: Our firm continued employees’ screening, safety and well-being. | 0.68 | |||

| Resp5: Our firm introduced flexibility in contracts with value chain partners (partial order and payment, partial shipments etc.). | 0.72 | |||

| Resp6: In response to social distancing, our firm quickly moved to telework/flexible work arrangements. | 0.94 | |||

| Recovery | ||||

| Rec1: Our firm has better-absorbed shocks and recovered in a short time. | 0.75 | 0.62 | 0.8 | 0.81 |

| Rec2: Our firm formed a cross-sector collaboration to restructure the current business model and recover from crises at less cost. | 0.69 | |||

| Rec3: Our firm has reinvigorated operational costs (re-budgeting, refinancing of the loan, sold un-productive assets, restaffing) to recover back to a normal state. | 0.78 | |||

| Rec4: Our firm has been reflecting and reimagining current business by integrating digital capabilities and reconsidering current buyers/suppliers’ networks. | 0.92 | |||

| Global food value chain’s competitiveness | ||||

| Comparing to the competitors, our firm has better: | ||||

| GFVCC1: customer satisfaction and value. | 0.95 | 0.83 | 0.95 | 0.93 |

| GFVCC2: delivery dependability. | 0.98 | |||

| GFVCC3: return on investment. | 0.96 | |||

| GFVCC4: time to market. | 0.68 | |||

| GFVCC5: growth in market share. | 0.94 | |||

Convergent validity was ensured with “average variance extracted (AVE)” which exceeded the recommended value of 0.50 (Fornell & Larcker, 1981). The discriminant validity was confirmed by two means: the square root of AVE for each construct was greater than the correlation amongst the particular construct and other constructs (see Table 3 ) (Fornell & Larcker, 1981); there was no issue of cross-loading of items on other constructs (Hair et al., 2010).

Table 3.

Discriminant validity.

| Construct | SS | PS | DS | CS | Rdns | Resp | Rec | GFVCC |

|---|---|---|---|---|---|---|---|---|

| SS | 0.83 | |||||||

| PS | 0.56 | 0.84 | ||||||

| DS | 0.71 | 0.67 | 0.81 | |||||

| CS | 0.61 | 0.65 | 0.55 | 0.84 | ||||

| Rdns | 0.51 | 0.52 | 0.66 | 0.72 | 0.80 | |||

| Resp | 0.54 | 0.58 | 0.73 | 0.59 | 0.63 | 0.78 | ||

| Rec | 0.53 | 0.59 | 0.64 | 0.65 | 0.57 | 0.69 | 0.79 | |

| GFVCC | 0.62 | 0.69 | 0.54 | 0.68 | 0.67 | 0.55 | 0.57 | 0.91 |

Diagonal = square root of AVE.

Furthermore, the second-order model was determined where the second-order variable (COVID-19 shocks) was regressed on three first-order variables (supply side shocks, production side shocks, and demand side shocks). The result indicated good model fit indices (“x2/df = 2.731, CFI = 0.913, GFI = 0.931, TLI = 0.923, IFI = 0.921, TLI = 0.881, AGFI = 0.901, RMSEA = 0.036, RMR = 0.034, p < 0.01”), thus confirming the presence of second-order construct in our model.

3.6. Structural model evaluation

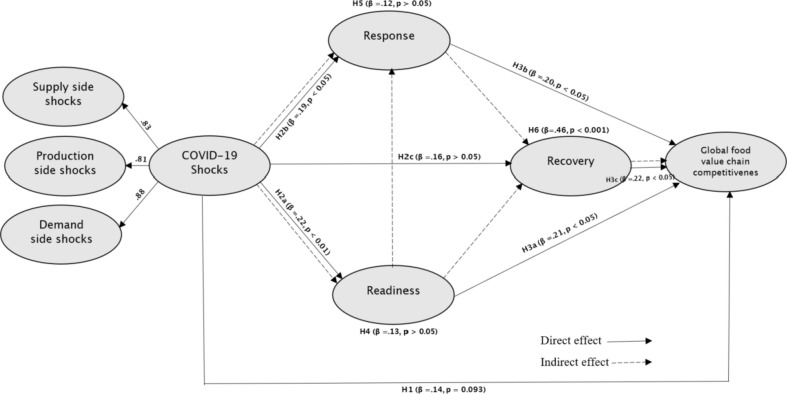

The goodness-of-model indices suggested that our model fits good to the data (Hair et al., 2010, Hu, 1999), including “x2/df = 1.425, CFI = 0.923, GFI = 0.921, TLI = 0.931, AGFI = 0.912, IFI = 0.924, TLI = 0.932, RMSEA = 0.025, RMR = 0.033, p < 0.001”. Also, all measurements have significant loading on the corresponding second-order construct (COVID-19 shocks). As can be seen in Fig. 1 and Table 4 , the direct path from COVID-19 shocks to GFVCC is positive but non-significant (β = 0.14, p > 0.05); thus, H1 was not supported. The direct path from COVID-19 shocks to readiness is positive and significant (β = 0.22, p < 0.01), thus corroborating H2a. Likewise, the direct path from COVID-19 shocks to response capabilities is positive and significant (β = 0.19, p < 0.05); thus, H2b is supported. Surprisingly, the direct path from COVID-19 shocks to recovery capabilities is positive but non-significant (β = 0.16, p > 0.05); hence, H2c was not supported. Finally, we found that response (β = 0.21, p < 0.05), readiness (β = 0.20, p < 0.05), and recovery (β = 0.18, p < 0.05) positively predict GFVCC. Thus, H2a, H2b, and H2c were supported.

Fig. 1.

The statistical model with results of hypothesised relationships.

Table 4.

Result of hypotheses.

| Hypothesised relationships | coefficient | p-value | Result |

|---|---|---|---|

| Direct effects | |||

| CS --> GFVCC | 0.14 | 0.093 | H2: not supported |

| CS --> Rdns | 0.22 | 0.004** | H2a: supported |

| CS --> Resp | 0.19 | 0.031* | H2b: supported |

| CS --> Rec | 0.16 | 0.086 | H2c: not supported |

| Rdns --> GFVCC | 0.21 | 0.021* | H3a: supported |

| Resp --> GFVCC | 0.20 | 0.024* | H3b: supported |

| Rec --> GFVCC | 0.18 | 0.027* | H3c: supported |

| Mediating (indirect) effects | |||

| CS --> Resp --> Rec --> GFVCC | 0.12 | 0.178 | H4: not supported |

| CS --> Rdns --> Rec --> GFVCC | 0.13 | 0.113 | H5: not supported |

| CS --> Rdns --> Resp --> Rec -->GFVCC | 0.46 | 0.000*** | H6: supported |

CS, COVID-19 shock; Rdns, readiness, Resp, response, Rec, recovery, GFVCC, global food value chain fcompetitiveness; *p < 0.05, **p < 0.01, ***p < 0.001.

3.6.1. Mediation effect

To test the mediation (indirect) effects, first, we constructed the model with all variables and related paths (see Fig. 1). From the analysis properties of Amos, we selected bootstrap with 2000 bootstrap samples and biased corrected confidence interval 95 to perform mediation analysis. Testing H3, we fixed/defined the path (CS --> Resp --> Rec --> GFVCC) and ran the model. The results indicated (see Table 4) that the indirect effect of COVID-19 shocks on GFVCC via Resp and Rec (β = 0.12, p > 0.05) was non-significant, thus H3 was not supported. We repeated the similar procedure for the two other paths representing H4 (CS --> Rdns --> Rec --> GFVCC) and H5 (CS --> Rdns --> Resp --> Rec -->GFVCC). The results (β = 0.13, p > 0.05) didn’t support the path representing H3. However, the findings (β = 0.46, p < 0.001) supported the path representing H5. The results thus indicate that, amidst the pandemic, GFVC competitiveness is achieved when firms build resilience by deploying all three important elements of SCRes (Rdns --> Resp --> Rec) in a sequential manner. The analysis clearly establishes that deployment of either Response and Recovery or Readiness and Recovery capabilities would not lead to effective SCRes and GFVC competitiveness.

3.6.2. Moderation test

Generally, it is believed that internationally dispersed firms are more resilient to disruption and perform well in the wake of unforeseen incidents. As such, to explore if there was a difference in disruptions and competitiveness levels amongst various network structures, we tested firms’ geographical dispersion as a categorical moderator variable. A multigroup analysis was employed using the grouping function in Amos graphics (Byrne, 2004, Koufteros and Marcoulides, 2006). The main dataset was segregated into two unique groups: firms with international networks (1 0 9); firms with both domestic and global networks (1 2 3). The variance in chi-square values (ΔX2 = 15.69) between unconstrained and fully constrained models indicated that the two models were significantly different (p < 0.05). To further comprehend the variation between groups, we selected/defined a main path in the model (CS --> Rdns --> Resp --> Rec -->GFVC) and run the test to note the difference in p-values and beta coefficients. The results indicated a significant difference between the two paths (p < 0.01) where the beta coefficient was stronger for domestic + global value chain networks (β = 0.36), compared to only global value chain networks (β = 0.21).

3.7. Control variables

Our sample constituted small and medium-sized firms. To test the impact of firm size on the main model, the sample was segregated into two main groups: small (99) and medium (1 3 2). Following the procedure by Koufteros and Marcoulides, 2006, Byrne, 2004, a multigroup test was run to see the variation in the strength of relationships between constructs for the two different groups of firms. The variance in chi-square values (ΔX2 = 6.16) indicated non-significant (p = 0.21 < 0.05) difference in results for small vs medium-size firms. A similar analysis procedure was adopted to test the possible influence of four food industry’s sub-sectors: dairy and meat; fruits, nuts and vegetables; wheat; beverages. The variance in chi-square (ΔX2 = 5.43) disclosed non-significant (p = 0.17 > 0.05) difference in results among industry sub-sectors. Thus, firm size and industry sub-sector did not influence the main findings of this study.

4. Discussion and implications

The COVID-19 outbreak presents an extraordinary and unprecedented situation putting the resilience of value chains to a test (Sharma, Adhikary, & Borah, 2020). Being globalised and complex, while many supply chains became prone to coronavirus disruptions, global food value chains have been even severely affected due to the long-stretched nature of such value chains. For some value chains, demand was drastically increased, and supply was not able to deal with the evolving situation. For others, both supply and demand were drastically disrupted due to production failure and the travel related restrictions imposed by the governments. Given this, a shortage of food supplies, price escalation, hoarding behaviours were observed in various regions of the world. Against such a backdrop, there has been increasing interest of scholars and practitioners to build more resilient global food value chains facing COVID-19 shocks. However, despite repeated calls for empirical evidence on supply chain resilience (SCRes) amidst the COVID-19 (Chowdhury et al., 2021, Ivanov and Dolgui, 2020, Remko, 2020), the significant part of the current scholarship is still conceptual. As such, the amount of subjectivity associated with the impact of the current outbreak of the pandemic made it difficult to fully ascertain the specific risks and effective response strategies by firms that are part of the global value chains. To this end, our study offers a new empirical angle into the literature by examining how exposure to the COVID-19 shock triggered firms to reimagine the SCRes capabilities and ultimately gained a competitive advantage. Our research speaks to the scholars and practitioners interested in understanding COVID-19 inflicted internal and external threats and challenges that provide impetus to cultivating specific SCRes capabilities—resulting in enhanced global competitiveness of value chains.

4.1. Theoretical implications

This study provides several contributions to the diverse streams of literature around COVID-19, SCRes and global value chains’ competitiveness. First, we make a noteworthy contribution to the existing body of knowledge through empirical evidence linking COVID-19 shocks, SCRes and competitiveness of global (food) value chains. As such, our paper expands the sparse empirical literature on global food value chains, in particular, and global value chains, in general. In doing so, we address the recent calls in the literature for empirical evidence at the nexus of resilience strategies, COVID-19 shocks and firms’ competitiveness (Chowdhury et al., 2021, Ivanov and Dolgui, 2020, Remko, 2020). In the pre-COVID 19 era, a range of enablers to SCRes can be seen (Ali and Golgeci, 2019), most of which proved ineffective to cope with the COVID-19 related prolonged shocks. On the other hand, during the COVID-19 era, most studies on resilience to COVID-19 are based on either conceptual or projection-based simulation models. Presumably, the relative scarcity of empirical/quantitative studies is due to the sudden occurrence of the pandemic, mobility restrictions and limited time to collect the empirical data. Nonetheless, our study steps into the under-explored territory of the past studies and empirically elucidate the mechanisms in which effective SCRes is instigated in response to the COVID-19 shocks and thereby sustain competitive advantage.

Current literature shows a conceptual debate on the number of elements or phases needed to create resilience to COVID-19, for instance: response (Leite et al., 2021, Paul and Chowdhury, 2020); response and recovery (Gunessee and Subramanian, 2020, Ivanov and Dolgui, 2020); readiness and recovery (Deaton and Deaton, 2020, Mollenkopf et al., 2021, Parker and Ameen, 2018); readiness, response and recovery (Hobbs, 2020, Singh et al., 2021). Our study settles down this ongoing tension on key components of SCRes—that is, we empirically validate that effective resilience is achieved when three significant elements of SCRes work together in a sequential order.

While theory grounded research allows to better understand the underlying problems and solutions amidst the COVID-19 crises—it is somewhat surprising that a vast majority of past studies are atheoretical. Underpinning the DCV (e.g., Teece, 2007, Teece, 2014, Barreto, 2010), this paper contributes to spares literature grounded by theoretical lenses. Specifically, we contribute to the empirical literature on DCV by demonstrating the mechanisms that lead to dynamic capabilities (readiness, response, recovery) in a changing and turbulent business environment. Underpinning DCV, we validate that competitiveness is expounded by the firms’ core capabilities (readiness, response, recovery) that help build, integrate, and reconfigure the internal and external competencies in the uncertain and turbulent business environment (COVID-19 shocks). Drawing upon the DCV (Teece et al., 1997, Teece, 2007), we characterise readiness, response and recovery as firms’ dynamic capabilities that help deal with the COVID-19 shocks and thereby maintain the competitiveness of GFVC.

Interestingly, as opposed to common wisdom, our analysis uncovers that firms with combinations of domestic and global value chains perform better than those possessing only global food value chains. This indicates that excessive moves to low-cost offshore destinations and long international logistics networks could make modern supply chains more vulnerable to disruptions. Our finding thus offers a contrary view to the research that overly stresses on geographically dispersed manufacturing facilities and offshore sourcing (Chowdhury et al., 2021). Before COVID-19, many firms increasingly focused on international value chains to enhance competitiveness. However, COVID-19 taught the lesson that heavy dependence on international networks negatively affects firms’ competitiveness in the face of unexpected global disasters due to the long-stretched and geographically dispersed supply chains. Therefore, companies should maintain a good balance between domestic and international networks to reduce vulnerabilities to global pandemics such as the COVID-19. Finally, our findings suggest that SCRes is a disruption driven (disruption-reaction balancing) property of a supply chain (Ivanov & Dolgui, 2020), and firms can mitigate external shocks by leveraging their key resources and effectively deploying the key capabilities (e.g., Teece, 2014).

4.2. Practical implications

Our study offers several useful implications which could help practitioners and policymakers to reimage the contemporary GFVCs. First, we provide an account of critical shocks and their precursors by mapping all three sides of GFVCs: supply-side, production side, and demand-side. Our analysis suggests that labour shortages, unavailability of transporters, loss of key suppliers were amongst the critical issues causing supply-side shocks. The production side shocks, on the other hand—involved a shortage of skilled workforce, delays in production time, closure of production sites and food waste. In addition, the demand-side shocks constituted hoarding behaviours, panic buying and inaccurate demand forecasting and lack of coordination between buyers and suppliers. Despite these crucial shocks, encouragingly some firms were able to maintain business operations and the competitiveness of their value chains. Through the analysis of these firms, we recognise a rigorous set of SCRes’ capabilities under three main categories (readiness, response, and recovery) helping to rebound from current shocks and prepare for the similar future events.

The readiness capabilities, which help prevent disruption, include the proactive changes to remote work arrangements, reduction in unnecessary expenditures, regular screening of workers, digitalisation, regular training and development of employees, use of omnichannel for sale, forward and backward integration and, close collaboration and resource sharing with government, industry bodies and other stakeholders.

The response capabilities, which help resist and alleviate the magnitude of negative impact when an incident materialises—comprise remote work arrangements, dedicated shipments, extended payables, expedited receivables, reduced operational costs through re-budgeting, regular screening of workers, constant communication with staff and other stakeholders, and flexible contracts with trading partners.

The recovery capabilities, which help rebound to normal business operations and maintain stability, necessitate re-structuring of current business models based on the lesson learnt from COVID-19. These include, but are not limited to, digitalisation initiatives, re-evaluation of the current suppliers and buyers’ networks, reconsideration of the current corporate plan(s), business diversification, re-building of cutomers and staff trust, realisation of funds through grants, loan re-financing, reduction in cash outflows, selling of non-productive assets, revisit operations in line with post-COVID market etc.

Our findings offer an optimistic and pragmatic view to practitioners that risks are inherent in the global food value chains and can arise anytime from unintended events (e.g., COVID-19) in the upstream supply chain—inbound operations or downstream demand side, thereby presenting serious disruption to the normal course of business operations. In essence, we argue that the competitiveness of firms lies in the way they make structural and parametrical changes and develop effective resilience in response to unanticipated events, such as COVID-19 shocks. Finally, a key finding is that the firms with domestic plus global value chain partners are more resilient and competitive compared to those holding only global networks. This finding implies that excessive reliance on offshoring could cause major disruptions specifically amidst the unexpected global disasters and, therefore, companies should strike a balance between domestic and global networks to remain competitive.

The United Nations’ Sustainable Developments Goals (SDGs) for 2030, which are aimed to achieve a better and sustainable future for all, strongly urge the researchers to help address 17 interlinked goals. Correspondingly, through enhancing resilience and competitiveness of GFVC, our research is amongst the few that contributes to the debate on the five goals: SDG 1 (no poverty) – economic growth and more job opportunity; SDG 2 (zero hunger) – sustained food supply at optimum prices; SDG 8 (decent work and economic growth) – more jobs for youth. SDG 12: Ensure sustainable consumption and production patterns and SDG 13: Take urgent action to combat climate change and its impacts.

5. Conclusion, limitations, and future research directions

This study was aimed to understand the ways in which firms in the GFVCs re-organise to achieve better resilience and maintain competitiveness. It is inferred that, for progressive firms, COVID-19 shocks worked as a trigger to build dynamic capabilities (readiness, response, and recovery) which, in turn, enhances the competitiveness of the GFVCs. While literature suggests discrepancies in the number of phases or elements of SCRes, we find that the effective resilience to the COVID-19 shocks and competitive advantage is achieved when the three dynamic capabilities work together and sequentially. We have provided a vigorous set of key capabilities to prepare, resist and recover from the current pandemic and similar events in the future (see Section 4.2, practical implications). Doing so, this study thus opens the black box of vital capabilities that are crucial for enhancing GFVCs’ performance and competitiveness against the increasing level of external shocks caused by the COVID-19. Furthermore, we found that excessive dependence on geographically dispersed manufacturing facilities and offshore sourcing increases the risk of disruption amidst global disasters such as those caused by COVID-19. As such, we suggest that creating a balance between onshoring and offshoring strategies can be vital for firms to mitigate the likelihood of disruptions from prolonged shocks such as the ongoing global pandemic.

Like many studies, our research is not free from limitations. First, the study uses data from a single country and industry which may cause sampling and geographical limitations. Thus, future studies could test our model across different countries and industrial sectors. Second, the study is cross-sectional and therefore cannot offer the benefits associated with a longitudinal study. The firms’ competitiveness measures are based on the subjective understanding of managers. The food industry is amongst the significant industries in many developing and developed countries of the world. Our research provides a valuable platform and leeway to replicate it in other parts of the world for the generalisation of findings. Future research can triangulate our findings through qualitative research. It will be insightful to see the effect of some moderators such as institutional distance and environmental dynamism in our proposed model. In this study, the outcome variable is global food value chains’ competitiveness; however, future research could examine how COVID-19 shocks and resilience interplay to influence firms' operational or quality performance and innovation. The model can be applied to the traditional manufacturing industry (automotive, chemical etc.) with some modifications to measure the constructs used in this study. SCRes and sustainability complement each other (Sarkis, 2020). During the pandemics, while carbon emission might have been reduced, there are increasing reports of waste and landfills with latex gloves, masks, packaging materials from disposal foods. In addition, COVID-19 has triggered civil unrest, unemployment, political turmoil, economic disasters. That said, our study can be expanded to test the interconnection between COVID-19 risks, SCRes and sustainability in supply chains. The emergence of Industry 4.0 technologies offers innovative ways to deal with adversities (Ali et al., 2020, Arslan et al., 2021). While we used some technologies in our measures of SCRes, it will be insightful to see the influence of a full range of Industry 4.0 technologies in our model. Thus, future studies could also examine how emerging technologies affect supply chains’ resilience and performance.

CRediT authorship contribution statement

Imran Ali: Writing – review & editing, Writing – original draft, Validation, Supervision, Software, Project administration, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Ahmad Arslan: Conceptualization, Methodology, Writing – original draft, Writing – review & editing. Maruf Chowdhury: Writing – review & editing, Writing – original draft, Methodology, Conceptualization. Zaheer Khan: Conceptualization, Supervision, Writing – original draft. Shlomo Y. Tarba: Conceptualization, Supervision, Writing – original draft.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Biographies

Imran Ali is currently a Lecturer (Assistant Professor) in Operations and Innovation Management at the School of Business and Law in the Central Queensland University, Melbourne Campus, Australia. Dr Imran also serves (fixed term) as a ‘Food Systems Expert’ at the FAO of the United Nations to develop resilient food systems in the developing and developed countries of the world. He holds a PhD in Business Management from the University of South Australia. His current research focuses on supply chain risk and resilience, Industry 4.0, the internet of things, blockchain, climate change, sustainable supply chain performance. Imran’s research has been featured in several good-quality journals and conference proceedings such as IEEE Transactions on Engineering Management, Production Planning and Control, Supply Chain Management: An International Journal, International Journal of Physical Distribution and Logistics Management, and Academy of Management Best Paper Proceedings, among others. In collaboration with UNDP and FAO of the UN, Imran has availed the opportunity to work on several promising projects around food supply chain and operations management.

Ahmad Arslan, D.Sc. (Econ. & Bus. Adm.) is currently working as an Associate Professor at the Department of Marketing, Management and International Business, Oulu Business School, University of Oulu, Finland. His earlier research has been published in prestigious academic journals like British Journal of Management, International Business Review, Human Resource Management, International Marketing Review, Scandinavian Journal of Management, Journal of Strategic Marketing, Journal for East European Management Studies, and Journal of Global Marketing, among others. Ahmad sits on the editorial board of the British Journal of Management, Journal of East-West Business and International Journal of Export Marketing), and reviews papers regularly for several prestigious journals in fields of management, marketing, and international business.

Maruf Chowdhury is a senior lecturer of Operations and Supply Chain Management at the University of Technology Sydney (UTS). He has extensive teaching and research experience in operations, supply chain management and decision modelling. He has published his research papers in top-tier journals such as International Journal of Production Economics, Omega, The International Journal of Management Science, Supply Chain Management: An International Journal and others. Dr Chowdhury has multiple methodological skills and he worked extensively in different national and international projects. As an expert in supply chain management, Dr Chowdhury has taught in different universities of Australia such as the University of Technology Sydney, University of Western Australia (UWA) and Curtin University. Dr Chowdhury has professional experiences in different industrial settings such as the Textile and Apparel industry, Petroleum refinery and others.

Zaheer Khan is a Professor in Strategy and International Business at the University of Aberdeen, UK. His research interests are international knowledge transfer, capability development of emerging market firms, automotive industry, sustainability, and cross-border alliances. His work has appeared in leading journals such as the Journal of International Business Studies, Global Strategy, Journal of World Business, Management International Review, British Journal of Management, International Business Review, Human Relations, Journal of Corporate Finance, Journal of Business Research, and Technological Forecasting and Social Change, among others. He is an Associate Editor of Critical Perspectives on International Business and sits on the editorial board of the British Journal of Management, Management International Review, Journal of World Business, International Studies of Management & Organization, and Journal of Knowledge Management.

Shlomo Y. Tarba is a Chair (Full Professor) in Strategy and International Business at the Business School, University of Birmingham, UK. Prof. Tarba is a Fellow of the Academy of Social Sciences. He is a member of the editorial boards of Journal of Management Studies, Journal of International Business Studies, Long Range Planning, and Journal of World Business. He has served as a Guest-Editor for the special issues at the Journal of Organizational Behavior (US, Wiley), Human Resource Management (US), California Management Review, Journal of Product Innovation Management, International Business Review, and Management International Review, among others. His research interests include cross-border mergers and acquisition resilience, agility, and organizational ambidexterity. Prof. Tarba's has published over 60 academic papers in highly ranked journals including Journal of Management (SAGE), Long Range Planning, Academy of Management Perspectives, Journal of Organizational Behavior, Human Relations, Human Resource Management (US, Wiley), British Journal of Management, Journal of Product Innovation Management, Journal of World Business, Management International Review, International Business Review, Journal of Corporate Finance, International Journal of Production & Economics, and others.

References

- ABARES . Australian Bureau of Agricultural and Resource Economics and Sciences (Australian Bureau of Agriculture and Resource Economics Sciences). Retrieved 10 September from. 2021. Agricultural outlook. [Google Scholar]

- Ali I., Arslan A., Khan Z., Tarba S.Y. The Role of Industry 4.0 Technologies in Mitigating Supply Chain Disruption: Empirical Evidence From the Australian Food Processing Industry. IEEE Transactions on Engineering Management. 2021:1–11. doi: 10.1109/TEM.2021.3088518. [DOI] [Google Scholar]

- Ali I., Gölgeci I. Where is supply chain resilience research heading? A systematic and co-occurrence analysis. International Journal of Physical Distribution & Logistics Management. 2019;49(8):793–815. [Google Scholar]

- Ali I., Gölgeci I. Managing climate risks through social capital in agrifood supply chains. Supply Chain Management: An International Journal. 2020;26(1):1–16. [Google Scholar]

- Ali I., Nagalingam S., Gurd B. Building resilience in SMEs of perishable product supply chains: Enablers, barriers and risks. Production Planning & Control. 2017;28(15):1236–1250. [Google Scholar]

- Ali I., Nagalingam S., Gurd B. A resilience model for cold chain logistics of perishable products. The International Journal of Logistics Management. 2018;29(3):922–941. [Google Scholar]

- Ali, I., & Aboelmaged, M. G. S. (2021). Implementation of supply chain 4.0 in the food and beverage industry: perceived drivers and barriers. International Journal of Productivity and Performance Management, ahead-of-print(ahead-of-print). https://doi.org/10.1108/IJPPM-07-2020-0393.

- Ali I., Govindan K. Extenuating operational risks through digital transformation of agri-food supply chains. Production Planning & Control. 2021;1–13 doi: 10.1080/09537287.2021.1988177. [DOI] [Google Scholar]

- Ali I., Gurd B. Managing operational risks through knowledge sharing in food supply chains. Knowledge and Process Management. 2020;27(4):322–331. [Google Scholar]

- Arslan, A., Cooper, C., Khan, Z., Golgeci, I., & Ali, I. (2021). Artificial intelligence and human workers interaction at team level: a conceptual assessment of the challenges and potential HRM strategies. International Journal of Manpower, ahead-of-print(ahead-of-print). https://doi.org/10.1108/IJM-01-2021-0052.

- Ali I., Satie S., Thai V. In: Supply Chain 4.0: Improving Supply Chains with Analytics and Industry 4.0 Technologies. Aktas E., Bourlakis M., Minis I., Zeimpekis V., editors. Kogan Page; UK: 2020. Adopting Industry 4.0 Technologies in Agri-Food Supply Chains; pp. 209–232. [Google Scholar]

- Altay N., Gunasekaran A., Dubey R., Childe S.J. Agility and resilience as antecedents of supply chain performance under moderating effects of organizational culture within the humanitarian setting: A dynamic capability view. Production Planning and Control. 2018;29(14):1158–1174. doi: 10.1080/09537287.2018.1542174. [DOI] [Google Scholar]

- Ali M.H., Suleiman N., Khalid N., Tan K.H., Tseng M.-L., Kumar M. Supply chain resilience reactive strategies for food SMEs in coping to Covid-19 crisis. Trends in Food Science & Technology. 2021;109:94–102. doi: 10.1016/j.tifs.2021.01.021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ambrosini V., Bowman C., Collier N. Dynamic capabilities: An exploration of how firms renew their resource base. British Journal of Management. 2009;20:9–24. [Google Scholar]

- Antonakis J., Bendahan S., Jacquart P., Lalive R. In: The Oxford Handbook of Leadership and Organizations. Day D.V., editor. Oxford University Press; New York, NY: 2014. Causality and endogeneity: Problems and solutions; pp. 93–117. [Google Scholar]

- Arslan A., Khan Z., Kontkanen M., Tarba S. In: COVID-19 and International Business: Change of Era. Marinov M., Marinova S., editors. Routledge; Oxon, UK: 2021. COVID-19 and the Changing Perception of Strategic Industries: Implications for International Business; pp. 89–102. [Google Scholar]

- Australian Food & Grocery Council. (2019). Food and beverage manufacturing state of the industry Retrieved from Canberra: file:///C:/Users/alii/Downloads/AFGC-SOI-2019-FINAL.pdf.

- Barreto I. Dynamic capabilities: A review of past research and an agenda for the future. Journal of Management. 2010;36(1):256–280. [Google Scholar]

- Bentler P.M., Chou C.-P. Practical Issues in Structural Modeling. Sociological Methods & Research. 1987;16(1):78–117. [Google Scholar]

- Blackhurst J., Dunn K.S., Craighead C.W. An empirically derived framework of global supply resiliency. Journal of Business Logistics. 2011;32(4):374–391. doi: 10.1111/j.0000-0000.2011.01032.x. [DOI] [Google Scholar]

- Bollen K.A. Wiley; New York: 1989. Structural equations with latent variables. [Google Scholar]

- Brusset X., Teller C. Supply chain capabilities, risks, and resilience. International Journal of Production Economics. 2017;184:59–68. [Google Scholar]

- Byrne B.M. Testing for multigroup invariance using AMOS graphics: A road less traveled. Structural Equation Modeling: A Multidisciplinary Journal. 2004;11(2):272–300. [Google Scholar]

- Chen J., Sohal A.S., Prajogo D.I. Supply chain operational risk mitigation. International Journal of Production Research. 2013;51(7):2186–2199. [Google Scholar]

- Cho D.S., Moon H.C. extended edition. World Scientific; Singapore: 2013. From Adam Smith to Michael Porter: Evolution of competitiveness theory. [Google Scholar]

- Chowdhury M.M.H., Quaddus M. Supply chain readiness, response and recovery for resilience. Supply Chain Management. 2016;21(6):709–731. doi: 10.1108/SCM-12-2015-0463. [DOI] [Google Scholar]

- Chowdhury M.M.H., Quaddus M. Supply chain resilience: Conceptualization and scale development using dynamic capability theory. International Journal of Production Economics. 2017;188:185–204. [Google Scholar]

- Chowdhury M.M.H., Quaddus M., Agarwal R. Supply chain resilience for performance: Role of relational practices and network complexities. Supply Chain Management. 2019;24(5):659–676. doi: 10.1108/SCM-09-2018-0332. [DOI] [Google Scholar]

- Chowdhury P., Paul S.K., Kaisar S., Moktadir M.A. COVID-19 pandemic related supply chain studies: A systematic review. Transportation Research Part E: Logistics and Transportation Review. 2021;148 doi: 10.1016/j.tre.2021.102271. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Conz E., Magnani G. A dynamic perspective on the resilience of firms: A systematic literature review and a framework for future research. European Management Journal. 2020;38(3):400–412. [Google Scholar]

- Craighead C.W., Ketchen D.J., Dunn K.S., Hult G.T.M. Addressing common method variance: Guidelines for survey research on information technology, operations, and supply chain management. IEEE Transactions on Engineering Management. 2011;58(3):578–588. [Google Scholar]

- Craighead C.W., Ketchen D.J., Darby J.L. Pandemics and supply chain management research: Toward a theoretical toolbox. Decision Sciences. 2020;51(4):838–866. doi: 10.1111/deci.12468. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Damali U., Miller J.L., Fredendall L.D., Moore D., Dye C.J. Co-creating value using customer training and education in a healthcare service design. Journal of Operations Management. 2016;47-48(1):80–97. [Google Scholar]

- Das K., Lashkari R.S. Risk readiness and resiliency planning for a supply chain. International Journal of Production Research. 2015;53(22):6752–6771. [Google Scholar]

- Deaton B.J., Deaton B.J. Food security and Canada's agricultural system challenged by COVID-19. Canadian Journal of Agriculture Economics. 2020;68(2):143–149. doi: 10.1111/cjag.v68.210.1111/cjag.12227. [DOI] [Google Scholar]

- Dillman D.A. John Wiley & Sons; Hoboken, N.J: 2011. Mail and Internet surveys: The tailored design method–2007 Update with new Internet, visual, and mixed-mode guide. [Google Scholar]

- Dixon S., Meyer K., Day M. Building dynamic capabilities of adaptation and innovation: A study of micro-foundations in a transition economy. Long Range Planning. 2014;47(4):186–205. [Google Scholar]

- Dubey R., Gunasekaran A., Bryde D.J., Dwivedi Y.K., Papadopoulos T. Blockchain technology for enhancing swift-trust, collaboration and resilience within a humanitarian supply chain setting. International journal of Production research. 2020;58(11):3381–3398. [Google Scholar]

- El Baz J., Ruel S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. International Journal of Production Economics. 2021;233 doi: 10.1016/j.ijpe.2020.107972. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Feurer, R., & Chaharbaghi, K. (1994). Defining Competitiveness. Management decision, 32(2), 49-58.

- Fornell C., Larcker D.F. Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research. 1981;18(1):39–50. [Google Scholar]

- Garnett P., Doherty B., Heron T. Vulnerability of the United Kingdom’s food supply chains exposed by COVID-19. Nature Food. 2020;1(6):315–318. doi: 10.1038/s43016-020-0097-7. [DOI] [PubMed] [Google Scholar]

- Gereffi G. What does the COVID-19 pandemic teach us about global value chains? The case of medical supplies. Journal of International Business Policy. 2020;3(3):287–301. [Google Scholar]

- Giannoccaro I., Iftikhar A. Mitigating ripple effect in supply networks: The effect of trust and topology on resilience. International Journal of Production Research. 2020;1–18 doi: 10.1080/00207543.2020.1853844. [DOI] [Google Scholar]

- Gölgeci I., Kuivalainen O. Does social capital matter for supply chain resilience? The role of absorptive capacity and marketing-supply chain management alignment. Industrial Marketing Management. 2020;84:63–74. [Google Scholar]

- Golgeci I., Y. Ponomarov S. Does firm innovativeness enable effective responses to supply chain disruptions? An empirical study. Supply Chain Management: An International Journal. 2013;18(6):604–617. [Google Scholar]

- Goddard E. The impact of COVID-19 on food retail and food service in Canada: Preliminary assessment. Canadian Journal of Agricultural Economics/Revue canadienne d'agroeconomie. 2020;68(2):157–161. [Google Scholar]

- Gu M., Yang L.u., Huo B. The impact of information technology usage on supply chain resilience and performance: An ambidexterous view. International Journal of Production Economics. 2021;232:107956. doi: 10.1016/j.ijpe.2020.107956. [DOI] [PMC free article] [PubMed] [Google Scholar]