Abstract

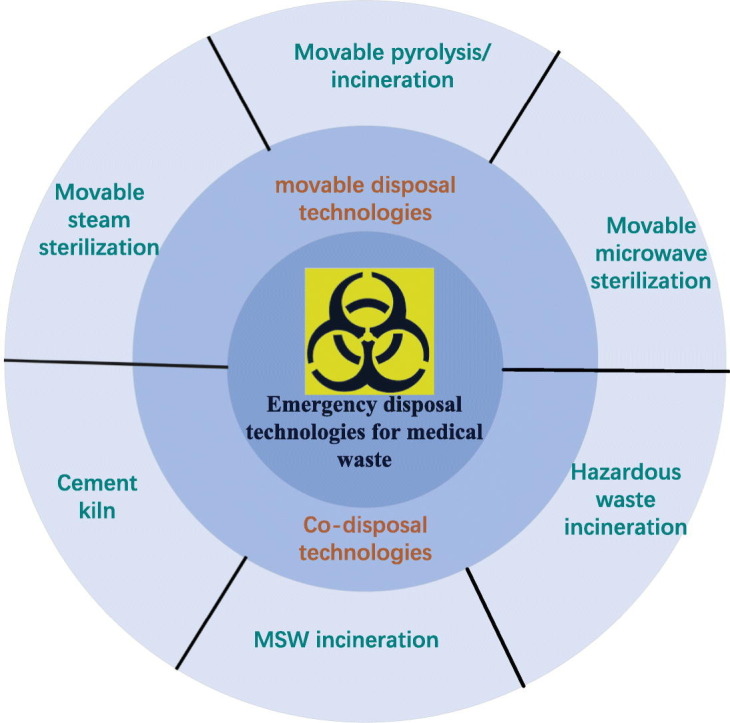

The surge of medical waste (MW) generated during the COVID-19 pandemic has exceeded the disposal capacity of existing facilities. The timely, safe, and efficient emergency disposal of MW is critical to prevent the epidemic spread. Therefore, this review presents the current status of MW generation and disposal in China and analyzes the characteristics and applicability of emergency disposal technologies. The results show that movable disposal facilities can dispose of infectious MW on site, even though most of their disposal capacity is at a low level (<5 t/day). Co-disposal facilities need to be reformed completely for emergency MW disposal, in which separate feeding systems should be taken seriously. Specifically, municipal solid waste (MSW) incineration facilities have great potential to improve emergency MW disposal capacities. For hazardous waste incineration facilities, compatibility of the wastes must be matched to the composition and calorific value of the waste. As for cement kiln, MW can only be used as an alternative fuel instead of a raw material for cement. Based on the environmental risk and technical adaptability, the six emergency MW disposal technologies are recommended to be prioritized as follows: movable microwave sterilization, movable steam sterilization, movable incineration, co-incineration with hazardous waste, co-incineration with MSW and co-disposal in cement kilns. Infectious MW, especially COVID-19 MW, should be prioritized for disposal by centralized and movable disposal facilities, while non-infectious MW can be disposed of using co-disposal facilities. All stakeholders should strengthen the delicacy management of the end-of-life stage of MW, including collection, classification, packaging identification, transportation, and disposal. Currently, it is necessary for centralized disposal enterprises to follow the emergency disposal operation flowchart. From a long-term strategic perspective, making full use of regional movable and co-disposal facilities in the megacities can effectively enhance the emergency MW disposal capacity.

Keywords: Medical waste, Life cycle management, Movable disposal, Municipal solid waste incineration, Hazardous waste incineration, Co-disposal in cement kiln

Graphical abstract

1. Introduction

Medical waste (MW) is defined as waste generated in the diagnosis, treatment, and immunization of human and animals, as well as related research, biological production, and testing (Purnomo et al., 2021, Purnomo et al., 2021; Windfeld and Brooks, 2015). Only medical solid waste is considered in this study, excluding liquid waste. MW generally contains massive organic compounds (e.g. human organs, plastics, cotton swabs, paper and fabrics) and inorganic compounds (e.g. glass and metal), in which organic compounds are prone to cause the breeding of mosquitoes, flies, rats and cockroaches, thereby spreading diseases (Chen and Guo, 2020). The MW piled up and decomposed in the open air will not only emit malodorous gases, but also pathogens, heavy metals and organic compounds contained in them will pollute surface water, groundwater and soil (Zheng et al., 2020b; Chen and Hao, 2020; Lee and Wen, 2018). Thus, MW is identified as the HW01 Hazardous Waste in China (Ministry of Ecology and Environment, 2021; Cao et al., 2021). In addition, during the COVID-19 pandemic, municipal solid waste (MSW) generated by designated medical institutions and quarantine locations should also be treated as MW due to its infectivity (Yang et al., 2021; Chen and Guo, 2020).

COVID-19 is a highly contagious respiratory infectious disease that can be spread through aerosols, large droplets (e.g. cough and sneeze), and direct contact with secretions or fomites (Yang et al., 2021). The rapid spread of COVID-19 has attracted global attention, subsequently, the World Health Organization (WHO) declared a global health emergency on January 30th, 2020 (Fadare and Okoffo, 2020; Yang et al., 2021; You et al., 2020). During the COVID-19 pandemic, medical workers and patients consumed extremely large amount of personal protective equipment (PPE) (e.g. gloves, face shields, goggles and coverall suits) (Zhao et al., 2021a). At present, most countries have formulated policies to force their citizens to wear masks in public. It is estimated that there are 129 billion masks and 65 billion gloves used globally per month (Chen et al., 2021; Prata et al., 2020). In February, 2020, 116 million disposable masks were produced every day in China, a 12-fold increase from before the COVID-19 pandemic (Chen et al., 2021; Ministry of Industry and Information Technology, 2020). Global consumption of PPE has led to a surge in MW generation. Recent studies have revealed that COVID virus can survive on surface materials for up to 9 days (Kampf et al., 2020), posing a challenge to the sustainable management of MW and the health management of public (Adyel, 2020; Borrelle et al., 2020; Chen et al., 2021), even though these are generally unlikely to serve as significant sources of infection/transmission (De-la-Torre et al., 2021). In China, MW must be disposal of by centralized disposal facilities, but the recent increase in MW has far exceeded the existing disposal capacity in severely affected areas (Zhao et al., 2021a; Zhao et al., 2021b). For instance, in Hubei Province, the initial outbreak of COVID-19 in China, the amount of MW generated during the epidemic increased significantly by approximate four times, and its peak production in Wuhan has exceeded the maximum disposal capacity by five times (Klemeš et al., 2020; Purnomo et al., 2021, Purnomo et al., 2021). Therefore, improving the level of emergency MW disposal is considered a key to prevent the spread of epidemic (Chang et al., 2020; Peng et al., 2020; Saadat et al., 2020; Wang et al., 2020).

On January 28th, 2020, Management and Technical Guidelines for Emergency Disposal of Medical Waste Infected by the Novel Coronavirus Pneumonia (Trial) was released in China to control the spread of virus and increase the disposal capacity of emergency MW (Ministry of Ecology and Environment, 2020a). According to the Guideline, movable disposal and co-disposal of MW facilities have been included in the facility list of emergency disposal (Zhao et al., 2021a). Wuhan employed these emergency technologies during the COVID-19 pandemic, and Fig. S1 (a) presents the MW disposal technologies used from February 21st to April 19th, 2020 (Chen et al., 2021). There were 34 mobile MW disposal facilities used in designated hospitals, Fangcang shelter hospitals, and temporary storage sites, from procurement (52.94%), social donation (29. 41%) and allocation by the Ministry of Ecology and Environment of China (17.65%) (Yang et al., 2021). Incineration, microwave disinfection and steam disinfection technologies were applied in these movable facilities in service, of which microwave disinfection accounts for the highest utilization rate (55.88%), followed by incineration (32.35%) (Yang et al., 2021). The total disposal capacity of mobile facilities reached 75.6 t per day (TPD) on March 21st, 2020. MSW incineration facilities have been used to MW disposal in Wuhan and some other cities during the COVID-19 pandemic (see Table S1) (Ma et al., 2020; Yang et al., 2021; Zhou et al., 2020a). In most Chinese cities, MW addition reached the highest value of 5% in co-disposal with MSW. The MSW incineration facilities in Wuhan incinerated 5806.4 t of MW, accounting for 46.09% of the total MW disposed of during the COVID-19 pandemic (from January 23rd, 2020 to April 24th, 2020) (see Fig. S1 (b)) (Yang et al., 2021). A total of 27 permits for co-disposal of hazardous waste and MW have been issued in China from 2004 to 2019, which improved the emergency disposal capacity (Ministry of Ecology and Environment, 2020b). Many hazardous waste disposal enterprises in China are all equipped with emergency MW disposal capabilities currently, which eased the pressure on MW management during the COVID-19 pandemic (Zhang et al., 2020). There are 68 cement enterprises in China with qualifications for the co-disposal of hazardous waste, with a total approved disposal capacity of 4.26 million tonnes, involving 85 production lines (Jin, 2020). Many cement enterprises have disposed of COVID-19 medical waste (CMW) in cement kilns. As of March 3rd, 2020, four cement production enterprises of Huaxin Cement Group have disposed of 133.4 t of MW, and BBMG Group has disposed of 6.35 t of MW and 1.29 t of general masks (Jin, 2020).

MW disposal technology and management have been widely discussed in the literatures. For MW disposal technologies, Wajs et al. (2019) introduced a mobile MW incinerator in Poland based on the composition analysis of MW. Wang et al. (2020) summarized the commonly applied incineration, chemical disinfection, and physical disinfection techniques for MW disinfection. Dharmaraj et al. (2021) studied thermochemical process, especially the utilization of pyrolysis process to treat MW. Their results show that the plastic wastes in MW can be converted into valuable energy products via pyrolysis process. A prospective review was conducted to analyze the potential thermochemical treatments for CMW and their possibility of its conversion into fuels (Purnomo et al., 2021, Purnomo et al., 2021). Su et al. (2021) critically and comprehensively reviewed the pyrolysis of MW and proved the feasibility of pyrolysis.

As for MW management, many studies have focused on China, as Wuhan was the first city to experience a large-scale epidemic during the outbreak. Chen et al. (2021) analyzed the performance of end-of-life management process of MW in Wuhan during the COVID-19 pandemic based on the MW generation, transportation, and disposal data collected in hospitals. The segregation, collection, storage, transportation and disposal of MW in Wuhan were investigated and analyzed to form integrated management measure (Yang et al., 2021). Kang et al. (2021) grabbed the Chinese government's management information on COVID-19 from the website of the China Ministry of Ecology and Environment via text mining method. As the situation in China improved, India became the new epicenter of the epidemic. Thus, MW management in India has been concerned by many researchers. The compromise of bio-medical waste (BMW) incineration capacity in India was studied during the COVID-19 pandemic with specific reference to the associated emissions and health impacts (Thind et al., 2021). Goswami et al. (2021) also studied the BMW in India during this period. They discussed the existing infrastructures, capacity utilization, policy guidelines, engineering practices and waste disposal of BMW in India. A comprehensive assessment of BMW in India was conducted to highlight the gap before and during the COVID-19 pandemic, and the implementation of BMW rules in India (Rajak et al., 2021). Besides, many other studies have focused on MW management strategies in countries around the world. The policies, potential solutions associated with sustainability and MW management in Africa were reviewed (Chisholm et al., 2021). El-Ramady et al. (2021) analyzed the current challenges of the MW management in developing countries through their planning for disposal of CMW. An overview of the consumption of CMW and PPE along with the production of hazardous solid waste were presented to propose preventive measures for developing countries (Adelodun et al., 2021). The potential influences of the COVID-19 pandemic on MW, PPE waste and MSW were reviewed, and the measures and policies of solid waste management in typical countries were discussed (Liang et al., 2021). Tripathi et al. (2020) evaluated the effect of COVID-19 on the end-of-life management of solid waste (e.g. masks, gloves, sanitizers) and briefly described the efforts in different countries to limit the spread of the virus through solid waste. A summary of general issues specific to CMW with tentative answers based on guidelines, rules and recommendations from national and international agencies published was prepared (Capoor and Parida, 2021). The different MW management strategies practiced in different countries, the challenges faced the COVID-19 pandemic, and the possible solutions were discussed (Das et al., 2021a).

Beyond the management of specific MW, the comprehensive analysis of MW disposal and management are also considered in previous studies. Liu et al. (2021) analyzed the MW disposal capacity in Wuhan City, Hubei Province and China in 2020, as well as the treatment measures taken by China during the COVID-19 pandemic. Disinfection technologies of CMW from separate collection to different physical and chemical treatment have been reviewed in Ilyas et al. (2020). They also discussed the policy briefly on the global CMW management. Hantoko et al. (2021) then emphasized the global challenges of CMW, and they argued the improvement of emergency disposal facilities and their emergency response process. However, few studies focused on the characteristics of emergency MW disposal technologies and facilities, and discussed MW management strategies based on the these technology characteristics. Thus, this review aims to introduce the generation and disposal of MW in China, and how China coped with the surge in MW during the COVID-19 pandemic. The technical details of different emergency MW disposal technologies and facilities are highlighted, especially the transformation of co-disposal facilities for MW disposal. We also aim to provide suggestions for global emergency MW disposal and management during the COVID-19 pandemic.

2. The status of MW generation and disposal in China

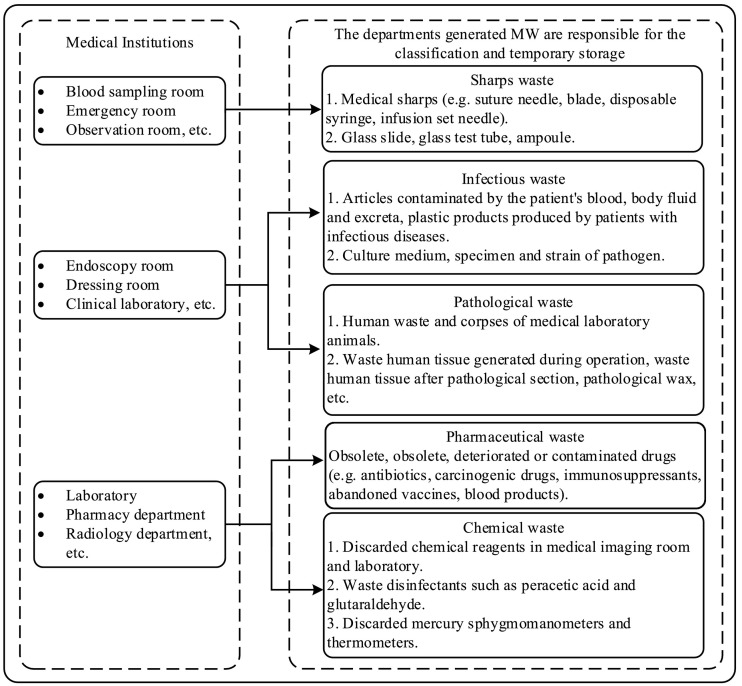

MW is mainly divided into infectious waste, pathological waste, sharps waste, pharmaceutical waste, chemical waste. Infectious MW contains infective pathogens, resulting in the diseases spread (Das et al., 2021a). Pathological MW refers to generally a small part or slice of any tissue, organ, or body part, taken from surgical or microbiological specimens from animal or human bodies (Das et al., 2021a; Yves Chartier et al., 2014). Sharps MW refers to scrap medical sharps made of metal, glass and other materials that can hurt human body. Pharmaceutical MW refers to disused drugs which are expired, obsoleted, deteriorated or contaminated. Chemical MW contains toxic, corrosive, flammable and explosive chemical substances (e.g. laboratory reagents, film developing reagents, expired/unused disinfectants, solvents, and waste containing heavy metals) (Das et al., 2021a; Yves Chartier et al., 2014). Fig. 1 presents the flow chart of MW generation. The stage of generating infectious waste should be given more attention. Thus, infectious MW and MSW generated by designated medical institutions and isolation locations should undoubtedly deserve attention during the COVID-19 pandemic. The management and disposal of MW will be discussed in the Section 4.1. The major stages to overcome are collection, classification, packaging identification, transportation and disinfection. Fig. S2 presents field pictures of the collection, storage, and disposal facilities.

Fig. 1.

The flow chart of MW generation. Adapted from (Chengdu Workers' Sanatorium of Sichuan Federation of Trade Unions, 2021).

2.1. Pre-epidemic status of MW generation and disposal

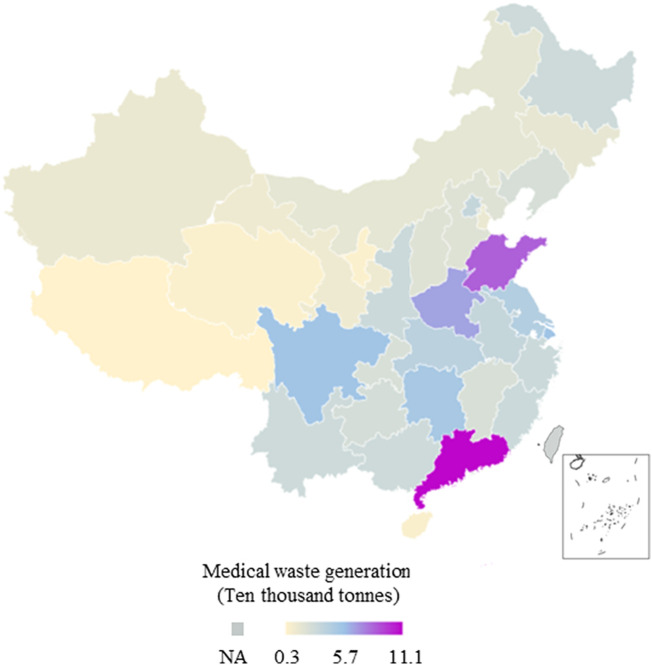

The evaluation of actual generation and disposal amount of MW is a critical first step in optimizing disposal and management system. In China, a total of 980 kilotonnes MW were collected and disposed of in 2018 (Cheng et al., 2020). Actual amount of MW disposed of by the disposal plants (with official permit) is shown in Fig. 2 (Ministry of Ecology and Environment, 2019). The Beijing-Tianjin-Hebei region collected and disposed of 69 kilotonnes MW, accounting for 7.0% of the total in China. The Yangtze River Delta region and Guangdong Province in the Greater Bay Area collected and disposed of 16.3 kilotonnes and 10.9 kilotonnes MW, accounting for 16.6% and 11.1% of the total in China respectively (Cheng et al., 2020; Zhang et al., 2020). Disposal technologies for MW are mainly incineration and non-incineration, and 588 kilotonnes MW were incinerated in China, accounting for 60.1% of the total (Sun et al., 2020; Cheng et al., 2020). The steam disinfection is the major non-incineration disposal technology and disposed of 332 kilotonnes MW, accounting for 33.9% of the total (Cheng et al., 2020). By the end of 2018, 407 business licenses for MW disposal (128 for incineration facilities, 255 for non-incineration facilities and 24 for co-disposal facilities) have been issued in China, with an approved operation scale of 1290 kilotonnes per year (Cheng et al., 2020). The amount of MW generated and disposed of in China is 1180 kilotonnes in 2019, 20.4% higher than in 2018 (see Fig. S3) (Ministry of Ecology and Environment, 2020d). The amount of MW generated and disposed of in Shandong, Zhejiang, Jiangsu, Hebei and Liaoning all increased by more than 10 kilotonnes.

Fig. 2.

Actual amount of MW disposed of by the disposal plants (with official permit) in each province (autonomous region and municipality) in China in 2018 (Ministry of Ecology and Environment, 2019).

MW disposal information of 158 prefecture-level cities (47% of the total) was collected and analyzed to compare their disposal pressure, some of which cannot provide information to calculate the load rate (Guangzhou Green Data Environmental Service Center, 2020). As shown in Supplementary Information A and Fig. S4, MW disposal information on 74 cities whose load rate exceed 80% is listed, and there is a mismatch between the disposal capacity and the actual demand in China. According to Notice of the State Council on Adjusting the Standards for Categorizing City Sizes, China's urban size is divided as shown in the Table S2. In 2018, 477,000 t of MW generated in 28 supercities, megacities and type I big cities, accounting for 48.7% of the total MW in China. As shown in Fig. S4, load rates of 16 supercities, megacities and typeIbig cities exceed 80%, the load rates of Beijing, Tianjin and Xiamen are even more than 130%. There are 25 cities whose load rates are over or equal to 100%, of which Zhangjiajie is highest at 205.93%, and the load rates of the other 33 cities are 80%–100%. In 2018, the average load rate of MW centralized disposal facilities in China reached 76.0%, with more than one-third of the load rate above 90%. One-fifth of the MW disposal facilities were in full load or overload operation (Zhang et al., 2020). In addition, centralized disposal facilities built in some remote areas are in poor operation due to the lack of rationality of the layout. Facility load rates in Qinghai, Tibet are extremely low, 17.2% and 27.7% respectively. Facility load rates in Guoluo, Haixi and Yushu of Qinghai Province are even lower than 10%, and many facilities in Tibet have not been in operation for a long time after completion, which needs attention (Cheng, 2020; Guangzhou Green Data Environmental Service Center, 2020).

2.2. Emergency status of MW generation and disposal during the COVID-19 pandemic

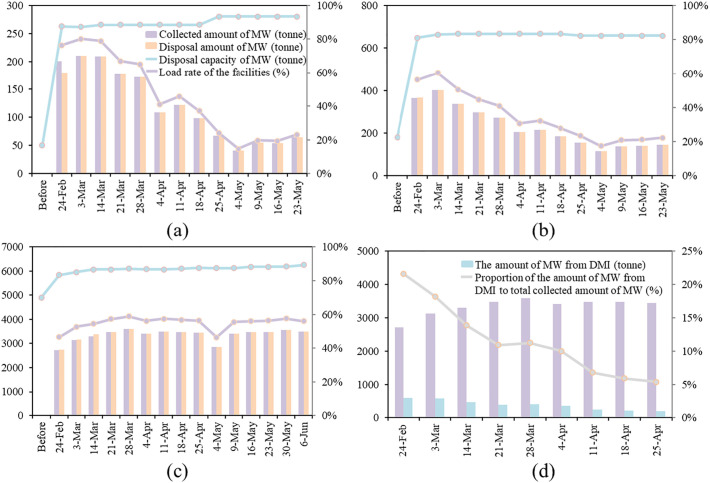

According to the reported statistics Ministry of Ecology and Environment, MW information in Wuhan City, Hubei Province and China is shown in Fig. 3 (Liu et al., 2021). From February 21st to March 2nd, 2020, tremendous amount of MW exceeded the disposal capacity, resulting in the temporary storage of MW, and the peak amount of stored MW reached 192 t on February 25th, 2020 (Chen et al., 2021; Yang et al., 2021). Therefore, local administrative departments built urgently 13 extra emergency storage sites whose total capacity reached 1118.6 t to increase rapidly the storage capacity of MW (Yang et al., 2021). Since March 2nd, 2020, Wuhan cancelled MW backlog and stopped using local temporary storage, and MW was temporarily stored in designated areas of the medical institutions and disposed of within 24 h after generation (Chen et al., 2021). In response to a tremendous amount of MW during the COVID-19 pandemic, MW disposal capacity of Wuhan increased from the initial 50.0 TPD to 265.6 TPD on March 11th, 2020 (Chen et al., 2021). As shown in Fig. 3 (a), the collected amount of MW decreased remarkably on April 4th, 2020 and drop to the normal level since May 4th, 2020. Meanwhile, the load rate of Wuhan dropped from overloaded during the severe epidemic to only 14.7% on May 4th, 2020 and has since stabilized at approximately 20.0%, which is of sufficient safe load rate for the timely MW disposal. As shown in Fig. 3 (b), the amount of MW generated in Hubei Province reached the peak value of 401 t on March 3rd, 2020, and then gradually decreased with the initial control of the COVID-19 -19 pandemic. As of May 23rd, 2020, the capacity of Hubei Province increased from 180.0 TPD before the epidemic to 658.4 TPD, and the operating load rate of the disposal facilities decreased from 60.4% on March 3rd, 2020 to approximately 20.0%. The downward trend is roughly the same as in Wuhan. As shown in Fig. 3 (c), peak daily collection of MW in China reached 3590.9 t on March 28th, 2020, and a total of 447 kilotonnes MW have been disposed of from January 20th to June 6th, 2020. In China, MW disposal capacity reached 6167.3 TPD, an increase of 25.8% from the 4902.8 TPD before the epidemic. As shown in Fig. 3 (d), the amount of CMW from designated medical institutions reached 403.7 t on February 24th, 2020, accounting for 21.6% of the collection on that day. Proportion of the amount of MW from DMI to the collection in China gradually decreased to 5.4% on April 25th, 2020.

Fig. 3.

The collected and disposal amount of MW, disposal capacity and load rate of the facilities in (a) Wuhan City; (b) Hubei Province; (c) China; and (d) the amount of MW from designated medical institution (DMI) for the COVID-19 epidemic prevention and control and its proportion in the total collected amount. Load rate: the ratio of the actual disposal amount to the disposal capacity.

2.3. The main problems of emergency MW management and disposal

The obvious problems exposed during the COVID-19 epidemic in China are as following.

-

1.

The emergency capacity reserve of centralized disposal facilities and the emergency disposal capacity that can be directly allocated are insufficient. The disposal facilities in many cities are routinely operating at full capacity or over capacity.

-

2.

MW transportation capacity is in serious shortage. There are not enough vehicles and personnel for the timely collection. In addition, there is a big gap in MW collection bags, transfer barrels, protective and disinfection supplies.

-

3.

There are no management requirements for pollutant discharge in emergency disposal situations in China. Characteristics of MW composition in emergency situations have also changed from the usual (e.g. more inorganic waste and increased water content), and there are no sampling and monitoring of pollutant emissions.

-

4.

The reserve of expert team of emergency MW disposal and management is insufficient, and there is a shortage of relevant talents.

3. Emergency MW disposal technologies

Global MW generation has surged, far exceeding the existing disposal capacity in areas with serious epidemic (Zhao et al., 2021a; Zhao et al., 2021b). In China, movable disposal (e.g. movable incineration equipment, movable steam sterilization cabin, movable microwave sterilization equipment) and co-disposal (i.e. MSW grate incinerator, hazardous waste incinerator, and cement kiln) of MW facilities have been approved for emergency MW disposal (Ministry of Ecology and Environment, 2020a).

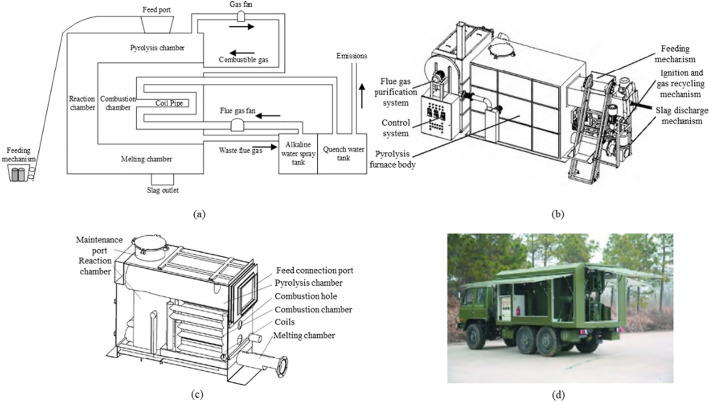

3.1. Movable pyrolysis/incineration

In the pyrolysis disposal vehicle, MW is heated and distilled under high temperature (800–1000 °C), anaerobic or anoxic conditions, and the pyrolysis process is shown in Fig 4 (a). Due to limited vehicle space, pyrolysis equipment must be miniaturized, which requires more compact structures and components (Han et al., 2018). The disposal capacity of the disposal vehicle is approximately 1 TPD, and the composition of the pyrolysis system and the pyrolysis furnace structure are shown in Fig 4 (b) and (c) (Han et al., 2018; Wu et al., 2015). From top to bottom, the pyrolysis furnace is composed of pyrolysis chamber, combustion chamber and melting chamber. The MW is sent into the pyrolysis chamber by the feeding mechanism on top of pyrolysis furnace (Han et al., 2015). The organic components in MW are initially pyrolyzed in the pyrolysis chamber to produce combustible gas (e.g. carbon monoxide, hydrogen, methane and other alkanes), which is sent to the combustion chamber for combustion to provide the heat for pyrolysis and coil pipe heating (Han et al., 2015; Wang et al., 2015). The residue is melted in the melting chamber and discharged outside the furnace for landfill. The flue gas from the combustion chamber passes through the lye spray water tank (deacidification and dust removal), the flue gas coil pipe and the quench water tank and finally discharged into the atmosphere (Han et al., 2018). The flue gas stay in the coil pipe for more than 2 s, and the temperature is controlled above 850 °C for the dioxins decomposition, and then enter the quench water tank for quenching to 250 °C to avoid the de novo reaction of dioxins (Han et al., 2018). Thermal calculations on the energy requirements and supply of pyrolysis equipment show that the 9 × 105 kcal heat energy produced by per tonne MW is sufficient for self-use (Han et al., 2018). About 20 L diesel (or other high calorific value fuel) is needed for the first ignition, and then the gas produced by the pyrolysis can supply heat to the system for continuous pyrolysis, which can effectively save energy and reduce operating costs (Han et al., 2018).

Fig. 4.

Pyrolysis disposal vehicle. (a) pyrolysis technique process; (b) the composition of the pyrolysis system; (c) pyrolysis furnace structure; (d) appearance. Adapted from (Han et al., 2018; Wu et al., 2012, Wu et al., 2015).

Pyrolysis disposal vehicle is mainly composed of chassis, carriage, pyrolysis furnace system, shaft power generation system and other ancillary equipment (Han et al., 2018). The chassis of EQ2102 off-road vehicle is selected as the loading platform, and the overall structural arrangement and appearance of the vehicle is shown in Fig 4 (d) and (e) Han et al., 2018; Wu et al., 2015). The carriage is a semi open aluminum frame structure carriage, and the carriage door is of corrugated aluminum structure (Han et al., 2018). The power can be supplied by the generator of the automobile chassis, which is not limited by the power supply conditions (Han et al., 2018).

As shown in Fig. S5, another movable incineration equipment is MW emergency disposal cabins, which is made by Nanjing Zhongship Oasis Environmental Protection Co., Ltd. (Diao, 2020). The equipment is integrated in three cabins (i.e. pretreatment and control cabins, incineration cabins and flue gas treatment cabins), with the disposal capacity of 5 TPD. Each cabin is a 20-foot standard container with a volume of about 30 cubic meters, which is suitable for various transportation methods (Diao, 2020). The virus can be effectively inactivated in the incinerator by burning at 850 °C for more than 2 sec. The flue gas treatment unit includes quenching device (wet deacidification), activated carbon injection device (dry deacidification), bag dust removal device, and the flue gas emission meets the requirements of the national standard GB18484. The main operation of the equipment is completed by the computer, and the personnel mainly carry out the monitoring operation.

3.2. Movable steam sterilization

Steam sterilization is the wet heat process, which is suitable for the treatment of infectious and sharps MW but not for pharmaceutical and chemical MW. Microorganisms on the transmission medium are killed by saturated water vapor with temperature higher than 100 °C (Wang et al., 2020). The latent heat released by the water vapor leads to protein denaturation and coagulation of microorganisms and the death of microorganisms (Wang et al., 2020). The movable steam sterilization cabin is designed by Aerospace Shenhe (Beijing) Environmental Protection Co., Ltd., and the MW treatment capacity of each equipment is 2.8 TPD. The equipment is mainly composed of several systems, i.e. feeding, steam generation and disinfection, crushing, waste gas and wastewater treatment (Aerospace Shenhe (Beijing) Environmental Protection Co., 2020; Ma, 2020). MW is disinfected by saturated steam at above 134 °C for 45 min and broken, packed for landfill or incineration. The equipment is equipped with flue gas and water vapor purification system to ensure that the emissions meet the standard. Installation and operation of the equipment only need the necessary water and high voltage electricity (or diesel), and the voltage needs 380 V (three-phase power supply). The operation area of the equipment is only 50 m2 (Aerospace Shenhe (Beijing) Environmental Protection Co., 2020). The equipment is equipped with the safety valve, pressure controller for overpressure protection, to prevent the boiler from explosion accidents due to excessive pressure. When the water supply stops, the boiler can stop working automatically to prevent the electric heating elements from being damaged or even burnt out.

3.3. Movable microwave sterilization

Movable microwave sterilization equipment can dispose of infectious, damaging, pathological MW (except for human limbs and organs), and dead poultry during an epidemic. Under the action of microwave field with certain intensity, the bacteria heat up due to the absorption of microwave energy, the protein is deformed and loses biological activity. Microwave sterilization is the result of the combined effect of microwave heating and biological effects, which can make microwave energy directly interact with microorganisms and kill them quickly (Wang et al., 2020). The microwave disinfection technology is characterized with short time, rapid action, energy saving, strong penetration, slow heat loss and low environmental pollution with no dioxins and malodorous gas, and wastewater (Ohtsu et al., 2011).

Movable microwave sterilization equipment adopts an automatic disposal system of hydraulic lifting, material crushing, microwave disinfection, and spiral discharge (Henan Liying Environmental Protection Technology Co. Ltd, 2020). MW treatment capacity is 3–10 TPD, and the sterilization rate is above 99.99%. The automatic feeding device lifts the MW to the feeding bin and enters the crushing system, where MW is crushed (Henan Liying Environmental Protection Technology Co. Ltd, 2020). Microwave irradiation and steam-assisted heating are conducted via the microwave disinfection system, and the flue gas is automatically collected and processed. After disinfection, MW is sent out for disposal (landfill or incineration). The whole set of equipment only needs electric drive, and only one person is required for operation due to the high degree of automation, which saves labor costs (Henan Liying Environmental Protection Technology Co. Ltd, 2020). The MW treatment is flexible and can be treated at any time, and the equipment can be shut down after treatment, minimizing energy loss and treatment costs.

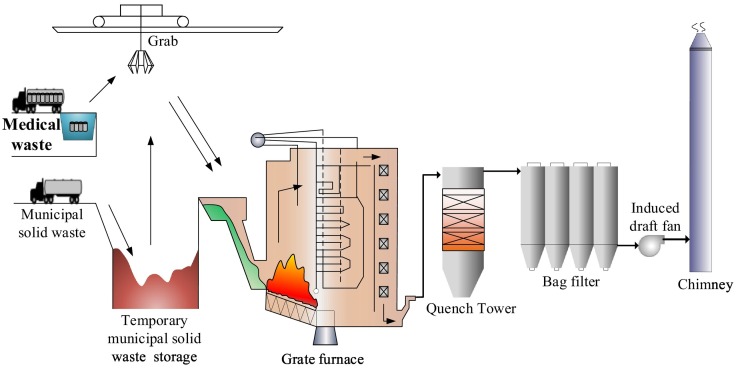

3.4. Co-disposal of MW and MSW

According to the technical standards, the main technical requirements of MSW incinerator and MW incinerator are the similar, and the operating conditions are close (Ma et al., 2020). The new coronavirus is heat sensitive, and the virus can be effectively inactivated at a temperature of 56 °C for 30 min (Ministry of Ecology and Environment, 2020c). The temperature in the MSW incinerator should be above 850 °C, and the residence time of MSW in the furnace is generally 1 to 1.5 h (grate furnace) for complete inactivation of the novel coronavirus (Zhou et al., 2020a). It is feasible to dispose of MW via MSW incineration facilities with an appropriate mixing ratio.

MSW incineration facilities have been successfully applied in MW emergency disposal in China and abroad. However, the content of hydrogen chloride and dioxins in the flue gas increase due to high plastic content in MW (Wang, 2013). Hence, Shanghai stipulated that MW (except chemical waste) must be less than 5 wt% (total mass of the mixed waste) when co-incinerated with MSW (Ministry of Ecology and Environment, 2020c). The incineration capacity of MSW incineration plants in China is generally 600–2000 TPD, so the capacity for co-disposal of MW is 30–100 TPD (Yang, 2017). From 2014 to 2019, the MSW incineration facilities in Shanghai have disposed of 3.877 × 104 t of MW, and the incineration flue gas met the requirements of the standards. In foreign countries, infectious waste can be disposed of as MSW after disinfection. In Klemetsrud, Oslo, Norway, mechanical grate incinerator was applied to infectious MW disposal, and MW cannot exceed 5 wt% of disposal capacities of MSW incineration facility (Ministry of Ecology and Environment, 2020c). During the 2009 H1N1 influenza virus outbreak in Japan, the “Guidelines for New Influenza Waste Management Measures” stated that the possibility of MW disposal by MSW facilities could be considered if there was concern that the amount of infectious waste exceeded the disposal capacity (Ministry of Ecology and Environment, 2020c). In America, MW is generally disinfected in medical institutions and disposed of via hazardous waste incineration facilities or MSW incineration facilities (Ministry of Ecology and Environment, 2020c).

MSW grate incinerators should be used for emergency MW disposal, and fluidized bed incinerators are not applicable (Ministry of Ecology and Environment, 2020c). Infectious waste, pathological waste, sharps waste can be disposed of with MSW, but chemical waste should not be disposed in MSW incinerators (Ministry of Ecology and Environment, 2020c). Feeding system is the key to co-incineration. The co-incineration process is shown in the Fig 5 . Two sets of storage and feeding systems are required for MW and MSW respectively. Emergency MW disposal can be divided into two situations according to whether the MW is pretreated by disinfection. If infectious MW is not pre-disinfected treatment, disinfection should be strengthened in the packaging, transport and disposal to reduce the infection risk. The damage probability of MW during the material grabbing can be reduced by strengthening packaging (e.g. double plastic bag packaging followed by disposable carton packaging, tape wrapping), improving the feeding technology (e.g. switching to hooks and net pockets instead of grab) and reducing the residence time in the waste pit (Ministry of Ecology and Environment, 2020c). The “micro negative pressure” environment is strictly implemented for the waste pit, and the gas is collected and directly put into the incinerator for disposal to ensure that infectious substances will not be released into the environment even if the package is damaged (Ministry of Ecology and Environment, 2020c). MW does not require fermentation but minimizes the pit residence time (Zheng et al., 2020a; Ma et al., 2020). The risk of infection during co-disposal of MW and MSW can be effectively prevented by six barriers (i.e. diversion, disinfection, reinforced packaging, improved feeding process, negative pressure, sanitation protection) (Ma et al., 2020). In addition, the chlorine content in fly ash may increase and the fly ash needs to be disposed of harmlessly (Zhao et al., 2020). The flue gas treatment unit is lack of quenching facilities, which cannot avoid de novo synthesis of dioxin at 180–550 °C. It is recommended to appropriately reduced the proportion of CMW to prevent excessive dioxins emissions, and the monitoring value of dioxins should be less than 0.1 ngTEQ/Nm3.

Fig. 5.

The process of co-disposal of MW by MSW incineration. Adapted from (Solid waste station, 2021).

Except for the system modifications, the upgrade of vulnerable equipment is another key. According to co-incineration operation data from Shanghai's Yuqiao MSW incineration power plant, the calorific value of waste increased by 15% due to the addition of MW, which lead to boiler overload operation (Wang, 2013). When low molten salt coking occurs in the furnace, the incineration temperature can be reduced appropriately. The incineration temperature can be adjusted to the normal operating temperature after burning low molten salt into the slag system (Ma, 2013). For refractory, it is suggested that SiC or better refractory should be used in the lower, middle and upper side walls of the grate, while clay or high alumina refractory should be used in other parts (Ma, 2013). Co-incineration affects the material of the equipment, easily causing a large area of refractory brick in the furnace shedding, the front arch of the refractory material large area damage, serious damage of superheater guard tile and grate. In addition, compared with MSW, acid contents (e.g. Chlorine and Sulfur) in flue gas is higher than MW, so wet process is suitable for flue gas purification of co-incineration (Ma, 2013).

Thus, co-incineration of MW may be detrimental to the operational cost and equipment life management due to system modifications, upgrades of fragile equipment and the increased activated carbon consumption for flue gas purification (Wang, 2013). MSW incinerators are recommended for emergency disposal rather than long-term disposal, and future co-incineration of MW requires further research on improved MSW incineration technologies.

3.5. Co-disposal of MW and hazardous waste

The operation and management requirements of hazardous waste incineration facilities are similar to those of MW incineration facilities, and these facilities can be a preferred alternative facility for MW disposal. The general disposal capacity of hazardous waste incineration facilities is 2–60 TPD (Ministry of Ecology and Environment, 2020e). Co-incineration of MW in hazardous waste incineration facilities has been practiced in China and abroad for many years. As shown in Fig. S6, hazardous waste incineration system includes pretreatment, feed, incineration, waste heat utilization, flue gas purification and other auxiliary systems (Leng, 2021). The design and transformation of the feeding system are critical for co-disposal of MW. The MW can be loaded by a hoist, and a MW container fixing mechanism is arranged on the elevator bucket. Bulk hazardous wastes are stored in the storage pit, which is grabbed into the bulk hopper by the crane, and the wastes are finally sent to the rotary kiln by the push rod feeder. The entry of barreled MW into the incinerator may release all the heat in a short time to destroy the container and generate strong flue gas flow. Hence, barreled MW and bulk hazardous waste should be put into the kiln in turn to restrain the fluctuation of incineration conditions. There are various harmful components in hazardous waste, so the compatibility of waste is the key link. It needs to be matched according to the composition and calorific value of the waste to ensure the stable operation of the kiln. The composition of the waste should be balanced to avoid concentrated incineration of harmful components and control the content of acidic pollutants. In addition, alkali metals (e.g. sodium and potassium) and halogens (e.g. chlorine) should be avoided to be incinerated simultaneously, because alkaline metals and halogen elements can form low melting salts, and excessive low melting salts can cause slag coking to affect the operation of the kiln and the service life of the refractory material.

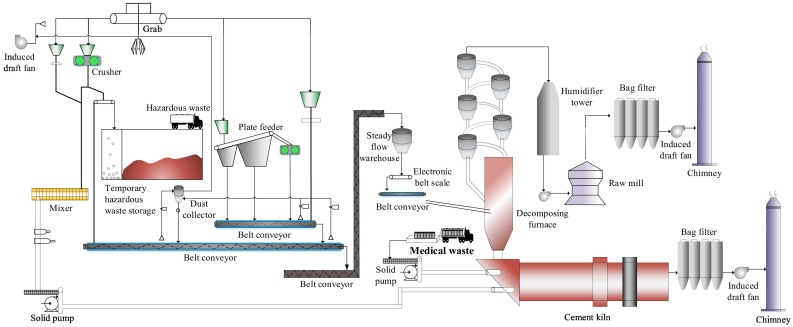

3.6. Co-disposal of MW in cement kiln

Cement is the largest industry in the field of building materials in China, with unique industry characteristics (e.g. 1500 °C high temperature and strong alkaline atmosphere) that can instantly kill germs and viruses. Cement kiln co-incineration technology is to put solid waste met the requirements into the cement kiln for disposal, and cement clinker is produced simultaneously. Practice in the cement industry has proved that co-disposal of MW in cement kilns is safe, free of secondary pollution, and the risk of MW infection can be eliminated (Jin, 2020). On March 16, 2020, Code of practice for emergency co-disposal of COVID-19 MW in cement kiln was issued to standardize and guide co-disposal of MW in cement kilns (China Building Materials Federation, 2020). In principle, storage facilities should not be available for the cement kiln co-incineration, and MW should be disposed of immediately. The transfer vehicle body should be disinfected and the MW packaging integrity should be checked before unloading. The MW should not be crushed before entering the kiln and should be directly fed into the kiln together with the primary packaging (e.g. packaging bag and sharps box). MW can only be used as an alternative fuel since hazardous waste cannot be used as cement raw material, and the capacity for co-disposal of MW is approximately 1–12 TPD, 1‰ of the clinker production capacity (China Building Materials Federation, 2020; Ministry of Environmental Protection, 2017). The co-incineration technology is shown in the Fig 6 , the high temperature section of the kiln tail is preferred for the dosing point of MW, including the decomposition furnace, the kiln tail smoke chamber, and the rising flue between the kiln tail smoke chamber and the decomposition furnace (Chen and Guo, 2020; Ministry of Environmental Protection, 2013). The dosing port should be equipped with an air-tight device to protect the operators from the hot air and hot materials when the kiln system is abnormal. The feeding rate and feeding interval should be limited, and the feeding rate should be less than 1 t/h and the feeding interval should be more than 5 min (Chen and Guo, 2020). Since the chlorine content of MW is generally 3–5%, which is much higher than that of general hazardous wastes and raw materials, it is necessary to match well when adding (Chen and Guo, 2020). Chlorine may have a corrosive effect on the kiln, so the kiln condition, emissions and clinker quality fluctuations should be monitored to ensure the normal operation of the cement kiln and the clinker quality during the addition (Chen and Guo, 2020).

Fig. 6.

The process of co-disposal of MW in cement kiln. Adapted from (China Conch Venture Holdings Co., 2021).

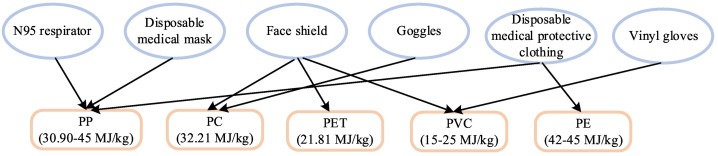

3.7. Summative analysis of emergency MW disposal technologies

CMW contains more PPE than normal MW, and plastic polymers are the main component of PPE as shown in Fig. 7 (Guo et al., 2021; Purnomo et al., 2021, Purnomo et al., 2021; Wen et al., 2021; Klemeš et al., 2020). Due to the high plastic content, the calorific value of CMW is higher than normal MW. Thus, CMW is suitable for incineration to recover heat energy. However, the dioxins content in flue gas and fly ash will increase due to the plastics with higher chlorine content in CMW, requiring strengthened dioxins emission monitoring (Wang, 2013). The comparison of emergency MW disposal technologies are shown in Table 1 . The main strengths of movable disposal technologies are the flexibility and convenience of installation, and the weakness is small disposal capacity. The main strength of co-disposal technologies is relatively large disposal capacity, and main weaknesses are high infection risk from MW transportation and MW disposal facility upgrading.

Fig. 7.

The main ingredient of PPE and the calorific value of plastic polymers (Purnomo et al., 2021, Purnomo et al., 2021; Klemeš et al., 2020; Triantou et al., 2014; Wasilewski and Siudyga, 2013).

Table 1.

Comparison of emergency MW disposal technologies (Aerospace Shenhe (Beijing) Environmental Protection Co., 2020; Chen and Guo, 2020; China Building Materials Federation, 2020; Henan Liying Environmental Protection Technology Co. Ltd, 2020; Ministry of Ecology and Environment, 2020c; Zhou et al., 2020a; Han et al., 2018; Ministry of Environmental Protection, 2017; Yang, 2017; Wu et al., 2015).

| Disposal facilities | Disposal capability (TPD) | Treatment temperature | Strengths | Weaknesses |

|---|---|---|---|---|

| Movable incineration equipment | 1–5 | 800–1100 °C |

|

|

| Movable steam sterilization cabin | 2–5 | >134 °C |

|

|

| Movable microwave sterilization equipment | 3–10 | >95 °C |

|

|

| MSW incineration facility | 30–100 | >850 °C |

|

|

| Hazardous waste incineration facility | 2–60 | >850 °C |

|

|

| Cement kiln | 1–12 | >1000 °C |

|

|

In addition, MW and MSW disposal and management are extremely hazardous to the health of workers exposed to waste during the life cycle stages, and the workers are at risk of contracting COVID-19 virus (Das et al., 2021b). In China, related workers have been instructed and trained to use respiratory, torso, hands, eyes and face, feet and other PPE, and the selected PPE must meet the relevant national standards (China Building Materials Federation, 2020). There are clear instructions for the wearing and use of PPE and detailed personnel health monitoring and management requirements. These workers were also instructed to wash their hands frequently with sanitizers and to disinfect security equipment and vehicles (Zhao et al., 2021b). The health protection of relevant workers is crucial, and the usage of appropriate PPE and safety measures for related workers is a vital priority for every country (Das et al., 2021b).

4. Emergency MW management

4.1. Emergency disposal technology selection

The selection of MW disposal technology should take into account environmental risk and technical adaptability. Among movable disposal technologies, the overall environmental impact of movable incineration is 2.17 times greater that of movable steam sterilization and 2.40 times greater that of movable microwave sterilization (Zhao et al., 2021a). Movable incineration facilities may pose greater environmental risks because it is more difficult to monitor online and control emissions. We recommend that government and industry associations introduce technical standards and guidelines for movable disposal facilities, and preference should be given to facilities with complete flue gas treatment units. Diesel consumed by the boiler in the steam sterilization may result in a slightly higher environmental impact than microwave sterilization, so movable microwave sterilization is preferable to steam sterilization (Zhao et al., 2021a). Movable disposal facilities are a vital component of the MW emergency disposal system and can be further applied to small and remote medical institutions even after the COVID-19 pandemic.

Since the chlorine content of MW is much higher than that of MSW, MW incineration is more prone to dioxins generation. For three co-disposal technologies, hazardous waste incineration facilities are most suitable for emergency MW disposal, because their secondary combustion chambers and quenching devices can effectively decompose dioxins and avoid dioxin synthesis. Compared with hazardous incineration facilities, neither MSW incineration nor cement kiln has secondary combustion chambers and quenching devices, which are not conducive to controlling dioxin emissions. For cement kiln, there is few flue gas purification equipment for dioxins and heavy metals, and these pollutants are simply diluted by the large amount of flue gas and discharged to the atmosphere. MSW incineration is better than cement kiln for MW disposal due to its combination of activated carbon jet and bag filter to purify dioxins and heavy metals in the flue gas. Overall, movable disposal facilities are much better than co-disposal facilities because they can dispose of MW on site, eliminating the infection risk and environmental impact of transportation. Therefore, movable disposal facilities should be prioritized for the CMW and infectious MW disposal, while co-disposal facilities are suitable for the non-infectious MW disposal. It is recommended that the priority of the six emergency MW disposal technologies is as follows: movable microwave sterilization, movable steam sterilization, movable incineration, co-incineration with hazardous waste, co-incineration with MSW and co-disposal in cement kilns. However, most of the movable disposal facilities are small in scale with a disposal capacity of less than 5 TPD, and co-disposal facilities have a larger disposal capacity. For areas with serious domestic and overseas outbreaks, in the absence of movable disposal facilities or insufficient disposal capacity, priority should be given to the preparation and application of hazardous waste incineration facilities for MW disposal, followed by MSW incineration facilities and cement kilns.

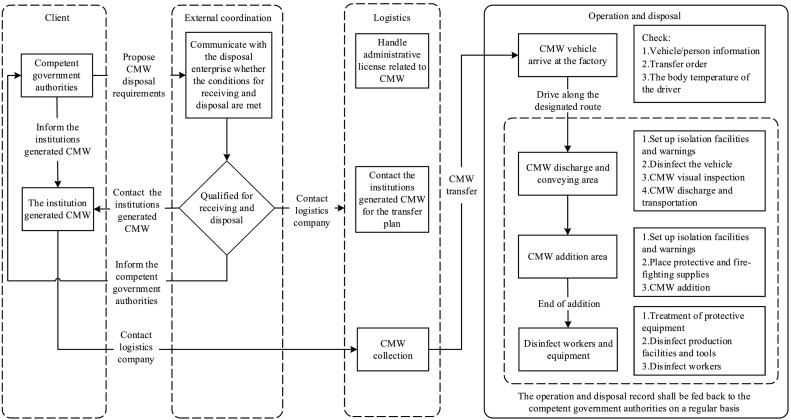

4.2. Emergency disposal processes

During the COVID-19 pandemic, meticulous management of MW at all stages of life cycle should be strengthened, including on-site collection, classification, packaging identification, transportation and disposal (Zhao et al., 2021a; Chen and Guo, 2020). According to Management and Technical Guidelines for Emergency Disposal of Medical Waste Infected by the Novel Coronavirus Pneumonia (Trial), the CMW operation flowchart is proposed in Code of practice for emergency co-disposal of COVID-19 MW in cement kiln, which can provide the practice for centralized disposal enterprises (Ministry of Ecology and Environment, 2020; China Building Materials Federation, 2020). Fig. 8 clarifies the relationship among stakeholders (e.g. centralized disposal enterprises, customers, and logistics) and their priorities in the operation process, the operation boundaries and procedures for the emergency CMW disposal. MW generated by medical institutions should be collected and classified in time to provide prerequisites for the selection of different disposal technologies. For CMW, labels such as “COVID-19” or “NCP” should appear in the notes to indicate its type. The temporary storage time in medical institutions should be within 24 h, and disposal enterprises should be notified to transport the MW during this period.

Fig. 8.

Operation flowchart for CMW disposal. Adapted from (China Building Materials Federation, 2020).

In the next handover stage, transportation personnel and administrators of disposal enterprises need to confirm and record the type and quantity of the CMW and the transport vehicle information in detail (e.g. the license plate number, driver and escort information, and the time of entering the factory). Transport vehicles should drive to the unloading and conveying area along the prescribed route and signs. It should be noted that the vehicle body must be fully disinfected before unloading, and two inspections should be carried out to ensure the integrity of the MW packaging and avoid the spillage. The distance between unloading and feeding point of CMW should not be set too long. After the mechanized transportation and unloading of CMW is carried out, the inside and outside of the cargo box must be fully disinfected. The dosing port is equipped with an air-tight device, which can be controlled by a double-layer air-lock valve plate. When feeding, at least one valve plate should be closed to protect the feeding operators from the influence of hot air and hot materials. It is proposed that a buffer zone should be set up during the CMW feeding process, and the configuration requirements of disinfection supplies and emergency equipment in the buffer zone are specified.

4.3. Recommendations for emergency MW management

In 2019, the generation of MW and MSW in 196 Chinese large and medium-sized cities were 843 kilotonnes and 235.6 million tonnes respectively (Ministry of Ecology and Environment., 2020). In China, MSW incineration facilities have huge emergency MW disposal potential, with a disposal capacity of over 1.18 million tonnes of MW at a minimum 1% addition of MW. However, the co-incineration of MW may increase operating costs and equipment life management overhead of MSW incineration facilities, making them unavailable for long-term MW disposal. Thus, further improvement of MSW incineration technology for emergency MW disposal may be the research direction in the near future. A total of 27 hazardous waste disposal permits have been issued in China for the simultaneous disposal of hazardous waste and MW, with relatively small MW disposal capacity (Cheng et al., 2020). The compatibility of wastes is an important factor that needs to be considered for the co-incineration of MW and hazardous waste. While ensuring the stable operation, the MW feed ratio can be adjusted and improved to increase emergency disposal capacity. There are 68 enterprises in China are qualified for co-disposal of hazardous wastes in cement kilns, with an approved disposal capacity of 4.26 million tonnes (Jin, 2020). In theory, there is enormous potential to enhance the emergency MW disposal capacity for cement kilns. In Chinese megacities, the emergency MW disposal capacity is insufficient, but the disposal capacity can be improved if the movable facilities, MSW incineration facilities, hazardous waste incineration facilities and cement kiln are fully utilized in the future (Zhou et al., 2020b). An emergency deployment mechanism can be established between cities with insufficient MW disposal capacity and regions with excess MW disposal capacity. For remote towns in large cities, MW should be transported to the disposal facilities in neighboring cities to avoid the economic costs and infection risk caused by long-distance transportation. MW disposal enterprises should design emergency response strategies to ensure the disposal efficiency, for instance, stipulating the receiving plan, the financial settlement methods, and the vehicle routes. The government should formulate a set of MW emergency management procedures to upgrade the emergency response system at both the national and local levels. Besides, the establishment of the emergency operation and expert teams should be established, and the enterprise suppliers should be determined in advance.

Based on the generation of MW and the number of beds in medical institutions over the years, it is estimated that the generation of MW will reach 1.5 million tonnes in 2025 (Cheng et al., 2020). According to the load rate target of the facilities constructed of less than 75%, the cities with the load rate of more than 50% of the centralized disposal facilities in 2018 need to increase their disposal capacity, which should reach twice the MW generation in 2018 to meet the demand during the 14th Five-Year Plan period. Specifically, the Work Plan for Comprehensive Waste Management in Medical Institutions issued in China on Feb. 24, 2020, mandates that (1) at least one centralized MW disposal facility should be built in each prefecture-level city by the end of 2020; (2) By the end of June 2022, establish regional collection, transfer or disposal of MW facilities based on the geographical location and population of the administrative region, and form an independent MW collection, transfer and disposal system for each county (city). Moreover, most of China's existing MW disposal facilities were built before 2010, and most cities have only one MW disposal plant, which covers a large number of low-capacity and old incineration facilities that need to be evaluated for their operation situation. Incineration facilities that are difficult to meet the emission standards should be technically reformed or replaced by alternative non-incineration technologies. Moreover, the cost assessment of the MW disposal industry should be conducted to speed up the rationalization of MW disposal charges. Emergency disposal capacity in megacities should theoretically be at least twice MW generated during non-epidemic period, correspondingly, Chinese cities need to increase their current disposal capacity. In detail, it is recommended to establish MW disposal system with a disposal capacity of 10 TPD per million population area. The hazardous waste incineration facilities, MSW incineration facilities, cement kiln co-disposal facilities in the region should be made full use of and included in the resource list of emergency MW disposal facilities.

5. Conclusions and recommendations

Global MW has increased dramatically during the COVID-19 pandemic. As the generation of MW far exceeds the disposal capacity of existing facilities, emergency disposal and management of MW has recently become a common challenge for countries around the world. This study reviews the emergency MW disposal technologies and analyzes the processes, superiorities, weaknesses, applicability, and limitations of different technologies. Pyrolysis, incineration, microwave disinfection and steam disinfection technologies applied to movable disposal facilities, which can dispose of CMW and other infectious waste on-site to reduce the infection spread of MW. The co-disposal facilities need to be reformed completely to reduce the infection risk, especially for their feeding system. Based on the environmental risk and technical adaptability, the six emergency MW disposal technologies are recommended in order of priority: movable microwave sterilization, movable steam sterilization, movable incineration, co-incineration with hazardous waste, co-incineration with MSW and co-disposal in cement kilns. CMW and infectious MW should be prioritized for disposal using central and movable disposal facilities, while non-infectious MW can be disposed of using co-disposal facilities.

In addition, delicacy management of the MW end-of-life stage, including collection, classification, packaging identification, transportation and disposal, should be strengthened. The operation flowchart for emergency disposal can provide the practice for the stakeholders. As for the long-term strategy, emergency MW disposal capacity is seriously insufficient in megacities. In the future, the regional mobile and co-disposal facilities should be fully utilized to solve the shortage of disposal capacity. In addition, cities with insufficient MW disposal capacity can establish an interregional emergency response coordination mechanism with neighboring cities with excess MW disposal capacity. The suggestions provided in this study are not only applicable to China, but also to countries with serious epidemics and huge MW disposal pressure.

In the future, technical guidelines and technical selection principles for emergency disposal facilities with different disposal capacities based on the technical applicability and cost-effectiveness should be further studied and discussed. The technology of co-incineration of MW and MSW also needs to be further improved to reduce the negative impact of long-term disposal of MW on the operating costs and equipment life of MSW incineration facilities. Besides, economic analysis of the MW disposal industry should be carried out to help rationalize the national MW disposal charges.

CRediT authorship contribution statement

Hailong Zhao and HanQiao Liu: Conceptualization, Methodology. Hailong Zhao, Haoyu Qiao, Yongyue Gong, Xiangnan Yu, Jianhua Zhou: Data curation, Writing-Original draft preparation. Hailong Zhao, HanQiao Liu, Guoxia Wei, Ning Zhang and Yuhang Wu: Writing- Reviewing and Editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This research was funded by Tianjin Postgraduate Research Innovation Project (2019YJSS007), Tianjin Technology Major Project and Engineering number 18ZXSZSF0012 and National Key Research and Development Program number 2017YFC0703100. The authors would also like to acknowledge Guangzhou Green Data Environmental Service Center for data support on medical waste pollution prevention information.

Editor: Damià Barceló

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.scitotenv.2021.152302.

Appendix A. Supplementary data

Supplementary material 1

Supplementary material 2

References

- Adelodun B., Ajibade F.O., Ibrahim R.G., Ighalo J.O., Bakare H.O., Kumar P., Eid E.M., Kumar V., Odey G., Choi K. Insights into hazardous solid waste generation during COVID-19 pandemic and sustainable management approaches for developing countries. J. Mater. Cycles Waste. 2021;23(6):2077–2086. doi: 10.1007/s10163-021-01281-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adyel T.M. Accumulation of plastic waste during COVID-19. Science. 2020;369:1314–1315. doi: 10.1126/science.abd9925. [DOI] [PubMed] [Google Scholar]

- Borrelle S.B., Ringma J., Law K.L., Monnahan C.C., Lebreton L., McGivern A., Murphy E., Jambeck J., Leonard G.H., Hilleary M.A., Eriksen M., Possingham H.P., De Frond H., Gerber L.R., Polidoro B., Tahir A., Bernard M., Mallos N., Barnes M., Rochman C.M. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science. 2020;369:1515–1518. doi: 10.1126/science.aba3656. [DOI] [PubMed] [Google Scholar]

- Cao Y., Yu X., Shan S., Wang L., Chen G., Zhang Z., Xu J. Pollution prevention policy on medical waste treatment and disposal in China: evolvement, problem analysis and suggestions (in Chinese) Chin. J. Environ. Eng. 2021;15(2):389–400. doi: 10.12030/j.cjee.202012018. [DOI] [Google Scholar]

- Capoor M.R., Parida A. Current perspectives of biomedical waste management in context of COVID-19”. Indian J. Med. Microbiol. 2021;39:171–178. doi: 10.1016/j.ijmmb.2021.03.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chang M., Tang Y., Yang L., Jiao S., Xu X., Liu Z., Li X. Analysis and reference of international medical waste management, treatment and disposal system (in Chinese) Environ. Prot. 2020;48:63–69. doi: 10.14026/j.cnki.0253-9705.2020.08.014. [DOI] [Google Scholar]

- Chen C., Chen J., Fang R., Ye F., Yang Z., Wang Z., Shi F., Tan W. What medical waste management system may cope with COVID-19 pandemic: lessons from Wuhan. Resour. Conserv. Recycl. 2021;170 doi: 10.1016/j.resconrec.2021.105600. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen X., Hao L. Discussion on the technical route of cement kiln co-disposal municipal solid waste and medical waste under the epidemic situation (in Chinese) China Cem. 2020:71–75. [Google Scholar]

- Chen Y., Guo C. 2020. Handbook of Emergency Disposal and Management of Medical Waste in China.http://bcrc.tsinghua.edu.cn/col/1256347643949/2020/06/22/1592834394326.html [Google Scholar]

- Cheng L. The 15th International Conference on Solid Waste Management and Technology (ICWMT15, also known as 2020 Global Waste Forum) 2020. Research on making up for shortcomings of centralized disposal system of medical waste during the 14th five year plan period. [Google Scholar]

- Cheng L., Zhang Z., Sun N., Liu S., Tao Y., Xu Z., Wang Z. Suggestions on making up for shortcomings in collection and treatment of medical waste and haz-ardous waste (in Chinese) Res. Environ. Sci. 2020;33:1698–1704. doi: 10.13198/j.issn.1001-6929.2020.05.38. [DOI] [Google Scholar]

- Chengdu Workers' Sanatorium of Sichuan Federation of Trade Unions . 2021. Flowchart of Medical Waste Disposal (In Chinese)http://www.cdgrlyy.org/common/attached/file/20120930/20120930184011_76627.pdf [Google Scholar]

- Chisholm J.M., Zamani R., Negm A.M., Said N., Abdel Daiem M.M., Dibaj M., Akrami M. Sustainable waste management of medical waste in african developing countries: a narrative review. Waste Manage. Res. 2021:734242X–2110291X. doi: 10.1177/0734242X211029175. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aerospace Shenhe (Beijing) Environmental Protection Co. Ltd. 2020. Space Movable Medical Waste Disposal Cabin (In Chinese)https://mp.weixin.qq.com/s?__biz=MzAxNjU2MDcwOA==&mid=100000290&idx=1&sn=06f5a454eb4c35518b87e8aebb8008ef&chksm=1bf3a5092c842c1f197c762b67291d2a10b107277a6b7de3a77d40f647989d54b74c28f1ac65#rd [Google Scholar]

- China Conch Venture Holdings Co. Ltdcollab. 2021. Co-disposal Technology of Industrial Solid Waste in Cement Kiln (In Chinese) [Google Scholar]

- Das A.K., Islam M.N., Billah M.M., Sarker A. COVID-19 pandemic and healthcare solid waste management strategy – a mini-review. Sci. Total Environ. 2021;778 doi: 10.1016/j.scitotenv.2021.146220. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Das A.K., Islam M.N., Billah M.M., Sarker A., Sveriges L. COVID-19 and municipal solid waste (MSW) management: a review. Environ. Sci. Pollut. Res. Int. 2021;28:28993–29008. doi: 10.1007/s11356-021-13914-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Pizarro-Ortega C.I., Dioses-Salinas D.C., Ammendolia J., Okoffo E.D. Investigating the current status of COVID-19 related plastics and their potential impact on human health. Curr. Opin. Toxicol. 2021;27:47–53. doi: 10.1016/j.cotox.2021.08.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dharmaraj S., Ashokkumar V., Pandiyan R., Halimatul Munawaroh H.S., Chew K.W., Chen W., Ngamcharussrivichai C. Pyrolysis: an effective technique for degradation of COVID-19 medical wastes. Chemosphere. 2021;275 doi: 10.1016/j.chemosphere.2021.130092. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Diao F. The Ministry of Environment's Nanjing Institute Rushed to Wuhan to Help With Exclusive Response (In Chinese) 2020. How to dispose of medical waste in Wuhan?http://www.mee.gov.cn/home/ztbd/2020/dyyqfkzjz/xdbs/dfkx/202002/t20200221_765009.shtml [Google Scholar]

- El-Ramady H., Brevik E.C., Elbasiouny H., Elbehiry F., Amer M., Elsakhawy T., Omara A.E., Mosa A.A., El-Ghamry A.M., Abdalla N., Rezes S., Elboraey M., Ezzat A., Eid Y. Planning for disposal of COVID-19 pandemic wastes in developing countries: a review of current challenges. Environ. Monit. Assess. 2021;193 doi: 10.1007/s10661-021-09350-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Federation China Building Materials. 2020. Code of Practice for Emergency Co-disposal of COVID-19 Medical Waste in Cement kiln (CBMF/Z 76-2020) (In Chinese. [Google Scholar]

- Goswami M., Goswami P.J., Nautiyal S., Prakash S. Challenges and actions to the environmental management of bio-medical waste during COVID-19 pandemic in India. Heliyon. 2021;7 doi: 10.1016/j.heliyon.2021.e06313. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guangzhou Green Data Environmental Service Center . 2020. Medical waste pollution prevention analysis and Suggestions (In Chinese)http://file.lvwang.org.cn/kindeditor/file/20200521/20200521064959_29761.pdf [Google Scholar]

- Guo X., Yao Y., Zhao H., Chi C., Zeng F., Qian F., Liu Z., Huo L., Lv Y. Environmental impacts of functional fillers in polylactide (PLA)-based bottles using life cycle assessment methodology. Sci. Total Environ. 2021;788 doi: 10.1016/j.scitotenv.2021.147852. [DOI] [PubMed] [Google Scholar]

- Han J., Ren X., Meng L., Su C. Research on harmless disposal method and equipment for medical waste in mobile hospital (in Chinese) Chin. Med. Equip. J. 2018;39:37–41. doi: 10.7687/j.issn1003-8868.2018.02.037. [DOI] [Google Scholar]

- Han J., Wu L., Zhang W., Wang Z. Design of on-board medical waste pyroly-sis furnace (in Chinese) Chin. Med. Equip. J. 2015;36:102–103. doi: 10.7687/J.ISSN1003-8868.2015.05.102. [DOI] [Google Scholar]

- Hantoko D., Li X., Pariatamby A., Yoshikawa K., Horttanainen M., Yan M. Challenges and practices on waste management and disposal during COVID-19 pandemic. J. Environ. Manag. 2021;286 doi: 10.1016/j.jenvman.2021.112140. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Henan Liying Environmental Protection Technology Co. Ltd . 2020. Skid Mounted Equipment for Medical Waste Disposal (In chinese)http://www.liyingchina.cn/product/69.html [Google Scholar]

- Ilyas S., Srivastava R.R., Kim H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020;749 doi: 10.1016/j.scitotenv.2020.141652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jin H. 2020. Cement Kiln for Co-disposal of Medical Wastes to Promote Epidemic Prevention and Control (in Chinese) DOI:10.16291 jcnki zgc.2020.03.005. [Google Scholar]

- Kampf G., Todt D., Pfaender S., Steinmann E. Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents. J. Hosp. Infect. 2020;104:246–251. doi: 10.1016/j.jhin.2020.01.022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang A., Ren L., Hua C., Song H., Dong M., Fang Z., Zhu M. Environmental management strategy in response to COVID-19 in China: based on text mining of government open information. Sci. Total Environ. 2021;769 doi: 10.1016/j.scitotenv.2021.145158. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Klemeš J.J., Fan Y.V., Tan R.R., Jiang P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sust. Energ. Rev. 2020;127 doi: 10.1016/j.rser.2020.109883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee J.C.K., Wen Z. Pathways for greening the supply of rare earth elements in China. Nat. Sustain. 2018;1:598–605. [Google Scholar]

- Leng X. 2021. Overview of Hazardous Waste Treatment Technology (in Chinese)https://huanbao.bjx.com.cn/news/20211111/1187324.shtml [Google Scholar]

- Liang Y., Song Q., Wu N., Li J., Zhong Y., Zeng W. Repercussions of COVID-19 pandemic on solid waste generation and management strategies. Front. Environ. Sci. Eng. 2021;15 doi: 10.1007/s11783-021-1407-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu L., Wu G., Feng Q., Chen Y., Duan L., Abdullah A.Z. E3S Web of Conferences 245. Vol. 2011. 2021. Emergency disposal and management of medical waste duringthe COVID-19 outbreak in China. [Google Scholar]

- Ma J. Research on co-incineration of municipal solid waste and medical waste (in Chinese) Chin. Environ. Prot. Ind. 2013:13–20. [Google Scholar]

- Ma T. Shenhe Environmental Protection: Mobile Medical Waste Disposal Shelter to Solve the Problem of Secondary Spread of Infectious Sources, Dual-use Technologies and Products for Both Military and Civilian Use (in Chinese) 2020. pp. 22–23. [DOI] [Google Scholar]

- Ma Y., Lin X., Wu A., Huang Q., Li X., Yan J. Waste Disposal & Sustainable Energy. Vol. 2. 2020. Suggested guidelines for emergency treatment of medical waste during COVID-19: Chinese experience; pp. 81–84. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ministry of Ecology and Environment . 2019. Annual Report on the Prevention and Control of Environmental Pollution by Solid Waste in Large and Medium-sized Cities in 2019 (In Chinese)https://www.mee.gov.cn/hjzl/sthjzk/gtfwwrfz/ [Google Scholar]

- Ministry of Ecology and Environment . 2020. Management and Technical Guidelines for Emergency Disposal of Medical Waste Infected by the Novel Coronavirus Pneumonia (Trial) (In Chinese) [Google Scholar]

- Ministry of Ecology and Environment . 2020. National Annual Report on Prevention and Control of Environmental Pollution by Solid Waste in Large and Medium Sized Cities in 2020 (In Chinese) [Google Scholar]

- Ministry of Ecology and Environment . 2020. Questions and Answers Related to Emergency Treatment of COVID-19 Medical Waste by Municipal Solid Waste Incineration Facilities (In Chinese)https://huanbao.bjx.com.cn/news/20200210/1041464.shtml [Google Scholar]

- Ministry of Ecology and Environment . 2020. Annual Report on the Prevention and Control of Environmental Pollution by Solid Waste in Large and Medium-sized Cities in 2020 (In Chinese)https://www.mee.gov.cn/hjzl/sthjzk/gtfwwrfz/ [Google Scholar]

- Ministry of Ecology and Environment . 2020. Standard for Pollution Control on Hazardous Waste Incineration (GB 18484—2020) (In Chinese) [Google Scholar]

- Ministry of Ecology and Environment . 2021 edition. 2021. National Hazardous Waste Directory. (In Chinese) [Google Scholar]

- Ministry of Environmental Protection . 2013. Environmental Protection Technical Specification for Co-disposal of Solid Wastes in Cement Kiln (HJ 662-2013) (In Chinese) [Google Scholar]

- Ministry of Environmental Protection . 2017. Notes on the Preparation of the Technical Specification for the Application and Issuance of Pollutant Permits for the Cement Industry (Draft for Comments) (In Chinese)https://www.mee.gov.cn/gkml/hbb/bgth/201705/t20170502_413305.htm [Google Scholar]

- Ministry of Industry and Information Technology COVID-19 pandemic prevention and control report (In Chinese) 2020. https://www.miit.gov.cn/ztzl/rdzt/xxgzbdgrdfyyqfkgz/gzdt/art/2020/art_cea12b5000b8474da3bd8e85918723f1.html Accessed 21 August 2021.

- Ohtsu Y., Onoda K., Kawashita H., Urasaki H. A comparison of microwave irradiation, electric, and hybrid heating for medical plastic-waste treatment. J. Renew. Sustain. Energy. 2011;3 [Google Scholar]

- Peng J., Wu X., Wang R., Li C., Zhang Q., Wei D. Medical waste management practice during the 2019–2020 novel coronavirus pandemic: experience in a general hospital. Am. J. Infect. Control. 2020;48(8):918–921. doi: 10.1016/j.ajic.2020.05.035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Prata J.C., Silva A.L.P., Walker T.R., Duarte A.C., Rocha-Santos T. COVID-19 pandemic repercussions on the use and management of plastics. Environ Sci Technol. 2020;54:7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- Purnomo C.W., Kurniawan W., Aziz M. Technological review on thermochemical conversion of COVID-19-related medical wastes. Resour. Conserv. Recycl. 2021;167 doi: 10.1016/j.resconrec.2021.105429. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Purnomo C.W., Kurniawan W., Aziz M. Technological review on thermochemical conversion of COVID-19-related medical wastes. Resour. Conserv. Recycl. 2021;167 doi: 10.1016/j.resconrec.2021.105429. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rajak R., Mahto R.K., Prasad J., Chattopadhyay A. Assessment of bio-medical waste before and during the emergency of novel coronavirus disease pandemic in India: a gap analysis. Waste Manage. Res. 2021:734242X–2110214X. doi: 10.1177/0734242X211021473. [DOI] [PubMed] [Google Scholar]

- Saadat S., Rawtani D., Hussain C.M. Environmental perspective of COVID-19. Sci. Total Environ. 2020;728 doi: 10.1016/j.scitotenv.2020.138870. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Solid Waste Station . 2021. Comparison of hazardous waste incineration and municipal solid waste incineration technology (In Chinese)https://www.sohu.com/a/471217716_121081610 [Google Scholar]

- Su G., Ong H.C., Ibrahim S., Fattah I., Mofijur M., Chong C.T. Valorisation of medical waste through pyrolysis for a cleaner environment: Progress and challenges. Environ. Pollut. 2021;279 doi: 10.1016/j.envpol.2021.116934. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun N., Liu F., Zhang Y., Ding Z. Thoughts and suggestions on reinforcing the weakness of medical waste collection and disposal facilities in China (in Chinese) Environ. Prof. Sci. 2020;46:120–126. [Google Scholar]

- Thind P.S., Sareen A., Singh D.D., Singh S., John S. Compromising situation of India’s bio-medical waste incineration units during pandemic outbreak of COVID-19: associated environmental-health impacts and mitigation measures. Environ. Pollut. 2021;276 doi: 10.1016/j.envpol.2021.116621. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Triantou Marianna I., Tarantili Petroula A., Andreopoulos Andreas G. 2014. Recycling and Reuse of Plastics Contained in Waste from Electrical and Electronic Equipment (Weee) chrome-extension://cdonnmffkdaoajfknoeeecmchibpmkmg/assets/pdf/web/viewer.html?file=http%3A%2F%2Fwww.athens2014.biowaste.gr%2Fpdf%2Ftriantou_et_al.pdf. [DOI] [PubMed] [Google Scholar]

- Tripathi A., Tyagi V.K., Vivekanand V., Bose P., Suthar S. Challenges, opportunities and progress in solid waste management during COVID-19 pandemic. Case Stud. Chem. Environ. Eng. 2020;2 doi: 10.1016/j.cscee.2020.100060s. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wajs J., Bochniak R., Golabek A. Proposal of a Mobile medical waste incinerator with application of automatic waste feeder and heat recovery system as a novelty in Poland. Sustainability. 2019;11:4980. [Google Scholar]

- Wang J., Shen J., Ye D., Yan X., Zhang Y., Yang W., Li X., Wang J., Zhang L., Pan L. Disinfection technology of hospital wastes and wastewater: suggestions for disinfection strategy during coronavirus disease 2019 (COVID-19) pandemic in China. Environ. Pollut. 2020;262 doi: 10.1016/j.envpol.2020.114665. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang W. Advantage and disadvantage of waste incinerator burning municipal solid waste with medical waste: taking Shanghai yuqiao municipal solid waste incineration plant as an example (in Chinese) Environ. Sanit. Eng. 2013;21:18–20. [Google Scholar]

- Wang Z., Han J., Wu L., Liu Y. Application research on new technology for on-board medical waste pyrolysis (in Chinese) Chin. Med. Equip. J. 2015;36:104–106. doi: 10.7687/J.ISSN1003-8868.2015.05.104s. [DOI] [Google Scholar]

- Wasilewski R., Siudyga T. Energy recovery from waste plastics. Chemik. 2013;67(5):435–445. [Google Scholar]

- Wen Z., Xie Y., Chen M., Dinga C.D. China’s plastic import ban increases prospects of environmental impact mitigation of plastic waste trade flow worldwide. Nat. Commun. 2021;12 doi: 10.1038/s41467-020-20741-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Windfeld E.S., Brooks M.S. Medical waste management – a review. J. Environ. Manag. 2015;163:98–108. doi: 10.1016/j.jenvman.2015.08.013. [DOI] [PubMed] [Google Scholar]

- Wu L., Wang Z., Han J., Zhang W., Wu C., Sun X., Cui X., Xu C. Development of pyrogenation treatment vehicle of medical wastes (in Chinese) Chin. Med. Equip. J. 2015;36:98–101. doi: 10.7687/J.ISSN1003-8868.2015.05.098. [DOI] [Google Scholar]

- Wu L., Wang Z., Wu C. The 17th Session of the 14th China Association for Science and Technology Annual Conference: Symposium on Environmental Hazards and Health Protection. 2012. Control technology research of exhaust gas emis-Sion in pyrolysis medical waste vehicle (in Chinese) [Google Scholar]

- Yang J. Electric Power Survey & Design. 71–75. 2017. Type selection of the garbage incinerator for project generating electricity throug refuse household garbage (in Chinese) [DOI] [Google Scholar]