Abstract

Ensuring food security in developing countries is highly challenging due to low productivity of the agriculture sector, degradation of natural resources, high post farming losses, less or no value addition, and high population growth. Researchers are striving to adopt newer technologies to enhance supply to narrow the food demand gap. Nanotechnology is one of the promising technologies that could improve agricultural productivity via nano fertilizers, use of efficient herbicides and pesticides, soil feature regulation, wastewater management, and pathogen detection. It is equally beneficial for industrial food processing with enhanced food production with excellent market value, elevated nutritional and sensing property, improved safety, and better antimicrobial protection. Nanotechnology can also reduce post-farming losses by increasing the shelf life with the aid of nanoparticles. However, further investigation is required to solve the safety and health risks associated with the technology.

Keywords: Agriculture, Food processing, Food security, Nanotechnology, Nanosensors

Agriculture; Food processing; Food security; Nanotechnology; Nanosensors.

1. Introduction

The foremost universal challenge on our planet is the question of establishing food security for a rapidly increasing population in the world. Predictions show that food demand is likely to rise from 59 to 98% for the world population reaching 9 billion by 2050 (Duro et al., 2020). Despite an increase of the world population particularly in developing countries, the global food supply interrupted by the expenditure of bio-resources for production of energy, manufacturing chemicals, high post farming loss, less value addition, inefficient distribution and marketing systems, and other factors (Barrett, 2021; Sekhon, 2014). Farmers throughout the world will focus on using new innovations and technologies for enhancing the production of crops through intensive and extensive agriculture. The current efforts further boosted through the use of nano-modified stimulants and precision farming. Agricultural efficiency, soil improvement, secure water use, distribution of food in stores, and its quality are basic factors of securing food that may be improved via advances in nanotechnology research (Ashraf et al., 2021; Sastry et al., 2011).

Newer technology that will increase the production and reduce food wastage is important to maintain sustainable living standards of the nation and improve food security. Nanotechnology can provide a path for producing foods with outstanding quality in highly improved workable form along with induction of nutrients bioavailability. Many research investigations are focusing on increasing the application of nanotechnology for the production of crop and food processing (Abobatta, 2018; Axelos and Van De Voorde, 2017; Dasgupta et al., 2015; Peters et al., 2016). Increment in articles, intellectual property, and patents in nano-agriculture-based food with fresh research tendencies in the processing of food, nutraceutical distribution, packing, quality control, and serviceable food is a highly expanding field in nanotechnology research (Dasgupta et al., 2015).

Nanotechnology is one of the promising areas to boost the availability of food and to manufacture newer products for beneficial purposes in agriculture, food, water, the environment, medicine, energy, and electronics. It is a developing and quickly growing region with new and exclusive applications in agriculture and food research (Sadeghi et al., 2017). Growing productivity and declining postharvest expenditure via better outcomes with the support of newer technical investigations with the help of nanotechnology and biotechnology in foodstuffs might be the best answer (Yadollahi et al., 2010). Few evolving areas regarding nanomaterials in agriculture are to reduce the number of spread chemicals, minimize nutrient losses in fertilization, and increased yield through pest and nutrient management (Prasad et al., 2017a). Some of the emerging topics of nanotechnology for food can be largely improved in the aspects of smart delivery of nutrients, bioseparation of proteins, rapid sampling of biological and chemical contaminants, nanoencapsulation of nutraceuticals, solubilization, delivery (Ravichandran, 2010; Sozer and Kokini, 2009). Food nanotechnology comprises the application of nanocarrier methodologies to strengthen the bioactive ingredients to modify their biological accessibility and barrier against several chemical or environmental variations (Mozafari et al., 2008). It induces better sensory characteristics like color, flavor, and texture and enhances reliability in food (Kalita and Baruah, 2019). It also improved the captivation and biological convenience of nutraceuticals (Jafari and McClements, 2017) and drug delivery systems (Safari and Zarnegar, 2014). Nanotechnology is benefiting food industries as a novel food packing supplies with modified mechanical, fencing, and antimicrobial characteristics (Mustafa and Andreescu, 2020; Rossi et al., 2017; Duncan, 2011). Nanotechnology-based sensors for trace detection observing the condition of diet in terms of transportation and storing, and encapsulation of food modifiers or additive materials were other merits of the technology (Chaudhry et al., 2008).

Nanotechnology-based applications have put forward the growing requirement of using nanoparticle in food biotechnology, science, food processing, food packaging, functional food development, food safety, detection of pathogens in food, and extended shelf-life of food and food foodstuffs (Singh et al., 2017). Nanomaterials perform very well in enhancing food security to support the development of food manufacturing industry. Depositing of food manufacturing equipment (via biofilm coating), nanofabricated filters, sieves and membranes, nanocomposite based and nanosized adsorbents and catalytic agents are also utilization areas for provision of assistance in the processing of food (Bartolucci, 2017). Adding nanomaterials into the packing of food are supposed to modify the hindrance felt during materials packing and can help decrease the involvement of valued raw ingredients and waste production (Sozer and Kokini, 2009).

In general, nanotechnology enables the most promising opportunities for the development of new and improved products. However, the public concern regarding health risks associated with nanotechnology products are questioned for many scientific communities which need further investigation (Kamarulzaman et al., 2020; Díaz-Soler et al., 2019; Han et al., 2018). This review paper aims to describe the fundamentals of nanotechnology, its application in agriculture, food research, postharvest, food process technology, packaging, and its role to support food security efforts as well as the challenges in the use of the technology in the food and agriculture system. In this review, studies published between 2016–2021 years were covered. However, based on the number of citations and relevance of the investigations, other articles were included outside the specified period. The search procedure was conducted in the database “Web of Science,” using different combinations of keywords or search strings. The keywords are nanotechnology, nanoscience, nanoparticles, agriculture, nanofertilizers, nanoherbicides, nanopesticides, nanosensors, nanoformulations, gene sequencing or nanocoding, nano coatings, nanoemulsions, nanocomposites, nanostructured materials, delivery, formulation, packaging, nanotubes, and nanotoxicity.

2. Fundamentals of nanotechnology

Nanotechnology means the “synthesis, designing, characterizing, and utilization of assemblies, tools, and systems via directing the morphology and size variation at nanometer level from 1 - 100 nm” (Yadollahi et al., 2010). For your reference, one nanometer-scale means one-billionth (10−9) of part of one meter which implies that the application of the technology at this size. Nanoscience and nanotechnologies considered as innovative attitudes in developmental research related to the learning of marvels and operation of substance at atomic, molecular, or macromolecular levels, at which stage their properties are considerably varied to those at bulk level (Potocnik, 2005). Here, the biological, chemical, and physical characteristics of resulting products are fundamentally different from those of bulk material. The investigation of properties at nanoscale gives birth to modified properties that could be used manufacturing novel materials with modified structures, newer tools, and products that could perform more efficiently.

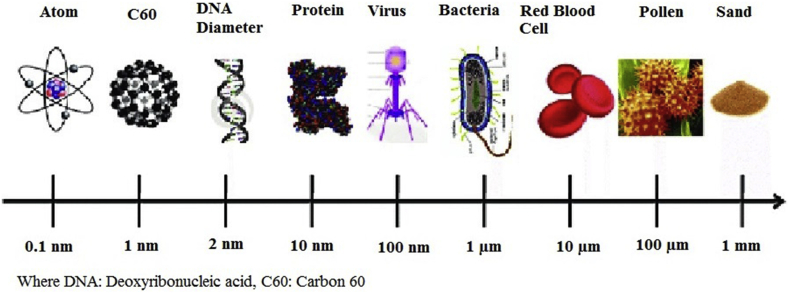

The differently displayed properties of materials at nano scale provided newer properties such as more strength, improved optical properties, modified antimicrobial potential, and outstanding superconductive nature (Axelos and Van De Voorde, 2017). They can adopt shapes like nanotubes, nanoparticles, nanofibers, fullerenes, nanosheets, and nanowhiskers (Cushen et al., 2012). As per published European Commission (EC) recommendation, a nanomaterial is defined as “natural, incidental, or industrial material with particles, in an unbound state or in the form of aggregate or agglomerate where 50% or more of the particles in the number and size distribution, one or more than one dimensions lies in the range of 1–100 nm” (Potocnik, 2011). A graphic exhibition of substances falling in “nano” (<100 nm) and “micro” (>100 nm) size scales is shown in Figure 1.

Figure 1.

A pictorial exhibition of things in the “nano” (<100 nm) and “micro” (>100 nm) size ranges. Where DNA: Deoxyribonucleic acid, C60: Carbon 60.

2.1. Approaches of nanotechnology

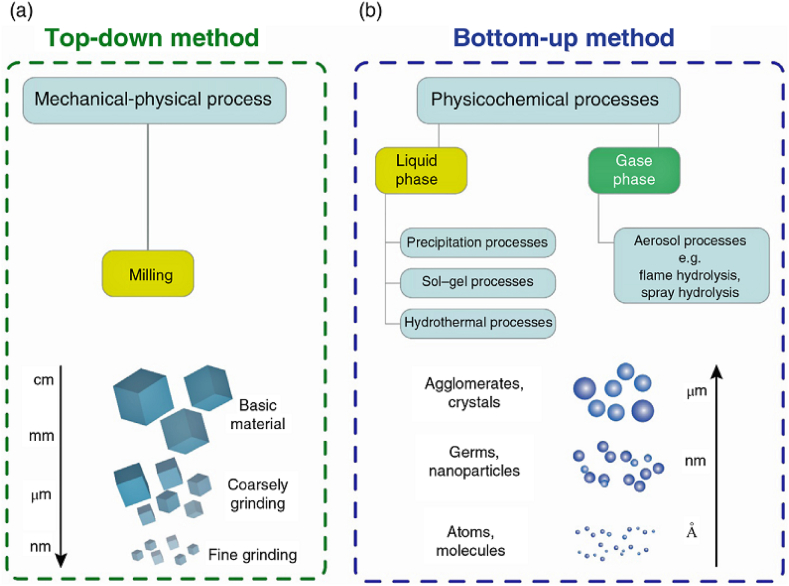

Nanotechnology can be applied via two opposite approaches that are “bottom-up” or “top-down” approach even in food technology. The top-down approach can be employed via the physical method undertaken for food and agriculturally based materials. Production of nanomaterials at a commercial scale presently employs mainly the ‘‘top-down” approach, where nanoscale materials are synthesized by size decrease of bulk precursors, via milling technique, nanolithography, or using precision engineering (De Azeredo, 2009; Sozer and Kokini, 2009). Dry milling protocol is employed to get grain flour with reduced size and hence more water-retaining ability. The top-down approach can enhance the antioxidant properties of green tea via size decreasing procedure (Shibata, 2002). According to a report, powdered green tea with 1000 nm size has higher digestion of nutrients and results in the enhanced ability for dismutase enzyme with enhanced removal of oxygen and hence elevated antioxidant activity (Sanguansri and Augustin, 2006). Another procedure called homogenization broadly used for dairy work regarding size reduction in case of globules, vaporization, and laser application associated with cooling is also supposed to be top-down protocol (Roohinejad and Greiner, 2017). The functionality of food material for the required purpose is a surface area with better properties. Top-down and bottom-up approaches are exhibited in Figure 2 and dependent upon size reduction as finer size material possesses bigger.

Figure 2.

Schematic of the (a) top-down and (b) bottom-up approaches for making nanoparticles. Adapted from Roohinejad and Greiner (2017) with permission copyright © 2017 John Wiley and Sons.

The top-down protocol is associated with nanotechnology-based devices are monitored with external power to yield the preferred parameters and specific initiation from larger dimensions having stuff with cutting to obtain the desired size (Sangeetha et al., 2017). Using the bottom-up protocol, atoms are converted into nanoscale materials or fixed self-assemblies using complex processes. Self-assembly depends on matching attractive and repulsive forces between molecule pairs used as building blocks for manufacturing efficient supramolecular assemblies (Sanguansri and Augustin, 2006). For example, self-assemblage or grouping of casein micelle gives rise to the formation of carbohydrate- Examples of self-assembled nanostructures in food include the organization of the casein micelle, the structures formed in protein-polysaccharide liposomes, and aggregates. According to a report, the bottom-up method provides a better opportunity for the synthesis of nanostructures with fewer flaws, enhanced identical chemical arrangement, and improved organization (Pathakoti et al., 2017).

3. The role of nanotechnology in achieving food security

The world is exposed to innumerable and unprecedented challenges due to increasing climate change, land constraints, increasing population, industrialization, low productivity, and high postharvest losses (Ndlovu et al., 2020; Gothandam et al., 2018). This has led to food insecurity worldwide. About 2 billion people in the world experience moderate or severe food insecurity (FAO, 2019). The lack of regular access to food puts them at greater risk of malnutrition and poor health. This vastly different world calls for new ways of thinking about food insecurity and its consequences (FAO, 2019). In order to achieve the required food at the global level, various methods and techniques have been put forth by researchers from around the world for boosting crop production, postharvest reduction, and ensuring sustainability (Sivarethinamohan and Sujatha, 2021). Ensuring a safe food supply to protect the health and wellbeing of people worldwide needs advanced technology. Recent research has shown the potential of nanotechnology in improving the agriculture sector by enhancing the efficiency of agricultural inputs and providing solutions to agricultural problems for improving food productivity and security (Singh et al., 2021). The role of nanotechnology in agriculture, postharvest loss reduction, and food processing towards achieving food security was discussed below.

3.1. Agriculture

Agriculture is practiced for food production via the cultivation of varied crops and raising of livestock. It is considered the backbone economy for most developing countries as a vital role in progress and development. The rising population in the world results in high demand for more food supply, and scientists and engineers are now practicing new methods to increase agricultural production (Baruah and Dutta, 2009). For the last several years, agriculture nanotechnology has focused on research and application to resolve agriculture and environmental issues sustainability, crop improvement, and enhanced productivity. Agricultural nanotechnology seems to be highly interesting for developing countries, regarding the decrease in hunger, underfeeding, and mortality rate in children (Gogos et al., 2012). Developed and emerging countries like Germany, the United States of America (USA), Brazil, China, India, France, and Korea show increased curiosity for using nanomaterials for agriculture uses as revealed via a more producing high number of publications and patents (Gogos et al., 2012).

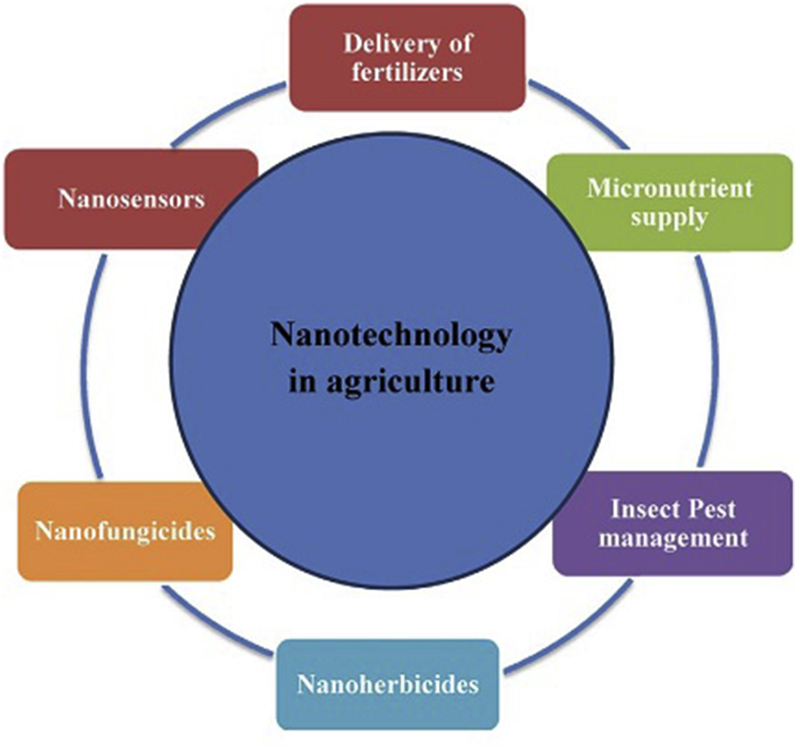

As a potential device, nanotechnology can be applied to renovate agricultural divisions; it helps in learning the biochemical pathways of crops via modifying the conservative methods for evaluating environmental issues and its application to production improvements (Prasad et al., 2017b). Comparisons of nanotechnology with environmentally friendly technologies and agricultural biotechnology show an opportunity for enhanced and quicker influence upon all constituents of the agricultural-value linkage for synchronized public benefits, legal, moral, and environmental effects (Sastry et al., 2011). The prospective use of nanoscale agrochemicals such as nanofertilizers, nanopesticides, nanosensors, and nanoformulations in agriculture has transformed traditional agro-practices, making them more sustainable and efficient (Figure 3). Multiple applications of nanotechnology exist in agriculture including wastewater treatment, reducing the quality of polluted soil, enhance the productivity of crops via security in terms of sensors to detect pathogens (Singh et al., 2021; Axelos and Van De Voorde, 2017). For instance, nanobiosensors is the wide ranging nanotools, scaffold the growth of high-tech agricultural farms and also stand proof for the practical and proposed applications of the nanotools in terms of agricultural inputs control and their management precision (Sivarethinamohan and Sujatha, 2021; Duhan et al., 2017). The application of nanopore bearing zeolite for slow discharge and improved efficacy of enrichers, nanosensors for measuring soil quality and smooth supply mechanisms for herbicides are among positive impact of nanotechnology in agriculture (Chinnamuthu and Boopathi, 2009). Several nanoparticles used for monitoring plant diseases are nano-forms of carbon, silica, silver, and alumino-silicates. The use of nanomaterials for agriculture is proposed to reduce spraying chemicals via the smooth supply of energetic compounds. It can minimize nutrient wastage during applying fertilizer and promote the harvests by enhancing the water and ingredient management (Gogos et al., 2012). The responses of different rice cultivars exposed to engineered nanoparticles at different growth stages and under different conditions were also reported (Wang et al., 2021).

Figure 3.

Schematic representation of applications of nanotechnology in agriculture. Adapted from Duhan et al. (2017) with permission copyright © 2017 Elsevier Ltd.

3.1.1. Nanotechnology to control plant diseases

About 20–40% of crops are lost due to plant pests and pathogens each year worldwide (Flood, 2010). In modern farming practices, pest management relies heavily on the application of pesticides, such as insecticides, fungicides, and herbicides. The development of cost-efficient, high-performing pesticides that are less harmful to the environment is crucial. The new concepts such as nanotechnology can offer advantages to pesticides, like reducing toxicity, improving the shelf-life, and increasing the solubility of poorly water-soluble pesticides, all of which could have positive environmental impacts (Mali et al., 2020; Worrall et al., 2018). The significance of agricultural nanotechnology, mainly for controlling diseases and safety has been reported elsewhere (Gogos et al., 2012; Rehmanullah et al., 2020; Sastry et al., 2010). Nano-based conventional herbicides and pesticides assist in the slow and continued supply of nutrients and agricultural chemicals in a controlled amount to the plants (Duhan et al., 2017). Nanoparticles may have also a key role in the control of insect pests and host pathogens (Khota et al., 2012). Type of polysaccharides such as chitosan, alginates, starch, and polyesters have been considered for the synthesis of nano-insecticides (Mali et al., 2020). In general, the use of nanoparticles to protect plants can occur via two different mechanisms: (a) nanoparticles themselves providing crop protection, or (b) nanoparticles as carriers for existing pesticides and can be applied by spray (Worrall et al., 2018). However, the use of nanomaterials in plant protection and production of food is under-explored (Prasad et al., 2017a).

3.1.2. Nanotechnology to improve quality of soil and fertilizer distribution

Nanotechnology for the management of crops is used as an essential technology for enhancing crop productivity. Nanomaterials and nanostructures, such as carbon nanotubes, nanofibers, and quantum dots are now exploited in agriculture research as biosensors for evaluating the quality of soil and fertilizer distribution. The purpose of nanoparticles is to minimize the spread of chemicals amount, reduce the nutrient loss during fertilization, and increase the quality and yield with proper nutrient (Sangeetha et al., 2021). The development and use of vermiculite, nanoclay, and zeolite could improve fertilizer efficacy and crop production for ecological agriculture in coarse-textured (Sivarethinamohan and Sujatha, 2021). Amending sandy loam soils with inorganic amendments reduce NH4–N passage and increasing the yield of N fertilizer in ecological agriculture systems (Mazloomi and Jalali, 2019). Nanoclay is systematized into a number of modules such as montmorillonite, bentonite, kaolinite, hectorite, and halloysite on the basis of chemical composition and nanoparticle morphology (Sivarethinamohan and Sujatha, 2021).

Most of the productivity of agricultural practices is heavily dependent on fertilizer use. Studies show that crop production is linearly determined by exhaustive application of fertilizers to increase soil fertility (Rehmanullah et al., 2020). The use of nano fertilizer is crucial to enhance crop production. Nano fertilizer is a material with nanometer-size which improves the delivery to plants and managed the slow release of nutrients into the soil gradually in a highly controlled way, hence stopping eutrophication and contamination of water (Davari et al., 2017). Nanotechnology makes the exploitation of nanostructured or nanomaterials for fertilizer transport or limited release routes to construct smooth fertilizer as new opportunities to modify nutrient usage efficacy and reduce charges for environmental safety (Hai-Xin et al., 2011). Nano-fertilizer could improve nutrient efficiency through encapsulation within nanoparticles which is conducted by three methods. (a) Nutrient encapsulation within nanoporous structures, (b) Coating of thin polymeric film, or (c) Delivery in the form of particle or suspensions with nanoscale sizes (Davari et al., 2017; Rai et al., 2012). Nanoscale fertilizers could lead to the more effective delivery of nutrients as their small size may allow them access to plant surfaces and transport channels (Mastronardi et al., 2015). Nano-fertilizer extracted and prepared from banana peels were used in the growth of tomatoes, peppers, or flowers (Sivarethinamohan and Sujatha, 2021). Nano fertilizers were used for the growth and improvement of different crops, for instance, nanoparticles of ZnO for chickpea, silicon dioxide and iron slag powder for maize, colloidal silica and NPK for tomato, TiO2 for spinach, gold and sulfur fertilizers were used for the growth of grapes (Sivarethinamohan and Sujatha, 2021). Fertilizer usage with nanoscale transporters may be subjected in a way so that they anchor the roots of the plant with the surrounding soil contents and organic material hence decreasing chemical loss and lessening environmental issues (Dasgupta et al., 2015). Nanoscale fertilizers can decrease the toxicity of soil and hence the potential undesirable impacts accompanied by high dosage are reduced (Davari et al., 2017). Such nano fertilizers slow down the nutrients release and extend the duration of fertilizer impact (Naderi and Danesh-Shahraki, 2013). TiO2 nanoparticles have shown a major effect on the growth of maize crop; moreover, SiO2 plus TiO2 nanoparticles elevated the action of nitrate and increased plant absorption potential, by controlled use of water and fertilizer with the efficient outcome (Abobatta, 2018; Sekhon, 2014).

3.1.3. Nanotechnology and gene sequencing

The use of nanotechnology also facilitated gene sequencing that contributed to the improved identification and use of plant trait means, modifying their potential to respond against environmental pressures and ailments. Quantum dots and nanoparticles have proved to a biological marker associated with outstanding accuracy (Sharon et al., 2010). Optical mapping of DNA in the age of nanotechnology and nanoscopy also reported (Levy-Sakin and Ebenstein, 2013). Optical mapping of DNA grants accesses to genetic and epigenetic information on individual DNA molecules. Nanopore sequencing could allow sequencing of single DNA molecules spanning tens of kbp (perhaps up to 100 kbp) thus lifting the limitations of short-read data (Levy-Sakin and Ebenstein, 2013). In general, nanotechnologies have been applied in a variety of contexts, including genome sequencing, targeted resequencing and discovery of transcription factor binding sites, noncoding RNA expression profiling, and molecular diagnostics (Elingarami et al., 2013).

3.2. Postharvest loss reduction

In developed countries, greater than 40% losses of food (cereals, roots and tubers, pulses and oil crops, vegetables and fruit, fish meat, and dairy) occurs at trade and customer stages, while in the case of developing countries, greater than 40% losses of food occur at post-harvest stage and processing point (FAO, 2019; Gustavsson et al., 2011). Newly harvested high moisture unpreserved yields may quickly deteriorate owing to microorganism's attack. Newer and advanced technologies such as nanotechnology can help for decreasing post-harvest losses. Nanotechnology application can minimize post-harvest losses by designing functional packing ingredients with the least quantities of bioactive constituents, improved gas and mechanical properties with a reduced effect on sensor qualities of vegetables and fruits (Flores-López et al., 2016).

Edible coatings are used as a liquid on food, generally by dipping the product in a solution-providing substance made by the structural medium (carbohydrate, lipid, protein, or mixture). They protect untreated foods from worsening via hindering dehydration, overturning respiration, refining textural features, aiding to preserve volatile aroma compounds, and decreasing the growth of microbes. Nano-coatings with edible quality deposited on different foodstuff provides a fence to gas and moisture exchange and delivering flavors, colors, enzymes, antioxidants, and browning resistant agents that may enhance the shelf life of synthetic foods (Zambrano-Zaragoza et al., 2018). The technology enables the formation of nanoscale coatings up to five nano meter thickness (Sekhon, 2010). The use of edible coatings and thin films are common for horticultural commodities. The use depends on properties like cost, availability, functional qualities, mechanical properties (elasticity, tension), photosensitive properties (brilliance and opacity), the fencing effect versus gas flow, structural hindrance to water migration, microbes and sensory suitability (Zambrano-Zaragoza et al., 2018; Falguera et al., 2011).

Various nanoscale edible coatings are applied to food to control the post-harvest excellence of new harvested products. Silver nanoparticles are of increasing attention recently owing to their antimicrobial properties essential for processing food. The use of PVP-based silver nanoparticles on asparagus, considerably delayed the growth of microbes, slowing the loss of weight and decreased changes in skin color (An et al., 2008). In another report, gelatin-derived edible coatings with cellulose nanocrystal considerably improved the shelf life of strawberries (Fakhouri et al., 2014). Chitosan-assisted nano-silica coating beneficially improved the physicochemical and physiological value regarding longan fruit within ambient temperature as compared to other treatments via proficiently providing an outstanding semi-permeable film (Shi et al., 2013). Moreover, chitosan film-based nano-SiO2 (Yu et al., 2012) and alginate or lysozyme-based nanolaminate coatings (Medeiros et al., 2014) investigated to reserve the value of fresh diets during prolonged storage. Nano-ZnO coating also reduced the microbial damage and kept the post-harvest value of some fruits during storing (Sogvar et al., 2016).

Nanotechnology can also be applied in grain quality control using nanosensors (Bouwmeester et al., 2009). The sensors are capable to respond to changes in the environment during storage (temperature, oxygen exposure, and relative humidity), degradation products, or contamination by microbes. They are also applied to respond to the presence of fungus or insects in the stored grain (Axelos and Van De Voorde, 2017). Nanosensors for grain quality observing have also been developed by using polymer nanoparticles that respond to volatile agents and other analytes in an environment of stored foods and hence detect the cause and the kind of decomposition involved (Neethirajan and Jayas, 2011).

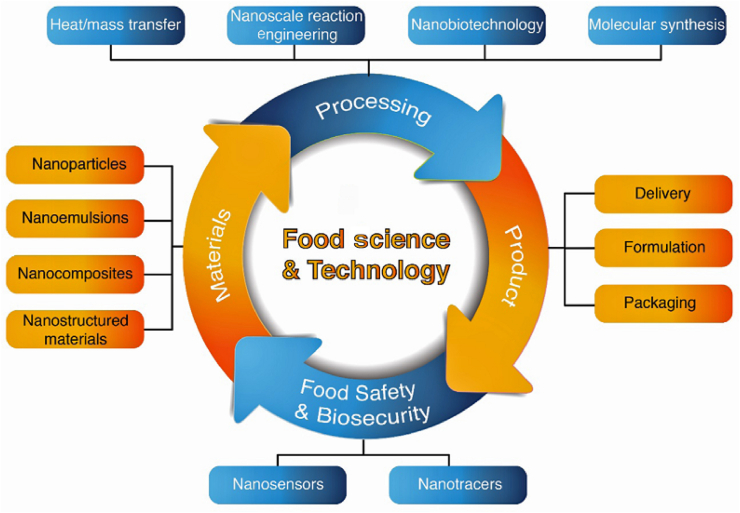

3.3. Food processing

Globally, biggest food companies searching for various methods to modify the competence, safety, value, and nutritional properties of food. Newer technologies are required for food industries to enhance productivity, market price, and quality. Plentiful uses of nanotechnology regarding food production and processing are developed including nano-based-food additives, nanoencapsulation, nanosensors, nanoparticles-based smart distribution systems, nano-packing, plus medicines, and health care (Rashidi and Khosravi-Darani, 2011). Its applications are also for encapsulation formation, biopolymer matrices, emulsions, simple solutions, and associated colloids offer effective delivery systems. Industrial food processing by nanotechnology is gaining momentum particularly, for flavor encapsulation or odor enhancement, modification of food texture or value improvement, newer gelation or viscosity increasing agents (Duncan, 2011). Food nanotechnology emphasizes the synthesis of nanometer-scale structures with exclusive properties be used for different purposes, such as delivery arrangements, food interaction surfaces having exclusive superficial properties, devices for food characterization, microfluidic instruments, sensor technology, and nanocomposite coatings, among numerous other uses (Sadeghi et al., 2017). The whole application of food science and technology is demonstrated in Figure 4.

Figure 4.

Nanotechnology applications in food science and technology. Adapted from Roohinejad and Greiner (2017) with permission copyright © 2017 John Wiley and Sons.

Formation of nanoemulsions takes place by minute emulsion droplets at the nanoscale (oil/water system) showing sizes <100 nm (Anton and Vandamme, 2011). They need higher mechanical energy like a high-pressure homogenizing step or using a microfluidizer or sonication protocol to form the distributed phases. Nanoemulsions minimize the requirement for stabilizers, owing to their protection against food breaking and split-up hence considerably decrease the amount of fat required (Dasgupta et al., 2015). Several nanoemulsions seem optically clear and possess many technical advantages for mixing into drinks (Prasad et al., 2017a). The final possessing products of nanoemulsions are very creamy like usual food products, having no changes felt to mouth and taste (Dasgupta et al., 2015). Nanoemulsions are applied to modify food for salad dressing, the flavor in oils, sweeteners, improved beverages, and other food processing.

In the case of food processing, nanomaterials are used in the form of food additives, anti-caking agents, transporters for nifty delivering of nutrients, antimicrobial agents, filling agents for increasing mechanical power and stability of the packing material, where food nanosensing is carried out to attain improved food value and security assessment (Ezhilarasi et al., 2013). This applies to food supplements in the case of nutraceuticals production based on enhanced stability along with bioavailability (Duncan, 2011).

A large number of food products contain nanoparticles naturally from the beginning. Numerous proteins containing foods are globular structures with 10–100 nm size range, while others consist chiefly, carbohydrates and lipids, constituting linear polymers with a thickness of <1 nm. Milk possesses casein, a protein existing at the nanoscale, or meat consists of filaments of proteins which are categorized as nanomaterial group (Prasad et al., 2017a).

The food and beverage sector are a high finance worldwide industry, and many food companies have been researching to improve production efficiency, food safety, and nutritional properties (Roohinejad and Greiner, 2017). The excellent benefits of using nanomaterials in the processing of meat and packing are increased bioavailability, antimicrobial properties, boosted sensory qualities plus directed delivery of compound with good bioactivity (Ramachandraiah et al., 2015). Nanotechnology is practiced for developing encouraging nano-protocols, fabrication of environmentally friendly processes and smart nano-packing, manufacturing products with best texture and taste, production of low-calorie beverages and food products based on the objectives of altering the lifestyles with healthy gains (Chaudhry et al., 2008; Katouzian and Jafari, 2016). It can produce tools for faster identification deficiencies of ingredients like atomic force microscopy (AFM) and is useful to detect pathogens in food via Nanosensors (Rashidi and Khosravi-Darani, 2011). AFM is a commanding device for the investigation of fine assemblages of foods and useful for molecular interaction at the nanoscale (Katouzian and Jafari, 2016).

Like other scientific areas, food science also applies newer nanotechnologies to increase the quality of life regarding customers with the aid of modified formulation of food, packing of food, novel ingredients production, and monitoring of processes which can deliver healthier, safe, high quality, precise food system with improved shelf life (Roohinejad and Greiner, 2017). Key linkages between food systems and nanotechnologies such as food processing, security, functionality, and economical aspects for distribution and efficiency are improving (Rashidi and Khosravi-Darani, 2011).

Multipurpose applications of nanotechnology in food processing are nanofiltration, nanoscale enzyme-based reactor, nanoencapsulation for absorption and modification, transfer of heat and mass, and nanofabrication. Nanofiltration is better in industries for the purification of pharmaceuticals and as an essential step for forgetting some solutes. It is also applied for the treatment of drinking water as well as dairy to modify the product quality by removing salt from lactose (Dasgupta et al., 2015). Heat and mass transfer nanofabrication enhanced heat resistance of packages.

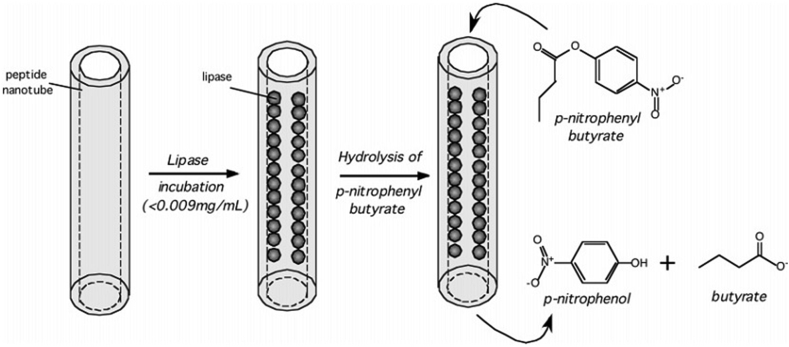

Nanoscale enzyme reactors are applied to modify processing and also in food treating methods for altering food mechanisms for enhanced flavor, dietary value, and varied health profits. Nanomaterial's addition results in higher enzyme assisted systems (to improve activity, shelf life, and economy) because of their aid in scattering through food media due to large surface-to-volume relations as compared to macroscale supported products (Yu et al., 2005). It is investigated that nanotubes of peptide resulted in improved enzyme supports over elevated temperature (65 °C) where the activity of the lipase in the nanotubes was noted to be 70% higher in comparison to fee lipases e.g., nano-SiO2 particles significantly hydrolyzed the olive oil with improved stability, reusability, and adaptability (Bai et al., 2006).

Nanoencapsulation protocol is applied to improve food products. This technique is practiced generally for improving the flavor, preservation, and to supply cooking balance. Nanocapsules in the form of nanoceramic pot may be employed to modify absorption for decreasing the cooking time as well as the quantity of spent oil, decrease in trans fatty acids because of using plant oil in place of hydrogenated one and lastly resulting in forming safer nano food production of nanocapsules for using in food to distribute nutrients for increased absorption. Nanoencapsulation conceal odors and tastes, manage interactions of food with active ingredients, control the discharge of dynamic agents, safeguard accessibility at a selected time with definite rate, and shield them against moisture, chemical, heat or biological interference during storage, processing, and application, with a further exhibition of similarity with other ingredients in system (Singh et al., 2017; Ubbink and Krüger, 2006; Weiss et al., 2006). Metallic oxides like SiO2 and TiO2 have been used as coloring or flow ingredients in food substances. SiO2 nanomaterials are applied in wasted food nanomaterials for transporting scents or aromas in food material (Dekkers et al., 2011).

3.4. Packaging

Packaging assists plentiful roles in food system. One of several significant functions is to save food from physical harm and quality decline. The packaging should be safer, passive, inexpensive, frothy, easily disposable or reusable, stable in storage and transport circumstances, and resilient to physical exploitation. The composition and type of packaging material influence the quality of food. Nanomaterials can improve the packaging properties of packaging stuff with lightweight, stronger envelop, heat resistance, and other properties. The use of nanotechnology in food packaging is effusively used and reported (Han et al., 2018; Kumar et al., 2018; Mihindukulasuriya and Lim, 2014; Noorbakhsh-Soltani et al., 2018). It is estimated that the global nano-based packaging food and beverages market was 4.13 billion USD in 2008 and raise to 7.3 billion until 2014, exhibiting an annual growth rate of 11.65% (Duncan, 2011).

Various metal and metal oxide nanoparticles are subjected to various active packing applications. The silver (Ag) and TiO2 are of great value in food packaging (Li et al., 2017; Zhao et al., 2012). Active packaging employs metal and metal oxide nanoparticles as antimicrobials like nanocomposites for food packing were employed (Pathakoti et al., 2017). TiO2 is frequently employed as an adsorbent material, stain, or catalytic substrate due to its semiconducting properties with the increased optical, electrical, and photosensitive outcome (Prakash et al., 2018). Blending of dispersed and antimicrobial Ag/TiO2 nanomaterials with polyethylene employed as packing agents regarding the storage of rice at a relative humidity of 70% and temperature of 37 °C with improved properties (Zhao et al., 2012).

Advantages associated with nanoparticles for food packaging include antimicrobial potential, mobilization of the enzyme, oxygen transport, and clue for the extent of exposure to degradation associated factor (De Azeredo, 2009). Nano-packing material produced a valuable sensing quality as compared to the usual packing material (Sharma et al., 2017). Mixing of nano-polymer containing polylactic acid with zinc oxide nanoparticles resulted in highly suitable interaction material for food packing with increased functionality (Martínez-Bueno et al., 2017). Zinc oxide treated semolina protein coating was tested for food packing with a considerable reduction in absorptivity of oxygen plus heat resistance (Jafarzadeh et al., 2017).

Nanoclay, silicates, and moisturized alumina-silicate have been applied as layers in food packaging (Weiss et al., 2006). Clay with silicate has also been mixed with polymers as a potential nanocomposite candidate with outstanding fencing properties for food packaging (Sharma et al., 2017). Food packaging potential has also been investigated for organoclay nanoparticles used as antimicrobial material (Fasihnia et al., 2018).

Cellulose has been observed as supportive material in numerous nanomaterials and has been employed in various applications owing to the bigger surface area of nanoparticles linked with their boosted activity (Sharma et al., 2017). It possesses great strength as a natural polymer, is inexpensive, greener friendly, and easily recyclable (Moustafa et al., 2019). Nano-composite films modified by nano-chitosan and nano-cellulose added films have been practiced for food packaging and have exhibited an increase in tensile power, elongation to breakage, clearance, and food protection characteristics (Noorbakhsh-Soltani et al., 2018). Manufacturing of nano-bio-composited films via polylactides-chitosan has proved them suitable for packaging with substantial and continued antioxidant potential in comparison to chitosan used alone (Basu et al., 2017). Nanocomposites of cellulose and copper with antibacterial properties have been applied for packaging as well as paper coatings (Pinto et al., 2013).

Chitosan films with nanometer thickness are high focus owing to their inherent antimicrobial characteristics and are applied broadly (Rieger et al., 2015). Nanoparticles of chitosan are synthesized via ionic gelation, by electrostatic interaction of positive amino sides of chitosan with polyanions as cross-linkers (Sharma et al., 2017). Chitosan/gelatin-based nanocomposite with Ag nanoparticles, are used for food packaging and seem to be extremely useful protective packing material for extending shelf life by 14 days for red grapes (Kumar et al., 2018). Chitosan-Ag and Chitosan-Au nanocomposites coating are applied as efficient antimicrobial candidates against gram-positive (Staphylococcus aureus) and gram-negative (Pseudomonas aeruginosa), yeast (Candida albicans) and fungi (Aspergillus niger) and yeast in packing (Youssef et al., 2014).

4. Nanotubes in food and agriculture

Nanotubes are Buckyballs having two sides decorated with other atomic groups incorporated in the typical hexagonal shape to give a hollow carbon tube (Scott, 2005). Nanotubes withstand high temperature, having a flexible and strong nature which is applied for use in medical tools, alumina, sports apparatus, and equipment for food processing (Rashidi and Khosravi-Darani, 2011). Nanotubular textures are made from several varied materials like inorganics, carbon, bio-microtubules, viral proteins, amyloid proteins, porins, lactalbumin, DNA28, carbohydrates, lipids, synthetic polymers, plus other organics (Scanlon and Aggeli, 2008). Synthesis and usage of enzyme-based nanotubes as supporting substrates for enzymes have been observed to enhance the catalytic action of nanotube-deposited lipases as shown in Figure 5.

Figure 5.

Illustration of lipase nanotube fabrication and its enzymatic application. Adapted from Yu et al. (2005) with permission copyright © 2005 American Chemical Society.

Carbon nanotubes induce improved mechanical properties in food packaging (Abdelmonem, 2020). Carbon nanotubes and polyamides have employed to increase the tensile strength of some polymers (Kim et al., 2008). Carbon nanotube-based biosensors have been practiced in detecting microbes, toxic elements, and other metabolites in beverages and food owing to their faster detection, simple protocol, and cheaper cost (Singh et al., 2017). TiO2 based carbon nanotubes have been witnessed to increase disinfectant potential against spores of Bacillus cereus (Krishna et al., 2005). Silver deposited TiO2 nanoparticles increased their bacterial killing effects Vs E. coli (Kim et al., 2006). Strong antimicrobial impacts of carbon nanotubes made them killed via direct contact (Abdelmonem, 2020).

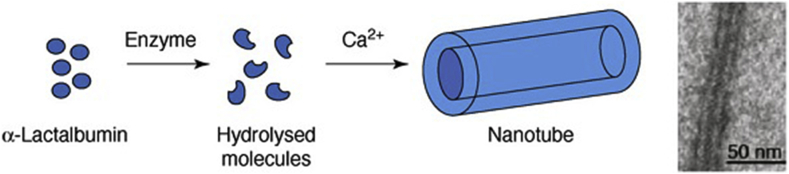

It was possible to obtain nanotubes from α-lactalbumin (milk proteins) via partial hydrolysis (Sozer and Kokini, 2009). Self-assemblage of partially hydrolyzed α -lactalbumin into nanotubes has illustrated in Figure 6. As per some study reports, α-lactalbumin nanotubes is increased viscosity and toughness are hence applicable as a thickener (Ipsen and Otte, 2007; Graveland-Bikker and De Kruif, 2006). It said that α-lactalbumin nanotubes are practicable in pharmaceutical and foods as viscosities, gelation agents (sol-gel formation) with controlled assemblage, encapsulation agents with fixed flavor, and drug delivery, and so on (Ipsen and Otte, 2007).

Figure 6.

Representation of the self-assembly of partially hydrolyzed α -lactalbumin into nanotubes in the presence of calcium ions (Ca2+). Adapted from Sozer and Kokini (2009) with permisssion copyright © 2009 Elsevier Ltd.

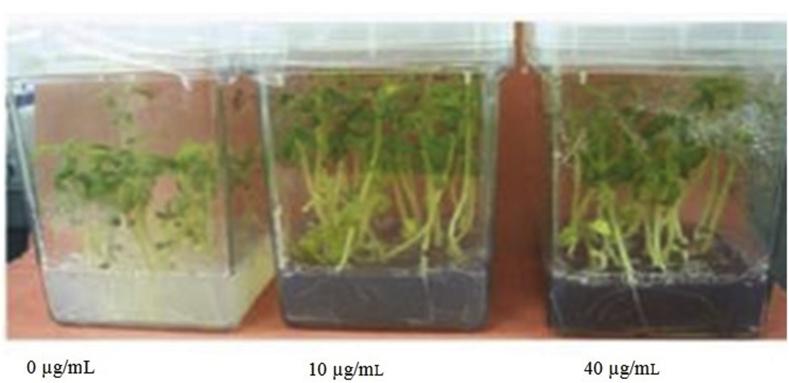

Nanotubes have also linked with modern agricultural activity. According to some reports, various nanoparticles can enter the cell walls of plants. It was known that carbon nanotubes can enter tomato seeds to affect their sprouting and development (Khodakovskaya et al., 2009). Figure 7 illustrates the germination of the development of tomato treated with various concentrations of carbon nanotubes (0, 10, and 40 μg/L) showing a wonderful growth in biomass. This is due to increased uptake of water by carbon nanotubes resulting in the improvement of the plant. Gold-derived mesoporous silica nanoparticles also entered through the cell wall and helped in the penetration of DNA into the cell (Torney et al., 2007).

Figure 7.

Growth performance of 25-day-old tomato seedlings grown on media without and with carbon nanotubes (10 and 40 ug/mL). Adapted from Khodakovskaya et al. (2009) with permission copyright © 2009 American Chemical Society.

5. Nanosensors in food and agriculture

The use of biosensors combined with improved technologies in the field of molecular biology, nanomaterials, and microfluidics have enormous applications for the productivity of crops. These are also applied to monitor the activity of microorganisms in the soil and able to predict the likely incidence of soil infections. The basic principle related to soil examination with the biosensor is to find out the comparative action of positive and negative microorganisms in soil depends upon variation on oxygen usage during their breathing. They also offer many opportunities in sensing contaminants and their hindrance, via using new properties related to nanomaterials (Baruah and Dutta, 2009). Biosensors for detection of the nitrate concentration in plants as well as detection for markers to identify infected plants are reported for methyl salicylate and azelaic acid (Griesche and Baeumner, 2020). The use of biosensors for monitoring of Penicillium digitatum infection in citrus fruit was reported (Chalupowicz et al., 2020). Smart delivery systems and nanosensors are applied to help in efficient natural agricultural means like nutrients, water, and chemicals using precision farming for example satellite monitoring, geographic systems, and distant detecting tools that remotely can detect pests on crops or indication of strain like drought (Sekhon, 2014). The application of independent sensors connected to GPS monitoring in real-time is thought to play a key role in nanotechnology-assisted tools (Davari et al., 2017). Arrangement of nanosensors can be carried out throughout the field for monitoring crop growth and soil parameters.

Nanosensors are getting attention and playing a big role in the development of the food industry for its efficient responding tools to detect gases, microbes, or toxic substances in packed foods. Nanobiosensors have been testified for detecting pathogens in processing plants or alerting clients, protocols, and providers on the safety position of food (Cheng et al., 2006). It has been also employed for the existence of impurities, mycotoxins, and microbes in food (Bratovčić et al., 2015). Allergens have also been detected via biosensors tools with the assistance of nanoparticles and the report is about to commercialize (Warriner et al., 2014). These tools can also detect the history of time, expiration date, and temperature.

6. The challenges of nanotechnology in food and agriculture system

Nanotechnology tremendously used for food and agricultural benefits as reviewed earlier. However, nanomaterials are associated with many safety issues due to their potential risk values penetrating the cells owing to their minute sizes and could exist in the system (De Azeredo, 2009; Rajput et al., 2020; Sharma et al., 2017). Enhanced application of nanotechnology in agricultural practices and food products are of tremendous concern amongst big sector of the society because of several antagonistic effects of different nanoparticles (Baruah and Dutta, 2009). Although properties and protection of the substances in bulk are generally evident, nanoscale complements repeatedly demonstrate varied properties as compared to those at the macroscale (De Azeredo, 2009). The threat associated with nanotechnology is largely due to the small size of nanoparticles with larger surface areas which are easily dispersible, penetrating cells to reach quite distant areas of the body, for causing potential toxicity (Dasgupta et al., 2015). Due to similarity in size with DNA, nanomaterials possess the chance to react with the biological specimens (Baruah and Dutta, 2009).

Degradation of nanocomposites can occur owing to environmental conditions with the release of inserted nanomaterials from polymeric texture into the environment (Moustafa et al., 2019). The strength of some food packaging, like low-density polyethylene, is changed after exposure to environmental effects, ultraviolet rays, or ozone in humid conditions (Han et al., 2018). According to Han et al. (2018), polyethylene samples with low density suffered oxidation under UV light or ozone-producing considerable change in structural, physical, and thermal properties. In the agriculture sector, pesticides and nano fertilizers are used are spread into the water, soil, or atmosphere, resulting in high health threat for farmers (Roohinejad and Greiner, 2017). The accumulation of nanoparticles in the soil is expected to impair plant growth and accumulate into edible tissues (Rajput et al., 2020).

Once the nanoparticles released into the agro-environment, it immediately begin to undergo a number of transformations. The interaction of nanoparticles within the human body is one of the most concerns. Nanoparticles can cause oxidative harm and provocative reactions and the wasted nanoparticles could possess the potential of causing toxicity (Han et al., 2018; Lewicka et al., 2013; Narei et al., 2017). Nanotoxicity is chiefly interceded via the tremendous production of free radicals, to give rise to oxidative anxiety and thus the cells become unable to sustain usual biological redox-regulated tasks (Pathakoti et al., 2017). The degradation of nano-clay present within low-density polyethylene aggregates can cause carcinoma of alveolar basal epithelial cells in humans (Kumar et al., 2018). Many studies have been conducted regarding the antibacterial mechanistic of Ag. But being a heavy metal, it can induce toxicity via denaturation of the proteins and enzymes in the body when present at high concentration; its migration threat might be estimated (Li et al., 2017). Studies on Ag and TiO2 nanoparticles and carbon nanotubes exhibited that these agents could enter blood circulation and their insoluble nature can result in their buildup in organs (Ramachandraiah et al., 2015; Sharma et al., 2017). TiO2 used as a food additive or in another form in food when entering the body may cause inflammation via oxidative stress, and genotoxicity results in instability of chromosomes (Baranowska-Wójcik et al., 2020).

Nanoparticles can get entry into the body via ingestion, inhalation, or cutaneous contact. A tremendous amount of nanomaterials usage in food packaging could be an issue of concern as their release from the contaminated food or the environment (Han et al., 2018). However, limited data are available regarding the migration of nanoparticles from the packing materials into food, along with their final toxicological impacts (De Azeredo, 2009; Pathakoti et al., 2017).

The choice of green nanofillers in nanocomposites research is highly crucial for the safety of environments, human health, and animals. Moreover, parameters like concentration, molecular weight, particle size, diffusivity, and stability of particular substances in polymer blend, temperature, pH value, polymeric structure and viscosity, contact time, mechanical pressure, and food composition are essential (Sharma et al., 2017). The accurate determination of environmentally released nanoparticles and their accumulation in plants, and the impact on health are also imperative to assess (Rajput et al., 2020).

Generally, effective guidelines, policies and regulatory systems are required for the safer utilization of nanoparticles in food industry. For instance, Food and Drug Administration (FDA) involved in the regulation of nanofoods and food packaging in the USA and European Union control the nanotechnology-based food ingredients in Europe (Nile et al., 2020). However, most countries producing nano materials do not have proper nanotechnology specific regulations (Nile et al., 2020). Therefore, complete government guidelines and legislations, as well as rigorous toxicological screening methodologies are essential for the legal nanotechnological applications (Nile et al., 2020).

7. Conclusions

Nanotechnology is a newly emerging, but highly expanding technology in many fields related to human activities and benefits worldwide. Its fascinating phenomena have been witnessed through several research findings that the nanoparticles and nanostructure improve various properties due to small size, larger surface area, and highly catalytic nature. Nanotechnology is crucial in achieving food security, especially in the agriculture sector. It can improve crop production by effective microbial, pest, and weed control with high economic value, security, and safety. It also plays a key role in food processing, food modification, stability, sensing, prolonged shelf life, minimized food losses, and provide safe food. Nanotechnology also minimizes post-harvest losses with better stability, safety, and packaging materials. Nanoparticles like Ag, Au, Zn, TiO2, ZnO, SiO2, and MgO commonly used in food processing, may also induce health risks due to easy penetration through the cell for adverse reactions within various humans, and animal organs as well as parts of plants. Such risks due to nanoparticles or nanocomposite could be controlled in future research via using greener synthesis and searching for easy and cheaper protocols for degradation and removal of existing nanomaterial from the sites of attack.

Declarations

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

No data was used for the research described in the article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

We highly and thankfully acknowledge Jimma University department of Postharvest Management and Wollega University department of Food and Nutritional Sciences. We are equally cordially thankful to the Honorable Director, HEJ Research Institute of Chemistry, ICCBS, Karachi University for provision of excellent support.

References

- Abdelmonem A.M. Carbon Nanomaterials for Agri-Food and Environmental Applications. Elsevier; 2020. Application of carbon-based nanomaterials in food preservation area; pp. 583–593. [Google Scholar]

- Abobatta W.F. Nanotechnology application in agriculture. Acta. Sci. Agri. 2018;2:99–102. [Google Scholar]

- An J., Zhang M., Wang S., Tang J. Physical, chemical and microbiological changes in stored green asparagus spears as affected by coating of silver nanoparticles-PVP. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2008;41:1100–1107. [Google Scholar]

- Anton N., Vandamme T.F. Nano-emulsions and micro-emulsions: clarifications of the critical differences. Pharm. Res. (N. Y.) 2011;28:978–985. doi: 10.1007/s11095-010-0309-1. [DOI] [PubMed] [Google Scholar]

- Ashraf S.A., Siddiqui A.J., Abd Elmoneim O.E., Khan M.I., Patel M., Alreshidi M., Moin A., Singh R., Snoussi M., Adnan M. Innovations in nanoscience for the sustainable development of food and agriculture with implications on health and environment. Sci. Total Environ. 2021;768:144990. doi: 10.1016/j.scitotenv.2021.144990. [DOI] [PubMed] [Google Scholar]

- Axelos M.A., Van De Voorde M. John Wiley & Sons; 2017. Nanotechnology in Agriculture and Food Science. [Google Scholar]

- Bai Y.-X., Li Y.-F., Yang Y., Yi L.-X. Covalent immobilization of triacylglycerol lipase onto functionalized nanoscale SiO2 spheres. Proc. Biochem. 2006;41:770–777. doi: 10.1016/j.jbiotec.2006.04.003. [DOI] [PubMed] [Google Scholar]

- Baranowska-Wójcik E., Szwajgier D., Oleszczuk P., Winiarska-Mieczan A. Effects of titanium dioxide nanoparticles exposure on human health—a review. Biol. Trace Elem. Res. 2020;193:118–129. doi: 10.1007/s12011-019-01706-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bartolucci C. In: Nanotechnology in Agriculture and Food Science. Axelos M.A., Van De Voorde M., editors. John Wiley & Sons; 2017. Nanotechnologies for agriculture and foods: past and future; pp. 1–14. [Google Scholar]

- Barrett C.B. Overcoming global food security challenges through science and solidarity. Am. J. Agric. Econ. 2021;103(2):422–447. [Google Scholar]

- Baruah S., Dutta J. Nanotechnology applications in pollution sensing and degradation in agriculture: a review. Environ. Chem. Letter. 2009;7:191–204. [Google Scholar]

- Basu A., Kundu S., Sana S., Halder A., Abdullah M.F., Datta S., Mukherjee A. Edible nano-bio-composite film cargo device for food packaging applications. Food Packag. Shelf Life. 2017;11:98–105. [Google Scholar]

- Bouwmeester H., Dekkers S., Noordam M.Y., Hagens W.I., Bulder A.S., De Heer C., Ten Voorde S.E., Wijnhoven S.W., Marvin H.J., Sips A.J. Review of health safety aspects of nanotechnologies in food production. Regul. Toxicol. Pharmacol. 2009;53:52–62. doi: 10.1016/j.yrtph.2008.10.008. [DOI] [PubMed] [Google Scholar]

- Bratovčić A., Odobašić A., Ćatić S., Šestan I. Application of polymer nanocomposite materials in food packaging. Croat. J. Food Sci. Technol. 2015;7:86–94. [Google Scholar]

- Chalupowicz D., Veltman B., Droby S., Eltzov E. Evaluating the use of biosensors for monitoring of Penicillium digitatum infection in citrus fruit. Sens. Actuators B Chem. 2020;311:127896. [Google Scholar]

- Chaudhry Q., Scotter M., Blackburn J., Ross B., Boxall A., Castle L., Aitken R., Watkins R. Applications and implications of nanotechnologies for the food sector. Food Addit. Contam. 2008;25:241–258. doi: 10.1080/02652030701744538. [DOI] [PubMed] [Google Scholar]

- Cheng M.M.-C., Cuda G., Bunimovich Y.L., Gaspari M., Heath J.R., Hill H.D., Mirkin C.A., Nijdam A.J., Terracciano R., Thundat T. Nanotechnologies for biomolecular detection and medical diagnostics. Curr. Opin. Chem. Biol. 2006;10:11–19. doi: 10.1016/j.cbpa.2006.01.006. [DOI] [PubMed] [Google Scholar]

- Chinnamuthu C., Boopathi P.M. Nanotechnology and agroecosystem. Madras Agri. J. 2009;96:17–31. [Google Scholar]

- Cushen M., Kerry J., Morris M., Cruz-Romero M., Cummins E. Nanotechnologies in the food industry–Recent developments, risks and regulation. Tren. Food Sci. Technol. 2012;24:30–46. [Google Scholar]

- Dasgupta N., Ranjan S., Mundekkad D., Ramalingam C., Shanker R., Kumar A. Nanotechnology in agro-food: from field to plate. Food Res. Int. 2015;69:381–400. [Google Scholar]

- Davari M.R., Kazazi S.B., Pivehzhani O.A. In: Nanotechnology. Prasad R., Kumar M., Kumar V., editors. Springer; Singapore: 2017. Nanomaterials: implications on agroecosystem. Nanotechnology; pp. 59–71. [Google Scholar]

- De Azeredo H.M. Nanocomposites for food packaging applications. Food Res. Inter. 2009;42:1240–1253. [Google Scholar]

- Dekkers S., Krystek P., Peters R.J., Lankveld D.P., Bokkers B.G., Van Hoeven-Arentzen P.H., Bouwmeester H., Oomen A.G. Presence and risks of nanosilica in food products. Nanotoxicology. 2011;5:393–405. doi: 10.3109/17435390.2010.519836. [DOI] [PubMed] [Google Scholar]

- Díaz-Soler B.M., Martínez-Aires M.D., López-Alonso M. Potential risks posed by the use of nano-enabled construction products: a perspective from coordinators for safety and health matters. J. Clean. Prod. 2019;220:33–44. [Google Scholar]

- Duhan J.S., Kumar R., Kumar N., Kaur P., Nehra K., Duhan S. Nanotechnology: the new perspective in precision agriculture. Biotechnol. Rep. 2017;15:11–23. doi: 10.1016/j.btre.2017.03.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Duncan T.V. Applications of nanotechnology in food packaging and food safety: barrier materials, antimicrobials and sensors. J. Coll. Interf. Sci. 2011;363:1–24. doi: 10.1016/j.jcis.2011.07.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Duro J.A., Lauk C., Kastner T., Erb K.H., Haberl H. Global inequalities in food consumption, cropland demand and land-use efficiency: a decomposition analysis. Glob. Environ. Change. 2020;64:102124. [Google Scholar]

- Elingarami S., Li X., He N. Applications of nanotechnology, next generation sequencing and microarrays in biomedical research. J. Nanosci. Nanotechnol. 2013;13(7):4539–4551. doi: 10.1166/jnn.2013.7522. [DOI] [PubMed] [Google Scholar]

- Ezhilarasi P., Karthik P., Chhanwal N., Anandharamakrishnan C. Nanoencapsulation techniques for food bioactive components: a review. Food Biopro. Technol. 2013;6:628–647. [Google Scholar]

- Fakhouri F., Casari A., Mariano M., Yamashita F., Mei L.I., Soldi V., Martelli S. vol. 64. IOP Publishing; 2014. Effect of a gelatin-based edible coating containing cellulose nanocrystals (CNC) on the quality and nutrient retention of fresh strawberries during storage. (IOP Conference Series: Materials Science and Engineering). No. 1. [Google Scholar]

- Falguera V., Quintero J.P., Jiménez A., Muñoz J.A., Ibarz A. Edible films and coatings: structures, active functions and trends in their use. Tren. Food Sci. Tech. 2011;22:292–303. [Google Scholar]

- FAO . 2019. The State of Food and Agriculture 2019. Moving Forward on Food Loss and Waste Reduction. Rome. [Google Scholar]

- Fasihnia S.H., Peighambardoust S.H., Peighambardoust S.J. Nanocomposite films containing organoclay nanoparticles as an antimicrobial (active) packaging for potential food application. J. Food Process. Preserv. 2018;42 [Google Scholar]

- Flood J. The importance of plant health to food security. Food Secur. 2010;2(3):215–231. [Google Scholar]

- Flores-López M.L., Cerqueira M.A., De Rodríguez D.J., Vicente A.A. Perspectives on utilization of edible coatings and nano-laminate coatings for extension of postharvest storage of fruits and vegetables. Food Eng. Rev. 2016;8:292–305. [Google Scholar]

- Gogos A., Knauer K., Bucheli T.D. Nanomaterials in plant protection and fertilization: current state, foreseen applications, and research priorities. J. Agric. Food Chem. 2012;60:9781–9792. doi: 10.1021/jf302154y. [DOI] [PubMed] [Google Scholar]

- Gothandam K.M., Ranjan S., Dasgupta N., Ramalingam C., Lichtfouse E. Springer International Publishing; Cham: 2018. Nanotechnology, Food Security and Water Treatment. [Google Scholar]

- Graveland-Bikker J., De Kruif C. Unique milk protein based nanotubes: food and nanotechnology meet. Trends Food Sci. Technol. 2006;17:196–203. [Google Scholar]

- Griesche C., Baeumner A.J. Biosensors to support sustainable agriculture and food safety. Trends Anal. Chem. 2020;128:115906. [Google Scholar]

- Gustavsson J., Cederberg C., Sonesson U., Van Otterdijk R., Meybeck A. FAO; Rome: 2011. Global Food Losses and Food Waste: Extent, Causes and Prevention. [Google Scholar]

- Hai-Xin C., Jiang J.-F., Liu Q. On plant nutrition smart delivery systems and precision fertilization. Plant Nutr. Fert. Sci. 2011;2:33. [Google Scholar]

- Han C., Zhao A., Varughese E., Sahle-Demessie E. Evaluating weathering of food packaging polyethylene-nano-clay composites: release of nanoparticles and their impacts. NanoImpact. 2018;9:61–71. doi: 10.1016/j.impact.2017.10.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ipsen R., Otte J. Self-assembly of partially hydrolysed α-lactalbumin. Biotechnol. Adv. 2007;25:602–605. doi: 10.1016/j.biotechadv.2007.07.006. [DOI] [PubMed] [Google Scholar]

- Jafari S.M., McClements D.J. Nanotechnology approaches for increasing nutrient bioavailability. Adv. Food Nutr. Res. 2017;81:1–30. doi: 10.1016/bs.afnr.2016.12.008. [DOI] [PubMed] [Google Scholar]

- Jafarzadeh S., Alias A., Ariffin F., Mahmud S. Characterization of semolina protein film with incorporated zinc oxide nano rod intended for food packaging. Pol. J. Food Nutr. Sci. 2017;67:183–190. [Google Scholar]

- Kalita D., Baruah S. Nanomaterials Applications for Environmental Matrices. Elsevier; 2019. The impact of nanotechnology on food; pp. 369–379. [Google Scholar]

- Kamarulzaman N.A., Lee K.E., Siow K.S., Mokhtar M. Public benefit and risk perceptions of nanotechnology development: psychological and sociological aspects. Technol. Soc. 2020;62:101329. [Google Scholar]

- Katouzian I., Jafari S.M. Nano-encapsulation as a promising approach for targeted delivery and controlled release of vitamins. Tren. Food Sci. Technol. 2016;53:34–48. [Google Scholar]

- Khodakovskaya M., Dervishi E., Mahmood M., Xu Y., Li Z., Watanabe F., Biris A.S. Carbon nanotubes are able to penetrate plant seed coat and dramatically affect seed germination and plant growth. ACS Nano. 2009;3:3221–3227. doi: 10.1021/nn900887m. [DOI] [PubMed] [Google Scholar]

- Khota L.R., Sankarana S., Majaa J.M., Ehsania R., Schuster E.W. Applications of nanomaterials in agricultural production and crop protection: a review. Crop Protect. 2012;35:64–70. [Google Scholar]

- Kim J.Y., Han S., Hong S. Effect of modified carbon nanotube on the properties of aromatic polyester nanocomposites. Polymer. 2008;49:3335–3345. [Google Scholar]

- Kim K.D., Han D.N., Lee J.B., Kim H.T. Formation and characterization of Ag-deposited TiO2 nanoparticles by chemical reduction method. Scripta Mater. 2006;54:143–146. [Google Scholar]

- Krishna V., Pumprueg S., Lee S.-H., Zhao J., Sigmund W., Koopman B., Moudgil B. Photocatalytic disinfection with titanium dioxide coated multi-wall carbon nanotubes. Process Saf. Environ. Protect. 2005;83:393–397. [Google Scholar]

- Kumar S., Shukla A., Baul P.P., Mitra A., Halder D. Biodegradable hybrid nanocomposites of chitosan/gelatin and silver nanoparticles for active food packaging applications. Food Packag. Shelf Life. 2018;16:178–184. [Google Scholar]

- Levy-Sakin M., Ebenstein Y. Beyond sequencing: optical mapping of DNA in the age of nanotechnology and nanoscopy. Curr. Opin. Biotechnol. 2013;24(4):690–698. doi: 10.1016/j.copbio.2013.01.009. [DOI] [PubMed] [Google Scholar]

- Lewicka Z.A., Oliva B.L., Yu W.W., Colvin V.L. Photochemical behavior of nanoscale TiO2 and ZnO sunscreen ingredients. J. Photochem. Photobiol. Chem. 2013;263:24–33. [Google Scholar]

- Li L., Zhao C., Zhang Y., Yao J., Yang W., Hu Q., Wang C., Cao C. Effect of stable antimicrobial nano-silver packaging on inhibiting mildew and in storage of rice. Food Chem. 2017;215:477–482. doi: 10.1016/j.foodchem.2016.08.013. [DOI] [PubMed] [Google Scholar]

- Mali S.C., Raj S., Trivedi R. Nanotechnology a novel approach to enhance crop productivity. Biochem. Biophys. Rep. 2020;24:100821. doi: 10.1016/j.bbrep.2020.100821. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Martínez-Bueno M., Hernando M., Uclés S., Rajski L., Cimmino S., Fernández-Alba A. Identification of non-intentionally added substances in food packaging nano films by gas and liquid chromatography coupled to orbitrap mass spectrometry. Talanta. 2017;172:68–77. doi: 10.1016/j.talanta.2017.05.023. [DOI] [PubMed] [Google Scholar]

- Mastronardi E., Tsae P., Zhang X., Monreal C., DeRosa M.C. Nanotechnologies in Food and Agriculture. Springer; Cham: 2015. Strategic role of nanotechnology in fertilizers: potential and limitations; pp. 25–67. [Google Scholar]

- Mazloomi F., Jalali M. Effects of vermiculite, nanoclay and zeolite on ammonium transport through saturated sandy loam soil: column experiments and modeling approaches. Catena. 2019;176:170–180. [Google Scholar]

- Medeiros B.G.D.S., Souza M.P., Pinheiro A.C., Bourbon A.I., Cerqueira M.A., Vicente A.A., Carneiro-Da-Cunha M.G. Physical characterisation of an alginate/lysozyme nano-laminate coating and its evaluation on ‘Coalho’cheese shelf life. Food Bioprocess Technol. 2014;7:1088–1098. [Google Scholar]

- Mihindukulasuriya S., Lim L.-T. Nanotechnology development in food packaging: a review. Tren. Food Sci. Technol. 2014;40:149–167. [Google Scholar]

- Moustafa H., Youssef A.M., Darwish N.A., Abou-Kandil A.I. Eco-friendly polymer composites for green packaging: future vision and challenges. Compos. B Eng. 2019;172:16–25. [Google Scholar]

- Mozafari M.R., Johnson C., Hatziantoniou S., Demetzos C. Nanoliposomes and their applications in food nanotechnology. J. Liposome Res. 2008;18:309–327. doi: 10.1080/08982100802465941. [DOI] [PubMed] [Google Scholar]

- Mustafa F., Andreescu S. Nanotechnology-based approaches for food sensing and packaging applications. RSC Adv. 2020;10(33):19309–19336. doi: 10.1039/d0ra01084g. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Naderi M., Danesh-Shahraki A. Nanofertilizers and their roles in sustainable agriculture. Intl. J. Agric. Crop Sci. 2013;5:2229. [Google Scholar]

- Narei H., Ghasempour R., Akhavan O. In: Carbon Nanotube-Reinforced Polymers: from Nanoscale to Macroscale. Rafiee R., editor. Elsevier; 2017. Toxicity and safety issues of carbon nanotubes; pp. 145–171. [Google Scholar]

- Neethirajan S., Jayas D.S. Nanotech nology for the food and bioprocessing industries. Food Bioprocess Technol. 2011;4:39–47. doi: 10.1007/s11947-010-0328-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ndlovu N., Mayaya T., Muitire C., Munyengwa N. Nanotechnology applications in crop production and food systems. Int. J. Plant Breed. Crop Sci. 2020;7(1):624–634. [Google Scholar]

- Nile S.H., Baskar V., Selvaraj D., Nile A., Xiao J., Kai G. Nanotechnologies in food science: applications, recent trends, and future perspectives. Nano-Micro Lett. 2020;12:45. doi: 10.1007/s40820-020-0383-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Noorbakhsh-Soltani S., Zerafat M., Sabbaghi S. A comparative study of gelatin and starch-based nano-composite films modified by nano-cellulose and chitosan for food packaging applications. Carbohydr. Polym. 2018;189:48–55. doi: 10.1016/j.carbpol.2018.02.012. [DOI] [PubMed] [Google Scholar]

- Pathakoti K., Manubolu M., Hwang H.-M. Nanostructures: current uses and future applications in food science. J. Food Drug Anal. 2017;25:245–253. doi: 10.1016/j.jfda.2017.02.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Peters R.J., Bouwmeester H., Gottardo S., Amenta V., Arena M., Brandhoff P., Marvin H.J., Mech A., Moniz F.B., Pesudo L.Q. Nanomaterials for products and application in agriculture, feed and food. Trends Food Sci. Technol. 2016;54:155–164. [Google Scholar]

- Pinto R.J., Daina S., Sadocco P., Neto C.P., Trindade T. Antibacterial activity of nanocomposites of copper and cellulose. BioMed Res. Int. 2013;280512 doi: 10.1155/2013/280512. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Potocnik J. Commission of the European Communities; Brussels: 2005. Nanosciences and Nanotechnologies: an Action Plan for Europe 2005-2009; pp. 1–16. [Google Scholar]

- Potocnik J. The European commission: commission recommendation of 18 October 2011 on the definition of nanomaterial. Off. J. Eur. Union. 2011;275:38–40. [Google Scholar]

- Prakash J., Sun S., Swart H.C., Gupta R.K. Noble metals-TiO2 nanocomposites: from fundamental mechanisms to photocatalysis, surface enhanced Raman scattering and antibacterial applications. Appl. Mater. Today. 2018;11:82–135. [Google Scholar]

- Prasad R., Bhattacharyya A., Nguyen Q.D. Nanotechnology in sustainable agriculture: recent developments, challenges, and perspectives. Front. Microbiol. 2017;8:1014. doi: 10.3389/fmicb.2017.01014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Prasad R., Kumar M., Kumar V. Springer Nature; Singapore: 2017. Nanotechnology: an Agricultural Paradigm; p. 371. [Google Scholar]

- Rai V., Acharya S., Dey N. Implications of nanobiosensors in agriculture. J. Biomater. Nanobiotechnol. 2012;3:315. [Google Scholar]

- Rajput V., Minkina T., Mazarji M., Shende S., Sushkova S., Mandzhieva S., Burachevskaya M., Chaplygin V., Singh A., Jatav H. Accumulation of nanoparticles in the soil-plant systems and their effects on human health. Ann. Agric. Sci. 2020;65:137–143. [Google Scholar]

- Ramachandraiah K., Han S.G., Chin K.B. Nanotechnology in meat processing and packaging: potential applications — a review. Asian-Australas. J. Anim. Sci. 2015;28:290–302. doi: 10.5713/ajas.14.0607. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rashidi L., Khosravi-Darani K. The applications of nanotechnology in food industry. Crit. Rev. Food Sci. Nutr. 2011;51:723–730. doi: 10.1080/10408391003785417. [DOI] [PubMed] [Google Scholar]

- Ravichandran R. Nanotechnology applications in food and food processing: innovative green approaches, opportunities and uncertainties for global market. Int. J. Green Nanotechnol. Phys. Chem. 2010;1:P72–P96. [Google Scholar]

- Rehmanullah Muhammad Z., Inayat N., Majeed A. In: New Frontiers in Stress Management for Durable Agriculture. Rakshit A., Singh H., Singh A., Singh U., Fraceto L., editors. Springer; Singapore: 2020. Application of nanoparticles in agriculture as fertilizers and pesticides: challenges and opportunities. [Google Scholar]

- Rieger K.A., Eagan N.M., Schiffman J.D. Encapsulation of cinnamaldehyde into nanostructured chitosan films. J. Appl. Polym. Sci. 2015;132:41739. [Google Scholar]

- Roohinejad S., Greiner R. In: Nanotechnology in Agriculture and Food Science. Axelos M.A., Van De Voorde M., editors. John Wiley & Sons; 2017. Nanoscience: relevance for agriculture and the food sector; pp. 347–362. [Google Scholar]

- Rossi M., Passeri D., Sinibaldi A., Angjellari M., Tamburri E., Sorbo A., Carata E., Dini L. Nanotechnology for food packaging and food quality assessment. Adv. Food Nutr. Res. 2017;82:149–204. doi: 10.1016/bs.afnr.2017.01.002. [DOI] [PubMed] [Google Scholar]

- Sadeghi R., Rodriguez R.J., Yao Y., Kokini J.L. Advances in nanotechnology as they pertain to food and agriculture: benefits and risks. Annu. Rev. Food Sci. Technol. 2017;8:467–492. doi: 10.1146/annurev-food-041715-033338. [DOI] [PubMed] [Google Scholar]

- Safari J., Zarnegar Z. Advanced drug delivery systems: nanotechnology of health design A review. J. Saudi Chem. Soc. 2014;18(2):85–99. [Google Scholar]

- Sangeetha J., Thangadurai D., Hospet R., Purushotham P., Karekalammanavar G., Mundaragi A.C., David M., Shinge M.R., Thimmappa S.C., Prasad R. Springer; Singapore: 2017. Agricultural Nanotechnology: Concepts, Benefits, and Risks. Nanotechnology; pp. 1–17. [Google Scholar]

- Sangeetha J., Hospet R., Thangadurai D., Adetunji C.O., Islam S., Pujari N., Al-Tawaha A.R.M.S. In: Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications. Kharissova O.V., Martínez L.M.T., Kharisov B.I., editors. Springer; Cham: 2021. Nanopesticides, nanoherbicides, and nanofertilizers: the greener aspects of agrochemical synthesis using nanotools and nanoprocesses toward sustainable agriculture. [Google Scholar]

- Sanguansri P., Augustin M.A. Nanoscale materials development–a food industry perspective. Trends Food Sci. Technol. 2006;17:547–556. [Google Scholar]

- Sastry K., Rashmi H., Rao N. Nanotechnology patents as R&D indicators for disease management strategies in agriculture. J. Intellec. Prop. Rights. 2010;15:197–205. [Google Scholar]

- Sastry R.K., Rashmi H., Rao N. Nanotechnology for enhancing food security in India. Food Pol. 2011;36:391–400. [Google Scholar]

- Scanlon S., Aggeli A. Self-assembling peptide nanotubes. Nano Today. 2008;3:22–30. [Google Scholar]

- Scott N. Nanotechnology and animal health. Rev. Sci. Tech. Off. Int. Epiz. 2005;24:425–432. doi: 10.20506/rst.24.1.1579. [DOI] [PubMed] [Google Scholar]

- Sekhon B.S. Food nanotechnology–an overview. Nanotechnol. Sci. Appl. 2010;3:1–15. [PMC free article] [PubMed] [Google Scholar]

- Sekhon B.S. Nanotechnology in agri-food production: an overview. Nanotechnol. Sci. Appl. 2014;7:31–53. doi: 10.2147/NSA.S39406. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharma C., Dhiman R., Rokana N., Panwar H. Nanotechnology: an untapped resource for food packaging. Front. Microbiol. 2017;8:1735. doi: 10.3389/fmicb.2017.01735. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharon M., Choudhary A.K., Kumar R. Nanotechnology in agricultural diseases and food safety. J. Phytol. 2010;2:83–92. [Google Scholar]

- Shi S., Wang W., Liu L., Wu S., Wei Y., Li W. Effect of chitosan/nano-silica coating on the physicochemical characteristics of longan fruit under ambient temperature. J. Food Eng. 2013;118:125–131. [Google Scholar]

- Shibata T. U.S. Patent 6,416,803; 2002. Method for Producing green tea in Microfine Powder. [Google Scholar]

- Singh H., Sharma A., Kumar S., Arya S.K., Bhardwaj N., Khatri M. Recent Advances in Applications of Nano-Agrochemicals for Sustainable Agricultural Development. Environ. Sci. Process. Impact. 2021 doi: 10.1039/d0em00404a. [DOI] [PubMed] [Google Scholar]

- Singh T., Shukla S., Kumar P., Wahla V., Bajpai V.K., Rather I.A. Application of nanotechnology in food science: perception and overview. Front. Microbiol. 2017;8:1501. doi: 10.3389/fmicb.2017.01501. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sivarethinamohan R., Sujatha S. vol. 2327. AIP Publishing LLC; 2021. Unlocking the potentials of using nanotechnology to stabilize agriculture and food production; p. 20022. (AIP Conference Proceedings). No. 1. [Google Scholar]

- Sogvar O.B., Saba M.K., Emamifar A., Hallaj R. Influence of nano-ZnO on microbial growth, bioactive content and postharvest quality of strawberries during storage. Innovat. Food Sci. Emerg. Technol. 2016;35:168–176. [Google Scholar]

- Sozer N., Kokini J.L. Nanotechnology and its applications in the food sector. Trends Biotechnol. 2009;27:82–89. doi: 10.1016/j.tibtech.2008.10.010. [DOI] [PubMed] [Google Scholar]

- Torney F., Trewyn B.G., Lin V.S.-Y., Wang K. Mesoporous silica nanoparticles deliver DNA and chemicals into plants. Nat. Nanotechnol. 2007;2:295. doi: 10.1038/nnano.2007.108. [DOI] [PubMed] [Google Scholar]

- Ubbink J., Krüger J. Physical approaches for the delivery of active ingredients in foods. Trends Food Sci. Technol. 2006;17:244–254. [Google Scholar]

- Wang Y., Deng C., Rawat S., Cota-Ruiz K., Medina-Velo I., Gardea-Torresdey J.L. Evaluation of the effects of nanomaterials on rice (oryza sativa L.) responses: underlining the benefits of nanotechnology for agricultural applications. ACS Agri. Sci. Technol. 2021;1(2):44–54. [Google Scholar]

- Warriner K., Reddy S.M., Namvar A., Neethirajan S. Developments in nanoparticles for use in biosensors to assess food safety and quality. Trends Food Sci. Technol. 2014;40:183–199. [Google Scholar]

- Weiss J., Takhistov P., Mcclements D.J. Functional materials in food nanotechnology. J. Food Sci. 2006;71:R107–R116. [Google Scholar]