Abstract

With declaring the highly transmissible COVID-19 as a pandemic, an unprecedented strain on healthcare infrastructures worldwide occurred. An enormous shortage in the personal protective equipment (PPE) and the spare parts (SP) for the mechanical ventilators ensued as a consequence of the failure of the centralized global supply chains. Additive manufacturing and Industrial Internet of Things (IIoT), as the pillars of Industry 4.0, arose as the robust noncentralized alternatives. When gathered and properly managed in the IIoT, 3D Printers (3DPs) can complement and support Healthcare 4.0 to face the current and future pandemics. Thus, this paper proposes a real-time green allocation and scheduling architecture designed and dedicated particularly for the large-scale distributed 3D printing tasks (3DPTs) of both PPE and SPs. Our proposed architecture comprises; a broker (B) and a cluster manager (CM). Dynamic status check for the 3DPs and admission control for 3DPTs are among the interconnected roles of CM. CM also performs task allocation and scheduling according to our proposed Online Ascending Load-Balancing Modified Best-Fit (OALMBF) allocation algorithm and Green Real-time Nesting Priority-Based Adaptive (GRNPA) scheduling algorithm. The performance of the proposed architecture was investigated under extremely high-load environments which resulted in a success ratio and a response rate of 99.9667% and 10.9665 seconds, respectively, for the 3000 3DPTs trial. These results proved the robustness and the scalability of our architecture that surpasses its state-of-the-art counterparts. Besides respecting the real-time requirements of the 3DPTs, the proposed architecture improves the utilization of the 3DPs and guarantees an even workload distribution.

Keywords: 3D printing, COVID-19, Healthcare 40, IIoT, Industry 40, nesting, scheduling

I. Introduction

COVID-19, a highly infectious disease with pneumonia-like symptoms caused by the novel severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), was declared as a global pandemic by the World Health Organization (WHO) only after three months into 2020. This virus is of the genus Betacoronavirus (

-CoV) that caused the two recent previous outbreaks of Severe Acute Respiratory Syndrome (SARS) and Middle East Respiratory Syndrome (MERS) [1]–[9].

-CoV) that caused the two recent previous outbreaks of Severe Acute Respiratory Syndrome (SARS) and Middle East Respiratory Syndrome (MERS) [1]–[9].

With its rapid transmissibility and the nonexistence of a clinically approved vaccine or antiviral drug, COVID-19 took aback the worldwide scientific, medical, and industrial communities. Globally, containment and mitigation are considered the keystones in managing this pandemic. With varying degrees of success in suppressing and eradicating this pandemic, most of the countries of the world are facing severe disruptions in the medical and economic sectors [1], [3].

Globally, health organizations are recommending social or physical distancing in order to flatten the curve of the new infections and thus avoiding the deluge of healthcare systems. Unfortunately, the results of this practice may take weeks to arise. Moreover, despite the technology and experience levels that each healthcare system has reached, the huge and rapid upsurge in the number of patients overwhelmed the medical infrastructure worldwide. In normal situations, this challenge would be faced by preplanned strategies such as stockpiling equipment, supplies, and medications. However, the sudden emergence of the highly infectious COVID-19 caused an enormous strain on the healthcare systems and hospitals worldwide to the extent that most of them have reported shortages of fundamental equipment such as ventilators for critically ill patients and personal protective equipment (PPE) for the front-line healthcare workers which include face shields, respirators, face masks, gloves, and gowns [10]–[14].

The current situation advocates the employment of Healthcare 4.0 concepts to help alleviate the direct or indirect negative consequences of the COVID-19 pandemic on the medical services and thus improving the healthcare provision [4]. Healthcare 4.0 represents the era of smart virtual personalized medicine and it is inspired by the fourth industrial revolution, namely, Industry 4.0. Shifting from the conventional hospital-centric care to a timely, virtual, decentralized care system, with the help of some concepts of Industry 4.0, is the leading principle of Healthcare 4.0. This shift is achieved by employing the emerging technologies of Internet of Things (IoT), artificial intelligence-enabled diagnostic tools, deep learning, blockchain, big data, wireless biosensors, wearable devices, telemedicine, home-based personalized healthcare, remotely triggered medications, mobile applications, robotics, and bioprinting of tissues and implants [15]–[24]. Integrating and implementing the suitable concepts of Healthcare 4.0 to face the COVID-19 crisis would help in reducing the physical crowding of patients in hospitals and the physical interactions between patients and physicians. Moreover, it would help in monitoring, caring, and delivering proper medications for mild symptoms COVID-19 patients while quarantined or isolated at their own homes, thus making room for the critically ill COVID-19 patients to be hospitalized. Owing to implementing some of these concepts, several countries managed to avoid the surge of the COVID-19 pandemic, thus saving not only more lives but also their economy as a consequence [1], [3], [4], [7], [8], [14].

On the other hand, the COVID-19 pandemic has triggered an unprecedented call for adopting all the newly emerging technologies of all fields to collaborate and help in this battle. This unsurpassed situation has proven the effectiveness of the transformation in the concept of manufacturing from traditional centralized, long lead-time, large-scale production to decentralized, distributed, rapid, small-scale, autonomous production. This shift represents the building block of Industry 4.0. By employing the foundations of Industry 4.0 such as artificial intelligence, big data analytics, blockchain, Industrial IoT (IIoT), cloud computing, cyber-physical systems, and additive manufacturing (AM), the current COVID-19 challenges can be tamed [1], [4], [10], [14], [25]–[30].

During the COVID-19 battle, surmounting the critical shortages of medical supplies arose as a priority. Additive manufacturing or 3D printing, a fundamental foundation of Industry 4.0, proved its robustness as an alternative to the traditional global supply chains that failed to meet the time-critical rapidly growing medical needs. 3D printing is a distributed, low-cost, on-demand, time-critical production technique. Employing the 3D printing technique in this battle led to the rapid scale-up production of PPE such as face shields, respirators, and face masks [12], [15], [16]. Moreover, 3D printing participated in manufacturing spare parts (SPs) for the mechanical ventilators and nasal swaps [16].

COVID-19 is a battle that must be won. The vulnerability of the global supply chains that have been exposed, as a result of their failure in meeting the critically growing demand of both PPE and SPs, proved to the world the unreliability of this system. Hence, the world resorted to arm with all the emerging digital technologies to overcome this crisis. From this perspective, this paper proposes employing the pillars of industry 4.0; IIoT, and AM; to gear up Healthcare 4.0 to face the consequences of the current and future pandemics. By gathering and intelligently managing the distributed 3DPs in the IIoT, these severe shortages can be defeated. Hence, to the authors’ best knowledge for the first time in literature, a real-time green 3D printing tasks’ (3DPTs) allocation and scheduling architecture tailored for the high load environments caused by the severe shortage of PPE and SPs is proposed. This architecture is divided into two folds, broker and cluster manager with each performing several interconnected roles. Besides, the proposed architecture employs our two built algorithms for allocating and scheduling large-scale 3D printing tasks, namely, Online Ascending Load-balancing Modified Best-Fit (OALMBF) allocation algorithm and Green Real-time Nesting Priority-based Adaptive (GRNPA) scheduling algorithm. Moreover, the proposed architecture not only balances the workload between the distributed 3D printers (3DPs) but also maximizes their utilization.

The rest of this paper is arranged as follows. Section 2 reviews the literature. In Section 3 the system model preliminaries are presented and the proposed architecture is explained. The simulation results are presented in section 4 along with the results of the comparisons with state-of-the-art architectures. The whole study is concluded in Section 5.

II. Related Work

Due to its high transmissibility, COVID-19 caused a huge and rapid increase in the number of patients that deluged the healthcare systems worldwide. The ravage in the medical infrastructure reached the extent of reporting shortages of essential medical supplies such as PPE and SPs for the ventilators. As a result, the manufacturing sector was put under huge stress and once again the conventional global supply chain proved its fragility and unreliability in critical times. Distributed 3D printing communities and companies collaborated to mitigate the negative consequences of the failure of the global supply chain system [10], [12], [31]–[35]. Moreover, the National Institutes of Health (NIH), Veterans Affairs (VA), the FDA, and America Makes joined forces to support the response of the 3D printing communities by establishing an online repository for sharing the clinically assessed 3D-printable designs [26], [36]–[38]. Thus, 3D printing proved its reliability in providing on-demand time-critical parts. In that light, when the distributed 3D printing services are gathered and properly managed in the IIoT, the production of these essential PPE and SPs will be controlled and the aspired success levels of meeting the large-scale 3D printing demands can be achieved.

In the literature, several papers presented architectures to manage the distributed 3D printing services in the CMFg (summarized in Table. 1). These papers studied the allocation and scheduling of a limited number of static 3D printing orders. Moreover, these papers proposed printing only one single part at a time. Zhou et al. [39] proposed a genetic algorithm-based service matching and selection method for 50 static 3D printing tasks and 100 3D printing service providers in the CMFg. Attributes of the 3D printing tasks such as model size, printing accuracy, printing material, printing cost, printing time, and logistics were included. In another study by Zhou et al. [40] an improved genetic algorithm-based 3D printing service scheduling method was proposed using the same aforementioned matching attributes. The simulations in their study included 60 static 3D printing tasks and 50 3D printing service providers. Luo et al. [41] proposed a bipartite graph-based matching framework for cloud 3D printing. The matching characteristics of both the 3D printing tasks and the printing resources were included along with the static and dynamic characteristics of the printers. Their simulations were done on a total number of 100 3D printing tasks and 50 groups of 3D printing resources. Wu et al. [45] proposed a cloud platform for distributed 3D printing services. Their service evaluation model and optimization algorithms are based on the fuzzy theory.

TABLE 1. Summary of the Literature Review.

| Author | Allocation | Scheduling | Nesting | 3DPs’dynamic status check | Admission control | Number of tasks | Number of 3DPs | Static | Dynamic (Real-time) | Used algorithms | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Zhou et al. | Yes | No | No | No | No | 50 | 100 | Yes | No | Genetic algorithm-based method. | [39] |

| Zhou et al. | Yes | Yes | No | No | No | 60 | 50 | Yes | No | Improved genetic algorithm-based method. | [40] |

| Luo et al. | Yes | No | No | Yes | No | 100 | 50 | Yes | No | Bipartite graph-based matching framework. | [41] |

| Li et al. | Yes | Yes | Yes | No | No | 660 | 6 | Yes | No | Best fit and adapted best-fit algorithms. | [42] |

| Chergui et al. | Yes | Yes | Yes | No | No | 200 | 28 | Yes | No | Mixed-Integer Linear Programming (MILP) model, and Earliest Due Date (EED) scheduling rule. | [43] |

| Kucukkoc et al. | Yes | Yes | Yes | No | No | 200 | 6 | Yes | No | MILP model. | [44] |

On the other hand, 3D printing machines can print more than one part simultaneously at the same time on the same build plate/platform, this technique is called nesting. The set of parts that will be nested and 3D printed at the same time is called a job. Li et al. [42] explored grouping different parts received from different customers and allocating them to a 3D printer to be printed at the same time as a single job, thus reducing the average printing costs. Two heuristic algorithms, namely, best fit and adapted best-fit algorithms were used to find the optimum solution for this problem. Chergui et al. [43] studied the same problem as well but took into consideration respecting the delivery times set by the customers for each part. The authors employed the mixed-integer linear programming (MILP) model to solve their scheduling and nesting problems. Moreover, Kucukkoc et al. [44] explored the same nesting and scheduling problems. The authors employed MILP models to solve the scheduling problems of single and multiple either identical or non-identical AM machines while considering minimizing the makespan.

Due to the ongoing COVID-19 crisis and the disruptions in the global supply chains, that entailed the emergence of many individual assistance attempts offered by the 3D printing services within each country worldwide to face this unprecedented shortage of essential equipment, an urgent call for a system that can intelligently gather, manage, and control all these efforts has arisen. In this context, we propose, to the authors’ best knowledge for the first time in literature, a real-time green allocation and scheduling architecture for distributed 3D printing tasks tailored to meet the huge demand of medical supplies represented by PPE and SPs for the mechanical ventilators during the COVID-19 pandemic. The proposed architecture is divided into two folds, namely, broker (B), and cluster manager (CM) with each fold performing several interconnected roles.

Our proposed architecture is noteworthy as it tackles the following aspects:

-

1)

Proposing a robust noncentralized alternative to the global supply chains that can withstand high load situations.

-

2)Proposing two algorithms for the real-time allocation and scheduling of the dynamic 3D printing tasks with evolving scenarios:

-

a.Online Ascending Load-balancing Modified Best Fit (OALMBF) allocation algorithm; and

-

b.Green Real-time Nesting Priority-based Adaptive (GRNPA) scheduling algorithm.

-

a.

-

3)

Respecting the real-time requirements of each 3D printing task.

-

4)

Building and employing an admission control algorithm to ensure the non-violation of the real-time requirements of all the tasks.

-

5)

Proposing nesting identical 3DPTs received from different demanders while respecting the constraints of the maximum printing area of each 3D printer and the real-time requirements for each task.

-

6)

Building and integrating a workload balancing algorithm to ensure the even distribution of the tasks among the 3D printing services.

-

7)

Improving the utilization of the distributed 3D printers by integrating working time limits and resting times for each 3D printer.

-

8)

Building and integrating a dynamic health status check algorithm for the 3D printers to rapidly compensate for the potential failure in any 3D printer.

III. The Proposed System Model

A. System Model Preliminaries

During the current COVID-19 crisis and its consequences that caused a huge shortage in PPE and spare parts for the mechanical ventilators, the demand for 3D printed alternatives has been raised. Therefore, this paper proposes a green real-time allocation and scheduling architecture for the real-time remote ordering of both PPE and spare parts. Throughout this paper, a 3DPT will refer to a 3D printing task or an order submitted to the IIoT system by the demander. The two terms 3DPT and order will be used interchangeably. Table. 2 presents all the notations and parameters used throughout this study. Each 3DPT is subdivided into the model type of the required part and its corresponding attributes. As a restriction, the system allows the demander to choose only one model type in each 3DPT. Nevertheless, each demander can submit more than one order and each order has a specific model. Along with choosing the model type of the required 3DPT from the database/library of the platform, the demander specifies its corresponding attributes. These attributes include the number of the required parts, priority, and the deadline for receiving the order. Each demander is allowed to specify any number of parts within each submitted 3DPT. The longitude and latitude of the location of the device (laptop, tablet, mobile) that has been used to place the order will be detected and used as the delivery address. This detected address is subject to change or modification by the demander.

TABLE 2. List of Notations.

| Notation | Description | Value |

|---|---|---|

|

Traffic load growth rate | {0.4, 0.9} |

|

Arrival rate | {0.25,5,10} |

|

Initial workload | {0.9} |

|

Standard deviation | {5} |

3DPT

|

A 3D printing task | [400,3000] |

| Px | Printer number x | |

|

The number of the printer | [1,60] |

| Current | At time t | |

| Prev | At time t-1 | |

rnk rnk |

The rank of a 3DPT in the ready queue of a 3DP | |

| PR | The priority of a 3DPT | [1,5] |

| cat | The category of both 3DPs and 3DPTs | {PPE, SP} |

| MN | Maximum Number | |

| LP | Lower Priority 3DPT | |

|

A 3DPT can be nested with other jobs | |

| NN | A 3DPT cannot be nested with other jobs | |

| sub | Sub-task | |

| NP | Number of parts in each 3DPT | |

| NPL | Number of parts’ limit for each 3DP | |

| PV | Printing volume | |

| PVL | Printing volume limit | |

| RT | Resting time of a 3DP | |

|

Arrival time of a 3DPT | |

|

Starting time of a 3DPT | |

|

Printing time of a 3DPT | |

|

Actual printing time of a 3DPT | |

|

Delivery time of a 3DPT | |

|

Finishing time of a 3DPT | |

|

Logistics time | |

|

Time constants of a 3DP | |

|

Warm-up time of a 3DP | [8,10] min |

|

Cooling-down time of a 3DP | [4,9] min |

|

Take-down time of a 3DP | [1,3] min |

| WTS | Working time summation of a 3DP | |

| WTL | Working time limit of a 3DP | |

| RWT | Remaining working time of a 3DP | |

| DL | Deadline for a 3DPT | |

|

Distance between a demander and a 3DP | |

Speed

|

The logistics speed | 60 km/hr |

| Lg | Longitude of a location | |

| Lat | Latitude of a location | |

| LT | The last task in the ready queue of a 3DP | |

| mt | Model type of a 3DPT |

The models that are incorporated in the database/library are divided into two types categories; protectives, and spare parts. The protectives category includes different models of face shields, respirators, ear savers for face masks, nasal swaps, and sanitizer/soap automatic dispensers. The spare parts category includes all the models of the needed spare parts for the mechanical ventilators.

On the other hand, each 3D printer incorporated in the system is dedicated to print parts from a certain category. In other words, the 3DPs are divided into two clusters with each cluster dedicated to print either protectives or spare parts. Besides, each 3D printer has its specific attributes. These attributes include its location, time constants (heating up, cooling down, and taking down), working time limit, and resting time duration. Moreover, the system’s 3DPs have a prespecified limit of the maximum number of parts (NPL) that can be printed simultaneously on the build plate/platform of each. This limit is specified according to the average maximum permissible printing volume of the available 3DPs.

Besides, throughout this paper, the process of printing more than one identical 3DPT simultaneously on the build plate/platform of any 3DP will be called nesting. Also, the set of 3DPTs that will be combined and printed in the same batch will be called a job.

B. The Proposed System Architecture Model

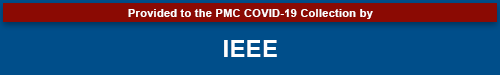

The proposed system, which has an overall running time complexity of

, is divided into a broker (B) and a cluster manager (CM) as illustrated in Fig. 1. This section provides a detailed description of B and CM.

, is divided into a broker (B) and a cluster manager (CM) as illustrated in Fig. 1. This section provides a detailed description of B and CM.

FIGURE 1.

The proposed system.

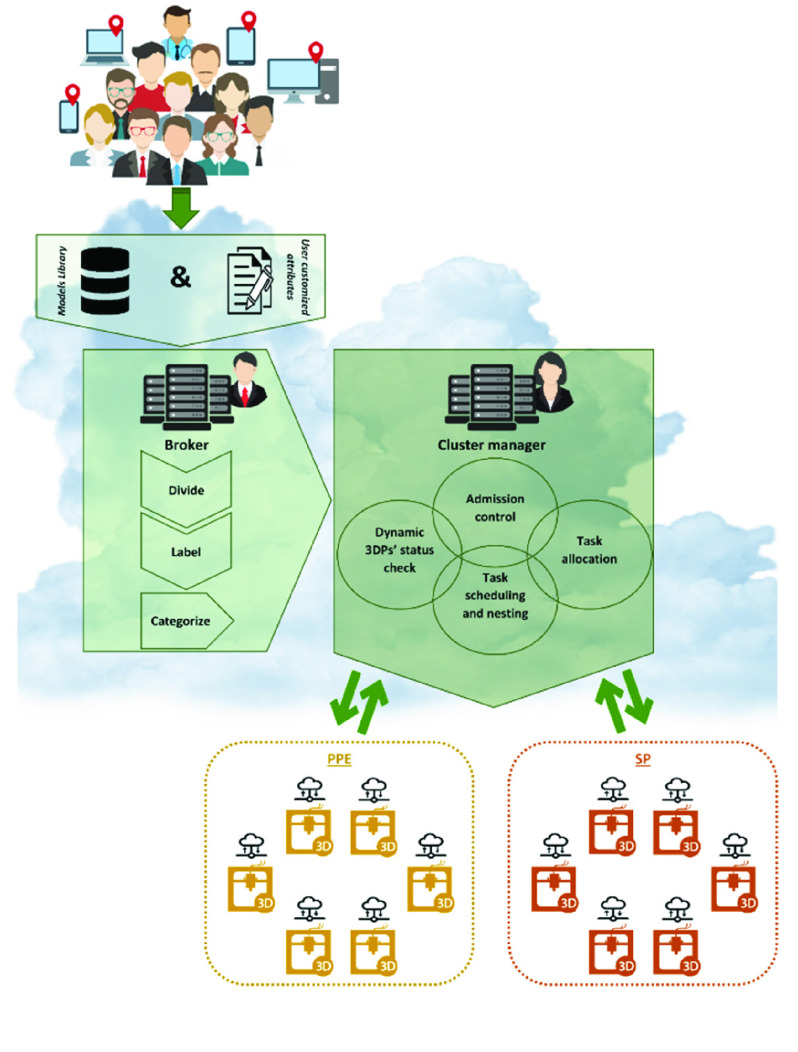

1). The Broker (B)

The broker has three roles as shown in Fig. 2. The first role of the broker is to divide the submitted 3DPTs which include a large number of identical models that exceed the system’s prespecified limit of the maximum number of parts (NPL) into subtasks. These subtasks are within the system’s 3D printing volume limit (PVL) and they will all share the same user-defined attributes of priority, deadline for receiving the order, and delivery address. The second role is to label each 3DPT or subtask either to “be nested” or not. The 3DPT or subtask is labeled “to be nested” if the number of the parts within this order is lower than 90% of the max predefined limit (NPL). Otherwise, it is labeled “not to be nested” thus it will be printed as a single job. The third role is to allocate each 3DPT or subtask to its corresponding cluster of 3DPs.

FIGURE 2.

Flowchart of the proposed broker.

2). The Cluster Manager (CM)

The cluster manager performs several interconnected roles which include a dynamic status check for the 3DPs, admission control, task allocation, and task scheduling and nesting.

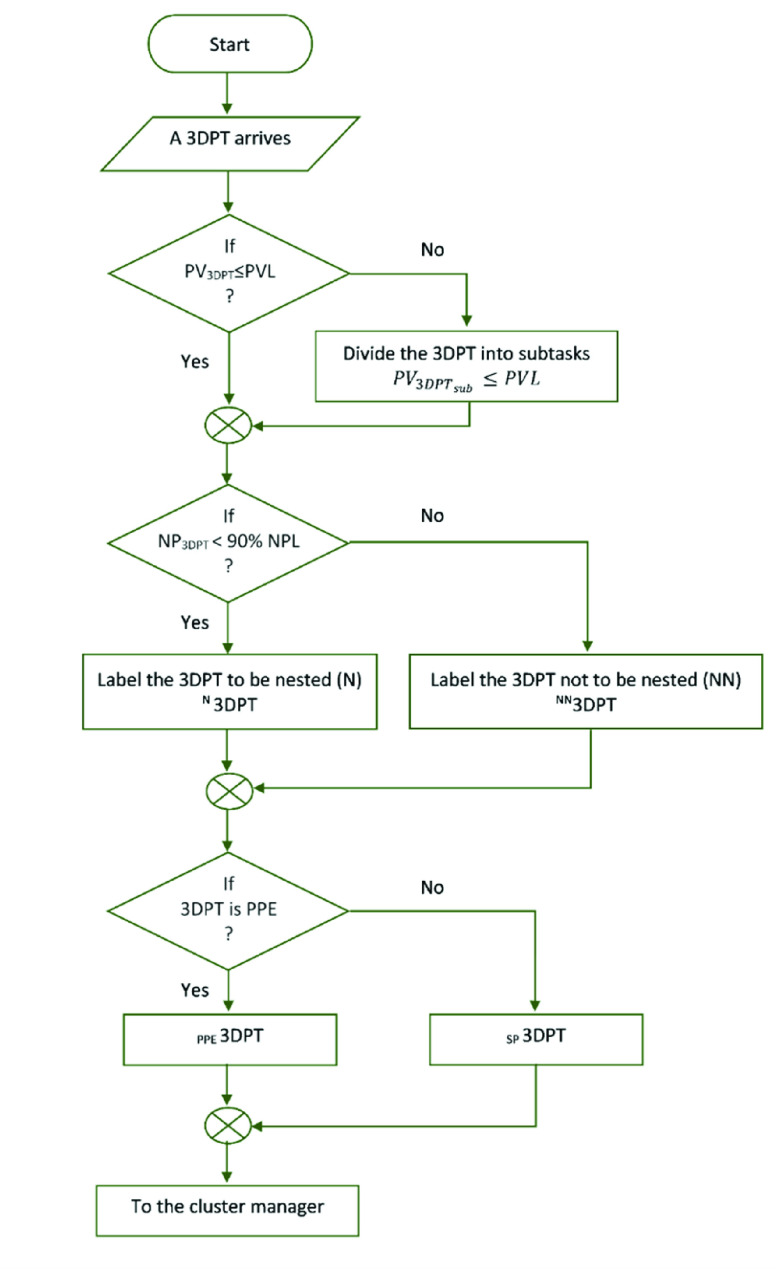

a: Dynamic Status Check for the 3DPs

The cluster manager has statistical data about each 3DP in the system. These data are divided into constants and time changing values. The constants are the working time limits (WTL) and the resting time durations (RT). The dynamic values that change with time are the remaining working times (RWT) and the working time summations (WTS). According to these constant and dynamic values, the cluster manager updates the status of each 3DP at each time tick to be either “waiting for 3DPTs”, “printing a 3DPT”, “resting/in maintenance”, or “back from rest”. Besides, the working time summation is updated by the cluster manager and set to zero and the remaining working time is set to its default value when the 3DP’s status is “back from rest”. Fig. 3. illustrates the algorithm of the dynamic status check.

FIGURE 3.

The proposed dynamic status check algorithm for the system’s 3DPs.

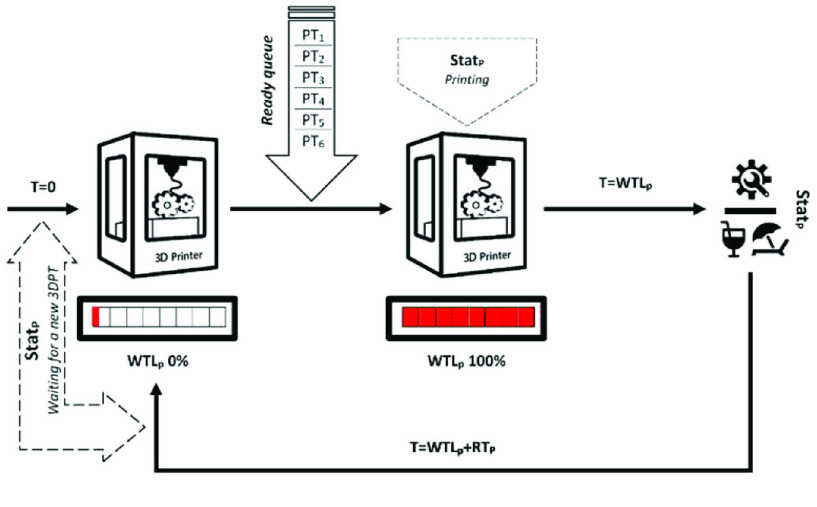

b: Admission Control

Our paper proposes a priority-based admission control algorithm. This admission control is not performed once a 3DPT has been submitted to the system. The cluster manager temporarily accepts all the submitted tasks regardless of their priorities as there is no prior knowledge of the upcoming 3DPTs or their priorities.

Each 3DP in the system has a “Ready Queue” that contains the 3DPTs that are successfully allocated and scheduled and ready to be printed on this 3DP. Moreover, the cluster manager places the 3DPT that did not find any vacant time slot in the “Ready Queues” of all the available 3DPs, after its first allocation and scheduling round, in a “Global Waiting Queue”.

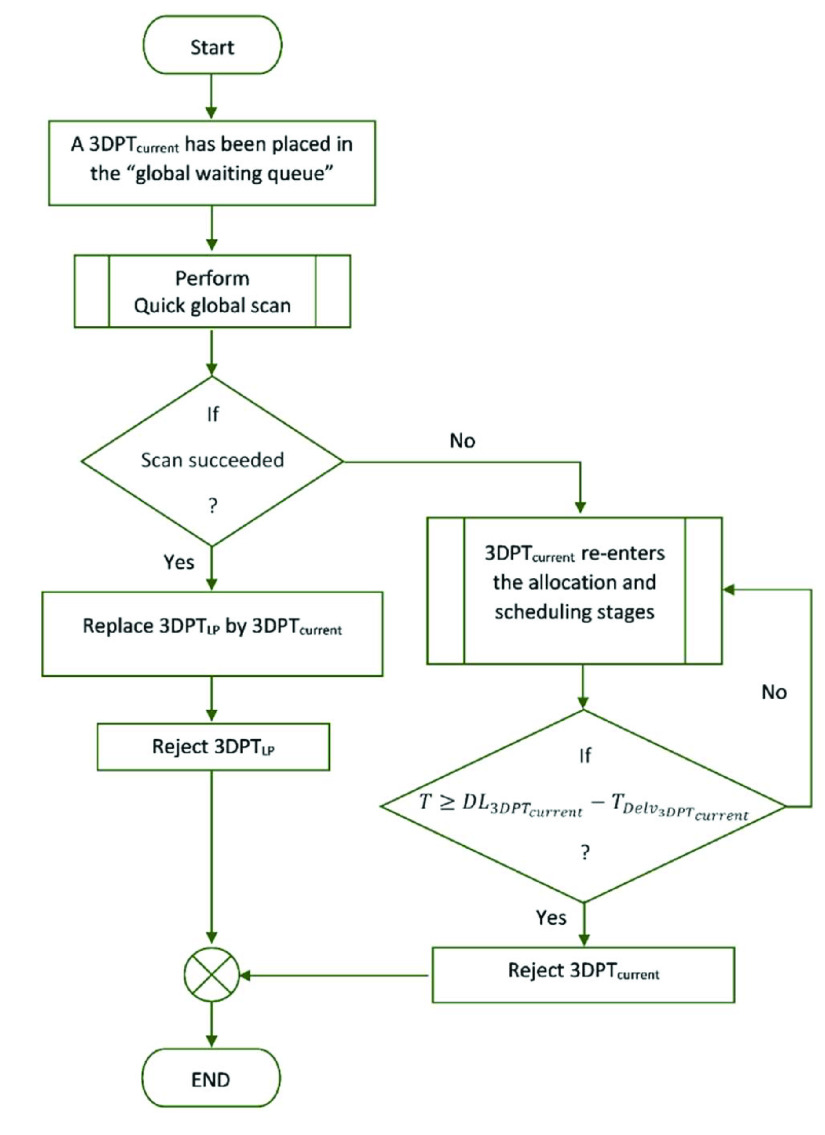

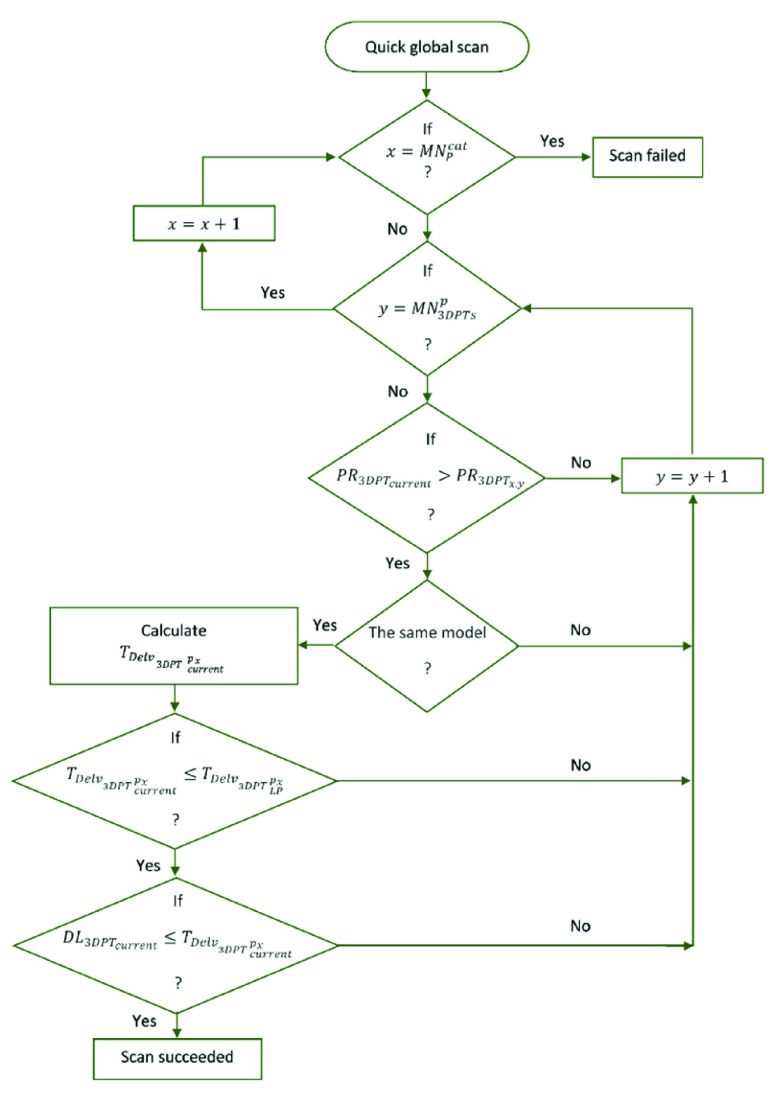

The admission control algorithm, shown in Figs. 4 and 5, is applied once a task is added to this “Global Waiting Queue” by performing a “Quick Global Scan” to the “Ready Queue” of each available 3DP to find a 3DPT that demands to print the same model with the same or higher time requirements but with a lower priority. If this global scan succeeded, then the lower priority task will be replaced with the task with the higher priority. Then, the lower priority task will be rejected. On the other hand, if the global scan failed, the 3DPT is kept in the “Global Waiting Queue”. The 3DPTs in the Global Waiting Queue re-enter the allocation and scheduling stages, which are described in the following sections, to find proper alternative 3DPs. The admission control algorithm rejects the 3DPTs that are kept in the “Global Waiting Queue” before approaching their deadline by a sufficient time that enables the execution of these tasks in any other 3D printing system.

FIGURE 4.

Flowchart of the proposed admission control algorithm.

FIGURE 5.

Flowchart of the proposed “Quick Global Scan” algorithm.

c: Task Allocation

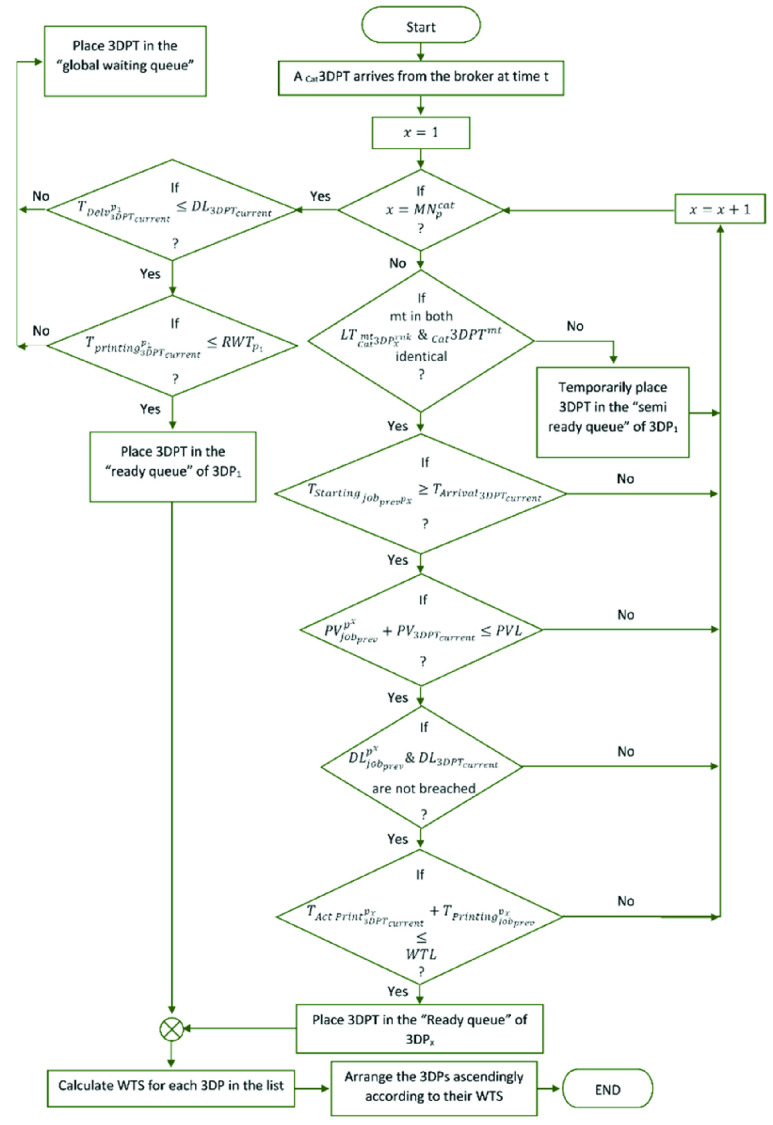

Fig. 6 illustrates the proposed algorithms for the allocation, scheduling, and nesting of the 3DPTs. The cluster manager allocates the received 3DPTs by employing our proposed online ascending load-balancing modified best fit (OALMBF) allocation algorithm.

FIGURE 6.

Flowchart of the proposed allocation, scheduling, and nesting algorithms.

The proposed OALMBF allocation algorithm is a modification of the Best-Fit Decreasing (BFD) bin-packing algorithm. Bin packing is an NP-hard combinatorial optimization problem. In bin-packing, the main goal is to pack N items with sizes in the range [0, 1] into the smallest possible number of bins such that the maximum capacity of each bin is 1 [46]–[52]. In its offline version, all the items are known from the beginning. On the other hand, in the online version of this problem, the items appear one at a time and each item must be assigned to a bin upon its arrival without any prior knowledge about the next items [46], [47], [53]–[55]. Best Fit Decreasing (BFD) is one of the heuristic algorithms that are used to solve this problem in its offline version. In the BFD, the items are sorted in decreasing order of size, then each item is assigned to the fullest bin in which it fits [47], [48], [56], [57]. In this paper, we propose modifications to the BFD to cope with the online nature of our problem.

In this paper, the items are the 3DPTs and the bins are the 3DPs. In our proposed OALMBF allocation algorithm, the 3DPTs that come at the same time are arranged in descending order according to their printing times. Unlike the ordinary algorithms used to solve the Bin Packing Problem (BPP) with the goal of minimizing the number of the used bins, our algorithm is designed to balance the workload between the available 3DPs in a manner that prevents either overloading or underloading a certain 3DP. Thus, to achieve this, the 3DPs are arranged in ascending order according to their working time summation at each time tick. Once the system receives a new 3DPT, it is allocated to the first 3DP in the arranged 3DPs’ list of its corresponding cluster.

d: Task Scheduling and Nesting

The cluster manager (CM) schedules the received 3DPTs by employing our proposed Green Real-time Nesting Priority-based Adaptive (GRNPA) scheduling algorithm. Our GRNPA scheduling algorithm proposes nesting more than one 3DPT consisting of identical models to be printed simultaneously using the same 3DP as a single job. This nesting process will be performed under certain constraints:

-

1)

The 3DPT is labeled “to be nested”.

-

2)

The different 3DPTs to be nested consist of identical models.

-

3)The whole volume needed for printing the job after adding the 3DPT is within the 3D printing volume limit (PVL) of the system’s 3DPs.

-

4)The 3DPT has arrived before the printing starting time of the previous job/task that it will be nested with.

-

5)The deadlines of the whole tasks included in this job, after adding this 3DPT, from the first task to the last task are not violated

-

6)The working time limit of the 3DP is not breached

If any of the 3DPTs labeled “to be nested” fails to meet one of these constraints, the cluster manager places this task in the “Semi-Ready Queue” of the first 3DP meanwhile resends this 3DPT to the allocation stage. In this reallocation, a search is done within the alternative 3DPs in the list respectively to find a suitable alternative job of identical models for this 3DPT to be nested with. If the 3DPT fails to be nested in any of the jobs of the alternative 3DPs, the cluster manager transfers this task from the “Semi-Ready Queue” of the first allocated 3DP to the “Ready Queue” of the same 3DP to be scheduled for printing as a new job if the following constraints are fulfilled:

-

1)Deadline

-

2)Working time limit (WTL)

If one of these constraints is not fulfilled the cluster manager places this task in the “Global Waiting Queue”.

On the other hand, in scheduling a 3DPT labeled “not to be nested”, this task is successfully allocated and scheduled in the “Ready Queue” of the first 3DP in the 3DPs’ arranged list and is printed as a whole new single job if it fulfills the previously described constraints of deadline and working time limit. If this 3DPT fails to fulfill any of these constraints, the cluster manager resends it to the allocator to assign it to the next 3DP in the arranged list. If all the reallocation trials fail, then the cluster manager places this task in the “Global Waiting Queue”.

IV. System Performance Evaluation

This section explores the performance and scalability of the proposed architecture. The simulations are done by using MATLAB Ⓡ R2019B. The times employed in these simulations are generated according to the following equations.

-

1)1 Arrival time: The task arrival times of the 3DPTs/orders are generated sequentially according to (10) which depends on the arrival rate (

).

).

where,

is the arrival time of the previous 3DPT, and

is the arrival time of the previous 3DPT, and

is a Gaussian random number with mean

is a Gaussian random number with mean

and variance

and variance

.

. -

2)Deadline: The deadline for each 3DPT is generated according to (11) which depends on the workload specification represented by

and

and

.

.

The delivery time

is calculated as in (12) to (17).

is calculated as in (12) to (17).

|

In the calculations of the deadline, it has been assumed that the 3DPT will be printed once it arrives.

|

Moreover, the values of the different parameters engaged in this study are randomly generated within the ranges specified in table. 2.

The conducted simulations aim at investigating the effect of changing the following parameters on the performance of the proposed architecture:

-

1)

Number of 3DPTs: The performance of our proposed system is tested under extremely high demanding environments, for the first time in literature according to the authors’ best knowledge. Therefore, this parameter is changed from 400 up to 3000 3DPT.

-

2)

Workload Specification: The traffic load growth rate (

) is one of the two parameters that represent the workload specification. The performance of our proposed system is monitored by varying the value of this parameter from

) is one of the two parameters that represent the workload specification. The performance of our proposed system is monitored by varying the value of this parameter from

for the normal workload situations to

for the normal workload situations to

for the high workload situations while adjusting the initial workload (

for the high workload situations while adjusting the initial workload (

) at 0.9.

) at 0.9. -

3)

Arrival Rate: The performance of our proposed system is monitored by varying the task arrival rate from

(a task every four ticks) to

(a task every four ticks) to

(a task every 0.1 tick).

(a task every 0.1 tick).

On the other hand, throughout this study, the number of 3DPs is fixed at 60 printers. All the graphs plot the average values obtained over 5 runs for each simulation trial. Performance metrics used throughout this study include:

-

1)

Response Rate (s): The time duration elapsed from the receipt of a 3DPT to its successful allocation and scheduling on the ready queue of one of the system’s 3DPs.

-

2)

Success Ratio (%): The ratio of the number of 3DPTs that have met their predefined deadlines to the total number of the accepted 3DPTs.

-

3)

Rejection Ratio (%): The ratio of the number of the rejected 3DPTs to the total number of the submitted 3DPTs.

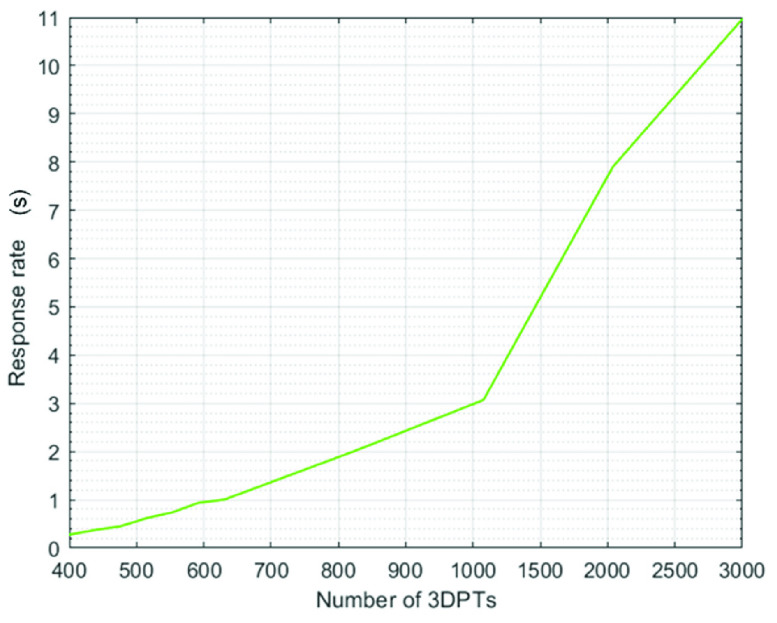

A. Response Rate

Increasing the number of 3DPTs increases the response rate of the proposed architecture as depicted in Fig. 7 10.9665 seconds represents the highest average response rate for our proposed system at the highest traffic load growth rate (

) and the maximum number of 3DPTs of 3000.

) and the maximum number of 3DPTs of 3000.

FIGURE 7.

The effect of increasing the number of 3DPTs on the average response rate of the proposed system. (

).

).

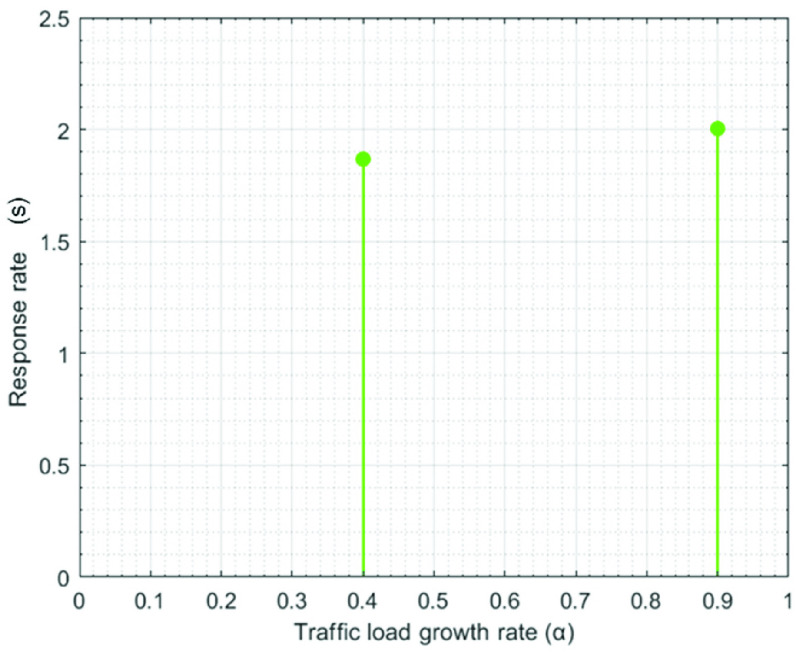

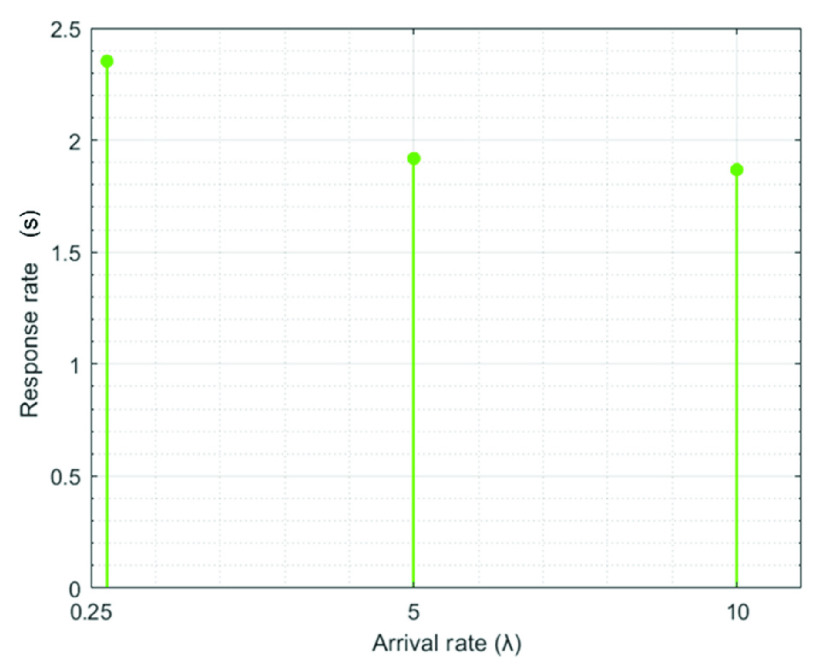

Moreover, as shown in Figs. 8 and 9 the proposed system copes with the evolving scenarios of the dynamic 3DPTs. Hence, the average response rate of the proposed architecture is highly dependent on both the workload specification of the submitted 3DPTs represented by

and the arrival rate

and the arrival rate

of the 3DPTs. Therefore, increasing the traffic load growth rate (

of the 3DPTs. Therefore, increasing the traffic load growth rate (

) increases the response rate to reach an average of 2.0039 seconds per task for the

) increases the response rate to reach an average of 2.0039 seconds per task for the

and 1500 3DPTs trials. On the contrary, increasing the arrival rate (

and 1500 3DPTs trials. On the contrary, increasing the arrival rate (

) of the 3DPTs lowers the response rate to reach an average of 1.8678 seconds per task for the

) of the 3DPTs lowers the response rate to reach an average of 1.8678 seconds per task for the

and 1500 3DPTs trials.

and 1500 3DPTs trials.

FIGURE 8.

The effect of increasing the traffic load growth rate (

) on the average response rate of the proposed system. (3DPTs

) on the average response rate of the proposed system. (3DPTs

).

).

FIGURE 9.

The effect of increasing the arrival rate of the 3DPTs (

) on the average response rate of the proposed system. (3DPTs

) on the average response rate of the proposed system. (3DPTs

).

).

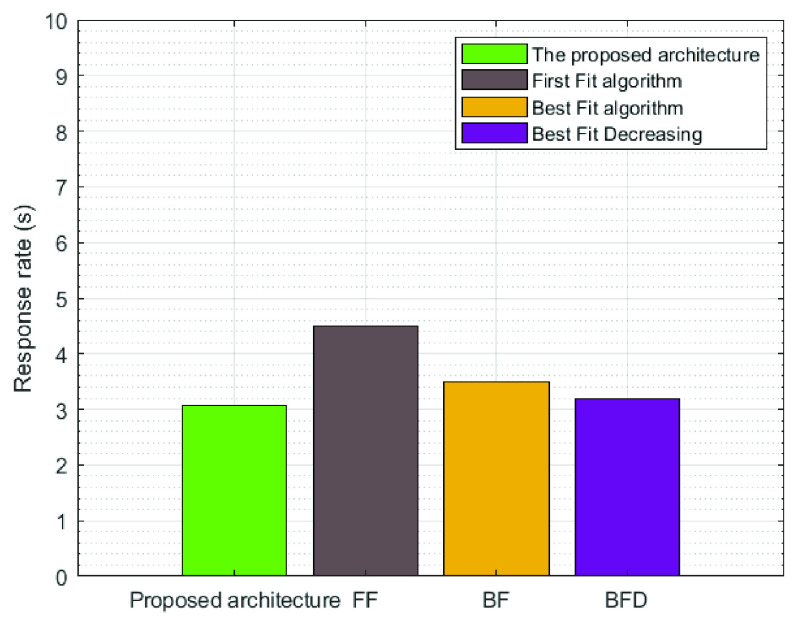

Fig. 10 shows a comparison between the average response rate of our proposed system and the average response rate of the same system when employing each of the First Fit (FF) algorithm, the Best-Fit (BF) algorithm, and the Best Fit Decreasing (BFD) algorithm instead of our proposed OALMBF allocation algorithm. It can be deduced from this figure that our proposed system has the most rapid response when compared to these algorithms. The rapid response property of our proposed system nominates it to be implemented in the IIoT highly dynamic scenarios.

FIGURE 10.

A comparison between the average response rate of the proposed architecture, the First Fit algorithm, the Best-Fit algorithm, and the Best Fit Decreasing algorithm. (3DPTs

).

).

B. Success Ratio

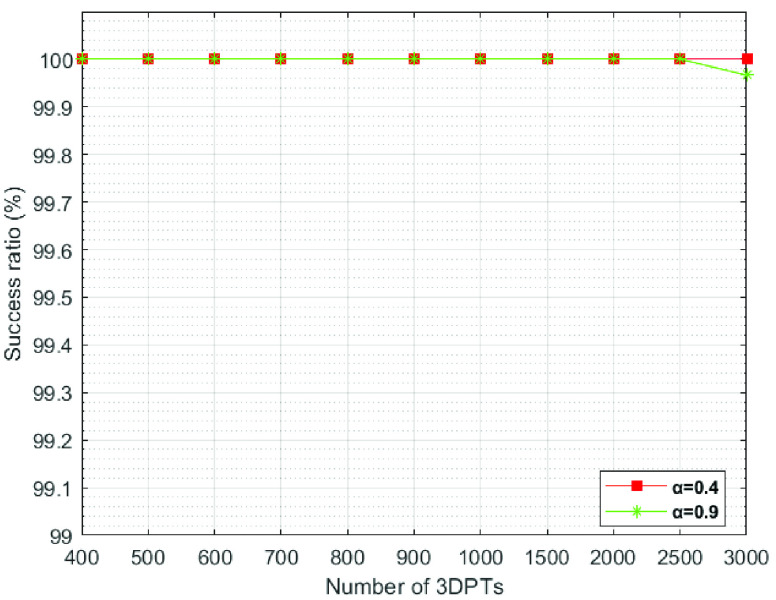

Fig. 11 shows the effect of increasing both the number of 3DPTs and the traffic load growth rate (

) on the average success ratio of the proposed system. At the normal traffic load growth rate (

) on the average success ratio of the proposed system. At the normal traffic load growth rate (

) increasing the number of the 3DPTs up to 3000 tasks did not affect the success ratio. However, increasing the number of the 3DPTs at the high traffic load growth rate (

) increasing the number of the 3DPTs up to 3000 tasks did not affect the success ratio. However, increasing the number of the 3DPTs at the high traffic load growth rate (

) led to a slight deterioration in the success ratio to reach an average of 99.9667% for the 3000 3DPTs trials. However, increasing the arrival rate

) led to a slight deterioration in the success ratio to reach an average of 99.9667% for the 3000 3DPTs trials. However, increasing the arrival rate

does not affect the average success ratio of the proposed architecture.

does not affect the average success ratio of the proposed architecture.

FIGURE 11.

The effect of increasing both the number of 3DPTs and the traffic load growth rate (

) on the success ratio of the proposed architecture. (

) on the success ratio of the proposed architecture. (

).

).

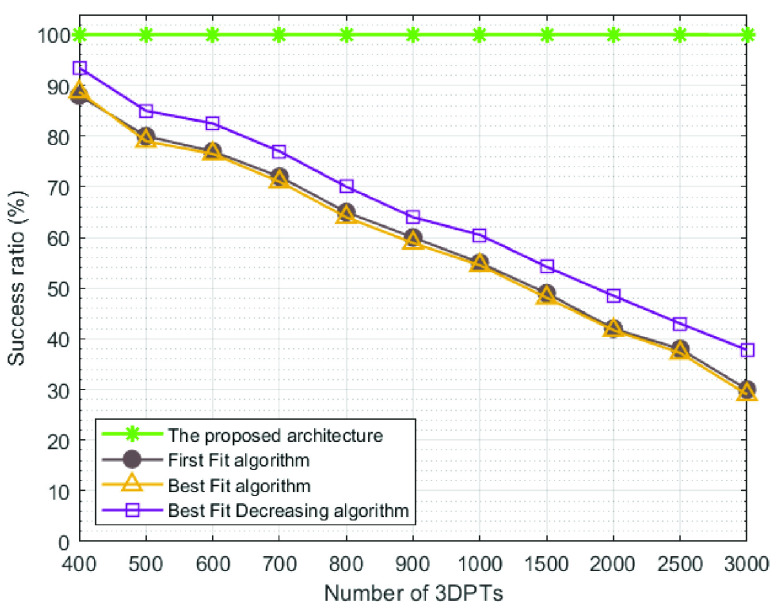

Fig. 12 shows a comparison between the average success ratio of our proposed system which employs our proposed OALMBF allocation algorithm and the average success ratio of the same system after replacing the OALMBF allocation algorithm with other allocation algorithms such as FF, BF, and BFD. This improvement in the success ratio (%) of our proposed system, that can be deduced from this figure, highlights its robustness especially in extremely high demanding environments.

FIGURE 12.

A comparison between the average success ratio (%) of the proposed architecture, the First Fit algorithm, the Best-Fit algorithm, and the Best Fit Decreasing algorithm. (

).

).

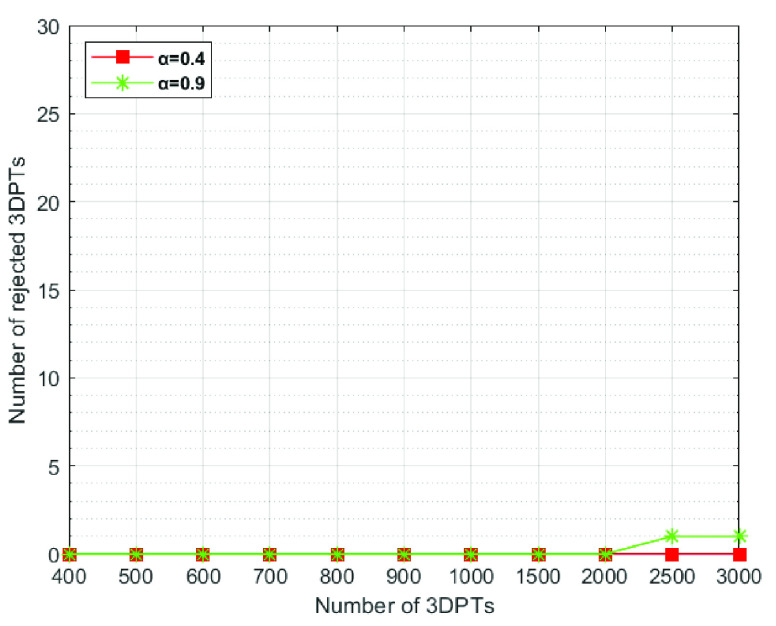

C. Rejection Ratio

As shown in Fig. 13 increasing both the number of 3DPTs and the traffic load growth rate

causes a slight increase in the average rejection ratio when the number of the 3DPTs reaches 2500. Increasing the number of 3DPTs up to 3000 did not cause a further increase. On the contrary, increasing the arrival rate of the 3DPTs does not affect the rejection ratio of the proposed architecture.

causes a slight increase in the average rejection ratio when the number of the 3DPTs reaches 2500. Increasing the number of 3DPTs up to 3000 did not cause a further increase. On the contrary, increasing the arrival rate of the 3DPTs does not affect the rejection ratio of the proposed architecture.

FIGURE 13.

The effect of increasing both the number of 3DPTs and the traffic load growth rate (

) on the average number of the rejected 3DPTs. (

) on the average number of the rejected 3DPTs. (

).

).

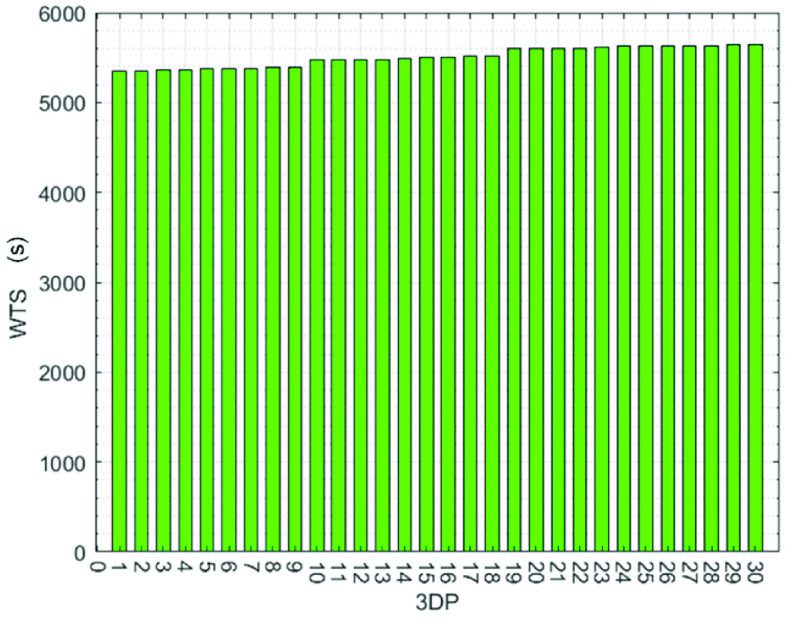

D. Load Balancing

Fig. 14 shows the average working time summation (WTS) for each 3DP in the list of the available 3DPs in the spare parts’ category. WTS represents the distribution of the 3DPTs on the 3DPs. It can be deduced from this figure that the 3DPTs are distributed among the 3DPs without either overloading or underloading certain 3DPS. This load balancing has been achieved as a result of applying our proposed OALMBF allocation algorithm and the 3DPs’ resting time algorithm

FIGURE 14.

The average working time summation (WTS) of each 3DP in the list of the 3DPs that are dedicated to print protectives. (3DPTs

).

).

V. Conclusion

This paper proposed a real-time green allocation and scheduling architecture tailored for the large-scale 3D printing demands of PPE and SPs during the current COVID-19 pandemic. By employing the pillar of Industry 4.0 represented by IIoT and AM, the proposed architecture was designed especially for facing the failure of the centralized global supply chains that led to a severe shortage in the PPE and SPs during the current and future crises. Our proposed architecture is divided into two folds, namely, broker and cluster manager. Both the broker and the cluster manager perform several roles. Dynamic status check for the 3DPs, admission control, task allocation, and task scheduling were among the interconnected roles of the cluster manager. Besides, this paper proposed the Online Ascending Load-Balancing Modified Best-Fit (OALMBF) allocation algorithm and the Green Realtime Nesting Priority-based Adaptive (GRNPA) scheduling algorithm. These two algorithms were employed by the cluster manager in the task allocation and task scheduling phases. Simulation results proved the robustness and the scalability of our proposed architecture particularly under high load environments that surpassed its state-of-the-art counterparts. Moreover, our proposed system not only improved the utilization of the 3DPs but also balanced the workload between them. As our study contributes to an evolving research field, it could be extended by employing various newly emerging algorithms such as game theory.

Biographies

Lamis R. Darwish received the B.Sc. and M.Sc. degrees in biomedical engineering from Helwan University, Cairo, Egypt, in 2009 and 2014, respectively, where she is currently pursuing the Ph.D. degree in biomedical engineering.

Since 2012, she has been a Research Assistant with the Mechanical Engineering Department, The American University in Cairo (AUC), Cairo. Her research interest includes real-time algorithms, Industrial Internet of Things (IIoT), Healthcare 4.0, Industry 4.0, bioprinting, biodegradable biomaterials, biodegradable bone implants, and natural fiber composites.

Mahmoud M. Farag received the B.Sc. degree in mechanical engineering from Cairo University and the M.Met. and Ph.D. degrees from the University of Sheffield, U.K.

He was a Visiting Scientist/Scholar with the University of Sheffield, U.K.; MIT, USA; the University of Kentucky-Lexington, USA; Aachen Technical University, Germany; and the Joint Research Center, Commission of the European Communities, Ispra, Italy. He currently serves as a Professor of Mechanical Engineering with The American University in Cairo (AUC). His academic interests include engineering materials and manufacturing. He has published four engineering textbooks, edited one book, and written several engineering book chapters. He has also authored or coauthored more than 100 papers in academic journals and conference proceedings on issues related to the effect of processing on the behavior of engineering materials. His current research interests include studying the behavior of nanostructured materials, with an emphasis on NiTi alloys, natural fiber-reinforced plastics, and biodegradable composite materials and using quantitative methods in selecting materials and processes for engineering applications. In addition to his academic work, he has extensive industrial and consulting experience. He has more than 45 years of teaching experience and has taught a variety of materials courses at different levels, ranging from introductory overview to sophomore/junior students to advanced topics to students pursuing their master’s degree. He has also taught manufacturing courses, focusing on how processing affects the properties of materials. Dr. Farag is a member of the American Society of Mechanical Engineers, the Materials Information Society, the American Society for Metals (ASM) International, the Institute of Materials, Minerals, and Mining, U.K., and the Egyptian Society for Engineers. He is listed in Marquis Who’s Who in the World, Who’s Who in Science and Engineering, and Who’s Who in Finance and Industry. He was a recipient of the Egyptian State Award for the promotion of science and the First Order of Merit in Arts and Sciences.

Mohamed T. El-Wakad was born in Cairo, Egypt, in 1953. He received the B.S. degree in mechanical engineering from Helwan University, the M.Sc. degree in medical engineering from The George Washington University, Washington, USA, in 1981, and the Ph.D. degree in biomedical engineering from Rensselaer Polytechnic Institute, Troy, NY, USA, in 1988.

From 1988 to 2013, he climbed the academic and administration ladder at the Faculty of Engineering, Helwan University, from Assistant Professor to Professor and Vice-Dean through acting Biomedical Engineering Department Head. From 2013 to 2019, he was the Head of Faculty at the Quality and Accreditation Unit. Since 2019, he has been the Vice Dean of the Faculty of Engineering & Technology, Future University in Egypt. He was on sabbatical leave from Oman (1997–2000) and Saudi Arabia (2004–2010). He carried out research activities in several international, regional, and national academic institutes in USA and Saudi Arabia. These institutions include RPI, Future University in Egypt (FUE), and the 10th of Ramadan Technological Institute. He established a strong research link initially with the Faculty of Oral and Dental Medicine, Cairo University, and later with similar faculties at Ain Shams, Tanta, and Minia Universities. His research interests include the biomechanics of dental prosthetic devices using strain gauge technology and finite element analysis (FEA), biomaterials for prosthetic devices, and rehabilitation equipment. He has published more than 50 scientific papers in high impact peer-reviewed journals as well as international, regional, and national conferences in USA, Germany, Belgium, Italy, Saudi Arabia, Qatar, and Egypt.

Dr. El-Wakad was the PI and Co-I member in several funded research projects in USA, Saudi Arabia, and Egypt. He served as a reviewer in several international conferences and journals as well as a referee in the promotion committees in Egypt. He is a reviewer at National Association for Quality Assurance and Accreditation (NAQAA), Head of team-establishing BME standards for Egyptian Ministry of Higher Education, and an Expert at the Quality Assurance & Accreditation Center, Helwan University.

References

- [1].Whitelaw S., Mamas M. A., Topol E., and Van Spall H. G. C., “Applications of digital technology in COVID-19 pandemic planning and response,” Lancet Digit. Heal., vol. 2, no. 8, pp. e435–e440, Aug. 2020, doi: 10.1016/S2589-7500(20)30142-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [2].Gulati A., Pomeranz C., Qamar Z., Thomas S., Frisch D., George G., Summer R., DeSimone J., and Sundaram B., “A comprehensive review of manifestations of novel coronaviruses in the context of deadly COVID-19 global pandemic,” Amer. J. Med. Sci., vol. 360, no. 1, pp. 5–34, Jul. 2020, doi: 10.1016/j.amjms.2020.05.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [3].Chettri S., Debnath D., and Devi P., “Leveraging digital tools and technologies to alleviate COVID-19 pandemic,” SSRN Electron. J., Jun. 2020, doi: 10.2139/ssrn.3626092. [DOI]

- [4].Golinelli D., Boetto E., Carullo G., Nuzzolese A. G., Landini M. P., and Fantini M. P., “How the COVID-19 pandemic is favoring the adoption of digital technologies in healthcare: A literature review,” medRxiv, Jan. 2020, doi:.[Online].Available:https://doi.org/10.1101/2020.04.26.20080341 [DOI] [PMC free article] [PubMed]

- [5].Ortiz-Prado E., Simbaña-Rivera K., Gómez- Barreno L., Rubio-Neira M., Guaman L. P., Kyriakidis N. C., Muslin C., Jaramillo A. M. G., Barba-Ostria C., Cevallos-Robalino D., Sanches-SanMiguel H., Unigarro L., Zalakeviciute R., Gadian N., and López-Cortés A., “Clinical, molecular, and epidemiological characterization of the SARS-CoV-2 virus and the coronavirus disease 2019 (COVID-19), a comprehensive literature review,” Diagnostic Microbiol. Infectious Disease, vol. 98, no. 1, Sep. 2020, Art. no.115094, doi: 10.1016/j.diagmicrobio.2020.115094. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [6].Lai C.-C., Liu Y. H., Wang C.-Y., Wang Y.-H., Hsueh S.-C., Yen M.-Y., Ko W.-C., and Hsueh P.-R., “Asymptomatic carrier state, acute respiratory disease, and pneumonia due to severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2): Facts and myths,” J. Microbiol., Immunol. Infection, vol. 53, no. 3, pp. 404–412, Jun. 2020, doi: 10.1016/j.jmii.2020.02.012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [7].Rahman M. S., Peeri N. C., Shrestha N., Zaki R., Haque U., and Hamid S. H. A., “Defending against the novel coronavirus (COVID-19) outbreak: How can the Internet of Things (IoT) help to save the world?” Health Policy Technol., vol. 9, no. 2, pp. 136–138, Jun. 2020, doi: 10.1016/j.hlpt.2020.04.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [8].Ting D. S. W., Carin L., Dzau V., and Wong T. Y., “Digital technology and COVID-19,” Nature Med., vol. 26, no. 4, pp. 459–461, Apr. 2020, doi: 10.1038/s41591-020-0824-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Li H., Liu S.-M., Yu X.-H., Tang S.-L., and Tang C.-K., “Coronavirus disease 2019 (COVID-19): Current status and future perspectives,” Int. J. Antimicrobial Agents, vol. 55, no. 5, May 2020, Art. no.105951, doi: 10.1016/j.ijantimicag.2020.105951. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Pearce J. M., “Distributed manufacturing of open source medical hardware for pandemics,” J. Manuf. Mater. Process., vol. 4, no. 2, p. 49, May 2020, doi: 10.3390/jmmp4020049. [DOI] [Google Scholar]

- [11].The Organisation for Economic Co-operation and Development. (Feb. 2020). Flattening the Covid-19 Peak?: Containment and Mitigation Policies Flattening the COVID-19 Peak?: Containment and Mitigation Policies. [Online]. Available: https://read.oecd-ilibrary.org/view/?ref=124_124999-yt5ggxirhc&title=Flattening_the_COVID-19_peak-Containment_and_mitigation_policies

- [12].Flanagan S. T. and Ballard D. H., “3D printed face shields: A community response to the COVID-19 global pandemic,” Academic Radiol., vol. 27, no. 6, pp. 905–906, Jun. 2020, doi: 10.1016/j.acra.2020.04.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [13].Ranney M. L., Griffeth V., and Jha A. K., “Critical supply shortages—The need for ventilators and personal protective equipment during the covid-19 pandemic,” New England J. Med., vol. 382, no. 18, p. e41, Apr. 2020, doi: 10.1056/NEJMp2006141. [DOI] [PubMed] [Google Scholar]

- [14].Vaishya R., Haleem A., Vaish A., and Javaid M., “Emerging technologies to combat the COVID-19 pandemic,” J. Clin. Experim. Hepatol., vol. 10, no. 4, pp. 409–411, Jul. 2020, doi: 10.1016/j.jceh.2020.04.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15].Thuemmler C. and Bai C., Health 4.0: How Virtualization and Big Data are Revolutionizing Healthcare. Cham, Switzerland: Springer, 2017. [Google Scholar]

- [16].Monteiro A. C. B., França R. P., Estrela V. V., Iano Y., Khelassi A., and Razmjooy N., “Health 4.0: Applications, management, technologies and review type of article: Review,” Med. Technol. J., vol. 2, no. 4, pp. 262–276, 2019, doi: 10.26415/2572-004X-vol2iss1p262-276. [DOI] [Google Scholar]

- [17].Jayaraman P. P., Forkan A. R. M., Morshed A., Haghighi P. D., and Kang Y., “Healthcare 4.0: A review of frontiers in digital health,” WIREs Data Mining Knowl. Discovery, vol. 10, no. 2, pp. 1–23, Mar. 2020, doi: 10.1002/widm.1350. [DOI] [Google Scholar]

- [18].Chen C., Loh E.-W., Kuo K. N., and Tam K.-W., “The times they are a-Changin–healthcare 4.0 is coming!,” J. Med. Syst., vol. 44, no. 2, pp. 40–44, Feb. 2020, doi: 10.1007/s10916-019-1513-0. [DOI] [PubMed] [Google Scholar]

- [19].Swayamsiddha S. and Mohanty C., “Application of cognitive Internet of medical things for COVID-19 pandemic,” Diabetes Metabolic Syndrome, Clin. Res. Rev., vol. 14, no. 5, pp. 911–915, Sep. 2020, doi: 10.1016/j.dsx.2020.06.014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [20].Chanchaichujit J., Tan A., Meng F., and Eaimkhong S., Healthcare 4.0. Singapore. Singapore: Springer, 2019. [Google Scholar]

- [21].Wehde M., “Healthcare 4.0,” IEEE Eng. Manag. Rev., vol. 47, no. 3, pp. 24–28, Sep. 2019, doi: 10.1109/EMR.2019.2930702. [DOI] [Google Scholar]

- [22].Nisar K. and Ibrahim A. A. A., “A model new for smart home technologies knee monitor and walking analyser,” in Advances in Intelligent Systems and Computing, vol. 739. Singapore: Springer, 2018, pp. 501–509. [Google Scholar]

- [23].Nisar K., Ibrahim A. A. A., Park Y. J., Hzou Y. K., Memon S. K., Naz N., and Welch I., “Indoor roaming activity detection and analysis of elderly people using RFID technology,” in Proc. 1st Int. Conf. Artif. Intell. Data Sci. (AiDAS), Sep. 2019, pp. 174–179, doi: 10.1109/AiDAS47888.2019.8970780. [DOI] [Google Scholar]

- [24].Nisar K., Ibrahim A. A. A., Wu L., Adamov A., and Deen M. J., “Smart home for elderly living using wireless sensor networks and an Android application,” in Proc. IEEE 10th Int. Conf. Appl. Inf. Commun. Technol. (AICT), Oct. 2016, pp. 1–8, doi: 10.1109/ICAICT.2016.7991655. [DOI] [Google Scholar]

- [25].Javaid M., Haleem A., Vaishya R., Bahl S., Suman R., and Vaish A., “Industry 4.0 technologies and their applications in fighting COVID-19 pandemic,” Diabetes Metabolic Syndrome, Clin. Res. Rev., vol. 14, no. 4, pp. 419–422, Jul. 2020, doi: 10.1016/j.dsx.2020.04.032. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [26].Tino R., Moore R., Antoline S., Ravi P., Wake N., Ionita C. N., Morris J. M., Decker S. J., Sheikh A., Rybicki F. J., and Chepelev L. L., “COVID-19 and the role of 3D printing in medicine,” 3D Printing Med., vol. 6, no. 1, p. 11, Dec. 2020, doi: 10.1186/s41205-020-00064-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [27].Shokrani A., Loukaides E. G., Elias E., and Lunt A. J. G., “Exploration of alternative supply chains and distributed manufacturing in response to COVID-19; a case study of medical face shields,” Mater. Des., vol. 192, Jul. 2020, Art. no.108749, doi: 10.1016/j.matdes.2020.108749. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [28].Zhu G., Chou M. C., and Tsai C. W., “Lessons Learned from the COVID-19 pandemic exposing the shortcomings of current supply chain operations: A long-term prescriptive offering,” Sustain., vol. 12, no. 14, pp. 1–19, 2020, doi: 10.3390/su12145858. [DOI] [Google Scholar]

- [29].Ivanov D., “Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic,” Ann. Oper. Res., vol. 22, p. 1, May 2020, doi: 10.1007/s10479-020-03640-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [30].Nayyar A. and Kumar A., A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development. Cham, Switzerland: Springer, 2020. [Google Scholar]

- [31].Salmi M., Akmal J. S., Pei E., Wolff J., Jaribion A., and Khajavi S. H., “3D printing in COVID-19: Productivity estimation of the most promising open source solutions in emergency situations,” Appl. Sci., vol. 10, no. 11, p. 4004, Jun. 2020, doi: 10.3390/app10114004. [DOI] [Google Scholar]

- [32].Attaran M., “3D printing role in filling the critical gap in the medical supply chain during COVID-19 pandemic,” Amer. J. Ind. Bus. Manage., vol. 10, no. 5, pp. 988–1001, 2020, doi: 10.4236/ajibm.2020.105066. [DOI] [Google Scholar]

- [33].Amin D., Nguyen N., Roser S. M., and Abramowicz S., “3D printing of face shields during COVID-19 pandemic: A technical note,” J. Oral Maxillofac. Surg., vol. 4, pp. 1–4, Dec. 2020, doi: 10.1016/j.joms.2020.04.040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [34].Wuest T., Kusiak A., Dai T., and Tayur S. R., “Impact of COVID-19 on manufacturing and supply networks—The case for AI-inspired digital transformation,” SSRN Electron. J., May 2020, doi: 10.2139/ssrn.3593540. [DOI]

- [35].Mueller T., “Eight weeks later-the unprecedented rise of 3D printing during the COVID-19 pandemic-A case study, lessons learned, and implications on the future of global decentralized manufacturing,” Appl. Sci., vol. 10, no. 12, pp. 1–14, 2020, doi: 10.3390/APP10124135. [DOI] [Google Scholar]

- [36].3D Printing in FDA’s Rapid Response to COVID-19|FDA.. Accessed: Aug. 20, 2020. [Online]. Available: https://www.fda.gov/emergency-preparedness-andresponse/coronavirus-disease-2019-covid-19/3d-printing-fdas-rapid-response-covid-19

- [37].COVID-19-America-Makes. Accessed: Aug. 20, 2020. [Online]. Available: https://www.americamakes.us/statement-on-covid-19/

- [38].COVID-19 Response|NIH 3D Print Exchange. Accessed: Aug. 20, 2020. [Online]. Available: https://3dprint.nih.gov/collections/covid-19-response

- [39].Zhou L., Zhang L., Ren L., and Laili Y., “Matching and selection of distributed 3D printing services in cloud manufacturing,” in Proc. IEEE Ind. Electron. Soc., Oct. 2017, pp. 4728–4733, doi: 10.1109/IECON.2017.8216815. [DOI] [Google Scholar]

- [40].Zhou L., Zhang L., Laili Y., Zhao C., and Xiao Y., “Multi-task scheduling of distributed 3D printing services in cloud manufacturing,” Int. J. Adv. Manuf. Technol., vol. 96, nos. 9–12, pp. 3003–3017, Jun. 2018, doi: 10.1007/s00170-017-1543-z. [DOI] [Google Scholar]

- [41].Luo X., Zhang L., Ren L., and Lali Y., “A dynamic and static data based matching method for cloud 3D printing,” Robot. Comput.-Integr. Manuf., vol. 61, Feb. 2020, Art. no.101858, doi: 10.1016/j.rcim.2019.101858. [DOI] [Google Scholar]

- [42].Li Q., Kucukkoc I., and Zhang D. Z., “Production planning in additive manufacturing and 3D printing,” Comput. Oper. Res., vol. 83, pp. 1339–1351, Dec. 2017, doi: 10.1016/j.cor.2017.01.013. [DOI] [Google Scholar]

- [43].Chergui A., Hadj-Hamou K., and Vignat F., “Production scheduling and nesting in additive manufacturing,” Comput. Ind. Eng., vol. 126, pp. 292–301, Dec. 2018, doi: 10.1016/j.cie.2018.09.048. [DOI] [Google Scholar]

- [44].Kucukkoc I., “MILP models to minimise makespan in additive manufacturing machine scheduling problems,” Comput. Oper. Res., vol. 105, pp. 58–67, May 2019, doi: 10.1016/j.cor.2019.01.006. [DOI] [Google Scholar]

- [45].Wu Y., Peng G., Chen L., and Zhang H., “Service architecture and evaluation model of distributed 3D printing based on cloud manufacturing,” in Proc. IEEE Int. Conf. Syst., Man, Cybern. (SMC), Oct. 2016, pp. 002762–002767, doi: 10.1109/SMC.2016.7844657. [DOI] [Google Scholar]

- [46].Seiden S. S., “On the online bin packing problem,” J. ACM, vol. 49, no. 5, pp. 640–671, Sep. 2002, doi: 10.1145/585265.585269. [DOI] [Google Scholar]

- [47].Sgall J., “Online bin packing: Old algorithms and new results,” in Language, Life, Limits (Lecture Notes in Computer Science), vol. 8493. Cham, Switzerland: Springer, 2014, pp. 362–372. [Google Scholar]

- [48].Balogh J., Békési J., Dósa G., Epstein L., and Levin A., “A new and improved algorithm for online bin packing,” Leibniz Int. Proc. Informat., vol. 112, pp. 1–46, Dec. 2018, doi: 10.4230/LIPIcs.ESA.2018.5. [DOI] [Google Scholar]

- [49].Abdel-Basset M., Manogaran G., Abdel-Fatah L., and Mirjalili S., “An improved nature inspired meta-heuristic algorithm for 1-D bin packing problems,” Pers. Ubiquitous Comput., vol. 22, nos. 5–6, pp. 1117–1132, Oct. 2018, doi: 10.1007/s00779-018-1132-7. [DOI] [Google Scholar]

- [50].Johnson D. S., “Fast algorithms for bin packing,” J. Comput. Syst. Sci., vol. 8, no. 3, pp. 272–314, 1974, doi: 10.1016/S0022-0000(74)80026-7. [DOI] [Google Scholar]

- [51].Dell’Amico M., Furini F., and Iori M., “A branch-and-price algorithm for the temporal bin packing problem,” Comput. Oper. Res., vol. 114, Feb. 2020, Art. no.104825, doi: 10.1016/j.cor.2019.104825. [DOI] [Google Scholar]

- [52].Baker B. S., “A new proof for the first-fit decreasing bin-packing algorithm,” J. Algorithms, vol. 6, no. 1, pp. 49–70, 1985, doi: 10.1016/0196-6774(85)90018-5. [DOI] [Google Scholar]

- [53].Renault M. P., Rosén A., and van Stee R., “Online algorithms with advice for bin packing and scheduling problems,” Theor. Comput. Sci., vol. 600, pp. 155–170, Oct. 2015, doi: 10.1016/j.tcs.2015.07.050. [DOI] [Google Scholar]

- [54].Epstein L. and Levin A., “On bin packing with conflicts,” in Proc. Conf. Computability Eur., vol. 4368, 2007, pp. 160–173. [Google Scholar]

- [55].Boyar J., Kamali S., Larsen K. S., and López-Ortiz A., “Online bin packing with advice,” Algorithmica, vol. 74, no. 1, pp. 507–527, Jan. 2016, doi: 10.1007/s00453-014-9955-8. [DOI] [Google Scholar]

- [56].Kang J. and Park S., “Algorithms for the variable sized bin packing problem,” Eur. J. Oper. Res., vol. 147, no. 2, pp. 365–372, Jun. 2003., doi: 10.1016/S0377-2217(02)00247-3. [DOI] [Google Scholar]

- [57].Korf R. E., “A new algorithm for optimal bin packing,” Proc. Natl. Conf. Artif. Intell., 2002, pp. 731–736. [Google Scholar]