Abstract

Objective:

To compare the archwires inserted during the final stages of the orthodontic treatment with the generated moments at 0.018- and 0.022-inch brackets.

Materials and Methods:

The same bracket type, in terms of prescription, was evaluated in both slot dimensions. The brackets were bonded on two identical maxillary acrylic resin models, and each model was mounted on the orthodontic measurement and simulation system. Ten 0.017 × 0.025-inch TMA and ten 0.017 × 0.025-inch stainless steel archwires were evaluated in the 0.018-inch brackets. In the 0.022-inch brackets, ten 0.019 × 0.025-inch TMA and ten 0.019 × 0.025-inch stainless steel archwires were measured. A 15° buccal root torque (+15°) and then a 15° palatal root torque (−15°) were gradually applied to the right central incisor bracket, and the moments were recorded at these positions. A t-test was conducted to compare the generated moments between wires within the 0.018- and 0.022-inch bracket groups separately.

Results:

The 0.017 × 0.025-inch archwire in the 0.018-inch brackets generated mean moments of 9.25 Nmm and 14.2 Nmm for the TMA and stainless steel archwires, respectively. The measured moments in the 0.022-inch brackets with the 0.019 × 0.025-inch TMA and stainless steel archwires were 6.6 Nmm and 9.3 Nmm, respectively.

Conclusion:

The 0.017 × 0.025-inch stainless steel and β-Ti archwires in the 0.018-inch slot generated higher moments than the 0.019 × 0.025-inch archwires because of lower torque play. This difference is exaggerated in steel archwires, in comparison with the β-Ti, because of differences in stiffness. The differences of maximum moments between the archwires of the same cross-section but different alloys were statistically significant at both slot dimensions.

Keywords: Torque, Moments, 0.018-inch slot, 0.022-inch slot, TMA, Steel

INTRODUCTION

The 0.018-inch bracket system was developed as an adaptation to the higher stiffness of stainless steel that would allow the material to be used for torquing control. Heavier archwires in a larger slot are too stiff for any application other than stabilization.1 A disadvantage of the 0.018-inch slot is that in many instances insufficient play between the wire and the bracket is present in applications where a heavier wire is needed.2 Additionally, precise delivery of torsional moment in the oral cavity is difficult because the working range in torsion of stainless steel wires is somewhat limited.3

Advances in metal manufacturing technology introduced variable-modulus orthodontics, which takes advantage of different alloys in archwire selection while maintaining the same or similar cross sections. The major benefit of this treatment approach is that before selecting the wire, the clinician can determine the amount of play that is required according to the desired movement type or treatment stage and irrespective of the material stiffness of the archwire. Now, because of the potential for varying the modulus, it appears that the larger slot size (0.022 inch) is more desirable as the clinician is no longer dependent on wire size for stiffness. Furthermore, the use of a larger slot allows for preferential orientation so that ribbon wires can be used.2

The material stiffness of the archwire could be determined with the aid of relative bending and torsional stiffness indices for various archwire composition/size combinations depicted on nomograms.4 Thereafter, considerable research has been conducted evaluating the torquing efficiency of various archwires into conventional and self-ligating brackets.5–13 Direct comparison of these results is difficult because of differences in configurations and testing devices. Moreover, bracket positioning and small variations in curvature of the crowns or thickness of the adhesive could affect the generated moments and thus the final buccolingual tooth inclination.14,15

The 0.018- and 0.022-inch bracket systems were compared regarding treatment duration,16,17 treatment outcome,17 and torque efficiency of stainless steel and NiTi archwires.13,18 The latter archwires have poor formability and cannot be used for torquing single teeth. Beta-titanium wires provide a combination of adequate springback, average stiffness, and good formability, and they can also be welded to auxiliaries.19 The aim of the present study was to assess the effect of archwire composition between 0.018- and 0.022-inch appliances on the moments generated in the sagittal plane on a central incisor from β-Ti and stainless steel rectangular archwires.

MATERIALS AND METHODS

Experimental Apparatus

The orthodontic measurement and simulation system (OMSS), a measuring device invented at the University of Bonn, is capable of complete three-dimensional registering of the orthodontic biomechanical systems during movement of the selected dental regions.20 This allows the evaluation of the forces and moments generated during the deactivation of a specific orthodontic mechanism or during the simulation of the desired tooth movement.21 The OMSS is based on the principle of the two-tooth model and consists of two independently controlled positioning tables on which are mounted the regions in question. These tables are equipped with six-component force/torque sensors that are connected to a central personal computer, which calculates the tooth movement with the aid of a mathematical model. Subsequently, the positioning tables are moved along the specified path. In the present experiment, the OMSS simulated the rotation of a central incisor in the sagittal plane and recorded the moments generated during this movement.

Configuration and Materials

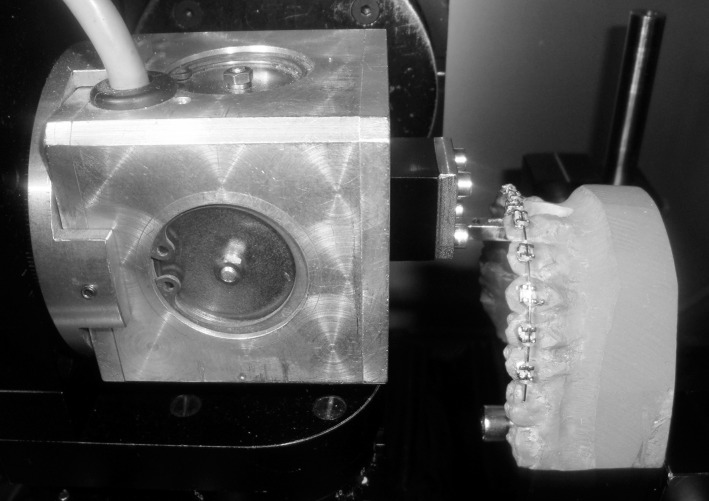

In this study, 0.018- and 0.022-inch brackets (Mini Diamond Twin, ORMCO, Orange, Calif) were used to evaluate the different archwires. The torque prescription in the central incisor/lateral incisor/canine/premolar brackets was 22°/14°/7°/0°, respectively, and the angulation was 5°/8°/10°/0°, respectively. Brackets up to the second premolars were bonded on two identical maxillary acrylic resin models with a leveled and aligned dental arch. Ideal stainless steel archwires were used to passively bond the brackets onto the models: 0.018 × 0.025-inch and 0.021 × 0.025-inch for the 0.018- and 0.022-inch brackets, respectively. The torque-force sensor of the OMSS was bonded on the right central incisor (11) bracket, and all the measurements were conducted on that tooth. These ideal archwires were used for the initial calibration of the system, and all forces/moments were nullified at this time (Figure 1).

Figure 1.

The positioning table of the OMSS with the model mounted on it. Its torque-force sensor replaced the right central incisor.

In the 0.018-inch series, ten 0.017 × 0.025-inch stainless steel and 10 TMA archwires of the same cross section (ORMCO) were measured. The same number of 0.019 × 0.025-inch stainless steel and TMA archwires were evaluated in the 0.022-inch series (ORMCO). The same investigator constructed all archwires with the aid of a template made from a photocopy of the resin model. For the ligation of the archwires into the brackets, 0.120-inch elastomeric ligatures were used (molded “O”, ORMCO).

The torque simulation by the OMSS involved rotation of the bracket along the central axis of the slot up to 15° buccally (+15°) and afterwards palatally (−15°). These movements were accomplished in steps of 0.5°. The moments were recorded at both end positions. After each rotation cycle, the bracket returned to its initial position. Each measurement was repeated once after re-ligation. The measuring range of the torquing moments in OMSS was ±450 Nmm, and the torque threshold was 0.2 Nmm. The OMSS during the measurement cycles was installed in a temperature-controlled chamber (VEM 03/400, Vötsch Heraeus, Hanau, Germany).

Statistical Analysis

The mean value of the two repeated measurements in every specimen of the generated moments was calculated at the maximum rotation separately for +15° and −15°. Student t-tests were used to compare generated moments between wires at 0.018- and 0.022-inch brackets separately, at −15° and +15°. All statistical analyses were performed with Stata 12.1 (Stata Corp, College Station, Tex).

RESULTS

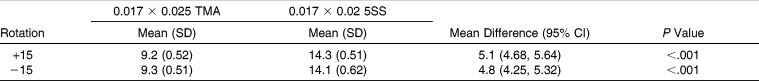

Similar values were recorded between ±15° in the 0.018-inch brackets. The insertion of a 0.017 × 0.025-inch TMA archwire generated mean moments of 9.25 Nmm in the central incisor (9.2 Nmm at +15° and 9.3 Nmm at −15°). In the same configuration but with a 0.017 × 0.025-inch stainless steel archwire, the measured mean moment was 14.2 Nmm (14.3 Nmm at +15° and 14.1 Nmm at −15°) (Table 1).

Table 1.

Mean Values, Standard Deviation (SD), Mean Difference and t-Test of the Labiopalatal Moment (Nmm) on the Displaced Central Incisor Between the 0.017 × 0.025-inch Archwires Into the 0.018-inch Brackets (n = 10)

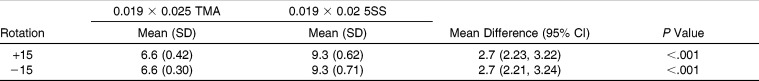

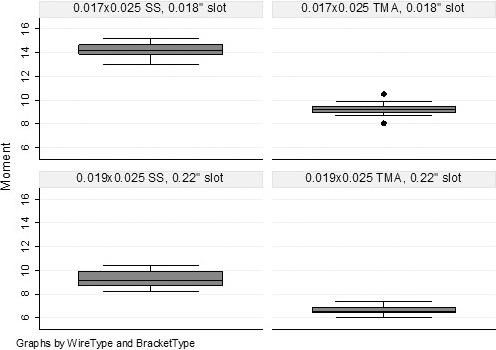

In the 0.022-inch slot brackets, the 0.019 × 0.025-inch TMA archwire yielded 6.6 Nmm, and the stainless steel of the same cross-section yielded 9.3 Nmm (Table 2, Figure 2). The same values were recorded between ±15° in the 0.022-inch brackets.

Table 2.

Mean Values, Standard Deviation (SD), Mean Difference and t-Test of the Labiopalatal Moment (Nmm) on the Displaced Central Incisor Between the 0.019 × 0.025-inch Archwires Into the 0.022-inch Brackets (n = 10)

Figure 2.

Box plots displaying the measured moments in Newton millimeters at the central incisor bracket between the different configurations (median values, interquartile range 25–75).

Four independent t-tests were used for statistical inferences, as shown in Tables 1 and 2. All four comparisons from the t-test were highly significant (P < .001).

DISCUSSION

The configurations evaluated could be used in clinical practice during the final stages of orthodontic treatment. Heavier archwires are rarely used in the 0.022-inch slot.9 According to the present results, the maximum efficiency in torquing teeth with stainless steel or TMA archwires derives at the 0.018-inch slot, but it is under debate whether these torque values are tolerable regarding resorption hazard. The time of treatment with rectangular archwires contributed significantly to apical root resorption,22 and teeth that had been moved for a longer time or with a higher magnitude of applied moments showed a higher degree of root resorption in width and depth.23 Surprisingly, lower moment magnitudes were found to induce root resorption, too.24

Ideal torque magnitude and torque threshold for root resorption are difficult to define. The etiology of root resorption is multifactorial and cannot be explained by mechanical factors alone. Additionally, at a given moment magnitude, the stresses on the periodontium are theoretically influenced by the location of the center of rotation and its relation to the center of resistance. The latter may change over time, even for the same tooth, because of the varying degree of periodontal anisotropy.25 A changing center of rotation during orthodontic movement is the rule rather than the exception; that is, different types of orthodontic movement might be involved in the movement path.26 An additional factor that could differentially accelerate root resorption in clinical cases using the setup of this experiment is the root proximity of the anterior teeth to the palatal cortical plate.27,28 As a result, the present findings could be used for comparison purposes but should not be regarded as absolute determinants of the ideal torquing efficiency of the various wire-bracket configurations.

The differences in torque measurements detected in the present study between slot types are attributed to differences in wire material and cross section as well as in torque loss between the two systems. The 0.017 × 0.025-inch archwires in the 0.018-inch slot generated higher moments than the 0.019 × 0.025-inch archwires because of lower torque play. The increase in the 0.018-inch system was about 40% in TMA and 50% in steel archwires. Theoretically, the torque play could be estimated, using appropriate tables or formulas, at about 7–8° in the 0.022-inch slot and half that amount for a 0.017 × 0.025-inch in the 0.018-inch slot.1,29,30 However, various experimental configurations revealed that torque play is actually higher in conventional5,6,31 and self-ligating bracket systems.11 Moreover, a recent clinical investigation suggests that play is more exaggerated in passive self-ligating brackets than in active ones.32 The inconsistency in torque play assessments between theoretical calculations and experimental configurations could be attributed to dimensional inconsistency of archwire and bracket as well as to rounded wire edges.3,30,31 In addition, the bracket slot could be tapered slightly, resulting in further torque-loss fluctuations between archwires of different cross sections.3 The OMSS model approximates the clinical situation, and the torque loss is notably higher than in the in vitro activating experiments. This is because the adjacent teeth give the archwire additional play;5 that is, both the play in the bracket receiving the torque and in the brackets delivering the torque must be negated.33

The differences in torque measurements detected in the present study within each slot type are attributed to differences in wire material and cross section. In the 0.018-inch slotted system, an increase of about 55% was noted at the 0.017 × 0.025-inch stainless steel archwire in comparison with the 0.017 × 0.025-inch TMA. The respective increase in the 0.022-inch slot/ 0.019 × 0.025-inch archwire system was about 41%. Initial research has shown that, in torsion, the elastic property ratios of an 0.019 × 0.025-inch β-Ti wire are virtually identical to those of an 0.018-inch SS wire, and a steel 0.017 × 0.025-inch or 0.019 × 0.025-inch archwire has triple the stiffness of a TMA of the same cross section.4 Further experiments concluded that steel and chrome-cobalt are a little less than twice as stiff as TMA and are four times stiffer than Nitinol in torsion.33 Regarding stainless steel archwires at 15° of torsion, further increase of the cross section from 0.017 × 0.025-inch to 0.018 × 0.025-inch in the 0.018-inch slot could double the moment magnitude. In the 0.022-inch slotted system, the increase of the 0.019 × 0.025-inch to 0.0215 × 0.028-inch could triple the moment magnitude.13

The differential effect of the interbracket wire length in torsion between the different archwires34 is minimized in the present experiment because models and brackets were identical. In any event, there are no exponential effects of length in torsion; in other words, stiffness in torsion is inversely proportional to length, and as a result, changes in length are not as powerful modifiers as they are in bending.1

Elastic ligatures were used during all the measurements cycles. These ligatures have a restraining effect that will lead to a small delivery of torque even though the play between wire and bracket has not been eliminated. This amount of torque is low, and its clinical effect is doubtful.33 In a previous study, it was found that after the elimination of archwire play and in torsion levels up to 40°, the torque moment with elastic ligation was significantly lower than with wire ligation, a difference that was not observed when using full slot size wires.13 According to these findings, the elastic ligation used in the present study with the 017 × 025-inch archwire in the 0.018-inch slotted brackets could have insubstantially influenced moment magnitudes. But this is not the case in the 0.022-inch brackets. The elastic ligatures used with the 0.019 × 0.025-inch archwires could have lowered the measured moments at about 20%. Dimension and polyurethane composition influence the seating force of the elastic ligature,35 and therefore, the findings of this study are not directly comparable to the present results. The indisputable disadvantage of elastic ligatures is their rapid force decay—which could exceed 50% in 24 hours—a fact rendering the engagement of the wire into the slot flexible and incomplete. Steel ligatures should be preferred in cases of maximum torque demands.35,36

The force system generated by an orthodontic mechanism is not the sole determinant of the final tooth movement. The anisotropic periodontal ligament and the saliva mediate between activation and tooth response. The experimental setup used in this investigation is a model that approximates very well the clinical situation where forces and moments are exerted by an archwire onto brackets, but the aforementioned factors, as well as intraoral aging, could influence the force system that experience the teeth.

CONCLUSIONS

The 0.017 × 0.025-inch stainless steel and β-Ti archwires in the 0.018-inch slot generated higher moments than the 0.019 × 0.025-inch archwires because of lower torque play. This difference is exaggerated in steel archwires, in comparison with the β-Ti, because of differences in stiffness.

Within each slot system, the β-Ti archwires generated lower moment than their stainless steel analogs. This difference was magnified in the 0.018-inch slot because of lower torque play.

REFERENCES

- 1.Thurow RC. Edgewise Orthodontics 4th ed. St Louis, Mo: Mosby; 1982. pp. 166–171. [Google Scholar]

- 2.Burstone CJ. Variable-modulus orthodontics. Am J Orthod. 1981;80:1–16. doi: 10.1016/0002-9416(81)90192-5. [DOI] [PubMed] [Google Scholar]

- 3.Meling TR, Odegaard J, Meling EO. On mechanical properties of square and rectangular stainless steel wires tested in torsion. Am J Orthod Dentofacial Orthop. 1997;111:310–320. doi: 10.1016/s0889-5406(97)70190-2. [DOI] [PubMed] [Google Scholar]

- 4.Kusy RP. On the use of nomograms to determine the elastic property ratios of orthodontic arch wires. Am J Orthod. 1983;83:374–381. doi: 10.1016/0002-9416(83)90321-4. [DOI] [PubMed] [Google Scholar]

- 5.Gmyrek H, Bourauel C, Richter G, Harzer W. Torque capacity of metal and plastic brackets with reference to materials, application, technology and biomechanics. J Orofac Orthop. 2002;63:113–128. doi: 10.1007/s00056-002-0065-x. [DOI] [PubMed] [Google Scholar]

- 6.Harzer W, Bourauel C, Gmyrek H. Torque capacity of metal and polycarbonate brackets with and without a metal slot. Eur J Orthod. 2004;26:435–441. doi: 10.1093/ejo/26.4.435. [DOI] [PubMed] [Google Scholar]

- 7.Morina E, Eliades T, Pandis N, Jäger A, Bourauel C. Torque expression of self-ligating brackets compared with conventional metallic, ceramic, and plastic brackets. Eur J Orthod. 2008;30:233–238. doi: 10.1093/ejo/cjn005. [DOI] [PubMed] [Google Scholar]

- 8.Huang Y, Keilig L, Rahimi A, et al. Numeric modeling of torque capabilities of self-ligating and conventional brackets. Am J Orthod Dentofacial Orthop. 2009;136:638–643. doi: 10.1016/j.ajodo.2009.04.018. [DOI] [PubMed] [Google Scholar]

- 9.Archambault A, Lacoursiere R, Badawi H, Major PW, Carey J, Flores-Mir C. Torque expression in stainless steel orthodontic brackets. A systematic review. Angle Orthod. 2010;80:201–210. doi: 10.2319/080508-352.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Archambault A, Major TW, Carey JP, Heo G, Badawi H, Major PW. A comparison of torque expression between stainless steel, titanium molybdenum alloy, and copper nickel titanium wires in metallic self-ligating brackets. Angle Orthod. 2010;80:884–889. doi: 10.2319/102809-604.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Major TW, Carey JP, Nobes DS, Heo G, Major PW. Mechanical effects of third-order movement in self-ligated brackets by the measurement of torque expression. Am J Orthod Dentofacial Orthop. 2011;139:e31–e44. doi: 10.1016/j.ajodo.2010.04.029. [DOI] [PubMed] [Google Scholar]

- 12.Major TW, Carey JP, Nobes DS, Heo G, Melenka GW, Major PW. An investigation into the mechanical characteristics of select self-ligated brackets at a series of clinically relevant maximum torquing angles: loading and unloading curves and bracket deformation. Eur J Orthod. 2011 July 12 doi: 10.1093/ejo/cjr076. Epub ahead of print. [DOI] [PubMed] [Google Scholar]

- 13.Hirai M, Nakajima A, Kawai N, et al. Measurements of the torque moment in various archwire-bracket-ligation combinations. Eur J Orthod. 2012;34:374–380. doi: 10.1093/ejo/cjr022. [DOI] [PubMed] [Google Scholar]

- 14.Miethke RR, Melsen B. Effect of variation in tooth morphology and bracket position on first and third order correction with preadjusted appliances. Am J Orthod Dentofacial Orthop. 1999;116:329–335. doi: 10.1016/s0889-5406(99)70246-5. [DOI] [PubMed] [Google Scholar]

- 15.van Loenen M, Degrieck J, De Pauw G, Dermaut L. Anterior tooth morphology and its effect on torque. Eur J Orthod. 2005;27:258–262. doi: 10.1093/ejo/cji007. [DOI] [PubMed] [Google Scholar]

- 16.Amditis C, Smith LF. The duration of fixed orthodontic treatment: a comparison of two groups of patients treated using edgewise brackets with 0.018″ and 0.022″ slots. Aust Orthod J. 2000;16:34–39. [PubMed] [Google Scholar]

- 17.Detterline DA, Isikbay SC, Brizendine EJ, Kula KS. Clinical outcomes of 0.018-inch and 0.022-inch bracket slot using the ABO objective grading system. Angle Orthod. 2010;80:528–532. doi: 10.2319/060309-315.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Mittal N, Xia Z, Chen J, Stewart KT, Liu SS. Three-dimensional quantification of pretorqued nickel-titanium wires in edgewise and prescription brackets. Angle Orthod. 2012 October 24 doi: 10.2319/062812-532.1. Epub ahead of print. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Kapila S, Sachdeva R. Mechanical properties and clinical applications of orthodontic wires. Am J Orthod Dentofacial Orthop. 1989;96:100–109. doi: 10.1016/0889-5406(89)90251-5. [DOI] [PubMed] [Google Scholar]

- 20.Bourauel C, Drescher D, Thier M. An experimental apparatus for the simulation of three-dimensional movements in orthodontics. J Biomed Eng. 1992;14:371–378. doi: 10.1016/0141-5425(92)90081-u. [DOI] [PubMed] [Google Scholar]

- 21.Drescher D, Bourauel C, Thier M. Application of the orthodontic measurement and simulation system (OMSS) in orthodontics. Eur J Orthod. 1991;13:169–178. doi: 10.1093/ejo/13.3.169. [DOI] [PubMed] [Google Scholar]

- 22.Linge L, Linge BO. Patient characteristics and treatment variables associated with apical root resorption during orthodontic treatment. Am J Orthod Dentofacial Orthop. 1991;99:35–43. doi: 10.1016/S0889-5406(05)81678-6. [DOI] [PubMed] [Google Scholar]

- 23.Casa MA, Faltin RM, Faltin K, Sander FG, Arana-Chavez VE. Root resorptions in upper first premolars after application of continuous torque moment. Intra-individual study. J Orofac Orthop. 2001;62:285–295. doi: 10.1007/pl00001936. [DOI] [PubMed] [Google Scholar]

- 24.Bartley N, Türk T, Colak C, et al. Physical properties of root cementum: part 17. Root resorption after the application of 2.5° and 15° of buccal root torque for 4 weeks: a microcomputed tomography study. Am J Orthod Dentofacial Orthop. 2011;139:e353–e360. doi: 10.1016/j.ajodo.2010.01.033. [DOI] [PubMed] [Google Scholar]

- 25.Halazonetis DJ. Computer experiments using a two-dimensional model of tooth support. Am J Orthod Dentofacial Orthop. 1996;109:598–606. doi: 10.1016/s0889-5406(96)70071-9. [DOI] [PubMed] [Google Scholar]

- 26.Smith RJ, Burstone CJ. Mechanics of tooth movement. Am J Orthod. 1984;85:294–307. doi: 10.1016/0002-9416(84)90187-8. [DOI] [PubMed] [Google Scholar]

- 27.Kaley J, Phillips C. Factors related to root resorption in edgewise practice. Angle Orthod. 1991;61:125–132. doi: 10.1043/0003-3219(1991)061<0125:FRTRRI>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 28.Horiuchi A, Hotokezaka H, Kobayashi K. Correlation between cortical plate proximity and apical root resorption. Am J Orthod Dentofacial Orthop. 1998;114:311–318. doi: 10.1016/s0889-5406(98)70214-8. [DOI] [PubMed] [Google Scholar]

- 29.Dellinger EL. A scientific assessment of the straight-wire appliance. Am J Orthod. 1978;73:290–299. doi: 10.1016/0002-9416(78)90135-5. [DOI] [PubMed] [Google Scholar]

- 30.Meling TR, Odegaard J, Seqner D. On bracket slot height: a methodologic study. Am J Orthod Dentofacial Orthop. 1998;113:387–393. doi: 10.1016/s0889-5406(98)80009-7. [DOI] [PubMed] [Google Scholar]

- 31.Fischer-Brandies H, Orthuber W, Es-Souni M, Meyer S. Torque transmission between square wire and bracket as a function of measurement, form and hardness parameters. J Orofac Orthop. 2000;61:258–265. doi: 10.1007/s000560050011. [DOI] [PubMed] [Google Scholar]

- 32.Cattaneo PM, Salih RA, Melsen B. Labio-lingual root control of lower anterior teeth and canines obtained by active and passive self-ligating brackets. Angle Orthod. 2012 December 18 doi: 10.2319/071212-575.1. Epub ahead of print. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Odegaard J, Meling T, Meling E. An evaluation of the torsional moments developed in orthodontic applications. An in vitro study. Am J Orthod Dentofacial Orthop. 1994;105:392–400. doi: 10.1016/S0889-5406(94)70134-2. [DOI] [PubMed] [Google Scholar]

- 34.Huang Y, Keilig L, Rahimi A, Reimann S, Bourauel C. Torque capabilities of self-ligating and conventional brackets under the effect of bracket width and free wire length. Orthod Craniofac Res. 2012;15:255–262. doi: 10.1111/j.1601-6343.2012.01553.x. [DOI] [PubMed] [Google Scholar]

- 35.Taloumis LJ, Smith TM, Hondrum SO, Lorton L. Force decay and deformation of orthodontic elastomeric ligatures. Am J Orthod Dentofacial Orthop. 1997;111:1–11. doi: 10.1016/s0889-5406(97)70295-6. [DOI] [PubMed] [Google Scholar]

- 36.Gioka C, Eliades T. Materials-induced variation in the torque expression of preadjusted appliances. Am J Orthod Dentofacial Orthop. 2004;125:323–328. doi: 10.1016/j.ajodo.2003.02.007. [DOI] [PubMed] [Google Scholar]